Page 1

The CAL 9500P

Programmable

Profiling

Temperature &

Process Controller

SL000272 33061/01/0900

Ordering information codes

Code

Model 48 x 48 mm 95

Outputs SSd / relay 00

relay / relay 11

SSd / SSd 22

4-20mA / relay B1

4-20mA / ssd B2

0-5V / relay C1

0-5V / ssd C2

0-10V / relay D1

0-10V / ssd D2

Output 3 Always relay 1

Programmer P

Inputs Sensor A

4-20mA B

0-5V C

0-10V D

Communications None fitted 0

RS232 fitted 2

RS485 fitted 4

Unused 00

Ordering example 1

Model 9500P ssd/relay/relay outputs

4-20mA input, RS485 fitted

95 00 1 P B 4 00 95 B2 1 P A 0 00

Ordering example 2

Model 9500 with 4-20mA/ssd/relay

outputs, sensor input, no comms

Codes for additional software and hardware

CALCOMMS charting & logging software

CALCOMMS CD Rom demo-disk

Communications board RS232

Communications board RS485

RS232 to RS485 converter

CALopc OPC server

CALpoll

10 01 XX 3 0 0

000124

3C 00 00 2 0 0

3C 00 00 4 0 0

3C 24 00 0 0 0

10 01 GB S 0 0

Available on the web

Temperature Controllers

This low-cost range is dedicated for

temperature control and also has the

added options for RS232 & RS485

communications boards. All controllers

have P.I.D. control, autotune, heat-cool

strategy and a single ramp-soak profile.

Solid State Relays

This range of solid-state relays completes

the solution from sensors to control

output. This catalogue shows a range of

hockey-puck style SSRs and the Solitron

range with built-in heat sinks that are easy

to specify and install.

Ask for these brochures for our other product ranges

Temperature Sensors

This comprehensive catalogue is full of

useful information as well as a wide range

of thermocouples and RTDs for all

applications. Also included is a range of

accessories from cables, connectors, glands

to thermowells.

Page 2

The CAL 9500P Programmable Temperature / Process Controller with Communications & Software Support

CAL innovators in control

Established in 1963, CAL is a dynamic and

strong company leading the industry in

single-loop controllers. CAL’s pioneering

spirit established many of today’s world

standards for controllers such as the first

48mm x 48mm (

followed by the first digital controller of the

same size and then the first 24mm x 48mm

1

(

/32NDDIN) controller.

CAL’s range of easy-to-use controllers are

complemented by a suite of software

products for communications, data-logging

and supervisory control.

CAL has developed a reputation based on

product support, innovation and attractivelystyled controllers that enhance our

customers’ equipment, panels and machines.

Note:

Standard colour is Jade

Green, other colours

are subject to minimum

order quantities.

1

/16THDIN) analogue controller,

The CAL 9500P programmable process

controller

The CAL 9500P is a versatile programmable controller

for temperature and process control applications. It is

designed to offer the highest functionality in a 48mm

x 48mm (1/16

TH

DIN) package.

The 9500P can be factory configured in a range of

process control or temperature control options

making the controller dedicated to the application,

ideal for both OEM and manufacturing process

applications.

This combination of programmable ramp/soak profiles,

process control inputs and 3 outputs, together with

RS232 or RS485 comms makes the CAL 9500P a

unique and affordable package.

Controller functionality

●

Full P.I.D. operation

●

Autotune at 75% of set-point or at set-point

●

Heat-cool operation

●

RS232 or RS485 communications options

●

CE, UL & CSA compliant

Inputs

●

Thermocouples & RTD (PT100, 2 or 3 wire)

●

Analogue – 0-20mA, 4-20mA, 0-50mV, 0-5V, 0-10V

Easy to scale input signals

CAL has made the task of scaling inputs very simple:

example: 4-20mA = 60–260 units, where 4mA = 60 units

note: 4-20mA corresponds to an input range of 10-50mV

Step 1, enter scale max’ = 260,

Step 2, enter scale min’ = 60,

Step 3, enter input max’ = 50 (i.e. 50mV = 20mA)

Step 4, enter input min’ = 10 (i.e. 10mV = 4mA).

Outputs (total of three outputs)

●

Solid state relay drive (SSD) and Relays (2 amp)

●

Analogue – 4-20mA, 0-5V, 0-10V

3-year warranty

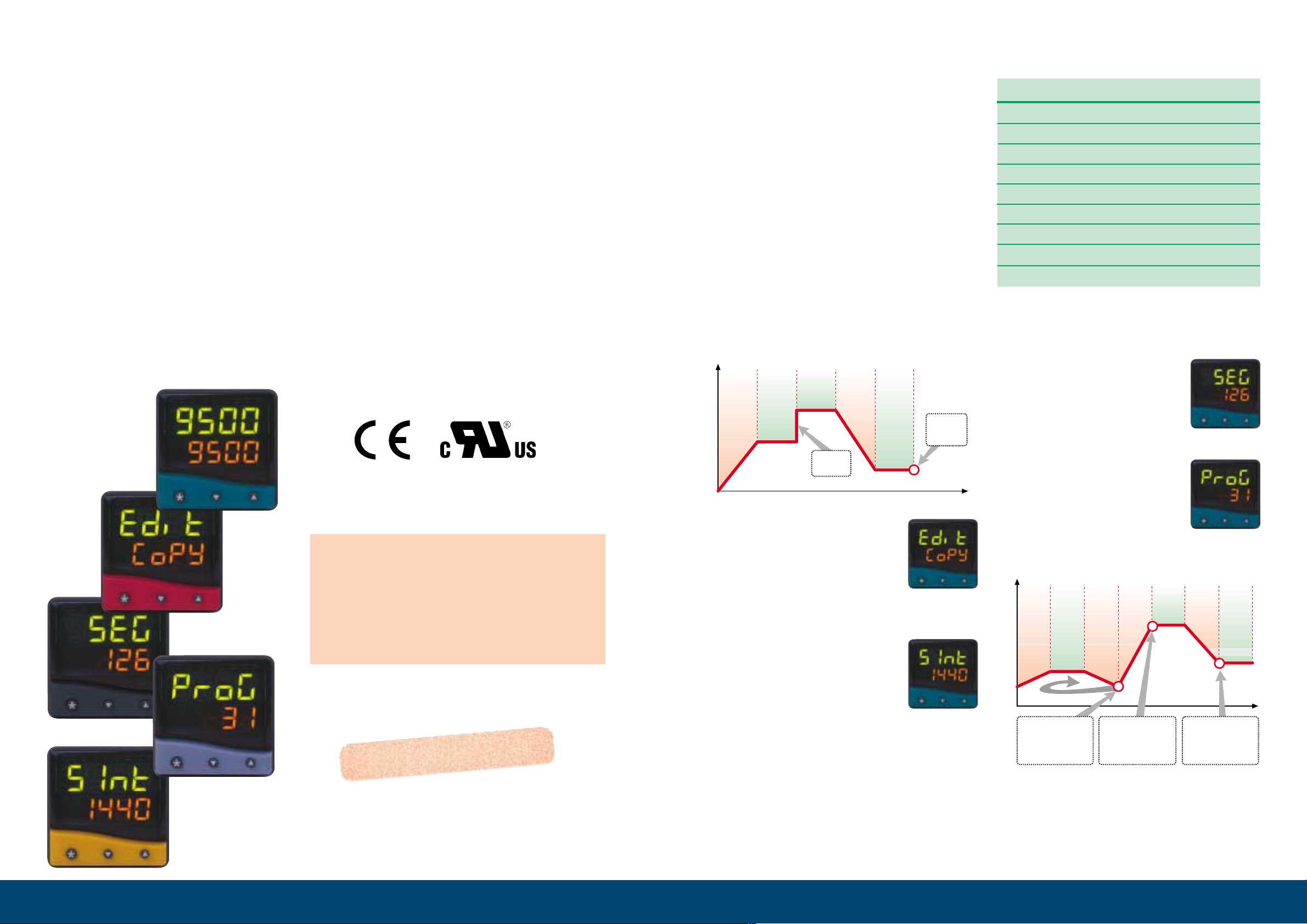

Programmer functionality

●

Up to 31 programs (profiles)

●

Up to 126 segments

●

Unlimited use of event outputs via the 2nd and 3rd

outputs

●

Copy/Paste/Edit/Delete functions to simplify program

building

●

Call another program as a sub-program segment

●

Up to 999 program loop cycles, or continuous loop

cycling

●

Hold back function, to ensure the next segment is not

started until the last segment reaches the set-point

●

3 power fail recovery options, (Hold, Continue or

Reset)

●

Front panel interrogation of the program position

●

Memory usage indication during programming.

(note: program capacity is a memory function and

different types of segment use more/less memory).

Profile of a single program

Set-point

Segment 1

Subset of the functions list:

●

hoLd Suspends program until run

●

on Run program

●

Edit Insert, delete or copy programs

Power failure modes

●

rSEt Reset to program start

●

Cont Continue from interruption

●

hoLd Hold at interruption

Segment types

●

SPr Ramp to next set-point

●

SoAK Hold set-point for set time

●

StEP Step to new set-point

●

LooP Repeat the program

●

CALL Call up another program

●

E.oP Generate an event output at end of segment

●

Edit Delete or insert a segment

Hold back function

●

hb.u Hold back, this function ‘holds back’ the

Segment 2

RAMP

SOAK

Segment 4

SOAK

Segment 3

STEP

Segment 5

RAMP

Segment 6

SOAK

ramping set-point until the measured value

catches up with the ramping set-point. This

function ensures that the time taken to ramp

does not reduce the next segment.

Segment 7

EVENT

OUTPUT

Time

Memory Allocation Table

Function Memory Usage

Ramp 4 Bytes

Ramp with Holdback 5 Bytes

Soak 2 Bytes

Step 3 Bytes

Loops (1-3) 1 Byte

Loop (4+) 2 Bytes

Call 1 Byte

Event Output 1 Byte

Program Header 1 Byte

Examples:

Maximum capacity; 351 Bytes, 126 segments per

program, 31 programs

Example 1 (349 Bytes)

One program of 116 segments

(58 ramps, 58 soaks)

Example 2 (340 Bytes)

4 programs of 28 segments

(14 ramps, 14 soaks)

Example 3 (341 Bytes)

31 programs of (ramp-soak-ramp)

The above ramps are without hold-back option

Set-point

Seg. 1

from 1 to 999 cycles

e.g. loop for 25 cycles

RAMP

Segment 4

Program LooP

Seg. 2

SOAK

Seg. 3

RAMP

Seg. 5

RAMP

Segment 6

Program CALL,

to call another program

e.g. Call Prog 5

Then go to 7

Seg. 7

SOAK

The CAL 9500P is potentially the most versatile and

flexible controller in its size and price range. The

above program shows what is possible from this

unique controller.

Seg. 8

Seg. 10

RAMP

E.oP Event Output

e.g. Trigger alarm on SP2

SOAK

CONTIN-

UOUS

Time

Segment 9

.

Page 3

Software and Connectivity

Using CAL controllers there’s a wide range of software support products designed to suit different applications.

Product

CALCOMMS

CALopc

CALpoll

CALCOMMSTMChart-recorder, Data-logging & Configuration software for Windows

CALCOMMSTMcharting and logging software is incredibly easy to use. It is designed to connect up to 128 controllers

by RS485 into a standard or industrial PC. This allows the user to program all functions of the controller and to

data-log the recorded process signals.

Description

Ideal for:

For use by:

Typical applications:

License cost

Development cost

Flexibility/versatility

Other comments

Easy to use and install

software application

requiring no design work.

Chart-recorders,

Data-logger,

Alarms

Plant/Process engineers,

Supervisors, Quality control,

System/Machine designers

Quality control, Process

optimisation, Lab equipment

$

$

✔

Only connect to CAL

Designed for simplicity with

many features

Software driver for OPC

client/server applications

such as SCADA.

Large SCADA applications

requiring many inputs other

than CAL

Process engineers,

Plant managers,

SCADA system builders.

Process control,

Manufacturing

$$$

$$$

✔✔✔

Connect to other h/w

User must also purchase the

SCADA software

Example demo program plus

source code to help you

build a custom application.

Custom software

applications dedicated to

one application.

Software engineers with

Visual C experience

OEM machines,

development projects

Gratis/web

$$$$$$

✔✔✔✔✔✔

As flexible as the s/w

For use with Visual C ++

Compiler

Functions

●

Data-logger for archiving process data

●

Chart-recorder for on-screen viewing of trends

●

Virtual instrument display

●

On-screen alarm displays

●

Configuration/programming tool for controllers

●

‘Cloning’ of instrument settings

●

Saving of applications of multiple controller set-ups

●

Remote set-point adjustment

Example of networked

controller configuration

into CALCOMMS

TM

FREE demo-disk

CD demo of CALCOMMS

charting & logging

software

®

Terminology:

SCADA Supervisory Control And Data Acquisition

OPC Object Linking and Embedding for Process Control

OEM Original Equipment Manufacturer

CALopc – OPC server

The CALopc server is a MODBUS RTU software product

designed for integration into OPC client/server

applications such as SCADA.

CALopc includes pre-configured templates for all CAL

controllers, together with controller bitmaps and the

7-segment LED true type font.

Using this OPC server allows ‘tags’ to be added to all

controller functions and built into the SCADA

application enabling the display and changing of any

parameters in a custom configured application for

complete process monitoring and control.

CALpoll – tools for custom software

engineers

CALpoll is a free of charge software product

available from www.cal-controls.com It includes an

example program and source code in Visual C++.

It is ideal for use by software engineers who wish to

create custom applications that need to

communicate with CAL controllers via the MODBUS

RTU protocol.

The source code includes routines for

communicating via MODBUS saving the software

engineer significant development time. The example

program also doubles as an ideal diagnostic tool for

proving that the communications hardware is set up

correctly.

For further details please contact CAL.

COM

port

RS 485 multidrop

connection from PC

to controllers

0

0

5

9

CAL

Relay

SSd

4-20mA

4-20mA

sensor

Flow Control

Ideal for:

Recording process data for manufacturing reporting,

quality control, health & safety purposes, or OEM

system development.

RS 485 – MODBUS RTU

– up to 128 controllers

CAL

Relay

Relay

4-20mA

sensor

Level Control

Applications:

Food industry, Dairy industry, Rubber & Plastics

manufacturing, Ovens, Furnaces, Kilns, Plastics

machines, Laboratory and Scientific equipment,

Bottling and beverage production and many other

process industries.

0

0

5

9

Relay

0

0

5

9

CAL

Relay

SSd

SSd

3-wire

PT100

Temperature Control

95

CAL

Relay

0-10V

0-10V

Pressure Control

0

0

Relay

.

.

Page 4

CAL 9500P Specifications

Thermocouple

9 types: B, E, J, K, L, N, R, S, T

Standards: IEC 584–1–1 : EN60584–1

CJC rejection: 20:1 (0.05°/°C) typical

External resistance: 100Ω maximum

Resistance thermometer

RTD/Pt100 2 or 3 wire

Standards: IEC751: EN60751 (100Ω 0°C/138.5Ω 100°C Pt)

Bulb current: 0.2mA maximum

Analogue process inputs 0 to 50mV, +/- 0.1%. 0-20mA, 4-20mA, +/- 0.1%. 0-5V, +/- 0.1%. 0-10V, +/- 0.1%

Applicable to all Thermocouple and RTD inputs (SM =sensor maximum)

Calibration accuracy: +/- 0.25%SM +/- 1°C

Sampling frequency: input 10Hz, CJC 2 sec.

Common mode rejection: Negligible effect up to 140dB, 240V, 50-60Hz

Series mode rejection: 60dB, 50-60Hz

Temperature coefficient: 50ppm/°C SM typical

Reference conditions: 22°C +/- 2°C, rated voltage after 15 minutes settling time.

Output devices

SSd1 and SSd2: Solid state relay driver: To switch a remote SSR 6Vdc (nominal) 20mA non-isolated

Relay 1,2,3 Miniature power relay: Form A/SPST contacts (AgCdO): 2A/250Vac resistive load

Analogue output: 4–20mA 500Ω max +/- 0.1% full scale typical

(check configuration)

0–5Vdc 10mA (500Ω min) +/- 0.1% full scale typical

0–10Vdc 10mA (1KΩ min) +/- 0.1% full scale typical

Technical Specifications

Typical Application

In this example the load temperature is monitored by a

temperature transducer/transmitter which provides a

4–20mA input signal to the controller. The 4–20mA output

has been allocated to SP1 to drive an SCR power

controller providing a phase angle controlled output to

the heater.

F1 Fuse: 1A time lag type to IEC127. CSA/UL rating

250Vac

F2 Fuse: High Rupture Capacity (HRC) Suitable for

maximum rated load current

S1 Switch: IEC/CSA/UL Approved disconnecting device.

4–20mA

Transducer

Mains

Heater

Analogue

power

controller

(+)

L

N

S1

(–)

17 18 19

4–20mA

Model 95B11P

INPUT

(–)

123456 78

User configurable

alarms

20 21 22 23 24

B – – –

(+)

F1

F2

LN

General

Displays: Upper, 4 Digits, high brightness green LED. 10mm (0.4”) high.

Lower, 4 Digits, high brightness orange LED 9mm (0.35”) high.

Digital range -199 to 9999. Hi-res mode -199.9 to 999.9.

LED output indicators - SP1 square, green; SP2/SP3 round, red

Keypad: 3 elastomeric buttons

Programmer functions:

Segments: Total of 126 per program

Programs: Maximum of 31 programs

Program memory: 351 Bytes (see memory allocation table)

Environmental

Humidity: Max 95% non-condensing

Altitude: up to 2000M

Installation: Categories ll and lll

Pollution: Degree ll

Protection: NEMA 4X, lP66 (Front panel only)

EMC emission: EN50081-1 FCC Rules 15 subpart J Class A

EMC immunity: EN50082-2

Ambient: 0-50ºC (32-130°F)

Mouldings: flame retardant polycarbonate

Weight: 180g (6.4 oz)

Safety: EN61010–/CSA22.2 No 1010.1 92 (see users manual)

Dimensions

Front facia: 51.0 x 51.0mm (2.0” x 2.0”) (includes gasket)

Sleeve length: 106.7mm (4.2”) (with gasket fitted)

Instrument body: 44.8 x 44.8mm (1.76” x 1.76”)

Overall length: 116.2mm (4.57”)

Model 9500P

(48x48mm) 1/16 DIN

51.0

(2.0)

includes

gasket

51.0 (2.0)

includes gasket

Dimensions in mm (inches)

116.2

(4.57)

44.8

(1.76)

44.8

(1.76)

106.7 (4.2)

with gasket fitted

Supply Voltage: 100–240Vac, 50–60Hz +/- 10% maximum permitted fluctuation

Power Requirements: 6.0VA (nominal)

.

9500P with COMMS board fitted

Loading...

Loading...