Page 1

ITC 220 Base Station, Locomotive & Wayside

RADIO TRANSCEIVER FOR RAILROAD PTC

Field Service Guide

ITC 220 Transceivers

PN 0046300120 Rev. A

Revised August 2012

Page 2

REVISION HISTORY

REV

DATE

REVISION DETAILS

A

August 2012

Initial release. Part number 0046300120.

Page 3

Important Notice

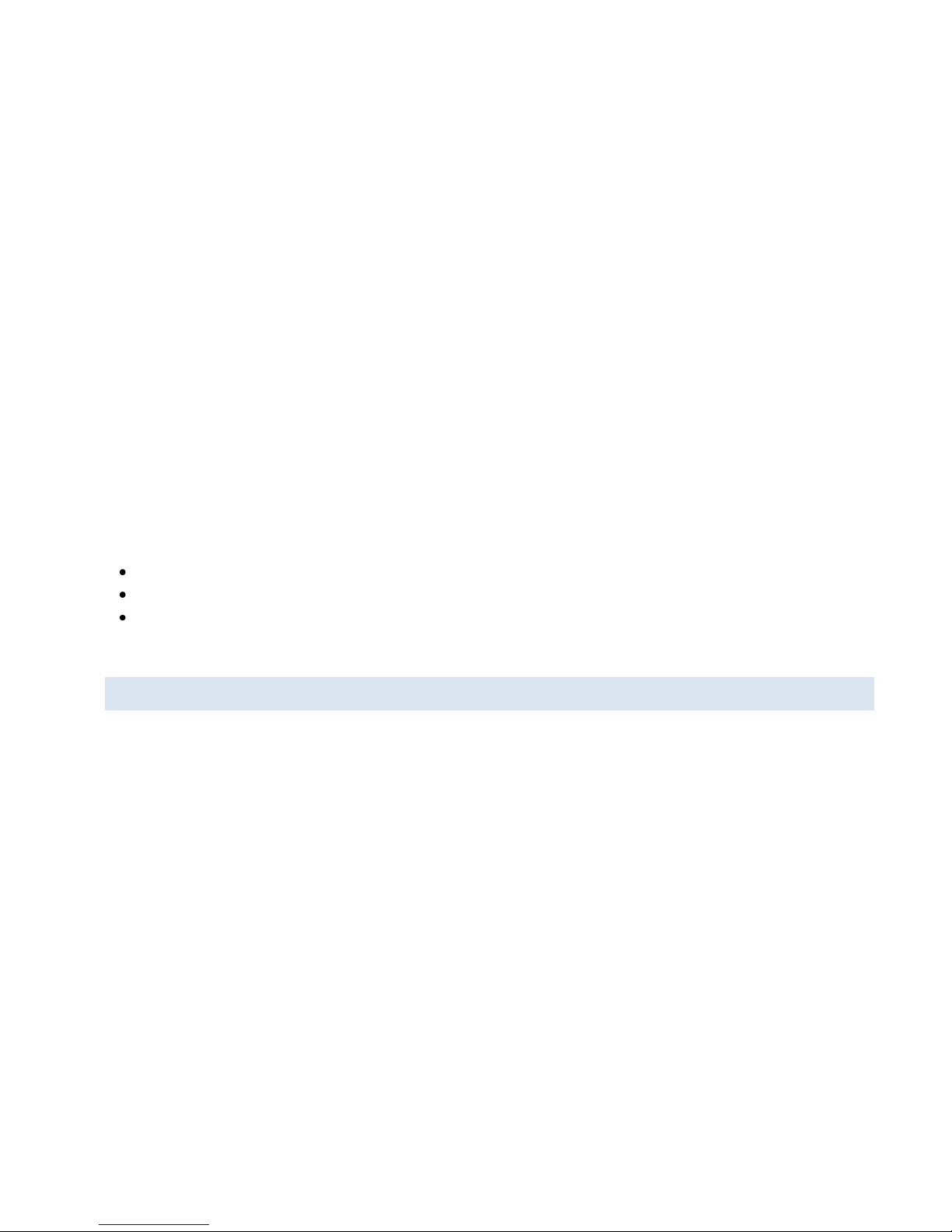

Radio Transceiver Model

Antenna application

Section and applicable table

ITC 220 Base Station Transceiver

Fixed installation

Section 6 Fixed Installations; Table 2 on Page 5

ITC 220 Locomotive Transceiver

Mobile installation

Section 4 Mobile Installations; Table 1 on Page 3

ITC 220 Wayside Transceiver

Fixed installation

Section 6 Fixed Installations; Table 2 on Page 5

ITC 220 Wayside Transceiver

Mobile installation

Section 4 Mobile Installations; Table 1 on Page 3

Because of the nature of wireless communication, transmission and reception of data can never be

guaranteed. Data may be delayed, corrupted (i.e. have errors), or be totally lost. Significant delays or losses

of data are rare when wireless devices such as CalAmp provides are used in a normal manner with a wellconstructed network. These products should not be used in situations where failure to transmit or receive

data could result in damage of any kind to the user or any other party, including but not limited to personal

injury or death, or loss of property. CalAmp accepts no responsibility for damages of any kind resulting from

delays or errors in data transmitted or received using the ITC 220 Base Station, Locomotive, or Wayside

Transceiver, or for failure to transmit or receive such data.

Copyright Notice

© Copyright 2012 CalAmp. All rights reserved.

Products offered may contain software proprietary to CalAmp or other parties. The offer of supply of these

products and services does not include or infer any transfer of ownership. No part of the documentation or

information supplied may be divulged to any third party without the express written consent of CalAmp.

CalAmp reserves the right to update its products, software, or documentation without obligation to notify

any individual or entity. Product updates may result in differences between the information provided in this

manual and the product shipped. For access to the most current product documentation and application

notes, visit www.calamp.com.

RF Exposure Compliance Requirements

The ITC 220 Base Station, Locomotive, and Wayside Transceivers are intended for use in the

railroad industry as Interoperable Train Control (ITC) Radio (ITCR), which is an important

component of Positive Train Control (PTC). The ITC 220 Base station, Locomotive, and

Wayside Transceiver units must be professionally installed and must ensure a minimum

separation distance between the antenna or radiating structure and any person. Refer to

Table 1 and 2 on pages 3 and 4 of the RF Energy Exposure Guide for ITC 220 Base Station,

Locomotive, and Wayside Transceivers Installed in Vehicles or at Fixed Sites for

recommended minimum lateral distance, as applicable for the antenna application, type of antenna, and

transmitting power.

It is the responsibility of the user to guarantee compliance with the FCC MPE regulations when operating this

device in a way other than described above. The installer of this equipment must ensure the antenna is

located or pointed such that it does not emit an RF field in excess of Health Canada limits for the general

population.

ITC 220 Base Station, Locomotive, and Wayside Transceivers use a low power radio frequency transmitter.

The concentrated energy from an antenna may pose a health hazard. People should not be in front of the

antenna when the transmitter is operating.

Recommended safety guidelines for the human exposure to radio frequency electromagnetic energy are

contained in the Canadian Safety Code 6 (available from Health Canada), the Federal Communications

Commission (FCC) Bulletin 65 and the Council of the European Union’s Recommendation of 12 July 1999 on

the limitation of exposure of the general public to electromagnetic fields (0 Hz to 300 GHz) (1999/519/EC).

Any changes or modifications not expressly approved by the party responsible for compliance (in the

country where used) could void the user’s authority to operate the equipment.

ITC 220 Base Station, Locomotive & Wayside Radio Transceiver Field Service Guide PN 0046300120 Rev. A | Page i

Page 4

TABL E OF CONTENTS

1 Overview ......................................................................................................................................... 1

1.1 General Description ............................................................................................................................................... 1

1.2 Operational Characteristics .................................................................................................................................... 2

1.3 Physical Description ............................................................................................................................................... 4

1.3.1 Base Station Transceiver ............................................................................................................................... 4

1.3.2 Locomotive Transceiver ................................................................................................................................ 7

1.3.3 Wayside Transceiver ..................................................................................................................................... 8

2 Follow Established Safety Guidelines ........................................................................................... 13

2.1 Electrical Safety .................................................................................................................................................... 13

3 Important Information for the User ............................................................................................. 13

3.1 Transmitter Warm-up Period (Base Station Transceiver Only ............................................................................. 13

3.2 Limiting RF Exposure ............................................................................................................................................ 13

3.3 Fixed Antenna Guidelines .................................................................................................................................... 14

3.4 RF Interference to Residential Receivers ............................................................................................................. 14

3.5 Equipment Modifications ..................................................................................................................................... 15

4 Transmitter Operation .................................................................................................................. 15

4.1 Transceiver Channelization And Frequency Range .............................................................................................. 15

4.2 Base Channel Restrictions .................................................................................................................................... 15

4.3 Transceiver-Radiated Power Limits ...................................................................................................................... 15

5 Transceiver Service ....................................................................................................................... 18

5.1 Recommended Equipment .................................................................................................................................. 18

5.2 Routine Maintenance........................................................................................................................................... 19

5.3 Visual Inspection .................................................................................................................................................. 21

5.3.1 Confirm SD Memory Card (CIM) is Installed and Seated ............................................................................ 21

5.3.2 LED Diagnostics ........................................................................................................................................... 21

5.4 Configure Computer Ethernet Ports to Communicate with the Transceiver ....................................................... 22

5.4.1 To Configure the Computer Ethernet 1 Interface for Communication with the Transceiver MAINT Port . 23

5.4.2 To Configure the Computer Ethernet 2 Interface for Communication with the Transceiver LAN Port ...... 25

5.4.3 Creating an XtermW Connection Profile ..................................................................................................... 28

5.4.4 Verify That the MAINT and LAN Ethernet Ports Are Operational ............................................................... 29

5.5 Review the Power On Self-Test (POST) Results .................................................................................................... 30

5.6 Verify Front Panel LEDS Are Operational (All Transceiver Types) and Verify Cooling Fans Are Operational (Base

Station Transceivers Only) ................................................................................................................................... 30

5.6.1 Verify All Front-Panel LEDs Are Operational ............................................................................................... 30

ITC 220 Base Station, Locomotive & Wayside Radio Transceiver Field Service Guide 0046300120 Rev. A | Page ii

Page 5

5.6.2 Verify Cooling Fans Are Operational (Base Station Transceivers Only) ...................................................... 32

5.7 Verify Settings That Allow the Transceiver to Transmit ....................................................................................... 33

5.7.1 Verify Transceiver Calibration Is Locked ..................................................................................................... 33

5.7.2 Verify the Transceiver is Commissioned ..................................................................................................... 34

5.8 Determine and Verify or Set GPS Coordinates (Base Station and Wayside Transceivers Only) .......................... 35

5.9 Transceiver Test and Adjustment Procedures ..................................................................................................... 35

5.9.1 Required Equipment ................................................................................................................................... 35

5.9.2 Measure and Adjust Peak RF Power Output ............................................................................................... 36

5.9.3 Measure Full-Rate Receiver Sensitivity ....................................................................................................... 46

5.9.4 Put a Trace On a Feature ............................................................................................................................ 48

5.10 Managing Software Application Images .............................................................................................................. 50

5.10.1 Determining Software Image Status ........................................................................................................... 51

5.10.2 Updating Software Images.......................................................................................................................... 52

5.10.3 Rolling Back an Image ................................................................................................................................. 56

5.10.4 Maintaining Multiple Software Images in the Transceiver ......................................................................... 58

6 Troubleshooting ............................................................................................................................ 60

6.1 Guidelines for Troubleshooting Common Problems ............................................................................................ 60

6.2 Power Problems ................................................................................................................................................... 61

6.3 SD Memory Card Problems .................................................................................................................................. 61

6.4 Antenna Problems................................................................................................................................................ 62

6.5 Transmission Problems ........................................................................................................................................ 63

6.6 Reception Problems ............................................................................................................................................. 64

6.7 Ethernet Connectivity Problems .......................................................................................................................... 64

6.8 RF Link Problems .................................................................................................................................................. 65

6.9 A Remote Transceiver Does Not Establish an RF Connection to the Base Station Transceiver ........................... 66

APPENDIX A — Abbreviations and Definitions ................................................................................... 68

APPENDIX B — Possible RF Antenna Configurations .......................................................................... 70

B.1 Base Station Transceiver ........................................................................................................................................... 70

B.2 Locomotive Transceiver ............................................................................................................................................ 71

B.3 Wayside Transceiver ................................................................................................................................................. 71

APPENDIX C — Block Diagrams ........................................................................................................... 72

C.1 Base Station Transceiver ........................................................................................................................................... 72

C.2 Locomotive Transceiver ............................................................................................................................................ 73

C.3 Wayside Transceiver ................................................................................................................................................. 73

APPENDIX D — Transceiver Cables ..................................................................................................... 75

D.1 Transceiver Power Cables ......................................................................................................................................... 75

D.1.1 Base Station Transceiver Power Cable .............................................................................................................. 75

ITC 220 Base Station, Locomotive & Wayside Radio Transceiver Field Service Guide PN 0046300120 Rev. A | Page iii

Page 6

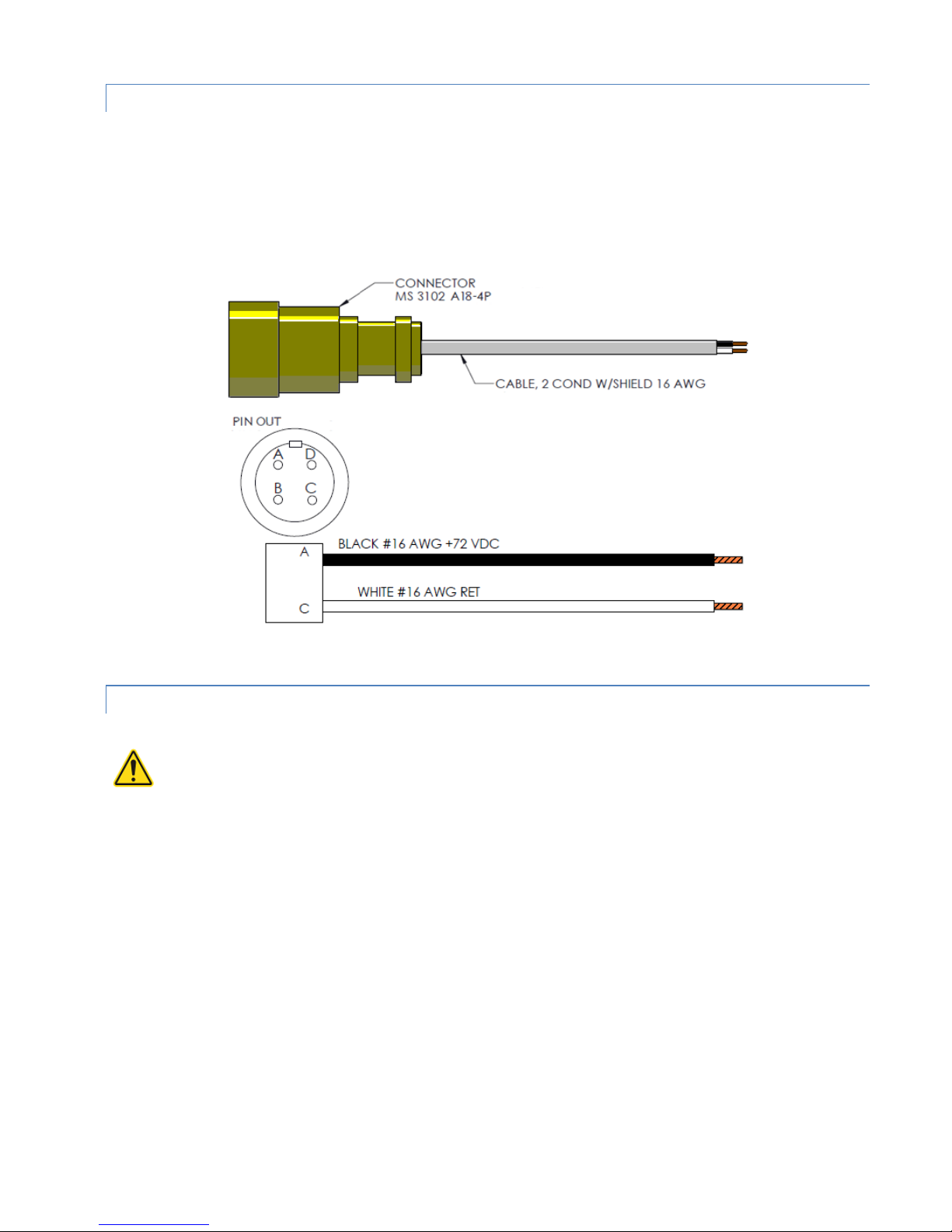

D.1.2 Locomotive Transceiver Power Cable ............................................................................................................... 76

D.1.3 Wayside Transceiver Power Cable .................................................................................................................... 76

D.2 Ethernet Cables ........................................................................................................................................................ 77

Base Station and Wayside Transceiver Ethernet Cables............................................................................................. 77

Locomotive Transceiver Ethernet Cable ..................................................................................................................... 77

APPENDIX E — GPS Satellite Constellation Overview and Antenna Planning Considerations ........... 79

E.1 GPS Satellite Constellation Overview ........................................................................................................................ 79

E.2 GPS Antenna Planning Considerations ...................................................................................................................... 79

E.2.1 Minimize Potential of GPS Antenna Issues ........................................................................................................ 80

E.2.2 Determine GPS Coordinates .............................................................................................................................. 81

APPENDIX F — Sample POST Results Typical for Properly Functioning Transceivers ........................ 84

APPENDIX G — Program Signal Generator for DQPSK ....................................................................... 87

G.1 Program Agilent E4438C to Test Transceivers with Sprints 18 to 23.02b ................................................................ 87

G.2 Program Agilent E4438C to Test Transceivers with Sprint 23.03 and Upward ........................................................ 89

G.3 Program F4438C Signal Generator for MSGPS (Multi-Satellite GPS) ........................................................................ 91

APPENDIX H — Forward Error-Correction Data-Packet Format Table ............................................... 92

APPENDIX I — Command Security ...................................................................................................... 93

I.1 Log On To the Transceiver ......................................................................................................................................... 93

I.2 Log Off From the Transceiver ..................................................................................................................................... 94

I.3 Change Your Transceiver Password ........................................................................................................................... 94

I.3.1 Forget Your Password? ....................................................................................................................................... 95

APPENDIX J — Commonly Used Diagnostic Commands ..................................................................... 96

INICHECK ..................................................................................................................................................................... 96

LINKSTAT ..................................................................................................................................................................... 96

REV ............................................................................................................................................................................. 97

STAT,RF ....................................................................................................................................................................... 97

STAT,HRX ..................................................................................................................................................................... 98

ITC 220 Base Station, Locomotive & Wayside Radio Transceiver Field Service Guide PN 0046300120 Rev. A | Page iv

Page 7

1 OVERVIEW

This ITC 220 Radio Transceiver Field Service Manual provides important electrical safety and radio-frequency

compliance information, and field service information for CalAmp ITC 220 Base Station, Locomotive, and Wayside

Transceivers.

This manual provides essential information for personnel who perform the following on ITC 220 Radio Transceivers,

including:

Field Service maintenance, minor repair, or replacement

Verification or transceiver operation, software settings, and radio characteristics

Advanced troubleshooting

Prerequisites for users of this manual who perform the above include:

Ability to work with standard radio-frequency (RF) test equipment, including knowledge of how to prevent personal

injury and equipment damage.

Ability to measure RF power, frequency, and other quantities, and analyze RF performance.

Working knowledge of the XtermW terminal emulation application that is used to configure and install updates in

the radio transceivers.

Familiarity with means to limit RF exposure from antennas and familiarity with the RF Energy Exposure Guide for ITC

Base Station, Locomotive, and Wayside Transceivers Installed in Vehicles or at Fixed Sites.

Familiarity with installation procedures in the Installation Guides for the Base Station, Locomotive, and Wayside

Transceivers.

Related Documents

Other documents related to this ITC 220 Radio Transceiver Field Service Guide include:

ITC 220 Base Station Transceiver Installation Guide; CalAmp PN 133991

ITC 220 Locomotive Transceiver Installation Guide; CalAmp PN 133971

ITC 220 Wayside Transceiver Installation Guide; CalAmp PN 133981

RF Energy Exposure Guide for ITC 220 Base Station, Locomotive, and Wayside Transceivers Installed in Vehicles or at

Fixed Sites; CalAmp PN 134069

Because installation of each type of radio transceiver is covered in the above-listed Installation Guides, installation

instructions are not repeated in this Field Service Guide. This Field Service Guide covers field service and advanced

troubleshooting topics beyond the scope and purpose of the Installation Guides.

1.1 GENERAL DESCRIPTION

Positive Train Control (PTC) is a technology solution that prevents train-to-train collisions, over-speed derailments,

movement of a train through a switch left in the wrong position, and incursion of trains into maintenance of way work

limits. Interoperable Train Control (ITC) defines industry-standard messaging and communication protocols that

support PTC and ensure interoperability between components.

CalAmp’s line of ITC 220 Radio Transceivers for locomotive, base station, and wayside applications are manufactured

specifically for use by North American Railroads for PTC applications. Operating between 217.6 to 222 MHz, these

multi-channel software-defined radio transceivers meet railroad requirements for ITC and are designed to meet

relevant railroad specifications for operation in the harshest environments. With high power capacity, CalAmp’s ITC

ITC 220 Base Station, Locomotive & Wayside Radio Transceiver Field Service Guide PN 0046300120 Rev. A | Page 1

Page 8

220 Radio Transceivers provide wireless packet data transport between locomotives, base stations, and wayside

locations.

Base Station Transceivers are installed at fixed locations and provide RF connectivity between back office and remote

applications. The backhaul between the Base radio transceiver and the Back Office is typically in the range of 56 kbps to

1 Mbps. Base Station Transceivers provide radio coverage to all wayside and operational locomotive transceivers in the

system.

Locomotive Transceivers are remote radios installed in the cab of locomotives and are the mobile element of the ITC

220 network. A Locomotive Transceiver communicates with the Back Office through a Base Station over a 220 MHz RF

link. Te establish this link, a Locomotive transceiver registers with the Base transceiver. As long as the Base is the best

link available, the locomotive will continue to communicate with the Back Office through that Base.

Wayside Transceivers are typically installed at waysides as remote, fixed location radios. In this application they provide

wayside signal status, switch position, and track integrity information to locomotives and must communicate with

locomotives even when there is no Base Radio coverage. Wayside radios enable wayside sites to communicate with the

Back office for maintenance and other purposes. Some wayside radios may have access to the Back Office through a

broadband connection.

The Base Station Transceiver, Locomotive Transceiver, and Wayside Transceiver form the transportation backbone on

which a messaging application provides communication capabilities between railroad assets and their back offices.

ITC 220 Base Station, Locomotive, and Wayside Transceivers are designed to meet the following specifications:

AAR Standard S-5702

ANSI/TIA-603-C-2004

MIL-STD-810E

1.2 OPERATIONAL CHARACTERISTICS

ITC 220 radio transceivers are designed to satisfy industry-standard ITC requirements as part of an integrated 220 MHz

radio (ITCR) network supporting the implementation of PTC systems. These transceivers are designed to provide

communication in an interoperable fashion enabling messages to occur across railroad boundaries.

Base Station Transceivers are available in two configurations, one of which requires +24 VDC nominal input power, and

the other requires +48 VDC nominal input power. Both models are almost identical, with the exception of their nominal

input power requirements.

ITC 220 radio transceivers have the following operational characteristics, with differences noted where they appear for

each of the three types of transceivers, and for +24 VDC and +48 VDC models of the Base Station Transceivers.

(Specifications are subject to change without notice.)

General

Frequency Range: 217.6-222.0 MHz

Channel Spacing: 25 kHz

Temperature Range: Operating: Base Station: -30°C to +70°C; Locomotive & Wayside -40°C to +70°C

Storage: -55°C to +85°C (Base Station, Locomotive & Wayside)

Operating Humidity: 0 - 95% non-condensing

ITC 220 Base Station, Locomotive & Wayside Radio Transceiver Field Service Guide PN 0046300120 Rev. A | Page 2

Page 9

Frequency Stability: Base Station: +/- 0.1 ppm over operating temperature range;

Locomotive & Wayside: +/- 1.5 ppm over operating temperature range

DC Input Voltage Base Station 48 V model: 42-54 VDC; Damage limit 60 VDC

Base Station 24 V model: 21-27 VDC; Damage limit 30 VDC

Locomotive: 45–100 VDC, Damage limit 120 VDC

Wayside: 10.9–15.5 VDC, Damage limit 17 VDC

DC Current Draw: Base Station 48 V model: Transmit: 6 A (peak) max. into 50 ohm load; 4 A typical;

Receive: 0.6 A max. while receiving

Base Station 24 V model: Transmit: 11 A (peak) max. into 50 ohm load; 7.5 A typical;

Receive: 1.2 A max. while receiving

Locomotive: Transmit: 4 A (peak) max. into 50 ohm load, 1.8 A typical;

Receive: 0.5 A max. while receiving

Wayside: Transmit 10 A (peak) max. into 50 ohm load, 7.5 A typical;

Receive: 1 A max. while receiving

DC Power Connector: Base Station: Threaded 5/16-18 studs for ring lug connection

Locomotive: MS 3102 A18-4P or equivalent

Wayside: Wago p/n 231-833/001-000

Size: Base Station: 19.2 in. width × 17.8 in. depth × 7 in. height (4U)

(Occupies 5U max. when installed with a vented shelf in a 19" EIA rack)

Locomotive: 6.2 in. (5×MCU) width × 12.8 in. depth × 9.2 in. height

(Occupies 5×MCU when installed in an LSI rack)

Wayside 15.5 in. width × 9.5 in. height × 2.0 in. depth

(Lugged back-plate allows mounting to 19" EIA rack horizontal bars)

Weight: Base Station: 27 lbs. (12 kg) approximate; <40 lbs. (18 kg) rack w/vented shelf

Locomotive: < 22 lbs. (10 kg)

Wayside: < 8 lbs. (5.5 kg)

Antenna Connector: Base Station: Three (3) Type N female: One (1) TX/RX (single antenna install), One (1)

RX1 (multi-antenna RX only), One (1) RX2 (diversity RX only)

Locomotive: Two (2) Type N female: One (1) TX/RX1 (transmit / primary receive), One

(1) RX2 (diversity)

Wayside: One (1) Type N female (TX/RX, no diversity support)

GPS Receiver: Base Station & Wayside: Active or passive antenna; Antenna power: 3.3 V 50 mA max;

Antenna connector: TNC female

Locomotive: None (GPS function is separate from the ITC 220 Locomotive Transceiver)

External Interface: Base Station & Wayside: Two (2) Ethernet 10/100 Mbps: One (1) data network port,

RJ-45; One (1) maintenance port, RJ-45

Locomotive Two (2) Ethernet: One (1) data network port, M12 – 8 pin

female; One (1) maintenance port, M12 - 8 pin female

Configuration Interface Module (CIM): SD Card

Display: Activity and diagnostic LEDs on front panel

Regulatory: Base Station & Locomotive: Complies with FCC Parts 2, 15, and 90;

Industry Canada SRSP-512

Wayside: Complies with FCC Parts 2, 15, and 90

ITC 220 Base Station, Locomotive & Wayside Radio Transceiver Field Service Guide PN 0046300120 Rev. A | Page 3

Page 10

Transmitter

RF Power Output: Base Station: 75 W PEP; adjustable to 10-75 W PEP

Locomotive: 50 W PEP; adjustable to 15-50 W PEP

Wayside: 25 W PEP; adjustable to 7.5-25 W PEP

Output Impedance: 50 ohms; Operating VSWR < 3:1

Modulation Waveforms: Base & Locomotive: 16 kbps pi/4DQPSK (linear); 32 kbps pi/4DQPSK (linear)

Wayside: 16 kbps pi/4DQPSK (linear)

Occupied Bandwidth: Meets 47CFR90.210 (f), five aggregated channels

Modulation Designators: Base & Locomotive: 16 kbps: 8K90DXW; 32 kbps: 17K8DXW

Wayside: 16 kbps: 8K90DXW

Conducted Spurious Emissions: – 25 dBm max.

Max. Duty Cycle Rating: Base Station: 50 %

Locomotive: 30 %

Wayside: 10 %

Receiver

Maximum Usable Sensitivity, Static BER<10-4: 16 kbps -111 dBm; 32 kbps -108 dBm

Adjacent Channel Selectivity: 70 dB at 25 kHz offset

Spurious Response Rejection: 70 dB

Intermodulation Response Rejection: 65 dB

High Input Level (-7 dBm) Locomotive only: BER < 10-4

Blocking (1 MHz offset) 80 dB

Number of Simultaneous Receiver Channels:

Base Station (24V & 48V) and Locomotive: Sixteen (16) paired as: eight (8) diversity;

seven (7) 16 kbps; one (1) auto 16 kbps/32 kbps

Wayside: Two (2) (no diversity support): One (1) 16kbps;

one (1) auto 16 kbps/32 kbps

1.3 PHYSICAL DESCRIPTION

1.3.1 BASE STATION TRANSCEIVER

The ITC 220 Base Station Transceiver is housed in a 4 unit-height (allow 5 unit height to mount with a vented shelf

underneath), 19-inch rack-mountable sheet metal chassis. Repositionable brackets allow for mounting the chassis in

forward or mid-plane positions in 19-inch channel-rack installations.

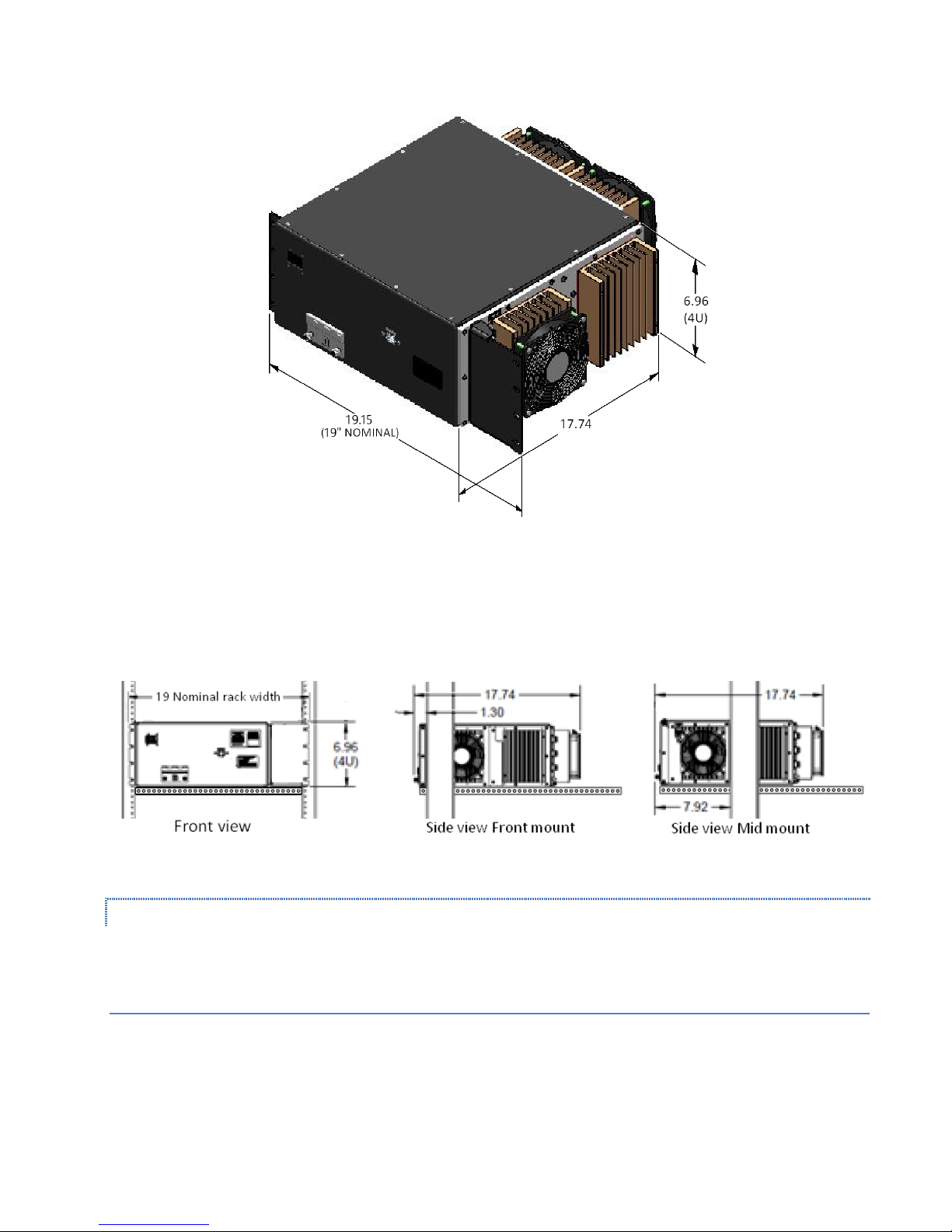

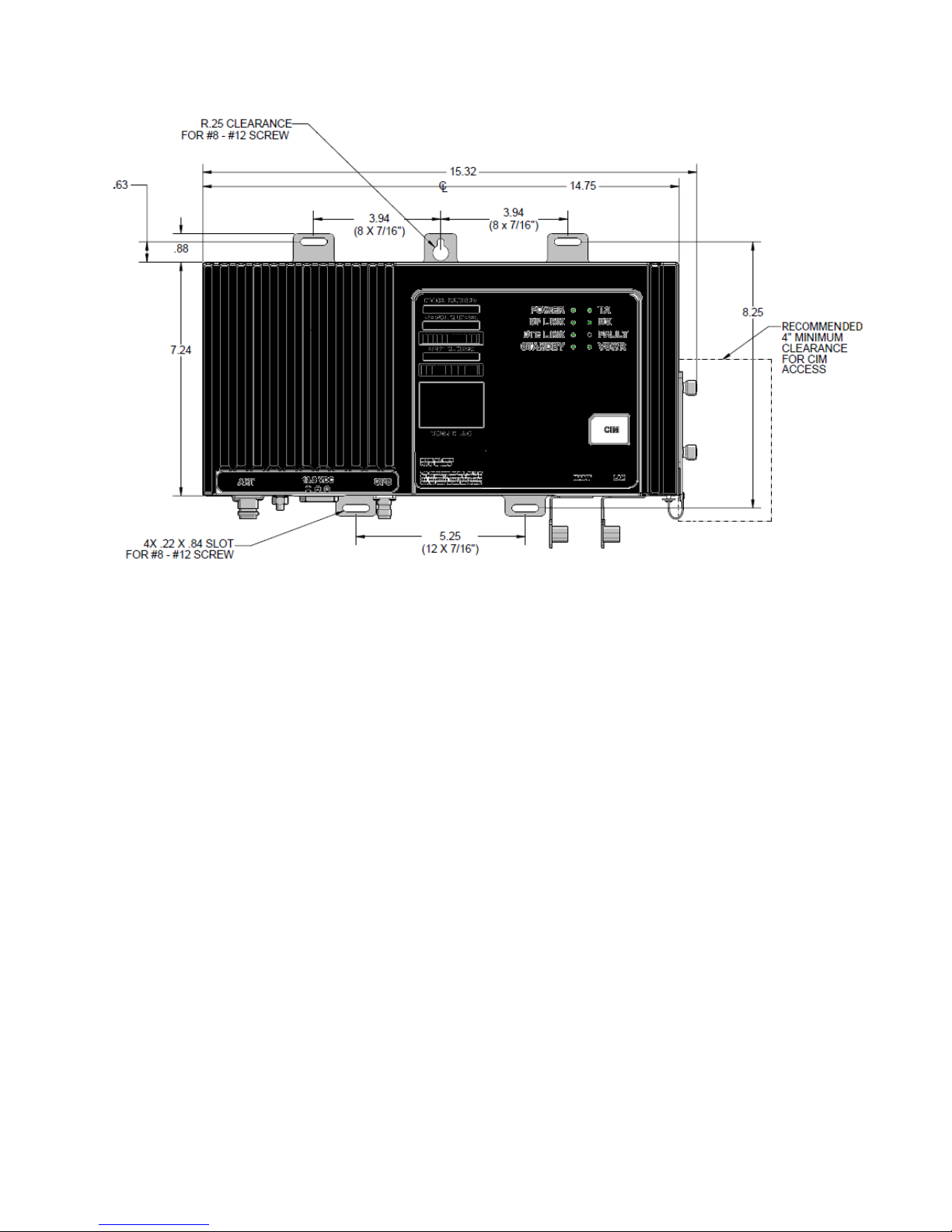

1.3.1.1 BASE STATION TRANSCEIVER DIMENSIONS

Overall dimensions of the ITC 220 Base Station Transceiver are 19.15 in. width × 17.74 in. depth × 6.96 in. (4U) height,

as shown in Figure 1, which follows.

ITC 220 Base Station, Locomotive & Wayside Radio Transceiver Field Service Guide PN 0046300120 Rev. A | Page 4

Page 11

Figure 1 ITC 220 Base Station Transceiver overall dimensions

(Dimensions shown are in inches.)

Reconfigurable mounting brackets allow the Base Station Transceiver to be front mounted or mid mounted in EIA 19"

rack applications. Dimensions of the unit as mounted in either of these configurations are shown in Figure 2 below.

(Dimensions shown are in inches.)

Figure 2 Base Station Transceiver overall dimensions in front mount and mid mount configurations in EIA 19" rack

1.3.1.2 BASE STATION TRANSCEIVER CONNECTIONS

All physical connections and interfaces are located on either the front or rear panel of the Base Station Transceiver.

1.3.1.2.1 BASE STATION TRANSCEIVER FRONT PANEL CONNECTIONS

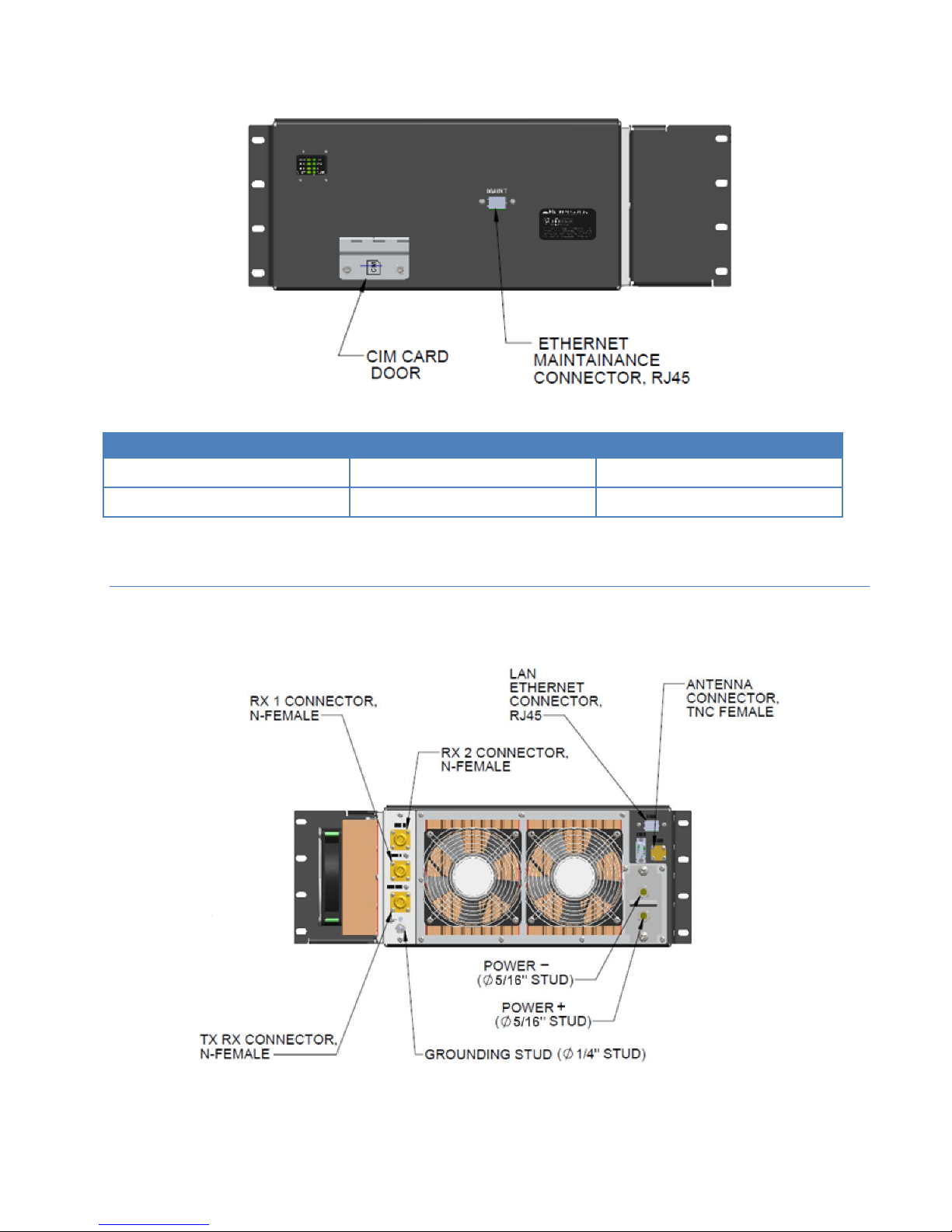

The following figure and table illustrate the interface connections on the front panel of the Base Station Transceiver.

ITC 220 Base Station, Locomotive & Wayside Radio Transceiver Field Service Guide PN 0046300120 Rev. A | Page 5

Page 12

Figure 3 Base Station Transceiver front panel interface connections

Interface

Connector Type

Label

Maintenance Ethernet

RJ-45

MAINT

CIM socket

SD memory card receptacle

CIM

Table 1 Base Station Transceiver front panel interface connections

1.3.1.2.2 BASE STATION TRANSCEIVER REAR CONNECTORS

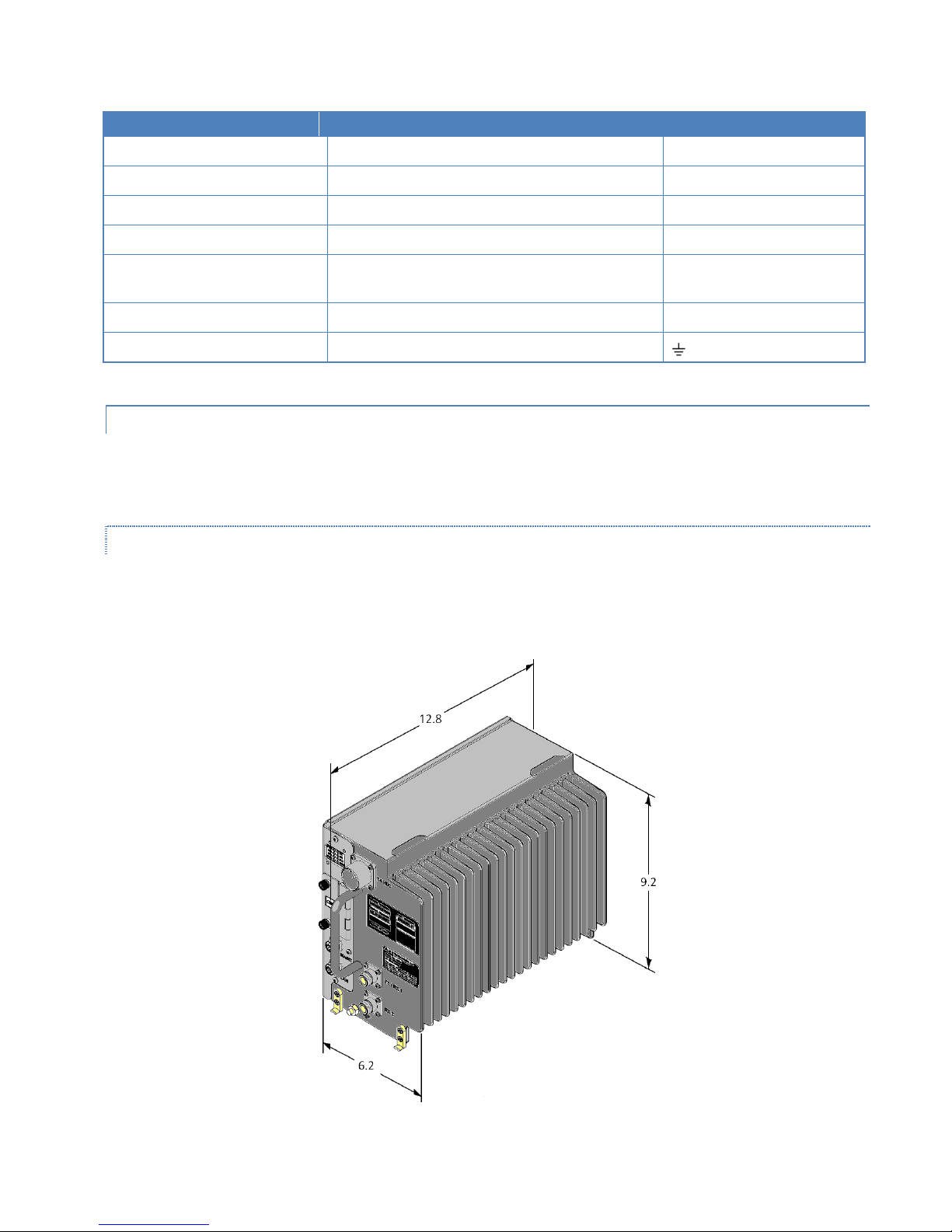

The following figure and table illustrate connectors at the rear of the Base Station Transceiver.

Figure 4 Connectors at rear of Base Station Transceiver

ITC 220 Base Station, Locomotive & Wayside Radio Transceiver Field Service Guide PN 0046300120 Rev. A | Page 6

Page 13

Table 2 Connectors at rear of Base Station Transceiver

Interface

Connector Type

Label

TX Antenna

Type N female

TX/RX

RX1 Antenna

Type N female

RX1

RX2 Antenna

Type N female

RX2

GPS Antenna

TNC female

GPS

DC Power Input

Threaded posts (studs) for ring lug connection

+24 VDC or

+48 VDC

Data Network Ethernet

RJ-45

LAN

Ground connection

Threaded post (stud) for ring lug connection

1.3.2 LOCOMOTIVE TRANSCEIVER

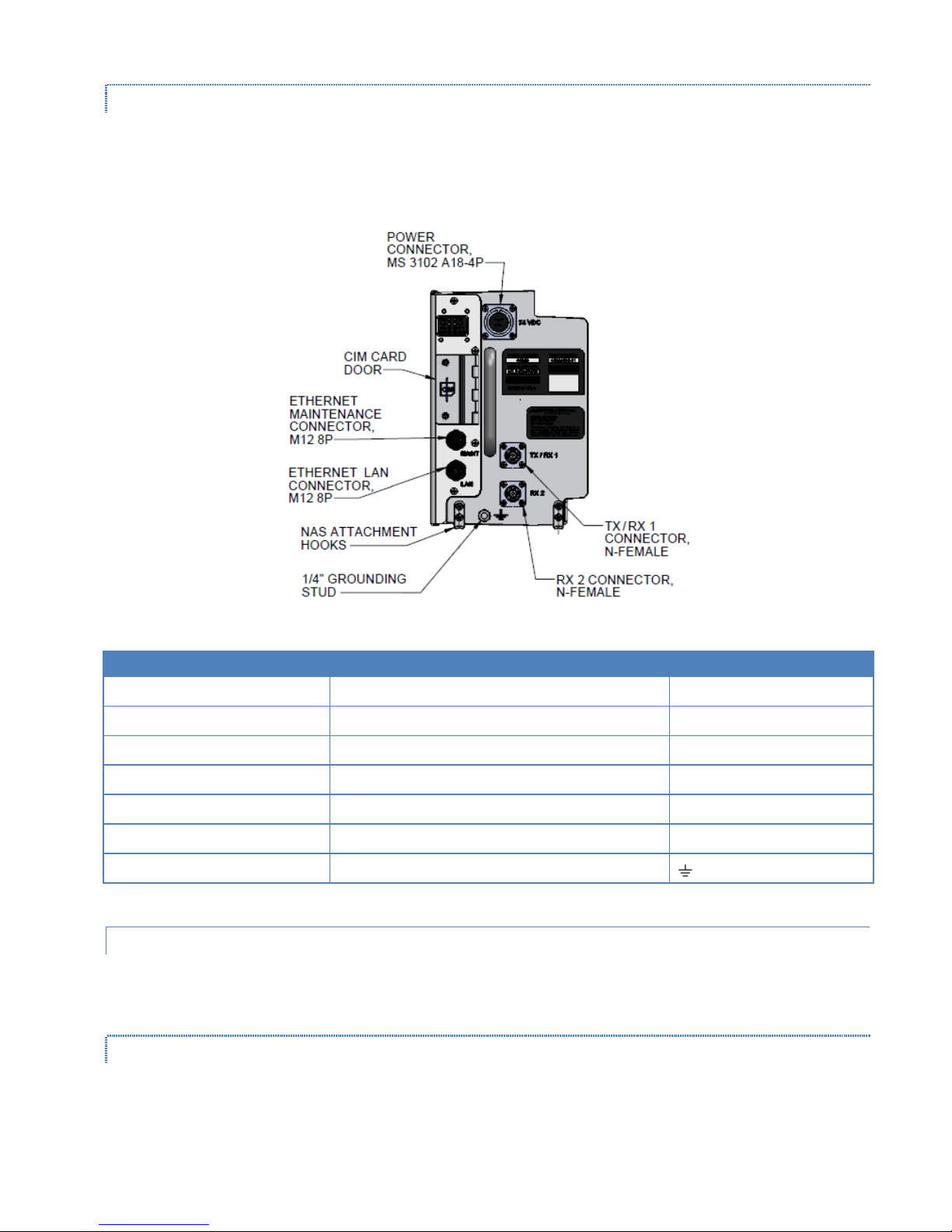

The ITC 220 Locomotive Transceiver is housed in a 5×MCU LSI rack-compatible chassis.

1.3.2.1 LOCOMOTIVE TRANSCEIVER DIMENSIONS

Overall dimensions of the ITC 220 Locomotive Transceiver are 6.2 in. width × 9.2 in. height × 12.8 in. depth, as shown in

Figure 1 , which follows.

Figure 5 ITC 220 Locomotive Transceiver overall dimensions

ITC 220 Base Station, Locomotive & Wayside Radio Transceiver Field Service Guide PN 0046300120 Rev. A | Page 7

(Dimensions shown are in inches.)

Page 14

1.3.2.2 LOCOMOTIVE TRANSCEIVER CONNECTIONS

Interface

Connector Type

Label

TX/RX1 Antenna

Type N female

TX/RX1

Diversity RX Antenna

Type N female

RX2

DC Power Input

MS-3102 A18-4P or equivalent

74 VDC PWR IN

Data Network Ethernet

M12 - 8 pin female, A-coded

LAN

Maintenance Ethernet

M12 - 8 pin female, A-coded

MAINT

CIM socket

SD memory card receptacle

CIM

Ground connection

Threaded post (stud) for ring lug connection

All physical connections and interfaces are located on the front panel of the Locomotive Transceiver.

The following figure and table illustrate the ports and connectors on the Locomotive Transceiver front panel.

Figure 6 Locomotive Transceiver ports and connectors

Table 3 Locomotive Transceiver front panel interface connections

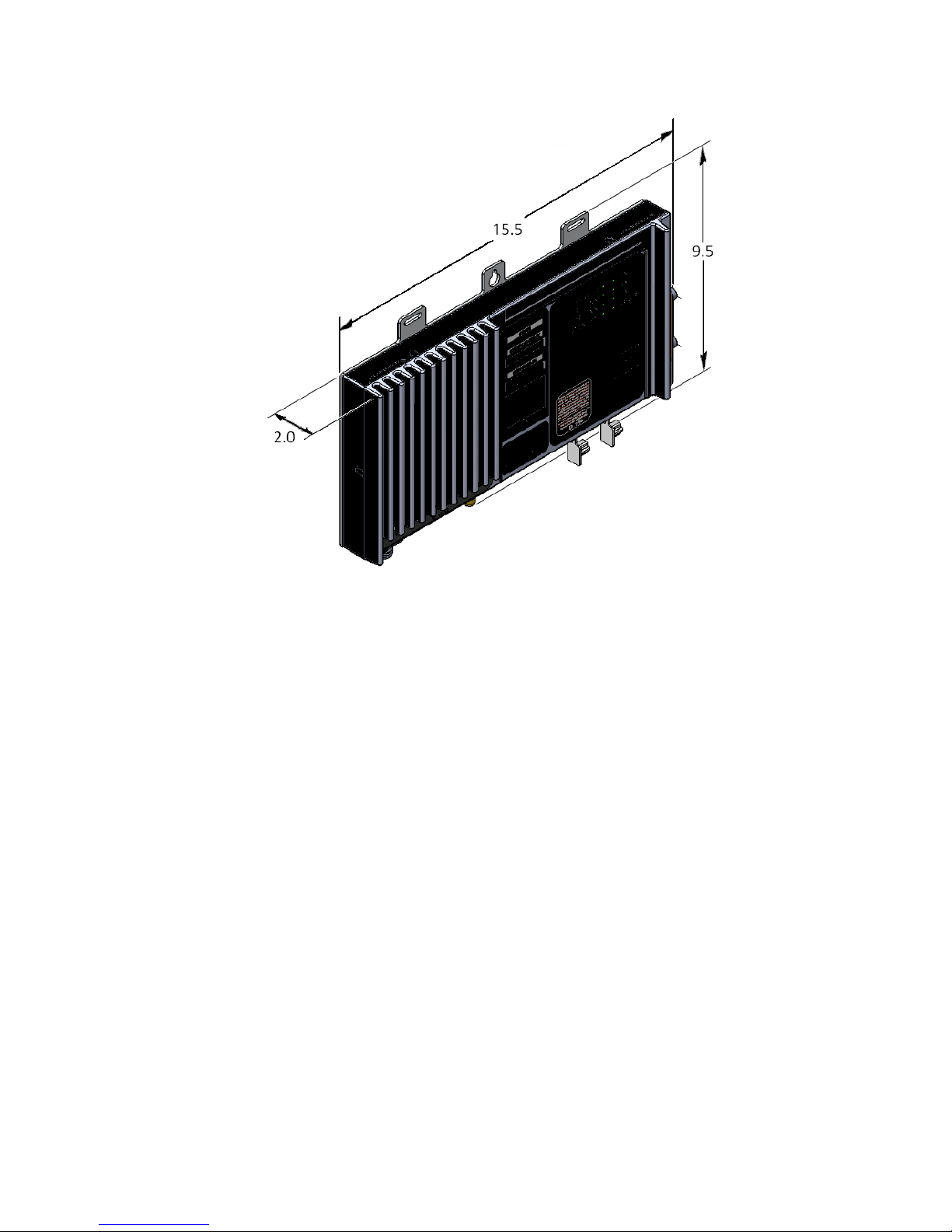

1.3.3 WAYSIDE TRANSCEIVER

The ITC 220 Wayside Transceiver is housed in a die-cast metal chassis. Mounting lugs at top and bottom of the chassis

allow for a variety of mounting options, including in 19-inch channel-rack installations.

1.3.3.1 WAYSIDE TRANSCEIVER DIMENSIONS

Overall dimensions of the ITC 220 Wayside Transceiver are approximately 15.5 in. width × 9.5 in. height × 2.0 in. depth,

as shown in Figure 1 below.

ITC 220 Base Station, Locomotive & Wayside Radio Transceiver Field Service Guide PN 0046300120 Rev. A | Page 8

Page 15

Figure 7 ITC 220 Wayside Transceiver overall dimensions

(Dimensions shown are in inches.)

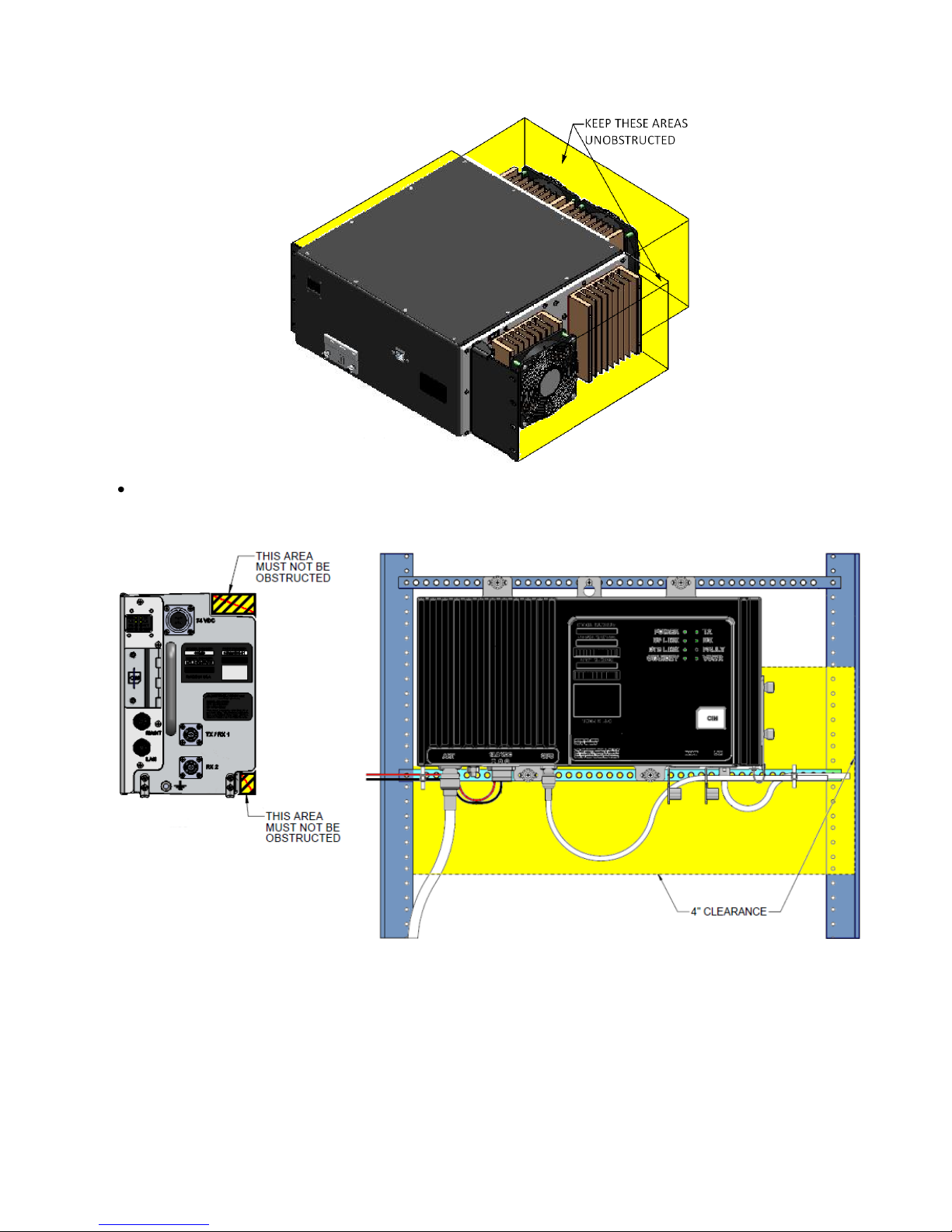

The Wayside Transceiver may be mounted vertically or horizontally, providing that the unit is mounted such that the

cooling fins, CIM card door, and cable connections are unobstructed. When mounting the unit, choose an orientation

that provides clear visibility of the status LEDs. Dimensions of mounting lugs for mounting the unit are shown in Figure

2, which follows.

ITC 220 Base Station, Locomotive & Wayside Radio Transceiver Field Service Guide PN 0046300120 Rev. A | Page 9

Page 16

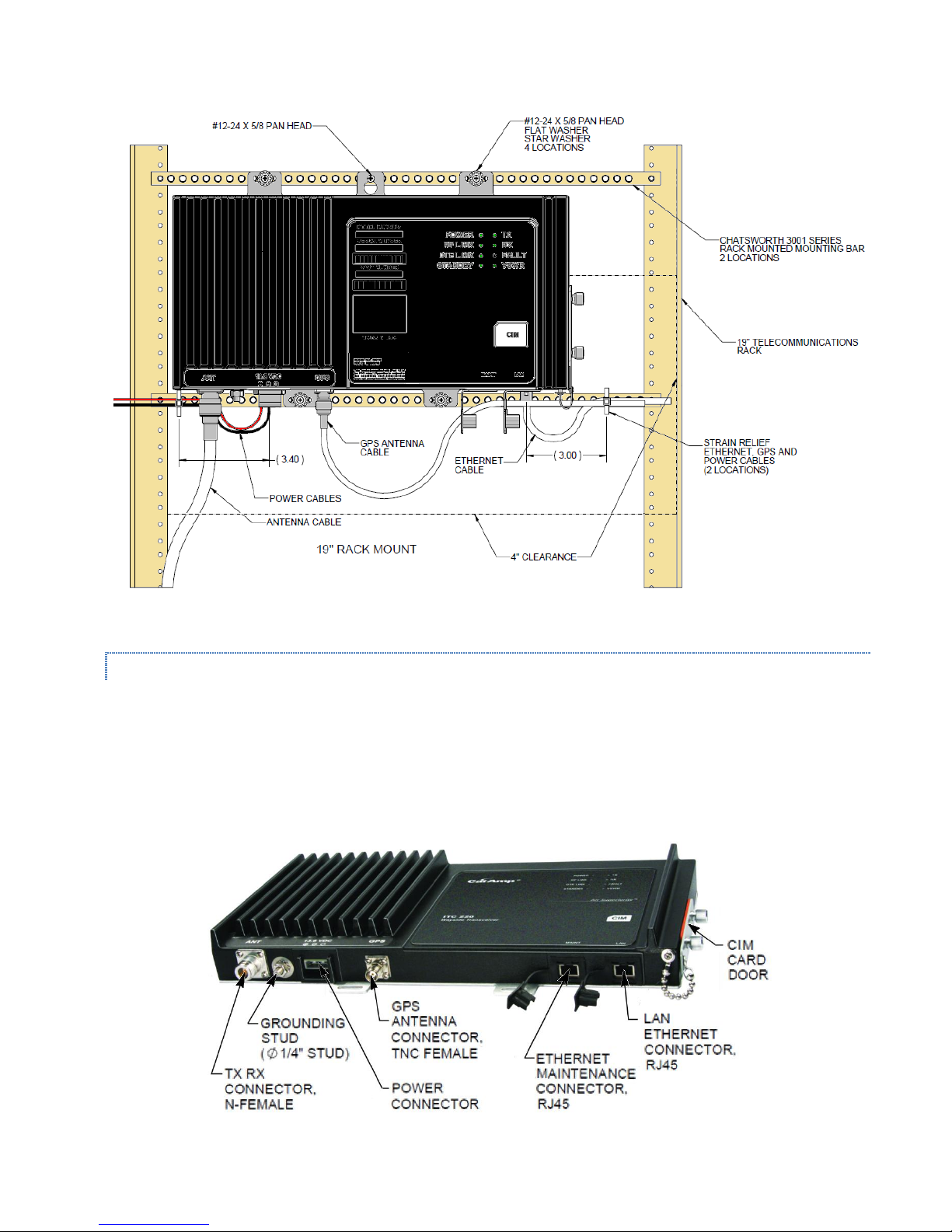

Figure 8 Wayside Transceiver mounting lug dimensions

(Dimensions shown are in inches.)

Spacing of mounting lugs and slotted holes provide versatility for mounting the Wayside Transceiver. Figure 9, which

follows, shows the recommended method of installing the Wayside Transceiver in a typical EIA 19" telecommunications

rack application.

ITC 220 Base Station, Locomotive & Wayside Radio Transceiver Field Service Guide PN 0046300120 Rev. A | Page 10

Page 17

Figure 9 Wayside Transceiver mounted in a typical EIA 19" rack application

(Dimensions shown are in inches.)

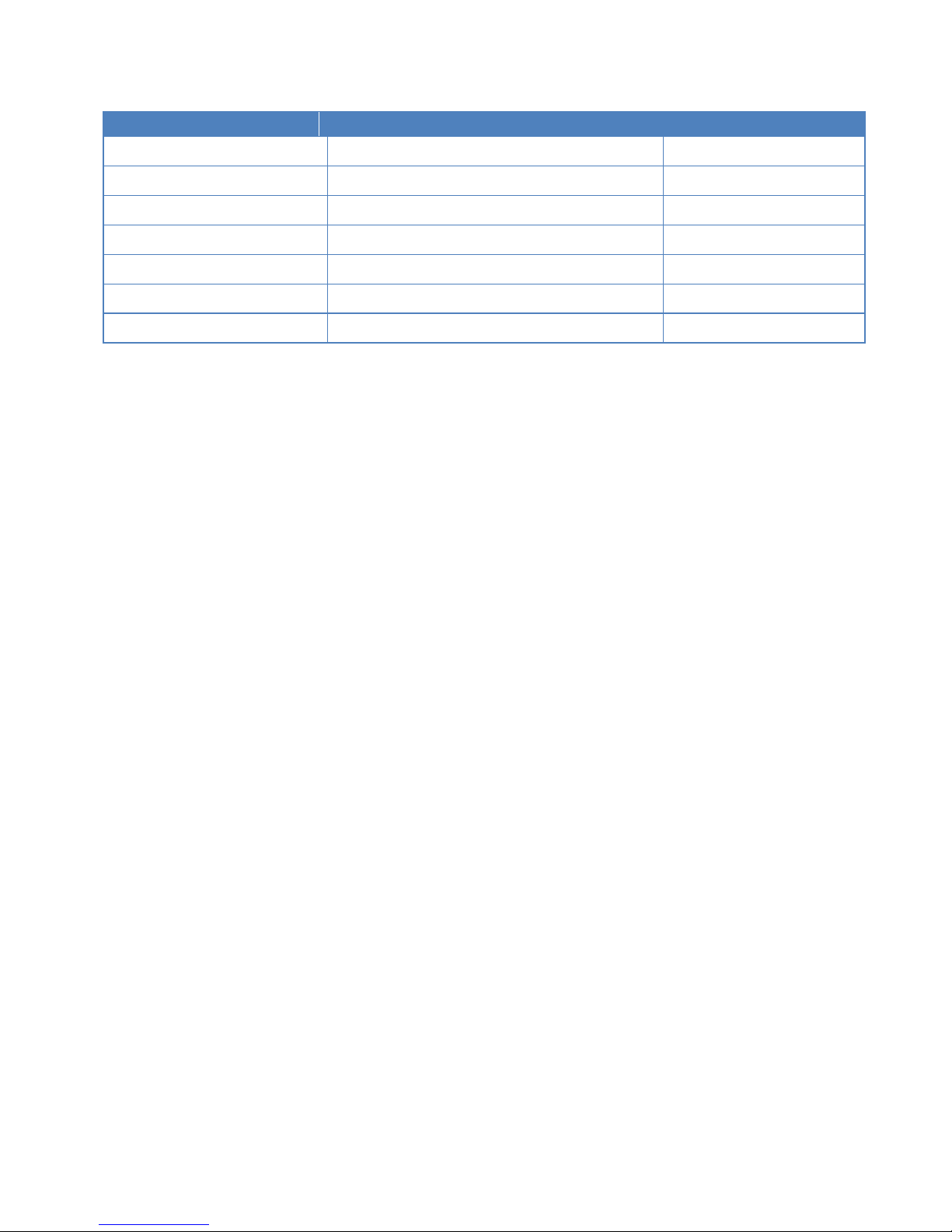

1.3.3.2 WAYSIDE TRANSCEIVER CONNECTIONS

All physical connections and interfaces are located at the bottom (as viewed with the unit mounted vertically) of the

Wayside Transceiver, except the CIM card slot, the door for which is in the right side of the unit (as viewed mounted

vertically).

The following figure and table illustrate the interface connections at the bottom panel of the unit.

Figure 10 Wayside Transceiver bottom panel interface connections

ITC 220 Base Station, Locomotive & Wayside Radio Transceiver Field Service Guide PN 0046300120 Rev. A | Page 11

Page 18

Table 4 Wayside Transceiver bottom panel interface connections

Interface

Connector Type

Label

TX RX Antenna

Type N female

ANT

DC Power Input*

Wago p/n 231-833/001-000

13.6 VDC

GPS Antenna

TNC female

GPS

Data Network Ethernet

RJ-45

LAN

Maintenance Ethernet

RJ-45

MAINT

CIM socket

SD memory card receptacle

CIM

Ground connection*

Threaded post (stud) for ring lug connection

*The Wayside Transceiver requires an external isolated power supply to provide ground isolation between the unit and

site electronics. Failure to use an isolated power supply (for example, connecting a unit directly to site batteries)

would induce a ground fault at the site since the unit is grounded to the bungalow both through the ground lug as

well as the GPS and 220 GHz RF narrowband antennas.

ITC 220 Base Station, Locomotive & Wayside Radio Transceiver Field Service Guide PN 0046300120 Rev. A | Page 12

Page 19

2 FOLLOW EST A BLISHED SAFE TY GUIDELINES

Caution – Please refer to the RF Energy Exposure Guide for ITC 220 Base Station, Locomotive, and Wayside

Transceivers Installed in Vehicles or at Fixed Sites that is packaged with each transceiver for specific

information regarding safe distances that must be maintained between personnel and energized

transmitting antennas.

Your employer has created safety guidelines that apply to your work environment and tasks. Please follow them. If you

have questions about general on-the-job safety concerns, please consult your employer’s established safety guidelines.

2.1 ELECTRICAL SAFETY

To reduce the risk of electric shock:

Follow your employer’s established electrical safety guidelines.

Disconnect power from the transceiver before removing the cover.

Be aware that removing the cover of the radio transceiver may expose you to dangerous voltages or other risks.

Avoid making internal adjustments to the radio transceiver when you are alone.

Avoid contact with a radio’s electrical components. Electric shock from voltages present with the radio transceiver

are potentially fatal.

Reassemble radio transceivers correctly. Incorrect reassembly of a radio transceiver can cause a harmful electric

shock to anyone who handles it.

3 IMPORTANT INFORMATION FOR THE USER

3.1 TRANSMITTER WARM-UP PERIOD (BASE STATION TRANSCEIVER ONLY)

The transmitter of the Base Station Transceiver uses a precision oven-controlled crystal oscillator (OCXO). The OXCO

warm-up period is one minute minimum after application of input power before any transmission should commence.

Locomotive and Wayside Transceivers use temperature-compensated crystal oscillators (TCXO), which do not require

warm-up time before the transmitter can be used.

3.2 LIMITING RF EXPOSURE

The information in the RF Energy Exposure Guide for ITC 220 Base Station, Locomotive, and Wayside Transceivers

Installed in Vehicles or at Fixed Sites (RF Energy Exposure Guide) is determined form FCC and Industry Canada rules

that, when followed, limit human exposure to radio frequency energy to acceptable levels. Note that although

transceivers and antennas are expected to be sited, installed, and maintained only by professionals in a controlledexposure environment, the RF Energy Exposure Guide lists the larger lateral safe distances for an uncontrolled

environment. Obeying these limits will protect both railroad employees and the general public.

Radio transceivers are intended to be operated with a fixed antenna in an Occupational/Controlled Exposure

environment per FCC OET 65 or Controlled Use Environment per IC RSS-102. The Maximum Permitted Exposure (MPE)

limit for devices in the presence of the general public in the 100-300 MHz range is 0.2 mW/cm2 = 2 W/m2 vs. 10 W/m2

in a controlled-exposure environment.

ITC 220 Base Station, Locomotive & Wayside Radio Transceiver Field Service Guide PN 0046300120 Rev. A | Page 13

Page 20

Radio transceivers are intended for use by railroad employees who have full knowledge of their exposure and can

Note – RF exposure compliance at multiple transmitter sites must be addressed on a site-by-site basis. It is

the responsibility of the licensee to ensure compliance with maximum exposure limits

exercise control over their exposure to meet FCC and IC limits. These radio devices are not intended for use by

consumers or the general population. Base station antennas must be positioned on towers or nonresidential buildings

that are generally unoccupied except while servicing the equipment therein.

Tables in the RF Energy Exposure Guide list the calculated lateral distances to be maintained between the general

public and an operational transmitter antenna for antenna types suitable in fixed and mobile applications.

3.3 FIXED ANTENNA GUIDELINES

This section contains antenna information and additional notes regarding methods to limit RF exposure.

The licensee is required to comply with limits on antenna location, power, and effective antenna height per 47CFR

Subpart T §90.701 et. Seq., or Industry Canada SRSP-512 §6.3 as applicable. The section titled “Transceiver-Radiated

Power Limits,” below, provides additional information on how to comply with ERP limits.

Refer to the RF Energy Exposure Guide, which is packaged with each Base Station and Locomotive Transceiver and

available online or by request, for specific guidelines regarding placement and installation of fixed antennas.

Acceptable fixed-antenna types are listed in the Rated Power and Recommended Lateral Distance tables in the RF

Energy Exposure Guide.

Install antennas in accordance with the manufacturer’s instructions.

Disable the transmitter when installing or servicing its antenna or transmission line.

Maintain a safe distance from energized transmitting antennas. Refer to the table of safe distances for Base radios

in the RF Energy Exposure Guide.

Unauthorized antennas, equipment modifications, or attachments could invalidate any equipment warranty or

authority to transmit. Modification could damage the radio transceiver and may violate FCC or IC regulations.

Contact CalAmp before using other antennas.

3.4 RF INTERFERENCE TO RESIDENTIAL RECEIVERS

Notice to user: This device complies with Part 15 of the FCC Rules. Operation is subject to the condition that this device

does not cause harmful interference.

Note: this equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part

15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a

residential installation. This equipment generates, uses, and can radiate radio-frequency energy and, if not installed

and used in accordance with the instructions, may cause harmful interference to radio communications. However,

there is no guarantee that interference will not occur in a particular installation. If this equipment does cause harmful

interference to radio or television reception, which can be determined by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of the following measures:

Reorient or relocate the receiving antenna.

Increase the separation between the equipment and receiver.

Connect the equipment to an outlet on a circuit different from that to which the receiver is connected.

Consult the dealer or an experienced radio/TV technician for help.

ITC 220 Base Station, Locomotive & Wayside Radio Transceiver Field Service Guide PN 0046300120 Rev. A | Page 14

Page 21

3.5 EQUIPMENT MODIFICATIONS

Caution – Any changes or modifications to this equipment not expressly approved by the party responsible

for compliance (in the respective country of use) could void the user’s authority to operate the equipment.

It is the responsibility of the licensee to comply with the effective radiated power limits based on operating

frequency, geographic location, and effective antenna height specified in 47CFR Subpart T §90.701 et. seq.,

or Industry Canada SRSP-512 §6.3, as applicable.

4 TR ANSMITTER OPERATION

It is the responsibility of the licensee to operate this radio transmitter in compliance with FCC and Industry Canada

service rules for 220-222 MHz, namely FCC Rules Part 90 Subpart T and Industry Canada SRSP-512.

4.1 TRANSCEIVER CHANNELIZATION AND FREQUENCY RANGE

Transceivers can be configured to transmit on any one of 80 selectable 25 kHz spaced channels ranging from 220.0125

to 221.9875 MHz inclusive. The spectrum included corresponds to all 5 kHz-wide FCC channels numbered from 1 at

220.0025 MHz to 400 at 221.9975 MHz. Each Base Station transmission occupies five of the FCC-defined 5 kHz

channels. The lowest radio channel center frequency is in the center of FCC channel 3 and the next is centered on FCC

channel 8, then 13, 18, and so on, up to the highest, which is centered with FCC channel 398.

4.2 BASE CHANNEL RESTRICTIONS

Section 90.715 of the FCC Rules lists the authorized frequencies of the 400 total 5 kHz wide channels. According to

§90.733(d), these can be aggregated into larger channel widths with the exceptions of FCC channels 161-170 and 181-

185. Therefore, the radio may not transmit on those channels or their 221 MHz counterparts, 361-370 and 381-385.

This corresponds to frequencies 220.8125, 220.8375, 220.9125, 221.8125, 221.8375, and 221.9125 MHz.

Please refer to Part 90 Subpart T and SRSP-512 for additional frequency use restrictions in Canadian and Mexican

border areas.

4.3 TRANSCEIVER-RADIATED POWER LIMITS

Important: The following supplementary antenna system information discusses means for the licensee to determine

effective radiated power (ERP) and to comply with regulatory power limits.

Licensees must comply with specific power vs. antenna height above average terrain (HAAT) limitations for fixedantenna stations per §90.729 or SRSP-512 §6.3 unless operating under an explicit waiver of the applicable rule. Note

that U.S. and Canadian power vs. antenna HAAT limitations are not identical and differ in this regard.

Licensees should also note that fixed and mobile installations transmitting between 221 and 222 MHz must limit

effective radiated power (ERP) to 50 W or 10log(50) + 30 = 47 dBm PEP referenced to the 2.15 dBi gain of a dipole. The

EIRP for this case is 49.15 dBm. Also note that the maximum ERP on FCC/IC channels 196-200 at 220.975 to 221.000

MHz is 2 watts.

ITC 220 Base Station, Locomotive & Wayside Radio Transceiver Field Service Guide PN 0046300120 Rev. A | Page 15

Page 22

Base Station:

Common single element fixed station antennas typically exhibit 2.1 to 5 dBi (0 to 2.9 dBd) gain and being vertically

polarized, are usually omnidirectional. Multi-element antennas are designed to concentrate RF radiated power

toward the horizon and away from the sky and the earth and, depending on the design criteria, provide azimuthal

gain directivity that decreases ERP in the direction of other base stations or increases ERP in a specific direction.

They may also be used to make up for large losses between transmitter and antenna. The isotropic gain of a

commonly-used two-element exposed dipole antenna is typically 7 to 8 dBi.

Once the allowable ERP is determined by applying all power-restrictive rules from above and the antenna gain is

known, the transmitter peak envelope power (PEP) output feeding the transmission line is determined by

subtracting the antenna gain in dBi from the EIRP and adding the loss from the antenna feedline and connectors

plus the loss from any combiners, cavity filters or lightning arresters. If the net value is greater than or equal to

48.75 dBm, then the 75 W maximum power of the Base transmitter can be used. If the value is less than 48.75 dBm,

then the transmitter output power should be reduced to the net value. Example for the 50 W ERP case: Antenna

gain = 8 dBi, feedline and connector loss = 2 dB. Assuming no other losses, the transmitter power output limit =

49.15-8+2 = 43.15 dBm PEP or 20.7 W PEP. In this case, the Base RF output power should be adjusted to 20.7 W PEP

or less.

If the calculated transmitter power limit is less than the minimum Base rated power of 10W PEP = 40 dBm PEP, then

an external RF attenuator would be inserted in the feed line to increase the loss between transmitter and antenna

to achieve compliance.

Locomotive

Antennas designed for locomotives at 220 MHz generally use a rugged cast aluminum body and are top-loaded

vertically polarized requiring a metal cab roof for a ground plane. They are necessarily electrically shorter than onefourth wavelength due to vertical space limitations. Maximum antenna gain is expected to be at 0 dBd – 2.15 dB.

FCC rule §90.729(b) limits mobile operation at 220-222 MHz to 50 W ERP, which is calculated relative to a free-

space dipole with 0 dBd = 2.15 dBi gain. Since the locomotive antenna has a maximum gain equal to a dipole and

the rated maximum transmitter output power is 50 W PEP, compliance with the 50 W ERP limit is assured.

The actual power will be less than 50 W ERP when the feedline and filter losses between transmitter and antenna

are taken into account. Minimum feedline loss is expected to be 0.5 dB and an inline 160 MHz reject filter adds 0.7

dB loss for a total loss of 1.2 dB. The actual ERP is therefore 47 – 1.2 = 45.8 dBm = 38 watts. The transmitter

installation cannot be operated on FCC channels 196-200 due to the 2 W limitation.

Wayside:

The allowable transmitter peak envelope power output in dBm is determined by subtracting the antenna gain in dBi

from 49.15, then adding the loss from the antenna feedline and connectors. If the result is greater than or equal to

44.85 dBm = 14.85 dBW then the maximum power output of the Wayside transmitter can be used. If the value is

less than 44.85 dBm, then the transmitter output power must be reduced to the calculated value.

Mobile installation: As an example of a mobile installation, consider a vertical half-wave ground plane on a vehicle

metal rooftop. In an ideal installation, the antenna gain = 2.4 dBd = 4.55 dBi. Ignoring connector losses, feedline loss

is at least 0.6 dB for 10 feet of Times Microwave LMR 195 Ultra Flex coaxial cable. Transmitter output power output

limit = 47 – 2.4 + 0.6 = 45.2 dBm PEP and therefore the system is compliant with the 50 W ERP limit. The actual ERP

in this case is 10^(14.85+2.4-0.6) = 46.2 W. This installation is not allowed to transmit on FCC channels 196-200

because the maximum ERP is greater than 2 watts.

ITC 220 Base Station, Locomotive & Wayside Radio Transceiver Field Service Guide PN 0046300120 Rev. A | Page 16

Page 23

Fixed installation: In a fixed installation, a common single element exposed folded dipole antenna without reflector

has 0 up to 2.9 dBd (2.1 to 5.0 dBi) azimuthal gain depending on the design.

Once the allowable ERP is determined by applying all power-restrictive rules from above and the antenna gain is

known, the transmitter peak envelope power output feeding the transmission line is determined by subtracting the

antenna gain in dBi from the EIRP and adding the loss from the antenna feedline and connectors plus the loss from

any external inline power sensors, combiners, filters, or lightning arresters. If the net value is greater than or equal

to 44.85 dBm, then the maximum power of the Wayside transmitter can be used. If the value is less than 44.85

dBm, then the transmitter output power must be reduced to the net value.

Example for the 50 W ERP case: Antenna gain = 2.9 dBd and feedline loss is at least 0.5 dB for 25 feet of Times

Microwave LMR -400 coax plus 0.4 dB for inline lightning arrester and three connectors. Assuming no other losses,

the transmitter power output limit = 47-2.9+0.9 dBm = 45 dBm PEP. In this case, the actual Wayside ERP is

44.85+2.9-0.9 dBm = 46.85 dBm = 48.4 W PEP and therefore the system is compliant with the 50 W ERP limit. This

installation is not allowed to transmit on FCC channels 196-200 because the maximum ERP is greater than 2 watts.

ITC 220 Base Station, Locomotive & Wayside Radio Transceiver Field Service Guide PN 0046300120 Rev. A | Page 17

Page 24

5 TR ANSCEIVER SERVICE

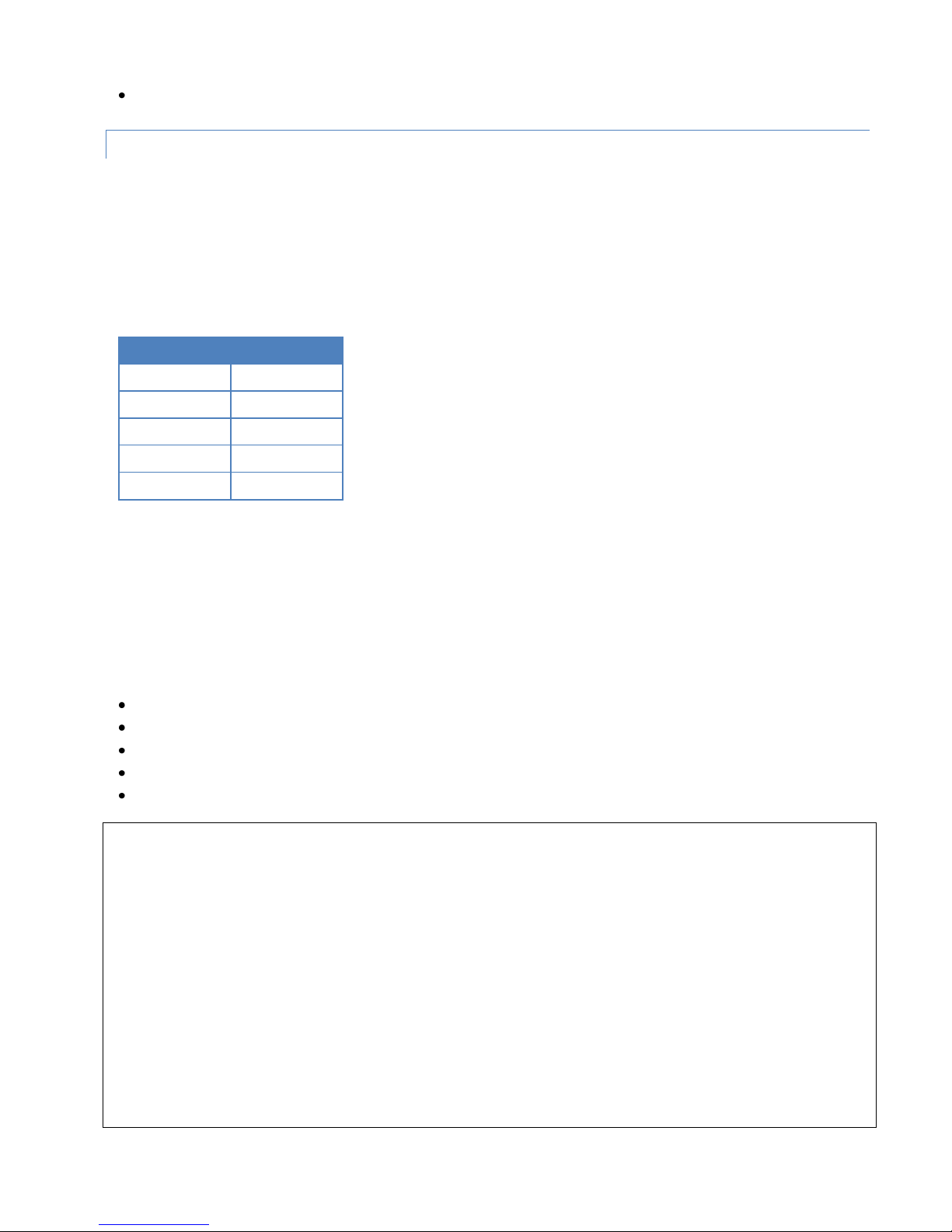

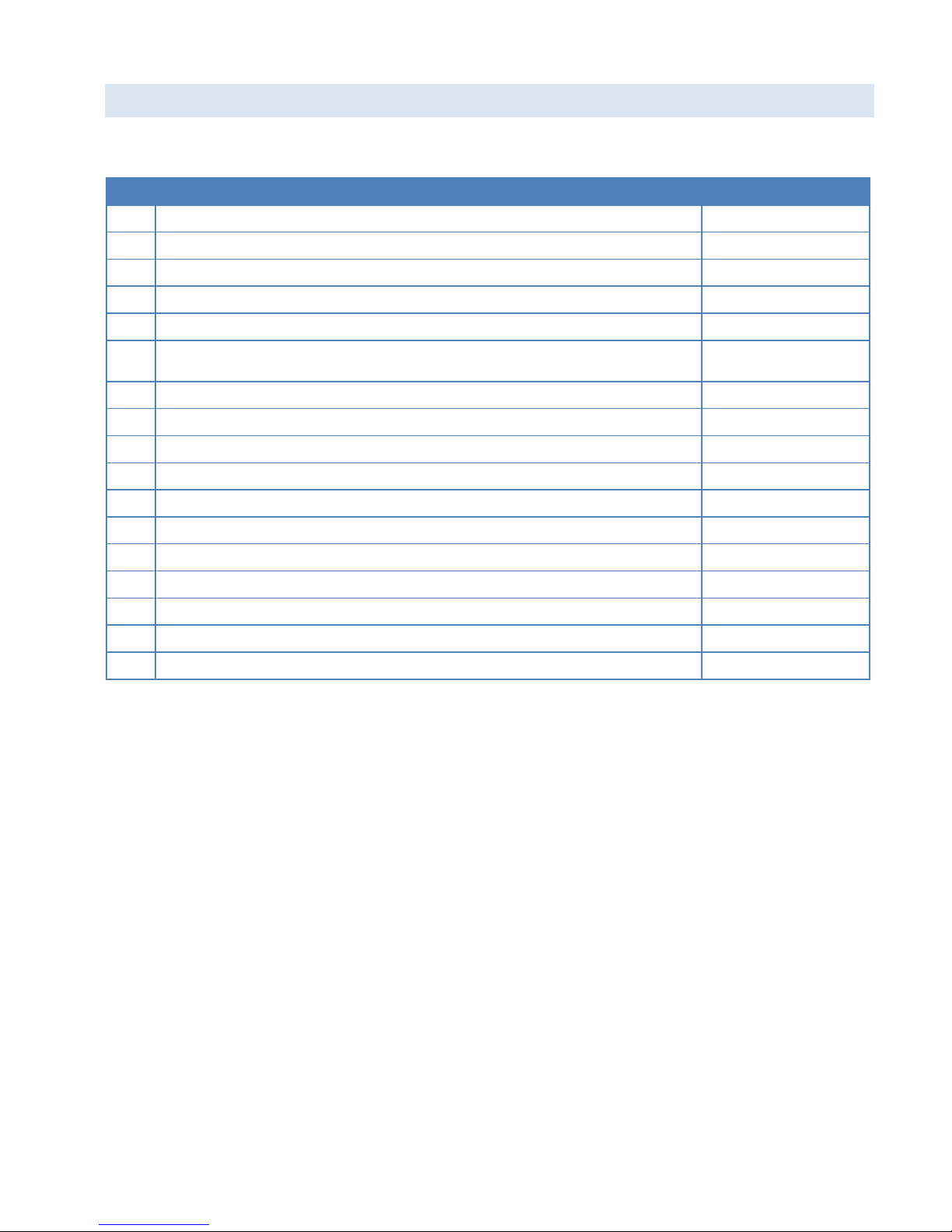

Type

Model

Notes

24 VDC power supply

For testing 24 V Base Station Transceiver—constant

voltage DC power supply with precision current output

display, capable of 10 A at 24 VDC

48 VDC power supply

For testing 48 V Base Station Transceiver—constant

voltage DC power supply with precision current output

display, capable of 5 A at 48 VDC

74 VDC power supply

For testing Locomotive Transceiver—constant voltage

DC power supply with precision current output

display, capable of 4A at 74 VDC

13.6 VDC power supply

For testing Wayside Transceiver—constant voltage DC

power supply with precision current output display,

capable of 10 A at 13.6 VDC

Vector signal generator

Agilent E4438C or

equivalent

Recommended option for 50 VDC, 50 W input

protection of RF signal output port. Preprogrammed

with DQPSK data packet and appropriate preamble

reqired by Sprint release. See APPENDIX G— Program

Signal Generator for DQPSK.

Vector signal analyzer

Agilent E9010A or

equivalent

Handheld RF spectrum analyzer

Anritsu or equivalent

10 MHz frequency standard

Standard Research

Systems model FS725

or equivalent

Base frequency adjustments require frequency

standard accuracy to 0.01 ppm or better.

60 dB power attenuator/load

Consists of two pieces with 100 W and 2 W min.

power rating.

Constant voltage DC power

supply

Verify unit supports voltage and current draw required

by unit under test.

Host computer with at least one

Ethernet port and XtermW or

equivalent terminal program

installed

If the host computer’s Ethernet port has not been

configured, then follow the instructions in 5.4

Configure Computer Ethernet Ports to Communicate

with the Transceiver.

Service technicians should be familiar with installation instructions provided in Installation Guides for Base Station,

Locomotive, and Wayside Transceivers. Installation procedures are summarized only briefly as they relate to service

procedures in this chapter. Refer to the Installation chapter of the Installation Guides for radio transceiver installation

details.

5.1 RECOMMENDED EQUIPMENT

Following is a list of test equipment required to perform tests and adjustments described in this Field Service Guide. It

is expected the user is familiar with the pieces of test equipment listed below. Instructions on how to use the following

equipment are beyond the scope of this document.

Table 5 Recommended equipment

ITC 220 Base Station, Locomotive & Wayside Radio Transceiver Field Service Guide PN 0046300120 Rev. A | Page 18

Page 25

Type

Model

Notes

Ethernet cable(s)

Category 5 or better

One Ethernet cable for each computer Ethernet port.

Standard Ethernet cable terminated with RJ-45

connectors.

Clip-on ammeter

Antenna / VSWR test kit

Cable ties as required

Digital volt meter

Network analyzer

Power (Watt) meter

Site tester

7/16"and 1/2" open-end

wrenches

7/16" wrench for 1/4" hex nut on grounding stud, on

all transceivers;

1/2" wrench for 5/16" hex nuts on power terminals,

Base Station Transceiver only

#2 Phillips head screwdriver

Torque wrench with 100 in.·lb.

capacity

Crimping tool

For assembling power cable(s), if required

5.2 ROUTINE MAINTENANCE

Transceivers require the following routine maintenance. The user (or person responsible for the equipment on site)

should check transceivers periodically to verify that each transceiver and cables are maintained and remain securely

supported, clear of dust and obstructions, and away from potential causes of overheating.

Remove dust and obstructions from heat-sink fins.

Ensure that the unit is not subjected to excessive heat from adjacent equipment.

Make sure that the unit is securely mounted and supported.

Restrain cables to prevent stress on connectors.

Make sure that the SD memory card (CIM) door is securely closed.

Keep the indicator-LED panel dust-free and LEDs viewable.

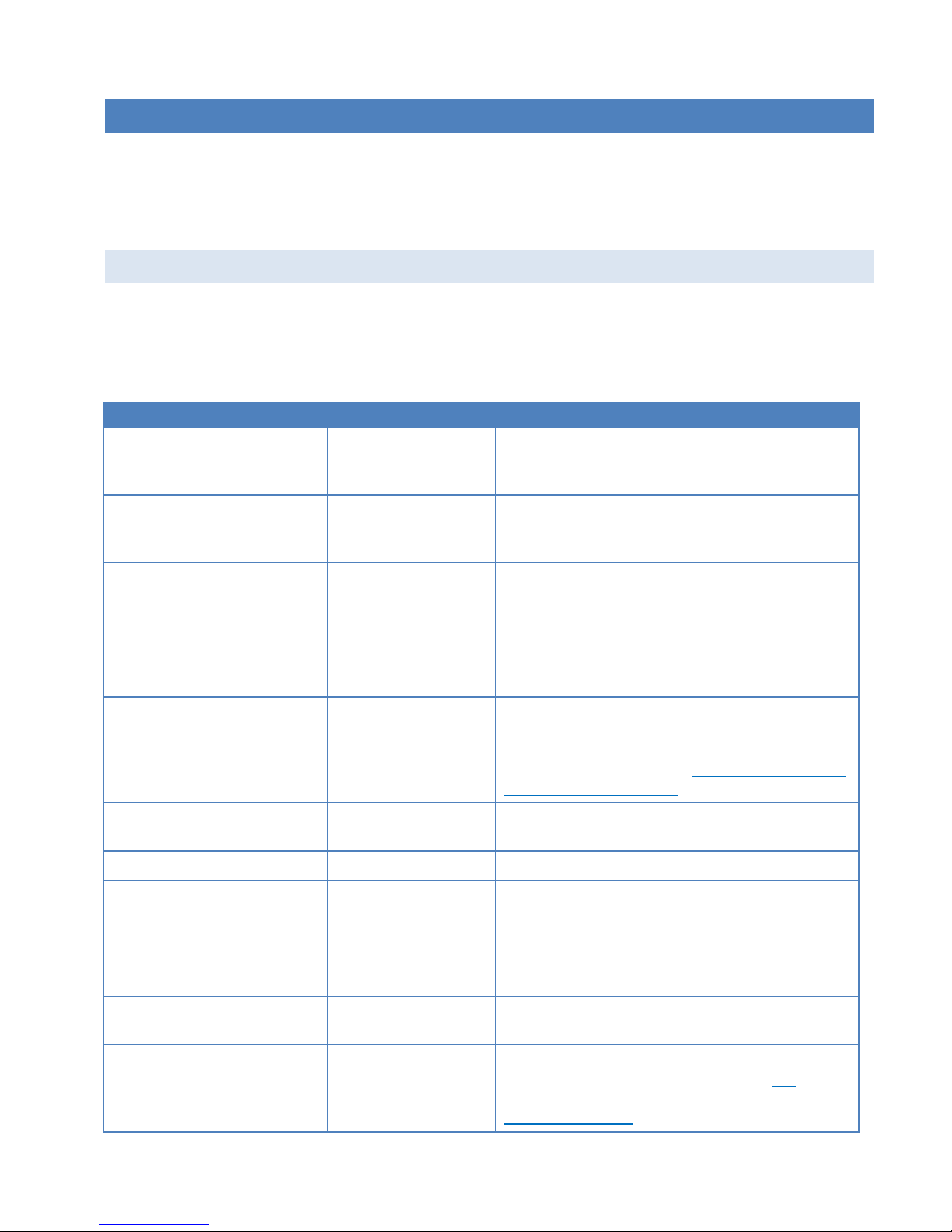

For Base Station Transceivers, check fan operation and make sure the fans are not obstructed. More advanced

information about checking fan operation is provided later in this chapter. The following figure illustrates the areas

to keep unobstructed.

ITC 220 Base Station, Locomotive & Wayside Radio Transceiver Field Service Guide PN 0046300120 Rev. A | Page 19

Page 26

Figure 11 Base Station Transceiver — areas must not be obstructed

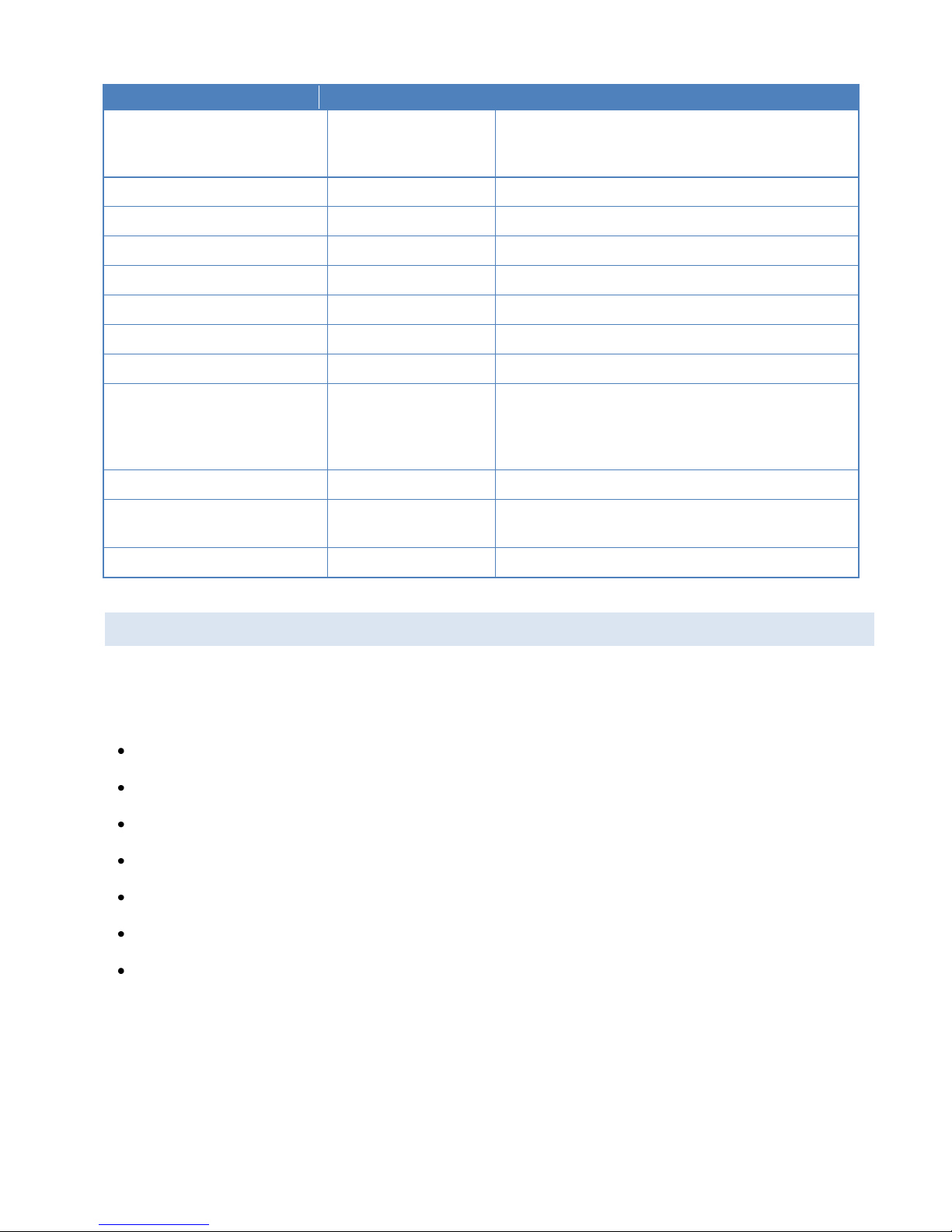

For Locomotive and Wayside Transceivers, verify clearances specified in installation instructions are maintained.

Figure 12 Locomotive and Wayside Transceiver — areas must not be obstructed

ITC 220 Base Station, Locomotive & Wayside Radio Transceiver Field Service Guide PN 0046300120 Rev. A | Page 20

Page 27

5.3 VISUAL INSPECTION

Label

Description

Color

PWR

Power — Blinking green LED indicates that the unit is on.

Green

TX

Illuminates when the radio transmitter is keyed.

Red

SWR

Illuminates when the VSWR of the TX port exceeds approximately 3:1.

Illuminates if the TX forward power is not within 25% of the RF output power setting.

(A time-stamped entry specifying the cause will be entered in the ALARM.LOG file and will

display in the XtermW window hen connected.)

Red

RX

Illuminates when the transceiver is receiving a valid 220 MHz PTC signal.

Amber

DTL

DTE Link — Illuminates when the transceiver establishes a connection to a Communication

Manager (CM) through the Ethernet network port.

Amber

Visually inspect the transceiver and note any dents or damage or missing or loose parts. Also verify heat-sink fins are

clear of dust and debris, that potential sources of excessive heat are not mounted near the transceiver, and that the

bullet points described in Routine Maintenance have been followed.

If you detect damage or missing parts, you will need to determine whether the transceiver is repairable or if it should

be replaced. Depending on what you determine, you may need to order replacement parts or a replacement

transceiver accordingly.

5.3.1 CONFIRM SD MEMORY CARD (CIM) IS I NSTALLED AND SEATED

Note: The SD memory card must be inserted in the orientation shown on the door.

To confirm the CIM card is installed and seated:

Open the CIM door to ensure the SD memory card is present in the CIM socket.

Push the SD memory card once to release it.

Push the SD memory card again to ensure it is seated in the socket.

Once confirmed, close and secure the CIM door.

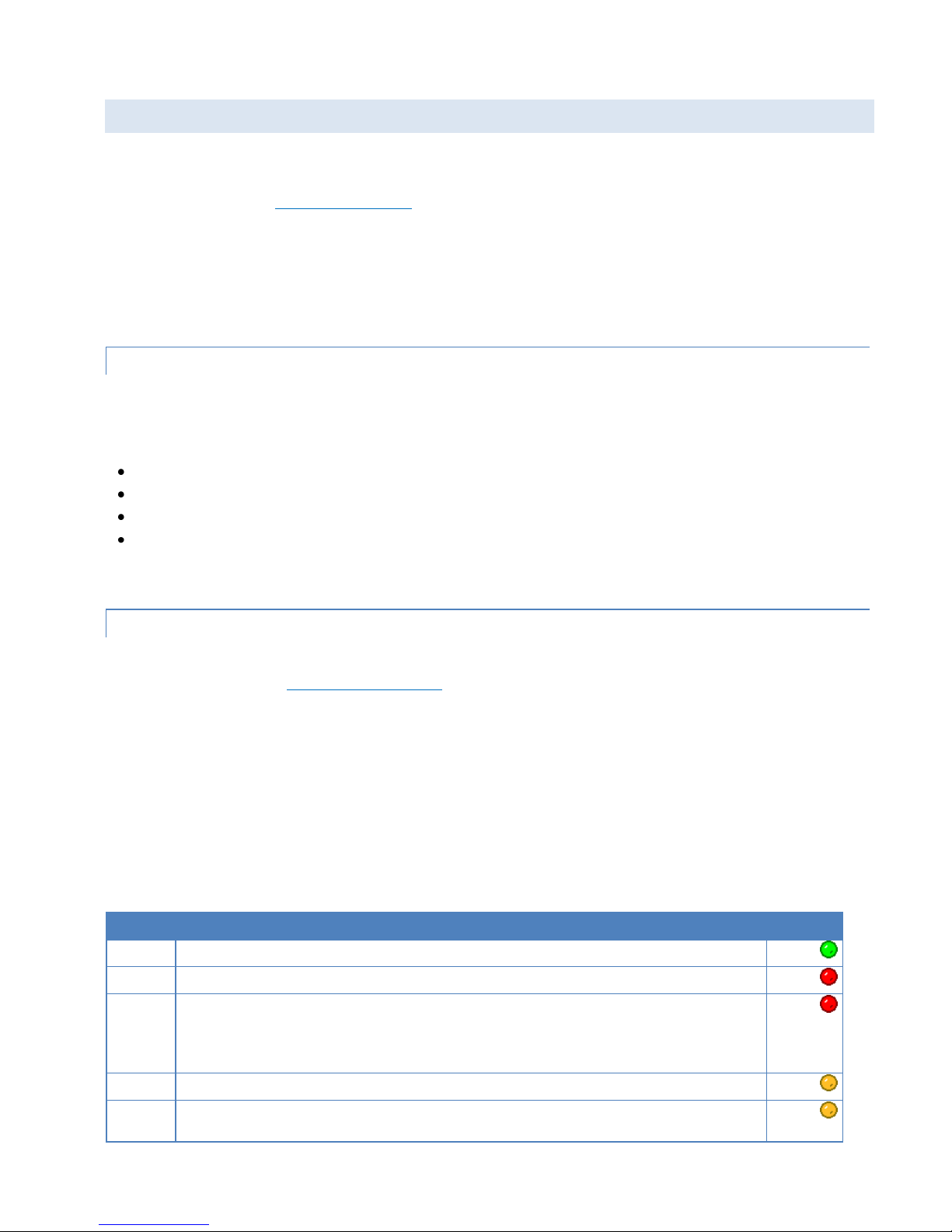

5.3.2 LED DIAGNOSTICS

The front panel LEDs show the general operational status of the transceiver after it has conducted a POST, which it

does each time it boots up. Table 6 Front panel LEDs includes a description of the function of each LED as well as the

color of each LED when the transceiver is functioning properly.

Note: If a problem occurs after the transceiver boots up, the front panel LEDs indicate the problem only after a reboot

of the transceiver (provided the problem persists).

Read the description of each LED carefully. Some LEDs, such as the PWR LED, indicate a problem when they are off.

Other LEDs, such as the FLT (Fault) and SWR, indicate a problem when they are lit. A time-stamped entry will be written

to the ALARM.LOG file on the CIM SD card and will be displayed onscreen when connected in XtermW whenever the

FLT or SWR LEDs are illuminated.

Table 6 Front panel LEDs

ITC 220 Base Station, Locomotive & Wayside Radio Transceiver Field Service Guide PN 0046300120 Rev. A | Page 21

Page 28

Label

Description

Color

RFL

RF Link — Illuminates when an RF link is established between two radios.

Amber

STBY

Standby — Illuminates when the transceiver is in standby mode, indicating TX is disabled.

Red

FLT

Fault — When illuminated, it indicates a variety of fault conditions not indicated by other

LEDs.

Possible faults indicated by the Fault LED include:

One or more internal radio supply voltages are below the minimum threshold.

The extended DC voltage to the transceiver is outside of the acceptable range.

One or more of the transceiver’s internal sensors is indicating a temperature exceeding

the allowable threshold.

The transceiver failed one or more self tests at power on.

TX forward power is not within 25% of the RF output power setting.

The CIM script file is not present or has invalid or corrupt data.

If the Fault LED illuminates, a time-stamped entry will display in XtermW specifying the

cause and will be entered in the Alarm.log file.

Red

A flashing PWR (Power) LED on the front panel indicates that the boot sequence has completed. The Ethernet port

connection becomes active within 10 seconds, allowing you to start an XtermW session.

The above indicators assist in troubleshooting common problems provided the LEDs are operational. If an LED is burnt

out or damaged, however, it will not be able to provide any indication when an error condition may exist. For this

reason, more advanced information about verifying that the LEDs are operational is provided later in this chapter.

5.4 CONFIGURE COMPUTER ETHERNET PORTS TO COMMUNICATE WITH THE T RANSCEIVER

It is recommended that you use a computer with two Ethernet interfaces so that your computer can communicate with

a transceiver’s MAINT and LAN Ethernet ports at the same time. You need XtermW installed on the computer and have

administrative rights to configure the Ethernet interfaces.

Notes:

The following configuration examples are for directly connecting to the transceiver and bypassing any network

infrastructure. If direct access to the transceiver cannot be obtained, then contact your network administrator for

instructions.

If you are using the factory defaults, then use the following examples. If you are not using the factory defaults, then

contact your network administrator for the appropriate IP settings.

For these examples, Ethernet 1 refers to the computer’s first Ethernet port and is used for communication with the

transceiver MAINT port, and Ethernet 2 refers to the computer’s second Ethernet port and is used for communication

with the transceiver LAN port. It is possible to communicate with the radio transceiver using a computer with a single

Ethernet port, but you will only be able to communicate with one port at a time, and you will need to reconfigure the

port each time to use the appropriate IP address for the transceiver port you are connecting to.

ITC 220 Base Station, Locomotive & Wayside Radio Transceiver Field Service Guide PN 0046300120 Rev. A | Page 22

Page 29

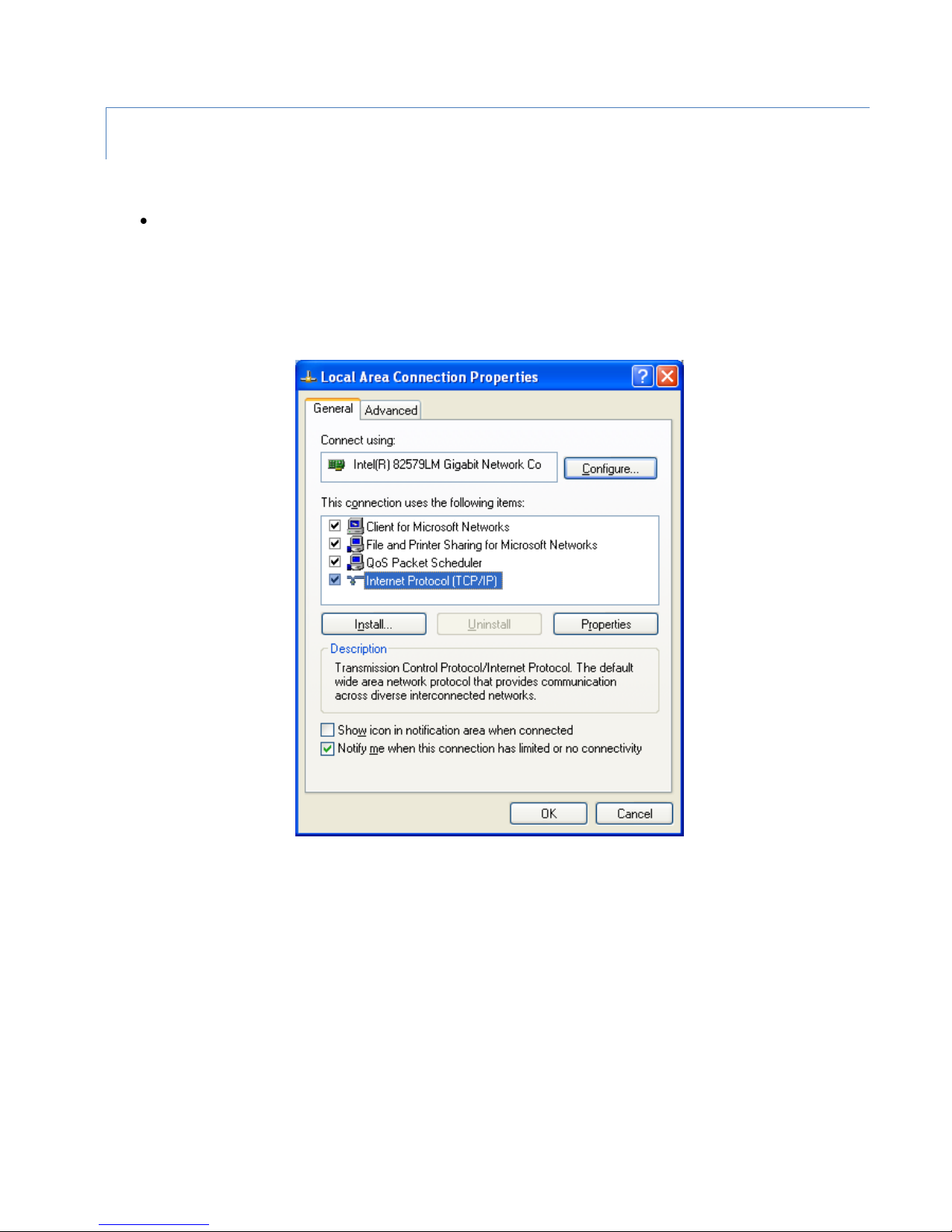

5.4.1 TO CONFIGURE TH E COMPUTER ETHERNET 1 INTERFACE FOR COMMUNICATION WITH

THE TRANSCE IVER MAINT PORT

1. On the computer, click Start, Control Panel, Network Connections, and then Local Area Connection.

There will be one Local Area Connection icon for each Ethernet port on the computer. Click the Local Area

Connection icon that corresponds to the first Ethernet port.

2. The Local Area Network Connection Status window opens. Click Properties and the Local Area Connection

Properties window for the first Ethernet connection opens.

Figure 13 Local Area Connection Properties window for Ethernet 1 connection

3. On the General tab, click on Internet Protocol (TCP/IP) to select it (you may have to scroll down in the items list to

see it—do not remove the check mark), and then click Properties.

ITC 220 Base Station, Locomotive & Wayside Radio Transceiver Field Service Guide PN 0046300120 Rev. A | Page 23

Page 30

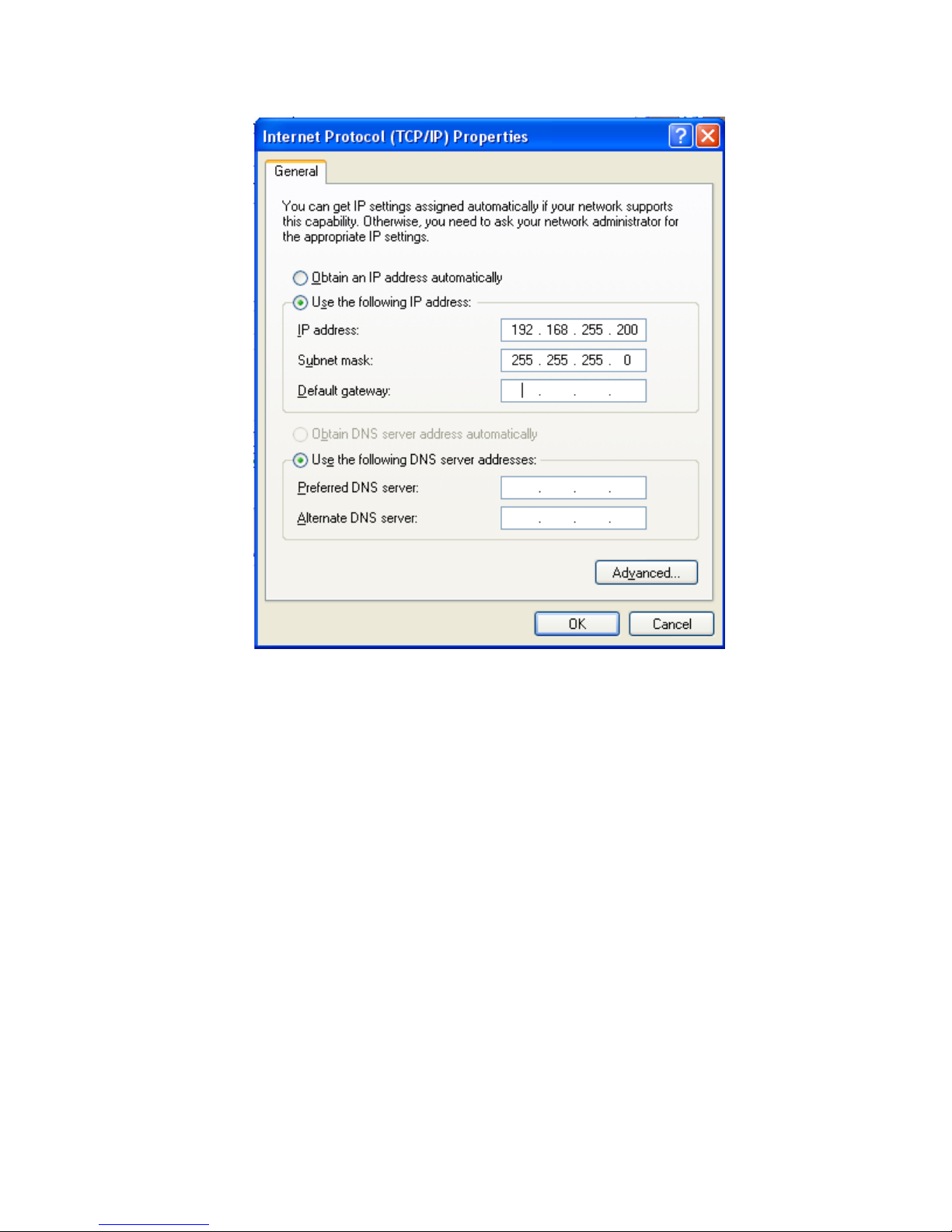

Figure 14 Internet Protocol (TCP/IP) Properties window for Ethernet 1 connection

4. Click Use the following IP address.

5. In the IP address box, enter 192.168.255.200.

6. In the Subnet mask box, enter 255.255.255.0.

7. Click OK.

ITC 220 Base Station, Locomotive & Wayside Radio Transceiver Field Service Guide PN 0046300120 Rev. A | Page 24

Page 31

8. In XtermW, set the connection properties for the MAINT port connection as shown in the following figure.

Figure 15 XtermW Configure Port window with settings for MAINT port

Note TCP/IP Settings for Host on the MAINT port is configured for IP address 192.168.255.201.

5.4.2 TO CONFIGURE THE COMPUTER ETHERNET 2 INT ERFACE FOR COMMUNICA TION WITH

THE TRANSCE IVER LAN PORT

1. On the computer, click Start, Control Panel, Network Connections, and then Local Area Connection.

There will be one Local Area Connection icon for each Ethernet port on the computer. Click the Local Area

Connection icon that corresponds to the second Ethernet port.

2. The Local Area Network Connection Status window opens. Click Properties and the Local Area Connection

Properties window for the second Ethernet connection opens.

ITC 220 Base Station, Locomotive & Wayside Radio Transceiver Field Service Guide PN 0046300120 Rev. A | Page 25

Page 32

Figure 16 Local Area Connection Properties window for Ethernet 2 connection

3. On the General tab, click on Internet Protocol (TCP/IP) to select it (you may have to scroll down the items list to

see it—do not remove the check mark) and then click Properties.

ITC 220 Base Station, Locomotive & Wayside Radio Transceiver Field Service Guide PN 0046300120 Rev. A | Page 26

Page 33

Figure 17 Internet Protocol (TCP/IP) Properties window for Ethernet 2 connection

4. Click Use the following IP address.

5. In the IP address box, enter 10.255.255.200.

6. In the Subnet mask box, enter 255.255.255.0.

7. Click OK.

ITC 220 Base Station, Locomotive & Wayside Radio Transceiver Field Service Guide PN 0046300120 Rev. A | Page 27

Page 34

8. In XtermW, set the connection properties for the LAN port connection as shown in the following figure.

Figure 18 XtermW Configure Port window with settings for LAN port

Note TCP/IP Settings for Host on the LAN port is configured for IP address 10.255.255.201.

5.4.3 CREATING AN XTERMW CONNECTION PROFILE

A connection profile is a group of configuration settings created in XtermW and saved to use again for convenience

when connecting to an Ethernet port using the same settings.

To create an XtermW connection profile

1. Open XtermW if it is not already open.

2. From the File menu, select New Connection and the Connection Description window opens.

Figure 19 Connection Description window

3. Enter a name for the connection and then click OK.

ITC 220 Base Station, Locomotive & Wayside Radio Transceiver Field Service Guide PN 0046300120 Rev. A | Page 28

Page 35

4. The Configure Port dialog window opens.

Figure 20 XtermW Configure Port window with settings for the MAINT port

5. Set Select Port Type to TCP/IP.

6. Set the Protocol to Stream.

7. Set TCP/IP Host and Port to the IP address and port for the Ethernet port you are connecting to.

The default IP address for the Transceiver MAINT port is 192.168.255.201.

The default IP address for the Transceiver LAN port is 10.255.255.201.

8. Set the Device Type and the rest of the settings in the window as shown in the figure.

9. Click OK to save the connection profile and connect to the specified Ethernet port.

To use a previously-saved connection profile in the future, open XtermW, and from the File menu, select Open, and

then select the connection profile to use.

5.4.4 VERIFY THAT THE MAINT AND LAN ETHERNET PORTS ARE OPERATIONAL

Use the preceding procedures to configure Ethernet ports of the test computer for connection to the Transceiver

MAINT and LAN ports, and connect the test computer to each these ports. The test computer should display an active

network connection on both ports (indicated in the System Tray in Windows XP) within 60 seconds.

ITC 220 Base Station, Locomotive & Wayside Radio Transceiver Field Service Guide PN 0046300120 Rev. A | Page 29

Page 36

5.5 REVIEW THE POWER ON SELF-TEST (POST) RESULTS

A POST is a series of several dozen tests that the transceiver quickly runs on itself, each time it boots up, to determine if

it has a problem or is missing critical information. The radio boots up when it is powered on or the BOOT command is

issued at the command line. Entering the POST command multiple times does not cause the tests to be re-run since

one execution of the tests are automatic at each power on.

POST results show whether the transceiver has passed a test, indicated by PASS, or failed a test, indicated by FAIL. The

results do not appear on the transceiver, which has no display screen. Instead, you send a command to the radio and

view the results on your computer monitor.

To view POST results, remove and reconnect DC power. The transceiver will automatically run internal diagnostics. A

flashing green PWR LED on the front panel indicates that the boot sequence has completed. Within 10 seconds the

Ethernet port becomes active.

Note — For the Base Station Transceiver, the transmitter is disabled for approximately 30 seconds after power is

applied. This delay allows the oven-controlled crystal oscillator to warm up enough to ensure the accuracy of the

transmitter frequency.

The computer must be configured and connected to the radio transceiver MAINT port, as explained in the previous

section. (Make sure your computer network card connected to the MAINT port has a fixed IP address of

192.168.255.200.)

To display the POST results:

1. If it is not already connected, connect the computer to the transceiver MAINT port, using a Category 5 or better

Ethernet cable.

2. On the computer, open the XtermW application, if it is not already open.

3. Click Send, click Command, and then type:

POST

4. Click OK.

5. View the POST results listing. See APPENDIX F— Sample POST Results Typical for Properly Functioning Transceiver.

5.6 VERIFY FRONT PANEL LEDS ARE OPERATIONAL (ALL TRANSCEIVER TYP ES) AND VERIFY

COOLING FANS ARE OPERATIONAL (BASE STATION TRANSCEIVERS ONL Y)

This section provides instructions to verify that all front-panel LEDs are operational and, for Base Station Transceivers,

to verify that the cooling fans are operational. (Only Base Station Transceivers are equipped with cooling fans.)

5.6.1 VERIFY ALL FRO NT-PANEL LEDS ARE OPERATIONAL

Front-panel LEDs must be operational to be useful in diagnosing transceiver problems. When not operational, they can

result in misleading information when attempting to troubleshoot problems.

ITC 220 Base Station, Locomotive & Wayside Radio Transceiver Field Service Guide PN 0046300120 Rev. A | Page 30

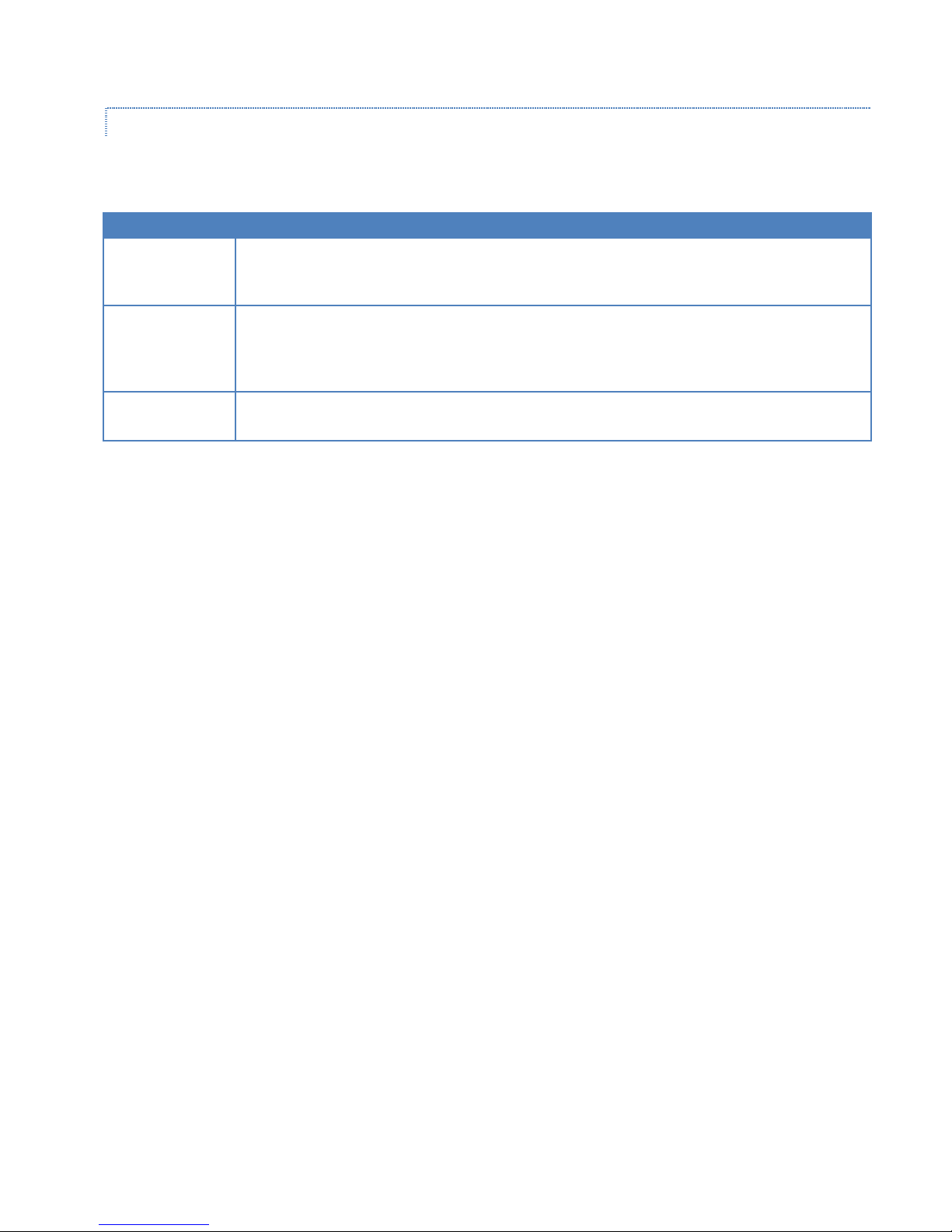

Page 37

To test the transceiver front-panel LEDs:

LED Label

IOD Value

LED Label

IOD Value

TX (Transmit link)

0x0020

STBY (Standby)

0x0400

SWR (VSWR)

0x0040

FLT (Fault)

0x0800

RX (Receive link)

0x0080

DTL (DTE Link)

0x0100

All On (except Power)*

0xFE0

RFL (RF Link)

0x0200

All Off (except Power)*

0x000

IOD Value

LED Label

LED Panel

LED Label

IOD Value

(none)

Power

Tx Transmit

0x0020

0x200

RF Link

Rx Receive

0x0080

0x100

DTE Link

Fault

0x0800

0x400

Standby

VSWR

0x0040

0xFE0

All On (except Power)*

0x000

All Off (except Power)*

1. If it is not already connected, connect the computer to the transceiver MAINT port, using a Category 5 or better

Ethernet cable.

2. On the computer, open the XtermW application, if it is not already open.

3. Click Send, click Command, and then type:

IOD,0xFE0

4. Click OK.

5. Verify that all LEDs illuminate, except the power LED (PWR) which will blink (as it does in normal operation when

power is applied to the transceiver).

6. Click Send, click Command, and then type:

IOD,0x000

7. Click OK.

8. Verify that all LEDs turn off, except the power LED which will continue to blink as in normal operation.

To test LEDs individually, use values from the following table with the IOD command to illuminate the associated LED.

Table 7 Front Panel LEDs and IOD values arranged by IOD value

*The PWR LED blinks; it does not illuminate solid on.

NOTE — Be sure to Send the Command IOD,0x000 (then click OK) to the transceiver when you have finished testing

the LEDs, to turn off all LEDs (except Power, which will blink), or alternatively restart the transceiver (using the BOOT

command, for example) to return all LEDs to normal operation.

Table 8 Front Panel LED IOD values arranged to panel LED arrangement

*The PWR LED blinks; it does not illuminate solid on.

ITC 220 Base Station, Locomotive & Wayside Radio Transceiver Field Service Guide PN 0046300120 Rev. A | Page 31

Page 38

5.6.2 VERIFY COOLING FANS ARE OPERATIONAL (BASE STATION TRANSCEIVERS ONLY)

Base Station Transceivers rely on the cooling fans being operational to help prevent overheating conditions. The Base

Station Transceiver has three cooling fans: one cooling fan is located on heat-sink fins on the right side of the

transceiver chassis, and two cooling fans are located on heat-sink fins at the rear of the unit.

To test the Base Station Transceiver cooling fans:

1. If it is not already connected, connect the computer to the transceiver MAINT port, using a Category 5 or better

Ethernet cable.

2. On the computer, open the XtermW application, if it is not already open.

3. Turn on the first fan, located on heat-sink fins at the right side of the transceiver:

a. Click Send, click Command, and then type:

FANS,ON,0

b. Click OK.

4. Verify that the first fan turns on and runs.

5. Turn on the second fan, located on the rear set of heat-sink fins to the right:

a. Click Send, click Command, and then type:

FANS,ON,1

b. Click OK.

6. Verify that the second fan turns on and runs.

7. Turn on the third fan, located on the rear set of heat-sink fins to the left:

a. Click Send, click Command, and then type:

FANS,ON,2

b. Click OK.

8. Verify that the third fan turns on and runs.

9. Turn each of the fans off, verifying that each turns off soon after clicking OK:

a. Click Send, click Command, and then type:

FANS,OFF,0

b. Click OK. The right-side fan turns off.

c. Click Send, click Command, and then type:

FANS,OFF,1

d. Click OK. The right rear fan turns off.

e. Click Send, click Command, and then type:

FANS,OFF,20

f. Click OK. The left rear fan turns off.

ITC 220 Base Station, Locomotive & Wayside Radio Transceiver Field Service Guide PN 0046300120 Rev. A | Page 32

Page 39