L IBERATOR 20

30

37

45

60

Liberator

L IBERATOR

S E R V I C E

M A N U A L

I Preface

Page 2

SERVICE MANUAL

LIBERATOR 20

LIBERATOR 30

LIBERATOR 37

LIBERATOR 45

LIBERATOR 60

CAIRE, Inc.

3505 County Road 42 West

Burnsville, MN 55306-3803

Customer/Technical Service:

Toll Free Phone (U.S.A.): 1-800-48 CAIRE (1-800-482-2473)

Toll Free Fax (U.S.A.): 1-888-WE CAIRE (1-888-932-2473) (To place an order)

Phone: 1-952-882-5000

Fax: 1-952-882-5178

This manual covers use and maintenance of the Liberator 20, Liberator 30, Liberator 37, Liberator 45, and Liberator 60

units (see below). It is intended for use by experienced personnel only.

No attempt should be made to fill or maintain this equipment until both this manual and Patient Operating Instruction

booklet have been read and fully understood.

The following abbreviations are used throughout this manual:

FCV — Flow Control Valve PRV — Primary Relief Valve

LED — Light Emitting Diode QDV — Quick Disconnect Valve

LO2 — Liquid Oxygen RA — Return Authorization

LPM — Liters Per Minute RP — Repair Procedure

NER — Normal Evaporation Rate R/R — Removal and Replacement

POI — Patient Operating Instructions SRV — Secondary Relief Valve

Definition of Terms

WARNING Description of a condition that can result in personal injury or death.

CAUTION Description of a condition that can result in equipment or component damage.

NOTE A statement containing information important enough to emphasize or repeat.

(ITEM) Item numbers used throughout this manual are shown on the illustrations beginning on page 35.

Model Side Fill Top Fill Dual Fill

(0-6 LPM)

L20 10562007 10564150 10660379

L30 10561995 10564133 10564176

L37 10562023 10564168 10660328

L45 10562015 10564141 10564184

L60 11068983 11069020 11208641

Model Side Fill Top Fill Dual Fill

(0-10 LPM)

L20 10879389 10879434 10879477

L30 10879400 10879442 10879493

L37 10879418 10879451 10879514

L45 10879426 10879469 10879522

L60 11075905 11075921 11374892

Model Side Fill Top Fill Dual Fill

(0-15 LPM)

L45 11177805 11018951 TBD

L60 11075948 11075972 11374876

IITable of Contents

Page 3

I. Preface 2

II. Table of Contents 3

III. Equipment Description 4

IV. Specifications 5

V. Safety 6

VI. Theory of Operation 7-9

VII. Unpacking/Setup Instructions 10

VIII. Operation 11-12

IX. Routine Maintenance 13-14

X. Troubleshooting/Repair 15

Troubleshooting Chart 16-17

Repair Procedures 18-31

Service Tools/Equipment/Supplies 32

XI. Parts Illustration (Top Fill G3.0 Units) 35

Parts Illustration (Side Fill G3.0 Units) 38

Parts Illustration (Dual Fill G3.0 Units) 42

Parts Illustration (Dual Fill G3.1 Units) 45

Parts Listing (Top Fill G3.0 Units) 33-34

Parts Listing (Side Fill G3.0 Units) 36-37

Parts Listing (Dual Fill G3.0 Units) 39-41

Parts Listing (Dual Fill G3.1 Units) 43-44

XII.Ordering Information/Return Policy 46-47

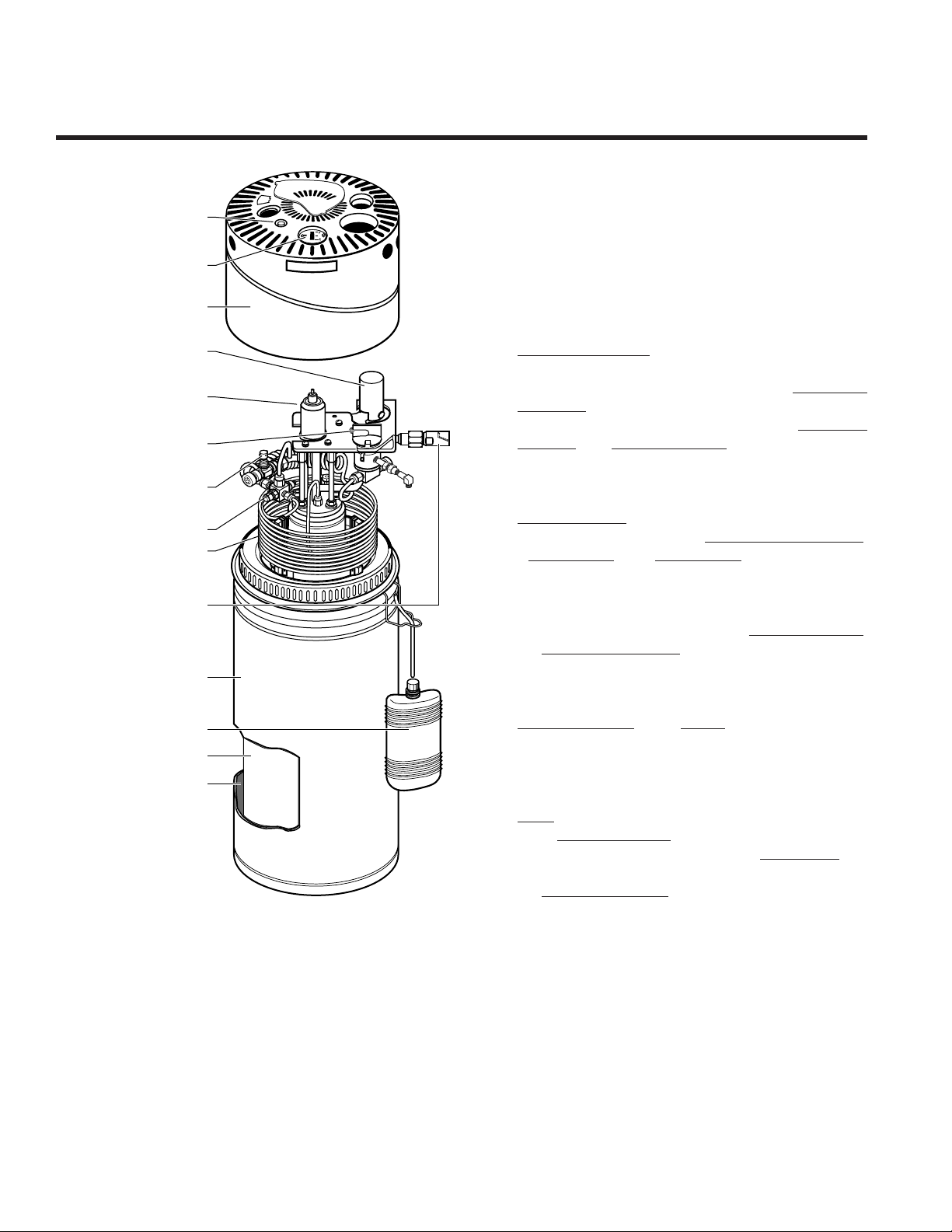

III Equipment Description

Page 4

The CAIRE Liberator is the stationary component of the

Liberator/Stroller supplementary oxygen system. The

Liberator incorporates a stainless steel cryogenic container

with the valves, plumbing, and associated hardware required

to deliver gaseous oxygen to the patient at near ambient

temperature.

The Liberator is comprised of four major assemblies.

Grouped according to function, they are:

1. Cryogenic Container – This assembly is a double walled,

vacuum insulated dewar for storing liquid oxygen at approximately -300 degrees Fahrenheit. The inner pressure vessel is designed to safely hold liquid oxygen and

is protected from over pressurization with the primary relief valve. The vacuum insulation between the inner and

outer vessel keeps the outside heat from evaporating the

cold liquid

2. Breathing Circuit – This circuit consists of the manifold

assembly, fixed orifice rotary flow control valve (FCV),

a breathing coil, and a warming coil. It withdraws liquid

oxygen from the cryogenic container, warms it to near

ambient temperature, and meters the oxygen gas to the

patient. The water that is formed when the cold liquid is

converted to gas is collected in the condensate bottle.

An economizer regulator is used to reduce any excessive head pressure while oxygen is being provided to the

patient.

3. Shroud Assembly – The shroud assembly houses and

protects the breathing circuit and liquid level meter.

Labels listing safety information and patient operating

instructions are affixed to the side of the shroud.

4. Meter – This system uses a capacitance probe and an electronic level meter (LED) readout to measure and display

the product contents at the touch of the meter switch.

An optional roller base can be provided to help move

the Liberator.

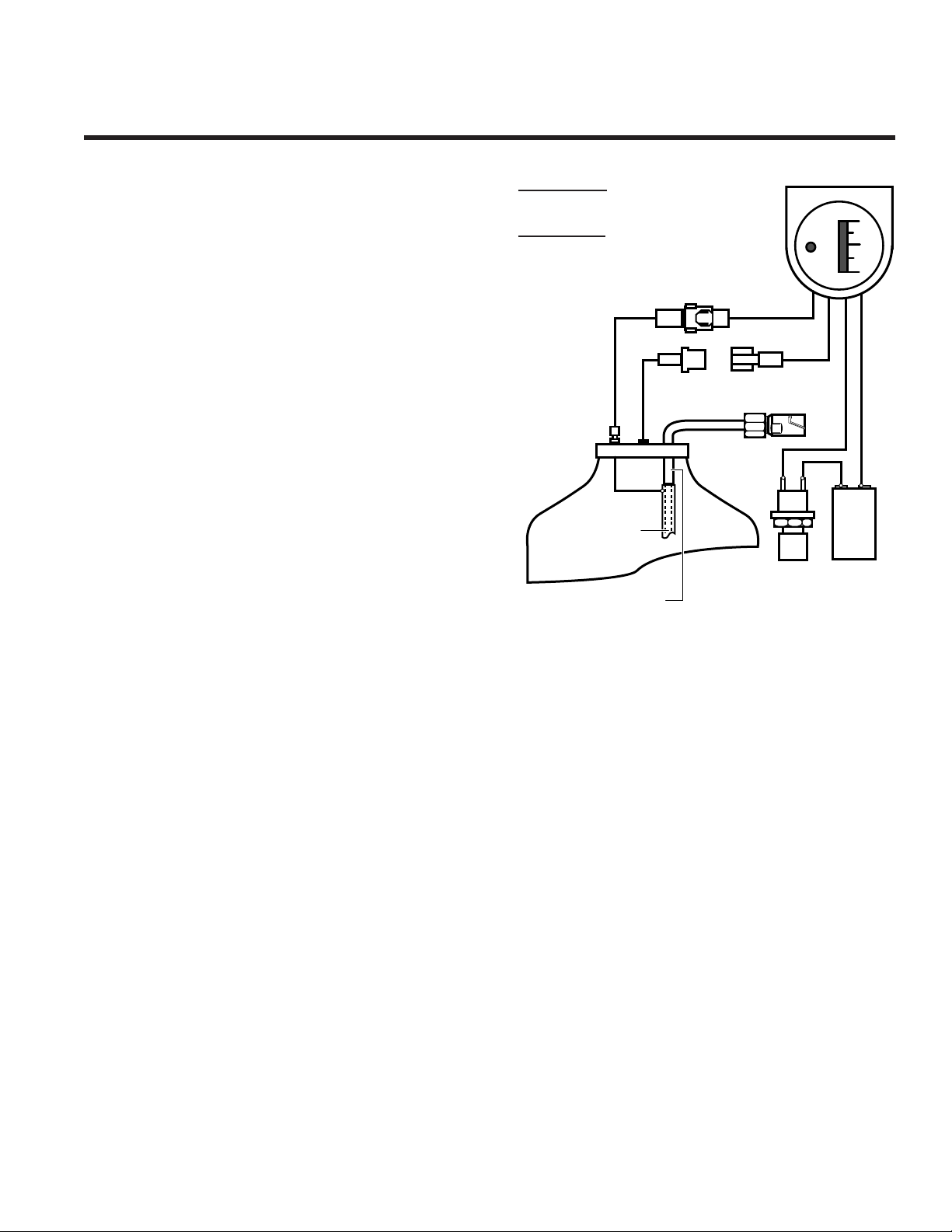

* For Top Fill or Dual Models Only

Meter Switch

Liquid Level Meter

Shroud

Portable Release

Button*

Top Fill Fitting*

(QDV)

Flow Control Valve

(FCV)

Vent Valve

Economizer Regulator

Breathing/Warming

Coils

Side Fill Fitting

(QDV)

Cryogenic Container

(Dewar)

Condensate Bottle

Inner Vessel

Vacuum Insulation

IVSpecifications (Nominal Values)

Page 5

LIBERATOR 20 LIBERATOR 30 LIBERATOR 37 LIBERATOR 45 LIBERATOR 60

Capacity

Pounds (L02): 52 75 92 112 144

Liquid Liters: 21.6 31.2 38.3 46.6 60

Gaseous Liters: 17,780 25,650 31,460 38,300 49,200

Selectable Flow Rates

Liters per minute (0-6 LPM): Off, .25, .5, .75, 1, 1.5, 2, 2.5, 3, 4, 5, 6

Liters per minute (0-10 LPM): Off, .5, .75, 1, 1.5, 2, 3, 4, 5, 6, 8, 10

Liters per minute (0-15 LPM) Off, .5, 1, 2, 3, 4, 5, 6, 8, 10, 12, 15

Flow Rate Accuracy ± .1 liter per minute or ±10% of flow setting, whichever is greater

Hours of Operation

@ 2 liters/minute: 148 213 262 319 410

Standard Fill Connections Side Side Side Side Side

Top Top Top Top Top

Operating Pressure

(Economizer Regulator) PSIG: 20 20 20 20 20

Primary Relief Valve Setting

PSIG: 23 23 23 23 23

Secondary Relief Valve Setting

PSIG: 30 30 30 30 30

Normal Evaporation Rate

Pounds per day: 1.5 1.5 1.5 1.5 1.6

Filling Time (Fast Fill Technique)

Minutes: Warm 2.5 3.0 3.5 4.0 5.5

Cold 1.5 2.0 2.5 3.0 4.0

Height

Inches: 24.5 29.5 32.75 37 39

Diameter

Inches: 14 14 14 14 16

Weight, Empty

Empty (Lbs.): 39 45 50 55 66

Full (Lbs.): 91 120 142 167 210

Fill Connector Type Side Mounted Rotary Coupling (Standard)

Top Mounted Push Coupling (Optional)

V Safety

Page 6

Oxygen, as it exists at standard atmospheric pressure and

temperature, is a colorless, odorless, and tasteless gas.

Oxygen constitutes 21% of the atmosphere, by volume. Aside

from its well-documented ability to sustain life, oxygen also

supports combustion, even though it is nonflammable. Many

substances which will burn in air, burn at a faster rate and at

a higher temperature in an oxygen enriched atmosphere. A

few materials that do not burn in air will burn as the oxygen

concentration increases. Some greases and many liquid solvents become extremely hazardous materials when placed in

an oxygen-enriched environment. In its liquid form, oxygen

is still odorless and tasteless, but is now pale blue in color.

At an operating pressure of 20 psig, the temperature of liquid oxygen is about -280° Fahrenheit. Skin exposed to such

a low temperature can become severely frostbitten.

These hazards require that certain safety precautions be taken

when working with or around gaseous and/or liquid oxygen:

1. Never permit combustible substances such as greases,

oils, solvents, or other compounds not oxygen compatible to contact any component of the unit exposed to

higher-than-atmospheric concentrations of gaseous or

liquid oxygen. This especially applies to tubing, fittings,

and valves.

2. Keep the oxygen equipment away from open flames or

electrical appliances such as heaters, stoves, toasters,

and other devices with heating elements.

3. Never permit smoking in an area where oxygen equipment is repaired, filled, or used.

4. Always wear goggles, a face shield, and insulated gloves

when working with or around liquid oxygen.

While CAIRE equipment is designed and built to the most

rigid standards, no piece of mechanical equipment can ever

be made 100% foolproof. Strict compliance with proper

safety practices is necessary when using a Liberator or

Stroller. We recommend that our distributors emphasize

safety and safe handling practices to their employees and

customers. While safety features have been designed into the

unit and safe operations are anticipated, it is necessary that all

distributor personnel carefully read and fully understand

WARNINGS, CAUTIONS, and NOTES throughout the man-

ual. Periodic review of this information is recommended.

WARNING: Excess accumulation of oxygen creates an oxygen-enriched atmosphere (defined by the Compressed Gas

Association as an oxygen concentration above 23%). In an

oxygen-enriched atmosphere, flammable items may burn vigorously and may explode. Certain items considered non-combustible in air may burn rapidly in such an environment. Keep

all organic materials and other flammable substances away

from possible contact with oxygen; particularly oil, grease,

kerosene, cloth, wood, paint, tar, coal dust, and dirt which

may contain oil or grease. DO NOT permit smoking or open

flame in any area where oxygen is stored, handled, or used.

Failure to comply with this warning may result in serious

personal injury.

WARNING: In the event a unit is dropped, tipped over, or

unreasonably abused, immediately, but cautiously, raise the

container to its normal vertical position. If substantial container damage has occurred, remove the liquid oxygen from

the vessel in a safe manner (RP 24). Purge the unit with an inert gas (nitrogen) and promptly return it to CAIRE for inspection. The container should be prominently marked

“CONTAINER DROPPED, INSPECT FOR DAMAGE.”

Failure to comply with these procedures may result in personal injury and can seriously damage the container.

WARNING: Personnel must remove liquid oxygen and depressurize the Liberator or Stroller before removing parts or

loosening fittings from a unit. Failure to do so may result in

personal injury because of the extreme cold of the liquid oxygen and the pressure in the vessel. External valves and fittings

can become extremely cold during liquid transfer.

WARNING: During transfer of liquid oxygen, components

will become extremely cold. Care should be used to avoid any

contact with these components, as serious burns may result.

WARNING: Keep filled unit upright at all times. Tip over

of filled unit may result in liquid oxygen leakage and/or oxygen enriched atmosphere.

WARNING: Only use replacement equipment which is compatible with liquid oxygen and has been cleaned for oxygen

use. Do not use regulators, fittings, hoses, etc. which have

been previously used in a non-oxygen service.

CAUTION: The Liberator should be moved by utilizing the

roller base or hand truck. The Liberator must be used, stored,

and transported in a vertical position. Do not lay, store, or

ship on its side.

IVTheory of Operation

Page 7

Filling

The Liberator is filled by connecting a pre-purged transfer

line with a fill adapter from a larger liquid oxygen source to

the Liberator female (side fill) or male (top fill) quick disconnect valve. The Liberator vent valve is opened. The pressure of the oxygen gas above the liquid in the source container forces liquid oxygen through the transfer line and into

the Liberator inner vessel.

There will be some oxygen vaporized during filling. This

gas is discharged through the vent valve. When the Liberator

is full, liquid oxygen is expelled. Closing the Liberator vent

valve and disconnecting the fill adapter from the Liberator

QDV terminates the fill process.

Saturation Pressure

The saturation point of a liquid is a steady-state condition

where the liquid has absorbed the maximum amount of heat

it can. Such a liquid is defined as being at its saturation pressure. For each saturation pressure, there is a corresponding

temperature; the higher the saturation pressure, the higher

the liquid temperature.

There are two conditions which can seriously affect the

overall efficiency and operation of the system:

1. Saturation pressure of the liquid oxygen in the fill source

is substantially higher than the Liberator operating pressure (oversaturated).

2. Saturation pressure of the liquid oxygen in the fill source

is substantially lower than the Liberator operating pressure (undersaturated).

For example, when a Liberator is filled from a liquid source

saturated at 100 psig, larger transfer losses will occur. This

is because the Liberator is designed to operate at 20 psig,

and the liquid it is filled with is saturated at a much higher

pressure and at its correspondingly higher temperature. It is

necessary for this liquid to desaturate to a lower pressure and

temperature before the relief valve will close and the

Liberator will operate properly.

In order to become saturated at 20 psig, the liquid oxygen

must give up enough heat for its temperature to be lowered

to that temperature corresponding to a pressure of 20 psig, as

shown in the graph. It accomplishes this by a vigorous boiling action. All of the gas generated by this boiling is vented

through the primary relief valve, and is lost.

If the saturation pressure of the liquid oxygen in the filling

vessel is lower than the normal operating pressure of the

Liberator, e.g., 10 psig, then the pressure building rod of

the Liberator must function to raise the system pressure to

the operating pressure of 20 psig. It may require as much as

several hours for the undersaturated liquid to become saturated at 20 psig. The time required for saturation to 20 psig

depends on the initial liquid saturation pressure.

FILLING

SATURATION CURVE

Vent Valve

Liquid

Gas

Fill Connection

(QDV)

Gas

-240

-250

-260

-270

TEMPERATURE (˚F )

2

-280

LIQUID O

-290

-300

0 255075100

(-278)

(-297)

SATURATION PRESSURE (PSIG)

(-251)

(-258)

VI Theory of Operation

Page 8

WARNING: Low oxygen flow rates to the patient may

result if the Liberator is filled with under-saturated liquid oxygen.

To minimize the effect of undersaturated liquid on the

Liberator, a fixed orifice has been installed in the outlet of

the vent valve. This orifice regulates the back pressure in the

unit during the fill process, resulting in more correct saturation pressures in the Liberator.

Operation

With liquid oxygen in the unit and the flow control valve and

vent valve closed, the pressure in the inner vessel will remain

near the primary relief valve setting of 23 psig.

In the Liberator, as in all vacuum-insulated cryogenic containers, some liquid (oxygen in this case) is always evaporating into a gas because no insulating system is perfect.

The rate of generation of this gas, with the flow control

valve closed, is called the normal evaporation rate (NER).

This gas is lost through the primary relief valve.

When the flow control valve is at any setting other than off,

and the economizer valve is open (pressure above 20 psig),

gaseous oxygen is forced from the head space in the inner

vessel, through the economizer valve, to the breathing coil.

This process conserves or “economizes” liquid oxygen by

withdrawing the head gas first, instead of allowing it to escape through the relief valve.

In the breathing coil, the cold gaseous oxygen is warmed to

near-ambient temperature while flowing to the flow control

valve, where it is metered and dispensed.

Whenever gas is removed from the space above the liquid

oxygen, the inner vessel internal pressure begins to drop

slightly. When the pressure drops to 20 psig, the economizer

valve closes, forcing liquid oxygen up the withdrawal tube

and through the warming coil where it becomes gas.

The gas then flows through the bypass tee to the breathing

coil, the flow control valve, and then the patient.

As the pressure in the container increases over 20 psig, the

economizer valve opens, and the cycle repeats, maintaining

constant oxygen flow, at the set flow rate, to the patient.

OPERATION PRESSURE

ABOVE 20 PSI

OPERATION PRESSURE

BELOW 20 PSI

Gas to Patient

Breathing

Coils

Warm-Up

Economizer

(Closed)

Coils

Breathing

Coils

Economizer

(Open)

Gas

Gas to Patient

VITheory of Operation

Page 9

Liquid Level Measurement

Liberators are equipped with a unique liquid level measurement system. This system measures the level of liquid oxygen

inside the unit with a capacitance probe and displays that liquid level on an LED bar graph meter called "Sur-Cal 3".

The liquid level probe consists of two concentric stainless

steel cylinders, which are inside the inner vessel. As the liquid oxygen level rises, the capacitance of this assembly goes

up. The meter measures this capacitance and displays it on

the LED bar graph.

Electrical connection between the Sur-Cal 3 meter and

the probe is made via a single conductor plug connector. The

male plug carries the coaxial cable from the meter. The female receptacle carries the same wire from the probe. A single ground wire is connected from the meter to a male spade

terminal on the corresponding meter ground wire. The SurCal 3is equipped with a short-circuit indicator which turns

all LED’s “off” when capacitance above approximately

375pF is reached.

The meter is powered by a nine volt battery. The meter has

a low battery (LOW BATT) indicator which signals the need

for battery replacement.

LIQUID LEVEL

METER

Probe Outer

Cylinder

Liquid Fill Tube

(Probe Inner Cylinder)

Plug Connector

Female Quick

Connect Valve

Meter Package

LOW

BATT.

+

+

Meter

Switch

Battery

3/4

1/4

+

+

9 Volt

F

1/2

E

_

_

VII Unpacking and Setup

Page 10

Unpacking

1. Always inspect carton for shipping damage. Report any

damage to freight company before signing bill of lading.

2. Check description on carton against your order.

3. Unpack unit, including condensation bottle, POI, and humidifier elbow kit.

4. Set aside several sets of packing materials in case a unit

must be returned to factory.

Setup

1. Install condensation bottle on bracket located below

shroud. Remove cap from bottle. Put condensation hose

inside bottle.

2. Install humidifier elbow following instructions in carton.

3. Visually inspect the Liberator for damage from improper

handling. Note any container dents, cracks in shroud,

missing or loose screws or other hardware, bent quick

disconnect valve or humidifier adapter.

4. Check for smooth operation of the flow control selector,

making sure that a positive detent is felt at all settings.

The flow control knob should be secure and properly

aligned.

5. Check the vent valve (Item 41) for smooth operation.

6. If possible, connect a Stroller to the Liberator to check

for smooth coupling, and to make sure the Stroller is in

proper alignment with the Liberator when mated.

7. Verify operation of the Sur-Cal 3 meter by depressing

the push button. LED segments will light, displaying the

level of liquid oxygen. If the unit is empty, only the bottom

segment should light. If it does not, or if other erroneous

indications are given, refer to the Troubleshooting/Repair

Section.

8. Check all labels for damage and wipe away any dust on

unit with a clean, dry, lint-free cloth.

9. If desired, flow control knob (Item 1) can be adjusted so

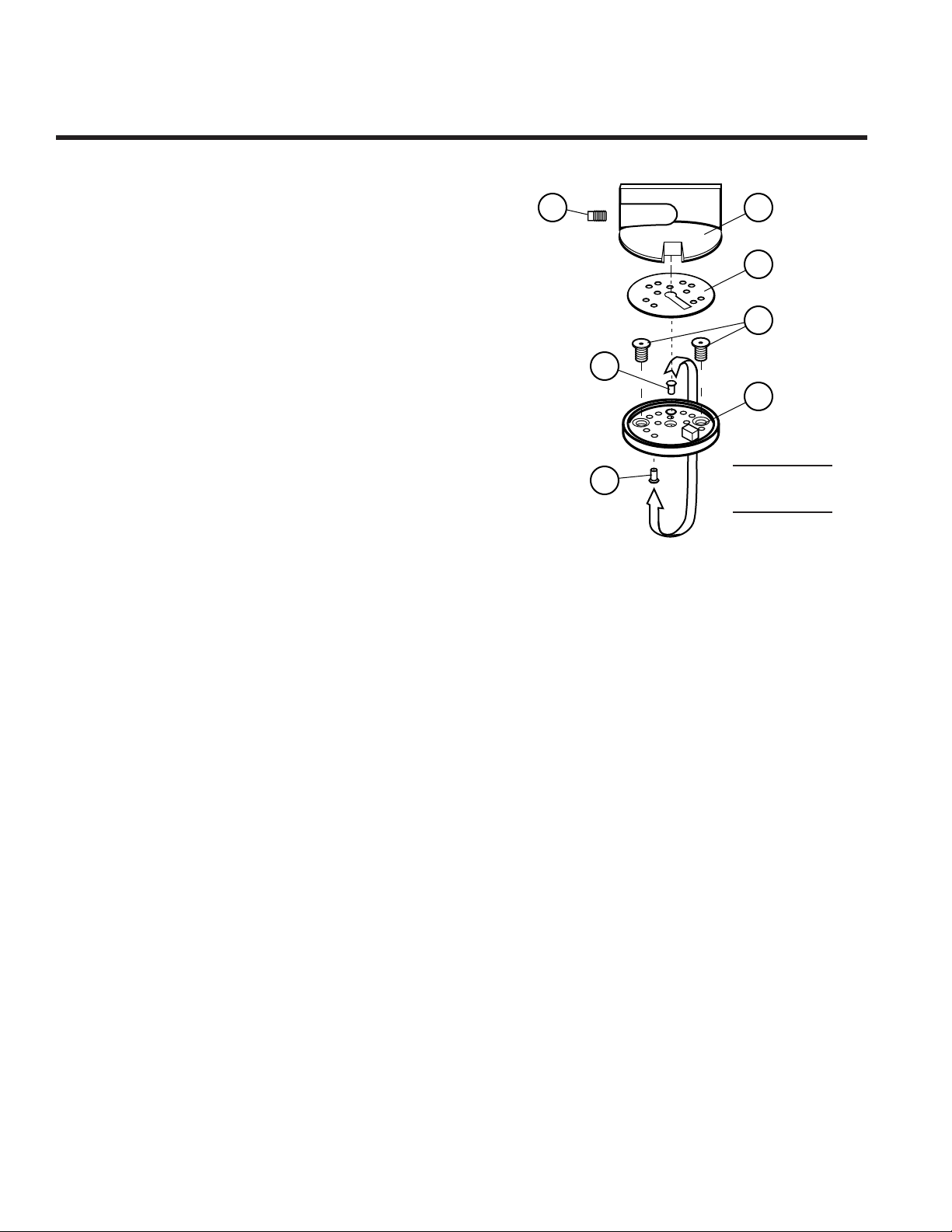

it will not exceed maximum prescribed flow rate.

a. Using hex key wrench, loosen setscrew if used (Item

17) in flow control knob and remove knob (Item 1).

b. Remove flow rate decal number disc (Item 2).

c. Remove two hex head screws (Item 4) from flow lock

plate (Item 3) and remove plate.

d. Remove locking pin (Item 65) from its storage position

on flow lock plate (Item 3) and place in underside of

hole corresponding to maximum allowable flow rate.

e. Replace flow lock plate (Item 3), number disc

(Item 2) and knob. Tighten screws (Item 4) to 4-6 inchpounds. Verify flow lock is at correct position.

ILLUSTRATION

FOR STEP 9

17

2

2

1/2

1/2

1

1

3/4

1/2

3

4

5

6

1/4

0

1

2

4

65

3

65

VIIIOperation

Page 11

Transport

CAUTION: Always ship, store, or transport a Liberator,

empty or full, in an upright position, properly secured to prevent damage.

Specifically designed roller bases are available for moving

the Liberators short distances on smooth surfaces. Hand

trucks are also available for moving the Liberators.

The Liberator 20, 30, 37, 45 and 60 may be moved about or

transported in a vehicle while full without damage. However,

the equipment should not be dropped or handled roughly, or

necktube damage may occur.

Filling

1. Fill Source

a. Fill source must contain a sufficient amount of liquid

oxygen to completely fill the Liberator (approximately

120% of Liberator volume).

b. The liquid oxygen in the fill source must be saturated

at 35-60 psig (50 psig is optimal).

c. The fill source must have correct fitting (5/8” * 45°

male flare) to connect to transfer line.

WARNING: Fill source must be in a well ventilated area

to prevent formation of oxygen enriched atmosphere.

2. Fill Procedure

a. Required Equipment:

♦ Fill source as outlined above

♦ Liquid oxygen transfer line

♦ Male transfer line adapter for side fill Liberators

♦ Female transfer line adapter for top fill Liberators

♦ Liberator vent valve wrench

♦ Eye protection

♦ Insulated gloves

b. If refilling partially filled Liberator, verify flow rates are

within tolerance specifications before filling.

c. Verify that liquid level meter is operating properly. The

LED display should indicate approximate level in unit.

The low battery LED should not be lit.

NOTE: If flow rates are out of specifications or liquid

level meter operates improperly, refer to Troubleshooting/

Repair section.

d. Verify that fill source has enough properly saturated

(35-60 psig) liquid oxygen to fill Liberator.

e. Connect transfer line to fill source. Connect proper

transfer line adapter to transfer line.

f. Fully open liquid valve on fill source.

WARNING: Wear insulated gloves and eye protection whenever working with liquid oxygen.

VIII Operation

Page 12

g. For male fill adapter:

Purge transfer line by placing adapter poppet (remove

protective cover) against side of unit and pressing in until poppet opens. Hold the poppet open for approximately five seconds, then release.

NOTE: Purge the transfer line any time fill source valve

has been closed.

h. Wipe reservoir fill connector with lint free rag if moist.

i. Weigh unit as required by local and federal standards.

j. Open reservoir vent valve.

k. Connect transfer line (liquid hose) to reservoir to begin

fill.

l. Connect a pressure gauge to oxygen outlet and open

the flow control valve to 2 lpm or greater.

m. While filling throttle the vent valve as required to keep

pressure at 20 psi nominal.

An alternate method to throttle the vent valve is to attach a flow meter to the oxygen outlet, set the flow control valve to 2 lpm, and then throttle the vent valve to

maintain a flow of 2 lpm. This is equivalent to using a

pressure gauge.

n. When liquid spurts from vent outlet, disconnect trans-

fer line.

o. Close reservoir vent valve immediately after removing

transfer line.

p. Disconnect pressure gauge (or flow meter) from oxygen

outlet.

CAUTION: Do not allow excessive venting of liquid

oxygen through the vent valve. Prolonged exposure may

freeze the valve in the open position.

q. Replace protective cover on adapter QDV and hang

adapter and transfer line using hook provided.

r. Verify that all flow rates are within tolerance specifi-

cations. Verify that liquid level meter indicates full.

NOTE: The liquid level indicating system is accurate

only after the vent valve is closed, and the oxygen has

been stabilized for five minutes.

IX

Routine Maintenance/Schedule A, Annual

There are two schedules for routine maintenance which the

home health care distributor may follow. These schedules

allow the distributor maximum flexibility while assuring that

equipment is operating properly.

Schedule A – Annual

A. Introduction

Routine maintenance is a series of steps used to assure that

equipment is functioning properly.

1. If a unit fails to pass a given test, one of two things may

be done.

a. Refer to Troubleshooting/Repair (Section X) of this

manual.

b. Return to CAIRE for repair.

2. Schedule – Maximum of one year between routine maintenance testing. Unit should be tested when a problem is

suspected.

B. Procedure

Follow the steps in order listed. If the unit fails any step,

refer to Troubleshooting/Repair (Section X) of this manual.

1. Visual Inspection:

a. Remove any LO2prior to maintenance (RP24).

b. Look for damaged or missing parts.

c. Verify that meter reads empty (one LED) and that the

low battery LED is not lit.

2. Component Test:

a. Remove shroud (RP2).

b. Pressurize to 25 psig (RP12) and check that PRV is

open.

c. Pressurize to 34 psig (RP12) and check that SRV is

open.

d. Recalibrate meter (RP5).

e. Test pressure retention (RP15).

f. Replace shroud (RP2).

3. Flow Test:

a. Fill with approximately 15 lbs. (2 LEDs) of properly

saturated LO

2

.

b.

Set FCV to maximum setting and run for one hour

minimum.

c. Check all flow settings to the following chart and

check pressure to be at least 18 psi.

4. Check Efficiency of Unit:

a. Set FCV to zero and allow bottle to warm up (10-15

minutes).

b. Inspect bottle for cold or sweaty condition and for ex-

cessive venting from relief valve (some venting is

normal).

c. If either condition is observed, conduct NER test

(RP32).

5. Prepare for Use:

a. Empty contents (RP24).

b. Allow unit to sit until warm (2-4 hours).

c. Clean outside of unit with household glass cleaner

and lint free cloth (do not get in any valves).

Page 13

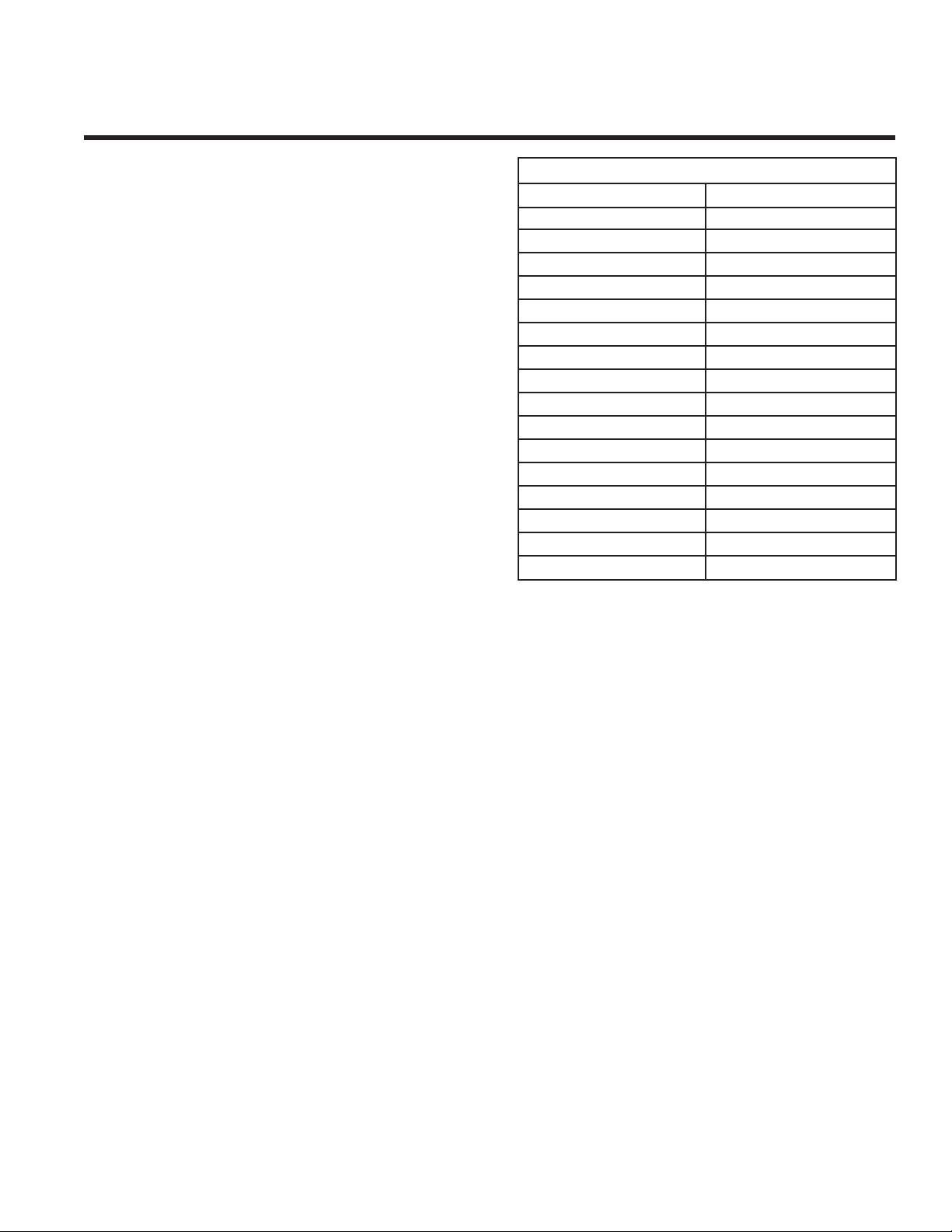

Reservoir Flow Test

FCV Setting LPM

OFF -0-

0.25 0.15 to 0.35

0.50 0.40 to 0.60

0.75 0.65 to 0.85

1.00 0.90 to 1.10

1.50 1.35 to 1.65

2.00 1.80 to 2.20

2.50 2.25 to 2.75

3.00 2.70 to 3.30

4.00 3.60 to 4.40

5.00 4.50 to 5.50

6.00 5.40 to 6.60

8.00 7.20 to 8.80

10.00 9.00 to 11.00

12.00 10.80 to 13.20

15.00 13.50 to 16.50

IX

Routine Maintenance/Schedule B, Continuous

Page 14

Schedule B – Continuous

A. Introduction

Continuous maintenance is a set of test or inspections done

consistently to assure equipment is functioning properly. It

can be done with equipment in service, by drivers or other personnel.

1. If a unit fails to pass a given test, it should be taken out of

service and sent to the Repair Center/Department for further inspection.

2. Schedule – Checks are made when the driver sees patient

and when moving equipment between patients.

B. Procedure

These inspections/ tests are done by driver as part of the

Standard Fill Procedure every time the reservoir is filled.

1. Visual Inspection:

a. Broken shroud.

b. Cold sweaty bottle (vacuum problem).

c. QDV not deformed.

2. Check prescription flow rate(s). Erie liter meter (± 0.25

lpm) can be used.

3. Check meter. Push meter button before fill and verify that

battery is not low and that meter is within one LED of

table below. After filling, verify that meter reads full.

These inspections/tests are done between patients.

1. Visual Inspection:

a. Broken shroud/flow control knob.

b. Cold sweaty bottle or excessive venting from relief

valve (vacuum problem). Some venting from relief

valve is normal.

c. QDV not deformed.

d. Inspect under shroud (without removal) for any visible

dirt or contaminants.

e. Inspect drain tube for visible dirt. Clean with a 6” cot-

ton swab to remove dirt.

2. Verify that meter battery is not low and meter is within one

LED of table. If unit is empty, verify meter reads empty,

then fill with approximately 15 pounds of liquid oxygen

and verity with chart.

3. Set FCV to maximum flow rate for one hour. Check all

flow settings to the following chart and check pressure to

be at least 18 psi.

4. If unit fails one of the above test, return to Repair

Center/Department or CAIRE. if units passes all tests,

clean outside of unit with household glass cleaner and lint

free cloth (do not get in any valves).

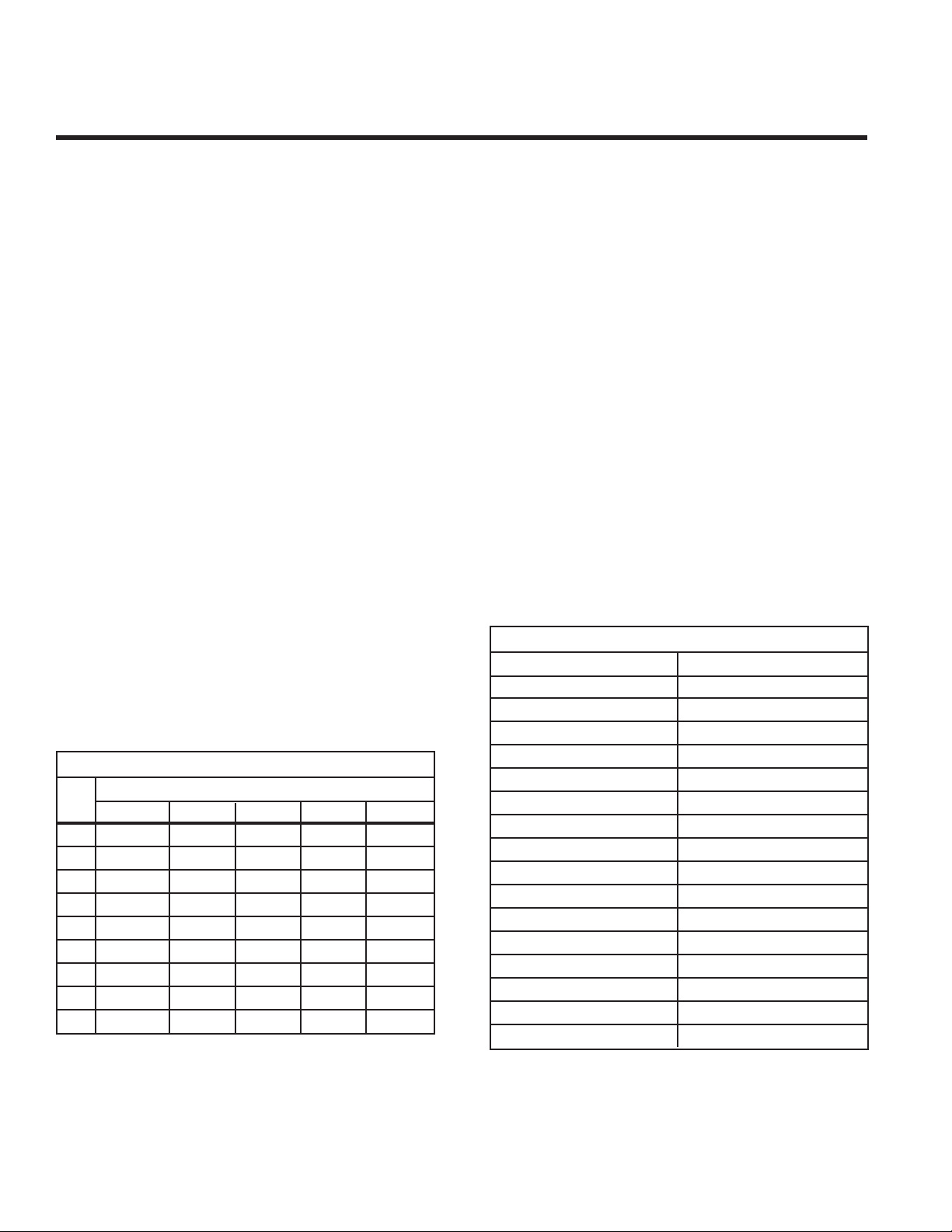

Contents vs. Meter Reading

Pounds of Oxygen

LED Lib 20 Lib 30 Lib 37 Lib 45 Lib 60

1 0.0-9.8 0.0-14.6 0.0-17.8 0.0-21.2 0.0-21.6

2 9.9-14.7 14.7-21.9 17.9-26.7 21.3-31.8 21.7-33.4

3 14.8-19.6 22.0-29.2 26.8-35.6 31.9-42.4 33.5-53.1

4 19.7-24.5 29.3-36.5 35.7-44.5 42.5-53.0 53.2-71.9

5 24.6-29.4 36.6-43.8 44.6-53.4 53.1-63.6 72.0-86.3

6 29.5-34.3 43.9-51.1 53.5-62.3 63.7-74.2 86.4-100.5

7 34.4-39.2 51.2-58.4 62.4-71.2 74.3-84.8 100.6-121.9

8 39.3-44.1 58.5-65.7 71.3-80.1 84.9-95.4 122.0-130.9

9 Above 44.1 Above 65.8 Above 80.2 Above 95.5 Above 131

Reservoir Flow Test

FCV Setting LPM

OFF -0-

0.25 0.15 to 0.35

0.50 0.40 to 0.60

0.75 0.65 to 0.85

1.00 0.90 to 1.10

1.50 1.35 to 1.65

2.00 1.80 to 2.20

2.50 2.25 to 2.75

3.00 2.70 to 3.30

4.00 3.60 to 4.40

5.00 4.50 to 5.50

6.00 5.40 to 6.60

8.00 7.20 to 8.80

10.00 9.00 to 11.00

12.00 10.80 to 13.20

15.00 13.50 to 16.50

Page 15

XTroubleshooting (Table of Contents)

Introduction ………………………………………………………15

Troubleshooting Charts…………………………………………16-17

Procedures

RP1 General ………………………………………………18

RP2 Shroud Assembly R/R ………………………………19

RP3 Condensation Bottle Bracket R/R ……………………19

RP4 Battery R/R …………………………………………19

RP5A Sur-Cal 3 Meter Calibration ……………………19-21

RP5B Sur-Cal 3.1™ Meter Calibration ……………………21

RP6 Manifold Capacitance Test …………………………22

RP7 Manifold Assembly R/R …………………………22-23

RP8 Resolder Feed-thru Wire ……………………………23

RP9 Manifold Harness Assembly R/R ……………………23

RP10 Clean/Dry Probe and Dewar …………………………23

RP11 Sur-Cal 3TMMeter R/R ………………………………24

RP12 Relief Valve Test ……………………………………24

RP13 Primary Relief Valve (PRV) R/R ……………………24

RP14 Secondary Relief Valve (SRV) R/R …………………25

RP15 Pressure Retention Test ………………………………25

RP16 Plumbing Leak Test …………………………………25

RP17 Warming and Breathing Coil Assembly R/R ………26

RP18 Vent Valve R/R ………………………………………26

RP19 Fill ……………………………………………………26

RP20 QDV Lip Seal R/R (Side Fill Only) ………………26-27

RP21 QDV Poppet Assembly R/R (Side Fill Only) ………27

RP22 QDV Assembly R/R (Top Fill and Dual Only) ………27

RP23 Stroller Pop-Off Assembly (Top Fill and Dual Only)…27

RP24 Empty Unit……………………………………………28

RP25 Warm Unit ………………………………………28-29

RP26 Flow Rate Test ………………………………………29

RP27 Operating Pressure Test………………………………29

RP28 Flow Meter Verification………………………………29

RP29 Economizer Regulator R/R …………………………30

RP30 Flow Control Valve (FCV) R/R ……………………30

RP31 Dewar R/R ………………………………………30-31

RP32 Normal Evaporation Rate (NER) Test ………………31

RP33 Cleaning Unit…………………………………………31

Tools ………………………………………………………………32

Fixtures/Equipment ………………………………………………32

Supplies ……………………………………………………………32

Introduction

1. These procedures are designed to be performed only by qualified personnel with proper equipment.

2. Any failure during routine maintenance checks will refer you to this section. See troubleshooting

chart for appropriate procedure.

X Troubleshooting Chart

Page 16

Page 17

XTroubleshooting Chart

To use the Troubleshooting Chart:

♦Start at the upper left corner.

♦The top line shows the steps of routine maintenance.

♦Unless otherwise noted by the arrows, the flow through the chart is down or to the right.

Page 18

X Repair Procedures

RP1 – General

The following procedures have been carefully prepared to

allow proper removal and replacement of defective components and should be used in conjunction with the

Troubleshooting Chart and the tests in this section.

WARNING: Make sure the unit is empty and vent valve is

open before replacing any component, except shroud assembly components or Lip Seals.

WARNING: The worker’s hands, tools, and clothing

should be free of all oils and greases.

WARNING: Parts that are welded in place must not be replaced in the field. Should these parts fail, return complete assembly or sub-assembly to factory for repair. DO

NOT use solder or silver solder to repair broken welds.

WARNING: The manufacturer of Krytox warns users not

to allow Krytox fluorolubricant to contaminate tobacco

products. Wash Krytox from hands before smoking.

WARNING: Do not use glues, thread locking compounds

or unapproved sealants on any repairs.

CAUTION: When replacing components, make sure that new

part is oriented exactly the same as original part prior to installation.

CAUTION: Some components require a specific amount of

torque when assembling. Follow torque requirements where

specified.

NOTE: All replacement parts must be factory approved,

cleaned for oxygen service, and stored in sealed plastic bags.

The repair area must be clean and separate from other areas.

Room air should be filtered, and as free from dust, soot, and

other contaminants as possible.

NOTE: When replacing components with pipe threads, use

TEFLON tape thread sealant. Apply two rounds of TEFLON

tape to threads near end of component, avoiding first thread.

NOTE: When assembling new compression fittings, tighten

1/8", 1/4" and 1/2" nuts eight flats after finger tight and 3/16"

nuts five flats after finger tight. When reassembling previously used compression fittings, tighten nuts one to two flats

after finger tight.

Page 19

XRepair Procedures

RP2 – Shroud Assembly R/R

a. Remove humidifier adapter (Item 25) from FCV (Item 24).

b. Remove top fill shroud cover ( Item 7a) if applicable.

c. Remove the one shroud mounting screw (Item 13).

d. Remove shroud (Item 7) by lifting up and moving side-

ways to clear the QDV (Item 15) or lifting straight up and

off for the top fill model.

e. Disconnect manifold harness assembly (Item) located

under shroud (Item 7).

f. To replace shroud assembly, reverse above procedure.

Torque humidifier adapter (Item 25) to 30-50 inch-lbs.

on aluminum FCV (Item 24).

RP3 – Condensation Bottle Bracket R/R

a. Remove condensate drain tube from bottle (Item 55)

and remove bottle from bracket (Item 56).

b. Remove condensate bottle bracket (Item 57) squeezing

legs together and pulling straight down.

c. To replace bracket, reverse above procedure.

RP4 – Battery R/R

a. Insert screwdriver blade into slot (Item A) in battery

cover (Item 10), located in top of shroud (Item 7), and

pry up lightly. Battery cover (Item 10) will pop up.

b. Remove battery covers (not shown).

c. Remove battery (Item 12) from cover (Item 10).

d. Remove terminal clip (Item B) from battery (Item 12).

e. To replace battery (Item 12), reverse above procedure.

RP5A – Sur-Cal 3 Meter Calibration

a. Simulator Box Calibration Procedure:

1. Connect adapter (Item A) to capacitance meter (Item B).

2. Turn on capacitance meter (Item B) and select 200 pF

range.

3. Move zero adjustment on front of meter (Item B)

until display reads zero.

4. Connect simulator (Item C) to adapter (Item A).

ILLUSTRATION FOR RP 2 & 3

12

7

10

A

B

60*

59*

61*

ILLUSTRATION FOR RP 4

59

13

5

7

7a

60

61

25

57

55

56

Page 20

F

E

18

C

19

D

E

F

5

B

10

12

X Repair Procedures

5. Set the capacitance for the 4th LED. The capacitance

meter (Item B) should read value listed below (switch

set to “4th LED”):

Res 20/30/37 17.3 pF ± 0.2 pF

Res 45 20.6 pF ± 0.2 pF

6. If meter (Item B) does not display correct reading, turn

proper adjustment screw (Item D) through hole in top

of simulator box (Item C).

7. Set the capacitance for the 9th LED. The capacitance

meter (Item B) should read value listed below (switch

set to “9th LED”):

Res 20/30/37 47.0 pF ± 0.2 pF

Res 45 55.0 pF ± 0.2 pF

8. If meter (Item B) does not display correct reading,

turn proper adjustment screw (Item E) through hole in

top of simulator box (Item C).

9. Disconnect simulator box (Item C) from female

adapter.

10. Simulator box (Item C) is now properly calibrated.

b. Meter Calibration Procedure:

NOTE: Make sure that Liberator is empty and at room

temperature before attempting calibration.

Recalibrate simulator box (Item C) each day before using.

1. Remove twist-lock meter lens (Item 18) by rotating it

counterclockwise. Lift out decal (Item 19).

2. Attach simulator box (Item C) to the meter connector

(Item F), LED display must be visible.

3. Switch simulator box to “4th LED”.

4. Verify that good battery (Item 12) is connected to battery terminal (Item B) on meter wiring.

5. Locate two adjustment screws (Item D & E) in meter

case.

6. Holding meter switch (Item 5) down, turn screw (Item D)

clockwise until 4th LED comes on. Turn it in opposite

direction until 4th LED just goes off. Release meter

switch (Item 5).

7. Switch simulator box to “9th LED”.

8. Depress meter switch (Item 5) in top cover. Turn 9th

LED adjustment screw (Item E) until 9th LED just

comes on. Release meter switch (Item 5).

9. Repeat Step 3, then depress meter switch (Item 5) to

verify that three LED’s are on.

+

-

B

C

A

94

D

E

ILLUSTRATION FOR RP 5A (section b)

ILLUSTRATION FOR RP 5A (section a)

Page 21

XRepair Procedures

10. Remove the simulator box (Item C) from the meter

connector (Item F). Press meter switch (Item 5). One

LED should come on.

11. Reapply a thin film of KRYTOX over the 6-pin connector to completely surround and cover the sockets

to make it waterproof.

12. Replace meter decal (Item 19) and lens (Item 18).

RP5B – Sur-Cal™ 3.1 Meter Calibration

Requires Calibration kit PN 10856013, Digital voltmeter with

high input impedance, display 1mV, and accuracy of ±0.5%, and

capacitance meter Ref 97403015 available from CAIRE.

1. Test the capacitance of the calibrator at least once

daily. The reading should be between 62.0 pF and 63.8

pF. When testing the calibrator make sure a good contact is made between the meter and calibrator, and that

the calibrator is inserted into the meter exactly as illustrated in RB5B (Item F).

2. Remove the clear twist lens and the decal such that the

meter face is exposed. The meter should be connected

to the empty warm unit.

3. Connect the banana plug ends of the calibrator to a

voltmeter.

4. Plug the calibrator (Item A) into the meter (Item B) as

shown in RP5B. The two male pins of the calibrator

should be inserted into the two female pins, near Pot

Screw (Item C) (cable from the calibrator is facing the

same direction as the cables of the meter).

5. Turn the meter on by depressing the meter switch. At

the same time, adjust the other Pot Screw (Item D) until a voltage of 0.000 ± 0.010 volts is obtained.

6. Remove the calibrator (Item A), flip it over (Item E),

and plug into the meter as shown. Once again the cable from the calibrator is facing the same direction as

the cables of the meter.

7.

Turn the meter on by depressing the meter switch. At the

same time, adjust Pot Screw (Item C) until the proper

voltage for the model size is obtained (see Voltage Table

for this value).

8. Repeat steps 4 through 7 as necessary. (Most likely

will not need to be repeated.)

If the meter does not seem to calibrate easily, turn Pot Screw

(Item C) 12 turns one direction, then 6 turns in the other and

attempt again.

BROWN/TAN SHROUD VOLTAGE

Sprint 3.555 ± .020 volts

Stroller 2.657 ± .020 volts

Liberator 20 2.972 ± .020 volts

Liberator 30 2.736 ± .020 volts

Liberator 45 2.736 ± .020 volts

GENERATION 3 VOLTAGE

Sprint 3.240 ± .020 volts

Stroller 2.657 ± .020 volts

Liberator 10 3.400 ± .020 volts

Liberator 20 3.200 ± .020 volts

Liberator 30 3.100 ± .020 volts

Liberator 37 3.035 ± .020 volts

Liberator 41 3.077 ± .020 volts

Liberator 45 & 60 2.736 ± .020 volts

Low Loss 32 & 41 3.035 ± .020 volts

D

B

C

E

A

+

–

-

F

BLACK

RED

ILLUSTRATION FOR RP5B

Alternate Method for Generation 3.1 Liquid Level

Meter Calibration Recommended for Units Using

Messenger Option for Highest Accuracy

1. Follow steps 2-5 as described above on an empty unit.

2. Fill Reservoir with liquid oxygen per normal manufacturer recommendations.

3. Attach the calibrator per step 4 above.

4. Turn the meter on by depressing the meter switch. At

the same time, adjust Pot Screw (Item C) until 2.900

± 0.020 volts is obtained. (All units, regardless of

model type, should read 2.900 ± 0.020 volts when

filled with liquid oxygen.)

Page 22

X Repair Procedures

RP6 – Manifold Capacitance Test

a. Capacitance Meter Set-Up:

1. Connect plug adapter to capacitance meter (Item B), following color code.

2. Turn on capacitance meter (Item B) and select 200 pF

range.

3. Move zero adjustment on front of meter (Item B) until

display reads zero.

b. Capacitance Test:

1. Remove shroud assembly (See RP 2).

2. Connect plug adapter (with jumper wire) to manifold

harness assembly (Item 29).

3. Connect alligator clip to ground.

4. Read manifold capacitance. May require changing meter

range.

5. Manifold capacitance specs:

Lib 20 175-210 pF

Lib 30 175-225 pF

Lib 37 175-225 pF

Lib 45 175-240 pF

Lib 60 175-220 pF

RP7 – Manifold Assembly R/R

a. Remove shroud assembly (See RP 2).

b1. If removing with coils:

1. Remove three rivets (Item 47) retaining breathing and

warming coils.

OR

b2. If removing manifold without coils:

1. Disconnect compression fitting (Item 34) from economizer valve (Item 35).

2. Disconnect compression fitting from liquid withdrawal

port (Item D). When disconnecting tube, be careful not to

kink vaporizer tube or internal TEFLON tube.

3. Disconnect compression fitting from FCV.

c. Remove the three screws (Item 37) from the FCV bracket

(Item 39).

d. Remove two manifold mounting screws (Item 31) and the

three stand off bolts (Item 32).

e. Lift manifold assembly straight up to remove.

NOTE: Make sure unit is

empty and at room temperature before testing.

WARNING: Before removing

manifold assembly, Liberator

must be empty, warm and

vent valve open.

ILLUSTRATION FOR RP 6

A

+

29

B

Page 23

XRepair Procedures

f. Place cover on top of dewar.

g. To replace manifold assembly, reverse above procedure.

Apply small amount of Krytox to O-ring (Item 50) before

assembly. Torque manifold mounting screws (Item 31) to

90-100 inch-lbs. using cross-tightening method.

RP8 – Resolder Feed-thru Wire

a Remove manifold assembly (See RP 7).

b. Strip approximately 1/8” of insulation from feed-thru wire

(Item A) if necessary.

c. Apply small amount of Stay-Clean flux to tinned area of

probe (Item B) using a cotton swab.

d. Resolder feed-thru wire (Item A) to tinned area of probe

(Item B). Add small amount of 60/40 solid wire solder if

necessary.

e. Clean flux residue with distilled water and cotton swab.

Dry thoroughly.

f. Replace manifold following listed procedure (RP 7).

RP9 – Manifold Harness Assembly R/R

a. Remove manifold assembly (See RP 7).

b. Unsolder feed-thru wire (Item A) from probe (Item B).

c. Loosen feed-thru nut (Item C) and remove harness.

d. To replace manifold harness, reverse above procedure.

Tighten feed-thru nut (Item C) 1 to 2 flats after finger tight.

e. Solder feed-thru wire (Item A) following resolder procedure

(See RP 8). Replace manifold assembly (See RP 7).

RP10 – Clean/Dry Probe and Dewar

Procedure 1:

a. Empty dewar per RP 24.

b. Warm dewar per RP 25.

c. If all moisture is not removed, go to procedure #2.

Procedure 2:

a. Remove manifold assembly (See RP 7).

b. Blow off probe assembly with clean, dry nitrogen gas.

c. Blow out inside of dewar with clean, dry nitrogen gas

until inside is clean and dry.

d. Replace manifold assembly (See RP 7).

CAUTION: Be careful not to

bend or damage manifold assembly or dewar neck tube.

ILLUSTRATION FOR RP 7, 8 & 9

37

39

32

31

34

43

D

35

41

C

50

49

B

A

45

48

47

Page 24

X Repair Procedures

RP11 – Sur-Cal 3 Meter R/R

a. Remove shroud (See RP 2).

b. Remove push button cap from meter switch (Item 5).

c. Remove switch retaining nut and lockwasher. Push meter

switch through hole.

d. Remove two screws and washers (Items 9 & 20) holding

meter. Remove meter assembly from shroud.

e. Remove nut from messenger connector (3.1 meter).

f. To replace Sur-Cal 3™ meter, reverse above procedure.

Tighten screws to 3-4 inch/lbs. only.

CAUTION: Be careful not to pinch wires!

RP12 – Relief Valve Test

NOTE: Liberator should be empty and warm before testing.

a. Remove shroud (See RP 2).

b. Assemble pressure gauge (Item A) and adapter (Item B)

(use TEFLON tape).

c. Connect gauge assembly to humidifier adapter (Item 26) on

FCV outlet. Open FCV (Item 24) to 6 lpm setting.

d. Assemble oxygen regulator and pneumatic hose (Item C)

with DISS fittings and male pneumatic test adapter (Item

D). Connect assembly to oxygen gas source.

e. Connect male pneumatic test adapter (Item D) to Liberator

QDV (Item 15).

f. Increase pressure to 25 psig. PRV (Item 62) must be open

(audible venting and/or bubbling of leak test solution).

g. Hold PRV (Item 62) closed and increase pressure to 34

psig. SRV (Item 28) must be open (audible venting and/or

bubbling of leak test solution).

h. Decrease pressure to 19 psig. Test relief valve with leak test

solution. A minimal amount of leakage (bubbling) is ac-

ceptable. If leakage is questionable, run pressure retention

test before changing relief valve.

RP13 – Primary Relief Valve R/R

WARNING: Liberator must be empty and vented before

starting procedure.

a. Remove shroud (See RP 2).

b. Remove PRV (Item 62) from economizer valve.

c. To replace PRV (Item 62), reverse above procedure. Snug

the PRV approximately 10 to 20 degrees clockwise after

the PRV body contacts the economizer regulator (mini-

mum of 20-30 inch-pounds).

35

62

28

24

ILLUSTRATION FOR RP 12

ILLUSTRATION FOR RP 13 & 14

24

35

26

28

15

C

B

D

A

Page 25

XRepair Procedures

RP14 – Secondary Relief Valve R/R

WARNING: Liberator must be empty and vented before

starting procedure.

a. Remove shroud (See RP 2).

b. Remove SRV (Item 28) from FCV (Item 24).

c. To replace SRV (Item 28), reverse above procedure. Use

TEFLON tape on threads.

RP15 – Pressure Retention Test

WARNING: Liberator must be empty and vented before

starting procedure.

a. Assemble pressure gauge (Item A) and adapter assembly

(Item B) (use TEFLON tape).

b. Connect gauge assembly to humidifier adapter (Item 26) on

FCV outlet. Open FCV (Item 24) to 6 lpm setting.

c. Assemble oxygen regulator, pneumatic hose with DISS

fittings (Item C) and male pneumatic test adapter (Item D).

Connect assembly to oxygen gas source.

d. Connect male pneumatic test adapter (Item D) to Liberator

QDV (Item 15).

e. Increase pressure to 20 psig.

f. Disconnect male pneumatic test adapter (Item D) from

QDV (Item 15).

g. Turn FCV valve (Item 24) to Off setting.

h. Allow unit to sit undisturbed for 60 minutes.

i. Turn FCV valve (Item 24) to 6 lpm setting.

j. If pressure gauge (Item A) indicates less than 19.0 psig,

unit fails test.

RP16 – Plumbing Leak Test

NOTE: Liberator should be empty and warm before testing.

a. Remove shroud (See RP 2).

b. Assemble pressure gauge (Item A) and adapter assembly

(Item B) (use TEFLON tape).

c. Connect gauge assembly to humidifier adapter (Item 26) on

FCV outlet. Open FCV (Item 24) to 6 lpm setting.

d. Assemble oxygen regulator, pneumatic hose (Item C) with

DISS fittings and male pneumatic test adapter (Item D).

Connect assembly to oxygen gas source.

D

C

15

A

26

28

62

24

B

e. Connect male pneumatic test adapter (Item D) to Liberator

QDV (Item 15).

f. Increase pressure to 19 psig.

g. Leak test all connections, joints, and valves with leak test

solution.

NOTE: PRV and SRV may leak slowly. Repair all other

leaks first and retest for pressure retention before chang-

ing relief valves.

h. Close FCV (Item 24) by turning to Off position. Remove

pressure gauge assembly from humidifier adapter (Item 26).

i. Disconnect pneumatic adapter (Item D) from QDV

(Item 15).

j. Leak test QDV poppet and FCV outlet.

k. Repair all leaks by following appropriate repair procedures.

ILLUSTRATION FOR RP 15 & 16

Page 26

X

Repair Procedures

WARNING: Liberator must

be empty and vented before

starting procedure.

ILLUSTRATION FOR RP 17 & 18

RP17 – Warming and Breathing Coil Assembly R/R

a. Remove shroud (See RP 2).

b. Disconnect breathing coil (Item 49) at the FCV (Item

24) by unscrewing the tube nut (Item 48).

c. Remove FCV bracket by removing the three screws

(Item 37).

d. Disconnect the two coils from the economizer (Item 35)

and the manifold by unscrewing the three connectors

(Item 48).

e. Remove three rivets (Item 47) holding coil brackets.

f. Remove warming and breathing coil assembly.

g. To replace coil assembly, reverse above procedure.

RP18 – Vent Valve R/R

a Remove shroud (See RP 2).

b. Remove muffler (Item 43).

c. Remove vent valve (Item 41) by unthreading valve nut

while supporting the valve to prevent it from turning.

d. Replace vent valve (Item 41). Support the valve to pre-

vent it from turning when tightening valve.

NOTE: Valve must be properly aligned to allow access

to handle through hole in shroud.

e. Replace muffler (Item 43).

f. Replace shroud.

RP19 – Fill

NOTE: For QDV leak test, Liberator needs only to be 1/4 to

1/2 full.

a. Fill Liberator following filling procedures in Operation

section of this manual.

RP20 – Quick Disconnect Valve Lip Seal R/R

(Side Fill only)

NOTE: Lip Seal may be changed on a full Liberator (side fill

version only).

a. Insert lip seal tool into Liberator female QDV (Item 15).

Engage tabs on tool with slots in retaining ring (Item 87).

b. Use wrench on hex end of tool. Push in on tool while

turning to engage tabs on tool with slots in retaining ring

(Item 87). Turn tool clockwise to loosen retaining ring

(Item 87). Remove the ring.

c. Remove lip seal (Item 88) from QDV (Item 15).

Jeweler’s screwdriver may be used if necessary, but seat-

ing surfaces must not be damaged.

d. Apply thin film of Krytox to lip seal O-Ring (Item 88).

37

39

43

41

35

24

47

49

48

45

Page 27

XRepair Procedures

e. Place retaining ring (Item 87) on tool. Place new lip seal

on tool.

f. Install in QDV body (Item15) by turning tool counter-

clockwise while pushing in on tool. Torque retaining

ring (Item 15b) to 20-25 inch-lbs.

RP21 – Quick Disconnect Valve

Poppet Assembly R/R (Side Fill only)

WARNING: Liberator must be empty and vented before

starting procedure.

a. Remove shroud (See RP 2).

b. Turn nut (Item C) holding QDV body (Item 15) to fill

tube clockwise to loosen. Hold QDV body (Item 15) with

wrench to prevent it from turning.

c. Disassemble QDV (Item 15).

d. Apply thin film of Krytox to O-ring (Item 16) located be-

tween valve body (Item 15) and fill tube. Replace entire

poppet assembly (Item 14).

e. Reassemble QDV (Item 15), matching alignment marks

on valve body and fill tube.

f. Torque nut (Item C) to 45-50 ft.-lbs. while holding valve

body (Item 15).

g. Replace shroud (See RP 2).

RP22 – Quick Disconnect Valve Assembly R/R

(Top Fill and Dual only)

Warning: Liberator must be empty and vented before

starting this procedure.

a. Remove shroud (See RP 2).

b. Remove two screws (Item 37) and washers (Item 38)

from pop-off assembly (Item 27) and remove pop-off

assembly.

c. Remove pop-off sleeve (Item 21) from QDV (Item 11).

d. Remove the top fill (QDV) by turning the QDV nut

(Item D) clockwise while holding the valve (Item 11)

with a wrench.

e.

Remove the retaining ring holding poppet in place.

f. Replace poppet, fully seating retaining ring into the QDV

body groove.

g. Reassemble QDV to fill tube, torquing nut to 45-50 ft./lbs.

while holding valve body.

h. Reassemble pop-off sleeve over QDV.

i. Reassemble pop-off assembly to unit, ensuring spring-to-pin

engagement into pop-off sleeve groove.

j. Replace shroud. (See RP2).

RP23 – Stroller Pop-Off Assembly

(Top Fill and Dual only)

a. Remove shroud (See RP 2).

b. Remove two screws (Item 37) and washers (Item 38)

from pop-off assembly (Item 27) and remove pop-off

assembly.

c. Remove pop-off sleeve (Item 21) from QDV (Item 11).

d.

Replace necessary parts.

e. Reassemble pop-off sleeve over QDV.

f. Reassemble pop-off assembly to unit, ensuring spring-to-pin

engagement into pop-off sleeve groove.

D

67

11

76

67

75

15

87

88

14

16

89

C

ILLUSTRATION FOR RP 20 & 21

ILLUSTRATION FOR RP 22

Page 28

X Repair Procedures

RP24 – Empty Unit

WARNING: Make sure open end of transfer line remains

inside cryogenic container. Wear insulated gloves and eye

protection when using this procedure. DO NOT reuse liquid oxygen.

a. Place one end of the transfer line (Item A) into a suit-

able cryogenic container such as an empty, clean

Liberator dewar. Connect a male transfer line adapter

(Item B) to the other end of the line.

NOTE: Female transfer line adapter should be substituted for item B in top fill version.

b. Connect the adapter to the Liberator QDV (Item 15),

keeping the vent valve (Item 41) closed.

c. Liquid oxygen will be discharged from the open end of

the transfer line into the empty container. Continue process until Liberator is empty.

d. If Liberator has no pressure, pressurize with the follow-

ing procedure.

1. Connect regulator (Item C) to oxygen gas source.

2. Connect pneumatic hose (Item D) to regulator and

Liberator DISS Fitting (Item E).

3. Adjust regulator (Item C) to supply 20 psig.

4. Set Liberator FCV (Item 24) to 6 lpm setting.

5. Continue until Liberator is empty.

RP25 – Warm Unit

a. Liberator may be allowed to sit (FCV off, vent closed) a

minimum of 48 hours after emptying.

b. To warm a Liberator in less time:

1. Connect regulator (Item C) to oxygen or nitrogen gas

source.

2. Connect pneumatic hose (Item D) to regulator (Item C)

and male pneumatic adapter (Item F).

NOTE: Female pneumatic adapter should be substituted for (Item F) in top fill version.

ILLUSTRATIONS FOR RP 24

ILLUSTRATION FOR RP 25

24

41

15

B

E

A

D

C

41

15

D

C

F

Page 29

XRepair Procedures

3. Adjust regulator to 20 psig. Open vent valve (Item 41)

to allow slow venting.

4. Allow Liberator to vent until 1-1/2 hours minimum

after vent valve (Item 41) defrosts.

RP26 – Flow Rate Test

NOTE: For flow rate test Liberator needs only to be 1/4 to 1/2

full.

a. Connect FCV outlet to flow meter inlet with respiratory

tubing. Make sure flow meter outlet is open and unobstructed and flow meter (Item G) is properly positioned.

b. Unit should operate for 1-1/2 hours minimum (overnight

is optimum). Test flow rate at each FCV (Item 24) position. Record all flow rates.

c. Flow rates must be nominal values within tolerances

listed in Specification section of this manual or unit fails

flow rate test.

NOTE: Be careful to allow for accuracy tolerances of

flow meter.

RP27 – Operating Pressure Test

a. Assemble pressure gauge (Item H) and adapter (Item J)

(use TEFLON tape).

b. Connect gauge assembly to DISS fitting on FCV outlet.

Open FCV (Item 24) to 6 lpm setting.

c. Read operating pressure on pressure gauge (Item H).

d. Operating pressure must be 18-22 psig or unit fails test.

RP28 – Flow Meter Verification

a. Flow meter accuracy is best verified by calibration lab-

oratory. Equipment should indicate liter per minute oxygen gas at 14.7 psia (0 psig) and 70° F.

b. Flow meter accuracy may also be tested by comparison

to one or more new, unused flow meters. This method

will increase confidence in accuracy of readings, but not

necessarily verify accuracy.

NOTE: If testing operating

pressure because of improper

flow rates, test immediately

after flow rate test.

ILLUSTRATION FOR RP 26 & 27

G

24

H

J

15

Page 30

X Repair Procedures

RP29 – Economizer Regulator R/R

a. Remove shroud (See RP2)

b. Loosen the two compression fitting nuts (Item 48) at

the economizer regulator (Item 35). Move coil away

from the regulator.

c. Remove the economizer regulator (Item 35) from the

vent tube (Item 34) by unscrewing the fitting.

d. Connect the inlet of the economizer regulator (Item 35)

to an oxygen pressure source as shown in the illustration.

e. Open the pressure source valve. Adjust the pressure

source regulator to 23 psi. The economizer regulator

should be set to open at 21.5 psig and close at 20.5 psig.

f. Slowly open valve (Item B) just enough to allow some

gas to escape.

g. Pressure gauge (Item A) will indicate the setting of

the economizer regulator. The setting is increased by

turning in the adjusting screw (Item C) or lowered by

backing the screw out.

h. Adjust valve (Item B) while watching the pressure on

gauge (Item A). Gas will flow through the regulator

when the set pressure is reached. The economizer regulator should be set to open at 21.5 psig and close at

20.5 psig.

RP30 – Flow Control Valve R/R

(See Illustration on Pg. 29)

a. Remove shroud (See RP 2).

b. Loosen compression fitting nut (Item 48) at connection

of coil and FCV assembly. Disconnect FCV assembly

(Item 24) from coil.

c. Remove the FCV knob (Item 1) and flow rate decal

(Item 2).

d. Unscrew (Item 4) to remove the FCV.

e. Remove the SRV (Item 28) from FCV (Item 24).

f. To replace FCV (Item 24), reverse above procedure.

NOTE: FCV must be assembled properly to align with

shroud.

RP31 – Dewar R/R

a. Remove shroud (See RP 2).

b. Remove manifold assembly with coils (See RP 7).

c. Remove condensate bottle (Item 56), drain tube (Item

55) and bracket (Item 54).

d.

Remove dewar cap from new dewar. Put cap on old dewar.

e. Clean/dry probe and dewar following procedure in this

section.

ILLUSTRATION FOR RP 29

ILLUSTRATION FOR RP 29

WARNING: Liberator must

be empty and vented before

starting procedure.

34

48

35

Pressure Source Valve

Set Above Desired

Regulator Setting

C

48

B

Out

35

In

A

C

Page 31

XRepair Procedures

ILLUSTRATION FOR RP 30

NOTE: Dewar may be repairable.

Refer to Return Policy section.

f. Assemble manifold assembly with coils to new dewar

following manifold assembly replacement procedure

(See RP 7). (Do not replace shroud.)

NOTE: QDV location is nearest the dewar vacuum pump

out port.

g. Replace condensate bottle (Item 56), bracket (Item 54)

and drain tube (Item 55).

h. Scribe part number and serial number on new dewar han-

dle similar to old dewar. Use vibrating engraver to make

part number and serial number on old dewar illegible.

i. Calibrate meter following procedure (See RP 5). (Do not

replace shroud.)

RP32 – Normal Evaporation Rate Test

a. Fill unit with correct amount of properly saturated liq-

uid oxygen following procedure:

Lib 20 25-30 pounds Lib 45 55-60 pounds

Lib 37 45-50 pounds Lib 60 65-70 pounds

Lib 30 35-40 pounds

b. Allow unit to sit undisturbed a minimum of 12 hours

with FCV in Off position and vent closed.

c. Weigh unit. Record weight and time.

NOTE: Weight must be within ± 0.05 pound.

d. Allow unit to sit undisturbed for a minimum of 24 hours.

e. Weigh unit. Record weight and time.

f. Calculate liquid loss rate (NER) in pounds L02/day using

the following formula

Weight lost in lbs.

NER = ———————— x 24 hours/day

Elapsed time in hrs.

Example

1.65 lbs.

NER = ————— x 24 hours/day

25.5 hrs.

NER = 1.55 lbs. loss per day

g. If NER is more than 2 pounds per day for a Liberator, the

dealer may want to send the unit to CAIRE for re-evac-

uation. Any unit over 5 pounds per day should be re-

moved from service and re-evacuated.

RP33 – Cleaning Unit

NOTE: Clean only after unit is empty and vented.

a. Clean using household glass cleaner and lint free cloth.

Do not get glass cleaner inside shroud or onto any valves.

b. Allow unit to dry thoroughly before using.

1B

2

4

3

39

24

28

25

48

Page 32

X Service Tools/Equipment/Supplies

Service Tools and Accessories available from CAIRE

Part No Description

10679862 Female Top Fill Pneumatic Test Adapter

10678157 Female Top Fill Transfer Line Adapter

CA200071 Krytox 240 AC Lubricant

CA200072 "Snoop" Leak Detection Fluid (gallon)

97200076 Erie "Liter Meter"

97212021 Male Side Fill Pneumatic Test Adapter

97212023 Male Side Fill Transfer Line Adapter w/Filter

CA005571 Transfer Line Adapter Cover

97217007 Pressure Gauge Adapter

CA400004 Replacement Filter/Male Transfer Line Adapter

97403016 Jeweler's Screwdriver

97403015 Capacitance Meter

97403574 Dewar Cap

97403577 0-60 psig Pressure Gauge

97404539 Stroller Cart

97404564 Transfer Line Swivel Connector

97405147 0-45 psig Oxygen Regulator

97405275 Wheelchair Bracket

97405277 Hand Truck w/o Stair Climber

97405278 Hand Truck w/Stair Climber

97405279 Pneumatic Hose with DISS Fittings

97405431 Liquid Oxygen Transfer Line – 6'

97405590 Lip Seal Service Tool

10597921 Sur-Cal 3

Simulator Box w/Adapter (G 3.0)

10597912

Sur-Cal3 Probe/Capacitance Meter Adapter (G 3.0)

10856013 Sur-Cal 3.1™Calibrator

10855491 External Messenger

CA406308 150 psi Relief Valve Assembly

CA406310 TEFLON Tape

CA406398 150 psi Relief Valve only

97406471 Tandem Tee Kit

97406555 Super Flex Liquid Oxygen Transfer Line – 6'

97406630 Dual Fill Head Tee

10662649 Service Manual

10661515 Conversion Kit TF to SF

10660361 Conversion Kit SF to Dual

10660344 Conversion Kit TF to Dual

10661523 Conversion Kit SF to TF

Required Tools

Hex Wrenches (various sizes)

Flat Blade Screwdriver

5/16” Nut Driver

Open End Wrenches (1/2” to 1-1/8”)

Side Cutters

Pliers

Torque Driver/Wrench (10-15 inch-lbs., 20-25 inch-lbs.,

60-80 inch-lbs., 90-100 inch-lbs., 45-50 ft.-lbs.)

Jeweler’s Screwdriver

Vibrating Engraver

Required Fixtures/Equipment

Capacitance Meter

Sur-Cal 3 Simulator Box with Adapter

Soldering Pencil

Oxygen Regulator

Pressure Gauge

Pressure Gauge Adapter

Flowmeter

02 Gas Source (HP bottle)

02 Liquid Source

N2 Gas or Clean Dry Compressed Air Source

Tubing (02 compatible)

Lip Seal Service Tool

Male Pneumatic Test Adapter

LO2 Transfer Line

Transfer Line Adapter with Filter

Dewar Cap

Vent Valve Wrench

Scale 0-150# with 0.05# increments

Voltmeter (x.xxx ± 5%)

Required Supplies

Stay-Clean Flux

Cotton Swabs

60-40 Solid Wire Solder

Distilled Water

Household Glass Cleaner

Lint-Free Cloth

TEFLON Tape

Krytox

SNOOP Leak Detection Fluid

For a complete list of accessories, see catalog #401-038-901.

XITop Fill G3.0 Units Parts List

Page 33

This section of the service manual contains lists and drawings

useful in selecting Liberator replacement parts and service

equipment. The Parts Diagram on page 35 is an exploded view

of a Liberator top fill unit applicable to either the Liberator 20,

30, 37 or 45. The numbers encircled in The Parts Diagram on

page 35 refer to specific replacement parts which are described

on pages 33 and 34, Section XI. Page 32 lists special tools and

equipment required to service the Liberator, several of which

are only available from CAIRE, Inc. All parts and equipment

listed in this section can be purchased from CAIRE, Inc.

Part Part Part Part

Ref. No. Number Number Number Number

Lib 20 Lib 30 Lib 37 Lib 45 Description Quantity

–

–

1

2

2

3

4

5

7

8

9

10

11

12

13

16

17

18

19

20

21

22

23

23

24

24

25

26

27

28

29

30

31

32

33

34

35

37

38

39

40

41

42

43

45

46

47

48

49

10564150

10879434

10567941

10567967

10816071

CA406438

CA002876

10484432

10562138

10564192

CA403690

10562154

10542031

CA110060

2910391

CA404838

CA405232

CA403406

10578076

10577891

10576441

10657831

10855985

11510882

10480511

10523403

CA405938

CA405451

10576513

10495289

10657823

10494841

CA406432

10620107

CA200038

10760273

10531833

CA405164

CA405145

N/A

10576450

10570517

10509960

10571069

10657760

CA005676

CA004412

10760273

10657778

10564133

10879442

10567941

10567967

10816071

CA406438

CA002876

10484432

10562138

10564192

CA403690

10562154

10542031

CA110060

2910391

CA404838

CA405232

CA403406

10578076

10577891

10576441

10657831

10855985

11510882

10480511

10523403

CA405938

CA405451

10576513

10495289

10657823

10494841

CA406432

10620107

CA200038

10760273

10531833

CA405164

CA405145

N/A

10576450

10570517

10509960

10571069

10657760

CA005676

CA004412

10760273

10657778

10564168

10879451

10567941

10567967

10816071

CA406438

CA002876

10484432

10562138

10564192

CA403690

10562154

10542031

CA110060

2910391

CA404838

CA405232

CA403406

10578076

10577891

10576441

10657831

10855985

11510882

10480511

10523403

CA405938

CA405451

10576513

10495289

10657823

10494841

CA406432

10620107

CA200038

10760273

10531833

CA405164

CA405145

N/A

10576450

10570517

10509960

10571069

10657760

CA005676

CA004412

10760273

10657778

10564141

10879469

10567941

10567967

10816071

CA406438

CA002876

10484432

10562138

10564192

CA403690

10562154

10542031

CA110060

2910391

CA404838

CA405232

CA403406

10578076

10577891

10576441

10657831

10855985

11510882

10480511

10523403

CA405938

CA405451

10576513

10495289

10657823

10494841

CA406432

10620107

CA200038

10760273

10531833

CA405164

CA405145

N/A

10576450

10570517

10509960

10571069

10657760

CA005676

CA004412

10760273

10657778

Liberator TF (Complete) 0-6 LPM. . . . . . . . . . . . . . . . A/R

Liberator TF (Complete) 0-10 LPM . . . . . . . . . . . . . . A/R

Knob, Flow Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Decal Flow Rate 0-6 LPM . . . . . . . . . . . . . . . . . . . . . . . . 1

Decal Flow Rate 0-10 LPM . . . . . . . . . . . . . . . . . . . . . . . 1

Lock Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Screw, Lock Plate to FCV . . . . . . . . . . . . . . . . . . . . . . . . 2

Cap, Push Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Shroud. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Label Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Meter Mount Washer . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Battery Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Top Fill QDV Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . 1

Battery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Screw, Shroud Mount . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Side Fill QDV O-Ring . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Screw, FCV Knob. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Lens, Twist Lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Decal, Meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Meter Mount Screw . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Sleeve, Pop-Off. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Wire Assembly, Ground . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Meter Assembly w/Messenger . . . . . . . . . . . . . . . . . . . . . 1

Meter Assembly w/o Messenger. . . . . . . . . . . . . . . . . . . . 1

Flow Control Valve 0-6 LPM. . . . . . . . . . . . . . . . . . . . . . 1

Flow Control Valve 0-10 LPM. . . . . . . . . . . . . . . . . . . . . 1

Humidifier Adapter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Elbow Male Humidifier . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Pop-Off Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Secondary RV 30 psi . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Harness Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

PB Rod . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Manifold Mount Screws . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Stand Off Bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Washers, Manifold Mount . . . . . . . . . . . . . . . . . . . . . . . . 5

Nut, 1/4 ODT BRS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Economizer Regulator 20 psi . . . . . . . . . . . . . . . . . . . . . . 1

Screw, #8 -32 MS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Washer, #8 Lock. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

(Replaced by 10905583)

Pin, Pop-Off Knob . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Vent Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Handle, Vent Valve. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Muffler, Vent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Warming Coil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Brackets, Vaporizer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Rivets, Vaporizer Brackets . . . . . . . . . . . . . . . . . . . . . . . . 3

Nut, 1/4 ODT BRS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Breathing Coil. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Page 34

XI Top Fill G3.0 Units Parts List

Part Part Part Part