Page 1

QuickSetter+™ Low-lead

balancing valve with flow meter

132 series

ACCREDITED

ISO 9001 FM 21654

Function

The QuickSetter+™ manual balancing valve contains a built-in flow

meter and sight gauge, negating the need for differential pressure

gauges and reference charts. Circuit balancing is fast, easy and

accurate. Constructed of DZR low-lead brass, QuickSetter+™ is

ideally suited for use in plumbing applications such as hot water

recirculation systems. The built-in check valve protects against circuit

thermo-siphoning. The outlet temperature gauge (optional) verifies the

fluid temperature in the circuit. The flow meter sight gauge is dry (not

exposed to the fluid) thus eliminating the possibility of gauge clouding/

scaling over time. The QuickSetter+™ can also be used in heating

systems.

Product range

132 series Balancing valve with flow meter, includes check valve

and optional outlet temperature gauge.............................................................connections

ISO 9001 No. 0003

½”, ¾”, 1”

sweat union and

CALEFFI

01283/16 NA

Replaces 01283/14 NA

¾”

press union

Technical specications

Materials

Valve

Body: DZR low-lead brass

Ball: stainless steel

Ball control stem: brass, chrome plated

Ball seal seat: PTFE

Control stem guide: PSU

Seals: EPDM

Flow meter

Body and headwork: DZR low-lead brass

Bypass valve stem: stainless steel

Springs: stainless steel

Seals: EPDM

Flow meter float and indicator cover: PSU

NSF/ANSI 372-2011, Drinking Water System Components-Lead Content

Reduction of Lead in Drinking Water Act, California Health and Safety Code

116875 S.3874, Reduction in Drinking Water Act, certified by ICC-ES, file PMG-1360.

Performance

Suitable Fluids: water, glycol solutions

Max. percentage of glycol: 50%

Max. working pressure: 150 psi (10 bar)

Working temperature range: 14 - 230°F (-10–110°C)

Flow rate range unit of measurement: 1/2 - 1 ¾ gpm

2 - 7 gpm

Accuracy: ±10%

Control stem angle of rotation: 90°

Control stem adjustment wrench: 9 mm

Connections

Main connections:

Lay length (press connection): size ¾ inch without gauge: 7

size

½”, ¾”, 1”

¾

inch with gauge: 10

sweat union

¾”

press union

5

/16"

1

/8"

Flow rate ranges

*with temperature gauge.

Code Connection Flow rate (gpm)

132439AFC

132536AFC

132539AFC

132639AFC

132459AFC

132556AFC

132559AFC

132659AFC

Code Connection Flow rate (gpm)

132438AFC*

132537AFC*

132538AFC*

132638AFC*

132458AFC*

132557AFC*

132558AFC*

132658AFC*

½" sweat 0.5 - 1.75 1.0

¾" press 0.5 - 1.75 1.0

¾" sweat 0.5 - 1.75 1.0

1" sweat 0.5 - 1.75 1.0

½" sweat 2.0 - 7.0 6.3

¾" press 2.0 - 7.0 6.3

¾" sweat 2.0 - 7.0 6.3

1" sweat 2.0 - 7.0 6.3

½" sweat 0.5 - 1.75 1.0

¾" press 0.5 - 1.75 1.0

¾" sweat 0.5 - 1.75 1.0

1" sweat 0.5 - 1.75 1.0

½" sweat 2.0 - 7.0 6.3

¾" press 2.0 - 7.0 6.3

¾" sweat 2.0 - 7.0 6.3

1" sweat 2.0 - 7.0 6.3

Fully

open

Cv

Fully

open

Cv

Page 2

4

3

2

1

5

7

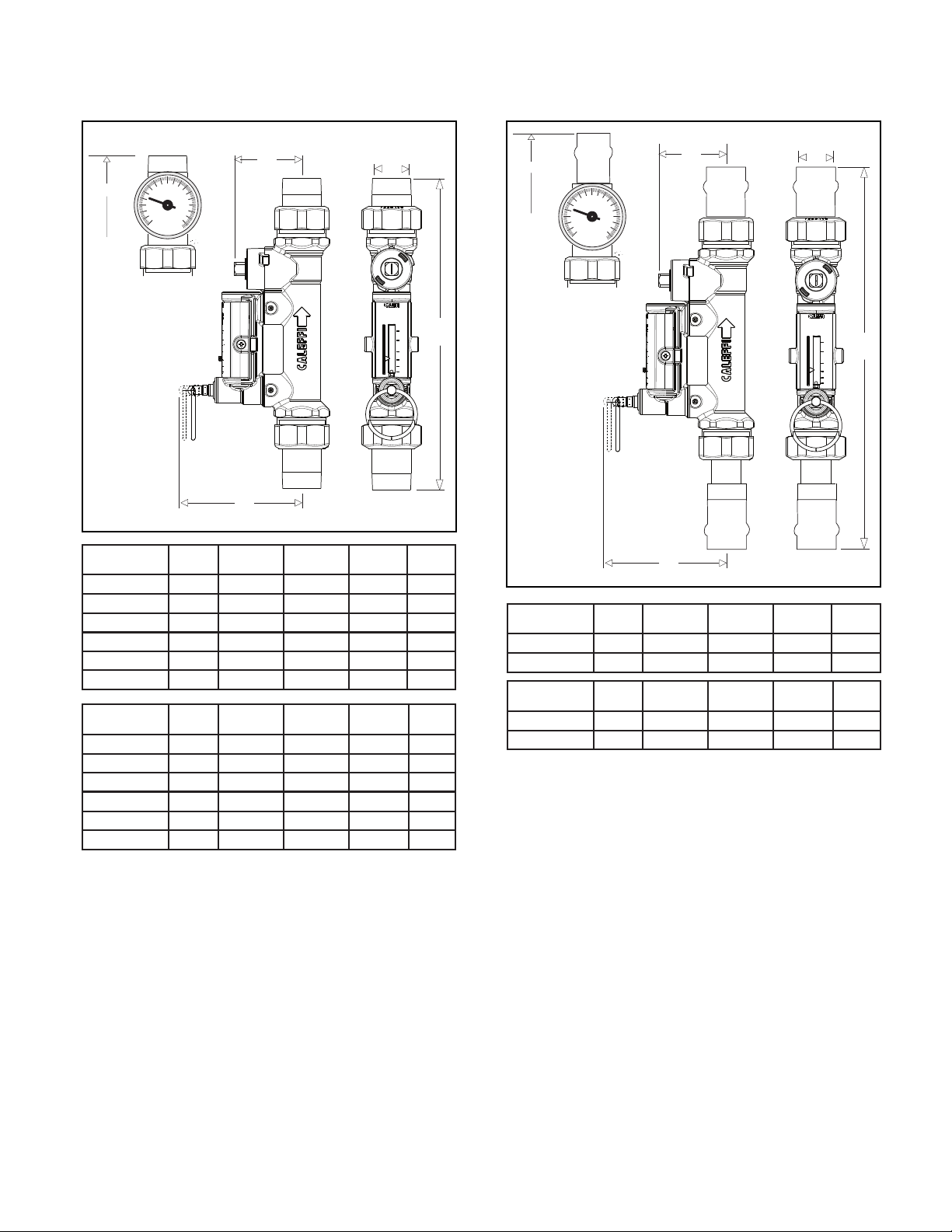

Dimensions

MIX

D

30

50

70

90

110

130

150

170

190

210

˚F

C

1.75

1.50

1.25

1.00

0.75

0.50

P.

A

MAX 150 psi

T.

MAX 230˚F

GPM

1.75

1.50

1.25

1.00

0.75

0.50

B

Code A B C D

132439AFC 1/2" 3 5/16" 1 13/16" 8 3/8" 2.0

132539AFC 3/4" 3 5/16" 1 13/16" 8 7/16" 1.8

132639AFC 1" 3 5/16" 1 13/16" 8 9/16" 2.4

132459AFC 1/2" 3 5/16" 1 13/16" 8 3/8" 2.0

132559AFC 3/4" 3 5/16" 1 13/16" 8 7/16" 1.8

132659AFC 1" 3 5/16" 1 13/16" 8 9/16" 2.4

Code A B C D

132438AFC* 1/2" 3 5/16" 1 13/16" 9 11/16" 2.4

132538AFC* 3/4" 3 5/16" 1 13/16" 9 13/16" 2.2

132638AFC* 1" 3 5/16" 1 13/16" 10 1/8" 2.8

132458AFC* 1/2" 3 5/16" 1 13/16" 9 11/16" 2.4

132558AFC* 3/4" 3 5/16" 1 13/16" 9 13/16" 2.2

132658AFC* 1" 3 5/16" 1 13/16" 10 1/8" 2.8

*with temperature gauge.

Wt

(lb)

Wt

(lb)

MIX

D

110

130

150

90

˚F

170

70

190

50

30

210

D

C

1.75

1.50

1.25

1.00

0.75

0.50

P.

T.

A

MAX 150 psi

MAX 230˚F

GPM

1.75

D

1.50

1.25

1.00

0.75

0.50

B

Code A B C D

132536AFC 3/4" 3 5/16" 1 13/16" 9 7/8" 1.8

132556AFC 3/4" 3 5/16" 1 13/16" 9 7/8" 1.8

Code A B C D

132537AFC* 3/4" 3 5/16" 1 13/16" 12 1/8" 2.2

132557AFC* 3/4" 3 5/16" 1 13/16" 12 1/8" 2.2

*with temperature gauge.

Wt

(lb)

Wt

(lb)

Page 3

3

2

1

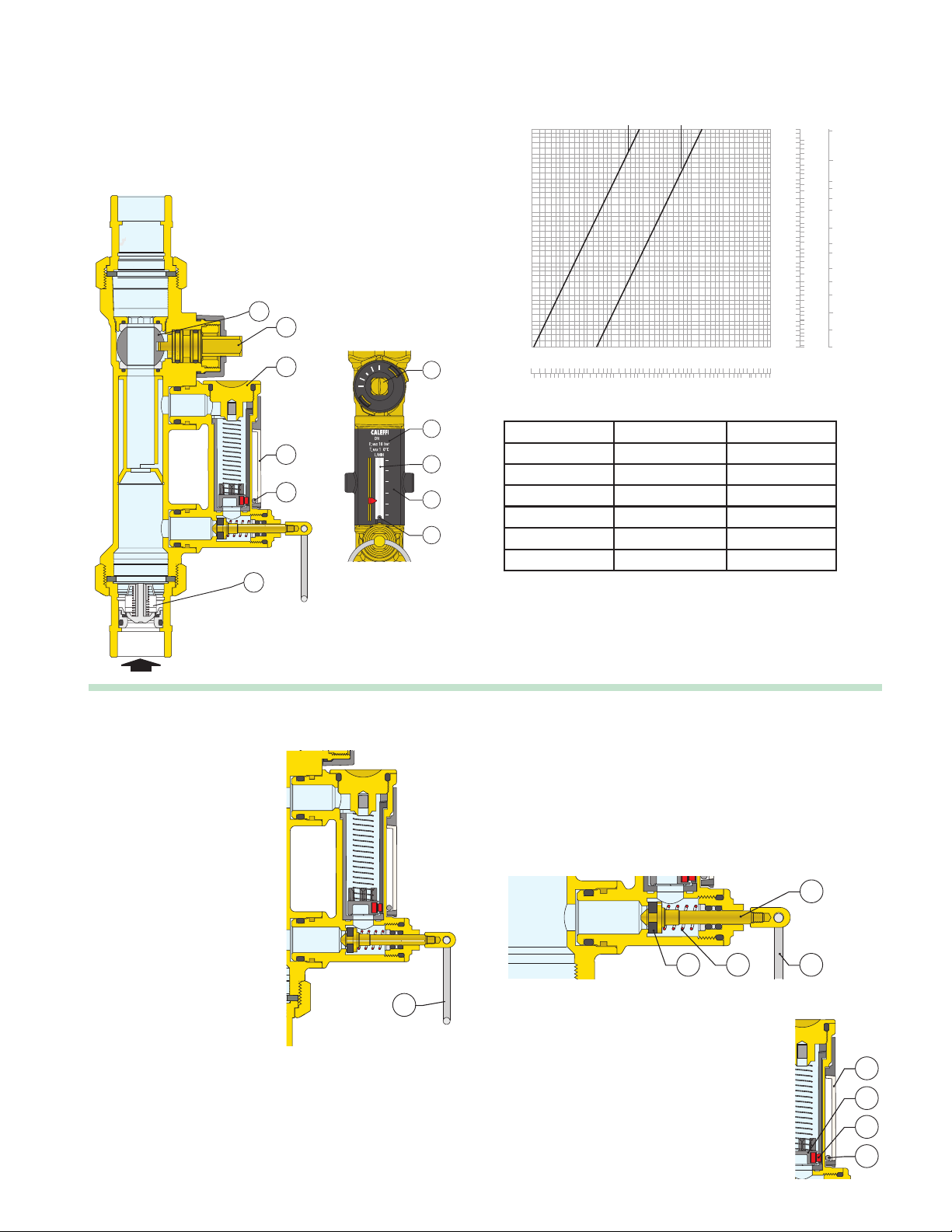

Operating principle

The balancing valve is a hydraulic device that

controls flow rate. The control mechanism is a

ball valve (1), operated by a control stem (2).

The flow rate is manually and properly set by

use of the convenient onboard flow meter (3)

housed in a bypass circuit on the valve body.

This circuit is automatically shut off during

normal operation. The flow rate is indicated

by a metal ball (4) sliding inside a transparent

channel (5) with an integral graduated scale (6).

The QuickSetter+ also includes a inlet check

valve (7) to prevent reverse flow.

1

2

3

2

Hydraulic characteristics at 100% open

p (psi)

∆

20

10

5

4

3

2

1

0.5

0.4 0.4

0.3

0.2

0.1

0.2

0.5

0

5

100

200

1/2 - 1-3/4 gpm

1

2

500

5

1000

2 - 7 gpm

10

2000

2050100

5000

10000

20000

25000

(psi) (bar)

20

10

5

4

3

2

1

0.5

0.3

0.2

0.1

0.050.05

)

00

2

gpm

G

(l/h) (

45000

1.0

0.5

0.4

0.3

0.2

0.1

0.05

0.04

0.03

0.02

0.01

0.005

0.003

(feet of head)

46.00

20.00

10.00

9.00

7.00

5.00

3.00

2.00

1.50

1.00

0.70

0.50

0.30

0.20

0.11

7

Construction details

Flow meter

When activated by pulling the

operating ring (2), the flow rate

is indicated on the flow meter

housed in a bypass circuit on the

valve body. When finished reading

the flow rate, the flow meter is

automatically shut off, isolating

it during normal operation.

Use of a flow meter greatly

simplifies the process of system

balancing since the flow rate can

be measured and controlled at any

time without differential pressure

gauges or reference charts. The

onboard flow meter eliminates the

need to calculate valve settings

during system setup. Additionally,

the unique onboard flow meter

offers unprecedented time and cost

savings by eliminating the long and

difficult procedure of calculating

pre-settings associated with using

traditional balancing devices.

15

5

1

4

3

7

5

6

5

4

6

3

2

4

Connection Flow rate (gpm) Fully open Cv

½" sweat 0.5 - 1.75 1.0

¾" sweat/press 0.5 - 1.75 1.0

1" sweat 0.5 - 1.75 1.0

½" sweat 2.0 - 7.0 6.3

¾" sweat/press 2.0 - 7.0 6.3

1" sweat 2.0 - 7.0 6.3

Flow meter bypass valve

The bypass valve (1) opens and closes the circuit between the flow

meter and the valve. The bypass valve is easily opened by pulling the

operating ring (2), and is automatically closed by the internal return

spring (3) when finished reading the flow rate. The spring and the

EPDM seal (4) provide a reliable seal to isolate the flow meter during

normal operation.

The operating ring (2) material has low thermal conductivity to avoid

burns if the flow meter is opened while hot fluid is passing through the

valve.

1

234

2

Ball/magnet indicator

The metal ball (4) that indicates the flow rate is not

in direct contact with the fluid passing through the

flow meter.

This is an effective and innovative measuring system

in which the ball slides up and down inside a

transparent channel (5) that is isolated from the fluid

flowing through the body of the flow meter. The ball

is moved by a magnet (6) connected to a float (7).

In this way the flow rate indication system remains

perfectly clean and provides reliable readings

over time.

5

7

6

4

Page 4

Complete closing and opening of the valve

765

432

7

6

5

4

3

2

7

6

5

4

3

2

CALEFFI

7

6

5

4

3

2

CALEFFI

765

432

765

432

7

6

5

4

3

2

CALEFFI

7

6

5

4

3

2

CALEFFI

765

432

The valve can be completely closed and opened. A slot on the control

stem indicates the valve position. When the control stem is turned

fully clockwise

perpendicular

(the slot is

to the axis

Completely closed Completely open

of the valve), the valve is

fully closed (A). When the

control stem is turned

fully counter-clockwise

(the slot is parallel to the

axis of the valve), the

valve is fully open (B).

A B

Installation

Install the balancing valve in a location that ensures free access to

the flow meter shutoff valve, control stem and flow rate indicator. To

ensure accurate flow measurement, straight sections of pipe installed

as shown is recommended.

132 series 132 series

Pump

5D

10D

The valve can be installed in any position with respect to the flow

direction shown on the valve body. Additionally, the valve can be

installed either horizontally or vertically.

Flow rate adjustment

The flow rate is adjusted as follows:

A. With the aid of the flow rate indicator (1), mark the desired flow rate.

B. Use the operating ring (2) to open the bypass valve slowly. This

allows fluid to flow through the flow meter (3). The bypass valve is

automatically closed under normal operating conditions.

A B

C. While holding the bypass valve open, use a wrench to turn the valve

control stem (4) to adjust the flow rate slowly. The resulting flow rate

is indicated by the metal ball (5) that slides up and down

inside a

transparent channel (6) marked by a graduated scale in gpm.

C D

765

7

6

5

4

3

2

432

E

765

432

2

3

4

5

6

7

D. Once the flow rate is properly adjusted, release the operating

ring (2) of the bypass valve. The valve will automatically return to

the closed position by means of an internal spring.

E.

A replacement bypass valve stem (7) with operating ring is available

in event it is damaged and inoperable. Order code F19346.

Page 5

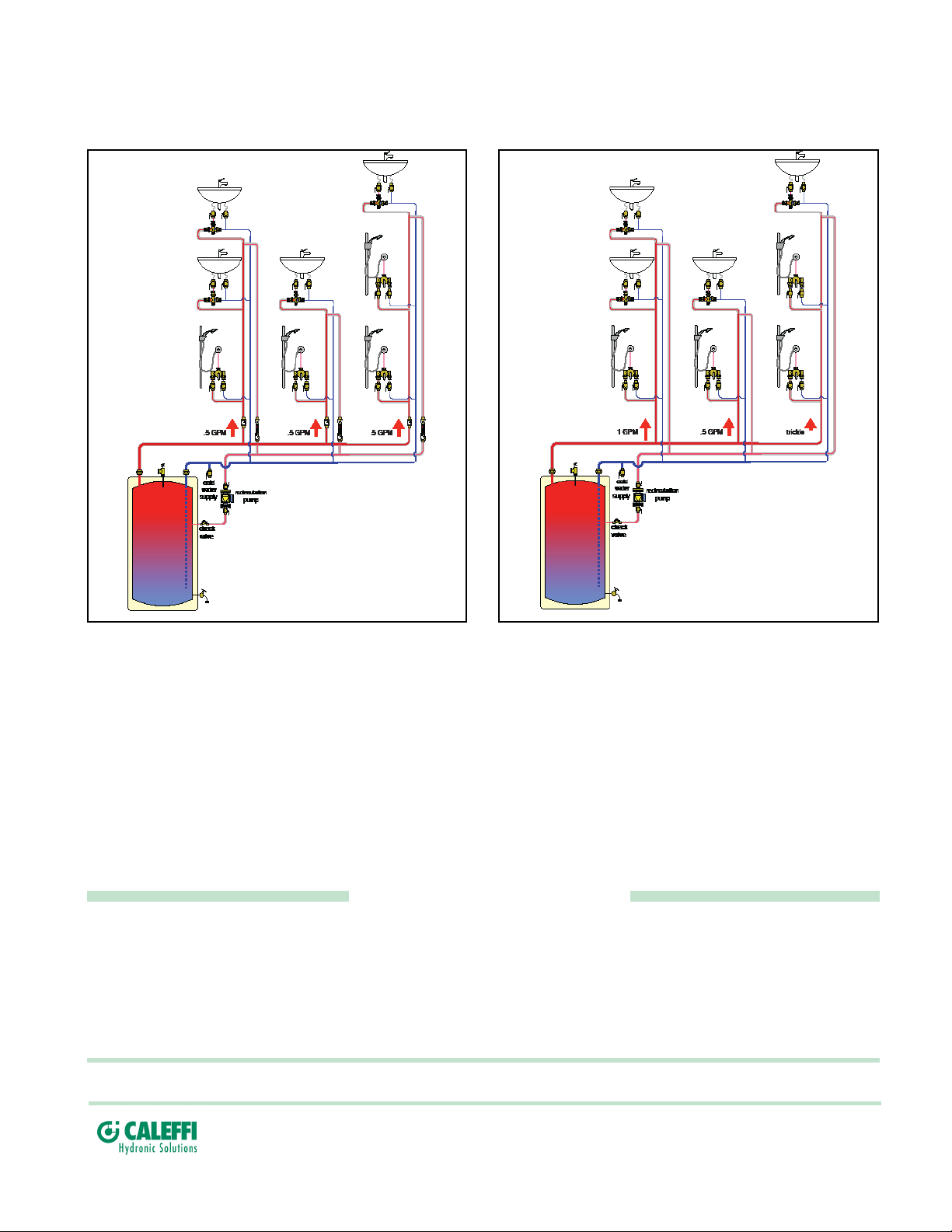

Hot water recirculation

Balanced example

Unbalanced example

Balancing made fast, easy, and accurate with QuickSetter+

Hot water recirculation systems are designed to minimize wait time for hot water to arrive when a fixture is opened. Systems left unbalanced or improperly

balanced result in wasted water down the drain, a costly and environmentally unfriendly situation - not to mention the undesired annoyance placed on

building occupants. The QuickSetter+ takes the guess work and labor out of balancing. With the valve's exclusively designed venturi mechanism, the

installer simply pulls the flow indicator by-pass pin, adjusts the flow to the desired flow rate while viewing the built-in sight gauge, and releases the pin.

Easy, accurate balancing in seconds. No instruments or reference graphs are needed.

SPECIFICATION SUMMARY

132 series

Balancing valve with flow meter. Sweat union connections ½”, ¾", 1". Press union connection ¾". DZR low-lead brass body (<0.25%

Lead content) certified by ICC-ES file PMG-1360. Stainless steel ball. Chrome-plated brass ball control stem. PTFE ball seal seat. PSU

control stem guide. DZR low-lead brass flow meter body and headwork. Stainless steel flow meter bypass valve stem. Stainless steel flow

meter springs. PSU flow meter float and indicator cover. EPDM seals. Provided with inlet flow check valve. Water and glycol solutions.

Maximum percentage of glycol 50%. Maximum working pressure 150 psi (10 bar). Working temperature range 14 to 230 degrees F

(-10 to 110 degrees C). Flow rate range unit of measurement gallons per minute (gpm). Accuracy ± 10%. Control stem angle of rotation

90°. Provide with optional mixed outlet termperature gauge, 30 to 210 degree F scale, 2 inch diameter.

We reserve the right to change our products and their relevant technical data, contained in this publication, at any time and without prior notice.

Calef North America, Inc.

3883 W. Milwaukee Road

Milwaukee, WI 53208

Tel: 414-238-2360 · Fax: 414-238-2366

sales@calef.com · www.calef.com

© Copyright 2016 Calef North America, Inc.

Loading...

Loading...