Page 1

www.caleffi.com

CALEFFI

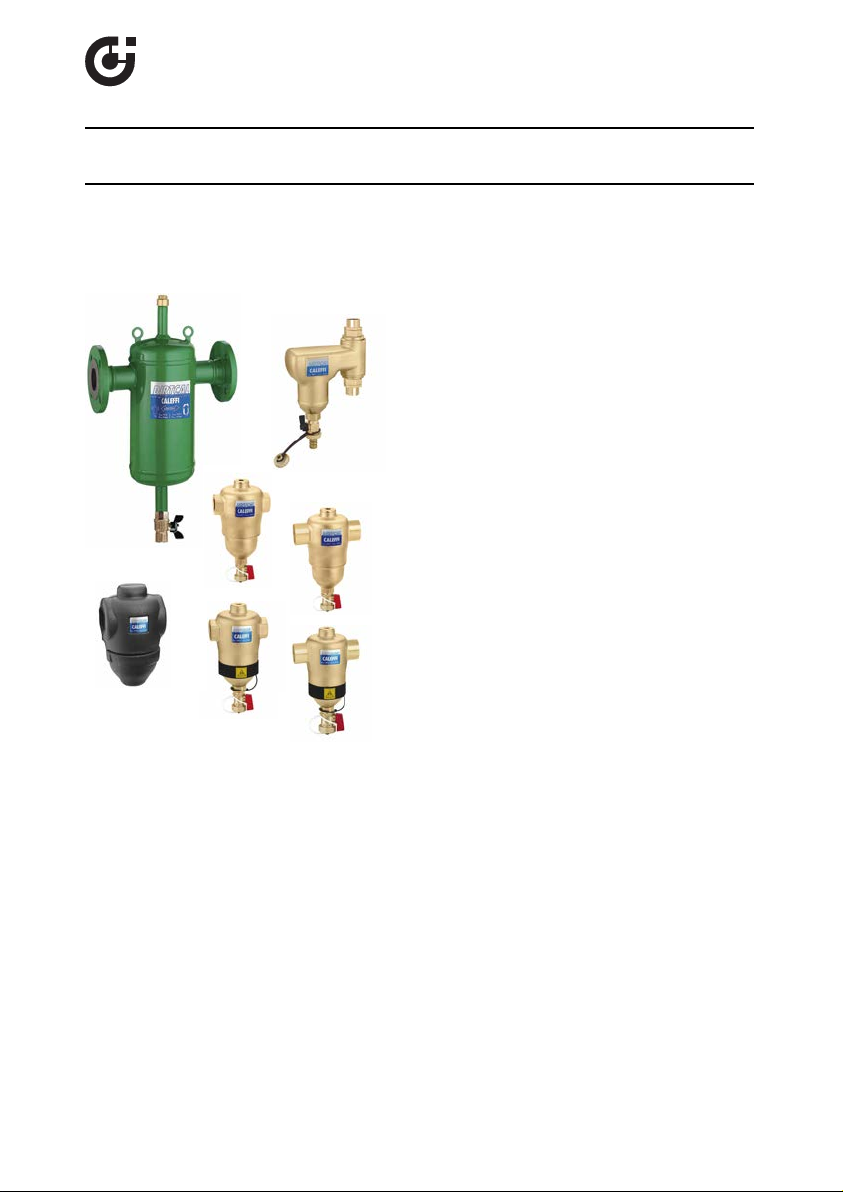

DIRTCAL®dirt separator

38643.05

© Cop y rig h t 2 0 12 Ca l ef f i

5462 - 5469 Series

Installation, commissioning and servicing instructions

Function

In heating and air conditioning control systems,

the circulation of water containing impurities may

result in rapid wear and damage to components

such as pumps and control valves. It also causes

blockages in the heat exchangers, heating

elements and pipes, resulting in a lower thermal

efficiency within the system. The dirt separator

separates off these dirt particles, which are mainly

made up of particles of sand and rust, collecting

them in a large collection chamber, from which

they can be removed even while the system is in

operation. This device is capable of efficiently

removing even the smallest particles, with

extremely limited head loss.

The sweat connection product is available in

versions for horizontal and vertical pipe

installations. The magnetic dirt separator is

available with NPT threaded or sweat connections

in versions for horizontal pipes only. Insulation

shells are available separately for field installation

for horizontal versions of the DIRTCAL®and

DIRTMAG®dirt separators.

Product range

5462 Series

5462 Series DIRTCAL dirt separator for horizontal pipes with sweat connections, sizes 1”–1

5463 Series DIRTMAG magnetic dirt separator for horizontal pipes with NPT threaded

5463 Series DIRTMAG magnetic dirt separator for horizontal pipes with sweat connections,

5465 Series Steel DIRTCAL dirt separator for horizontal pipes with ANSI flanged connections,

5469 Series DIRTCAL dirt separator for vertical pipes with sweat connections, sizes 3/4”–1”

NA5465 Series Steel DIRTCAL dirt separator for horizontal pipes with ANSI flanged connections

CBN5462 Series

DIRTCAL dirt separator for horizontal pipes with NPT threaded connections, sizes

3/4”–2”

1/4” - 1 1/2" - 2"

connections, sizes 1”–2”

sizes 1”–2”

sizes 2"–4"

(ASME and CRN Registered), sizes 2"–2 1/2"–3"–4"–5”–6"

Insulation shells for DIRTCAL series 5462 and DIRTMAG series 5463, sizes 3/4"-2".

1

Page 2

SAFETY INSTRUCTION

This safety alert symbol will be used in this manual to draw attention to safety

related instructions. When used, the safety alert symbol means.

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED! FAILURE TO

FOLLOW THESE INSTRUCTIONS MAY RESULT IN A SAFETY HAZARD.

CAUTION: All work must be performed by qualified personnel trained in the

proper application, installation, and maintenance of systems in accordance

with all applicable codes and ordinances.

CAUTION: If the DIRTCAL®dirt separator is not installed, commissioned

and maintained properly, according to the instructions contained in this

manual, it may not operate correctly and may endanger the user.

CAUTION: Make sure that all the connecting pipework is water tight.

CAUTION: When making the water connections, make sure that the

pipework connecting the DIRTCAL®is not mechanically over-stressed.

Over time this could cause breakages, with consequent water losses

which, in turn, could cause harm to property and/or people.

CAUTION: Water temperatures higher than 100°F (38°C) can be

dangerous. During the installation, commissioning and maintenance of the

DIRTCAL®dirt separator, take the necessary precautions to ensure that

such temperatures do not endanger people.

Leave this manual for the user

Technical specifications

Brass body dirt separators

Connections: - Main: 3/4”, 1”, 1 1/4”, 1 1/2”, 2” NPT female

- Top: 1/2” F (with plug)

- Drain: 3/4” garden hose connection

Materials: - Body, dirt collection chamber and top plug: brass

- Internal element: glass reinforced nylon PA66G30

- Hydraulic seal: EPDM

- Drain cock: brass

Suitable fluids: water, glycol solution

Max percentage of glycol: 50%

Max working pressure: 150 psi (10 bar)

Temperature range: 32–250°F (0–120°C)

Particle separation capacity: to 5 µm (0.2 mil)

2

1”–1 1/4” - 1 1/2" - 2" sweat

vertical: 3/4" - 1" sweat

vertical: hose connection

(stainlesss steel, 5469 series)

Page 3

Steel body dirt separators

(kPa)

1"

1 1/4"

1 1/2"

2”

2 1/2”3”4”

3/4"

5”

6”

2”

0.

1

0.

05

0.09

0.08

0.07

0.06

0.035

0.04

0.045

0.12

0.14

0.16

0.18

0.25

0.3

0.35

0.

2

1

0

.1

0

0.2

0

0.5

0.9

0.8

0.7

0.6

0.12

0.14

0.16

0.18

0.25

0.3

0.35

0.4

0.45

1.2

1.4

1.6

1.8

2.5

3

2.0

1

0.

5

0.9

0.8

0.7

0.6

0.45

0.4

0.09

0.08

0.07

0.06

0.025

0.03

0.02

(

ft of water

)

∆p(ft of water

)

100

2

10

5

20

50

1000

200

500

0.

1

0.

05

0.09

0.08

0.07

0.06

0.035

0.04

0.045

0.12

0.14

0.16

0.18

0.25

0.3

0.35

0.

2

1

0.

5

0.9

0.8

0.7

0.6

0.45

0.4

0.025

0.03

0.02

678

9

1214161825

3

0

35

4045

60708090

120

140

160

180

250

400

45

0

300

35

0

600

7008009

00

3

3.544.5

2.5

BRASS BODY

STEEL BODY

G (l/s) (gpm)

2

0.5

10

1

5

0.6

0

.70.80.91.2

1

.4

1

.6

1

.82.5

3

3

.5

4

4

.5

678

9

12141618254045

20

30

355060

70

0.25

0.40

0.45

0.20

0.30

0.35

3/4" - 1”

Vertical

Connections: - Main: 2", 2 1/2", 3", 4", 5”, 6" ANSI B16.5 150 CLASS RF

Flanged (ASME & CRN registered)

2", 2 1/2", 3", 4" ANSI B16.5 150 CLASS RF Flanged

- Top: 3/4” M (with plug)

- Drain: 1” NPT

Materials: - Body: epoxy resin painted steel

- Int. element: stainless steel

- Hydraulic seal: non-asbestos fiber

- Drain cock: brass

Suitable fluids: water, glycol solution

Max percentage of glycol: 50%

Max working pressure: 150 psi (10 bar)

Temperature range without insulation: 32–250°F (0–120°C)

Particle separation capacity: to 5 µm (0.2 mil)

Hydraulic characteristics

3/4”

18.8

3/4”-1” *

19.91”32.6

Size

Cv

* Vertical versions

The maximum fluid velocity recommended at the unit connections is~4 f/s.

The following table shows the maximum flow rates to comply with this condition.

3/4”

6

0.4

3/4”-1” *

9.0

0.57

Size

gpm

l/s

* Vertical versions

BRASS BODY STEEL BODY

BRASS BODY STEEL BODY

1”

9.3

0.6

1 1/4”

56.6

1 1/4”

15.3

1.0

1 1/2”

73.3

1 1/2”

23.9

1.5

2”882 1/2”

2”

81

2”

2”

37

36

2.35

2.28

3

1763”2114”3285”520

2 1/2”

62

3.9

3”

4”

94

148

5.9

9.3

5”

259

16.3

6”

842

6”

376

23.7

Page 4

CHILLER

Tmax110∞C

P

max10bar

Tmax105∞C

P

max10bar

BI-DIRECTIONAL

Tmax 110∞C

P

max 10bar

Tmax 105∞C

P

max 10bar

BI-DIRECTIONAL

Tmax110∞C

P

max10bar

Tmax105∞C

P

max10bar

BI-DIRECTIONAL

Tmax110∞C

P

max10bar

Tmax105∞C

P

max10bar

BI-DIRECTIONAL

Installation

The dirt separator must always be installed in a vertical position, preferably on the return

circuit upstream of the boiler (or chiller). This enables it to intercept dirt particles already

present in the circuit, particularly when it is first started, before they reach the boiler (or chiller).

Flow direction for the DIRTCAL and DIRTMAG dirt separators is bi-directional; flow in either

direction is permitted.

4

Page 5

1

1

Draining off dirt

The dirt separator collection

chamber has a ball drain

cock. Using the handle

provided it is possible to drain

off the accumulated dirt

particles even with the system

in operation.

Procedure for removing insulation and draining dirt

particles in the DIRTMAG series 5463

WARNING: The symbol shown

on the removable ring indicates the

presence of magnets that generate a

strong magnetic field. This could cause

damages to electronic devices kept in

its proximity.

1. Remove the insulation by taking off

the bottom casing of the collection

chamber first, and if necessary, the

top insulation casing later.

2. Remove the magnetic ring

containing the two magnets, that

during operation attracted the

ferrous particles.

3. Flush out the ferrous and nonferrous

debris by turning the handle to open

the drain valve.

4. When finished, replace the insulation

shells.

Maintenance

To perform maintenance, simply use

a 26 mm hexagon wrench (1) to

unscrew the dirt collection chamber,

to which the inner mesh element is

connected for removal and for

cleaning.

5

Page 6

CALEFFI

Use of top connector

Tmax110∞C

P

max10bar

Tmax 105∞C

P

max10bar

BI-DIRECTIONAL

The connector on top of the dirt separator can be used for

optional installation of an automatic air vent valve, Caleffi code

C

502243A for the threaded or sweat versions- 5462 Series (A),

replacing the standard 1/2" NPT Male plug (pn NA10044).

Use Caleffi code 501502A for the flanged version 5465 Series (C)

-replacing the standard 3/4" NPT

End Cap (pn 41525).

Use bottom connector

The dir t separators come

complete with drain valves

A

B

installed on the bottom port:

Caleffi code 538402 FD for

horizontal

threaded or sweat

versions- 5462 series (A),

538400 for vertical versions5469 series, code NA39753 for

the flanged version - 5465

series (C).

Safety

The dirt separator must be installed by a licensed plumber in accordance with

national regulations and/or relevant local requirements.

Make sure that all connecting joints are water tight.

When making pipe connections take care not to damage the thread in the body of the valve by over

tightening. Take care not to apply too much force to the body of the valve when making pipe

connections.

Water temperatures greater than 120°F may cause serious burns. When installing, using and

maintaining dirt separators take appropriate measure to ensure that these temperatures do not

cause harm to persons.

Leave this manual at the service of users for their use

Caleffi North America, Inc.

3883 W. Milwaukee Road

Milwaukee, WI 53208

T: 414.238.2360 F: 414.238.2366

6

Loading...

Loading...