Application guide for using communications option for

CAL 3300 / 9300 / 9400 / 9500P controllers - Doc: 33010 / 06 / 0106

Introduction

The 3300 / 9300/ 9400 / 9500P series controllers can all be ordered

or retrofitted with either an RS232 or RS485 serial communications

board. If the controller has the communication board fitted then skip

to the section titled Installation/cabling.

Feature RS232 RS485

Type of transmission lines Unbalanced Differential

Maximum number of drivers 1 128

Maximum number of receivers 1 128

Maximum cable length 15m 1200m

Maximum data rate 19.2Kb/sec 19.2Kb/sec

Maximum CMV +/- 25V +12 to –7V

The table lists the features of both RS232 and RS485 standards.

Cable: To ensure data integrity over long transmission distances, it is

recommended that good quality RS485 cable is used.

Recommended: RS485 - Belden 9841, RS232 - Belden 9501.

Available from leading cable distributors, and stocked by CAL.

Fitting a communications interface board

The RS232 and RS485 interface boards are interchangeable and are

fitted in exactly the same way, please read the fitting and safety

instructions before proceeding.

Caution: Live circuits can hold charge for short periods

after isolation from voltage supply.

Electrostatic precautions should be observed when

handling the controller out of its sleeve.

After isolating the controller from its supply, the controller front bezel

and circuit board assembly can be unplugged from the sleeve. Grasp

the bezel firmly by the recess on each side and pull. A screwdriver can

be used as a lever if required.

To fit the RS232 or RS485 interface you will require the following

parts, which are supplied with the interface.

Nylon full nut

Code: 082-042

Brass half nut

Code: 082-041

Nylon screw

Code: 082-028

Nylon spacer

Code: 082-012

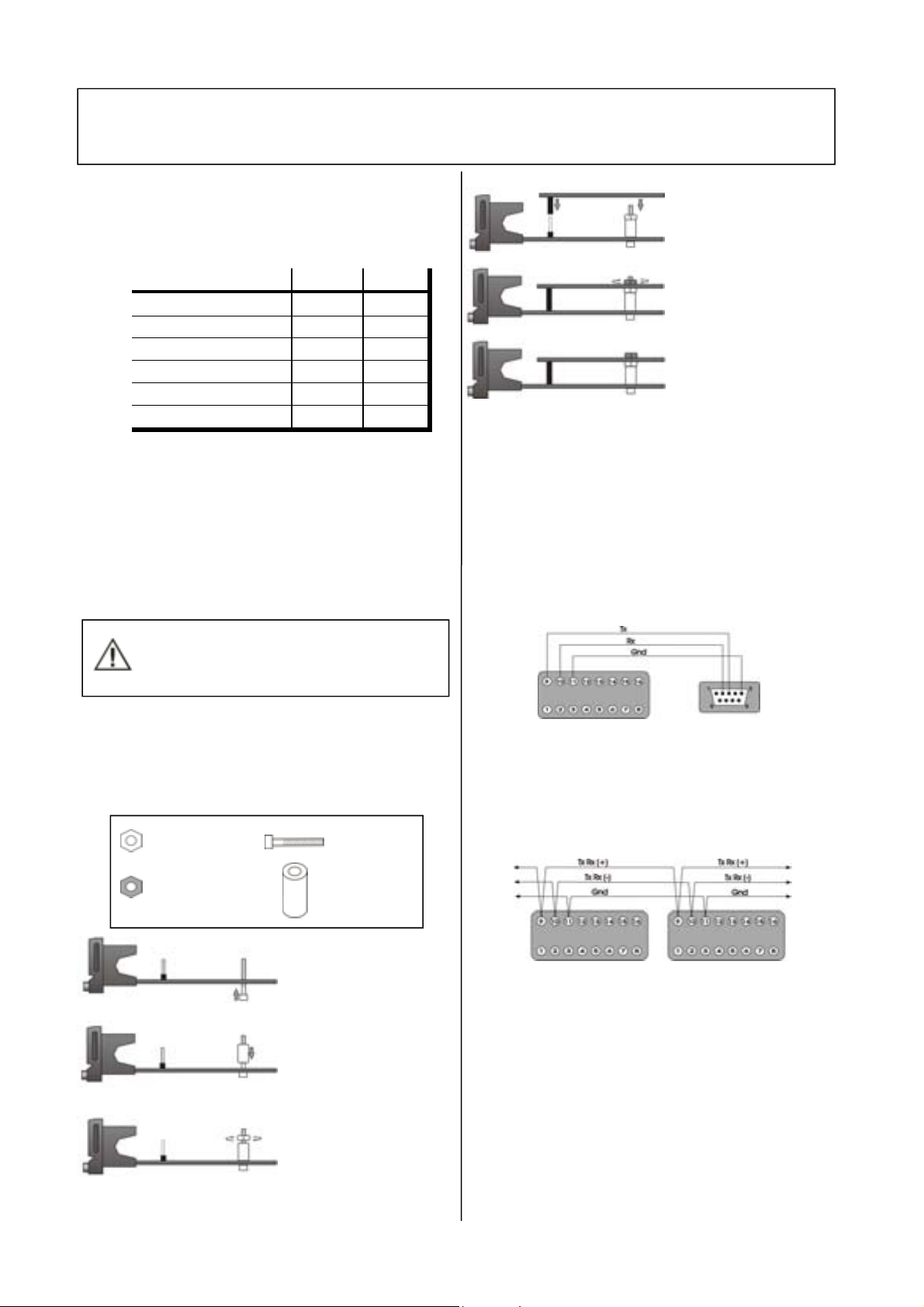

Plug the 5-way female connector on

the comms board into the 5-way

male connector on the controller

board ensuring that the connectors

are all in alignment. At the same time

ensure the hole in the comms board

fits over the screw thread

Screw the half nut onto the comms

board. Do not overtighten but ensure

that it’s tight enough to stop the

board from moving

Cut the top of the screw thread so

that it is level with the top of the

brass nut

Now you are ready to refit the controller into its case. To do this carefully slide

the PCB into the case aligning it with the connector arms at the rear. Then press

the bezel assembly firmly into the sleeve until the latch clicks in order to

compress the gasket and seal to NEMA4 / IP66

Installation / Cabling

RS232 Connections

RS232 has been widely used for interfacing peripherals to PC’s and is

designed for serial communications with a single instrument up to

distances of 15m, in a low electrical noise environment.

Connection is via a screened two-cored cable where the voltage

signal on each line is referenced to the screen which is grounded. .

Most PCs have one or two RS232 compatible ports fitted as standard.

If no RS232 ports are available, an RS232-USB converter cable may be

required.

Controller rear terminal

RS485 Connections

RS485 is half duplex serial communications link and is the standard

most commonly used for industrial applications due to its high noise

immunity and multi-drop capability. It enables a PC to communicate

with up to 128 instruments over distances of up to 1200m. The

option will require the addition of an RS485 interface card, or a

separate RS232 / RS485 converter.

To

Additional

units

PC com port

DB-9 Pin

To RS485

interface

Insert the nylon screw into the 3mm

diameter hole at the bottom left-hand

corner of the controller board.

Each RS485 interface or converter has specific connection and

Controller 1 Controller 2

termination biasing requirements which will be detailed in their

installation instructions. The general principles are as follows.

Place the spacer over the Nylon

screw thread.

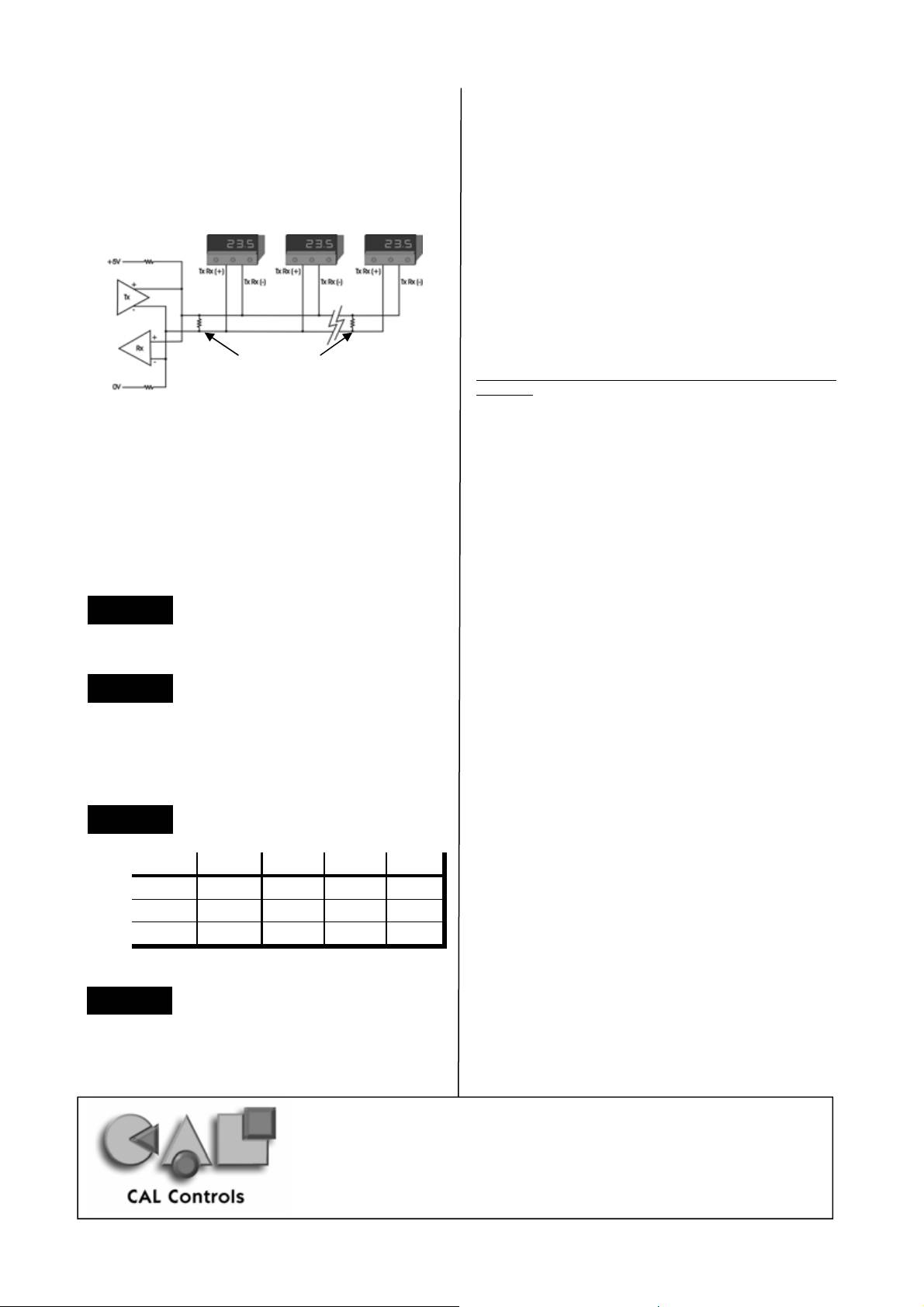

Terminations : Because each wire is a transmission line, it must be

properly terminated to prevent reflections. Where multiple

instruments are daisy chained together a 120Ω resistor should be

fitted at the connection to the PC and to the last instrument in the

chain. (see diagram overleaf). When fitting termination resistors it may

Screw the Nylon nut onto the screw.

Do not overtighten as this will damage

the screw thread.

be necessary to fit bias resistors and an external power supply as the

PC’s integral RS232 port cannot exude sufficient power.

Bias resistors: When transmission lines are not transmitting, they

remain in an indeterminate state which can allow receivers to receive

invalid data bits due to electrical noise on the cable. To prevent this,

the lines should be forced into a known state by fitting two 620Ω

bias resistors to one point (node), see diagram overleaf.

If an RS485 interface card or converter is being fitted to the PC,

separate bias resitors may not be needed because they may already

be fitted to the card. Check the manufacturers specification.

Please note that the KK systems converter supplied by CAL, includes

bias resistors and a jack socket for additional power supply.

As previously mentioned RS485 cards and converters differ greatly in

their requirements and therefore the installation instructions supplied

with the interface should be read carefully.

Bias resistor

620Ω

120Ω 120Ω

620Ω

Bias resistor

Termination resistors

Diagram showing bias and termination resistors

KK Systems K3-ADE TB RS232/485 converter.

If you purchased the KK Systems RS232 / 485 converter from CAL

Controls please refer to ‘ KK Systems K3-ADE TB - Application Guide’

for more details (our document number 33083)

Instrument Comms Settings.

Immediately after power-up, both instrument and PC comms settings

need to be made compatible before communication between them is

possible. Instrument defaults are shown below with available options.

Note: these parameters are found in ‘level C’ of the controller.

ADDR

(Address)

BAUD

(Baud rate)

DATA

(Data)

Settings Start bits Data bits Parity Stop bits

Default 1 8 n (none) 1

Option 1 1 8 e (even) 1

Option 2 1 8 o (odd) 1

DBUG

(Debug)

This is a unique identification number that must

be allocated to each instrument connected to

the network.

Default = 0. Options: 1 to 247

The setting determines the serial

communication data transmission rate in bits/

sec, this must match the PC settings.

Default = 9600. Options: 1200,2400

4800, 9600

19200.

Note: If a comms board has been retro-fitted

the default baud rate is 1200.

Sets the transmission format, this must match

the PC settings.

Data format table

Commissioning and troubleshooting aid. Display

shows when the instrument is transmitting or

receiving data by rapidly flashing three

horizontal segments of the first and last

segments of the display.

First Digit = Tx. Last Digit = Rx

Default = Off Options: off, on.

Only use dbuG during commissioning or trouble-shooting because it

shares display segments and therefore corrupts the normal display.

Configuring instrument comms settings

This should be done immediately after power up and is only possible

from the instrument front panel.

On power-up the controller will display the self test sequence

followed by alternating INPT and NONE

Note: During the following procedure the display will revert to

alternating INPT and NONE after 60 seconds of keying

activity, but will retain any settings already completed. Should this

occur or in the event of becoming ‘lost’ in the program, please start

again from the alternating INPT and NONE display.

To select Level C (communications settings)

Press T once display will alternates with LEVL and 5.

Press and hold À and press T five times to reach LEVL C.

Note: Level C is only visible when the comms interface board is fitted

to the unit.

To set the instrument comms address

Press S once display alternates between ADDR and 0.

Press and hold À and press S to index the chosen address number

(1 to 247)

Note: In the absence of any conflicting information the following

comms settings should be left as default values (see ‘instrument

comms settings’)

To read or adjust comms settings

Baud rate

Press S once display alternates BAUD and 9600

(default setting)

Press and hold À and use S or T keys to select preferred value.

Data Format

Press S once display will alternate DATA and 18N1

(default setting)

Press and hold À and use S or T keys to select preferred setting.

Debug setting

Press S once display alternates DBUG and OFF

(default setting)

Press and hold À and use S key to select ON

To enter settings into memory

Press and hold S and T for 3 seconds, display alternates

INPT and NONE.

To check settings; repeat the above procedure.

The unit is now ready to be configured from the PC.

Note: Where more than one instrument is connected to the system, it

is useful at this point to list them by location, title and comms

address. The list can then be used as a reference to ensure that the

instruments are given the same identity when configuring the comms

link from the PC.

Further Information

Go to www.cal-controls.com for more details.

Modbus communications guide -

programs from PC’s or PLCs.

CALpoll toolkit

code.

Visual Basic toolkit

CALgrafix

for Visual C++ developers include .exe and source

available via support@cal-controls.com .

charting logging and configuration software, which includes

an OPC-based client and server.

For engineers developing their own

Bury Mead Road, Hitchin, Herts, SG5 1RT, UK

CAL Controls Ltd

Tel +44 (0) 1462 436161

Fax +44 (0) 1462 451801

e-mail sales@cal-control.co.uk

www.cal-controls.com

1117 S. Milwaukee Av, Libertyville, IL60048, USA

CAL Controls Inc

Tel (847) 680-7080

Fax (847) 816-6852

e-mail sales@cal-control.com

33010/000M10/06/0106

Loading...

Loading...