Page 1

CADILLAC

OPERATOR'S

MANUAL

FILE

COPY

DO

mr

REMOVE

&

^

liMTlON NO. 370-1

lit mitring </ duplicate »/ this Mtinmil, specif} the

above number or the engine number oj the c?r.

Page 2

Table

of

Contents

CHAPTER

\--Cadillac

Service

'

Cadillac-La Salle Service Stations—Service card—Service contractService charges—Repair parts—The owner's obligation- Lubrication—

Inspection.

CiiAFrER

II—Operation

8 1

Locks—Ignition switch lock—Gasoline gauge—Throttle control

- '

Carburetor choke control—Spark control—Starter pedal-

Oil

pressure

gauge—Ammetei—Clutch pedal—Transmission control -Coasting

Brakes—Lighting switch- -Danger

of

running engine

in

closed garage.

CHAPTER

311—Equipment 21

Windshield

and

ventilation- Windshield cleaner Adjustable seats

Cigar lighters—Tools—TIKES—Inllation pressure- Spare wheel carrier

—Spare tire carrier—Use

of

jack

in

changing tires—Changing tires

-

Tire balancing marks.

CHAPTER

IV—Lubrication 29

Lubrication schedule—Lubrication Notice—Lubrication chart-

LUBRICANTS— Engine oil — Gear lubricant — Chassis grease—Wheel

bearing grease—Water pump grease—ENGINE LUBRICATION—Oil

I

level—Crankcase ventilating system and oil filter—Replacing engine oil.

,

CHAPTER

V—Cold

Weather Operation

36 S

PREPARING

FOR

COLD WEATHER—Anti-freezing solutions

j

Capacity

ol

cooling system—Winter lubrication-Storage battery-

Gasoline system—STARTING

THE

ENGINE—Choke button

-

Priming

the

carburetor—Position

of

throttle hand lever—Position of

spark control—Use

of

starter—Use

of

accelerator before engine is warm.

CHAPTER

VI—

General

Care

43

Storage battery—Cooling system—Gasoline filter—Temporary brake

adjustment—BODY—Care

of

finish—Care

of the

top—Cleaning

up-

holstery—Door hardware.

CHAPTER

VII—Storing Car 49 j

Engine—Storage battery—Tires—Body

and

top—Taking

car out of ,

storage.

[

CHAPTER

VIII—Specifications

and

License Data

. . • ^ i

W

CHAPTER

lbQ m,t- £.

CADILLAC

SERVICE

HPHE

owner

of a

Cadillac

car has

purchased

not

simply a line

1

piece

of

machinery, ingeniously designed

and

carefully

built—he

has

purchased a pleasant

and

dependable mode

of

transportation.

The

car

itself

is

only

one

factor

in

securing this

transportation—the

other factor

is

Cadillac Service, which

is

built

upon a standard policy, clearly defined

to the car

owner

and

guaranteeing

him

efficient

service everywhere

at

standard prices under

factory

regulation.

Cadillac-La

Salle Service Stations

Cadillac

Service extends wherever Cadillac

and

La Salle cars

are

sold. Service stations

conducted

by

Cadillac distrib-

utors

and

dealers

are

designa-

ted

as

"Authorized Cadillac-

La

Salle Service Stations"

and

are

identified

by the

exclusive

sign

illustrated

on

this page.

Wherever

this sign is displayed,

the

owner will find

an

organ-

ization

prepared

to

service

Cadillac

cars. This means prop-

er

equipment, factory trained

personnel, a stock

of

genuine

replacement

parts

and

stand-

ardized

policies

and

methods. c- , , k • ,^ ,„ , o ,.

1

rig. 1.

Authorized Cadillac-La Salle

The

car

owner's first

and sf

rvicc .statibns display this sign

at

iiic

t,di

uwnci » nisi

aim the

service entrance.

most

frequent contact with

Cadillac

Service will naturally

be in the

service station

of the

distributor

or

dealer

who

sold

him the car and who

therefore

has

the

greatest interest

at

stake

in

assuring

him

satisfaction.

[3]

Page 3

CADILLAC SERVICE CARD

Th4*i.te«.r<lfy that

Mr. Joseph Brow

Nevertheless,

he

may

feel perfectly free

to

use

his car for

ex-

tended travel without depriving himself

of

the

service benefits

to which

he is

entitled

at

his

local service station.

He

will find

other Authorized Cadillac-La Salle Service Stations able

and

willing

to

render

the

same service.

Service Card

As a means

of

introduction

at

other Authorized Cadillac-

La Salle Service Stations, every purchaser

of a

Cadillac

car

is

given credentials

in

the

form

of a

Service Card. This card

is

mailed

to

him

by the

Cadillac factory immediately after

the

delivery

of the car is

reported

by the

distributor

or

dealer.

It is

supplied

in a

celluloid case,

and

is

intended

to

be

carried

in a

holder

on the car.

Upon presentation

of

this

Service Card

to any Au-

thorized Cadillac

- La

Salle

Service Station,

the car

owner

is

entitled

to

uni-

form standard service

in

accordance with

the

Cadillac Owner Service Policy.

This Policy

is

explained

in detail

in a

certificate

issued

to

each owner

and

mailed

to him

with

his

Service Card. Briefly,

it

entitles

the

owner

to:

1.

All

adjustments, free

of all

charges, that

may

be

required

within

90

days after

the

original delivery date

(as

shown

on

the card), provided

the

mileage

of

the car

does

not

exceed 3000

and

the

adjustments

are not

made necessary

by

accident, abuse

or neglect. This includes everything except lubrication, washing

and storing.

2.

Fiee replacement

of

any

part which

has

proved

to the

Cadillac Motor

Car

Company's satisfaction

to be

defective

in

[41

ta*fc

Mwy

id

Cadillac

«ar,

EntlM No.__300j QQQ ...

i~_.CedlUaarLA_SaHe.Sales

Co-*

.. Mortonville,

N.

Y.

sfe »i,Altl« 1. XQfSQ _ andiaaniiikd tarantna

if f*OMPT7TmCli:Nf

an

d

COURTfOUS «r.i« (torn ANV

JV AOTHORUEDCAOtLLACSeUVKtSTATIOft. VnMpr.i~.i9TP tte> af tfcta card ha •• ••» •milled to racain rank* it. ward«1 aixa -Ilk th*

I*TH»

"I itw Standard Cadillac Sw.i»

FBIM*

aa

*' ' - 1 an tha

fcack

«( thU card.

CADILLAC MOTOR CAR COMPANY, Onraii. Mid..

ML

Fig.

2.

Tlic Service Card, when properly

signed, identifies a Cadillac owner

at

any

authorized Cadillac-La Salle service station.

material

or

work mans hip within

one

year after

the

delivery

date,

provided

the

mileage

of

the car

does

not

exceed 12,000

and

that

the

replacement

was not

made necessary

by

accident, abuse

or neglect. This includes material

and

labor.

The Service Card

is

not

transferable,

and the

no-charge service

set forth above

is

effective only while

the car

is in

the

hands

of

its original owner.

Standard Service Contract

Owners

may

be

assured

of

continuous satisfactory operation

and maintenance

of

their cars

at a predetermined, economical cost

by purchasing a Standard Service Contract.

Two

contracts

are

available covering complete lubrication

and

all

adjustments

and

repairs made necessary

by

normal wear.

The

first Contract covers

the first

12

months

or

12,000 miles

and the

second covers

the

second

12

months

or

second 12,000 miles.

The Standard Service Contract

is

based

on

Cadillac's principle

of preventive service

and

insures

the

owner

the

greatest amount

of satisfaction with

rhe

fewest possible interruptions. This

is

accomplished

by

complete lubrication

on

schedule

and

regular

inspection

to

anticipate

the

need

of

adjustment

and

repair,

eliminating

the

necessity

of

service between inspections.

The Contract

is

recognized

by all

authorized Cadillac-La Salle

service stations

in the

United States

and

Canada regardless

of

where

the

Contract

was

purchased.

The

owner

is

thus assured

of

all Contract service

due him

without additional charge wherever

he

may

travel,

the

same

as if

the

work

was

performed

by the

Service Station from which

the

Contract

was

purchased.

These Contracts

are

available

at all

Cadillac sales rooms

and

authorized service stations. Owners

are

urged

to

purchase

Standard Service Contracts

at

the

time

of

delivery

of

the new car.

Service Charges

Service work other than that described above

is

performed

by

Authorized Cadillac-La Salle Service Stations

on a flat-rate basis.

When a car

enters

the

service station,

it

is

promptly inspected

by

a tester,

who

then quotes

the

owner

an

exact price

for the

work

he finds necessary.

The

owner authorizes

the

work

at

this

price,

and

when

he

receives

his

bill, this

is the

price

he

pays.

[5]

Page 4

Charges prevailing at Authorized Cadillac-La Salle Service

, .» Sta£jrpn$ are based on standard schedules furnished by the Cadillac

S'^y « Motor Car Company. These schedules call for methods and

tools approved by the same engineers who designed and built

the car, assuring the highest quality of work at the lowest

possible price. Standard Price Schedules are open to inspection

by owners at any Authorized Cadillac-La Salle Service Station.

Repair Parts

Genuine Cadillac parts, manufactured to the same rigid

specifications as the parts entering into the original assembly of

the car, are carried in stock by Authorized Cadillac-La Salle

Service Stations. They are sold at uniform prices throughout

the United States, and are not subject to the addition of hand-

ling, excise or other supplementary charges. Printed price lists,

published by the Cadillac Motor Car Company, are open to

inspection by owners at any authorized Cadillac distributor's

or dealer's establishment.

The Owner's Obligation

All of these service facilities are placed at the disposal of the

Cadillac owner, in order that his car may be a continuous source

of satisfaction and utility. This result cannot be guaranteed,

however, unless the owner fulfills certain definite obligations

himself,

as follows:

1.

To drive the car at moderate speeds for the first 500 miles.

2.

To operate the car in accordance with the instructions

contained in this manual.

3.

To check the engine oil level every 100 to 150 miles, and

add oil as often as necessary to keep the indicator at "full."

4.

To check the tire pressure at least every week, and keep

it up to the recommended pressure—40 pounds in front and rearon cars driven at high speeds, 45 pounds in front.

5.

To add distilled water to the storage battery every 1000

[6]

miles,

and in warm weather every 500 miles, or at least every

two weeks.

6. To have the car lubricated every 1000 miles, or once a

v month, in accordance with the lubrication schedule on page 28.

I 7. To take the car to an Authorized Service Station for

inspection every 1000 miles, or at least once a month.

Lubrication

<

I The first five items above are details which do not necessarily

) warrant a visit to the service station. For lubrication, however,

the owner is urged to patronize Authorized Cadillac-La Salle

I Service Stations, because they are prepared to furnish this service

• in a manner that cannot be duplicated elsewhere. Only approved

lubricants are used, the specifications of which have been worked

j out by Cadillac engineers to give the best possible results.

Workmen who specialize on Cadillac cars know exactly where

lubrication points are located and how much lubricant to apply.

The charge for this lubrication service is only about half a cent

a mile, which includes the cost of the lubricants.

Inspection

Preventive service is a fundamental principle of Cadillac

' Service. "Preventive service" is the practice of inspecting the

car at regular intervals and making those adjustments that need

attention before the need becomes an emergency. Inspections

should be made every 1000 miles, in order to insure transportation satisfaction. Authorized Cadillac-La Salle Service Stations

( will make such inspections without charge, provided no disI mantling of units is necessary.

| The Cadillac owner is urged to take full advantage of this,

not only while the car is new, but throughout its entire life.

i Preventive service rendered every 1,000 miles or once

i a month by an Authorized Cadillac-La Salle Service

| Station, is the surest guarantee of long life and com' plete motoring satisfaction at the least possible

expense.

W

Page 5

CHAPTER II

OPERATION

O

NE

of the first things the driver of a new car should do is

to familiarize himself with the various controls described

in the following chapter.

Locks

Each car is equipped with two each of two different keys.

The handles of one set of keys are hexagonal in shape: these

keys unlock the combination ignition switch and transmission

lock, the lock on the front door, the spare wheel carrier and thfe

battery box. The keys in the other set have oval handles: these

keys unlock the rear doors of chauffeur driven cars, the rear decks

of roadsters and coupes, and the various package compartments.

The lock number is stamped on each key, but not upon the

face of the lock. The owner should make a record of the key

numbers as soon as he takes delivery of his car, so that in the

event both keys are lost, a duplicate key can easily be obtained

from a Cadillac distributor or dealer.

The right front door can be locked from the inside to prevent

intruders from forcing their way into the car. This can be

accomplished simply by turning the key to the locked position

on the outside before entering the car. The door will then be

locked from the outside, although it can be opened from the

inside in the usual manner.

Ignition Switch

Lock

The lock in the center of the instrument panel controls both

the ignition switch and the transmission lock. When the key

is turned, the cylinder of the lock will slide out about half an

[8]

inch, turning on the ignition and unlocking the transmission

by means of a cable connection to the shifter shafts. To shut

off the ignition and lock the transmission, turn the key to the

locked position and push the lock cylinder all the way in. The

car can be locked when the transmission is in neutral or in reverse.

Do not attempt to shut off" the ignition when the transmission is

in any forward gear. Be sure to remove the key before leaving

the car.

Gasoline

Gauge

The gasoline gauge, marked "Fuel," is the small dial on the

extreme left. This gauge indicates in gallons the quantity of

fuel in the tank at the

rear of the car, and is

operated electrically by

current taken from the

ignition circuit. To

read from the gauge

the quantity of fuel

in the tank, the

ignition must be

turned

on.

Throttle

Control

The throttles of the

two carburetors are

controlled by a hand •

lever and a foot pedal or accelerator. The normal position of

the hand lever for driving the car is all the way up, to "CLOSE".

In this position the throttles of the carburetors are open just

enough to permit the engine to run at idling speed after it is

warm. For starting, however, the lever should be moved approximately one-fourth the way down, and should be left in this

position until the engine is warm enough to permit the lever to

be returned to the idling position without stalling the engine.

(Also see Chapter on "Cold Weather Operation.")

^ iw>iminhi

Turn on i«nirion

to re;ul "au^e

/7¾.

3. The gasoline gauge is operated elec-

trically by current iron) the ignition circuit.

M

Page 6

Carburetor Choke Control

Correct use of the choke control is essential not only to quick

starting of the engine, but also to the life of the engine. The

button must be pulled our far enough in starting to provide an

explosive mixture quickly so that the battery is not unnecessarily discharged by useless cranking. The button must also be

left out far enough during the warming-up period so that the

engine will run without missing and "popping back."

On the other hand, it should not be pulled out any further or

left out any longer than is necessary to accomplish these results,

because some of the excess liquid gasoline in the enriched mixture

does not burn and may wash off the oil on the cylinder walls,

interfering with proper lubrication of the pistons. Push the button all the way in as soon as this

can be done without causing

"popping back."

If the engine still retains heat

from previous running, the choke

control should not be used with-

Fig. 4. The choke button out first attempting to start the

must be held out while the . , .

starter is cranking the engine. engme on the normal mixture.

If the choke button is pulled out

for starting a hot engine the mixture may be made so rich that

starting will be impossible.

The choke button is not a priming device. It has no effect

whatever on the fuel or the fuel mixture unless the engine is

being cranked or is running under its own power. To have

any effect, the button must be pulled out and kept partly out

during the cranking operation.

[10]

Spark Control

Correct timing of the ignition in relation to the positions of

the pistons is controlled automatically by the timer-distributor,

which provides for all ordinary advancing and retarding of the

spark.

A hand control is also provided. This is the button at the left

on the instrument panel. This button should be pushed all the

way in (full advance) for starting and for all ordinary driving.

The button can be pulled partly out to retard the spark in case

of "ping" caused by carbon, heavy pulling, the use of regular

(not anti-knock) gasoline, or in case there should ever be occasion

to crank the engine by hand.

The Cadillac V-12 engine is a high compression engine and it

will perform most satisfactorily when an anti-knock fuel is used.

Regular gasoline can be used, although this may necessitate

driving with the spark slightly

retarded to avoid "ping." The -v ,/

spark should be retarded just i

'••

__^ \

to the point where the engine

"'pings"

slightly on rapid acceleration. This slight amount of

spark knock is absolutely harmless to the engine and is an indication to the driver that the spark is

F>g y Drjve wjth spark con

.

set at the point that will give trol as far advanced as possible.

maximum power and economy. :

Carbon deposit, which accumulates with use in all engines,

also causes spark knock and in time may require retarding the

spark. Regardless of the kind of fuel or the presence of carbon,

the correct setting of the spark control at any time is at the point

where the engine "pings" slightly on rapid acceleration.

["I

Page 7

Starter Pedal

The starter pedal is at the right of the accelerator. Pushing

this pedal forward brings into action the electric motor that

cranks the engine for starting. Do not push the starter pedal

when the engine is running.

The starter pedal is only one of the controls that must be manipulated to start the engine. Unless there is an explosive mix-

ture in the cylinders and a spark to ignite it, it is useless to

crank the engine. The starter pedal should not be operated,

therefore, until the necessary preliminary steps have been taken.

The following, in their proper order, are the various steps that

must be performed when starting the engine:

1.

Place the throttle lever

about one - fourth the way

down from the "CLOSE" position.

2.

See that the spark con-

trol button is all the way in.

3.

Make sure that the transmission control lever is in

neutral.

4.

Turn on the ignition.

F/£. «. The starter pedal is only one 5 Unless the engine is Still

of the controls that must be used to °

start the engine. warm, pull out the choke

button. If the engine is still

warm, do not pull out the choke button unless the engine fails

to start on the normal mixture.

6. To start the engine, push the starter pedal forward,

releasing it as soon as the engine starts. If the engine does not

start readily, do not run the battery down by continuing to

crank the engine, but look for the trouble and correct it. (See

below for probable causes for the engine failing to start.)

7.

Push the choke button in part way as soon as the engine

[12]

stairs,

and all the wav 111 as soon as the engine is warm enough

to permit it.

8. Note whether pressure is indicated on the oil pressure

gauge ami stop the engine at once if no pressure is indicated.

9. Move the throttle lever up to the "CLOSE" position as

soon as the engine is warm enough to permit it.

In cold weather, disengage the clutch during the cranking

; operation. This relieves the starter of the necessity of turning

I the transmission gears, which are immersed in lubricant. The

J additional load is small in warm weather when the lubricant is

j thin, but in cold weather the power required to turn the gears

j through the thickened lubricant adds unnecessarily to the

j load on the starter and the battery.

What To Do If The Engine Fails To Start

If the engine does not start readily, release the starter pedal

and look for the cause.

1

i

' The ignition may not be turned on.

There may be no gasoline in the tank in the rear of the car.

There may be no gasoline in the vacuum tank on the dash.

If the fuel supply should give out on the road, so that the vacuum

tank on the dash becomes empty, it will be necessary after

refilling the tank to add gasoline to the vacuum tank.

The carburetors may be flooded by unnecessary use of the

choke when the engine is warm. To get rid of the surplus gasoline in the cylinders open the throttle wide, and, with the

ignition turned off, hold the starter pedal down for 10 to 15

> seconds. Then return the throttle lever to the usual position

I for starting, turn on the ignition and try once more to start the

I engine.

[13]

Page 8

Oil Pressure Gauge

The small dial at the left of the

clock is the oil pressure gauge.

This gauge does not indicate the

quantity of oil in the engine. It

indicates only the

pressure

under

which the oil is forced to the

engine bearings.

Fig.7. The oil gauge does not

indicate ijuantity; it only shows

the pressure under which oil is

forced to the engine bearings.

I

When the engine is not running,

the pointer on the oil pressure

gauge should remain at zero, but

as soon as the engine is started and as long as it runs, the gauge

should show pressure. If no pressure is indicated when the

engine is running, stop the engine at once and determine the 1

cause. Serious damage may be done if the engine is run without

oil pressure.

Ammeter

The ammeter shows how much current the generator is furnishing the battery when the motor is running and how much the

lights and ignition are drawing from the battery when the generator is not charging. It does not register the current drawn by

the starting motor when starting the engine nor the total output

of the generator when the lights

are on.

The ammeter should indicate ,

on the "Charge" side most of '

the time, otherwise, more current

will be taken out of the battery

than is put into it and the battery

will eventually become fully dis-

charged, j

Fi%.

S.

The ammeter indicates

the amount of electrical current

flowing to or from the battery.

are in use, the ammeter should show "Charge" as soon as the

car is running ten or twelve miles per hour in high gear. If

the ammeter should show "Discharge" with all lights off,

either when the engine is not running or when the car is running

more than twelve miles per hour, the cause should be investigated.

Clutch Pedal

The clutch has two uses: First, to enable the car to be started

gradually and without jerk or jar; second, to permit shifting of

the transmission gears. The operation of the clutch is discussed

below in connection with the transmission control. Further

comment is unnecessary at this point, except the following sug-

gestions to the driver:

Do not drive with the foot resting on the clutch pedal. The

Cadillac clutch operates so easily that even the weight of the

driver's foot may unintentionally cause the clutch to slip.

Do not form the practice of disengaging the clutch whenever

the brakes are applied. Most occasions for use of the brakes

require only slowing down without stopping or even shifting

gears.

A skilled driver will not touch the clutch pedal until the

car is just about to stop or

until he is about to shift to a

lower gear. It is a mistaken

idea that applying the brakes

with the clutch engaged is

more

severe on the brake lining.

The opposite is actually the

case,

proof of which is in the

fact that in coasting down

grades, the resistance of the

engine is used to assist the

brakes in controlling the car

speed.

Ordinarily, when no lights

[H]

It will be observed in oper-

Fig.9. A good driver uses the clutch

pedal only when shifting gears or about

to stop.

[15]

m

' e?8

&l>i

tm

U3

.1»

• *

i +

$H*

;i

w

1..1

I

1 <t-

i a,

Page 9

ating the clutch pedal that the pedal oilers almost no resistance until it has been moved about one inch. It is at this >

point that it actually begins to disengage the clutch. It is J

important that the pedal have this "lost motion." If the full pressure of the clutch springs is felt just as soon as

the control pedal is moved, the control rod should be read-

justed. Failure to make this adjustment will result in the

clutch slipping.

Transmission Control

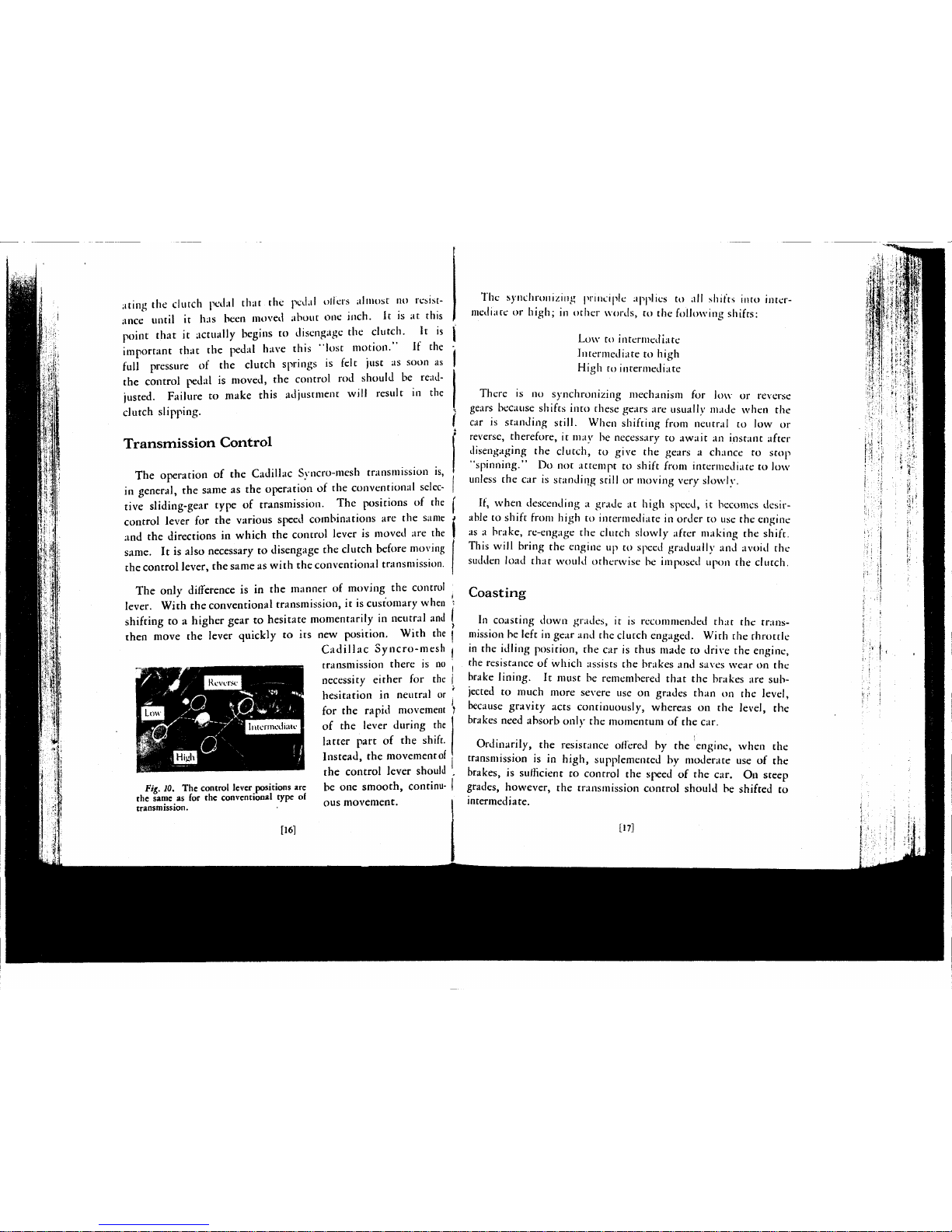

The operation of the Cadillac Syncro-mesh transmission is,

in general, the same as the operation of the conventional selective sliding-gear type of transmission. The positions of the i

control lever for the various speed combinations are the same t

and the directions in which the control lever is moved are the |

same. It is also necessary to disengage the clutch before moving

the control lever, the same as with the conventional transmission.

The only difference is in the manner of moving the control

lever. With the conventional transmission, it is customary when •

shifting to a higher gear to hesitate momentarily in neutral and I

then move the lever quickly to its new position. With the I

Cadillac Syncro-mesh j

transmission there is no

necessity either for the j

hesitation in neutral or

for the rapid movement ?

of the lever during the

latter part of the shift.

Instead, the movement

of

the control lever should ,

Fig.

10.

The control lever positions are be one smooth, Continu- |

the same as for the conventional type of

transmission. . ous movement. I

[161

The synchronizing principle applies to all shifts into inter-

mediate or

high;

in other words, to the following shifts:

Low to intermediate

Intermediate to high

High to intermediate

There is no synchronizing mechanism for low or reverse

gears because shifts into these gears are usually made when the

car is standing still. When shifting from neutral to low or

reverse, therefore, it may be necessary to await an instant after

disengaging the clutch, to give the gears a chance to stop

"spinning." Do not attempt to shift from intermediate to low

unless the car is standing still or moving very slowly.

If, when descending a grade at high speed, it becomes desir-

able to shift from high to intermediate in order to use the engine

as a brake, re-engage the clutch slowly after making the shift.

This will bring the engine up to speed gradually and avoid the

sudden load that would otherwise be imposed upon the clutch.

Coasting

In coasting down grades, it is recommended that the transmission be left in gear and the clutch engaged. With the throttle

in the idling position, the car is thus made to drive the engine,

the resistance of which assists the brakes and saves wear on the

brake lining. It must be remembered that the brakes are subjected to much more severe use on grades than on the level,

because gravity acts continuously, whereas on the level, the

brakes need absorb only the momentum of the car.

Ordinarily, the resistance offered by the engine, when the

transmission is in high, supplemented by moderate use of the

brakes, is sufficient to control the speed of the car. On steep

grades, however, the transmission control should be shifted to

intermediate.

[17]

Page 10

Do not turn oil the ignition when coasting with the car

driving the engine. Contrary to a common impression, this

does not appreciably increase the resistance, and is likely to

cause damage to the engine. Even with the throttle closed,

some fuel is admitted to the cylinders, and if this is not burned,

it condenses on the cylinder walls and washes away the oil

which lubricates the pistons.

Brakes

The foot brakes are internal brakes of the shoe type, applied

on all four wheels through a mechanical linkage.

When applying the brakes while driving on wet asphalt streets

or slippery roads more care should be exercised and more time

should be allowed for stopping the car than is necessary on dry

pavements. The brakes should be applied gently while the

clutch is still

engaged.

The clutch should not be released until

the car has almost stopped.

Do not attempt sudden stops. Cadillac four-wheel brakes

minimize the possibility of skidding under slippery conditions,

but their effectiveness should not induce anyone to drive less

carefully.

As the brake lining wears, the pedal must be pushed farther

down to apply the brakes. Do not wait until the pedal goes all

the way to the floor board before having the brakes readjusted.

Readjustment is recommended as soon as the pedal must be

pushed down to within one inch of the floor board. A temporary

adjustment of the brakes is explained on page 46.

For parking, the brakes are operated by the hand lever at the

right of the transmission control lever.

Lighting Switch

The lighting switch control is at the upper end of the steering

column in the center of the steering wheel. The lever has four

[18]

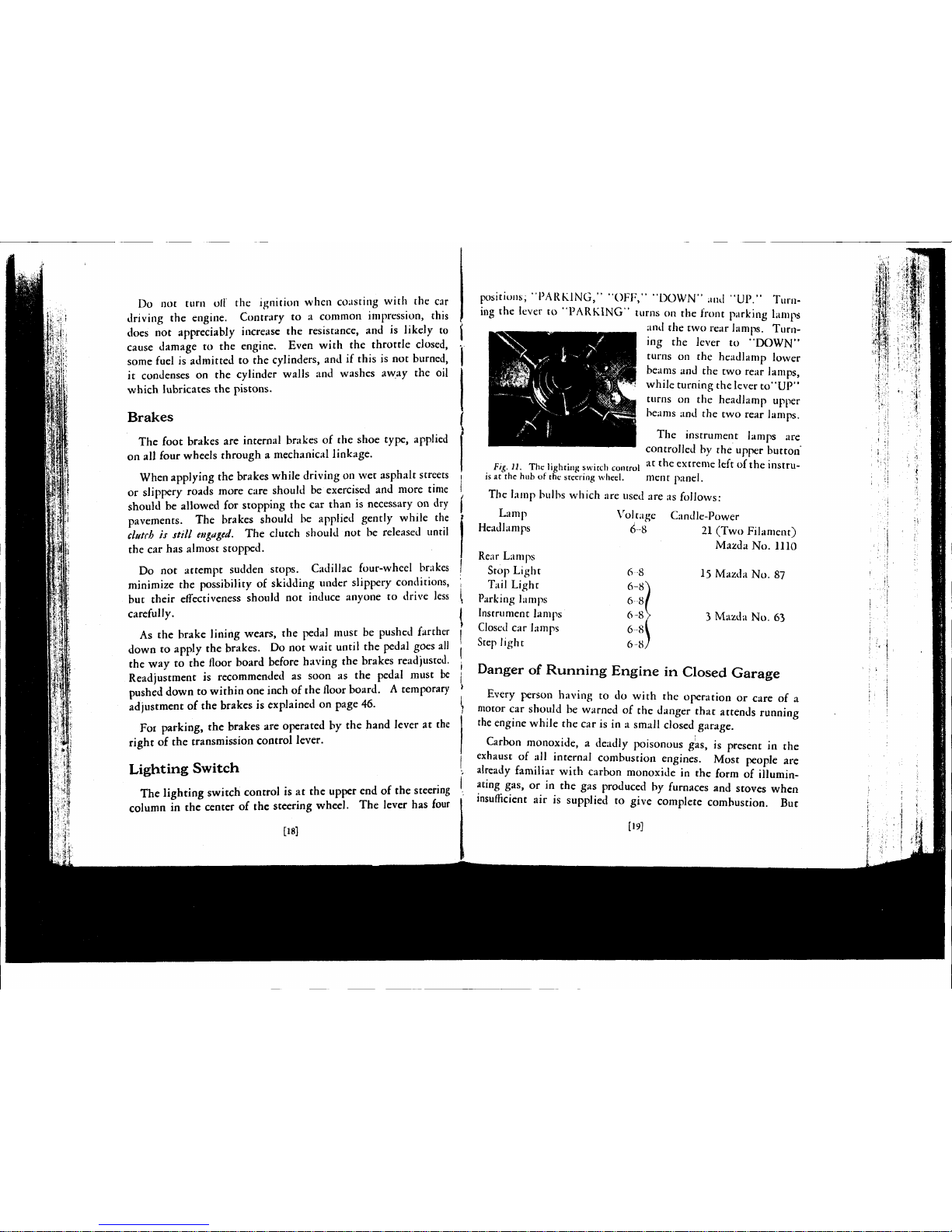

positions, -PARKING," "OFF," "DOWN" and "UP." Turn-

ing the lever to "PARKING" turns on the front parking lamps

and the two rear lamps. Turning the lever to "DOWN"

turns on the headlamp lower

beams and the two rear lamps,

while turning the lever to"UP"

turns on the headlamp upper

beams and the two rear lamps.

The instrument lamps are

controlled by the upper button

_.,,_.,... • , i at the extreme left of the instru-

Fig. )1. The lighting switch control

is at the hub of the steering wheel. ment panel.

The lamp bulbs which are used are as follows:

Lamp

Headlamps

Rear Lamps

Stop Light

Tail Light

Parking lamps

Instrument lamps

Closed car lamps

Step light

Vol tage

u

6-8

6-a\

6 8/

6-8V

6-81

6-8/

Candle-Power

21 (Two Filament)

Mazda No. 1110

15 Mazda No. 87

3 Mazda No. 63

Danger of Running Engine in Closed Garage

Every person having to do with the operation or care of a

motor car should be warned of the danger that attends running

the engine while the car is in a small closed garage.

Carbon monoxide, a deadly poisonous gas, is present in the

exhaust of all internal combustion engines. Most people are

already familiar with carbon monoxide in the form of illuminating gas, or in the gas produced by furnaces and stoves when

insufficient air is supplied to give complete combustion. But

[19]

Page 11

illuminating gas and coal gas have an unpleasant odor, which

serves as a warning, whereas carbon monoxide, as produced in

the internal combustion engine, is colorless, tasteless and almost

odorless, so that the victim may be overcome before he is aware

of the.danger. When the engine exhausts into the open air,

the carbon monoxide is so diluted that it has no effect. It is

when the engine is run for a time in a closed room that the proportion of carbon monoxide in the air may increase to the point

at which continued breathing of it would be fatal. The United

States Public Health Service advises that the average automobile

engine warming up in a single car garage will give off enough

carbon monoxide in three minutes to endanger life.

Proper precaution must be taken in cold weather when the

natural tendency is to keep the garage doors and windows

closed. The practice of letting the engine warm up in a closed

garage before opening the doors is unsafe. The risk is made

greater By the fact that the enriching of the mixture by manipulation of the carburetor choke increases the amount of carbon

monoxide formed.

[201

CHAPTER III

EQUIPMENT

I

N

addition to the controls and instruments used in driving,

the car is equipped with various devices which are for the

convenience and comfort of the occupants, and are used only as

occasion demands. It is suggested that the driver anticipate his

use of such equipment by becoming familiar at once with the

directions contained in this chapter.

Windshield and Ventilation

Cadillac closed cars are equipped with a one-piece slanting

windshield that can be moved up and down by means of the

handle just above the windshield (Fig. 12). For the ventilation

under the cowl, the windshield should be raised not more than

one inch, so that the lower

edge of the glass is still

below the ledge over the in-

strument board. With the

windshield in this position

air is deflected into the driving compartment through an

opening in the cowl just forward of the instrument board.

If desired, the windshield can

be raised above the level of

the ledge over the instrument

board, so that air can enter

Fig.

12.

The straight type windshield

is controlled by the handle above the

windshield.

the car directly.

Cowl ventilators are also provided on the closed cars to supple-

ment the ventilation provided by the windshield. These venti-

[21]

Page 12

lators are at the sides of the cowl compartment and open toward

the rear, serving as outlets for the air entering under the windshield.

In warm weather, satisfactory ventilation in the front com-

partment cannot be expected unless the hood doors are open.

Ordinarily, these should be opened at the beginning of warm

weather and left open for the season. The temperature in the

front compartment can thereafter be controlled by the windshield

and ventilators.

Windshield Cleaner

The windshield cleaner consists of two wiper blades, operated

by the suction or vacuum in the intake manifold on the engine.

The cleaner is controlled by the lower button at the extreme lefthand end of the instrument board. This button, when pulled

all the way out, will cause one blade to work on each half of the

windshield, cleaning the entire glass. Pulling the button half

way out will cause both blades to operate on the left hand half

of the windshield, cleaning only the part in front of the driver.

To park both blades at the extreme left of the windshield when

they are not needed to clean the glass, pull the control button

half way out, wait until the left-hand blade travels over to meet

the right-hand blade and returns with it to the left-hand side;

then push the button all the way in.

Adjustable Seat

The front seat is adjustable on all Cadillac closed cars, except

those that are intended to be chauffeur-driven. Except on the

five passenger coupe, the entire front seat can be moved forward

or backward. This adjustment is controlled by a handle on the

center of the seat base, just above the floorboards. As the front

seat on the five-passenger coupe is divided, only the driver's

half of the seat is adjustable.

[22]

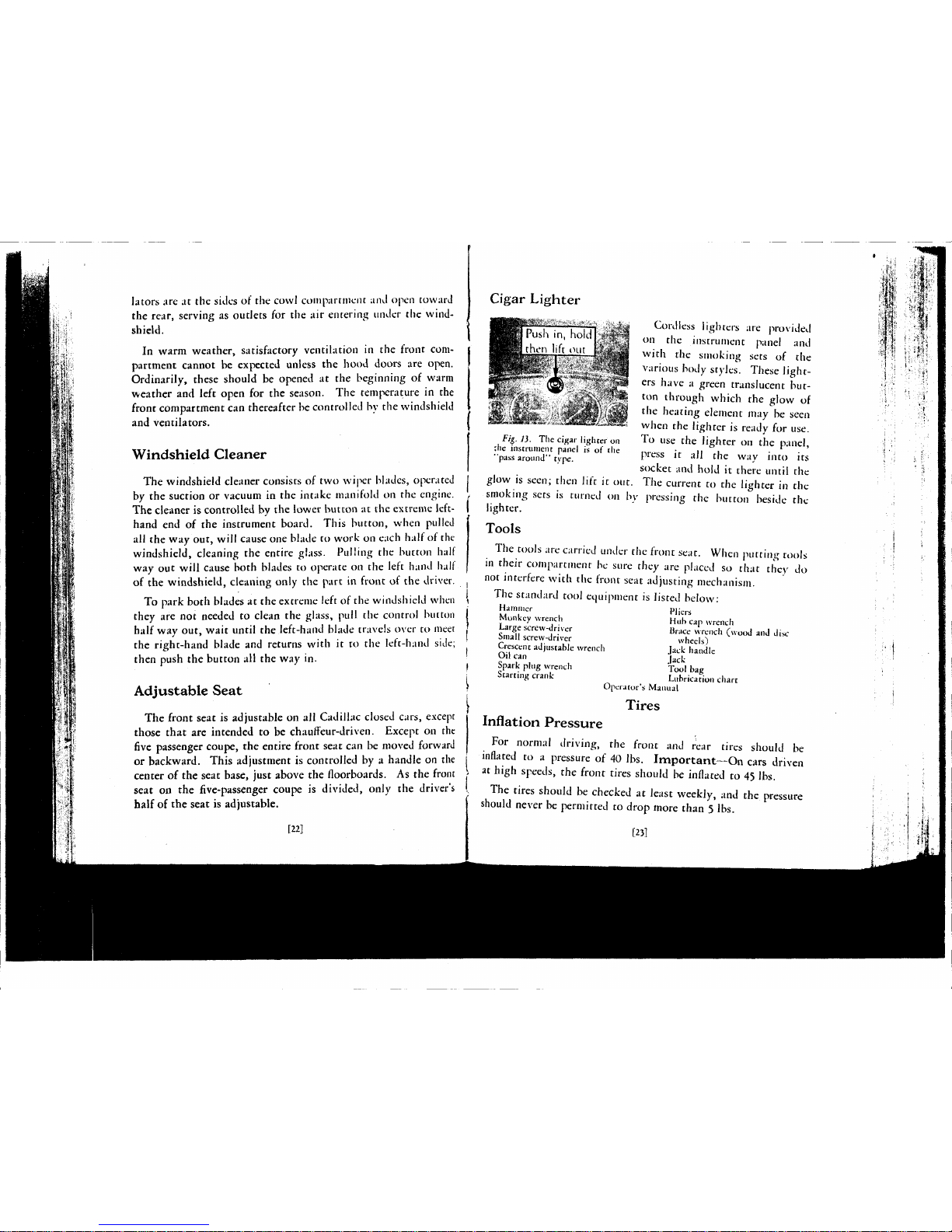

Cigar Lighter

[Push in, hold

lift out

aa^Wi"

i, - • ?,>. ':*•»

-,¾¾¾¾

}

'^- ^mw-*^

I!<KIMII;

Cordless lighters are provided

on the instrument panel and

with the smoking sets of the

various body styles. These light-

ers have a green translucent button through which the glow of

the heating element may be seen

when the lighter is ready for use.

To use the lighter on the panel,

press it all the way into its

socket and hold it there until the

The current to the lighter in the

pressing the button beside the

Fig. 1). The

cigar

lighter

on

;he

instrument

panel

is of the

"pass

around"

type.

glow is seen; then lift it out.

smoking sets is turned on b\

lighter.

Tools

The tools are carried under the front scat. When putting tools

in their compartment be sure they are placed so that they do

not interfere with the front seat adjusting mechanism.

The standard tool equipment is listed below:

Hammer

Pliers

Monkey wrench

Huh cap

wrench

Large screw-driver Brace

wrench

(wood

and

disc

Small

screw-driver wheels)

Crescent

adjustable

wrench

Jack

handle

Oil can

Jack

Spark plug

wrench

Tool

bag

Starting

crank Lubrication

chart

Operator's

Manual

Tires

Inflation Pressure

For normal driving, the front and rear tires should be

inflated to a pressure of 40 lbs. Important—On cars driven

at high speeds, the front tires should be inflated to 45 lbs.

The tires should be checked at least weekly, and the pressure

should never be permitted to drop more than 5 lbs.

,1¼

•iV

[23]

Page 13

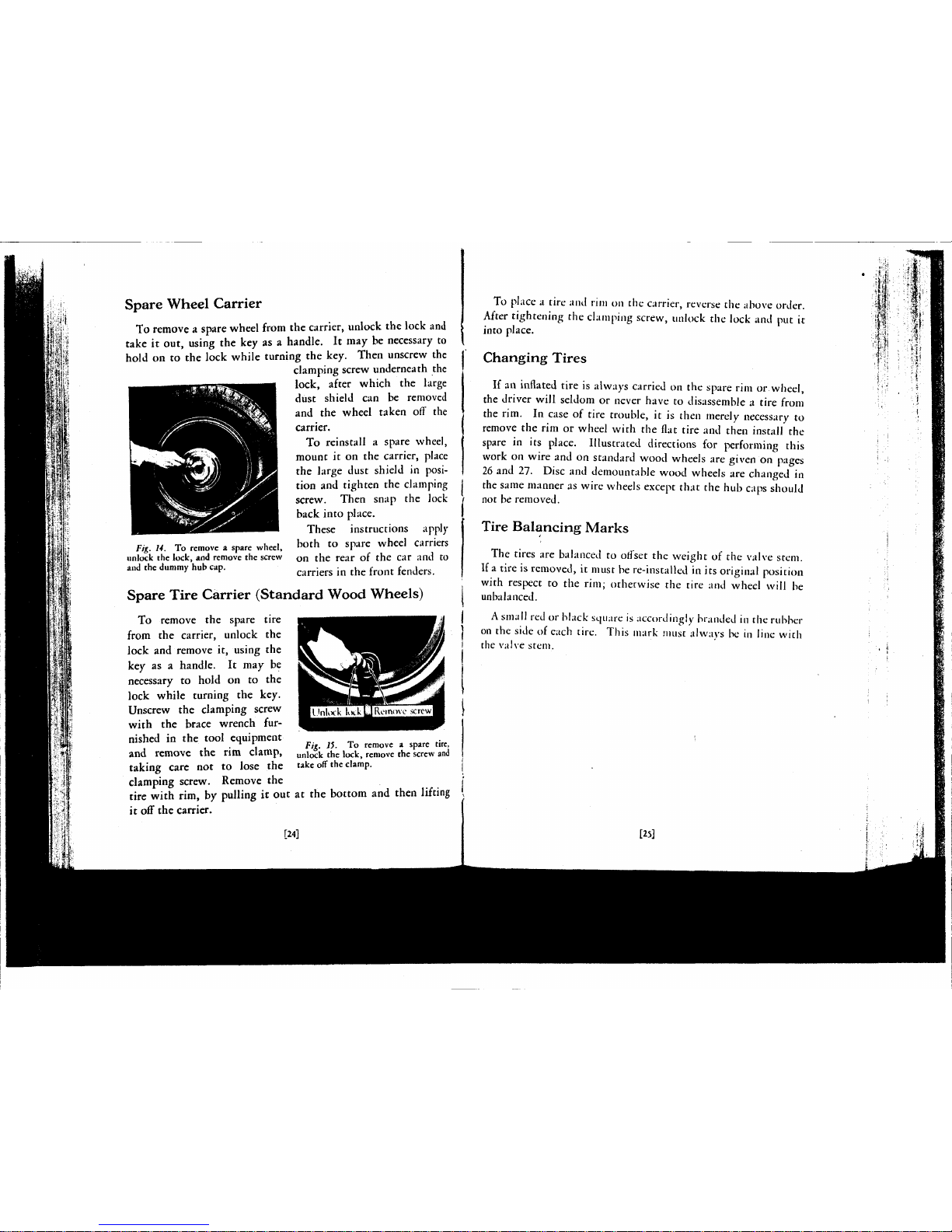

Spare Wheel Carrier

To remove a spare wheel from the carrier, unlock the lock and

take it out, using the key as a handle. It may be necessary to

hold on to the lock while turning the key. Then unscrew the

clamping screw underneath the

lock, after which the large

dust shield can be removed

and the wheel taken off the

carrier.

To reinstall a spare wheel,

mount it on the carrier, place

the large dust shield in position and tighten the clamping

screw. Then snap the lock

back into place.

These instructions apply

both to spare wheel carriers

on the rear of the car and to

carriers in the front fenders.

Fig. 14. To remove a spare wheel,

unlock the lock, and remove the screw

and the dummy hub cap.

Spare Tire Carrier (Standard Wood Wheels)

To remove the spare tire

from the carrier, unlock the

lock and remove it, using the

key as a handle. It may be

necessary to hold on to the

lock while turning the key.

Unscrew the clamping screw

with the brace wrench furnished in the tool equipment

and remove the rim clamp,

taking care not to lose the

clamping screw. Remove the

tire with rim, by pulling it out

it off the carrier.

Fig. 15. To remove a spare tire,

unlock the lock, remove the screw and

take off the clamp.

at the bottom and then lifting

[24]

To place a tire and rim on the carrier, reverse the above order.

After tightening the clamping screw, unlock the lock and put it

into place.

Changing Tires

If an inflated tire is always carried on the spare rim or wheel,

the driver will seldom or never have to disassemble a tire from

the rim. In case of tire trouble, it is then merely necessary to

remove the rim or wheel with the flat tire and then install the

spare in its place. Illustrated directions for performing this

work on wire and on standard wood wheels are given on pages

26 and 27- Disc and demountable wood wheels are changed in

the same manner as wire wheels except that the hub caps should

not be removed.

Tire Balancing Marks

The tires are balanced to offset the weight of the valve stem.

If a tire is removed, it must be re-installed in its original position

with respect to the rim; otherwise the tire and wheel will be

unbalanced.

A

small red or black square is accordingly branded in the rubber

on the side of each tire. This mark must always be in line with

the valve stem.

[25]

Page 14

,1

!

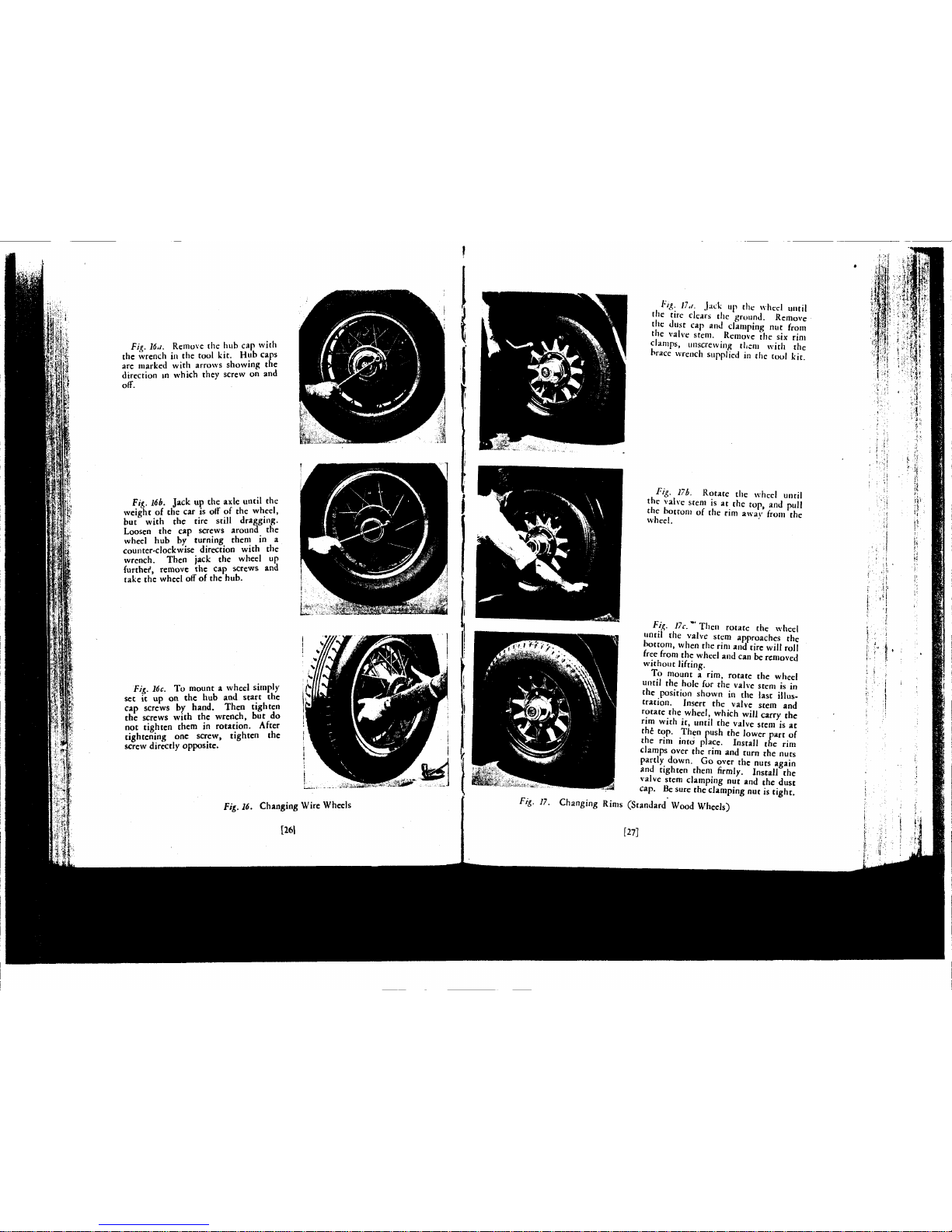

Fig. 16a. Remove the hub cap with

the wrench in the tool kit. Hub caps

are marked with arrows showing the

direction in which they screw on and

off.

Fig.

16b.

Jack up the axle until the

weight of the car is off of the wheel,

but with the tire still dragging.

Loosen the cap screws around the

wheel hub by turning them in a

counter-clockwise direction with the

wrench. Then jack the wheel up

further, remove the cap screws and

take the wheel off of the hub.

Fig.

16c.

To mount a wheel simply

sec it up on the hub and start the

cap screws by hand. Then tighten

the screws with the wrench, but do

not tighten them in rotation. After

tightening one screw, tighten the

screw directly opposite.

Fig. 16. Changing Wire Wheels

[261

tig- 17u. Jack up the wheel until

the tire clears the ground. Remove

the dust cap and clamping nut from

the valve stem. Remove the six rim

clamps, unscrewing them with the

brace wrench supplied in the tool kit.

Fig. 17b. Rotate the wheel until

the valve stem is at the top, and pull

the bottom of the rim away from the

wheel.

Fig. 17c."Then rotate the wheel

until the valve stem approaches the

bottom, when the rim and tire will roll

free from the wheel and can be removed

without lifting.

To mount a rim, rotate the wheel

until the hole for the valve stem is in

the position shown in the last illustration. Insert the valve stem and

rotate the wheel, which will carry the

rim with it, until the valve stem is at

th£ top. Then push the lower part of

the rim into place. Install the rim

clamps over the rim and turn the nuts

partly down. Go over the nuts again

and tighten them firmly. Install the

valve stem clamping nut and the dust

cap.

fie sure the clamping nut is tight.

(Standard Wood Wheels)

[27]

Page 15

LUBRICATION SCHEDULE

CADILLAC

370

ENGINE

NO.

DATE DELIVERED

OO

NOT

WAIT

POR

SCHEDULE LUBRICATIONS

BEFORE ADDING ENGINE

OIL.

THE

OIL

LEVEL

SHOULD

BE

CHECKED EVERY MO

TO IM

MILES

ANO

OIL

ADDED

IF THE

INDICATOR BALL

IS

•

CLOW ••PULL." THIS

IS

ESPECIALLY

IM-

PORTANT

ON

CARS DRIVEN

AT

MICH SPEEDS.

N

0

z

<

w

(A

0

z

z

g

<

U

£

3

01

Q

Z

<

n

tf)

0

Z

z

0

h

<

o

5

a

3

J

PR

O

0

2

<

•

t

z

z

0

<

u

E

0

3

J

0

Z

<

f-

«•>

i

z

z

0

<

u

£

c

3

J

ADD LIQUID

TO

ADD ENGINE

OIL

AS NECESSARY

STARTER. GENERATOR AND

BRAKE PINS

AND

CONNECTIONS

DOOR HARDWARE

GREASE

GUN

WATER PUMP

CLUTCH RELEASE BEARING

AND BRAKE A SSI ST ER

•ADO WATER

TO

STORAGE BATTERY

CHECK TIRE INFLATION

DRAIN

AND

REPLACE

TEST

OIL

FILTER

TRANSMISSION—ADO LUBRICANT

RE

STI

EER1NG GEAR—ADO

ONT

BRAKE TRUNNIONS

AND

SPEEDOMETER DRIVE SHAFT

FAN

••REFILL SHOCK ABSORBERS

••REPLACE

OIL

FILTER CARTRIDGE

AND CLEAN

OIL PAN

AND SCREEN

LUBRICANT

WATER

OR

ANTI-PREC2E

ENGINE

OIL

ENGINE

OIL

ENGINE

OIL

ENGINE

OIL

CHASSIS

GREASE

WATER PUMP

GREASE

WHEEL BEARING

GREASE

Dl STILLED

WATER

ENGINE

OIL

GEAR

LUBRICANT

GEAR

LUBRICANT

GEAR

LUBRICANT

LIGHT

ENGINE

OH.

CHASSIS

GREASE

WHEEL BEARING

GREASE

CHASSIS

GREASE

CHASSIS

QREASB

SPECIAL ON.

LUBRICATION

NO. AND

MILEAGE

AT

WHICH

DUE

1

I

o

o

o

o

o

o

o

o

o

o

t

i

o

o

o

o

o

o

o

o

o

o

o

1

?

o

o

o

o

o

o

o

o

o

o

o

o

o

o

I

§

o

o

o

o

o

o

o

o

o

o

o

I

1

0

o

0

o

o

o

o

o

o

o

•

1

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

J

I

o

o

o

o

o

o

o

o

o

o

•

I

o

o

o

o

o

o

o

o

o

o

o

•

1

o

o

o

o

o

o

o

o

o

o

o

o

o

o

10

I

o

o

o

o

u

o

o

o

o

o

o

EVERY 12.000 MILES

II

1

o

o

o

o

o

o

o

o

o

o

11

1

o

o

u

u

o

o

o

o

o

o

o

u

o

o

o

o.

o

o

o

o

o

•IN

SUMMER INSPECT BATTERY EVERY

see

MILES

OR

AT

LEAST

EVERT t WEEKS.

•*RECOfcmFNDED BUT NOT INCLUOEO IN LUBRICATIONS 0 AND 11.

THE FOLLOWING OPERATIONS CANNOT

BE

PLACED

ON A

MILEAGE BASIS

AND ARE NOT

INCLUDED

IN

THE ABOVE SCHEDULE

THIN REAR AXLE AND TRANSMISSION LUBRICANT-AS REQUfREQ

f>OR

LOW TEMPERATURES.

DRAIN

AND

REPLACE REAR AXLE

AND

TRANSMISSION LUBRICANT—AT BEGINNING

OP

MILD WEATHER

IN SPRING.

RECORD

ON

OTHER SIDE

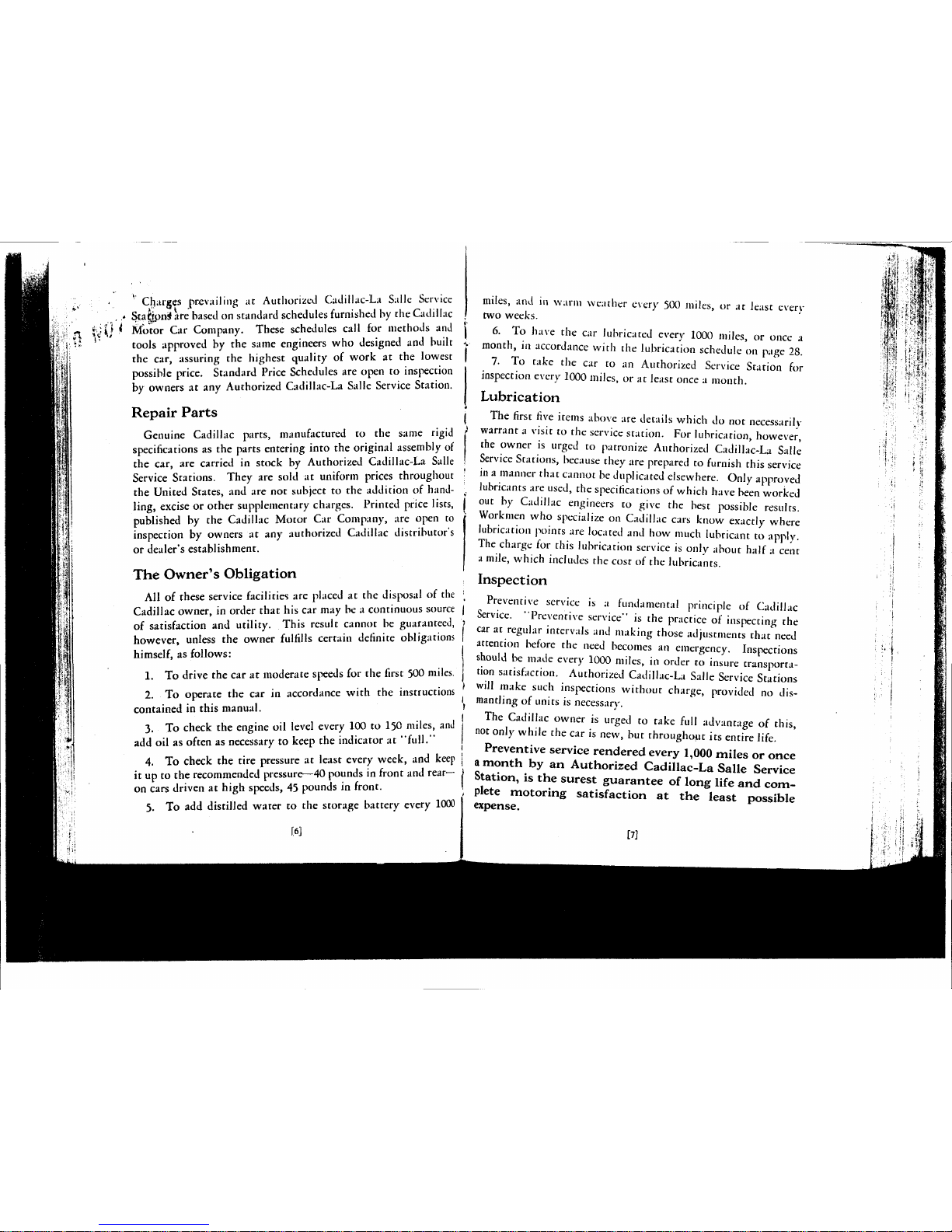

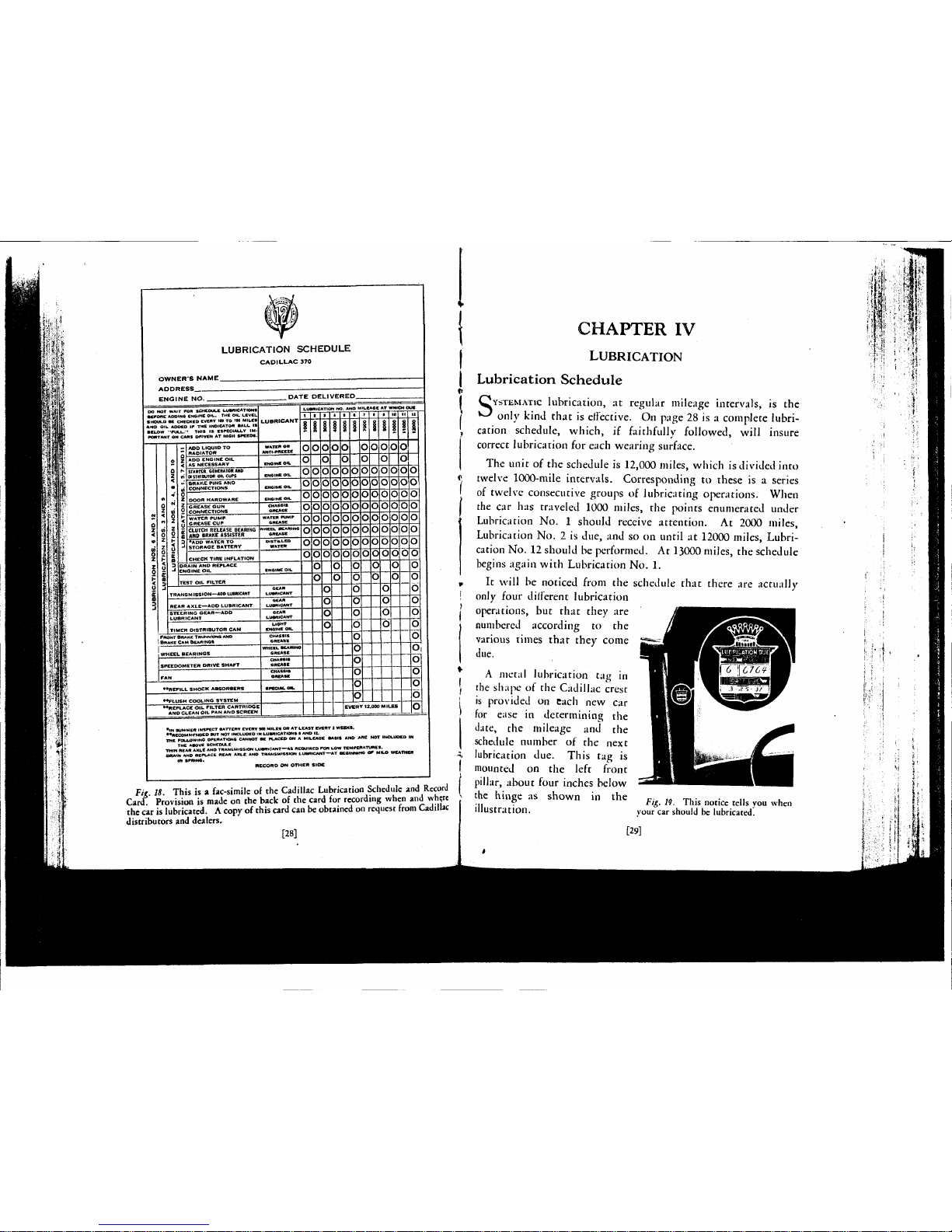

Fig.

18.

This

is a

fac-simile

of the

Cadillac Lubrication

Schedule

and

Record

Card.

Provision

is

made

on the

back

of the

card

for

recording

when

and

where

the

car

is

lubricated. A copy

of

this

card

can be

obtained

on

request

from

Cadillac

distributors

and

dealers.

[28]

CHAPTER

IV

LUBRICATION

Lubrication Schedule

S

YSTEMATIC

lubrication,

at

regular mileage intervals,

is the

only kind that

is

effective.

On

page

28 is a

complete lubri-

cation schedule, which,

if

faithfully followed, will insure

correct lubrication

for

each wearing surface.

The unit

of the

schedule

is

12,000 miles, which

is

divided into

twelve 1000-mile intervals. Corresponding

to

these

is a

series

of twelve consecutive groups

of

lubricating operations. When

the

car has

traveled

1000

miles,

the

points enumerated under

Lubrication

No. 1

should receive attention.

At

2000 miles,

Lubrication

No.

2 is

due,

and so on

until

at

12000 miles, Lubri-

cation

No. 12

should

be

performed.

At

13000 miles,

the

schedule

begins again with Lubrication

No.

1.

It will

be

noticed from

the

schedule that there

are

actually

only four different lubrication

operations,

but

that they

are

JttKKKKtBSBBtEKL

numbered according the

^^^^I^K^KUS^BH

various times that they come

J-^^^^H^H^E^^BHSI

A metal lubrication

tag in

HHH ^•liUailiO^Br

the shape

of the

Cadillac crest Hui^M

^¾

«>iIIIMR

mmW

is provided

on

each

new car

^MS_§Sj ^^gjgppV^

for ease

in

determining

the

fll^^l

date,

the mileage and the

^BBBI

^^

schedule number

of the

next

HBRH

j^'

lubrication

due.

This

tag is

wK^m^JM»'s-t^^^^mmm1mWM

mounted

on the

left JpH^Hsfl^BBR^HsBR^Lfl

pillar, about four inches below

:^"»MBB^B^^E^B^BB»T4^^B«

the hinge

as

shown

in the

Fig M_ This noticc

Kl|s you

when

illustration.

your

car

should

be

lubricated.

[29]

I

Page 16

The driver can easily check this with the speedometer mileage

by opening the left front door a few inches. Authorized CadillacLa Salle service stations, after performing each schedule operation,

post the number of the next operation due and the mileage at

which it is due. When the mileage recorded by the speedometer

is the same as the mileage marked on the notice, the car may be

taken to any authorized Cadillac-La Salle service station, and,

without further ordering other than specifying "schedule lubrication," the car will receive the exact lubrication necessary.

Although the schedule is expressed in terms of miles, it is

intended that the car be lubricated once each month if the

mileage traveled is less than 1000 since the last lubrication

operation was performed. This lubrication work can be done

while the car is in the service station for its regular monthly or

1000-mile inspection.

Lubrication Chart

The lubrication chart (18 x 24 inches in size) which accompanies this manual gives complete detailed instructions for

lubricating the car. All of the points which require lubrication

are designated on this chart, together with the kind of lubricant

to be used, the method of applying it and the frequency with

which it should be applied.

The operations are grouped on the chart in the same manner

as on the schedule sfrown in Fig. 18. If the car is lubricated at

an "Authorized Station," this schedule will be followed; if not,

whoever does the lubrication should follow the schedule and

chart exactly.

Lubricants

The selection of proper lubricants should be one of the first

concerns of the owner in his attention to the lubrication of the

[301

car. The lubricants must not only be of high quality, but their

i viscosity and other characteristics must be suited to the car.

t The owner is urged to consult the distributor or dealer from

whom he purchased his car in regard to the names of lubricants

J which have been tested and approved for use in the Cadillac car.

I Engine Oil

f

I The chart of engine oil recommendations given on page 32

I indicates the proper grades of oil to be used for average driving

) and for prolonged high speed driving.

Gear Lubricant

Lubricant conforming to the specifications for Gear Lubricant

must be used in the transmission, rear axle and steering gear.

It is particularly important that only recommended lubricants

be used in the transmission. Engine oil or soap greases will not

perform satisfactorily.

Lubricants conforming to these specifications may be used

without thinning during all weather, except winter weather

below temperatures of 20° above zero. Below this temperature,

thinning with kerosene is necessary, unless grease of sufficiently

low pour point is used to secure easier gear shifting and proper

lubrication of gears and bearings. See an authorized CadillacLa Salle service station for recommendations on this lubricant.

Important: The Gear Lubricant known as "sulphurized" oil

and designated by "E. P.," following its S. A. E. classification

is not satisfactory for use in the transmission or rear axle on

Cadillac cars and should not be used in these assemblies under

any circumstances. This lubricant is injurious to bronze parts

such as are used in gear assemblies of all higher quality cars and

is particularly injurious to the synchro-mesh transmission.

Chassis Grease

Lubricant conforming to the specifications for Chassis Grease

is recommended for all chassis points fitted with grease gun con-

[31]

' '"I

IAI?^

Page 17

nections. Do not use ordinary cup grease, as such greases are

not effective enough to lubricate satisfactorily over the 1000mile interval.

Wheel Bearing Grease

Greases approved under the specifications for Wheel Bearing

Grease are suitable for lubricating the wheel bearings and the

clutch release bearing.

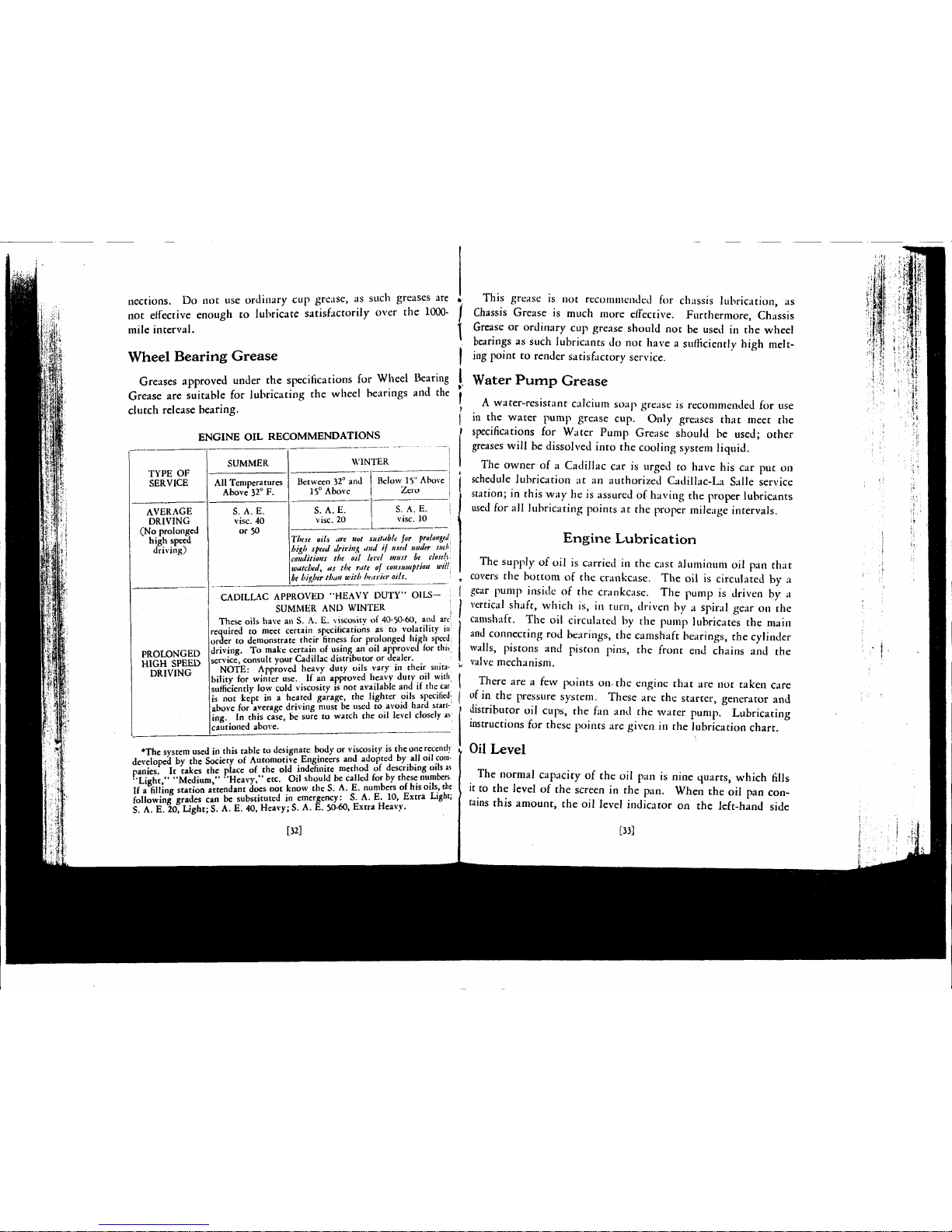

ENGINE OIL RECOMMENDATIONS

TYPE OF

SERVICE

AVERAGE

DRIVING

(No prolonged

high speed

driving)

PROLONGED

HIGH SPEED

DRIVING

SUMMER

All Temperatures

Above 32° F.

S. A. E.

vise.

40

or 50

WINTER

Between 32° and

15° Above

S. A. E.

vise.

20

Below 15° Above

Zero

S. A. E.

vise.

10

Ttiese oils are Hot suitable for

prolonged

high

speed

driving and if used

under such

conditions the oil level must be closely

watched^

as the rate of

consumption

will

be higher

than with

heavier

oils.

CADILLAC APPROVED 'HEAVY DUTY" OILS- j

SUMMER AND WINTER ;

These oils have an S. A. E. viscosity of 40-50-60, and arc'

required to meet certain specifications as to volatility in

order to demonstrate their fitness for prolonged high speed

driving. To make certain of using an oil approved for this;

service, consult your Cadillac distributor or dealer.

NOTE: Approved heavy duty oils vary in their suita-

bility for winter use. If an approved heavy duty oil with

|

sufficiently low cold viscosity is not available and if the car

is not kept in a heated garage, the lighter oils specified:

above for average driving must be used to avoid hard start-!

ing. In this case, be sure to watch the oil level closely as

cautioned above.

•The system used in this table to designate body or viscosity is the one recently

developed by the Society of Automotive Engineers and adopted by all oil companies. It takes the place of the old indefinite method of describing oils as

"Light," "Medium," "Heavy," etc. Oil should be called for by these numbers.

If a filling station attendant does not know the S. A. E. numbers of his oils, the

following grades can be substituted in emergency: S. A. E. 10, Extra Light;

S. A. E. 20, Light; S. A. E. 40, Heavy; S. A. E. 50-60, Extra Heavy.

[32]

This grease is not recommended for chassis lubrication, as

Chassis Grease is much more effective. Furthermore, Chassis

Grease or ordinary cup grease should not be used in the wheel

bearings as such lubricants do not have a sufficiently high melting point to render satisfactory service.

Water Pump Grease

A water-resistant calcium soap grease is recommended for use

in the water pump grease cup. Only greases that meet the

specifications for Water Pump Grease should be used; other

greases will be dissolved into the cooling system liquid.

The owner of a Cadillac car is urged to have his car put on

schedule lubrication at an authorized Cadillac-La Salle service

station; in this way he is assured of having the proper lubricants

used for all lubricating points at the proper mileage intervals.

Engine Lubrication

The supply of oil is carried in the cast aluminum oil pan that

covers the bottom of the crankcase. The oil is circulated by a

gear pump inside of the crankcase. The pump is driven by a

vertical shaft, which is, in turn, driven by a spiral gear on the

camshaft. The oil circulated by the pump lubricates the main

and connecting rod bearings, the camshaft bearings, the cylinder

walls,

pistons and piston pins, the front end chains and the

valve mechanism.

There are a few points on-the engine that are not taken care

of in the pressure system. These are the starter, generator and

distributor oil cups, the fan and the water pump. Lubricating

instructions for these points are given in the lubrication chart.

Oil Level

The normal capacity of the oil pan is nine quarts, which fills

it to the level of the screen in the pan. When the oil pan contains this amount, the oil level indicator on the left-hand side

[33]

Page 18

I'l^'r

a. T

ff

(I

IP'

|V J'

ih

n

4

P

r 1

h

M

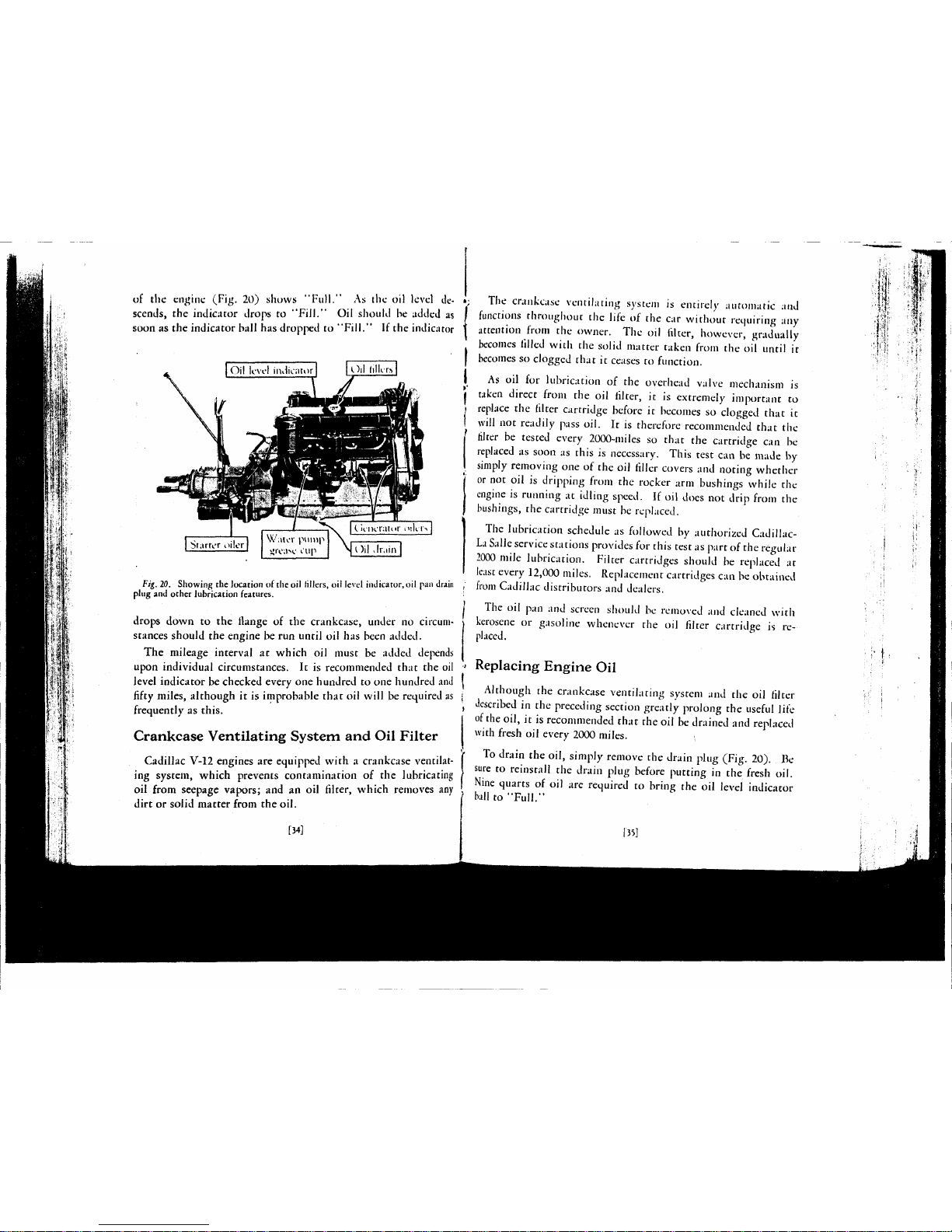

of the engine (Fig. 20) shows "Full." As the oil level descends, the indicator drops to "Fill." Oil should be added as

soon as the indicator ball has dropped to "Fill." If the indicator

Oil tillers

Starrer oiler

Wntvr ptunp

«re;iM' I'up

Oil Jr.iin

Fig. 20. Showing the location of the oil fillers, oil level indicator, oil pan drain

plug and other lubrication features.

drops down to the flange of the crankcase, under no circumstances should the engine be run until oil has been added.

The mileage interval at which oil must be added depends

upon individual circumstances. It is recommended that the oil

level indicator be checked every one hundred to one hundred and

fifty miles, although it is improbable that oil will be required as

frequently as this.

Crankcase Ventilating System and Oil Filter

Cadillac V-12 engines are equipped with a crankcase ventilating system, which prevents contamination of the lubricating

oil from seepage vapors; and an oil filter, which removes any

dirt or solid matter from the oil.

[34]

The crankcase ventilating system is entirely automatic and

functions throughout the life of the car without requiring any

attention from the owner. The oil filter, however, gradually

becomes filled with the solid matter taken from the oil until it

becomes so clogged that it ceases to function.

As oil for lubrication of the overhead valve mechanism is

taken direct from the oil filter, it is extremely important to

replace the filter cartridge before it becomes so clogged that it

will not readily pass oil. It is therefore recommended that the

filter be tested every 2000-miles so that the cartridge can be

replaced as soon as this is necessary. This test can be made by

simply removing one of the oil filler covers and noting whether

or not oil is dripping from the rocker arm bushings while the

engine is running at idling speed. If oil does not drip from the

bushings, the cartridge must be replaced.

The lubrication schedule as followed by authorized CadillacLa Salle service stations provides for this test as part of the regular

2000 mile lubrication. Filter cartridges should be replaced at

least every 12,000 miles. Replacement cartridges can be obtained

from Cadillac distributors and dealers.

The oil pan and screen should be removed and cleaned with

kerosene or gasoline whenever the oil filter cartridge is replaced.

Replacing Engine Oil

Although the crankcase ventilating system and the oil filter

described in the preceding section greatly prolong the useful life

of the oil, it is recommended that the oil be drained and replaced

with fresh oil every 2000 miles.

To drain the oil, simply remove the drain plug (Fig. 20). Be

sure to reinstall the drain plug before putting in the fresh oil.

Nine quarts of oil are required to bring the oil level indicator

ball to "Full."

135]

H

Page 19

CHAPTER V

COLD

WEATHER

OPERATION

OATISFACTORY

operation of the car in freezing weather depends

^-^ upon having the car prepared for cold weather and in giving

it the special attention which is required at that time. In this

chapter has been grouped all the information relating to care

and operation of the car during cold weather. It should be

reviewed just prior to the beginning of the winter season.

Preparing

for

Cold

Weather

Anti-Freezing

Solutions

The available commercial materials for preparing anti-freezing

solutions for automobile radiators are denatured alcohol, methanol (synthetic wood alcohol), distilled glycerine, and ethylene

glycol.

Denatured alcohol and methanol solutions are, at present, the

most generally used anti-freezing solutions. These preparations

are widely distributed, afford protection against freezing, and are

not injurious to the cooling system.

There are two principal objections to denatured alcohol and

methanol—they are lost by evaporation, and are harmful to the

car finish. Any material accidentally spilled on the finish should

be flushed off immediately with a large quantity of water.

Solutions of these materials in the radiator must be tested

periodically and sufficient methanol or alcohol should be added to

replace the loss by evaporation. Otherwise, the engine or radiator, or both, are likely to be damaged by freezing. Evaporation

is much more rapid on heavy runs, and the solution should be

tested more often under such circumstances.

Methanol, for aiiti-Jrceze purposes, is sold in the United States

in the correct concentration to give the same protection against

freezing as denatured alcohol. The table below may be used for

both denatured alcohol and methanol.

Lowest

Temperature

Ex-pec tcJ

10 F.

0 F.

-10 F.

—20 F.

-30 F.

Per cent

In

Volume

30

38

45

51

57

Specific <-i

1,at 60"

Ocuamrct AKi>lml

.9668

.9567

.9475

.9350

.9260

ravitv

IV) •

MdllJH,"

.972

.964

.957

.950

.944

Qts.

Alcohol

required to make

6 pals, solution

Vx

9)

A

10?

4

12

13*.,

I

Distilled glycerine and ethylene glycol solutions are, in first

cost, more expensive than alcohol, but as they are not lost by

evaporation, only water need be added to replace evaporation

' losses, except that any solution lose mechanically, by leakage,

foaming,

etc.,

must be replaced by additional new anti-freezing

solution. These solutions under ordinary conditions are not

injurious to the car finish.

! The principal objections to glycerine and ethylene glycol arc

I the tendency of these solutions to loosen the scale and iron rust

| which forms in the water passages of the cylinder block and head,

and the difficulty of securing and maintaining tight, leak proof

connections. It is absolutely necessary to thoroughly clean and

, Hush the entire cooling system before glycerine or ethylene

glycol is used.

I It is also necessary to tighten or replace the cylinder head

I

gaskets and pump packing. The cylinder head gaskets must be

kept tight to prevent the solution from leaking into the crank-

case where it might cause gumming and sticking of the moving

( parts. The pump packing must be kept tight to prevent air

\ from being drawn into the cooling system in order to avoid

I foaming and other difficulties which may result when air is

j present.

[361

!37l

Page 20

Ethylene glycol, sold in the U. S. for anti-freezing purposes, is

chemically treated to overcome the principal difficulties men-

tioned in the above paragraph, and under normal operating conditions with tight hose connections and cylinder head gaskets

should be satisfactory for use in the cooling systems.

Glycerine or ethylene glycol should be used in accordance

with the instructions and in the proportions recommended by

the anti-freeze manufacturer.

In using a hydrometer to determine the temperature at which

a solution will freeze, the test must be made at the temperature

at which the hydrometer is calibrated. If the solution is warmer

or colder, it must be brought to this temperature or correction

must be made for the difference in temperature, otherwise large

errors may result. Freezing point hydrometers can not be used

interchangeably, a different float being required for denatured

alcohol, methanol, glycerine and ethylene glycol. In some cases

these errors may be as large as 30 degrees Fahrenheit.

Salt solutions, such as calcium or magnesium chloride, sodium

silicate, etc., honey, glucose and sugar solutions and oils are not

satisfactory for use in automobile radiators.

Capacity of Cooling System

The capacity of the cooling system is 6½ gallons when filled

to the level of the overflow pipe. The cooling system may be

filled to this level since the overflow pipe is connected to a condenser tank which operates automatically to prevent excessive

loss of the cooling liquid.

It is important that there are no leaks in the cooling system

and that the radiator cap is turned down so that it is air tight,

to insure proper operation of the condenser.

Winter Lubrication

Lubrication of the car requires special attention in winter, not

only to insure proper lubrication of the moving parts, but to

[38]

secure the same ease of operation in starting, steering and shifting

gears as during warm weather.

The chart of engine oil recommendations on page 32 gives the

proper grade of oil to be used for cold weather driving. It will

be noted that lighter oils can be used for cold weather providing

no prolonged high speed driving is done. For prolonged high

speed driving, "Heavy duty" oils must be used. Authorized

Cadillac-La Salle Service Stations are prepared with full information on winter lubrication.

The lubricant in the transmission and rear axle should be

thinned with kerosene as soon as the weather is so cold that the

transmission gears are hard to shift. If a sufficient amount of

kerosene is added to provide for the lowest winter temperature

expected, it will not be necessary to add kerosene again there-

after during the winter. Ten per cent (a little over half a pint)

of kerosene, if added, will take care of temperatures down to ten

below zero.

There are several lubricants on the market which have a low

enough pour point so that they will not require thinning. See an

authorized Cadillac-La Salle Service Station for information on

these lubricants. If one has been regularly used, no kerosene

should be added. Thinning of such a lubricant is not only unnecessary, but defeats the purpose of using it because it would

have to be drained and replaced on return of warm weather.

Steering gear lubricant, in any case, should not be thinned as

the pressure between the worm and sector will force out the

thinned lubricant, resulting in excessive wear. A lubricant of

low enough cold test so as not to require thinning should be used.

Storage Battery

The electrical system of an automobile has much more to do

in winter than in summer. The engine is harder to crank and

must usually be cranked longer before it starts. The lights are

also used to much greater extent than during the long days of

[39]

Page 21

summer. All this means that the battery must be ready for

increased demands.

It is therefore a good plan in preparing for the winter season

to see that the battery is fully charged, that the battery connections are clean and tight, and that the charging rate is sufficient

to take care of the requirements of the system.

Gasoline System

The carburetors on the Cadillac engine have automatic com- •

pensation for temperature. Nevertheless it is a good plan to

have the carburetor adjustment checked when cold weather

arrives. This inspection should give special attention to the

carburetor choke control to make sure that the enriching device

is fully effective at each carburetor when the choke button is

operated.

In warm weather, a small amount of water in the gasoline has

little or no effect on the running of the engine. In freezing

weather, however, even a small amount of water may freeze

and stop the entire flow of fuel to the carburetors. One of the

things to be done in preparing for winter weather, therefore, is

to clean the gasoline filter and the sediment chambers in the

gasoline system.

Starting the Engine

Choke Button

The first difference between starting the engine in cold weather

and starting the engine in warm weather is in the greater use ot

the choke necessary in cold weather. Gasoline does not vaporize

as readily at low temperatures, and in order to supply the cylinders with a gaseous mixture rich enough to be ignited, the

proportion of liquid gasoline to air must be increased.

At the same time, it is important not to apply the choke more

than is necessary. The unvaporized gasoline collects on the

[40]

cylinder walls and works down past the pistons, washing off

the lubricant as it goes. Although dilution of the oil supply

with this unburned gasoline is minimized by the crankcase

ventilating system, it is best to avoid an excess of liquid gasoline

in the combustion chambers by careful and judicious use of the

choke.

The following rule should govern the use of the choke in

winter weather: Pull the choke back just as far as it is necessary

to start the engine, but as soon as the engine starts, return the

button as far as possible without causing the engine to stop or

slow down. Then push the button all the way in as soon as the

engine is warm enough to permit doing so.

Priming the Carburetors

In extremely cold weather, if the engine does not start after

cranking for a few seconds with the choke button fully applied,

release the starter pedal. Then prime the carburetors by opening

and closing the throttle once or twice rather rapidly with the

accelerator. Opening and closing the throttle operates a throttle

pump on each carburetor and raises the level of the gasoline in

the carburetors. The carburetors should never be primed in

warm weather and should not be primed unnecessarily in cold

weather. Excessive priming is likely to make starting difficult

rather than easy.

Position of Throttle Hand Lever

The correct position of the throttle hand lever for starting in

cold weather is the same as for starting under other conditions,