Page 1

ASSE 1070

www.caleffi.com

CALEFFI

38531.04

Scald Protection Three-Way Thermostatic Mixing Valve

© Cop yri ght 2 0 10 Ca l ef f i

5213 Series

Installation, commissioning and servicing instructions

Function

Scald Protection Three-Way Thermostatic mixing valves are used in

applications where the user must be protected from the danger of

scalding caused by hot water.

The Caleffi 5213 series provides water at a safe and usable

temperature in situations where the control of the temperature of

the water discharging from a terminal fitting is of the utmost

importance, i.e. within hospitals, schools, nursing homes, etc.

The valve is designed to prevent the flow of water discharging from

the mixed water outlet in the event of the failure of hot or cold supply.

The Caleffi 5213 series is a high performance thermostatic

mixing valve and is ASSE 1070 listed.

The valve is complete with check valve at both hot and cold inlets.

Product range

5213 series scald protection three-way thermostatic mixing valve.

Union thread NPT male connections, sizes 1/2”, 3/4”,1”;

Union sweat connection, size 1/2”, 3/4”, 1”.

Technical characteristics

Materials: - Valve body and Regulating Spindle: low-lead brass (<0.25% Lead content)

Temperature adjustment range: 85–120°F (29–49°C)

Temperature set: must be commissioned on site to achieve desired temperature

Temperature control: ±3°F (±2°C)

Cold inlet temperature: Minimum 39°F (4°C); Maximum 85°F (29°C)

Hot inlet temperature: Minimum 120°F (49°C); Maximum 185°F (85°C)

Maximum working pressure: Static 140 psi (10 bar); Dynamic 70 psi (5 bar)

Minimum working pressure (dynamic): 1.5 psi (0.1 bar)

Maximum unbalanced dynamic supply (hot/cold or cold/hot): 6:1

Minimum temperature differential between hot water inlet

and mixed water outlet to ensure thermal shutoff function: 18°F (10°C)

Minimum temperature differential between mixed water outlet

and cold water inlet to ensure stable operation: 9°F (5°C)

Minimum flow rate for stable operation: 1 gpm (4 l/min)

Certified to: ASSE 1070 Listed

Lead Plumbing Law Compliance: (0.25% Max. weighted average lead content)

- Lead Plumbing Law Certified by IAPMO R&T

- Internal shutter: PPO

- Sealing elements: EPDM

- Cover: ABS

1

Page 2

SAFETY INSTRUCTION

This safety alert symbol will be used in this manual to draw attention to safety related

instructions. When used, the safety alert symbol means ATTENTION! BECOME ALERT!

YOUR SAFETY IS INVOLVED! FAILURE TO FOLLOW THESE INSTRUCTIONS MAY

RESULT IN A SAFETY HAZARD.

CAUTION: All work must be performed by qualified personnel trained in the

proper application, installation, and maintenance of systems in accordance

with all applicable codes and ordinances.

CAUTION: If the thermostatic mixer is not installed, commissioned and

maintained properly, according to the instructions contained in this

manual, it may not operate correctly and may endanger the user.

CAUTION: Make sure that all the connecting pipework is water tight.

CAUTION: When making the water connections, make sure that the mixer

connecting pipework is not mechanically over-stressed. Over time this

could cause breakages, with consequent water losses which, in turn,

could cause harm to property and/or people.

CAUTION: Water temperatures higher than 100°F can be dangerous.

During the installation, commissioning and maintenance of the

thermostatic mixer, take the necessary precautions to ensure that such

temperatures do not endanger people.

CAUTION: In the case of highly aggressive water, arrangements must be

made to treat the water before it enters the thermostatic mixer, in

accordance with current legislation. Otherwise the mixer may be

damaged and will not operate correctly.

Leave this manual for the user.

2

Page 3

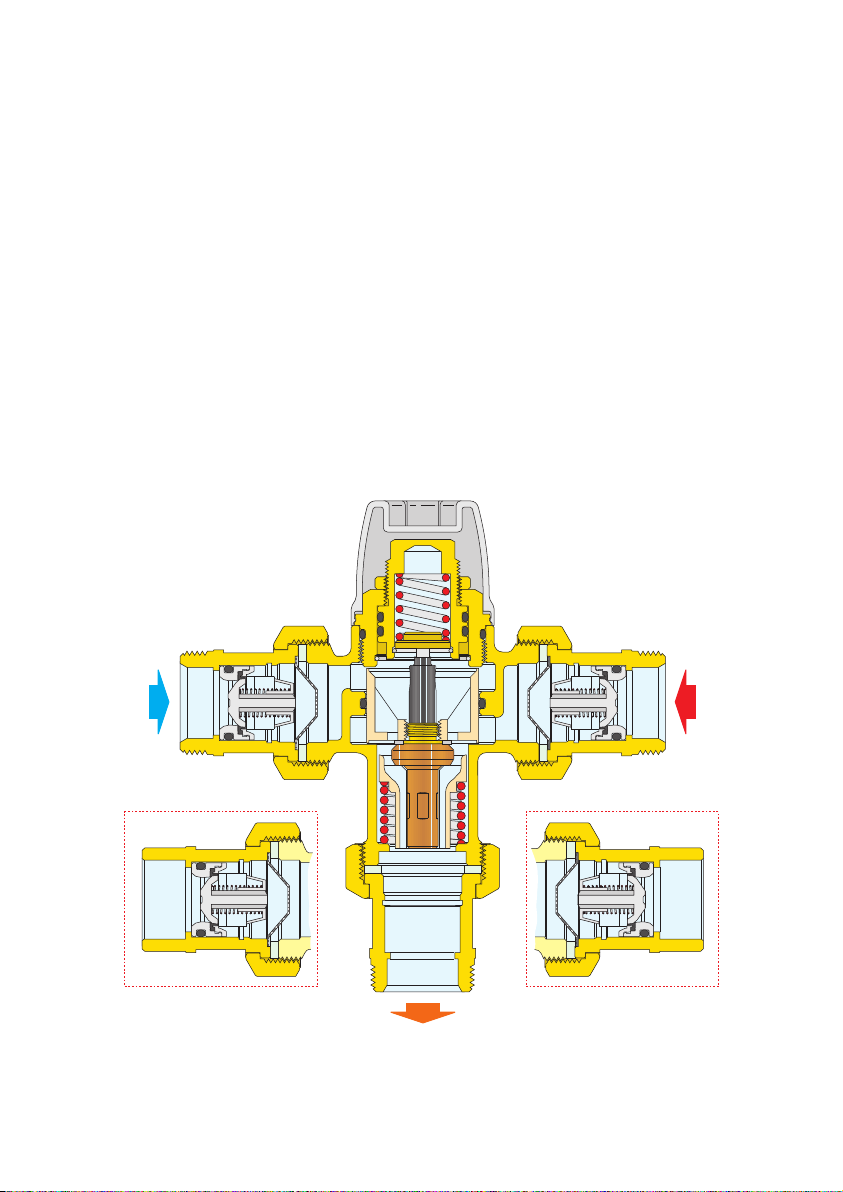

Operating Principle

COLD

HOT

MIXED

A thermostatic mixing valve mixes hot and cold water in such a way as to maintain constant set

temperature of the mixed water at the outlet.

A thermostatic element is fully immersed into the mixed water. This element then contracts or

expands causing movement of the piston, closing either the hot or cold inlets, regulating the

flow rates entering the valve.

If there are variations of temperature or pressure at the inlets, the internal element automatically

reacts to restore the original temperature setting.

Thermal shutoff

In the event of a failure of either the hot or cold supply, the piston will shut off, stopping water

discharging from the mixed water outlet.

The Caleffi valve requires a minimum temperature differential from hot inlet to mixed water outlet

of 18°F (10°C) to ensure the correct operation of the thermal shutoff feature.

Sweat version

3

Page 4

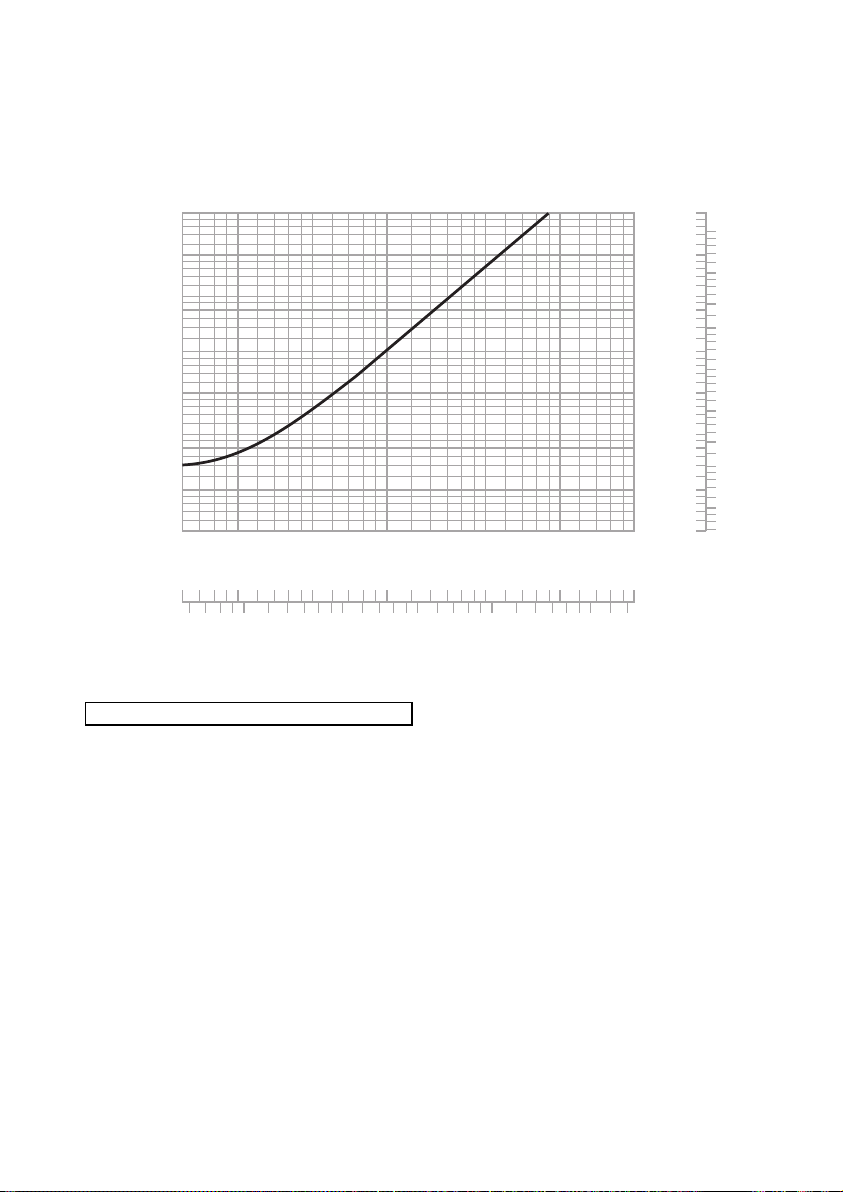

Flow rate graph

10

0.1

2

5

1

0.2

0

.

3

0.

5

20

50

∆p (psi)

G (l/min) (

gpm

)

10

2

3

5

2

0

0

.

1

1

0

.

2

0

.

3

0.

5

(psi) (bar)

10

2

3

5

2

0

1

0.5

10

2

5

2

0

0.01

0

.

1

0

.

02

0

.

03

0

.

05

1

.

0

0

.2

0.3

0

.

5

4

0

.4 0.4

4

0.0

4

0

.4

0.3

1/2", 3/4", 1" • Cv= 2 • Kv=1.7 (m3/h)

Flow rate-use

The Caleffi 5213 series is a thermostatic mixing valve suitable for single or multiple point of

use applications in accordance with installation rules and indications specified in ASSE 1070

standards.

The system must be sized taking into account the current legislation with regard to the nominal

flow rate of each outlet.

4

Page 5

8

11

12

9

10

4

6

7

5

2

3

1

VALVE BODY

UNION NUT, Quantity 3 per valve

UNION WASHER, Quantity 3 per valve

INLET PORT MALE TAILPIECE

WITH INTEGRAL CHECK VALVE

Quantity 2 per valve

INLET PORT CONIC FILTER,

Quantity 2 per valve

TEMPERATURE SPINDLE LOCKING NUT

FLOW CONVEYOR

THERMOSTATIC ELEMENT

'O' RING SEAL

LOWER SPRING

UPPER BODY

PROTECTIVE CAP

13

OUTLET PORT TAILPIECE,

Quantity 1 per valve

4a

'O' RING SEAL

9118

7

6

3

5

4

1

2

10

9 10 12

4a

12

13

11

Exploded diagram

B

5

Sweat version

Page 6

Fittings table

1/2” 3/4” 1”

Item Item Item Q.ty NPT Sweat NPT Sweat NPT Sweat

number description per Valve 521342A 521349A 521352A 521359A 521362A 521369A

9 Union Washer 3 R50055

10 Union Nut 1” 3 R61008/C

Inlet Male Tailpiece

11

with Check Valve

12 Inlet conic filter 2 R52429

13 Outlet Tailpiece 1 R31981 NA10002 R31901A NA10003 59817A* 59834A*

*Tailpiece fitting with integral union nut - 1" NPT and Sweat models require only 2 separate 1" union nuts (item 10)

Installation

The following instructions must be read prior to the installation of a Caleffi valve 5213 series. The

installer should also be aware of his responsibility and duty of care to ensure that all aspects of the

installation comply with current regulations and legislation.

The Caleffi 5213 series should be installed using the appropriate Standard, Code of Practice and

legislation applicable to each state and following the details in this manual.

The Caleffi 5213 series must be installed by a licensed plumber.

Prior to the installation of the Caleffi 5213 series valve, the system must be checked to ensure that the

system operating conditions fall within the recommended operating range of the valve, i.e.

verify supply temperatures, supply pressures, risk assessments, etc.

The supply system into which the Caleffi 5213 series is to be installed must be thoroughly flushed and

cleaned to remove any debris which may accumulate during the installation. Failure to remove any

debris will affect the performance and the manufacturer’s warranty on the product.

In areas that are subject to high levels of aggressive water, provision must be made to treat the water

prior to it entering the valve.

The valve can be installed in any position, whether vertical or horizontal. It is essential that the access

to the valve is not obstructed for future maintenance that may be required to the valve or associated

fittings.

It is essential that when the installation is designed and/or installed, all current legislation is noted, e.g.

the maximum distance from the outlet of the valve to any terminal fitting.

The connecting hot and cold water supplies must be connected to the valve strictly in accordance

with the indications on the body of the valve.

The inlets of the valves are clearly marked with the letter H (Hot) and C (Cold).

The outlet is marked with the word MIX.

Where one or both the incoming supply pressures are excessive, a Caleffi pressure reducing valve

should be fitted to reduce the pressure(s) within the limits.

Any thermostatic mixing valve must be installed with isolating valves, line strainers and check valves

at both the inlets. Isolating valves are required so that the water supply to the valve can be isolated

in the event that servicing is required. Strainers are required to prevent debris from entering the valve.

Check valves are required to both hot and cold inlets to prevent cross-connection.

The Caleffi 5213 series is supplied complete with the check valves at the hot and cold inlets.

The check valve of the sweat version must be dismantled from the tail piece before soldering and then

reassembled.

To ensure that the performance of the Caleffi 5213 series valve is maintained (in the event of cold

water failure), the temperature of the hot water supply at the point of entry to the valve must be a

minimum of 18°F higher than the set mixed water discharge temperature.

The pipework to and from the valve must not be used to support the weight of the valve.

If the valve is not installed correctly, it will not function correctly and may put the user in danger.

2 59893A 59904A 59840A 59905A 59894A 59906A

6

Page 7

Installation diagram

Pressure

reducing valve

(if required)

Isolating

valve

Isolating

valve

Strainer

& check

valve

Strainer

& check

valve

T

Pressure

reducing valve

(if required)

Temperature

limiting valve

(if required)

HOT SUPPLY COLD SUPPLY

MIXED

OUTLET

MIX

MIX

HOT

COLD

MIX

MIX

HOT

COLD

Point of use

Multiple use

Multiple use with sensor faucet

7

Page 8

Commissioning

Upon completion of the installation, the valve should be tested and commissioned as per the

procedure outlined below or as specified by the local authority.

The following instructions should be read and understood prior to commissioning the Caleffi

5213 series valve. If, under any circumstances, there are aspects of the installation/system

which do not comply with our requirements or the specifications as laid down, the valve must

not be put into service until the installation/system does comply.

1) Ensure that the system is throughly clean and free from debris prior to commissioning the

thermostatic mixing valve.

2) We recommend that the commissioning of temperatures is carried out using a suitably

calibrated and accurate digital thermometer.

The valve is commissioned by measuring the mixed water temperature at the outlet.

3) In accordance with the anti-scald requirements, water installation shall deliver hot water at

the outlet of the sanitary fixtures used primarily for personal hygiene purposes at a

temperature not exceeding:

· 120°F (49°C) or as specified by authority having jurisdiction.

4) The temperature at the outlet of each valve must be set taking into consideration any

fluctuations which may occurr within the system due to simultaneous demand.

5) Once the supply temperatures are stabilised and the normal operating conditions are

established, the valve can be commissioned. Due to the unique design of the cap, the

temperature setting can be adjusted by removing the cap from the valve body and

reversing the cap onto the temperature adjustment spindle. We suggest that the following

sequence is followed when commissioning the valve.

a) Set the mixed water discharge temperature to the required temperature.

b) Measure and record the temperature of hot and cold water supplies at the

connections to the valve.

c) Measure and record the temperature of the water discharging from the largest and

smallest volume draw off points.

d) Perform the thermal shut-off test. Isolate the cold water supply to the Caleffi valve

and monitor the mixed water temperature. The outlet flow should quickly cease

flowing.

e) Measure and record the maximum mixed water temperature. The temperature

should not exceed the temperature allowed by the applicable standard or code of

practice for each state.

f) Restore the cold water supply to the valve and measure and record the outlet

temperature after the mixed water temperature has stabilised. The final temperature

found during this test should not exceed the permitted values +3°F.

6) Once the desired temperature has been reached, the adjustment spindle can be locked in

position using the locking nut supplied with the valve.

7) Once the desired temperature is established, remove the cap from the temperature

adjustment spindle and secure the head back on to the valve into its original position to

prevent tampering by unauthorised persons.

We recommend that the above information is recorded in the Commissioning Report and

updated on the Service Report when any work is carried out on the valve.

8

Page 9

Temperature adjustment

1

2

3

View of temperature adjustment

Fitting temperature adjustment cap

Temperature adjustment cap in place

4

Locking adjustment spindle with locking nut

9

Page 10

Maintenance

In service tests should be carried out regularly to monitor and record the performance of the

valve. Deterioration in performance can indicate the need for servicing of the valve and/or

water supply. If, during these tests, the mixed water temperature has changed significantly

from the previous test results, record the change before re-adjusting the mixed water

temperature. If the final mixed water temperature is greater than the permitted values, we

recommend that the details quoted in Installation and Commissioning sections are verified and

that service work is required.

We recommend that at least every 12 months, or more frequently if the need arises, that the

following aspects are checked to ensure that the optimum performance level of the valve is

maintained.

With reference to the exploded diagram on page 5:

1) On the Caleffi 5213 series valves, the inlet conic filters (12) on both the hot and cold water

supplies can be removed for cleaning by unscrewing the inlet union nuts and carefully

pulling apart the connecting pipework.

2) The built in check valves (11) on the Caleffi 5213 series valves can be accessed in a similar

way to 1) to ensure freedom of operation and correct working.

3) In case of service work, the internal components of the valve can be dis-assembled for

cleaning and discaling:

a) Remove the cap of the valve (1) and the locking nut (2)

b) Remove the upper body (3) using a suitable spanner

c) Remove parts 5-7 noting the correct orientation

d) Remove all signs of scale and dirt from the internal part using a suitable de-scaling

solution.

e) Re-assemble all the components

Once the serviceable items have been dealt with we recommend that the commissioning

details as stated previously are repeated ensuring that a suitably accurate thermometer is

used.

Should the valve still not function correctly, it may be necessary to replace the thermal element

or other components. Refer to spare part kits and contact Service Department for details and

advices.

Spare parts

With reference to the exploded diagram, the spare parts are available on request for Caleffi

5213 series valves, see table on page 6.

10

Page 11

Troubleshooting

Under normal operating conditions the Caleffi 5213 series thermostatic mixing valve will

provide a very high level of performance. However, in some circumstances, when our

maintenance plan is not followed, the following problems may arise.

Symptom

Hot water at the cold taps

Fluctuating mixed water

temperature

Erratic flow of water from

the valve

No flow of water from the

valve

Cause

a) Operation of the insert

check valve is hindered;

check valve is not

sealing correctly.

b) Check valves not fitted.

a) Erratic supply

temperatures at the

inlets of the valve.

b) Starvation of the water

supplies at the inlets

of the valve.

c) Incorrect commissioning

of the valve.

a) Insufficient water

supplies.

b) Fluctuations in supply

pressures/temperatures.

c) Adverse effect created

by other draw off points

on the system.

a) In-line filters blocked.

b) Insufficient supply

pressures.

c) Debris obstructing valve

operation.

Corrective action

· Replace faulty check

valves

· Restore inlet conditions

within the limits of the

valve.

· Stabilize inlet supply

conditions.

· Clean filters.

· Restore inlet supplies.

· Clean debris or scale

from valve.

Valve does not shutoff

when tested

a) Installation not in

accordance with our

recommendations.

b) The minimum

temperature differential

not achieved.

c) Internal mechanism

hindered by debris.

11

· Install as oulined in the

instructions.

· Raise hot water

temperature.

· Clean debris or scale

from valve.

Page 12

CALEFFI

Caleffi North America, Inc.

3883 West Milwaukee Road

Milwaukee, WI 53208

T: 414.238.2360 F: 414.238.2366

Loading...

Loading...