Page 1

Thermostatic mixing valves,

low-lead, high-flow

5231 series

CALEFFI

ACCREDITED

ISO 9001 FM 21654

ISO 9001 No. 0003

01256/14 NA

Function

The thermostatic mixing valve is used in systems producing domestic

hot water or in radiant heating systems. Its function is to maintain the

temperature of the mixed water supplied to the user at a constant set

value when there are variations in the supply pressure and temperature

of the incoming hot and cold water or in the flow rate.

The 5231 series thermostatic mixing valves are ASSE 1017 approved for

point of distribution and are designed specifically for systems requiring

high flow rates and precise, stable temperature control.

ASSE 1017

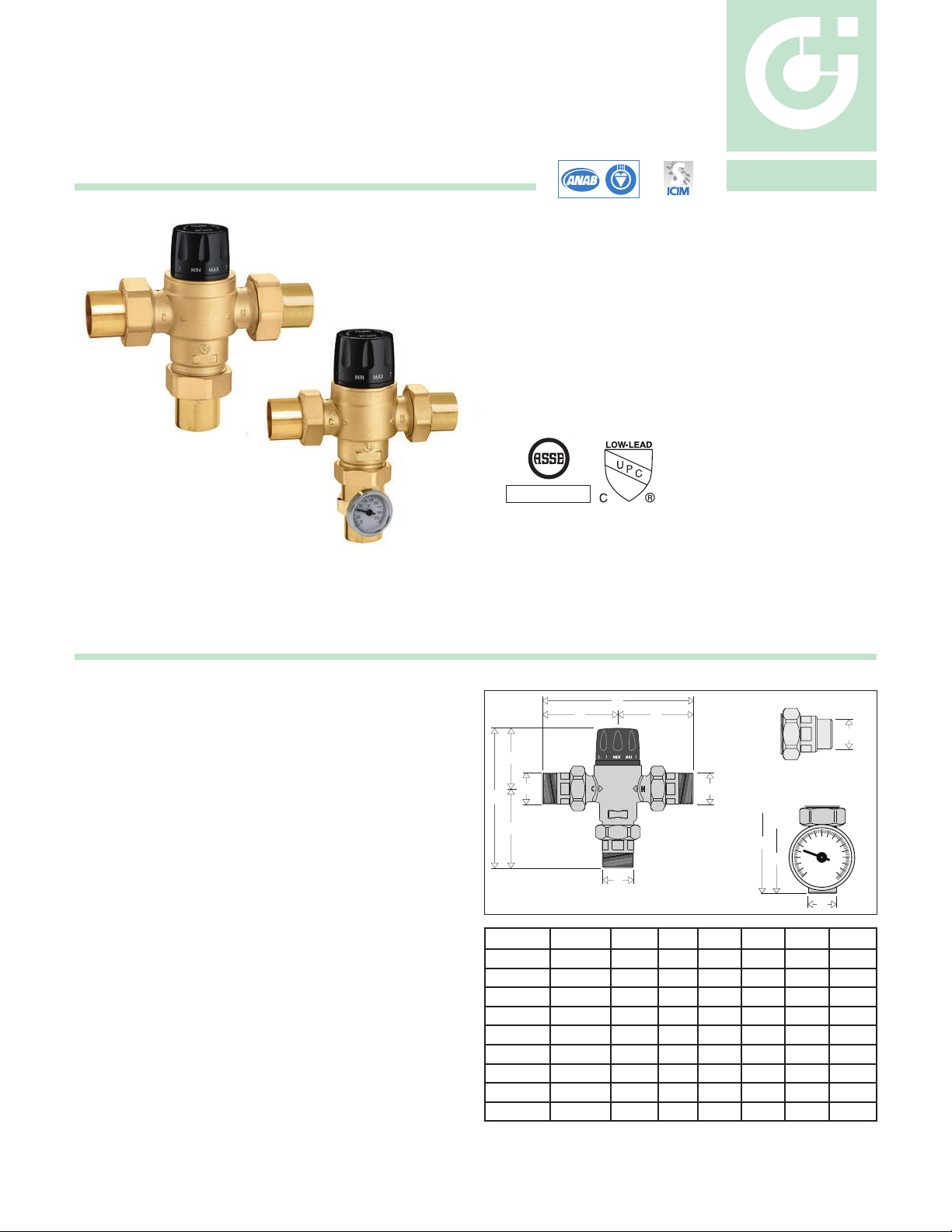

Product Range

Code 5231_0A Thermostatic mixing valve (ASSE 1017) with threaded connections.........................................................sizes 1”, 1-1/4”, 1-1/2”, 2” union NPT male

Code 5231_8A Thermostatic mixing valve (ASSE 1017) with sweat connections................................................................... sizes 1”, 1-1/4”. 1-1/2", 2" union sweat

Code 523177A Thermostatic mixing valve (ASSE 1017) with sweat connections and outlet temperature gauge..................................... sizes 1-1/4” union sweat

Technical specification

Materials: - Body: Low-lead brass

- Shutter: PPSG40

- Springs: Stainless steel

- Seals: EPDM

Suitable fluds: Water, glycol solutions

Maximum percentage of glycol: 30% glycol solution

Setting range:

See table on page 3

Temperature stability: ± 3°F (± 2°C)

Max working pressure (static): 200 psi (14 bar)

Max operating differential pressure: 70 psi (5 bar)

Hot water inlet temperature range: 120 – 195°F (49 – 91°C)

Cold water inlet temperature range: 39 – 80°F (3.9 – 26.6°C)

Mixed temperature range: 95 – 150°F (35 – 66°C)

Maximum inlet pressure ratio (H/C or C/H): 2:1

Minimum temperature difference between hot water inlet

and mixed water outlet for optimum performance: 20°F (11°C)

Maximum water hardness: 10 grains

Certifications:

1. cUPC Listed to ASSE 1017/CSA B125.3. Reduction of

Lead in Drinking Water Act Compliant: 0.25% Max.

weighted average lead content. Reduction of Lead in

Drinking Water Act Certifed by IAPMO R&T.

2. Meets requirements of ANSI/NSF 372-2011.

Dimensions

C

B B

F

A

D

HC

A

E

Sweat version

110

130

90

D

F

70

E

50

30

150

170

190

210

A

A

Code A B C D E F Wt (lb)

523160A 1" NPT 4" 8" 7 5/8" 4 3/16" 3 3/8" 7.0

523168A 1" SWT 3 5/16" 6 5/8" 7" 3 1/2" 3 3/8" 7.0

523170A 1 1/4" NPT 4 1/8" 8 1/4" 7 3/4" 4 5/16" 3 3/8" 7.1

523177A 1 1/4" SWT 3 3/8" 6 3/4" 7 5/8" 4 1/8" 3 3/8" 8.5

523178A 1 1/4" SWT 3 3/8" 6 3/4" 7" 3 1/2" 3 3/8" 7.1

523180A 1 1/2" NPT 5 1/8" 10

523188A 1 1/2" SWT 4 1/16" 8 1/8" 8 1/8" 4 3/8" 3 3/4" 17

523190A 2" NPT 5 1/8" 10

523198A 2" SWT 4 5/16" 8 5/8" 8 5/8" 4 7/8" 3 3/4" 18

1/4" 9 3/16" 5 7/16" 3 3/4" 17

1/4" 9 1/2" 5 3/4" 3 3/4" 18

A

Page 2

“Legionella” - Scalding risk

Principle of Operation

In systems producing domestic hot water

with storage, in order to avoid the dangerous

bacteria known as ”Legionella”, the hot

water must be stored at a temperature of at

least 140°F. At this temperature it is certain

that the growth of the bacteria causing this

infection will be totally eliminated. However,

at this temperature the water cannot be

used directly, as it may cause scalding. For

example, at 130°F, partial burning takes

place in 30 seconds and at 140°F total

burning takes place in 5 seconds.

In view of the above, it is necessary to install a

thermostatic mixing valve which can

· reduce the temperature at the point of use

to a value lower than that of storage;

· maintain this value when the incoming

pressure and temperature conditions

vary.

Thermal disinfection

The diagram below shows the behavior of

the bacteria “Legionella Pneumophila” when

the temperature conditions of the water

in which it is contained vary, in laboratory

sample population.

In order to ensure proper thermal

“disinfection”, the value must not be below

140°F.

:

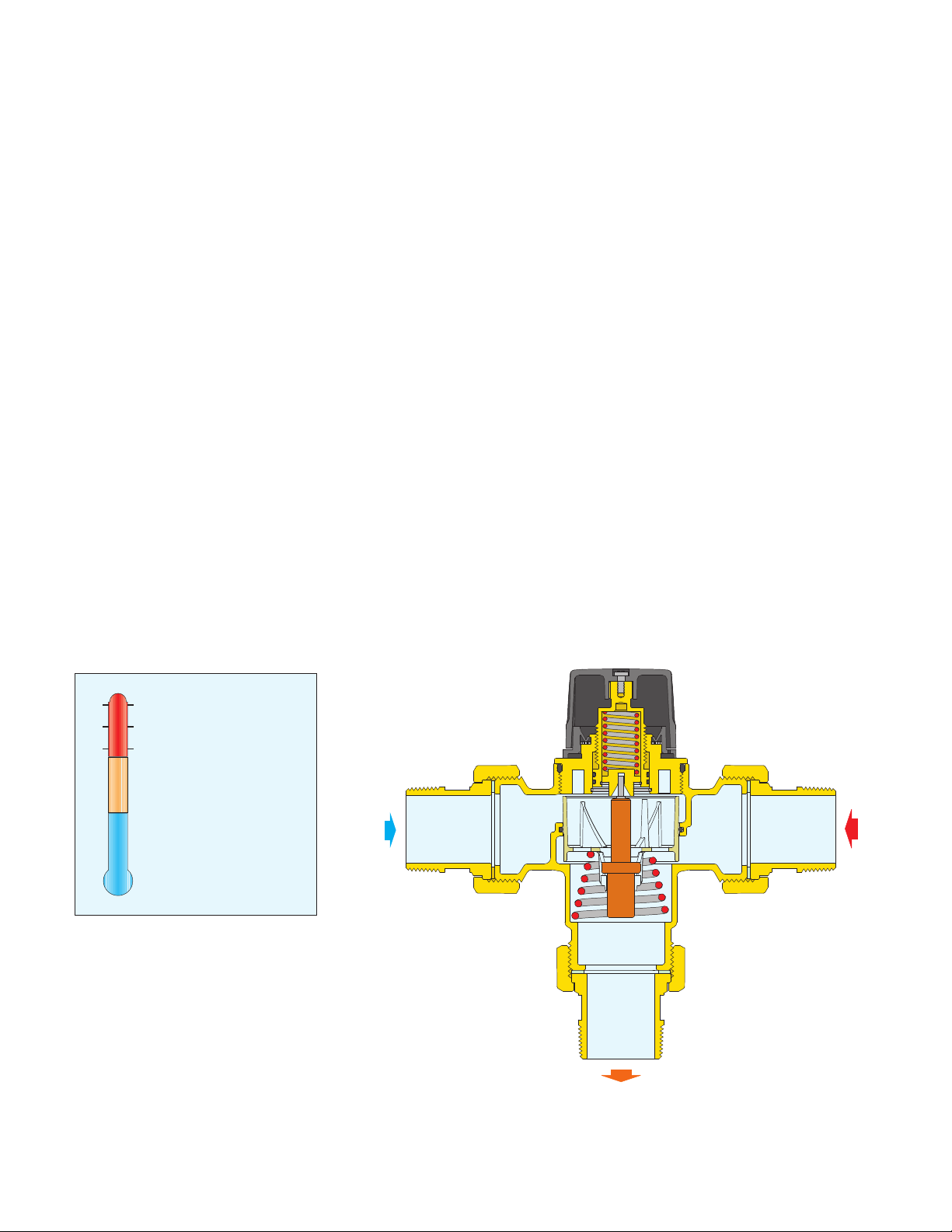

A thermostatic mixing valve mixes hot and cold water in such a way as to maintain a constant

set temperature of the mixed water at the outlet.

A thermostatic element is fully immersed into the mixed water. It then contracts or expands

causing movement of the piston, closing either the hot or cold inlets, regulating the flow rates

entering the valve. If there are variations of temperature or pressure at the inlets, the internal

element automatically reacts attempting to restore the original temperature setting.

Thermal shutoff

In the event of a failure of either the hot or cold supply, the piston will shut off, stopping water

discharging from the mixed water outlet.

The Caleffi valve requires a minimum temperature differential from hot inlet to mixed water outlet

of 20°F (11°C) to ensure the correct operation of the thermal shutoff feature.

Construction details

Double seat

The mixing valve has a special actuator which acts on a double water passage seat. This

produces a high flow rate with a reduced resistance, at the same time maintaining accurate

temperature control.

Anti-wear surfaces

The materials of construction in the 5231 series thermostatic mixing valve eliminates the

problem of jamming caused by mineral deposits. All the working parts, such as the PPSG40

shutter and EPDM seals, are made of a special anti-scale material, with a low friction coefficient,

providing long term high performance.

Low inertia thermostat

The temperature-sensitive element, the “motor” of the thermostatic mixing valve, is characterized

by a low heat inertia; this means that it reacts rapidly to variations in the incoming temperature

and pressure conditions, reducing the valve response times.

Temperature setting and locking

The control knob permits temperature setting, between min. and max., in one turn (360°). It

also has a tamper-proof system to lock the temperature at the set value.

160

140

120

100

80

60

32

Reference documents

For the prevention and control of Legionella,

see the National Regulations and applicable

Code of Practice.

Kills bacteria instantly

Kills 90% of bacteria in 2 minutes

Kills 90% of bacteria in 2 hours

Optimum temperature

for growth of bacteria

Surviving bacteria inactive

COLD

HOT

MIXED

Page 3

Use

Min 1234567Max

77 84 91 102 109 118 126 136 149

Pos.

T (ϒF)

with: T

HOT

= 155ϒF (68ϒC) · T

25 29 33 39 43 48 52 58 65T (ϒC)

Caleffi 5231 series thermostatic mixing valves are designed to be installed at the hot

water heater (ASSE 1017 models).

ASSE 1017 models are designed to be installed at the hot water heater and cannot

be used for tempering water temperature at fixtures as a point-of-use valve. They

are not designed to provide scald protection or anti-chill service and should not be

used where ASSE 1070 devices are required. Wherever a scald protection feature is

required, ASSE 1070 model mixing valves need to be installed. For safety reasons, it

is advisable to limit the maximum mixed water temperature to 120°F.

Instantaneous production of hot water

Caleffi 5231 series thermostatic mixing valves should not be used in conjunction

with boilers giving instantaneous production of domestic hot water. This would

compromise the correct operation of the boiler.

Radiant heating systems

Caleffi Series 5231 thermostatic mixing valves can also be used for controlling the

flow temperature in radiant heating systems, for constant and accurate control with

ease of installation.

Installation

Before installing a Caleffi 5231 series thermostatic mixing valve, the system must be

inspected to ensure that operating conditions are within the range of the mixing valve,

checking, for example, the supply temperature, supply pressure, etc.

Systems where the Caleffi 5231 series thermostatic mixing valve will be installed must

be drained and cleaned out to remove any dirt or debris which may have accumulated

during installation. Failure to remove dirt or debris may affect performance and the

manufacturer’s product guarantee. Demineralized water use is highly recommended

as the warranty is voided if used on water with hardness greater than 10 grains.

The installation of filters of appropriate capacity at the inlet of the water from the supply

line is always advisable.

The water must be sufficienctly treated before it enters the valve in areas with highly

agressive water. Caleffi 5231 series thermostatic mixing valves must be installed in

accordance with the diagrams in this manual, taking into account all current applicable

standards.

Caleffi 5231 series thermostatic mixing valves can be installed in any position, either

vertical or horizontal.

The following are shown on the thermostatic mixing valves body:

- Hot water inlet, color red.

- Cold water inlet, color blue.

- Mixed water outlet, marked “MIX”.

In systems with thermostatic mixing valves, check valves must be installed to prevent

undesirable fulid backflow. The 5231 is approved to ASSE 1017, and as such does

not contain integral check valves, so those must be sourced separately. It is essential

that access to the valve is totally unobstructed for any maintenance which may be

required to the valve or connections. The piping from/to the valve must not be used

to support the weight of the valve itself.

Commissioning

After installation, the valve must be tested and commissioned in accordance with the

instructions given below, taking into account current applicable standards.

1) The system must be clean and free from any dirt or debris

before commissioning the thermostatic mixing valves. Be sure water hardness

is less than 10 grains.

2) It is recommended that the temperature is set using a suitable calibrated

digital thermometer. The valve must be commissioned by measuring the

temperature of the mixed water at the outlet.

3) The maximum outlet temperature from the valve must be set taking account

of the fluctuations due to simultaneous use.

4) Adjust the temperature using the adjusting knob on the valve.

For safety reasons, it is advisable to limit the maximum mixed water

temperature to 120°F in domestic hot water systems.

Temperature setting

The temperature is set to the required value by means of the knob with the

graduated scale, located on the top of the valve.

Caution: In systems with thermostatic mixing valves,

check valves must be installed to prevent undesirable

fluid backflow. The 5231 models do not contain integral

check valves, and must be sourced separately.

Locking the setting

Position the knob at the required value,

unscrew the top screw, slide off the knob and

put it back in such a way that the handle fits

into the internal slot of the knob. Tighten the

head screw

.

3

1

M

I

2

N

M

A

X

7

Point of Distribution ASSE 1017 Approved

Size

1" NPT 523160A 4.4 40 7

1" Sweat 523168A 4.4 40 7

1 ¼" NPT 523170A 4.4 40 7.6

1 ¼" Sweat w/ temp 523177A 4.4 40 7.6

1¼" Sweat 523178A 4.4 40 7.6

1 ½" NPT 523180A 8.8 70 13

1 ½" Sweat 523188A 8.8 70 13

2" NPT 523190A 8.8 70 14.2

2" Sweat 523198A 8.8 70 14.2

*Recommended flow rates for temperature stabilty: ± 3°F (± 2°C).

Setting the temperature

The temperature is set to the required value by means of the adjusting

knob with the graduated scale on the top of the valve.

Flow curve

∆

p (psi)

20

10

5

4

3

2

1

0.5

0.4 0.4

0.3

0.2

0.1

2

.1

Connection

1” 1 1/2” 2”

5

.3

Model

104

95

35

109

40 43 47 50 54 58 61 66

10

1

117

1 1/4”

20

1.5

Min.

Flow*

(GPM)

122

129

136 142 150

INLET

50

3.25

Max.

Flow*

(GPM)

∆p

(psi) (bar)

20

10

5

4

3

2

1

0.5

0.3

0.2

0.1

)

100

gpm

G

(l/s) (

CV

1.0

0.5

0.4

0.3

0.2

0.1

0.05

0.04

0.03

0.02

0.01

Page 4

Applications diagrams

712

M

MIN

A

X

HOT

RED

MIX

COLD

BLUE

Radiant heating system application

SUPPLY

HOTCOLD

7

X

A

M

MIN

1

2

MIX

CALEFFI

CALEFFI

I

I

F

F

F

F

E

E

L

L

A

C

CA

10

10

10

10

10

10

8

8

8

8

8

8

6

6

6

6

6

6

4

4

4

4

4

4

2

2

2

2

2

2

0

0

0

0

0

0

CALEFFI

CALEFFI

RETURN

Recirculation with point-of-distribution thermostatic mixing valves

For domestic recirculating systems that include a single ASSE 1017

point-of-distribution thermostatic mixing valve, such as the Caleffi

5231 series thermostatic mixing valves, the piping installation below

is recommended.

In any reciculating hot water distribution system there will be times

when the circulator is operating, but no hot water is being drawn at

the fixtures. Under this condition, heat continually dissipates from

the piping forming the recirculation loop. If the loop is relatively

short, and well insulated, the rate of heat loss should be very small.

If the loop is long, and uninsulated, the rate of heat loss could be

substantially greater.

To maintain the recirculating water at the desired delivery temperature

the heat lost from the loop must be replaced. This requires some

water flow between the loop and the hot water source. Ideally, this

flow is adjusted so that the rate of heat trasfer from the hot water

source to the loop exactly balances the rate of heat loss from the

loop's piping.

The figure (below right) shows a "bypass valve" (1), and "return

valve" (2), which regulates how much warm water from the return

side of the recirculating loop flows back to the storage tank. When

there is no demand for hot water at the fixtures, the flow of return

water to the tank will equal the rate of hot water flow from the tank to

the inlet port of the mixing valve. Ideally, this flow should be adjusted

so that the rate of heat transfer from the tank to the recirculating

loop exactly balances the rate of heat loss from the recirculating

loop. This allows the water temperature leaving the mixing valve to

remain stable.

The bypass valve (1) and possibly the return valve (2) must be

adjusted when there is no domestic water draw on the recirculating

loop (when all the fixtures are off). Begin with the bypass valve

(1) fully closed, and the return valve (2) fully open. Turn on the

recirculating circulator and let it run for several minutes. The supply

water temperature leaving the mixing valve will likely be lower than

the setting of the valve, since there is no return flow to the tank.

Slowly open the bypass valve (1) and monitor the temperature

leaving the mixing valve. It will likely begin rising as some water

returns to the tank, and an equal flow of hot water moves from

the tank to the hot port of the mixing valve. When the temperature

leaving the mixing valve remains stable, and is at or very close to the

temperature set on the mixing valve, the bypass valve is correctly

set.

The return valve (2) can remain fully open unless a situation occurs

where the bypass valve (1) is fully open, but the temperature leaving

the mixing valve is still too low. If this occurs, partially close the

return valve (2) to add flow resistance. This forces more flow through

the bypass valve (1). Repeat the previously described procedure

of slowly opening the bypass valve (1) until the water temperature

leaving the mixing valve is stable.

Radiant loop

Key to symbols

Safety relief valve

Check valve

Isolation valve

Expansion vessel

Filter

Pump

Globe Valve

Domestic water system with recirculation

STORAGE

HOT WATER

HEATER

T

7

X

A

M

N

MI

1

2

2

1

Page 5

SPECIFICATION SUMMARIES

5231 series

Adjustable thermostatic mixing valve. cUPC Listed to ASSE 1017/CSA B125.3. Threaded NPT or sweat connections from 1” to

2” with unions and tailpieces. Low-lead brass body (<0.25% lead content) certified by IAPMO R&T. Meets requirements of ANSI/

NSF 372-2011. PPSG40 shutter, stainlless steel springs, and EPDM seals. Maximum working pressure 200 psi (14 bar). Maximum

operating differential pressure 70 psi (5 bar). Mixed temperature setting range 95 to 150°F (35 to 66°C), Temperature stability

± 3°F (± 2°C). Maximum water hardness: 10 grains. Provided with tamper-proof temperature locking. Provide with optional mixed

outlet temperature gauge for 1 1/4" union sweat model, 30 to 210°F scale, 2 inch diameter.

We reserve the right to change our products and their relevant technical data, contained in this publication, at any time and without prior notice.

Caleffi North America, Inc.

3883 W. Milwaukee Road

Milwaukee, WI 53208

Tel: 414-238-2360 · Fax: 414-238-2366

sales@caleffi.com · www.caleffi.com/usa/en-us

© Copyright 2014 Caleffi North America, Inc.

Loading...

Loading...