Petite Digital Stirrer User Manual

Online Warranty Registration

To register the warranty for your Caframo stirrer online, please complete the

registration found at

www.CaframoLabSolutions.com/product-registration/

II

Language Index

English ..................................................................................................................1

French..................................................................................................................11

Spanish ................................................................................................................21

German ...............................................................................................................31

Contents

Language Index 1

Packing List 2

Introduction 2

Safety Label Legend 3

Safety Instructions 3

General Instructions 4

Approvals 4

Installation in the Laboratory 5

Environmental Operating Conditions 5

Auto Start 6

Dimensions 6

Technical Data 7

Torque Capabilities 7

General Operating Instructions 8

Cleaning and Service 9

Warranty and Product Liability 10

Accessories 10

1

250MN004

Rev00

Packing List

Compare the contents of the shipment (BDC250 or BDC250U1) to the items on

the following list to ensure all parts are received with the stirrer. Do not discard the

container and packing materials until all parts are accounted for. It is recommended

that the original packing materials be kept for transportation and storage.

• Petite digital stirrer *

• Power supply *

• Instruction manual *

• Allen key, (2) collet set screws *

• Stand support rod and lock nut

* Included with BDC250MU1 (motor only)

• Stand base

• (2) Impeller blades

• (2) Impeller lock screws

• Impeller shaft

Universal Power Supply

Included with BDC250U1, BDC250MU1.

• Interchangeable plugs for:

a. North America/Mexico/Japan

b. Europe

c. Australia/China

d. UK/Singapore

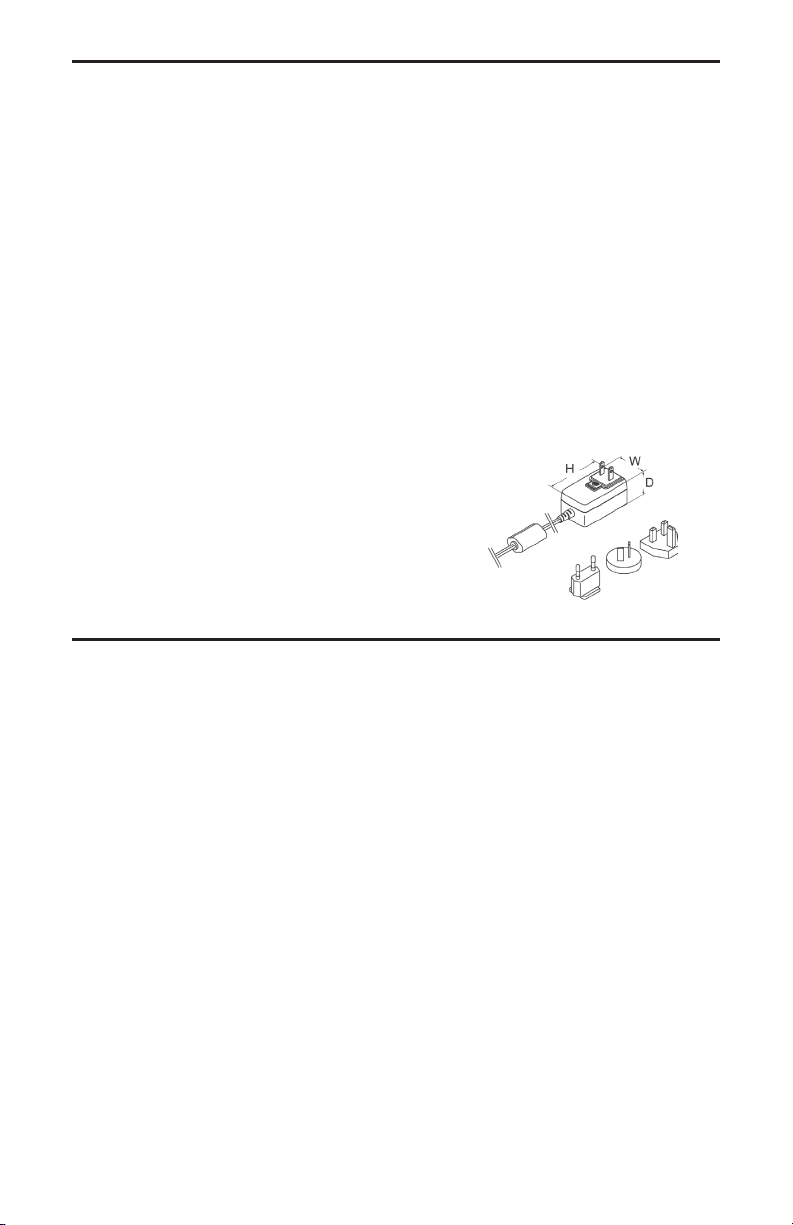

• Measures H 68, W 50, D 39.3 mm

• RoHS compliant & CE marked

(a)

(d)

(c)

(b)

Introduction

This stirrer is specically designed for professional use in the laboratory and for

use in industry to stir liquids with various properties and applications.

This stirrer uses a high efciency brushless DC motor. The speed is kept constant

with continuous feedback to the motor. When torque demands are outside the

stirrer’s range, integrated electronic overload protection ensures no damage can

occur to the electronics, motor or transmission.

The stirrer is designed for reliability and durability. There are no wear parts

that require user service during the normal life of the stirrer. There are no user

serviceable parts.

2

Safety Label Legend

CAUTION: Read operating instructions carefully and

in full.

RECYCLE: Recycle in accordance with the waste

electronic & electrical equipment (WEEE) directive.

Safety Instructions

1. All operators must be familiar with the stirrer and read this entire manual.

If the stirrer is used in a manner not specied by the manufacturer, the

protection provided by the equipment may be impaired.

2. The stirrer must be securely xed to a stable support such as the provided stand. If other stands are used, the unit must be secured such that it

will not fall if tipped.

3. CAUTION: This is not an explosion proof stirrer. Do not use in a highly

ammable or explosive environment.

4. Spinning impellers can cause severe personal injuries. Operators must

use extreme care and good judgment when mixing at any speed.

5. All mixing paddles and impellers must be in good condition with straight

shafts. If the stirrer vibrates at high speeds, check the paddle shaft for

damage, and repair or replace if needed.

6. Extreme care must be taken when mixing chemicals to ensure that no

chemicals are splashed outside the mixing vessel. Care must be taken

when changing to faster mixing speeds.

7. Ensure that the mixing impeller does not contact the containment vessel.

8. Do not operate while standing in water. Keep the unit dry and do not

immerse any part, except the mixing paddle into any liquids. Protect unit

and operator from splashing.

9. Ensure that no loose clothing, jewellery, or hair can become entangled in

any rotating parts. A fast spinning chuck can cause injury to operator.

10. Power can be interrupted to the stirrer by pressing the power button. In

an emergency, disconnect the main power cord.

11. Ensure the power button and mains power cord of the stirrer can be

accessed immediately, directly and without risk at any time, and above

all, in case of fault.

12. The stirrer must be used with supplied power cord. The cord and plug

type are important safety elements. Do not use an inadequately rated

cord and plug. Do not alter plug.

3

General Instructions

Read Safety Instructions: Unpack the stirrer carefully. Ensure the stirrer is not

damaged and verify the contents against the packing list. If the stirrer is damaged

or the contents do not correspond with the packing list, notify your supplier immediately.

Read the manual carefully! Make sure that all users read this manual thoroughly

before operating the stirrer. For further questions or inquiries, please contact:

Caframo Limited

501273 Grey Road 1

Georgian Bluffs ON N0H 2T0, Canada

Tel: 519-534-1080

Toll Free: 800-567-3556 (within USA and Canada)

Website: www.CaframoLabSolutions.com

E-mail: labsales@caframo.com

Approvals

Standards

CAN/CSA C22.2 No. 61010-1-12

North America

CAN/CSA-C22.2 No. 61010-2-051-15

UL 61010-1 (3rd Edition)

UL 61010-2-051

FCC Part 15, Class A

ICES003

Europe,

Australia, New

Zealand

CSA Canadian Standards Association

CE Communité European (European Community)

UL Underwriters Laboratories

FCC Federal Communications Commission

IEC The International Electrotechnical Commission

ICES Interference Causing Equipment Standards

EMC Electromagnetic Compatibility

EMI Electromagnetic Interference

IEC 61010-1, IEC 61010-2-051

EMC/EMI standard IEC 61326-1

4

Installation

(BDC250MU1 includes motor only)

Stand Assembly

Remove lock nut. Insert the threaded end of the stand rod into the stand base.

Turn rod clockwise to tighten. Secure with lock nut.

Stirrer Installation

Slide the clamp opening over the top of the stand rod. Lower to desired height.

Turn clamp knob to securely tighten the stirrer onto the stand rod. Connect supplied power cord to stirrer. Connect power cord to a grounded electrical outlet.

Impeller Assembly

Add impeller blade(s) to impeller shaft. Tighten screw to secure.

Impeller Installation

Insert impeller shaft into collet opening until it stops. Tighten set screw.

Environmental Operating Conditions

The BDC250 stirrer must operate in the following conditions:

Indoors

1. Altitudes up to 2000 m (6500 ft.).

2. Temperatures from 5oC to 40oC (41oF to 104oF).

3. Maximum relative humidity 80% for temperatures up to 31oC (88oF) decreasing

linearly to 50% relative humidity at (104oF).

4. Pollution degree 2 in accordance with IEC 664.

5

Auto Start

This stirrer includes an optional Auto Start feature. When set, the stirrer will resume

mixing after a power failure, when power has been removed by control equipment

(i.e., PLC) or when the power has been cut (i.e., stirrer unplugged). When power

is restored, the stirrer will automatically ramp up to the last set speed and resume

mixing. The stirrer ships from the factory with Auto Start disabled.

To set the Auto Start feature rst ensure stirrer is powered off. Press and hold the

Increase Button then press the Power Button. A dot will illuminate in the bottom

right corner of the LED display to indicate the Auto Start feature is active. Press

power button to turn the stirrer on and begin mixing.

To disable the Auto Start rst ensure stirrer is powered off. Press and hold the Decrease Button then press the Power Button. The dot on the LED display will go out

to indicate the feature has been disabled.

Dimensions

j Four-digit LED display

Button - power on/off

Button - Increase rpm

Button - Decrease rpm

Collet

Housing

Clamp opening

Clamp knob

6

Technical Data

Model Number BDC250

Speed range 50 to 2500 rpm

Maximum torque 10 Ncm

Mechanical output power 1/50 hp

Input to power supply

Electrical output from power

supply to Stirrer

Weight - Stirrer only

Weight - Total package

AC 100 to 240 volts, 50/60 Hz (must use

supplied power cord)

DC 24 volts, 1 amp

0.37 kgs (0.8 lbs)

1.47 kgs (3.2 lbs)

Maximum volume 2 litres, water-like viscosity

Molded housing

Chemical-resistant, ame retardant acetal

copolymer. Recyclable.

Keypad Waterproof, chemical-resistant polyester

Power cord length 1.8 m (6 ft)

Stainless steel collet Fits 6 mm shaft (0.24 in)

Led display accuracy ±10 rpm or ±3%, whichever is greater, 4 digit

Torque Capabilities

Torque Curve

12

10

8

6

Torque (Ncm)

4

2

0

0 250 500 750 1000 1250 1500 1750 2000 2250

RPM

7

General Operating Instructions

The stirrer must be securely mounted as specied in the installation instructions.

Ensure the mixing shaft and blade are securely attached. The stirrer is now ready

for use to mix liquids.

Button Operation Functions

Power Button - Turns the stirrer motor on and off. When initially

turned on, stirrer will spin at 50 rpm following a 5 second delay.

Increase Button - Increases the speed. If pressed within ve seconds

of the stirrer being turned on it will stir at the last speed before turned

off.

Decrease Button - Decreases the speed. If pressed within ve

seconds of the stirrer being turned on it will stir at 50 rpm.

OL Indicates an overload condition. The load is too great for the stirrer and must

be reduced. To reset stirrer turn power back on.

Safety is built into this stirrer. When it is turned on (Auto Start not enabled) it pauses for 5 seconds before it starts to mix. The last speed used is displayed. The user

has three options.

1. Do nothing. The stirrer will start to stir at 50 rpm after ve seconds.

2. Press the increase button and the stirrer will start to stir at the last speed set

before powered off. This speed is displayed.

3. Press the decrease button and the stirrer will start to stir at 50 rpm.

8

Cleaning and Service

Cleaning

Unplug stirrer prior to cleaning. Using a mild soap and water solution, wipe the

housing and control panel of the stirrer with a damp cloth. Do not use chlorine

bleach, chlorine-based cleanser, abrasives, ammonia, steel wool, or scouring pads

with metal content or similar harsh solvents or abrasives. These may damage the

surface of the stirrer.

Service

Do not attempt to service or repair stirrer. If the stirrer housing is opened, the warranty becomes void. Contact Supplier for return authorization and return instructions. Clean the stirrer so that it is free from any materials which may be harmful.

Provide an SDS or other safety data sheets for all chemicals used in conjunction

with this stirrer where appropriate. Place the stirrer and its parts into the original

packing to protect and prevent damage during transport. Follow shipping directions provided by Caframo when return is authorized and RMA issued.

CAUTION:

Failure to clean, service, and handle the stirrer as outlined above can cause it

to fail which could impair the safety of the user.

9

Warranty and Product Liability

Warranty

Caframo warrants the herein described product of its manufacture for three years

from receipt of the equipment by the purchaser, against defects in material and

workmanship. Warranty registration is available on the Service and Support page

of our website (www.CaframoLabSolutions.com).

This limited warranty covers parts and labour. If the stirrer housing is opened, the

warranty becomes void.

This warranty may only be altered by a specically published amendment. No

individual has authorization to alter the provisions of this warranty policy or its

amendments. Expendable items are not covered by this warranty. Damages due

to corrosion or accidental breakage are not covered.

Product Liability

Under no circumstances shall Caframo be liable for indirect, consequential, or special damages of any kind.

Caframo reserves the right to make technical changes without prior notice.

Accessories

The following accessories are available for purchase.

Shaft and Impellers - Part No. S100

(1) Mixing shaft, 186 x 6.35 mm (7 3/8 x 0.24)

(1) Radial blade, 12.7 x 30.5 mm (0.4 x 1.1 in)

(1) Axial blade, 12.7 x 30.5 mm (0.4 x 1.1 in)

Stand - Part No. A215

(1) Base

(1) Hollow stand rod with lock nut, 495 x 9.5 mm (19.7 x 3/8 in)

10

Index Langue

Anglais ...................................................................................................................1

Français ..............................................................................................................11

Espanol ................................................................................................................21

Allemand ..............................................................................................................31

Sommaire

Index Langue 11

Liste de colisage 12

Introduction 12

Légende des étiquettes de sécurité 13

Consignes de sécurité 13

Instructions générales 14

Homologations 14

Installation 15

Environnement et conditions de fonctionnement 15

Auto Start (mise en marche automatique) 16

Dimensions 16

Données techniques 17

Capacités de couple 18

Consignes de fonctionnement 18

Nettoyage et maintenance 19

Garantie et responsabilité produit 20

Accessoires 20

11

Liste de colisage

Vérier que tous les éléments gurant dans la liste (BDC250 & BDC250U1) suivante sont contenus dans l’emballage. Ne pas jeter le contenant et l’emballage

tant que cette vérication n’a pas été effectuée. Il est recommandé de garder

l’emballage d’origine pour le transport et l’entreposage.

• Petit agitateur digital *

• Cordon d’alimentation *

• Manuel d’utilisation *

• Clé hexagonale, (2) vis de serrage

• Tige d’agitation

* Compris avec BDC250MU1 (moteur uniquement)

• (2) Tiges à hélices

• (2) Vis de verrouillage de l’hélice

• Base du statif

• Tige de soutien du statif et contreécrou

Alimentation universelle

• Inclus avec BDC250U1, BDC250MU1

• Prises interchangeables pour

a. Amérique du Nord / Mexique / Japon

b. Europe

c. Australie / Chine

d. Royaume-Uni / Singapour

• Mesures H 68 W 50 D 39,3 mm

• Conforme ROHS et marqué CE .

(a)

(d)

(c)

(b)

Introduction

Cet agitateur a été spécialement conçu pour une utilisation professionnelle en

laboratoire et pour une utilisation industrielle standard. Il permet, par une technique

d’agitation, de remuer des liquides aux propriétés et applications diverses et

variées.

L’appareil est équipé d’un moteur à courant continu sans balai à haut rendement.

La vitesse est constamment conservée grâce à une rétroaction permanente du

moteur. Lorsque les exigences de couple sont supérieures à celles de l’agitateur,

une protection électronique intégrée contre les surcharges évite que les

composants électroniques, le moteur et la transmission ne soient endommagés.

L’agitateur a été conçu pour être able et durable. L’appareil ne contient aucune

pièce d’usure et ne nécessite donc aucun entretien. Aucune pièce ne peut être

réparée par l’utilisateur.

12

Loading...

Loading...