Page 1

Workshop Manual

NAVIGATOR

Copyright by

MVAGUSTA MOTORCYCLES S.p.A.

Via G. Macchi , 144 (Schiranna)

21100 VARESE - ITALY

1st Edition

Printed in Italy

Print no. - 8A0095860

1

Page 2

Introduction

This publication is intended for CAGIVA Workshops and is designed to help authorized

personnel in service and repair operations. Familiarity with the specifications provided

herein is a key factor in ensuring effective training of operators.

To make the manual easy to understand, the different paragraphs are identified by

icons that point out the subjects being dealt with.

Notes having special meanings are marked with the following symbols:

Accident-prevention rules for the operator and other people working close by.

There is a possibility that the vehicle and/or its components may be damaged.

Further information on the operation being performed.

Tips

To avoid problems and obtain the best possible results, CAGIVA recommends observ-

ing the following general rules:

- Before carrying out any repairs, evaluate the customer’s report of the vehicle’s malfunction and ask any questions that may help clarify the nature of the problem.

- Clearly identify the causes of the malfunction. This manual provides the fundamentals of troubleshooting, which the operator will complete with his personal experience

and the participation in the periodic training courses organized by CAGIVA.

- Make a rational plan of the repair so as to avoid wasting time in collecting spares,

preparing tools, etc.

- Only perform the operations that are required to reach the part to be repaired. Helpful

guidelines are provided in the disassembling and removing procedures described in

this manual.

General repairing rules

1 Always replace gaskets, sealing rings and cotter pins with new ones.

2 When loosening or tightening nuts or screws, always begin with the largest, or with

the one at the centre. Tighten with the prescribed torques using a crosswise pattern.

3 Always mark the parts and positions that might be exchanged when reassembling.

4 Use genuine CAGIVA spares, and lubricants of the recommended brands.

5 Use special tools as specified.

6 Consult the Technical Circulars, as they may contain updated information on adjust-

ing and service procedures.

2

Page 3

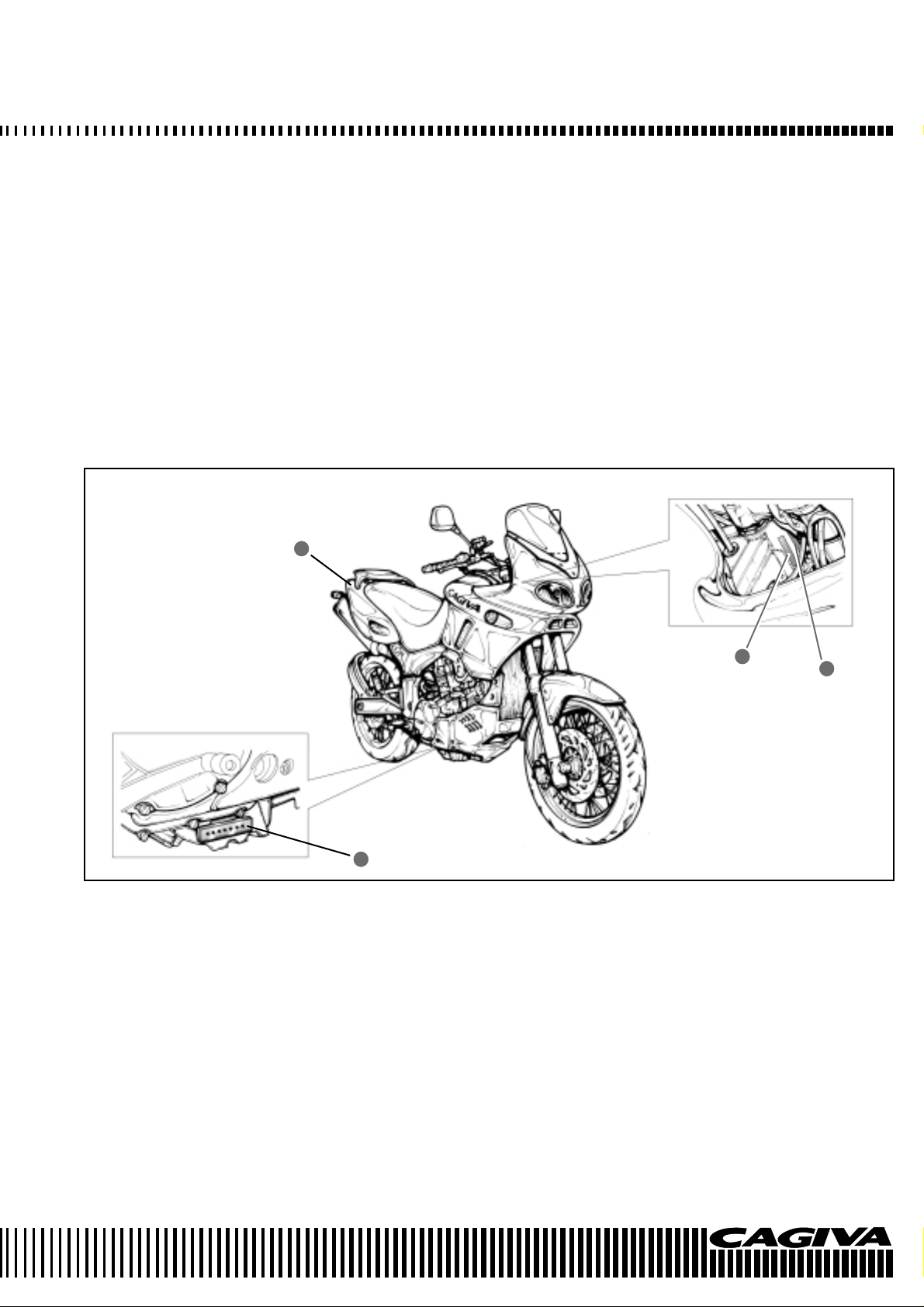

IDENTIFICATION DATA

The vehicle is identified by the following:

- Motorcycle serial number (1) on the right side of the head tube.

- Engine serial number (2) on the lower part of the right-hand crankcase half.

- Colour code on plate (3) inside the glove compartment under the saddle.

- Homologation data on the plate applied to the frame lower tube, next to the steering

head tube.

When ordering spares, always mention the motorcycle and engine serial numbers and

the colour code.

3

1

2

4

3

Page 4

Contents

Section Page

General information..................................................................... A 5

Maintenance............................................................................................B9

Injection - Air intake system ........................................................ C 45

Engine ......................................................................................... D 119

Suspensions and wheels ............................................................ E 299

Brakes ......................................................................................................F 324

Electrical equipment.................................................................... G 338

Engine cooling............................................................................. H 376

Specific tooling ............................................................................ I 390

Tightening torques....................................................................... L 394

Index .........................................................................................................M 400

4

Page 5

GENERAL INFORMATION

Section

A

A.1

Page 6

GENERAL INFORMATION

Dimensions and weight .......................................................... A-3

Engine unit ............................................................................. A-3

Transmission unit ................................................................... A-3

Frame..................................................................................... A-4

Front suspension.................................................................... A-4

Rear suspension .................................................................... A-4

Wheels and brakes ................................................................ A4

Electrical system .................................................................... A-4

Instrument panel .................................................................... A-4

Fuel/oil/coolant/fork oil capacity ............................................. A-4

A.2

Page 7

GENERAL INFORMATION

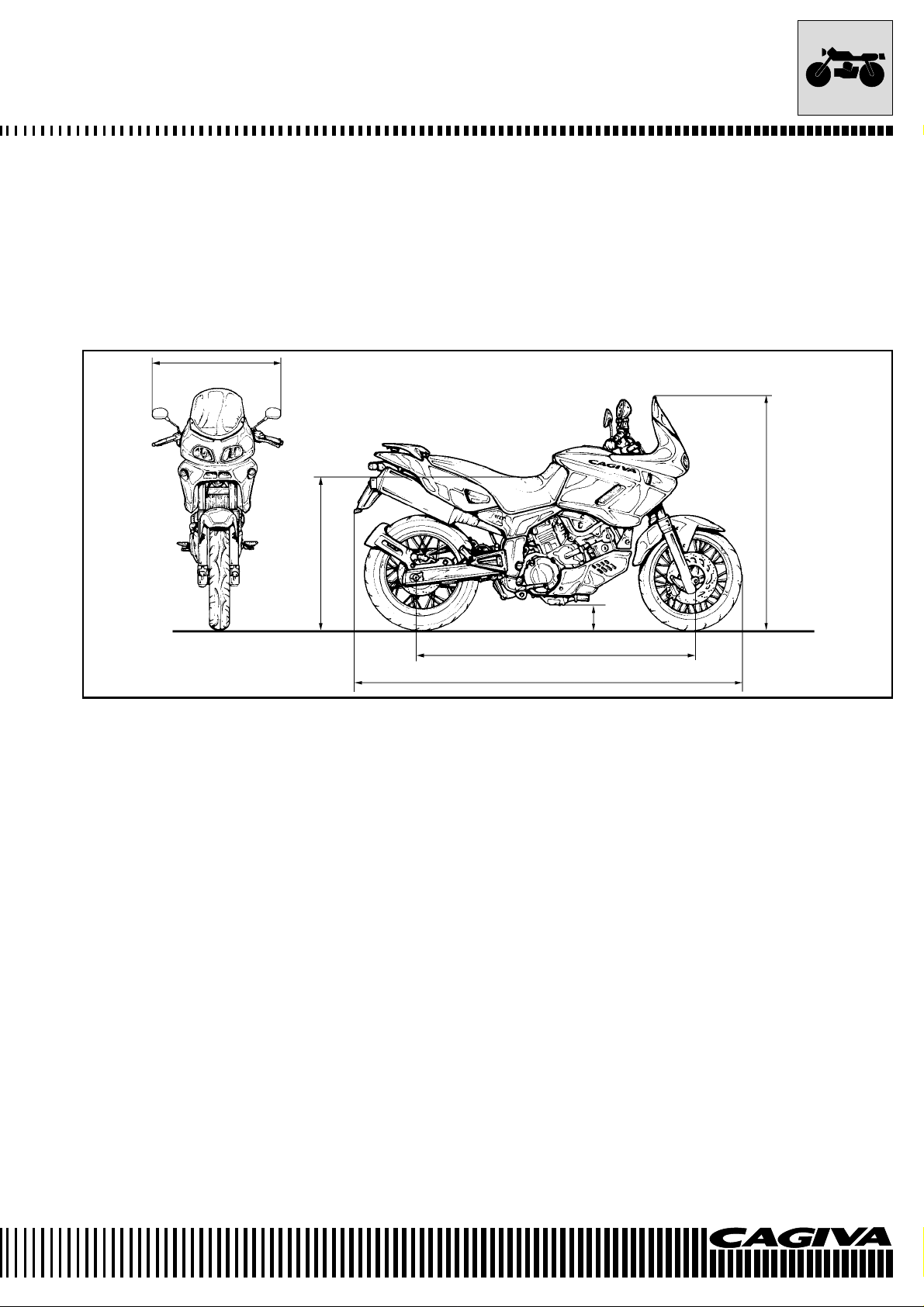

DIMENSIONS AND WEIGHTS

NAVIGATOR

Overall length .......................................................................... 2168 mm

Overall width ........................................................................... 790 mm

Overall height .......................................................................... 1290 mm

Wheelbase .............................................................................. 1530 mm

Ground clearance.................................................................... 180 mm

Seat height .............................................................................. 850 mm

Dry weight ............................................................................... 222 kg

790

850

1290

180

1530

2168

ENGINE UNIT

Type ............................................................................................ Liquid cooled, DOHC, TSCC four stroke

Number of cylinders .................................................................... 2

Bore............................................................................................. 98,0 mm

Stroke.......................................................................................... 66 mm

Displacement .............................................................................. 996 cm

Compression ratio ....................................................................... 11.3 : 1

Fuel feed system......................................................................... Injection

Air filter ........................................................................................ Non woven synthetic material

Starter system ............................................................................. Electric

Lubrication system ...................................................................... Wet sump

3

TRANSMISSION UNIT

Clutch .......................................................................................... Wet multi-plate type

Gearbox ...................................................................................... 6 speed constant mesh

Gear change ............................................................................... 1 down, 5 up

Primary reduction ........................................................................ 1.838 (57/31)

Final reduction............................................................................. 2.562 (41/16)

Gear ratios, 1a ............................................................................ 2.666 (32/12)

2a .................................................................. 1.933 (29/15)

3a .................................................................. 1.500 (27/18)

4a .................................................................. 1.227 (27/22)

5a .................................................................. 1.086 (25/23)

6a .................................................................. 1.000 (24/24)

Transmission chain ..................................................................... 5/8” x 5.16”

A.3

Page 8

GENERAL INFORMATION

FRAME

Type ........................................................................................... Rectangular and square box section tubular framework

in highly resistant steel with box-type strengthening

supports at the fork fulcrum attachment.

FRONT SUSPENSION

Type ........................................................................................... Conventional advanced pivot hydraulic telescopic fork

with 45 mm diameter tubes. Telescopic movement 150 mm.

Steering angle ............................................................................ 32° (left and right)

Steering head angle ................................................................... 25°

Trail ............................................................................................ 110 mm

REAR SUSPENSION

Type ............................................................................................Single hydraulic shock absorber progressively damped

with external pre-load adjustment of the spring and

extension of the hydraulic braking effect. Wheel travel 160 mm.

WHEELS AND BRAKES

Front brake................................................................................. Twin disc

Rear brake ................................................................................. Single disc

Front tyre.................................................................................... Metzeler ME Z4 C – 110/80 – 18”

Rear tyre .................................................................................... Metzeler ME Z4 – 150/70 – 17”

ELECTRICAL SYSTEM

Transistorised electronic ignition

Ignition phase............................................................................. 3° before T.D.C. at 1300 rpm

Spark plugs ................................................................................ NGK CR8EK or DENSO U24ETR

Battery........................................................................................ 12v 10Ah

Generator ................................................................................... Three phase AC generator

Fuses ......................................................................................... 30/30/15/15/15/10/10A

Headlight unit ............................................................................. Main beam: condenser halogen bulb H1 12v-55w

Dipped beam: polyellipsoidal bulb H3 12v-55w

Sidelight ..................................................................................... 12v 5w

Direction indicators..................................................................... 12v 10w

Number plate light ...................................................................... 12v 5w

Brake/tail light............................................................................. 12v 21/5w

INSTRUMENT PANEL

Instrument bulb .......................................................................... 12V 1.2W

Warning lights ............................................................................ 12V 2W

FUEL/OIL/COOLANT/FORK OIL CAPACITY

Fuel tank ..................................................................................... 20 L

Engine oil: oil change .................................................................. 3100 ml

oil change with filter ................................................ 3300 ml

overhaul .................................................................. 3600 ml

Engine coolant ............................................................................ 2000 ml

Fork oil (each tube) ..................................................................... 680 ml

A.4

Page 9

MAINTENANCE

Section

B

B.1

Page 10

MAINTENANCE

Maintenance and tuning......................................................... B-4

Compression check................................................................ B-23

Oil pressure check ................................................................. B-24

Technical data ........................................................................ B-25

B.2

Page 11

MAINTENANCE

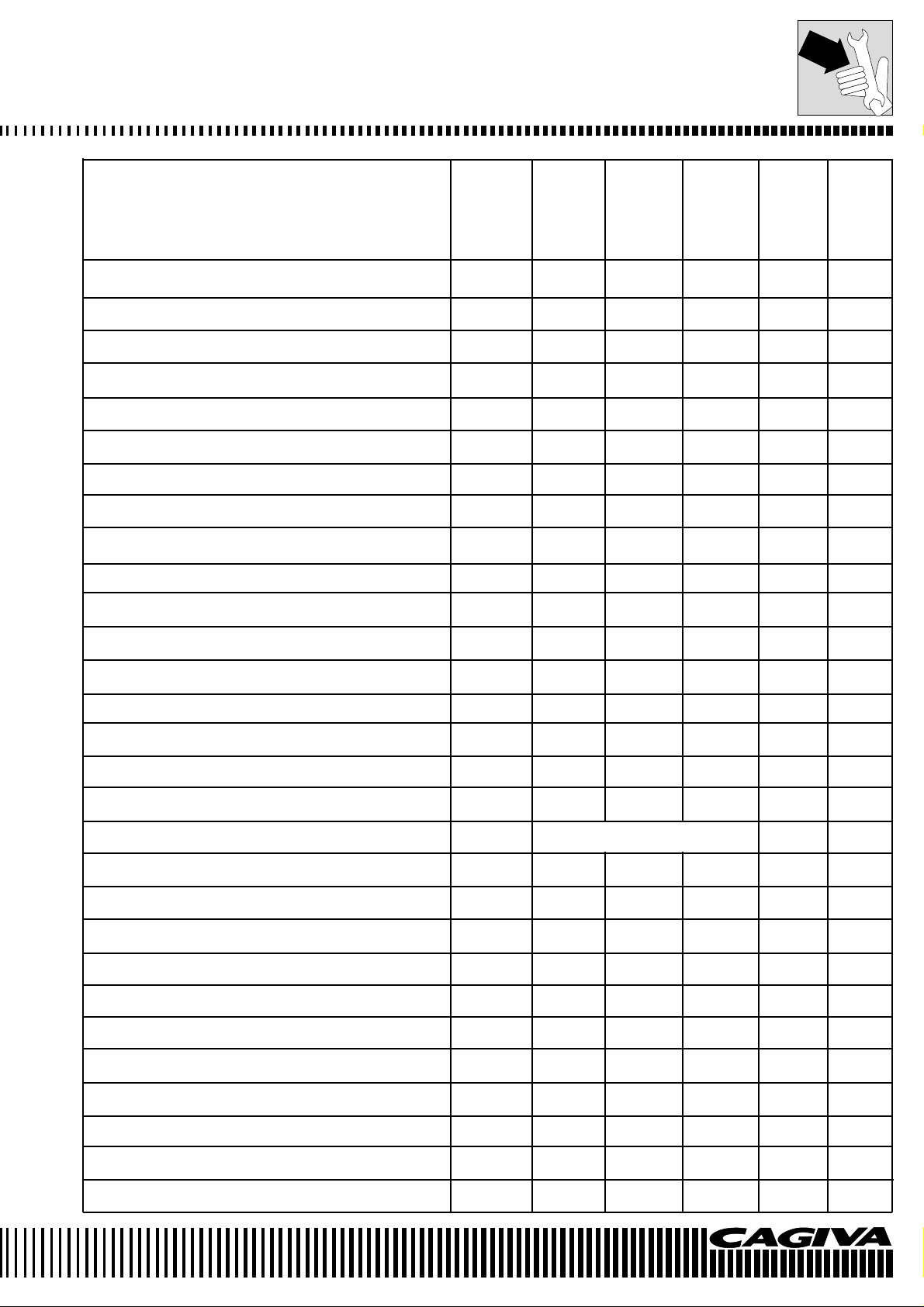

Check ■ Substitution ● First Every Every Every Every Every

1000 km 1000 km 6000 km 12000 km 20000 km 24000 km

Engine oil Check level ■

Engine oil Substitute ●●

Engine oil filter Substitute ●●

Coolant Check level ■■

Coolant Substitute

Valve tappet clearance adjustment Check/adjust ■

Timing chain tension Check/adjust ■■

Synchronisation butterfly valves Check/adjust ■

Spark plugs Check/substitute ■■●

Fuel filter Substitute ●

Air filter Check/substitute ■●

Fuel feed system Check ■

Brake fluid Check level ■■

Brake fluid Substitute

Brake disc pads Check ■

Brake discs Check ■

Braking system Check ■

Braking system Bleed air Every 20000 km

Every 2 years

Every 2 years

/every 2 years

Accelerator control Check/adjust ■■

Clutch control Check ■■

Steering Check bearing play ■■

Fork Substitute oil

Secondary transm

Crown and pinion, chain Check/substitute ■

Tyres Check pressure/substitute ■■

Screws and bolts Check for tightness ■■

Fuel tubing Substitute

Clutch cover screws Check for tightness ■

Rear wheel bearings Check ■

ission chain

Check tension/lubrication ■■

Every 2 years

Every 4 years

●

B.3

Page 12

MAINTENANCE

MAINTENANCE AND TUNING

This section describes the servicing procedures for each part of periodical maintenance.

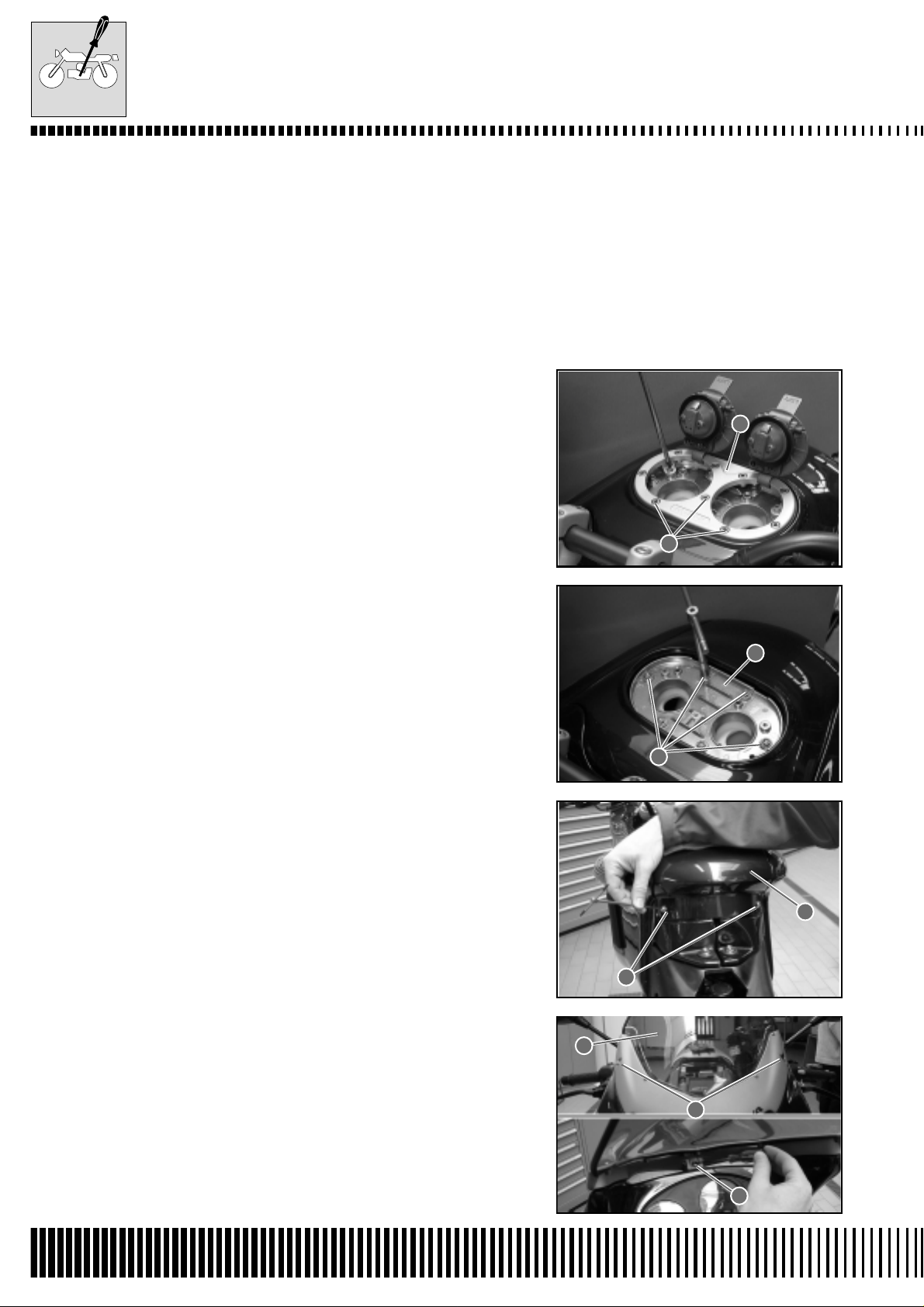

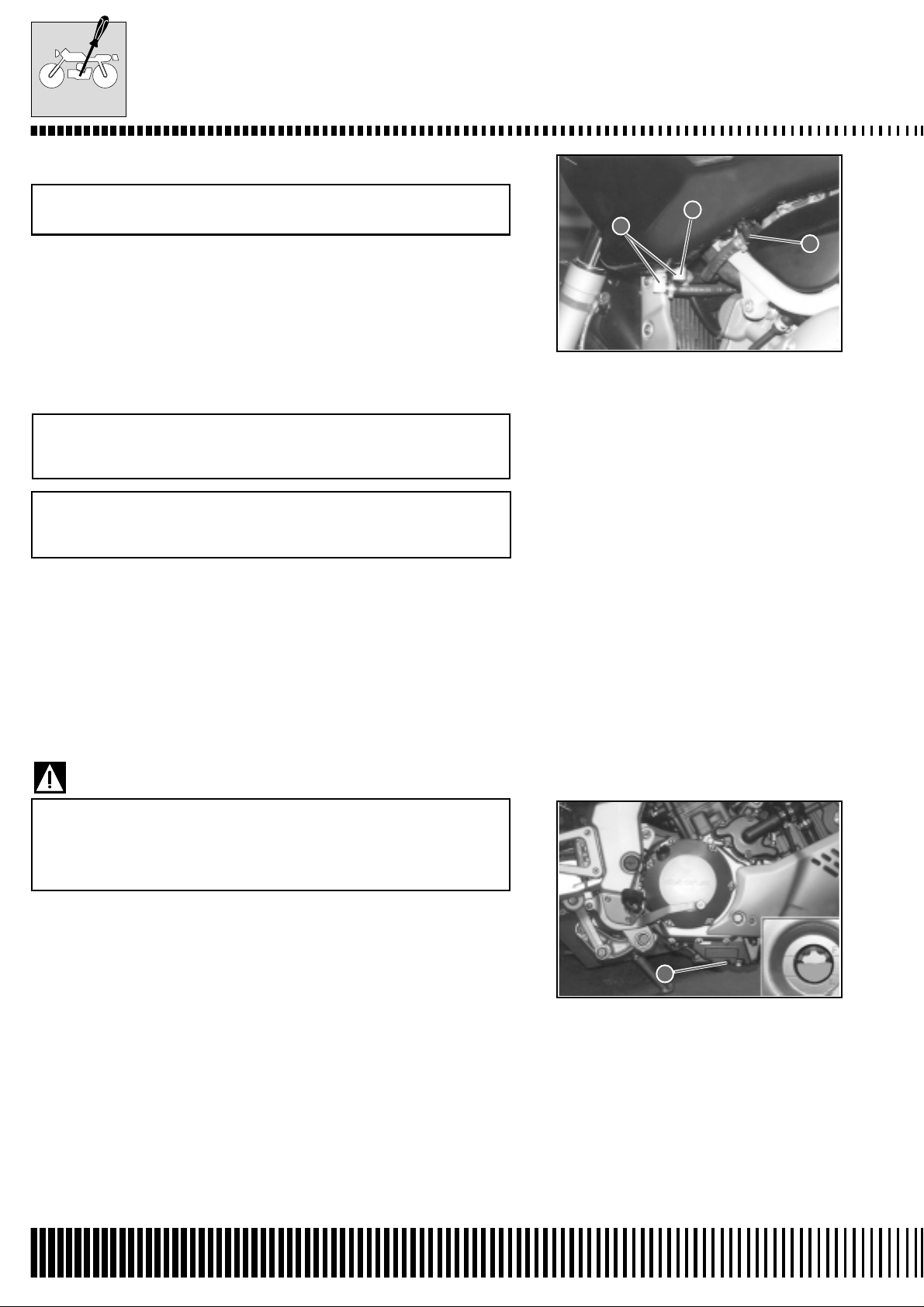

FUEL TANK REMOVAL

To complete this operation it is necessary to previously remove the

seat.

• Remove the complete fuel tap assembly by unscrewing the three

screws 1 indicated in the figure.

• Extract the flange 2 of the petrol covers.

2

• Remove the six screws 3 using an 8mm spanner.

• Extract the plate 4 paying attention to the two washers underneath.

• Remove the tank cover 5 by unscrewing the two screws 6.

• Remove the windshield 7 by unscrewing the three screws 8 shown

in the figure.

1

4

3

5

6

B.4

7

8

8

Page 13

MAINTENANCE

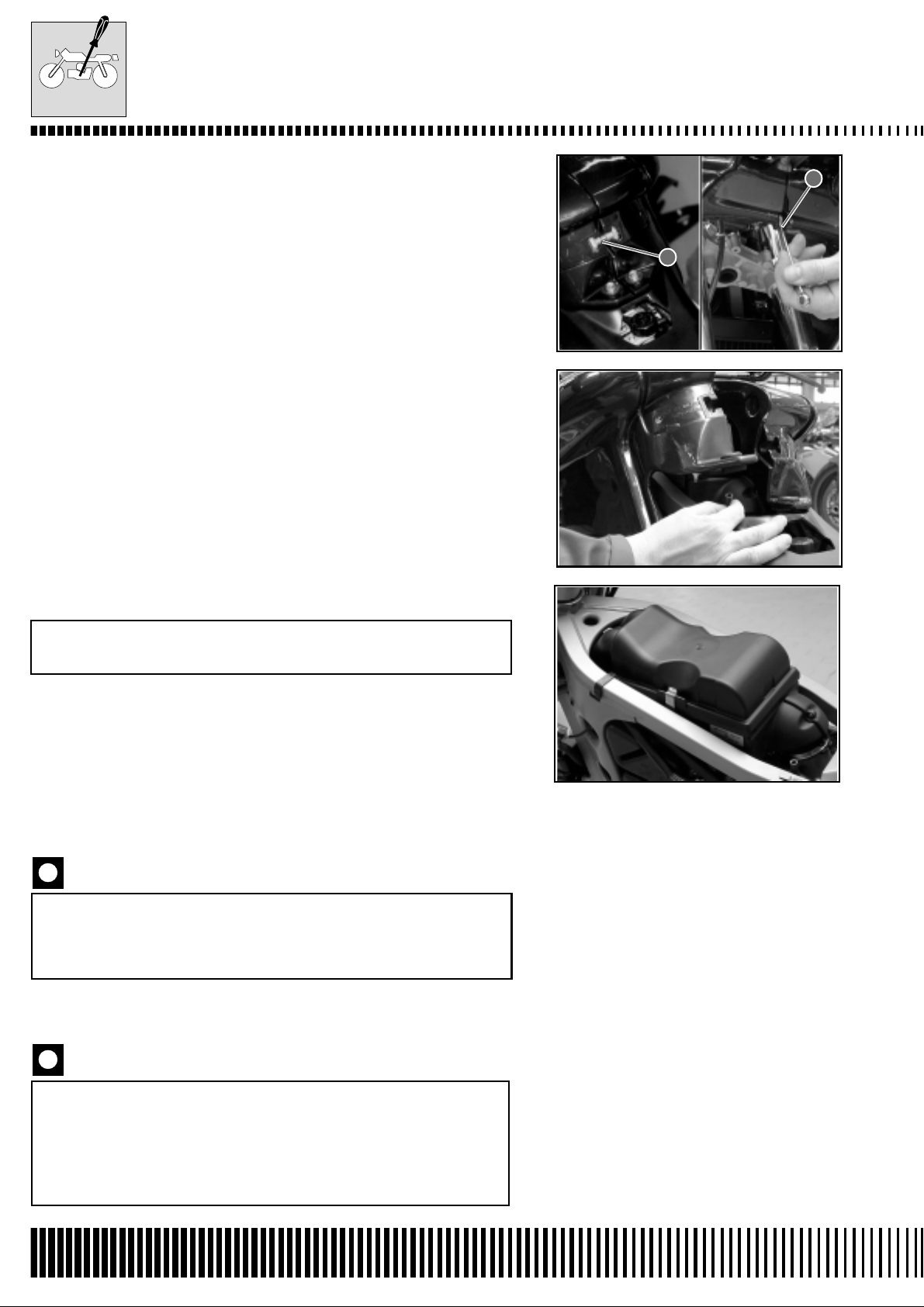

• Remove the fairing by unscrewing the five screws 1. There is one

front screw and four screws highlighted in the figure.

• Remove the front protection by unscrewing the two lower screws

2, as shown in the figure.

1

1

• Disconnect the indicator connectors. One is indicated in the figure

and the other is on the opposite side of the machine.

• Disconnect the fuel tubes from the left fuel tank. The fuel tubes

are attached to the fuel tank by rapid attachments and their removal automatically blocks the exit of fuel. It is necessary to push

the lever 3 and slide out the elbow union 4 to disassemble it. Before effecting reassembly , check that the small pin 4 is completely

extended. If it is not in position, push on the lever 3 to bring it into

position.

2

3

4

• Disconnect the reserve fuel sensor connector attached to the right

fuel tank.

B.5

Page 14

MAINTENANCE

• Slacken and remove the two tank union clamps 1. One is situated

at the front of the vehicle and the other at the back of the tank.

• Finally, remove the two fixing screws 2. Disconnect the overflow

tube from the left fuel tank.

1

1

AIR FILTER

Check every 6000 km (or 6 months)

Substitute every 12000 km (or 12 months).

• It is necessary to remove the fuel tanks before removing the air

filter.

• Carefully eliminate dust and dirt from the filter element by using

compressed air.

The compressed air must be blown from the exterior of

the filter element. If compressed air is used internally, the

dust and dirt will be pushed into the pores of the filter

thereby reducing the flow of air to the same element.

• To assemble a clean or new filter element, carry out the operation

of disassembly in the reverse order.

Should the motorcycle be used frequently on dusty roads,

the filter element must be cleaned more frequently. The

use of the engine without a filter or with a broken filter

element will certainly shorten the life of the engine. Check

that the air filter is always in good condition. The long life

of the engine depends a lot on this component!

B.6

Page 15

MAINTENANCE

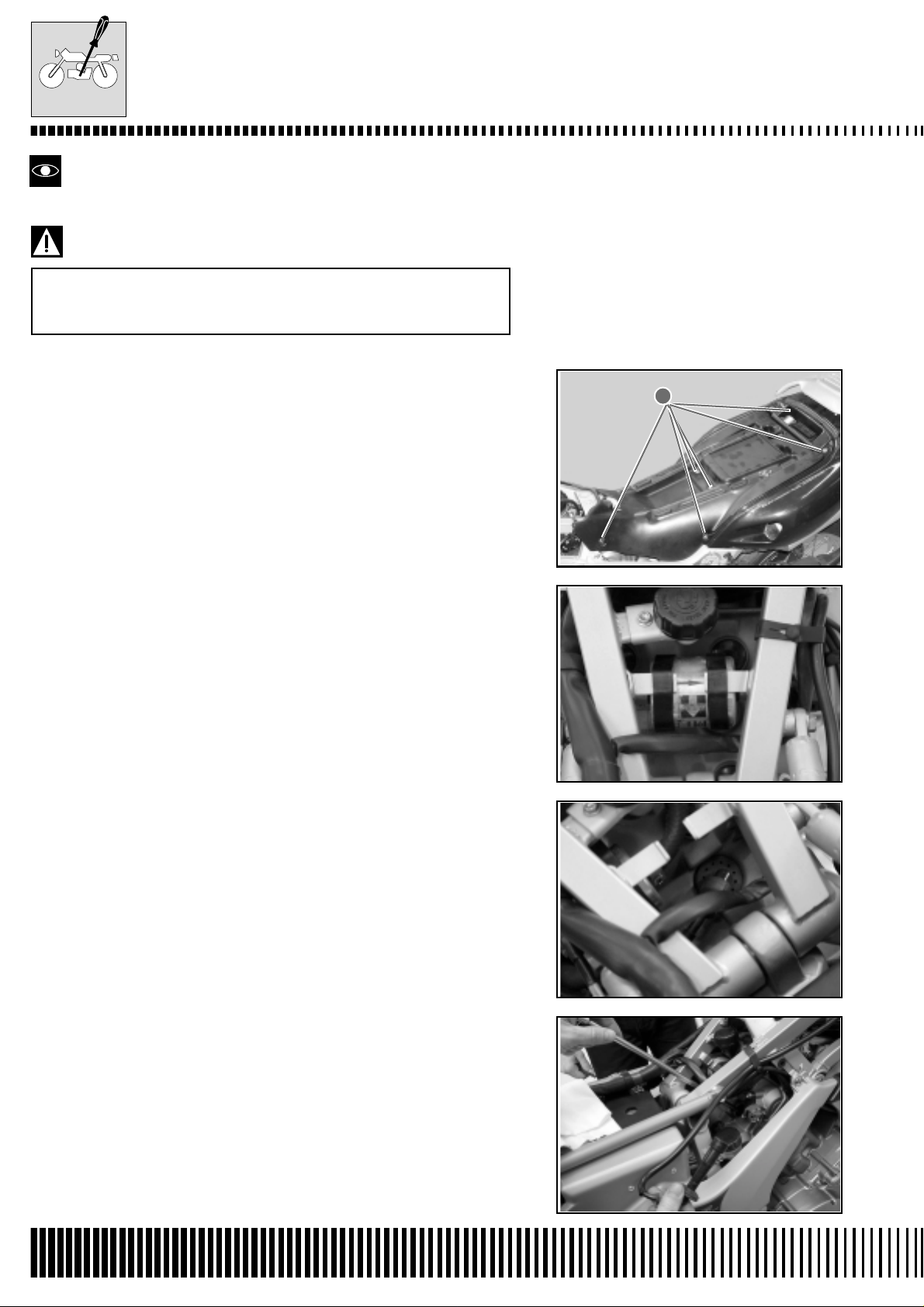

SPARK PLUGS

Check every 6000 km (or 6 months)

Substitute every 12000 km (or 12 months)

After the first 1000 km it is necessary to remove the spark plugs,

clean them and check the distance between the electrodes (0.6÷0.7

mm).

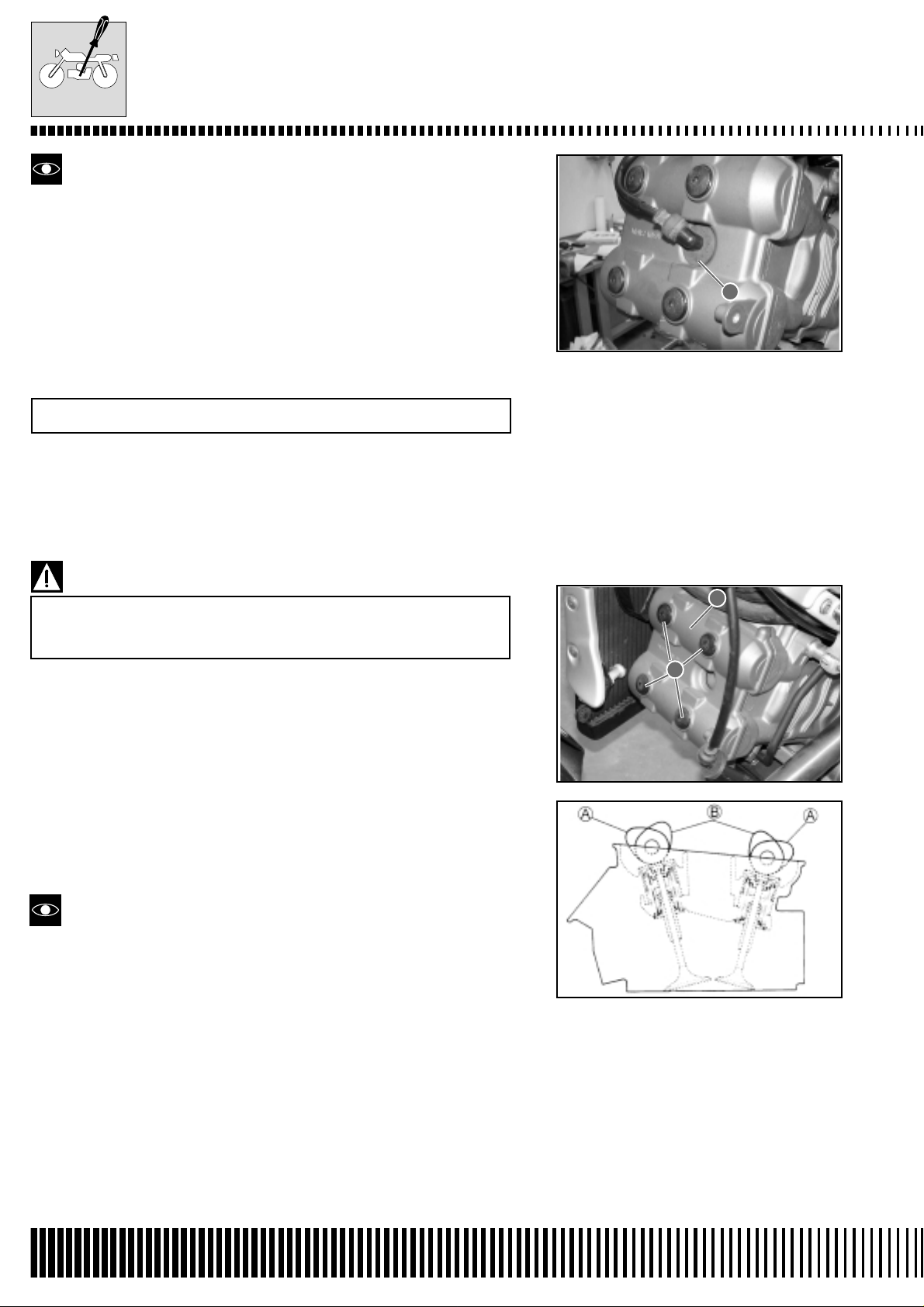

REMOVAL OF SPARK PLUG N° 1 (FRONT)

• Remove the sump guard by unscrewing the two screws 1. One

screw is indicated in the figure whilst the other screw is on the

other side.

1

• Disconnect the fuel tubes.

• Remove the left side protection of the radiator.

• Remove the lower radiator fixing and its spacer. Unhook the radiator from its mountings.

• Push the radiator down so that there is access to the forward spark

plug.

• Remove the spark plug insulated cap.

• Unscrew the spark plug as shown in the figure.

During this operation, pay attention to the front mudguard.

Place a piece of cloth between the radiator and the mudguard as shown in the figure.

B.7

Page 16

MAINTENANCE

Be careful to not damage the finning of the radiator.

The radiator and engine can provocate serious burns when

they are hot. Wait until the radiator and the engine are cool

enough to be touched before carrying out this operation.

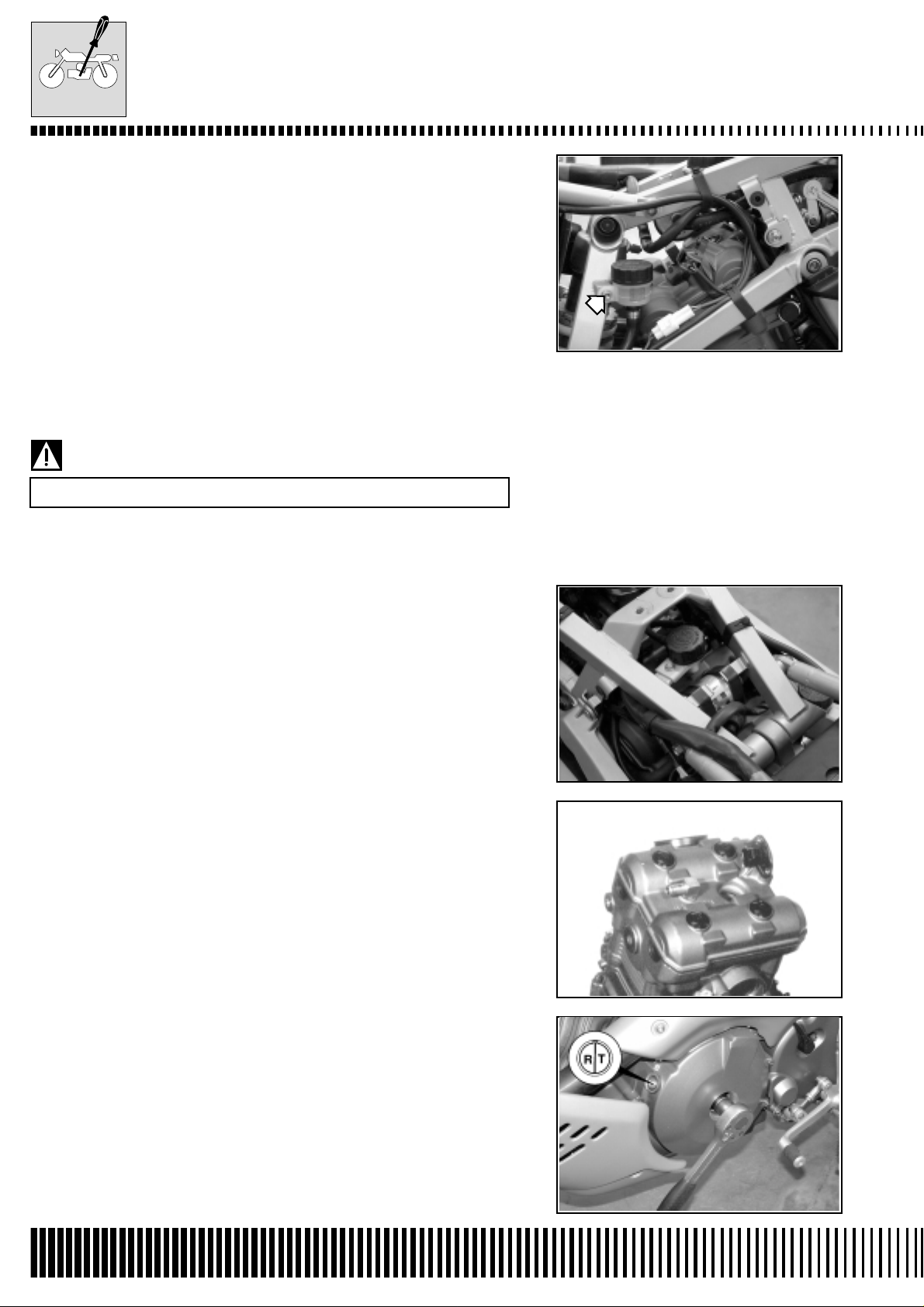

REMOVAL OF SPARK PLUG N° 2 (REAR)

• Remove the seat.

• Remove the seat compartment by unscrewing the eight screws 1.

Six of theses screws are shown in the figure.

1

• Unhook the rubber mountings of the fuel filter.

• Remove the spark plug insulated cap.

• Remove the spark plug.

B.8

Page 17

MAINTENANCE

HEAT GRADE CODE

• Check the heat grade code of the spark plug.

NGK CR8EK

DENSO U24ETR

The type “R” spark plug has a resistor on the central electrode to

avoid radio disturbance.

CARBON DEPOSITS

• Check the spark plugs for carbon deposits. If there are deposits,

use the appropriate machine or a pointed tool to eliminate them.

Take care in using the pointed tool.

THE GAP BETWEEN THE SPARK PLUG ELECTRODES

• Measure the gap between the spark plug electrodes using feeler

blades. Adjust the gap if it is not correct, using the following information:

Specific tool: 800096651: Feeler gauge

800096872: Feeler gauge

Standard

Normal gap between the electrodes of the spark plug A: 0,6÷0,7 mm

THE CONDITION OF THE ELECTRODES

• Controllare se gli elettrodi sono usurati o bruciati. Se essi fossero

estremamente usurati o bruciati,sostituire la candela.

Sostituire la candela anche in caso di rottura dell’isolante o danneggiamento della filettatura.

When a spark plug substitution is made, check the pitch

size and the length of the thread. If the threading is too

short, carbon residues will be deposited on the threading

of the cylinder head thereby possibly causing damage to

the engine.

REPLACING THE SPARK PLUG AND INSULATED CAP

Carefully screw the spark plug into place by hand before

tightening with a plug spanner. This is to avoid damage to

the aluminium threading.

• Manually screw in the spark plugs into the cylinder heads and

tighten them to the specific torque.

A A

Torque pressure

Spark plug: 11 N·m (1,1 kg-m)

B.9

Page 18

MAINTENANCE

When the front and rear spark plug insulated caps are pushed on,

turn the triangular signs on the insulated caps A towards the exhaust side of the cylinders.

VALVE TAPPET CLEARANCE ADJUSTMENT

Check every 24000 km (or every two years)

• Remove the seat.

FRONT CYLINDER

• Remove the spark plug as described in page B-7.

• Remove the front cylinder head valve cover 1 by unscrewing the

four screws 2 shown in the figure.

A

When removing the valve cover, be careful that the locating pins or the gasket do not fall to the ground or inside

the cover opening.

The valve tappet clearances vary between the inlet and the exhaust

valves.

The valve tappet clearance adjustment must be checked and adjusted:

1) During periodical maintenance.

2) When tappet maintenance is carried out.

3) When the camshafts are removed for maintenance.

Valve tappet clearances (cold):

Inlet : 0.10 - 0.20 mm

Exhaust : 0.20 - 0.30 mm

* Valve tappet clearances must be checked when the piston is in

the top dead centre (T.D.C.) position of the compression cycle.

* The inlet and exhaust cams of the front cylinder in position A indi-

cate that the front piston is in the top dead centre (T .D.C.) position

of the compression cycle.

* The inlet and exhaust cams of the rear cylinder in position B indi-

cate that the rear piston is in the top dead centre (T .D.C.) position

of the compression cycle.

* Specified valve tappet clearances are with a COLD engine.

* Use a 17 mm spanner to turn the camshaft when checking the

valve tappet clearances. The camshaft must be turned in the direction of normal engine operation. Both spark plugs must be removed.

1

2

IN.

EX.

B.10

Page 19

MAINTENANCE

• Remove the plug of the generator cover 1 and the timing cover

inspection plug 2.

• Turn the engine camshaft to bring the piston of the N° 1 cylinder

(front) to the top dead centre (T.D.C.) position of the compression

cycle. Align the “F/T” line on the generator rotor with the timing

inspection hole line and bring the camshafts to the indicated position in page B- 10.)

2

1

• To check the valve tappet clearances of the N° 1 cylinder (front),

insert a feeler gauge between the valve stem and the cam. If the

clearance is not correct, adjust it within the specified range.

REAR CYLINDER

• Remove the seat, the seat compartment and the spark plug as

described in page B-8.

• Remove the left and right hand side panels by unscrewing the two

screws.

• Disconnect the oil vapour tube from the left hand side of the machine.

B.11

Page 20

MAINTENANCE

• Unhook the rear brake fluid chamber by unscrewing the screw

shown in the figure.

• Disconnect the electrical connector of the camshaft position sensor.

• Remove the sensor by unscrewing the two relative screws.

• Disassemble the fuel filter from its supports and disconnect it from

the fuel tubes, taking care to not spill any fuel.

Place a cloth underneath the fuel filter.

• Disassemble the expansion tank cover assembly.

• Remove the rear cylinder head valve cover by unscrewing the

four relative screws shown in the figure.

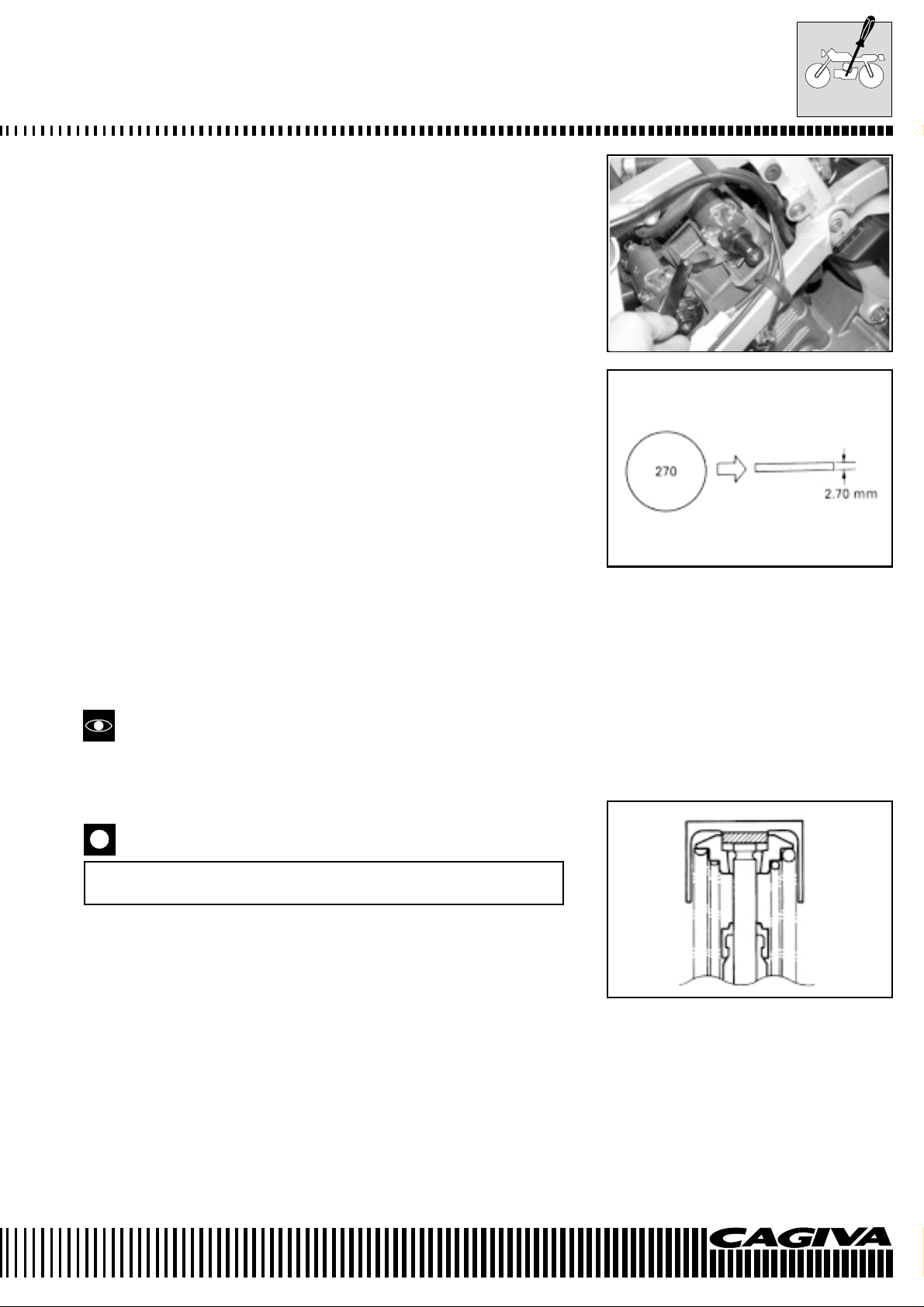

• Rotate the crankshaft 270° (3/4 of a turn) to bring the piston of N°

2 cylinder (rear) to T.D.C. of the compression cycle. Align the “R/

T” line on the rotor of the generator with the counter-line of the

timing synchronisation inspection hole and bring the camshafts in

the position indicated at page B-7.

B.12

Page 21

MAINTENANCE

• Check the valve tappet clearance of the N° 2 cylinder (rear) using

the same procedure used for the N° 1 cylinder (front) and adjust

as necessary.

VALVE TAPPET CLEARANCE ADJUSTMENT

The valve tappet clearance adjustment is regulated by the substitution of the valve stem pad with another that is thicker or thinner.

• After having removed the cylinder head valve covers, remove the

intake and exhaust camshafts as described in chapter D.

• Remove the cup and pad with the fingers or a magnet.

• Check the number on the pad. This number indicates the thickness of the pad as illustrated.

• Choose a substitute pad that allows a valve tappet clearance within

the prescribed range. There are 25 sizes of pad available that vary

in thickness from 2.30 mm to 3.50 mm in increments of 0.05 mm.

Insert the chosen pad into the valve stem end with the numbers

towards the cam.

Check the thickness of the pad with a micrometer to ascertain that

it is the correct size.

See the selection table of the thickness of the pads for details.

(Pages B-10 and B-11).

* Do not forget to apply some engine oil to the surfaces of the pad.

* During the positioning of the pad, check that the surface with the

numbers points towards the tappets.

Reassemble the camshafts in the correct way.

(See page D-102)

• After having reassembled the pads and the camshafts, rotate the

engine so that the valve mechanism becomes completely depressed. This causes the expulsion of any oil entrapped in the

seat between the pad and the cam that could probably cause incorrect clearances. Check again the clearance to verify that it is

within the prescribed limits.

• Reassemble the following parts after having completed the valve

tappet clearance check.

Page

* Cylinder head valve covers ..................................................D-78

* Spark plugs and insulated caps ................................... B-5 e B-6

* Timing synchronisation inspection cover..............................D-79

* Generator cover screw .........................................................D-79

B.13

Page 22

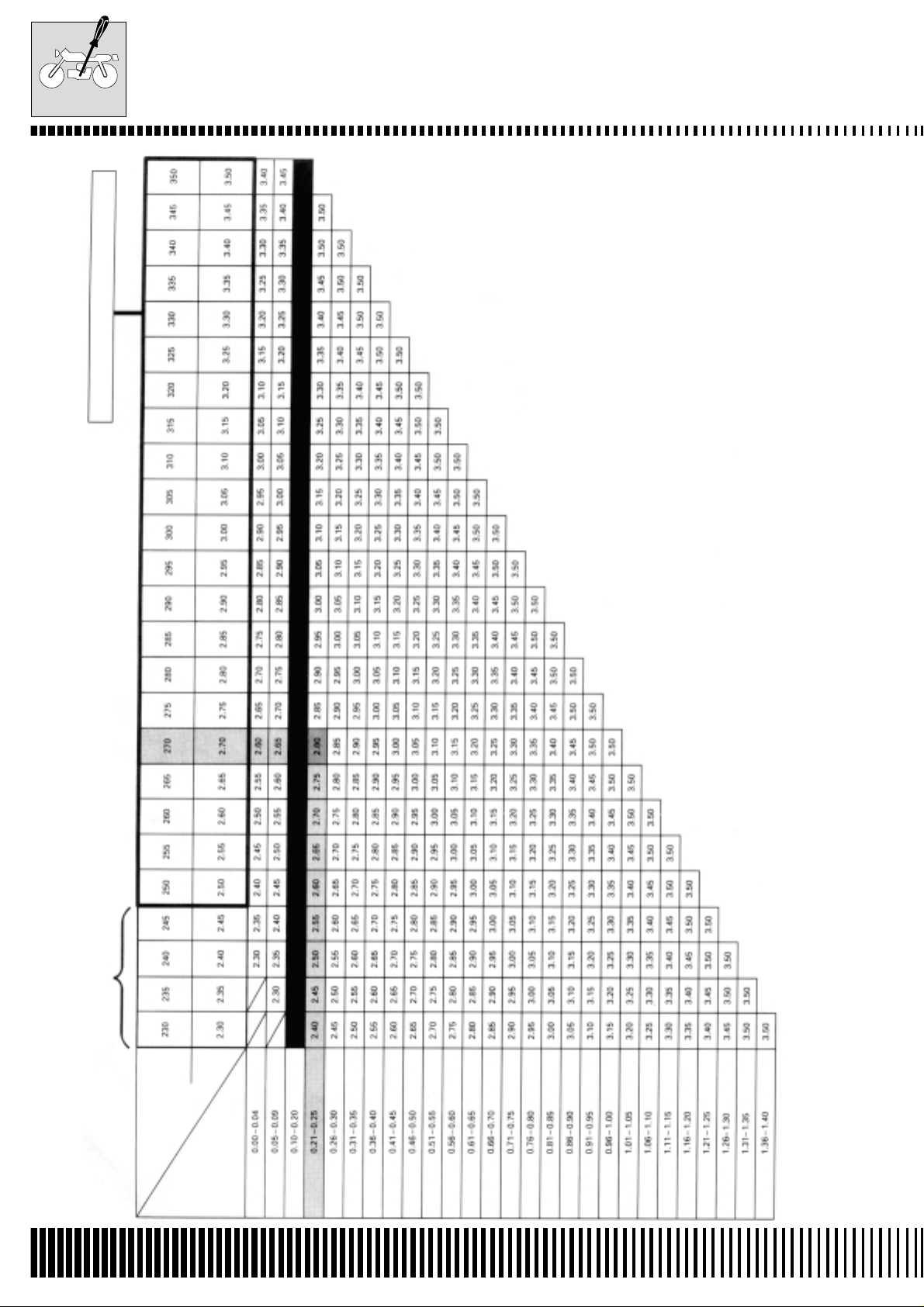

VALVE PAD SET

(12800-41810)

MAINTENANCE

(INTAKE SIDE)

FOR EXAMPLE

INTAKE VALVE PADS SELECTION TABLE

NO. (12892.41C00.XXX)

The valve tappet clearance is 0.23 mm

The thickness of the actual pad is 0.70 mm

HOW TO USE THIS TABLE:

1. Measure the clearance of the valve (cold engine).

2. Measure the thickness of the actual pad.

3. Make the vertical column (valve tappet clearance) and horizontal column (thickness) match.

The pad to use is 2.80 mm

SPECIFIED CLEARANCE/NO ADJUSTMENT NECESSARY

B.14

OPTIONAL

ACTUAL

SUFFIX NO.

MEASURED

(mm)

PAD

THICKNESS

CLEARANCE

(mm)

Page 23

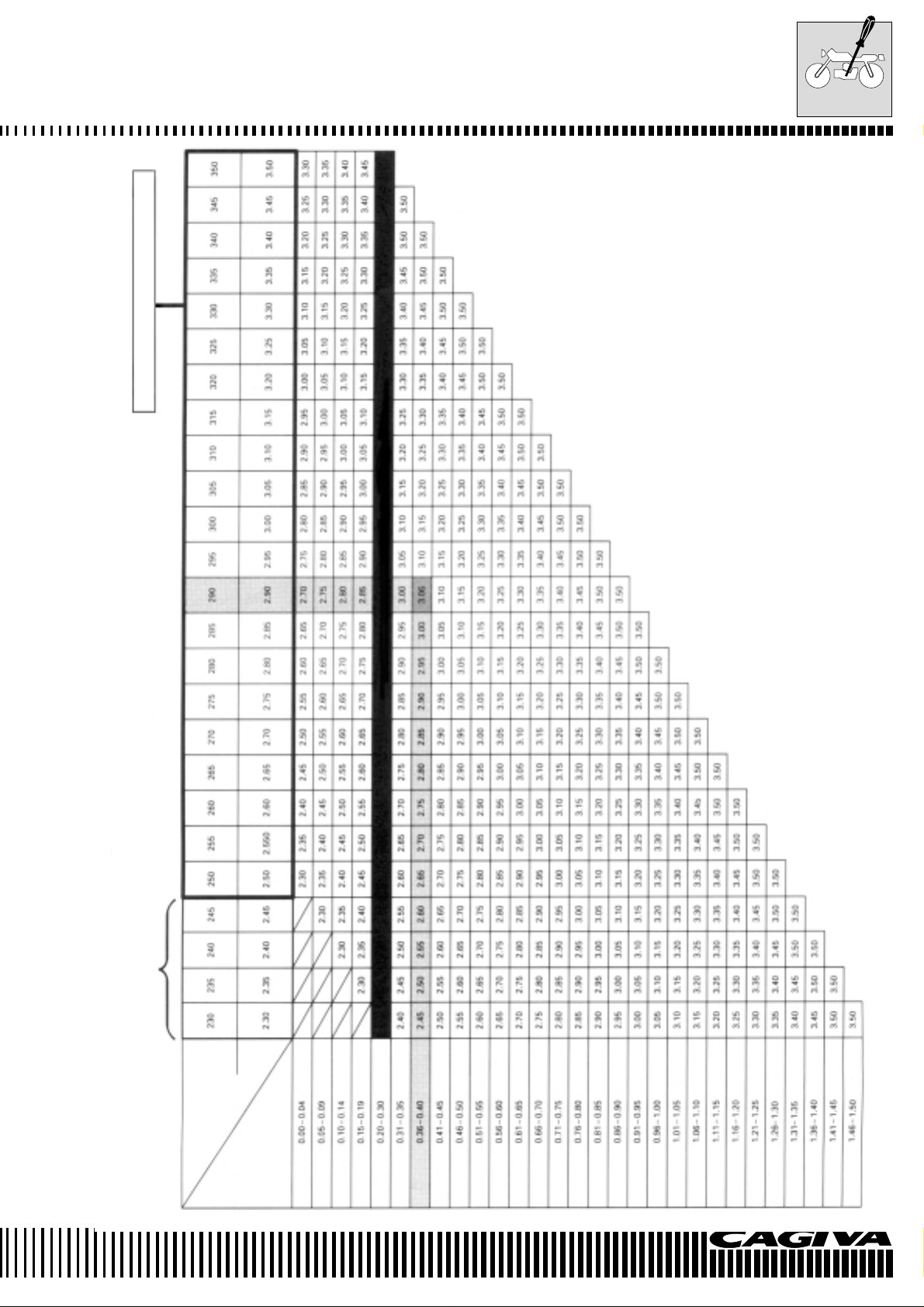

VALVE PAD SET

(12800-41810)

MAINTENANCE

(EXHAUST SIDE)

FOR EXAMPLE

EXHAUST VALVE PADS SELECTION TABLE

NO. (12892.41C00.XXX)

The valve tappet clearance is 0.23 mm

The thickness of the actual pad is 0.70 mm

HOW TO USE THIS TABLE:

1. Measure the clearance of the valve (cold engine).

2. Measure the thickness of the actual pad.

3. Make the vertical column (valve tappet clearance) and horizontal column (thickness) match.

The pad to use is 2.80 mm

SPECIFIED CLEARANCE/NO ADJUSTMENT NECESSARY

OPTIONAL

SUFFIX NO.

ACTUAL

MEASURED

(mm)

PAD

THICKNESS

CLEARANCE

(mm)

B.15

Page 24

FUEL TUBING

MAINTENANCE

Check every 6000 km (or 6 months).

Substitute every 4 years.

After removing the fuel tank, check to see if the feed tube 1 and

return tubes 2 and 3 are damaged or show signs of leaking. Substitute the tubes if any defects are found.

ENGINE OIL AND OIL FILTER

(ENGINE OIL)

Change at 1000 km (or 1 month).

Change every 6000 km (or 6 months).

(OIL FILTER)

Substitute at 1000 km (or 1 month).

Substitute every 18000 km (18 months).

The oil must be changed whilst the engine is hot. The oil filter must

be substituted at the above-mentioned intervals at the same time as

an oil change.

2

3

1

ENGINE OIL CHANGE

• Place the machine in a vertical position.

• Place a container underneath the engine and drain the used oil

into the container by unscrewing the sump plug 1 and the filling

plug 2.

Used oil contains dangerous substances that can damage

the environment. To change the oil it is recommended to

use our service network that can dispose of the oil respecting the environment and the norms in force.

• Tighten the sump plug 1 to the specified torque and pour new oil

into the filling hole 2. The engine holds 3.1 litres of oil. Use only oil

with an API SF or SG classification and a viscosity of SAE 10W/

40.

Torque pressure

Sump plug: 23 N.m (2.3 kg-m)

• Switch on the engine and leave it to heat up for several minutes.

• Switch off the engine and wait approximately one minute. Check

the oil level in the inspection window 3. If the level is below the

countersign “L”, add oil until it reaches the countersign “F”. If the

level exceeds the countersign “F” then discharge enough oil to

arrive at the countersign “F”.

1

B.16

Page 25

MAINTENANCE

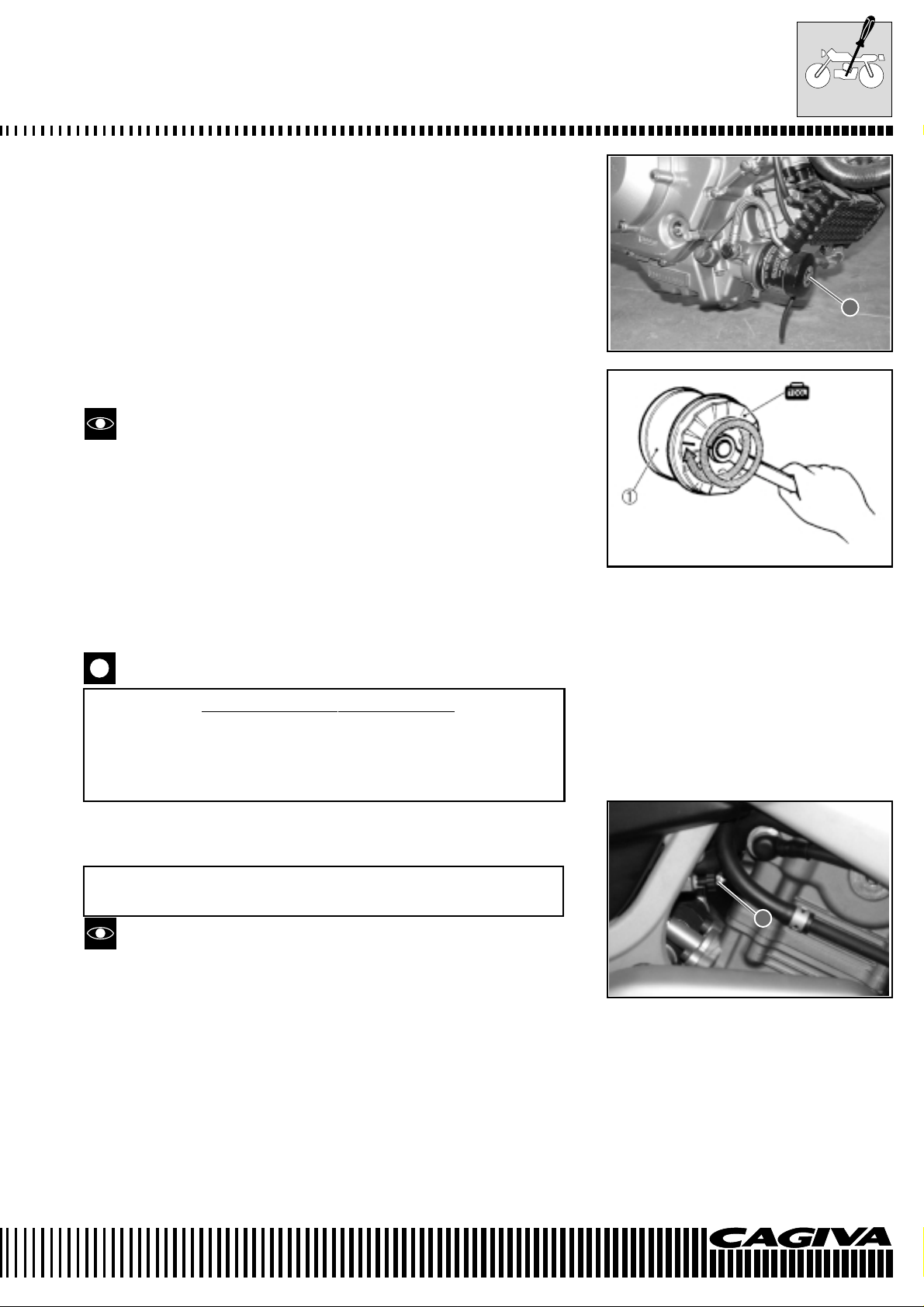

OIL FILTER SUBSTITUTION

• Drain the engine oil following the same procedure described for

the oil change.

• Remove the oil filter 1 utilising the appropriate wrench (special

tool).

• Apply a light layer of engine oil to the gasket of the new filter before assembly.

• Assemble the new filter by screwing it in by hand until the gasket

comes into contact with the oil filter container. Tighten by two turns

utilising the oil filter wrench (special tool).

Special tool: 800096659: Oil filter wrench

Tighten the filter correctly by utilising the special wrench.

Never tighten the oil filter by hand.

• Refill with new engine oil and check the level by following the same

procedure used for the oil change.

1

OIL CAPACITY

Oil change: 3.1 litres

Oil filter change: 3.3 litres

Engine overhaul: 3.6 litres

Utilise only

ORIGINAL CAGIVA OIL FILTERS. Filters and

spare parts of other makes could differ with regards to the

threading (diameter and pitch), filter performance and duration. Possible damage may occur to the engine with consequent loss of oil.

MINIMUM TICKOVER

Check at 1000 km (or 1 month).

Every 6000 km (or 6 months).

Carry out this adjustment when the engine is hot.

• Switch on the engine and adjust the tickover as specified by rotating the accelerator stop screw 1.

1

Minimum tickover:

1300±1350 rpm

B.17

Page 26

MAINTENANCE

ACCELERATOR CABLE PLAY

Check at 1000 km (or 1 month)

Every 6000 km (or 6 months).

Adjust the accelerator cable play following these three phases.

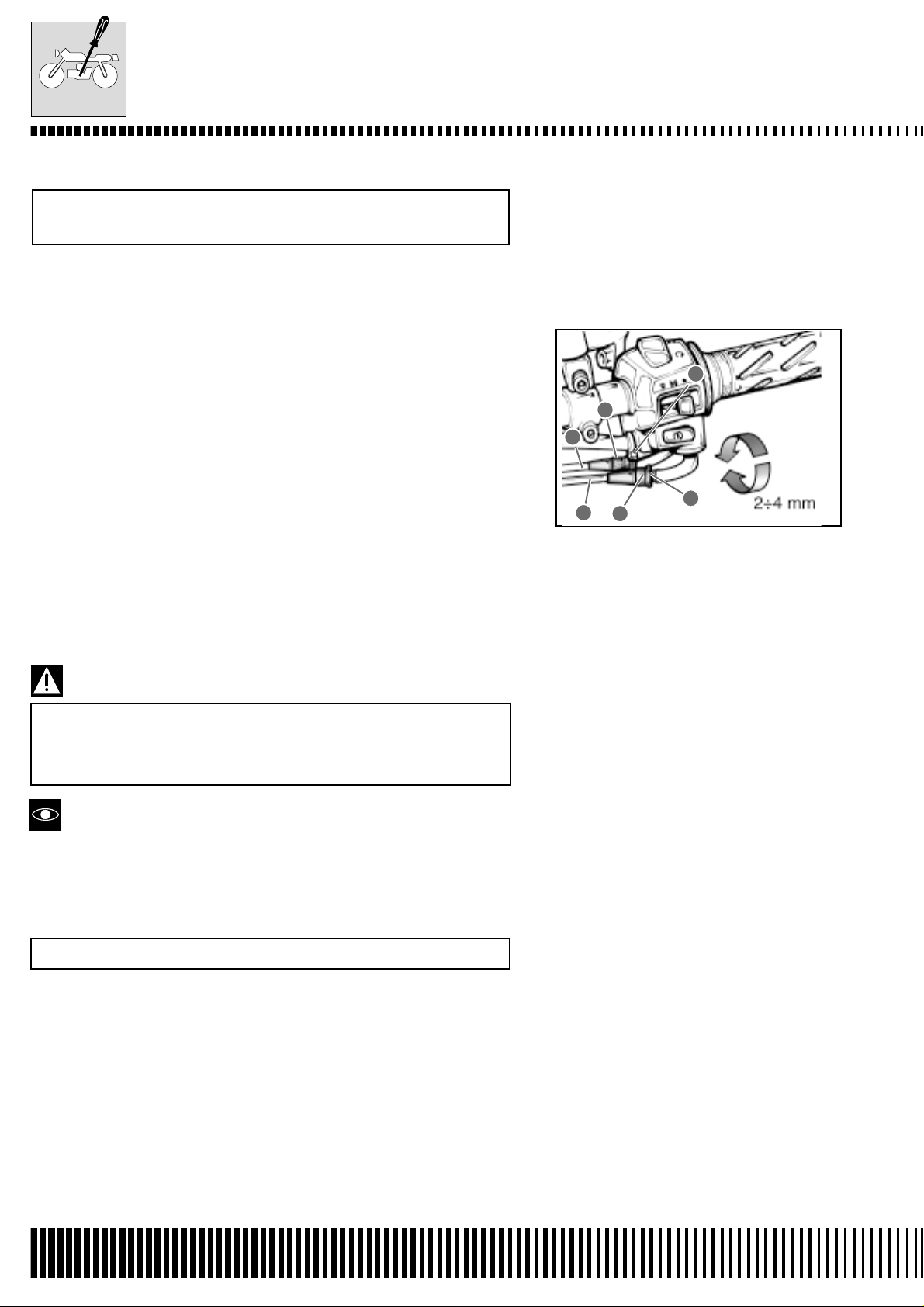

First phase:

• Slacken the locknut 1 of the accelerator return cable B and completely screw in the screw adjuster 2.

Second phase:

• Slacken the locknut 3 of the accelerator opening cable A.

• Screw or unscrew the screw adjuster 4 until the accelerator cable

play is 2.0 – 4.0 mm at the accelerator handgrip.

• Tighten the locknut 3 whilst keeping the screw adjuster 4 locked in

position.

Third phase:

• Keeping the accelerator handgrip in the closed position, slowly

unscrew the screw adjuster 2 of the accelerator return cable B

until a resistance is felt.

• Tighten the locknut 1 whilst keeping the screw adjuster 2 locked in

position.

Accelerator cable play: 2.0-4.0 mm

After making the adjustments, check that the handlebar

movement does not cause an increase in the tickover. The

accelerator handgrip should return smoothly and automatically into position without any stiffness.

3

4

A

B

2

1

Greater adjustments can be carried out using the lateral adjuster on

the butterfly valve body of the carburettor.

SYNCHRONISA TION OF THE CARBURETTORS

Check every 12000 km (or 12 months)

(See page C-73)

B.18

Page 27

CLUTCH

MAINTENANCE

Check every 6000 km (or 6 months).

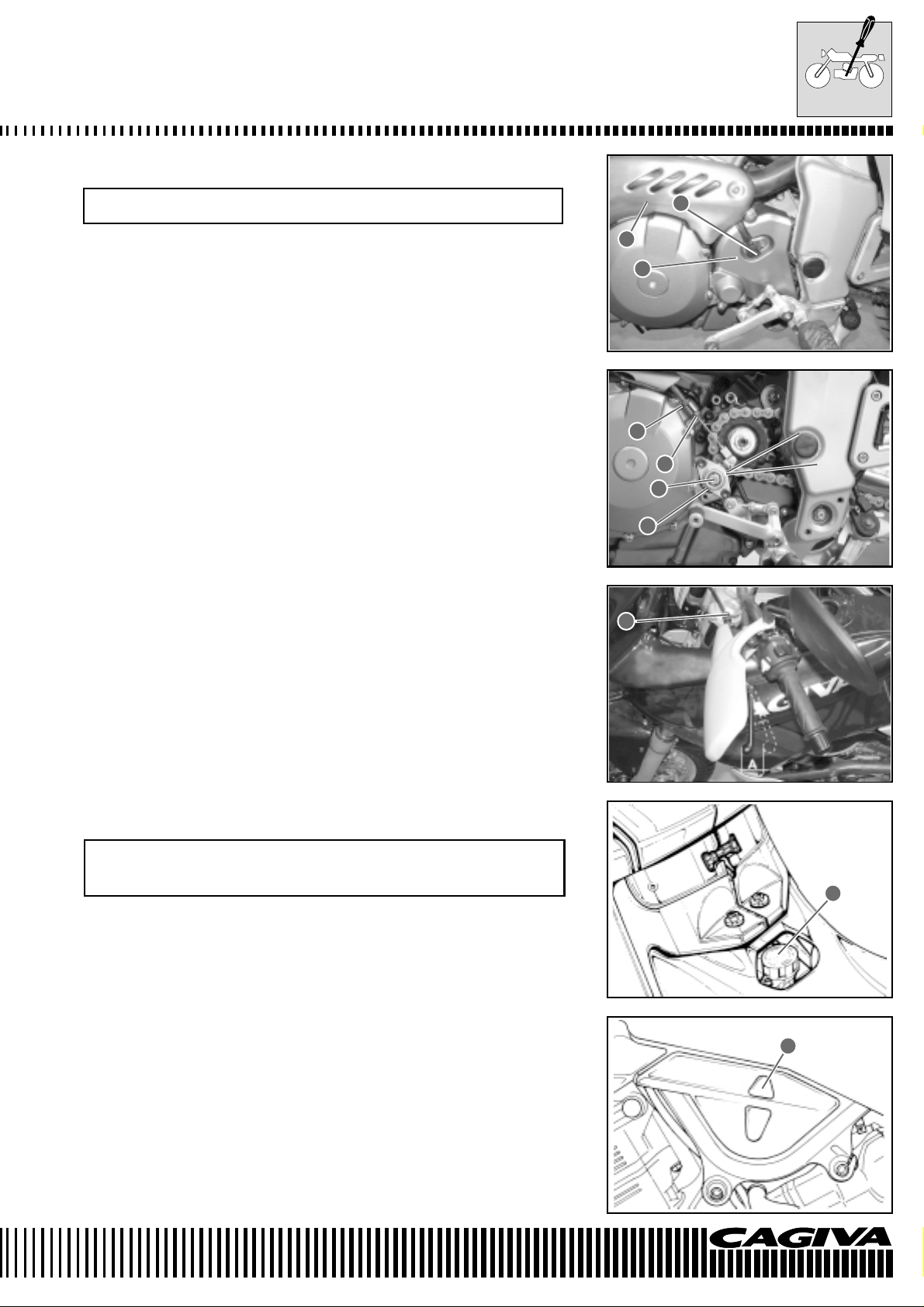

• Remove the speed sensor 1.

• Remove the left hand footrest from the frame by unscrewing the

two relative screws.

• Remove the engine pinion cover 2 by unscrewing the three relative screws.

• Remove the exhaust protection 3.

• Screw in the clutch lever assembly adjuster screw 8.

• Slacken the locknut 4 and completely unscrew the screw adjuster

5.

• Slacken the locknut 6 and rotate the screw adjuster 7 to obtain 5 10 degrees of play at the end of the clutch lever.

• Tighten the locknut 6.

• Slowly screw in the adjuster screw 5 until resistance is felt.

• Unscrew the screw adjuster 5 a

1

/4 of a turn and then tighten the

locknut 4.

• Screw or unscrew the screw adjuster 8 to obtain 10-15 mm of play

A at the end of the clutch lever.

Clutch lever play A: 10-15 mm

1

3

2

7

→

6

5

4

8

5°-10°

COOLING SYSTEM

Check every 1000 km (or 1 month)

Substitute the engine coolant every two years

ENGINE COOLANT LEVEL CHECK

The cooling of the engine is by forced circulation with a centrifugal

pump (situated on the left side of the engine), a by-pass valve thermostat and a radiator. The opening of the thermostat and the consequent flow of liquid in the radiator are activated when the temperature reaches ª 82°C. (maximum opening 95°C.). The system contains ª 2.3 litres of AGIP COOL engine coolant.

Make sure that the machine is on level ground and that it is in a

vertical position with both wheels placed on the ground.

Check that the level inside the expansion tank is between the MIN

and MAX levels shown on the left hand side of the machine 2.

If necessary , top up the engine coolant via the cap 1 positioned underneath the seat.

1

2

B.19

Page 28

MAINTENANCE

ENGINE COOLANT CHANGE

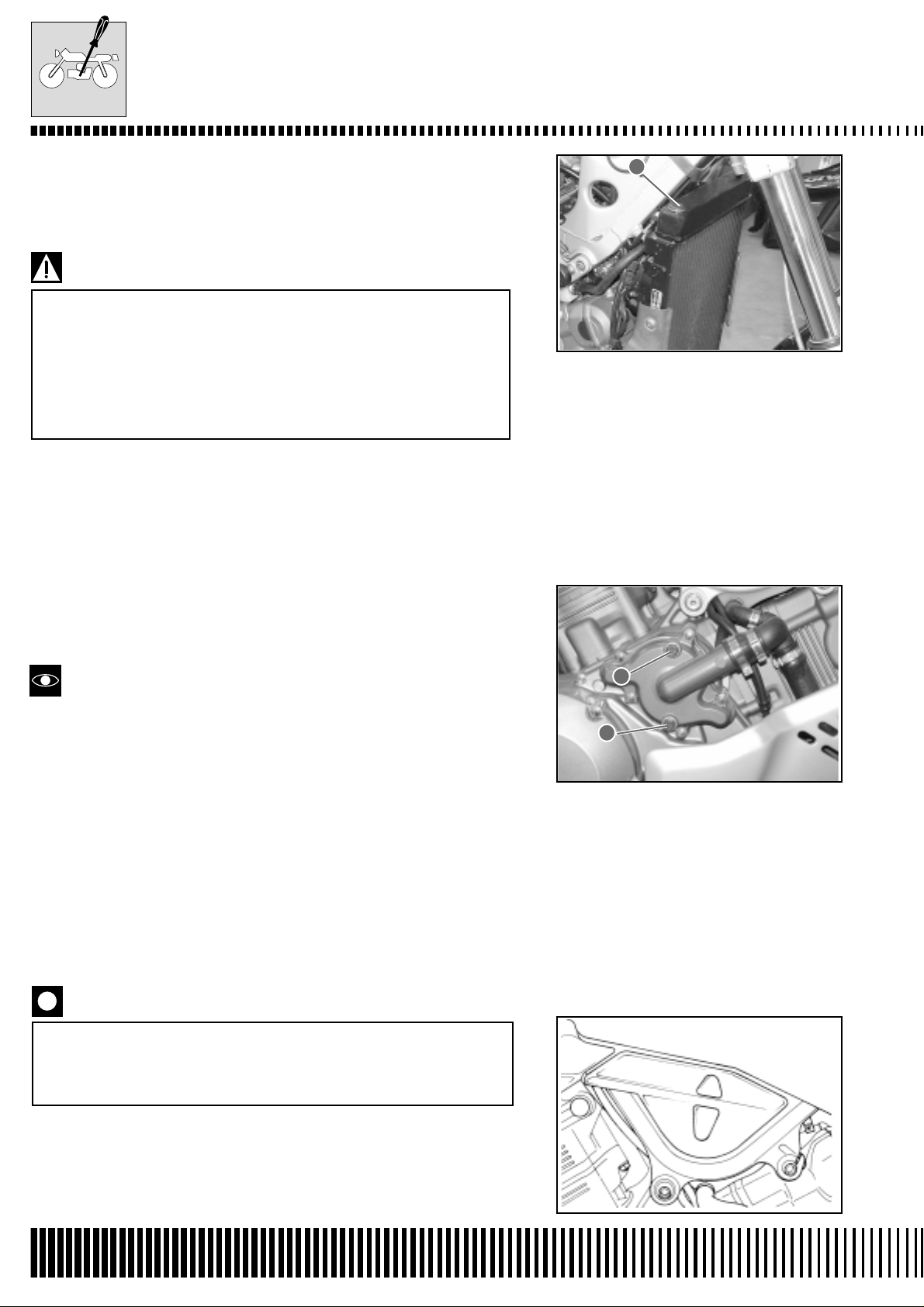

• After having removed the tank, remove the radiator cap 1, the

expansion tank cap and the drain plugs 2 end 3. Drain the engine

coolant.

* Do not remove the radiator cap when the engine is hot.

Boiling liquid or steam can cause serious burns.

* The engine coolant is harmful if swallowed or if it comes

into contact with the skin or the eyes. If the coolant comes

into contact with the skin or eyes, rinse abundantly with

water. If it is swallowed, provocate vomiting and immediately call a doctor.

• Wash the radiator with water if necessary.

• Tighten the coolant drain plugs 2 and 3 to the specified torque.

Torque pressure

Coolant drain plugs 2 and 3: 13 N.m (1.3 kg-m)

• Via the refill hole 5, fill the radiator with the specified engine coolant until it reaches the neck of the radiator.

• Bleed air out of the system via the bleed nut 2.

1

See chapter H for information regarding the engine coolant.

• Tighten the air bleed nut to the specified torque.

Torque pressure

Air bleed nut 4: 13 N.m (1,3 kg-m)

• Switch on the engine and completely bleed the air from the system via the radiator neck.

• Add engine coolant until it reaches the neck of the radiator.

• Tightly close the radiator cap 1.

• Add coolant until it reaches the maximum level of the expansion

tank.

• Tightly close the expansion tank cap.

• Heat up the engine and then let it cool. Add engine coolant until

the upper level mark of the tank.

Repeat the above-mentioned procedure several times to

check that the radiator is completely full of engine coolant. The upper level of the coolant is shown on the side of

the tank.

2

3

Engine coolant capacity: 2000 ml

B.20

Page 29

MAINTENANCE

RADIATOR TUBES

• Remove the sump guard protection 5 by unscrewing the two screws

6 indicated in the figure. Push it aside in the direction of the arrow.

Check to see if the radiator tubes are damaged, cracked or leak. If

any defect is found, substitute the tubes immediately.

TRANSMISSION CHAIN

Check at 1000 km (or 1 month)

Every 6000 km (or 6 months)

Clean and lubricate every 1000 km.

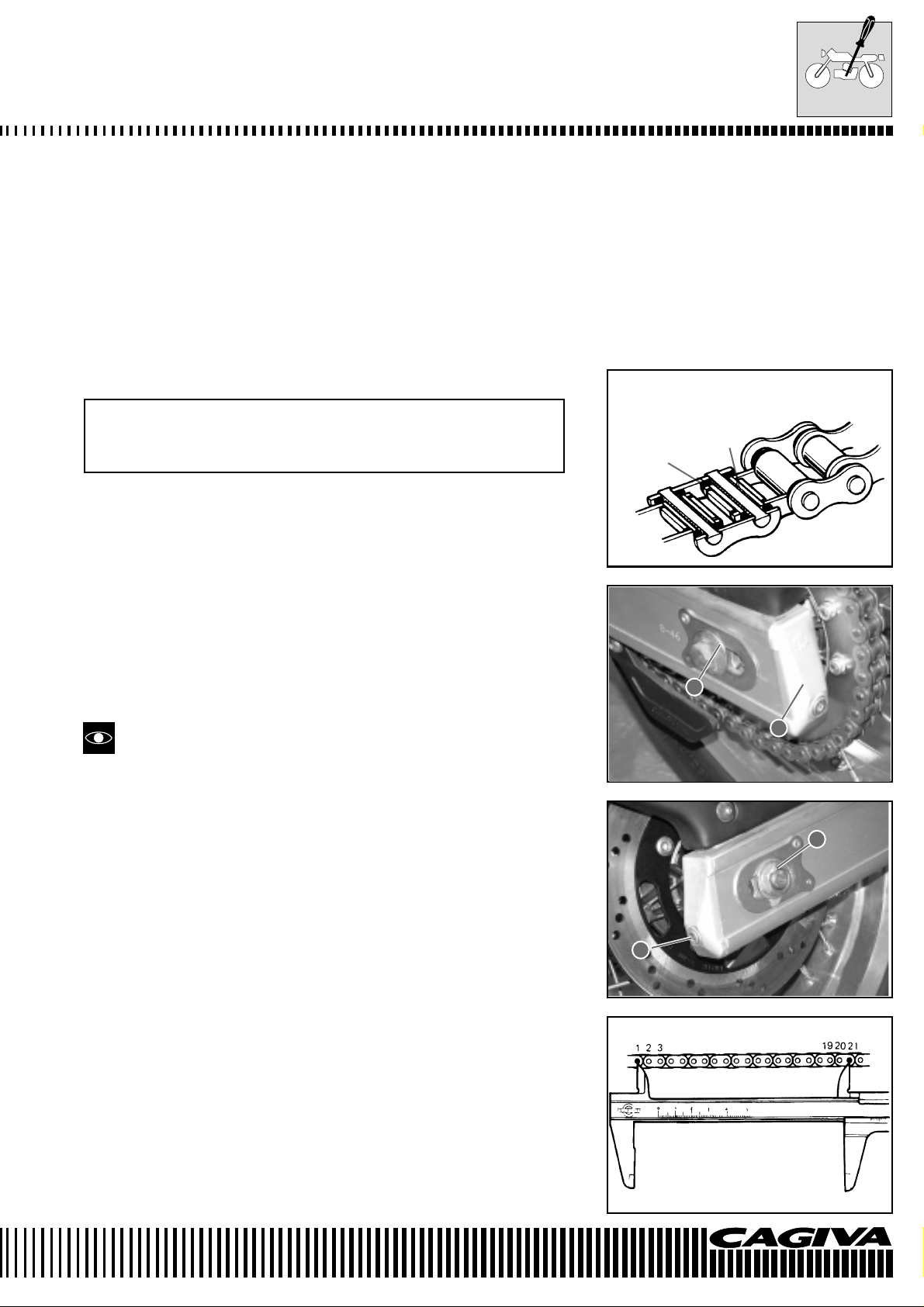

Visually check the transmission chain for the following defects. Put

the machine on a jack and a block of wood. Slowly rotate the rear

wheel by hand with the engine in neutral.

* Slack pins * Excessive wear

* Damaged rollers * Incorrect chain adjustment

* Dry or rusty links

* Missing O-rings * Bent or seized links

Grease

O-ring

The chain must be substituted if any one of these defects is found.

Substitute also the crown and pinion wheels when substituting the

transmission chain.

CHECK

• Slacken the axle nut 1.

• Completely tighten the chain by adjusting the screw adjusters 2.

• Count 21 pins (20 pitches) of the chain and measure the distance

between the two points. If the distance exceeds the operating limits, the chain must be substituted.

1

2

1

2

Operating limit (20 pitches of the transmission chain):

323 mm

B.21

Page 30

MAINTENANCE

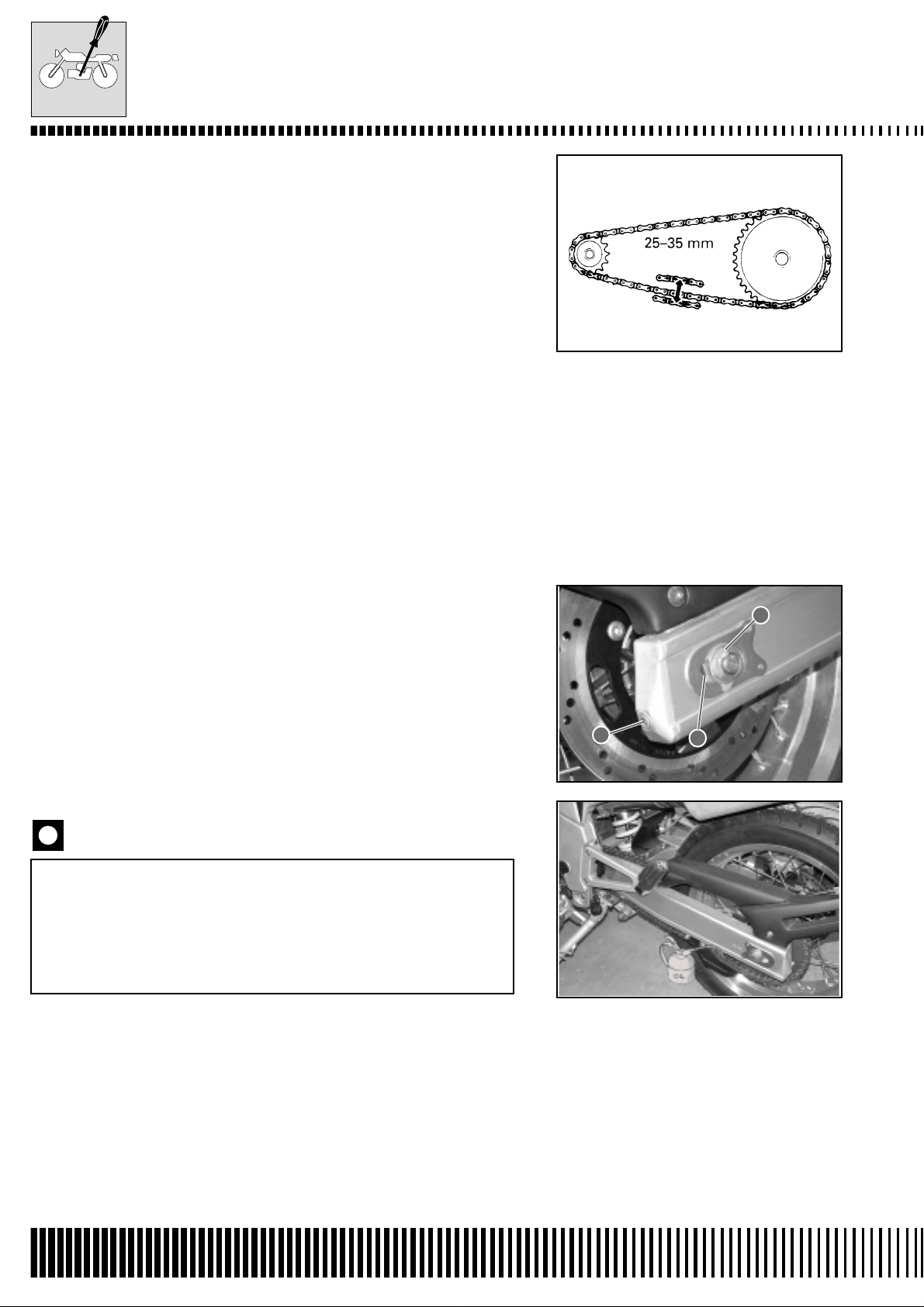

CHAIN ADJUSTMENT

• Slacken or tighten both chain screw adjusters 1 until the chain

reaches a slack of 25-35 mm in the central position of the chain

between the crown and pinion. The marks A on both screw adjusters must be in the same position of the scale to ensure the correct

alignment of the wheel.

• To make accurate adjustments, place the machine on the side

stand.

• After having correctly adjusted the chain, tighten the axle nut 2 to

the specified torque.

• Recheck the chain slack after having tightened the axle nut 2.

Torque pressure

Rear axle nut: 63,7÷ 68,6 N·m (6,5 ÷ 7 kg-m)

CLEANING AND LUBRICATION

• Wash the chain with kerosene. If the chain tends to rust quickly,

shorten the maintenance intervals.

Do not use Trichloroethylene, petrol or other similar liquids. These liquids possess an excessive solvent power

and more importantly, can damage the O-rings that keep

the grease inside the spaces between the rollers and pins.

Long life of the chain depends on the presence of grease

in these spaces.

• After having washed and dried the chain, grease it with high viscosity engine oil or with lubricants specifically produced for chains

with O-rings.

2

1

A

B.22

Page 31

BRAKES

MAINTENANCE

(BRAKES)

Check at 1000 km (or 1 month)

Every 6000 km (or 6 months)

(BRAKE AND BRAKE FLUID TUBING)

Check every 6000 km (or 6 months). Substitute the tubes

every four years. Substitute the brake fluid every two years.

BRAKE FLUID LEVEL CHECK

• Place the machine in a vertical position with the handlebars straight.

• Check the level of the brake fluid by observing the minimum level

mark on the front 1 and rear 2 brake fluid chambers.

• If the level is inferior to the minimum level mark, add brake fluid to

the following specification.

Specification and classification: DOT 4

The braking system of this machine has been filled with

glycol-based brake fluid. Do not use or mix different types

of fluids such as silicone or petrol-based fluids. Do not

use brake fluid from old, used or non-sealed containers.

Do not use leftover fluids from previous maintenance or

left for long periods of time.

1

2

Spillage or leaks of brake fluid are dangerous and immediately discolour painted surfaces. Check the brake tubing and joints for cracks or leaks before riding.

BRAKE PADS

• Remove the blocking plates 1 and the locating pins.

• Pull out the pads from underneath.

The wear of the pads can be visually checked by observing the

groove A on the surface of the pad. When the groove disappears, it

is necessary to substitute the pads (see chapter about the braking

system).

When reassembling, make sure that the pads are completely inserted into their positions. Consult the chapter

about the braking system.

1

A

B.23

Page 32

MAINTENANCE

• To change the rear brake pads, proceed as follows:

• Remove the two screws of the rear spray guard 3 rotate it as shown

in the figure.

Substitute the pads in pairs to guarantee maximum braking performance..

BRAKE PEDAL HEIGHT

The rear brake pedal must have a travel of 10-15 mm before the

braking action takes place. If it is necessary, make the adjustment as

follows:

- Slacken the nut 5;

- Using nuts 6 or 7, position the pedal in the desired position.

- When the adjustment is completed, tighten the nut 7.

Torque pressure

Rear brake pedal locknut 1: 18 N.m (1.8 kg-m)

3

1

MAINTENANCE

To change the rear brake disc pads, proceed as follows:

- Remove the 2 screws 1 of the rear mudguard 2 and rotate it as

shown in the figure.

- Remove the pincer assembly from the forks by unscrewing the

2 relative screws 3.

- Remove the 2 pins 4 that keep the pads in place.

Proceed with checking the pads for wear in the same way as for

the front brake pads.

Reassemble everything in the reverse order of removal.

5

6

7

4

3

1

1

2

B.24

Page 33

MAINTENANCE

BLEEDING THE AIR FROM THE BRAKING SYSTEM

The air that is trapped in the braking system acts as a cushion, absorbing the greater part of the pressure exerted by the brake pump.

The performance of the brake pincer is therefore compromised. The

presence of air in the system is indicated by a “sponginess” of the

brake lever or pedal and a reduction in the braking performance. As

this situation could be highly dangerous for both rider and the machine, it is necessary to effect the bleeding of the air from the braking system immediately following maintenance on the brakes. This

procedure is carried out as follows:

• Refill the brake fluid chamber with brake fluid until it reaches the

“UPPER” mark.

• Replace the chamber cover to avoid the entry of dirt.

• Remove the rubber cap and apply a plastic tube to the bleed valve

nipple. Insert the free end of the tube in a container.

Torque pressure

Air bleed valve nipple: 7.5 N.m (0.75 kg-m)

• Front brake: bleed out the air via the bleed valve nipple.

• Squeeze and release the brake lever several times in rapid succession and then squeeze it without releasing the lever. Slacken

the bleed valve nipple rotating it a 1/4 of a turn so that the fluid can

pour out into the container. This releases the tension on the brake

lever and allows it to move towards the handgrip of the handlebar.

Close the valve, squeeze and release the brake lever again and

reopen the valve. Repeat this operation until the fluid that pours

into the container does not contain bubbles of air.

• The bleeding must be carried out on both front brake pincers at

the same time.

During the bleeding of the brake system, top up the brake fluid chamber with brake fluid as necessary . There must always be brake fluid

in the chamber.

• Close the bleed valve nipple and disconnect the plastic tube. Refill

the brake fluid chamber with brake fluid until the fluid reaches the

“UPPER” mark.

Handle brake fluids with care. They chemically react with

paint, rubber, etc.

• The only difference in the procedure for the rear brake is that it is

a pedal and not a lever that activates the brake.

B.25

Page 34

MAINTENANCE

TYRES

Check every 6000 km (or 6 months)

CONDITION OF THE TREAD

Badly worn tyres decrease the road holding and are therefore dangerous. It is recommended that tyres be changed when the tread reaches

the minimum level.

Operating limit

Tread depth (front): 2.0 mm

(rear): 2.0 mm

TYRE PRESSURES

If the tyre pressures are too high or too low, the steering is negatively influenced and tyre wear is accelerated.

Maintain the correct tyre pressures to obtain the maximum road

holding and the maximum life from the tyres.

Cold tyre pressures are as follows:

COLD TYRE RIDER ONLY RIDER + PASS.

PRESSURE

kPa kg/cm

2

kPa kg/cm

2

FRONT 220 2,2 240 2,4

REAR 240 2,4 260 2,6

The standard tyres mounted on this machine are 110/80 –

18” for the front wheel and 150/70 – 17” for the rear wheel.

The use of different tyres to those specified could cause

instability . It is highly recommended to use tyres of the prescribed size.

TYRE TYPE

TUBELESS

STEERING

Check at 1000 km (or 1 month)

Every 12000 km (or 12 months)

The steering must be adjusted correctly to obtain a smooth rotating

action of the handlebar and a safe ride. Steering that is too stiff

obstructs the smooth rotation of the handlebars whilst steering that

is too slack brings poor stability to the machine. Place the machine

on its stand so that the front wheel is raised from the ground. Grip

the forks where the wheel hub is and pull forwards to check that the

steering head play is not excessive. If excessive play is found, carry

out the adjustment of the steering bearings as described in the Suspension chapter of this manual.

B.26

Page 35

MAINTENANCE

COMPRESSION TEST

The compression of a cylinder is an optimum indicator of the internal condition of the engine.

The decision to overhaul the engine is often the result of a compression test. Amongst the periodical maintenance

data to be found at the dealer are also the compression measurements for each maintenance operation.

COMPRESSION SPECIFICATION (automatic decompression activated)

Standard Limit Difference

1300-1700 kPa 1100 kPa 200kPa

( 13-17 kg/cm

Low compression could indicate one of the following conditions:

* Worn piston or piston rings

* Piston rings seized in the grooves

* Poor valve closure

* Head gasket broken or defective

2

) ( 11 kg/cm2 ) ( 2 kg/cm2 )

Overhaul the engine in the following cases:

* The compression of one of the cylinders is less than 1100 kPa (11 kg/cm

2

).

* The difference between the compression of the two cylinders is more than 200 kPa.

* All values of the compression are less than 1300 kPa (13 kg/cm2) even if they are more than 1100 kPa (11 kg/cm2).

COMPRESSION TEST PROCEDURE

* Before verifying the engine compression, check that the cylinder head bolts are tightened to the correct torque

and that the valves are adjusted correctly.

* Heat up the engine before proceeding with the test.

* Check that the battery is fully charged.

• Carry out the compression test as follows:

• Remove the seat and the plastic underneath the seat.

• Remove both spark plugs (see page B-7.)

• Screw in the compression meter in one of the spark plug holes

making sure that it is correctly tightened.

• Keep the accelerator handgrip in the fully open position.

• Turn over the engine with the electric starter motor for several

seconds and note the maximum reading of the compression me-

ter. This is the compression of that cylinder.

• Repeat the procedure for the other cylinder.

Special tool: 800096660: Compression meter

800096652: Compression sensor adaptor

B.27

Page 36

MAINTENANCE

OIL PRESSURE TEST

Periodically check the oil pressure for an approximate evaluation of the condition of the moving parts of the engine.

OIL PRESSURE SPECIFICATION

More than 300 kPa (3.0 kg/cm2) at 3000 rpm, oil temperature

60°C. Less than 600 kPa (6.0 kg/cm

If the pressure of the oil is more or less than those specified, consider the following causes:

LOW OIL PRESSURE

* Oil filter blocked

* Oil leak in the system

* O-ring damaged

* Defective oil pump

* One or more of these problems together

HIGH OIL PRESSURE

* Excessive oil viscosity

* Oilways blocked

* Or both problems together

2

)

OIL PRESSURE TEST PROCEDURE

Switch on the engine and check that the oil pressure warning light is

illuminated. If it remains illuminated, check the electrical circuit of the

oil pressure warning light. If the circuit is in good condition, check the

oil pressure as follows:

• Remove the plug from the main oil way.

• Insert the oil manometer along with its attachment in the position

indicated.

• Heat up the engine as follows:

Summer: 10 minutes at 2000 rpm

Winter: 20 minutes at 2000 rpm

• After the heating up, increase the speed to 3000 rpm (check the

revcounter) and take the reading of the oil manometer.

Special tool: 80009661: oil pressure measuring tube

800096662: oil pressure measuring adaptor

800096663: instrument (for high pressures)

Torque pressure

Main oil way plug: 10 N.m (1.0 kg-m)

B.28

Page 37

TECHNICAL DATA

MAINTENANCE

VALVE + GUIDE

PART STANDARD LIMIT

Valve diameter Intake 40 –––––

Exhaust 33 –––––

Valve tappet clearance (cold) Intake 0.10-0.20 –––––

Exhaust 0.20-0.30 –––––

Valve stem/guide play Intake 0.010-0.037 –––––

Exhaust 0.030-0.057 –––––

Valve stem distortion Intake and

Exhaust

Valve guide – internal diameter Intake and

Exhaust

Valve stem – external diameter Intake 5.475-5.490 –––––

Exhaust 5.455-5.470 –––––

Valve stem decentralising Intake and

Exhaust

Valve head thickness Intake and

Exhaust

Valve seat width Intake and

Exhaust

Valve head radial decentralising Intake and

Exhaust

Valve spring floating width Internal –––––– 37.0

(intake and exhaust) External –––––– 40.7

Valve spring tension Internal 6.2 kg at 33.1 mm length –––––

(intake and exhaust) External 15.4 kg at 36.6 mm length –––––

–––––– 0.35

5.500-5.512 –––––

–––––– 0.05

–––––– 0.5

0.9-1.1 –––––

–––––– 0.03

Unit: mm

CAMSHAFT + CYLINDER HEAD

PART STANDARD LIMIT

Cam height Intake 37.770-37.838 37.47

Exhaust 36.380-36.448 36.08

Camshaft seat pin oil play Intake and

exhaust

Camshaft seat support Intake and

internal diameter exhaust

Camshaft seat pin external diameter Intake and

exhaust

Camshaft decentralising Intake and

exhaust

Intermediate gearing push play/N° 2

timing sprocket 0.15-0.29

Cylinder head deformation –––––– 0.05

0.019-0.053 0.150

22.012-22.025 –––––

21.972-21.993 –––––

––––– 0.10

–––––

Unit: mm

B.29

Page 38

MAINTENANCE

CYLINDER + PISTON + PISTON RINGS

Unit: mm

PART STANDARD LIMIT

Compression pressure 1300-1700 kPa 1100 kPa

(automatic decompression activated)

Compression pressure difference

(13-17 kg/cm2) (11 kg/cm2)

––––––

200 kPa

(2 kg/cm

2

)

Piston/cylinder play 0.015-0.025 0,12

Cylinder diameter 98.000-98.015 Lines or scratches

Piston diameter 97.980-97.995

97.880

Measured 10 mm from the base of the skirt

Cylinder deformation –––––– 0.05

Piston ring floating end play 1st Approx. 6.8 5.4

2nd Approx. 9.9 7.9

Piston ring end play 1st 0.15-0.35 0.5

2nd RN 0.15-0.30 0.5

Piston ring/groove play 1st –––––– 0.18

2nd –––––– 0.15

Piston ring groove width 1st 0.93-0.95 –––––

1.55-1.57 –––––

2nd 1.01-1.03 –––––

Oil scavenger ring

Piston ring width 0.84-0.89 –––––

1st

2.51-2.53 –––––

1.40-1.42 –––––

2nd 0.97-0.99 –––––

Gudgeon pin hole - internal diam. 22.002-22.008 22.030

Gudgeon pin - external diameter 21.992-22.000 21.980

CONNECTING ROD + CRANKSHAFT

Unit: mm excluding the

ratios

PART STANDARD LIMIT

Connecting rod big end - int. diam. 22.010-22.018 22.040

Connecting rod small end - lateral play

0.17-0.32 0.50

Connecting rod small end – width 21.95-23.00 –––––––

Gudgeon pin length 44.17-44.22 –––––––

Small end oil play 0.032-0.056 0.080

External diameter - Gudgeon pin 44.976-45.000 –––––––

Seat pivot oil play 0.018-0.045 0.080

External diameter – seat pivot 47.985-48.000 ––––––

Crankshaft axial play 0.050-0.100 ––––––

Crankshaft bearing shell thickness 1.925-2.175 ––––––

B.30

Page 39

MAINTENANCE

OIL PUMP

PART STANDARD LIMIT

Oil pump reduction ratio 1.301 (57/31 x 29/41) –––––

Oil pressure (at 60°C.) More than 300 kPa (3.0 kg/cm

2

) at 3000 rpm –––––

CLUTCH

PART STANDARD LIMIT

Clutch lever play 10-15 –––––

Clutch main plate thickness 2.92-3.08 –––––

Clutch main plate teeth width ––––– 12.9

Clutch disengagement screw 1/4 of a turn backwards –––––

Clutch main plate deformation ––––– 0.10

Clutch spring floating length ––––– 29.6

THERMOSTAT + RADIATOR + FAN

PART STANDARD LIMIT

Thermostat valve opening temp. 82° C –––––

Thermostat valve lifting up temp. 95° C –––––

Radiator cap valve opening

pressure

Fan thermal switch

activating temperature

Coolant sensor 20° C Approx. 2.45 kΩ –––––

resistance 50° C Approx. 0.811 kΩ –––––

temperature 80° C Approx. 0.318 kΩ –––––

OFF➝ ON

ON➝ OFF

110° C Approx. 0.142 kΩ –––––

130° C Approx. 0.088 kΩ –––––

110 kPa (1,1 kg/cm2)

Approx. 105° C –––––

Approx. 100° C –––––

GEARCHANGE + TRANSMISSION CHAIN

PART STANDARD LIMIT

Primary reduction ratio 1.838 (57/31) –––––

Secondary reduction ratio 2.235 (58/17) –––––

Gear ratios 1st 2.666 (32/12) –––––

2nd 1.933 (29/15) –––––

3rd 1.500 (27/18) –––––

4th 1.227 (27/22) –––––

5th 1.086 (25/23) –––––

6th 1.000 (24/24) –––––

Crown/pinion ratio 2.562 (41/16) –––––

Gearchange fork play 0.1-0.3 0.50

Gearchange fork width 5.0-5.1 –––––

Gearchange fork thickness 4.8-4.9 –––––

Transmission chain Type Regina 136 ORP –––––

Links 106 links –––––

Length: 20 pitches

––––– 323

Unit: mm excluding the

ratios

–––––

Unit: mm excluding ratios

B.31

Page 40

MAINTENANCE

PART STANDARD LIMIT

Transmission chain slack 25-35 –––––

Gearlever travel 5 –––––

Rear brake lever travel 10÷15 –––––

INJECTOR + FUEL PUMP + FUEL PRESSURE ADJUSTER

P ART TECHNICAL CHARACTERISTICS NOTES

Injector resistance 11-16 ohms at 20°C.

Fuel pump flow Approx. 1 litre per minute at 290 kPa (2.9 kg/cm2)

Fuel pressure adjuster Approx. 290kPa (2.9 kg/cm

2

)

operating pressure

FI SENSOR + AIR INTAKE CONTROL VALVE

P ART TECHNICAL CHARACTERISTICS NOTES

CMP sensor resistance 0.9-1.3 kΩ

CMP sensor peak voltage More than 0.8 V

CKP sensor resistance 184-276 Ω

CKP sensor peak voltage More than 4 V

IAP sensor incoming voltage 4.5-5.5 V

IAP sensor outgoing voltage Approx. 1.8 V at minimum

TP sensor incoming voltage 4.5-5.5 V

TP sensor resistance (closed) Approx. 1.2 kΩ

(open) Approx. 4.4 kΩ

TP sensor outgoing (closed) Approx. 1,1 V

voltage (open) Approx. 4.2 V

ECT sensor incoming voltage 4.5-5.5 V

ECT sensor resistance 2.3-2.6 KΩ a 20° C

IAT sensor incoming voltage 4.5-5.5 V

IAT sensor resistance 2.2-2.7 kΩ a 20° C

AP sensor incoming voltage 4.5-5.5 V

AP sensor outgoing voltage Approx. 3.6 V at 760 mmHg (100 kPa)

TO sensor resistance 60-64 KΩ

TO sensor voltage Approx. 2.5 V

GP sensor voltage More than 0.6 V (from the 1st to the 6th)

Injector voltage Battery voltage

Primary ignition coil peak voltage More than 280 V (when the engine turns)

VCSV resistance 36-44 kΩ

Air intake control valve

operating rpm

B.32

Opening rpm More than 4000 rpm

Closing rpm Les than 3800 rpm

Page 41

MAINTENANCE

CARBURATORE

P ART TECHNICAL CHARACTERISTICS

Minimum rpm - choke 2000 rpm at 20°-30° 3500-4000 at 90°

Minimum rpm – tickover 1300-1350 rpm

Accelerator cable play 2.0-4.0 mm

ELECTRICAL SYSTEM

P ART TECHNICAL CHARACTERISTICS NOTES

Timing synchronisation 3° BTDC at 1200 rpm

Firing order1·2

Spark plugs Type NGK: CR8EK

Denso:U24ETR

Electrode

gap

Spark performance More than 8 at 1 atm.

Camshaft position sensor

resistance

Ignition coil resistance Low 3-5 Ω + terminal / - terminal

High 20-28 kΩ

Camshaft position sensor

peak voltage

Primary ignition coil peak voltage More than 280 V

Generator winding resistance 0.1-1.0 Ω Y - Y

Max. outgoing wattage-generator Approx. 380W at 5000 rpm

Generator voltage without a

charge (cold engine)

Ignition relay resistance 3-6 Ω

Battery Type FIAMM 6E9

Capacity 12V (9 Ah) 32.4kC

Standard electrolyte

density

Fuses Headlight HI 15A

LO 15A

Direction

indicators

Injection

relay

Main fuse

More than 70V (CA) at 5000 rpm

184-276 Ω BI-G

More than 4,0 V

1.265÷1.275

0.6-0.7

15A

10A

15A

Unit: mm excluding ratios

+ terminal / spark plug

insulated cover

B.33

Page 42

MAINTENANCE

WATTAGE

P ART TECHNICAL CHARACTERISTICS

Headlight HI 60

LO 55

Sidelight 5

Stop/tail light 21/5

Direction indicators 10

Revcounter light 1.2

Direction indicator warning light 2

Main beam warning light 2

Neutral warning light 2

Fuel level warning light 2

Number plate light 5

BRAKES + WHEELS

PART STANDARD LIMIT

Rear brake pedal travel 5 –––––

Brake disc thickness Front 4.0±0.2 3.5

Rear 5.0±0.2 4.5

Brake disc deformation

(front and rear)

Wheel deformation Axial < 0.5 2

(front and rear) Radial < 0.8 2

Wheel spindle axial deformation

Front

Rear

––––– 0.30

< 0.1 0.2

Unit: W

Unit: mm

B.34

Page 43

MAINTENANCE

PART STANDARD LIMIT

Axial deformation – wheel Front –––––– 0.5

Rear ––––– 0.5

Wheel dimensions Front 3.00“X18” –––––

Rear 4.25 “X17”

Tyre dimensions Front 110/80 -18” –––––

Rear 150/70 -17” –––––

Tread depth Front ––––– 2.0

Rear ––––– 2.0

SUSPENSION

PART STANDARD LIMIT

Fork travel 150 –––––

Fork spring floating length 280 –––––

Fork oil level 180 –––––

Rear spring assembly

installed length

Rear wheel travel 160 –––––

Fork shaft pin deformation ––––– 0.30

180 –––––

TYRE PRESSURES

COLD TYRE RIDER ONLY WITH PASSENGER

PRESSURES kPa kg/cm

FRONT 220 2.2 240 2.4

REAR 240 2.4 260 2.6

2

kPa kg/cm

2

B.35

Page 44

MAINTENANCE

FUEL + COOLANT

P ART TECHNICAL CHARACTERISTICS NOTES

Fuel type The fuel must be 95 octane petrol or higher.

It is recommended that lead free petrol be used.

Fuel tank capacity 20 L

Engine oil type AGIP TEC 4T 10W/40 SINT 20005W/40

Engine oil capacity Oil change 3100 ml

Filter change 3300 ml

Overhaul 3600 ml

Fork oil type SAE 7.5

Fork oil capacity

(each leg)

Brake fluid type AGIP BRAKE 4

Coolant type Use antifreeze coolant that is compatible

with aluminium radiators. Mix with a

ratio of 50/50 with distilled water only.

Coolant capacity

680 cc

2000 ml

B.36

Page 45

INJECTION - AIR INTAKE SYSTEM

Section

C

C.1

Page 46

INJECTION - AIR INTAKE SYSTEM

Maintenance precautions ....................................................... C-3

FI system technical characteristics ........................................ C-9

Intake air system technical characteristics............................. C-21

FI system - position of parts ................................................... C-26

FI system diagram.................................................................. C-27

FI system - electrical diagram ................................................ C-28

Auto-diagnostic function......................................................... C-29

Security function..................................................................... C-32

FI system diagnostics............................................................. C-33

Fuel feed system.................................................................... C-51

Butterfly body ......................................................................... C-55

Intake air system .................................................................... C-78

Sensors .................................................................................. C-80

C.2

Page 47

INJECTION - AIR INTAKE SYSTEM

MAINTENANCE PRECAUTIONS

Observe the following when handling components of the FI system

or when carrying out maintenance on the system.

CONNECTORS/COUPLINGS

• When putting connectors together , make sure that the connectors

are pushed fully home until a click is heard.

• When pulling apart a snap connector , release the stop before disconnecting. When connecting, push in until a click is heard.

• When disconnecting a coupling, make sure to grip the body of the

coupling and do not pull on the leads.

• Check that the terminals of each connector/coupling are not loose

or bent.

• Check for corroded or dirty terminals. A good contact will not be

made if the terminals are corroded and not perfectly clean.

Click

Click

• If there are circuit problems, check each lead by hand. If there are

cracks or breaks in the insulation, repair or substitute the leads.

• When carrying out measurements on electrical connectors with a

tester, insert the probe into the connector from the wiring system

side of the connector/coupling.

• If it is not possible to insert the probe from the wiring side, take

particular care not to bend the male terminal or open the female

terminal when inserting the probe on the terminal side of the coupling.

Never insert the probe into a male terminal.

• Check terminal connections to see if the male terminals are bent

or the female terminals are too open or both terminals are loose,

corroded or dirty.

2

1

1

Coupling

Probe

2

2

3

Coupling

1

Probe

2

3

Male terminal

1

2

C.3

Page 48

INJECTION - AIR INTAKE SYSTEM

FUSES

• Always search for the cause of a blown fuse. Eliminate the cause

and then substitute the fuse.

• Use only fuses of the correct amperage.

• Do not use wire or another substitute for a fuse.

ECM/VARIOUS SENSORS

• Seeing that each component is a high precision part, take care to

not damage the said components during the removal/installation

phases.

INCORRECT

• Take care to not touch the electrical terminals of the ECM. The

static electricity of the body can damage the component.

• Before connecting or disconnecting an ECM coupling, make sure

that the ignition switch is in the OFF position. This will prevent

damage to the electronic parts.

• Do not connect the battery with inverted polarities. This will instantly damage components of the FI system when the circuit is

switched on.

ignition switch

INCORRECT

C.4

Page 49

INJECTION - AIR INTAKE SYSTEM

• Do not remove the terminals of the battery whilst the engine is

running.

If a terminal is removed, this would cause an inverted electrical

force that would seriously damage the ECM.

• Before measuring the voltage on any terminal of the electrical system, check that the voltage of the battery is 11V higher. Terminal

checks carried out with an insufficient battery voltage can cause

diagnostic errors.

• Never connect any tester (voltmeter, ampmeter, etc.) to the ECM

when its coupling is disconnected. This could cause damage.

• Never connect an ohmmeter to the ECM with the coupling connected. This could cause damage to the ECM and the sensors.

• Use a good quality ohm-meter/voltmeter. It will not be possible to

obtain precise test results or possible personal injuries could result if bad quality equipment is used.

ELECTRICAL CIRCUIT TESTING PROCEDURE

There are various methods of testing electrical circuits. The one

described here is the general method for testing open circuits or

short circuits using an ohmmeter and a voltmeter.

OPEN CIRCUIT TESTS

The probable causes of open circuits are described as follows. Check

the connectors/couplings and terminals with particular attention because these are frequently the cause of an open circuit.

• Loose connection of a connector/coupling.

• Poor contact of the terminal (because of dirt, corrosion, rust or

foreign objects, etc.).

• Leads not insulated properly.

• Poor connection between the lead and the terminal.

C.5

Page 50

INJECTION - AIR INTAKE SYSTEM

• Disconnect the negative polarity cable from the battery.

• Check to see if the connectors/couplings and both ends of the

circuit are not loose. Also check the snap-fit couplings for correct

insertion.

• Check the tightness of the female terminals of the circuit by using

a test male terminal.

Visually check each terminal for poor contacts (caused by dirt,

corrosion, rust, foreign bodies, etc.). Check that each terminal is

correctly inserted into the couplings.

If the terminal is loose, adjust it to increase the tightness or substitute the terminal. They must be clean and free of corrosion that

could impede a good contact.

• Using the continuity and voltage testing procedure described as

follows, check for an open circuit or a poor contact of the wiring

terminals. Locate the defect and repair..

1

Sensor

Check to see if the connection is loose

1

Check the contact pressure by inserting and

removing the male terminal once only

1

ECM

Check that each terminal is aligned correctly and is not bent

Continuity test

• Measure the resistance between the terminals of the coupling and

both ends of the circuit being tested (as indicated between position A and C).

If no continuity is indicated (complete resistance or over the limit

of the scale), signifies that the circuit between terminals A and C is

open.

• Disconnect the coupling in the circuit (coupling B in the figure) and

measure the resistance between the terminals A and B.

If there is no continuity signifies that the circuit between the terminals A and B is open. If continuity is indicated, the circuit is open

between the terminals B and C or the coupling B is defective.

1

2

Loose fitting

1

Open circuit

2

Worn lead (one thread left of the braiding)

3

B

A

A

3

ECM

C

ECM

C.6

B

C

Page 51

INJECTION - AIR INTAKE SYSTEM

Voltage test

If the circuit tested has fewer volts than normal, the voltage test can

also be used as a continuity test.

• With all connectors/couplings connected and with voltage running

through the circuit being tested, measure the voltage between each

terminal and Earth.

If the measuring is carried out as indicated in the figure on the right

and the results are as indicated below, signifies that the circuit is

open between terminals A and B.

Voltage between:

C and Earth: approx. 5 V

B and Earth: approx. 5 V

A and Earth: 0 V

However, if the values are those indicated below signifies that there

is an anomalous resistance of a level corresponding to the drop in

voltage in the circuit between the terminals A and B.

Voltage between:

C and Earth: approx. 5 V

B and Earth: approx. 5 V Drop of 2 V

A and Earth: approx. 3 V

A

B

C

SHORT CIRCUIT TESTS (wiring - Earth)

• Disconnect the negative polarity cable of the battery.

• Disconnect the connectors/couplings and both ends of the circuit

being tested.

Disconnect all connectors/couplings between the circuit being tested

and any other circuits.

The diagnosis will not be accurate if this is not done.

• Measure the resistance between the terminal and one end of the

circuit (terminal A in the figure) and Earth. If continuity is indicated

signifies that there is a short circuit to Earth between the terminals

A and C of the circuit.

B

A

C

To other parts

Other parts

C.7

Page 52

INJECTION - AIR INTAKE SYSTEM

• Disconnect the coupling in the circuit (coupling B) and measure

the resistance between the terminals A and Earth.

If continuity is indicated signifies that there is a short circuit to Earth

between the terminals A and B of the circuit.

USE OF THE TESTER

• Use batteries for the tester that are in good condition.

• Ensure that the tester is correctly adjusted to the range of tests to

be conducted.

• As the resistance can vary according to the tester being used and

the temperature, the tester must be used as follows.

Use of the tester

• An incorrect connection of the + and - probes can cause damage

inside the tester.

• If the voltage and the current are not known, carry out the test

utilising the highest range possible.

• Start with the tester at 0 ohms before testing each resistance or

after having changed the range of the resistance.

• When the resistance is measured with a multi-tester, also measure the resistance the charge is missing. Subtract this resistance

from that measured under charge to obtain the effective resistance.

(Resistance (Resistance in abmeasured)

• When resistance is measured with a multi-tester , “infinite” becomes

10.00 Mohm and “1” flashes on the display.

• Check that no voltage has been applied before carrying out testing. If voltage is present, the tester could be damaged.

• Switch off the tester when not in use.

-

sence of charge)

=(effective resistance)

Left side

A

B

C

* When connecting the multi-tester, place copper adaptors (exter-

nal diameter: - 0.5 mm) on the rear part of the coupling and then

connect the probes to the adaptors.

* Use copper adaptors as described above, to prevent damage to

the protective rubber sleeves of the impermeable couplings.

C.8

Page 53

INJECTION - AIR INTAKE SYSTEM

FI SYSTEM TECHNICAL CHARACTERISTICS

INJECTION TIME (INJECTION VOLUME)

The factor that determines the timing of the injection is the time of the basic injection. This is calculated on the basis

of intake air pressure, the rpm of the engine, the opening of the throttle and various other adjustments that are

determined according to signals received from various sensors that reveal the engine and riding conditions.

ECM

Intake air pressure sensor Intake air pressure

(IAP sensor) signal

Crankshaft position sensor Engine rpm of injected

(CKP sensor) signal fuel

Throttle position sensor Throttle opening

(TP sensor) signal

Various sensors

Injectors

Various signals

→

Injection signal

→

Basic volume

→

→

Adjustment

→

Final volume

of injected fuel

→

→

C.9

Page 54

INJECTION - AIR INTAKE SYSTEM

INJECTION TIME ADJUSTMENT (VOLUME)

Various sensors allow injection time adjustments (volume) to be carried out on the basis of the following signals.

SIGNAL

ATMOSPHERIC PRESSURE SENSOR SIGNAL

ENGINE COOLANT TEMPERATURE SENSOR

SIGNAL

INTAKE AIR TEMPERATURE SENSOR SIGNAL

BATTERY VOLTAGE SIGNAL

GEARCHANGE/ENGINE RPM POSITION SIGNAL

IGNITION SIGNAL

ACCELERATION/DECELERATION SIGNAL

DESCRIPTION

When the atmospheric pressure is low, the sensor

sends a signal to the ECM to reduce the injection

time (volume).

When the temperature of the engine coolant is low,

the injection time (volume) is increased.

When the temperature of the intake air is low, the

injection time (volume) is increased.

Battery voltage is supplied to the ECM to make it

function. This voltage is taken and used as a signal

for the adjustment of the injection time (volume). A

low voltage determines a longer injection time for the

injection volume adjustment.

At high engine rpm, the injection time (volume) is

increased in the 5th and 6th gears. The SRAD system

makes this adjustment.

When the engine is being switched on, a larger

volume of fuel is injected into the system.

During acceleration, the injection time of the fuel

(volume) is increased in relation to the speed with

which the throttle is opened and the rpm of the engine. During deceleration, the injection of fuel is

interrupted. Injection is reactivated when the butterfly

valve is reopened.

INJECTION KILL CONTROL

SIGNAL

CRASH SENSOR SIGNAL

RPM LIMITER SIGNAL

DESCRIPTION

If the motorcycle crashes to the ground, the crash

sensor sends a signal to ECM. At the same time, this

signal causes an interruption of the electrical feed to

the fuel pump, the injectors and the ignition coil.

The functioning of the fuel injectors is interrupted

when the rpm of the engine reaches maximum level.

The rpm limiter interrupts the ignition system and

therefore the interruption signal is sent to the ECM.

C.10

Page 55

INJECTION - AIR INTAKE SYSTEM

FUEL FEED SYSTEM

The fuel feed system consists of the fuel tank, fuel pump, fuel filter, feed tube, feed tubing (including the fuel

injectors), pressure regulator and the return feed tube. The fuel is pumped from the tank to the fuel pump and the

pressurised fuel flows into the injector installed in the fuel feed tubing. As the fuel pressure applied at the fuel

injector (the pressure of the fuel in the feed tubing) is always maintained at a higher value than the suction of the

carburettor, the fuel is injected into the carburettor in a conical dispersion when the injector opens according to the

injection signal received from the ECM.

The excess fuel refused by the pressure regulator returns to the fuel tank via the return fuel tube.

ELECTRIC FUEL PUMP

The electric fuel pump, which is situated on the left hand side of the machine, is of the rotating lobe volumetric type.

The pump motor has permanent magneto brushes.

The pump has a non-return valve to avoid the emptying of the fuel system when the pump is not in function.

It is also provided with a pressure valve that short circuits the air feed when there is a pressure more than 5 bar.

This avoids overheating the electric motor.

The ECM controls the ON/OFF condition of the fuel pump as described in the FUEL PUMP CONTROL SYSTEM

section.

C.11

Page 56

INJECTION - AIR INTAKE SYSTEM

FUEL PRESSURE REGULATOR

The fuel pressure regulator is a diaphragm release valve that consists of a diaphragm, spring and a valve. It

always maintains the pressure of the fuel to the injector at 2.9 kg/cm

carburettor. When the fuel pressure rises more than 2.9 kg/cm

the fuel opens the regulator valve and therefore the excess fuel returns to the fuel tank via the return fuel tube.

2

2

(290 kPa) above the pressure in the carburettor,

(290 kPa) higher than the pressure in the

(Open valve)

Spring

Diaphragm

Fuel from

the pump

Fuel returns

to the tank

Suction

Valve

(Closed valve)

Spring