Cadel aquos 15, ibis 11, ibis 15, ibis 22, ibis 22 h2o Installation, Use And Maintenance Manual

...

©2014 CADEL srl | All rights reserved – tutti i diritti riservati

en

PELLET THERMOSTOVE

installation, use and maintenance manual

aquos

15 -

aquos

22 -

aquos 22 h

2

o

ibis

11 -

ibis

15 -

ibis

22 -

ibis 22 h

2

o

idron

11 -

idron

15 -

idron

22 -

idron 22 h

2

o

2

AQUOS - IBIS - IDRON

EN

Summary

1 INTRODUCTION ................................................4

1.1 DEAR CUSTOMER ..........................................4

1.2 REVISIONS TO THE PUBLICATION .................4

1.3 CARE OF THE MANUAL AND HOW TO

CONSULT IT ...........................................................4

1.4 SYMBOLS USED IN THE MANUAL ..................4

2 WARNINGS ......................................................4

2.1 INFORMATION: ..............................................5

2.2 INTENDED USE ...............................................5

2.3 INTERVENTION REQUEST ...............................5

2.4 SPARE PARTS .................................................6

3 WARNINGS FOR THE CORRECT DISPOSAL OF

THE PRODUCT ...........................................................6

4 WARRANTY CONDITIONS ................................6

5 INSTALLATION INSTRUCTIONS ..........................7

5.1 PELLETS ...........................................................7

5.2

PRECAUTIONS REGARDING INSTALLATION ...

8

5.3 THE OPERATING ENVIRONMENT ..................8

5.4 MINIMUM DISTANCES ...................................8

5.5

CONNECTION OF THE FUME EXHAUST PIPE ....

9

5.6 CONNECTIONS ...........................................10

5.7 OPERATING PROBLEMS RELATED TO

DRAUGHT DEFECTS IN THE CHIMNEY ...............11

6

TECHNICAL DRAWINGS AND CHARACTERISTICS ....

12

6.1 DIMENSIONS ................................................12

7 INSTALLATION AND ASSEMBLY ......................19

7.1 PREPARATION AND UNPACKING ..............19

7.2 CERAMIC AND METAL SIDES INSERTION

(AQUOS) .............................................................21

7.3 METAL SIDES INSERTION (IDRON) ..............22

7.4 METAL FRAME INSERTION (IBIS)..................22

8 PLUMBING CONNECTION ..............................23

8.1 PLUMBING SYSTEM CONNECTION ............23

8.2 CONNECTION DIAGRAM STOVE (AQUOS 15

- 22 / IBIS 15 - 22 / IDRON 15 -22) .....................23

8.3

CONNECTION DIAGRAM FOR HYDRO STOVE EQUIPPED

WITH KIT FOR DOMESTIC HOT WATER PRODUCTION (AQUOS

22 H2O / IBIS 22 H2O / IDRON 22 H2O) ...........................

23

8.4 CONNECTION DIAGRAM FOR HYDRO STOVE

(IBIS 11 / IDRON 11) ...........................................24

8.5 SYSTEM CONNECTIONS .............................24

8.6 SYSTEM FILLING ...........................................25

8.7

DOMESTIC HOT WATER PRODUCTION KIT (AQUOS 22

H2O / IBIS 22 H2O / IDRON 22 H2O STOVES ONLY) .....

26

8.8 WATER CHARACTERISTICS .........................26

9 ELECTRICAL CONNECTIONS ..........................27

9.1 GENERAL PRECAUTIONS ............................27

9.2 ELECTRICAL CONNECTION........................27

10 INITIAL START-UP .............................................28

10.1 GENERAL PRECAUTIONS ...........................28

10.2 OPENING/CLOSING THE DOOR ...............29

10.3 SETTINGS TO BE CARRIED OUT BEFORE THE

INITIAL START-UP .................................................29

10.4 LOADING THE PELLETS ...............................29

11 MENU ITEMS ....................................................29

11.1 CONTROL PANEL DISPLAY ........................29

11.2 MAIN MENU................................................30

11.3 SETTINGS MENU ..........................................30

11.4 ADJUSTMENTS MENU .................................33

12 PRELIMINARY NOTIONS .................................34

12.1 SYSTEM CONFIGURATIONS DEPENDING ON

THE MODEL .........................................................34

13 OPERATION .....................................................37

13.1 OPERATING MODE ....................................37

13.2

EXTERNAL THERMOSTAT CONNECTION (E) ....

38

13.3 START-UP .....................................................39

13.4 POWER OUTPUT .........................................39

13.5

PROGRAMMED MODE (TIMER) - MAIN MENU ...

39

13.6 PROGRAMMING EXAMPLES: ....................40

13.7 NOTES FOR TIMER OPERATION .................40

13.8 AUTO ECO MODE (SEE SECTION F-G) .....40

13.9 SLEEP FUNCTION (MAIN MENU) ...............40

13.10 AUXILIARY BOILER (SEE SECTION I) .........41

13.11 PELLETS RECIPE (SEE SECTION J) .............41

13.12

SMOKE RPM VARIATION (SEE SECTION K) ....

41

13.13 PUMP ON T (EXPERIENCED USERS ONLY) -

SEE SECTION H ...................................................41

13.14 MAXIMUM POWER (EXPERIENCED USERS

ONLY) - SEE SECTION L ......................................41

13.15

CHIMNEY SWEEP FUNCTION (FOR MAINTENANCE

TECHNICIANS ONLY) - SEE SECTION N .....................

41

13.16 SEASON FUNCTION (SEE SECTION P) .....41

13.17 FEED SCREW (SEE SECTION D) ................42

13.18 COMPONENTS TEST (SEE SECTION M) ....42

14 SAFETY DEVICES AND ALARMS .....................42

14.1 SAFETY DEVICES .........................................42

14.2 PRESSURE SWITCH ......................................42

14.3 SMOKE TEMPERATURE PROBE ...................42

14.4 CONTACT THERMOSTAT IN THE FUEL

HOPPER ..............................................................42

14.5

CONTACT THERMOSTAT IN THE BOILER ....

42

14.6 WATER TEMPERATURE PROBE ...................42

3

AQUOS - IBIS - IDRON

EN

14.7 ELECTRICAL SAFETY ...................................42

14.8 SMOKE FAN ................................................42

14.9 GEAR MOTOR ............................................42

14.10 TEMPORARY POWER CUT .......................42

14.11 FAILED START-UP ......................................42

14.12 ANTIFREEZE FUNCTION ............................43

14.13 PUMP ANTI-SEIZURE FUNCTION ...............43

14.14 ALARM ALERTS .........................................43

14.15 ALARM RESET............................................44

14.16 NORMAL SHUTDOWN (ON THE PANEL: OFF

WITH FLASHING FLAME) ....................................44

14.17 BLACKOUT WITH THE BOILER ON ............44

14.18 BLACKOUT ABOVE 10” WITH BOILER IN

SHUTDOWN STAGE ............................................44

15 MAINTENANCE AND CLEANING ...................44

15.1 DAILY OR WEEKLY CLEANING PERFORMED

BY THE USER ........................................................45

15.2 BEFORE EACH START-UP ............................45

15.3 CLEANING THE GLASS ...............................45

15.4 CLEAN THE EXCHANGER AND THE

UNDERGRATE SPACE EVERY 2/3 DAYS. ...........45

15.5 PERIODIC CLEANING PERFORMED BY A

QUALIFIED TECHNICIAN ....................................46

15.6 CLEANING THE HEAT EXCHANGER ..........46

15.7

CLEANING THE EXCHANGER AND PIPE UNIT (AQUOS 15-

22-22 H2O / IBIS 15-22-22 H2O / IDRON 15-22-22 H2O) ......

46

15.8 CLEANING THE UPPER COMPARTMENT ...46

15.9

CLEANING THE LOWER COMPARTMENT ...

47

15.10 CLEANING THE EXCHANGER AND PIPE UNIT

(IBIS 11 / IDRON 11) ...........................................47

15.11

CLEANING THE UPPER COMPARTMENT ...

47

15.12

CLEANING THE LOWER COMPARTMENT

...47

15.13 CLEANING THE SMOKE DUCT AND GENERAL

CHECKS: .............................................................48

15.14 END-OF-SEASON SHUTDOWN .................49

16 PROBLEMS/CAUSES/SOLUTIONS ...................50

16.1

CHECKING THE INTERNAL COMPONENTS ....

50

4

AQUOS - IBIS - IDRON

EN

1

INTRODUCTION

1.1 DEAR CUSTOMER

Thank you for having chosen our product.

To allow for optimal operation and for you to enjoy the warmth and sense of wellbeing that the re can convey

in your home, we advise you to read this manual carefully before starting up the product for the rst time.

1.2 REVISIONS TO THE PUBLICATION

The content of this manual is strictly technical and property of CADEL srl.

No part of this manual can be translated into another language and/or altered and/or reproduced, even

partially, in another form, by mechanical or electronic means, photocopied, recorded or similar, without prior

written approval from CADEL srl.

The company reserves the right to make changes to the product at any time without prior notice. The proprietary

company reserves its rights according to the law.

1.3 CARE OF THE MANUAL AND HOW TO CONSULT IT

• Take care of this manual and keep it in an easily accessible place.

• Should the manual be misplaced or ruined, request a copy from your retailer or directly from the authorised

Technical Assistance Department.

1.4 SYMBOLS USED IN THE MANUAL

ATTENTION:

carefully read and understand the relative message because failure to comply with what is

written can cause serious damage to the product and put the user’s safety at risk.

INFORMATION:

failure to comply with these provisions will compromise the use of the product.

OPERATING SEQUENCES:

sequence of buttons to be pressed to access the menus or make adjustments.

MANUAL

carefully read this manual or the relative instructions.

2

WARNINGS

• Installation, electrical connection, functional verication and maintenance must only be performed by

qualied or authorised personnel.

• Install the product in accordance with all the local and national laws and Standards applicable in the relative

place, region or country.

• This product is not intended for use by persons (including children) with reduced physical, sensory or mental

• capabilities, or lack of experience and knowledge, unless they are supervised or trained on how to use the

product by a person responsible for their safety.

• Only use fuel recommended by the company. The product must not be used as an incinerator. It is strictly

forbidden to use liquid fuel.

• The instructions provided in this manual must always be complied with to ensure the product and any

electronic appliances connected to it are used correctly and accidents are prevented.

• The user, or whoever is operating the product, must read and fully understand the contents of this installation

and use guide before performing any operation. Errors or incorrect settings can cause hazardous conditions

5

AQUOS - IBIS - IDRON

EN

and/or poor operation.

• Do not use the product as a ladder or supporting structure.

• Do not place laundry on the product to dry. Any clothes horses or similar objects must be kept at a safe

distance from the product.

• Fire hazard.

• All liability for improper use of the product is entirely borne by the user and relieves the Manufacturer from any

civil and criminal liability.

• Any type of tampering or unauthorised replacement with non-original spare parts could be hazardous for the

operator’s safety and relieve the company from any civil and criminal liability.

• Most of the surfaces of the product are very hot (door, handle, glass, smoke outlet pipes, etc.). Avoid contact

with these parts unless adequate protective clothing is worn or appropriate means are used, such as heat

protective gloves or cold handle type operating systems.

• It is forbidden to operate the product with the door open or the glass broken.

• The product must be powered by a system that is equipped with an effective earth system.

• Switch the product off in the event of a fault or malfunctioning.

• Accumulated unburned pellets in the burner after each “failed start-up” must be removed before starting

up again.

• Do not wash the product with water. The water could get inside the unit and damage the electrical insulation

and cause electric shocks.

• Do not stand in front of the product for a long time. Do not overheat the room where the product is installed.

This could cause injuries and health problems.

• Do not put any fuel other than wood pellets in the hopper.

• Install the product in rooms that are adequately protected against re and equipped with all the utilities such

as supplies (air and electricity) and smoke outlets.

• If a re breaks out inside the chimney, switch the appliance off, disconnect it from the mains and do not open

the door. Then contact the competent authorities.

• The product and the ceramic/serpentine cladding must be stored in a place where there is no humidity and

must not be exposed to the elements.

• It is recommended not to remove the feet that support the product in order to guarantee adequate insulation,

especially if the ooring is made of ammable material.

• If the ignition system is faulty, do not force ignition with ammable materials.

• Special maintenance must only be performed by authorised and qualied personnel.

• Assess the static conditions of the surface on which the weight of the product will rest and provide suitable

insulation if it is made of ammable material (e.g. wood, tted carpet or plastic).

2.1 INFORMATION:

Please contact the retailer or qualied personnel authorised by the company to resolve a problem.

• only fuel stipulated by the company must be used.

• Check and clean the smoke outlet pipes regularly (connection with the product).

• The product is not a cooking appliance.

• Always keep the cover of the fuel hopper closed.

• Keep this instruction manual in a safe place as it must accompany the product throughout its working life. If it

is sold or transferred to another user, always make sure that the manual accompanies the product.

• According to (EU) No. 305/2011 regulation, the “ Declaration of Performance” is available online at the web

sites www.cadelsrl.com / www.free-point.it.

2.2 INTENDED USE

The product only works with wood pellets and must be installed indoors.

2.3 INTERVENTION REQUEST

The company declines all liability if the product and any other accessory is used incorrectly

or altered without authorisation.

All parts must be replaced with original spare parts.

The request must be sent to the retailer who will forward it to the Technical Assistance Service.

6

AQUOS - IBIS - IDRON

EN

2.4 SPARE PARTS

Only use original spare parts. The retailer or service centre can provide all the useful information regarding spare

parts.

It is recommended not to wait for the parts to be worn before having them replaced. It is important to perform

regular maintenance.

3

WARNINGS FOR THE CORRECT DISPOSAL OF THE PRODUCT

The owner is the sole party responsible for demolishing and disposing of the product. This must be performed in

compliance with laws related to safety and environmental protection in force in his/her country.

At the end of its working life, the product must not be disposed of as urban waste.

It must be taken to a special differentiated waste collection centre set up by the local authorities or to a retailer

that provides this service.

Separating and recycling prevents potential negative effects on the environment and health (often caused by

inappropriately disposing of product parts). It also allows materials to be recovered in order to obtain signicant

savings in energy and resources.

4

WARRANTY CONDITIONS

The company guarantees the product, with the exception of elements subject to normal wear listed below, for

a period of 2 (two) years from the date of purchase attested by:

• a document to serve as proof of purchase (invoice and/or receipt) that shows the name of the vendor and

the date on which the purchase was made;

• forwarding of the completed certicate of guarantee within 8 days of purchase.

Furthermore, the product must be installed and started by specialised personnel who must, where provided,

issue a declaration of conformity of the plant and of the proper functioning of the product, for the warranty to

be valid and effective.

We recommend testing the product before completion with the relative nishes (claddings, painting of walls,

etc.).

Installations not meeting the current standards, improper use and lack of maintenance as expected by the

manufacturer, void the product warranty.

The guarantee is valid on the condition that the instructions and warnings contained in the use and maintenance

manual are observed, and therefore the product is used correctly.

The replacement of the entire system or the repair of one of its components does not extend the guarantee

period, and the original expiry date remains unchanged.

The guarantee covers the replacement or free repair of parts recognised as being faulty at source due to

manufacturing defects.

To benet from the guarantee, in the event of a fault, the customer must have the guarantee certicate and

present it with the proof of purchase document to the Technical Assistance Ofce.

The guarantee does not cover malfunctions and/or damage to the appliance that arise due to the following

causes:

• Damage caused during transportation or relocation.

• All parts that develop faults due to negligence or improper use, incorrect maintenance, installation that does

not comply with the manufacturer’s instructions (always refer to the installation and use manual provided with

the appliance).

• Incorrect dimensioning with regards to the use or faults in the installation or failure to adopt the necessary

devices to guarantee proper execution.

• Improper overheating of the equipment, use of fuels not conforming to the types and quantities indicated in

the instructions provided.

• Further damage caused by incorrect user interventions in an attempt to x the initial fault.

• Worsening of the damage due to the continued use of the equipment by the user, once the defect has been

noticed.

• In the presence of a boiler, any corrosions, incrustations or breaks caused by water ow, condensation,

hardness or acidity of the water, improperly performed descaling treatments, lack of water, mud or limescale

deposits.

• Inefciency of chimneys, ues or parts of the plant affecting the equipment.

• Damage caused by tampering with the appliance, atmospheric agents, natural disasters, vandalism,

electrical discharges, res, faults in the electric and/or hydraulic system.

Also excluded from this guarantee are:

• Parts subject to normal wear such as gaskets, glass, claddings and cast iron grids, painted, chrome-plated or

gilded parts, handles and electric cables, bulbs, indicator lights, knobs, all parts which can be removed from

7

AQUOS - IBIS - IDRON

EN

the hearth.

• Variations in colour of the painted or ceramic/serpentine parts and craquelure ceramics as they are natural

characteristics of the material and product use.

• Masonry work.

• Plant parts (if present) not supplied by the manufacturer.

Any technical interventions on the product to eliminate the above-said defects and consequent damages must

be agreed upon with the Technical Assistance Centre, who reserves the right to accept the relative appointment

or not. However, said interventions will not be carried out under warranty but as technical assistance to be

granted at part of any eventual and specic agreed conditions and in accordance with the fee in force for the

work to be carried out.

The user will also be charged for any costs incurred to remedy the incorrect technical interventions, tampering

or damage to the appliance, not attributable to original faults.

Save for the legal or regulatory limits, the guarantee does not cover the containment of atmospheric and

acoustic pollution.

The company declines all liability for any damage which may be caused, directly or indirectly, to persons,

animals or objects as a consequence of non compliance with any prescription specied in the manual, especially

warnings regarding installation, use and maintenance of the appliance.

5

INSTALLATION INSTRUCTIONS

The requirements in this chapter refer to the regulations of the Italian installation Standard UNI 10683. In any case,

always comply with the regulations in force in the country of installation

5.1 PELLETS

Wood pellets are manufactured by hot-extruding compressed sawdust which is produced during the processing

of natural dried wood (without paints). The compactness of the material is guaranteed by the lignin contained

in the wood itself and allows pellets to be produced without glue or binders.

The market offers different types of pellets with characteristics that vary according to the wood mixtures used.

The diameter varies between 6 and 8 mm, with a standard length ranging from 5 to 30 mm. Good quality pellets

have a density that varies between 600 and over 750 kg/m3, with a moisture content that ranges from 5% to 8%

of its weight.

Pellets have technical advantages besides being an ecological fuel, as the wood residue is used completely,

thereby achieving cleaner combustion than that of fossil fuels.

Good-quality wood has a caloric value of 4.4 kW/kg (15% moisture, after about 18 months of seasoning),

whereas that of pellets is 4.9 kW/kg. To ensure good combustion, the pellets must be stored in a dry place and

protected from dirt. Pellets are usually supplied in 15 kg bags, therefore, storing them is very convenient.

Good quality pellets guarantee good combustion, thereby decreasing harmful emissions into the atmosphere.

Fig. 1 - Pellet’s bag

The poorer the quality of the fuel, the more often the internal parts of the brazier and

combustion chamber must be cleaned.

DINplus, Ö-Norm M7135 and Pellet gold are examples of the major quality certications of pellets in the European

market and guarantee that the following are complied with:

• caloric value: 4.9 kWh/kg.

• Water content: max 10% of the weight.

• Percentage of ash: max 0.5% of the weight.

• Diameter: 5 – 6 mm.

• Length: max 30 mm.

8

AQUOS - IBIS - IDRON

EN

• Content: 100% untreated wood with no added binding agents (max percentage of bark: 5%).

• Packaging: in bags made from environmentally friendly or biologically decomposable material.

The company strongly recommends using certied fuel for its products (DINplus, Ö-Norm

M7135 or Pellet Gold).

Poor quality pellets or others that do not comply with that specied previously compromises

the operation of your product and can therefore render the warranty and product liability

null and void.

5.2 PRECAUTIONS REGARDING INSTALLATION

IMPORTANT!

Product installation and assembly must be carried out by qualied personnel.

The product must be installed in a suitable place for it to be regularly opened and routine maintenance to be

performed.

The site must be:

• compliant for proper operation.

• Equipped with an adequate smoke expulsion system.

• Equipped with ventilation intake from outside.

• Equipped with 230V 50 Hz power supply with an EC compliant earth system.

The product must be connected to a chimney or an internal or external vertical duct that complies with the

regulations in force. The product must be positioned in such a way that the electrical socket is accessible.

IMPORTANT!

The product must be connected to a chimney or a vertical duct that can expel the smoke

at the highest point of the building.

In any case smoke derives from combustion of types of wood and if it comes in contact with

or close to walls, these can become dirty. Moreover, utmost attention is required as they are

almost invisible but very hot and can cause burns. The holes of the external air inlet and the

smoke outlet pipe must be drilled before positioning the product.

5.3 THE OPERATING ENVIRONMENT

In the case of presence of other heating appliances, appropriate air inlets must provide appropriate air ow for

the proper running of each appliance.

In case that in the place where the appliance is installed, other extraction funs (for example exhaust fans) are

present and running, disease can be caused because of the lack of combustion air.

The installation of the product is not allowed in bedrooms, bathrooms or in rooms where

it has already been installed another heating appliance without independent air inlet

(replace, stove, etc.).

It is forbidden to install the product in places with explosive athmosfere.

The oor where the appliance is installed must be properly dimensioned in order to bear its

weight.

The ambient ventilation can be adjusted towards the rear wall only in case of the presence

of a proper duction insulated from hot air ow.

5.4 MINIMUM DISTANCES

If the walls are not ammable place the stove at a minimum rear distance of at least 10 cm. In case of ammable

walls keep the stove at a minimum rear distance (A) of 5 cm, lateral (B) of 10 cm, minimum distance from the

pipe to the wall (E) 50 and front distance of 100 cm.

In case of presence of object considered ammable such as pieces of furniture, curtains and sofas the distance

from the stove must considerably be increased,

9

AQUOS - IBIS - IDRON

EN

If the oor is made of wood, it is recommended to place a oor protection in accordance

with the Standards in force in the country of installation.

Fig. 2 - Distances to follow

TYPE NON-FLAMMABLE WALLS FLAMMABLE WALLS

AQUOS 15-22-22 H2O A = 5 cm / B = 5 cm A = 10 cm / B = 10 cm

IBIS 11-15-22-22 H2O A = 5 cm / B = 5 cm A = 10 cm / B = 10 cm

IDRON 11-15-22-22 H2O A = 5 cm / B = 5 cm A = 10 cm / B = 10 cm

5.5 CONNECTION OF THE FUME EXHAUST PIPE

When making the hole for the passage of the smoke discharge pipe, one must take into account the possible

presence of ammable materials. If the hole must be made through a wooden wall or thermolabile material,

the INSTALLER MUST rst of all use the appropriate wall tting (minimum diameter 13 cm) and suitably insulate the

pipe of the product that passes through it using adequate insulating materials (1.3 - 5 cm thick with minimum

thermal conductivity 0.07 W/m°K).

The same minimum distance must be applied if the pipe of the product must pass through vertical or horizontal

sections near the thermolabile wall.

It is recommended to use an insulated double-wall pipe in external sections in order to prevent condensation

from forming.

The combustion chamber works with depression. The fume pipe for fume exhaust will be in depression when

conncted to an efcient chimney ow.

Always use pipes and ttings with appropriate seals that guarantee tightness.

It must be possible to inspect all sections of the ue duct and they must be removable for

periodic internal cleaning (T-tting with inspection hole).

Position the product considering all the above requirements and instructions.

IMPORTANT!

All 90° angles (max. 3) in the smoke exhaust duct must be preferably tted with the relative

T-ttings with inspection hole.

TO THE CONNECTION WITH THE CHIMNEY FLUE THERE CANNOT BE USED MORE THAN 2-3 mt

(WITH INCLINATION BELOW 3%) OF HORIZONTAL PIPE AND THERE MUST NOT BE USED MORE

THAN 3 CURVES WITH ANGLE \x3e 90°. IT IS FURTHER ADVISABLE NOT TO EXCEED THE LENGHT

OF 6 METERS WITH THE Ø 80 mm PIPE.

10

AQUOS - IBIS - IDRON

EN

Fig. 3 - Pellet stove installation example

5.6 CONNECTIONS

CONNECTION TO THE FLUE PIPE

CONNECTION TO AN EXTERNAL DUCT

WITH AN INSULATED OR DOUBLE-WALL PIPE

CONNECTION TO THE FLUE PIPE

The internal dimensions of the chimney

pipe must not exceed 20x20 cm or

20 cm in diameter; in the event of

bigger sizes or bad chimney conditions

(e.g. cracks, poor insulation, etc.), it is

advisable to t a stainless steel pipe

of suitable diameter throughout the

length of the chimney right to the top.

The minimum internal dimensions of the

external duct must be 10x10 cm or 10 cm

in diameter and must not exceed 20x20

cm or 20 cm in diameter. Only stainless

steel insulated (double-wall) pipes must

be used, which are smooth on the inside

and xed to the wall. Flexible stainless

steel pipes must not be used.

The connection between the product

and the ue or the smoke duct must

not have an inclination below 3% in the

horizontal sections, which must have a

maximum overall length of 2/3 m. The

vertical section between one T-tting

and another (angle) must not be less

than 1.5 m.

11

AQUOS - IBIS - IDRON

EN

LEGEND

1 Windproof

2 Flue

3 Inspection

Use adequate instruments to verify that there is a minimum draught of 5 Pa.

Set-up an inspection hole at the bottom of the chimney to perform periodic checks and

cleaning, which must be done annually.

The connection to the chimney must be sealed and the ttings and pipes recommended

by us must be used (CE marked in accordance with EN1856-2 with the minimum requisites:

T200 and P1).

You must ensure that a windproof chimneypot is installed in accordance with the regulations

in force.

This type of connection guarantees smoke expulsion even in the event of a temporary

power cut.

5.7 OPERATING PROBLEMS RELATED TO DRAUGHT DEFECTS IN THE CHIMNEY

Among all the weather and geographical conditions that affect chimney operation (rain, fog, snow, altitude

a.s.l., exposure to sunlight, orientation to the cardinal points, etc.), the wind is certainly the most determinant.

In fact, besides the thermal depression caused by the difference in temperature between inside and outside

the chimney, there is another type of depression (or overpressure): dynamic pressure caused by the wind. An

updraft always increases depression and therefore the draught. A horizontal wind increases depression provided

the chimneypot has been installed properly. A downdraft always decreases depression, at times inverting it.

Fig. 4 - Example of depression

LEGEND

A Less favourable points

B Most favourable position

Besides the direction and force of the wind, the position of the chimney and the chimneypot with respect to the

roof of the building and the surrounding landscape is also important.

The wind also affects chimney operation indirectly by creating overpressure and depression zones within the

building as well as outside. An internal overpressure can be created in rooms that are directly exposed to the

wind (2), which can enhance the draught in stoves and replaces, however, it can be counteracted by the

external overpressure if the chimneypot is situated on the side exposed to the wind (1). On the other hand, a

dynamic depression can be created in rooms that are opposite the wind direction (3), which competes with the

natural thermal depression generated by the chimney, however, this can be compensated for (sometimes) by

placing the smoke duct opposite the wind direction (4).

IMPORTANT!

The operation of the pellet product is signicantly affected by the chimney layout and

position.

Hazardous conditions can only be resolved by qualied personnel setting the product

appropriately.

12

AQUOS - IBIS - IDRON

EN

Fig. 5 - Wind inuence

6

TECHNICAL DRAWINGS AND CHARACTERISTICS

6.1 DIMENSIONS

Fig. 6 - Aquos 15 - Aquos 22 - Aquos 22 H2O dimensions

13

AQUOS - IBIS - IDRON

EN

Fig. 7 - Ibis 11 dimensions

14

AQUOS - IBIS - IDRON

EN

Fig. 8 - Ibis 15 - Ibis 22 - Ibis 22 H2O dimensions

15

AQUOS - IBIS - IDRON

EN

Fig. 9 - Idron 11 dimensions

16

AQUOS - IBIS - IDRON

EN

Fig. 10 - Idron 15 - Idron 22 - Idron 22 H2O dimensions

17

AQUOS - IBIS - IDRON

EN

TECHNICAL CHARACTERISTICS

AQUOS 15 AQUOS 22

(Max) total thermal power:

15,4 kW (13244 Kcal/h) / 13

kW (11180 Kcal/h)

21 kW (18060 Kcal/h) / 17 kW

(14620 Kcal/h)

(Max) total thermal power:

4,4 kW (3784 Kcal/H) / 3 kW

(2580 Kcal/h)

4,4 kW (3784 Kcal/h) / 3 kW

(2580 Kcal/h)

(Max) Introduced power: 16,6 kW 22,6 kW

Efciency at Max 92,1 % 92,5 %

Efciency at Min 95,0 % 95 %

Temperature of exhaust

smoke at Max

145 °C 160 °C

Temperature of exhaust

smoke at Min

71 °C 71 °C

Particulate/OGC/Nox (13%

O

2

)

1,5 mg/Nm

3

- 0,32 mg/Nm3 -

123 mg/Nm

3

(13% O2)

1,7 mg/Nm

3

- 0,15 mg/Nm3 -

132 mg/Nm

3

(13% O2)

CO at 13% O

2

at Min and at

Max

0,040 - 0,011 % 0,040 - 0,012 %

CO

2

at Min and at Max 7,03% - 11% 7,0 % - 12,5 %

Recommended draught at

Max power

0,10 mbar - 10 Pa 0,10 mbar - 10 Pa

Recommended draught at

Min power

0,05 mbar - 5 Pa 0,05 mbar - 5 Pa

Mass of smoke at Min and

at Max

4,5 - 10,4 g/sec 4,5 - 12,6 g/sec

Hopper capacity 44 litri 44 litri

Type of pellet fuel Pellet d.6-8 x 5-30 mm Pellet d.6-8 x 5-30 mm

Pellet hourly consumption *

Min ~ 0,9 kg/h - Max ~ 3,4

kg/h

Min ~ 0,9 kg/h - Max ~ 4,9

kg/h

Autonomy * Min ~ 32 h - Max ~ 9 h Min ~ 28 h - Max ~ 5 h

Heatable volume m

3

** 332/40 - 379/35 - 443/30 452/40 - 516/35 - 602/30

Combustion air inlet External diameter 50 mm External diameter 50 mm

Smoke outlet External diameter 80 mm External diameter 80 mm

Nominal electrical power Max 420 W - Med 120 W Max 420 W - Med 120 W

Supply voltage and

frequency

230 Volt / 50 Hz 230 Volt / 50 Hz

Net weight 156 - 166 kg 157 - 167 kg / 160 - 170 kg

Weight with packaging 166 - 176 kg 167 - 177 kg / 170 - 180 kg

18

AQUOS - IBIS - IDRON

EN

TECHNICAL CHARACTERISTICS

IBIS 11 IBIS 15 IBIS 22 - IBIS 22 H2O

(Max) total thermal power:

11,6 kW (9976 kcal/h) / 10

kW (8600 kcal/h)

15,4 kW (13244 Kcal/h) / 13

kW (11180 Kcal/h)

21 kW (18060 Kcal/h) / 17 kW

(14620 Kcal/h)

(Max) total thermal power:

3,6 kW (3096 kcal/h) / 2,5 kW

(2150 kcal/h)

4,4 kW (3784 Kcal/H) / 3 kW

(2580 Kcal/h)

4,4 kW (3784 Kcal/h) / 3 kW

(2580 Kcal/h)

(Max) Introduced power: 12,6 kW 16,6 kW 22,6 kW

Efciency at Max 91,5 % 92,1 % 92,5 %

Efciency at Min 96 % 95,0 % 95 %

Temperature of exhaust

smoke at Max

140 °C 145 °C 160 °C

Temperature of exhaust

smoke at Min

70 °C 71 °C 71 °C

Particulate/OGC/Nox (13%

O

2

)

11 mg/Nm

3

- 2,5 mg/Nm3 -

181 mg/Nm

3

(13% O2)

1,5 mg/Nm

3

- 0,32 mg/Nm3 -

123 mg/Nm

3

(13% O2)

1,7 mg/Nm

3

- 0,15 mg/Nm3 -

132 mg/Nm

3

(13% O2)

CO at 13% O

2

at Min and at

Max

0,034 - 0,011 % 0,040 - 0,011 % 0,040 - 0,012 %

CO

2

at Min and at Max 6,7% – 8,7% 7,03% - 11% 7,0 % - 12,5 %

Recommended draught at

Max power

0,10 mbar – 10 Pa 0,10 mbar - 10 Pa 0,10 mbar - 10 Pa

Recommended draught at

Min power

0,05 mbar – 5 Pa 0,05 mbar - 5 Pa 0,05 mbar - 5 Pa

Mass of smoke at Min and

at Max

3,6 – 11,0 g/sec 4,5 - 10,4 g/sec 4,5 - 12,6 g/sec

Hopper capacity 37 litri 44 litri 44 litri

Type of pellet fuel Pellet d.6-8 x 5-30 mm Pellet d.6-8 x 5-30 mm Pellet d.6-8 x 5-30 mm

Pellet hourly consumption *

Min ~ 0,8 kg/h - Max. ~ 2,5

kg/h

Min ~ 0,9 kg/h - Max ~ 3,4

kg/h

Min ~ 0,9 kg/h - Max ~ 4,9

kg/h

Autonomy * Min ~ 36 h - Max. ~ 10 h Min ~ 32 h - Max ~ 9 h Min ~ 28 h - Max ~ 5 h

Heatable volume m

3

** 249/40 – 285/35 – 333/30 332/40 - 379/35 - 443/30 452/40 - 516/35 - 602/30

Combustion air inlet External diameter 50 mm External diameter 50 mm External diameter 50 mm

Smoke outlet External diameter 80 mm External diameter 80 mm External diameter 80 mm

Nominal electrical power Max 420 W - Med 120 W Max 420 W - Med 120 W Max 420 W - Med 120 W

Supply voltage and

frequency

230 Volt / 50 Hz 230 Volt / 50 Hz 230 Volt / 50 Hz

Net weight 144 kg 149 kg 150 / 153 kg

Weight with packaging 154 kg 159 kg 160 / 163 kg

19

AQUOS - IBIS - IDRON

EN

TECHNICAL CHARACTERISTICS

IDRON 11 IDRON 15 IDRON 22 - IDRON 22 H2O

(Max) total thermal power:

11,6 kW (9976 kcal/h) / 10

kW (8600 kcal/h)

15,4 kW (13244 Kcal/h) / 13

kW (11180 Kcal/h)

21 kW (18060 Kcal/h) / 17 kW

(14620 Kcal/h)

(Max) total thermal power:

3,6 kW (3096 kcal/h) / 2,5 kW

(2150 kcal/h)

4,4 kW (3784 Kcal/H) / 3 kW

(2580 Kcal/h)

4,4 kW (3784 Kcal/h) / 3 kW

(2580 Kcal/h)

(Max) Introduced power: 12,6 kW 16,6 kW 22,6 kW

Efciency at Max 91,5 % 92,1 % 92,5 %

Efciency at Min 96 % 95,0 % 95 %

Temperature of exhaust

smoke at Max

140 °C 145 °C 160 °C

Temperature of exhaust

smoke at Min

70 °C 71 °C 71 °C

Particulate/OGC/Nox (13%

O

2

)

11 mg/Nm

3

- 2,5 mg/Nm3 -

181 mg/Nm

3

(13% O2)

1,5 mg/Nm

3

- 0,32 mg/Nm3 -

123 mg/Nm

3

(13% O2)

1,7 mg/Nm

3

- 0,15 mg/Nm3 -

132 mg/Nm

3

(13% O2)

CO at 13% O

2

at Min and at

Max

0,034 - 0,011 % 0,040 - 0,011 % 0,040 - 0,012 %

CO

2

at Min and at Max 6,7% – 8,7% 7,03% - 11% 7,0 % - 12,5 %

Recommended draught at

Max power

0,10 mbar – 10 Pa 0,10 mbar - 10 Pa 0,10 mbar - 10 Pa

Recommended draught at

Min power

0,05 mbar – 5 Pa 0,05 mbar - 5 Pa 0,05 mbar - 5 Pa

Mass of smoke at Min and

at Max

3,6 – 11,0 g/sec 4,5 - 10,4 g/sec 4,5 - 12,6 g/sec

Hopper capacity 37 litri 44 litri 44 litri

Type of pellet fuel Pellet d.6-8 x 5-30 mm Pellet d.6-8 x 5-30 mm Pellet d.6-8 x 5-30 mm

Pellet hourly consumption *

Min ~ 0,8 kg/h - Max. ~ 2,5

kg/h

Min ~ 0,9 kg/h - Max ~ 3,4

kg/h

Min ~ 0,9 kg/h - Max ~ 4,9

kg/h

Autonomy * Min ~ 36 h - Max. ~ 10 h Min ~ 32 h - Max ~ 9 h Min ~ 28 h - Max ~ 5 h

Heatable volume m

3

** 249/40 – 285/35 – 333/30 332/40 - 379/35 - 443/30 452/40 - 516/35 - 602/30

Combustion air inlet External diameter 50 mm External diameter 50 mm External diameter 50 mm

Smoke outlet External diameter 80 mm External diameter 80 mm External diameter 80 mm

Nominal electrical power Max 420 W - Med 120 W Max 420 W - Med 120 W Max 420 W - Med 120 W

Supply voltage and

frequency

230 Volt / 50 Hz 230 Volt / 50 Hz 230 Volt / 50 Hz

Net weight 130 kg 134 kg 135 / 138 kg

Weight with packaging 140 kg 144 kg 145 / 148 kg

* Data that may vary depending on the type of pellets used

**Heatable volume based on the requested power per m3 (respectively 40-35-30 Kcal/h per m3)

Tested according to EN 14785 in accordance with Directive 89/106/EEC (Construction Products).

7

INSTALLATION AND ASSEMBLY

7.1 PREPARATION AND UNPACKING

The AQUOS / IBIS / IDRON stoves with steel sides come in 1 pack:

• It contains the stove and also the steel sides with the proles (Fig. 11 page 20)

The AQUOS stoves with ceramics come in 2 packs:

• One contains the stove.

20

AQUOS - IBIS - IDRON

EN

• One contains the ceramics (Fig. 12 page 20). In this case there will be a single pack for the structure (the

box with the ceramics will be placed on top of the pack with the structure).

Fig. 11 - Example of stove + steel sides packaging Fig. 12 - Example of ceramics packaging

Open the pack, remove the four screws that secure the base of the stove to the pallet, two to the right and two

to the left (see Fig. 13 page 20) and position the stove in the selected place, ensuring that it complies with the

above instructions.

Fig. 13 - Removal of packaging screws

The stove body or unit must always be kept in a vertical position when handled and moved by using carts

only. Pay particular attention to the door and its glass, protecting them from mechanical knocks that would

compromise their integrity. Always handle the product with care. If possible, unpack the stove near the chosen

place of installation.

The packaging materials are neither toxic nor harmful, and therefore no particular disposal measures are

required. Therefore, the end user is responsible for product storage, disposal or possible recycling in compliance

with the relative applicable laws.

Do not store the stove unit or its cladding without their packaging.

Position the stove without its cladding and connect it to the ue pipe. Use the four adjustable feet (J) to get

the stove correctly levelled so that the smoke outlet (S) is lined up with the connecting pipe (H). Once the

connection operations are complete, assemble the cladding (ceramics or steel sides).

If the stove needs to be connected to a discharge pipe which goes through the rear wall (to then connect to

the ue), take utmost care not to force the joint.

21

AQUOS - IBIS - IDRON

EN

If the stove smoke outlet is forced or used improperly to lift it or position it, the operation of

the stove can be damaged irreparably.

Fig. 14 - 1. Turn the feet clockwise to lower the stove - 2. Turn the feet counterclockwise to raise the stove

7.2 CERAMIC AND METAL SIDES INSERTION (AQUOS)

Remove, on the upper part, the metal top (A).

Take the ceramic sides (B) or the metal side (B1) from the box and insert them onto the prole (C) in correspondence

of the guide, from the top downwards.

Repeat the same operation for both sides.

Reposition the metal top.

Fig. 15 - Sides insertion

We recommend using small velcro felt disks, to be applied to the ends of the ceramics to

prevent contact between them.

We recommend inserting the ceramics when installation of the stove is complete.

22

AQUOS - IBIS - IDRON

EN

7.3 METAL SIDES INSERTION (IDRON)

Remove, on the upper part, the metal top (A).

Take the side panel (B) and x it to the stove: slide the side hole into the screw xed on the stove (C).

Repeat the same operation for both sides.

Reposition the metal top (A).

Fig. 16 - Metal sides insertion

7.4 METAL FRAME INSERTION (IBIS)

Remove the metal sides (A).

Place the frame (B) and x it trough the screws on its 4 inner points (see detail C).

Repeat the same operation for both sides.

Reposition the metal sides (A).

Fig. 17 - Metal sides insertion

23

AQUOS - IBIS - IDRON

EN

8

PLUMBING CONNECTION

8.1 PLUMBING SYSTEM CONNECTION

IMPORTANT!

If installation of the product involves interaction with another, pre-existing system complete

with heating

equipment (gas boiler, methane boiler, diesel boiler, etc.), contact qualied personnel,

who subsequently will be responsible for conformity of the system in compliance with the

applicable law in force.

The Company declines all responsibility for damage to persons or things in the event of

failed or incorrect operation, if the aforementioned warnings are not complied with.

8.2 CONNECTION DIAGRAM STOVE (AQUOS 15 - 22 / IBIS 15 - 22 / IDRON 15 -22)

Fig. 18 - Plumbing connection

LEGEND

A1 3/4”M heating water delivery

A2 3/4”M heating water return 3/4”M

C 3 bar 1/2” M safety valve

E 3/4”M system draining and emptying

8.3 CONNECTION DIAGRAM FOR HYDRO STOVE EQUIPPED WITH KIT FOR DOMESTIC HOT WATER

24

AQUOS - IBIS - IDRON

EN

PRODUCTION (AQUOS 22 H2O / IBIS 22 H2O / IDRON 22 H2O)

Fig. 19 - Plumbing connection

LEGEND

A1 3/4”M heating water delivery

A2 3/4”M heating water return 3/4”M

C 3 bar 1/2” M safety valve

E 1/2”F system emptying

B1 Domestic hot water delivery

B2 Domestic hot water return

8.4 CONNECTION DIAGRAM FOR HYDRO STOVE (IBIS 11 / IDRON 11)

Fig. 20 - Plumbing connection

LEGEND

A1 3/4”M heating water delivery

A2 3/4”M heating water return 3/4”M

C 3 bar 1/2” M safety valve

E 3/4”M system draining and emptying

8.5 SYSTEM CONNECTIONS

Make the connections to the corresponding ttings shown in the diagram on the previous page. Make sure the

pipes are not placed under tension or undersized.

25

AQUOS - IBIS - IDRON

EN

IT IS STRONGLY RECOMMENDED TO WASH THE ENTIRE SYSTEM BEFORE CONNECTING THE

STOVE IN ORDER TO GET RID OF RESIDUES AND DEPOSITS.

Upstream from the stove, always install gate valves so as to disconnect it from the plumbing

system should it be necessary to move it, or when it requires routine and/or special

maintenance. Connect the stove using hoses so that the stove is not connected too tightly

to the system, and to allow slight movements.

The pressure discharge valve (C) must always be connected to a water drain pipe. The pipe

must be adequate to support the water’s high temperature and pressure.

Fig. 21 - Plumbing connection

LEGEND

A Tap

B Domestic system

C Pressure discharge

D Hoses

8.6 SYSTEM FILLING

To ll the system, the stove can be equipped with an end piece (optional) with a check valve (D), for manual

lling of the heating system (if the optional is not installed, the lling tap on the main boiler will be used). During

this operation, any air in the system is released from the automatic vent valve located under the top.

To allow the valve to vent, it is recommended to loosen the grey cap by one turn and leave the red cap locked

(see gure). The lling pressure of the system WHEN COLD must be 1 bar. If during operation the system pressure

drops (due to evaporation of gases dissolved in the water) to values lower than the minimum ones indicated

above, the user must use the lling tap to bring the pressure back up to its initial pressure.

For proper operation of the stove WHEN HOT, the pressure in the boiler must be 1.5 bar.

To monitor system pressure, the end piece (optional) is equipped with a pressure gauge (M).

Upon completion of this lling operation, always close the tap.

Fig. 22 - End piece with a lling tap (D) and pressure gauge (M)

(Accessory)

Fig. 23 - Vent valve under the top

26

AQUOS - IBIS - IDRON

EN

8.7 DOMESTIC HOT WATER PRODUCTION KIT (AQUOS 22 H2O / IBIS 22 H2O / IDRON 22 H2O

STOVES ONLY)

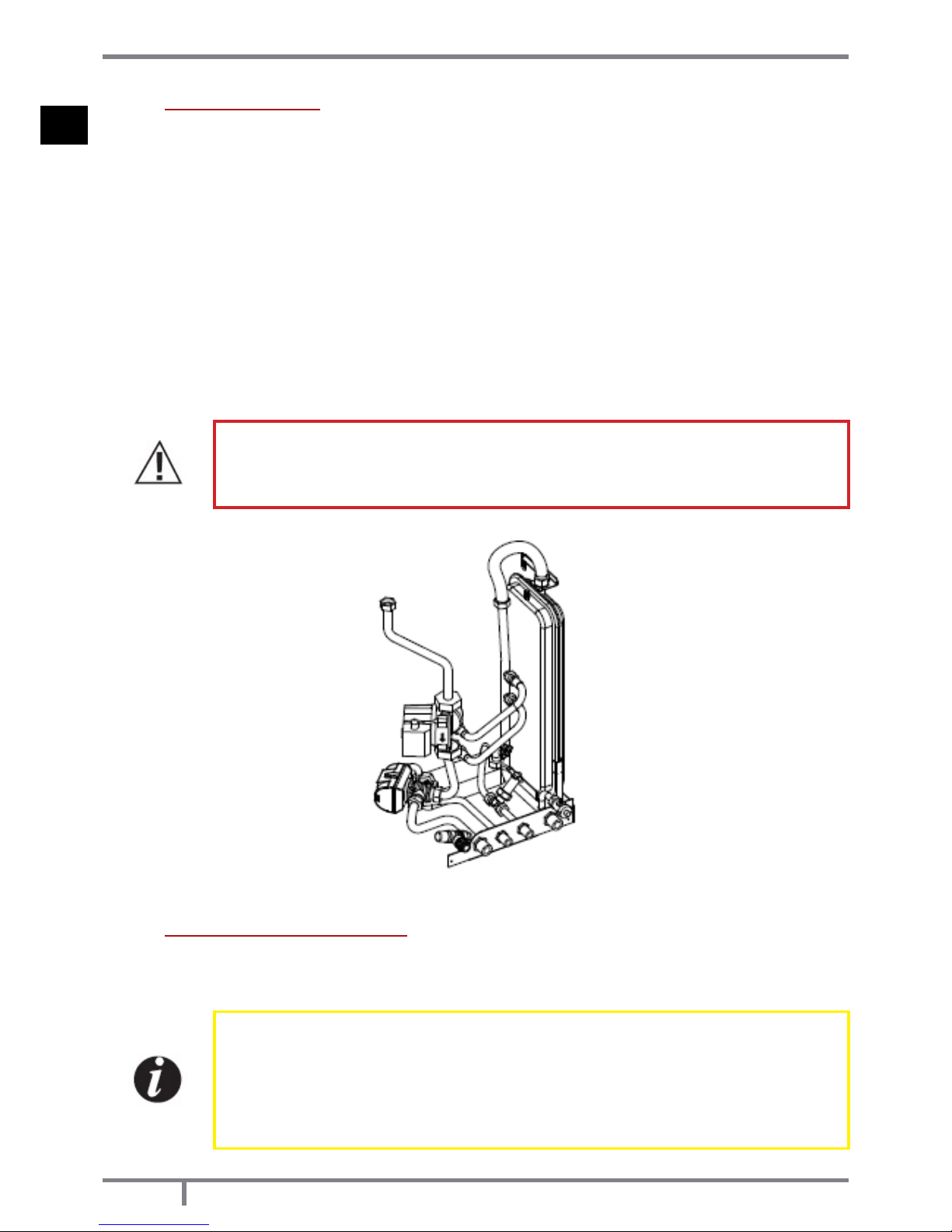

The AQUOS 22 H2O, IBIS 22 H2O and IDRON 22 H2O stoves are equipped with a complete kit for the production

of domestic water made up of:

• Plate heat exchanger

• A 3-way diverter valve

• Flow switch

• Pipes and ttings for connection

The kit comes preassembled by the manufacturer and it is designed to heat domestic water directly from the

home water supply system.

When hot water is required and the tap is turned, the internal water ow switch will send a signal to the diverter

valve to channel the hot water contained in the boiler to the plate heat exchanger. The temperature of

the domestic water highly depends on the temperature of the water inside the heating system. This can be

calculated to a good degree of accuracy by taking 10°-15°C away from the value shown on the stove control

panel (which is the temperature of the water in the boiler).

If hot domestic water is needed while the stove is ‘Switch-Off’ or in ‘ECOSTOP off’ mode, the stove will automatically

and immediately begin the start-up process to heat the water inside the boiler, and then the domestic hot water.

To ensure that the plate heat exchanger continues to work properly over time, one must be aware of the system

water hardness to prevent deposits from forming.

If the water in your home is very hard, you are advised to install a softening system upstream.

You are advised to service the plate exchanger annually to eliminate limescale and mineral

salts sediments or to replace the heating plates with new ones. These spare parts are

supplied by the manufacturer.

Fig. 24 - Domestic water production kit

8.8 WATER CHARACTERISTICS

The characteristics of the water used to ll the system are very important to prevent the build-up of mineral salts

and the formation of incrustations along the pipes, in the boiler and in the heat exchangers.

Therefore, please ASK YOUR PLUMBER FOR HIS ADVICE CONCERNING:

Hardness of water circulating in the system, to prevent problems of incrustation and

limescale, especially in the domestic water heat exchanger. (\x3e 25° French).

Installation of a water softener (if water hardness exceeds 25° French).

Filling the system with treated water (demineralised).

Possibly providing an anti-condensation circuit.

Installation of hydraulic shock absorbers to prevent water hammering along the ttings and

pipes.

27

AQUOS - IBIS - IDRON

EN

If you have very extensive systems (with a large amount of water) or which require frequent relling, the installation

of water softening systems.

It should be remembered that incrustations drastically reduce performance due to their

extremely low thermal conductivity.

9

ELECTRICAL CONNECTIONS

9.1 GENERAL PRECAUTIONS

Electrical safety of the system is ensured only when it is properly connected to an efcient earthing system made

in compliance with the safety standards in force: gas, water or heating systems pipes are not suitable as earth

connections.

One must check this essential safety requirement; if in doubt, request an accurate inspection of the electrical

system to be carried out by qualied personnel, because the boiler manufacturer is not responsible for any

damage caused by failure to earth the system.

Have professionally qualied personnel check the electrical system is suitable for the maximum power absorbed

by the heating system, ensuring in particular that the diameter of cables is appropriate for the power absorbed

by the loads.

The use of any component that is powered by electricity entails compliance with some basic rules such as:

• do not touch the appliance with wet and/or damp body parts and/or bare feet;

• do not pull the electric cables;

• do not leave the appliance exposed to weathering (rain, sun, etc.);

• do not allow the appliance to be used by children or inexperienced persons.

230V electrical power supply connection

Installation of the boiler accessory electrical components requires electrical connection to a 230 V – 50 Hz mains:

This connection must be state of the art according to the CEI standards in force.

Hazard!

Electrical installation must be carried out by a qualied technician only.

Before performing connections or any operation on the electrical parts, always disconnect

the power supply and make sure it cannot be accidentally reconnected.

Please note that the boiler electrical power line must be tted with a bipolar switch with

a contact gap greater than 3 mm, easy to access, in order to make any maintenance

operations quick and safe.

The power cable must be replaced by authorised technical personnel. Failure to comply with the provisions

listed above may compromise the safety of the appliance.

9.2 ELECTRICAL CONNECTION

First connect the power cable to the side of the boiler and then to a wall socket.

The main switch at the side must only be activated to switch the boiler on; otherwise, it is advisable to keep it

switched off.

It is recommended to disconnect the boiler power cable when the boiler is not used.

Fig. 25 - Electrical connection of the stove

28

AQUOS - IBIS - IDRON

EN

10

INITIAL START-UP

10.1 GENERAL PRECAUTIONS

Remove all components that could burn from the brazier and glass (manual, various adhesive labels and any

polystyrene).

Check that the brazier is positioned correctly and rests properly on the base.

Fig. 26 - Check the brazier

After a long period of inactivity, remove any pellets left in the hopper (using a vacuum

cleaner with a long pipe ), as they could have absorbed moisture, thereby altering their

original characteristics and no longer being suitable for combustion.

The rst start-up may not be successful as the feed screw is empty and does not always

manage to load the required amount of pellets in the brazier in time for the re to be

regularly ignited.

CANCEL THE FAILED START-UP ALARM STATUS BY PRESSING AND HOLDING KEY 1 (ESC).

REMOVE THE PELLETS FROM THE BRAZIER AND REPEAT START-UP.

If a ame does not ignite after a number of failed start-ups, even though the pellet supply is correct, make sure

the brazier is set in place correctly, which must be interlocked in its seat and free from any ash deposits. If no

anomaly is found during this inspection, there may be a problem with the product components or installation

may not be correct.

REMOVE THE PELLETS FROM THE BRAZIER AND CONTACT AN AUTHORISED TECHNICIAN.

Avoid touching the boiler during the initial start-up, as the paint in this stage hardens; by

touching the paint, the steel surface may be exposed.

It is good practice to guarantee effective ventilation in the room during the initial start-up,

as the boiler will emit some smoke and smell of paint.

Do not stand close to the product and air the room. The smoke and smell of paint will disappear after about an

hour of operation, however, remember they are not harmful in any case.

The boiler will be subject to expansion and contraction during the start-up and cooling phases, therefore slight

creaking noises may be heard.

This is absolutely normal as the structure is made of laminated steel and must not be considered a defect.

It is extremely important to make sure the boiler is not immediately overheated and the temperature is increased

gradually, initially using low power.

This will prevent damaging the ceramic or serpentine tiles, the welds and the steel structure.

29

AQUOS - IBIS - IDRON

EN

DO NOT EXPECT HEATING EFFICIENCY IMMEDIATELY!!!

10.2 OPENING/CLOSING THE DOOR

ATTENTION!

The door must be closed properly for the boiler to work correctly.

Use suitable protective clothing (such as gloves) to open the boiler door.

10.3 SETTINGS TO BE CARRIED OUT BEFORE THE INITIAL START-UP

Once the power cable is connected in the rear part of the stove, turn the switch, also placed at the rear, to

position (I). To switch the stove on or off press key 1 on the control panel.

Fig. 27 - Key and display

10.4 LOADING THE PELLETS

Fuel is loaded from the upper part of the stove by opening the door. Pour the pellets into the hopper.

To ease the procedure carry out the operation in two steps:

Pour half of the contents into the hopper and wait for the fuel to settle on the bottom.

Then complete the operation by pouring in the rest.

Never remove the protection grille from within the hopper. When loading prevent the pellet

bag from coming into contact with hot surfaces.

No other type of fuel other then pellets, in compliance with above-mentioned specications,

is to be inserted into the hopper.

Store the back-up fuel at a suitable safety distance.

Do not pour the pellets directly onto the brazier but only into the hopper.

Most of the stove surfaces are very hot (door, handle, glass, smoke outlet pipes, hopper

door, etc.). It is therefore recommended to avoid coming into contact with these parts

without adequate protective clothing.

11

MENU ITEMS

11.1 CONTROL PANEL DISPLAY

Menu items.

30

AQUOS - IBIS - IDRON

EN

Fig. 28 - Display

LEGEND

1 Boiler lighting/shutdown

2 Scrolling of programming menu to decrease.

3 Menu

4 Scrolling of programming menu to increase.

5 Decrease set temperature/programming functions.

6 Increase set temperature/programming functions.

7 Display.

11.2 MAIN MENU

It is accessed by pressing key 3 (menu). The items that are accessed are:

• Date and Time

• Timer

• Sleep (only with the stove on)

• Settings

• Info

Date and time setting

To set the date and time act as follows:

• Press the “menu” button.

• Select “Date and Time”.

• Select by pressing “menu”

• Scroll with the arrows and select the variables to be modied one at a time: Day, Hours, Minutes, Day number,

Month, Year.

• Select “menu” to conrm.

• Modify with the + - keys.

• Finally press “menu” to conrm and “esc” to exit.

Timer setting (see relative chapter)

Sleep setting (see relative chapter)

11.3 SETTINGS MENU

The SETTINGS menu allows to act on the boiler operating mode:

A. Language.

B. Cleaning (displayed only when the boiler is switched off).

C. Feed screw loading (displayed only when the boiler is switched off).

D. Tones.

E. External thermostat (activation).

F. Auto Eco (activation).

G. Eco-Shutdown T (default 10 minutes).

H. Pump on T (default 50°C).

I. Auxiliary boiler (default deactivated).

J. Pellet recipe.

K. Smoke rpm % ventilation.

L. Maximum power (1-5 - default 5).

31

AQUOS - IBIS - IDRON

EN

M. Components test (displayed only when the boiler is switched off)

N. “Chimney sweep” function (activated only when the boiler is switched on, for eld emissions test).

O. System conguration.

P. Season.

Q. Technical menu.

NOTE: Some of the items listed above cannot be activated in certain “system congurations”.

a - Language

To select the language act as follows:

• Press the “menu” button.

• Scroll to “Settings” using the arrows

• Press “menu” to conrm.

• Scroll to “language” using the arrows.

• Press “menu” to conrm.

• With the + - keys select the language of interest (IT/EN/DE/FR/ES/NL/PL/DA)

• Press “menu” to conrm and “esc” to exit.

b - Cleaning

To select “Cleaning” (only when the boiler is switched off) act as follows:

• Press the “menu” button.

• Scroll to “Settings” using the arrows

• Press “menu” to conrm.

• Scroll to “Cleaning” using the arrows.

• Press “menu” to conrm.

• Select “On” with the + - keys.

• Press “menu” to conrm and “esc” to exit.

c - Feed screw loading

To select “Feed screw loading” (only when the boiler is switched off) act as follows:

• Press the “menu” button.

• Scroll to “Settings” using the arrows

• Press “menu” to conrm.

• Scroll to “Feed screw loading” using the arrows.

• Press “menu” to conrm.

• Select “Enable” with the + - keys.

• Press “menu” to conrm and “esc” to exit.

d - Tones

This function is disabled by default, so to enable act as follows:

• Press the “menu” button.

• Scroll to “Settings” using the arrows

• Press “menu” to conrm.

• Scroll to “tones” using the arrows.

• Press “menu” to conrm.

• Select “On” with the + - keys.

• Press “menu” to conrm and “esc” to exit.

e - External thermostat (see relative chapter)

f - Auto-Eco activation

To select the Auto-Eco function act as follows:

• Press the “menu” button.

• Scroll to “Settings” using the arrows

• Press “menu” to conrm.

• Scroll to “Auto-Eco” using the arrows.

• Press “menu” to conrm.

• Select “On” with the + - keys.

• Press “menu” to conrm and “esc” to exit.

g - Eco Shutdown t

To select the Eco - shutdown t function act as follows:

• Press the “menu” button.

• Scroll to “Settings” using the arrows

• Press “menu” to conrm.

• Scroll to “Eco - shutdown t” using the arrows.

32

AQUOS - IBIS - IDRON

EN

• Press “menu” to conrm.

• Enter the minutes with the + - keys.

• Press “menu” to conrm and “esc” to exit.

h - Pump On T

To select the Pump On T function act as follows:

• Press the “menu” button.

• Scroll to “Settings” using the arrows

• Press “menu” to conrm.

• Scroll to “Pump On T” using the arrows.

• Press “menu” to conrm.

• Modify the °C with the + - keys.

• Press “menu” to conrm and “esc” to exit

i - Auxiliary boiler

One must install an additional module (optional) to enable start-up of an auxiliary boiler in the event the boiler

is switched off or in alarm conditions. By default this function is deactivated, if needed activate it to access the

settings menu.

l - Pellet Recipe

To change the recipe act as follows:

• Press the “menu” button.

• Scroll to “Settings” using the arrows

• Press “menu” to conrm.

• Scroll to “Pellet recipe” using the arrows.

• Press “menu” to conrm.

• Modify the % with the + - keys.

• Press “menu” to conrm and “esc” to exit

m - Smoke rpm % ventilation

To change the parameter act as follows:

• Press the “menu” button.

• Scroll to “Settings” using the arrows

• Press “menu” to conrm.

• Scroll to “Smoke rpm variation” using the arrows.

• Press “menu” to conrm.

• Modify the % with the + - keys.

• Press “menu” to conrm and “esc” to exit

n - Maximum power

To change the power act as follows:

• Press the “menu” button.

• Scroll to “Settings” using the arrows

• Press “menu” to conrm.

• Scroll to “Maximum power” using the arrows.

• Press “menu” to conrm.

• Change the power from 01 to 05 with the + - keys

• Press “menu” to conrm and “esc” to exit

o - Components test

To activate the “Components test” function (only when the boiler is switched off) act as follows:

• Press the “menu” button.

• Scroll to “Settings” using the arrows

• Press “menu” to conrm.

• Scroll to “Components test” using the arrows.

• Press “menu” to conrm.

• Select the test to be performed with the + - keys

• Press “menu” to conrm and “esc” to exit

p - Chimney sweep function

To activate the “Chimney sweep” function act as follows:

• Press the “menu” button.

• Scroll to “Settings” using the arrows

• Press “menu” to conrm.

• Scroll to the “Chimney sweep” function using the arrows.

33

AQUOS - IBIS - IDRON

EN

• Press “menu” to conrm.

• Select “On” with the + - keys (Off by default)

• Press “menu” to conrm and “esc” to exit

q - System conguration

To change the system conguration act as follows:

• Press the “menu” button.

• Scroll to “Settings” using the arrows

• Press “menu” to conrm.

• Scroll to “System conguration” using the arrows.

• Press “menu” to conrm.

• Change the conguration from 01 to 05 with the + - keys

• Press “menu” to conrm and “esc” to exit.

r - Season

To change the function act as follows:

• Press the “menu” button.

• Scroll to “Settings” using the arrows

• Press “menu” to conrm.

• Scroll to “Season” using the arrows.

• Press “menu” to conrm.

• Select “Summer” or “Winter” with the + - keys.

• Press “menu” to conrm and “esc” to exit.

s - Technical menu

To access the technical menu one must contact an assistance centre as one needs a password to enter.

To intervene on the “technical menu” act as follows:

• Press the “menu” button.

• Scroll to “Settings” using the arrows

• Press “menu” to conrm.

• Scroll to “Technical menu” using the arrows.

• Press “menu” to conrm.

• Select “Product Type”, “Service”, “Parameters”, “DHW Parameters”, “Meters memories”, “Enable fan” and

“Puffer data” with the + - keys.

• Press “menu” to conrm and “esc” to exit

11.4 ADJUSTMENTS MENU

To access the adjustments menu act as follows:

• Press the + - keys

• Scroll with the <> arrows and select “Set Room T” or “Set Water T” or “Exchanger Speed”

• Press “menu” to access the selected option.

• Modify with the + - keys.

• Press “menu” to conrm and “esc” to exit.

Important!

The stoves come in different types, some have a fan and some have domestic hot water

(DHW).

Therefore within the stove functions one must bear in mind the features of the purchased

product.

34

AQUOS - IBIS - IDRON

EN

12

PRELIMINARY NOTIONS

12.1 SYSTEM CONFIGURATIONS DEPENDING ON THE MODEL

Upon installation, the product must be set according to the type of system, selecting the appropriate parameter

in the “SETTINGS” menu.

The possible congurations are 5, as described below:

CONFIGURATION DESCRIPTION

1

Room temperature management via the boiler probe or by enabling the external room

thermostat.

2

2.1 Room temperature management via the boiler probe or by enabling the external room

thermostat; instantaneous DHW production with plate heat exchanger.

2.2 Room temperature management via the boiler probe or by enabling the external room

thermostat; instantaneous hot domestic water production for boiler or storage tank with

thermostat (optional).

3

Room temperature management via boiler probe or enabling the external room thermostat;

boiler hot domestic water production with ntc probe (10 kΩ ß3435).

4 External Puffer management controlled by thermostat.

5 External Puffer management controlled by ntc probe (10 kΩ ß3435).

Fig. 29 - Conguration 1 (factory setting for heating version only)

35

AQUOS - IBIS - IDRON

EN

Fig. 30 - Conguration 2.1 (factory setting for version with domestic hot water - DHW)

Fig. 31 - Conguration 2.2

36

AQUOS - IBIS - IDRON

EN

Fig. 32 - Conguration 3

Fig. 33 - Conguration 4

37

AQUOS - IBIS - IDRON

EN

Fig. 34 - Conguration 5

LEGEND

1 Stove

2 Heating delivery

3 Heating return

4 Zone valves

5 Heating bodies

6 Hot domestic water

7 Cold domestic water

8 Domestic water boiler

9 Diverter valve

10 Boiler thermostat

11 Thermostatic mixing valve

12 Domestic water 10 kΩ β3434 NTC probe

13 Heating puffer

14 Heating system circulator

15 Puffer thermostat

16 Puffer 10 kΩ β3434 NTC probe

17 Safety valve

13

OPERATION

13.1 OPERATING MODE

The operating mode for hydro boilers is AUTOMATIC only (manual mode is not envisioned). Flame modulation is

managed according to the “System conguration” of the room probe placed on the rear of the appliance (see

drawing), by the external thermostat, by the boiler water temperature or by the NTC probes.

38

AQUOS - IBIS - IDRON

EN

Fig. 35 - Operating mode

13.2 EXTERNAL THERMOSTAT CONNECTION (E)

EXTERNAL THERMOSTAT (not included with the boiler, to be provided by the user).

The temperature of the boiler can also be controlled by an external room thermostat. It is located in a central

position of the room where the boiler is installed. It provides a closer match between the heating temperature

requested of the boiler and what it actually provides.

Fig. 36 - Electrical thermostat connection

LEGEND

POS. 1-2 External thermostat

POS. 3-4 Puffer/boiler probe

POS. 5 Earthing

POS. 6-7 Additional boiler

39

AQUOS - IBIS - IDRON

EN

Connect the cables from the external thermostat to points 1-2 of the terminal block on the boiler.

Once the thermostat has been connected one must enable it.

In order to do this, proceed as follows:

• Press the “menu” button.

• Scroll to “Settings” using the arrows.

• Select by pressing “menu”.

• Scroll once again to “External thermostat” using the arrows.

• Select by pressing “menu”.

• Press the - + buttons.

• Select “On” to activate the external thermostat.

• Press the “menu” button to conrm.

• Press the “esc” button to exit.

13.3 START-UP

Press key 1 (esc) to begin start-up, the control panel displays ON with a ashing ame. When the ame stops

ashing the boiler has reached the “power output” operating mode.

The room temperature set by default is 20°C, if one wishes to change it act as instructed in the adjustments

menu; act likewise to set the heating water temperature and the room fan speed (if envisaged). To activate

external thermostat if any see the relative section.

13.4 POWER OUTPUT

Once the start-up stage is complete the control panel will display ON with a xed ame at level 3. The subsequent

ame modulation at lower or higher powers is managed autonomously and upon reaching the temperatures

set in the “System conguration”.

13.5 PROGRAMMED MODE (TIMER) - MAIN MENU

Setting the current day and time is essential for the proper operation of the timer.

There are six TIMER programmes, for each one the user can decide the start-up and shutdown time as well as the

day of the week in which it is active.

When one or more programmes are active, the panel alternately displays the boiler status and TIMER “n” whereby

“n” is the number relating to the activated timer programmes, separated from each other with a dash

Example:

TIMER 1 Timer programme 1 active.

TIMER 1-4 Timer programmes 1 and 4 active.

TIMER 1-2-3-4-5-6 Timer programmes all active.

EXAMPLE OF PROGRAMMING

With boiler on or off:

access the MENU,

scroll to TIMER with the <> arrows,

press the “Menu” key

the system proposes “P1” (Press the <> keys for the subsequent timers P2,P3, P4, P5, P6)

to activate “P1” press the “Menu” key

press + - and select “ON”

conrm with the “Menu” key

At this point it will propose 00:00 as starting time, with key + - adjust the starting time and press the “menu” key

to conrm.

The next step proposes a shutdown time of 10 minutes above that set for start-up: press the + key and adjust the

shutdown time, conrm with the “menu” key.

Subsequently the system proposes the days of the week in which to activate or deactivate the previously set

timer. With the - or + key highlight with the white background the day in which one wishes to activate the timer

and conrm with the “menu” key. If no day of the week is conrmed as active, in turn the timer programme will

not appear active in the status screen.

Continue to program the following days or press “ESC” to exit. Repeat the procedure to program the other

timers.

40

AQUOS - IBIS - IDRON

EN

13.6 PROGRAMMING EXAMPLES:

P1 P2

on off day on off day

08:00 12:00 mon 11:00 14:00 mon

Boiler on from 08:00 to 14:00

on off day on off day

08:00 11:00 mon 11:00 14:00 mon

Boiler on from 08:00 to 14:00

on off day on off day

17:00 24:00 mon 00:00 06:00 tue

Boiler on from 17:00 on monday to 06:00 on tuesday

13.7 NOTES FOR TIMER OPERATION

• Start-up with the timer always takes place with the last temperature and ventilation settings (or with default

20°C and V3 settings in the event they have never been changed).

• Start-up time ranges from 00:00 a 23:50

• If the shutdown time is not already memorised, it proposes a start-up time in + 10 minutes.

• A timer programme switches the boiler off at 24:00 of one day and another programme switches it on at 00:00

of the next day: the boiler stays on.

• A programme proposes a start-up and shutdown in times included within another timer programme: if the

boiler is already on, start will not have any effect, while OFF will switch it off.

• In the boiler on and timer active condition, press the OFF key and the boiler will switch off, it will switch on

automatically at the next time set on the timer.

• In the boiler off and timer active condition, press the ON key and the boiler will switch on, it will switch off at

the time set on the active timer.

13.8 AUTO ECO MODE (SEE SECTION F-G SETTINGS MENU PAGE 30)

To activate the “Auto Eco” mode and adjust the time refer SETTINGS MENU page 30.

The possibility to adjust the “ECO shutdown t” comes from the need to ensure proper operation in the various

rooms the boiler can be installed in and prevent continuous shutdowns and start-ups in the event the temperature

is subject to sudden changes (air currents, poorly insulated rooms, etc.).

The ECO shutdown procedure is activated automatically when all the power demand devices involved in the

“system conguration” are satised: room probe/external thermostat, ow switch, puffer thermostat/ntc (10 kΩ

ß3435) or boiler thermostat/ntc (10 kΩ ß3435). If all devices present are satised the “ECO shutdown t” time

decrease starts (by default 10 minutes, it can be changed within the “Settings menu”). During this stage the

panel displays ON with a small ame and alternately Chrono (of active) - Eco active. The minutes indicating the

countdown for the Eco Stop are shown at the top of the display. The ame goes into P1 and stays there until the

programmed “Eco shutdown t” time has elapsed and if the conditions are still satised, it goes into the shutdown

stage. The ECO switch off countdown resets if one of the devices boosts power again.

When switch off starts the panel displays: Off - Eco Active - small ashing ame.

Once the boiler has reached the off condition, the panel displays OFF-ECO with the extinguished ame symbol.

To restart from ECO the following conditions must be satised simultaneously:

• Power demand

• After 5 minutes from the beginning of shutdown.

• TH2O < TSetH2O.

• If the domestic hot water (DHW) demands power - if envisaged - the rst 5’ are ignored and the boiler restarts

as needed.

NOTE: In conguration 4 - 5 the Auto Eco mode is enabled automatically. Even when one sets the “summer”

function in conguration 2 - 3 it is enabled automatically. In the cases where it is designed to be active, it is not

possible to deactivate the mode.

13.9 SLEEP FUNCTION (MAIN MENU)

The sleep function is activated only when the boiler is switched on and allows to quickly set a time at which the

product must switch off.

To set the Sleep function act as follows:

41

AQUOS - IBIS - IDRON

EN

• Enter MENU

• Scroll to SLEEP with the <> arrows

• Press Menu

• With the + - keys adjust the desired shutdown time.

The panel proposes a shutdown time of 10 minutes from the current time, adjustable with key 4 until the next day

(I can therefore delay the shutdown for up to a maximum of 23 hours and 50 minutes).

If the SLEEP function is active with the TIMER active the rst has priority over the latter, therefore the boiler will not

switch off at the time set on the timer but instead by the time established by the sleep function, even if later than

the time set on the timer.

13.10 AUXILIARY BOILER (SEE SECTION I SETTINGS MENU PAGE 30)

One must install an additional module (optional) to enable start-up of an auxiliary boiler in the event the stove

is switched off or in alarm conditions. By default this function is deactivated, if needed activate it to access the

settings menu.

13.11 PELLETS RECIPE (SEE SECTION J SETTINGS MENU PAGE 30)

This function is for adapting the stove to the pellets that are being used. In fact, as there are several types of

pellets on the market, boiler operation is extremely variable depending on the fuel quality. In the event the