CAEN

Tools for Discovery

n

Electronic Instrumentation

User Manual UM3148

DT5730/DT5725

8-Channel 14-bit 500/250 MS/s Digitizer

Rev. 2 - 10 June 2016

Purpose of this Manual

This document contains the full hardware description of the DT5730 and DT5725 digitizers and the principle of operating as

Waveform Digitizer (based on the hereafter called default firmware).

Firmware version of reference: rel. 4.8_0.5

For any reference to registers in this user manual, please refer to document [RD2] at the digitizer web page.

Change Document Record

Date

Revision

Changes

14 February 2014

00

Initial release

15 December 2014

01

Added new § 6 on cooling management and § 7 on temperature protection.

Updated § Trigger Management. General revision.

10 June 2016

02

Fully reviewed to the new DT5725 digitizer (250 MS/s). Updated § 1, § 3, § 5,§ 8, §

Clock Distribution, § PLL Mode, § Trigger Clock, § Channel Calibration, § Custom

Sized Events, § Event Structure, § Trigger Distribution, § DPP-PSD Control

Software, § 13. Added § Changing the ADC Frequency, § CAENScope, §

MC²Analyzer (MC²A)

Symbols, abbreviated terms and notation

GUI

Graphical User Interface

DPP

Digital Pulse Processing

ETTT

Extended Trigger Time Tag

OS

Operating System

PSD

Pulse Shape Discrimination

TTT

Trigger Time Tag

Reference Documents

[RD1] GD2512 – CAENUpgrader QuickStart Guide

[RD2] UM5118 – 725-730 Families Default Firmware Registers

[RD3] GD2783 – First Installation Guide to Desktop Digitizers & MCA

[RD4] UM1934 - CAENComm User & Reference Manual

[RD5] UM1935 - CAENDigitizer User & Reference Manual

[RD6] UM2091 - CAEN WaveDump User Manual

[RD7] GD2483 - WaveDump QuickStart Guide

[RD8] UM2092 - CAENSCOPE User Manual

[RD9] UM2580 - Digital Pulse Shape Discriminator (DPP-PSD) User Manual

[RD10] UM3182 - DPP-PHA and MC

2

Analyzer User Manual

[RD11] GD2728 – How to make Coincidences with CAEN Digitizers

All documents can be downloaded at: http://www.caen.it/csite/LibrarySearch.jsp

CAEN S.p.A.

Via Vetraia, 11 55049 Viareggio (LU) - ITALY

Tel. +39.0584.388.398 Fax +39.0584.388.959

info@caen.it

www.caen.it

© CAEN SpA – 2016

Disclaimer

No part of this manual may be reproduced in any form or by any means, electronic, mechanical, recording, or

otherwise, without the prior written permission of CAEN SpA.

The information contained herein has been carefully checked and is believed to be accurate; however, no responsibility

is assumed for inaccuracies. CAEN SpA reserves the right to modify its products specifications without giving any

notice; for up to date information please visit www.caen.it.

MADE IN ITALY : We stress the fact that all the boards are made in Italy because in this globalized world, where getting

the lowest possible price for products sometimes translates into poor pay and working conditions for the people who

make them, at least you know that who made your board was reasonably paid and worked in a safe environment. (this

obviously applies only to the boards marked "MADE IN ITALY", we cannot attest to the manufacturing process of "third

party" boards).

CAEN

Electronic Instrumentation

UM3148 – DT5730/DT5725 User Manual rev. 2

4

Index

Purpose of this Manual ....................................................................................................................... 2

Change Document Record ................................................................................................................ 2

Symbols, abbreviated terms and notation ....................................................................................... 2

Reference Documents ........................................................................................................................ 2

Index ........................................................................................................................................ 4

List of Figures......................................................................................................................... 5

List of Tables .......................................................................................................................... 5

1 Introduction ..................................................................................................................... 6

2 Block Diagram ................................................................................................................ 8

3 Technical Specifications ............................................................................................... 9

4 Packaging and Compliancy ........................................................................................ 10

5 Power Requirements ................................................................................................... 11

6 Cooling Management ................................................................................................... 12

7 Temperature Protection .............................................................................................. 13

8 Panels Description ....................................................................................................... 14

Front Panel ......................................................................................................................................... 15

Rear Panel .......................................................................................................................................... 18

9 Functional Description ................................................................................................ 19

Analog Input Stage ............................................................................................................................ 19

Clock Distribution ............................................................................................................................... 20

PLL Mode............................................................................................................................................ 21

Changing the ADC Frequency......................................................................................................... 21

Trigger Clock ...................................................................................................................................... 21

Acquisition Modes ............................................................................................................................. 22

Channel Calibration ..................................................................................................................................... 22

Acquisition Run/Stop .................................................................................................................................. 26

Acquisition Triggering: Samples & Events ........................................................................................... 27

Multi-Event Memory Organization ........................................................................................................... 28

Custom Sized Events .....................................................................................................................................................28

Event Structure ............................................................................................................................................. 29

Event Format Example ...................................................................................................................................................30

Acquisition Synchronization ..................................................................................................................... 31

Trigger Management ......................................................................................................................... 32

Software Trigger ........................................................................................................................................... 32

External Trigger ............................................................................................................................................ 32

Self-Trigger .................................................................................................................................................... 33

Trigger Coincidence Level ......................................................................................................................... 35

Trigger Distribution ..................................................................................................................................... 39

Example ...........................................................................................................................................................................40

Reset, Clear and Default Configuration ......................................................................................... 41

Global Reset .................................................................................................................................................. 41

Memory Reset ............................................................................................................................................... 41

Timer Reset .................................................................................................................................................... 41

Data Transfer Capabilities ................................................................................................................ 42

Block Transfers ............................................................................................................................................ 42

Single Data Transfer .................................................................................................................................... 42

Optical Link and USB Access .......................................................................................................... 43

10 Drivers & Libraries ....................................................................................................... 44

Drivers ................................................................................................................................................. 44

Libraries .............................................................................................................................................. 44

11 Software Tools .............................................................................................................. 46

CAEN

Electronic Instrumentation

UM3148 – DT5730/DT5725 User Manual rev. 2

5

CAENUpgrader .................................................................................................................................. 46

CAENComm Demo ........................................................................................................................... 47

CAEN WAVEDump ........................................................................................................................... 48

CAENScope ....................................................................................................................................... 49

DPP-PSD Control Software ............................................................................................................. 50

MC²Analyzer (MC²A) ......................................................................................................................... 51

12 HW Installation.............................................................................................................. 52

Power-on Sequence .......................................................................................................................... 52

Power-on Status ................................................................................................................................ 52

13 Firmware and Upgrades .............................................................................................. 53

Default Firmware Upgrade ............................................................................................................... 54

Upgrade Files Description ......................................................................................................................... 54

DPP Firmware Upgrade .............................................................................................................................. 54

Upgrade File Description ...............................................................................................................................................54

14 Technical Support ........................................................................................................ 55

Returns and Repairs ......................................................................................................................... 55

Technical Support Service ............................................................................................................... 55

List of Figures

Fig. 2.1: Block Diagram ........................................................................................................................................................................8

Fig. 4.1: Front view .............................................................................................................................................................................10

Fig. 5.1: AC/DC power supply provided with the module ..............................................................................................................11

Fig. 8.1: Front panel view ..................................................................................................................................................................14

Fig. 8.2: Rear panel view ...................................................................................................................................................................14

Fig. 9.1: Analog Input Diagram .........................................................................................................................................................19

Fig. 9.2: Clock Distribution Diagram .................................................................................................................................................20

Fig. 9.3: Typical channel before the calibration (A and B) and after the calibration (C) ...........................................................22

Fig. 9.4: Automatic calibration at WaveDump first run ..................................................................................................................24

Fig. 9.5: Temperature monitoring with manual calibration in WaveDump software ..................................................................24

Fig. 9.6: Channel calibration in DPP-PSD Control Software ........................................................................................................25

Fig. 9.7: Channel calibration in MC2Analyzer software .................................................................................................................25

Fig. 9.8: Trigger overlap .....................................................................................................................................................................27

Fig. 9.9: Block Diagram of the trigger management ......................................................................................................................32

Fig. 9.10: Self Trigger and Trigger Request logic for Ch0 and Ch1 couple. A single trigger request signal is generated...33

Fig. 9.11: Channel over/under threshold signal ..............................................................................................................................33

Fig. 9.12: Channel pulse signal ........................................................................................................................................................34

Fig. 9.13: Trigger request management at mezzanine level with Majority level = 0 .................................................................36

Fig. 9.14: Trigger request management at motherboard level with Majority level = 0 ..............................................................36

Fig. 9.15: Trigger request relationship with Majority level = 1 and T

TVAW

≠ 0 .............................................................................37

Fig. 9.16: Trigger request relationship with Majority level = 1 and T

TVAW

= 0 .............................................................................38

Fig. 9.17: Trigger configuration on GPO front panel output connector .......................................................................................39

Fig. 10.1: Required libraries and drivers ..........................................................................................................................................45

Fig. 11.1: CAENUpgrader Graphical User Interface ......................................................................................................................46

Fig. 11.2: CAENComm Demo Java and LabVIEW graphical interface .......................................................................................47

Fig. 11.3: CAEN WaveDump ............................................................................................................................................................48

Fig. 11.4: CAENScope main frame ..................................................................................................................................................49

Fig. 11.5: DPP-PSD Control Software: Top – DPP settings Tab and typical 60Co Total Charge Spectrum; Bottom - PSD

2-D Scatter Plot ...................................................................................................................................................................................50

Fig. 11.6: MC²Analyzer (MC²A) software tool .................................................................................................................................51

Fig. 12.1: Front panel LEDs status at power ON............................................................................................................................52

List of Tables

Tab. 1.1: Table of models and related items .....................................................................................................................................7

Tab. 3.1: Specifications table ..............................................................................................................................................................9

Tab. 9.1: Buffer Organization ............................................................................................................................................................28

Tab. 9.2: TRG OPTIONS configuration table .................................................................................................................................29

Tab. 9.3: Event Format Example ......................................................................................................................................................30

CAEN

Electronic Instrumentation

UM3148 – DT5730/DT5725 User Manual rev. 2

6

1 Introduction

The DT5730 is a Desktop module housing a 8-channel 14-bit 500 MS/s FLASH ADC Waveform Digitizer with software

selectable 2 Vpp or 0.5 Vpp input dynamic range on single ended MCX coaxial connectors. The DC offset is adjustable in

the ±1 V (@ 2 Vpp) or ±0.25 (@ 0.5 Vpp) range via a 16-bit DAC on each channel (see § Analog Input Stage).

Operationally, the mod. DT5725 differs from the DT5730 for working at 250 MS/s sampling frequency.

The ADC resolution and the sampling frequency make these digitizers well suited for mid-fast signal detection systems

(e.g. liquid or inorganic scintillators coupled to PMTs or Silicon Photomultipliers).

Each channel has a SRAM Multi-Event Buffer divisible into 1 ÷ 1024 buffers of programmable size. Two sizes of the

channel digital memory are available by ordering option (see Tab. 1.1).

DT5730 and DT5725 digitizers are provided with FPGAs that can run special DPP firmware for Physics Applications (see

§ 13).

A common acquisition trigger signal can be fed externally via the front panel TRG-IN input connector or via software.

Alternatively, each channel is able to generate a self-trigger when the input signal goes under/over a programmable

threshold. For each couple of adjacent channels, the relevant self-triggers are then processed to provide out a single

trigger request. In the DPP firmware, the trigger requests can be used at channel level for the event acquisition

(independent triggering), while in the default firmware they can be processed by the board to generate a common

trigger causing all the channels to acquire an event simultaneously. The trigger from one board can be propagated to

the other boards through the front panel GPO output connector.

During the acquisition, the data stream is continuously written in a circular memory buffer. When the trigger occurs,

the digitizer writes further samples for the post trigger and freezes the buffer that can be read by one of the provided

readout links. The acquisition can continue without any dead time in a new buffer.

DT5730 and DT5725 feature front panel CLK-IN connector as well as an internal PLL for clock synthesis from

internal/external references. Multi-board synchronization is supported, so all DT5730 or all DT5725 can be

synchronized to a common clock source and ensuring Trigger time stamps alignment. The fan-in of an external clock

signal to each CLK-IN is required. Once synchronized, all data will be aligned and coherent across the multi-board

system.

Each module houses USB 2.0 and Optical Link interfaces. USB 2.0 allows data transfers up to 30 MB/s. The Optical Link

(CAEN proprietary CONET protocol) supports transfer rate of 80 MB/s and offers Daisy chain capability. Therefore, it is

possible to connect up to 8 ADC modules to a single A2818 Optical Link Controller, or up to 32 using a A3818 (4-link

version). Optical Link and USB accesses are internally arbitrated.

CAEN

Electronic Instrumentation

UM3148 – DT5730/DT5725 User Manual rev. 2

7

Board Models

Description

Product Code

DT5730

DT5730 - 8 ch. 14bit 500 MS/s Digitizer: 640kS/ch,CE30, SE

WDT5730XAAAAA

DT5730B

DT5730B - 8 ch. 14bit 500 MS/s Digitizer: 5.12MS/ch,CE30, SE

WDT5730BXAAAA

DT5725

DT5725 - 8 ch. 14bit 250 MS/s Digitizer: 640kS/ch,CE30, SE

WDT5725XAAAAA

DT5725B

DT5730B - 8 ch. 14bit 250 MS/s Digitizer: 5.12MS /ch,CE30, SE

WDT5725BXAAAA

DPP Firmware⁽*⁾

Description

Product Code

DPP-PSD

(730 family)

DPP-PSD - Digital Pulse Processing for Pulse Shape Discrimination (x730)

WFWDPPNGAA30

DPP-PSD

(725 family)

DPP-PSD - Digital Pulse Processing for Pulse Shape Discrimination (x725)

WFWDPPNGAA25

DPP-PHA

(730 family)

DPP-PHA - Digital Pulse Processing for Pulse Height Analysis (x730)

WFWDPPTFAA30

DPP-PHA

(725 family)

DPP-PHA - Digital Pulse Processing for Pulse Height Analysis(x725)

WFWDPPTFAA25

Related Products

Description

Product Code

A2818

A2818 – PCI Optical Link (Rhos compliant)

WA2818XAAAAA

A3818A

A3818A – PCIe 1 Optical Link

WA3818AXAAAA

A3818B

A3818B – PCIe 2 Optical Link

WA3818BXAAAA

A3818C

A3818C – PCIe 4 Optical Link

WA3818CXAAAA

Accessories

Description

Product Code

A317

Clock Distribution Cable

WA317XAAAAAA

A318

SE to Differential Clock Adapter

WA318XAAAAAA

A654

Single Channel MCX to LEMO Cable Adapter

WA654XAAAAAA

A654 KIT4

4 MCX TO LEMO Cable Adapter

WA654K4AAAAA

A654 KIT8

8 MCX TO LEMO Cable Adapter

WA654K8AAAAA

A659

A659 - Single Channel MCX to BNC Cable Adapter

WA659XAAAAAA

A659 KIT4

4 MCX TO BNC Cable Adapter

WA659K4AAAAA

A659 KIT8

8 MCX TO BNC Cable Adapter

WA659K8AAAAA

AI2730

Optical Fibre 30 m simplex

WAI2730XAAAA

AI2720

Optical Fibre 20 m simplex

WAI2720XAAAA

AI2705

Optical Fibre 5 m simplex

WAI2705XAAAA

AI2703

Optical Fibre 30 cm simplex

WAI2703XAAAA

AY2730

Optical Fibre 30 m duplex

WAY2730XAAAA

AY2720

Optical Fibre 20 m duplex

WAY2720XAAAA

AY2705

Optical Fibre 5 m duplex

WAY2705XAAAA

Tab. 1.1: Table of models and related items

⁽*⁾ Multi-license packs are also available. Please, refer to the Digitizer web page for the relevant ordering options.

CAEN

Electronic Instrumentation

UM3148 – DT5730/DT5725 User Manual rev. 2

8

2 Block Diagram

DAC

AMC [FPGA]

ADC &

MEMORY

CONTROLLER

ADC

BUFFERS

x8 channels

ROC [FPGA]

- Readout Controller

- Optical link Interface

- USB interface

- Global Trigger Logic

- I/O Control Logic

MUX

OSC

CLOCK

MANAGER

(AD9520)

LOCAL BUS

CLK IN

TRG IN

GPI

USB

INPUTS

FRONT PANEL

GPO

OPTICAL LINK

G1 or G4

PGA

Fig. 2.1: Block Diagram

CAEN

Electronic Instrumentation

UM3148 – DT5730/DT5725 User Manual rev. 2

9

3 Technical Specifications

GENERAL

Form Factor 154x50x164 mm3 (WxHxD) Desktop

ANALOG INPUT

Channels

8 channels

Single ended

Connector

MCX

Bandwidth

250 MHz (DT5730)

125 MHz (DT5725)

Impedance

Zin = 50 Ω

Full Scale Range

0.5 or 2 Vpp (default)

SW selectable

Offset

Programmable 16-bit

DAC for DC offset

adjustment on each

channel.

Range: ±1 V (@2Vpp);

±0.25 V (@0.5Vpp)

DIGITAL CONVERSION

Resolution

14 bits

Sampling Rate

500 MS/s Simultaneously on each channel (DT5730

250 MS/s Simultaneously on each channel (DT5725)

ADC CLOCK GENERATION

Clock source: internal/external

On-board programmable PLL provides generation of the main board clocks from an internal (50 MHz

local Oscillator) or external (front panel CLK-IN connector) reference

DIGITAL I/O

CLK-IN (AMP Modu II)

AC coupled differential input clock.

LVDS, ECL, PECL, LVPECL, CML

(single ended NIM/TTL available by CAEN

adapter)

Jitter<100ppm requested

TRG-IN (LEMO)

External trigger digital input

NIM/TTL, Z

in

= 50 Ω

GPO (LEMO)

General purpose digital output

NIM/TTL, Rt = 50 Ω

GPI (LEMO)

General purpose digital input

NIM/TTL, Zin = 50 Ω

MEMORY

640 kS/ch or 5.12 MS/s Multi-event Buffer divisible into 1 ÷ 1024 buffers

Independent read and write access; programmable event size and pre/post-trigger

TRIGGER

Trigger Source

Self-trigger: channel over/under-

threshold for Common or Individual (DPP

firmware only) Trigger generation

External-trigger: Common trigger by

TRG-IN connector

Software-trigger: Common trigger by

software command

Trigger Propagation

GPO programmable digital output

Trigger Time Stamp

Default FW: 31-bit counter, 16 ns resolution, 17 s range;

48-bit extension available by firmware

DPP-PHA/DPP-PSD FW (DT5730): 31-bit counter, 2 ns

resolution, 4 s range; 47-bit extension available by

firmware; 10-bit and 2 ps fine time stamp by digital CFD

(DPP-PSD FW only); 64-bit extension available by software

DPP-PHA/DPP-PSD FW (DT5725): 31-bit counter, 4 ns

resolution, 8 s range; 47-bit extension available by

firmware; 10-bit and 4 ps fine time stamp by digital CFD

(DPP-PSD FW only); 64-bit extension available by software

SYNCHRONIZATION

Clock Propagation

One-to-many: clock distribution from an

external clock source on CLK-IN

connector

Acquisition Synchronization

Sync, Start/Stop through digital I/O (TRG-IN or GPI input,

GPO output)

Trigger Time Stamps Alignment

By GPI input connector

ADC & MEM. CONTROLLER

Altera Cyclone EP4CE30 (one FPGA serves 4 channels)

COMMUNICATION

INTERFACE

Optical Link

CAEN CONET proprietary protocol

Up to 80 MB/s transfer rate

Daisy chainable: it is possible to

connect up to 8 or 32 ADC modules to a

single Optical Link Controller

(respectively A2818 or A3818)

USB

USB 2.0 compliant

Up to 30 MB/s transfer rate

DPP FW SUPPORTED

DPP-PSD for the Pulse Shape Discrimination (e.g. Neutron-Gamma discrimination)

DPP-PHA for the Pulse Height Analysis

FIRMWARE UPGRADE

Firmware can be upgraded via USB/Optical Link

SOFTWARE

General purpose C libraries, configuration tools, readout software (Windows and Linux support)

POWER CONSUMPTIONS

DT5730

2.8 A @ 12 V (Typ.)

DT5725

t.b.d. Tab. 3.1: Specifications table

CAEN

Electronic Instrumentation

UM3148 – DT5730/DT5725 User Manual rev. 2

10

4 Packaging and Compliancy

DT5725 and DT5730 modules are Desktop boards housed in a 154 W x 50 H x 164 D mm³ alloy box.

Fig. 4.1: Front view

CAUTION: to manage the product, consult the operating instructions provided.

A POTENTIAL RISK EXISTS IF THE OPERATING INSTRUCTIONS ARE NOT

FOLLOWED!

CAEN provides the specific document “Precautions for Handling, Storage and

Installation” available in the documentation tab of the product web page that the user

is mandatory to read before to operate with CAEN equipment.

CAEN

Electronic Instrumentation

UM3148 – DT5730/DT5725 User Manual rev. 2

11

5 Power Requirements

Both DT5725 and DT5730 modules are powered by the external AC/DC stabilized power supply provided with the

digitizer and included in the delivered kit.

The DT5730 typical power consumption is 2.8 A (@ +12 V).

Note.: Using a different power supply source, like battery or linear type, it is recommended the source to provide +12

V and, at least, 3.5 A in case of DT5730; the power jack is a 2.1 mm type, a suitable cable is the RS 656-3816 type (or

similar)

Fig. 5.1: AC/DC power supply provided with the module

CAEN

Electronic Instrumentation

UM3148 – DT5730/DT5725 User Manual rev. 2

12

6 Cooling Management

Starting from revision 4 of the motherboard (readable at 0xF04C address of the Configuration ROM), DT5730 and

DT5725 feature an automatic fan speed control to guarantee an appropriate cooling in consequence of internal

temperature variations. The automatic control is managed by the ROC FPGA firmware from revision 4.4 on.

CAEN HEARTLY RECOMMENDS TO MONITOR THE TEMPERATURE OF THE ADC CHIPS DURING THE BOARD

OPERATION BY READING AT REGISTER ADDRESS 0x1nA8.

The user can manually set the fan speed through the bit[3] at register address 0x8168 (refer to [RD2]):

Hardware revision ≥ 4 and ROC FPGA firmware revision ≥ 4.4

• Bit[3] = 0 (default) sets the automatic fan speed control;

• Bit[3] = 1 sets HIGH the fan speed.

Hardware revision < 4 and ROC FPGA firmware revision < 4.4

• Bit[3] = 0 (default) sets LOW the fan speed;

• Bit[3] = 1 sets HIGH the fan speed.

WARNING: It is recommended not to run ROC FPGA firmware revision < 4.4 on DT5730 or DT5725 with hardware

revision ≥ 4 as the fans will work always at the maximum speed to prevent from hardware damages, but with a high

noisiness on the other hand.

CAEN

Electronic Instrumentation

UM3148 – DT5730/DT5725 User Manual rev. 2

13

7 Temperature Protection

TEMPERATURE PROTECTION IS NOT AVAILABLE FOR DEFAULT FIRMWARE RELEASES < 4.5_0.3 (REFER TO § 13)

To preserve hardware damages, DT5730 and DT5725 implement an automatic turning off of the board channels in

event of internal over-temperature. Internal temperature can be monitored through register address 0x1nA8.

The over-temperature limit is fixed at 70°C. As soon as the internal temperature exceeds 70°C, the board enters the

temperature protection condition and the firmware automatically performs the following actions:

• turns off all the channel ADCs;

• stops the acquisition, if running (data possibly stored at that moment can be readout in any case).

This status is valid as long as the internal temperature remains over 62°C. Starting from 61°C, the user is allowed to

turn on the channel ADCs again and restart the acquisition, if necessary.

The temperature protection can be controlled through register addresses 0x8104 and 0x81C0.

CAEN

Electronic Instrumentation

UM3148 – DT5730/DT5725 User Manual rev. 2

14

8 Panels Description

Fig. 8.1: Front panel view

Fig. 8.2: Rear panel view

CAEN

Electronic Instrumentation

UM3148 – DT5730/DT5725 User Manual rev. 2

15

Front Panel

ANALOG INPUT

FUNCTION

Input connectors (CH0 to CH7) receiving the

input analog signals.

ELECTRICAL SPECS

Input dynamics: 2 or 0.5 Vpp (SW selectable)

Input impedance (Zin): 50 Ω.

MECHANICAL SPECS

Series: MCX connectors.

Type: CS 85MCX-50-0-16.

Manufacturer: SUHNER

Suggested plug: MCX-50-2-16 type.

Suggested cable: RG174 type.

CLK IN

FUNCTION

Input connector for the external clock.

ELECTRICAL SPECS

Sign. type: differential (LVDS, ECL, PECL, LVPECL,

CML). CAEN provides single-ended to differential

A318 cable adapter (see Tab. 1.1) for CLK-IN.

Coupling: AC.

Z

diff

: 100 Ω.

MECHANICAL SPECS

Series: AMPMODU connectors.

Type: 3-102203-4 (3-pin).

Manufacturer: AMP Inc.

PINOUT

CLK IN LED (GREEN): indicates the external clock is enabled.

CAEN

Electronic Instrumentation

UM3148 – DT5730/DT5725 User Manual rev. 2

16

GPO

FUNCTION

General purpose programmable digital output

connector to propagate:

the internal trigger sources;

the channel probes (i.e. signals from the

mezzanines);

GPI signal

according to register addresses 0x8110 and

0x811C, or

the motherboard probes (i.e. signals

from the motherboard), like the Run

signal, ClkOut signal, ClockPhase signal,

PLL_Unlock signal or Busy signal

according to register address 0x811C.

ELECTRICAL SPECS

Signal level: NIM or TTL.

Requires 50 Ω termination.

MECHANICAL SPECS

Series: 101 A 004 connectors.

Type: DLP 101 A 004-28.

Manufacturer: FISCHER.

Alternatively:

Type: EPL 00 250 NTN.

Manufacturer: LEMO.

TRG IN

FUNCTION

Digital input connector for the external trigger.

ELECTRICAL SPECS

Signal level: NIM or TTL.

Input impedance (Zin): 50 Ω.

MECHANICAL SPECS

Series: 101 A 004 connectors.

Type: DLP 101 A 004-28.

Manufacturer: FISCHER.

Alternatively:

Type: EPL 00 250 NTN.

Manufacturer: LEMO.

GPI

FUNCTION

General purpose programmable input connector.

Can be used to reset the time stamp (see § Timer

Reset) or to start/stop the acquisition.

ELECTRICAL SPECS

Signal level: NIM or TTL.

Input impedance (Zin): 50 Ω.

MECHANICAL SPECS

Series: 101 A 004 connectors.

Type: DLP 101 A 004-28.

Manufacturer: FISCHER.

Alternatively:

Type: EPL 00 250 NTN.

Manufacturer: LEMO.

CAEN

Electronic Instrumentation

UM3148 – DT5730/DT5725 User Manual rev. 2

17

OPTICAL LINK PORT

FUNCTION

Optical LINK connector for data readout and flow

control. Daisy chainable. Compliant to Multimode

62.5/125μm cable featuring LC connectors on both

sides.

ELECTRICAL SPECS

Transfer rate: up to 80 MB/s.

MECHANICAL SPECS

Series: SFF Transceivers.

Type: FTLF8519F-2KNL (LC connectors).

Manufacturer: FINISAR.

PINOUT

LINK LEDs (GREEN/YELLOW): right LED (GREEN) indicates the network presence, while left LED (YELLOW) signals the

data transfer activity.

USB PORT

FUNCTION

USB connector for data readout and flow control.

ELECTRICAL SPECS

Standard: compliant to USB 2.0 and USB 1.0.

Transfer rate: up to 30 MB/s.

MECHANICAL SPECS

Series: USB connectors.

Type: 787780-2 (B-Type).

Manufacturer: AMP Inc.

USB LINK LED (GREEN): indicates the USB communication is active.

DIAGNOSTICS LEDs

TTL (GREEN): indicates the TTL standard is set for GPO, TRG IN, GPI;

NIM (GREEN): indicates the NIM standard is set for GPO, TRG IN, GPI;

PLL LOCK (GREEN): indicates the PLL is locked to the reference clock;

PLL BYPS (GREEN): indicates the PLL drives directly the ADCs. PLL circuit is

switched off and PLL LOCK LED is turned off;

RUN (GREEN): indicates the acquisition is running (data taking). See § Acquisition

Run/Stop;

TRG (GREEN): indicates the trigger is accepted.

DRDY (GREEN): indicates the event/data is present in the Output Buffer.

BUSY (RED): indicates all the buffers are full for at least one channel.

CAEN

Electronic Instrumentation

UM3148 – DT5730/DT5725 User Manual rev. 2

18

Rear Panel

SPARE LINK

FUNCTION

Auxiliary connector reserved for CAEN usage.

ELECTRICAL SPECS

Not available.

MECHANICAL SPECS

Series: Header connectors.

Type: 7610-5002-5+5.

Manufacturer: 3M.

DC INPUT

FUNCTION

Input connector for the desktop Digitizer main

power supply from the external AC/DC adapter.

ELECTRICAL SPECS

Typ. Input voltage: +12 VDC.

MECHANICAL SPECS

Series: CC power supply connectors

Type: RAPC722X (DC power jack).

Manufacturer: Switchcraft Inc.

PINOUT

C

ON/OFF SWITCH

FUNCTION

Panel switch for module power supply

ON/OFF:

O → power supply OFF.

I → power supply ON.

ELECTRICAL SPECS

Not available.

MECHANICAL SPECS

Series: A1 switches.

Type: A11331122000 (Single pole two way)

Manufacturer: Molveno.

IDENTIFYING LABEL

FUNCTION

Board’s identifying label indicating:

the model;

the serial number (S/N);

the symbol of the CE conformity marking.

CAEN

Electronic Instrumentation

UM3148 – DT5730/DT5725 User Manual rev. 2

19

9 Functional Description

Analog Input Stage

Input dynamics can be 2 V

pp

(default) or 0.5 V

pp

, by software selection (basing on the Programmable Gain Amplifier in

the scheme of Fig. 9.1), on single ended MCX coaxial connectors (see § 8). A 16-bit DAC allows to add a DC offset in

order to preserve the full dynamic range also in the extreme case of unipolar positive or negative input signal. The

input bandwidth ranges from DC to 250 MHz (@3dB) for DT5730, to 125 MHz (@3dB) for DT5725, by 2nd order linear

phase anti-aliasing low-pass filter.

+1.00

0

+2.00

-1.00

-2.00

Input Dynamic Range: 2 Vpp

Positive Unipolar

DAC = FSR

Negative Unipolar

DAC = 0

Bipolar

DAC = FSR/2

+0.25

0

-0.50

-0.25

-0.50

Input Dynamic Range: 0.5 Vpp

Positive Unipolar

DAC = FSR

Negative Unipolar

DAC = 0

Bipolar

DAC = FSR/2

MCX

OpAmp

50ohm

DAC

Vref

14 bit

ADC

Input

FPGA

16 bit

+

-

DC Offset

PGA

G1 or G4

Fig. 9.1: Analog Input Diagram

Setting the input range requires a write access at register address 0x1n28, while at register address 0x1n98 it is

possible to configure the DC offset level.

CAEN

Electronic Instrumentation

UM3148 – DT5730/DT5725 User Manual rev. 2

20

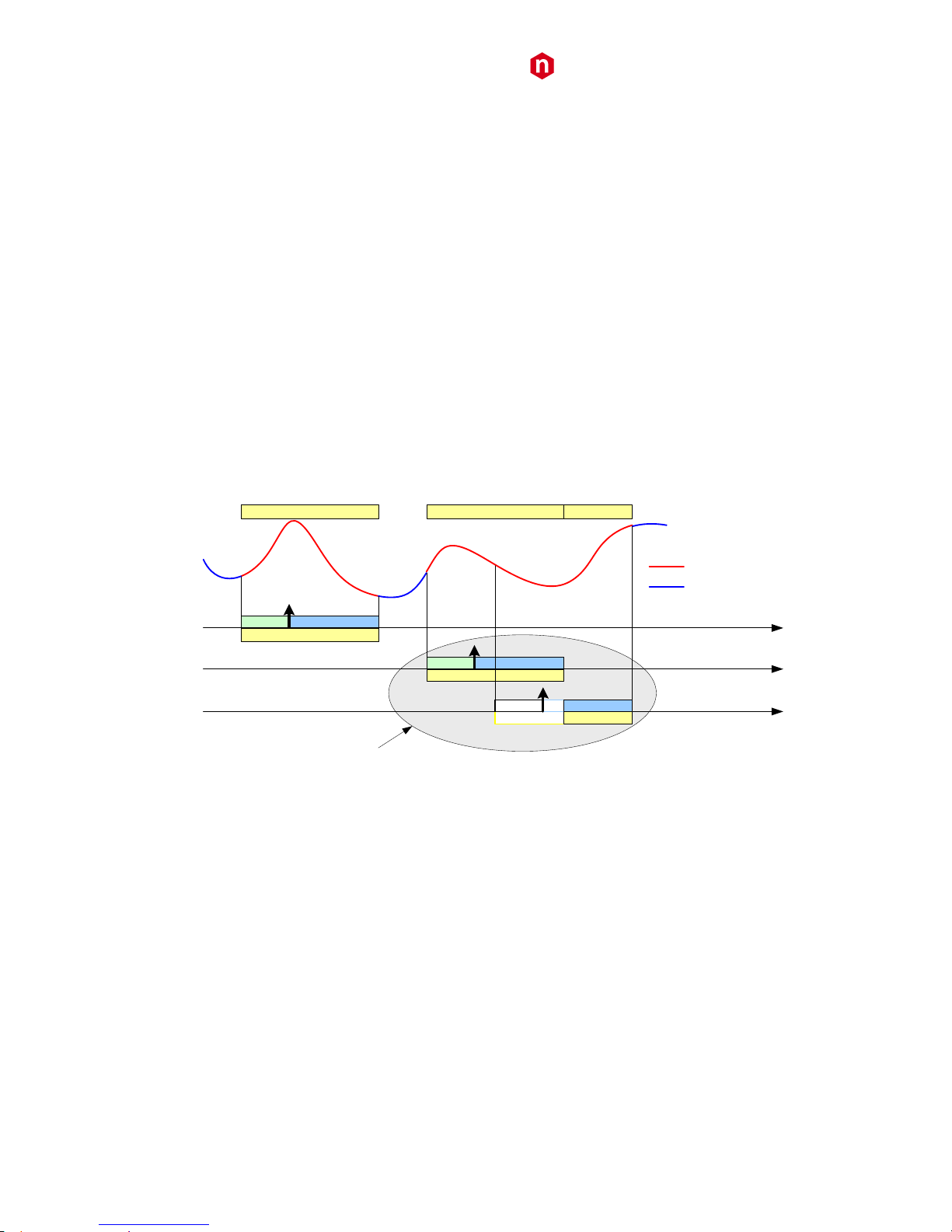

Clock Distribution

The module clock distribution takes place on two domains: OSC-CLK and REF-CLK; the former is a fixed 50MHz clock

provided by an on- board oscillator, the latter provides the ADC sampling clock.

OSC-CLK handles Local Bus (communication between motherboard and mezzanine boards; see red traces in Fig. 9.2).

REF-CLK handles ADC sampling, trigger logic, acquisition logic (samples storage into RAM, buffer freezing on trigger)

through a clock chain. Such domain can use either an external (via front panel signal on CLK-IN) or an internal (via local

oscillator) source; in the latter case, OSC-CLK and REF-CLK will be synchronous (the operation mode remains the same

anyway).

DT5730 and DT5725 use an integrated phase-locked-loop (PLL) and clock distribution device, AD9520. It is used to

generate the sampling clock for ADCs and the mezzanine FPGA (SAMP-CLK0/SAMP-CLK1), as well as the trigger logic

synchronization clock (TRG-CLK).

Both clocks can be generated from the internal oscillator (50 MHz) or from external clock input. By default, the board

uses the internal clock as PLL reference (REF-CLK).

The external clock can be selected by write access at register address 0x8100 (refer to [RD2]). The external clock signal

must be differential (LVDS, ECL, PECL, LVPECL, CML) with a jitter lower than 100ppm (see § Tab. 3.1).

AD9520 configuration can be changed and stored into non-volatile memory. Changing the AD9520 configuration is

primarily intended to be used for external PLL reference clock frequency change:

DT5730 and DT5725 lock to an external 50 MHz clock with default AD9520 configuration (see § PLL Mode).

Refer to the AD9520 datasheet for more details:

http://www.analog.com/static/imported-files/data_sheets/AD9520-3.pdf

(in case the active link above doesn’t work, copy and paste it on the internet browser)

MUX

OSC

CLK IN

50MHz

REF-CLK

Trigger & Sync

Logic

TRG IN

LOCAL BUS

Local Bus

Interface

Acquisition

& Memory

Control

Logic

MEZZANINE

TRIGGER

SYNC

LOCAL-TRGs

MUX

Phase

Detector

AD9520

CLK1

Sdiv

Sdiv

Rdiv

REFIN

INTCLK

CTRL

Ldiv

Odiv

Ndiv

SAMP-CLK0

FPGA (AMC)

ADC

CH7

SCLK

DATA

SYNC

SRAM

FIFO

ADC

CH0

SCLK

DATA

Ldel

Odel

Local Bus

Interface

FPGA (ROC)

SYNCB

TRG-CLK

SyncB

RAMCLK

DATA

FANOUT

OSC-CLK

SAMP-CLK1

4

DFF

VCXO

.

.

.

.

.

.

.

.

Fig. 9.2: Clock Distribution Diagram

CAEN

Electronic Instrumentation

UM3148 – DT5730/DT5725 User Manual rev. 2

21

PLL Mode

The Phase Detector within the AD9520 device allows to couple REF-CLK with a VCXO (500 MHz frequency) providing

out the nominal ADCs frequency (500 MHz for DT5730 and 250 MHz for DT5725); for this purpose, it is necessary that

REF-CLK is a submultiple of the VCXO frequency.

As introduced in § Clock Distribution, the source of the REF-CLK signal can be external (see Fig. 9.2) on CLK-IN front

panel connector or internal from the 50 MHz local oscillator. The following options are allowed:

1. 50 MHz internal clock source – It’s the standard operating mode, where the default AD9520 configuration

doesn’t require to be changed. OSC-CLK = REF-CLK.

2. 50 MHz external clock source – In this case it is not required to reprogram the AD9520 dividers, as the external

clock reference is identical to the frequency of the internal oscillator. CLK-IN = OSC-CLK = REF-CLK.

Note that, In order the board to sense the external signal on CLK-IN and use it as new reference, bit[6] at

register address 0x8100 must be set (see [RD2]).

3. External clock source different from 50 MHz – In this case, the user is required to program the AD9520 dividers

in order to lock the VCXO to REF-CLK in order to provide out the 500 MHz (DT5730) or 250 MHz (DT5725)

nominal sampling frequency. In principle, the allowed external frequencies are submultiples of the VCXO

frequency (500 MHz). CLK-IN = REF-CLK.

Note: the user who wants to work as in point 3, please contact CAEN indicating the required reference clock frequency

to check its feasibility and then receive the PLL programming file. The “Upgrade PLL” function in CAENUpgrader

software tool can be used to update the digitizer PLL. See § 11 for the program description and refer to [RD1] for

documentation. The programming file also takes care to set the board to sense the external signal on CLK-IN.

Changing the ADC Frequency

Please, contact CAEN (see § 14) for information on the feasibility to operate the DT5730/DT5725 with a sampling

frequency lower than the nominal.

Trigger Clock

TRG-CLK signal has a 125-MHz frequency, that is equal to 1/4 (DT5730) or 1/2 (DT5725) of SAMP-CLK. In consequence, a

4 samples (DT5730) or 2 samples (DT5725) “uncertainty” occurs over the acquisition window.

CAEN

Electronic Instrumentation

UM3148 – DT5730/DT5725 User Manual rev. 2

22

Acquisition Modes

Channel Calibration

The module performs a self-calibration of the ADCs at its power-on. Anyway, in order to achieve the best performance,

the calibration procedure is recommended to be executed by the user, on command, after the ADCs have stabilized

their operating temperature. The calibration will not need to be repeated at each run unless the operating

temperature changes significantly, or clock settings are modified (e.g. switching from internal to external clock).

A B

C

Fig. 9.3: Typical channel before the calibration (A and B) and after the calibration (C)

CAEN

Electronic Instrumentation

UM3148 – DT5730/DT5725 User Manual rev. 2

23

The diagram below schematizes the flow for a proper calibration:

BOARD

CONFIGURATION

Temperature or Clock

variation

Acquisition sessions

(n cycles)

POWER-ON

TEMPERATURE

STABILIZATION

LOOP

CALIBRATE

START RUN

STOP RUN

At low level, the ADCs temperature can be read at the register address 0x1nA8, while the calibration must be performed

through register address 0x809C. The following steps are required:

• Write whatever value at register address 0x809C: the self-calibration process will start simultaneously

on each channel of the board and the "Calibrating bit" flag of register address 0x1n88 will be set to 0.

• Poll the "Calibrating bit" flag until it returns to 1.

Note: It is normally not required to calibrate after a board reset but, if a Reset command is intentionally issued to the

digitizer (write access at register address 0xEF24) to be directly followed by a calibration procedure, it is recommended

to wait for the board to reach stable conditions (indicatively 100 ms) before to start the calibration.

At the library level, developers can exploit the CAENDigitizer library (see § 10) dedicated routines like ReadTemperature()

function for temperature readings, Set/GetChannelDCOffset for DC Offset management, Reset() function to reset the

board, and the Calibrate() function which executes the channel calibration steps above described.

IMPORTANT NOTE: Starting from CAENDigitizer release 2.6.1, the Reset() function has been modified so that it no

longer includes the channel calibration routine implemented in the code. This calibration must be performed on

command by the dedicated Calibrate() function. Please, see the Library user manual for reference ([RD5]).

CAEN

Electronic Instrumentation

UM3148 – DT5730/DT5725 User Manual rev. 2

24

At software level, CAEN manages the on command channel calibration in different readout software (please, refer the

relevant software User Manual for details).

➢ WaveDump

1. Lauch WaveDump. This software performs an automatic ADC calibration and displays a message when it is

completed (see Fig. 9.4).

Fig. 9.4: Automatic calibration at WaveDump first run

This allows the user to start using the program sure that the digitizer has been calibrated at least once.

NOTE THAT: If SKIP_STARTUP_CALIBRATION parameter is set to YES in WaveDump configuration file, the automatic

start-up calibration is not performed and no message is displayed

2. At any time, the user can check the channel temperatures (with the acquisition not running) by issuing multiple

“m” commands from the keyboard.

3. In case of significant variations, issuing a “c” command provokes a manual channel calibration to be executed

(see Fig. 9.5).

Fig. 9.5: Temperature monitoring with manual calibration in WaveDump software

4. A new acquisition can start.

Please, refer to WaveDump User Manual for complete software description ([RD6]).

CAEN

Electronic Instrumentation

UM3148 – DT5730/DT5725 User Manual rev. 2

25

➢ DPP-PSD Control Software

1. Launch DPP-PSD Control Software

2. Connect to the digitizer

3. Before to start the acquisition, go to the “Stats” tab and monitor the channel temperatures displayed in the

relevant column until you see they don’t vary significantly

4. Go to the “General” tab and press the “Calibrate” button

5. Start the acquisition

Fig. 9.6: Channel calibration in DPP-PSD Control Software

➢ MC

2

Analyzer

1. Launch MC

2

A

2. Connect to the digitizer

3. Before to start the acquisition, monitor the channel temperatures in Tools->ADC calibration

4. Press “Calibrate” button to perform the calibration

5. Start the acquisition

Fig. 9.7: Channel calibration in MC2Analyzer software

CAEN

Electronic Instrumentation

UM3148 – DT5730/DT5725 User Manual rev. 2

26

Acquisition Run/Stop

The acquisition can be started and stopped in different ways, according to bits[1:0] setting at register address 0x8100

and bit[2] of the same register:

- SW CONTROLLED (bits[1:0] = 00): Start and Stop take place by software command. Bit[2] = 0 means

stopped, while bit[2] = 1 means running.

- GPI CONTROLLED MODE (bits[1:0] = 01): If the acquisition is armed (i.e. bit[2] = 1), then Run starts when

GPI is asserted and stops when GPI returns inactive. If bit[2] = 0, the acquisition is always off.

- FIRST TRIGGER CONTROLLED (bits[1:0] = 10): bit[2] = 1 arms the acquisition and the Start is issued on the

first trigger pulse (rising edge) on the TRG-IN connector. This pulse is not used as a trigger; actual triggers

start from the second pulse on TRG-IN. The Stop acquisition must be SW controlled (i.e. reset of bit[2]).

CAEN

Electronic Instrumentation

UM3148 – DT5730/DT5725 User Manual rev. 2

27

Acquisition Triggering: Samples & Events

When the acquisition is running, a trigger signal allows to:

- Store the 31-bit counter value of the Trigger Time Tag (TTT).

The counter (representing a time reference), like so the Trigger Logic Unit (see Fig. 9.2) operates at a

frequency of 125 MHz (i.e. 8 ns or 4 ADC clock cycles in case of DT5730, while 2 ADC clock cycles in case of

DT5725). Due to the way the acquired data are written into the board internal memory (i.e. in 4-sample

bunches), the TTT counter is read every 2 trigger logic clock cycles, which means the trigger time stamp

resolution results in 16 ns (i.e. 62.5 MHz). Basing on that, the LSB of the TTT is always “0”;

- Increment the EVENT COUNTER.

- Fill the active buffer with the pre/post-trigger samples, whose number is programmable (Acquisition

window width), freezing then the buffer for readout purposes, while acquisition continues on another

buffer.

An event is therefore composed by the trigger time tag, pre- and post-trigger samples and the event counter.

Overlap between “acquisition windows” may occur (a new trigger occurs while the board is still storing the samples

related to the previous trigger); this overlap can be either rejected or accepted (programmable via software).

If the board is programmed to accept the overlapped triggers (by programming at register address 0x8000), as the

“overlapping” trigger arrives, the current active buffer is filled up, then the samples storage continues on the

subsequent one. In this case events will not have all the same size (see Fig. 9.8 below)

TRIGGER

PRE POST

ACQUISITION WINDOW

Recorded

Not Recorded

Overlapping Triggers

EVENT n EVENT n+1 EVENT n+2

Fig. 9.8: Trigger overlap

A trigger can be refused for the following causes:

- Acquisition is not active.

- Memory is FULL and therefore there are no available buffers.

- The required number of samples for building the pre-trigger of the event is not reached yet; this happens

typically as the trigger occurs too early either with respect to the RUN Acquisition command (see §

Acquisition Run/Stop) or with respect to a buffer emptying after a Memory FULL status (see § Acquisition

Synchronization).

- The trigger overlaps the previous one and the board is not enabled for accepting overlapped triggers.

As a trigger is refused, the current buffer is not frozen and the acquisition continues writing on it. The EVENT COUNTER

can be programmed in order to be either incremented or not. If this function is enabled, the EVENT COUNTER value

identifies the number of the triggers sent (but the event number sequence is lost); if the function is not enabled, the

EVENT COUNTER value coincides with the sequence of buffers saved and readout.

CAEN

Electronic Instrumentation

UM3148 – DT5730/DT5725 User Manual rev. 2

28

Multi-Event Memory Organization

Each channel of the DT5730/DT5725 features a SRAM memory to store the acquired events. The memory size for the

event storage is 640 kS/ch or 5.12 MS/s, according to the board version (see Tab. 1.1), and it can be divided in a

programmable number of buffers, Nb (N

b

from 1 up to 1024), by register address 0x800C, as described in Tab. 9.1

below.

Register Value

Buffer Number

(Nb)

Size of one Buffer (Samples)

SRAM 640 kS/ch⁽*⁾

SRAM 5.12 MS/ch⁽*⁾

0x00

1

640k - 10

5.12M - 10

0x01

2

320k - 10

2.56M - 10

0x02

4

160k - 10

1.28M - 10

0x03

8

80k - 10

640k - 10

0x04

16

40k - 10

320k - 10

0x05

32

20k - 10

160k - 10

0x06

64

10k - 10

80k - 10

0x07

128

5k - 10

40k - 10

0x08

256

2560 - 10

20k - 10

0x09

512

1280 - 10

10k - 10

0x0A

1024

640 - 10

5120 - 10

Tab. 9.1: Buffer Organization

Having 640 kS memory size as reference, this means that each buffer contains 640k/Nb samples (e.g. Nb = 1024 means

640 samples in each buffer).

⁽*⁾IMPORTANT: For AMC FPGA firmware release < 0.2, the Size of one Buffer related to each Buffer Number must be

intended as the number of the samples in Tab. 9.1. without decreasing by 10 samples.

Custom Sized Events

In case an event size minor than the buffer size is needed, the user can set the value N

LOC

at register address 0x8020;

the event is so forced to be made by 10*N

LOC

samples. Setting NLOC = 0, the custom size is disabled. The value of N

LOC

must be set in order that the relevant number of samples does not exceed the buffer size and it mustn’t be modified

while the acquisition is running.

Note: Even using the custom size setting, the number of buffers and the buffer size are not affected by N

LOC

, but they

are still determined by Nb.

The concepts of buffer organization and custom size directly affect the width of the acquisition window (i.e.

number of the digitized waveform samples per event). The Record Length parameter defined in CAEN

software (such as WaveDump and CAENScope introduced in § 11) and the Set/GetRecordLength() function

of the CAENDigitizer library (refer to [RD5] ) rely on these concepts.

CAEN

Electronic Instrumentation

UM3148 – DT5730/DT5725 User Manual rev. 2

29

Event Structure

The event can be readout via Optical Link or USB; data format is 32-bit long word (see Tab. 9.3)

An event is structured in:

• Header (four 32-bit words)

• Data (variable size and format)

Header consists in 4 words including the following information:

• EVENT SIZE (Bit[27:0] of 1

st

header word) = It is the size of the event (number of 32-bit long words);

• BOARD FAIL FLAG (Bit[26] of 2

nd

header word) = Implemented from ROC FPGA firmware revision 4.5 on

(reserved otherwise), this bit is set to “1” in consequence of a hardware problem (e.g. PLL unlocking or overtemperature condition). The user can collect more information about the cause by reading at register address

0x8104 and contact CAEN Support Service if necessary (see § 14);

• Bit[24] (2

nd

header word) = This bit identifies the event format; it is reserved and must be 0;

• Bit[23:8] (2

nd

header word) = Starting from revision 4.6 of the ROC FPGA firmware, these 16 bits can be

programmed to provide different trigger information according to the setting of the bits[22:21] at register

address 0x811C (Tab. 9.2).

Note: for ROC FPGA firmware revisions lower than 4.6. these bits are reserved.

REGISTER 0x811C

Bits[22:21]

FUNCTIONAL

DESCRIPTION

Bit[23:8]

(16 bits in the2nd header word)

00

(default)

Not used

Must be 0

01

Event Trigger Source

Indicates the trigger source causing the

event acquisition:

Bits[23:19] = 0000

Bit[18] = Software Trigger

Bit[17] = External Trigger

Bit[16] = 0

Bits[11:8] = Trigger requests from the

couple of channels (refer to § Self-Trigger)

10

Extended Trigger Time Tag

(ETTT)

A 48-bit Trigger Time Tag (ETTT)

information is configured, where Bits[23:8]

contributes as the 16 most significant bits

together to the 32-bit TTT field (4th header

word).

Note: in the 48-bit TTT, the overflow bit is

not provided.

11

Not used

reserved

Tab. 9.2: TRG OPTIONS configuration table

• CHANNEL MASK (Bit[7:0] of 2

nd

header word) = It is the mask of the channels participating in the event. This

information must be used by the software to acknowledge which channel the samples are coming from.

• EVENT COUNTER (Bit[23:0] of 3

rd

header word) = This is the trigger counter; it can count either accepted

triggers only, or all triggers.

CAEN

Electronic Instrumentation

UM3148 – DT5730/DT5725 User Manual rev. 2

30

• TRIGGER TIME TAG (Bit[31:0] of 4

th

header word) = It is the 31-bit Trigger Time Tag information (31-bit counter

and 32nd bit as roll over flag), which is the trigger time reference. If the ETTT option is enabled, then this field

becomes the 32 less significant bits of the extended 48-bit trigger time tag information in addition to the 16 bits

(MSB) of the TRG OPTIONS field (2nd event word). Note that, in the ETTT case, the roll over flag is no more

provided. The trigger time tag is reset either as the acquisition starts or via front panel signal on GPI connector,

and increments with 125-MHz frequency (every 4 ADC clock cycles in case of DT5730 or 2 ADC clock cycles with

DT5725). The trigger time tag value is read at half this frequency (62.5 MHz). So, the trigger time tag

specifications result in 16 ns resolution and 17 s range(i.e. 8 ns*(231-1)), which can be extended to 625 h (i.e. 8

ns*(248-1)) by the Extended Trigger Time Tag option.

Data are the samples from the enabled channels. Data from masked channels are not read.

Event Format Example

Tab. 9.3 shows the event data format of DT5730/DT5725 when all the 8 channels are enabled. The structure is

described in § Event Structure.

31 30 29 28 27 262524 23 22 21 20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

EVENT SIZE

TRIGGER TIME TAG

101 0

RES.

EVENT COUNTER

SAMPLE [1] – CH[0] SAMPLE [0] – CH[0]

SAMPLE [3] – CH[0] SAMPLE [2] – CH[0]

SAMPLE [N-1] – CH[0] SAMPLE [N-2] – CH[0]

SAMPLE [1] – CH[1] SAMPLE [0] – CH[1]

SAMPLE [3] – CH[1] SAMPLE [2] – CH[1]

SAMPLE [N-1] – CH[1] SAMPLE [N-2] – CH[1]

HEADER DATA CH0 DATA CH1

SAMPLE [1] – CH[7] SAMPLE [0] – CH[7]

SAMPLE [3] – CH[7] SAMPLE [2] – CH[7]

SAMPLE [N-1] – CH[7] SAMPLE [N-2] – CH[7]

DATA CH7

BOARD-ID

0 00 0

0 0

0 0

0 0

0 0

0 0

0 0

0 0

0 0

0 0

0 0

0 0

0 0

0 0

0 0

0 0

0 0

0 0

PATTERN CHANNEL MASK [7:0]

RESERVED

RESERVED BF

RESERVED / TRG OPTIONS

RES.

0

Tab. 9.3: Event Format Example

CAEN

Electronic Instrumentation

UM3148 – DT5730/DT5725 User Manual rev. 2

31

Acquisition Synchronization

Each channel of the digitizer is provided with a SRAM memory that can be organized in a programmable number Nb of

circular buffers (Nb = [1:1024], see Tab. 9.1). When the trigger occurs, the FPGA writes further a programmable number

of samples for the post-trigger and freezes the buffer, so that the stored data can be read via USB or Optical Link. The

acquisition can continue without dead-time in a new buffer.

When all buffers are filled, the board is considered FULL: no trigger is accepted and the acquisition stops (i.e. the

samples coming from the ADC are not written into the memory, so they are lost). As soon as at least one buffer is read

out, the board exits the FULL condition and acquisition restarts.

Note: When the acquisition restarts, no trigger is accepted until at least the entire buffer is written. This means that

the dead time is extended for a certain time (depending on the size of the acquisition window) after the board exits

the FULL condition.

A way to eliminate this extra dead time is by setting bit[5] = 1 at register address 0x8100. The board is so programmed

to enter the FULL condition when N-1 buffers are written: no trigger is then accepted, but samples writing continues in

the last available buffer. As soon as one buffer is readout and becomes free, the boards exits the FULL condition and

can immediately accept a new trigger. This way, the FULL reflects the BUSY condition of the board (i.e. inability to

accept triggers); if required, the BUSY signal can be provided out on the digitizer front panel through the GPO LEMO

connector (bit[20], bits[19:18] and bits[17:16] at register address 0x811C).

Note: when bit[5] = 1, the minimum number of circular buffers to be programmed is N = 2.

In some cases, the BUSY propagation from the digitizer to other parts of the system has some latency and it can

happen that one or more triggers occur while the digitizer is already FULL and unable to accept those triggers. This

condition causes event loss and it is particularly unsuitable when there are multiple digitizers running synchronously,

because the triggers accepted by one board and not by other boards cause event misalignment.

In this cases, it is possible to program the BUSY signal to be asserted when the digitizer is close to FULL condition, but it

has still some free buffers (Almost FULL condition). In this mode, the digitizer remains able to accept some more

triggers even after the BUSY assertion and the system can tolerate a delay in the inhibit of the trigger generation.

When the Almost FULL condition is enabled by setting the Almost FULL level (register address 0x816C) to X, the BUSY

signal is asserted as soon as X buffers are filled, although the board still goes FULL (and rejects triggers) when the

number of filled buffers is N or N-1, depending on bit[5] at register address 0x8100 as described above.

It is possible to provide the BUSY signal on the digitizer front panel GPO output (bit[20], bits[19:18] and bits[17:16] at

register address 0x811C are involved).

CAEN

Electronic Instrumentation

UM3148 – DT5730/DT5725 User Manual rev. 2

32

Trigger Management

According to the default firmware operating, all the channels in a board share the same trigger (board common

trigger), so they acquire an event simultaneously and in the same way (a determined number of samples according to

buffer organization and custom size settings, and position with respect to the trigger given by the post-trigger).

Note: For the trigger management in the DPP firmware operating, please refer to [RD9] and [RD10].

The generation of a common acquisition trigger is based on different trigger sources (configurable at register address

0x810C):

• Software trigger

• External trigger

• Self-trigger

• Coincidence

TRG IN

Enable Mask

x4

COMMON TRIGGER

SW TRG

GPO

(TRG OUT)

TRG_REQ [3:0]

D Q

SCLK

Acquisition

Logic

Memory

Buffers

Local Bus

Interface

Mother Board

x4

4

4

ADC

ADC

CH0

CH1

TRG_REQ [0]

SELF-TRIG. SET.

OVTHR PULSE

SELF-TRIG. SET.

PULSEOVTHR

AND

ONLY 0

ONLY 1

OR

Mezzanine

4

4

Fig. 9.9: Block Diagram of the trigger management

Software Trigger

Software triggers are internally produced via a software command (write access at register address 0x8108) through

USB or Optical Link.

External Trigger

A TTL or NIM external signal can be provided in the front panel TRG-IN connector (configurable at register address

0x811C). If the external trigger is not synchronized with the internal clock, a 1-clock period jitter occurs.

CAEN

Electronic Instrumentation

UM3148 – DT5730/DT5725 User Manual rev. 2

33

Self-Trigger

Each channel is able to generate a self-trigger signal when the digitized input pulse exceeds a configurable threshold

(register address 0x1n60). The self-triggers of each couple of adjacent channels are then processed to provide out a

single trigger request. The trigger requests are propagated to the central trigger logic where they are ORed to produce

the board common trigger, which is finally distributed back to all channels causing the event acquisition (see Fig. 9.9).

Fig. 9.10 schematizes the self-trigger and trigger request logic having the channel 0 and channel 1 couple as an

example.

CH0

CH1

PULSE

OVTHR

Bits[1:0] of 0x1084

PULSE

OVTHR

SELF_TRG [0]

SELF_TRG [1]

AND

ONLY 0

ONLY 1

OR

Bit[2] of 0x1084

TRG_REQ [0]

Fig. 9.10: Self Trigger and Trigger Request logic for Ch0 and Ch1 couple. A single trigger request signal is generated.

The FPGA, by register address 0x1n84, can be programmed in order the self-trigger to be:

▪ an over/under-threshold signal (see Fig. 9.11). This signal can be programmed to be active (i.e. “1”) as long as

the input pulse is over the threshold or under the threshold (depending on the trigger polarity bit at register

address 0x8000).

CH0 IN

THRESHOLD

over-threshold signal [0]

under-threshold signal [0]

Fig. 9.11: Channel over/under threshold signal

CAEN

Electronic Instrumentation

UM3148 – DT5730/DT5725 User Manual rev. 2

34

▪ a pulse of configurable width (see Fig. 9.12). The width parameter can be set at register address 0x1n70.

CH0 IN

THRESHOLD

pulse [0]

WIDTH

Fig. 9.12: Channel pulse signal

The FPGA, by register address 0x1n84, can be programmed in order the trigger request for a couple of adjacent

channels to be the

AND,

ONLY CH(n),

ONLY CH(n+1),

OR

of the relevant self-trigger signals (see Fig. 9.10).

Default Conditions: by default, the FPGA is programmed so that the trigger request is the OR of two pulses of 4nswidth.

Note: the above described configurability of both the self-trigger logic and the trigger request logic are supported only

by AMC FPGA firmware releases > 0.1.

Previous firmware don’t implement the register address 0x1n84 as well as the 0x1n70, the self-trigger is intended only

as the over/under threshold signal and a trigger request is intended only as the OR of the self-triggers couple.

CAEN

Electronic Instrumentation

UM3148 – DT5730/DT5725 User Manual rev. 2

35

Trigger Coincidence Level

Operating with the default firmware, the acquisition trigger is a board common trigger. This common trigger allows the

coincidence acquisition mode to be performed through the Majority operation.

Note: From AMC FPGA firmware release > 0.1, it is possible to program the self-trigger logic as described in § Self-

Trigger.

Enabling the coincidences is possible by writing at register address 0x810C:

- Bits[3:0] enable the trigger request signals to participate in the coincidence;

- Bits[23:20] set the coincidence window (T

TVAW

) linearly in steps of the Trigger clock (8 ns);

- Bits[26:24] set the Majority (i.e. Coincidence) level; the coincidence takes place when:

Number of enabled trigger requests > Majority level

Supposing bits[3:0] = FF (i.e. all the 4 trigger request are enabled) and bits[26:24] = 01 (i.e. Majority level = 1), a board

common trigger is issued whenever at least two of the enabled trigger requests are in coincidence within the

programmed T

TVAW

.

The Majority level must be smaller than the number of trigger requests enabled via bits[3:0] mask. By default,

bits[26:24] = 00 (i.e. Majority level = 0), which means the coincidence acquisition mode is disabled and the T

TVAW

is

meaningless. In this case, the board common trigger is simple OR of the signals from the enabled channels pairs.

CAEN

Electronic Instrumentation

UM3148 – DT5730/DT5725 User Manual rev. 2

36

Fig. 9.13 and Fig. 9.14 show the trigger management in case the coincidences are disabled

CH0 THRESHOLD

CH0 (enabled) IN

Over-threshold signal [CH0]

CH1 THRESHOLD

CH1(enabled) IN

Over-threshold signal [CH1]

TRG_REQ [0]

MEZZANINE

CH2 THRESHOLD

CH2 (enabled) IN

Over-threshold signal [CH2]

CH3 THRESHOLD

CH3(enabled) IN

Over-threshold signal [CH3]

TRG_REQ [1]

Fig. 9.13: Trigger request management at mezzanine level with Majority level = 0

TRG_REQ [0]

MOTHERBOARD

TRG_REQ [1]

ORed signal

COMMON TRIGGER

(Maj. Lev. = 0)

Fig. 9.14: Trigger request management at motherboard level with Majority level = 0

CAEN

Electronic Instrumentation

UM3148 – DT5730/DT5725 User Manual rev. 2

37

Fig. 9.15 and shows the trigger management in case the coincidences are enabled with Majority level = 1 and T

TVAW

is a

value different from 0. In order to simplify the description, CH1 and CH3 channels are considered disabled, so that the

relevant trigger requests are the over-threshold signals from CH0 and CH1.

CH2 THRESHOLD

TRG_REQ [0]

TRG_REQ [1]

CH0(enabled) IN

CH0 THRESHOLD

TRIGGER

(Maj.lev = 1)

CH2(enabled) IN

ORed signal

TTVAW

MEZZANINE

MOTHERBOARD

Fig. 9.15: Trigger request relationship with Majority level = 1 and T

TVAW

≠ 0

Note: with respect to the position where the common trigger is generated, the portion of input signal stored depends

on the programmed length of the acquisition window and on the post trigger setting.

CAEN

Electronic Instrumentation

UM3148 – DT5730/DT5725 User Manual rev. 2

38

Fig. 9.16 shows the trigger management in case the coincidences are enabled with Majority level = 1 and T

TVAW

= 0 (i.e.

1 clock cycle). In order to simplify the description, CH1 and CH3 channels are considered disabled, so that the relevant

trigger requests are the over-threshold signals from CH0 and CH1.

CH2 THRESHOLD

TRG_REQ [0]

TRG_REQ [1]

CH0(enabled) IN

CH0 THRESHOLD

TRIGGER

(Maj.lev = 1)

CH2(enabled) IN

ORed signal

TTVAW

MEZZANINE

MOTHERBOARD

Fig. 9.16: Trigger request relationship with Majority level = 1 and T

TVAW

= 0

In this case, the common trigger is issued if at least two of the enabled trigger requests are instantaneously in

coincidence (no TTVAW is waited).

Note: a practical example of making coincidences with the digitizer in the standard operating is detailed in [RD11].

CAEN

Electronic Instrumentation

UM3148 – DT5730/DT5725 User Manual rev. 2

39

Trigger Distribution

As described in § Trigger Management, the OR of all the enabled trigger sources, synchronized with the internal clock,

becomes the common trigger of the board that is fed in parallel to all channels, consequently provoking the capture of

an event. By default, only the Software Trigger and the External Trigger participate in the common acquisition trigger

(refer to the red path on top of Fig. 9.17).

A Trigger Out signal is also generated on the relevant front panel GPO connector (NIM or TTL), and allows to extend the

trigger signal to other boards. Thanks to its configurability (see Fig. 9.17), GPO can propagate out:

- the OR of all the enabled trigger sources (only the Software Trigger is provided by default, as in the red

path of Fig. 9.17);

- the OR, AND or MAJORITY exclusively of the channel trigger requests.

TRG_REQ[3:0]

GPO

0x8110

Bits[9:8]

00

01

10

TO THE CHANNELS

COMMON ACQUISITON TRIGGER

0x811C

Bits[17:16]

3

3

00

01

MB PROBES

10

PB PROBES

11

GPI

3

SW TRG

EXT TRG

MASK 1

0x810C

Bits[3:0]

MASK 4

0x8110

Bits[3:0]

OR

AND

MAJORITY

OR

MASK 2

MASK 3

0x810C

Bits[31:30]

0x8110

Bits[31:30]

SW TRG

EXT TRG

OR

TRG SOURCES

0x8110

Bits[12:10]

EXT TRG

SW TRG

Fig. 9.17: Trigger configuration on GPO front panel output connector

The registers involved in the GPO programming are:

- Register address 0x8110;

- Register address 0x811C.

Note: Refer to [RD2] for registers complete description.

CAEN

Electronic Instrumentation

UM3148 – DT5730/DT5725 User Manual rev. 2

40

Example

For instance, it could be required to start the acquisition on all the channels of a multi-board system as soon as one of

the channels of a board (board “n”) crosses its threshold. Trigger Out signal is then fed to an external Fan Out logic

unit; the obtained signal has then to be provided to the external trigger input TRG-IN of all the boards in the system

(including the board which generated the Trigger Out signal). In this case, the programming steps to perform are

following described:

1. Register 0x8110 on board “n”:

- Enable the desired trigger request as Trigger Out signal on board “n” (by bits[3:0] mask);

- Disable Software Trigger and External Trigger as Trigger Out signal on board “n” (bits[31:30] = 00);

- Set Trigger Out signal as the OR of the enabled trigger requests on board “n” (bits[9:8] = 00).