Caladair EXAECO 10, EXAECO Series, EXAECO 13, EXAECO 17, EXAECO 22 Operating And Commissioning Instructions

EXAECO ®

HIGH EFFICIENCY RECOVERY UNIT

OPERATING AND COMMISSIONING INSTRUCTIONS

MS-CDF-002

Ind D

Maj. 02/11/2018

Créé par : JC

Validé par : AR

Page 1/49

EXAECO ®

HIGH EFFICIENCY RECOVERY UNIT

OPERATING AND COMMISSIONING INSTRUCTIONS

MS-CDF-002

Ind D

Maj. 02/11/2018

Créé par : JC

Validé par : AR

Page 2/49

TABLE DES MATIERES

I. RECEIVING THE EQUIPMENT ................................................................................................................. 4

I.1. Checks on reception ........................................................................................................................ 4

I.2. Unpacking ........................................................................................................................................ 4

I.3. Storing ............................................................................................................................................. 4

I.3.a. End of life ................................................................................................................................. 4

II. INSTALLATION ........................................................................................................................................ 5

II.1. Handling .......................................................................................................................................... 5

II.1. Space required ................................................................................................................................ 5

II.2. Setting up ........................................................................................................................................ 6

II.2.a. Connection of separate modules ............................................................................................ 6

III. GENERAL FONCTIONNING ..................................................................................................................... 8

III.1. GENERALITE ................................................................................................................................. 8

III.2. ANALYSE FONCTIONNELLE .......................................................................................................... 8

III.3. MODE DE REGULATION ............................................................................................................... 9

III.3.a. ECO : ......................................................................................................................................... 9

III.3.b. DIVA® ........................................................................................................................................ 9

III.3.c. LOBBY® : ................................................................................................................................... 9

III.3.d. MAC2® : ................................................................................................................................... 9

III.3.e. QUATTRO® : ............................................................................................................................. 9

III.4. COMPOSITION ........................................................................................................................... 10

III.5. ELEMENT IN CONTROL CABINET ............................................................................................... 11

IV. ELECTRICAL WIRING ............................................................................................................................. 12

IV.1. POWER SUPPLY.......................................................................................................................... 12

IV.2. TEMPERATURE SENSOR WIRING ............................................................................................... 12

IV.3. TERMINAL BLOCKS .................................................................................................................... 12

IV.4. Wiring and operation of rotative exchanger ............................................................................. 14

IV.5. Wiring and operation of 3 ways mixed dampers (FEE) ............................................................. 15

IV.6. Filter pressure switch wiring ..................................................................................................... 16

IV.7. Fan pressure switch ................................................................................................................... 16

IV.8. Pressure transmitter of LOBBY®/MAC2®/QUATTRO® ................................................................ 16

IV.9. Motors wiring ............................................................................................................................ 17

IV.10. CO2 transmitter wiring .............................................................................................................. 17

IV.11. Night Cooling (Surventilation nocturne) ................................................................................... 17

IV.12. Hot water coil intergrated (H) / Changeover water coil (CO) et cold coil C .............................. 18

IV.13. DX cold coil or changeover DX coil ............................................................................................ 19

IV.14. Electrical Battery ....................................................................................................................... 19

IV.15. Fonction incendie ...................................................................................................................... 20

IV.16. Raccordement du MODBUS / WEB / BACNET ........................................................................... 20

V. SETTINGS .............................................................................................................................................. 21

V.1. Display ........................................................................................................................................... 21

V.2. Exemple of setting ........................................................................................................................ 21

V.1. Standard settings (opérator menu) .............................................................................................. 22

V.1.a. Menu running mode .............................................................................................................. 23

V.1.b. Temperature menu ................................................................................................................ 24

V.1.c. Ventilation menu ................................................................................................................... 25

EXAECO ®

HIGH EFFICIENCY RECOVERY UNIT

OPERATING AND COMMISSIONING INSTRUCTIONS

MS-CDF-002

Ind D

Maj. 02/11/2018

Créé par : JC

Validé par : AR

Page 3/49

V.1.d. Timer menu ............................................................................................................................ 26

V.2. Operator parameters modification ( password 3333 required) ................................................... 27

V.2.a. Dates and hours clocks setting .............................................................................................. 27

V.2.b. CO2 setpoint modification for three ways mixing damper (FEE) (except DIVA et QUATTRO)

28

V.2.c. Temperature setpoint modification ...................................................................................... 28

V.2.d. Forced stop of the unit or forced start LS or HS on the remote control ............................... 28

V.2.a. Choice of language................................................................................................................. 28

V.3. Intermediate settings (service level) ............................................................................................ 28

V.3.a. Menu configuration en accès service .................................................................................... 29

V.4. Modification of the services parameters (password 2222) .......................................................... 29

V.4.a. Regulation mode of the unit [(1) chapter V.3.a] ................................................................... 29

V.4.b. Overventilation parameters [(2) chapter V.3.a] .................................................................... 29

V.4.c. CO2 setpoint for DIVA / QUATTRO option [(3) Chapter V.3.a] ............................................. 29

V.4.d. Minimum opening percentage of the 3 ways mixing damper (FEE) [(4) chapitre V.3.a] ..... 29

V.5. Administrator settings .................................................................................................................. 30

V.5.a. Configuration menu with admin level access ........................................................................ 30

V.6. Modification of the service parameters ....................................................................................... 31

V.6.a. MODBUS ................................................................................................................................ 31

V.6.b. Communication WEB ............................................................................................................. 31

V.6.c. BACNET .................................................................................................................................. 32

V.6.d. Fire funtion activation ........................................................................................................... 32

VI. REPAIR .................................................................................................................................................. 33

VI.1. Different types of defaults....................................................................................................... 33

VI.2. List of alarms ............................................................................................................................. 33

VI.3. Acknowledge the default « timer service » .............................................................................. 35

VII. MAINTENANCE.................................................................................................................................. 36

VII.1. Mandatory maintenance ........................................................................................................... 36

VII.2. Battery replacement ................................................................................................................. 36

VIII. ANNEXES ........................................................................................................................................... 38

VIII.1. Power diagram EXAECO 10 ....................................................................................................... 38

VIII.2. Power diagram EXAECO 13-22 .................................................................................................. 39

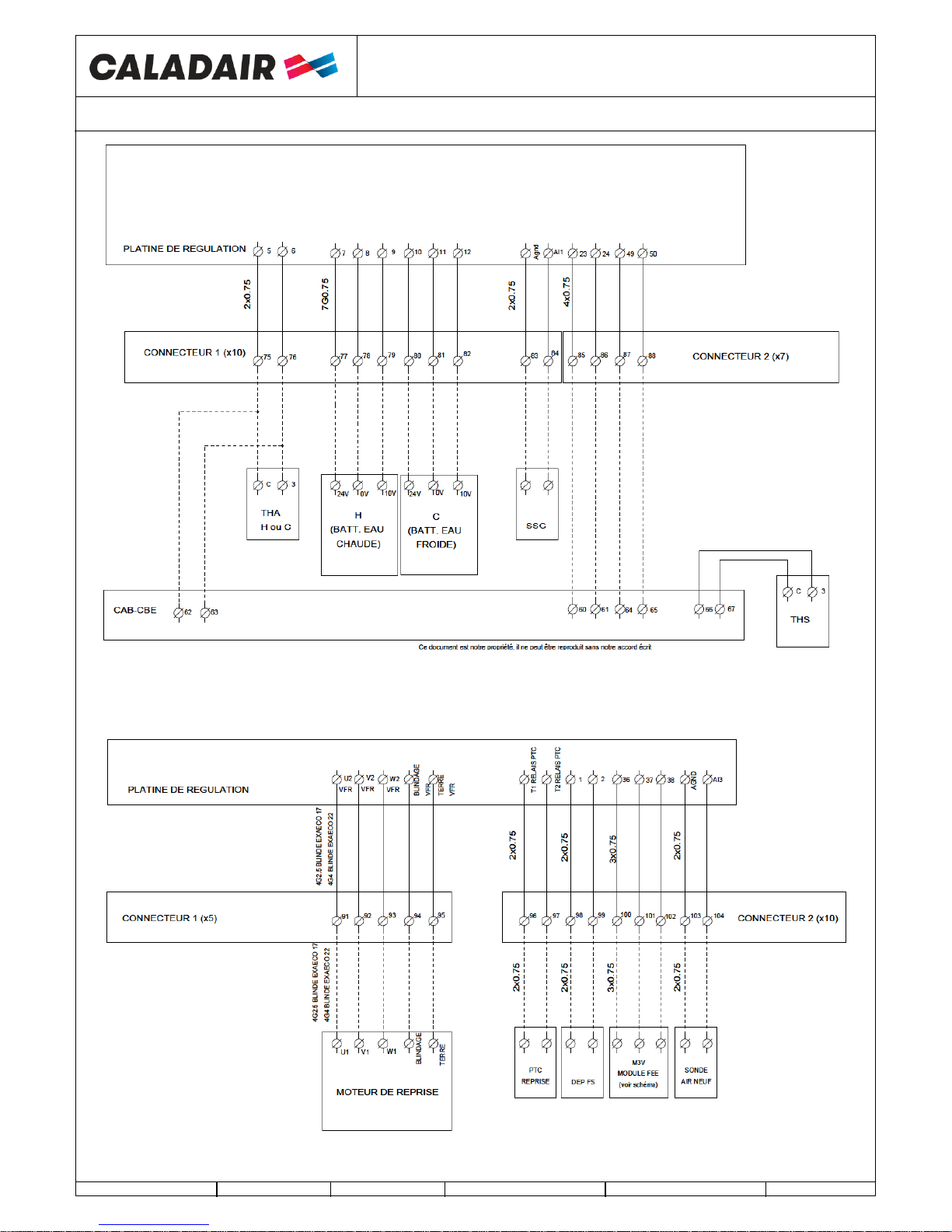

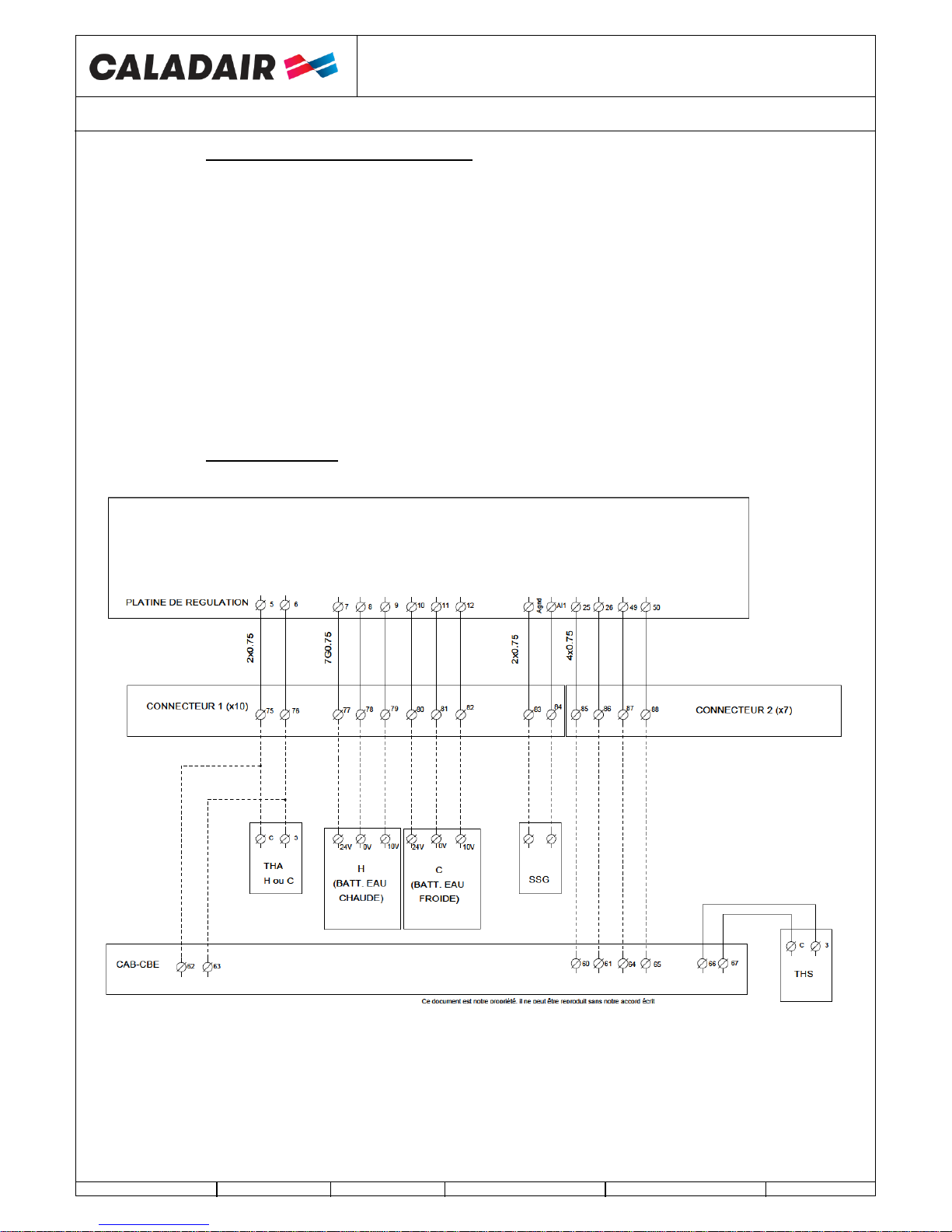

VIII.3. Control diagram ......................................................................................................................... 40

VIII.4. Motors wiring ............................................................................................................................ 42

VIII.5. Aeraulics diagram ...................................................................................................................... 43

VIII.5.a. EXAECO 10 .......................................................................................................................... 43

VIII.5.b. EXAECO 13 .......................................................................................................................... 43

VIII.5.c. EXAECO 17 .......................................................................................................................... 44

VIII.5.d. EXAECO 22 .......................................................................................................................... 44

VIII.5.e. Opening percentage curve of the FEE module .................................................................. 45

VIII.6. MODBUS register table ............................................................................................................. 46

IX. NOTES .................................................................................................................................................. 49

EXAECO ®

HIGH EFFICIENCY RECOVERY UNIT

OPERATING AND COMMISSIONING INSTRUCTIONS

MS-CDF-002

Ind D

Maj. 02/11/2018

Créé par : JC

Validé par : AR

Page 4/49

I. RECEIVING THE EQUIPMENT

The units are delivered fixed on longitudinal members or on blocks then wrapped in plastic film.

I.1. Checks on reception

When the equipment is received, the state of the packaging and the equipment must be checked. In the event of damage, make

an accurate note of any problems on the carrier's delivery note

I.2. Unpacking

When the equipment is unpacked, check the following:

o The total number of packages is present.

o All accessories are present (dampers, roof, electric switchgear, etc.). After unpacking the equipment, the waste must

be disposed of in compliance with the current standards.

o No packaging should be discarded into the environment

I.3. Storing

The equipment must be stored in shade, in a dry place, at a temperature between -20°C and 40°C. The packaging can’t be

considered sufficient for an external storage.

I.3.a. End of life

In accordance with the partnerships with the compagny ECOLOGIC. CALADAIR fulfills the obligations to finance the

collection, removal and treatment of Waste Electrical and Electronic Equipment.

At the end of the life of this equipment, the user contacts the company ECOLOGIC who will propose a collection solution or a

place of deposit for the product.

Contacts for pick-up requests:

E-mail: operations-pro@ecologic-france.com

Phone: 01 30 57 79 14

Internet: www.e-dechet.com

SAFETY INSTRUCTIONS

In compliance with the current norms, the machine should be installed only by a technical person qualified for this type

of work.

Use the required personal protection devices so as to avoid injuries caused by electrical and mechanical hazards (injuries

by touching panels, sharp edges, etc.). Use EN170 protective eyewear and ear protection.

Do not use the unit for an other used which it designed. This unit can’t be use for extract or supply dangerous air.

Move the machine as given in chapter handling.

Grounding is carried out in compliance with current standards. Never start the device without grounding

Before any intervention ensure that device is powered off and wait for complete stop of every rotative component such as

damper, fan, rotative exchanger…

During device is running inspection doors must be mounted and closed.

Start is to be done only with padlockable swith.

Do not shut off or short circuit the safety and control equipment.

During interventions, be carefull with hot components such as hot water coil or electric resistances.

The machine should be installed in compliance with fire norms.

The waste must be disposed of in compliance with the current standards. No packaging should be discarded into the

environment.

We disclaim any responsibility for any damages resulting from wrong utilisation of the equipment, reparation,

modification or non compliance of these instructions.

EXAECO ®

HIGH EFFICIENCY RECOVERY UNIT

OPERATING AND COMMISSIONING INSTRUCTIONS

MS-CDF-002

Ind D

Maj. 02/11/2018

Créé par : JC

Validé par : AR

Page 5/49

II. INSTALLATION

II.1. Handling

The units must only be moved in their installation position.

If the device is handled using a fork-lift truck, ensure this supports the load-bearing structure.

If the device is moved using a crane, use four cables of identical lengths. These must be at least as long as the greatest distance

between two fastening points.

II.1. Space required

In general, it is desirable to have an access space at least equal to the dimension B for maintenance.

EXAECO ®

HIGH EFFICIENCY RECOVERY UNIT

OPERATING AND COMMISSIONING INSTRUCTIONS

MS-CDF-002

Ind D

Maj. 02/11/2018

Créé par : JC

Validé par : AR

Page 6/49

II.2. Setting up

The unit must be laid on a sufficiently rigid and flat surface (use vibration mounts if necessary). For the HVAC connection,

select duct sections based on dimensions of the flexible bands that should be properly stretchedhe ducts should be insulated

and the first accessories should be at 2.5 times the diameter (Tee elbow ...). Install the unit such that bad weather or ambient

temperature cannot damage the internal items of the unit during installation as well as when used later

Provide a siphon on each condensate drainage pipe. A siphon can only be used for one drainage system.

Note: the siphon must be connected in accordance with Best Practices in order that the condensates are

removed as efficiently as possible.

The height H must be at least equal to the maximum internal negative pressure of the unit (Dp in mm).

Example : Dp = 500 Pa @ 50 mm CE

H > 50 mm 2H > 100 mm

The unit placed outside must always be fixed to the floor of the support frame, so that it can not move or fall (take into account

the force of the wind). Also provide a roof (DPE) as well as awnings rain (AGE) if necessary (optional).

II.2.a. Connection of separate modules

The connecting brackets between boxes are prefixed on each of the modules of EXAECO.

If necessary, wedge the boxes so that the amounts of these are perfectly parallel.

Bring the modules together and secure them by tightening the bolts (provided) with the mounting brackets (M6 x 16). Also

tighten the M8 X30 bolt (supplied) on the chassis.

II.2.a.1. Climatic module (version ELITE)

Connect the 2 quick connectors and the clear tube for the LOBBY versions.

EXAECO ®

HIGH EFFICIENCY RECOVERY UNIT

OPERATING AND COMMISSIONING INSTRUCTIONS

MS-CDF-002

Ind D

Maj. 02/11/2018

Créé par : JC

Validé par : AR

Page 7/49

II.2.a.2. Principal module (EXAECO 17-22)

EXAECO ®

HIGH EFFICIENCY RECOVERY UNIT

OPERATING AND COMMISSIONING INSTRUCTIONS

MS-CDF-002

Ind D

Maj. 02/11/2018

Créé par : JC

Validé par : AR

Page 8/49

III. GENERAL FONCTIONNING

III.1. GENERALITE

EXAECO® range are programme of double-flow units with high efficiency recovery, self-regulating recovery meant for office

and industrial installations. Its performance is greater than 80%.

EXAECO® ELITE : (example EXAECO ELITE HC) manage on or two coil H = Heat water coil / E = Electrical / C-CO =

Cooling or changeover Coil / HC = Hot water coil + cooling water coil / EC =Electrical battery + cooling water coil / HDX =

Hot water coil + DX coil R410A / EDX = Electrical + Cooling DX coil R410A / DX-DXR = Colling DX coil or changeover

DX coil R410A.

The EXAECO® standard allows the management of the blowing temperature with external compensation below 13 ° C (air

law) and depending on the recovery above 13 ° C.

III.2. ANALYSE FONCTIONNELLE

Except SEASON version

Starting sequence :

o The supply air fan starts and the fresh air register opens.

o The extract air fan starts and the extract air register opens

o Temperature regulation starts defined in the regulation mode set. Electric heater (if set), starts with airflow controller.

Pumps start.

o After a defined time, alarms management function is activated. Installation is in normal mode.

Start conditions :

Installation starts when one of these conditions are filled:

o Timer normal or reduced are activate

o Manual start is activated with controller

o One of the digital input for extended operation is activated.

Stop sequence :

Installation stops with following process:

o Deactivation of the alarm management function.

o Electric heater stops (if set).

o After a defined time (individually defined for each fan) fans are stopped.

o Supply and return air registers are closed .

o Signals toward actuator are reset and pumps closed

Stop conditions :

Installation stops when one these conditions are filled:

o Timers normal or reduced are not activated and digital input for extended operation is not activated.

o Digital Input for External stop is activated.

o Manual stop is activated with controller

o An alarm configured with stop function is activated. Installation will automatically start when alarm is reset.

EXAECO ®

HIGH EFFICIENCY RECOVERY UNIT

OPERATING AND COMMISSIONING INSTRUCTIONS

MS-CDF-002

Ind D

Maj. 02/11/2018

Créé par : JC

Validé par : AR

Page 9/49

Speed HS

Speed LS

III.3. MODE DE REGULATION

III.3.a. ECO :

1 or 2 speeds adjustable « MODE VENTIL (%) »

Adjustment of a minimum speed (LS - 1/2) and a maximum speed (HS - 1/1) in %.

Fitted with a factory turned clocked set

• (RECIRCULATION) from 05h00 to 07h00

• (HS - 1/1) from 07h00 to 22h00

• (LS - 1/2) from 00h00 to 05h00 and from 22h00 to 24h00

Possibility of adding a remote forced start (LS - 1/2) or (HS - 1/1) (free voltage contact NO)

Possibility of adding a remote forced stop (contacts secs NO) et une marche forcée recirculation (contacts secs NO)

III.3.b. DIVA®

Proportional ventilation between two airflows (LS/HS) with CO2 management

« AUTO CO2 MODE »

Adjustment of a minimum speed (LS - 1/2) and a maximum speed (HS - 1/1) in %

CO2’s setpoint is set in factory to 1000ppm (compliant to French RT2012).

Variation between (LS - 1/2) and (HS - 1/1) is managed from CO2 level

(No modulation regarding the CO2 on the three way dampers)

Fitted with a factory turned clocked set in (LS - 1/2). (Recirculation from 05h00 to 07h00)

Possibility of adding a remote forced start (LS - 1/2) or (HS - 1/1) (free voltage contact NO)

Possibility of adding a remote forced stop (contacts secs NO) et une marche forcée recirculation (contacts secs NO)

Nota : In order for the CO2 regulation works, installation must follow these constraints :

o Clock (HS - 1/1) is not activated (normal speed timer)

o Clock (LS - 1/2) is activated (reduced speed Timer)

o External operation (HS - 1/1) and external stop are not activated.

III.3.c. LOBBY® :

Constant pressure ventilation. (Pa) « CONSTANT PA MODE»

Constant pressure adjustement (Pa).

Fitted with a factory turned clocked set in (LS - 1/2) from 00h00 to 24h00.

Possibility of adding a remote forced start (LS - 1/2) or (HS - 1/1) (free voltage contact NO)

Possibility of adding a remote forced stop (contacts secs NO) et une marche forcée recirculation (contacts secs NO)

III.3.d. MAC2® :

1 or 2 constant air flow (m3/h) adjustable « MODE CONSTANT M3/H »

Adjustment of a minimum constant air flow (LS - 1/2) and a maximum air flow (HS - 1/1) in m3/h

Équipée d’une horloge réglée d’usine en :

o (RECIRCULATION) de 05h00 à 07h00

o (GV - 1/1) de 07h00 à 22h00

o (PV - 1/2) de 00h00 à 05h00 et de 22h00 à 24h00

Possibility of adding a remote forced start (LS - 1/2) or (HS - 1/1) (free voltage contact NO)

Possibility of adding a remote forced stop (contacts secs NO) et une marche forcée recirculation (contacts secs NO)

III.3.e. QUATTRO® :

1 or 2 constant air flow (m3/h) adjustable « MODE CONSTANT M3/H » with CO2 management

Adjustment of a minimum constant air flow (LS - 1/2) and a maximum air flow (HS - 1/1) in m3/h

CO2’s setpoint is set in factory to 1000ppm (compliant to French RT2012).

Variation between (LS - 1/2) and (HS - 1/1) is managed from CO2 level

(No modulation regarding the CO2 on the three way dampers)

Fitted with a factory turned clocked set in (LS - 1/2) from 00h00 to 24h00.

Possibility of adding a remote forced start (LS - 1/2) (free voltage contact NO)

Possibility of adding a remote forced stop (contacts secs NO) et une marche forcée recirculation (contacts secs NO)

Nota : In order for the CO2 regulation works, installation must follow these constraints :

o Clock (HS - 1/1) is not activated (normal speed timer)

o Clock (LS - 1/2) is activated (reduced speed Timer)

o External operation (HS - 1/1) and external stop are not activated.

Speed HS

Speed LS

EXAECO ®

HIGH EFFICIENCY RECOVERY UNIT

OPERATING AND COMMISSIONING INSTRUCTIONS

MS-CDF-002

Ind D

Maj. 02/11/2018

Créé par : JC

Validé par : AR

Page 10/49

III.4. COMPOSITION

Nom

Détails

RMR/RMS/RMRE

Extract damper / Supply damper / Recirculation damper

VR

Extract air fan

C2

Connector to connect modules of EXAECO 17 and 22

CO2

CO2 sensor

REGULATION

Control cabinet

SRG

Extract temperature sensor

C1

Connector to connect module module ELITE

THA

External frost guard thermostat (version ELITE H)

THS

Overheat security switch (version ELITE E)

SSG

Supply temperature sensor

VS

Supply air fan

ROUE

Rotative exchanger

DEPFS

Filter pressure switch

SEG

Outdoor temperature sensor

AIR

REPRIS

VS

VR

SRG

SEG

CO2

C1

RMS

RMR

RMRE

ROUE

REGULATION

SSG

SIPHON

ALIM CAB-CBE

DEPFS

BATT 1

BATT 2

THS

THA

AIR

EXTERIEUR

C2

AIR

AIR

NEUF

EXAECO ®

HIGH EFFICIENCY RECOVERY UNIT

OPERATING AND COMMISSIONING INSTRUCTIONS

MS-CDF-002

Ind D

Maj. 02/11/2018

Créé par : JC

Validé par : AR

Page 11/49

III.5. ELEMENT IN CONTROL CABINET

Nom

Détails

1

CORRIGO E283W3 CLD (Master controller)

2

CORRIGO E283W3 CLD (Slave controller)

3

Terminal blocks (1 to 26)

4

DEPS (Supply pressure switch for version Standard and DIVA) or TRPS (Supply pressure transmitter

for LOBBY, MAC2 et QUATTRO)

5

TRAFO Transformer 230/24V

6

DEPR (Extract pressure switch for version Standard and DIVA) or TRPS (Extract pressure transmitter

for LOBBY, MAC2 et QUATTRO)

7

Terminal blocks (27 to 74)

8

DEP FR filter pressure switch

9

Terminal blocks (main supply)

10

Control breaker

11

Proximity security switch

12

VF ROUE frequency converter of rotative exchanger

13

Control relay R1 = AN + PURE / R2 = AR / R3 = ROUE / R4 = FEE

14

SRG Extract temperature air fan

15

Relay PTO S (relay for thermal security of supply air fan (except EXAECO 10)

16

Relay PTO R (relay for thermal security of extract air fan (except EXAECO 10)

17

VF S (frequency converter of supply air fan) (except EXAECO 10)

18

VF R ( frequency converter of extract air fan ) (except EXAECO 10)

2

4

5

10

8

15

18

EXAECO ®

HIGH EFFICIENCY RECOVERY UNIT

OPERATING AND COMMISSIONING INSTRUCTIONS

MS-CDF-002

Ind D

Maj. 02/11/2018

Créé par : JC

Validé par : AR

Page 12/49

IV. ELECTRICAL WIRING

IV.1. POWER SUPPLY

IV.2. TEMPERATURE SENSOR WIRING

Temperature sensors are connected on the controller

o SSG : Supply temperature sensor on terminal blocks 9 and 10 of the connector placed between EXAECO and the

ELITE module

o SEG : Outdoor temperature sensor on Agnd(30) and AI2(32) (slave)

o SRG : Extract temperature sensor on Agnd(33) and AI3 (34) (slave)

IV.3. TERMINAL BLOCKS

*Connect directly on controller CORRIGO

** Connect directly on controller CORRIGO and 8A max on all DO

Designation

Terminal blocks

Wiring

DEP FS

DEP FR

1-2

3-4

Connect to terminal of exhaust filter switch

Connect to terminal 1 and 3 of return filter switch

C1 (connector)

5-6-7-8-9-10-11-25-2649-50 Agnd et AI1

Connect to the connector C1

Agnd and AI ext 1 are placed on CORRIGO E282-S CLD

TRPS

14 / Agnd* + UI Ext 1*

Connect to supply Pressure Transmitter

DEPS

15 + UI Ext 1*

Connect to terminal 1 and 3 of supply pressure switch

TRPR

16 / Agnd* + UI Ext 2*

Connect to return pressure Transmitter

DEPR

17 + UI Ext2*

Connect to terminal 1 and 3 of return pressure switch

CO2

18 / Agnd* UI Ext 4*

Connect to terminal 1 and 3 of return pressure switch

7

1

2

4 6 8

3

5

9

10

12

11

13

14

15

16

17

18

19

20

21

22

23

24

25

26

EXAECO ®

HIGH EFFICIENCY RECOVERY UNIT

OPERATING AND COMMISSIONING INSTRUCTIONS

MS-CDF-002

Ind D

Maj. 02/11/2018

Créé par : JC

Validé par : AR

Page 13/49

*Connect directly on controller CORRIGO

** Connect directly on controller CORRIGO and 8A max on all DO

Designation

Terminal blocks

Wiring

MF GV

39-40

Connect to NO free voltage contact of normal Speed extended operation

MF PV

41-42

Connect to NO free voltage contact of reduced Speed extended operation

ARR Externe

43-44

Connect to NO free voltage contact of external stop

IND P

45-46

Connect to the default contact of Heating and cooling circulator. Défault =

closed contacte (free voltage contact mandatory)

MF Recycl

47-48

Connect to NO free voltage contact of Recirculation extended operation

Heating pump**

49-50

Connect to hot water circulator (Note : 24V 2AMax to relay)

DAD

57-58

59-60

57-58 Connect to the power supply of the DAD (L et N)

59-60 = Connect to the default contact of the DAD (10-11) (shunted if not

used)

ADP (shunted if not

used)

61-62

Connect on fire emergency stop (free voltage NC contact)

Cooling pump **

63-64

Connect to cold water circulator (Note : 24V 2AMax to relay)

NC (Night cooling)

(LOBBY®)

65-66

24V output available if unit runs with the optional LOBBY EC for opening

dampers during Night Cooling. (pay attention : 24V 2A Max to relay)

Heating demand

71-72

24V output available if unit is in heating demand. Could be used to manage

DX coils (pay attention : 24V 2A Max to relay)

Cooling demand

73-74

24V output available if unit is in cooling demand. Could be used to manage

DX coils (pay attention : 24V 2A Max to relay)

33

51

27

52

28

53

54

30

55

56

32

57

58

34

29

31

59

35

60

36

61

62

38

63

37

39

46

64

40

65

41

66

67

43

68

69

45

70

71

47

42

44

72

48

73

49

74

50

EXAECO ®

HIGH EFFICIENCY RECOVERY UNIT

OPERATING AND COMMISSIONING INSTRUCTIONS

MS-CDF-002

Ind D

Maj. 02/11/2018

Créé par : JC

Validé par : AR

Page 14/49

IV.4. Wiring and operation of rotative exchanger

Rotative exchanger is factory wired

CORRIGO controller drives automatically the bypass thanks to programmation and sensor mounted in standard on EXAECO

units.

In winter: when heat is needed, The rotative exchanger starts to recover maximum of calories. This recovery is associated with

3 ways mixed dampers If it is not enough to reach the temperature setpoint, hot battery starts running.

En été :

COLD RECOVERY : if outside temperature is higher than inside temperature and cold is needed , The rotative exchanger

starts to recover maximum of calories. This recovery is associated with 3 ways mixed dampers. If it is not enough to reach the

setpoint, cold battery starts running.

FREE COOLING : if outside temperature is lower than inside temperature and cold is needed , The rotative exchanger stops to

bring directly outside fresh air. This recovery is associated with 3 ways mixed dampers. If it is not enough to reach temperature

setpoint cold battery starts running.

EXAECO ®

HIGH EFFICIENCY RECOVERY UNIT

OPERATING AND COMMISSIONING INSTRUCTIONS

MS-CDF-002

Ind D

Maj. 02/11/2018

Créé par : JC

Validé par : AR

Page 15/49

IV.5. Wiring and operation of 3 ways mixed dampers (FEE)

3 ways mixed dampers are factory wired

CORRIGO controller drives automatically the bypass thanks to programmation and sensor mounted in standard on EXAECO

units.

RECIRCULATION : The recirculation function is used to warm up the building when it is not occupied (BOOST function).

When activated, the 3-way module is completely recycled. Hot and cold outputs are active. The recirculation function is set as

standard from 05:00 to 07:00. It can be actuated either by the clock 5 or by an external free voltage contact connected between

the terminals 47-48. If the Night Cooling function is active, then it will have priority over recirculation.

For LOBBY® EC versions, a 24V output (to be relayed) is available between terminals 69-70 to force the opening of the

dampers during the recirculation period. To wire independently of the Night Cooling output

The functions below will not be active if the control panel is associated with a DIVA or QUATTRO option

TEMPERATURE FUNCTION OF MODULE FEE

In winter : When you are in hot demand, the 3-way module closes appropriately until the maximum recycling (minimum fresh

air flow rate can be adjusted (see chapter V.6.d)) to recover a maximum of calories. This recovery is associated with the rotary

exchanger. If it is not enough to reach the temperature setpoint, the hot battery goes into action

In summer :

COLD RECOVERY: If the outdoor temperature is higher than the indoor temperature and when there is a cold demand, the 3way module closes appropriately until the maximum recycling (minimum fresh air flow rate can be adjusted to This recovery is

associated with the rotary heat exchanger If it is not enough to reach the temperature setpoint, the cold battery goes into action.

FREE COOLING: If the outdoor temperature is lower than the indoor temperature and you are in cold demand, the 3-way

module opens appropriately until all fresh air to recover a maximum of calories. This recovery is associated with the rotary

exchanger. If it is not enough to reach the temperature setpoint, the cold battery goes into action

CO2 FUNCTION OF THE FEE MODULE: The 3-way module also manages the indoor air quality. In the case where the CO2

level in the building is higher than the setpoint then the signal imposing the most fresh air (temperature or CO2) will have

priority.

EXAECO ®

HIGH EFFICIENCY RECOVERY UNIT

OPERATING AND COMMISSIONING INSTRUCTIONS

MS-CDF-002

Ind D

Maj. 02/11/2018

Créé par : JC

Validé par : AR

Page 16/49

IV.6. Filter pressure switch wiring

The supply air filter pressure switch is factory connected

IV.7. Fan pressure switch

The fans pressure switchs are factory connected

IV.8. Pressure transmitter of LOBBY®/MAC2®/QUATTRO®

Fans pressure transmitters are factory connected

1

DEPFR

DEP FS

TRPS/R

MAC2 - QUATTRO

EXAECO ®

HIGH EFFICIENCY RECOVERY UNIT

OPERATING AND COMMISSIONING INSTRUCTIONS

MS-CDF-002

Ind D

Maj. 02/11/2018

Créé par : JC

Validé par : AR

Page 17/49

IV.9. Motors wiring

See chapter VIII.4

IV.10. CO2 transmitter wiring

CO2 transmitter is factory connected

IV.11. Night Cooling (Surventilation nocturne)

This function is used during summer to cool down buildings during nights with outside cool air. It decreases the cold needs

during days. Night Cooling function runs only from 00:00 AM to 7:00 h AM. During Night Cooling, hot and cool outputs are

locked on 0V. Exchanger runs only with fresh air. At the end of Night Cooling period heating is blocked to 0V during 60

minutes.

Start conditions: customizable in chapter V.5.b.2

o Outside temperatures are higher to 22°C during the day.

o Clocks are setted in LS or stopped during 00h00 and 07h00.

o Outside temperature is lower than 18°C during Night Cooling period

o Outside temperature is higher to 10°C during Night Cooling period

o Room temperature is higher to 18°C

During Night Cooling period fans are running 85% of their capacity. This speed is adjustable (see chapter V.5.b.2)

For LOBBY versions, a 24V output (to relay) is available between 22 and DO7 terminals to force the opening of damper’s

zone during Night Cooling period.

Tube remote

after battery

for ELITE

version

LOBBY

EXAECO ®

HIGH EFFICIENCY RECOVERY UNIT

OPERATING AND COMMISSIONING INSTRUCTIONS

MS-CDF-002

Ind D

Maj. 02/11/2018

Créé par : JC

Validé par : AR

Page 18/49

IV.12. Hot water coil intergrated (H) / Changeover water coil (CO) et cold coil C

For units equipped with a cold battery or changeover, the additional module is equipped with a removable stainless

steel condensate tray with integrated siphon. Connection of the PVC pipe diameter 32 to predict.

Connection between the additional module and the B1 junction box to be made.

Pay attention to let the doors free of access (ducts, cables)

In the ELITE and EDEN version, the battery is already installed in the central unit, the Antifreeze Thermostat is connected.

However, you must wire the 3-way valve. If you are using a hot coil battery, also connect the THA (Thermostat Antifreeze)

and remove the supply temperature sensor after the battery

THE VALVE MUST BE CONNECTED OFF

Connect the actuator of the 3-way valve as follows:

Hot Battery :

Terminal 77 of the connector B1 (additional module) on +24V (G) of the actuator

Terminal 78 of the connector B1 (additional module) on 0V (G0) of the actuator

Terminal 79 of the connector B1 (additional module) on 10V (Y) of the actuator

Connect the NC contact (C et 2) of THA (THermostat Antigel) on terminal 75 and 76 of the connector B1 (additional module)

Possibility to connect the hot water circulator to the control unit on the terminals 49 and 50. (Note: 24V output to relay)

Possibility to connect a free voltage contact NO pump fault on the terminals 45 et 46

Cold battery :

Terminal 80 of the connector B1 (additional module) on +24V (G) of the actuator

Terminal 81 of the connector B1 (additional module) on 0V (G0) of the actuator

Terminal 82 of the connector B1 (additional module) on 10V (Y) of the actuator

Connect the NC contact (C et 2) of THA (THermostat Antigel) on terminal 75 and 76 of the connector B1 (additional module)

Possibility to connect the cold water circulator to the control unit on the terminals 63 and 64. (Note: 24V output to relay)

Possibility to connect a free voltage contact NO pump fault on the terminals 45 et 46

Changeover battery :

Red wire of changeover thermostat (CO) on 10V (Y) of the actuator

Terminal 77 of the connector B1 (additional module) on +24V (G) of the actuator

Terminal 78 of the connector B1 (additional module) on 0V (G0) of the actuator

Terminal 79 of the connector B1 (additional module) on brown wire of changeover thermostat (CO)

Terminal 82 of the connector B1 (additional module) on black wire of changeover thermostat (CO)

Connect the NC contact (C et 2) of THA (THermostat Antigel) on terminal 75 and 76 of the connector B1 (additional module)

Possibility to connect the hot water circulator to the control unit on the terminals 49 and 50. (Note: 24V output to relay)

Possibility to connect the cold water circulator to the control unit on the terminals 63 and 64. (Note: 24V output to relay)

Possibility to connect a free voltage contact NO pump fault on the terminals 45 et 46

EXAECO ®

HIGH EFFICIENCY RECOVERY UNIT

OPERATING AND COMMISSIONING INSTRUCTIONS

MS-CDF-002

Ind D

Maj. 02/11/2018

Créé par : JC

Validé par : AR

Page 19/49

IV.13. DX cold coil or changeover DX coil

A condensate connection via a siphon is to be expected.

Possibility of connections :

• 24 V available when the unit is on hot or cold demand.

• 0-10V hot and cold analogue outputs.

Hot demand :

• 24V digital output : To be connected to terminals 71 and 72 and to give the run command to drive a DX module

(Attention 24V 2A Max to relay)

• 0-10V analogue output : To be connected to terminals 8 and 9 (8 = 0V and 9 = 0 / 10V)

Cold demand :

• 24V digital output : To be connected to terminals 73 and 74 and to give the run command to drive a DX module

(Attention 24V 2A Max to relay)

• 0-10V analogue output : To be connected to terminals 11 and 12 (11 = 0V and 12 = 0 / 10V)

WARNING: The 24V and 0-10V operating commands do not manage any safety, anti-short cycle ... direct expansion.

IV.14. Electrical Battery

EXAECO ®

HIGH EFFICIENCY RECOVERY UNIT

OPERATING AND COMMISSIONING INSTRUCTIONS

MS-CDF-002

Ind D

Maj. 02/11/2018

Créé par : JC

Validé par : AR

Page 20/49

IV.15. Fonction incendie

See configuration chapter V.8

There are 2 ways to drive the fire function:

o Emergency Fireman stop: cable between 61 and 62 terminals (NC free voltage contact). Total stop of the central

control. (no display available)

o Fire alarm: this function controls exhaust and return fans with 5 modes available in the parameters of the regulation

(the function can be activated on site). “fire alarm” will be will be on the display.

1. « stop » : complete stop of the unit

2. «continuous work » : Start of the unit in HS, fire function will have priority on all the other alarms.

3. «Normal work» : keeps the unit running with parameters activated on site (Stop/LS/HS)

4. « Supply fan only » : start or keeps in HS the supply fan (extract stopped)

5. « Extract fan only » : starts or keeps in HS the extract fan (supply stopped)

Digital input « external stop » is priority on fire function.

This function is not adapted anymore to the French market and will be in all cases validated by the control office.

Digital input fire alarm will be connected between DI8 terminal of the slave controller and 45 of the terminal block (free

voltage contact required)

IV.16. Raccordement du MODBUS / WEB / BACNET

See configuration chapter V.8

MODBUS RS485 and BACNET MSTP: Use armoured cable 2 crossed pairs wire type BELDEN 8723 or similar to connect

BMS to controller (to connect to port 1 (BANE) / connect armour to N and don’t connect E)

WEB / MODBUS TCP/IP et BACNET IP: to connect to TCP/IP port

EXAECO ®

HIGH EFFICIENCY RECOVERY UNIT

OPERATING AND COMMISSIONING INSTRUCTIONS

MS-CDF-002

Ind D

Maj. 02/11/2018

Créé par : JC

Validé par : AR

Page 21/49

V. SETTINGS

V.1. Display

EXAECO® is delivered in standard with ED9200IP65 display

Once accessed to the emulator settings , you will have access to all function and screens below

o Directional arrows up, down left and right help to navigate in the menus.

o Up and Down buttons help to increase or decrease the values of a parameter when you have access to. Right and left

buttons help to navigate inside the parameter.

o OK button help to enter the value and to confirm a choice. C button helps to cancel it.

o Alarm button (red) allows the access of the defaults list.

o Left arrow also helps to go out of the alarm menu and go back to the main menu

o Cursors indicate the possible movements and which arrows to press.

V.2. Exemple of setting

o Move the cursor to the required menu

In the required menu: press OK

Enter the password if necessary

o Enter the required value with arrows or with numerical keyboard

o Press OK to valid and go to next step.

When values are updated press the left arrow to come back to the welcome screen

Hour : ex : 10:33

Date : ex : 08/12/23 (year/month/day)

Day : ex : Mardi

EXAECO ®

HIGH EFFICIENCY RECOVERY UNIT

OPERATING AND COMMISSIONING INSTRUCTIONS

MS-CDF-002

Ind D

Maj. 02/11/2018

Créé par : JC

Validé par : AR

Page 22/49

V.1. Standard settings (opérator menu)

Words in normal writing = viewing only / Words in bold = Modification is possible / Outlined words in bold=

Modification is possible with password 3333 … = non accessible or not used

ATTENTION : Do not modify parameters which are not in bold characters, in this case no after sales will be

admitted

Regulation mode

Year: month :day Hour

System: state of unit

SP : Setpoint T°C Act : T°C actuelle

CORRIGO E

Battery type

Control type

PG number

Ventilation

Version :

Id number:

Choose language

English (10)

List of the accessible and modifiable main

menus with password 3333.

Humidity regulation menu is only accessible

when unit is in humidity control mode

(10) Language setting (see chapiter V.4.e)

Running mode

Temperature

Ventilation

Timer

Access right

EXAECO ®

HIGH EFFICIENCY RECOVERY UNIT

OPERATING AND COMMISSIONING INSTRUCTIONS

MS-CDF-002

Ind D

Maj. 02/11/2018

Créé par : JC

Validé par : AR

Page 23/49

V.1.a. Menu running mode

(7) Unit Start/Stop (see chapter V.4.e)

(10) Language setting (see chapiter V.4.f)

Running mode

Regulation mode

Year: month :day Hour

System: state of unit

SP : Setpoint T°C Act : T°C actuelle

CORRIGO E

Battery type

Control type

PG number

Ventilation

Version :

Id number:

Running mode

…

Running mode

Auto (7)

Running time

Vent.SAF: 00.0 H

Viewing the history alarms (use the

down arrow to scroll through the

history)

Alarm report

Input/Output

...

AI Ext1

(Analogue Input)

AI1: T° AS (suuply)

AI2: T° Ext (outdoor)

AI3: T° AR (extract)

AI4: CO2

DI

(Digital input)

DI1: Recirculation

DI2:

DI3: Rotative exchanger

default

UI Ext1

(Universal Input)

UAI1: Press AS

(LOBBY / MAC2 et QUATTRO)

UAI2: Press AR

(LOBBY / MAC2 et QUATTRO

...

UDI1: Start VAS

UDI2: Start VAR

...

Running time

Vent.EAF: 00.0 H

DI Ext1

(Digital Input)

DI1: Al Filter1

DI2: Al Filter2

DI3: Over heat

ou External frost guard

DI4: Ext 1/2

DI5: Ext 1/1

DI6: Ext stop

DI7: P1 Heat

Choose language

English (10)

EXAECO ®

HIGH EFFICIENCY RECOVERY UNIT

OPERATING AND COMMISSIONING INSTRUCTIONS

MS-CDF-002

Ind D

Maj. 02/11/2018

Créé par : JC

Validé par : AR

Page 24/49

V.1.b. Temperature menu

(8) Temperature setpoint setting (see chapter V.4.d)

AO

(analogue outputs)

Input/Output

Running mode

AO1: Y4 S-Suppl

(0V = recycling)

(10V = Fresh air)

...

DO

(Digital output)

DO1: Reg. AN

DO2: Reg. Recy

DO3: Heat demand

DO4: Cool demand

AO1: Y1 Heating.

AO2: Y2 Exchang.

AO3: Y3 Cool

AO4: Ctrl SAF

AO5: Ctrl EAF

AO Ext1

(analogue outputs)

DO1: V.freq SAF

DO2: V freq EAF

DO3: Rot exch. activ.

DO4: Heat Pump

DO5: Cool pump.

DO6: Surventil.activ

DO7: Somme alarme

DO Ext1

(Digital output)

Temperature.

Extract Temperature

Real:

Setpoint : 21°C (8)

...

Setpoint comp ext

-20°C = 25°C (8)

-15°C = 24°C (8)

-10°C = 23°C (8)

Consigne comp ext

-5°C = 23°C (8)

0°C = 22°C (8)

5°C = 20°C (8)

Setpoint comp ext

10°C = 18°C (8)

15°C = 18°C (8)

Outdoor temp :

Supply temp

Real : Cons

Setpoint :

EXAECO ®

HIGH EFFICIENCY RECOVERY UNIT

OPERATING AND COMMISSIONING INSTRUCTIONS

MS-CDF-002

Ind D

Maj. 02/11/2018

Créé par : JC

Validé par : AR

Page 25/49

V.1.c. Ventilation menu

(5) Speeds, pressures, airflows (see chapter V.4.b)

(6) CO2 setpoint except DIVA and QUATTRO (voir chapitre V.4.c)

Ventilation

Frequency control SAF

(STANDARD OU DIVA)

Output: 70 (5) %

or

Pressure Control SAF

(LOBBY)

Real : 183Pa (example)

Setpoint : 180 Pa(5)

or

Air flow SAF

(MAC2 QUATTRO)

Real : 1503m3/h (example)

Setpoint : 1500m3/h(5)

Frequency control SAF

Sp 1/1: 70% (5)

Sp 1/2: 50% (5)

...

CO2 (except DIVA® OU QUATTRO® )

Réal : 654ppm (exemple)

Setpoint : 1000ppm (6)

Pressure Control SAF

Sp 1/1: non utilisé

Sp 1/2: 180Pa (5)

...

Air flow SAF

Sp 1/1: 5000m3/h (5)

Sp 1/2: 2500m3/h (5)

...

Frequency control EAF

(STANDARD OU DIVA)

Output: 70 (5) %

or

Pressure Control EAF

(LOBBY)

Real : 183Pa (example)

Setpoint : 180 Pa(5)

or

Air flow EAF

(MAC2 QUATTRO)

Real : 1503m3/h (example)

Setpoint : 1500m3/h(5)

Pressure Control SAF

Sp 1/1: non utilisé

Sp 1/2: 180Pa (5)

...

Contrôle pression VAR

Cons 1/1: non utilisé

Cons 1/2: 180Pa (5)

...

Air flow SAF

Sp 1/1: 5000m3/h (5)

Sp 1/2: 2500m3/h (5)

...

EXAECO ®

HIGH EFFICIENCY RECOVERY UNIT

OPERATING AND COMMISSIONING INSTRUCTIONS

MS-CDF-002

Ind D

Maj. 02/11/2018

Créé par : JC

Validé par : AR

Page 26/49

V.1.d. Timer menu

1. Hour and date setting (see chapter V.4.a)

2. HS program setting (see chapter V.4.a)

3. LS program setting (see chapter V.4.a)

4. Holidays period setting (see chapter V.4.a)

9. Holidays period setting (see chapter V.4.a)

Timer normal speed

Normal speed

Monday (2)

Per 1 : 07:00 - 22:00

Per 2 : 00:00 - 00:00

Normal speed

Monday - Friday (2)

Per 1 : 07:00 - 22:00

Per 2 : 00:00 - 00:00

Normal speed

Tuesday (2)

Per 1 : 07:00 - 22:00

Per 2 : 00:00 - 00:00

Etc…until sunday + holidays

Timer

Hour / Date

Hour : 15:54 (1)

Date : 2011-01-25 (1)

Day : Tuesday (1)

Timer reduced speed

Slow speed

Monday (3)

Per 1 : 00:00 - 05:00

Per 2 : 22:00 - 24:00

Slow speed

Monday - Friday (3)

Per 1 : 00:00 - 05:00

Per 2 : 22:00 - 24:00

Slow speed

Tuesday (3)

Per 1 : 00:00 - 05:00

Per 2 : 22:00 - 24:00

Etc…until sunday + holidays

Holydays (mm:jj) until 24 periods (4)

1: 01-01 - 01:01 (example 1er Janvier)

2: 12-25 - 12:25 (example 25 décembre)

Holidays

Access rights

Entrer

Exit

Enter password of the autorisation level

required : ****

Current level:

Exit this autorisation level ? NO or YES

Current level

Timer 5

Tuesday (9)

Per 1 : 05:00 - 07:00

Per 2 : 00:00 - 00:00

Etc…until sunday + holidays

Timer 5

(Timer to star up

RECIRCULATION)

EXAECO ®

HIGH EFFICIENCY RECOVERY UNIT

OPERATING AND COMMISSIONING INSTRUCTIONS

MS-CDF-002

Ind D

Maj. 02/11/2018

Créé par : JC

Validé par : AR

Page 27/49

V.2. Operator parameters modification ( password 3333 required)

V.2.a. Dates and hours clocks setting

V.2.a.1. Date and hour of the CORRIGO controller [(1) chapter V.3.d]

Access : Hour Date setting

Date and hour of the regulator are set by defaut in the CORRIGO controller. Summer/Winter time is automatically managed.

V.2.a.2. Hour programmation of the functionning system [(2) (3) chapter V.3.d]

Access :

o Timer normal speed : Time settings / normal speed program

o Timer reduced speed : Time settings / slow speed program

o Timer recirculation : Time settings / Timer 5

System is set to work in normal speed (HS-1/1) 07:00 - 22:00 in slow speed (LS-1/2) 22:00 - 06:00 except DIVA / LOBBY /

QUATTRO versions which work in slow speed (LS-1/2)

As indicated in arborescence you also have the possibility to modify Monday to Friday periods by pressing the right button

when you are on the Monday screen

Nota : if slow speed (LS-1/2) and normal speed (HS-1/1) are activated in the same time window, unit works in high speed

Operation exceptions:

DIVA®/QUATTRO® : For CO2 regulation do not activate any normal speed time window (GV-1/1)

o LOBBY: Only slow speed clock (LS-1/2) must be activated

o NIGHT COOLING: Only works if unit is in slow speed (LS-1/1) between 00:00 and 07:00.AM

(Example: If unit is in (LS-1/2) between 02:00 and 06:00 and in (HS-1/1) the rest of the time. Then NIGHT

COOLING is allowed to work only from 02:00 to 06:00 AM)

V.2.a.3. Holidays periods [(4) chapter V.3.d]

Access : Time settings / Holidays

The system is set without vacation period. In case you wish to reduce the operating time during holiday periods, set the holiday

operating hours as described in chapter V.3.4), then set your holiday days.Modification de la vitesse / pression en PV et GV

V.2.a.4. ECO / DIVA® / [(5) chapitre V.3.c]

Access : ventilation Regul / Frequency control VAS 1/1 and 1/2 or frequency control VAR 1/1 et 1/2

You can modify the rotation speed of the unit in PV-1/2 (slow speed) and in HS-1/1 (normal speed) for each fan to set the

airflows.

o To set the initial airflow (GV-1/1), force the system in normal speed with available terminals « Forced start HS »

(bridge between 41 and 42 terminals).

o To set the initial airflow LS, force the system in slow speed with available terminals « Forced start LS » (bridge

between 39 and 40 terminals).

V.2.a.5. LOBBY® [(5) chapitre V.3.c]

Access : ventilation Regul / Pressure control VAS 1/2 or Pressure control VAR 1/2

You can modify the constant pressure of the unit for each fan to set the airflows.

o To set the initial airflows LS, force the le system in normal speed with available terminals « Forced start LS » »

(bridge between 39 and 40 terminals).

V.2.a.6. MAC2®/QUATTRO® [(5) chapitre V.3.c]

Access : ventilation Regul / Airflow control VAS 1/1 and 1/2 or Airflow control VAR 1/1 and 1/2

You can modify the rotation speed of the unit in PV-1/2 (slow speed) and in HS-1/1 (normal speed) for each fan to set the

airflows.

o To set the initial airflow (GV-1/1), force the system in normal speed with available terminals « Forced start HS »

(bridge between 41 and 42 terminals).

o To set the initial airflow LS, force the system in slow speed with available terminals « Forced start LS » (bridge

between 39 and 40 terminals).

EXAECO ®

HIGH EFFICIENCY RECOVERY UNIT

OPERATING AND COMMISSIONING INSTRUCTIONS

MS-CDF-002

Ind D

Maj. 02/11/2018

Créé par : JC

Validé par : AR

Page 28/49

V.2.b. CO2 setpoint modification for three ways mixing damper (FEE) (except DIVA et

QUATTRO)

[(6) chapitre V.3.c]

Access : CO2

You can modify the CO2 setpoint. (1000ppm in standard)

V.2.c. Temperature setpoint modification

[(8) chapitre V.3.b]

Access : temperature Regul

Regulation is based on the temperature control of :

o Supply with external compensation (set in standard). Supply temperature setpoint follows outside temperature in

compliance with RT 2012 norm.

o Extract

V.2.d. Forced stop of the unit or forced start LS or HS on the remote control

[(7) chapter V.3.a]

Access : running Mode / running Mode

You can stop (7) (stop) unit with CORRIGO controller or do a forced start LS (7) (manual speed 1/2) or HS (7) (manual

speed 1/1). In standard unit works automatically with clocks (7) (Auto)

If unit do not work in automatic mode an alarm will start. Manual speed 1/1 and manual speed 1/2 modes must be used

only for the commissioning and repair. An other setting will lead to a failure of the unit.

V.2.a. Choice of language

[(10) chapter V.3]

Access: Starting screen / language choice

V.3. Intermediate settings (service level)

Type of regulation type setting, Night Cooling parameters and CO2 setpoint require an acess to the Configuration menu.

You need the access right to the « Service » level. Follow the instrcuctions below.

Enter 2222 with directional arrows and validate with OK. Press left arrow twice to reach the access of the menus. In case of

mistake press C button twice and start again.

Access right

Enter

Enter password 2222 of the

required level :

Current level : SERVICE

EXAECO ®

HIGH EFFICIENCY RECOVERY UNIT

OPERATING AND COMMISSIONING INSTRUCTIONS

MS-CDF-002

Ind D

Maj. 02/11/2018

Créé par : JC

Validé par : AR

Page 29/49

V.3.a. Menu configuration en accès service

V.4. Modification of the services parameters (password 2222)

V.4.a. Regulation mode of the unit [(1) chapter V.3.a]

Access : Configuration / Regulation function.

Regulation type is set by default in the CORRIGO controller in outside compensation exhaust. You can also select return

control mode.

(ATTENTION, if you want to regulate following a room temperature, select the regulation mode« Ctrl extract » Any

other mode will lead to the failure of the unit)

V.4.b. Overventilation parameters [(2) chapter V.3.a]

Access : Configuration / Night cooling

Night cooling speed is set in standard in 85%. You can modify it. You can also change the temperature of Night Cooling

activation (outside temperature day…) and deactivate it.

V.4.c. CO2 setpoint for DIVA / QUATTRO option [(3) Chapter V.3.a]

Access: Configuration / Ctrl CO2/COV

CO2 setpoint is set in standard: LS = 800ppm HS = 1000ppm. Unit will increase its speed proportionally to reach its maximum

speed when CO2 will be at 1000ppm.

V.4.d. Minimum opening percentage of the 3 ways mixing damper (FEE) [(4) chapitre V.3.a]

Accés : Configuration / Ctrl CO2/COV

En standard à 30% d’ouverture soit 10% d’air neuf – Voir courbe de correspondance chapitre VIII.5

Configuration

Regulation Function

Night Cooling

Ctrl CO2/VO

Lim Mini damper

Regulation Function

Mode:

Supply t+comp ext (1)

Night cooling activated : YES (2)

Outdoor temp activation : 22°C (2)

Outdoor T° night

High 18°C (2)

Low 10°C (2)

Room mini Temp: 18°C (2)

Speed : 85%

Ctl CO2/COV activated :

If timer ON

Type : Fans

Speed 1/2 : 800 ppm (3)

Speed 1/1 : 1000 ppm (3)

Diff : 160ppm

1. Regulation type choice (see chapter V.6.a)

2. Parameters modification Night Cooling (see chapter V.6.b)

3. CO2 set point modification (only in DIVA and QUATTRO) (see chapter V.6.c)

4. Limit mini damper (except DIVA et QUATTRO) (see chapter V.6.D)

Lim. Mini damper

Active

Limit min : 30% (4)

except DIVA MAC2

EXAECO ®

HIGH EFFICIENCY RECOVERY UNIT

OPERATING AND COMMISSIONING INSTRUCTIONS

MS-CDF-002

Ind D

Maj. 02/11/2018

Créé par : JC

Validé par : AR

Page 30/49

V.5. Administrator settings

Activation of the communication, dehumidification and fire function requires an access to Configuration menu in system

level. You have to get the access rights to « Admin » level. Follow the instructions below:

Enter 1111 with directionnal arrows and validate with OK button. Press left arrow twice to reach the menu. In case of mistake

press C button twice and start again

V.5.a. Configuration menu with admin level access

Access rights

Enter

Enter password 1111

Of the required autoris.

Current level : ADMIN

Configuration

Communication

Système

Port 1

Esclave

1 et 2 Activation MODBUS RS485 and settings (see chapter V.6)

3 et 4 Activation BACNET MSTP and settings (see chapter V.6)

5 et 6 Settings TCP/IP(see chapter V.6)

7 et 8 Activation du BACNET IP and settings (see chapter V.6)

9 Adressage Repetiteur (voir chapitre V.6)

Communication

Modbus esclave

Port 1

Active (1)

Device name : - (4)

Mac : 0 (4)

Id appareil Bas : 2640 (4)

Id appareil Haut : 0 (4)

(x10000)

Vitesse : 9600 Bps(4)

Ad. maître max : 127 (4)

Adresse Modbus : 1 (2)

Vitesse : 9600 Bps (2)

2 bits d’arrêt : Oui (2)

Parité Non (2)

Adresses

PLA : 254 (9)

ELA : 254 (9)

Communication

Bacnet MSTP

Port 1

Active (3)

TCP/IP

IP : - (6)

Subnet Mask - (6)

Subnet Mask - (6)

Gateway - (6)

DHCP : OUI (5)

Ip actuel :

Communication

Bacnet IP

Active (7)

Device name : - (8)

Adresse BBMD : 0 (8)

Id appareil Bas : 2640 (8)

Id appareil Haut : 0 (8)

(x10000)

N° port UDP bas 7808(8)

N° port UDP haut 4(8)

(x10000)

EXAECO ®

HIGH EFFICIENCY RECOVERY UNIT

OPERATING AND COMMISSIONING INSTRUCTIONS

MS-CDF-002

Ind D

Maj. 02/11/2018

Créé par : JC

Validé par : AR

Page 31/49

V.6. Modification of the service parameters

V.6.a. MODBUS

You will find the simplified MODBUS at the end of the instructions and commissioning manual.

Access : Configuration / Communication

MODBUS TCP/IP is activate in standard in DHCP. Possibility to know DHCP adress or set IP fixe [(5)(6) chapter V.7],

Modbus Port = 502 / Device ID = 255

Le MODBUS RS 485 must be activate [(1) chapitre V.7]. Possibility to set speed, parity, stop bits… [(2) chapter V.7].

Modbus Type

1 = Coil status register (Modus fonction 1, 5 et 15)

2 = Input status register (Modus fonction 2)

3 = Holding register (Modus fonction 3, 6 et 16)

4 = Input resister (Modus fonction 4)

Supported Modbus functions

Read Coils (1)

Read discrete input (2)

Read Holding registers (3)

Read Input registers (4)

Write single Coils (5)

Write single register (6)

Write multiple Coils (15)

Write multiple register (16)

EXOL Type

R = Real (-3.3E38 – 3.3E38)

I = Integer (-32768 – 32767)

X = Index (0 – 255)

L = Logic (0/1)

Transmission mode

Controller is set in RTU mode

A maximum of 47 registers can be read in one message

V.6.b. Communication WEB

You have the possibility to communicate via TCP/IP WEB in language. In this case the device is delivered with Web page and

regulator set in DHCP.

Possibility to know DHCP adress or set IP fixe [(5)(6) chapter V.7], or via E-tool software http://www.regin.se

EXAECO ®

HIGH EFFICIENCY RECOVERY UNIT

OPERATING AND COMMISSIONING INSTRUCTIONS

MS-CDF-002

Ind D

Maj. 02/11/2018

Créé par : JC

Validé par : AR

Page 32/49

V.6.c. BACNET

You will find the simplified BACNET at the end of the instructions and commissioning manual.

Accès : Configuration / Communication

BACNET IP must be activate [(7) chapter V.7]. Possibility to know DHCP adress or set IP fixe [(5)(6) chapter V.7].

Possibility to set ID / N°port… [(8) chapter V.7].

BACNET MSTP must be activate [(3) chapter V.7]. Possibility to set speed, ID, adress… [(4) chapter V.7]. Speed = 9600 /

MAC adress = 0 / Device ID = 2640 / Max master = 127

BACnet Type

10XXX = Read and write Binary

20XXX = Read binary

30XXX = Read and write analogue

40XXX = Read analogue

30XXX = Read and write multistate

40XXX = Read multistate

(XXX = MODBUS Adress)

AV = Analogue Value

BV = Binary Value

MSV = Multistate value

BMMD Adress : The BBMD adress is used for discovering devices taht are attached to different BACnet/IP subnets and

separates by an IP router. The address is entered as host:host can be the host’s name if DNS ins configures. If DNS is not

configured, the host address should be entered in the format xxx.xxx.xxx.xxx follwed by the port number (default settings

47808)

MAC : The MAC address of the device. This need to be unique only to the subnet.

Device ID : The ID of a device, used to identify it on the BACnet network. This number cannot be duplicated anywhere on the

BACnet network and must therefore be unique. To set an ID value of 34600, the low number would be set to 4600 and the high

number to 3

For more information see CORRIGO Pics via http://www.regin.se

V.6.d. Fire funtion activation

Setting of the Paramétrage de l’entrée

Access : Configuration / Input Output / DI ext / DI8

Déclarer l’input DI ext 8 en « Al fire » « NO »

Paramétrage de la fonction

Access : Configuration / Fire function

Choose the required mode when activating the fire function

« Stop » : Complete stop of the unit

«Continuous operation »: Start or keeping of the unit in HS. Fire function will have priority on all others alarms.

«Normal operation»: keeps the unit in the same parameters chosen on site (stop/LS/HS)

« Exhaust fan only »: Start or keep in HS the exhaust fan (return is stopped)

« Return fan only »: Start or keeps in HS the return fan (exhaust stopped)

Alarm setting

Access: Configuration / alarm configuration

Enter alarm number « 10 » go on the right and enter in priority « C alarm C » « Active »

EXAECO ®

HIGH EFFICIENCY RECOVERY UNIT

OPERATING AND COMMISSIONING INSTRUCTIONS

MS-CDF-002

Ind D

Maj. 02/11/2018

Créé par : JC

Validé par : AR

Page 33/49

VI. REPAIR

VI.1. Different types of defaults

EASY control units are equipped with alarms. When the red LED flashes, press the alarm key (red) to display the fault. This

one will be class A, or C (see details below)

Type of defect:

A: The fault stops the ventilation system. The unit will not start until the problem has been solved and the fault has been

acknowledged.

C: The fault does not stop the ventilation system and disappears automatically as soon as the problem has been solved.

To acknowledge a fault press the alarm button (red), "cancel" and then "save" the fault using the arrows and the OK key. Be

careful not to "block"

Description

Cause

CORRIGO screen do not light up

- Unit is not powered correctly (LED P/B of CORRIGO switched off)

- To light up the screen, press a button (backlit).

- Command fuse is disused

Fans do not start

- Clocks are on 0

- No external start order

- External stop

- Active alarm

Remote control do not run

or gives wrong values

Remote control further than 100m

Repetitor is not connected correctly

VI.2. List of alarms

n°

Affichage

Description

Type

Tempo

Cause

1

Malfunction

supply air fan

(Ext UDI1 must be

closed « on »if fan

runs)

Or

Ext UAI1 must be

higher than 30Pa if

fan runs )

A

30s (120s

for

LOBBY)

1. Pressure switch is wrongly connected (pressure

switch must be set in 30Pa).

2. Pressure on the transmittor is lower to 30Pa.

(LOBBY®) (contact us)

3. Motor is disused

4. Thermic protection motor is activated

5. Check the connection of the crystal tubes (Chapter

IV.7 and IV.8

6. Presence of water in the crystal tube

7. 0-10V motor is inverted

1

Malfunction

extract air fan

(Ext UDI2 must be

closed « on »if fan

runs)

Or

Ext UAI2 must be

higher than 30Pa if

fan runs )

A

30s (120s

for

LOBBY)

1. Pressure switch is wrongly connected (pressure

switch must be set in 30Pa).

2. Pressure on the transmittor is lower to 30Pa.

(LOBBY®) (contact us)

3. Motor is disused

4. Thermic protection motor is activated

5. Check the connection of the crystal tubes (Chapter

IV.7 and IV.8

6. Presence of water in the crystal tube

7. 0-10V motor is inverted

3

Pump fault

Ext DI7 mus be

open « off » if there

is no fault

C

0s

The circulator fault contact is closed

EXAECO ®

HIGH EFFICIENCY RECOVERY UNIT

OPERATING AND COMMISSIONING INSTRUCTIONS

MS-CDF-002

Ind D

Maj. 02/11/2018

Créé par : JC

Validé par : AR

Page 34/49

6

Filter guard 1

Ext DI1 must be

open « off » if there

is no default

C

5s

1. Filters are dirty

2. Filters pressure switches are wrongly connected

(Pressure switches must be set on 150 Pa for G4

200Pa for F7).

8. Control the connection of the crystal tubes (chapter

IV.6

8

External frost

guard

Ext DI3 must be

closed « Fer »if

there is not default

C

120s

1. THA thermostat is not set on 5°C

2. THA thermostat s disused

3. Circulating pump is disused

4. 3 ways valve 3 is wrongly connected, hydraulically

or is disused

15

High supply air

temp

Ext AI1 is mounted

higher than 50°C

A

30s

1. Exhaust temperature is higher than 50°C

2. Temperature setting is too high

3. Exhaust fan is stopped (vent

AS Default) when hot battery is in full capacity.

23

Electric heating

is overheated

Ext DI3 must be

closed « Fer » if

there is no default

A

5s

1. Safety thermostat THS is activated. To reset THS,

push on the rearmament on the electric battery

2. Power cut

3. Exhaust fan is stopped (vent

AS Default) when electric battery is in full capacity

27

Sensor error

outdoor temp

Control the value

Ext AI2

A

5s

Outside temperature sensor SEG is disused .Outside

temperature sensor SEG is wrongly connected (see chapter

IV.3)

29

Rotation sentinel

exchanger

Control the value

DI6

C

300s

The belt of the exchanger is brocken

31

Supply air fan

control error

Difference higher

than 50Pa between

exhaust setpoint

and pressure on

Ext UAI1

C

30min

The network of blowing do not correspond to the fan or

to the setpoint.

Filter is dirty

32

Extract air fan

control error

Difference higher

than 50Pa between

exhaust setpoint

and pressure on

Ext UAI2

C

30min

Return network do not correspond to the fan or to the

setpoint.

Filter is dirty

35

Manual

Runs in manual

mode

C

5s

Default à titre indicatif (le centrale est passée à l’arrêt en PV

ou en GV directement sur l’afficheur (voir (7) chapitre V.3.a)

36 à

44

… in Manual

mode

Functions are

modified in

manual mode

C

5s

In the Auto Manual menu everything must be in Auto.

48

Internal battery

error

Error battery intern

A

5s

Intern battery of the CORRIGO is disused

Change the battery quickly in order to not loose programm.

See chapter VII.2

49

Sensor error

supply air temp

Control the

Value on Ext AI1

A

5s

Outside temperature sensor SSG is disused

Outside temperature sensor SSG is wrongly connected (see

chapter V.3.a)

50

Sensor error

extract air temp

Contrôler la

valeur sur Ext AI3

A

5s

Outside temperature sensor SRG is disused

Outside temperature sensor SRG is wrongly connected (see

chapter V.3.a)

55

Sensor error

pressure VAS

Control the value

on Ext UAI1

A

5s

0-10V signal is inverted

Pressure transmittor on fresh air is in short-circuit

EXAECO ®

HIGH EFFICIENCY RECOVERY UNIT

OPERATING AND COMMISSIONING INSTRUCTIONS

MS-CDF-002

Ind D

Maj. 02/11/2018

Créé par : JC

Validé par : AR

Page 35/49

56

Sensor error

extract VAR

Control the value

on Ext UAI2

A

5s

0-10V signal is inverted

Pressure transmittor on intake air is short circuited

59

CO2 sensor error

Control the

Value on Ext AI4

A

5s

0-10V signal is inverted

CO2 transmittor is in short-circuit

85

… in manual

mode

Functions are

modified in

manual mode

A

5s

In Manuel Auto menu everything must be in Auto.

86

Time for service

Regular visit

C

5s

See chapter VI.3

87

… in manual

mode

Functions are

modified in

manual mode

C

5s

In Manuel Auto menu everything must be in Auto.

VI.3. Acknowledge the default « timer service »

These settings require an access to the setting menu. You need the access rights to “service” level. Follow the instructions

below.

Enter the code 2222 with directional arrows then press the OK button. Press the left arrow twice to reach the menus. In case of

mistake press C button twice and start again.

An alarm occurs every 6 months to remind the maintenance visit. Enter YES to reset the counter to zero

Settings

Reset to zero

Filters counter

filter alarm

Reset to zero of the

Timer : YES

access rights

Enter

Enter password 2222

Of the required autoris. level:

Current level : SERVICE

EXAECO ®

HIGH EFFICIENCY RECOVERY UNIT

OPERATING AND COMMISSIONING INSTRUCTIONS

MS-CDF-002

Ind D

Maj. 02/11/2018

Créé par : JC

Validé par : AR

Page 36/49

VII. MAINTENANCE

VII.1. Mandatory maintenance

Outside the unit

Check the ducts, flexible sleeves, anti-vibrating plots; replace them if necessary. Check that all elements connected to the unit

do not give any vibration to the unit.

Unit and Regulation

Check connection every year

Filtration

Do not damage the filters

Classification

Max pressure drop

Efficency of the

filtration

EUROVENT

Reference

Washing*

(Water + light detergent )

Aspiration*

Exhaust*

Gravimetric

150Pa

EU4

G4

Limited (1 to 4 times)

YES

Opacimetric

200Pa

EU7

F7

NO

Periodicity of the cleaning

Componants

1 MONTH

3 MONTHS

6 MONTHS

12 MONTHS

Filtration

Blowing

(for the G4filters)

Cleaning

(for the G4filters)

Washing

(for the G4filters )

Replacement

Of the filters if needed

Rotative exchanger (12 month)

Check belt and change it if necessary

VII.2. Battery replacement

When low battery alarm starts and red LED is lighting, this indicates that the safety battery for the safeguard of the memory