Caframo BDC250 User Manual

Petite Digital Stirrer

English

Instruction Manual

pages 2-7

Espanõl

Manual de intrucciones

pages 14-19

Français

Mode d’emploi

pages 8-13

Deutsch

Bedienungsanleitung

pages 20-25

Contents

GENERAL INSTRUCTIONS ............................................ .......... 3

SAFETY INSTRUCTIONS ............................................... .......... 3

APPROVALS ................................................................... .......... 4

TECHNICAL DATA ........................................................... .......... 4

STIRRER DESCRIPTION ................................................ .......... 5

INSTALLATION ............................................................... .......... 5

ENVIRONMENTAL OPERATING CONDITIONS ............ .......... 6

GENERAL OPERATING INSTRUCTIONS ..................... .......... 6

CLEANING, SERVICE, TRANSPORT & STORAGE ...... .......... 6

WARRANTY AND PRODUCT LIABILITY ....................... .......... 7

PACKING LIST

Petite digital stirrer• Impeller shaft•

Power cord• (2) Impeller blades•

Stand base• (2) Impeller lock screws•

Stand support rod and lock nut• Instruction manual•

250PK004

Rev0 - 01/08

2

GENERAL INSTRUCTIONS

Read all safety instructions before operating.

Unpack the stirrer carefully. Ensure the stirrer is not damaged and verify

the contents against the packing list. If the stirrer is damaged or the

contents do not correspond with the packing list, notify your supplier

immediately.

Read the manual carefully! Make sure that all users read the manual

thoroughly before operating the stirrer. For further questions or inquiries,

please contact:

Caframo Ltd.

RR #2, Wiarton, Ontario, Canada N0H 2T0

Tel: (519) 534-1080

Toll free in USA and Canada: (800) 567-3556

Fax: (800) 209-6786

Email: labsales@caframo.com

Web site: www.caframo.com

SAFETY INSTRUCTIONS

Each operator should read all instruction before using this device.

The stirrer must be securely xed to a stable support such as the

provided stand. If other stands are used, the unit must be secured such

that it will not fall if tipped.

CAUTION: This is not an explosion-proof stirrer. Do not use in a highly

ammable or explosive environment.

Spinning paddles or impellers can cause severe personal injuries.

Operators must use extreme care and good judgment when mixing at

any speed.

All mixing paddles and impellers must be in good condition with straight

shafts. If the stirrer vibrates at high speeds, check the paddle shaft for

damage, and repair or replace if needed.

Extreme care must be taken when mixing chemicals to ensure that no

chemicals are splashed outside the mixing vessel. Care must be taken

when changing to faster mixing speeds.

Ensure that the mixing impeller does not contact the containment vessel.

Do not operate while standing in water. Keep the unit dry and do not

immerse any part, except the mixing paddle into any liquids. Protect unit

and operator from splashing.

3

Ensure that no loose clothing, jewelry, or hair can become entangled in

any rotating parts. A fast spinning chuck can cause injury to operator.

Power can be interrupted to the stirrer by pressing the power button. In

an emergency, disconnect the main power cord.

APPROVALS

North American

Constructed in accordance with CAN/CSA-C22.2 (1010),

FCC 15/ICES-003/EN 55011

Tested to the same standards as IEC61010.

European

Constructed in accordance with EMC/EMI standard EN613261:2006 (EN55011, conducted and radiated emissions, EN610003-2, EN61000-4-2, EN61000-4-3, EN61000-4-4, EN61000-4-5,

EN61000-4-6)

RoHS and WEEE compliant.

TECHNICAL DATA

Model Number BDC250

Speed range 50 To 2500 rpm

Maximum torque 10 Ncm

Mechanical output power 1/100 hp, 7 watts

Input to power supply AC 100 to 240 volts, 50/60 hz (must use

supplied Caframo power cord)

Electrical output from power

supply to stirrer

Weight - stirrer only

Weight - total package

Maximum volume 2 liters, water-like viscosity

Molded housing Chemical-resistant, high-impact nylon.

Keypad Waterproof, chemical-resistant polyester

Power cord length 6 ft

Keyless chuck Fits 6 mm shaft

LED display accuracy ±10 rpm, 4 digit

Technical specications subject to change without notice.

DC 24 V, 0.5 A

0.9 lbs (.4 kgs)

3.1 lbs (1.42 kgs)

Recyclable (PA).

4

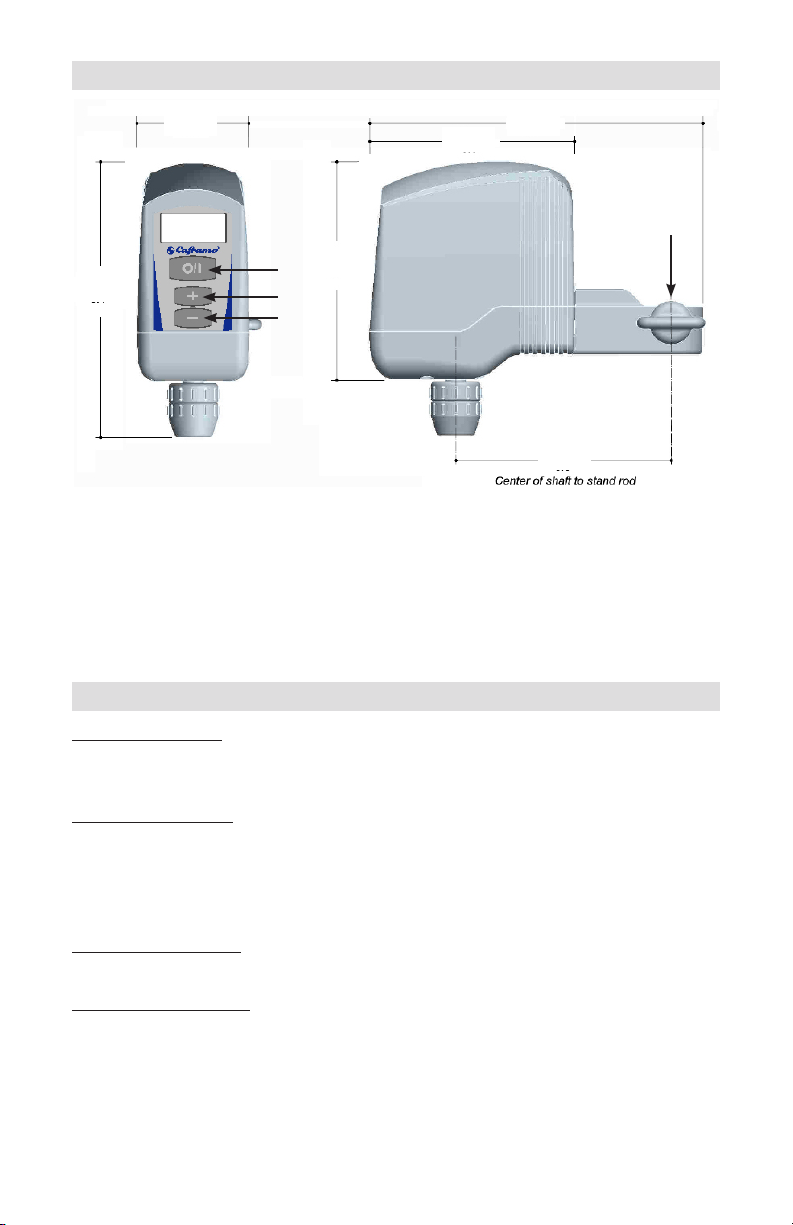

STIRRER DESCRIPTION

2.1”

53 mm

3.8”

96 mm

6.2”

157 mm

Ô

Õ

5.1”

130 mm

Î

4.0”

102 mm

Ï

Ó

Ð

Ñ

Ò

3.9”

100 mm

Four-digit LED display

Î

Button - power on/off

Ï

Button - increase rpm

Ð

Button - decrease rpm

Ñ

Keyless chuck

Ò

Housing

Ó

Clamp opening

Ô

Clamp knob

Õ

INSTALLATION

Stand Assembly

Remove lock nut. Insert the threaded end of the stand rod into the stand

base. Turn rod clockwise to tighten. Secure with lock nut.

Stirrer Installation

Slide the clamp opening over the top of the stand rod. Lower to desired

height. Turn clamp knob to securely tighten the stirrer onto the stand

rod. Connect supplied power cord to stirrer. Connect power cord to a

grounded electrical outlet.

Impeller Assembly

Add impeller blade(s) to impeller shaft. Tighten screw to secure.

Impeller Installation

Turn lower half of chuck to open. Do not remove completely. Insert

impeller end into chuck opening until it stops. Turn lower half of chuck

(nger tight) to close chuck and secure impeller.

5

ENVIRONMENTAL OPERATING CONDITIONS

The BDC250 stirrer must operate in the following conditions:

Indoors

•

Altitudes not exceeding 2000 meters

•

Temperature from 41 to 104°F (5 to 40°C)

•

Maximum relative humidity 80% for temperatures up to 87°F (31°C)

•

decreasing linearly to 50% relative humidity at 104°F (40°C)

Pollution degree 2 in accordance with IEC 664 “Normally only

•

non-conductive pollution occurs. Occasionally, however, temporary

conductivity caused by condensation may be expected.”

GENERAL OPERATING INSTRUCTIONS

The stirrer must be securely mounted as specied in the installation

instructions. Ensure the mixing shaft and blade are securely attached.

The stirrer is now ready for use to mix liquids.

Button Operation Functions:

Power Button - Turns the stirrer motor on and off.

When initially turned on, stirrer will spin at 50 rpm.

Increase Button - Increases the speed.

Decrease Button - Decreases the speed.

OL Indicates an overload condition. The load is too great for the

stirrer and must be reduced. To reset stirrer turn power off

and back on.

CLEANING, SERVICE, TRANSPORT & STORAGE

Cleaning

Using a mild soap and water solution, wipe the housing and control

panel of the stirrer with a damp cloth. Do not use chlorine bleach,

chlorine-based cleanser, abrasives, ammonia, steel wool, or scouring

pads with metal content or similar harsh solvents or abrasives. These

may damage the surface of the instrument.

Service

Do not attempt to service or repair a Caframo stirrer. If the stirrer

housing is opened, the warranty becomes void. Contact Caframo for

return authorization and return instructions.

6

Transport and Storage

Clean stirrer so that it is free from any materials which may be harmful.

Provide an MSDS or other safety data sheets for all chemicals used in

conjunction with this stirrer where appropriate. Place the stirrer and its

parts into the original packing to protect and prevent damage during

transport. Seal the original packing with packing tape. Store the packed

stirrer in a dry place.

CAUTION: Failure to clean, service, and handle the stirrer

as outlined above can cause it to fail which could impair the

safety of the user.

WARRANTY AND PRODUCT LIABILITY

Warranty

Caframo warrants the herein described product of its manufacture for

three years from receipt of the equipment by the purchaser, against

defects in material and workmanship. Warranty registration is available

on-line at www.caframo.com or ll out the supplied warranty registration

card.

This limited warranty covers parts and labor. If the stirrer housing is

opened, the warranty becomes void.

This warranty may only be altered by a specically published

amendment. No individual has authorization to alter the provisions of this

warranty policy or its amendments. Expendable items are not covered by

this warranty. Damages due to corrosion or accidental breakage are not

covered.

Liability

Under no circumstances shall Caframo be liable for indirect,

consequential, or special damages of any kind.

Caframo reserves the right to make technical changes without prior

notice.

7

Sommaire

CONSIGNES GENERALES ........................................................ 9

CONSIGNES DE SECURITE ..................................................... 9

HOMOLOGATIONS .................................................................10

DONNEES TECHNIQUES ........................................................ 10

DESCRIPTION DE L’AGITATEUR ............................................ 11

INSTALLATION ........................................................................ 11

ENVIRONNEMENT ET CONDITIONS

DE FONCTIONNEMENT .......................................................... 12

CONSIGNES GENERALES DE FONCTIONNEMENT ............ 12

NETTOYAGE, ENTRETIEN, TRANSPORT & STOCKAGE ..... 13

GARANTIE ET RESPONSABILITÉ PRODUIT ........................14

LISTE DE COLISAGE

Petit agitateur digital • Tige à hélice•

Cordon d’alimentation • (2) Tiges à hélices •

Base du statif • (2) Vis de verrouillage de l’hélice •

Tige de soutien du statif et

• Manuel d’utilisation •

contre-écrou

8

Loading...

Loading...