Page 1

2000 Cadillac DeVille

Outer Center Pillar Sectioning 1-4

Outer Front Pillar Sectioning 1-2

Quarter Panel Sectioning 1-6

Body Dimensions 1-17/18

Inner Center Pillar Sectioning 1-10

Inner Front Pillar Sectioning 1-9

Outer Wheelhouse Sectioning 1-12

Rear Rail Sectioning 1-13

Page 2

Outer Front Pillar, Center Pillar

and Quarter Panel Sectioning

CAUTION: When performing service on or near the Supplemental

Inflatable Restraint (SIR) components or the SIR wiring, the SIR system

must be disabled. Failure to follow the correct procedure could cause air

bag deployment, personal injury or unnecessary SIR system repairs.

The full body side outer panel comes as a one-piece assembly and can be

replaced at factory seams after removal of glass and roof. Any one of these

procedures can be performed separately, or in any combination, dependent

upon the extent of damage to the vehicle. Sectioning must take place in

specified areas only (Fig. 1-1). Remove front glass when sectioning front pillar

and rear glass for rear pillar repair.

IMPORTANT: When replacing panels that involve servicing stationary

glass, refer to GM Service Bulletin 43-10-48 before performing any

priming or refinishing.

Fig.␣ 1-1 — 2000 DeVille Outer Frame Sectioning Locations

2000 cadillac deville 1-1

Page 3

Outer Front Pillar

Sectioning

Removal Procedure

IMPORTANT: Sectioning should be performed

only in the recommended areas. Failure to do

so may compromise the structural integrity of

the vehicle.

1. Visually inspect and restore as much of the

damage as possible to factory specifications.

2. Remove the following:

• Fender

• Windshield

• Door

• Hinge pillar blocks

3. Determine sectioning locations. Section in

approved areas only (see Fig.␣ 1-1).

4. Mark locations and cut part through outer

panel only.

5. Locate factory welds and drill out, noting

number and locations of welds (Fig.␣ 1-2).

6. Locate and drill out spot welds on weather

strip retainer as necessary. It is not necessary

to remove complete retainer.

7. Remove outer panel.

8. Note placement and number of foam baffles

for new installation. If baffles are damaged,

replacement service parts are available.

IMPORTANT: Hinge pillar blocks must be

replaced if damaged.

9. Clean adhesive and sealer from hydroformed

reinforcement tube as necessary. Note

location for reinstallation.

Fig.␣ 1-2 — Drill Out Welds

100 MM (4 IN)

Service Part Preparation

1. Cut service part in corresponding locations to

fit original cut lines. Leave a gap of one-andone half times the metal thickness of

sectioning joint.

2. Create 100␣ mm (4␣ in) backing plate on rocker

panel from unused portion of service part

(Fig.␣ 1-3).

3. In windshield pillar area, use the hydroformed

inner rail for backing plate.

4. Drill 8␣ mm (5/16␣ in) plug weld holes in service

part according to original locations as noted.

Drill plug weld holes spaced 40␣ mm (1-5/8␣ in)

apart along backing plate location 25␣ mm

(1␣ in) from joint edge.

1-2 2000 cadillac deville

GAP = ONE-AND-ONE-HALF TIMES

THE METAL THICKNESS

Fig.␣ 1-3 — Rocker Panel Backing Plate

Page 4

Fig.␣ 1-4 — Plug Weld and Stitch Weld

Installation Procedure

IMPORTANT: Remove all foam prior to welding

this section of the service panel.

1. Prepare mating surfaces.

2. Apply weld-through primer to mating surfaces

prior to assembly.

3. Weld backing plates to vehicle at rocker.

IMPORTANT: Replace hinge pillar blocks

prior to welding outer panel.

4. Apply windshield bonding adhesive to the

hydroformed reinforcement as noted from

removal procedure.

5. Position service part on vehicle. Clamp in

place. Check for proper fit.

6. Plug weld accordingly (Fig. 1-4).

7. Stitch weld along both sectioning joints. Make

25␣ mm (1␣ in) welds along the seam with

25␣ mm (1␣ in) gaps between, then go back and

complete the stitch weld to ensure structural

integrity of the vehicle.

8. Install insulating foam as necessary in areas

noted from original baffle locations.

IMPORTANT: Prior to refinishing, refer to

the publication GM4901M-D-2000 “GM

Approved Refinish Materials” for

recommended products. Do not combine

paint systems. Refer to paint manufacturer’s

recommendations.

9. Refinish as necessary.

2000 cadillac deville 1-3

Page 5

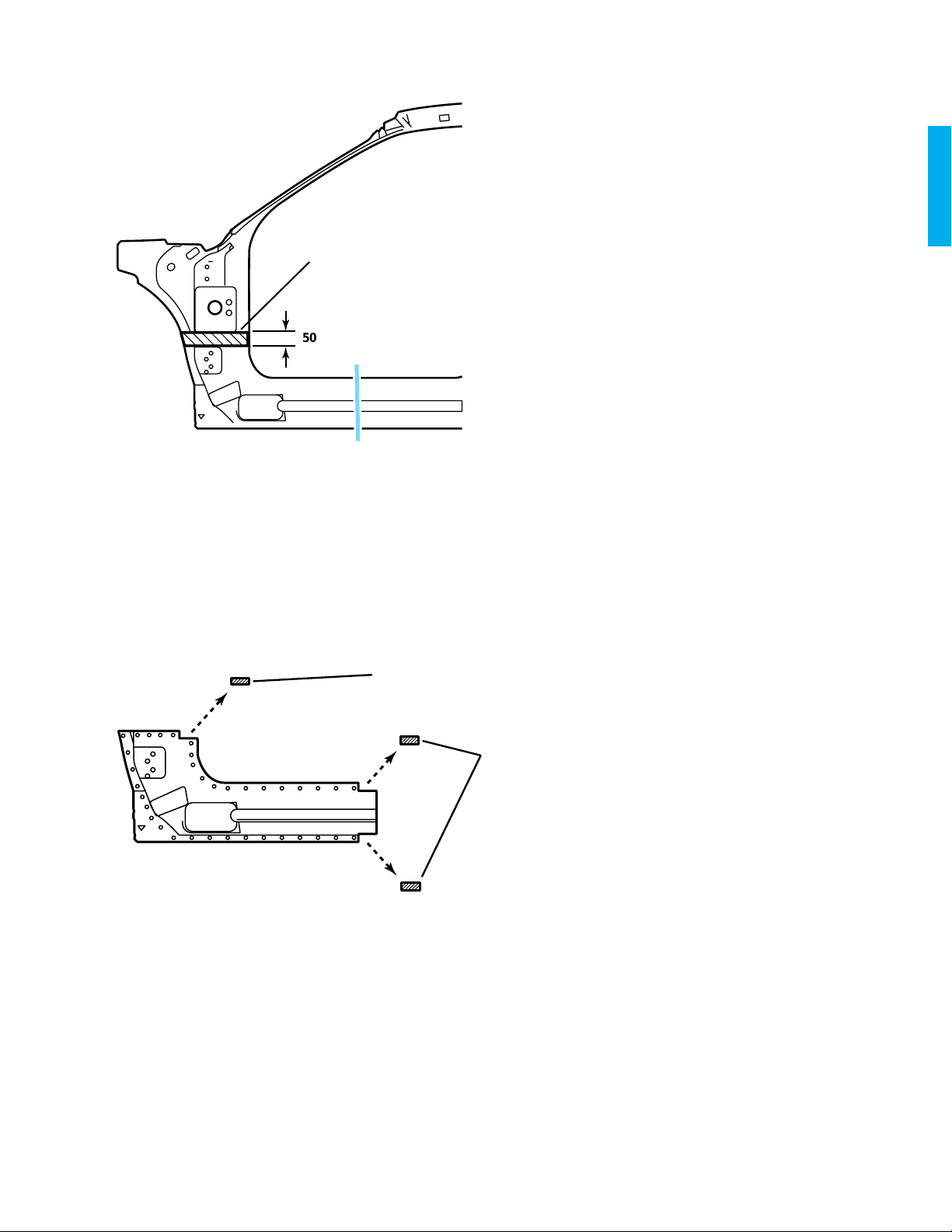

Outer Center Pillar

50 MM (2 IN)

GAP =

ONE-AND-ONE-HALF

TIMES THE MET AL

THICKNESS

Sectioning

Removal Procedure

IMPORTANT: Sectioning should be performed

only in the recommended areas. Failure to do so

may compromise the structural integrity of the

vehicle.

1. Locate an approved sectioning area in the

center pillar (Fig.␣ 1-5).

2. Mark and scribe a line. This is the cut location.

3. Cut Center Pillar at cut line. Use caution not to

cut inner reinforcement.

4. Create cut lines on rocker within approved

sectioning locations. Cut the rocker vertically

along cut lines.

5. Drill out factory welds. Note number and

location of welds.

6. Remove the damaged part.

7. Note placement and number of foam baffles

for new installation. If baffles are damaged,

replacement service parts are available.

IMPORTANT: Hinge pillar blocks must be

replaced if damaged.

Fig.␣ 1-5 — Outer Center Pillar – Sectioning

Locations

Preparation Of Service Part

1. On the service part, at center pillar mark a

horizontal line in corresponding locations

to original sectioning cut. Leave a gap of oneand-one-half times the thickness of the metal

at the sectioning joint (Fig. 1-6).

2. Mark vertical cut lines in rocker areas to

correspond with original section lines. Leave a

gap of one-and-one-half times the metal

thickness (see Fig. 1-3).

3. Cut the outer doorframe opening service part

along these three section lines.

4. Cut two 100␣ mm (4␣ in) pieces from the unused

portion of the service part for backing plates

in rocker.

5. Cut one 50␣ mm (2␣ in) backing plate for pillar

(Fig. 1-6). Remove the flange on each side of

the backing plates so that they will fit behind

the sectioning joint.

6. Drill 8␣ mm (5/16␣ in) plug weld holes in service

part according to original locations, as noted.

Drill plug weld holes spaced 40␣ mm (1-5/8␣ in)

apart along backing plate locations. Space

these holes 25␣ mm (1␣ in) from the joint edge

on the rocker panels and 13␣ mm (1/2␣ in) from

the joint edge on the pillar.

Fig.␣ 1-6 — Create Pillar Backing Plate

1-4 2000 cadillac deville

Page 6

Fig.␣ 1-7 — Outer Center Pillar – Installation

Installation Procedure

1. Install sleeves on vehicle at rocker and center

pillar areas using plug welds.

2. Replace hinge blocks and bolts.

3. Prepare mating surfaces.

IMPORTANT: Prior to refinishing, refer to the

publication GM4901M-D-2000 “GM

Approved Refinish Materials” for

recommended products. Do not combine

paint systems. Refer to paint manufacturer’s

recommendations.

4. Apply weld-through primer to mating

surfaces prior to assembly.

5. Align part and clamp in place. Check fit

(Fig. 1-7).

6. Spot blast plug weld areas.

7. Plug weld as necessary in original spot weld

locations and at backing plates.

8. Stitch weld at section joints, one inch on and

one inch off, as necessary, then go back and

complete the stitch weld. This will create a

solid joint with minimal heat distortion.

9. Dress welds and finish seams as necessary.

10. Refinish as necessary.

2000 cadillac deville 1-5

Page 7

Quarter Panel Sectioning

Removal Procedure

The service part comes with lower quarter panel

extension and taillamp pocket attached. These

parts can be left on the vehicle if not damaged.

Drill out factory welds on the car and service part

and use the outer panel only.

IMPORTANT: When replacing panels that

involve servicing stationary glass, refer to GM

Service Bulletin 43-10-48 before performing any

priming or refinishing.

IMPORTANT: Sectioning should be performed

only in the recommended areas (Fig. 1-8).

Failure to do so may compromise the structural

integrity of the vehicle.

IMPORTANT: It may be necessary to unplug

and remove one end of the body wiring harness

that runs through quarter pillar lower extension

if it is necessary to replace extension.

1. Visually inspect and restore as much of the

damage as possible to the factory

specifications.

2. Remove all related panels and components.

3. Remove all sealers, sound deadeners and anticorrosion materials as necessary.

4. Determine sectioning locations in rocker area

(Fig. 1-8).

5. Mark a line and cut in approved sectioning

areas of rocker.

6. In upper quarter panel door opening, locate

the fourth weatherstrip hole (1).

7. Measure down 25␣ mm (1␣ in) and mark a line.

8. In back-glass opening, locate rear edge of roof

panel.

9. Measure down 25␣ mm (1␣ in), and scribe a

second line. Connect marks at both locations

to create a cut line.

10. Cut part at marked locations.

11. Locate, mark and drill out all factory welds.

Note the number and location of welds for

installation of the service assembly.

12. Remove damaged panel. Note placement and

number of foam baffles for new installation. If

baffles are damaged, replacement service parts

are available.

1

25 MM (1 IN)

Fig.␣ 1-8 — Outer Rear Pillar Sectioning

1-6 2000 cadillac deville

Page 8

Fig.␣ 1-9 — Outer Rear Pillar Preparation

Fig.␣ 1-10 — Outer Rear Pillar Installation

Preparation Of Service Part

1. Cut service part in corresponding locations to

fit original cut lines. Leave a gap of one-andone-half times the metal thickness of

sectioning joint (Fig. 1-9).

2. Create 100␣ mm (4␣ in) backing plate on rocker

panel from unused portion of service part.

3. Create a 50␣ mm (2␣ in) backing plate on

quarter panel from unused portion of old

quarter panel.

4. Drill 8␣ mm (5/16␣ in) plug weld holes as noted

from original locations. At backing plates,drill

8␣ mm plug weld holes 13␣ mm (1/2␣ in) from

seam spaced 40␣ mm (1 1/2␣ in) apart.

Installation Procedure

1. Position service part on vehicle. Check fit

using body dimensions.

2. Temporarily remove service part.

3. Prepare mating surfaces.

IMPORTANT: Prior to refinishing, refer to

the publication GM4901M-D-2000 “GM

Approved Refinish Materials” for

recommended products. Do not combine

paint systems. Refer to paint manufacturer’s

recommendations.

4. Apply weld through primer to mating

surfaces.

5. Install GM P/N 12399117 Sealing Strip

between outer wheelhouse and gas door

pocket.

6. Weld backing plates into position on body.

7. Position service part and clamp in place. Spot

blast plug weld areas. Plug weld as necessary

in original locations and along backing plates.

8. Stitch weld along entire sectioning joint. Make

25␣ mm (1␣ in) welds along the seam with

25␣ mm (1␣ in) gaps between them (Fig. 1-10).

9. Go back and complete the stitch weld. This

will create a solid joint with minimal heat

distortion.

10. Clean and prepare welded surfaces, as

necessary.

11. Install all sealers, sound deadeners and anticorrosion materials as necessary. Install

acoustic foam baffles as noted from original

part.

12. Apply two-part catalyzed primer.

13. Refinish as necessary.

14. Install all related panels and components.

2000 cadillac deville 1-7

Page 9

Inner Front Pillar, Center Pillar

and Rear Wheelhouse Sectioning

CAUTION: When performing service on or near the SIR

components or the SIR wiring, the SIR system must be disabled.

Failure to follow the correct procedure could cause air bag

deployment, personal injury or unnecessary SIR system repairs.

The full bodyside inner panel comes as a one piece assembly and can

be replaced at factory seams after removal of outer panel, roof and

glass. Any one of these procedures can be performed separately, or

in any combination dependent upon the extent of damage to the

vehicle.

Fig.␣ 1-11 — 2000 DeVille Inner Frame Sectioning Locations

1-8 2000 cadillac deville

Page 10

1

50 MM (2 IN)

Fig.␣ 1-12 — 2000 DeVille Inner Front Pillar

Sectioning Locations

Inner Front Pillar

Sectioning

Removal Procedure

IMPORTANT: Sectioning should be performed

only in the recommended areas. Failure to do so

may compromise the structural integrity of the

vehicle.

1. Visually inspect and restore as much of the

damage as possible to factory specifications.

2. Remove outer panel according to specified

directions in Outer Panel Removal procedure.

3. Remove all necessary components to allow

access to repair area.

4. Locate and mark a horizontal line 50␣ mm

(2␣ in) down from the raised, square portion of

the hinge pillar (Fig. 1-12). This will be your

cut location (1).

5. At rocker panel, locate and mark a vertical cut

line in the approved sectioning location

(Fig.␣ 1-12).

6. Cut at the two marked locations. Use caution

to cut through one layer of metal only.

7. Locate and drill out factory welds noting the

number and location of welds.

8. Remove damaged section from vehicle.

1

Fig.␣ 1-13 — 2000 DeVille Inner Front Pillar Service

Part

Preparation of Service Part

1. On hinge pillar, scribe a cut line 25␣ mm (1␣ in)

below the raised, square portion of the hinge

pillar. This will create a 25␣ mm (1␣ in) overlap

on the service part.

2. Notch the panel on the door weather-strip

flange (1) to prevent excessive metal thickness

2

in this area (Fig. 1-13).

3. In rocker area, locate and mark a cut line in

the recommended sectioning area. Allow for a

50␣ mm (2␣ in) overlap to the vehicle sectioning

areas (Fig. 1-13).

4. Cut along marked sectioning lines to create

service part.

5. Notch upper and lower edges of service part

(2) to prevent excessive metal thickness in this

area (Fig. 1-13).

6. Drill plug weld holes spaced 40␣ mm (1-5/8␣ in)

apart along overlap flanges. Place holes

25␣ mm (1␣ in) from edge on rocker panel and

13␣ mm (1/2␣ in) from edge on hinge pillar.

2000 cadillac deville 1-9

Page 11

Installation Procedure

1. Prepare mating surfaces.

IMPORTANT: Prior to refinishing, refer to

the publication GM4901M-D-2000 “GM

Approved Refinish Materials” for

recommended products. Do not combine

paint systems. Refer to paint manufacturer’s

recommendations.

2. Prime with two-part catalyzed primer.

3. Position part on vehicle and clamp in place.

Measure and check for fit (Fig.1-14).

4. Spot blast plug weld areas.

5. Plug weld accordingly.

6. Stitch weld at hinge pillar and rocker panel.

7. Dress and finish weld seam as necessary.

8. Refinish as necessary.

9. Install related panels and components as

necessary.

Inner Center Pillar

Sectioning

Removal Procedure

1. Remove necessary trim and outer panels.

2. Secure wiring harness away from repair area.

3. Locate the laser weld in the center pillar upper

area (Fig. 1-15).

4. Measure down 25␣ mm (1␣ in) from the laser

weld line and scribe a horizontal line. This is

the cut location.

5. At the front door rocker area, scribe a vertical

cut line within the preferred sectioning area.

6. At the rear door rocker area, scribe a vertical

cut line within the preferred sectioning area.

7. Cut on the three scribed lines.

8. Drill out factory spot welds noting their

location for installation of the service part.

9. Remove the damaged panel.

Fig.␣ 1-14 — 2000 DeVille Inner Center Pillar Detail

LASER WELD

25 MM

(1 IN)

1-10 2000 cadillac deville

Fig.␣ 1-15 — 2000 DeVille Inner Center Pillar

Page 12

NOTCH

FLANGES

NOTCH

FLANGES

LASER

WELD

NOTCH

FLANGES

NOTCH

FLANGES

Preparation of Service Part

1. Cut center pillar at laser weld location. This

will allow a 25␣ mm (1␣ in) overlap to the

vehicle for welding (Fig. 1-16).

2. Notch the weather strip flange to prevent

excessive metal thickness in these areas.

3. In front and rear door rocker areas of service

part, scribe vertical cut lines to allow a 50␣ mm

(2␣ in) overlap of original cut lines on vehicle.

4. Cut on the scribed lines. Notch the

weatherstrip and lower flanges to prevent

excessive metal thickness in these areas.

5. Drill 8␣ mm (5/16␣ in) plug weld holes every

40␣ mm (1-5/8␣ in) along rocker overlaps,

25␣ mm (1␣ in) from edge of overlap. On center

pillar, drill weld holes 13␣ mm (1/2␣ in) from

edge.

6. Drill 8␣ mm (5/16␣ in) plug weld holes on weld

flanges as noted from original panel.

Fig.␣ 1-16 — 2000 DeVille Inner Center Pillar – Preparation

Installation Procedure

1. Prepare mating surfaces.

IMPORTANT: Prior to refinishing, refer to

the publication GM4901M-D-2000 “GM

Approved Refinish Materials” for

recommended products. Do not combine

paint systems. Refer to paint manufacturerís

recommendations.

2. Prime repair areas with two-part catalyzed

primer.

3. Clamp part in position. Check for proper fit

(Fig.␣ 1-17).

4. Spot blast plug weld areas.

5. Plug weld as necessary.

6. Stitch weld along sectioned areas.

7. Finish seams as necessary.

8. Refinish as necessary.

9. Install all related panels and components.

Fig.␣ 1-17 — 2000 DeVille Inner Center Pillar – Installation

2000 cadillac deville 1-11

Page 13

Outer Wheelhouse

Sectioning

Removal Procedure

1. Locate horizontal laser-weld line in upper

quarter area (Fig. 1-18).

2. Measure down 25␣ mm (1␣ in) and scribe a cut

line.

3. On the vehicle rocker area, locate and scribe a

vertical cut line in the recommended section

area.

4. Cut panel at scribed locations.

5. Drill out factory welds. Note the number and

location of welds.

6. Remove the damaged panel.

Preparation Of Service Part

1. Locate laser weld line on service part

(Fig. 1-19).

2. Cut along laser weld line.

3. In specified sectioning location of rocker area,

create a vertical cut line. Allow for a 50␣ mm

(2␣ in) overlap of service part to rocker area on

the vehicle.

4. Cut service part along marked locations.

5. Trim a 20␣ mm x 50␣ mm (7/8 in x 2␣ in) tab at

top and bottom of section area of service part

to allow for a flush fit at pinch welds.

6. Drill plug weld holes in service part as noted

from original panel.

7. Drill 8␣ mm (5/16␣ in) plug weld holes along

section areas 25␣ mm (1␣ in) from edge on

rocker and 13␣ mm (1/2␣ in) from edge in upper

quarter area.

Installation Procedure

1. Install new part and clamp in place.

Check for fit.

IMPORTANT: Prior to refinishing, refer to

the publication GM4901M-D-2000 “GM

Approved Refinish Materials” for

recommended products. Do not combine

paint systems. Refer to manufacturer’s

recommendations.

2. Apply two-part catalyzed primer.

3. Spot blast weld areas.

4. Perform stitch weld, plug weld, grind and

finish as necessary.

5. Use a brushable seam sealer on inside seam.

6. Install all related panels and components.

MINIMUM

50 MM (2 IN)

CUT

LINE

Fig.␣ 1-18 — 2000 DeVille Outer Wheelhouse

SECTIONING

AREA

LASER WELD

CUT LINE

25 MM

(1 IN)

Removal

LASER WELD LINE

TRIM

TAB

TRIM

TAB

Fig.␣ 1-19 — 2000 DeVille Outer Wheelhouse

Preparation

1-12 2000 cadillac deville

Page 14

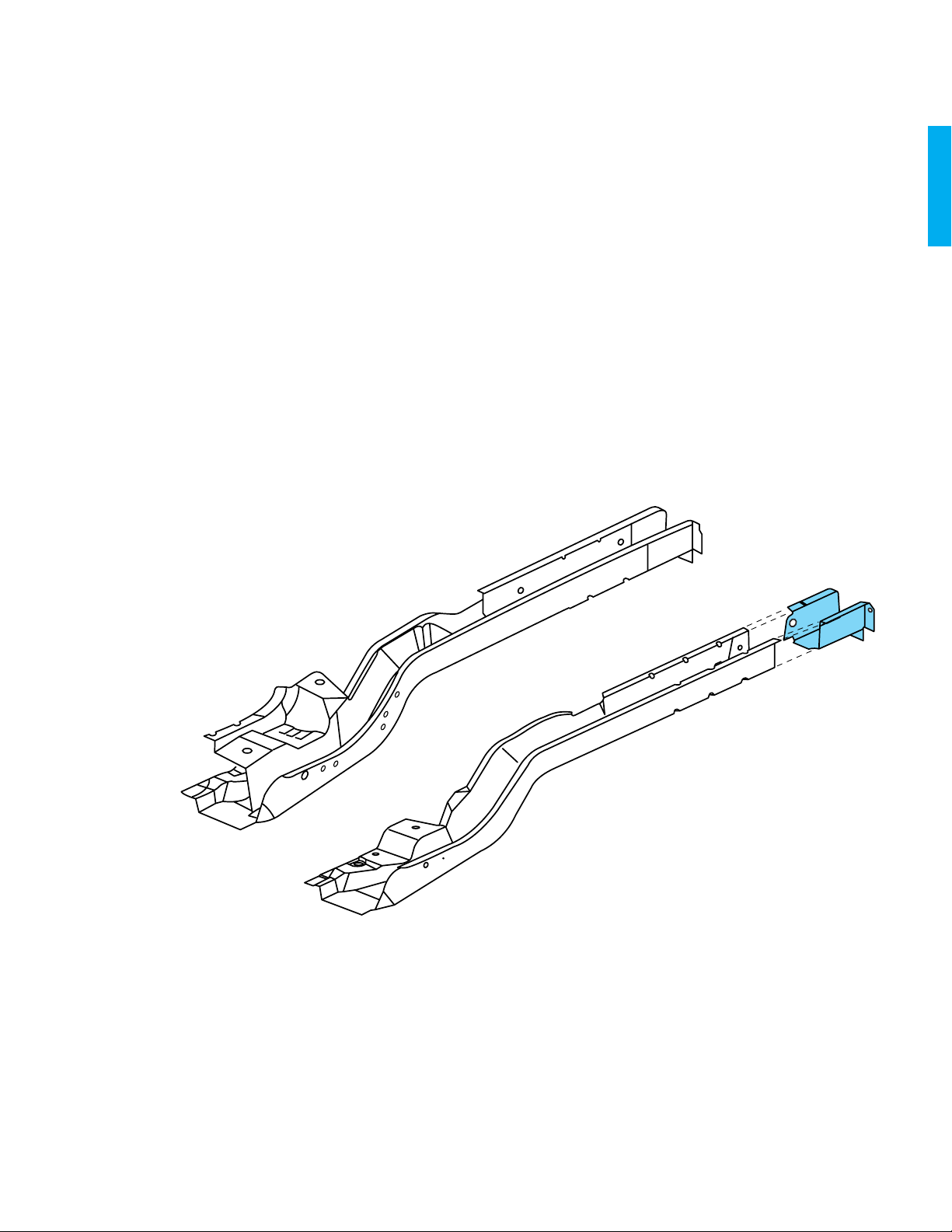

Rear Rail Sectioning

The rear rail is available as a complete assembly. It consists of an

outer panel, two inner reinforcements, a rail extension, and all

necessary component mounting brackets (Fig. 1-20). The outer

panel and rear mounting brackets are also available separately to

facilitate sectioning. Additionally, there is a crossbar that connects

the two rear rails for added strength and rigidity.

Complete rear rail replacement can be performed by drilling out all

the factory welds. The outboard flange at the forward end of the

rail must be cut in one location and bent upward, and the bottom

flange of the crossbar must be bent downward. The rear rail can

then be lowered from the vehicle (see Fig. 1-21). When installing

the service rail, the outboard flange must be cut and bent up, installed, then straightened, and aligned. Weld as necessary.

Rear rail sectioning procedures can be used to repair the rear rail if

just the portion rearward of the crossbar is damaged. The rear rail

outer panel is available separately for sectioning.

NOTE: The rail extension panel can also be purchased

separately.

Fig.␣ 1-20 — Rear Rail Panels

2000 cadillac deville 1-13

Page 15

Removal Procedure

1. Visually inspect and restore as much of the

damage as possible to factory specifications.

2. Remove all related panels and components.

3. Cut the rear rail along the rearward flange of

the crossbar (Fig. 1-21). Continue this cut

around the rear rail.

4. Drill out the factory welds on the end of the

rear rail inner reinforcement and extension.

5. Remove the damaged portion of the rear rail

and rail extension.

6. Either move the end of the rear rail inner rein-

forcement forward, or cut this part and remove

it from the rear rail.

1-14 2000 cadillac deville

Fig.␣ 1-21 — Full Rail Replacement

Page 16

FRT

Fig.␣ 1-22 — Cut the Rail for Sectioning

Fig.␣ 1-23 — Create Tabs on the New Rail

Section

Installation Procedure

1. Using the original part as a guide, mark a line

on the service rail 35␣ mm (1-5/16␣ in) forward

of the cut made to the original part; this

should be approximately 535␣ mm (21␣ in)

without the extension attached to the rail. This

will provide an overlap for welding the service

section (see Fig. 1-20).

2. Cut the service rail along the marked lines

and discard the unused section (Fig. 1-22).

3. Cut and remove approximately 35␣ mm

(1-5/16␣ in) of the flanges on the service-rail.

Cut a 5␣ mm (1/4␣ in) gap approximately

35␣ mm (1-5/16␣ in) along the corners of

the service rail to create tabs (Fig. 1-23).

4. Step the tabs inward to allow the service rail

to fit inside the original rail (Fig. 1-24).

5. Position the modified service rail inside the

original rail, allowing 35␣ mm (1-5/16␣ in)

of overlap.

6. Check the position of the service rear rail

section using three-dimensional measuring

equipment and tack weld in three locations

along all three sides of the rail (Fig. 1-25).

Stitch weld along the entire seam and replace

factory welds as necessary.

7. Drill two 8␣ mm (5/16␣ in) holes for plug

welding in each of the three sides of the rail

approximately 30␣ mm (1-3/16␣ in) from the

sectioning joint, plug weld through the drilled

holes into the service rail.

8. Clean and prepare welded surfaces.

IMPORTANT: Prior to refinishing, refer to

the publication GM4901M-D-2000 “GM

Approved Refinish Materials” for

recommended products. Do not combine

paint systems. Refer to manufacturer’s

recommendations.

9. Apply sealers and anti-corrosion materials as

necessary.

10. Prime with two-part catalyzed primer.

11. Install all related components.

Fig.␣ 1-24 — Step Tabs Inward on the New Rail

Section

FRT

Fig.␣ 1-25 — Install the New Rail Section

2000 cadillac deville 1-15

Page 17

Engine Compartment Dimensions – 2000 Cadillac

DeVille

Ø

A

B

C

ZERO

LINE

19 MM

GAGE

HOLE

F

ALL LENGTHS MEASURED

E

Description Location Length Width Height

Strut mount hole A 367 565 1014

Strut mount hole B 509 575 1029

Strut mount hole C 437 693 1027

Bumper mount hole D 1273 603 520

Bumper mount hole E 1273 605 640

Fender mount hole F 12 774 368

All dimensions are measured in millimeters, from a zero line, center line, and a common datum. All dimensions are symmetrical, unless otherwise specified.

D

FROM Ø LINE AT TOP

HINGE 19 MM HOLE

ALL MEASUREMENTS

HOLE CENTER TO CENTER

1-16 2000 cadillac deville

Page 18

Underbody Dimensions – 2000 Cadillac DeVille

Ø

540

WIDTH

504

427

430

496

553

577

HEIGHT

LENGTH

469 552 526

B

A

925

1092

C

888

348 358 537 496

D

1752

2537

E

F

3191

G

Description Location Length Width Height

28 mm mounting nut A 1092 540 469

19 mm x 25 mm gage slot B 925 504 552

16 mm gage hole C 0 427 526

19 mm gage hole D 888 430 348

23 mm gage hole E 1752 496 358

Top spring mounting pad F 2537 553 537

19 mm x 25 mm gage hole G 3191 577 496

All dimensions are measured in millimeters, from a zero line, center line, and a common datum. All dimensions are symmetrical, unless otherwise specified.

DATUM LINE

2000 cadillac deville 1-17

Page 19

Body Side Dimensions – 2000 Cadillac DeVille

ø

A

WIDTH

HEIGHT

LENGTH

829

836

591 930964 665 1004

0

B

0

1140

1140

840

849

C

D

E

2183

827

DATUM LINE

F

Description Location Length Width Height

19 mm gage hole A 0 — —

19 mm gage hole B 0 836 591

19 mm gage hole C 0 829 930

19 mm gage hole D 1140 840 964

Lower hinge bolt hole E 1140 849 665

16 mm upper latch mounting hole F 2183 827 1004

All dimensions are measured in millimeters, from a zero line, center line, and a common datum. All dimensions are symmetrical, unless otherwise specified.

1-18 2000 cadillac deville

Loading...

Loading...