Page 1

CADDY CORPORATION

Air SystemsFood Service Equipment

Tray Make-Up

Conveyor

Systems

Page 2

PROJECT:

ITEM NO:

LOCATION:

page 1 of 1

All specifications subject to change without notice

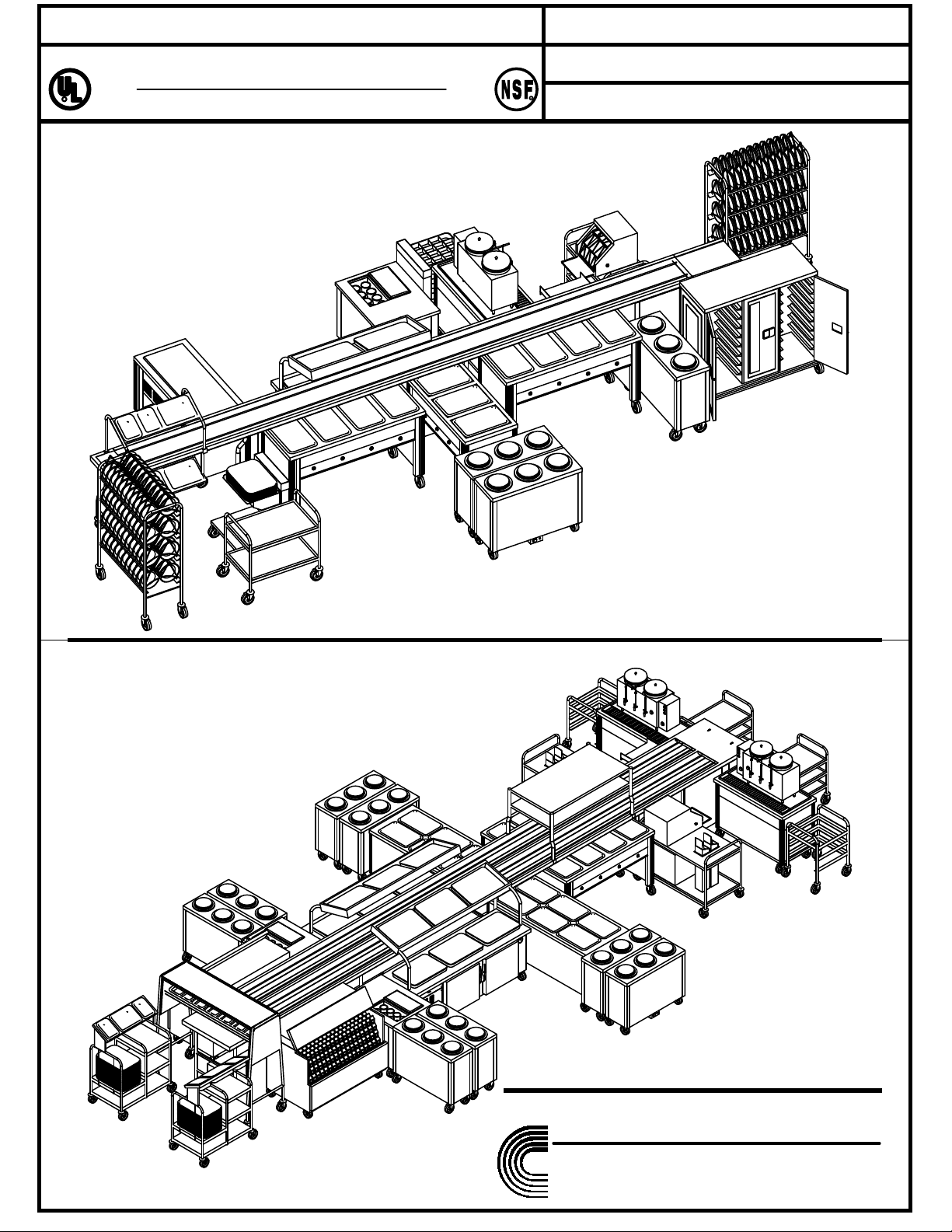

TRAY MAKE-UP CADDY-VEYOR

"XL" SERIES

R

COLD

FOOD

UNIT

MILK AND

ICE CREAM

DISPENSER

HEATED

UNDERLINER

DISPENSER

UTILITY

CART

TRAY

STARTER

HOT

FOOD

UNIT

HOT

FOOD

UNIT

HEATED

PLATE

DISPENSER

COFFEE

AND MUG

DISPENSER

DOME

COVER

DISPENSER

TRAY

DELIVERY

TRUCK

MODEL

XL-1

SINGLE TRACK

POWERED

recommended for

institutions with

150 TO 400 BEDS

Single track powered unit for time-saving tray completion in

medium to moderately large institutions. Elevated conveyor

bed reduces operating space, cuts down on stretching and

turning to lessen fatigue.

MUG

DISPENSER

COFFEE

URN

STAND

TOASTER

CADDY

MODEL

XL-2

DOUBLE TRACK

POWERED

recommended for

institutions with

400 TO 650 BEDS

Double track powered unit for maximum efficiency in large

hospitals. Serves as two conveyors in one without requiring

large extra floor space. Trays are served from both sides

simultaneously, thus double tray production.

08/07

CADDY Food Service Systems

509 Sharptown Road P.O. Box 345

Bridgeport, NJ 08014-0345

Tel: 856-467-4222 Fax: 856-467-5511

internet: www.caddycorp.com

CADDY CORPORATION

TRAY

STARTERS

HEATED

UNDERLINER

DISPENSER

HEATED

PLATE

DISPENSER

ICE CREAM

DISPENSER

COLD

FOOD

UNIT

HOT

FOOD

UNIT

BEVERAGE

DISPENSER

Page 3

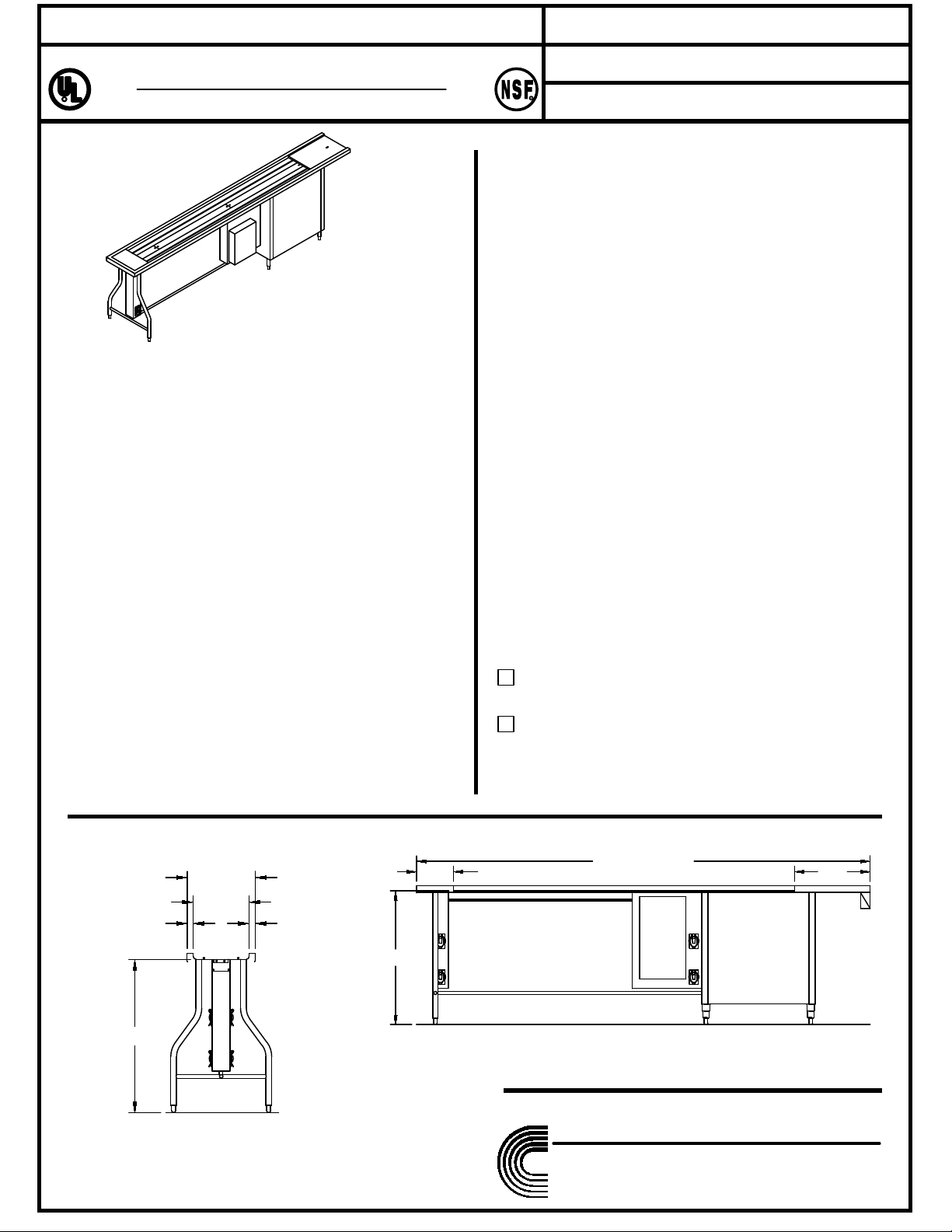

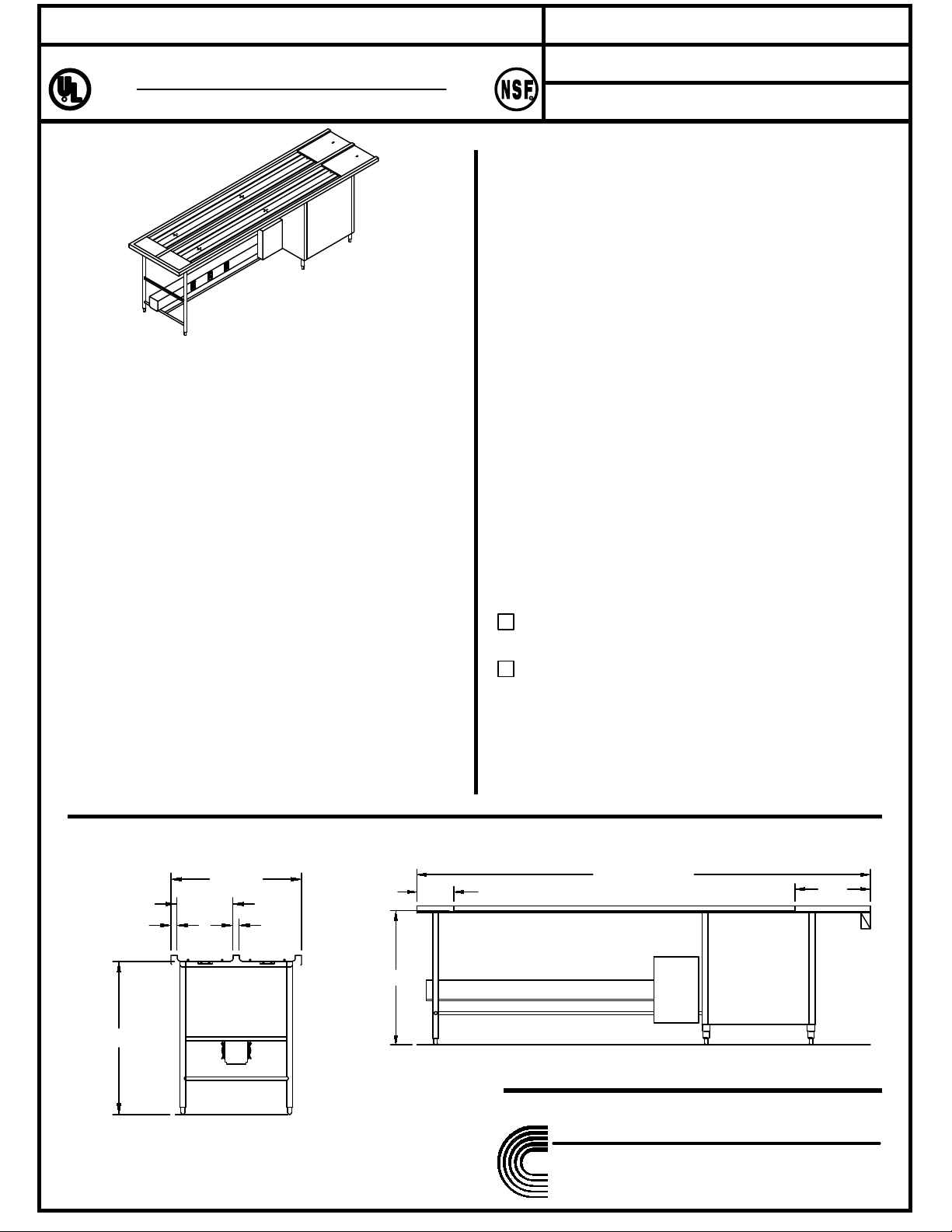

1'-6 3/4"

3'-6 1/2"

1'-3 1/2"

1 3/4" 1 3/4"

NOMINAL LENGTH

2'-0"11 3/4"

3'-6 1/2"

PROJECT:

ITEM NO:

LOCATION:

page 1 of 2

All specifications subject to change without notice

TRAY MAKE-UP CADDY-VEYOR

XL-1 SERIES

R

Series XL-1 EXPRESS LINE Tray make-up conveyor to be

as manufactured by Caddy Corporation Unit shall be 19"

wide x ________ long, and to accommodate flat bottom

trays up to 15" wide. (Specify dimensions of trays to be

used.)

Conveyor belt to consist of dual 1/2" diameter

Dura-San belting. Belting itself is USDA accepted, highly

resistant to abrasion, dirt, oil and most chemicals, maintains

tension without springs, sprockets or links, continuous

without ends or mechanical connection devices. Start end to

be provided with 6" long tray rest. discharge end to have 20"

FEATURES

xElevated design to accommodate tray assembly support

equipment underneath, thereby saving 15-20% floor

space as compared to conventional assembly lines.

xSingle track powered unit for time-saving tray completion

in medium to moderately large institutions.

xElevated conveyor bed cuts down on stretching and

turning to lessen fatigue.

long tray pick-up area, with limit switch activated by

stainless steel lever protruding through slot in belt bed. Belt

to be driven only on top surface of conveyor bed. No drain

pans. All bearings to be heavy duty ball-type, with sealed

lubrication.

Conveyor bed to be 14 gauge stainless steel of

welded construction, ground and polished. Conveyor bed

height to be 42 1/2" and to elevated over support equipment.

Structural Supports to be stainless steel and welded

to underside of conveyor bed. Conveyor to be provided with

a screwed in place access panel at tail end providing access

to bearings.

Drive housing to consist of 18 gauge stainless steel

enclosure on two sides with removable 18 gauge panels.

Conveyor belt to direct drive by variable speed motor with

range of belt speed 5 to 40 feet per minute rated for

120/208/60/3 phase, 4 wire plus separate ground.

Motor to be controlled manually through an on/off

push-button switch and automatically through a limit switch,

both located at discharge end. All wired to splashproof SCR

controller with low voltage and overload protection. All

electrical components above, as well as the motor, to be

completely interwired through waterproof flex conduit and

splashproof conduit connectors, terminating in waterproof

circuit breaker panel(s).

Leg assembly of 16 gauge tubular stainless steel 1

5/8" O.D. and 1" O.D. crossbracing completely welded.

SPECIFICATIONS:

Stationary Unit

Fitted with adjustable stainless steel bullet feet.

Mobile Unit

Fitted with 5" diameter polyurethane tired casters, two with

brakes. Conveyor shall have 6'-0" long power cord.

(Continue specifications by selecting stationary or mobile model)

08/07

CADDY Food Service Systems

509 Sharptown Road P.O. Box 345

Bridgeport, NJ 08014-0345

Tel: 856-467-4222 Fax: 856-467-5511

internet: www.caddycorp.com

CADDY CORPORATION

Page 4

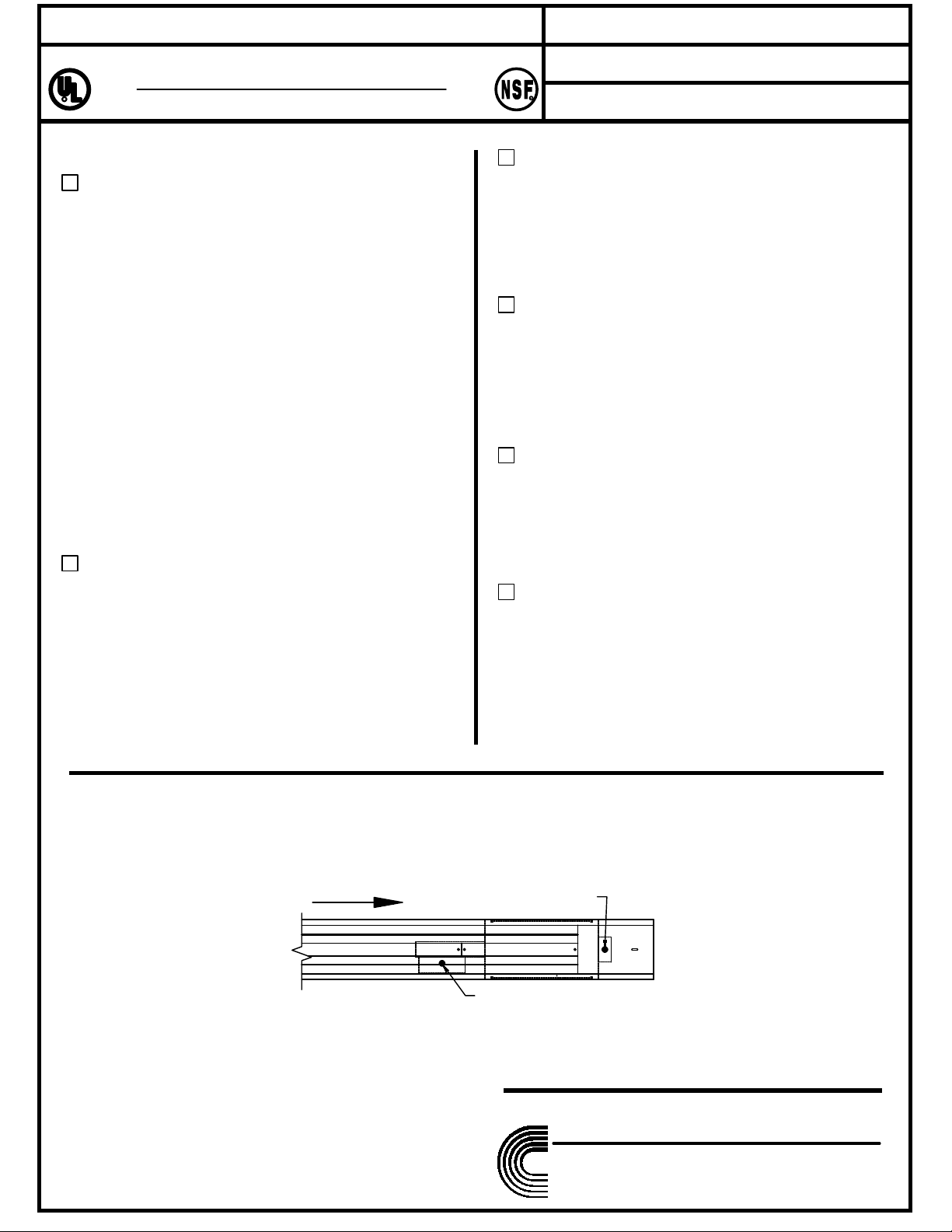

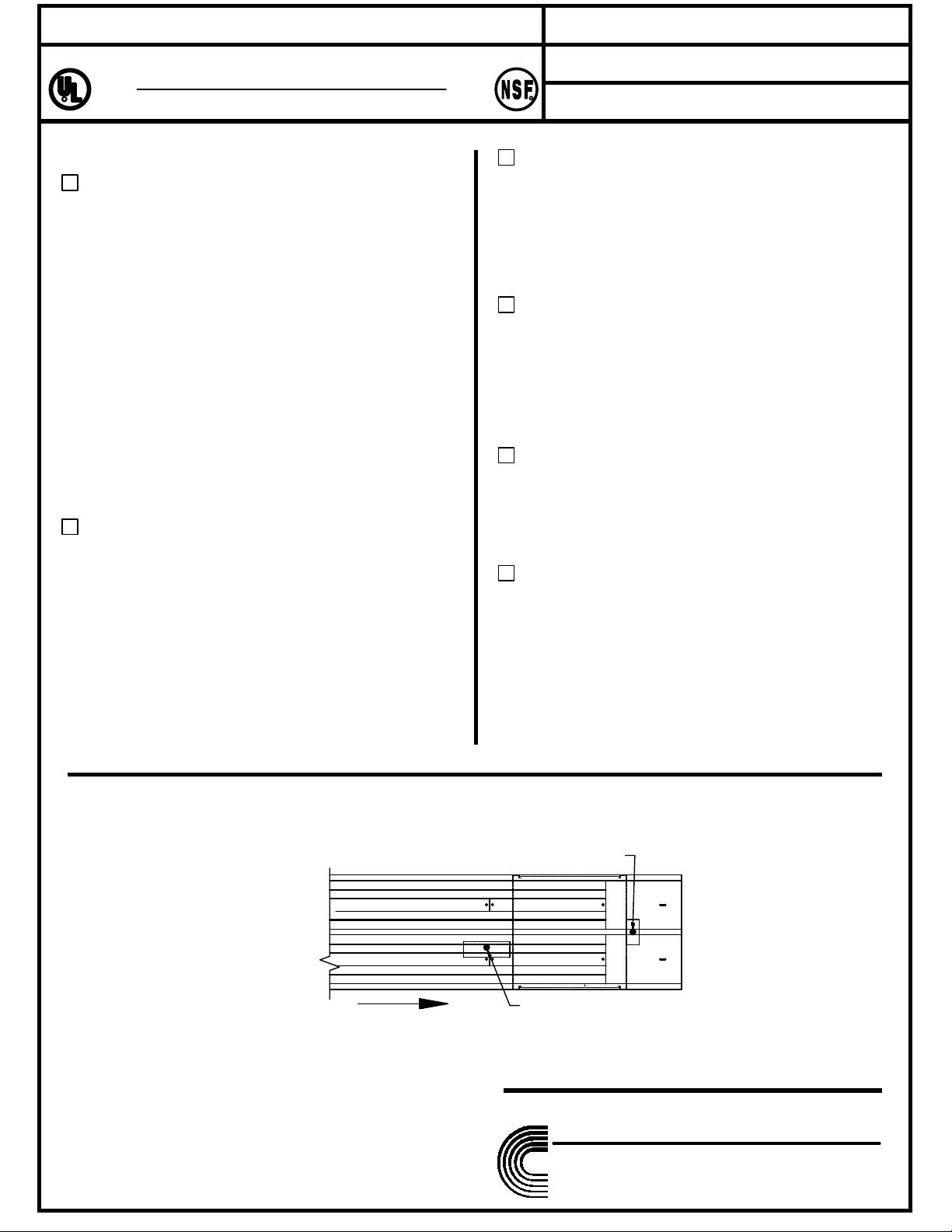

ROUGH-IN LOCATION

WITH NO WIREWAY

ROUGH-IN LOCATION

WITH A WIREWAY

PROJECT:

ITEM NO:

LOCATION:

All specifications subject to change without notice

R

Caddy-veyor to be furnished with a stainless steel wireway

recessed under conveyor bed with removable screw cover.

Wireway will distribute to power risers locate at each leg

assembly. Both sides of power riser to be provided with

moisture-proof electric outlets with hinged covers for

adjoining mobile equipment, all as indicated on plan. Outlets

wired to one or more circuit breaker panels with each

receptacle having its own circuit breaker control with manual

reset feature and shut-off. All electrical work to be ready for

single final connection by others to a circuit breaker panel at

the job site.

Specify number of outlets, as well as voltage, phase,

wattage or motor size and location for each electrical plug-in

outlet required. Preferred input voltage is 120/208v, 3ph, 5

wire system including ground.

*IMPORTANT NOTE ON ELECTRICAL DATA*

Maximum allowable amperage for mobile tray make-up

conveyor is 100 amps 3 phase. If total amperage exceeds

100 amp, 3 phase, a second circuit breaker panel will be

require. A separate electric connection is needed in the field

for EACH circuit breaker panel on the conveyor.

Optional Features:

Wireway with Factory Installed Electric Outlets

Work and storage shelf to be Model ACC-2010 made of 16

gauge stainless steel flanged up at rear and both sides.

Shelf supported by stainless steel tubular leg with adjustable

stainless steel bullet foot. Shelf size to be 20" X 10". Rear of

shelf to be contoured to fit over and slide along curbing of

conveyor and provided with positive locking clip to engage

lower edge of conveyor bed.

Removable Work and Storage Shelf for Advance

Make-Up of Soup and Beverages

Double overshelf to be Model ACC-6015 and to set on

curbing of conveyor. To be approximately 5'-0" long with two

shelves 15" wide of 16 gauge stainless steel turned down 1"

on all four sides, supported by splayed legs of 1" O.D. 16

gauge stainless steel tubing with guides at bottom to slide to

any convenient location.

Double Overshelf for Storage of Cookies, Crackers,

Desserts, etc.

Stationay Conveyor

Sketches shown are for general layout purposes only,

subject to changes without prior notice consistent with latest

design changes. For final dimensional and roughing data,

special drawings applicable to a specific order should be

requested from Caddy Engineering Department.

page 2 of 2

TRAY MAKE-UP CADDY-VEYOR

XL-1 SERIES

Overhead tray starter shelf to be Model T-565 and to set on

curbing of conveyor. To be approximately 3'-0" long with

sloped shelf of 16 gauge stainless steel turned down 1" on

front and back. Cutout in shelf to accommodate three pans

4" deep. Mounted on legs of 1" O.D. 16 gauge stainless

steel tubing with guides at bottom to slide to any convenient

location.

Overhead Starter Shelf

A set of 3 stainless steel pans (one full, two 1/3 pan) for

T-565 or T-566

Stainless Steel Pans

Undermount tray starter shelf to be Model T-566 and to be

mounted under conveyor bed with two 14 gauge stainless

steel brackets. To be approximately 3'-0" long with sloped

shelf of 16 gauge stainless steel turned down 1" on front and

back. Cutout in shelf to accommodate three pans 4" deep.

Undermount Starter Shelf

08/07

CADDY Food Service Systems

509 Sharptown Road P.O. Box 345

Bridgeport, NJ 08014-0345

Tel: 856-467-4222 Fax: 856-467-5511

internet: www.caddycorp.com

CADDY CORPORATION

Page 5

3'-6 1/2"

3'-0 1/4"

1'-3 1/2"

1 3/4" 1 3/4"

NOMINAL LENGTH

2'-0"

11 3/4"

3'-6 1/2"

PROJECT:

ITEM NO:

LOCATION:

page 1 of 2

All specifications subject to change without notice

TRAY MAKE-UP CADDY-VEYOR

XL-2 SERIES

R

SPECIFICATIONS:

FEATURES

xServies as two conveyors in one without requiring extra

large floor space.

xDouble track powered unit for maximum efficiency in

large institutions.

xElevated conveyor bed cuts down on stretching and

turning to lessen fatigue.

to be driven only on top surface of conveyor bed. No drain

pans. All bearings to be heavy duty ball-type, with sealed

lubrication.

Conveyor bed to be 14 gauge stainless steel of

welded construction, ground and polished. Conveyor bed

height to be 42 1/2" and to elevated over support equipment.

Structural Supports to be stainless steel and welded to

underside of conveyor bed. Conveyor to be provided with a

screwed in place access panel at tail end providing access

to bearings.

Drive housing to consist of 18 gauge stainless steel

enclosure on two sides with removable 18 gauge panels.

Conveyor belt to direct drive by variable speed motor

with range of belt speed 5 to 40 feet per minute rated for

120/208/60/3 phase, 4 wire plus separate ground.

Motor to be controlled manually through an on/off

push-button switch and automatically through a limit switch,

both located at discharge end. All wired to splashproof SCR

controller with low voltage and overload protection. All

electrical components above, as well as the motor, to be

completely interwired through waterproof flex conduit and

splashproof conduit connectors, terminating in waterproof

circuit breaker panel(s).

Leg assembly of 16 gauge tubular stainless steel 1

5/8" O.D. and 1" O.D. crossbracing completely welded.

Series XL-2 EXPRESS LINE Tray make-up conveyor to be

as manufactured by Caddy Corporation Unit shall be 36 1/4"

wide x ________ long, and to accommodate flat bottom

trays up to 15" wide. (Specify dimensions of trays to be

used.)

Conveyor belt to consist of dual 1/2" diameter

Dura-San belting. Belting itself is USDA accepted, highly

resistant to abrasion, dirt, oil and most chemicals, maintains

tension without springs, sprockets or links, continuous

without ends or mechanical connection devices. Start end to

be provided with 6" long tray rest. discharge end to have 20"

long tray pick-up area, with limit switch activated by

stainless steel lever protruding through slot in belt bed. Belt

Stationary Unit

Fitted with adjustable stainless steel bullet feet.

Mobile Unit

Fitted with 5" diameter polyurethane tired casters, two with

brakes. Conveyor shall have 6'-0" long power cord.

(Continue specifications by selecting stationary or mobile model)

08/07

CADDY Food Service Systems

509 Sharptown Road P.O. Box 345

Bridgeport, NJ 08014-0345

Tel: 856-467-4222 Fax: 856-467-5511

internet: www.caddycorp.com

CADDY CORPORATION

Page 6

ROUGH-IN LOCATION

WITH NO WIREWAY

ROUGH-IN LOCATION

WITH A WIREWAY

PROJECT:

ITEM NO:

LOCATION:

All specifications subject to change without notice

R

Caddy-veyor to be furnished with a recessed stainless steel

wireway and electric outlets with hinged moisture proof

covers for adjoining mobile equipment on both sides, all as

indicated on plan. Outlets wired to one or more circuit

breaker panels with each receptacle having its own circuit

breaker control with manual reset feature and shut-off. All

electrical work to be ready for single final connection by

others to a circuit breaker panel at the job site.

Specify number of outlets, as well as voltage, phase,

wattage or motor size and location for each electrical plug-in

outlet required. Preferred input voltage is 120/208v, 3ph, 5

wire system including ground.

*IMPORTANT NOTE ON ELECTRICAL DATA*

Maximum allowable amperage for mobile tray make-up

conveyor is 100 amps 3 phase. If total amperage exceeds

100 amp, 3 phase, a second circuit breaker panel will be

require. A separate electric connection is needed in the field

for EACH circuit breaker panel on the conveyor.

Optional Features:

Wireway with Factory Installed Electric Outlets

Work and storage shelf to be Model ACC-2010 made of 16

gauge stainless steel flanged up at rear and both sides.

Shelf supported by stainless steel tubular leg with adjustable

stainless steel bullet foot. Shelf size to be 20" X 10". Rear of

shelf to be contoured to fit over and slide along curbing of

conveyor and provided with positive locking clip to engage

lower edge of conveyor bed.

Removable Work and Storage Shelf for Advance

Make-Up of Soup and Beverages

Double overshelf to be Model ACC-6015 and to set on

curbing of conveyor. To be approximately 5'-0" long with two

shelves 15" wide of 16 gauge stainless steel turned down 1"

on all four sides, supported by splayed legs of 1" O.D. 16

gauge stainless steel tubing with guides at bottom to slide to

any convenient location.

Double Overshelf for Storage of Cookies, Crackers,

Desserts, etc.

Stationay Conveyor

Sketches shown are for general layout purposes only,

subject to changes without prior notice consistent with latest

design changes. For final dimensional and roughing data,

special drawings applicable to a specific order should be

requested from Caddy Engineering Department.

page 2 of 2

TRAY MAKE-UP CADDY-VEYOR

XL-2 SERIES

Overhead tray starter shelf to be Model T-565 and to set on

curbing of conveyor. To be approximately 3'-0" long with

sloped shelf of 16 gauge stainless steel turned down 1" on

front and back. Cutout in shelf to accommodate three pans

4" deep. Mounted on legs of 1" O.D. 16 gauge stainless

steel tubing with guides at bottom to slide to any convenient

location.

Overhead Starter Shelf

A set of 3 stainless steel pans (one full, two 1/3 pan) for

T-565 or T-566

Stainless Steel Pans

Undermount tray starter shelf to be Model T-566 and to be

mounted under conveyor bed with two 14 gauge brackets.

To be approximately 3'-0" long with sloped shelf of 16 gauge

stainless steel turned down 1" on front and back. Cutout in

shelf to accommodate three pans 4" deep.

Undermount Starter Shelf

08/07

CADDY Food Service Systems

509 Sharptown Road P.O. Box 345

Bridgeport, NJ 08014-0345

Tel: 856-467-4222 Fax: 856-467-5511

internet: www.caddycorp.com

CADDY CORPORATION

Page 7

1'-6 3/4"

3'-6 1/2"

1'-3 1/2"

1 3/4" 1 3/4"

NOMINAL LENGTH

2'-0"11 3/4"

3'-6 1/2"

PROJECT:

ITEM NO:

LOCATION:

page 1 of 2

All specifications subject to change without notice

TRAY MAKE-UP CADDY-VEYOR

XL-1C PRISON PACKAGE

R

Series XL-1C PRISON LINE Tray make-up conveyor to be

as manufactured by Caddy Corporation Unit shall be 19"

wide x ________ long, and to accommodate flat bottom

trays up to 15" wide. (Specify dimensions of trays to be

used.)

Conveyor belt to consist of dual 1/2" diameter

Dura-San belting. Belting itself is USDA accepted, highly

resistant to abrasion, dirt, oil and most chemicals, maintains

tension without springs, sprockets or links, continuous

without ends or mechanical connection devices. Start end to

be provided with 6" long tray rest. discharge end to have 20"

Mobile Unit

Fitted with 5" diameter polyurethane tired casters, two with

brakes. Conveyor shall have 6'-0" long power cord.

FEATURES

xNo parts can be removed.

xNo concealed places to store contraband

xAll exposed fasteners are heavy duty stainless steel

tamper-proof fasteners.

xElevated designed to accommodate tray assembly

support equipment underneath, thereby saving 15-20%

floor space as compared to conventional assembly lines.

xSingle track powered unit for time-saving tray completion

in medium to moderately large institutions.

xElevated conveyor bed cuts down on stretching and

turning to lessen fatigue.

long tray pick-up area, with limit switch activated by

stainless steel lever protruding through slot in belt bed. Belt

to be driven only on top surface of conveyor bed. No drain

pans. All bearings to be heavy duty ball-type, with sealed

lubrication.

Conveyor bed to be 14 gauge stainless steel of

welded construction, ground and polished. Legs to be 16

gauge tubular stainless steel 1 5/8" O.D. with 1" O.D.

crossbracing completely welded. Conveyor bed height to be

42 1/2" and to elevated over support equipment.

Structural supports to be stainless steel and welded

to underside of conveyor bed. Conveyor to be provided with

an access panel at tail end providing access to bearings.

Panel to be screwed in place with tamper-proof stainless

steel security screws.

Drive housing to consist of 18 gauge stainless steel

enclosure on two sides with removable 18 gauge panels.

Panels to be fastened with tamper-proof stainless steel

security screws. Housing to have 6 1/2" high adjustable

stainless steel feet. Bottom of housing to have perforated

stainless steel panel welded in place. No place to store

contraband will be allowed.

Conveyor belt to direct drive by variable speed motor

with range of belt speed 5 to 40 feet per minute rated for

120/208/60/3 phase, 4 wire plus separate ground.

Motor to be controlled manually through an on/off

push-button switch and automatically through a limit switch,

both located at discharge end. All wired to splashproof SCR

controller with low voltage and overload protection. All

controls and wiring to be protected from disassembly and

unauthorized adjustments.

SPECIFICATIONS:

(Continue specifications by selecting stationary or mobile model)

08/07

CADDY Food Service Systems

509 Sharptown Road P.O. Box 345

Bridgeport, NJ 08014-0345

Tel: 856-467-4222 Fax: 856-467-5511

internet: www.caddycorp.com

CADDY CORPORATION

Page 8

ROUGH-IN LOCATION

WITH NO WIREWAY

ROUGH-IN LOCATION

WITH A WIREWAY

PROJECT:

ITEM NO:

LOCATION:

All specifications subject to change without notice

R

Caddy-veyor to be furnished with a stainless steel

wireway recessed under conveyor bed with removable

screw cover. Wireway will distribute to power risers locate at

each leg assembly. Both sides of power riser to be provided

with moisture-proof electric outlets with hinged covers for

adjoining mobile equipment, all as indicated on plan. Outlets

wired to one or more circuit breaker panels with each

receptacle having its own circuit breaker control with manual

reset feature and shut-off. All wireway fasteners and

receptacle fasteners to be heavy duty tamper-proof stainless

steel security type. All electrical work to be ready for single

final connection by others to a circuit breaker panel at the

job site.

Specify number of outlets, as well as voltage, phase,

wattage or motor size and location for each electrical plug-in

outlet required. Preferred input voltage is 120/208v, 3ph, 5

wire system including ground.

*IMPORTANT NOTE ON ELECTRICAL DATA*

If total amperage exceeds 100 amp, 3phase, a second

circuit breaker panel may be require. For mobile tray

make-up conveyor the maximum allowable amperage for

each circuit breaker panel with 6'-0" cord and plug is 100

amps. A separate electric connection is needed in the field

for EACH circuit breaker panel on the conveyor.

Optional Features:

Wireway with Factory Installed Electric Outlets

Work and storage shelf to be Model ACC-2010 made of 16

gauge stainless steel flanged up at rear and both sides.

Removable Work and Storage Shelf for Advance

Make-Up of Soup and Beverages

Double overshelf to be Model ACC-6015 and to set on

curbing of conveyor. To be approximately 5'-0" long with two

shelves 15" wide of 16 gauge stainless steel turned down 1"

on all four sides, supported by splayed legs of 1" O.D. 16

gauge stainless steel tubing with guides at bottom to slide to

any convenient location.

Double Overshelf for Storage of Cookies, Crackers,

Desserts, etc.

Stationay Conveyor

Sketches shown are for general layout purposes only,

subject to changes without prior notice consistent with latest

design changes. For final dimensional and roughing data,

special drawings applicable to a specific order should be

requested from Caddy Engineering Department.

page 2 of 2

TRAY MAKE-UP CADDY-VEYOR

XL-1C PRISON PACKAGE

Overhead tray starter shelf to be Model T-565 and to set on

curbing of conveyor. To be approximately 3'-0" long with

sloped shelf of 16 gauge stainless steel turned down 1" on

front and back. Cutout in shelf to accommodate three pans

4" deep. Mounted on legs of 1" O.D. 16 gauge stainless

steel tubing with guides at bottom to slide to any convenient

location.

Overhead Starter Shelf

A set of 3 stainless steel pans (one full, two 1/3 pan) for

T-565 or T-566

Stainless Steel Pans

Undermount tray starter shelf to be Model T-566 and to be

mounted under conveyor bed with two 14 gauge bracket. To

be approximately 3'-0" long with sloped shelf of 16 gauge

stainless steel turned down 1" on front and back. Cutout in

shelf to accommodate three pans 4" deep.

Undermount Starter Shelf

Shelf supported by stainless steel tubular leg with adjustable

stainless steel bullet foot. Shelf size to be 20" X 10". Rear of

shelf to be contoured to fit over and slide along curbing of

conveyor and provided with positive locking clip to engage

lower edge of conveyor bed.

08/07

CADDY Food Service Systems

509 Sharptown Road P.O. Box 345

Bridgeport, NJ 08014-0345

Tel: 856-467-4222 Fax: 856-467-5511

internet: www.caddycorp.com

CADDY CORPORATION

Page 9

PROJECT:

ITEM NO:

LOCATION:

page 1 of 2

All specifications subject to change without notice

R

MODEL

XL-S

SKATEWHEEL

recommended for

institutions with

up to 150 BEDs

unlimited length as desired

This superior non-powered unit brings a cost cutting tray make-up system to

small hospitals and nursing homes. Affords the most sophisticated method of

achieving economy and simplicity of operation. Non-mechanized, non

powered, utilizing the skatewheel principle of tray movement.

FEATURES

x Most economical non-mechanized, non-powered

Caddy-veyor. Use only for flat bottom trays. (Not used for

trays with irregular bottoms).

Series XL-S Skatewheel tray make-up conveyor to be as

manufactured by Caddy Corporation. Unit shall be 19 1/4"

wide x ________ long, and to accommodate flat bottom

trays up to 16" wide. (Specify dimensions of trays to be

used.)

Conveyor bed to have two rows of 1.9" O.D. plastic

skatewheels with stainless steel ball bearings spaced on

approximately 2 1/4" centers and mounted with stainless

steel hardware. Conveyor to be provided with 16 gauge

stainless steel bed of welded construction, ground and

Specification:

polished. Conveyor bed height to be 42 1/2" and to elevated

over support equipment. Both longitudinal curbings for

conveyor bed to have channeled edges with 1" turndown

and extending 1 1/2" above the top of the skatewheels.

Structural supports to be stainless steel and welded to

underside of conveyor bed. Each end of conveyor bed to be

provided with tray stop and hand lift access with bed

cleanout provision.

Leg assembly of 16 gauge tubular stainless steel 1

5/8" O.D. and 1" O.D. crossbracing completely welded.

(Continue specifications by selecting stationary or mobile model)

Stationary Unit

Fitted with adjustable stainless steel bullet feet.

Mobile Unit

Fitted with 5" diameter polyurethane tired casters, two with

brakes. Conveyor shall have 6'-0" long power cord.

TRAY MAKE-UP CADDY-VEYOR

NON-POWERED XL-S

08/07

CADDY Food Service Systems

509 Sharptown Road P.O. Box 345

Bridgeport, NJ 08014-0345

Tel: 856-467-4222 Fax: 856-467-5511

internet: www.caddycorp.com

CADDY CORPORATION

FROST

TOP UNIT

MILK AND

ICE CREAM

DISPENSER

UNDERLINER

DISPENSER

TRAY

STARTER

TOASTER

AND STAND

COFFEE

AND MUG

DISPENSER

DOME

COVER

DISPENSER

TRAY

DELIVERY

TRUCK

HOT FOOD

UNIT

Page 10

1'-7 1/4"

1'-4 1/4"

1 1/2" 1 1/2"

3'-6 1/2" 3'-7 3/4"

NOMINAL LENGTH

3'-6 1/2"

PROJECT:

ITEM NO:

LOCATION:

page 2 of 2

All specifications subject to change without notice

R

MODEL XL-S

Double overshelf to be Model ACC-6015 and to set on

curbing of conveyor. To be approximately 5'-0" long with two

shelves 15" wide of 16 gauge stainless steel turned down 1"

on all four sides, supported by splayed legs of 1" O.D. 16

gauge stainless steel tubing with guides at bottom to slide to

any convenient location.

Double Overshelf for Storage of Cookies, Crackers,

Desserts, etc.

Overhead tray starter shelf to be Model T-565 and to set on

curbing of conveyor. To be approximately 3'-0" long with

sloped shelf of 16 gauge stainless steel turned down 1" on

front and back. Cutout in shelf to accommodate three pans

4" deep. Mounted on legs of 1" O.D. 16 gauge stainless

steel tubing with guides at bottom to slide to any convenient

location.

Overhead Starter Shelf

A set of 3 stainless steel pans (one full, two 1/3 pan) for

T-565 or T-566

Stainless Steel Pans

Undermount tray starter shelf to be Model T-566 and to be

mounted under conveyor bed with two 14 gauge brackets.

To be approximately 3'-0" long with sloped shelf of 16 gauge

stainless steel turned down 1" on front and back. Cutout in

shelf to accommodate three pans 4" deep.

Undermount Starter Shelf

Caddy-veyor to be furnished with a stainless steel wireway

recessed under conveyor bed with removable screw cover.

Wireway will distribute to power risers locate at each leg

assembly. Both sides of power riser to be provided with

moisture-proof electric outlets with hinged covers for

adjoining mobile equipment, all as indicated on plan. Outlets

wired to one or more circuit breaker panels with each

receptacle having its own circuit breaker control with manual

reset feature and shut-off. All electrical work to be ready for

single final connection by others to a circuit breaker panel at

the job site.

Specify number of outlets, as well as voltage, phase,

wattage or motor size and location for each electrical plug-in

outlet required. Preferred input voltage is 120/208v, 3ph, 5

wire system including ground.

*IMPORTANT NOTE ON ELECTRICAL DATA*

Maximum allowable amperage for mobile tray make-up

conveyor is 100 amps 3 phase. If total amperage exceeds

100 amp, 3 phase, a second circuit breaker panel will be

require. A separate electric connection is needed in the field

for EACH circuit breaker panel on the conveyor.

Optional Features:

Wireway with Factory Installed Electric Outlets

TRAY MAKE-UP CADDY-VEYOR

NON-POWERED XL-S

08/07

CADDY Food Service Systems

509 Sharptown Road P.O. Box 345

Bridgeport, NJ 08014-0345

Tel: 856-467-4222 Fax: 856-467-5511

internet: www.caddycorp.com

CADDY CORPORATION

Page 11

1'-7 1/4"

1'-4 1/4"

1 1/2" 1 1/2"

3'-6 1/2" 3'-7 3/4"

PROJECT:

ITEM NO:

LOCATION:

page 1 of 1

All specifications subject to change without notice

R

MODEL XL-R

Double overshelf to be Model ACC-6015 and to set on

curbing of conveyor. to be approximately 5'-0" long with two

shelves 15" wide of 16 gauge stainless steel turned down 1"

on all four sides, supported by splayed legs of 1" O.D. #16

gauge stainless steel tubing with guides at bottom to slide to

any convenient location.

Double Overshelf for Storage of Cookies, Crackers,

Desserts, etc.

Overhead tray starter shelf to be Model T-565 and to set on

curbing of conveyor. To be approximately 3'-0" long with

sloped shelf of 16 gauge stainless steel turned down 1" on

front and back. Cutout in shelf to accommodate three pans

4" deep. Mounted on legs of 1" O.D. 16 gauge stainless

steel tubing with guides at bottom to slide to any convenient

location.

Overhead Starter Shelf

A set of 3 stainless steel pans (one full, two 1/3 pan) for

T-565 or T-566

Stainless Steel Pans

Undermount tray starter shelf to be Model T-566 and to be

mounted under conveyor bed with two 14 gauge brackets.

To be approximately 3'-0" long with sloped shelf of 16 gauge

stainless steel turned down 1" on front and back. Cutout in

shelf to accommodate three pans 4" deep.

Undermount Starter Shelf

Caddy-veyor to be furnished with a stainless steel wire way

recessed under conveyor bed with removable screw cover.

Wireway will distribute to power risers locate at each leg

assembly. Both sides of power riser to be provided with

moisture-proof electric outlets with hinged covers for

adjoining mobile equipment, all as indicated on plan. Outlets

wired to one or more circuit breaker panels with each

Optional Features:

Wireway with Factory Installed Electric Outlets

TRAY MAKE-UP CADDY-VEYOR

NON-POWERED XL-R

FEATURES

xHeavy duty deluxe tray make-up Roller-veyor, will handle

any type trays (flat bottom or irregular bottom).

Non-mechanized, non-powered.

Series XL-R Roller tray make-up conveyor to be as

manufactured by Caddy Corporation. Unit shall be 19 1/4"

wide x ________ long, and to accommodate trays up to 16"

wide. (Specify dimensions of trays to be used.)

Conveyor bed to have a single row of full width 1 1/4"

O.D. plastic rollers with stainless steel balls in nylon

bearings, spaced on approximately 3" centers with stainless

steel hardware. Conveyor to be provided with 16 gauge

stainless steel bed of welded construction, ground and

polished. Conveyor bed height to be 42 1/2" and to elevated

over support equipment. Both longitudinal curbings for

conveyor bed to have channeled edges with 1" turndown

and extending 1 1/2" above the top of the skatewheels.

Structural supports to be stainless steel and welded to

underside of conveyor bed. Each end of conveyor bed to be

provided with tray stop and hand lift access with bed

cleanout provision.

Leg assembly of 16 gauge tubular stainless steel 1

5/8" O.D. and 1" O.D. crossbracing completely welded.

(Continue specifications by selecting stationary or mobile model)

Stationary Unit

Fitted with adjustable stainless steel bullet feet.

Mobile Unit

Fitted with 5" diameter polyurethane tired casters, two with

brakes. Conveyor shall have 6'-0" long power cord.

receptacle having its own circuit breaker control with manual

reset feature and shut-off. All electrical work to be ready for

single final connection by others to a circuit breaker panel at

the job site.

Specify number of outlets, as well as voltage, phase,

wattage or motor size and location for each electrical plug-in

outlet required. Preferred input voltage is 120/208v, 3ph, 5

wire system including ground.

*IMPORTANT NOTE ON ELECTRICAL DATA*

Maximum allowable amperage for mobile tray make-up

conveyor is 100 amps 3 phase. If total amperage exceeds

100 amp, 3 phase, a second circuit breaker panel will be

require. A separate electric connection is needed in the field

for EACH circuit breaker panel on the conveyor.

Specification:

Provide single row of full width 1 1/4" O.D. plastic rollers with

stainless steel balls in nylon bearings, spaced at

approximately 3" centers with stainless steel spring loaded

hexagon snap-in shafts.

1 1/4" O.D. Spring Loaded Plastic Rollers

08/07

CADDY Food Service Systems

509 Sharptown Road P.O. Box 345

Bridgeport, NJ 08014-0345

Tel: 856-467-4222 Fax: 856-467-5511

internet: www.caddycorp.com

CADDY CORPORATION

Page 12

PROJECT:

ITEM NO:

LOCATION:

page 1 of 2

All specifications subject to change without notice

TRAY MAKE-UP CADDY-VEYOR

TM-10 SERIES

indicated on plan. Outlets wired to one or more circuit

breaker panels with each receptacle having its own circuit

breaker control with manual reset feature and shut-off. All

electrical work to be ready for single final connection by

others to a circuit breaker panel at the job site.

Specify number of outlets, as well as voltage, phase,

wattage or motor size and location for each electrical plug-in

outlet required. Preferred input voltage is 120/208v, 3ph, 5

wire system including ground.

Provide a welded 16 gauge stainless steel beltwasher

Model BWF with top and bottom fan shaped sprays

arranged so lukewarm water thoroughly washes all belt

surfaces after which belt is wiped continuously. Beltwasher

to have hinged drop-down splash proof stainless steel

access door. Washer to be fitted interconnected water

pressure reducing valve, water pressure gauge, shutoff

valve and thermostatically controlled mixing valve with

check valves. Bottom of beltwasher to have 1 1/2" drain with

tailpiece and two removable stainless steel perforated scrap

basket. Beltwasher piping to be complete with approved

type vacuum breaker and check valve. All piping exposed to

view to be chrome plated.

R

(for conveyor over 24 feet long, add the following paragraph)

Auxiliary drain to be provided near start end of conveyor

to obtain proper pitch of drain pan.

(for conveyor with a turn, add the following paragraph)

Conveyor to be of configuration as shown on plan.

Curved section to have positive hold-down tracks made of

non-metallic material at least 1/2" thick with built-in solid

lubricant for continuous lubrication of conveyor belt.

Materials which transmit heat due to high friction and

resistance are not acceptable. Belt capable of movement

through a turn of 22" (standard) radius to the center of the

conveyor belt. (Other radii available upon request.)

Model with turn should be specified

where building limitations or

obstacles prohibit the use of a

straight conveyor. May be specified

in L-shaped, U-shaped, serpentine

or practically any shape.Can't go

straight:

Specify Model TM-10 with turns

SPECIFICATIONS:

Series TM-10 Tray Make-Up Conveyor to be as

manufactured by Caddy Corporation, of length as indicated

on plan and for trays up to 17 1/2" wide. Conveyor to be U.L.

and N.S.F. listed with labels affixed.

Conveyor belt to consist of a stainless steel chain having

approximately 3/4" pitch with 10" wide snap-on slats. Slats

to have tapered edges on all sides and molded with integral

hold-down tabs. Slats of low friction polycarbonate

compound replaceable without the use of special tools and

disassembling of belt chain. Slats not to overlap in any

position to provide effective access of cleaning agents to all

parts of the assembled belt and conveyor bed. Start end to

be provided with 12" long tray rest. Discharge end to have

24" long tray pickup area, with limit switch activated by

stainless steel lever protruding through slot in belt bed. All

bearings to be heavy duty ball type, with sealed lubrication.

Caddy-veyor bed to be constructed of 14 gauge

stainless steel Type 304 with all edges turned down into 2"

wide channels. Top of bed at longitudinal edges to be raised.

All joints to be continuously welded, ground and polished.

Between the drive and tail ends, unit to have 3 1/2" wide

stainless steel channel bracing on approximately 5'-0"

centers. Conveyor to be provided with stainless steel catch

pan running the full length and pitched to beltwasher.

Conveyor to be enclosed on both sides by full length

skirting approximately 12" high consisting of removable 18

gauge stainless steel panels to provide full access.

Drive housing to consist of 18 gauge stainless steel

enclosure on two sides with removable rear panel and

opposite hinged access door with full height pull. Housing to

set on 6 1/2" high adjustable stainless steel feet. Balance of

conveyor to be supported by 1 5/8" O.D. stainless steel legs

with adjustable stainless steel feet and welded 1" O.D.

stainless steel lateral and longitudinal braces. Conveyor to

be chain driven by variable speed motor with range of belt

speed 0 to 40 feet per minute rated for 120/208/60/3 phase,

4 wire plus separate ground.

Motor to be controlled manually through an on/off push

button switch and automatically through a limit switch, both

located at discharge end. All wired to splash proof SCR

controller with low voltage and overload protection. All

electrical components above, as well as the motor to be

conveniently located in drive enclosure and to be completely

inter wired through waterproof flexible and conduit and

splash proof circuit connectors.

Caddy-veyor to be furnished with a recessed stainless

steel wireway and electric outlets with hinged moisture proof

covers for adjoining mobile equipment on both sides, all as

Fresh Water Beltwasher:

08/07

CADDY Food Service Systems

509 Sharptown Road P.O. Box 345

Bridgeport, NJ 08014-0345

Tel: 856-467-4222 Fax: 856-467-5511

internet: www.caddycorp.com

CADDY CORPORATION

Page 13

D

CB

A

NOMINAL LENGTH

2'-0" 3'-0"

2'-10"

1'-0"

1'-10 1/4"

1'-0"

1'-6 1/4"

2" 2"

NOTE: ALL ROUGH-INS TO BE 4"AFF

DESCRIPTION

ROUGH-IN SCHEDULE

1 1/2" I.P.S. WASTE

SYM

A

QTY

1

1/2" I.P.S. HOT WATER

B

1

1/2" I.P.S. COLD WATER

C

1

ELECTRICAL CONNECTION

D

1

PROJECT:

ITEM NO:

LOCATION:

page 2 of 2

All specifications subject to change without notice

TRAY MAKE-UP CADDY-VEYOR

TM-10 SERIES

R

(Continue specifications, indicating applicable service)

Automatic Water Saver Control for

Fresh Water Beltwasher

Operation of beltwasher to be controlled by solenoid valve

integrally wired to on/off switch of conveyor to provide

automatic operation of beltwasher while conveyor is running.

A separate on/off switch to be provided to permit operation

of conveyor without beltwasher.

Beltwasher with Recirculating Water

Provide a welded 16 gauge stainless steel beltwasher

Model BWR with top and bottom fan shaped sprays

arranged so lukewarm water thoroughly washes all belt

surfaces after which belt is wiped continuously. Beltwasher

to have hinged drop-down splash proof stainless steel

access door. Washer to be fitted interconnected water

pressure reducing valve, water pressure gauge, shutoff

valve and thermostatically controlled mixing valve with

check valves. Bottom of beltwasher to have two removable

stainless steel perforated scrap basket and 1 1/2" drain with

tailpiece and removable constant overflow standpipe to

maintain water level. A pump to be provided to recirculate

water from reservoir through spray nozzles. Recirculating

system to include a removable filter to facilitate cleaning.

Operation of beltwasher is continuous. A separate on/off

switch to be provided to permit operation of conveyor

without beltwasher. All piping exposed to view to be chrome

plated.

Optional Features:

Timed Belt Washing Cycle

Beltwasher to be controlled by automatic timer activated by

a push button switch inside beltwasher housing in such a

manner that the conveyor and beltwasher will operate

without interruption for an adjustable cycle of up to 16

minutes. After completion of wash cycle the conveyor is

ready for the next start-up.

(Recommended for reduction of water consumption and / or in

conjunction with detergent injection.)

(for clean-up operations.)

Detergent Injector

A siphon type detergent injector working in conjunction with

the beltwasher water supply is to be furnished.

(Select for maximum sanitation. Recirculating beltwasher

optional feature is recommended with this option.)

Removable Work and Storage Shelf

Work and storage shelf to be Model ACC-2010 made of 16

gauge stainless steel flanged up at rear and both sides.

Shelf is supported by stainless steel tubular leg with an

adjustable stainless steel bullet foot. Shelf size is 20" x 10".

Rear of shelf to be contoured to fit over and slide along the

curbing of the conveyor and provided with a positive locking

clip to engage the lower edge of the conveyor bed.

Double Overshelf

Double overshelf to be Model ACC-6015 and to set on the

curbing of the conveyor. Two shelves to be 5'-0" long x 15"

wide of 16 gauge stainless steel turned down 1" on all four

sides, supported by splayed legs of 1" O.D. 16 gauge

stainless steel tubing with guides at the bottom to slide to

any convenient location.

PLAN VIEW

ELEVATION VIEW

END VIEW

08/07

CADDY Food Service Systems

509 Sharptown Road P.O. Box 345

Bridgeport, NJ 08014-0345

Tel: 856-467-4222 Fax: 856-467-5511

internet: www.caddycorp.com

CADDY CORPORATION

Page 14

PROJECT:

ITEM NO:

LOCATION:

page 1 of 2

All specifications subject to change without notice

SPECIFICATIONS:

Unit shall be 20 1/4" wide x 34" high and ________ long,

which includes 12" starter section and 24" tray pickup at

discharge end.

Top of 14 gauge stainless steel (with raised sides

including stainless steel drive housing). Unit shall have 2

removable 18 gauge stainless steel panels and a removable

crumb shelf inside housing.

Drive with 1/4 h.p. washdown-type motor, reduction

gear, on/off switch, limit switch with tripper arm interwired in

a NEMA 4 enclosure. Unit shall be overload protected and

U.L. listed stationary or mobile.

Leg assembly of 16 gauge tubular stainless steel

1 5/8" O.D. and 1" O.D. crossbracing completely welded.

R

Traymaster TR-10

Tray Make-Up Conveyor shall

have variable speed 10" wide

self-tracking stainless steel

chain. Chain shall have snap

on/off low friction

polycarbonate slats

removable without the use of

tools. Slats shall not overlap

for ease of cleaning and

sanitation.

GENERAL SPECIFICATIONS:

Servmaster SM-10

Tray Make-Up Conveyor

shall have variable speed 10"

wide X 1/8" thick deep fused

moisture-proof double sided

PVC belt with adjustable

take-up device for tracking.

(Select one)

Stationary Unit

Fitted with adjustable stainless steel bullet feet.

Mobile Unit

Fitted with 5" diameter polyurethane tired casters, two with

brakes. Conveyor shall have 6'-0" long power cord.

Provide a recessed stainless steel wireway and electric

outlets with hinged moistureproof covers for adjoining mobile

equipment on both sides. Outlets wired to one or more

circuit breaker panel(s) as determined by application with

each receptacle having its own circuit breaker control with

manual reset feature and shutoff. All electrical work to be

ready for single final connection by others to each circuit

breaker panel at job site.

Specify number of outlets, as well as voltage, phase,

wattage or motor size and location for each electrical plug-in

outlet required. Preferred input voltage is 120/208v, 3ph, 5

wire system including ground.

*IMPORTANT NOTE ON ELECTRICAL DATA*

Maximum allowable amperage for mobile tray make-up

conveyor is 100 amps 3 phase. If total amperage exceeds

100 amp, 3 phase, a second circuit breaker panel will be

require. A separate electric connection is needed in the field

for EACH circuit breaker panel on the conveyor.

Optional Features:

Wireway with Factory Installed Electric Outlets

Work and storage shelf to be Model ACC-2010 made of 16

gauge stainless steel flanged up at rear and both sides.

Shelf supported by stainless steel tubular leg with adjustable

stainless steel bullet foot. Shelf size to be 20" X 10". Rear of

shelf to be contoured to fit over and slide along curbing of

conveyor and provided with positive locking clip to engage

lower edge of conveyor bed.

Removable Work and Storage Shelf for Advance

Make-Up of Soup and Beverages

Double overshelf to be Model ACC-6015 and to set on

curbing of conveyor. to be approximately 5'-0" long with two

shelves 15" wide of 16 gauge stainless steel turned down 1"

on all four sides, supported by splayed legs of 1" O.D. #16

gauge stainless steel tubing with guides at bottom to slide to

any convenient location.

Double Overshelf for Storage of Cookies, Crackers,

Desserts, etc.

TRAY MAKE-UP CADDY-VEYOR

Choice of Polycarbonate Slatted

or Stretchless PVC Belt

FEATURES

xIdeal as banquet or assembly conveyors for tray up to 17"

wide.

EX.: airlines, school lunchrooms or convention centers.

MODEL TR-10

MODEL SM-10

TR-10 belt is low

friction polycarbonate

slatted belt.

PVC belt is stretchless.

Replaces obsolete moisture

absorbing and fraying fabric

and neoprene belts.

PVC belt is FDA approved.

(Continue specifications by selecting stationary or mobile model)

08/07

CADDY Food Service Systems

509 Sharptown Road P.O. Box 345

Bridgeport, NJ 08014-0345

Tel: 856-467-4222 Fax: 856-467-5511

internet: www.caddycorp.com

CADDY CORPORATION

Page 15

ROUGH-IN LOCATION

WITH NO WIREWAY

ROUGH-IN LOCATION

WITH A WIREWAY

NOMINAL LENGTH

2'-0"

2'-10"

11"

1'-8 1/4"

2'-10"

1'-4 1/4"

2" 2"

1'-8 1/4"

2'-10"

1'-4 1/4"

2" 2"

2'-10"

9"

NOMINAL LENGTH

2'-0"

PROJECT:

ITEM NO:

LOCATION:

page 2 of 2

All specifications subject to change without notice

R

Stationay Conveyor

TRAY MAKE-UP CADDY-VEYOR

Choice of Polycarbonate Slatted

or Stretchless PVC Belt

SM-10 ELEVATION VIEW

TR-10 ELEVATION VIEW

SM-10 SECTION

TR-10 SECTION

MODEL TR-10

MODEL SM-10

Sketches shown are for general layout purposes only,

subject to changes without prior notice consistent with latest

design changes. For final dimensional and roughing data,

special drawings applicable to a specific order should be

requested from Caddy Engineering Department.

08/07

CADDY Food Service Systems

509 Sharptown Road P.O. Box 345

Bridgeport, NJ 08014-0345

Tel: 856-467-4222 Fax: 856-467-5511

internet: www.caddycorp.com

CADDY CORPORATION

Page 16

1'-7 1/4"

1'-4 1/4"

1 1/2" 1 1/2"

2'-10" 2'-11 1/4"

PROJECT:

ITEM NO:

LOCATION:

page 1 of 1

All specifications subject to change without notice

R

TRAY MAKE-UP CADDY-VEYOR

NON-POWERED / RCF

FEATURES

xHeavy duty deluxe tray make-up Roller-veyor, will handle

any type trays (flat bottom or irregular bottom).

Non-mechanized, non-powered.

Series RCF Roller tray make-up conveyor to be as

manufactured by Caddy Corporation Unit shall be 19 1/4"

wide x ________ long, and to accommodate trays up to 16"

wide. (Specify dimensions of trays to be used.)

Conveyor bed to have a single row of full width 1 1/4"

O.D. plastic rollers with stainless steel balls in nylon

bearings, spaced on approximately 3" centers with stainless

steel hardware. Conveyor to be provided with 16 gauge

stainless steel bed of welded construction, ground and

polished. Conveyor to be 34" high to top of rollers. Both

longitudinal curbings for conveyor bed to have channeled

edges with 1" turndown and extending 1 1/2" above

the top of the roller. Structural supports to be stainless steel

and welded to underside of conveyor bed. Each end of

conveyor bed to be provided with tray stop and hand lift

access with bed cleanout provision.

Leg assembly of 16 gauge tubular stainless steel

1 5/8" O.D. and 1" O.D. crossbracing completely welded.

Specification:

(Continue specifications by selecting stationary or mobile model)

MODEL RCF

Stationary Unit

Fitted with adjustable stainless steel bullet feet.

Mobile Unit

Fitted with 5" diameter polyurethane tired casters, two with

brakes. Conveyor shall have 6'-0" long power cord.

Provide a recessed stainless steel wireway and electric

outlets with hinged moistureproof covers for adjoining mobile

equipment on both sides. Outlets wired to one or more

circuit breaker panel(s) as determined by application with

each receptacle having its own circuit breaker control with

manual reset feature and shutoff. All electrical work to be

ready for single final connection by others to each circuit

breaker panel at job site.

Specify number of outlets, as well as voltage, phase,

wattage or motor size and location for each electrical plug-in

outlet required. Preferred input voltage is 120/208v, 3ph, 5

wire system including ground.

*IMPORTANT NOTE ON ELECTRICAL DATA*

Maximum allowable amperage for mobile tray make-up

conveyor is 100 amps 3 phase. If total amperage exceeds

100 amp, 3 phase, a second circuit breaker panel will be

require. A separate electric connection is needed in the field

for EACH circuit breaker panel on the conveyor.

Optional Features:

Wireway with Factory Installed Electric Outlets

Work and storage shelf to be Model ACC-2010 made of 16

gauge stainless steel flanged up at rear and both sides.

Shelf supported by stainless steel tubular leg with adjustable

stainless steel bullet foot. Shelf size to be 20" X 10". Rear of

shelf to be contoured to fit over and slide along curbing of

conveyor and provided with positive locking clip to engage

lower edge of conveyor bed.

Removable Work and Storage Shelf for Advance

Make-Up of Soup and Beverages

Double overshelf to be Model ACC-6015 and to set on

curbing of conveyor. to be approximately 5'-0" long with two

shelves 15" wide of 16 gauge stainless steel turned down 1"

on all four sides, supported by splayed legs of 1" O.D. 16

gauge stainless steel tubing with guides at bottom to slide to

any convenient location.

Double Overshelf for Storage of Cookies, Crackers,

Desserts, etc.

Provide single row of full width 1 1/4" O.D. plastic rollers with

stainless steel balls in nylon bearings, spaced at

approximately 3" centers with stainless steel spring loaded

hexagon snap-in shafts.

1 1/4" O.D. Spring Loaded Plastic Rollers

08/07

CADDY Food Service Systems

509 Sharptown Road P.O. Box 345

Bridgeport, NJ 08014-0345

Tel: 856-467-4222 Fax: 856-467-5511

internet: www.caddycorp.com

CADDY CORPORATION

Page 17

1'-7 1/4"

1'-4 1/4"

1 1/2" 1 1/2"

2'-10" 2'-11 1/4"

PROJECT:

ITEM NO:

LOCATION:

page 1 of 1

All specifications subject to change without notice

R

TRAY MAKE-UP CADDY-VEYOR

NON-POWERED / SWF

MODEL SWF

FEATURES

xMost economical non-mechanized, non-powered

Caddy-veyor. Use only for flat bottom trays. (Not used for

trays with irregular bottoms).

Series SWF Skatewheel tray make-up conveyor to be as

manufactured by Caddy Corporation. Unit shall be 19 1/4"

wide x ________ long, and to accommodate flat bottom

trays up to 16" wide. (Specify dimensions of trays to be

used.)

Conveyor bed to have two rows of 1.9" O.D. plastic

skatewheels with stainless steel ball bearings spaced on

approximately 2 1/4" centers and mounted with stainless

steel hardware. Conveyor to be provided with 16 gauge

stainless steel bed of welded construction, ground and

polished. Conveyor to be 34" high to top of skatewheels.

Both longitudinal curbings for conveyor bed to have

channeled edges with 1" turndown and extending 1 1/2"

above the top of the skatewheels. Structural supports to be

stainless steel and welded to underside of conveyor bed.

Each end of conveyor bed to be provided with tray stop and

hand lift access with bed cleanout provision.

Leg assembly of 16 gauge tubular stainless steel 1 5/8"

O.D. and 1" O.D. crossbracing completely welded.

Specification:

(Continue specifications by selecting stationary or mobile model)

Stationary Unit

Fitted with adjustable stainless steel bullet feet.

Mobile Unit

Fitted with 5" diameter polyurethane tired casters, two with

brakes. Conveyor shall have 6'-0" long power cord.

Provide a recessed stainless steel wireway and electric

outlets with hinged moistureproof covers for adjoining mobile

equipment on both sides. Outlets wired to one or more

circuit breaker panel(s) as determined by application with

each receptacle having its own circuit breaker control with

manual reset feature and shutoff. All electrical work to be

ready for single final connection by others to each circuit

breaker panel at job site.

Specify number of outlets, as well as voltage, phase,

wattage or motor size and location for each electrical plug-in

outlet required. Preferred input voltage is 120/208v, 3ph, 5

wire system including ground.

*IMPORTANT NOTE ON ELECTRICAL DATA*

Maximum allowable amperage for mobile tray make-up

conveyor is 100 amps 3 phase. If total amperage exceeds

100 amp, 3 phase, a second circuit breaker panel will be

require. A separate electric connection is needed in the field

for EACH circuit breaker panel on the conveyor.

Optional Features:

Wireway with Factory Installed Electric Outlets

Work and storage shelf to be Model ACC-2010 made of 16

gauge stainless steel flanged up at rear and both sides.

Shelf supported by stainless steel tubular leg with adjustable

stainless steel bullet foot. Shelf size to be 20" X 10". Rear of

shelf to be contoured to fit over and slide along curbing of

conveyor and provided with positive locking clip to engage

lower edge of conveyor bed.

Removable Work and Storage Shelf for Advance

Make-Up of Soup and Beverages

Double overshelf to be Model ACC-6015 and to set on

curbing of conveyor. to be approximately 5'-0" long with two

shelves 15" wide of 16 gauge stainless steel turned down 1"

on all four sides, supported by splayed legs of 1" O.D. 16

gauge stainless steel tubing with guides at bottom to slide to

any convenient location.

Double Overshelf for Storage of Cookies, Crackers,

Desserts, etc.

PRECISION SKATEWHEELS

WITH STAINLESS STEEL

BALL BEARINGS ON 2 1/4"

CENTERS

08/07

CADDY Food Service Systems

509 Sharptown Road P.O. Box 345

Bridgeport, NJ 08014-0345

Tel: 856-467-4222 Fax: 856-467-5511

internet: www.caddycorp.com

CADDY CORPORATION

Page 18

1'-7 1/4"

1'-4 1/4"

1 1/2" 1 1/2"

ADJUSTABLE

FROM

4'-6 1/2" TO

4'-0 1/2"

RCC SWC

1'-7 1/4"

1'-4 1/4"

1 1/2" 1 1/2"

1'-2 1/2"

10 1/2"

PROJECT:

ITEM NO:

LOCATION:

page 1 of 1

All specifications subject to change without notice

R

TRAY MAKE-UP CADDY-VEYOR

CANTILEVERED MOBILE CONVEYOR (RCC/SWC)

TABLE OR HOT FOOD MOUNT CONVEYOR (SKW)

MODEL RCC

FEATURES

x Provides maximum flexibility in the positioning of Roller or

Skatewheel conveyor during serving time in conjunction

with hot food Caddy. Conveyor can be rolled away and

stored with not in use.

Cantilevered support structure of all welded stainless

steel construction with all welds ground smooth and

polished. Base to be formed of two 12 gauge stainless steel

channels fitted with four heavy duty 4" swivel casters, two

with brakes. Uprights to be 1 5/8" O.D. stainless steel tubing.

Support braces of 12 gauge stainless steel welded to

stainless steel to stainless steel sleeves allowing vertical

adjustment of conveyor bed from 14 1/2" to 20 1/2" above

top deck of hot food Caddy.

Conveyor (covered under separate specifications section) to

be bolted to the two cantilever brackets resulting in unitized

mobile assembly. Entire assembly to be:

Specification:

Model SWC

Tray make-up conveyor to be

as manufactured by Caddy

Corporation. Unit shall be 19

1/4" wide x ________ long,

and to accommodate flat

bottom trays up to 16" wide.

(Specify dimensions of trays

to be used.)

Model RCC

Tray make-up conveyor to be

as manufactured by Caddy

Corporation. Unit shall be 19

1/4" wide x ________ long,

and to accommodate trays up

to 16" wide. (Specify

dimensions of trays to be

used.)

(Select one)

MODEL SKW

FEATURES

x Skatewheel conveyor can turn any table or hot food unit

into an efficient system for assembling trays for upto 150

beds.

xMost economical non-mechanized, non-powered

Caddy-veyor. Use only for flat bottom trays. (Not used for

trays with irregular bottoms).

Series SKW Skatewheel tray make-up conveyor to be as

manufactured by Caddy Corporation. Unit shall be 19 1/4"

wide x ________ long, and to accommodate flat bottom

trays up to 16" wide. (Specify dimensions of trays to be

used.)

Conveyor bed to have two rows of 1.9" O.D. plastic

skatewheels with stainless steel ball bearings spaced on

approximately 2 1/4" centers and mounted with stainless

steel hardware. Conveyor to be provided with 16 gauge

stainless steel bed of welded construction, ground and

polished. Conveyor to be 10 1/2" above hot food unt or

table. Both longitudinal curbings for conveyor bed to have

channeled edges with 1" turndown and extending 1 1/2"

above the top of the skatewheels. Structural supports to be

1" x 1/4" stainless steel flat bar with mounting holes and

welded to underside of conveyor bed. Each end of conveyor

bed to be provided with tray stop and hand lift access with

bed cleanout provision.

Specification:

MODEL SWC

08/07

CADDY Food Service Systems

509 Sharptown Road P.O. Box 345

Bridgeport, NJ 08014-0345

Tel: 856-467-4222 Fax: 856-467-5511

internet: www.caddycorp.com

CADDY CORPORATION

Loading...

Loading...