Page 1

59633-4 MaxVU Rail Full Manual

59633-MaxVU Rail Full Manual (EN) - Page 1 of 127

Page 2

Contents

Warning Symbols Used through the Manual: .............................................................................................. 9

Warranty & Returns Statement .................................................................................................................... 10

Warranty ...................................................................................................................................................... 10

Limitations ................................................................................................................................................... 10

Installation ....................................................................................................................................................... 11

Guidance Notes for Installation ............................................................................................................... 11

Implications of Double Insulation ............................................................................................................. 11

Unpacking ................................................................................................................................................... 12

Cleaning ...................................................................................................................................................... 12

Mounting & Unmounting .......................................................................................................................... 12

Optional bus connector ........................................................................................................................ 12

Mounting & Unmounting from DIN Rail ............................................................................................... 12

Electrical Installation...................................................................................................................................... 13

Installation Considerations and Advice .................................................................................................. 13

AC Power Wiring (100 to 240Vac versions) ............................................................................................ 13

Wire Isolation ............................................................................................................................................... 13

Use of Shielded Cable ............................................................................................................................... 13

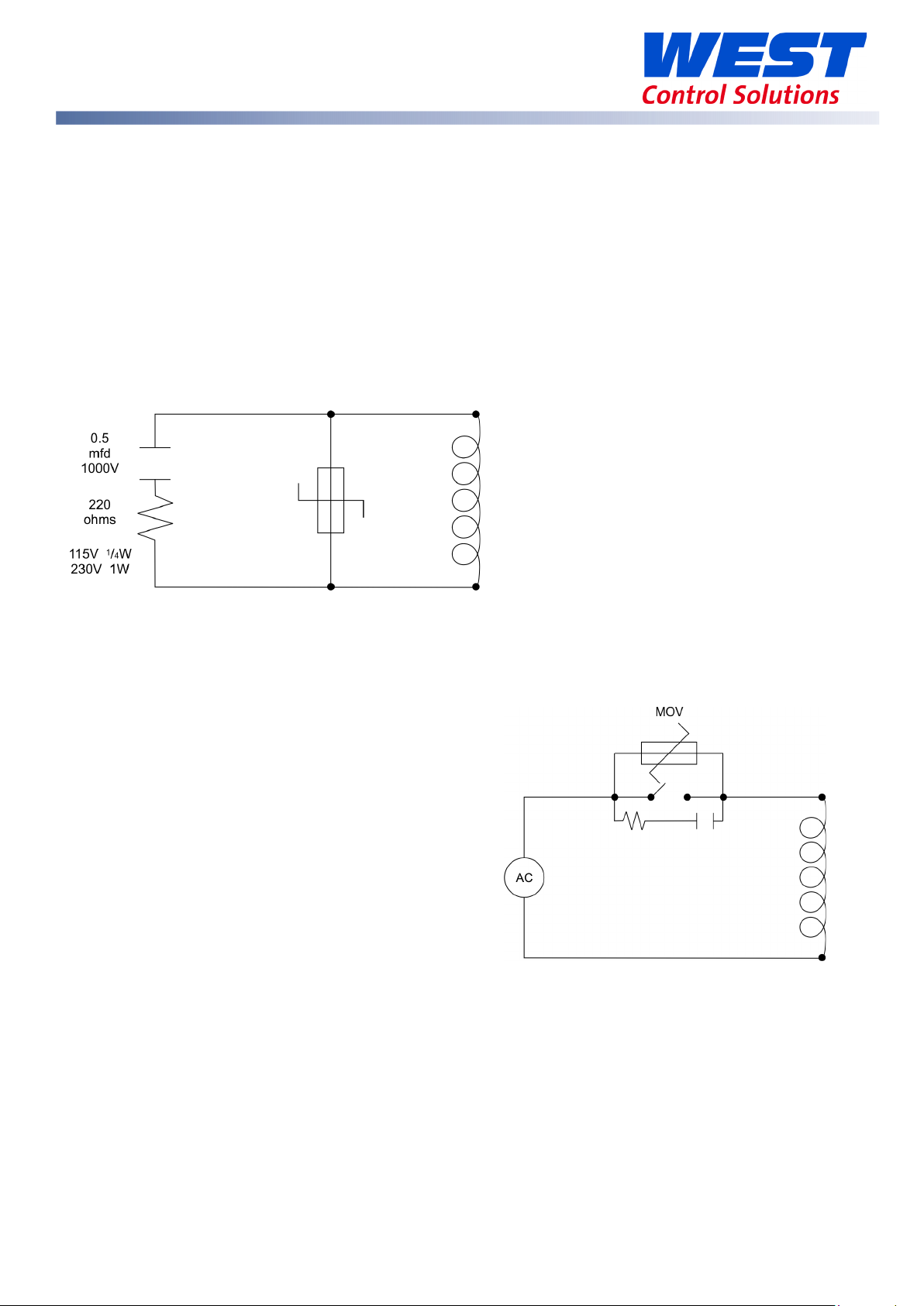

Noise Suppression at Source .................................................................................................................... 14

Inductive coils ......................................................................................................................................... 14

Contacts .................................................................................................................................................. 14

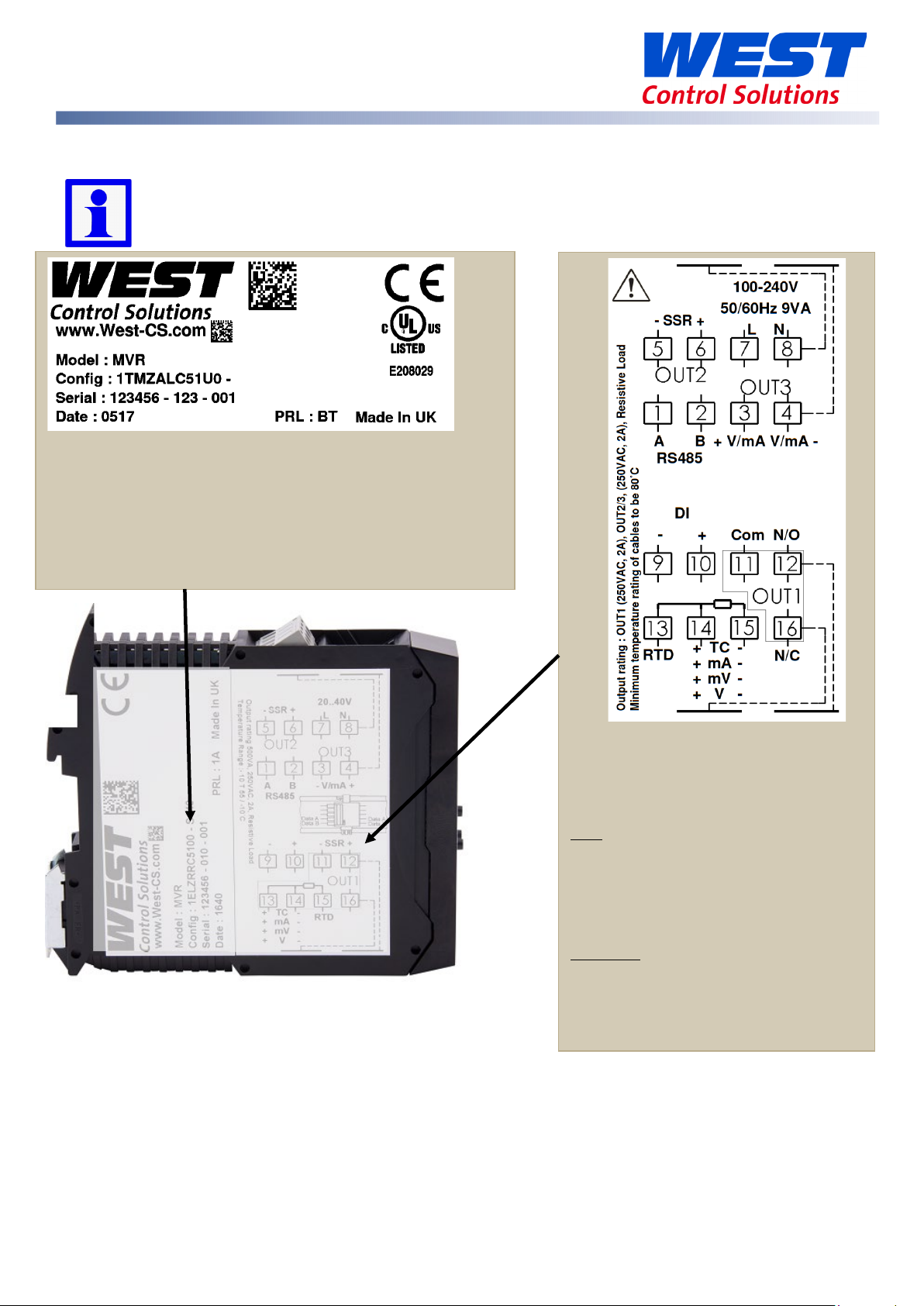

MaxVU Rail Product Labels .......................................................................................................................... 15

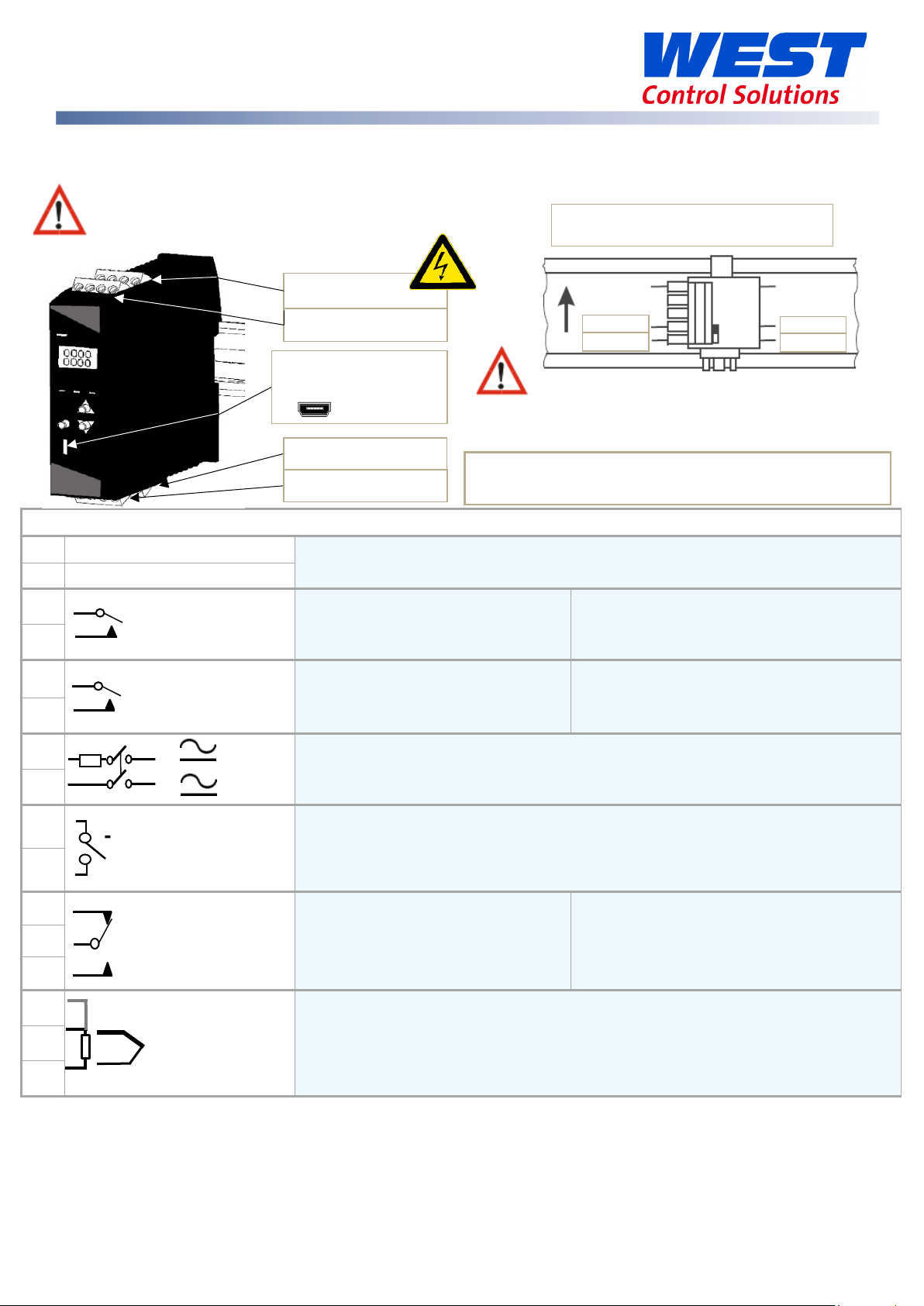

Power Connection .................................................................................................................................... 16

MaxVU Rail Isolation Chart ....................................................................................................................... 16

MaxVU Rail Terminal Wiring .......................................................................................................................... 17

Temperature Sensor Identification & Connection .................................................................................... 18

Sensor Placement (Thermocouple or RTD) ......................................................................................... 18

Thermocouple ............................................................................................................................................ 18

Thermocouple & RTD (PT100) Connections ............................................................................................ 19

Thermocouples ....................................................................................................................................... 19

59633-MaxVU Rail Full Manual (EN) - Page 2 of 127

Page 3

3 Wire RTD ................................................................................................................................................ 19

2 Wire RTD ................................................................................................................................................ 19

4 Wire RTD ................................................................................................................................................ 19

Relay Output Details .................................................................................................................................. 20

SSR Drive Output Details............................................................................................................................ 20

Linear Output Details ................................................................................................................................. 20

Powering Up ................................................................................................................................................... 21

Powering Up Procedure ............................................................................................................................ 21

First Power Up or Factory Default ................................................................................................................ 21

Auto-Tuning from Setup menu ..................................................................................................................... 22

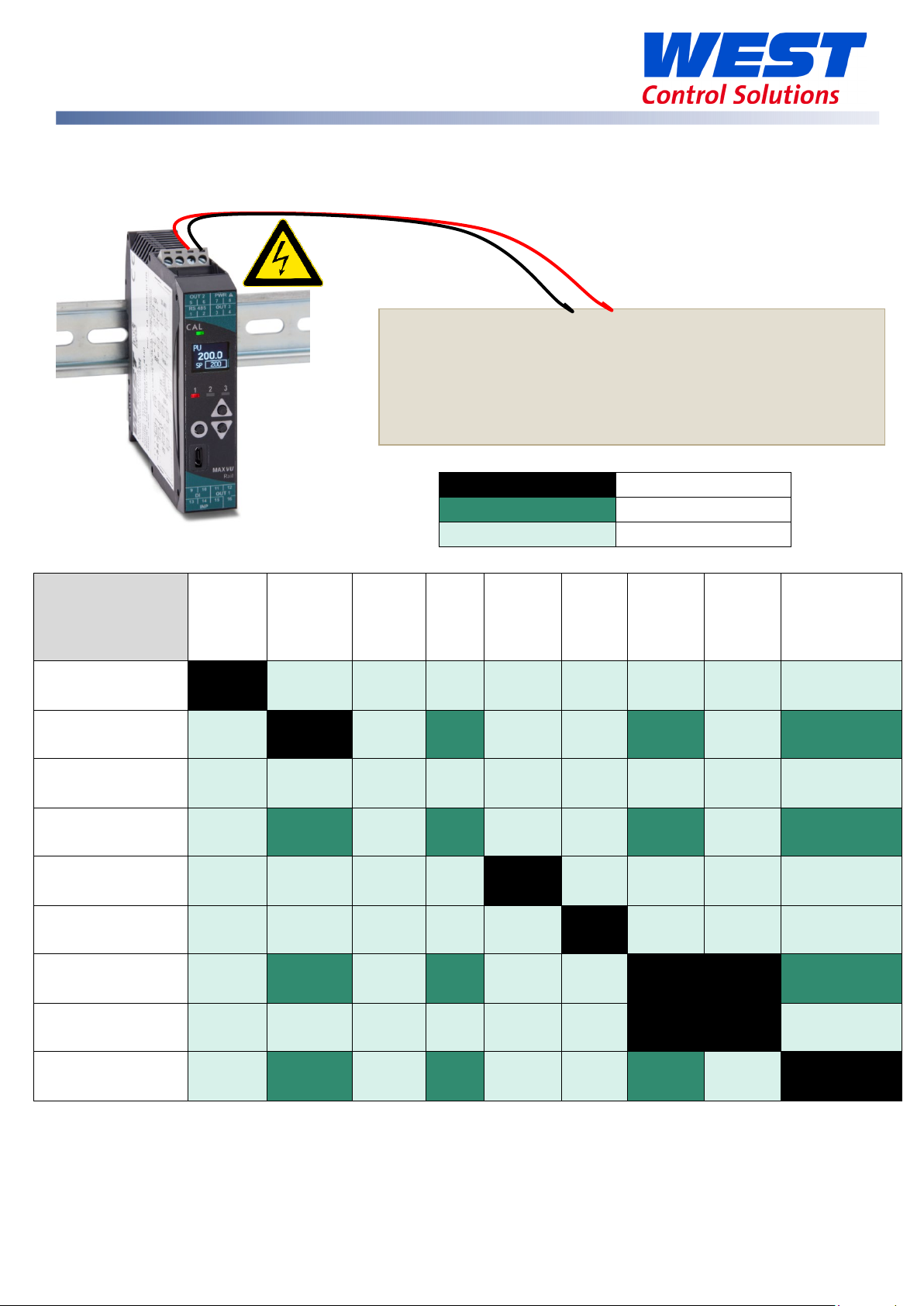

MaxVU Rail Model Range ............................................................................................................................ 22

Front Panel ...................................................................................................................................................... 23

General Navigation & Editing ...................................................................................................................... 23

Navigating to Setup Mode or Advanced Configuration from Operator Mode .............................. 24

Mode Access and Lock Codes ............................................................................................................... 24

Returning to Operator Mode ................................................................................................................... 24

Lock Code View Screen ........................................................................................................................... 24

Time Display .................................................................................................................................................... 25

Use of the Controller for Non-Temperature Applications ........................................................................ 25

MaxVU Rail use as a Transmitter .................................................................................................................. 25

Operator Mode & Screens on Standard & Extrusion models .................................................................. 26

Warnings & Messages ................................................................................................................................... 28

Pop-Up Alerts .............................................................................................................................................. 28

Pop-Up Alert List ...................................................................................................................................... 28

Message List ................................................................................................................................................ 29

MaxVU Rail Factory Defaults .................................................................................................................... 31

Factory Default procedure ...................................................................................................................... 31

Setup mode parameters for Standard & Extrusion models ..................................................................... 32

Advanced Configuration mode for Standard & Extrusion models ........................................................ 35

User menu ................................................................................................................................................... 36

59633-MaxVU Rail Full Manual (EN) - Page 3 of 127

Page 4

Input menu ................................................................................................................................................. 37

User Calibration menu............................................................................................................................... 38

Outputs menu ............................................................................................................................................ 38

Control menu for Standard model only ................................................................................................. 40

Control menu for Extrusion model only ................................................................................................... 41

Setpoint menu for Standard model only ................................................................................................ 43

Setpoint menu for Extrusion model only ................................................................................................. 44

Alarm menu ................................................................................................................................................ 44

Communications menu ............................................................................................................................ 45

Display menu .............................................................................................................................................. 45

Operator Screens menu ........................................................................................................................... 46

Information menu ...................................................................................................................................... 47

Exiting the Advanced Configuration mode .......................................................................................... 47

User Calibration Menu .................................................................................................................................. 48

Single point calibration (PV Offset) ......................................................................................................... 48

Two Point Calibration ................................................................................................................................ 49

Base Input Calibration .................................................................................................................................. 50

Equipment Required for Checking or Calibrating the Universal Input ............................................... 50

Calibration Check ..................................................................................................................................... 50

Base Calibration Procedure ..................................................................................................................... 51

Calibrating the mV Input .......................................................................................................................... 51

Calibrating other input types ................................................................................................................... 52

Calibration Input States ......................................................................................................................... 53

Calibration Progress ............................................................................................................................... 53

Calibration Modbus Addresses ................................................................................................................ 53

Automatic Tuning .......................................................................................................................................... 54

Running the Pre-Tune ................................................................................................................................ 54

Running Tune at SP .................................................................................................................................... 55

Tuning at SP Troubleshooting.................................................................................................................... 55

Tuning at SP for Heat and Cool ............................................................................................................ 56

59633-MaxVU Rail Full Manual (EN) - Page 4 of 127

Page 5

Digital Input Operation ................................................................................................................................. 56

Timer Feature .................................................................................................................................................. 59

Delay, Ramp and Timer diagram ............................................................................................................ 60

Extrusion Model Only Features ..................................................................................................................... 61

Non-Linear Cooling function .................................................................................................................... 61

Soft Start function ....................................................................................................................................... 64

Extrusion Only Parameters in the Control menu .................................................................................... 65

Limiter Models ................................................................................................................................................ 66

Introduction to the Limiter model ............................................................................................................ 66

Limiter Modbus Communications ............................................................................................................ 66

Limiter Digital Input .................................................................................................................................... 67

Limiter Operator Mode & Screens ............................................................................................................... 68

Limiter Output Latching ............................................................................................................................ 68

Limiter Clearing Latched Outputs ........................................................................................................ 68

Limiter Start-up Latch ............................................................................................................................. 69

Limiter Sensor Break Detection ................................................................................................................ 69

Limiter Output 3 – Linear, Relay or SSR drive .......................................................................................... 69

Limiter Setup mode parameters .................................................................................................................. 70

Limiter Advanced Configuration parameters ........................................................................................... 73

Limiter - Input Menu ................................................................................................................................... 73

Limiter - User Calibration Menu ................................................................................................................ 74

Limiter - Outputs Menu .............................................................................................................................. 75

Limiter - Communications Menu .............................................................................................................. 77

Limiter - Display Menu ............................................................................................................................... 77

Limiter - Information Menu ........................................................................................................................ 78

Limiter - Exiting from Advanced Configuration mode.......................................................................... 78

MaxVU / MaxVU Rail Configurator PC Software ....................................................................................... 79

Firmware and Language Updating ........................................................................................................ 82

Serial Communications ................................................................................................................................. 83

Supported Protocol ................................................................................................................................... 83

59633-MaxVU Rail Full Manual (EN) - Page 5 of 127

Page 6

RS485 Configuration .................................................................................................................................. 83

RS485 Device Addressing.......................................................................................................................... 83

Link Layer ..................................................................................................................................................... 84

Supported Modbus Functions .................................................................................................................. 85

Function Descriptions ............................................................................................................................. 85

Modbus Addresses ........................................................................................................................................ 87

Commonly Used Modbus Addresses ...................................................................................................... 87

Standard and Extrusion Modbus Addresses ........................................................................................... 88

Limiter Modbus Addresses ........................................................................................................................ 96

Specification for MaxVU Rail ...................................................................................................................... 101

MaxVU Rail Product Coding ...................................................................................................................... 104

Standard (MVR-x0x-xxxx-xxxx) and Extrusion (MVR-xEx-xxxx-xxxx) models ....................................... 104

Limiter model (MVR-xTx-xxxx-xxxx) ......................................................................................................... 105

FAQs .............................................................................................................................................................. 106

What happens if my Lock Code has been Changed or I forget my Lock Codes? ....................... 106

What is the difference between PID control & On-Off control? ....................................................... 106

My MaxVU Rail is giving an incorrect reading, what should I do? .................................................... 107

What is an Annunciator? ........................................................................................................................ 107

What is a Limiter / Limit Controller? ....................................................................................................... 107

What does Exceed Condition mean? .................................................................................................. 108

What does ‘Latching’ mean? ................................................................................................................ 108

What is a Retransmit Output? ................................................................................................................ 108

Why does my MaxVU Rail still say OFF even when I change the setpoint? .................................... 108

Glossary ......................................................................................................................................................... 109

Actual Setpoint ........................................................................................................................................ 109

Alarm Hysteresis ........................................................................................................................................ 110

Alarm Operation ...................................................................................................................................... 111

Alarm Inhibit .............................................................................................................................................. 112

Automatic Reset (Integral time) ............................................................................................................ 112

Auto-Tune .................................................................................................................................................. 112

59633-MaxVU Rail Full Manual (EN) - Page 6 of 127

Page 7

Band Alarm Value.................................................................................................................................... 112

Basic Setpoint Control ............................................................................................................................. 112

Bias (Manual Reset) ................................................................................................................................. 112

Bumpless Transfer ..................................................................................................................................... 113

Calibration - 2 Point (High/Low PV Offset) ........................................................................................... 113

Calibration - Single Point (PV Offset) ..................................................................................................... 113

Control Type ............................................................................................................................................. 113

Controller................................................................................................................................................... 114

Cool Proportional Band .......................................................................................................................... 114

Cycle Time ................................................................................................................................................ 114

Deadband ................................................................................................................................................ 114

Derivative .................................................................................................................................................. 114

Deviation Alarm ....................................................................................................................................... 114

Heat or Cool Output Power Limits ......................................................................................................... 114

Heat Proportional Band .......................................................................................................................... 115

Input Filter Time ......................................................................................................................................... 115

Input Range and Input Span .................................................................................................................. 115

Limit Controller or Limiter ......................................................................................................................... 115

Loop Alarm ............................................................................................................................................... 115

Manual Mode ........................................................................................................................................... 116

Master & Slave.......................................................................................................................................... 116

On-Off Control .......................................................................................................................................... 117

On-Off Differential (Hysteresis) ............................................................................................................... 117

PID Control ................................................................................................................................................ 117

Overlap/Deadband ................................................................................................................................ 118

Pre-Tune ..................................................................................................................................................... 119

PV High Alarm Value ............................................................................................................................... 119

PV Low Alarm Value ................................................................................................................................ 120

Process Variable (PV) .............................................................................................................................. 120

Rate (Derivative) ...................................................................................................................................... 120

59633-MaxVU Rail Full Manual (EN) - Page 7 of 127

Page 8

Reset / Integral ......................................................................................................................................... 120

Reverse Acting ......................................................................................................................................... 120

Scale Range Maximum ........................................................................................................................... 120

Scale Range Minimum ............................................................................................................................ 121

Serial Communications Option .............................................................................................................. 121

Setpoint ..................................................................................................................................................... 121

Setpoint Upper Limit and Setpoint Lower Limit .................................................................................... 121

Ramp Rate ................................................................................................................................................ 122

Solid State Relay (SSR) ............................................................................................................................. 122

Solenoid Valve ......................................................................................................................................... 122

Time Proportioning Control ..................................................................................................................... 123

Tuning PID .................................................................................................................................................. 123

Tune at Setpoint ....................................................................................................................................... 124

Running Tune at Setpoint from Automatic Control. ............................................................................ 124

Running Tune at Setpoint from Manual Control. ................................................................................. 125

Contact Details ............................................................................................................................................ 127

59633-MaxVU Rail Full Manual (EN) - Page 8 of 127

Page 9

This manual supplements the Concise Product manual supplied with the instrument. Information in

this manual is subject to change without notice.

Copyright © West Control Solutions, all rights reserved. No part of this publication may be

reproduced, transmitted, transcribed or stored in a retrieval system, or translated into any

language in any form by any means without the written permission of West Control Solutions.

Copies of this manual are available in electronic format on the West Control Solutions web sites

www.west-cs.com, www.west-cs.co.uk, www.west-cs.fr & www.west-cs.de.

Warning Symbols Used through the Manual:

Risk of electric shock.

The international hazard symbol is used to alert user to hazardous voltages.

Risk of Electrostatic Discharge (ESD) to components. Precautions must be

taken to reduce ESD which can damage some electronic components.

Caution, care must be taken, refer to the manual for further instructions.

Equipment is protected throughout by double insulation, when installed

properly.

It is important to read this manual before installing or commissioning the unit.

Important information or tip.

Both alternating or direct current could be present.

59633-MaxVU Rail Full Manual (EN) - Page 9 of 127

Page 10

Warranty & Returns Statement

This information is to be used with the published Terms & Conditions.

These products are sold by West Control Solutions under the warranties set forth in the following

paragraphs. Such warranties are extended only with respect to a purchase of these products, as

new merchandise, directly from West Control Solutions or from a West Control Solutions distributor,

representative or reseller and are extended only to the first buyer thereof who purchases them

other than for the purpose of resale.

Warranty

These products are warranted to be free from functional defects in material and workmanship for

three years from the time the products leave West Control Solutions factory and to conform at

that time to the specifications set forth in the relevant West Control Solutions instruction manuals

sheet or sheets.

THERE ARE NO EXPRESSED OR IMPLIED WARRANTIES, WHICH EXTEND BEYOND THE WARRANTIES

HEREIN AND ABOVE SET FORTH. NO WARRANTY IS MADE OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE WITH RESPECT TO THE PRODUCTS.

Limitations

West Control Solutions shall not be liable for any incidental damages, consequential damages,

special damages, or any other damages, costs or expenses excepting only the cost or expense of

repair or replacement as described above. Products must be installed and maintained in

accordance with West Control Solutions instructions. There is no warranty against damage to the

product resulting from corrosion. Users are responsible for the suitability of the products to their

application.

For a valid warranty claim, the product must be returned carriage paid to the supplier within the

warranty period. The product must be properly packaged to avoid damage from electro-static

discharge (ESD) or other forms of harm during transit.

Where there is any uncertainty in information, although we strive to have accurate

translations, the UK English version will be the most accurate and up to date versions of

any manuals.

59633-MaxVU Rail Full Manual (EN) - Page 10 of 127

Page 11

WARNING: This product can expose you to chemicals including

arsenic, which is known to the State of California to cause cancer.

For more information go to

This equipment is protected throughout by double insulation, when

installed properly. This type of installation does not need an earth

connection, but it is vital for safety reasons, that the instr

replaced if the instrument housing is broken.

Installation

www.P65Warnings.ca.gov

Guidance Notes for Installation

Installation should only be performed by technically competent personnel.

It is the responsibility of the installing engineer to ensure that the configuration is safe.

Local regulations regarding electrical installation & safety must be observed (e.g. US

National Electrical Code (NEC) or Canadian Electrical Code.

• Standards compliance shall not be impaired when fitting into the final

installation.

• Impairment of protection will occur if the product is used in a manner not specified by the

manufacturer.

• Due to the low weight of this instrument there are no special lifting or carrying

considerations.

• Ensure that supplementary insulation suitable for Installation Category II is

achieved when fully installed.

• To avoid possible hazards, accessible conductive parts of the final installation should be

protectively earthed in accordance with EN61010 for Class 1 equipment.

• Output wiring should be within a Protectively Earthed cabinet.

• Sensor sheaths should be bonded to protective earth or not be accessible.

• Live parts should not be accessible without the use of a tool.

• When fitted to the final installation, an IEC/CSA APPROVED disconnecting device should be

used to disconnect both LINE and NEUTRAL conductors simultaneously.

• Do not position the equipment so that it is difficult to operate the disconnecting device.

• Ventilation slots must not be covered and adequate air circulation must be allowed.

• Use conductor sizes 30-12 AWG, minimum temp rating of cables to be 80°c.

It is strongly recommended that applications incorporate a high or low limit protective

device or ‘limiter’, which will shut down the equipment at a pre-set process condition, to

prevent possible damage to property or products.

Implications of Double Insulation

59633-MaxVU Rail Full Manual (EN) - Page 11 of 127

ument is

Page 12

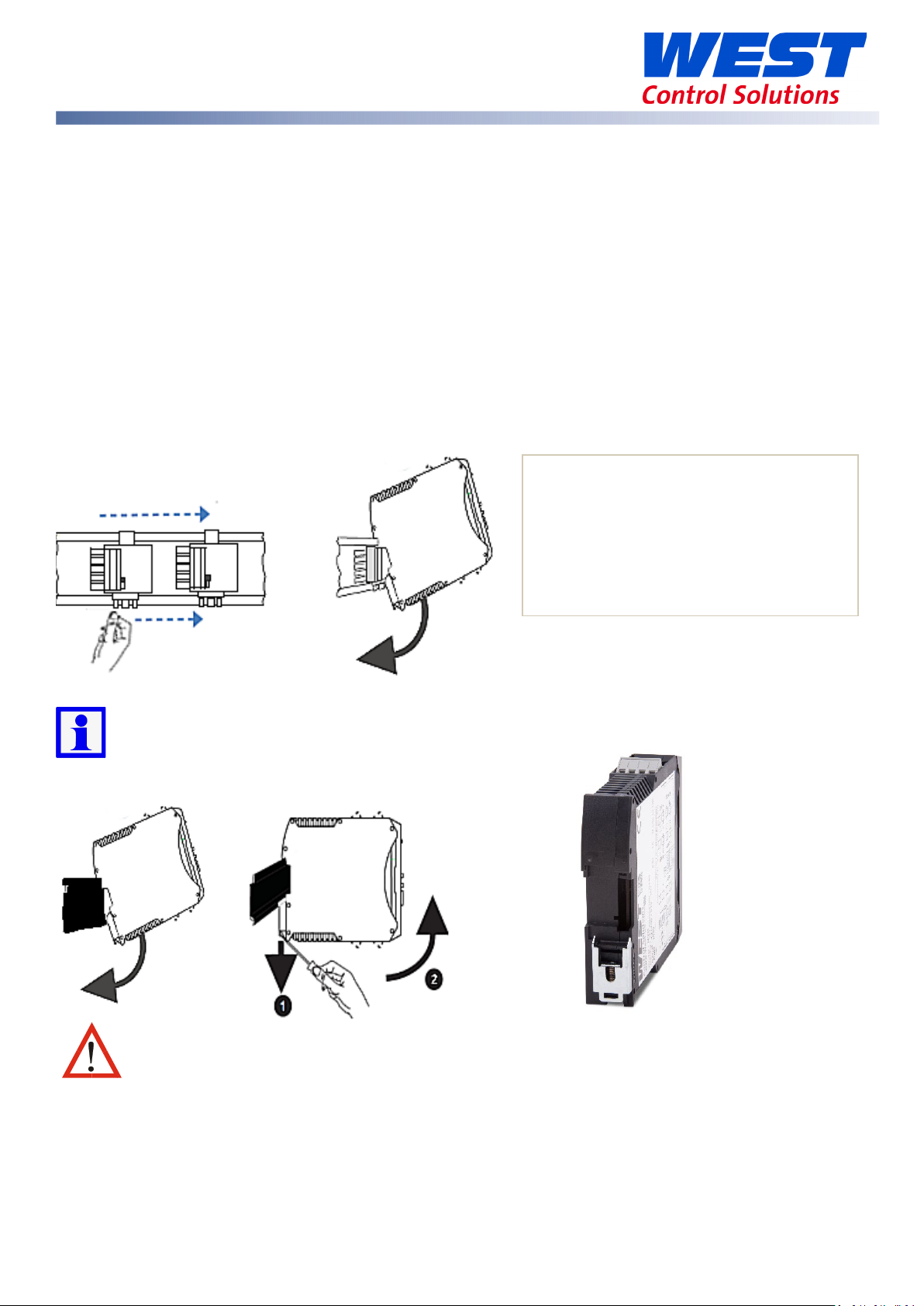

The optional bus connection should

Unpacking

Carefully remove the product from its packing. Please retain the packing for future use.

A single sheet concise manual is also supplied in one or more languages. Examine the delivered

items for damage or defects. If any are found, contact your supplier immediately.

Cleaning

Clean the front panel by wiping down with a dry cloth. Never allow water or any other substances

to ingress into the instrument.

Mounting & Unmounting

This instrument is designed for indoor back of panel use.

Optional bus connector

be slid onto the DIN Rail before fitting

the MaxVU Rail.

The connectors must be pushed

together to share the bus

This bus connection links up the optional RS485 communications connections without

extra wiring but does not supply power.

Mounting & Unmounting from DIN Rail

To prevent overheating, ensure the specified air-gaps are allowed, and that there is

adequate air flow inside the panel. Refer to environmental specifications.

59633-MaxVU Rail Full Manual (EN) - Page 12 of 127

Page 13

The only wires that should run together are those of the same category.

Electrical Installation

Installation Considerations and Advice

Ignition transformers, arc welders, motor drives, mechanical contact relays and

solenoids are examples of devices that generate electrical noise in typical industrial

environments. The following guidelines MUST be followed to minimise their effects.

If the instrument is being installed in existing equipment, the wiring in the area should be checked

to ensure that good wiring practices have been followed.

Noise-generating devices such as those listed above should be mounted in a separate enclosure.

If this is not possible, separate them from the instrument, by the largest distance possible.

If possible, eliminate mechanical contact relays and replace with solid-state relays. If a

mechanical relay cannot be replaced, a solid-state relay can be used to isolate the instrument.

A separate isolation transformer to feed only the instrumentation should be

considered. The transformer can isolate the instrument from noise found on the AC

power input.

AC Power Wiring (100 to 240Vac versions)

In mains power versions, it is good practice to ensure that the ac neutral is at or near ground

(earth) potential. A proper neutral will help ensure maximum performance from the instrument.

Wire Isolation

Four voltage levels of input and output wiring may be used with the unit:

• Analogue input (for example thermocouple, RTD, VDC, mVDC or mADC)

• Relays outputs

• SSR Driver outputs

• AC power

If any wires need to run parallel with any other lines, maintain a minimum space of 150mm

between them.

If wires MUST cross each other, ensure they do so at 90 degrees to minimise interference.

Use of Shielded Cable

All analogue signals must use shielded cable. This will help eliminate electrical noise induction on

the wires. Connection lead length must be kept as short as possible keeping the wires protected

by the shielding. The shield should be grounded at one end only. The preferred grounding

location is at the sensor, transmitter or transducer.

59633-MaxVU Rail Full Manual (EN) - Page 13 of 127

Page 14

Noise Suppression at Source

Usually when good wiring practices are followed, no further noise protection is necessary.

Sometimes in severe electrical environments, the amount of noise is so great that it must be

suppressed at source. Many manufacturers of relays, contactors, etc. will supply 'surge suppressors'

which mount on the noise source. For those devices that do not have surge suppressors supplied,

Resistance-Capacitance (RC) networks and/or Metal Oxide Varistors (MOV) may be added.

Inductive coils

MOVs are recommended for transient suppression in inductive coils, connected in parallel and as

close as possible to the coil. Additional protection may be provided by adding an RC network

across the MOV.

Contacts

Arcing may occur across contacts when they open and close. This results in electrical noise as well

as damage to the contacts. Connecting a properly sized RC network can eliminate this arcing.

For any circuits of up to 3 Amps, a combination of a 47 Ohm resistor and 0.1 microfarad capacitor

(rated at 1000 Volts) is recommended. For circuits from 3 to 5 Amps, connect two of these in

parallel. Always observe the current rating of the relays on the controller and ensure this is not

exceeded.

59633-MaxVU Rail Full Manual (EN) - Page 14 of 127

Page 15

MaxVU Rail Product Labels

The example product & wiring label below is for illustration only. Actual label

information varies with the model code / hardware configuration purchased.

The product label shows the part number, production

information and approvals.

Model and Config codes make up the part number

(see MaxVU Rail Product Coding section), followed by

the unit serial number, country & date of manufacture,

and Product Revision Level.

The wiring label shows the power

requirements, connector positions

and terminal number.

This example is:

TOP

1 & 2 Rear = RS485 Comms

3 & 3 Rear = Linear Out 3

5 & 6 Front = SSR Driver Out 2

7 & 8 Front = 100-240VAC power.

BOTTOM

9 & 10 Rear = Digital Input

11, 12 Rear & 16 Front = Relay Out 1

13, 14 & 15 Front = Process Input

59633-MaxVU Rail Full Manual (EN) - Page 15 of 127

Page 16

Non-

Isolated

No Isolation

Reinforced Isolation

Power Connection

To avoid damaging your instrument it is critical the power connection is made to the correct

terminals.

Power is connected to pins 7 & 8.

Top, rear connector on the right-hand side.

(front connector omitted from picture for clarity)

The green LED shows when power is correctly connected.

Not Applicable

MaxVU Rail Isolation Chart

Universal

PSU

Universal Input

Relay

SSR

Linear

RS485 Comms

Non-Isolated

Digital Input

PSU

Input

Relay SSR Linear

RS485

Com

ms

Isolated

Digital

Input

Isolated

Digital

Input

Configuration

Port

Digital Input

Configuration Port

59633-MaxVU Rail Full Manual (EN) - Page 16 of 127

Page 17

Use cables with 80°C minimum temperature rating, conductor sizes 30-12 AWG.

1

RS485 A (Rx/Tx+)

2

RS485 B (Rx/Tx-)

L +

CONV-BA-00-00-00-MV.

1|2|3|4

Dedicated

5|6|7|8

13|14|15|16

9|10|11|12

Data A

Data B

Data A

Data B

Relay COM /

Relay NO /

+

Volt-free or TTL

compatible

Relay COM / SSR-

Relay NO / SSR+

TC / RTD / Linear +

TC / RTD / Linear -

RTD

Relay COM / SSR-

Relay NO / SSR+

Relay NC

Bus connector pin-outs

Diagrams show all possible option combinations so check

MaxVU Rail Terminal Wiring

Caution: Check information label on housing for correct operating voltage before

connecting supply to Power Inputs.

NEVER DIRECTLY CO

Configuration Port

configuration socket to a USB port, use adaptor

your exact product specification before connecting.

Never directly connect the dedicated

3

4

5

6

7

8

9

10

16

11

12

13

Communications

Linear +

Linear -

Output 3 – Standard & Extrusion

models

Output 2 – Standard & Extrusion

models

Power – low power or mains (hardware dependent)

Output 3 (Alarm 2 or Retx PV) – Limiter

model

Alarm 1 output – Limiter model

N -

Digital Input

Output 1 – Standard and Extrusion

models

Limit output – Limiter model (Relay only)

14

15

59633-MaxVU Rail Full Manual (EN) - Page 17 of 127

Input – thermocouple, RTD or linear

Page 18

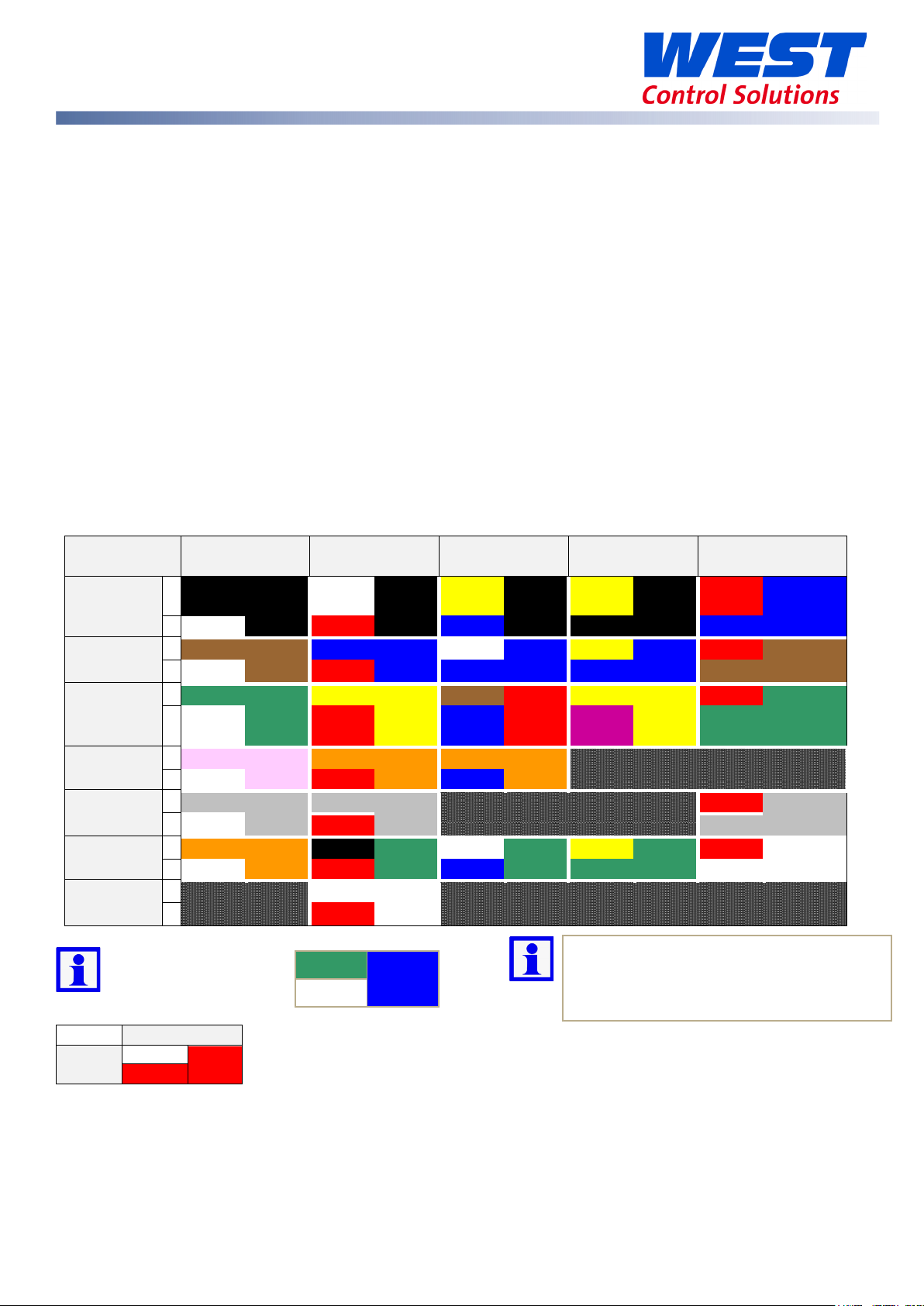

Type

International

USA ANSI MC

British BS1843

French

German

+

Black

Black

White

Black

Yellow

Black

Yellow

Black

Red

Blue

-

White

Red

Blue

Black

Blue

+

Brown

Brown

Blue

Blue

White

Blue

Yellow

Blue

Red

Brown

-

White

Red

Blue

Blue

Brown

+

Green

Green

Yellow

Yellow

Brown

Red

Yellow

Yellow

Red

Green

-

White

Red Blue

Purple

Green

+

Pink

Pink

Orange

Orange

Orange

Orange

-

White

Red

Blue

+

Grey

Grey

Grey

Grey

Red

Grey

-

White

Red

Grey

+

Orange

Orange

Black

G

White

Green

Yellow

Green

Red

White

-

White

Red

Blue

Green

White

+

White

White

-

Red

+

-

Lead Colours

White

Red

Important: Using the wrong type of

Temperature Sensor Identification & Connection

Sensor Placement (Thermocouple or RTD)

If the temperature probe is to be subjected to corrosive or abrasive conditions, it must be

protected by an appropriate thermo-well. The probe must be positioned to reflect true process

temperature:

• In a liquid media - the most agitated area

• In air - the best circulated area

The placement of probes into pipe work some distance from the heating vessel leads to ‘transport

delay’, which results in poor control.

Locate the MaxVU as close as practical to the sensor to keep lead-length to a minimum.

Thermocouple

Thermocouples are identified by wire colour, and where possible, the outer insulation as well.

IEC584-3 is the most common standard, but several standards have been used worldwide. This

therefore is only a guide.

J

T

K

N

B

R & S

C (W5)

PT100

IEC584-3

*

*

Note:

* = Wire is magnetic

Red

96.1

Wire

Wire

reen

Sheath

NFC 42-324

DIN 43710

extension cable will cause incorrect

readings.

59633-MaxVU Rail Full Manual (EN) - Page 18 of 127

Page 19

Refer also to the Input Type range table in the Setup menu.

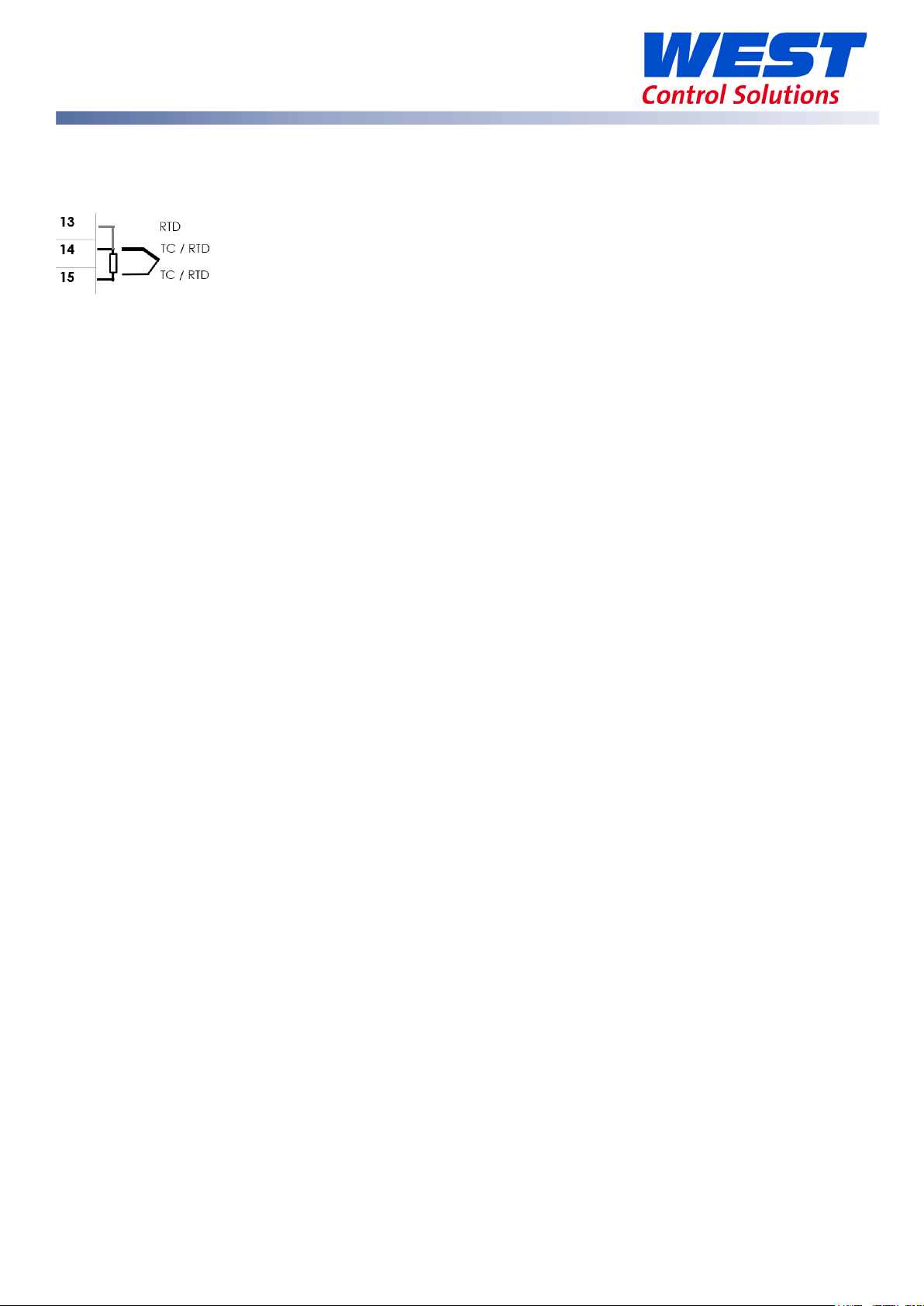

Thermocouple & RTD (PT100) Connections

Thermocouples

Connect your thermocouple to terminals 14 (positive) & 15 (negative). Carefully follow the chart

above, because correct polarity is vital for proper operation.

3 Wire RTD

The MaxVU Rail is designed to support a compensated 3 wire PT100. A PT100 normally 1 white and

2 red wires. The resistive element is between the white (connect to terminal 15) & 1 red wire

(connect to terminal 14). The 2nd red wire (connect to terminal 13) is required for automatic lead

length compensation.

2 Wire RTD

If is recommended to use a 3-wire PT100 RTD sensor. 2-wire PT100s should only be used with lead

lengths less than 3 metres. To use a 2-wire PT100 connect to terminals 14 & 15, then place a wire

link between terminals 13 & 14 in place of the third wire.

4 Wire RTD

A 4-wire PT100 can be used provided it is connected as a 3-wire type, with the 2

nd

white wire is not

used.

The resistive element is between the 1 white wire (connect to terminal 15) & 1 red wire (connect to

terminal 14). The 2

nd

red is connected to terminal 13 for the automatic lead length compensation.

The remaining white wire must be left unconnected (cut short or tied back to prevent it touching

other connections).

59633-MaxVU Rail Full Manual (EN) - Page 19 of 127

Page 20

3

COM

4

N/O

11

12

COM (Common)

N/O (Normally Open)

16

N/C (Normally Closed)

5 6 3

SSR drive -ve

4

SSR drive +ve

11

SSR drive -ve

16

SSR drive +ve

5 6 3

Linear +ve

4

Linear -ve

Relay Output Details

Relays are rated for 2A maximum at 250Vac (resistive load).

Output 1 (Relay option) Form A SPDT Output 2 or Output 3 (Relay option) Form C SPST

SSR Drive Output Details

The SSR driver outputs give a >10VDC ‘on’ signal at 20mA maximum. Use a separate connection

to the +ve & -ve of each output. Do not common together.

Output 1 (SSR Drive option) Output 2 or Output 3 (SSR Drive option)

Linear Output Details

The Linear Output is an option for Output 3. Select from 0 to 10V, 2 to 10V, 0 to 20mA, 4 to 20mA,

0 to 5V or 1 to 5V in the setup or input configuration menus.

Output 3 (Linear option)

59633-MaxVU Rail Full Manual (EN) - Page 20 of 127

Page 21

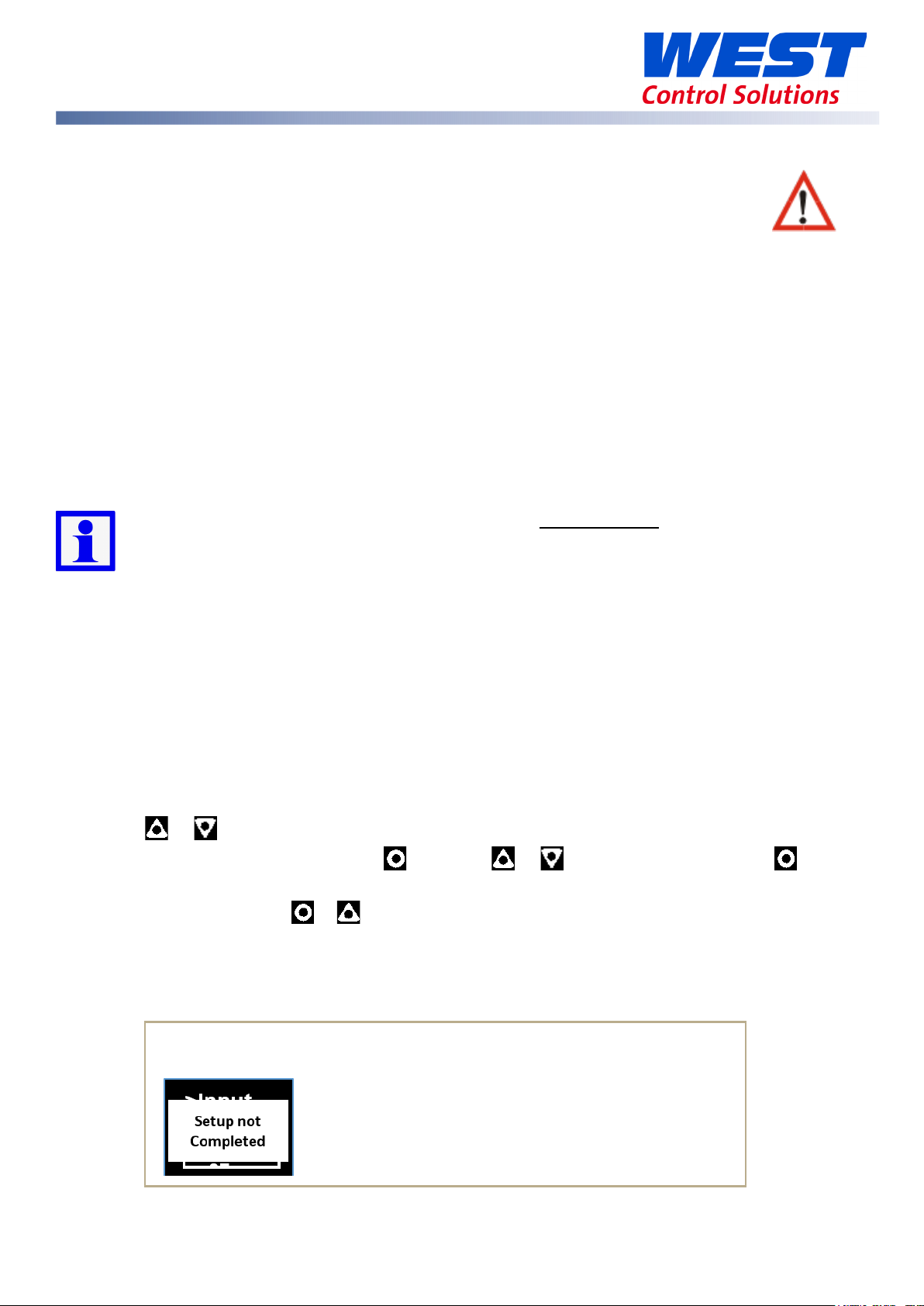

The Pop-Up alert “Setup not Complete” may appear as a reminder

Powering Up

ENSURE SAFE WIRING PRACTICES HAVE BEEN FOLLOWED.

WHEN POWERING UP FOR THE FIRST TIME, ISOLATE THE POWER FROM THE OUTPUT

CONNECTIONS.

The instrument must be powered from a supply according to the wiring label on the side of the

unit. (100vac to 240Vac, or 24 Vac/dc depending upon the model purchased.)

Carefully check the supply voltage and connections before applying power.

Powering Up Procedure

At power-up, a self-test procedure is run, during which a product logo screen is displayed.

When powering up for the first time the instrument starts up in the Setup Mode after the product

logo screen is displayed.

You must complete the Setup by cycling through all parameters before exiting the Setup

Mode, and using the device for the first time. Otherwise the device will go into the Setup

Mode, again, on subsequent power ups.

Once it has been correctly set-up, the instrument will enter the Operator Mode, after self-test,

and any future access to the Setup or Advanced Configuration Modes is lock code protected.

First Power Up or Factory Default

When the unit is initially powered up or the user restores the factory defaults to the device, it

immediately enters the Setup menu without requiring an unlock code. The user must then cycle

through every parameter, to either view or adjust the value, and then exit the menu.

1. Use or to review every parameter.

2. Change value if necessary using , then use or to adjust the value, then to

save.

3. Exit Setup by pressing & together.

If the above steps are not followed the Setup has not been completed so the device will go into

Setup, again, on every subsequent power up.

that you need to finish the Setup.

59633-MaxVU Rail Full Manual (EN) - Page 21 of 127

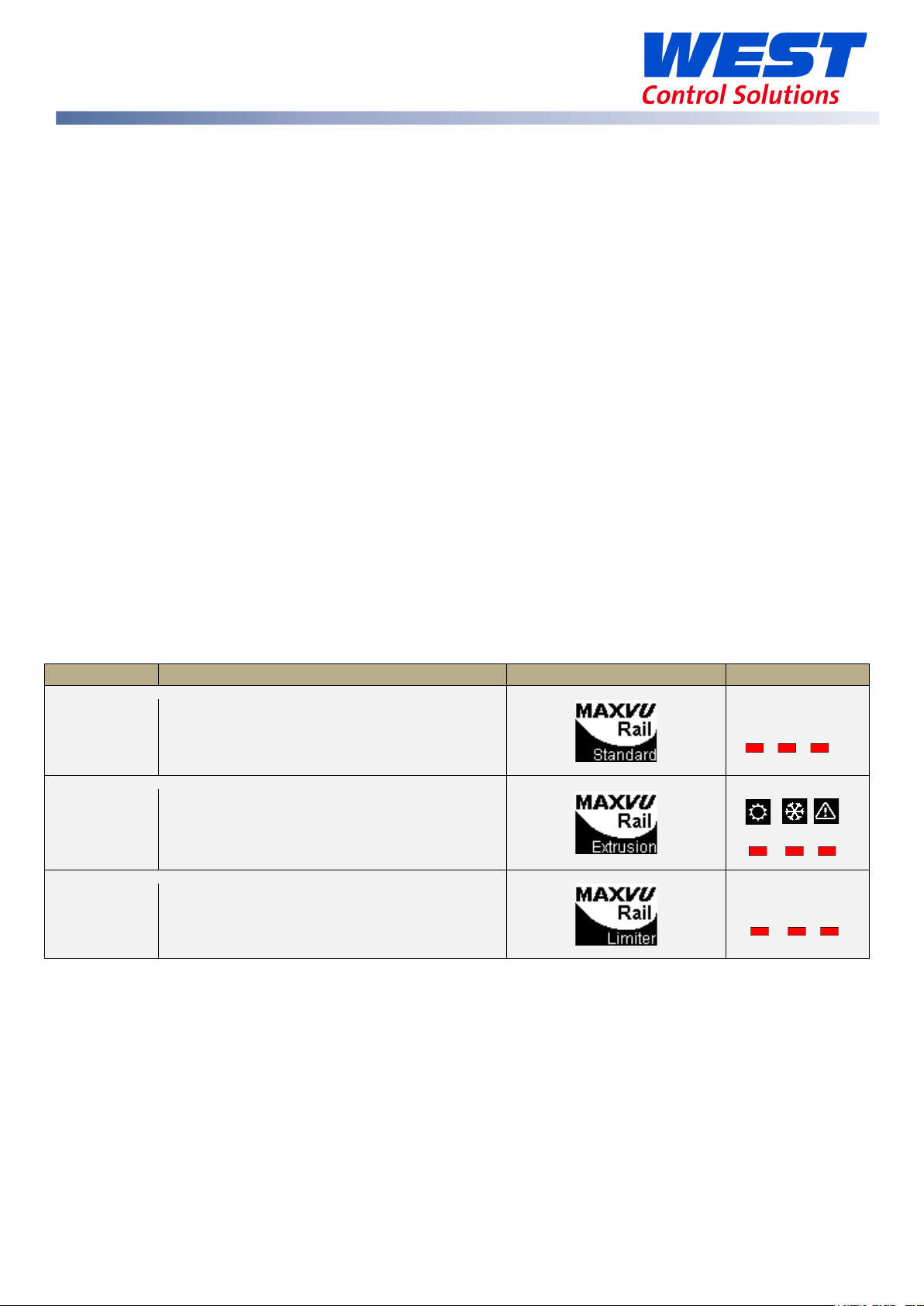

Page 22

Type

Purpose

Start-up Splash screen

Status LEDs

General temperature and other

PID or On/Off control.

1 2 3

Auto-Tuning from Setup menu

The controller can be auto-tuned from the Setup Mode.

1. Pre-tune

Pre-Tune auto-tuning will not engage if:

• Controller is set to On/Off control (Heat Proportional Band or Cool Proportional Band =

On.Off)

• Setpoint is ramping (Ramp Rate is not OFF)

• PV is within 5% of the input range (scale range) from Setpoint (applies for Pre-Tune only).

2. Auto-tune at setpoint

Auto-tune at setpoint auto-tuning will not engage if:

• Controller is set to On/Off control (Heat Proportional Band or Cool Proportional Band =

On.Off)

• Setpoint is ramping (Ramp Rate is not OFF)

• Start Tune at SP is not available for Heat & Cool processes.

Please also refer to the Automatic Tuning section for tuning advice.

MaxVU Rail Model Range

The MaxVU Rail has 3 different model types – Standard, Extrusion and Limiter. The table below

shows some easily recognisable differences and explains their intended purpose.

Standard

Extrusion

Limiter

Plastic extrusion applications –

Over or Under PV prevention, without

All models have mechanical characteristics, specifications and many of the parameters in

common. However, there is a separate section with more information focused on the Limiter.

The tables and parameters applicable to all models have grey or brown borders.

The parameters tables specific to the Standard and Extrusion models are blue, and the Limiter specific areas are green.

applications –

PID or On/Off control.

control functions.

LM EX AL

59633-MaxVU Rail Full Manual (EN) - Page 22 of 127

Page 23

3 navigation keys:

Standard:

Extrusion:

Limiter:

By default, the display turns off after 5 minutes without any key presses.

menu, parameter Screen Timeout. Any key press turns the display back on.

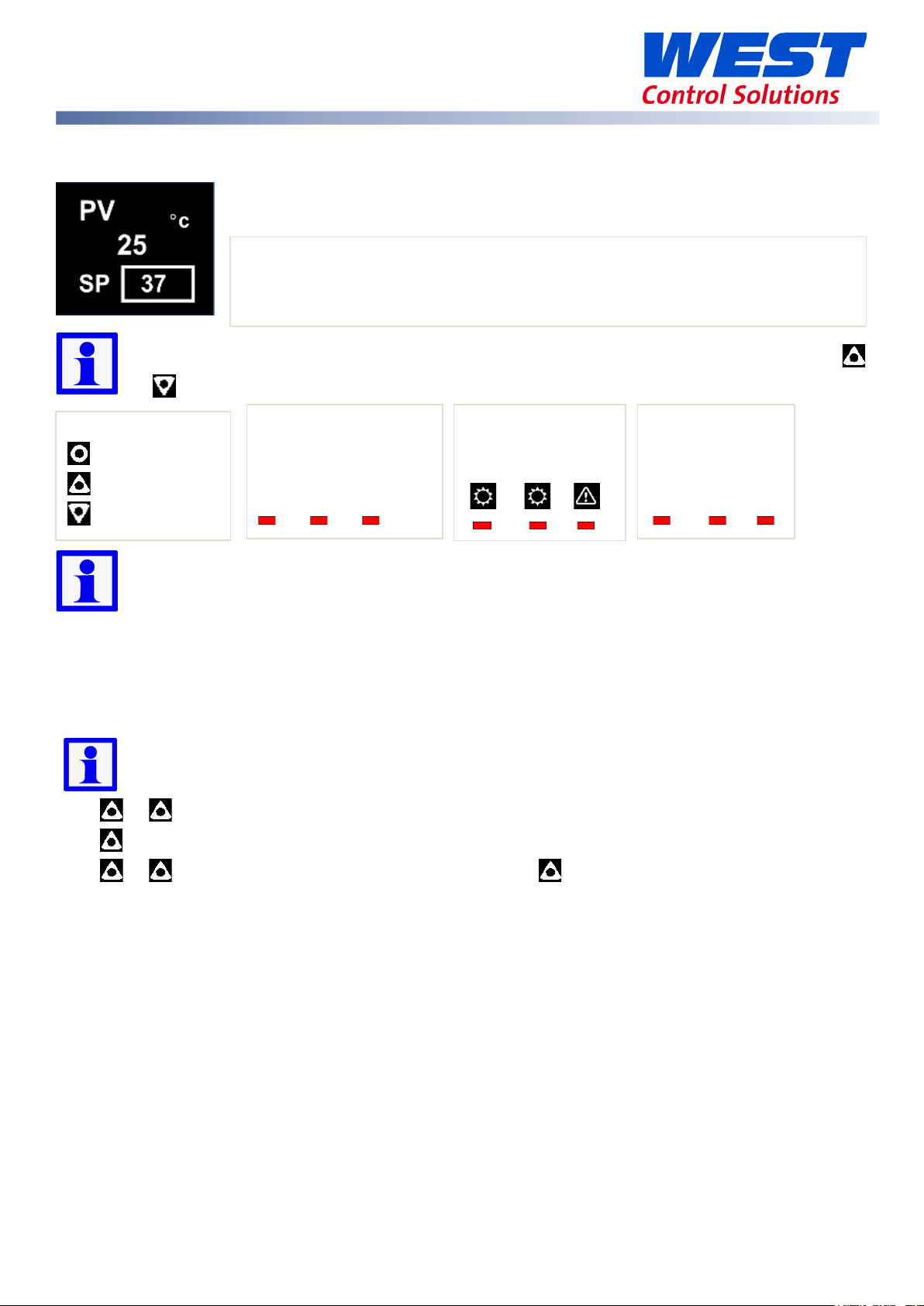

Front Panel

The main screen showing PV & SP, and the subsequent screens accessed from it using

or , are called the Operator Screens or Operator Mode.

Display shows PV (process variable), units, SP (setpoint), alarm/latch statuses,

error & warning messages.

This is configurable in the Advanced Configuration, in the Display sub-

Ok/Select

Up

Down

3 Output Status LEDs

1 2 3

3 Status LEDs for:

Heat Cool Alarm

3 Status LEDs for

LM EX AL

°C or °F are shown for temperature inputs only. Blank for linear type input (i.e. mA, V or

mV).

General Navigation & Editing

The device detects what options are fitted and intelligently hides parameters that are not relevant

to your current configuration.

These navigation instructions are common to all versions of the MaxVU Rail.

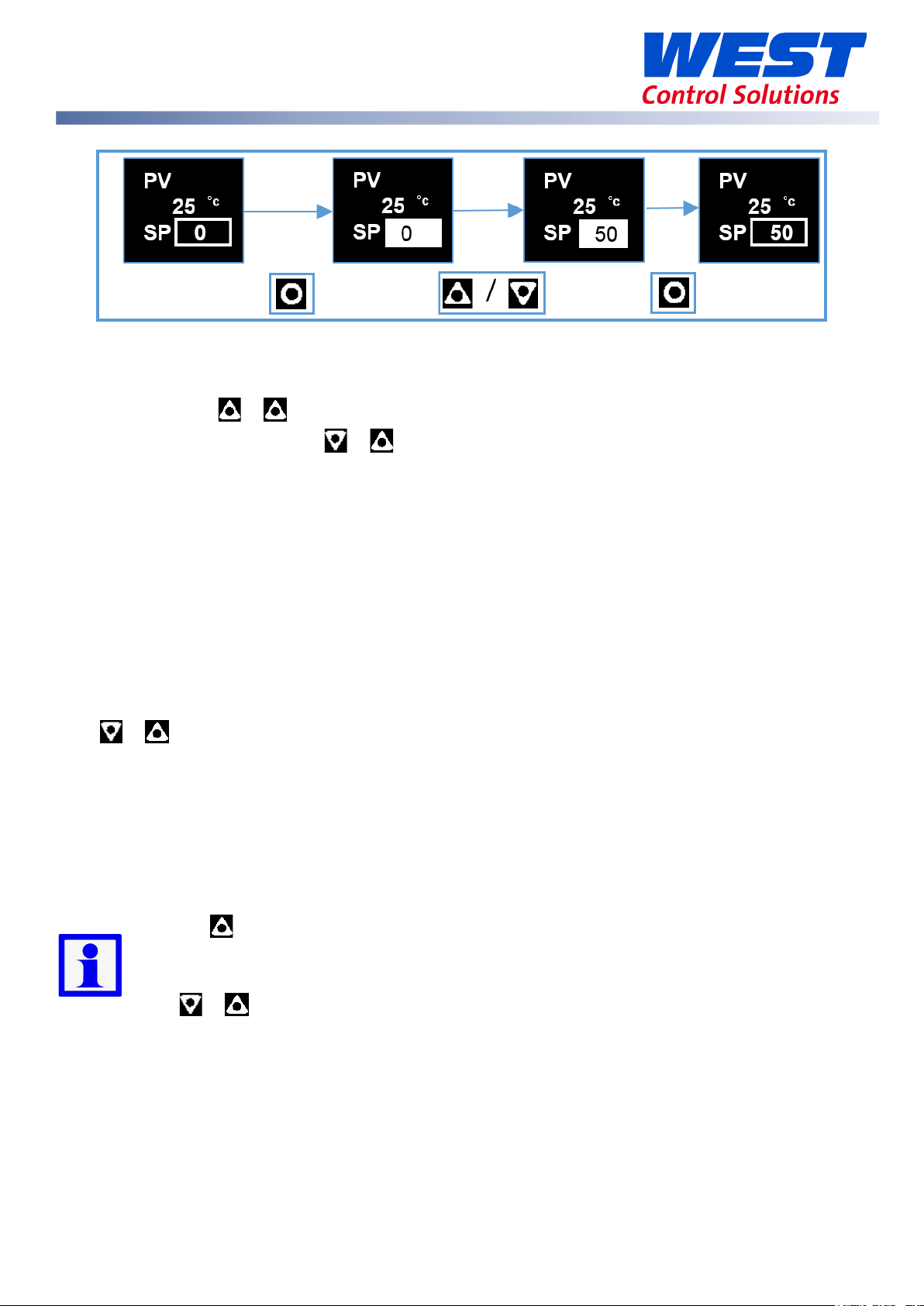

Press or keys to navigate between parameters or menu items.

Press to highlight a parameter value, ready for editing.

Press or to change the parameter value, then press within 60 seconds to confirm

change.

For example, changing the setpoint (SP). This example is for Standard or Extrusion models.

59633-MaxVU Rail Full Manual (EN) - Page 23 of 127

Page 24

Navigating to Setup Mode or Advanced Configuration from Operator Mode

Setup Mode - press & .

Advanced Configuration - press & .

The Setup Mode has fewer parameters and is intended for quick set up of simple applications.

Advanced Configuration gives access to all parameters for more complex application.

Mode Access and Lock Codes

Separate lock codes can be set for the Setup mode and for the Advanced Configuration mode.

Setup mode lock code – default

Advanced Configuration mode lock code – default

10.

20.

Returning to Operator Mode

Press & to move back one level (from Advanced Configuration sub-menus you may need

to move up 2 or more levels). After 120 seconds without key presses the unit returns automatically

to the first Operator mode screen.

Lock Code View Screen

If you don’t know the lock codes for any of the password protected menus, they can be found as

follows:

Hold the button whilst powering up for the lock code view screen and from this

screen the lock-codes (passwords) can be seen or changed. Be patient, it takes approx.

30 seconds to enter this screen at start-up.

Press & to exit.

59633-MaxVU Rail Full Manual (EN) - Page 24 of 127

Page 25

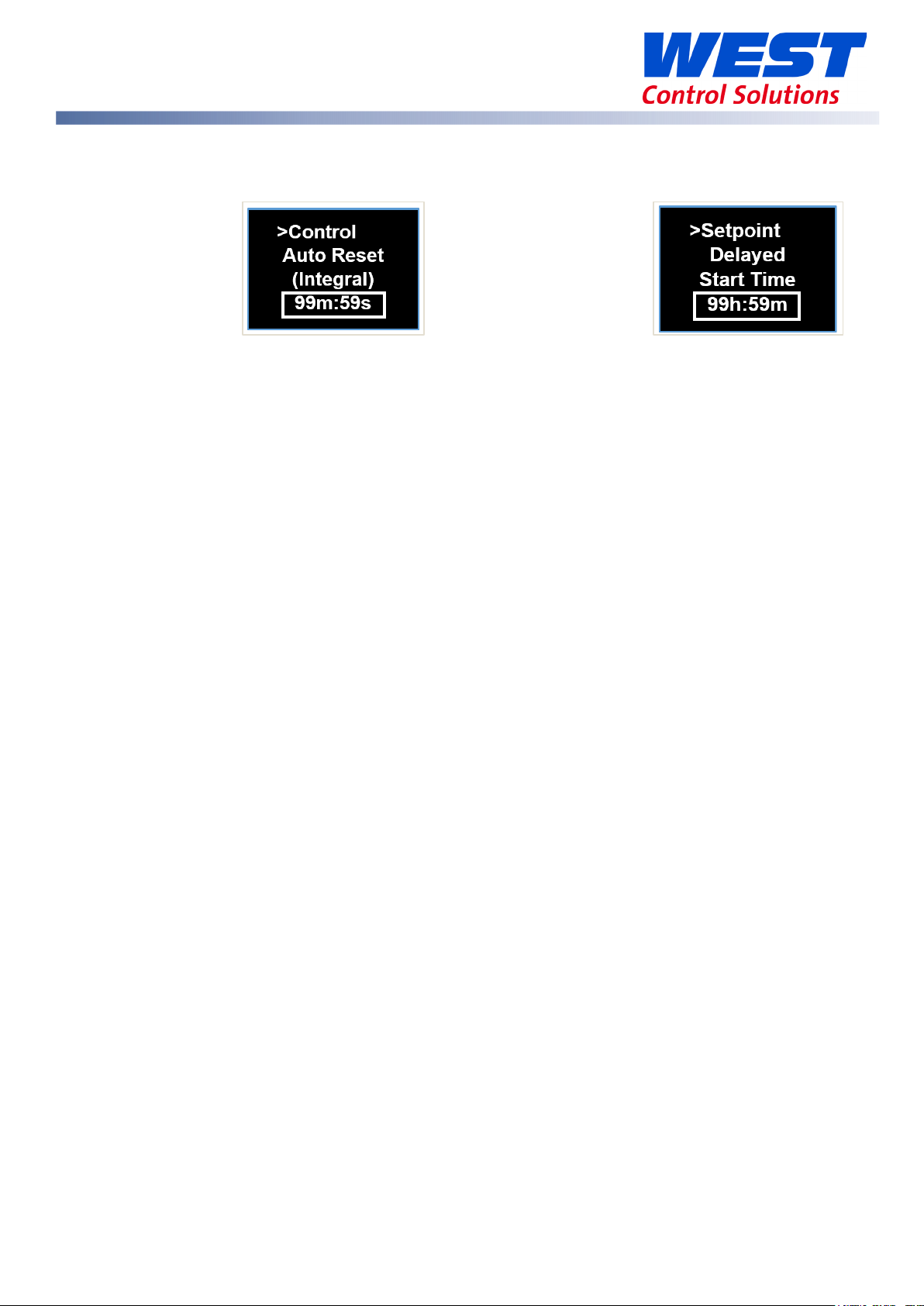

minutes:seconds

hours:minutes

Time Display

Time values are displayed on the MaxVU Rail as shown in the examples below.

Use of the Controller for Non-Temperature Applications

In this controller, the Primary and Secondary outputs are referred to as “HEAT” and “COOL”.

The majority of applications for the Standard model controller involve temperature measurement

and control, either via a direct sensor or indirectly via a linear dc input. However, this model can

also be used for other process types, such as Relative Humidity, for example.

If your process is not temperature, then the parameters labelled as “HEAT” refer to reverse acting

outputs used to increase the process value and “COOL” to decrease the process value.

As an example, you may have a system that reads and controls humidity. The “HEAT” output

drives the humidifier (adding moisture) and the “COOL” output drives the de-humidifier

(extracting the moisture from the air). Use the “HEAT” parameters to control the humidifier and the

“COOL” parameters to control the de-humidifier.

MaxVU Rail use as a Transmitter

The Standard MaxVU Rail model can be used as a “transmitter” to retransmit the process value or

controller setpoint via Output 3, if the linear option is fitted. The parameter Usage in the Linear

Output sub-menu can be set to PV Retransmit or SP Retransmit.

In the Display menu, the parameter Transmitter can be used to enable Transmitter view. This hides

the Setpoint from view. Note: control functions will remain active if they have been configured.

59633-MaxVU Rail Full Manual (EN) - Page 25 of 127

Page 26

Transmitter screen is present on Standard model only.

Transmitter parameter = Enable, SP is hidden.

in

PV

Show”

Operator

Alarm State

Alarm State

Alarm 1

Alarm 2

Loop

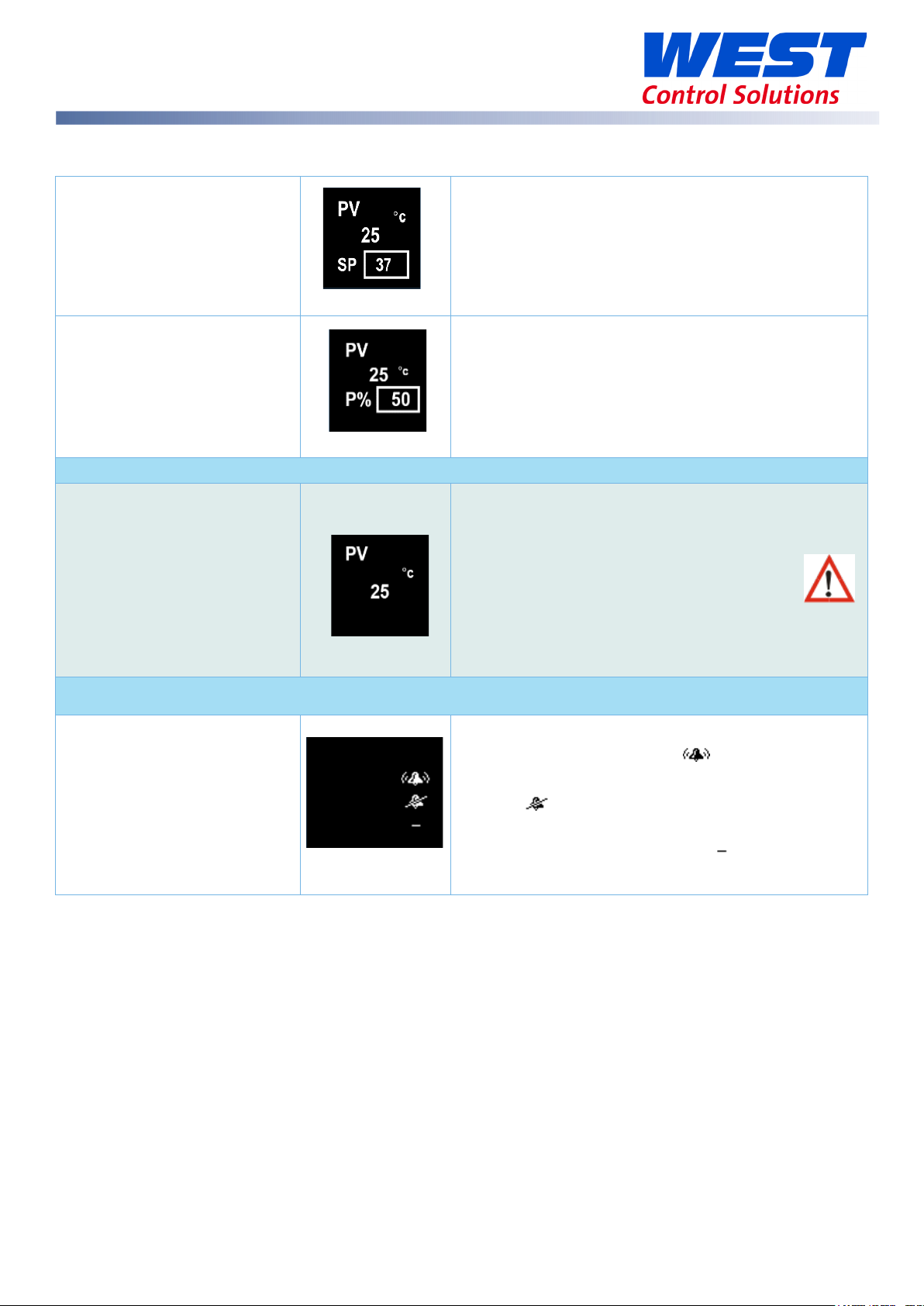

Operator Mode & Screens on Standard & Extrusion models

User Screen

Temperature Unit.

PV – process variable (e.g. process temperature)

SP - Setpoint

Manual control

PV – process variable (e.g. process temperature)

Manual Power is shown as P%.

Important: The device still functions as a controller

Transmitter view enabled

using the local Setpoint.

To act as a PV transmitter the parameter Usage

the Linear Output sub-menu needs to be set to

Retransmit.

Important: The following parameters are only displayed if set to “

Alarm configured, but not triggered

in the

sub-menu.

Alarm triggered

Alarm not set

59633-MaxVU Rail Full Manual (EN) - Page 26 of 127

Page 27

Latch State

Output Latched

Latch

, but

output not

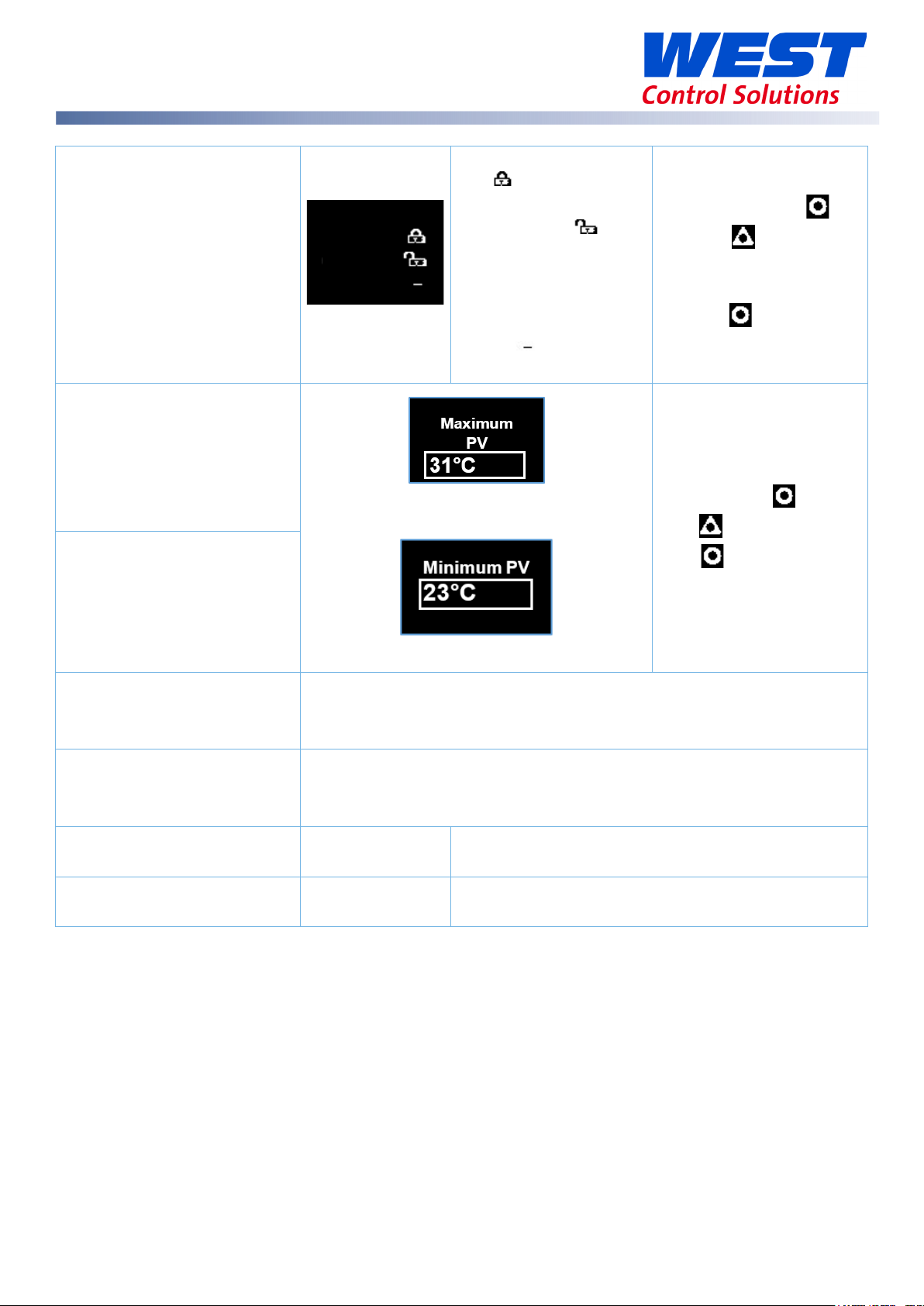

Maximum PV

Minimum PV

Control Enable

OFF

ON

Manual Control Enable

OFF

ON

P% xxx

Time On Remaining

Visible when On Timer is active.

Delay Time Remaining

Visible when Delay Timer is active.

Latch State

Out 1

Out 2

Out 3

configured

Latched

Latch not set

Screens show the Maximum & Minimum

PV reached.

To clear press

then to select

Yes.

Press to accept.

To clear press

then to select “Yes”.

Press to accept.

59633-MaxVU Rail Full Manual (EN) - Page 27 of 127

- Control output(s) disabled. (Ignored when in manual mode).

- Control output(s) enabled.

- Automatic control, PID or On-Off control available.

- Manual control, Manual Power shown as

On Timer

Delay Timer

See Ramp & Timers diagram.

See Ramp & Timers diagram.

.

Page 28

Message

Description

Alarm 1

Alarm 1 is active.

Alarm 2

Alarm 2 is active.

Alarm 1 & 2

Alarm 1 and 2 are active.

Control Enabled

Alerts user that the control is re-enabled. (not Limiter.)

Calibration Pass

Factory calibration (Full Input Calibration has passed.)

Calibration Fail

Factory calibration (Full Input Calibration has failed.)

Tuning in Progress

Tune at Setpoint or Pre-Tune is running. (Not Limiter.)

Setup not completed

Please refer to First Power Up or Factory Default section.

Offset in use

SP offset is being used in Setpoint sub-menu.

Limiter only, indicates when the limit value has been

exceeded.

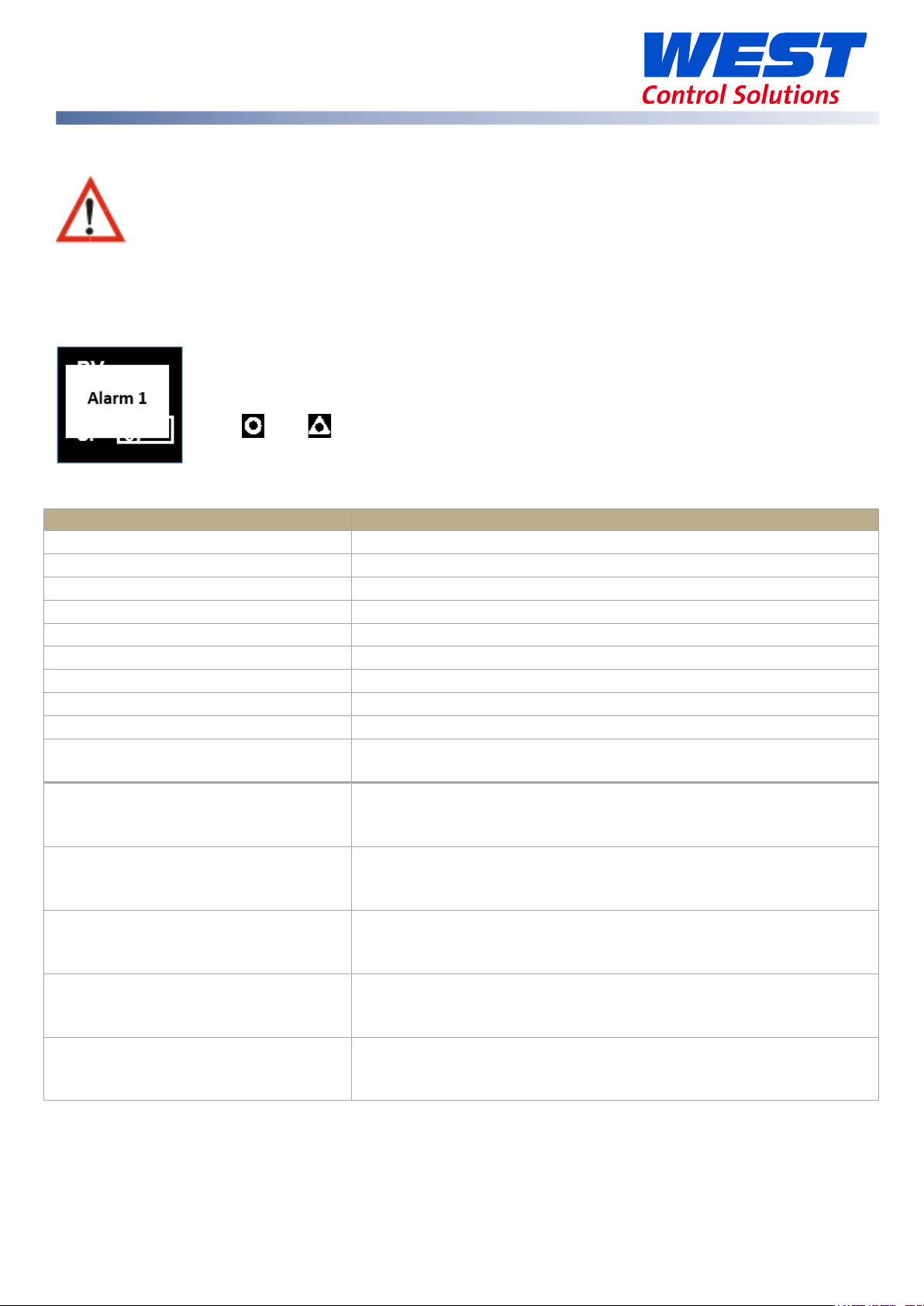

Warnings & Messages

Do not continue running your process until any issues are resolved.

Pop-Up Alerts

Pop-up alerts appear in front of the current screen. They must be acknowledged before you can

access other screens.

For example, Pop-up alert for Alarm 1.

Press and together to clear the pop-up alert.

Pop-Up Alert List

Limit Exceeded

Tune Error

PV within 5% of SP

Tune Error

Setpoint is ramping

Tune Error

Control is ON/OFF

Tune Error

Control is manual

Tune Error

Tune at Setpoint not able to run

PV within 5% of the scale range input from SP (for Pre-Tune).

Try a different setpoint or narrow the scale range input.

Setpoint is ramping. Turn off ramping and try again.

Control is not set to PID, i.e. the proportional band = 0. Set the

proportional band to any other value and try again.

Manual control enabled when attempting Pre-Tune. Use Tune

At Setpoint or set Manual Control Enable to OFF.

Tune at setpoint has timed out or cannot run.

59633-MaxVU Rail Full Manual (EN) - Page 28 of 127

Page 29

Message

Description

ALARM

Alternates with PV and shows one, or both, Alarms are active.

LATCH

Alternates with PV, one or more outputs are latched on & no alarm is active.

LIMIT

On Limiter model, alternates with PV to show Limit is active.

Process variable input >5% over-range.

Process variable input >5% under-range.

Also, check that Scale Range Minimum is low enough for your application.

Break detected in process variable input sensor, wiring or wrong input type

OPEN

models), or Limit state set until resolved on Limiter model.

Selected input range is not calibrated.

models), or Limit state set until resolved on Limiter model.

TUNE

Alternating with SP shows Auto-tuning is in progress.

P%

Manual power value replaces setpoint, shows P% xxx of power.

Ramp

Setpoint ramp is active (alternates with actual setpoint).

Control is disabled. Control output(s) are off.

Input if Digital I/P Action is set to Ctrl Enable/Disable.

DELAY

Shows when Delay Timer is active, control is off until the timer finishes.

Tuning messages

tErr1

PV within 5% of the scale range input from SP (for Pre-Tune). Try a different

setpoint or narrow the scale range input.

tErr2

Setpoint is ramping.

tErr3

Control is ON/OFF. Control is not set to PID, i.e. the proportional band = 0.

Tune Error

Sensor Break

Tune Error

Timer Running

Message List

Messages seen in the operator mode.

Message Description

Check your sensor.

Timer Running. Set the Enable Timer parameter to Disabled.

HIGH

Check for possible issues with sensor or connections.

Also, check that Scale Range Maximum is high enough for your application.

LOW

OPEN

ERROR

OFF

Check for possible issues with sensor or connections.

selected.

Shows

until resolved, Control is disabled on Standard or Extrusion

Shows ERROR until resolved, Control is disabled on Standard or Extrusion

Enable control by setting Control Enable to ON or check state of the Digital

The Automatic Tuning parameter must be changed to Off to clear any tuning message.

Display alternates between the tuning code & setpoint.

59633-MaxVU Rail Full Manual (EN) - Page 29 of 127

Page 30

tErr4

Control is manual. Set Manual Control Enable to OFF.

tErr5

Tune at Setpoint not able to run.

tErr6

Sensor Break.

tErr7

Timer Running. Set the Enable Timer parameter to Disabled before attempting

to run tuning again.

tErr8

Control is disabled. Please check it is safe to enable control and then go to

the User menu to change Control Enable to ON.

Tuning messages

The Automatic Tuning parameter must be changed to Off to clear any tuning message.

Display alternates between the tuning code & setpoint.

59633-MaxVU Rail Full Manual (EN) - Page 30 of 127

Page 31

A confirmation screen appears.

MaxVU Rail Factory Defaults

The factory default values for parameters are shown in the right-hand column of the parameter

lists. When the factory default process is performed all the parameters will be returned to these

values.

The Reset to Defaults can be found in the sub-menu Display in the Advanced Configuration

on all models.

Factory Default procedure

Press to highlight No.

Press to move highlight to Yes.

Press to accept.

If you are sure press to show Yes (leave as

No to cancel).

Press to confirm your choice.

The instrument shows the default for the Input

Type and its default value.

The user must review all parameters in the

Setup menu before exiting.

59633-MaxVU Rail Full Manual (EN) - Page 31 of 127

Page 32

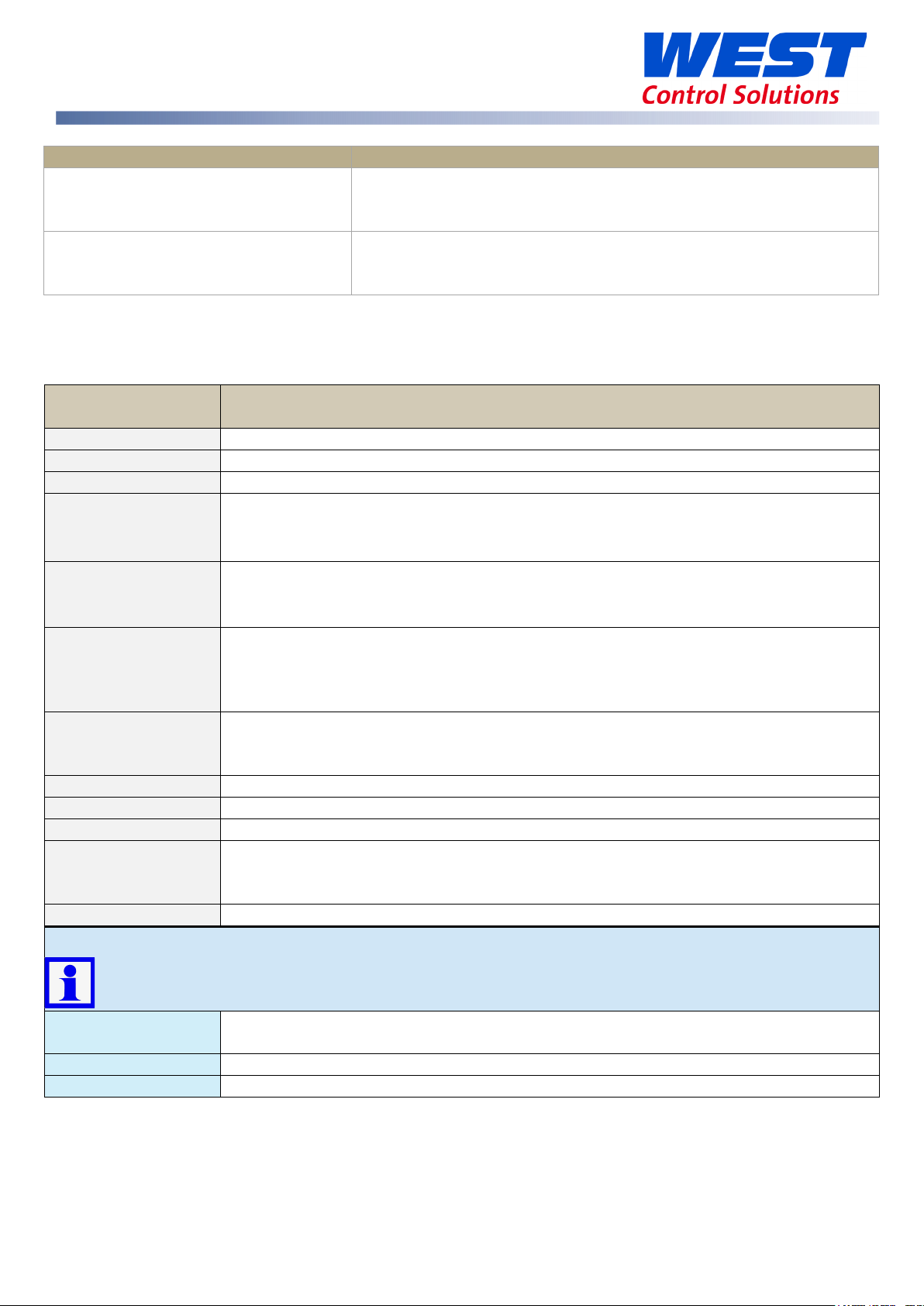

Parameter

Description

Default Value

* Maximum of 1 decimal place for temperature inputs J, K, L, T & PT100.

J Thermocouple *

-200 – 1200ºC

-128.8 – 537.7ºC

K Thermocouple *

-240 – 1373ºC

-128.8 – 537.7ºC

PT100 *

-199 – 800ºC

-128.8 – 537.7ºC

B Thermocouple

100 – 1824ºC 211 – 3315ºF

C Thermocouple

0 – 2320ºC 32 – 4208ºF

L Thermocouple *

0 – 762ºC

0.0 – 537.7ºC

N Thermocouple

0 – 1399ºC 32 – 2551ºF

R Thermocouple

0 – 1795ºC 32 – 3198ºF

S Thermocouple

0 – 1762ºC 32 – 3204ºF

T Thermocouple *

-240 – 400ºC

-128.8 – 400.0ºC

Setup mode parameters for Standard & Extrusion models

If necessary, press & to enter Setup from Operator mode.

Enter code for Setup Lock (default = 10) using & , then press .

1. For the Limiter model refer to the Limiter Model focus section.

2. Some parameters may be hidden depending on the model or other settings.

3. Note the permissible ranges for each temperature sensor type, below. For example,

the B type thermocouple readings cannot have a decimal point, and it cannot

measure below 100 ºC or above 1824 ºC

4. Where allowed the number of decimal points is set by the Decimal Place parameter.

The table below continues onto the next page.

>Input

Type

-328 – 2192ºF

-400 – 2503ºF

-328 – 1472ºF

32 – 1403ºF

-199.9 – 999.9ºF

-199.9 – 999.9ºF

-199.9 – 999.9ºF

K Thermocouple

32.0 – 999.9ºF

-400 – 752ºF

59633-MaxVU Rail Full Manual (EN) - Page 32 of 127

-199.9 – 752.0ºF

Page 33

Parameter

Description

Default Value

Linear dc

0 – 20mA

4 – 20mA

** 0 – 50mV is only linear dc input available on Extrusion models.

>Input

Units parameter hidden when linear input is used and units are not shown on the display

0000 – no decimal point

Scale Range maximum & minimum are only visible when input is a linear dc type.

>Input

Maximum for user working range.

>Input

Minimum for user working range.

None

Heat

>Output 2

Same options as Output 1 Usage

>Output 3

Same options as Output 1 Usage

If a Relay or SSR drive is fitted in Output 3 you will see >Output 3.

If the Linear option is fitted in Output 3 you will see the >Linear Outp menus instead.

Units

>Input

Decimal Place

Scale Range Maximum

Scale Range Minimum

>Input

Digital I/P Action

0 – 50mV**

0 – 5V

0 – 10V

10 – 50mV

1 – 5V

2 – 10V

°C or °F

000.0 – one decimal point

00.00 – two decimal points (linear dc only)

0.000 – three decimal points (linear dc only)

Alarm Reset (clears latched alarms)

Ctrl Enable/Disable (disables control)

Ctrl Auto/Manual

Pre-Tune Start/Stop

Tune at SP Start/Stop

°C

0000

1000

0

None

Cool

Non Linear Cooling (on Extrusion model only)

>Output 1

Usage

Alarm 1

Alarm 2

Alm. 1or 2 (logical ‘OR’ of Alarm 1 & 2)

Loop Alarm

Usage

Usage

59633-MaxVU Rail Full Manual (EN) - Page 33 of 127

Heat

Alarm 1

Alarm 2

Page 34

Parameter

Description

Default Value

Heat

0-10V

Maximum PV or SP value corresponding to

Minimum PV or SP value corresponding to

Range minimum to range maximum,

OFF

Same options as Alarm 1.

Setpoint

Target setpoint.

0

>Coms Unit Address

Modbus address from 1 to 255

1

>Coms Baud Rate

1200, 2400, 4800, 9600, 19200 & 38400 bps

9600

>Coms Parity

Odd, Even or None

None

>Control

>Linear Outp

Usage

>Linear Outp

Type

>Linear Outp

Scale Range Maximum

>Linear Outp

Scale Range Minimum

>Alarm 1

Value

>Alarm 2

Value

Cool

PV Retx

SP Retx

2-10V

0-20mA

4-20mA

0-5V

1-5V

maximum linear output for retransmission.

minimum linear output for retransmission.

or OFF (maximum +1).

disables alarm.

Default PV High alarm type.

Default PV Low alarm type.

PV Retx

0-10V

1373

-240

1373

-240

Automatic Tuning

Off, Start Pre-Tune or Start Tune at SP *** Off

1. *** The Start Tune at SP function is not available for Heat & Cool processes.

2. If the Input Type is changed, input scaling and alarm values are set to new values

based on the maximum and minimum of the new input type. If necessary, review these

settings.

If necessary, press and to clear the “Control is Enabled” Pop Up Alert then

press & to exit the Setup mode.

59633-MaxVU Rail Full Manual (EN) - Page 34 of 127

Page 35

Menu Name (letters are sub-menus)

1. User

7. Alarms

2. Input

8. Communication

3. User Calibration

9. Display

4. Outputs

10. Operator Screens

5. Control

11. Information

6. Setpoint & Timer

Advanced Configuration mode for Standard & Extrusion models

The Advanced Configuration mode gives access to all the parameters accessible from the front

panel; however, the device hides parameters that are not relevant to your exact model code

specification & configuration.

The Advanced Configuration mode has eleven menus, some of which contain further sub-menus.

a) Alarm 1

b) Alarm 2

c) Options

a) Output 1

b) Output 2

c) Output 3 or Linear Outp

Please refer to the Limiter Model for those models.

The Setpoint can be locked by setting Setpoint Upper Limit and Setpoint Lower Limit to the

same value.

For basic applications, it may be sufficient to use the simpler Setup mode to set-up. See previous

sections.

Otherwise, press & to enter Advanced Configuration from Operator screen.

Enter Advanced Lock-code (default of 20) using and , then press .

59633-MaxVU Rail Full Manual (EN) - Page 35 of 127

Page 36

Parameter

Description

Default Value

Alarm triggered

Output Latched

Screens show

OFF

ON

OFF

ON

P% xxx

Alarm State

Alarm 1

Alarm 2

Loop

Latch State

Out 1

Out 2

Out 3

User menu

Applicable to both Standard & Extrusion models.

Alarm State

Latch State

Alarm set, but not

triggered

n/a

Alarm not set

Latch configured,

but output not

n/a

Latched

Latch not set

To clear any latched outputs, press then to select Yes.

Press to accept.

Maximum PV

To clear the stored value press then to select

Yes.

Minimum PV

Press to accept.

- Control output(s) disabled. (Ignored when in

Control Enable

manual mode).

- Control output(s) enabled.

- Automatic control, PID or On-Off control

Manual Control Enable

available.

- Manual control, Manual Power shown as

the Maximum

& Minimum PV

reached.

ON

OFF

59633-MaxVU Rail Full Manual (EN) - Page 36 of 127

Page 37

Parameter

Description

Default Value

Refer to Input types in the table in the Setup

Display Units either °C or °F.

Units hidden when linear input is used and no unit is shown on the display

0000

For temperature inputs, enter the maximum

For temperature inputs, enter the minimum

Input filter time value to reduce noise.

Enable Enables the internal thermocouple CJC

None

Input menu

Applicable to Standard & Extrusion models.

Input Type

Units

Decimal Place

Scale Range Maximum

Scale Range Minimum

Filter Time

menu section for a full list of inputs available.

This parameter is hidden when input is a linear

type and °C or °F are hidden from the display.

000.0

00.00 (not for temperature)

0.000 (not for temperature)

working range. For linear inputs, enter the

display value for the maximum input level

working range. For linear inputs, enter the

display value for the minimum input level.

OFF or 0.5 to 100.0 seconds in 0.5 increments

K thermocouple

°C

0000

Maximum allowed

for Input Type.

Minimum allowed

for Input Type.

2.0

CJC Enable

(Cold Junction Compensation).

Disable Disables the internal CJC. If disabled,

external compensation must be provided.

Alarm Reset (clears latched alarms)

Digital I/P Action

Ctrl Enable/Disable (disables control)

Ctrl Auto/Manual

Pre-Tune Start/Stop

Tune at SP Start/Stop

The input scale range, consisting of Scale Range Maximum & Scale Range Minimum

above, is used to narrow the working range of the controller.

If the measured value is more than 5% above or below the scaled range PV display is

replaced by HIGH (over-range) or LOW (under-range).

The scale range also affects if Pre-Tune will run. If the PV is <5% of the scaled range from

setpoint Pre-Tune cannot be used.

Enable

None

59633-MaxVU Rail Full Manual (EN) - Page 37 of 127

Page 38

Parameter

Description

Default Value

Shifts the input value up or down by this offset

Enter value at which the low point error was

Enter equal, but opposite offset value to the

Enter value at which the high point error was

Enter an equal, but opposite offset value to the

Parameter

Description

Default Value

Output 1 sub-menu

Direct

Reverse

Off

On

Direct

Reverse

User Calibration menu

Applicable to Standard & Extrusion models.

Offset

Low Point

Low Offset

High Point

High Offset

value, across the entire range.

measured.

observed low point error.

measured.

observed high point error.

Outputs menu

Applicable to Standard & Extrusion models.

Heat (Reverse acting control)

Cool (Direct acting control)

Non Linear Cooling (Extrusion model only)

Usage

(i.e. logical ‘OR’ of Alarm 1 & 2)

Alarm 1

Alarm 2

Alm. 1or2

Loop Alarm

0

Lower Limit

0

Upper Limit

0

Heat

- Output active when alarm triggers

Alarm Action

- Output active when alarm is not

triggered

- Alarm doesn’t latch

Latching

– Alarm latches (remains in active state until

cleared)

LED Indicator

59633-MaxVU Rail Full Manual (EN) - Page 38 of 127

- LED Indicator lit when output is active

- LED Indicator lit when output is inactive

Direct

Off

Direct

Page 39

Parameter

Description

Default Value

Output 2 sub-menu

Usage

Same options as Output 1 - Usage

Alarm 1

Alarm Action

Same options as Output 1 - Alarm Action

Direct

Latching

Same options as Output 1 - Alarm Latching

Off

LED Indicator

Same options as Output 1 - LED Indicator

Direct

Output 3 sub-menu

If a Relay or SSR drive is fitted in Output 3, this sub-menu is visible.

Usage

Same options as Output 1 Usage

Alarm 2

Alarm Action

Same options as Output 1 - Alarm Action

Direct

Alarm Latching

Same options as Output 1 - Alarm Latching

Off

LED Indicator

Same options as Output 1 - LED Indicator

Direct

Linear Outp sub-menu

If the Linear option is fitted in Output 3, this sub-menu is visible.

Heat (Reverse acting control)

0-10V

Display value at which retransmission output is at

Display value at which retransmission output is at

Usage

Type

Scale Range Maximum

Scale Range Minimum

Cool (Direct acting control)

Retransmission of PV or SP:

PV Retx

SP Retx

2-10V

0-20mA

4-20mA

0-5V

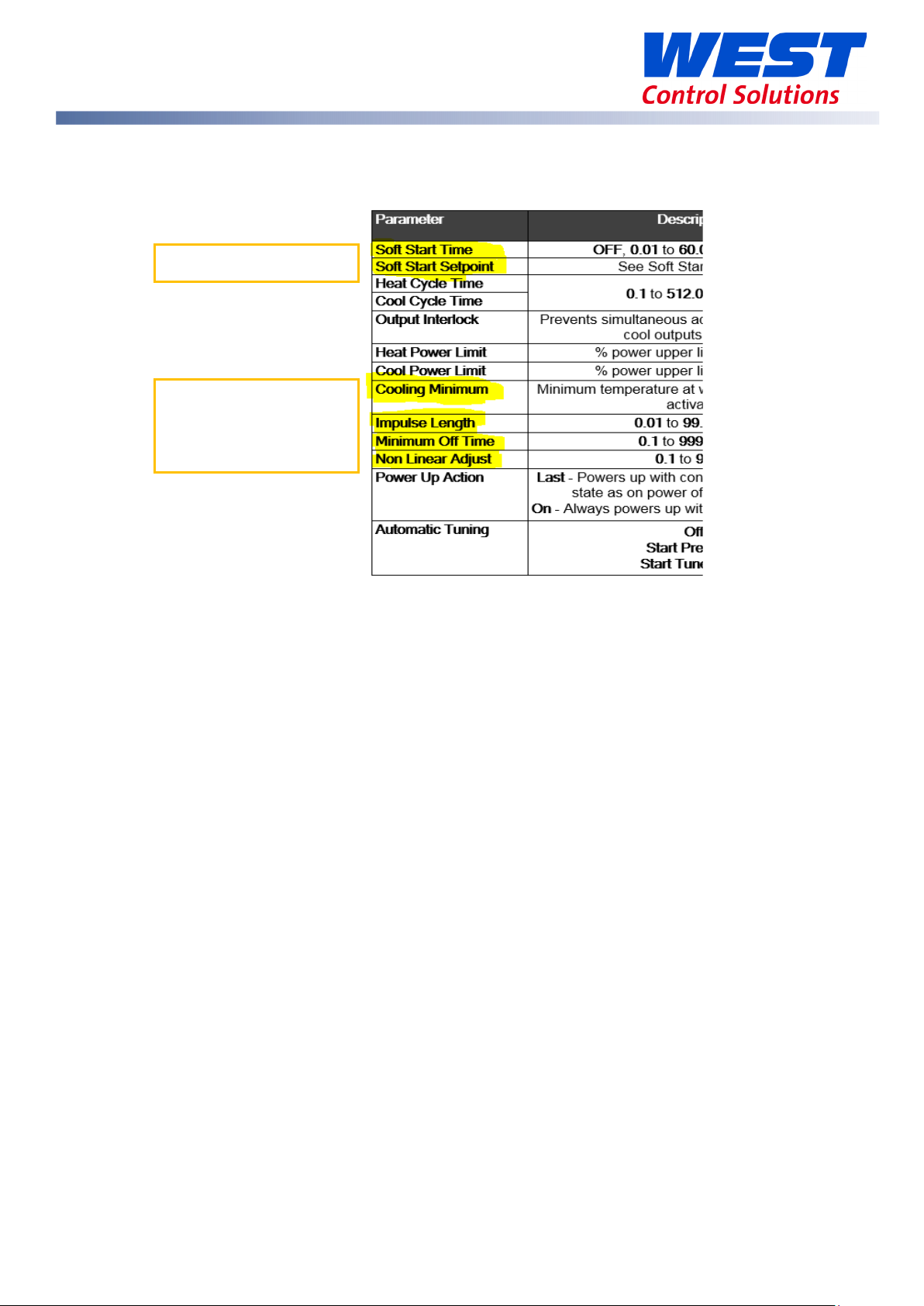

1-5V