Page 1

CADILLAC

OPERATOR'S

MANUAL

EDITION

NO.

355-CX1

In

ordering

a duplicate of

this

Manual

specify the

above

number or the engine number of the car.

Page 2

Table

of

Contents

CHAPTER

I—Cadillac

Service

3

Cadillac-La

Salle Service Stations—Identification

Card—Care

of the

Car—Authorized

Service—Preventive Service—Repair Parts—Service

Charges—Flac Rate Service—Standard Service Contract—Lubrication

Agreement.

CHAPTER

II—Lubrication 11

Lubrication

Schedule—Lubrication

Notice—LUBRICANTS—Engine

Oil—Transmission

Lubricant—Rear Axle Lubricant—Steering Gear

Lubricant—Chassis

Lubricant—Clutch

and Wheel Bearing Lubricant—

Water

Pump

Lubricant—ENGINE

LUBRICATION—Oil

Level—Crank-

case

Ventilating

System

and Oil Filter—Changing Engine

Oil.

CHAPTER

III-—Operation

18

Gasoline Gauge—Oil Pressure Gauge—Ammeter—Temperature Indicator—Throttle Control—Choke Control—Starting

the

Car—Starting

Hints—Ride

Regulation—Lighting Switch—DRIVING

HINTS—

Speed—Gravel Roads—Hills—Slippery Roads—Danger of Running

Car

in

Closed Garage.

CHAPTER

IV—Cold

Weather

Operation

26

PREPARING

FOR

COLD

WEATHER—Anti-Freezing

Solutions-

Winter

Lubrication—Storage Battery— Gasoline

System—STARTING

THE

ENGINE—Choke

Button—Position

of

Throttle Hand Lever-

Priming

the

Carburetor—Use

of

Starter—Use

of

Accelerator Before

Engine

is

Warm.

CHAPTER

V—Equipment . . . 32

Locks

and Keys—Ignition Switch Lock—Door Locks—Package

Com-

partment—Interior Lights

and

Switches—No-Draft Ventilation—

Windshield Cleaner—Sun Visor—Adjustable Seat—Cigar Lighter—

Tools—Tires—Use

of

Jack—Spare Wheel Carrier—Changing Wheels.

CHAPTER

VI—General

Care

42

Storage

Battery—Generator Charging Rate—Spark Plug—Cooling

System—Gasoline System—Carburetor Air Cleaner—Brakes—Tires—

Removing Tires from Wheels—Tire Balancing

Marks—Lights—Replac-

ing Map Lamp Bulb—Aiming

the

Headlamps—Storing

the

Car—

BODY—Care

of the

Finish—Care

of the

Top—Cleaning Upholstery

—Door

hardware—Body Adjustments.

CHAPTER

VII—Specifications and

License

Data

59

[2]

CHAFTER4_;<f

«W

CADILLAC

SERVICE

T

HE

OWNER

of

a Cadillac

motor

car has

purchased a fine

piece

of

machinery

to

serve

him as a

pleasant

and

dependable

means

of

transportation.

The

Cadillac

provides

this

means;

pleasant

because

of its

fine

performance,

comfort

and

ease of

con-

trol;

dependable

because

of the

care

with

which

it was

built

and

because

of

Cadillac

Service,

which

operates

on a

standard

policy,

guaranteeing

the

owner

efficient

service

everywhere

at

standard

prices

under

factory

regulation.

Cadillac-La

Salle

Ser-

vice

Stations

Cadillac

Service

is

available

wherever

Cadillac and La

Salle

cars

are

sold.

Service

stations

conducted

by

Cadillac distribu-

tors

and

dealers

are

designated

as "Authorized

Cadillac-La

Salle

Service

Stations,"

and are

identified

by the

exclusive

sign

shown

on

this

page.

Wherever

this

sign

is

displayed,

the

owner

will find an

organization

prepared

to

service

Cadillac

cars.

This

means

proper

equipment,

factory-trained

personnel,

a

stock

of

genuine

replacement

parts

and

standardized

policies

and

methods.

Fif.l.

AuthorizedCadillac-LaSalle

Service

Stations

display

this

sign

at

the

service

entrance.

[31

Page 3

Table

of Contents

CHAPTER

I—Cadillac

Service

. 3

Cadillac-LaSalle

Service

Stations—Identification

Card—Care

of the

Car—Authorized

Service—Preventive Service—Repair Parts—Service

Charges—Flat Rate Service—Standard Service Contract—Lubrication

Agreement.

CHAPTER

II—Lubrication

11

Lubrication

Schedule—Lubrication Notice—LUBRICANTS—Engine

Oil—Transmission

Lubricant—Rear Axle Lubricant—Steering Gear

Lubricant—Chassis

Lubricant—Clutch

and Wheel Bearing Lubricant—

Water

Pump

Lubricant—ENGINE

LUBRICATION—Oil

Level—Crank-

case

Ventilating

System

and Oil Filter—Changing Engine

Oil.

CHAPTER

III—Operation 18

Gasoline Gauge—Oil Pressure Gauge—Ammeter—Temperature Indicator—Throttle Control—Choke Control—Starting the Car—Starting

Hints—Ride Regulation—Lighting Switch—DRIVING

HINTS—

Speed—Gravel Roads—Hills—Slippery Roads—Danger of Running

Car

in

Closed Garage.

CHAPTER

IV—Cold

Weather

Operation

26

PREPARING

FOR

COLD

WEATHER—Anti-Freezing

Solutions-

Winter

Lubrication—Storage Battery— Gasoline

System—STARTING

THE

ENGINE—Choke

Button—Position of Throttle Hand Lever-

Priming

the Carburetor—Use of Starter—Use of Accelerator Before

Engine is

Warm.

CHAPTER

V—Equipment

. . . 32

Locks

and Keys—Ignition Switch Lock—Door Locks—Package

Com-

partment—Interior Lights and Switches—No-Draft Ventilation—

Windshield Cleaner—Sun Visor—Adjustable Seat—Cigar Lighter—

Tools—Tires—Use of Jack—Spare Wheel Carrier—Changing Wheels.

CHAPTER

VI—General

Care

42

Storage

Battery—Generator Charging Rate—Spark Plug—Cooling

System—Gasoline System—Carburetor Air Cleaner—Brakes—Tires—

Removing Tires from Wheels—Tire Balancing Marks—Lights—Replac-

ing Map Lamp Bulb—Aiming the Headlamps—Storing the

Car—

BODY—Care

of the Finish—Care of the Top—Cleaning Upholstery

—Door hardware—Body Adjustments.

CHAPTER

VII—Specifications

and

License

Data 59

[2]

CHAPTER^

/<t£

fa

CADILLAC

SERVICE

* //^>r.

T

HE

OWNER

of a Cadillac

motor

car has purchased a

fine

piece

of machinery to

serve

him as a

pleasant

and

dependable

means

of transportation. The Cadillac

provides

this

means;

pleasant

because

of its

fine

performance, comfort and

ease

of con-

trol;

dependable

because

of the

care

with

which it was built and

because

of Cadillac

Service,

which

operates

on a standard

policy,

guaranteeing

the

owner

efficient

service

everywhere

at

standard

prices

under factory

regulation.

Cadillac-La

Salle

Ser-

vice

Stations

Cadillac

Service

is

available

wherever

Cadillac and La

Salle

cars

are sold.

Service

stations

conducted

by Cadillac distribu-

tors

and

dealers

are

designated

as "Authorized Cadillac-LaSalle

Service

Stations,"

and are

identified

by the

exclusive

sign

shown

on

this

page.

Wherever

this

sign

is displayed, the ^-

1

' Authorized

Cadillac-La

Salle

.„

_ , . . Service

Stations

display

this

sign

at

owner

will find an

organization

the

service

entrance.

prepared to

service

Cadillac

cars. This

means

proper

equipment,

factory-trained

personnel,

a

stock

of

genuine

replacement

parts

and standardized

policies

and

methods.

131

Page 4

1

9

Page 5

1

joe car

qy^^y^ist

and most frequent contact with

Cadillac

fServke

i|^(ij;irry

will

be in the service station of the distributor

fciQeJler

who sold

him

the

car and

who therefore has the

greatest

interest at stake in assuring him satisfaction.

Cadillac

Service is

so organized, however, that the owner may feel perfectly free to

use his

car

for extended travel, secure in the knowledge that other

Authorized

Cadillac-La

Salle Service Stations are able

and

willing

to offer the

same

service benefits to which he is entitled at his

local

service station.

Identification

Card

As

a means of introduction at other

Authorized

Cadillac-

La

Salle Service Stations, every purchaser of a

Cadillac

car is

given credentials in the

form

of an Identification

Card.

This

card

is mailed to the owner by the

Cadillac

Motor

Car

Company

as soon as delivery of the car is reported by the distributor or

———^

dealer. It is

supplied

in a

cel-

luloid

case

and is intended

to be

carried

in a holder on

the

car.

This

holder

is located under the cowl in the

driving

compartment on the

right-hand

side of the car

as shown in

figure

3-

Upon

presentation of this

Identification

Card

at any

Authorized

Cadillac-LaSalle

Service

Station, the car

owner is assured of

standard

CADILLAC

IDENTIFICATION CARD

115 Third

Street.

MortoaYllle.

N. 1.

i

d.Hn.y

.1

Ca4iH.<

....

Ca«tii*

M~

5000000

»^SsiillS£_l»Salle SaiesJ&aiBKL-

Mortonvllle, II,

Y.

Sf „

Jsnuary

1, 1953 .„j,. „ _i„

£4 \ PROMPT, EFFICIENT

-nd

COURTEOUS

....1«

l.om

ANY

* A l/THORlZEO

CADILLAC

SERVICE

STATION-

CADILLAC

MOTOR CAR

COMPANY,

Ortrrtt.

Mich.

Fig.

2. The [Identification

Card,

when

properly

signed, introduces the owner at

any

Authorized

Cadillac-La

Salle Service

Station.

Cadillac

Service under factory regulation.

Care

of the

Car

A

fine piece of machinery, such as the

Cadillac,

naturally re-

quires

a certain amount of care to assure smooth

running,

de-

pendability

and

long life, and the owner

will

derive the utmost in

14]

continuous satisfaction and utility

from

operation of the car by

following

the instructions given below:

1.

Drive

the

car

at moderate

speeds

for the first 500 miles. •

2. Operate the car in accordance with the instructions con-

tained

in this

manual.

3.

Check

the engine oil level every 100 to 150 miles and add

oil

as often as necessary to keep the indicator at

"Full."

4.

Check

the air pressure of the tires at

least

once a

week

and

keep it up to the recommended pressure—40 pounds front and

rear;

on cars driven at high

speeds,

45 pounds in front.

5. Add distilled water to

the storage battery every

1000 miles, and in warm

weather every 500 miles, or

at

least

every two

weeks.

6.

Have

the

car

lubricated

every 1000 miles, or at

least

once each month in ac-

cordance

with

the

lubrication

schedule given on page 10.

7. Have the car inspected

by

an

Authorized

Cadillac-

La

Salle Service Station

every 1000 miles, or at

least

once a month.

Fig.

3.

The

Identification

Card

should be

kept in its holder under the cowl at all

times.

Authorized

Service

The

first five

items

above do not necessarily warrant a visit to

the service station.

The

last two, however,

require

the attention

of

those

whose

knowledge and experience qualifies them to per-

form

the

required

work efficiently

and

in

accordance

with factory

recommendations.

A

car

such as the

Cadillac

V-8,

built with

skill,

precision and

151

Page 6

9

Page 7

fine

workmanship, is deserving of the finest care of qualified ex-

perts

in any service work

that

may be required. Authorized

Cadillac-La

Salle Service Stations are qualified to do this work in ''

t

a

manner not to be duplicated elsewhere

because

they have

greater

reason to be interested in the operation of the

Cadillac

owner's

v

car. Their personnel are specialists; they have had more experience on

Cadillac

and La Salle cars than anyone

could

have

who

works on all makes of cars. They have up-to-date, expert

information

on

Cadillac

adjustments and service methods supplied j>

by

the factory in regular publications and special bulletins. [

Preventive Service

i

Preventive service is the fundamental principle of

Cadillac

Service.

It is based on the knowledge

that

regular expert

atten-

tion

keeps emergency service at a minimum, assuring continuous >

satisfactory operation of the car

with

a minimum of interruption

and expense.

The

first thought, of course, is the proper protection of all

working

parts

through correct lubrication according to schedule.

The

second, of

great

importance, is systematic inspection every

1000

miles, or once a month, so

that

any necessary adjustments

may be made before the need becomes an emergency. <

Authorized

Cadillac-La

Salle Service Stations

will

make such

inspections without charge. Lubrication and any necessary

adjustments

will

then be performed at standard prices under '

factory

regulation after the owner has approved the work and the

prices.

'i

Repair

Parts t

}

Genuine

Cadillac

parts, manufactured to the

same

rigid

specifi-

cations as the

parts

originally

used in the car, are carried in stock

by

Authorized

Cadillac-La

Salle Service Stations. They are

sold

at uniform prices throughout the

United

States

and are not subject to the addition of handling, excise or other supplementary '

charges. Printed price lists, published by the

Cadillac

Motor

Car

Company, are open to inspection by owners at any

Cadillac

distributor's or dealer's service station.

Service

Charges

Authorized

Cadillac-La

Salle Service Stations, in line

with

the

Cadillac

policy

of serving the owner to his

best

advantage, are

prepared to offer service in

three

ways:

1. Individual operations on a flat-rate basis, authorized by the

owner as occasion requires.

2. A Standard Service Contract covering complete mechanical

maintenance—lubrication, inspection, all adjustments and repairs—over a period of one year or

12,000

miles at a

fixed

price.

3. A Lubrication Agreement covering 12 scheduled lubrica-

tions and 12 thorough inspections over a period of

12,000

miles

at a

fixed

price. Under this plan any adjustments or repairs the

owner authorizes are paid for as

individual

operations.

The owner may obtain service in any of

these

three

ways he

chooses. Certain

advantages

are to be derived from the Standard

Service

Contract or the Lubrication Agreement, but the owner

may purchase service in any of

these

forms

with

perfect

assurance

that

the work

will

be done in accordance

with

Cadillac

standards.

Flat

Rate Service

When

a car

enters

the service station, it is promptly inspected

by

an expert

tester

who

quotes

the owner an exact price,

which

in

practically

every

case

includes material as

well

as labor, for the

work

he finds necessary. The owner then authorizes the work at

this price and when he receives the

bill,

this is the price he pays.

Charges prevailing at Authorized Service Stations are based on

standard schedules furnished by the

Cadillac

Motor

Car

Com-

pany. These schedules

call

for methods and tools approved by

the

same

engineers who designed and built the car,

thus

assuring

the highest quality of work at the lowest possible price. Standard

price

schedules are open to owners for inspection at any Author-

ized

Cadillac-La

Salle Service Station.

[61

[71

Page 8

ft

Page 9

IN

Standard

Service

Contract

'

The

Standard

Cadillac

Service Contract is available to owners j

who wish to be assured of continuous satisfactory operation and v

maintenance of their cars at a predetermined, economical

cost.

^

It is based on Cadillac's principle of preventive service insuring

the

greatest

satisfaction with the

fewest

possible interruptions. f

Complete

lubrication on schedule and thorough inspection to j

anticipate the need of adjustment and repair largely eliminates

the need of service

between

regular inspections. *

The

Service Contract is recognized by all Authorized

Cadillac-

i

La

Salle Service Stations in the United

States

regardless of where

it may have been purchased. The owner is thus assured of all ,'

Contract

service due him without additional charge wherever

he may travel. He

needs

only to present the identification

card

issued to him at the time the

Contract

is purchased to receive this '

service the

same

as if the work was performed by the service >

station from which the

Contract

was purchased.

These contracts are available at all

Authorized

Service Stations.

Three

contracts are available to cover each of three periods; the

first year or first

12,000

miles, the second year or second

12,000

miles and the

third

year or

third

12,000

miles, respectively.

Owners

are urged to take advantage of the conveniences offered

by

Contract

ownership to obtain efficient and expert service under ,

factory regulations for their cars at the predetermined economical

1

cost.

'

Lubrication

Agreement

Owners

who do not purchase a Service Contract are urged to ^

purchase a

Lubrication

Agreement.

Lubrication

according to i

schedule is the most important attention required by the car

and

<

the

Lubrication

Agreement

assures

this service regularly over

a period of

12,000

miles at a saving of more than

30%

of the total

cost

of the

twelve

operations if

paid

for

individually.

i

The

Lubrication

Agreement is recognized by all Authorized i

Cadillac-La

Salle Service Stations in the United

States,

the

same

as the Service Contract, and the identification cardneed only be-'

presented to have the work scheduled performed at any/Authorized Service Station regardless of where the Agreement' was

purchased.

The

holder of a

Lubrication

Agreement is relieved of the

thought of lubrication

cost

during the entire

12,000

mile period

by

budgeting his

expense

beforehand. He

needs

only take his car

to the service station at monthly or 1000 mile intervals and

request "schedule lubrication" to obtain all of the lubricarion

due, performed according to factory specifications.

Regardless of how the owner prefers to have the

necessary service performed on his car, the surest

guarantee of long life and complete motoring

satis-

faction at the

least

possible

expense

is correct

lubrication and preventive service rendered every 1,000 miles

or

once

a month by an Authorized

Cadillac-La

Salle

Service Station.

18]

19]

Page 10

1

Page 11

OWNEF

ADORE

ENG1N

LUBRICATION

SCHEDULE

CADILLAC

355-C

'S

MAMJT

OWNEF

ADORE

ENG1N

OWNEF

ADORE

ENG1N

E

NO

DATF

DPI

ivpnrn

OO NOT

WAIT

FOR

SCM&OULt

LUBRICATIONS

BEFORE ADDING ENGINE OIL.

THE

OIL. LEVEL

SHOULD BE

CHECKED

EVERT

109

TO

1*0

MILES

ANO

OIL

ADDED

IF THE

IHOtCATOR

CALL \%

BELOW

"FULL."

THIS

IS

ESPECIALLY IM-

PORTANT ON

CARS

DRIVEN

AT

HIGH

SPEEDS.

LUBRICANT

LUBRICATION

NO. AND MILEAGE AT

WHICH

DUE

OO NOT

WAIT

FOR

SCM&OULt

LUBRICATIONS

BEFORE ADDING ENGINE OIL.

THE

OIL. LEVEL

SHOULD BE

CHECKED

EVERT

109

TO

1*0

MILES

ANO

OIL

ADDED

IF THE

IHOtCATOR

CALL \%

BELOW

"FULL."

THIS

IS

ESPECIALLY IM-

PORTANT ON

CARS

DRIVEN

AT

HIGH

SPEEDS.

LUBRICANT

1

*

4

< I

• •

ta II

OO NOT

WAIT

FOR

SCM&OULt

LUBRICATIONS

BEFORE ADDING ENGINE OIL.

THE

OIL. LEVEL

SHOULD BE

CHECKED

EVERT

109

TO

1*0

MILES

ANO

OIL

ADDED

IF THE

IHOtCATOR

CALL \%

BELOW

"FULL."

THIS

IS

ESPECIALLY IM-

PORTANT ON

CARS

DRIVEN

AT

HIGH

SPEEDS.

LUBRICANT

1 1 1 1

i

I I

000«

I

100001

1

I

0

z

<

0

z

z

0

<

0

z

as

D

J

«i

O

z

<

(ft

0

z

z

0

<

o

tz

a

0

J

| LUBRICATION NOS.

2,

4.

8

ANO

10

0

Z

<

tl)

0

z

z

0

h

<

0

IT

tn

0

-J

ADO

LIQUID

TO

RADIATOR

WATER

OR

ANTI.

FREEZE

O

0

O o o

O

0

o

O O O O

0

z

<

0

z

z

0

<

0

z

as

D

J

«i

O

z

<

(ft

0

z

z

0

<

o

tz

a

0

J

| LUBRICATION NOS.

2,

4.

8

ANO

10

0

Z

<

tl)

0

z

z

0

h

<

0

IT

tn

0

-J

ADD

ENGINE

OIL

AS

NECESSARY

ENGINE

OIL

o

O

O

o o o

0

z

<

0

z

z

0

<

0

z

as

D

J

«i

O

z

<

(ft

0

z

z

0

<

o

tz

a

0

J

| LUBRICATION NOS.

2,

4.

8

ANO

10

0

Z

<

tl)

0

z

z

0

h

<

0

IT

tn

0

-J

STMtTEB.

GENERATOR

*Ht>

DISTRIBUTOR

Oft

CUPS

BRAKE

AND

RIDf

REGULATOR

PINS

AND

CONNECTIONS

BME^EEEEEEEEEEl

•HHEEEEEEEEEEEEi

0

z

<

0

z

z

0

<

0

z

as

D

J

«i

O

z

<

(ft

0

z

z

0

<

o

tz

a

0

J

| LUBRICATION NOS.

2,

4.

8

ANO

10

0

Z

<

tl)

0

z

z

0

h

<

0

IT

tn

0

-J

ACCELERATOR

ROCKER

SHAFT

O

o o o O

o o

O

O

E

O

El

0

z

<

0

z

z

0

<

0

z

as

D

J

«i

O

z

<

(ft

0

z

z

0

<

o

tz

a

0

J

| LUBRICATION NOS.

2,

4.

8

ANO

10

0

Z

<

tl)

0

z

z

0

h

<

0

IT

tn

0

-J

DOOR

HAROWARE

FNGINE

OIL

o o o o

O

O

O O O O

o o

0

z

<

0

z

z

0

<

0

z

as

D

J

«i

O

z

<

(ft

0

z

z

0

<

o

tz

a

0

J

| LUBRICATION NOS.

2,

4.

8

ANO

10

0

Z

<

tl)

0

z

z

0

h

<

0

IT

tn

0

-J

OREASE

GUN

CONNECTIONS

LUBRICANT

o o

o O O

O

O O O

o

O

o

0

z

<

0

z

z

0

<

0

z

as

D

J

«i

O

z

<

(ft

0

z

z

0

<

o

tz

a

0

J

| LUBRICATION NOS.

2,

4.

8

ANO

10

0

Z

<

tl)

0

z

z

0

h

<

0

IT

tn

0

-J

WATER

PUMP

GREASE

CUP

WATER

PUMP

LUBRICANT

o o o

O

O

O

O

o

O

o

O O

0

z

<

0

z

z

0

<

0

z

as

D

J

«i

O

z

<

(ft

0

z

z

0

<

o

tz

a

0

J

| LUBRICATION NOS.

2,

4.

8

ANO

10

0

Z

<

tl)

0

z

z

0

h

<

0

IT

tn

0

-J

CLUTCH

RELEASE

FORK

WHEEL

BLARING

LUBRICANT

o

o o

o

O

o

O O

o

O O

o

0

z

<

0

z

z

0

<

0

z

as

D

J

«i

O

z

<

(ft

0

z

z

0

<

o

tz

a

0

J

| LUBRICATION NOS.

2,

4.

8

ANO

10

0

Z

<

tl)

0

z

z

0

h

<

0

IT

tn

0

-J

•ADD

WATER

TO

STORAGE

BATTERY

OIS

TILLED

o

o

o

o

a

o

o

O O

o

O

O

0

z

<

0

z

z

0

<

0

z

as

D

J

«i

O

z

<

(ft

0

z

z

0

<

o

tz

a

0

J

| LUBRICATION NOS.

2,

4.

8

ANO

10

0

Z

<

tl)

0

z

z

0

h

<

0

IT

tn

0

-J

CHECK

TIRE

INFLATION

ESEEEEEEESE3

0

z

<

0

z

z

0

<

0

z

as

D

J

«i

O

z

<

(ft

0

z

z

0

<

o

tz

a

0

J

| LUBRICATION NOS.

2,

4.

8

ANO

10

DRAIN

ANO

REPLACE

ENGINE

OIL

.NGINI-.

OIL

•

o

•

o

• O • O •

O

•

o

0

z

<

0

z

z

0

<

0

z

as

D

J

«i

O

z

<

(ft

0

z

z

0

<

o

tz

a

0

J

| LUBRICATION NOS.

2,

4.

8

ANO

10

CLUTCH

RELEASE

BEARING

WHEEL

HEARING

LUBRICANT

o

o

o

O O

o

0

z

<

0

z

z

0

<

0

z

as

D

J

«i

O

z

<

(ft

0

z

z

0

<

o

tz

a

0

J

TRANSMISSION—M>0

LUBRICANT

TRANSMISSION

LUBRICANT

o O

O

o

0

z

<

0

z

z

0

<

0

z

as

D

J

«i

O

z

<

(ft

0

z

z

0

<

o

tz

a

0

J

REAR

AXLE—ADD

LUBRICANT

REAR A ALE

LUBRICANT

o O

O

o

0

z

<

0

z

z

0

<

0

z

as

D

J

«i

O

z

<

(ft

0

z

z

0

<

o

tz

a

0

J

STEERiNO

GEAR—ADD

LUBRICANT

STEERING

GEAR

LUBRICANT

O O

O

O

0

z

<

0

z

z

0

<

0

z

as

D

J

BRAKE

ASSISTER

LIGHT

MACHINE

Oil.

O

o

0

z

<

0

z

z

0

<

0

z

as

D

J

SFRINO

COVERS

GEAR

LUBRICANT

O

O

0

z

<

0

z

z

0

<

0

z

as

D

J

WHEEL

BEARINGS

WHEEL

BEARING

LUBRICANT

O

O

0

z

<

0

z

z

0

<

0

z

as

D

J

S

PEEOO

METER

OR

IVE

SHAFT

LUBRICANT

O

O

0

z

<

0

z

z

0

<

0

z

as

D

J

"REFILL

SHOCK

ABSORBERS

SFECIAL

OIL

O

o

0

z

<

0

z

z

0

<

0

z

as

D

J

"CLEAN

CARBURETOR

AIR

CLEANER

O

o

0

z

<

0

z

z

0

<

0

z

as

D

J

"FLUSH

COOLING

SYSTEM

AND

ADO INHIBITOR

O

o

••REPLACE

OIL FILTER

CARTRIOGE

CLEAN

OIL PAN ANO

SCREEN

EVERY

12.O00

MILES

o

•IN

SUMMER

INSPECT

BATTER*

INVERT

IOO

MILES

OR AT

LEAST

EVERT t WEEKS,

"RECOMMENDED

BUT NOT

INCLUDED

IN

LUBRICATIONS

• AND

II.

THE

FOLLOWING

OPERATIONS

CANNOT

BE PLACED ON A

MILEAGE

BASIS

AND ARC NOT

INCLUDED

IN)

THE

ABOVE

SCHEDULE;

CHANGE

REAR

AXLE

AND

TRANSMISSION

LUBRICANT—At

REQUIRED

FOR LOW

TEMPERATURES

IM

FALL

OR

WINTER ANO AT

BEGINNING

OF

MILD

WEATHER

"N

SPRING.

RECORD

ON

OTHER

SIDE

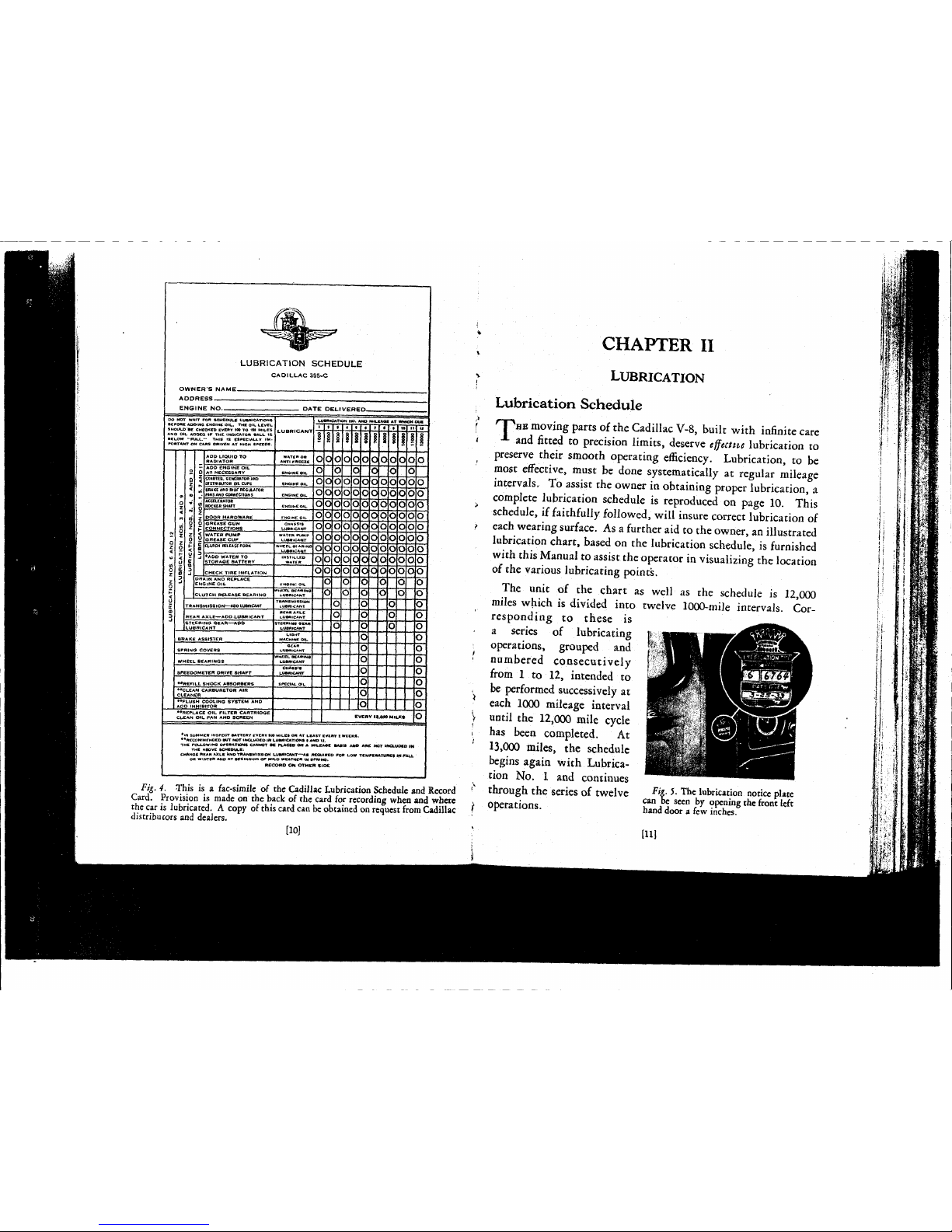

Fig.

4. This

is a

fac-simile

of

the Cadillac Lubrication

Schedule

and Record

Card.

Provision

is

made

on the back

of

the card for recording

when

and

where

the car is lubricated. A copy

of

this

card can be

obtained

on

request

from Cadillac

distributors

and

dealers.

[10]

CHAPTER

II

LUBRICATION

Lubrication

Schedule

T

HE

moving parts of the

Cadillac

V-8,

built with infinite care

and

fitted

to

precision limits,

deserve

tffectne

lubrication

to

preserve their

smooth

operating efficiency. Lubrication,

to be

most

effective,

must

be

done

systematically

at

regular

mileage

intervals, To

assist

the owner in obtaining proper lubrication,

a

complete

lubrication

schedule

is

reproduced on

page

10. This

schedule,

if faithfully followed, will insure correct lubrication of

each

wearing surface. As a further aid to the owner, an illustrated

lubrication chart,

based

on the lubrication

schedule,

is furnished

with

this

Manual

to

assist

the operator in visualizing the location

of the various lubricating points.

The

unit

of

the

chart

as

well

as

the

schedule

is

12,000

miles

which is divided into

twelve

1000-mile

intervals.

Cor-

responding

to

these

is

a

series

of

lubricating

operations, grouped

and

numbered

consecutively

from

1 to

12,

intended

to

be performed

successively

at

each

1000

mileage

interval

until

the

12,000

mile

cycle

has

been

completed.

At

13,000

miles,

the

schedule

begins

again with

Lubrica-

tion No. 1 and

continues

through the

series

of

twelve

Fi£-J

-

The lubrication

notice

plate

.

can

be

seen

by

opening

the

front

left

Operations. hand

door

a few

inches.

[11]

Page 12

Lubrication

Notice

^

|Arnetal

plate in the shape of the

Cadillac

Crest is provided to

|\y

serve as a lubrication

notice

and

record.

This

plate is mounted on

y

the left front door

pillar

just below the top hinge as shown in

figure

5.

Authorized

Cadillac-La

Salle Service Stations, after

performing

each schedule

operation,

post on this plate the

number

of the next

operation

and the mileage at which it

will

be due.

Thus,

when

the mileage

recorded

on

the speedometer is the same as the mileage

marked

on the notice, the car may be taken to any

Authorized

Cadillac-La

Salle Service Station, and, without further ordering

other than specifying "schedule

lubrication,"

the

car

will

receive

the exact

lubrication

necessary.

Although

the schedule is expressed in terms of miles the car

should

be lubricated once each month even though the mileage

indicated

on the speedometer is

less

than

1000

since the last

lubrication

operation was performed. The

lubrication

work can

be done while the car is in the service station for its regular

monthly

or

1000

mile inspection.

Lubricants

The

selection of proper lubricants should be one of the first

concerns of the owner in his attention to the lubrication of the

car.

The lubricants must not only be of high quality but their

viscosity and other characteristics must be suited to the purpose

for

which they are to be used.

Cadillac

engineers have worked out in detail the specifications

for

the lubricant required for each point to

meet

the particular

conditions of speed, load, temperature and

kind

of metals in

contact.

Authorized

Cadillac-La

Salle Service Stations are prepared to

furnish

lubricants under

these

specifications to give the

best

re-

sults

in their respective localities.

When

the car is

lubricated

by

[12]

someone not familiar with

Cadillac

specifications, lubricants

should

be

called

for

by

the

S. A. E.

viscosities

recommended

in

the

following

paragraphs.

Engine

Oil

Engine

oil recommendations are given in the chart below. It

should

be noted that different grades of oil are to be used for

average

driving

and for prolonged high speed

driving

in both

summer

and

winter.

SUMMER

WINTER

TYPE

OF

TYPE

OF

SERVICE

AH

Temperatures

Above

32°

F.

Between

32°

and

Below

15°

Above

AH

Temperatures

Above

32°

F.

15°

Above

Zero

AVERAGE

S.

A. E.

S.

A. E.

S.

A. E.

DRIVING

vise. 40

vise. 20

vise

10

(No prolonged

or

50

(No prolonged

or

50

high

speed

These

oils

are not

suitable

for

prolonged

driving)

high

speed

driving

and if

used

under

such

driving)

conditions

the oil

levil mart

1»

watched,

as the

rate

be

higher

than

with

heavier

oils.

CADILLAC

APPROVED "HEAVY DUTY" OILS-

SUMMER

AND

WINTER

These oils have an S. A. E. viscosity of

40-50-60,

and are

required

to

meet

certain specifications as to volatility in

order

to demonstrate their

fitness

for prolonged high speed

Idriving.

To make certain of using an oil approved for this

service, consult your

Cadillac

distributor or dealer,

j

NOTE:

Approved

heavy duty oils vary in their suita-

bility

for winter use. If an approved heavy duty oil with

sufficiently low cold viscosity is not available and if the car

is not kept in a heated garage, the lighter oils specified

jabove for average

driving

must be used to avoid

hard

start-

ling.

In this

case,

be sure to watch the oil level closely as

cautioned above.

f.

^V7"

601

u,sed

in

fable t0

designate

body

or

viscosity

is

the one

d™-!™™!

by

the Society

of

Automotive

Engineers^

adopted

by

alToU

compares

1¾

the place : of the old mdefinite method of describing oils as "St "

"Medium

"

arte /

tC

- °i

Sh°Uld

•*

Called

for

h

r

^numbers. If a

fillings

taSon

lS^d0?-

n0t

kn°W

S- A- E

Dambas

°

f his

*c

followinggfadS"an

PROLONGED

HIGH SPEED

DRIVING

[131

Page 13

Transmission

Lubricant

Gear

oil of S. A. E. viscosity 160 should be used in the trans-

mission at temperatures above 20° F. For temperatures below

20°

F,

a light oil of S. A.

E.

viscosity 90 should be used or the oil

used during summer weather should be thinned with kerosine.

Some of the lubricants designated by

"EP"

following their

S. A.

E.

classification, and

some

other lubricants which are being

marketed,

are injurious to bronze parts and should not be used in

Cadillac

cars under any circumstances. Likewise,

soap

greases

will

not satisfactorily lubricate

these

gears

and should not be

used.

Rear

Axle

Lubricant

Gear

lubricant of S. A. E. viscosity 160 should be used in the

rear

axle. For extremely low temperatures, it may be necessary

to change to a light lubricant of S. A. E. viscosity 90 or to thin

the lubricant with kerosine as

suggested

under "Transmission

Lubricants."

Steering

Gear

Lubricant

The

selection of the proper lubricant for the steering gear is of

special importance, particularly to avoid

hard

steering in cold

weather. A special steering gear lubricant suitable for extreme

heat

and cold is available and should be used in the steering gear

the year

round.

Chassis

Lubricant

A

good

grade of

chassis

lubricant

should be used for all

chassis

points indicated in the lubrication chart as requiring this type of

lubricant.

Ordinary

cup

grease

is not satisfactory and if, in an

emergency, it is used in place of

chassis

lubricant,

the

car

should

again be lubricated within 300 or 400 miles.

Clutch

and

Wheel

Bearing

Lubricant

The

front wheel bearings and the clutch

release

bearingshould

be

lubricated with a good grade of

Clutch

and Wheel Bearing

[141

Lubricant

having a high melting point.

Ordinary

grease

at

these

points is likely to melt and run on to the brakes or the

clutch.

Water

Pump

Lubricant

A

water-resistant

calcium

soap

lubricant

having a high melting

point is recommended for use in the water pump

grease

cup.

Only

lubricants of this type should be used; other

lubricants

will

be dissolved into the cooling

system

liquid.

Cup

greases

and

wheel bearing lubricants are entirely unsuited for this purpose.

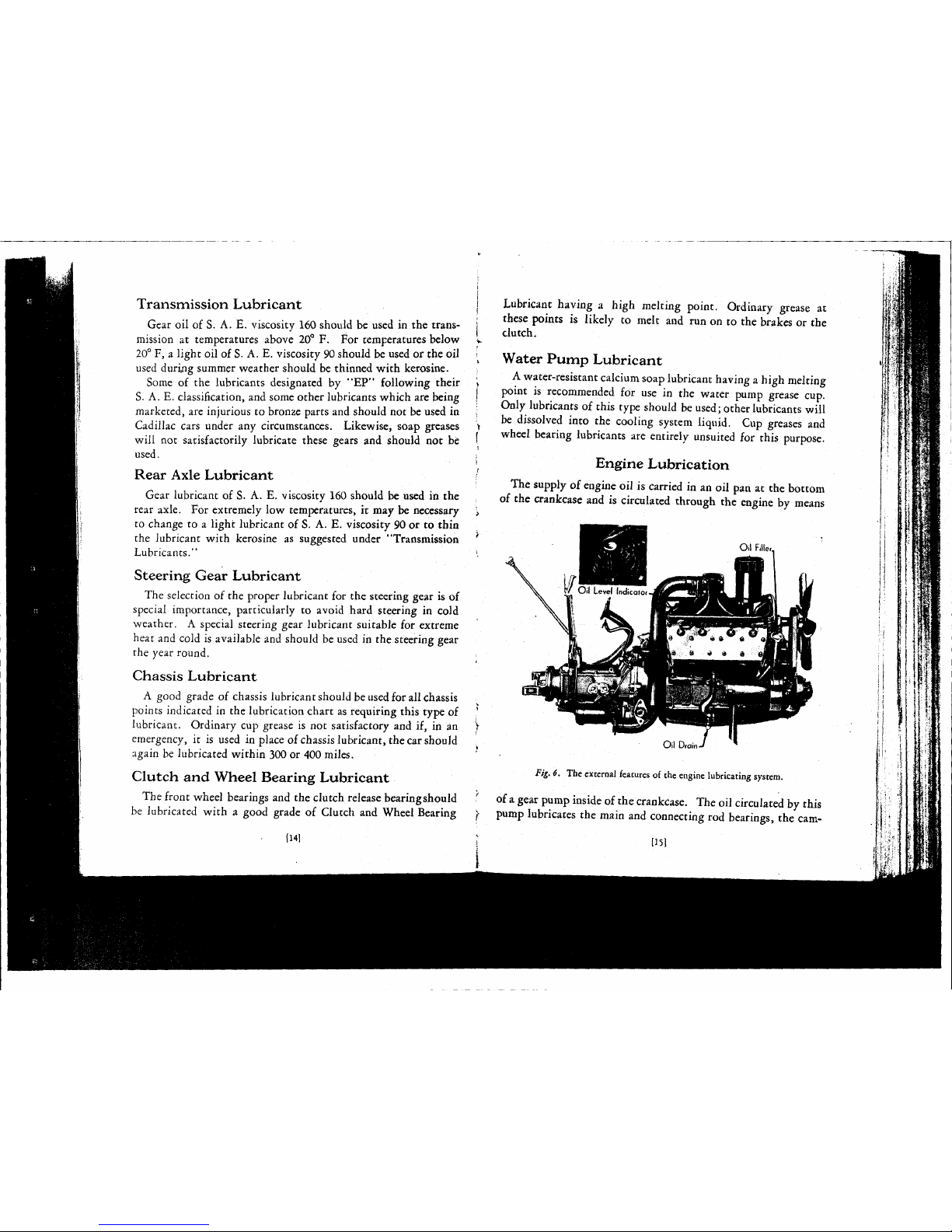

Engine

Lubrication

The

supply of

engine

oil is carried in an oil pan at the bottom

of

the crankcase and is circulated through the

engine

by means

Fig.

6. The external features of the

engine

lubricating system.

of a gear pump inside of the crankcase. The oil circulated by this

pump

lubricates the main and connecting rod bearings, the cam-

[15]

Page 14

shaft bearings, the

cylinder

walls, the pistons and the piston pins,

the front end chains, the valve mechanism and the fan.

There

are a few points on the engine that cannot be taken care

of

by the pressure system and

these

points should be lubricated

according

to the instructions given in the

lubrication

chart.

This

includes the starting motor, the generator, the distributor and

the water pump.

Oil

Level

The

normal

capacity of the oil pan is eight

quarts

which

fills

it

to the level of the screen in the pan.

When

the oil pan contains

this amount the oil level indicator

between

the two blocks at

the rear of the engine (figure 6)

shows

"Full."

The oil level

should

be checked every 100 to 150 miles and, whenever

neces-

sary,

enough oil should be added to

bring

the indicator up to

"Full."

It should never be permitted to drop below

"Fill."

Particular

attention should be

paid

to the oil level in

case

of

prolonged

driving

at high speed. At high

speeds

the oil is con-

sumed many times as

rapidly

as at city

driving

speeds

and oil

must be added more frequently to maintain the

proper

level.

Crankcase

Ventilating System and

Oil

Filter

Cadillac

V-8

engines

are equipped with a crankcase ventilating

system and an oil filter to keep the oil in the

best

condition

possible.

The

ventilating system,

which

functions automatically,

prevents dilution and contamination of the oil by removing the

vapors which

seep

past the pistons.

The

oil filter removes

dirt

and solid matter

from

the oil

until

it gradually

becomes

so clogged that it

ceases

to function. The

filter

cartridge

must then be replaced.

Normally,

replacement

should

be at

12,000

miles. The oil pan and screen should be

removed

and thoroughly washed with gasoline every

12,000

miles to remove any carbon or foreign particles that may

have collected.

116]

Changing

Engine

Oil

The

useful life of the engine oil is greatly prolonged by the use

of

the crankcase ventilating system and the oil filter, but the oil

pan

should be drained and the engine oil replaced every

2000

miles. To

drain

the oil, simply remove the

drain

plug (figure 6)

and

allow the oil to flow into a receptacle placed under the car.

The

drain

plug should then be reinstalled and tightened securely

before pouring in fresh

oil.

Eight

quarts are required to

bring

the oil level indicator to

"Full."

1171

Page 15

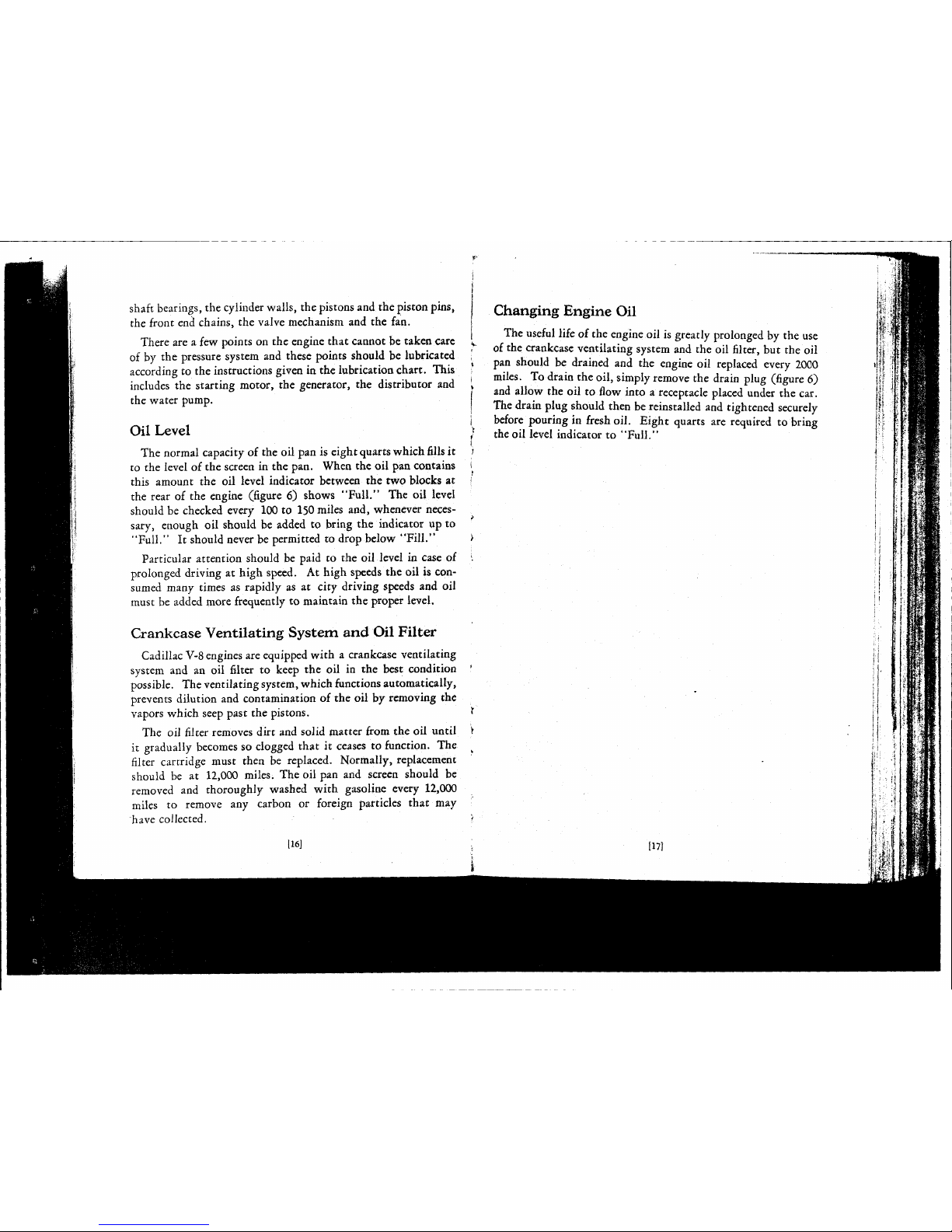

CHAPTER

III

OPERATION

O

NE

of the first things the

driver

of the

Cadillac

V-8

should do

is to familiarize himself with the location and use of the

instruments and controls described in this chapter.

Gasoline

Gauge

The

gauge

marked

"Gasoline" indicates

in

gallons the quantity

of

fuel in the tank at the rear of the car.

This

gauge

operates

electrically

and

indicates

the quantity of fuel

only

tvhen

the

ignition

is

turned

on.

When the tank is

being filled and the

driver

wishes

to check

the amount of fuel in

the tank, he should first

shut off the

engine

to

comply

with filling

station regulations and

then switch on the igni-

tion so that the

gauge

will

operate.

Fig.

7. General arrangement of the

driving

controls.

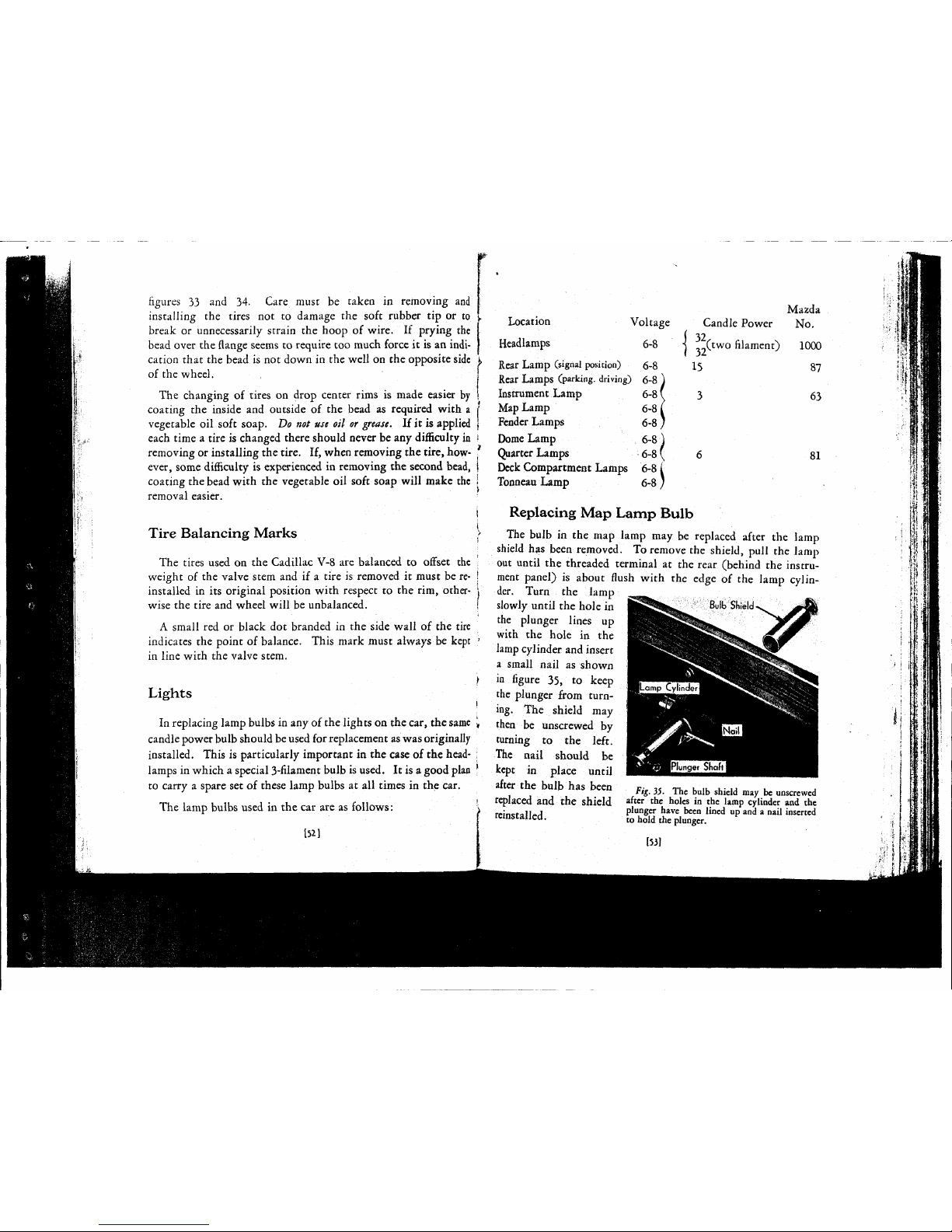

Oil

Pressure Gauge

The

oil pressure

gauge

indicates only the pressure under which

the oil is being forced to the

engine

bearings. It

does

not

indicate

the

quantity

of oil in the engine. The

gauge

should indicate zero

as long as the

engine

is not running, but as soon as it is started

and

as long as it runs, it should

show

pressure. If no pressure is

indicated when the

engine

is running, the

engine

should be

stopped at once. Serious damage may result if the

engine

is fun

for

any length of time whatever with no oil pressure.

[181

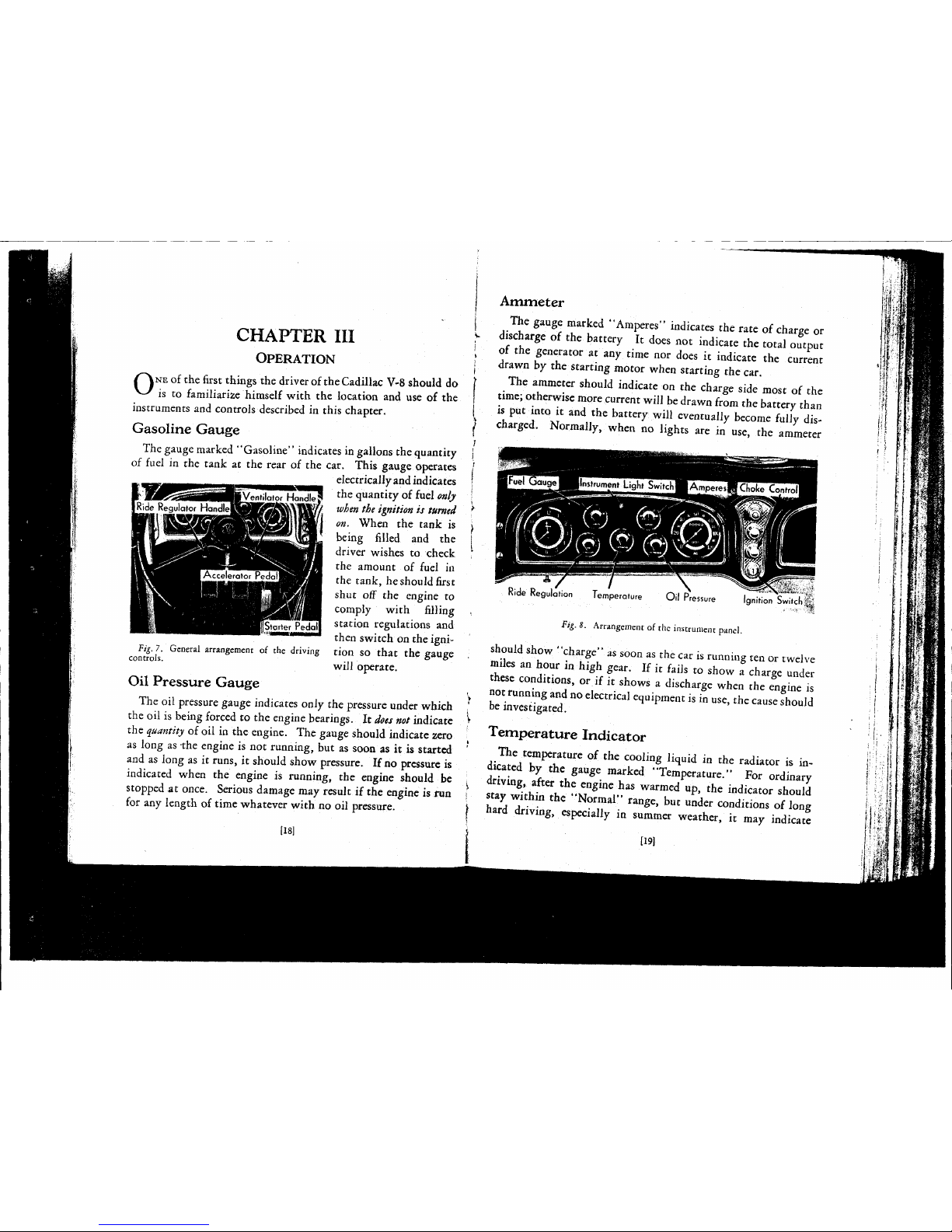

Ammeter

The

gauge

marked "Amperes" indicates the rate of charge or

discharge of the battery It

does

not indicate the total output

of

the generator at any time nor

does

it indicate the current

drawn

by the starting motor when starting the car.

The

ammeter should indicate on the charge

side

most of the

time; otherwise more

current

will be

drawn

from the battery than

is put into it and the battery will eventually become fully dis-

charged.

Normally, when no lights are in use, the ammeter

Ride

Regulation

Temperature

Oil

Pressure

Igninon

Sw.tch

;

Fig.

8.

Arrangement of the instrument panel.

should

show

"charge" as soon as the car is

running

ten or

twelve

miles an hour in high gear. If it fails to

show

a charge under

these

conditions, or if it

shows

a discharge when the

engine

is

not

running

and

no electrical equipment is in use, the

cause

should

be investigated.

Temperature

Indicator

The

temperature of the cooling

liquid

in the radiator is in-

dicated by the

gauge

marked "Temperature." For ordinary

driving,

after the

engine

has warmed up, the indicator should

stay

within the

"Normal"

range, but under conditions of long

hard

driving,

especially in summer weather, it may indicate

[19]

Page 16

r

»

Page 17

"Hoc."

This

is to be ex|

efficient operation of the

Fig.

9. The hood ports may be

opened by

pulling

out on the

wind-

splits.

opened by simply

pulling

out on

Throttle

Control

The

throttle of the

carburetor

is

controlled by a hand lever and

a

foot pedal or accelerator. The

normal

position of the hand

lever for

driving

the car is all

the way up to

"CLOSED."

In

this position the throttle of the

carburetor

is open just enough

to permit the engine to run at

idling

speed after it is

warm.

For

starting, however, the lever

should

be moved approximately

ed and

will

not interfere with

gine. If it indicates "Hot"

after short runs and under

average operating conditions,

however, the

cause

should be

investigated. The temperature

indicator

will

always show a

temporary

rise in temperature

immediately

after stopping the

engine.

This

likewise is a

natural

condition and is due

to the residual heat in the

engine.

For

average operation in

warm

weather, the hood ports

should

be open.

Ordinarily,

these

ports should be opened

at the start of

warm

weather in

the spring and left open

until

the beginning of cold weather

in

the

fall.

They

may be

the windsplits on the

hood

ports.

Fig.

10.

The throttle hand control

is the top lever on the hub of the

steering wheel.

[20]

one-fourth

the way down, and should be left in this position

until

the engine is

warm

enough to

permit

the

lever

to

be

returned

to the

idling

position without stalling the engine. (Also see

Chapter

on

"Cold

Weather

Operation.")

Carburetor

Choke

Control

Correct

use of the choke control is essential not only to

quick

starting

of the engine, but also has an

important

effect

on the life

of

the engine. The button must be pulled out far enough in

starting

to provide an explosive mixture

quickly

so that the

battery

is not unnecessarily discharged by

useless

cranking.

The

button

must also be left out far enough

during

the warming-up

period

so that the engine

will

run

without missing

and

"popping-

back."

On

the other

hand,

it should not be pulled out any further or

left out any longer than is necessary to accomplish

these

results,

because

some

of the

excess

liquid

gasoline in the

enriched

mixture

does

not

burn

and may wash off the oil on the cylinder walls,

interfering

with proper lubrication of the pistons. The button

should

be pushed all the way in as soon as this can be done with-

out causing "popping-back."

If

the engine still retains heat

from

previous

running,

the choke

control

should not be used without first attempting to start the

engine on the

normal

mixture. If the choke button is pulled out

for

starting a hot engine the mixture may be made so

rich

that

starting

will

be impossible.

The

choke button is not a

priming

device. It has no

effect

whatever on the fuel or the fuel

mixture

unless

the engine is being

cranked

or is

running

under its own power. To have any

effect,

it must be pulled out and kept partly out

during

the

cranking

operation.

Starting

the Car

To

start the car,

first

make sure the transmission is in neutral

[21]

Page 18

1.

«

Page 19

and

the

hand

throttle is in the normal starting position.

Then

pull

out the choke

(unless

the car is warm from previous

running),

switch on the ignition by turning the key to the

left

until

the lock cylinder springs out, and

step

on the starter.

As

soon as the

engine

starts,

release

the starter pedal and push

the choke button in as far as possible without stalling the engine.

When

the

engine

warms up,

push

the

choke

button

all

the

way in.

The

proper

use of the choke control will permit the

engine

to

run

smoothly until it warms up. The

engine

should never be raced

to warm it up. Racing

the

engine

is not only

a

\ unnecessary, but in-

Choke Control j effective.

Starting

Hints

In

cold weather, dis-

engage

the clutch to

get a quicker start and

to relieve the battery of

the

strain

of

turning

the

transmission gears.

If

the

engine

does

not

start

readily,

release

the

starter pedal and look

for

the cause.

Do

not

run

down the

battery

by too

much

use of the starter motor when the

engine

does

not start readily.

First

find

the

cause;

otherwise, the battery

may

be run

down

sufficiently to make starting impossible.

Check

the

contents

of the gasoline tank.

See

that the throttle

hand

lever

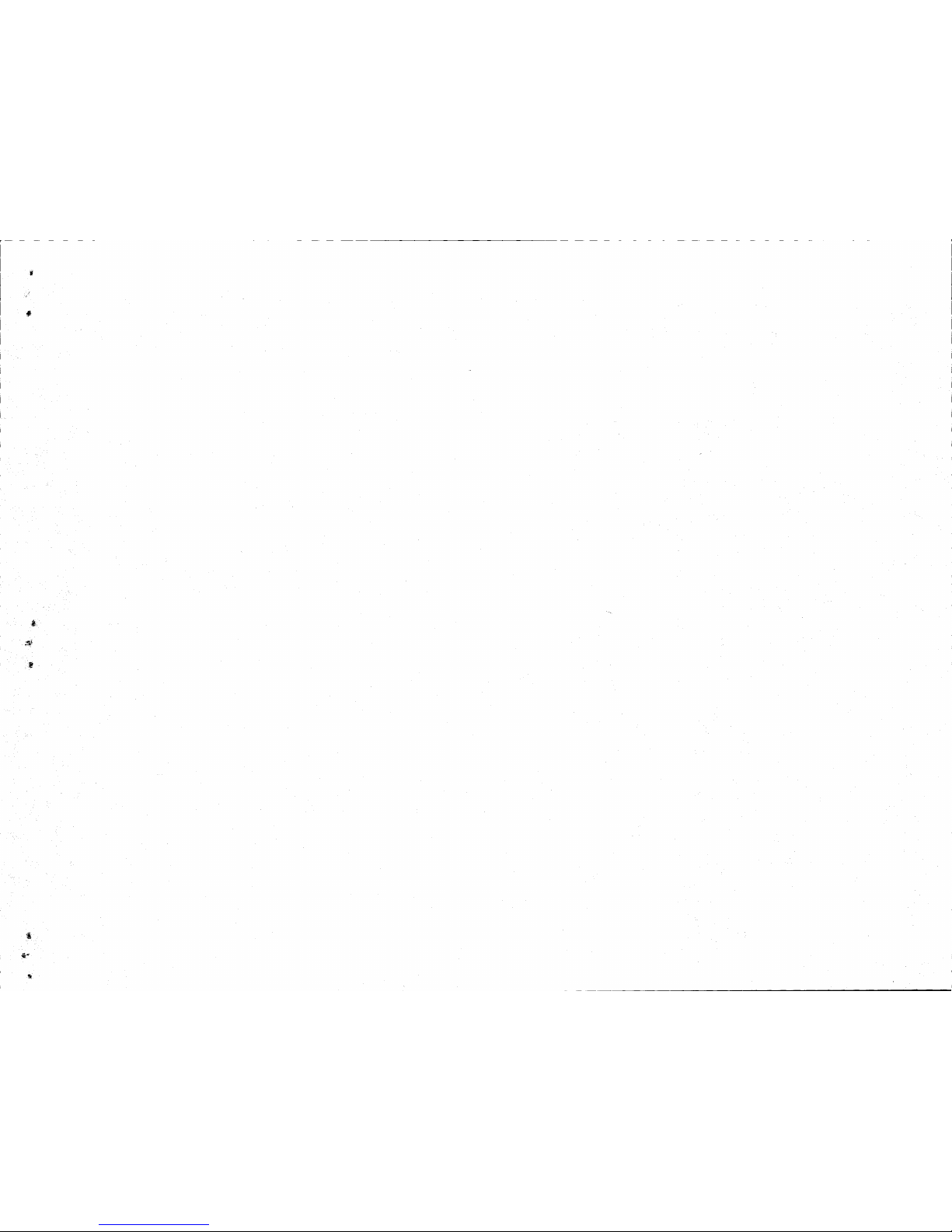

is in the normal starting

position

and that the choke control has been used properly.

If

the carburetor is choked from unnecessary use of the choke

control

or unnecessary priming with the accelerator pedal (see

Fig.

11. The position of the hand throttle and

the proper use of the choke control is of

par-

ticular

importance in starting the car.

[22]

page

31),

turn

off the ignition, move the hand throttle to the

fully

open position and hold the starter pedal down for 10 to 15

seconds

to get

rid

of the surplus gasoline. Next,

return

the hand

throttle to the normal starting position,

turn

on the ignition

and

step

on the starter.

Ride

Regulation

The

driver

may control the action of the shock absorbers at any

time to suit the conditions of

road

and

speed.

The

control

handle

is located beneath the

instrument panel on the

left-hand

side

of the

car

next

to the steering

column.

The

degree

of

control

is indicated by a dial

on

the instrument panel

labeled "Ride Regulation,"

and

marked

with

five

degrees,

ranging

from

"free" to

"firm."

In

general, "free" is for

slow

speeds

over city

pavements, while

"firm"

is for

fast

speeds

over rough roads, but

the

driver

can

best

deter-

mine by

trial

the

degree

of

firmness

or

softness

best

suited to his

requirements under conditions of car load, speed and the

road.

Fig.

12. The

degree

of ride regulation can be

controlled

by the handle on the

left

hand

side

of

the steering column.

Lighting

Switch

The

lighting switch control is located at the center of the

steering wheel opposite the throttle control. The lever has four

positions;

"Parking,"

"Off,"

"Passing" and

"Driving."

Turn-

ing

the lever to

"Parking"

turns on the parking lamps and the

[23]

Page 20

«

•f

Page 21

two rear lamps.

Turning

the

lever to "Passing" turns on

the headlamp lower beam and

the two rear lamps, while

turn-

ing

the lever to

"Driving"

turns on the headlamp upper

beams and the two rear lamps.

Driving

Hints

Fig.B.

The

headlight switch

is

the The driver

owes

it to other

Wr lever

on

the hut of the steering ^

q[ the

str£ets

and high

.

ways

as well as himself to

drive

in

such a way that the car is always under his complete control.

The

driving

equipment on the

Cadillac

V-8—the brakes, the

ride

control, the lighting equipment and the synchro-mesh

transmission—is designed to afford maximum

safety

at all times,

but there are certain conditions requiring special care to make its

use fully effective.

Speed

The

Cadillac

V-8 can be driven at

speeds

faster than the driver

will

ever require. The car

operates

so smoothly that the driver

sometimes

fails to appreciate the speed at which he is

driving.

He

must, therefore, use judgment

in

driving

to keep the

car

always

in

control.

Blind

curves, hills, rough roads,

side

roads

and

wind-

ing

roads require a slower speed than smooth concrete straight-

aways

where the driver may see clearly for considerable distance

ahead. Where the vision ahead is limited, speed should be kept

low enough so that the car can be stopped within a

safe

distance

for

any emergency.

Gravel

Roads

Adjust

the Ride Regulator control to whatever

degree

of

firm-

ness

required to prevent

excessive

bouncing and

side

sway. Do

not

swerve

quickly or hold to the outside

edge

of the road on a

curve.

[241

Hills

When

approaching the top of a

hill,

be prepared for any cars

coming

up the other side.

The

transmission should never be shifted to neutral for coasting

downhill.

If it is desired to

coast,

keep the transmission in gear

and

simply

disengage

the clutch. If the speed of the car

becomes

excessive

while coasting down

hill,

engage

the clutch and use the

engine

to

assist

the brakes. It must be remembered that the

brakes are subjected to much more

severe

use on grades, where

they must absorb the force of gravity as well as the momentum

of

the car, than on the level where they must absorb only the

momentum of the car.

Ordinarily,

the resistance offered by the

engine

with the transmission in high gear, supplemented by moderate use of the brakes,

is sufficient to control the speed of the car. If

excessive

use of the

brakes is still required, however, the transmission should be

shifted to intermediate.

Slippery

Roads

When

stopping on slippery pavements, keep the car in gear and

the clutch engaged until the car is nearly stopped.

Apply

the

brakes gently.

This

will minimize the possibility of skidding.

Do

not attempt sudden

stops.

Danger

of

Running

the Car in

Closed

Garage

Always

open the doors of the garage before starting the car.

Carbon

monoxide, a deadly poison gas, is present in the

exhaust

of

all

internal combustion

engines

and for

safety,

this gas must be

allowed to

escape

outside the garage. Under normal starting

and

warming

up

of the

engine

in a two

car

garage enough gas will

accumulate in three or four minutes to overcome any occupants.

When

the choke is used

excessively,

such as for cold weather

starting, the accumulation is more

rapid.

Carbon

monoxide is colorless,

tasteless

and almost odorless.

It

gives

no

warning.

Open

the

garage

doors

before

starting

the

engine.

[251

Page 22

CHAPTER

IV

COLD

WEATHER OPERATION

S

ATISFACTORY

operation of the car in freezing temperatures

depends upon having the car prepared for cold weather and

in

giving it the special

attentions

which are

required

under such

conditions.

All

the

information

relating to the

care

and

operation

of

the car

during

cold weather has been grouped in this chapter

to

assist

the operator in maintaining the fine performance of the

car

throughout the winter as well as the summer.

This

chapter

should be reviewed just before the beginning of the winter

season

so that

full

benefit may be had of all the

suggestions

it contains.

Preparing

for

Cold

Weather

Anti-Freezing

Solutions

In

selecting anti-freezing solutions for winter operation the

local

conditions and the type of service must be considered. The

following information is given to enable the

individual

owner to

more intelligently

select

the anti-freezing solution

best

suited to

meet

his own conditions.

The

available commercial materials for

preparing

anti-freezing

solutions for automobile radiators are denatured alcohol, methanol

(synthetic wood alcohol), distilled glycerine, and

ethylene

glycol.

Denatured

alcohol and methanol solutions are at present, the

most generally used anti-freezing solutions. Denatured alcohol

and

methanol are widely distributed, afford protection against

freezing, and are not

injurious

to the materials used in the cooliag

system.

There

are two

principal

objections to denatured alcohol and

methanol. These materials are

lost

by evaporation, especially on

heavy runs, and

unless

the solution in the radiator is

tested

U61

periodically

and sufficient anti-freeze added to replace the

loss

by

evaporation, the motor or radiator, or both, are likely to be

damaged by freezing. The car

finish

is damaged by contact with

denatured alcohol or methanol solutions or vapors, and any

material

accidentally spilled on the finish should be

flushed

off

immediately with a large quantity of water.

Methanol

for anti-freeze purposes is sold in the United

States

in

the correct concentration to

give

the

same

protection against

freezing as denatured alcohol. The table below may be used for

both denatured alcohol and methanol.

Qts.

Alcohol

Lowest

Per

cent

Specific

Gravity

or

Methanol

Temperature

by

Cat 60° F.">

required

to make

Expected

Volume

Denatured Akoho

Methanol

6½gal.

solution

10

F.

30

.9668

.972

1¾

OF.

38

.9567

.964

10

—10

F.

45

•9475

.957

11¼

—20

F.

51

.9350

.950

13¾

—30

F.

57

.9260

.944

14¾

Important: The special inhibitor used

in

the cooling

system

(see

page

44)

affects

the hydrometer readings of the solution and

allowances must be made for the difference.

With

the

inhibitor

in

the cooling system, the actual freezing temperature of

an

alcohol

or

methanol solution is five

degrees

higher than indicated by the

hydrometer. In other words, if the hydrometer reading indicates

protection down to zero, the actual protection would be only

down to five

degrees

above zero and similarly throughout the

scale.

Distilled

glycerine and

ethylene

glycol solutions are, in first

cost,

more

expensive

than alcohol but, as they are not

lost

by

evaporation, only water need be added to replace evaporation

losses.

Any solution

lost

mechanically, however, either by

leakage or foaming, must be replaced by additional new antifreezing solution. These solutions, under

ordinary

conditions,

are not

harmful

to the car finish.

The

principal

objections to glycerine and

ethylene

glycol are

the tendency of

these

solutions to loosen rust and scale, which

I27J

Page 23

i

j

i

i

j

i

s

*

Page 24

form

in the water

passages

of the cylinder blocks and heads, and

the difficulty of securing and maintaining tight, leakproof connections. It is absolutely necessary that the entire cooling

system

be thoroughly cleaned and flushed before glycerine or

ethylene

glycol

is used.

It is

also

necessary to tighten or replace the cylinder head

gaskets,

hose

connections and pump packing. The cylinder head

gaskets

must be kept tight to prevent the solution from leaking

into the crankcase where it might

cause

gumming and sticking

of

the moving parts. The pump packing must be kept tight to

prevent air

from

being drawn into the cooling system, in

order

to

avoid

foaming and other difficulties which may result when air

is present.

Ethylene

glycol (Prestone), sold in the United

States

for antifreezing purposes, and radiator glycerine, produced under the

formula

approved by the Glycerine Producers' Association, are

chemically treated to overcome the difficulties mentioned in the

above paragraph, and, under normal operating conditions, with

tight

hose

connections and cylinder head

gaskets,

should be

satisfactory for use in the cooling system.

Glycerine

and

ethylene

glycol should be used in accordance

with the instructions and in the proportions recommended by the

anti-freeze manufacturer. These solutions generally contain

inhibitors

acting in the

same

manner as the special inhibitor used

in

Cadillac

cars, and when

these

solutions are used, the proportion of the inhibitor should not be increased by the use of the

special inhibitor in the cooling system. Too large a percentage of the inhibitor will increase rather than

retard

foaming and

result in more

rapid

formation of rust and

scale

as well as the

loss

of

the anti-freeze solution by spillage.

In

using a hydrometer to determine the temperature at which

a solution will freeze, the

test

must be made at the temperature

at which the hydrometer is calibrated. If the solution is warmer

or

colder, it must be brought to this temperature or large errors

may result. In

some

cases

these

errors may be as large as 30

degrees

Fahrenheit. Freezing point hydrometers are not inter-

[28]

changeable. A different float is required for denatured alcohol,

methanol, glycerine and

ethylene

glycol.

Salt solutions, such as calcium chloride, magnesium chloride

or

sodium silicate, kerosine, honey,

glucose

and sugar solutions

are not satisfactory for use in automobile radiators.

The

capacity of the cooling

system

is

6½

gallons when filled to

a point about 1½ inches below the top of the filler neck which is

located under the hood on the right-hand

side

of the car. (See

Fig.

26, Page 44.)

Winter

Lubrication

Lubrication

of the car requires special attention in winter, not

only to insure proper protection for the moving parts, but to

secure the

same

ease

of

operation

in starting, steering

and

shifting

gears

as

during

warm weather.

The

chart of

engine

oil recommendations on

page

13

gives

the

proper

grade of

engine

oil to be used for cold weather

driving.

It

will

be noticed that lighter oils can be used during cold weather

providing

the car is not driven at high

speeds.

"Heavy duty"

oils, however, must be used for prolonged high speed

driving

in

winter as well as summer to prevent

excessive

oil consumption.

The

lubricant in the transmission and rear axle should be

thinned or replaced with a lubricant of suitable cold viscosity as

soon as the

gears

are

hard

to shift.

The

lubricant used

during

winter weather in the steering gear

should have a low cold viscosity and should preferably be an all

year-round

lubricant. Steering gear lubricants should not under

any circumstances be thinned with kerosine as the pressure between

the

worm

and sector will force out a thinned lubricant and

permit

excessive

wear at this point.

Storage Battery

The

electrical

system

of a car has much more to do in winter.

The

stiffness

of the lubricant makes the

engine

harder

to crank in

cold

weather and it generally is cranked longer before it starts.

The

lights are

also

used to a much greater

extent

than

during

the

[29]

Page 25

«•

Page 26

p-

long

days of summer. All this means that the battery must be j

ready

for increased demands. }

It is a good plan in

preparing

for the winter season, therefore, f

to see that the battery is fully charged, that the battery con- f

nections

are

clean

and

tight,

and

that the

charging

rate

is sufficient f

to take care of the requirements of the system. At the same time,

the

spark

plugs, the contact points