Page 1

COMMERCIAL IN CONFIDENCE

CAL 3300/9300/9400/9500(P)

MODBUS RTU

COMMUNICATIONS GUIDE

7th September 2000

ISSUE 1.10

Doc:33034 Iss:002

Page 2

COMMERCIAL IN CONFIDENCE

Page 1

DESCRIPTION

This document describes the interaction between a CAL Controller with the communications option

fitted and a PC/PLC attached to the bus and acting in a command mode.

There are fundamental limitations placed on the interactions. These arise from the intrinsic properties

of the CAL controllers, with just three control buttons and a multi-level menu with increment or

decrement value change process.

The standalone CAL controllers currently perform a verification on each change to ensure that illegal

values (e.g. ones outside the limit range for a particular thermocouple, etc.) are not accepted .The PC

application needs to replicate the verification checks that the CAL controllers would perform before

transmitting the new data out over the bus to the instrument. The CAL controllers assume that the

values they receive have been checked against limits and are valid - no further verification is carried

out. Upon receipt of the new values and an exit program mode sequence the CAL controllers write the

new values to memory and then restart.

_Copyright Cal Controls Ltd 1999. All rights strictly reserved. No part of this documentation shall be

reproduced ,stored in a retrieval system, or copied in any form, without prior written permission from

Cal Controls Ltd. Every effort has been taken to ensure the accuracy of this specification. However due

to our policy of continuous development to improve our products, this could without notice, result in

amendments or omissions to this document. Neither is any liability assumed for damage, injury, loss,

or expenses resulting from the use of this document.

Page 3

COMMERCIAL IN CONFIDENCE

Page 2

1. MEMORY MAP OF PARAMETERS

WARNING:- As with any computer system writing to any unauthorised memory address will

inevitably cause malfunction and may put the instrument in an indeterminate or dangerous state. It is

the users responsibility to ensure correct use.

The instruments uses a 8051 type processor. This has two types of RAM: the internal 256 bytes and

the external 256 bytes, data is also stored in EEPROM (non-volatile ram). Each data area requires a

different access method internally.

Data can be accessed as either one byte or a two byte word - the word need not necessarily lie on an

even address boundary. To simplify ModBus messages the unit decodes the MSB of the ModBus

address to select which type of memory to access - thus all memory looks the same to the end user.

Decoding is as follows:

bit 7 bit 6 bit 5 bit 4 bit 3 bit 2 bit 1 bit 0

always 0 always 0 always 0 1=security always 0 1=NVram 1=external 1=one byte

so that the following addresses specify the given memory areas:

• 00xxH references internal memory - two bytes wide

• 01xxH references internal memory - one byte wide

• 02xxH references external memory - two bytes wide

• 03xxH references external memory - one byte wide

• 04xxH references NV memory - two bytes wide

• 05xxH references NV memory - one byte wide

note that messages with both bits 1 and 2 set are misleading and should not occur, however, they will

be interpreted as if bit 2 was 0. Bit 4 is used to indicate reserved messages - see the section Security

Messages below.

Two types of bit value may exist:

• those which can be set and cleared as a single operation (i.e. directly addressable) are

defined as type bit.

• those which must be set or cleared by reading a byte, masking the bit, then writing the

byte.

Bit addresses are represented by both the absolute hex address and also by bit number (in decimal) if

the bit is directly addressable. Note that, in this document, the bit number is one based (1..128) which

matches the usual representation of ModBus.

The byte and word addresses given are the absolute HEX locations in the instrument.

Depending on the type of ModBus driver being used, these may need to be converted to a

decimal address, plus 1, since some ModBus drivers subtract 1 from the address given. Thus to

access the Baud Rate (03D6) a ModBus driver would need decimal address 983 (982 + 1).

Shaded sections denote contiguous address space which may be read and written as multiple

registers if the remote software can handle this. NOTE that due to space limitations the current

implementation does not allow multiple address access - only one word can be accessed per

message.

To facilitate easy reading, the following tables are listed in address order, not the order on the menus.

Extreme care must be taken to write only to those locations indicated. Writing to any other

locations WILL corrupt the instrument, but the effects may not necessarily be immediately

noticed.

Page 4

COMMERCIAL IN CONFIDENCE

Page 3

1.1 Internal data formats

The instrument stores data in a variety of ways to allow a full range of values to be held in the minimum

space possible. Most are represented by a multiple of the displayed value - this is given as a scale

factor in the table below: for instance, temperatures are stored in 10ths of a degree, so a displayed

value of 123.4 degrees is stored as 1234 - this is shown in the tables as temp * 10. Some time values

are stored in 40ms units so a time of 1 second would be stored as 25. A few parameters - mainly the

times - have different scale factors and offsets depending on their current value - these are detailed

individually.

Parameters are incremented/decremented by fixed step sizes depending on their current value within

limits which may change depending on the current value of other parameters. Many parameters

increment and decrement in the same manner - this is referred to in the tables as normal inc/dec - in

these cases parameters move in 0.1 steps between —9.9 and 9.9, otherwise in steps of 1. Note that

when incrementing or decrementing, the internal storage format must be taken into account and also

whether the display is in hi-res mode - values sent to the instrument must match the current mode.

Note also that in the 9500 instrument parameters marked with [LIN] are stored in degrees*10 when the

selected input is a thermocouple or RTD and units of 1 when the selected input is linear. Also note that

while linear input is selected the display of values on the instrument is effected by the setting in DECP

not Disp.

The instrument provides no error checking on values transmitted to it - the user must ensure that new

values are checked for consistency before uploading.

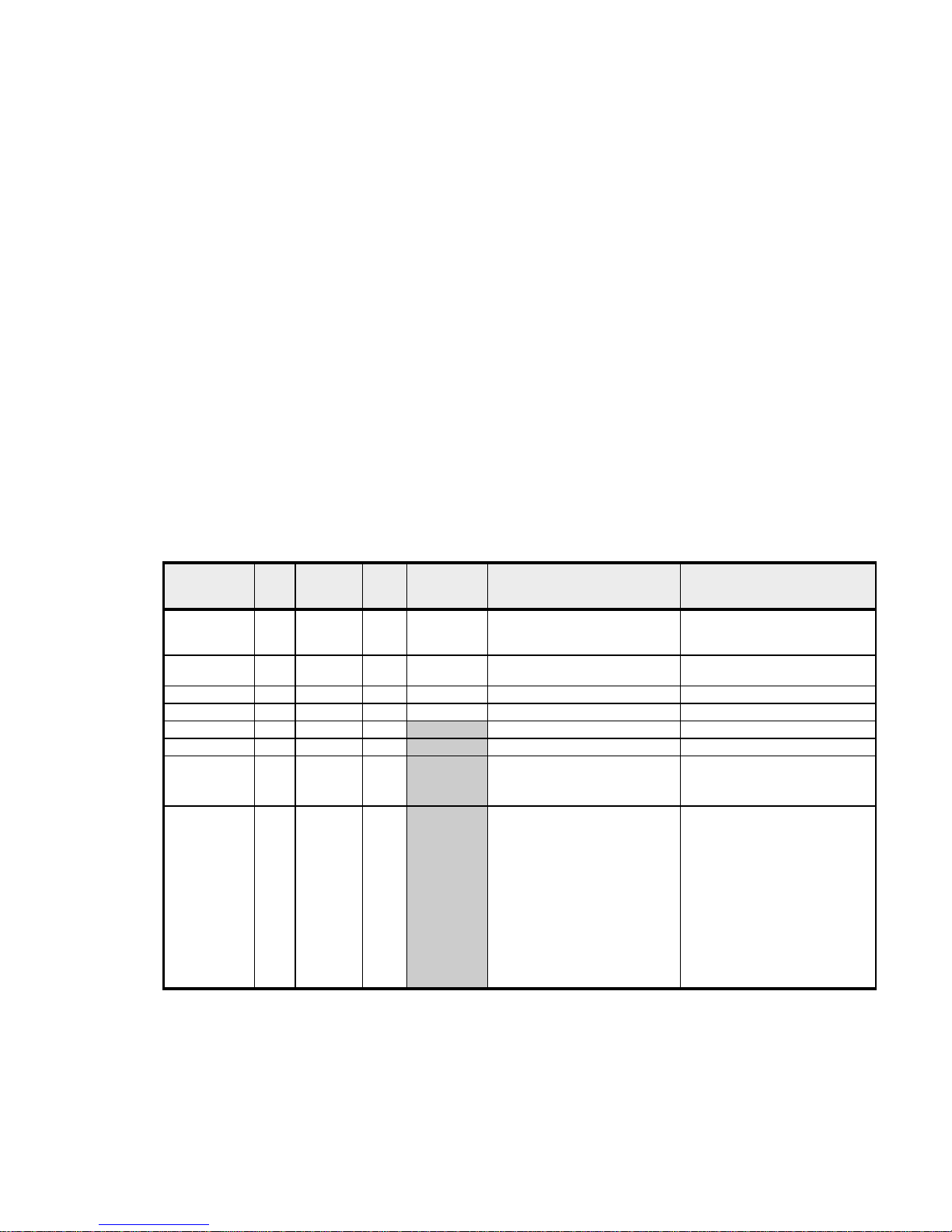

1.2 Variables not on menu structure

Parameter

Name

Size Address

(hex)

R/W ModBus

Function

read/write

Internal Storage, Step rate in

Internal units

Comments

SP1 2 007F RW 3/6 Degrees * 10 [LIN]

step 1 from LoSc to HiSc

The setpoint required. See 1.2.1

below regarding initialising a new

instrument

Setpoint

safety check

1 0125 RW 3/6 see note 1.2.1 below for correct

usage of this byte

Temperature 2 001C R 3/6 Degrees * 10 [LIN] stored as 10ths of deg C

security byte 1 0300 W 6 no scaling see 2.3 for security messages

Ramp Byte 1 0305 R 3 no scaling see 1.2.2 below for bit meanings

Display Byte 1 0306 R 3 no scaling see 1.2.3 below for interpretation

Display State 2 0205 R 3 no scaling a word read enables Ramp byte

and Display Byte to be read with a

single message

Model

(Type of inst

and output

configuration)

2 04FC R

3 0X01 33/9300 RLY / SSD

0X02 33/9300 SSD / SSD

0X03 33/9300 RLY / RLY

0X07 9400 RLY / SSD

0X08 9400 SSD / SSD

0X09 9400 RLY / RLY

0x10 9500 SSD / RLY / RLY

0x11 9500 SSD / SSD / RLY

0x12 9500 RLY / RLY / RLY

0x13 9500 ANLG / RLY / RLY

0x14 9500 ANLG / SSD / RLY

Type of instrument and output

configuration are determined by

the hardware, but can be read

from the address 04FC

The Ramp and Display bytes have been kept together so that a single word read at address 0x0205

can be used to obtain full information about the state of the instrument display.

Page 5

COMMERCIAL IN CONFIDENCE

Page 4

1.2.1 Initialising the Setpoint

The instrument is provided with a safety lock to prevent it from controlling until the setpoint has been

set. This lock is automatically released the first time that the setpoint is changed from the instrument

front panel. If it is required to initialise a new instrument (or after the parameters have been reset), this

lock may be released remotely by performing the following sequence:

tempbyte = (read byte at ModBus address 0125 hex)

tempbyte = tempbyte OR 0x02 {i.e. set bit 1}

(write tempbyte back to ModBus address 0125 hex)

Note that this sequence is only required to unlock the instrument from its reset state - it is not

necessary to perform this sequence each time the setpoint is changed. The other bits within this byte

are used internally and must not be modified.

1.2.2 Ramp Byte

The Ramp Byte holds bits which show what stage of a ramp/soak sequence is currently active:

• bit 1 set = in ramp phase, display periodically flashing SPr

• bit 2 set = in soak phase, display periodically flashing Soak

• bit 3 set = sequence finished, control dormant, display flashes Stop

• bit 6 set = Holdback LED on front display lit (9500P only)

note that these bits are mutually exclusive (except the holdback bit), and the flashing display is of lower

priority than the displays recorded by the Display Byte. If no bit is set, the instrument is not in a

ramp/soak sequence. If the unit has finished a ramp but no soak time is specified (SOAK= - - ) bit 2

will remain set.

The other bits in the Ramp Byte are used internally by the instrument. The Ramp Byte must not be

written to - unpredictable and possibly dangerous instrument behaviour will result.

1.2.3 Display Byte

The Display Byte records the message currently being shown on the instrument display, and also

mirrors the state of the SP LED s - note that although these may be read by a remote program, their

values may change rapidly in real time. Due to the time lag in processing communications messages it

may not be possible to exactly mimic the display on a remote screen - particularly for short cycle times.

The hi nibble conveys the following meanings:

• Bit 7 set = SP2 LED lit

• Bit 6 set = SP1 LED lit

• Bit 5 set = add FAIL display to other indications

• Bit 4 set = SP3 LED lit (9500 only)

The low nibble of the Display Byte indicates the current alternating message being displayed, thus

after the top 2 bits are masked off, the following values indicate the display message:

0x01 = PARK / temp

0x02 = -AL- / temp

0x03 = TUNE / temp

0x23 = TUNE / FAIL

0x04 = TUNE / ATSP / temp

0x05 = HAND / heat power ratio

0x25 = HAND / FAIL

0x26 = INPT / FAIL

0x27 = DATA / FAIL

These messages take display precedence over any others. If one of the Display Byte messages is

indicated, the remote program must ignore the state of the Ramp Byte.

Page 6

COMMERCIAL IN CONFIDENCE

Page 5

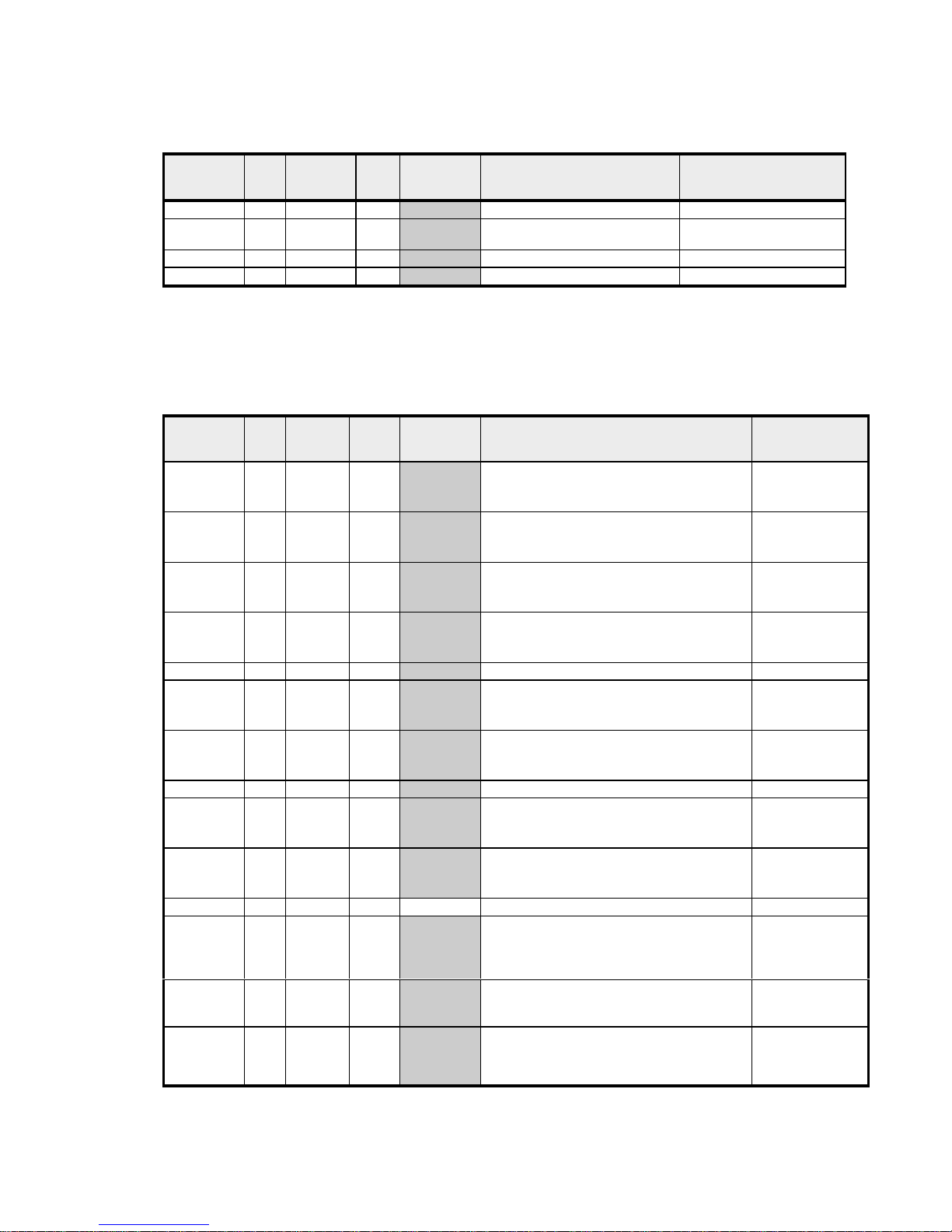

1.3 Level C - parameters in address order

Parameter

Name

Size Address

(hex)

R/W ModBus

Function

read/write

Internal Storage, Step rate in

Internal units

Comments

Addr 1 03D5 RW 3/6 0..255 valid range 1..247

Baud 1 03D6 RW 3/6 0=1200, 1=2400, 2=4800, 3=9600,

4=19200

Data 1 03D7 RW 3/6 0=18n1, 2=18e1, 3=18o1,

Dbg 1 03D8 RW 3/6 0=off, 1=on

note that all changes to the communications level parameters take effect immediately on leaving the

menu, or on receipt of the exit program mode command. The dbg feature may be set on or off. When

on, the right-most digit will flash 3 horizontal segments on receipt of a character when a

communications board is fitted, the left-most digit will flash on transmission of a character.

1.4 Level 1 - parameters in address order

Parameter

Name

Size Address

(hex)

R/W ModBus

Function

read/write

Internal Storage, Step rate in Internal units,

Limits

Comments

Set.2 2 0081 RW 3/6 Degrees * 10 [LIN]

Step 0.1 or 1 depending on disp selection

min=LoSc, max=HiSc

Ofst 2 0083 RW 3/6 Degrees * 10 [LIN]

normal inc/dec

see separate details for limits

Band 2 0085 RW 3/6 Degrees * 10 [LIN]

normal inc/dec

min=0.1 max=25% of Sensor Maximum

9500 max is

100% of sensor

maximum

Bnd.2 2 0087 RW 3/6 Degrees * 10 [LIN]

normal inc/dec

see separate details for limits

Tune 1 0189 RW 3/6 0=off, 1=on, 2=park, 3=at Setpoint

Dac 1 018A RW 3/6 stored as value*2 so 0.5 is stored as 1

step by 0.5

Min=0.5 max=5.0

Int.t 1 018B RW 3/6 intt * 10 up 10.0, then intt+90

normal inc/dec

0=off min=0.1, max=60

Der.t 1 018C RW 3/6 1 — 200 in 1 sec steps

Cyc.t 1 018D RW 3/6 Cyct * 10 up 10.0, then Cyct+90

normal inc/dec

0=off min=0.1, max=81

Cyc.2 1 018E RW 3/6 Cyc2 * 10 up 10.0, then Cyc2+90

normal inc/dec

0=off min=0.1, max=81

SP.lk bit 0028 RW 1/5 0=off, 1=on

SPrr 2 02D0 RW 3/6 Stored as SPrr

if <100 step by 1, if <1000 step by 5 else step by

10

min=0 max=9990

9500 display

effected by DECP

when LIN input

selected

Soak 2 02D2 RW 3/6 0xFF00 = - - , 0=off, otherwise Soak * 10

Step by 1 up to 120, then 5 up to 300 then by 10

min = 1, max=1440

SPrn 1 03D4 RW 3/6 0=off, 1=on, 2=hold 9500P See Level P

section for notes

on starting a

program

Page 7

COMMERCIAL IN CONFIDENCE

Page 6

1.5 Level 2 - parameters in address order

Parameter

Name

Size Address

(hex)

R/W ModBus

Function

read/write

Internal Storage, Step rate in

Internal units, Limits

Comments

SP1.P

SP1_ontime

SP1_proptime22

0062

0078

RR3

3

not stored must be computed as

SP1_ontime/SP1_proptime

*100%

Disp bit 002A RW 1/5 0=low res, 1= high res

Hand 1 018F RW 3/6 No scaling

step by 1

min 0=off, max=100

PL.1 1 0190 RW 3/6 No scaling

step by 1

min=0, max=100

PL.2 1 0191 RW 3/6 No scaling

step by 1

min=0, max=100

SP2.A 1 0192 RW 3/6 0=none, 1=dvhi, 2=dvlo, 3=band,

4=fshi, 5=fslo, 6=cool

9500P 7=EOP

SP2.b 1 0193 RW 3/6 0=none, 1=ltch, 2=hold, 3=ltho,

4=nlin

Hi.SC 2 0094 RW 3/6 HiSc * 10 [LIN]

step by 0.1 or 1

min=Sensor Min, max=Sensor Max

Lo.SC 2 0096 RW 3/6 LoSc * 10 [LIN]

step by 0.1 or 1

min=Sensor Min, max=Sensor Max

Inpt 1 0198 RW 3/6 0=none, 1=Tcb, 2=Tce, 3=Tcj,

4=Tck, 5=Tcl, 6= Tcn, 7=TcR,

8=Tcs, 9=Tct, 10=RTD, 11=lin1

12=lin2, 13=lin3, 14=lin4, 15=lin5

9500

11=lin

12-15 unused

Unit 1 0199 RW 3/6 0=none, 1=C, 2=F, 3=bar, 4=PSI,

5=Ph, 6=Rh, 7=set

Page 8

COMMERCIAL IN CONFIDENCE

Page 7

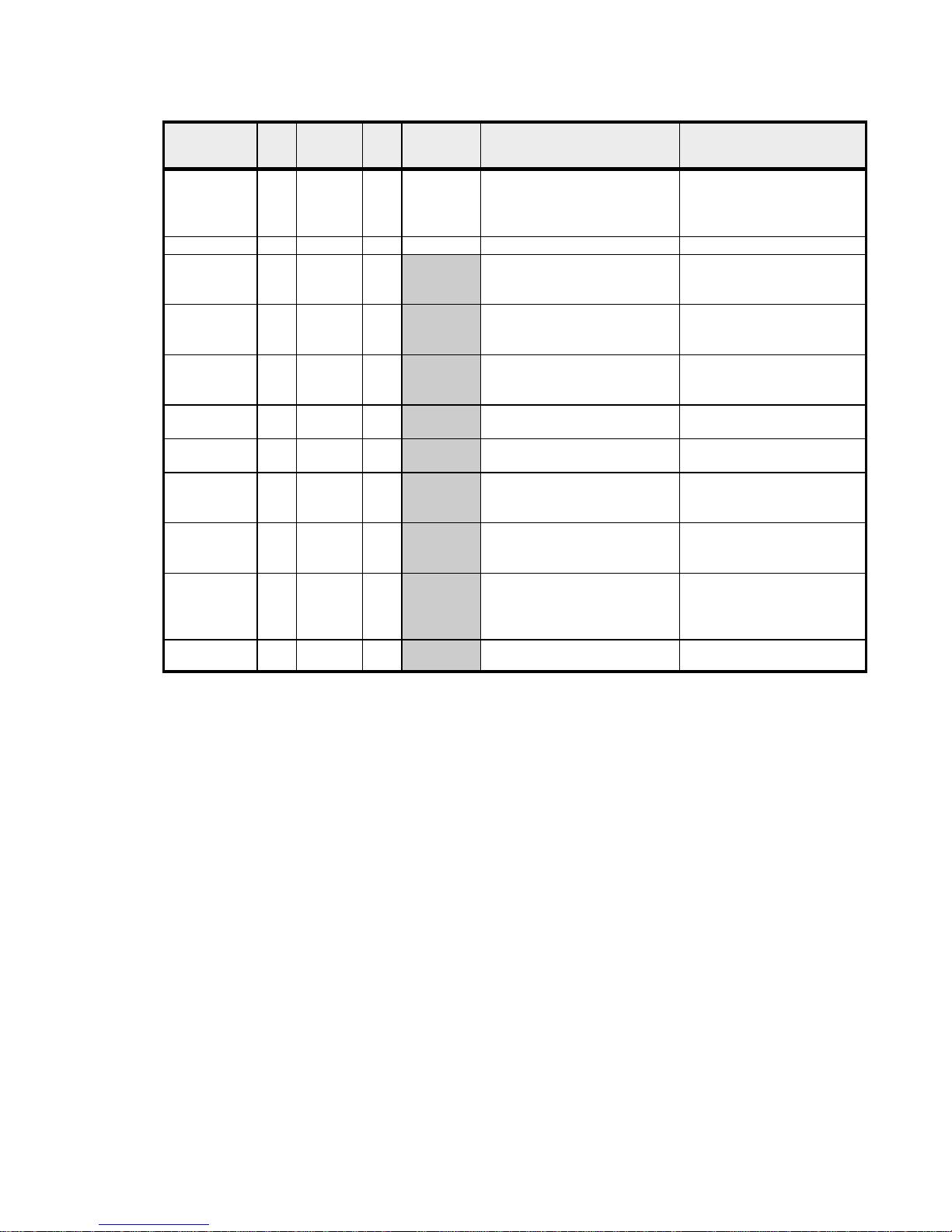

1.6 Level 3 - parameters in address order

Parameter

Name

Size Address

(hex)

R/W ModBus

Function

read/write

Internal Storage, Step rate in

Internal units, Limits

Comments

SP1.d 1 019D R 3/6 0=none, 1=rly, 2=ssd, 3=rly1,

4=rly2

5=ssd1(ssd2)

9500

0=none 1,3,4,10=ssd

2,5,6,8=rly 7,9=anlg

SP2.d N/A N/A N/A N/A Not stored Inverse of SP1.d

Burn 1 019E RW 3/6 0=upsc, 1=dnsc, 2=1u2d, 3=1d2u

Rev.d 1 019F RW 3/6 0=1r2d, 1=1d2d, 2=1r2r, 3=1d2r

Rev.l 1 01A0 RW 3/6 0=1n2n, 2=1l2n, 3=1n2l, 4=1l2l

Span 2 00A1 RW 3/6 Span * 10 [LIN]

normal inc/dec

min = -0.25 * Sensor Min

max = 0.25 * Sensor Max

Zero 2 00A3 RW 3/6 Zero * 10 [LIN]

normal inc/dec

min = -0.25 * Sensor Min

max = 0.25 * Sensor Max

Chek bit 0026 RW 1/5 0=off, 1=on

Read (var) 2 computed from 2 vars (below)

Read(hi) - Read(lo) with

degC to decF if required (if

unit=1)

Read (hi) 2 007A R 3 Read(hi) * 10 [LIN]

Read (lo) 2 007C R 3 Read(lo) * 10 [LIN]

Data (Ct A) 2 0432 R 3 CtA * 25

Data (Ct B) 2 0434 R 3 CtB * 25

Data (Ct 1) 2 0436 R 3 Ct1 * 25

Data (Ct 2) 2 0438 R 3 Ct2 * 25

Data (Ct 3) 2 043A R 3 Ct3 * 25

Data (Ct 4) 2 043C R 3 Ct4 * 25

Data (Os 1) 2 043E R 3 Os1 * 10 [LIN]

Data (us) 2 0440 R 3 Us * 10 [LIN]

Data (Os 2) 2 0442 R 3 Os2 * 10 [LIN]

Ver

(S/W ver)

2 04FD R 3 0xFFFF/ 0x01 means ver 391

0x02 means ver 392

0x03 means ver 941

0x04 means ver 951

0X05 means ver 952

3300/9300 ver 1

3300/9300 ver2

9400 ver 1

9500 ver 1

9500 P ver 2

Rset bit 0027 RW 1/5 0=none, 1=all

1.7 Level 4 - parameters in address order

Parameter

Name

Size Address

(hex)

R/W ModBus

Function

read/write

Internal Storage, Step rate in

Internal units, Limits

Comments

Der.S 1 019A RW 3/6 Ders * 10

Dis.S 1 019B RW 3/6 0=dir, then 1..32

step by 1

min=0, max=32

Lock 1 019C RW 3/6 0 = none, 1=lev3, 2=lev2, 3=all

Prog bit 002D 1/5 0 = auto, 1=stay

No.Al bit 002E RW 1/5 0 = off, 1=on

Page 9

COMMERCIAL IN CONFIDENCE

Page 8

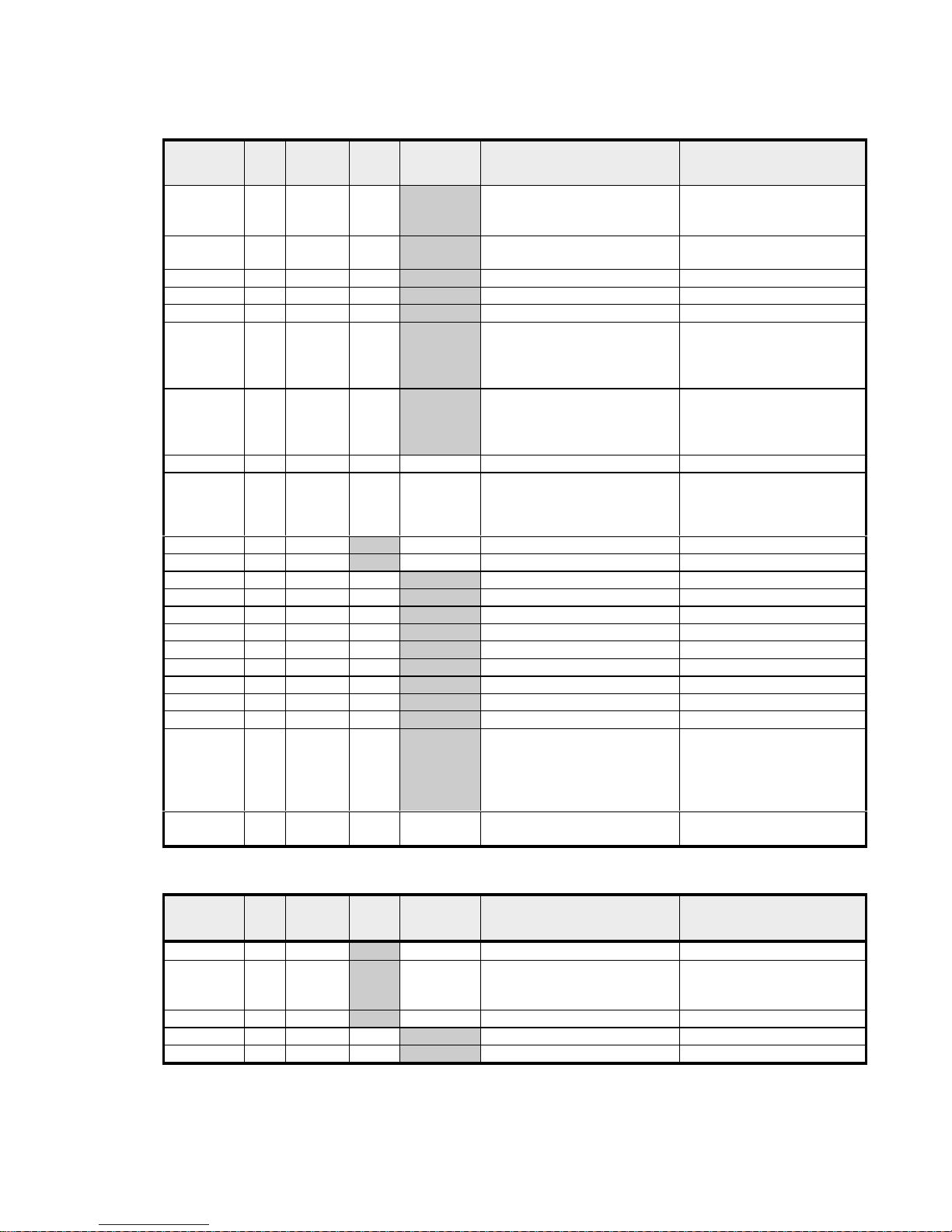

1.8 Level A – parameters in address order (9500 only)

Parameter

Name

Size Address

(hex)

R/W ModBus

Function

read/write

Internal Storage, Step rate in

Internal units, Limits

Comments

An.Hi 2 02D9 RW 3/6 AnHi

Step=1

min=-1999, max=9999

An.Lo 2 02DB RW 3/6 AnLo

Step=1

min=-1999, max=9999

Hi.In 2 02DD RW 3/6 HiIn * 10

step=0.1

min=0.1, max 50.0

HiIn must always be 0.1 above

the LoIn setting

Lo.In 2 02DF RW 3/6 LoIn * 10

step=0.1

min=0.0, max 49.9

DECP 1 03E1 RW 3/6 0=0000, 1=000.0, 2=00.00 Decp over-rides the Disp setting

in level 2 while linear input

selected

SP3.A 1 03E2 RW 3/6 0=none, 1=dvhi, 2=dvlo, 3=band,

4=fshi, 5=fslo

9500P 7=EOP

SP3.B 1 03E3 RW 3/6 0=none, 1=ltch, 2=hold, 3=ltho

Brn.3 1 03E4 RW 3/6 0=upsc, 1=dnsc

Rev.3 1 03E5 RW 3/6 0=3d, 1=3r

Set.3 2 02E8 RW 3/6 Degrees * 10 [LIN]

step=0.1

min=0.0, max=2500

When LIN sensor selected

max=9999

Hys.3 2 02EA RW 3/6 Hys3 * 10 [LIN]

step=0.1

min=0.1, max=100% of HiSc

Note: The level A menu is only available in the 9500 instrument.

1.9 Level P – parameters in address order (9500P only)

Parameter

Name

Size Address

(hex)

R/W ModBus

Function

read/write

Internal Storage, Step rate in

Internal units, Limits

Comments

MaxProg 1 033A R 3 Maximum Program Number Generated by the instrument, do

not write to this location.

Prog 1 036C RW 3/6 Program Number

min=1, max=MaxProg

To start a program write the

number of the program to run

and then set the value of

Sprn(Level 1) to ON or HOLD

Note: the program will not start

until after the exit program mode

Note: The level P menu is only available in the 9500P instrument.

Note: The other elements of the programmer (Level P) menu are unavailable from the communications

interface.

Page 10

COMMERCIAL IN CONFIDENCE

Page 9

2. ACTIONS REQUIRED TO COMMUNICATE WITH THE

INSTRUMENTS

These versions of the instruments have ModBus functions codes 1,3,5,6 and 16 implemented. Note

that although function code 16 (write multiple registers) is recognised, this cannot deal with more than

a single 2 byte register write and will return an error if more registers are attempted. There is no facility

to read multiple registers, nor to read or write multiple bits.

2.1 Notes

• Un-implemented function codes do not yet return error code 01.

• Function code 15 (read multiple registers) is not implemented.

2.2 Implementation restrictions

A number of restrictions are made :

• Multiple register reads are not implemented, since the opportunity to use them is very

limited and there is not sufficient memory to buffer long messages.

• Multiple bit reads and writes are not implemented, since we do not have any consecutive

bits available to the user.

2.3 Security Messages

To allow communications to safely manipulate the instrument a number of security messages

have been implemented. CAL Controls see these as important safety features, which offer a

number of advantages, especially when configuring a safety critical application.

The messages to enter program mode only have to be sent once to access the Internal

parameters of the instrument and then any number of adjustments can be made. The advantage

this offers is that sending the enter program mode message, causes the push buttons on the

instrument to be locked out. This feature prevents potentially dangerous conditions arising

from simultaneous adjustment of the instrument locally whilst adjustments are being sent over

the communications link.

The messages to exit program mode causes the instrument to write back any internal

parameter changes to the NVram, and then use these settings. This means that any changes

made will not take effect until the instrument has received the exit program mode message. The

advantage this offers is that all adjustments take place at the same time. If for instance you are

configuring alarm functions you will not get false alarms due to setting the alarm mode before a

valid alarm set point has been programmed, also all PID terms are implemented together,

whereas separate adjustment of PID functions may cause greater control instability.

To prevent inadvertent changes a security byte must be set immediately before any security message

is transmitted - this byte is automatically reset after each message.

Each security message is numbered 1 to 6, this number must be set into the security byte immediately

prior to the message, if the security byte does not match the security message number, the message

will be ignored and no response will be issued. Messages 1 to 4 are implemented but currently have no

direct use.

Note: The 9500 does not require the security byte messages to be sent to enter and exit

program mode, the messages not required are noted below.

The correct sequence to set new parameters into the instrument is as follows:

Page 11

COMMERCIAL IN CONFIDENCE

Page 10

1. Write the security byte with value 5 (9500 — Not Required)

2. Send message number 5 (enter program mode)

3. Send messages as required to change desired parameters

4. Write the security byte with value 6 (9500 — Not Required)

5. Send message number 6 (exit program mode)

It is possible to write to parameters without using this sequence, but the unit will simply

hold new values in the menu structure, and will not apply the new values to the

process control variables. However, if new parameters are uploaded and then the

menu entered from the front panel, any uploaded parameters will be effective on

leaving the menu. When using communications the enter program mode / exit

program mode message sequence must be sent to cause any new values to be

applied to the controller.

2.3.1 Enter Program Mode

Byte No Meaning Value

1 Slave address xx

2 ModBus Function code (write register) 06

3 Security message function marker (1=security, 5=function 5) 15

4 not used (any value may be sent) xx

5 not used (any value may be sent) xx

6 not used (any value may be sent) xx

7 CRC lo byte ??

8 CRC hi byte ??

The security byte must be set to 5 prior to this message (not required for 9500). If the

instrument is successfully set into remote program mode, and the keyboard is

successfully locked, the response will be the same as the message. If the instrument

is currently in manual menu entry mode, an error response code 6 (device busy) will

be returned. This command may be repeated while already in remote program mode

with no ill effect.

2.3.2 Exit Program Mode

Byte No Meaning Value

1 Slave address xx

2 ModBus Function code (write register) 06

3 Security message function marker (1=security, 6=function 6) 16

4 not used (any value may be sent) xx

5 not used (any value may be sent) xx

6 not used (any value may be sent) xx

7 CRC lo byte ??

8 CRC hi byte ??

The security byte must be set to 6 prior to this message (not required for 9500). The response will be

the same as the message if the instrument is currently in remote program mode, and a restart will be

initiated, otherwise an error response code 1 (illegal function) will be returned.

Page 12

COMMERCIAL IN CONFIDENCE

Page 11

2.4 ModBus Message Construction.

The following message function codes are implemented in the instrument. Where a value of xx is

shown, substitute the correct value for your installation and the data item required. All CRCs are shown

as ?? since must be automatically generated according to the data contained in the message.

2.4.1 Read Coil Status (single bit read)

Byte No Meaning Value (hex)

1 Slave address xx

2 ModBus Function code (read coil status) 01

3 Starting Address MSB, always 00

4 Starting Address LSB xx

5 No of points MSB 00

6 No of points LSB 01

7 CRC lo byte ??

8 CRC hi byte ??

Note that in this implementation, only one bit may be read per message, so the number of

points should always be set to 1, but in fact this value is ignored anyway. If the address is not a

valid readable bit, an error response code 2 (invalid address) is returned, otherwise the

following response is sent:

Byte No Meaning Value (hex)

1 Slave address xx

2 ModBus Function code (read coil status) 01

3 Byte count 01

4 Bit value (01 if bit is set, 00 if not) 00 or 01

5 CRC lo byte ??

6 CRC hi byte ??

2.4.2 Read Holding Registers

Byte No Meaning Value (hex)

1 Slave address xx

2 ModBus Function code (read holding register) 03

3 Starting Address MSB xx

4 Starting Address LSB xx

5 No of registers MSB 00

6 No of registers LSB 01

7 CRC lo byte ??

8 CRC hi byte ??

Note that the only one register may be read per message, so the number of registers should be 1

(although this value is ignored in this implementation). The normal response will be:

Byte No Meaning Value (hex)

1 Slave address xx

2 ModBus Function code (read register) 03

3 Byte count (always 2, even though the register may be only 1

byte wide)

02

4 Data MSB (will be 0 if a single byte register) xx

5 Data LSB xx

6 CRC lo byte ??

7 CRC hi byte ??

Page 13

COMMERCIAL IN CONFIDENCE

Page 12

2.4.3 Force Single Coil (write single bit)

Byte No Meaning Value (hex)

1 Slave address xx

2 ModBus Function code (force coil) 05

3 Starting Address MSB, always 00, all bits are in internal

memory

00

4 Starting Address LSB xx

5 Force Data MSB (FF sets the bit, 00 clears it) FF or 00

6 Force Data LSB (always 00) 00

7 CRC lo byte ??

8 CRC hi byte ??

An error response code 2 (illegal address) will be returned if the bit is not a valid writeable bit,

otherwise the response is the same as the above message.

2.4.4 Preset Single Register

Byte No Meaning Value (hex)

1 Slave address xx

2 ModBus Function code (write register) 06

3 Starting Address MSB xx

4 Starting Address LSB xx

5 Data MSB xx

6 Data LSB xx

7 CRC lo byte ??

8 CRC hi byte ??

The normal response is the same as the message. An error response code 2 (illegal address)

will be returned if the address is not within the processor bounds.

2.4.5 Preset Multiple Registers

Byte No Meaning Value (hex)

1 Slave address xx

2 ModBus Function code (write register) 10

3 Starting Address MSB xx

4 Starting Address LSB xx

5 Number of registers MSB 00

6 Number of registers LSB 01

7 Number of bytes to follow 02

8 Data MSB xx

9 Data LSB xx

10 CRC lo byte ??

11 CRC hi byte ??

note that this function is a subset of the normal ModBus function code 16 in that only one register of up

to 2 bytes may be written. Thus byte numbers 5, 6 and 7 must be as shown, otherwise an error

response with error code 1 (illegal request) will be returned.

Page 14

COMMERCIAL IN CONFIDENCE

Page 13

2.5 Exception Code Responses

There are 5 possible responses to received messages:

2.5.1.1 Broadcast message

There is never any response to a broadcast message (one with slave address 0). The

message will be acted on if possible, any errors will go unreported.

2.5.1.2 Slave receives incomplete or corrupt message

No response is returned.

2.5.1.3 Slave receives full message but CRC is incorrect

No response is returned

2.5.1.4 Slave receives message correctly, and acts on it correctly

The normal response as detailed under each message heading is returned.

2.5.1.5 Slave receives full message correctly, but cannot act on it

An error response, as detailed under each message heading, is returned as follows

Byte No Meaning Value

1 Slave address xx

2 Original ModBus Function code but with top bit set 8x

3 Error code xx

4 CRC lo byte ??

5 CRC hi byte ??

The following error codes are implemented :

• 01 - illegal function - not fully implemented in these versions except for

exit program mode when not in program mode, and for function code 16.

In future releases will be returned on receipt of any function code not

implemented.

• 02 - illegal data address

• 04 - slave device failure - not currently implemented in these versions ,

but will be returned if the NVram causes problems when reading or writing

• 06 - slave busy - returned if the keyboard is in use when an enter

program mode request is received.

Page 15

COMMERCIAL IN CONFIDENCE

Page 14

2.6 CRC calculation

NOTE that the CRC algorithm published in the Modicon ModBus Protocol Guide (PI-MBUS-300

Rev G, Nov 1994) IS WRONG!!!! However, the quick C program using the lookup tables is correct.

The correct algorithm is given here

1. Load a 16 bit register with FFFF (all 1 s). Call this the CRC register.

2. Exclusive OR the first 8 bit byte of the message with the low-order byte of the 16 bit CRC

register, putting the result back into the CRC register

3. Look at the Least Significant Bit of the CRC register and remember it. Call it the LastBit

4. Shift the CRC register one bit right, putting 0 in the top bit

5. If the LastBit was 1, Exclusive OR the CRC register with value A001h (1010 0000 0000

0001)

6. Repeat steps 3,4,5 until 8 shifts have been performed

7. Repeat from step 2 for the next byte of the message until all bytes have been processed

8. The final contents of the CRC register is the CRC value to use

9. When the CRC is placed in the message, the Least Significant Byte is sent first, then the

Most Significant Byte

2.6.1 CRC calculation in C code

There are two ways to implement the CRC, one uses the above algorithm, the other uses precomputed lookup tables which make for a faster calculation. This is given correctly in the ModBus

guide, and can be downloaded from the Internet (search for ModBus and CRC and Generation) and is

not repeated here. The long winded way is as follows (where mess[] holds the message):

unsigned short crc;

unsigned short thisbyte;

unsigned short shift;

unsigned char highbyte, lowbyte;

unsigned char lastbit, i;

crc=0xffff;

for (i=0; i<len(mess); i++)

{

thisbyte= mess[i];

crc = crc^thisbyte;

for (shift=1; shift<=8; shift++)

{

lastbit = crc & 1;

crc = (crc >> 1) & 0x7fff;

if (lastbit==1)

{

crc = crc^0xA001 ;

}

}

}

highbyte=(crc>>8)&0xff;

lowbyte=crc&0xff;

Page 16

COMMERCIAL IN CONFIDENCE

Page 15

Reading the CAL Controllers Setpoint

An 8 byte message must be transmitted to the CAL Controller as follows:

byte 0 : Slave address xx

byte 1 : Read Register Function code 03 hex

byte 2 : High Byte of Register address 00 hex

byte 3 : Low byte of Register address 7F hex

byte 4 : Number of Registers to read (high byte) 00 hex

byte 5 : Number of Registers to read (low byte) 01 hex

byte 6 : CRC lo byte xx

byte 7 : CRC hi byte xx

Note that the CRC must be transmitted with the lo byte first. Bytes must be transmitted in a single

burst, without gaps between each byte - any gap of longer than 1.5 times a character width will cause

the CAL Controller to ignore the message.

The following example shows how to construct a message to read the setpoint, the various sections of

this code would normally be held in separate functions, and would be optimised for better speed, but

this example shows the thought process involved (note also that C uses zero based arrays):

unsigned char mess[8], reply[8];

void BuildMessageToReadSetPoint()

{ unsigned char highbyte,lowbyte;

unsigned short crc,thisbyte,i,shift,lastbit; /* 16 bit word values */

mess[0] = 0x01; /* slave address */

mess[1] = 0x03; /* read function */

mess[2] = 0x00; /* address hi byte */

mess[3] = 0x7F; /* address lo byte */

mess[4] = 0x00; /* number of data points hi byte */

mess[5] = 0x01; /* number of data points lo byte */

/* compute the CRC over the first 6 chars of the message */

crc=0xffff;

for (i=0; i<=5; i++)

{ thisbyte = mess[i];

crc = crc ^ thisbyte;

for (shift = 1; shift <= 8; shift++)

{ lastbit = crc & 0x0001;

crc = (crc >> 1) & 0x7fff;

if (lastbit == 0x0001)

{ crc = crc ^ 0xa001 ;

}

}

}

highbyte = (crc >> 8) & 0xff;

lowbyte = crc & 0xff;

mess[6] = lowbyte;

mess[7] = highbyte;

}

the 8 characters in the message can now be transmitted to the communications port.

Page 17

COMMERCIAL IN CONFIDENCE

Page 16

After a short delay (approx. 10ms), the CAL Controller will respond with a 7 byte reply. Assuming the

Setpoint to be 200 degrees this would be:

byte 0 : Slave address xx

byte 1 : Function code 03 hex

byte 2 : Number of data bytes to follow 02 hex

byte 3 : High byte of Setpoint value 07 hex

byte 4 : Low byte of Setpoint value D0 hex

byte 5 : Low byte of CRC value ?? hex

byte 6 : High byte of CRC value ?? hex

These characters should be stored in a reply array, and the CRC computed (as above) over the first 5

characters and compared with bytes 5 and 6, the reply should be accepted only if they match. If there

are any errors in the transmitted message, the reply will be missing altogether or the reply will be an

error response. Either way, only accept the reply if the Function code is 03 and the CRC is correct.

The CALController stores the Setpoint internally in 10th degree units, so the value can be computed

as:

setpoint = ((reply[3] << 8) + reply[4]) / 10 ;

or, in a language other than C:

setpoint = ((reply[3] * 256) + reply[4]) / 10 ;

Reading the temperature

Exactly the same method is used as above, except replace byte 2 and 3 of the message with the

register address of the Temperature thus:

byte 2 : High byte of Temperature address 00 hex

byte 3 : Low byte of Temperature address 1C hex

The temperature will be returned in bytes 3 and 4 of the reply, exactly as the example for Setpoint, and

this must also be divided by 10 to bring it to degrees. Note that the temperature is always returned in

Centigrade, so any Fahrenheit conversion must be made by the PC.

A typical message would be:

[01][03][00][1C][00][01][45][CC]

A typical reply would be:

[01][03][02][00][C4][B9][D7]

which shows the temperature to be 00C4 hex, 196 decimal, which is 19.6 degrees centigrade.

Page 18

COMMERCIAL IN CONFIDENCE

Page 17

Writing the Setpoint

Writing to the CAL Controller requires a three stage process which prevents simultaneous access from

the front panel. To prevent accidental changes caused by unreliable communications, a sequence of

messages must be sent in strict order.

1. Lock the keypad - a sequence referred to as enter program mode

2. Write new values to the CAL Controller

3. Unlock the keypad and restart with the new values - a sequence referred to as exit program

mode

1. Enter Program Mode

To enter the programming mode of the CAL Controller, two messages must be transmitted - both must

be recognised, in strict sequence, as valid for the operation to be successful. The first message

informs the controller that the next message is a security locking message, if the second message is

not acknowledged correctly, the whole sequence must be re-started from message 1.

1st Message:

byte 0 : Slave address xx

byte 1 : Function code (write register) 06 hex (always)

byte 2 : Register Address high byte 03 hex (always)

byte 3 : Register Address low byte 00 hex (always)

byte 4 : Register Value high byte 00 hex (always)

byte 5 : Register Value low byte 05 hex (always)

byte 6 : CRC low byte ??

byte 7 : CRC high byte ??

The controller should reply with an identical response, if not, this message should be re-

transmitted until the response is correct.

Note: the 9500 does not require the security message to be sent.

2nd Message:

byte 0 : Slave address xx

byte 1 : Function code (write register) 06 hex (always)

byte 2 : Register Address high byte 15 hex (always)

byte 3 : Register Address low byte 00 hex (always)

byte 4 : Register Value high byte 00 hex (always)

byte 5 : Register Value low byte 00 hex (always)

byte 6 : CRC low byte ??

byte 7 : CRC high byte ??

The CAL Controller should reply with an identical response, if not, the message pair is lost and

the sequence must be repeated from message 1.

Page 19

COMMERCIAL IN CONFIDENCE

Page 18

2. Write the Setpoint value

The setpoint value must be sent in the same units as are currently displaying on the controller, that is,

in Degrees Fahrenheit, if selected, otherwise in Centigrade. The value to be transmitted must be an

integer number of 10ths of a degree. For example, to transmit a value of 432.1 degrees, the setpoint

register must be set to 4321 (decimal) which is 10E1 (hex). The following message writes the setpoint,

in this example xx would be 10 (hex) and yy would be E1 (hex).

byte 0 : Slave address xx

byte 1 : Function code (write register) 06 hex (always)

byte 2 : Register Address high byte 00 hex (always)

byte 3 : Register Address low byte 7F hex (always)

byte 4 : Setpoint Value high byte xx

byte 5 : Setpoint Value low byte yy

byte 6 : CRC low byte ??

byte 7 : CRC high byte ??

3. Exit program mode

A two part sequence, similar to the enter program mode sequence is required to accept the new values

and unlock the controller keypad. Similarly, both messages must be present in strict sequence for the

values to take effect.

1st Message:

byte 0 : Slave address xx

byte 1 : Function code (write register) 06 hex (always)

byte 2 : Register Address high byte 03 hex (always)

byte 3 : Register Address low byte 00 hex (always)

byte 4 : Register Value high byte 00 hex (always)

byte 5 : Register Value low byte 06 hex (always)

byte 6 : CRC low byte ??

byte 7 : CRC high byte ??

The controller should reply with an identical response, if not, this message should be retransmitted until the response is correct.

Note: the 9500 does not require the security message to be sent.

2nd Message:

byte 0 : Slave address xx

byte 1 : Function code (write register) 06 hex (always)

byte 2 : Register Address high byte 16 hex (always)

byte 3 : Register Address low byte 00 hex (always)

byte 4 : Register Value high byte 00 hex (always)

byte 5 : Register Value low byte 00 hex (always)

byte 6 : CRC low byte ??

byte 7 : CRC high byte ??

The CAL Controller should reply with an identical response, if not, the message pair is lost and

the exit program mode sequence must be repeated from message 1.

Any changes made will only take effect on receipt a valid exit program mode sequence - if the

controller is de-powered before this sequence is completed, the previously stored values will be used.

Page 20

COMMERCIAL IN CONFIDENCE

Page 19

3.0 VALUE / LIMIT CHECKING

The purpose of this section of the document is to lay down the allowable range of adjustment for all

functions addressable over the communications link.

LEVEL C

Function Values / Limits

ADR 1 — 247

BAUD 1200 2400 4800 9600 19200

DATA 18N1 18E1 18O1

DBUG OFF ON

LEVEL 1

Function Values / Limits

TUNE OFF ON PARK AT.SP

BAND 0.1 — 9.9 10 — 25% of the selected sensors full scale, deg C or F

(9500 - 100% of the selected sensors full scale, deg C or F)

INT.T OFF 0.1 — 9.9 10 — 60 Minutes

DER.T OFF 1 — 200 Seconds

DAC 0.5 — 5.0 ( In 0.5 steps)

CYC.T A-- ON.OF 0.1 — 9.9 10 — 81 Seconds

OFST Detailed later dependant on other functions.

SP.LK OFF ON

SPRR 0 — 9990 Deg / Hr

SPRN ON OFF HOLD

SOAK -- 0 — 1440 Min

SET.2 Detailed later dependant on other functions.

BND.2 Detailed later dependant on other functions.

CYC.2 ON.OF 0.1 — 9.9 10 — 81 Seconds.

LEVEL 2

Function Values / Limits

SP1.P 0 - 100 % ( Read only )

HAND OFF 1 — 100 %

PL1 100 — 0 %

PL2 100 — 0 %

SP2.A NONE DV.HI DV.LO BAND FS.HI FS.LO COOL E.OP (9500P)

SP2.B NONE LT.CH HOLD LT.HO NLIN

DISP 1 Deg 0.1 Deg

HI.SC Detailed later dependant on other functions.

LO.SC Detailed later dependant on other functions.

INPT NONE B E J K L N R S T RTD LIN1 LIN2 LIN3 LIN4 LIN5

(9500 — LIN1-5 replaced by LIN )

UNIT NONE *C *F BAR PSI PH RH SET

LEVEL 3

Function Values / Limits

SP1.D NONE RLY SSD RLY1 RLY2 SSD1

(9500 — NONE RLY SSD ANLG depending on hardware present)

SP2.D NONE RLY SSD RLY1 RLY2 SSD2 (9500 as above)

BURN UP.SC DN.SC 1U.2D 1D.2U

REV.D 1R.2D 1D.2D 1R.2R 1D.2R

REV.L 1N.2N 1I.2N 1N.2I 1I.2I

SPAN Detailed later dependant on other functions.

ZERO Detailed later dependant on other functions.

READ VAR* HI* LO* ( Read only ).

TECH CTA CTB CT1 CT2 CT3 CT4 OS1 US OS2 (Read only ).

VER 391 392 941 951 952 ( Read only ).

RSET NONE ALL

Page 21

COMMERCIAL IN CONFIDENCE

Page 20

LEVEL 4

Function Values / Limits

LOCK NONE LEV.3 LEV.2 ALL

PROG AUTO STAY

NO.AL OFF ON

DIS.S DIR 1 - 32

DER.S 0.1 — 1.0

LEVEL A

Function Values / Limits

AN.HI -1999 - 9999

AN.LO -1999 - 9999

HI.IN 0.1 — 50.0

LO.IN 0.0 — 49.9

DECP 0000 000.0 00.00

SP3.A NONE DV.HI DV.LO BAND FS.HI FS.LO E.OP (9500P)

SP3.B NONE LTCH HOLD LT.HO

BRN.3 UPSC DNSC

REV.3 3D 3R

SET.3 Detailed later dependant on other functions.

HYS.3 0.1 — 100 % of HISC

FUNCTIONS DEPENDANT ON OTHER SETTINGS - ADJUSTABLE LIMITS

This section details the valid limits of adjustment for functions that are inter dependant on each other.

Flow diagrams are used to demonstrate the order in which the functions should be checked to obtain

valid limits. Also included in this section are tables of maximum and minimum adjustment limits for

each sensor and the default HI.SC and LO.SC settings.

Note: that the checks for > INPT = LIN apply to the 9500 only.

SP1 > INPT = LIN > HISC > LOSC > SP.LK > DECP

SP1 > INPT = Others > UNIT > DISP > HISC > LOSC > SP.LK

So set point 1 is adjustable between the current high and low scale settings, as long as the setpoint

lock is off.

OFST > INPT = LIN > CYC.T = ON.OF > 0.0 to 25% of sensor full scale > DECP

= 0.1 to 81 > 0.0 to 50% of BAND setting > DECP

= Others > CYC.T = ON.OF > UNIT > DISP > 0.0 to 25% of sensor full scale

= 0.1 to 81 > DISP > 0.0 to 50% of BAND setting

So OFST is adjustable between +/- 0.0 and 50 % of SP1 proportional band setting or +/- 25 % of

sensors full scale max setting ( see tables 1 and 2 for sensor scales ).Resolution of adjustment is

dependant on DISP setting.

SET.2 > INPT = LIN > SP2.A = FSHI FSLO > -1999 to 9999 > DECP

= DVHI BAND > 0 to 2500 > DECP

= DVLO > 0 to —2500 > DECP

= COOL > -1999 to 2500 > DECP

= Others > SP2.A = DVHI BAND > DISP > 0 - 250

= DVLO > DISP > 1 > 0 to -250

> 0.1 > 0 to -199.9

= FSHI FSLO > UNIT > DISP > sensor full scale min to max

= COOL > DISP > 1 > -250 to 250

> 0.1 > -199.9 to 250.0.

If you change SP2.A at any time then the value of SET.2 defaults to zero.

BND.2 > SP2.A = DVHI to FSLO > INPT > UNIT > DISP > 0.1 to sensor full scale.

= COOL > INPT > UNIT > DISP > 0.1 to 25% of sensor full scale.

So BND.2 is adjustable between 0.1 and the selected sensors full scale, except when you select

COOL mode then you have an upper limit of 25% of the selected sensors full scale.

Page 22

COMMERCIAL IN CONFIDENCE

Page 21

HISC > INPT = LIN > 1 to 9999 > DECP

= Others > UNIT > DISP > sensor full scale min to max

LOSC > INPT = LIN > 0 to 9999 > DECP

= Others > UNIT > DISP > sensor full scale min to max

So the limits of both of these functions is defined by the type of sensor , C or F , and 1* or 0.1*.

Note that the value of LOSC must be below the value of HISC.

SPAN > INPT = LIN > 0 to 2500 > DECP

= Others > UNIT > DISP > +/- 25% of sensor full scale

So this function is adjustable from —25% to +25% of sensor full scale , in what ever units are selected,

adjustment is in 0.1 increments between —9.9 and 9.9 after this it is in 1 degree increments.

ZERO > This function has the same adjustment range as SPAN.

SPRR > INPT = LIN > 0 to 9995 > DECP

= Others > DISP > 0 to 9995

READ > INPT = LIN > value > DECP

= Others > DISP >value

TECH > INPT = LIN > value > DECP

= Others > DISP >value

9500 specific functions and values

LOIN > HIIN

The value of LOIN must always be 0.1 less that the value of HIIN

ANLO > -1999 to 9999 > DECP

ANHI > -1999 to 9999 > DECP

HYS.3 > INPT =LIN > HISC > 1 — HISC > DECP

=Others > HISC > UNIT > DISP > 0.1 — HISC

The value of HYS.3 ranges from 0.1 up to HISC

SET.3 > INPT = LIN > SP3.A = FSHI FSLO > -1999 to 9999

= DVHI BAND > 0 to 2500

= DVLO > 0 to -2500

= Others >SP3.A = FSHI FSLO > UNIT > DISP > sensor full scale min to max

= DVHI BAND > 0 to 250.0

= DVLO > DISP > 1 > 0 to -250

> 0.1 > 0 to —199.9

If you change SP3.A at any time then the value of SET.3 defaults to zero.

There are a number of functions which when changed can have an effect on the values of other

functions, the rules relating to these will be covered in this section.

1/ As mentioned earlier changing SP2.A will cause SET.2 to default to zero.

2/ Changing the value of DISP will cause the resolution of SET.2 . HISC . LOSC . and set point 1 to

change, and also values above 1000 will default to 999.9 if selecting hi- resolution.

3/ If you move set point one to a point outside the limits of HISC or LOSC , then set point 1 will default

to the value of the function it is closest to.

4/ If you select a different INPT sensor this will cause the HISC and LOSC values to change to the

default values of the newly selected sensor. Then obviously the new HISC and LOSC values need to

check that set point 1 is still within these limits. For default values of HISC and LOSC see tables 3 / 4.

5/ The UNIT function has a number of options , but *C and *F are the options we need to consider here

, all other options PH ,RH ,PSI, etc. are treated the same as *C. A number of functions change their

values when you change UNIT and it depends which function you ve changed as to what type of

conversion is performed. The two types of conversion are absolute and relative.

Note that the 9500 instrument with a linear input selected ignores the setting of the UNIT

function.

Page 23

COMMERCIAL IN CONFIDENCE

Page 22

The absolute conversion uses the formula-

TempF abs = 32 +(TempCabs X 1.8 ) for converting *C to *F

And

TempC abs = TempF abs — 32 / 1.8 for converting *F to *C

The relative conversion uses the formula-

TempF rel =TempC rel X 1.8 for converting *F to *C

And

TempC rel = TempF rel / 1.8 for converting *C to *F

Here is a list of the functions that are effected by a *C to *F conversion, and if a relative or absolute

conversion is needed.

FUNCTION CONVERSION NOTES

Set point 1 Absolute

HISC Absolute

LOSC Absolute

OFST Relative

BAND Relative

BND.2 Relative

ZERO Relative

SPAN Relative

READ Relative

TECH Relative Conversion only performed on

OS1 US OS2

SET.2 Absolute/Relative Absolute — FSHI FSLO

Relative — DVHI DVLO BAND COOL

SET.3 Absolute/Relative Absolute — FSHI FSLO

Relative — DVHI DVLO BAND

HYS.3 Relative

Page 24

COMMERCIAL IN CONFIDENCE

Page 23

TABLE 1 MIN/MAX SENSOR FULL SCALE DEGREE C

SENSOR MIN MAX MIN 0.1 MAX 0.1

B 0 1800 0.0 999.9

E 0 600 0.0 600.0

J 0 800 0.0 800.0

K - 50 1200 - 50.0 999.9

L 0 800 0.0 800.0

N - 50 1200 - 50.0 999.9

R 0 1600 0.0 999.9

S 0 1600 0.0 999.9

T - 200 250 - 199.9 250.0

RTD - 200 400 - 199.9 400.0

LIN1 0 400 0.0 400.0

LIN2 - 25 400 - 25.0 400.0

LIN3 0 3000 0.0 999.9

LIN4 - 250 3000 - 199.9 999.9

LIN5 0 3000 0.0 999.9

LIN (9500

)

0 9999 N/A N/A

TABLE 2 MIN/MAX SENSOR FULL SCALE DEGREE F

SENSOR MIN MAX MIN 0.1 MAX 0.1

B 32 3272 32.0 999.9

E 32 1112 32.0 999.9

J 32 1472 32.0 999.9

K - 58 2192 - 58.0 999.9

L 32 1472 32.0 999.9

N - 58 2192 - 58.0 999.9

R 32 2912 32.0 999.9

S 32 2912 32.0 999.9

T - 273 482 - 199.9 482.0

RTD - 273 752 - 199.9 752.0

LIN1 N/A

LIN2 N/A

LIN3 N/A

LIN4 N/A

LIN5 N/A

LIN (9500

)

N/A

Page 25

COMMERCIAL IN CONFIDENCE

Page 24

TABLE 3 HI.SC / LO.SC DEFAULT SETTINGS DEGREE C

SENSOR DEFAULT LOSC DEFAULT HISC DEFAULT LOSC DEFAULT HISC

B 0 1800 0.0 999.9

E 0 600 0.0 600.0

J 0 800 0.0 800.0

K 0 1200 0.0 999.9

L 0 800 0.0 800.0

N 0 1200 0.0 999.9

R 0 1600 0.0 999.9

S 0 1600 0.0 999.9

T 0 250 0.0 250.0

RTD 0 400 0.0 400.0

LIN1 0 400 0.0 400.0

LIN2 0 400 0.0 400.0

LIN3 0 3000 0.0 999.9

LIN4 0 3000 0.0 999.9

LIN5 0 3000 0.0 999.9

LIN (9500

)

0 9999 N/A N/A

TABLE 4 HI.SC / LO.SC DEFAULT SETTINGS DEGREE F

SENSOR DEFAULT LO.SC DEFAULT HI.SC DEFAULT DEFAULT HI.SC

B 32 3272 32.0 999.9

E 32 1112 32.0 999.9

J 32 1472 32.0 999.9

K 32 2192 32.0 999.9

L 32 1472 32.0 999.9

N 32 2192 32.0 999.9

R 32 2912 32.0 999.9

S 32 2912 32.0 999.9

T 32 482 32.0 482.0

RTD 32 752 32.0 752.0

LIN1 N/A

LIN2 N/A

LIN3 N/A

LIN4 N/A

LIN5 N/A

LIN (9500

)

N/A

Loading...

Loading...