Page 1

59615 MaxVU Rail Std Controller Concise manual (EN)

59615-1 MaxVU Rail Standard Controller

Concise Manual

1. INSTALLATION

Installation Guidance

Installation should only be performed by technically competent personnel.

Standards compliance shall not be impaired when fitting into the final installation.

It is the responsibility of the installing engineer to ensure that the configuration is safe.

Local regulations regarding the electrical installation & safety must be observed.

Impairment of protection will occur if the product is used in a manner not specified by the

manufacturer.

Due to the low weight of this instrument there are no special lifting or carrying considerations.

Designed to offer a minimum of Basic Insulation only.

Ensure that supplementary insulation suitable for Installation Category II is achieved when fully

installed.

To avoid possible hazards, accessible conductive parts of the final installation should be

protectively earthed in accordance with EN61010 for Class 1 equipment.

Output wiring should be within a Protectively Earthed cabinet.

Sensor sheaths should be bonded to protective earth or not be accessible.

Live parts should not be accessible without the use of a tool.

When fitted to the final installation, an IEC/CSA APPROVED disconnecting device should be used

to disconnect both LINE and NEUTRAL conductors simultaneously.

Do not position the equipment so that it is difficult to operate the disconnecting device.

Ventilation slots must not be covered and adequate air circulation must be allowed.

Use conductor sizes 30-12 AWG, minimum temp rating of cables to be 80c.

Terminal Wiring

CAUTION: Check information label on housing for correct operating

voltage before connecting supply to Power Inputs.

Diagrams show all possible option combinations, check your exact

product specification before connecting.

2. FRONT PANEL

Navigation & Editing

Press or keys to navigate between parameters or menu items.

Press to highlight and edit a parameter value.

Press or to change the parameter value, then press within 60 seconds to

confirm change.

For example, changing the setpoint (SP).

Navigating to Setup Mode or Advance Configuration from Operator Mode:

Setup Mode - press & .

Advanced Configuration - press & .

Returning to Operator Mode:

Press & to move back one level. After 120 seconds without key presses the

unit returns automatically to the first Operator Mode screen.

3. SETUP (& FIRST POWER UP)

Important Note: When powered up for the first time, or after a factory reset (default) the

instrument enters Setup.

The device remains in Setup, or will keep powering up back into Setup, until all

parameters have been reviewed and the user exits Setup.

Some parameters may be hidden depending on configuration & hardware.

Alternatively press & to enter Setup from Operator screen and & to exit.

Setup Lock

Enter code & press

Default 10

Parameter

Description

Default Value

>Input

Type

J Thermocouple *

K Thermocouple

-200 – 1200ºC

-328 – 2192ºF

-128.8 – 537.7ºC

-199.9 – 999.9ºF

K Thermocouple *

-240 – 1373ºC

-400 – 2503ºF

-128.8 – 537.7ºC

-199.9 – 999.9ºF

PT100 *

-199 – 800ºC

-328 – 1472ºF

-128.8 – 537.7ºC

-199.9 – 999.9ºF

B Thermocouple

100 – 1824ºC

211 – 3315ºF

C Thermocouple

0 – 2320ºC

32 – 4208ºF

L Thermocouple *

0 – 762ºC

32 – 1403ºF

0.0 – 537.7ºC

32.0 – 999.9ºF

N Thermocouple

0 – 1399ºC

32 – 2551ºF

R Thermocouple

0 – 1795ºC

32 – 3198ºF

S Thermocouple

0 – 1762ºC

32 – 3204ºF

T Thermocouple *

-240 – 400ºC

-400 – 752ºF

-128.8 – 400.0ºC

-199.9 – 752.0ºF

Linear dc

0 – 20mA

0 – 50mV

0 – 5V

0 – 10V

4 – 20mA

10 – 50mV

1 – 5V

2 – 10V

>Input

Units

°C or °F (hidden when a linear input is used)

°C

* Maximum of 1 decimal place for temperature inputs marked.

>Input

Decimal Place

0000 *

000.0 *

00.00

0.000

0000

Scale Range max & min only visible when input is a linear type.

>Input

Scale Range Maximum

Maximum for application working range.

1000

>Input

Scale Range Minimum

Minimum for application working range.

0

>Input

Digital I/P Action

None

Alarm Reset (clears latched alarms)

Ctrl Enable/Disable (disables control)

Ctrl Auto/Manual

Pre-Tune Start/Stop

Tune at SP Start/Stop

Ctrl

Enable/Disable

>Output 1

Usage

Heat Power

Cool Power

Alarm 1

Alarm 2

Alm. 1or2

Loop Alarm

Heat Power

Control Loop Alarm time is 2x Integral (PID) or Loop Alarm Time (if mode is On.Off)

>Output 2

Usage

Same options as Output 1 Usage

Alarm 1

>Output 3

Usage

or

>Linear Outp

Usage

Same options as Output 1 Usage.

Heat

Cool

Retx PV

Retx SP

Alarm 2

Retx SP

>Linear Outp

Type

0-10V

2-10V

0-20mA

4-20mA

0-5V

1-5V

0-10V

>Linear Outp

Scale Range Maximum

Maximum PV value corresponding to

maximum linear output.

Input type Max

>Linear Outp

Scale Range Minimum

Minimum PV value corresponding to

minimum linear output.

Input type Min

>Alarm 1

Value

Range minimum to range maximum, or OFF

(maximum +1). OFF disables alarm.

Default PV High alarm type.

1373

>Alarm 2

Value

Same options as Alarm 1.

Default PV Low alarm type.

-240

Setpoint

Target setpoint.

0

>Coms Unit Address

Modbus address from 1 to 255

1

>Coms Baud Rate

1200, 2400, 4800, 9600, 19200 & 38400

9600

>Coms Parity

Odd, Even or None

None

>Control

Automatic Tuning

Off, Start Pre-Tune or Start Tune at SP *

Off

*Start Tune at SP not available for Heat & Cool processes.

When you exit if necessary, press and to clear Control is Enabled Pop Up Alert.

4. OPERATOR MODE

Name

Details

User Screen

PV - top

SP - bottom

Temperature Unit - right.

Manual control

Manual Power is shown as P%.

Transmitter view

enabled

Transmitter parameter = Enable, SP is

hidden.

Important: The device still functions as a

controller, using the local Setpoint.

Important: Visibility for parameters below must be set to Show in Operator sub-menu.

Alarm State

To clear

latches press

then to select

Yes.

Press to

accept.

Alarm active

Alarm set, but not

active

Alarm not set

Latch State

Output Latched

Latch set, but

output not Latched

Latch not set

Maximum PV

To clear press then to select

Yes. Press to accept.

Screens show the

Maximum & Minimum PV

reached.

Minimum PV

Control Enable

OFF - Control output(s) disabled. (Ignored when in manual mode).

ON - Control output(s) enabled.

Manual Control

Enable

OFF - Automatic control, PID or On-Off control available.

ON - Manual control, Manual Power shown as P% xxx.

Time On Remaining

On Timer

Visible when On Timer is active.

See Ramp & Timers diagram.

Delay Time

Remaining

Delay Timer

Visible when Delay Timer is active.

See Ramp & Timers diagram.

Warnings & Error Messages

Caution: Do not continue your process until any issues are resolved.

Name

Details

Pop up Alerts:

Warnings and

Confirmations

For example, Pop Up Alert for Alarm 1.

Pop Up Alerts need to be acknowledged.

Press and to clear Pop Up Alert.

Pop up Alerts: Alarm 1, Alarm 2, Alarm 1 & 2, Starting Calibration, Calibration Ongoing,

Calibration Fail, Control is Enabled, Tune Error messages, Tuning in progress, Setup

not Completed & Offset in use (SP offset).

ALARM

Alternates with PV to show Alarm is active.

LATCH

Alternates with PV.

One or more outputs are latched on and no alarm is active.

HIGH

Process variable input > 5% over-range.

LOW

Process variable input > 5% under-range.

OPEN

Break detected in process variable input sensor, wiring or wrong

input type selected. Shows OPEN until resolved, control is off.

ERROR

Selected input range is not calibrated.

Shows ERROR until resolved, control is off.

TUNE

Alternates with SP. Auto-tuning is in progress.

P%

Manual power value replaces setpoint, shows P% xxx of power.

Ramp

Alternates with actual setpoint. Setpoint ramp is active.

OFF

Control is disabled. Control output(s) are off.

Control Delayed

Visible when Delay Timer is active. Control output(s) are off.

Tuning in progress

Alternates with setpoint. Tuning is active.

Tune Errors

Display alternates between Tune Error & Setpoint.

Remains visible until Automatic Tuning is turned Off.

tErr1

PV within 5% of SP (for pre-tune)

tErr2

Setpoint is ramping

tErr3

Control is ON/OFF (not PID)

tErr4

Control is manual

tErr5

Tune at Setpoint not able to run

tErr6

Sensor Break

tErr7

Timer Running

tErr8

Control is Disabled

5. SPECIFICATIONS

Important: Check your product code for exact hardware fitted.

PROCESS INPUT

Thermocouple

Calibration:

0.25% of full range, 1LSD & 1°C for Thermocouple CJC.

BS4937, NBS125 & IEC584.

PT100 Calibration:

0.25% of full range, 1LSD.

BS1904 & DIN43760 (0.00385//°C).

DC Calibration:

0.25% of full range, 1LSD.

Sampling Rate:

4 per second.

Impedance:

>1M resistive, except dc mA (5) and V (47k)

Sensor Break Detection:

Thermocouple, RTD, 4 to 20mA, 10 to 50mV, 2 to 10V and 1 to

5V ranges only. Control outputs turn off at sensor break.

DIGITAL INPUT (Isolated or Non-Isolated version)

Functions:

Reset Alarm, Control Enable/Disable, Auto/Manual, Pre-Tune

Start/Stop or Tune at SP Start/Stop.

Signal:

Non-isolated - Open or Close only.

Isolated - Open (2 to 24Vdc) or Closed (<0.8Vdc).

Closed to Open transition = Reset, Enabled, Auto or Start.

OUTPUTS

Relay Contacts:

Form C SPDT (Op 1) / Form A SPST relay (other), 2A @ 250Vac.

Relay Lifetime:

>150,000 operations at rated voltage/current, resistive load.

SSR Driver Capability:

SSR drive voltage >10V at 20mA

Output 3 option only: DC (Linear)

Types:

0 to 20mA, 4 to 20mA, 0 to 5V, 0 to 10V or 2 to 10V

Load Resistance:

Current Output 500 max, Voltage Output 500 min.

Resolution:

8 bits in 250ms (10 bits in 1s typical, >10 bits in >1s typical).

RS485 SERIAL COMMUNICATIONS (Modbus RTU)

Data Rate:

1200, 2400, 4800, 9600, 19200 or 38400 bps.

OPERATING CONDITIONS

Usage:

For indoor use only, DIN-rail mounted in suitable enclosure.

Ambient Temp:

<95% humidity 0°C to 55°C (Operating), –10°C to 80°C (Storage).

Relative Humidity:

20% to 95% non-condensing.

Altitude:

< 2000m

Power Supply:

Mains power version - 100 to 240Vac 10%, 50/60Hz, 9VA

Low voltage version - 24Vac +10/-15% 50/60Hz 9VA or 24Vdc

+10/-15% 5W.

ENVIRONMENTAL

Standards:

CE, UL & cUL.

EMI:

EN61326-1:2013, Table 2 & Class A.

Warning: This is a Class A product. In a domestic environment, this product may cause

radio interference in which case the user may be required to take adequate measures.

Safety:

UL61010-1 Edition 3, EN61010-1 Version 2010,

Pollution Degree 2 & Installation Class 2.

Protection Rating:

IP20.

PHYSICAL

Unit Size:

Height - 99mm; Width – 22.5mm; Depth - 121mm

Ventilation:

A space of 80mm must be allowed above & below each unit.

Weight:

0.20kg maximum

ISOLATION

Ok /

Select

Up

Down

LEDs show respective output state: 1 2 3

Display turns off after 5, 15 or 30

minutes without key presses.

Bus Connector

pin-outs:

* Dedicated

configuration port

* NEVER DIRECTLY CONNECT DEDICATED CONFIGURATION SOCKET TO A USB PORT.

A

Data A

Data B

RS485 Data A (Rx/Tx+)

Communications

Output 3

Output 2

Power

Digital Input

RS485 Data B (Rx/Tx-)

Relay COM / Linear +

Relay NO / Linear -

Relay COM / SSR -

Relay NO / SSR +

Relay COM / SSR -

Relay NO / SSR +

Relay NC

Output 1

TC / RTD / Linear +

Volt-free or TTL

Compatible

L +

N -

TC / RTD / Linear -

RTD

B

Display shows PV (process variable),

units, SP (setpoint), alarm/latch

statuses, error & warning messages.

Input

Alarm State

Alarm 1

Alarm 2

Loop

Latch State

Out 1

Out 2

Out 3

Bus Connector (optional)

Mounting & Unmounting

Non-Isolated

Digital Input

Isolated Digital

Input

Configuration

Port

Configuration

Port

NonIsolated

Digital

Input

Isolated

Digital

Input

RS485 Comms

Not Applicable

No Isolation

Reinforced

Isolation

RS485

Comms

Linear

Linear

SSR

SSR

Relay

Relay

Universal Input

Universal

Input

PSU

PSU

or

Page 2

59615 MaxVU Rail Std Controller Concise manual (EN)

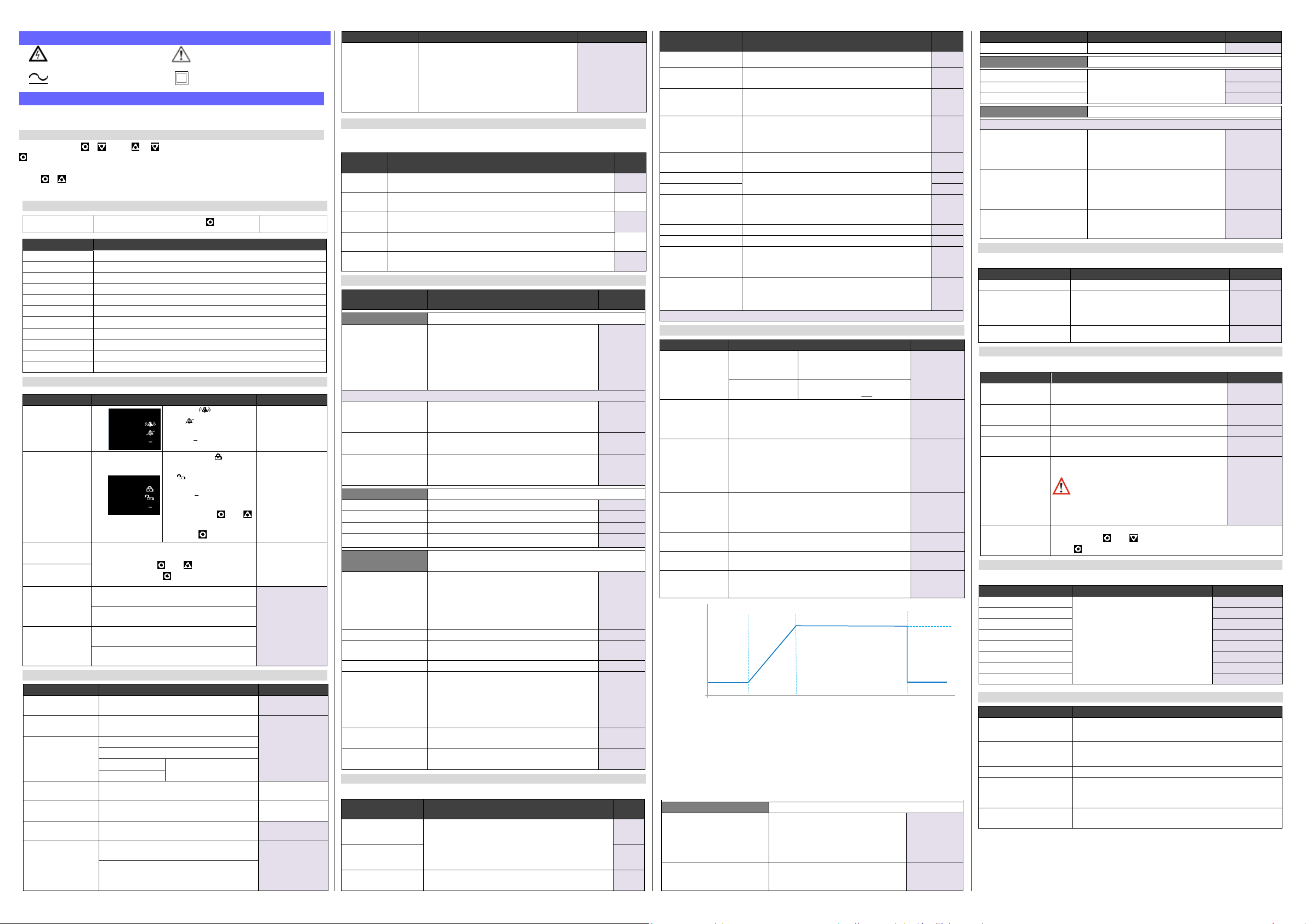

6. SAFETY & WARNING SYMBOLS

Risk of electric shock.

Caution, refer to the manual.

Alternating or direct current

could be present.

Equipment protected through-out

by double insulation.

7. ADVANCED CONFIGURATION

Advanced Configuration gives access to all possible parameters; however, the device

hides parameters that are irrelevant to your exact product specification & configuration.

Advanced Configuration Navigation

Enter by pressing & . Press or to navigate to the required menu, then press

to enter.

Press & to exit up 1 level. Depending upon which menu you enter it may be

necessary to exit 2 or 3 levels for Operator Mode.

Advanced Configuration main menu

Advanced Lock

Enter code & press

Default 20

Menus

Description

User

Includes Status, Control & Manual Mode enable/disable.

Input

Configure the process input.

User Calibration

Single or two-point calibration adjustments for the process input.

Outputs

Configuration parameters for the outputs.

Control

PID control tuning & configuration parameters.

Setpoint & Timer

Setpoint & timer settings.

Alarms

Alarm configuration.

Communication

Modbus communications settings.

Display

Lock codes and Factory Default.

Operator Screens

Control what appears in Operator Mode.

Information

View serial number & manufacturing details.

User

Parameter

Description

Default Value

Alarm State

Alarm active

Alarm set, but not

active

Alarm not set

n/a

Latch State

Output

Latched

Latch set but output

not Latched

Latch not set

To clear press then

to select Yes.

Press to accept.

n/a

Maximum PV

Maximum and Minimum PV recorded whilst

powered up or since last reset.

To clear press then to select Yes.

Press to accept.

n/a

Minimum PV

Control Enable

OFF - Control output(s) disabled. (Ignored

when in manual mode) SP replaced by OFF.

ON

ON - Control output(s) enabled. Setpoint visible

in User screen.

Manual Control

Enable

OFF - Instrument in automatic control mode

(PID or On-Off control).

OFF

ON - Manual control ON. Power shown as

Pxxx % in Operator mode, in place of SP.

Input

Parameter

Description

Default Value

Input Type

See Input Type table in SETUP (& FIRST

POWER UP).

K Thermocouple

Units

Displayed as °C or °F

(Units are hidden when a linear input is used)

°C

Decimal Place

0000

0000

000.0

00.00

Not for temperature.

0.000

Scale Range

Maximum

Maximum for application working range

Max allowed for

Input Type.

Scale Range

Minimum

Minimum for application working range

Min allowed for

Input Type.

Filter Time

OFF or 0.5 to 100.0 seconds in 0.5

increments

2.0

CJC Enable

Enable Enables the internal thermocouple

CJC (Cold Junction Compensation).

Enable

Disable Disables the internal CJC.

External compensation must be provided for

thermocouples.

Parameter

Description

Default Value

Digital I/P Action

None

Alarm Reset (clears latched alarms)

Ctrl Enable/Disable

Ctrl Auto/Manual

Pre-Tune Start/Stop

Tune at SP Start/Stop (not available for

heat/cool)

Ctrl Enable/Disable

User Calibration

Single-point offset or two-point calibration adjustment for process input. Can be used

together, if required.

Parameter

Description

Default

Value

Offset

Shifts the input value up or down by a single offset amount across

the entire range.

0

Low Point

Enter value at which the low point error was measured.

Lower

Limit

Low Offset

Enter equal, but opposite offset value to the observed low point

error.

0

High Point

Enter value at which the high point error was measured.

Upper

Limit

High Offset

Enter an equal, but opposite offset value to the observed high

point error.

0

Outputs

Parameter

Description

Default

Value >Output 1

Usage

Heat

Cool

Alarm 1

Alarm 2

Alm. 1or2

Loop Alarm

Heat

Control Loop Alarm is set as 2x Integral (PID) or Loop Alarm Time (On.Off control)

Alarm Action

Direct - Output active when alarm triggers

Reverse - Output active when alarm is not

triggered

Direct

Latching

Off - Alarm doesn’t latch

On – Alarm latches & needs to be cleared

Off

LED Indicator

Direct - LED Indicator lit when output is active

Reverse - LED Indicator lit when output is

inactive

Direct

>Output 2

Usage

Same options as Output 1 - Usage

Alarm 1

Alarm Action

Same options as Output 1 - Alarm Action

Direct

Latching

Same options as Output 1 - Alarm Latching

Off

LED Indicator

Same options as Output 1 - LED Indicator

Direct

>Output 3

or >Linear Outp

3rd output - either Relay/SSR driver (Output 3) or Linear.

>Output 3

Usage

>Linear Outp

Usage

Output 3 - same options as Output 1 - Usage

Heat

Cool

PV Retransmit

SP Retransmit

Output 3:

Alarm 2

Linear:

SP

Retransmit

>Output 3 Alarm Action

Same options as Output 1 - Alarm Action

Direct

>Output 3 Alarm

Latching

Same options as Output 1 - Alarm Latching

Off

>Output 3 LED Indicator

Same options as Output 1 - LED Indicator

Direct

>Linear Outp

Type

0-10V

2-10V

0-20mA

4-20mA

0-5V

1-5V

0-10V

>Linear Outp

Scale Range Maximum

Display value for maximum output, -1999 to 9999

Input type

Max

>Linear Outp

Scale Range Minimum

Display value for minimum output, -1999 to 9999

Input type

Min

Control

PID control tuning & configuration & Loop Alarm. Hidden if no control outputs are set.

Parameter

Description

Default

Value

Proportion Heat Band

ON/OFF (0.0) or PID control in display units.

1 to 9999 - 0 decimal places

0.1 to 999.9 - 1 decimal place

0.01 to 99.99 - 2 decimal places

0.001 to 9.999 - 3 decimal places

161

Proportion Cool Band

161

Auto Reset (Integral)

0.01 to 99.59.

and OFF (0.00) (minutes & seconds).

5.00

Parameter

Description

Default

Value

Rate (Derivative)

0.01 to 99.59 or OFF (0.00) (minutes & seconds).

1.15

Overlap/

Deadband

In display units, range -20 to +20% of Heat & Cool

Proportional Band

0

Differential

(On/Off)

Visible when using On/Off control.

In display units centred about the setpoint.

Range: 0.1% to 10.0% of input span

8

Loop Alarm Time

Visible when On/Off control & Loop Alarm assigned to

an output.

Sets time before the loop alarm triggers.

(minutes & seconds)

99.59

Manual Rst (Bias)

Manual Reset 0 to 100%

(-100% to 100% if heat/cool control)

25%

Heat Cycle Time

0.1 to 512.0 seconds

32.0

Cool Cycle Time

32.0

Output Interlock

Prevents simultaneous activation of both heat & cool

outputs. On / Off

Only set to On if Overlap/Deadband = 0.

Off

Heat Power Limit

% power upper limit 0 to 100%

100%

Cool Power Limit

% power upper limit 0 to 100%

100%

Power Up Action

Last - Powers up with control enable in the same state

as on power off or power failure.

On - Always powers up with control enabled.

Last

Automatic Tuning

Off

Start Pre-Tune

Start Tune at SP *

Off

*Start Tune at SP not available for Heat & Cool process.

Setpoint

Parameter

Description

Default Value

Enable Timer

Enabled

Enables the Delay and On

Timers. Applies at next powerup / control enable.

Disabled

Disabled

Delay and On Timers ignored.

(Setpoint ramping still functions.)

Delayed Start Time

Time from power-up or control enable before control

begins from 00.01 to 99.59.

or OFF (0.00. (hours & minutes)

If OFF control starts immediately.

OFF

Ramp Rate

Rate actual setpoint changes from current PV to

target setpoint following power-up or control enable.

From 0.001 to 9999.

or OFF (1000) (Units / hr).

Any setpoint changes also follow this rate.

OFF

On Time

The time the target setpoint will be maintained once

reached, from 00.01 to 99.59

or Off (00.00) (hours & minutes)

Infinite (100.00) - control remains on indefinitely.

Infinite

Upper Limit

Used to limit the Maximum setpoint value.

Scale Range

Maximum

Lower Limit

Used to limit Minimum setpoint value.

Scale Range

Minimum

Offset

Offsets the setpoint. For use in multi-zone setpoint

slave applications.

Offset in use pop-up appears when SP is changed.

0

Alarms

Parameter

Description

Default Value

>Alarm 1

Type

None

PV High

PV Low

Deviation

Band

PV High

Value

Range minimum to range maximum, or

OFF (maximum +1). OFF disables

alarm.

1373

Parameter

Description

Default Value

Hysteresis

0 to full span.

1

>Alarm 2

Type

Same options as Alarm 1

PV Low

Value

-240

Hysteresis

1

>Options

Alarm Inhibit temporarily deactivates alarms at power-up & on change in setpoint.

Alarm Inhibit

None

Alarm 1

Alarm 2

Alarm 1 & 2

None

Alarm Notification

None

Alarm 1

Alarm 2

Alarm 1 & 2

Alarm 1 & 2

Sensor Break Alarm

On - activates both alarms, if

configured, when a sensor break is

detected.

Off

Communications

Modbus communications settings, only shown when RS485 option is fitted.

Parameter Name

Description

Default Value

Unit Address

Modbus address from 1 to 255

1

Baud Rate

Coms data rate in kbps

1200, 2400, 4800, 9600, 19200 & 38400.

9600

Parity

Parity checking: Odd, Even or None

None

Display

Lock codes & Factory Defaults.

Parameter Name

Description

Default Value

Setup Unlock Code

View & adjust Setup lock code.

From 1 to 9999 or Off for no lock code.

10

Advanced Unlock

Code

View & adjust Advanced lock code.

From 1 to 9999 or Off for no lock code.

20

Screen Timeout

Screensaver time 5, 15 or 30 mins.

5

Selected language

Display language, 2 available – English plus either

German or French.

English

Transmitter

Transmitter view Enable hides the setpoint.

Important: The device still functions as a

controller even though SP is hidden.

For transmitter function, Linear Outp – Usage

must be PV Retransmit or SP Retransmit.

Disable

Reset to Defaults

Reset parameters back to factory defaults.

To clear press then to select Yes.

Press to accept.

Operator Screens

Controls what appears in Operator Mode.

Parameter Name

Description

Default Value

Control Enabled

Hide or Show parameters in Operator

Mode.

Hide

Manual Ctrl Enabled

Hide

Alarm State

Hide

Latch State

Show

Maximum PV

Hide

Minimum PV

Hide

Remaining On Time

Hide

Remaining Delay Time

Hide

Information (Read-Only)

Parameter Name

Description

PRL

DOM

The hardware/software revision level.

Date of manufacture (mmyy).

FW Version

FW Type

The firmware version number & code type.

Serial

Instrument serial number.

Out1

Out2

Out3

SSR (SSR driver) or Relay

SSR (SSR driver) or Relay.

None, SSR (SSR driver), Relay or Linear.

Comm

DI

Comms option - Fitted or None.

Digital Input options – Iso (isolated) or NonIs (non-isolated).

① ② ③

④

Ramp & Timers diagram – delay, ramp and timer

① From power up or control enable the unit delays process control until the Delay Timer

expires (time set by Delayed Start Time).

② Setpoint ramps from the current PV to the target setpoint at Ramp Rate (SPr indicates

ramping). If Ramp Rate is OFF the active setpoint steps directly to target setpoint.

③ When the active setpoint reaches the target setpoint, the On Timer counts down (time

set by On Time).

④ When the On Timer finishes the control switches off. If On Time is set to INF then the

control stays on.

Please refer to the full manual for further information on any topic.

Alarm State

Alarm 1

Alarm 2

Loop

Latch State

Out 1

Out 2

Out 3

Loading...

Loading...