Page 1

www.caleffi.com

OPTIMISER®digital regulator

for heating systems with solid fuel generator

18146.01EN

© Cop yr igh t 2 014 Ca lef fi

INSTALLATION AND COMMISSIONING MANUAL

CONTENTS

Function

Warnings

Technical data

Display and commands

General functions

1522 series

1

2

2

4

4

Function

®

The OPTIMISER

possible to combine a solid fuel generator with another type

of generator already present in the heating system.

The digital regulator automatically manages the two

generators, receiving the signal from the probes and

activating the pumps, the motorized diverter valves in the

system, according to the heating circuit needs.

Depending on the type and quantity of installed probes, the

regulator supports the following system solutions:

- heating;

- production of domestic hot water by means of storage or

instantaneous with plate heat exchanger;

- management of inertial water storage in parallel on the

heating circuit or alternatively management of an

independent solar system and direct inertial water

storage.

digital regulator code 152200 makes it

Available programs

Hydraulic diagrams of programs

5

7

1

Page 2

WARNINGS

The following instructions must be read and understood before installing, commissioning and

maintaining the regulator.

The safety symbol is used in this manual to draw attention to the relative safety instructions. The

meaning of this symbol is as follows:

CAUTION!

YOUR SAFETY IS INVOLVED. FAILURE TO FOLLOW THESE INSTRUCTIONS MAY

RESULT IN INJURY.

- The digital regulator must be installed by a licensed installer in accordance with national regulations and/or

relevant local requirements.

- If the digital regulator is not installed, commissioned and maintained correctly in accordance with the instructions

in this manual, then it might not work properly and may endanger the user.

CAUTION: Risk of electric shock. The rear panel is live. Cut off the electric supply

before carrying out any work. Failure to follow these instructions may result in

personal injury or damage to property.

LEAVE THIS MANUAL AS A REFERENCE GUIDE FOR THE USER

Technical data

Regulator

Electric supply: 230 V (ac) ±10%; 50-60 Hz

Power consumption: 5,5 VA

Output signals: 10 relay contacts for heating

Contact rating: 250 V (ac), 8 (2) A (max 9 A in total)

Protection class: II

Protection class: IP 40

Clock data retention with no electric supply: 24 h

EEPROM data retention with no electric supply: permanent

Ambient conditions

Ambient temperature:

Operation: 0–55°C EN 60721-3-3 Cl. 3K3, max. humidity 85%

Transportation:-10–70°C EN 60721-3-2 Cl. 2K2, max. humidity 95%

Storage: -5–50°C EN 60721-3-1 Cl. 1K2, max. humidity 95%

When the solid fuel generator is equipped with an anti-condensation valve, it is good practice to set the minimum

working temperature of the solid fuel generator (TSG, settable in the regulator menu) to a value at least 2°C higher than

the anti-condensation valve setting.

Temperature probe* for solid fuel generator flow, domestic

water storage, domestic heat exchanger, inertial water storage

in parallel on the heating system, solar water storage.

NTC type

Working range: -20–100°C

Two-wire cable

Temperature probe* for solar collector

Pt1000 type

Cable length: 3 m

Cable SIHF,

Cross section: 2 x 0,5 mm

Max working temperature: 180°C

*The use of the probes is specified in the “Available programs”

heading on page 5.

2

- Anti-condensation valve setting: °C

- Minimum working temperature of the

solid fuel generator (TSG, working temperature range: 20–85°C): °C (factory setting: 55°C).

It is good practice to compile the two blank fields to facilitate any system checks to be performed.

2

Page 3

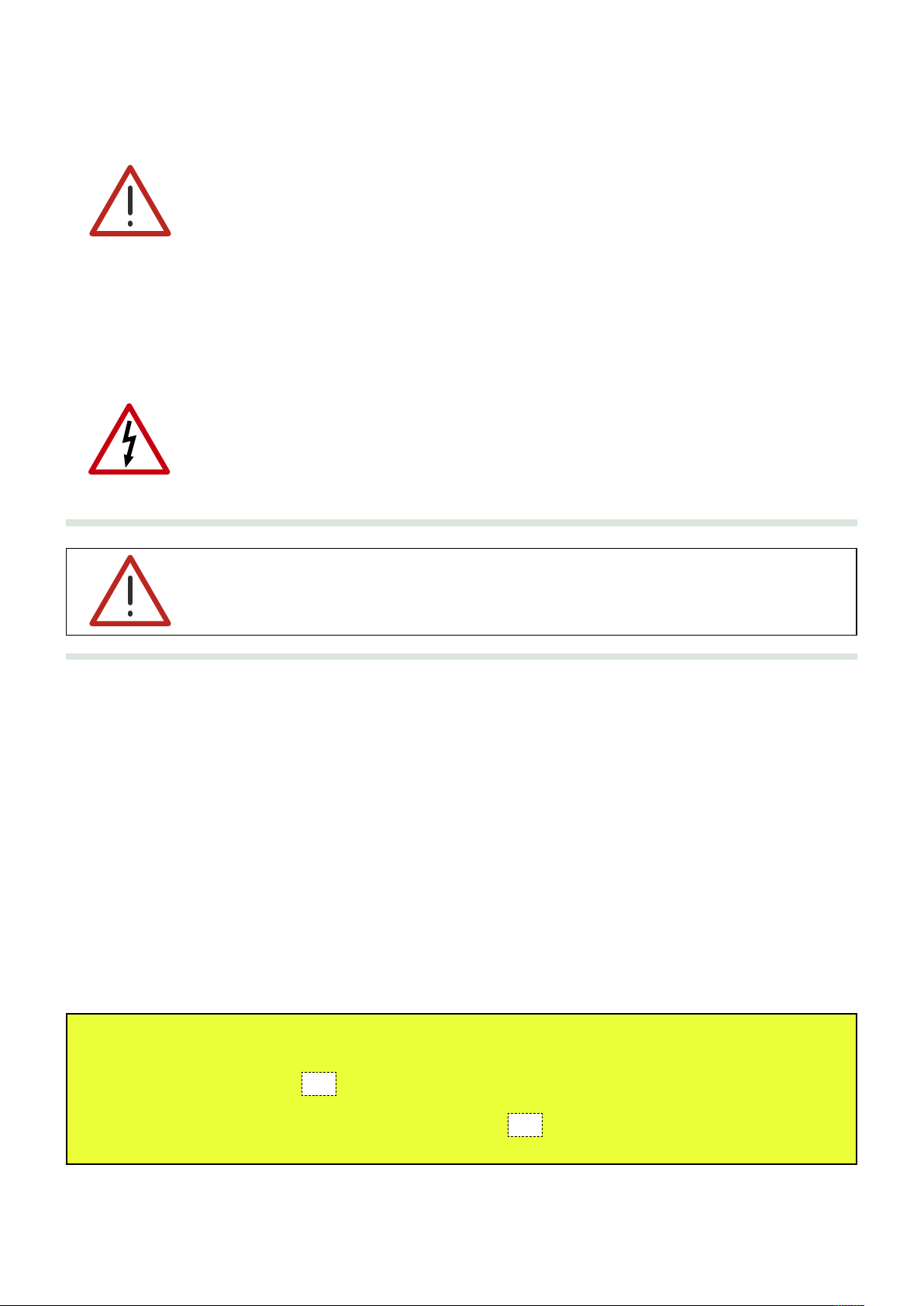

NTC probes* resistance table: for solid fuel generator flow, domestic water storage, domestic heat exchanger, inertial water

100 23 1/2”

ø 6,4

A

C

B

650 3

L (m)

B

A

AB

628 2

L (m)

B

A

AB

1,530

55 9 11

L (m)

B

A

C

D

D

43 17 1/4”

ø 6,4

C

B

A

storage in parallel on the heating system, solar water storage.

°C

-20

-18

-16

-14

-12

-10

-8

-6

-4

Pt1000 probe* resistance table: for solar collector.

Ω

14616

13211

11958

10839

9838

8941

8132

7405

6752

°C

-2

±0

+2

+4

+6

+8

+10

+12

+14

Ω

6164

5634

5155

4721

4329

3974

3652

3360

3094

°C

+16

+18

+20

+22

+24

+26

+28

+30

+32

Ω

2852

2632

2431

2247

2079

1925

1785

1657

1539

°C

+34

+36

+38

+40

+42

+44

+46

+48

+50

Ω

1430

1331

1239

1154

1076

1004

938

876

819

°C

+52

+54

+56

+58

+60

+62

+64

+66

+68

Ω

767

718

673

631

592

556

522

491

462

°C

+70

+72

+74

+76

+78

+80

+82

+84

+86

Ω

434

409

386

364

343

324

306

290

274

°C

+88

+90

+92

+94

+96

+98

+100

Ω

260

246

233

221

210

199

189

°C

-10 961 65 1252

-5 980 70 1271

0 1000 75 1290

5 1019 80 1309

10 1039 85 1328

15 1058 90 1347

20 1078 95 1366

25 1097 100 1385

30 1117 105 1404

35 1136 110 1423

40 1155 115 1442

45 1175 120 1461

50 1194 140 1536

55 1213 160 1611

60 1232 170

CAUTION

Install Pt1000 probe, with red silicone sheath cable (Tmax 180°C), on the solar collector.

Dimensions

NTC probe and contact probe

holder code 150009

Ω

°C

Immersion pocket

code 150029

Ω

NTC probe

code 150006

Pt1000 probe

code 257006

Probe connection

The cable connecting probes to the regulator must be

installed in a dedicated raceway. If the connection

cable shares the raceway with other power cables, an

earthed shielded cable must be used.

Any alteration to the wiring of the regulator could

result in electrical disturbance.

After performing work on the wiring, the regulator

must be reset by cutting off the electric supply for a

few seconds. Cable length can be increased to 100 m

using a 1 mm

2

cross section cable.

Immersion pocket

code 257004

Relay box

code F29525

Probe Type Supply Standard application Optional application

S1* NTC series

S2* NTC optional - probe code 150006 + pocket code 257004

S3* NTC optional - probe code 150006 + pocket code 150029

S4* NTC series

S5* NTC series

Sol2* NTC optional - probe code 150006 + pocket code 257004

Sol1* Pt1000 optional -

*The use of the probes is specified in the “Available programs” heading on page 5.

See instruction sheet,

code 28134

probe + contact probe holder:

code 150009

immersion pocket code 150029

probe code 150006 +

pocket code 257004

probe + contact probe holder:

code 150009

3

immersion type: probe code 257006 +

pocket code 257004

-

-

Page 4

5

-

+

Optimiser

1

2

3

4

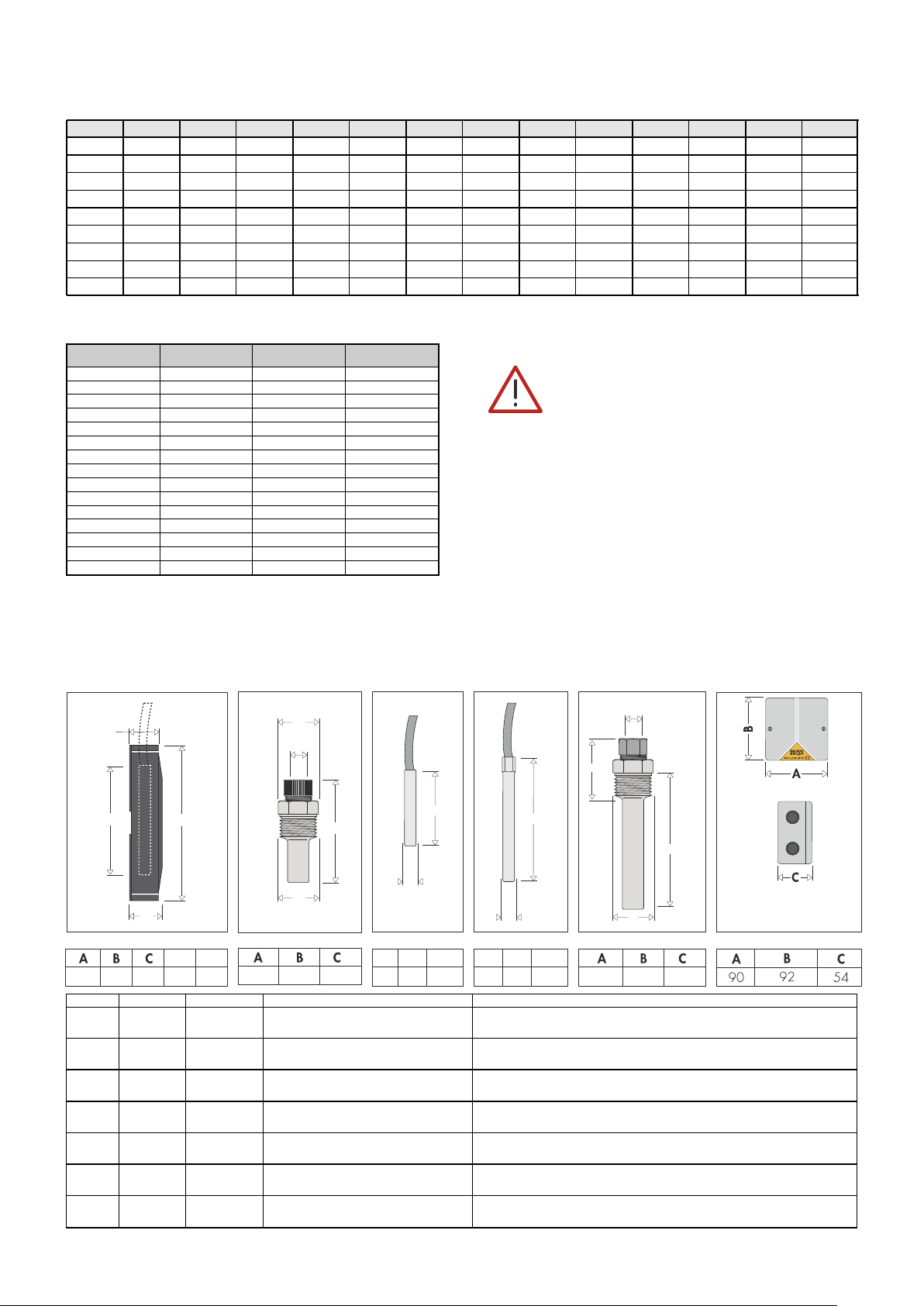

Display and commands

-

+

-

- -

General functions

Display

The regulator is equipped with a display to read and program the

control parameters, such as cut-in temperatures, function

activation delay times, thermal disinfection programs, solar system

control, etc. All the system’s functional parameters can be

configured to match individual requirements by means of the

“Select” knob and the three function keys.

Block protection function “Block Protect.”

When it is powered on, the regulator performs an initial check,

activating the valves and pumps to which it is connected. The

message “Block Protect.” appears on the display.

Pump and diverter valve anti-clog function

To prevent clogging of the pumps and diverter valves due to

prolonged stoppages, the regulator activates them for 60 seconds

after each period of 24 consecutive hours of disuse.

Control description

1- Operating status indicator LED.

2- Mini DIN connector on front of panel for PC connection.

3- Menu display.

4- Select knob: selection of functions menu and parameter editing.

5- Function keys

Display

The display (3) shows the text with the main operating information.

In the absence of control signals, after four minutes the display

reverts to the initial page.

Select knob and function keys

Select knob (4): can be rotated or pressed

Turn the Select knob clockwise or

anticlockwise to select the options of the

function menu or to modify the values of the

various user-settable parameters.

Press the Select knob to open the submenu

relative to the selected option.

Function keys (5): can be pressed

Esc: change the display of the selected menu

point and return to the previous menu level

Frost protection

When the solid fuel generator flow temperature reaches a minimum

user-settable value, the regulator activates the primary side pump

to prevent the circuit from freezing.

Anti-legionella function (programs 5 and 8 only)

The regulator keeps the domestic water storage at the minimum set

temperature and raises the temperature in order to perform thermal

disinfection in accordance with customizable times.

Instantaneous domestic hot water production (programs 6 and

9 only)

The regulator manages the instantaneous domestic hot water

production by means of a second heat exchanger and, if

necessary, it sends the water to the boiler for thermal integration by

means of the (optional) SOLARINCAL kit (code 265359).

Overtemperature safety function

The regulator is equipped with a solid fuel generator

overtemperature monitoring function.

When the user-settable emergency temperature is reached on the

solid fuel generator, the regulator generates an alarm signal and

starts the pumps to dissipate the excess heat to the system or to an

emergency user service. This latter function can be activated by

means of a specific menu item. In this case, it is necessary to install

a diverter valve, driven by the regulator, to transfer the flow to the

emergency user service.

Probe control

Solid fuel generator flow temperature sensor error

When the working temperature range detected is below 0°C or

above 110°C, the following status is activated automatically: pumps

OFF, while the display shows the message “probe error” and the

LED flashes green and red alternately.

Info: displays brief information on the current

menu point

Set: executes the change, confirming the

selected parameter value

LED

The LED (1) gives status information by means of a multicoloured

diode:

- flashing green: regulator initialisation

- steady green: regulator operating

- flashing green/red: regulator operating with probe error or alarm

- flashing red: regulator checking loop

- steady red: regulator error.

To set parameters use the document

“MENU LIST” code 28180 supplied in the pack

4

Page 5

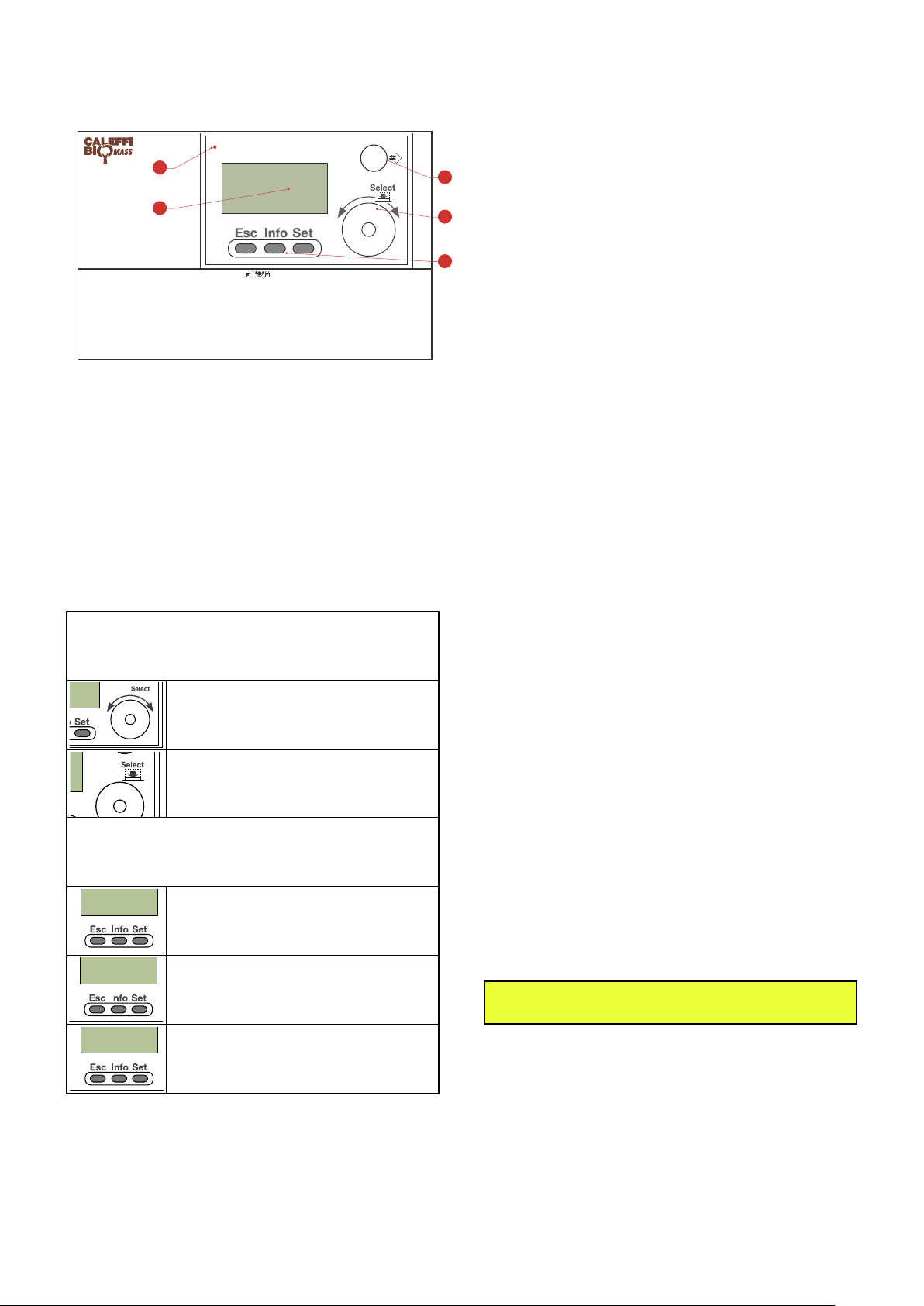

Available programs

ON

1 2 3 4

ON

12 34

ON

1 2 3 4

ON

1 2 3 4

ON

12 34

ON

12 34

HIGH VOLTAGE

JUNCTION BOX

LOW VOLTAGE

JUNCTION BOX

HIGH VOLTAGE LOW VOLTAGE

®

OPTIMISER

digital regulator code 152200 can be used in accordance with 6 different system configurations (programs), comprising a basic

factory-set configuration and 5 optional configurations selectable by means of the table shown below and activatable by means of the dipswitches

on the regulator. To access the dipswitches open the cover under the display. The regulator is supplied with the factory settings and probes

required to perform basic program 4.

Program

configuration

Description Probes utilised Position of

program

selectors

Software

code

Hydraulic

diagram

on page

(dipswitches)

4

(basic factory set

program)

Heating + management of

inertial water storage in

parallel on the heating

system*

S1 - - S4 S5 PR83 7

Heating and domestic hot water

5

with storage + management of

inertial water storage in parallel

S1 S2 - S4 S5 PR84 8

on the heating system*

Heating and instantaneous

6

domestic hot water + management

of inertial water storage in parallel

S1 S3 - S4 S5 PR85 9

on the heating system*

Heating with direct inertial

7

water storage with tank-in-

tank domestic hot water

S1 - Sol 1 Sol 2 - PR86 10

production, solar system

Heating with direct inertial

8

water storage, domestic hot

water storage integrated with

S1 S2 Sol 1 Sol 2 - PR87 11

solar system

Heating with direct inertial water

9

storage integrated with solar

system, instantaneous domestic

S1 S3 Sol 1 Sol 2 - PR88 12

hot water production

Programs 1,2 and 3 (not listed in the table but however available) are functionally equivalent to programs 7,8 and 9 respectively but without

thermal solar components. For specific setting (dipswitches and probes to be used) please see instruction sheet 28169 (www.caleffi.com).

NOTE The probes are all of the NTC type (grey cable) except for probe Sol1 utilised by solar programs 7, 8 and 9, which

is type Pt1000 with red cable.

* refer to operating logic of program “management of inertial water storage in parallel on the heating system” on the next page.

Location of cable glands

When making the electrical connections, observe the following sequence for wiring the terminal board.

- If the regulator is to be wall mounted with the consequent use of the supplied cable glands and downward cable outlet, regulations require that just

one cable can transit through each hole of the cable gland, therefore a maximum of 6 high voltage cables and 6 low voltage cables can be utilised.

It is therefore recommended to comply with the following table of connections and use two additional junction boxes complete with suitable inlet and

outlet cable glands, in accordance with the diagram given. The earth connection must be made in the junction box.

- If the regulator is installed in an electrical cabinet, the cable outlet must be via the openings at the rear of the unit, always keeping high and

low voltage cables separated. The earth connection must be made in the electrical cabinet.

Electric connection

Electric supply 2x1,5 mm

Pump P1

Pump P2

Gas generator contact C

Solid fuel generator contact K

Diverter valve V1

Diverter valve V4 to optional dissipator

Domestic priority diverter valve V2 or domestic priority

HIGH VOLTAGE

Valve V5 for loading the inertial water storage in

Probe S5 or solar water storage probe Sol2 2x0,75 mm

Probe S4 or solar collector probe Sol1 2x0,75 mm

Room thermostat TA or adjustment thermostat TR contact

Domestic water storage probe S2 or probe S3 on

LOW VOLTAGE

diverter valve V3

SOLARINCAL type diverter valve

parallel or solar circuit pump Psol

Probe S1 2x0,75 mm

domestic heat exchanger outlet

Flow switch F 2x0,75 mm

Recommended electrical cable:

nr. wires for cross-section

4x1 mm

4x1 mm

4x1 mm

6x1 mm

2x1 mm

2x1 mm

2x0,75 mm

2

2

2

2

2

2

2

2

2

2

2

2

Dedicated

cable gland

5

A

B

C

D

E

F

G

H

I

L

M

N

Page 6

HEATING

BOILER

HEATING

BOILER

SOLID FUEL

GENERATOR

SOLID FUEL

GENERATOR

SOLID FUEL

GENERATOR

SOLID FUEL

GENERATOR

HEATING

BOILER

HEATING

BOILER

*Operating logic of program “management of inertial water storage in parallel on the heating system”.

In accordance with construction and system regulations or depending on system management requirements it may be necessary to use an

inertial water storage on the heating system.

The regulator is supplied as standard with the parameters and probes required to manage a heating system with inertial water storage in

parallel on the heating system.

The operating logic is shown in the adjacent figures:

Phase 1: direct supply to system. With a thermal energy demand

from the room thermostat, the regulator activates the solid fuel

generator and connects it, once it is able to supply energy, directly

to the secondary circuit bypassing the inertial water storage in

parallel. Valve V5 connects the inertial water storage in parallel with

the heating system so that it can receive any excess heat energy.

Phase 2: loading of water storage with system idle. When the

room heating demand is met, with the thermostat no longer

requesting heat energy but with the solid fuel generator still

capable of providing it (e.g. due to an energy surplus caused by

excessive fuel stoking), the regulator connects the solid fuel

generator to the parallel water storage, which thus serves to store

the surplus heat energy.

Phase 1: direct supply to system

Phase 2: loading of water storage

with system idle

Phase 3: unloading of water storage with generator off. The

parallel water storage is used as an energy source at the time of the

next room heating demand if the solid fuel generator is not

operating, not yet at working temperature or not stoked with fuel.

The previously accumulated heat energy is thus drawn from the

parallel water storage.

Phase 4: gas boiler activation.

Only when the solid fuel generator is not operating and the parallel

water storage has no energy reserve, it is necessary to start the gas

boiler, which at that point is the only device able to supply heat

energy to the heating system. Valve V5 isolates the parallel water

storage from the rest of the circuit to avoid loading it with heat

energy delivered by the gas boiler.

Phase 3: unloading of water

storage with generator off

Phase 4: gas boiler activation

6

Page 7

Hydraulic diagrams of programs

ON

12 34

V5

M M

S5

D

D

T

P1

P2

C

V1

RT

D

K

S1

K

S1

S4

V4

V5 S5 S4

F29525

KV4CP1 P2 C V1

S1

RT

-

+

Optimiser

Regulator 152200

V5=Zone valve 6443..3BY

Com.

Relè 1 VA

8 VA

LN

N10

Heating system

HEATING

BOILER

Optional

dissipator

Closed vessel

Open vessel

wiring to be made

Wiring diagram

L Live

N Neutral

L’

1

Live jumper

2 ON pump P2

ON pump P1

3’ Gas generator C

3 Gas generator C

N Neutral common

4 ON diverter valve V1

5

NO

ON diverter valve V4

to optional dissipator

5

NC

6’ Solid fuel generator K

10 ON valve V5 to load the

parallel water storage

N Neutral common

6’ Solid fuel generator K

y1 Probe S1

y

2 Probe S1

y4 Probe S5

y5 Probe S5 and S4

common

y6 Probe S4

x2 Room thermostat

RT contact

x3 Room thermostat

RT contact

SOLID FUEL

GENERATOR

SOLID FUEL

GENERATOR

INERTIAL

WATER

STORAGE

IN PARALLEL

Wiring diagram of F29525

relay box - 230 V ˜ 50 Hz

V5

D

V5

D

Program 4 (software code PR83): BASIC FACTORY PROGRAM

Heating + management of inertial water storage in parallel on the heating system

Number of probes utilised: 3

Probe S1 located on solid fuel generator flow

Probe S5 located on heat exchanger inlet on secondary side of circuit

Probe S4 located on the inertial water storage in parallel on the heating system

Operating principle

The 1522 series regulator automatically manages a system composed of a solid fuel generator, integration gas boiler and inertial water storage

in parallel on the heating system.

On the request of room thermostat RT (not supplied in the pack), the regulator activates the solid fuel generator with priority using contact K

(for generators that can be activated electrically). When the minimum working temperature of the solid fuel generator has been reached (as

detected by probe S1), the regulator starts pump P1, diverts valve V1 to connect the heat exchanger to the system and starts pump P2. With

the solid fuel generator off or not yet at working temperature, the regulator starts the integration boiler by means of contact C, stopping pumps

P1 and P2 and diverting diverter valve V1 to the boiler.

In the case of solid fuel generator overtemperature, the regulator sends the flow rate of the secondary circuit either to the system (in the

presence of room thermostat demand) or to an optional dissipation system, if present.

The inertial water storage in parallel is managed in accordance with the logic described on page 6. By means of diverter valve V5 (not supplied

in the pack, e.g.: Caleffi 6443..3BY series + relay box code F29525) the regulator manages all phases of loading and unloading of the water

storage, which is kept closed only if the gas boiler has been activated. Connection of the parallel water storage to the rest of the system is

managed by the regulator by comparing the temperature readings of probes S1 (located on the solid fuel generator flow pipe), S5 (located on

the heat exchanger return line) and S4 (located on the parallel water storage). For probe S5 it is advisable to use the following working

set-points: 45°C for radiator systems, 30°C for radiant panel systems. The gas boiler starts when the solid fuel generator temperature is below

the minimum working temperature TSG (measured by probe S1) and the heat exchanger return temperature TR (measured by probe S5) is 5°C

below the value set on the regulator (TR set, fixed hysteresis value 5K).

7

Page 8

-

+

Optimiser

V5

F29525

KV2CP1 P2 C V1

RT

S2

S1

S5 S4

V5

K

S1

K

S1

M M

D

D

T

P1

V2

P2

C

V1

S2

RT

D

S4

S5

Com.

Relè 1 VA

8 VA

LN

N10

Wiring diagram

L Live

N Neutral

L’ Live jumper

1 ON pump P1

2 ON pump P2

4 ON diverter valve V1

5

NO

ON diverter valve V2

for domestic priority

5

NC

10 ON valve V5 to load

the parallel water

storage

y1 Probe S1

y

2 Probe S1

y4 Probe S5

Probe S4

y5 Probe S5 and

S4 common

y6

x2 Room thermostat

RT contact

x3 Room thermostat

RT contact

x4 Domestic water

storage probe S2

x5 Domestic water

storage probe S2

wiring to be made

Heating

system

Domestic

water

system

DCW

DHW

Open vessel

Closed vessel

6 Solid fuel

generator K

3 Gas generator C

3’ Gas generator C

N Neutral common

6’

Solid fuel

generator K

N Neutral common

SOLID FUEL

GENERATOR

SOLID FUEL

GENERATOR

INERTIAL

WATER

STORAGE

IN PARALLEL

HEATING

BOILER

Wiring diagram of F29525

relay box - 230 V ˜ 50 Hz

Regulator 152200

V5=Zone valve 6443..3BY

V5

D

V5

D

ON

1 2 3 4

Program 5 (software code PR84)

Heating, domestic hot water with storage + management of inertial water storage in parallel on the heating system.

Number of probes utilised: 4

Probe S1 located on solid fuel generator flow

Probe S2 (not supplied in the pack) located on domestic water storage

Probe S5 located on heat exchanger inlet on secondary side of circuit

Probe S4 located on the inertial water storage in parallel on the heating system

Operating principle

The 1522 series regulator automatically manages a system composed of a solid fuel generator, integration gas boiler, inertial water storage in

parallel on the heating system and domestic hot water production by means of a water storage.

When the minimum working temperature of the solid fuel generator has been reached (as detected by probe S1), the regulator starts pump P1,

diverts valve V1 to connect the heat exchanger to the system and starts pump P2. With the solid fuel generator off or not yet at working

temperature, the regulator starts the integration boiler by means of contact C, stopping pumps P1 and P2 and diverting diverter valve V1 to the boiler.

In the case of a solid fuel generator overtemperature, the regulator sends the flow rate of the secondary circuit either to the system (in the

presence of a room thermostat demand) or to the domestic water storage if it is not yet at

operating temperature or lower than the limit temperature. The domestic water storage is

maintained at operating temperature by probe S2 and priority diverter valve V2. The regulator

performs thermal disinfection of the domestic water storage in accordance with four

user-selectable preset programs, keeping it for two hours at the disinfection temperature

“Legio.-Temp”, settable in the range 40–75°C. The user can anyway add further disinfection

periods (designated TP points in the menu).

The inertial water storage in parallel is managed in accordance with the logic described on

page 6. By means of diverter valve V5 (not supplied in the pack, e.g.: Caleffi 6443..3BY series

+ relay box code F29525) the regulator manages all phases of loading and unloading of the

water storage, which is kept closed only if the gas boiler has been activated. Connection of the parallel water storage to the rest of the system

is managed by the regulator by comparing the temperature readings of probes S1 (located on the solid fuel generator flow pipe), S5 (located

on the heat exchanger return line) and S4 (located on the parallel water storage). For probe S5 it is advisable to use the following working

set-points: 45°C for radiator systems, 30°C for radiant

minimum working temperature TSG (measured by probe S1) and the heat exchanger return temperature TR (measured by probe S5) is 5°C below the

value set on the regulator (TR set, fixed hysteresis value 5K).

8

Program

0 No disinfection

1 Mon. 2-4

2 Sat. 10-12

3 Sun. 10-12

4 Mon. and Wed. 2-4

Disinfection

day

Disinfection

time slot

panel systems. The gas boiler starts when the solid fuel generator temperature is below the

Page 9

-

+

Optimiser

V5

V4

M M

D

K

S1

K

S1

D

D

T

P1

V3

P2

C

V1

F

S3

RT

D

SOLARINCAL

M

D

S5

S5 S4

KC V4

SOLAR

INCAL

P1 P2 V1 V3

RT

S3

F

S1

V5

F29525

S4

Regulator 152200

V5=Zone valve 6443..3BY

Com.

Relè 1 VA

8 VA

LN

N10

Wiring diagram of F29525

relay box - 230 V ˜ 50 Hz

Domestic

water

system

DHW

Optional

dissipator

Heating

system

Open vessel

Closed vessel

Wiring diagram

L

Live

L’

Live jumper

1 ON pump P1

2 ON pump P2

N Neutral common

3’ Gas generator C

3 Gas generator C

5

NO

ON diverter valve V3

for domestic priority

5NCON diverter valve V3

to heating system

6’ Solid fuel generator K

6 Solid fuel generator K

N Neutral common

7 SOLARINCAL with flow

to user

8

SOLARINCAL with flow

to domestic integration

10

ON valve V5 to load the

parallel water storage

y1 Probe S1

y

2 Probe S1

y4 Probe S5

y5

Probe S5 and

S4 common

y6 Probe S4

y8 ON flow switch F

y9

ON flow switch F

x2 Room thermostat

RT contact

x3 Room thermostat

RT contact

x4 Probe S3 on domestic

exchanger outlet

x5 Probe S3 on domestic

exchanger outlet

wiring to be made

N Neutral

4 ON diverter valve V1

9 On diverter valve V4

SOLID FUEL

GENERATOR

INERTIAL

WATER

STORAGE

IN PARALLEL

HEATING

BOILER

SOLID FUEL

GENERATOR

V5

D

V5

D

ON

12 34

Program 6 (software code PR85)

Heating, instantaneous domestic hot water + management of inertial water storage in parallel on the

heating system.

Number of probes utilised: 4

Probe S1 located on solid fuel generator flow

Probe S3 (not supplied in the pack) located on domestic heat exchanger outlet

Probe S5 located on heat exchanger inlet on secondary side of circuit

Probe S4 located on the inertial water storage in parallel on the heating system

9

Operating principle

The 1522 series regulator automatically manages a system composed of a solid fuel generator, gas integration boiler (for heating and domestic

hot water), inertial water storage in parallel on the heating system and instantaneous domestic hot water production by means of a plate heat

exchanger.

When the minimum working temperature of the solid fuel generator has been reached (as detected by probe S1), the regulator starts pump P1,

diverts valve V1 to connect the heat exchanger to the system and starts pump P2. With the solid fuel generator off or not yet at working

temperature, the regulator starts the integration boiler by means of contact C, stopping pumps P1 and P2 and diverting diverter valve V1 to the

boiler.

In the case of solid fuel generator overtemperature, the regulator sends the flow rate of the secondary circuit either to the system (in the

presence of room thermostat demand) or to an optional dissipation system, if present.

When a domestic user tap is opened, on a signal from flow switch F, the regulator operates priority valve V3 to produce instantaneous hot water

with the solid fuel generator only if the latter is already at working temperature. Probe S3 reads the water temperature at the domestic heat

exchanger outlet and, if necessary, the regulator integrates the domestic hot water by supplying it to the gas boiler by means of a diverter valve

(not supplied in the pack, e.g. SOLARINCAL kit code 265359).

The inertial water storage in parallel is managed in accordance with the logic described on page 6. By means of diverter valve V5 (not supplied

in the pack, e.g.: Caleffi 6443..3BY series + relay box code F29525) the regulator manages all phases of loading and unloading of the water

storage, which is kept closed only if the gas boiler has been activated. Connection of the parallel water storage to the rest of the system is

managed by the regulator by comparing the temperature readings of probes S1 (located on the solid fuel generator flow pipe), S5 (located on

the heat exchanger return line) and S4 (located on the parallel water storage). For probe S5 it is advisable to use the following working setpoints: 45°C for radiator systems, 30°C for radiant panel systems. The gas boiler starts when the solid fuel generator temperature is below the

minimum working temperature TSG (measured by probe S1) and the heat exchanger return temperature TR (measured by probe S5) is 5°C

below the value set on the regulator (TR set, fixed hysteresis value 5K).

Page 10

Optional

dissipator

Closed vessel

Open vessel

Sol 1

Psol

Sol 2

Heating system

SOLID FUEL

GENERATOR

SOLID FUEL

GENERATOR

DIRECT

TANK IN TANK

INERTIAL WATER STORAGE

HEATING

BOILER

Wiring diagram

L Live

L

’ Live jumper

N Neutral

1 ON pump P1

2 ON pump P2

3’ Gas generator C

3 Gas generator C

4 ON diverter valve V1

5

NO

ON diverter valve V4

to optional dissipator

5

NC

6’ Solid fuel generator K

6 Solid fuel generator K

10 ON solar circuit pump Psol

y1 Probe S1

y

2 Probe S1

y5 Solar water storage

probe Sol2

y6 Solar water storage

probe Sol2

y7 Solar collector

probe Sol1

y8 Solar collector

probe Sol1

x2 Adjustable thermostat

TR contact

x3 Adjustable thermostat

TR contact

S

Sol 2 Sol 1

Psol

wiring to be made

N Neutral common

N Neutral common

ON

1 2 3 4

Program 7 (software code PR86)

Heating with direct inertial water storage with tank-in-tank domestic hot water production, solar system

Number of probes utilised: 3

Probe S1 located on solid fuel generator flow

Probe Sol1 (not supplied in the pack) located on the solar collector

Probe Sol2 located on the tank-in-tank water storage

Operating principle

The 1522 series regulator automatically manages a system composed of a solid fuel generator, integration gas boiler and tank-in-tank direct

inertial water storage combined with a solar system.

On the request of the adjustment thermostat TR (not supplied in the pack) located on the water storage, the regulator activates the solid fuel

generator using contact K (for generators that can be activated electrically).

When the minimum working temperature of the solid fuel generator has been reached (as detected by probe S1), the regulator starts pump P1,

diverts valve V1 to connect the heat exchanger to the system and starts pump P2. With the solid fuel generator off or not yet at working

temperature, the regulator starts the integration boiler by means of contact C, stopping pumps P1 and P2 and diverting diverter valve V1 to the

boiler.

In the case of solid fuel generator overtemperature, the regulator sends the flow rate of the secondary circuit either to the water storage (in the

presence of a demand from adjustment thermostat TR) or to an optional dissipation system, if present.

The regulator allows to manage a simple solar thermal circuit connected to the lower coil of the tank-in-tank inertial water storage.

When the minimum working temperature of the solar collector is reached, temperature difference ΔT is checked between probe Sol1 on the

solar collector and probe Sol2 on the lower section of the tank-in-tank water storage: if higher than the set value, solar circuit pump Psol is

started. Pump Psol continues to run for a selectable minimum time period and it stops if ΔT falls below the set value or when the set temperature

for the tank-in-tank inertial water storage is reached.

The regulator manages possible overtemperatures of the solar collector by starting pump Psol to dissipate the excess heat.

10

Page 11

Sol2

T

C

S2

RT

DCW

DHW

Open vessel

Closed vessel

IHeatin g

system

Sol 1

Psol

S1

SOLID FUEL

GENERATOR

SOLID FUEL

GENERATOR

DIRECT

INERTIAL

WATER

STORAGE

HEATING

BOILER

RT

Wiring diagram

L Live

N

Neutral

L’ Live jumper

1 ON pump P1

2 ON pump P2

3’ Gas generator C

3Gas generator C

4ON diverter valve V1

5NOON diverter valve V2

for domestic priority

5

NC

10 ON solar circuit

pump Psol

y1 Probe S1

y2 Probe S1

y5 Solar water storage

probe Sol 2

y6 Solar water storage

probe Sol 2

y7 Solar collector

probe Sol 1

y8 Solar collector

probe Sol 1

x2 Room thermostat

RT contact

x3 Room thermostat

RT contact

x4 Domestic water

storage probe S2

x5 Domestic water

storage probe S2

S

Sol 2 Sol 1Psol

wiring to be made

NNeutral common

NNeutral common

S

ON

1 2 3 4

Program 8 (software code PR87)

Heating with direct inertial water storage, domestic hot water production with storage integrated with

solar system

Number of probes utilised: 4

Probe S1 located on the direct inertial water storage flow pipe to the secondary circuits

Probe S2 (pocket not supplied in the pack) located on the domestic water storage

Probe Sol1 (not supplied in the pack) located on the solar collector

Probe Sol2 located on the domestic water storage

Operating principle

Adjustment thermostat TR (not supplied in the pack) keeps the direct inertial water storage at working temperature by activating the solid fuel

generator.

On request of the room thermostat RT (not supplied in the pack), 1522 series regulator draws energy by priority from the direct inertial water

storage. When the water storage minimum working temperature has been reached (read by probe S1), the regulator starts pump P1, diverts

valve V1 to connect the heat exchanger to the heating system and starts pump P2. If the water storage is not at working temperature, the

regulator activates the integration boiler by means of contact C, stopping pumps P1 and P2 and diverting diverter valve V1 to the boiler.

In the case of direct inertial water storage overtemperature, the regulator sends the flow rate of the secondary circuit either to the system (in

the presence of a room thermostat demand) or to the domestic water storage, if it is not yet at working temperature or below the limit

temperature.

The domestic water storage is maintained at operating temperature by probe S2 and priority

diverter valve V2. The regulator performs thermal disinfection of the domestic water storage

in accordance with four user-selectable preset programs, keeping it for two hours at the

disinfection temperature “Legio.-Temp”, settable in the range 40–75°C. The user can

anyway add further disinfection periods (designated TP points in the menu).

The regulator allows to manage a simple thermal solar circuit connected to the lower coil of

the domestic water storage. When the minimum working temperature of the solar collector

is reached, the temperature difference ΔT is checked between probe Sol1 on the solar

collector and probe Sol2 on the lower section of the domestic water storage: if higher than

the set value, solar circuit pump Psol is started. Pump Psol continues to run for a selectable

minimum time period and it stops if ΔT falls below the set value or when the set temperature for the domestic water storage is reached. The

regulator manages possible overtemperatures of the solar collector by starting pump Psol to dissipate the excess heat.

11

Program

0 No disinfection

1 Mon. 2-4

2 Sat. 10-12

3 Sun. 10-12

4 Mon. and Wed. 2-4

Disinfection

day

Disinfection

time slot

Page 12

RT

Wiring diagram

L Live

N

Neutral

L’ Live jumper

1 ON pump P1

2 ON pump P2

3’ Gas generator C

3 Gas generator C

4 ON diverter valve V1

5

NO

ON diverter valve V3

for domestic priority

5

NC

ON diverter valve V3

to heating system

RT

7 SOLARINCAL with

flow to user

8 SOLARINCAL with

flow to domestic

integration

9 On diverter valve V4

10 ON solar circuit

pump Psol

y1 Probe S1

y2

Probe S1

y5 Solar water storage

probe Sol 2

y6 Solar water storage

probe Sol 2

y7 Solar collector

probe Sol 1

y8 Solar collector probe

Sol 1, ON flow switch

y9 ON flow switch

x2 Room thermostat

RT contact

x3 Room thermostat

RT contact

x4 Probe S3 on

domestic exchanger

outlet

x5 Probe S3 on

domestic

exchanger outlet

Sol 2

wiring to be made

V4

SOLID FUEL

GENERATOR

SOLID FUEL

GENERATOR

Open

vessel

Closed

vessel

C

F

S3

RT

Heating system

Domestic

water

system

SOLARINCAL

DHW

D

Optional

dissipator

S1

Sol 1

Psol

DIRECT

INERTIAL

WATER

STORAGE

N Neutral common

HEATING

BOILER

ON

12 34

Program 9 (software code PR88)

Heating with direct inertial water storage integrated with solar system, instantaneous domestic hot

water production

Number of probes utilised: 4

Probe S1 located on the direct inertial water storage flow pipe to the secondary circuits

Probe S3 located on domestic heat exchanger outlet

Probe Sol1 (not supplied in the pack) located on the solar collector

Probe Sol2 located on the direct inertial water storage

Operating principle

Adjustment thermostat TR (not supplied in the pack) keeps the direct inertial water storage at working temperature by activating the solid fuel

generator.

On request of the room thermostat RT (not supplied in the pack), 1522 series regulator draws energy by priority from the direct inertial water

storage. When the water storage minimum working temperature has been reached (read by probe S1), the regulator starts pump P1, diverts

valve V1 to connect the heat exchanger to the heating system and starts pump P2. If the water storage is not at working temperature, the

regulator activates the integration boiler by means of contact C, stopping pumps P1 and P2 and diverting diverter valve V1 to the boiler.

In the case of direct inertial storage overtemperature, the regulator sends the flow rate of the secondary circuit either to the system (in the

presence of a room thermostat demand) or to an optional dissipator, if present.

When a domestic user tap is opened, on a signal from flow switch F, the regulator operates priority valve V3 to produce instantaneous hot water

with the direct inertial storage only if the latter is at working temperature. Probe S3 reads the water temperature at the domestic heat exchanger

outlet and, if necessary, the regulator integrates the domestic hot water by supplying it to the gas boiler by means of a diverter valve (not

supplied in the pack, e.g. SOLARINCAL kit code 265359).

The regulator allows to manage a simple thermal solar circuit connected to the lower coil of the direct inertial water storage. When the solar

collector minimum working temperature is reached, temperature difference ΔT is checked between probe Sol1 on the solar collector and probe

Sol2 on the lower section of the direct inertial water storage: if higher than the set value solar circuit pump Psol is started. Pump Psol continues

to run for a selectable minimum time period and it stops if ΔT falls below the set value or when the set temperature for the direct inertial water

storage unit is reached. The regulator manages possible overtemperatures of the solar collector by starting pump Psol to dissipate the excess

heat.

12

Loading...

Loading...