Page 1

Circulation units

for solar thermal systems, with solar regulator DeltaSol® C+

268-269 series

INSTALLATION AND COMMISSIONING MANUAL

INDEX

28199

Function

Product range

Technical specifications

Characteristic components

Installation

Filling the system

1

2

3

4

5

Function

Circulation units are used on the primary circuit of

solar thermal systems to control the temperature

in the hot water storage. The pump inside the

units is activated by the signal arriving from the

regulator. Moreover, safety and functional devices

for optimum control of the circuit are fitted in the

units.

They are available with flow and return connection

or with return connection only.

Some versions are also complete with the digital

regulator DeltaSol

suitable for the operation and control of 9 different

types of solar thermal systems.

®

C+ for solar thermal systems,

Commissioning

Components

Application diagrams

1

6

7

8

Page 2

NOTICE

The following instructions must be read and understood before installing, commissioning and

servicing the circulation unit.

The safety symbol is used in this manual to draw attention to the respective safety instructions.

The meaning of this symbol is as follows:

N.B! YOUR SAFETY IS INVOLVED. FAILURE IN FOLLOWING THESE INSTRUCTIONS MAY

RESULT IN INJURIES.

- The circulation unit for solar thermal systems must be installed by a qualified technician in compliance with

relevant national and/or local regulations.

- If the circulation unit is not installed, commissioned and serviced correctly in accordance with the instructions

given in this manual, it might not work properly and could put the user in danger.

- Make sure that all connection fittings are watertight.

- When realising hydraulic connections, make sure that threaded connections are not overstressed mechanically.

Over time, excessive stress may cause breakages with hydraulic leaks and damage to property and/or personal injury.

- Water temperatures exceeding 50°C may cause severe burns.

- When installing, commissioning and servicing, take the necessary precautions so that these temperatures will not

be hazardous for people.

CAUTION: Risk of electric shock. Remove the power supply before carrying out any work.

Failure in following these instructions may result in personal injury or damage to

property.

Product range

Code 268050 Circulation unit with return connection 1–13 l/min size 3/4”

Code 269050 Circulation unit with flow and return connection 1–13 l/min size 3/4”

Code 268250 Circulation unit with return connection, with regulator DeltaSol

Code 269250 Circulation uniti with flow and return connection, with regulator DeltaSol

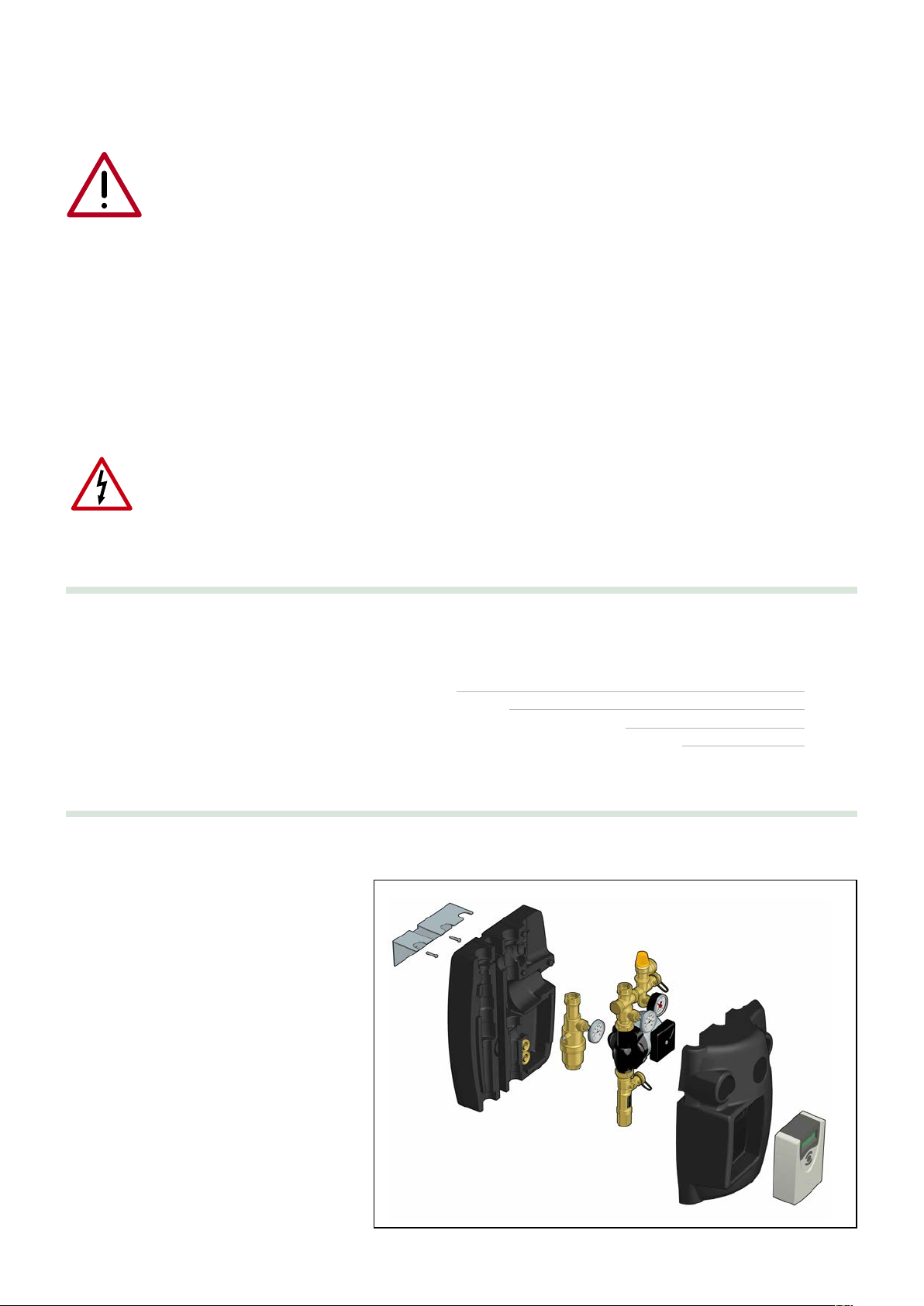

Package content

The package contains:

Circulation units

• The solar circulation unit complete with front

and rear insulation.

• The wall fixing bracket.

Regulator (only for versions complete with)

• Solar regulator DeltaSol®C+.

• 4 temperature probes.

Accessories:

• Bag of 2 M5 screws, S6 screw anchors and

washers.

®

C+ 1–13 l/min size 3/4”

®

C+ 1–13 l/min size 3/4”

2

Page 3

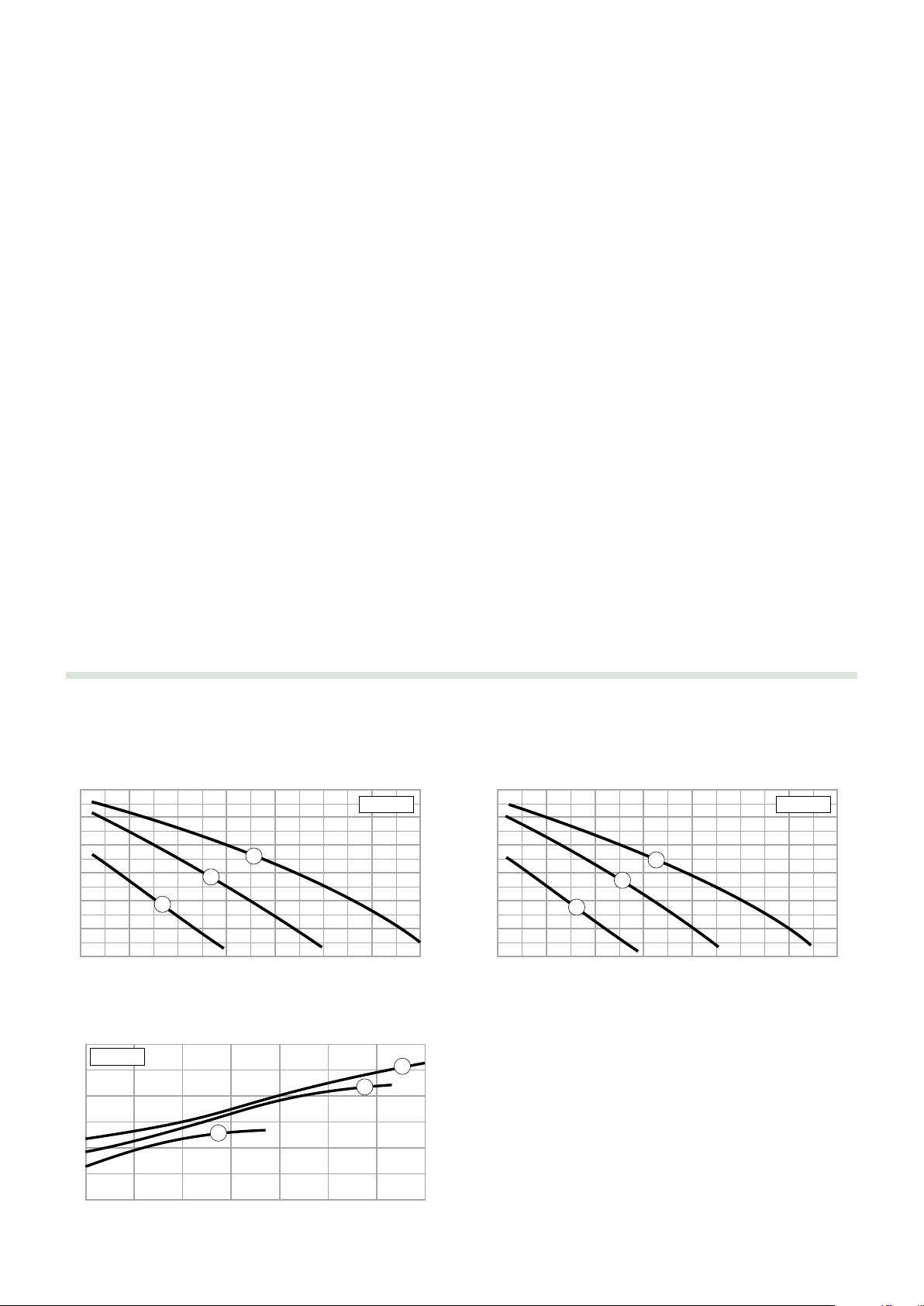

Technical specifications

0

0

H (mm w.g.)

G (m

3

/h)

H (kPa)

0

1

2

3

UPS 15-65

6

5

4

3

2

1

60

50

40

30

20

10

0,2 0,4 0,6 0,8 1,0 1,2 1,4

0

0

H (mm w.g.)

G (m

3

/h)

H (kPa)

0

1

2

3

UPS 15-65

6

5

4

3

2

1

60

50

40

30

20

10

0,2 0,4 0,6 0,8 1,0 1,2 1,4

0

P (W)

G (m

3

/h)

20

30

40

50

60

70

80

0,2 0,4 0,6 0,8 1,0 1,2 1,4

1

2

3

UPS 15-65

Materials

Shut-off valves

Body: brass EN 12165 CW617N

Check valve: brass EN 12164 CW614N

Temperature gauge: steel / aluminium

Air separator device

Body: brass EN 12165 CW617N

Instrument holder

Body: brass EN 12165 CW617N

Seals: EPDM

O-Rings: EPDM

Flow meter

Body: brass EN 12165 CW617N

Transparent level gauge: PSU

Flow indicator: brass EN 12164 CW614N

Hydraulic seals: EPDM

Insulation

Material: EPP

Average thickness: 30 mm

Density: 45 kg/m

Working temperature range: -5–120°C

Thermal conductivity: 0,037 W/(m·K) at 10°C

Reaction to fire (UL 94): class HBF

Performance

Medium: water, glycol solutions

Max. percentage of glycol: 50%

Max. working temperature:

- deaerator side flow: 160°C

- pump side return: 110°C

Max. working pressure: 10 bar

Safety relief valve working temperature range: -30–160°C

Safety relief valve setting: 6 bar (for other settings, see 253 series)

Check valve min. opening pressure (∆p): 2 kPa (200 mm w.g.)

Working temperature range of shut-off and check valve: -30–160°C

Working temperature range of flow meter : -10–110°C

Flow rate adjustment: 1–13 l/min

Flow rate indicator accuracy: ±10%

Pressure gauge scale: 0–10 bar

Temperature gauge scale: 0-160°C

Connections: 3/4” F

Hose connection: 3/4” M

Fill/drain connections: with Ø 15 mm hose connection

Grundfos Solar 15-65 pump

Body: cast iron GG 15/20

Electric supply: 230 V - 50 Hz

3

Max. pressure: 10 bar

Max. temperature: 110°C

Protection class: IP 42

Digital regulator

Electric supply: 230 V - 50 Hz

Nominal power consumption: 1,5 VA (12 V (ac))

4 Pt1000 probe inputs

2 relay outputs with semiconductor with contact rating: 1 A

–

2 temperature probes with working range: -50

200°C

Probe cable working temperature range: -50–70°C

2 temperature probes with working range: -50–200°C

Probe cable working temperature range: -50–180°C

Ambient temperature range: 0–40°C

Protection class: IP 20

Dimensions: 172 x 111 x 49 mm

Head available at the circulation unit connections

268 series Flow rate adjustment range 1–13 l/min 269 series Flow rate adjustment range 1–13 l/min

Power consumption

3

Page 4

Characteristic components

1

2

3

4

5

8

9

11

10

16

16

a

a

a

a

a

a

a

a

aaa

a

a

a

a

a

a

a

a

a

a

a

aa

a

a

a

a

a

a

a

a

a

a

aa

a

a

a

a

a

a

a

a

a

a

aaa

a

a

a

a

a

a

a

a

a

a

a

aa

0

20

40

60

80

100

120

140

160

c

o

n

f

o

r

m

e

n

o

r

m

e

I

S

P

E

S

L

0

2

4

6

8

10

bar

CL 2.5

1

13

11

9

7

5

3

l/min

10

a

a

a

a

a

a

a

a

a

a

a

a

aaa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aa

a

a

a

a

a

a

a

a

a

a

aaa

a

a

a

a

a

a

aa

a

a

a

aaa

a

a

a

a

a

a

aa

a

aa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

0

20

40

6080100

120

140

160

0

20

40

6080100

120

140

160

c

o

n

f

o

r

m

e

n

o

r

m

e

I

S

P

E

S

L

0

2

4

6

8

10

bar

CL 2.5

7

9

16

16

1

13

11

9

7

5

3

l/min

1

2

3

4

11

5

8

6

12

13

75° 65°

12°

14

15

1) Grundfos Solar 15-65 circulation pump

2)

Safety valve with adjustable outlet type 253 series

3) Fill/drain cock with control key

4) Instrument holder fitting with pressure gauge

5) Flow meter

6) Deaerator with air vent

7) Flow temperature gauge

8) Return temperature gauge

9) Pre-formed shell insulation

10) Shut-off valve with built-in check valve

11) Connection kit for expansion vessel (optional)

12)

Display with synoptic diagram and temperature indication*

13) Regulating keys*

14) Temperature probe*

15) Stainless steel probe pocket code 257004 (optional)

16) Hose connection

* only for versions with DeltaSol®C+ regulator

4

Page 5

Installation

a

a

a

a

a

a

a

a

aaa

a

a

a

a

a

a

a

a

a

a

a

aa

a

a

a

a

a

a

a

0

20

40

6080100

120

140

160

0

20

40

6080100

120

140

160

c

o

n

f

o

r

m

e

n

o

r

m

e

I

S

P

E

S

L

0

2

4

6

8

10

bar

CL 2.5

A

1

13

11

9

7

5

3

l/min

• Fix the wall support bracket, using the fixing screws supplied in the pack (1).

• Insert the rear insulation, through the notch provided (2).

• Insert the unit components in the insulation using the special notches made in the bracket and the slots in the components. Block the

components on the bracket, pulling them downwards to that they click into their housing (3).

• Establish the position for installing the expansion vessel at a distance allowed by the length of the flexible pipe, using the bracket provided.

The latter allows the use of expansion vessels with a maximum capacity of 24 l, see the instructions concerning the accessories (4).

• Install the pipes of the whole system and connect the solar unit. Secure the components and the pipes to the rear insulation.

Fully tighten all the fittings.

• The unit’s threaded fittings are tightened and tested in the assembly phase at the factory. However, when commissioning it is necessary to

check the seal of the fittings, performing a pressure test.

• Make the electrical connections of the system, as specified in the regulator instruction manual. Apply the front part of the insulation.

1

Filling the system

• Open the shut-off valve coupled with the automatic air vent, installed in the highest point of the solar thermal system (1).

• Open the shut-off and check valves, turning the control stems (2) through 45° (do not remove the temperature gauges).

• Fill by means of a pump, using the cock (A) located at the lowest point of the system, until air no longer comes out of the air vent (1). If the

solar thermal system is made using water premixed with antifreeze, any top-ups must be carried out using a mixture with the same

proportions.

• Close the shut-off valve of the air vent (3).

• Close the cock (A).

1

234

2

3

5

Page 6

Flushing the system

a

a

a

a

a

a

a

a

a

a

a

a

aaa

a

a

a

a

a

a

a

a

a

a

a

aa

a

a

a

a

a

a

a

0

20

40

6080100

120

140

160

0

20

40

6080100

120

140

160

c

o

n

f

o

r

m

e

n

o

r

m

e

I

S

P

E

S

L

0

2

4

6

8

10

bar

CL 2.5

1

13

11

9

7

5

3

l/min

Close the flow meter regulating ball valve (1). Then open the fill/drain cock, by turning it counter-clockwise using the cap with control key (2).

•

• By means of a (separate) external pump applied on the fill/drain cock of the safety unit (3), let the medium flow through the solar panels and

the heat exchange circuit until the medium comes out of the fill/drain cock (4) of the flow meter.

• Briefly open the flow meter ball valve (4) to expel all the air from the system.

• Leave the external pump running on the system for a few minutes to ensure correct flushing.

1

34

Commissioning

• Close the flow meter fil/drain cock (1) and increase the system pressure up to the maximum design pressure, by means of the external filling

pump applied to the fill/drain cock of the safety unit.

equipped with control key.

• Open the valves of the unit (3) and switch on the pump of the solar circulation unit (do not remove the temperature gauges).

• Let the water circulate for a certain time, then check the water tightness.

• Open the air vent again, installed in the highest point of the solar thermal system, repeating the deaeration phase, briefly activating the

circulation pump.

• Restore the desired working pressure with the filling pump.

• The system flow rate may be changed by means of the flow meter (4). This modulation is performed by the ball valve with which it is

equipped (see respective characteristics). To regulate/limit the flow rate it is recommended to follow the indications of the solar panel

manufacturer.

• After the first operating hours, the solar thermal system must be deaerated again, both in the highest point and on the air separator (on the

versions where this is contemplated).

Once deaeration has been completed, check the system pressure and if necessary restore to the desired working pressure.

2

When this pressure is reached (2), close the fill/drain cock of the safety unit using the cap

1234

Draining the system

• The draining operation is necessary if the system has been filled only with water and there is a risk of frost.

• Open the shut-off and check valves, turning the ball valve through 45°. Open the air vents in the highest point.

• Open the drain cock at the lowest point of the system.

6

Page 7

Shut-off and check valves

13

11

9

7

open closed

2

3

0

°

F

1

1

0

°

C

Flow meter

The shut-off valves are equipped with a built-in check valve,

positioned inside the ball.

1. To allow the passage of the fluid

in both directions, the ball valves

must be opened at 45°, using a

9 mm fixed wrench.

The check valve is opened by the

ball, see figure (A).

2. In normal system operation, the

ball valves must be completely

open.

A

The flow meter is a floating gauge flow rate measurator with a

built-in regulating ball valve.

It works within the range of 1–13 l/min.

The flow meter must be fitted in a vertical position only.

Captive nut

Flow rate adjustment

Fitting 1/2” F

Graduation

Thermometric

label

Fitting 3/4” F

Air separator device

The solar circulation units with flow and return connection are

equipped with an air separator device on the flow line. The gases

separated from the thermal carrier medium collect at the top of the

deaerator.

The collected gases must be evacuated from time to time (every

day after commissioning and afterwards, depending on the

quantity of air, once a week or once a month) using the manual air

vent with a suitably sized screwdriver.

To maintain optimal efficiency of the solar thermal system,

afterwards, it is necessary to

vent the system every six

months by using the deaerator.

A thermometric label is placed on the back of the flow meter to

signal if the maximum permitted temperature (110°C) has been

exceeded:

white color = temperature not exceeded;

dark color = maximum temperature exceeded.

The label removal makes the manifacturer warranty on the device

expire.

The level is taken from the

top edge of the float.

➜

Correction for liquids with different density

The variation in the flow rate reading remains within the range of

accuracy indicated (±10%), for glycol percentages up to 50%.

Full closing and opening of the valve

➜

N.B! Use only a

wrench to regulate the flow

9mm fixed

meter.

The valve can be

completely opened or

closed.

A slot on the obturator

stem indicates the

status of the valve.

7

Fully closed

Fully open

AB

Page 8

Application diagrams

Shut-off valve

Pump

Air vent

Expansion vessel

Temperature gauge

Safety relief valve

2

a

a

a

a

a

a

a

a

a

a

aaa

a

a

a

0

20

40

6080100

120

140

160

c

o

n

f

o

r

m

e

n

o

r

m

e

I

S

P

E

S

L

0

2

4

6

8

10

bar

CL 2.5

c

o

n

f

o

r

m

e

n

o

r

m

e

I

S

P

E

S

L

0

2

4

6

8

10

bar

CL 2.5

a

a

a

a

a

a

a

a

a

a

aaa

a

a

a

0

20

40

6080100

120

140

160

c

o

n

f

o

r

m

e

n

o

r

m

e

I

S

P

E

S

L

0

2

4

6

8

10

bar

CL 2.5

c

o

n

f

o

r

m

e

n

o

r

m

e

I

S

P

E

S

L

0

2

4

6

8

10

bar

CL 2.5

1

13

11

9

7

5

3

l/min

1

13

11

9

7

5

3

l/min

a

a

a

a

Shut-off valve

Pump

Air vent

Expansion vessel

Temperature gauge

Safety relief valve

Automatic

filling

2

a

a

a

a

a

a

a

a

aaa

a

a

a

a

a

a

a

a

a

a

a

aa

a

a

0

20

40

6080100

120

140

160

0

20

40

6080100

120

140

160

c

o

n

f

o

r

m

e

n

o

r

m

e

I

S

P

E

S

L

0

2

4

6

8

10

bar

CL 2.5

0

20

40

6080100

120

140

160

c

o

n

f

o

r

m

e

n

o

r

m

e

I

S

P

E

S

L

0

2

4

6

8

10

bar

CL 2.5

c

o

n

f

o

r

m

e

n

o

r

m

e

I

S

P

E

S

L

0

2

4

6

8

10

bar

CL 2.5

0

20

40

6080100

120

140

160

c

o

n

f

o

r

m

e

n

o

r

m

e

I

S

P

E

S

L

0

2

4

6

8

10

bar

CL 2.5

c

o

n

f

o

r

m

e

n

o

r

m

e

I

S

P

E

S

L

0

2

4

6

8

10

bar

CL 2.5

1

13

11

9

7

5

3

l/min

1

13

11

9

7

5

3

l/min

1

13

11

9

7

5

3

l/min

a

a

a

a

a

a

a

8

Loading...

Loading...