Page 1

CADDY CORPORATION

Air SystemsFood Service Equipment

Commercial Kitchen

Exhaust Systems

Model SHW

Water-Wash Style

Page 2

CADDY CORPORATION

Air SystemsFood Service Equipment

Commercial Kitchen

Exhaust Systems

Model SHW

Wall Mount Style

Page 3

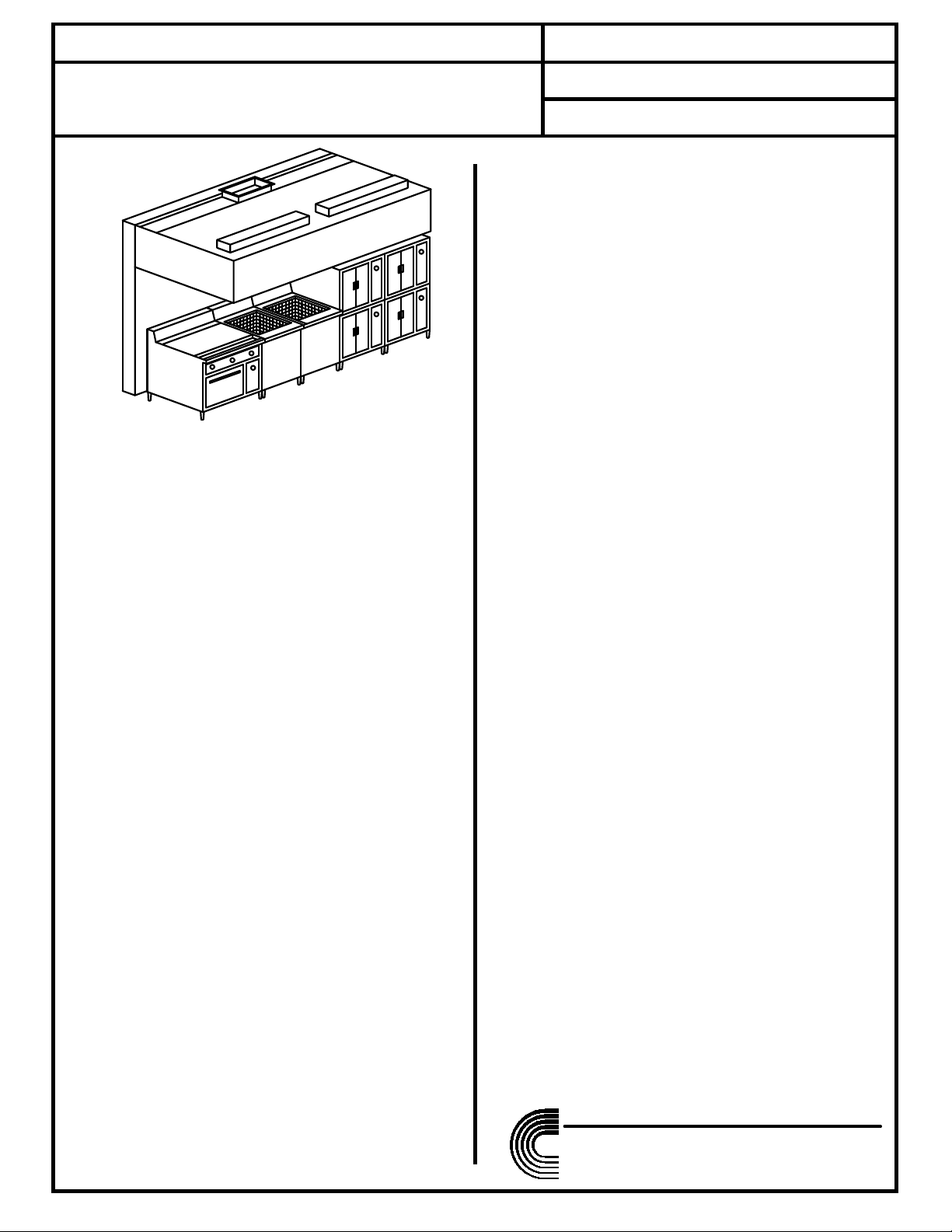

PROJECT:

ITEM NO:

Model SHW-C-W

LOCATION:

General Specifications

Furnish CADDYAirSystems Exhaust Hood Model

SHW-C-W as shown on the plans and as described in the

following specifications.

Description

The CADDYAirSystems0RGHO³6+:³9HQWLODWRULVD

water-wash type and is UL Listed under the standards set

forth in UL 710 "Exhaust Hoods for Commercial Cooking

Equipment". This ventilator is 95% grease extraction

efficient when operated and maintained in accordance with

design specifications. This high efficiency is accomplished

by utilizing a high velocity centrifugal grease extractor, with

the air inlet opening parallel to the cooking equipment it

serves. Each ventilator shall have three full-length horizontal

baffles for centrifugal grease extraction and shall be

equipped with one full-length wash manifold with upper and

lower brass spray nozzles for superior extraction.

Ventilators shall operate at air quantities as illustrated on

plans.

Waterwash Ventilator

General

Exhaust hood shall be constructed of 18 gauge type 300

series stainless steel. All exposed surfaces to have a

number # 4 finish. Construction to meet all requirements of

NFPA 96 and NSF Standard No.2. To include necessary

hanger brackets at front and rear for suspending from

building overhead structure.

Accessibility and Inspection

Full length removable inspection doors shall be provided so

that service can be performed on all interior components.

Automatic Washdown System

Ventilator to be equipped with one full length wash manifold

with spray nozzles for automatic detergent injected wash

XVLQJ)WR)KRWZDWHU3OXPELQJDQGHOHFWULFDO

components for operation of the automatic wash system to

be housed in the CADDYAirSystems0RGHO³&3(³FRQWURO

panel.

Plumbing/Electrical

Ventilators to be factory pre-plumbed and pre-wired to a

single connection point. Ventilators built in multiple sections

to be furnished with unions and junction boxes for field

connections by applicable trades.

Application

Wall mounted exhaust-only canopy style for use over all

types of cooking equipment.

509 Sharptown Road P.O. Box 345

Bridgeport, NJ 08014-0345

Tel: 856-467-4222 Fax: 856-467-5511

internet: www.caddycorp.com

CADDY CORPORATION

CADDY Air Systems

All specifications subject to change without notice

08/07

Light Fixtures

All light fixtures shall be pre-wired to a single connection

point. Ventilators built in multiple sections to be furnished

with junction boxes for ease of field connection by the

electrical trades. Light bulbs furnished and installed by the

Kitchen Equipment Contractor.

Exhaust Fans

Exhaust fans are to be provided and installed by others in

compliance with local codes. Fans should be induced

draft, squirrel cage design, equipped with backward

inclined blades.

Fire Protection

NFPA 96 and local codes require a fire extinguishing system

for protection of the duct collar and plenum of all ventilators,

as well as for the protection of various cooking appliances

such as deep fat fryers, griddles, ranges, and broilers, which

may be a source of ignition of grease. Consult factory and

local fire officials for exact requirements. UL Listed fire

protection systems may be pre-piped by Caddy at the time of

manufacture, assuring concealment of piping and detectors.

Approvals

Ventilator shall be UL Listed, listed by NSF and be in

accordance with all of the recommendations set forth by

NFPA 96. All ventilators must meet all applicable codes.

page 1 of 2

Page 4

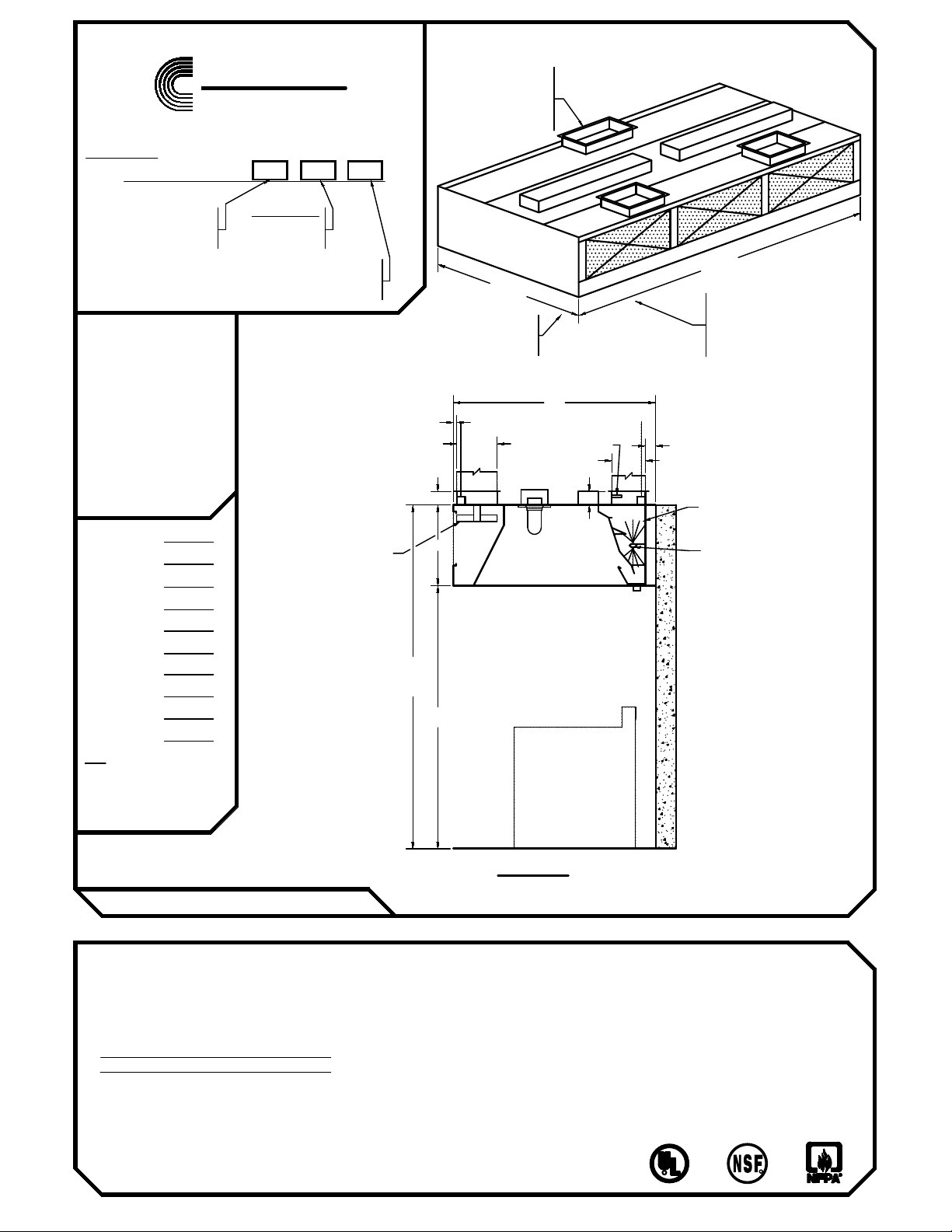

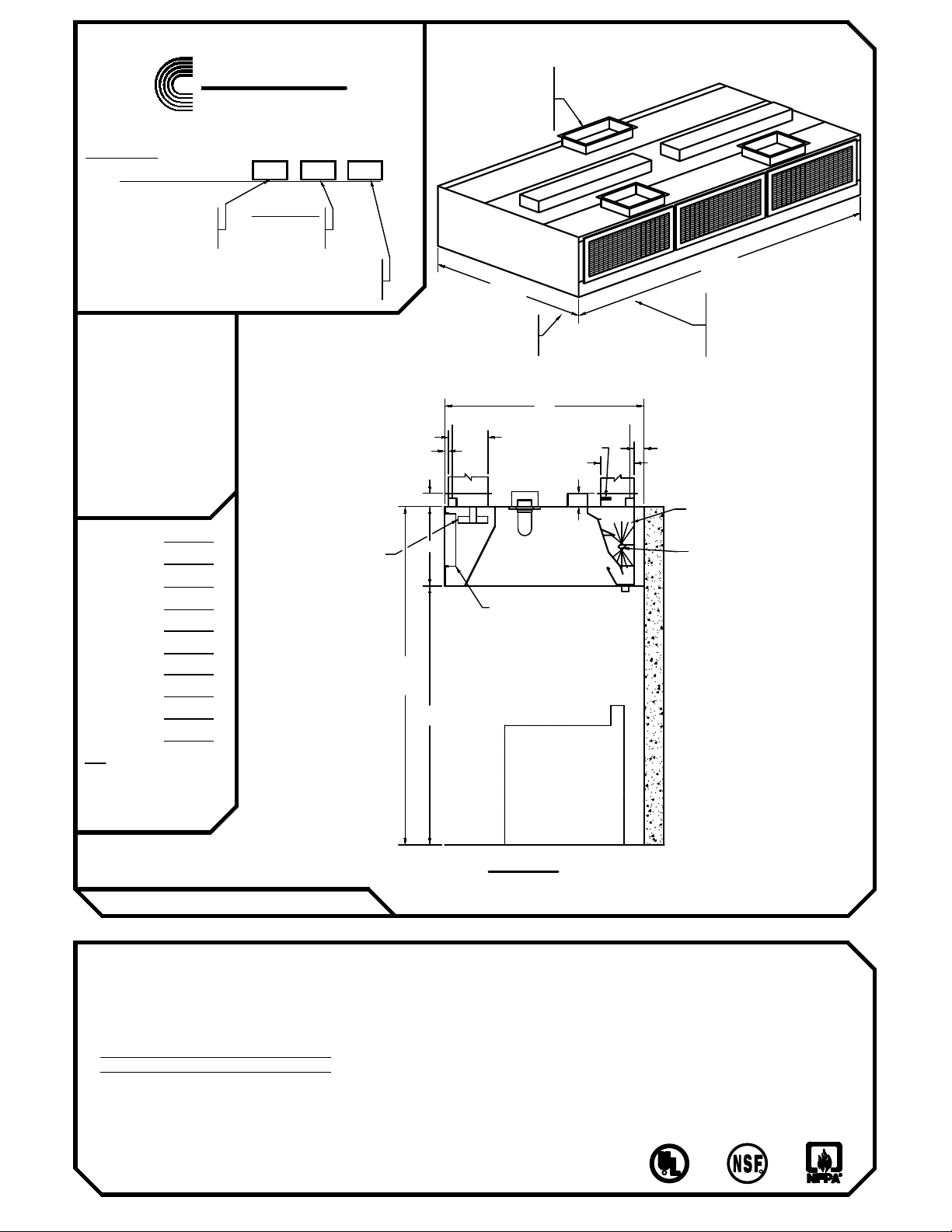

8'-6"

FIN. CLG.

HEIGHT

[ ] VERIFY

6'-6"

A.F.F.

_'-_"

EQUIPMENT

UNDER HOODS

BY K.E.C.

2'-0"

10"

3"

SIMPLEX WATER WASH

TYPE GREASE EXTRACTOR

DUAL ACTION

SPRAY MANIFOLD

4"

FENWAL

THERMOSTAT

SECTION

MODEL:

ENGINEERING DATA

Ventilator Length

Maximum ventilator length in a single section is 14'-0".

For lengths greater than 14'-0", join two or more sections.

Verify access conditions into building and kitchen space

prior to length selection.

Ventilator Hanging Weight

Wt./ lineal ft. Lbs. 90

Electrical Requirements

Provide 120 volt, single phase, 60 hertz, 15 amp (min.) 24 hour service

to CPE control panel (refer to CPE engineering

cut sheet). Control panel to be fused separately. Light fixtures to be

powered by a 120/1/60 circuit.

Mechanical Requirements

The volume of exhaust required is a function of the type of

cooking equipment served by the ventilator, and the type

and volume of product cooked. Refer to the CADDY AirSystems

Master Engineering Data Chart to determine exhaust volume,

duct collar sizes, static pressure drop, water consumption and

ventilator drain sizes.

NOTE: Refer to CADDY AirSystems

Master Engineering Data Sheet in engineering

data section for determining light, medium, and heavy duty cooking

equipment, C.F.M. requirements (exhaust and supply), duct collar

sizes and static pressure requirements.

ADD THE OVERALL

LENGTH (IN INCHES) OF

THE VENTILATOR AFTER

MODEL DESIGNATION

ADD THE OVERALL WIDTH

(IN INCHES) OF THE

VENTILATOR AFTER

MODEL DESIGNATION

DAMPER TYPE

ND - NO DAMPER

FL - FUSIBLE LINK

T - THERMOSTAT

DRAWINGS NOT TO SCALE

SHW-C-W - - -

______X______

DIMENSION VARIES

WITH DEPTH OF THE

EQUIPMENT AND

REQUIRED OVERHANG

EXHAUST DUCT

COLLAR LOCATED

IN CENTER OR AT

ANY POINT ALONG

LENGTH OF THE

PLENUM

14'-0" MAX. UNIT LENGTH. FOR

GREATER LENGTH, JOIN TWO

OR MORE UNITS TOGETHER.

ALLOW 6"MIN. OVERHANG AT

EACH END. IF CHARBROILER

IS AT END, OVERHANG 12"

STANDARD LIGHT FIXTURES

(__) 100 WATT INCANDESCENT

(__) RECESSED INCANDESCENT

(__) RECESSED FLUORESCENT

(IF RECESSED FLUORESCENT

SPECIFY SIZE)

CONSULT FACTORY FOR

NON-STANDARD HEIGHTS

12" MIN. FRONT OVERHANG

6" MIN. SIDE OVERHANG

(12" MIN. SIDE OVERHANG

FOR CHARBROILER)

ITEM #

EST. WEIGHT

LENGTH

WIDTH

HEIGHT

EXHAUST-CFM

DUCT SIZE

S.P.

H.W. INLET SIZE

DRAIN SIZE

GPM @ 40 PSI

:$7(57(03))

NOTE: 5 MIN. WASH CYCLE

PER 24 HR PERIOD

CADDY AirSystems

R

R

CADDY

Air Systems

All specifications subject to change without notice

08/07

Page 5

PROJECT:

ITEM NO:

Model SHW-C-W-PA

LOCATION:

General Specifications

Furnish CADDYAirSystems Exhaust Hood Model

SHW-C-W-PA as shown on the plans and as described in

the following specifications.

Waterwash Ventilator

Make-Up Air (Front Face Discharge)

Ventilator shall have 40% open stainless steel perforated

screens along front face for face discharge of tempered

make-up air. This type of make-up air is the most common

and advantageous method of bringing air into the kitchen via

the kitchen exhaust ventilator. Typically supply volume is

80%, or more depending upon the desired air balance.

6XSSO\DLUWHPSHUDWXUHVKRXOGUDQJHIURP))EXW

PD\EHDVORZDV)GHSHQGLQJRQDLUYROXPH

distribution, internal heat load, and desired ambient room

temperature.

Application

Wall mounted canopy style for use over all types of cooking

equipment where integral make-up air is required.

509 Sharptown Road P.O. Box 345

Bridgeport, NJ 08014-0345

Tel: 856-467-4222 Fax: 856-467-5511

internet: www.caddycorp.com

CADDY CORPORATION

CADDY Air Systems

All specifications subject to change without notice

08/07

Light Fixtures

All light fixtures shall be pre-wired to a single connection

point. Ventilators built in multiple sections to be furnished

with junction boxes for ease of field connection by the

electrical trades. Light bulbs furnished and installed by the

Kitchen Equipment Contractor.

Exhaust Fans

Exhaust fans are to be provided and installed by others in

compliance with local codes. Fans should be induced

draft, squirrel cage design, equipped with backward

inclined blades.

Fire Protection

NFPA 96 and local codes require a fire extinguishing system

for protection of the duct collar and plenum of all ventilators,

as well as for the protection of various cooking appliances

such as deep fat fryers, griddles, ranges, and broilers, which

may be a source of ignition of grease. Consult factory and

local fire officials for exact requirements. UL Listed fire

protection systems may be pre-piped by Caddy at the time of

manufacture, assuring concealment of piping and detectors.

Approvals

Ventilator shall be UL Listed, listed by NSF and be in

accordance with all of the recommendations set forth by

NFPA 96. All ventilators must meet all applicable codes.

Description

The CADDYAirSystems0RGHO³6+:³9HQWLODWRULVD

water-wash type and is UL Listed under the standards set

forth in UL 710 "Exhaust Hoods for Commercial Cooking

Equipment". This ventilator is 95% grease extraction

efficient when operated and maintained in accordance with

design specifications. This high efficiency is accomplished

by utilizing a high velocity centrifugal grease extractor, with

the air inlet opening parallel to the cooking equipment it

serves. Each ventilator shall have three full-length horizontal

baffles for centrifugal grease extraction and shall be

equipped with one full-length wash manifold with upper and

lower brass spray nozzles for superior extraction.

Ventilators shall operate at air quantities as illustrated on

plans.

General

Exhaust hood shall be constructed of 18 gauge type 300

series stainless steel. All exposed surfaces to have a

number # 4 finish. Construction to meet all requirements of

NFPA 96 and NSF Standard No.2. To include necessary

hanger brackets at front and rear for suspending from

building overhead structure.

Accessibility and Inspection

Full length removable inspection doors shall be provided so

that service can be performed on all interior components.

Automatic Washdown System

Ventilator to be equipped with one full length wash manifold

with spray nozzles for automatic detergent injected wash

XVLQJ)WR)KRWZDWHU3OXPELQJDQGHOHFWULFDO

components for operation of the automatic wash system to

be housed in the CADDYAirSystems0RGHO³&3(³FRQWURO

panel.

Plumbing/Electrical

Ventilators to be factory pre-plumbed and pre-wired to a

single connection point. Ventilators built in multiple sections

to be furnished with unions and junction boxes for field

connections by applicable trades.

page 1 of 2

Page 6

8'-6"

FIN. CLG.

HEIGHT

[ ] VERIFY

6'-6"

A.F.F.

_'-_"

EQUIPMENT

UNDER HOODS

BY K.E.C.

2'-0"

40% OPEN STN./STL.

PERFORATED DIFFUSER

1"

4"

1'-0"

10"

3"

SIMPLEX WATER WASH

TYPE GREASE EXTRACTOR

DUAL ACTION

SPRAY MANIFOLD

4"

FENWAL

THERMOSTAT

SECTION

MODEL:

ADD THE OVERALL

LENGTH (IN INCHES) OF

THE VENTILATOR AFTER

MODEL DESIGNATION

ADD THE OVERALL WIDTH

(IN INCHES) OF THE

VENTILATOR AFTER

MODEL DESIGNATION

DAMPER TYPE

ND - NO DAMPER

FL - FUSIBLE LINK

T - THERMOSTAT

DRAWINGS NOT TO SCALE

SHW-C-W-PA- - -

______X______

DIMENSION VARIES

WITH DEPTH OF THE

EQUIPMENT AND

REQUIRED OVERHANG

EXHAUST DUCT

COLLAR LOCATED

IN CENTER OR AT

ANY POINT ALONG

LENGTH OF THE

PLENUM

14'-0" MAX. UNIT LENGTH. FOR

GREATER LENGTH, JOIN TWO

OR MORE UNITS TOGETHER.

ALLOW 6"MIN. OVERHANG AT

EACH END. IF CHARBROILER

IS AT END, OVERHANG 12"

ENGINEERING DATA

Ventilator Length

Maximum ventilator length in a single section is 14'-0".

For lengths greater than 14'-0", join two or more sections.

Verify access conditions into building and kitchen space

prior to length selection.

Ventilator Hanging Weight

Wt./ lineal ft. Lbs. 105

Electrical Requirements

Provide 120 volt, single phase, 60 hertz, 15 amp (min.) 24 hour service

to CPE control panel (refer to CPE engineering

cut sheet). Control panel to be fused separately. Light fixtures to be

powered by a 120/1/60 circuit.

Mechanical Requirements

The volume of exhaust required is a function of the type of

cooking equipment served by the ventilator, and the type

and volume of product cooked. Refer to the CADDY AirSystems

Master Engineering Data Chart to determine exhaust volume,

duct collar sizes, static pressure drop, water consumption and

ventilator drain sizes.

NOTE: Refer to CADDY AirSystems

Master Engineering Data Sheet in engineering

data section for determining light, medium, and heavy duty cooking

equipment, C.F.M. requirements (exhaust and supply), duct collar

sizes and static pressure requirements.

STANDARD LIGHT FIXTURES

(__) 100 WATT INCANDESCENT

(__) RECESSED INCANDESCENT

(__) RECESSED FLUORESCENT

(IF RECESSED FLUORESCENT

SPECIFY SIZE)

CONSULT FACTORY FOR

NON-STANDARD HEIGHTS

12" MIN. FRONT OVERHANG

6" MIN. SIDE OVERHANG

(12" MIN. SIDE OVERHANG

FOR CHARBROILER)

ITEM #

EST. WEIGHT

LENGTH

WIDTH

HEIGHT

EXHAUST-CFM

DUCT SIZE

S.P.

H.W. INLET SIZE

DRAIN SIZE

GPM @ 40 PSI

:$7(57(03))

NOTE: 5 MIN. WASH CYCLE

PER 24 HR PERIOD

CADDY AirSystems

R

R

CADDY

Air Systems

All specifications subject to change without notice

08/07

Page 7

PROJECT:

ITEM NO:

Model SHW-C-W-ASI

LOCATION:

General Specifications

Furnish CADDYAirSystems Exhaust Hood Model

SHW-C-W-ASI as shown on the plans and as described in

the following specifications.

Waterwash Ventilator

Make-Up Air (Internal Discharge)

Ventilator shall have a fully insulated supply plenum, with

duct collar/fire damper assemblies, and air registers

internally mounted for discharging untempered make-up air

directly into canopy of ventilator. The amount of make-up air

supplied through this design is directly related to the type of

cooking equipment located beneath the hood. The

percentage of supply air distributed will vary as a function of

the thermal currents generated by each individual appliance.

When specifying this style, consult factory for specific supply

volumes. This air may be untempered in most areas,

depending upon climatic conditions and the type of cooking

HTXLSPHQW,IWKHGHVLJQWHPSHUDWXUHLVEHORZ)FRQVXOW

factory for supply volumes and design considerations.

Application

Wall mounted canopy style for use over all types of cooking

equipment where integral make-up air is required.

509 Sharptown Road P.O. Box 345

Bridgeport, NJ 08014-0345

Tel: 856-467-4222 Fax: 856-467-5511

internet: www.caddycorp.com

CADDY CORPORATION

CADDY Air Systems

All specifications subject to change without notice

08/07

Light Fixtures

All light fixtures shall be pre-wired to a single connection

point. Ventilators built in multiple sections to be furnished

with junction boxes for ease of field connection by the

electrical trades. Light bulbs furnished and installed by the

Kitchen Equipment Contractor.

Exhaust Fans

Exhaust fans are to be provided and installed by others in

compliance with local codes. Fans should be induced

draft, squirrel cage design, equipped with backward

inclined blades.

Fire Protection

NFPA 96 and local codes require a fire extinguishing system

for protection of the duct collar and plenum of all ventilators,

as well as for the protection of various cooking appliances

such as deep fat fryers, griddles, ranges, and broilers, which

may be a source of ignition of grease. Consult factory and

local fire officials for exact requirements. UL Listed fire

protection systems may be pre-piped by Caddy at the time of

manufacture, assuring concealment of piping and detectors.

Approvals

Ventilator shall be UL Listed, listed by NSF and be in

accordance with all of the recommendations set forth by

NFPA 96. All ventilators must meet all applicable codes.

Description

The CADDYAirSystems0RGHO³6+:³9HQWLODWRULVD

water-wash type and is UL Listed under the standards set

forth in UL 710 "Exhaust Hoods for Commercial Cooking

Equipment". This ventilator is 95% grease extraction

efficient when operated and maintained in accordance with

design specifications. This high efficiency is accomplished

by utilizing a high velocity centrifugal grease extractor, with

the air inlet opening parallel to the cooking equipment it

serves. Each ventilator shall have three full-length horizontal

baffles for centrifugal grease extraction and shall be

equipped with one full-length wash manifold with upper and

lower brass spray nozzles for superior extraction.

Ventilators shall operate at air quantities as illustrated on

plans.

General

Exhaust hood shall be constructed of 18 gauge type 300

series stainless steel. All exposed surfaces to have a

number # 4 finish. Construction to meet all requirements of

NFPA 96 and NSF Standard No.2. To include necessary

hanger brackets at front and rear for suspending from

building overhead structure.

Accessibility and Inspection

Full length removable inspection doors shall be provided so

that service can be performed on all interior components.

Automatic Washdown System

Ventilator to be equipped with one full length wash manifold

with spray nozzles for automatic detergent injected wash

XVLQJ)WR)KRWZDWHU3OXPELQJDQGHOHFWULFDO

components for operation of the automatic wash system to

be housed in the CADDYAirSystems0RGHO³&3(³FRQWURO

panel.

Plumbing/Electrical

Ventilators to be factory pre-plumbed and pre-wired to a

single connection point. Ventilators built in multiple sections

to be furnished with unions and junction boxes for field

connections by applicable trades.

page 1 of 2

Page 8

8'-6"

FIN. CLG.

HEIGHT

[ ] VERIFY

6'-6"

A.F.F.

_'-_"

EQUIPMENT

UNDER HOODS

BY K.E.C.

2'-0" ACCESS

PANEL

AIR REGISTER(S)

40% OPEN STN./STL.

PERFORATED DIFFUSER

UL 555 CLASSIFIED

FIRE DAMPER

))86,%/(/,1.

1"

1'-0"

4"

10"

3"

SIMPLEX WATER WASH

TYPE GREASE EXTRACTOR

DUAL ACTION

SPRAY MANIFOLD

4"

FENWAL

THERMOSTAT

SECTION

MODEL:

ADD THE OVERALL

LENGTH (IN INCHES) OF

THE VENTILATOR AFTER

MODEL DESIGNATION

ADD THE OVERALL WIDTH

(IN INCHES) OF THE

VENTILATOR AFTER

MODEL DESIGNATION

DAMPER TYPE

ND - NO DAMPER

FL - FUSIBLE LINK

T - THERMOSTAT

DRAWINGS NOT TO SCALE

SHW-C-W-ASI- - -

______X______

DIMENSION VARIES

WITH DEPTH OF THE

EQUIPMENT AND

REQUIRED OVERHANG

EXHAUST DUCT

COLLAR LOCATED

IN CENTER OR AT

ANY POINT ALONG

LENGTH OF THE

PLENUM

14'-0" MAX. UNIT LENGTH. FOR

GREATER LENGTH, JOIN TWO

OR MORE UNITS TOGETHER.

ALLOW 6"MIN. OVERHANG AT

EACH END. IF CHARBROILER

IS AT END, OVERHANG 12"

ENGINEERING DATA

Ventilator Length

Maximum ventilator length in a single section is 14'-0".

For lengths greater than 14'-0", join two or more sections.

Verify access conditions into building and kitchen space

prior to length selection.

Ventilator Hanging Weight

Wt./ lineal ft. Lbs. 105

Electrical Requirements

Provide 120 volt, single phase, 60 hertz, 15 amp (min.) 24 hour service

to CPE control panel (refer to CPE engineering

cut sheet). Control panel to be fused separately. Light fixtures to be

powered by a 120/1/60 circuit.

Mechanical Requirements

The volume of exhaust required is a function of the type of

cooking equipment served by the ventilator, and the type

and volume of product cooked. Refer to the CADDY AirSystems

Master Engineering Data Chart to determine exhaust volume,

duct collar sizes, static pressure drop, water consumption and

ventilator drain sizes.

NOTE: Refer to CADDY AirSystems

Master Engineering Data Sheet in engineering

data section for determining light, medium, and heavy duty cooking

equipment, C.F.M. requirements (exhaust and supply), duct collar

sizes and static pressure requirements.

STANDARD LIGHT FIXTURES

(__) 100 WATT INCANDESCENT

(__) RECESSED INCANDESCENT

(__) RECESSED FLUORESCENT

(IF RECESSED FLUORESCENT

SPECIFY SIZE)

CONSULT FACTORY FOR

NON-STANDARD HEIGHTS

22" MIN. FRONT OVERHANG

6" MIN. SIDE OVERHANG

(12" MIN. SIDE OVERHANG

FOR CHARBROILER)

ITEM #

EST. WEIGHT

LENGTH

WIDTH

HEIGHT

EXHAUST-CFM

DUCT SIZE

S.P.

H.W. INLET SIZE

DRAIN SIZE

GPM @ 40 PSI

:$7(57(03))

NOTE: 5 MIN. WASH CYCLE

PER 24 HR PERIOD

CADDY AirSystems

R

R

CADDY

Air Systems

All specifications subject to change without notice

08/07

Page 9

PROJECT:

ITEM NO:

Model SHW-C-W-AA

LOCATION:

General Specifications

Furnish CADDYAirSystems Exhaust Hood Model

SHW-C-W-AA as shown on the plans and as described in

the following specifications.

Waterwash Ventilator

Make-Up Air (Front Face Discharge)

Ventilator shall have air registers along front face for face

discharge of tempered make-up air. This type of make-up air

is the most common and advantageous method of bringing

air into the kitchen via the kitchen exhaust ventilator.

Typically supply volume is 80%, or more depending upon the

desired air balance. Supply air temperature should range

IURP))EXWPD\EHDVORZDV)GHSHQGLQJRQ

air volume, distribution, internal heat load, and desired

ambient room temperature.

Application

Wall mounted canopy style for use over all types of cooking

equipment where integral make-up air is required.

509 Sharptown Road P.O. Box 345

Bridgeport, NJ 08014-0345

Tel: 856-467-4222 Fax: 856-467-5511

internet: www.caddycorp.com

CADDY CORPORATION

CADDY Air Systems

All specifications subject to change without notice

08/07

Light Fixtures

All light fixtures shall be pre-wired to a single connection

point. Ventilators built in multiple sections to be furnished

with junction boxes for ease of field connection by the

electrical trades. Light bulbs furnished and installed by the

Kitchen Equipment Contractor.

Exhaust Fans

Exhaust fans are to be provided and installed by others in

compliance with local codes. Fans should be induced

draft, squirrel cage design, equipped with backward

inclined blades.

Fire Protection

NFPA 96 and local codes require a fire extinguishing system

for protection of the duct collar and plenum of all ventilators,

as well as for the protection of various cooking appliances

such as deep fat fryers, griddles, ranges, and broilers, which

may be a source of ignition of grease. Consult factory and

local fire officials for exact requirements. UL Listed fire

protection systems may be pre-piped by Caddy at the time of

manufacture, assuring concealment of piping and detectors.

Approvals

Ventilator shall be UL Listed, listed by NSF and be in

accordance with all of the recommendations set forth by

NFPA 96. All ventilators must meet all applicable codes.

Description

The CADDYAirSystems0RGHO³6+:³9HQWLODWRULVD

water-wash type and is UL Listed under the standards set

forth in UL 710 "Exhaust Hoods for Commercial Cooking

Equipment". This ventilator is 95% grease extraction

efficient when operated and maintained in accordance with

design specifications. This high efficiency is accomplished

by utilizing a high velocity centrifugal grease extractor, with

the air inlet opening parallel to the cooking equipment it

serves. Each ventilator shall have three full-length horizontal

baffles for centrifugal grease extraction and shall be

equipped with one full-length wash manifold with upper and

lower brass spray nozzles for superior extraction.

Ventilators shall operate at air quantities as illustrated on

plans.

General

Exhaust hood shall be constructed of 18 gauge type 300

series stainless steel. All exposed surfaces to have a

number # 4 finish. Construction to meet all requirements of

NFPA 96 and NSF Standard No.2. To include necessary

hanger brackets at front and rear for suspending from

building overhead structure.

Accessibility and Inspection

Full length removable inspection doors shall be provided so

that service can be performed on all interior components.

Automatic Washdown System

Ventilator to be equipped with one full length wash manifold

with spray nozzles for automatic detergent injected wash

XVLQJ)WR)KRWZDWHU3OXPELQJDQGHOHFWULFDO

components for operation of the automatic wash system to

be housed in the CADDYAirSystems0RGHO³&3(³FRQWURO

panel.

Plumbing/Electrical

Ventilators to be factory pre-plumbed and pre-wired to a

single connection point. Ventilators built in multiple sections

to be furnished with unions and junction boxes for field

connections by applicable trades.

page 1 of 2

Page 10

8'-6"

FIN. CLG.

HEIGHT

[ ] VERIFY

6'-6"

A.F.F.

_'-_"

EQUIPMENT

UNDER HOODS

BY K.E.C.

2'-0"

1'-0"

AIR REGISTER(S)

4"

1"

40% OPEN STN./STL.

PERFORATED DIFFUSER

10"

3"

SIMPLEX WATER WASH

TYPE GREASE EXTRACTOR

DUAL ACTION

SPRAY MANIFOLD

4"

FENWAL

THERMOSTAT

SECTION

MODEL:

ADD THE OVERALL

LENGTH (IN INCHES) OF

THE VENTILATOR AFTER

MODEL DESIGNATION

ADD THE OVERALL WIDTH

(IN INCHES) OF THE

VENTILATOR AFTER

MODEL DESIGNATION

DAMPER TYPE

ND - NO DAMPER

FL - FUSIBLE LINK

T - THERMOSTAT

DRAWINGS NOT TO SCALE

SHW-C-W-AA- - -

______X______

DIMENSION VARIES

WITH DEPTH OF THE

EQUIPMENT AND

REQUIRED OVERHANG

EXHAUST DUCT

COLLAR LOCATED

IN CENTER OR AT

ANY POINT ALONG

LENGTH OF THE

PLENUM

14'-0" MAX. UNIT LENGTH. FOR

GREATER LENGTH, JOIN TWO

OR MORE UNITS TOGETHER.

ALLOW 6"MIN. OVERHANG AT

EACH END. IF CHARBROILER

IS AT END, OVERHANG 12"

ENGINEERING DATA

Ventilator Length

Maximum ventilator length in a single section is 14'-0".

For lengths greater than 14'-0", join two or more sections.

Verify access conditions into building and kitchen space

prior to length selection.

Ventilator Hanging Weight

Wt./ lineal ft. Lbs. 105

Electrical Requirements

Provide 120 volt, single phase, 60 hertz, 15 amp (min.) 24 hour service

to CPE control panel (refer to CPE engineering

cut sheet). Control panel to be fused separately. Light fixtures to be

powered by a 120/1/60 circuit.

Mechanical Requirements

The volume of exhaust required is a function of the type of

cooking equipment served by the ventilator, and the type

and volume of product cooked. Refer to the CADDY AirSystems

Master Engineering Data Chart to determine exhaust volume,

duct collar sizes, static pressure drop, water consumption and

ventilator drain sizes.

NOTE: Refer to CADDY AirSystems

Master Engineering Data Sheet in engineering

data section for determining light, medium, and heavy duty cooking

equipment, C.F.M. requirements (exhaust and supply), duct collar

sizes and static pressure requirements.

STANDARD LIGHT FIXTURES

(__) 100 WATT INCANDESCENT

(__) RECESSED INCANDESCENT

(__) RECESSED FLUORESCENT

(IF RECESSED FLUORESCENT

SPECIFY SIZE)

CONSULT FACTORY FOR

NON-STANDARD HEIGHTS

12" MIN. FRONT OVERHANG

6" MIN. SIDE OVERHANG

(12" MIN. SIDE OVERHANG

FOR CHARBROILER)

ITEM #

EST. WEIGHT

LENGTH

WIDTH

HEIGHT

EXHAUST-CFM

DUCT SIZE

S.P.

H.W. INLET SIZE

DRAIN SIZE

GPM @ 40 PSI

:$7(57(03))

NOTE: 5 MIN. WASH CYCLE

PER 24 HR PERIOD

CADDY AirSystems

R

R

CADDY

Air Systems

All specifications subject to change without notice

08/07

Page 11

PROJECT:

ITEM NO:

Model SHW-C-W-ASII

LOCATION:

General Specifications

Furnish CADDYAirSystems Exhaust Hood Model

SHW-C-W-ASII as shown on the plans and as described in

the following specifications.

Waterwash Ventilator

Make-Up Air (Perimeter Down Discharge)

Up to 80% of the exhaust air may be supplied through this

down discharge system. However, the air must be tempered

WRDPLQLPXPRI)WRDYRLGGLVFRPIRUWWRRSHUDWLRQV

personnel.

Application

Wall mounted canopy style for use over all types of cooking

equipment where integral make-up air is required.

509 Sharptown Road P.O. Box 345

Bridgeport, NJ 08014-0345

Tel: 856-467-4222 Fax: 856-467-5511

internet: www.caddycorp.com

CADDY CORPORATION

CADDY Air Systems

All specifications subject to change without notice

08/07

Light Fixtures

All light fixtures shall be pre-wired to a single connection

point. Ventilators built in multiple sections to be furnished

with junction boxes for ease of field connection by the

electrical trades. Light bulbs furnished and installed by the

Kitchen Equipment Contractor.

Exhaust Fans

Exhaust fans are to be provided and installed by others in

compliance with local codes. Fans should be induced

draft, squirrel cage design, equipped with backward

inclined blades.

Fire Protection

NFPA 96 and local codes require a fire extinguishing system

for protection of the duct collar and plenum of all ventilators,

as well as for the protection of various cooking appliances

such as deep fat fryers, griddles, ranges, and broilers, which

may be a source of ignition of grease. Consult factory and

local fire officials for exact requirements. UL Listed fire

protection systems may be pre-piped by Caddy at the time of

manufacture, assuring concealment of piping and detectors.

Approvals

Ventilator shall be UL Listed, listed by NSF and be in

accordance with all of the recommendations set forth by

NFPA 96. All ventilators must meet all applicable codes.

Description

The CADDYAirSystems0RGHO³6+:³9HQWLODWRULVD

water-wash type and is UL Listed under the standards set

forth in UL 710 "Exhaust Hoods for Commercial Cooking

Equipment". This ventilator is 95% grease extraction

efficient when operated and maintained in accordance with

design specifications. This high efficiency is accomplished

by utilizing a high velocity centrifugal grease extractor, with

the air inlet opening parallel to the cooking equipment it

serves. Each ventilator shall have three full-length horizontal

baffles for centrifugal grease extraction and shall be

equipped with one full-length wash manifold with upper and

lower brass spray nozzles for superior extraction.

Ventilators shall operate at air quantities as illustrated on

plans.

General

Exhaust hood shall be constructed of 18 gauge type 300

series stainless steel. All exposed surfaces to have a

number # 4 finish. Construction to meet all requirements of

NFPA 96 and NSF Standard No.2. To include necessary

hanger brackets at front and rear for suspending from

building overhead structure.

Accessibility and Inspection

Full length removable inspection doors shall be provided so

that service can be performed on all interior components.

Automatic Washdown System

Ventilator to be equipped with one full length wash manifold

with spray nozzles for automatic detergent injected wash

XVLQJ)WR)KRWZDWHU3OXPELQJDQGHOHFWULFDO

components for operation of the automatic wash system to

be housed in the CADDYAirSystems0RGHO³&3(³FRQWURO

panel.

Plumbing/Electrical

Ventilators to be factory pre-plumbed and pre-wired to a

single connection point. Ventilators built in multiple sections

to be furnished with unions and junction boxes for field

connections by applicable trades.

page 1 of 2

page 1 of 2

Page 12

8'-6"

FIN. CLG.

HEIGHT

[ ] VERIFY

6'-6"

A.F.F.

_'-_"

EQUIPMENT

UNDER HOODS

BY K.E.C.

2'-0"

AIR REGISTER(S)

4"

UL 555 CLASSIFIED

FIRE DAMPER

))86,%/(/,1.

1'-0"

1"

40% OPEN STN./STL.

PERFORATED DIFFUSER

10"

3"

SIMPLEX WATER WASH

TYPE GREASE EXTRACTOR

DUAL ACTION

SPRAY MANIFOLD

4"

FENWAL

THERMOSTAT

SECTION

MODEL:

ADD THE OVERALL

LENGTH (IN INCHES) OF

THE VENTILATOR AFTER

MODEL DESIGNATION

ADD THE OVERALL WIDTH

(IN INCHES) OF THE

VENTILATOR AFTER

MODEL DESIGNATION

DAMPER TYPE

ND - NO DAMPER

FL - FUSIBLE LINK

T - THERMOSTAT

DRAWINGS NOT TO SCALE

SHW-C-W-ASII- - -

______X______

DIMENSION VARIES

WITH DEPTH OF THE

EQUIPMENT AND

REQUIRED OVERHANG

EXHAUST DUCT

COLLAR LOCATED

IN CENTER OR AT

ANY POINT ALONG

LENGTH OF THE

PLENUM

14'-0" MAX. UNIT LENGTH. FOR

GREATER LENGTH, JOIN TWO

OR MORE UNITS TOGETHER.

ALLOW 6"MIN. OVERHANG AT

EACH END. IF CHARBROILER

IS AT END, OVERHANG 12"

ENGINEERING DATA

Ventilator Length

Maximum ventilator length in a single section is 14'-0".

For lengths greater than 14'-0", join two or more sections.

Verify access conditions into building and kitchen space

prior to length selection.

Ventilator Hanging Weight

Wt./ lineal ft. Lbs. 105

Electrical Requirements

Provide 120 volt, single phase, 60 hertz, 15 amp (min.) 24 hour service

to CPE control panel (refer to CPE engineering

cut sheet). Control panel to be fused separately. Light fixtures to be

powered by a 120/1/60 circuit.

Mechanical Requirements

The volume of exhaust required is a function of the type of

cooking equipment served by the ventilator, and the type

and volume of product cooked. Refer to the CADDY AirSystems

Master Engineering Data Chart to determine exhaust volume,

duct collar sizes, static pressure drop, water consumption and

ventilator drain sizes.

NOTE: Refer to CADDY AirSystems

Master Engineering Data Sheet in engineering

data section for determining light, medium, and heavy duty cooking

equipment, C.F.M. requirements (exhaust and supply), duct collar

sizes and static pressure requirements.

STANDARD LIGHT FIXTURES

(__) 100 WATT INCANDESCENT

(__) RECESSED INCANDESCENT

(__) RECESSED FLUORESCENT

(IF RECESSED FLUORESCENT

SPECIFY SIZE)

CONSULT FACTORY FOR

NON-STANDARD HEIGHTS

22" MIN. FRONT OVERHANG

6" MIN. SIDE OVERHANG

(12" MIN. SIDE OVERHANG

FOR CHARBROILER)

ITEM #

EST. WEIGHT

LENGTH

WIDTH

HEIGHT

EXHAUST-CFM

DUCT SIZE

S.P.

H.W. INLET SIZE

DRAIN SIZE

GPM @ 40 PSI

:$7(57(03))

NOTE: 5 MIN. WASH CYCLE

PER 24 HR PERIOD

CADDY AirSystems

R

R

CADDY

Air Systems

All specifications subject to change without notice

08/07page 2 of 2

Page 13

PROJECT:

ITEM NO:

Model SHW-C-W

LOCATION:

General Specifications

Furnish CADDYAirSystems Exhaust Hood Model

SHW-C-W-ASII as shown on the plans and as described in

the following specifications.

Make-Up Air (Perimeter Down Discharge)

Up to 80% of the exhaust air may be supplied through this

down discharge system. However, the air must be tempered

WRDPLQLPXPRI)WRDYRLGGLVFRPIRUWWRRSHUDWLRQV

personnel.

Application

Wall mounted canopy style for use over all types of cooking

equipment where integral make-up air is required.

509 Sharptown Road P.O. Box 345

Bridgeport, NJ 08014-0345

Tel: 856-467-4222 Fax: 856-467-5511

internet: www.caddycorp.com

CADDY CORPORATION

CADDY Air Systems

All specifications subject to change without notice

08/07

Light Fixtures

All light fixtures shall be pre-wired to a single connection

point. Ventilators built in multiple sections to be furnished

with junction boxes for ease of field connection by the

electrical trades. Light bulbs furnished and installed by the

Kitchen Equipment Contractor.

Exhaust Fans

Exhaust fans are to be provided and installed by others in

compliance with local codes. Fans should be induced

draft, squirrel cage design, equipped with backward

inclined blades.

Fire Protection

NFPA 96 and local codes require a fire extinguishing system

for protection of the duct collar and plenum of all ventilators,

as well as for the protection of various cooking appliances

such as deep fat fryers, griddles, ranges, and broilers, which

may be a source of ignition of grease. Consult factory and

local fire officials for exact requirements. UL Listed fire

protection systems may be pre-piped by Caddy at the time of

manufacture, assuring concealment of piping and detectors.

Approvals

Ventilator shall be UL Listed, listed by NSF and be in

accordance with all of the recommendations set forth by

NFPA 96. All ventilators must meet all applicable codes.

Description

The CADDYAirSystems0RGHO³6+:³9HQWLODWRULVD

water-wash type and is UL Listed under the standards set

forth in UL 710 "Exhaust Hoods for Commercial Cooking

Equipment". This ventilator is 95% grease extraction

efficient when operated and maintained in accordance with

design specifications. This high efficiency is accomplished

by utilizing a high velocity centrifugal grease extractor, with

the air inlet opening parallel to the cooking equipment it

serves. Each ventilator shall have three full-length horizontal

baffles for centrifugal grease extraction and shall be

equipped with one full-length wash manifold with upper and

lower brass spray nozzles for superior extraction.

Ventilators shall operate at air quantities as illustrated on

plans.

General

Exhaust hood shall be constructed of 18 gauge type 300

series stainless steel. All exposed surfaces to have a

number # 4 finish. Construction to meet all requirements of

NFPA 96 and NSF Standard No.2. To include necessary

hanger brackets at front and rear for suspending from

building overhead structure.

Accessibility and Inspection

Full length removable inspection doors shall be provided so

that service can be performed on all interior components.

Automatic Washdown System

Ventilator to be equipped with one full length wash manifold

with spray nozzles for automatic detergent injected wash

XVLQJ)WR)KRWZDWHU3OXPELQJDQGHOHFWULFDO

components for operation of the automatic wash system to

be housed in the CADDYAirSystems0RGHO³&3(³FRQWURO

panel.

Plumbing/Electrical

Ventilators to be factory pre-plumbed and pre-wired to a

single connection point. Ventilators built in multiple sections

to be furnished with unions and junction boxes for field

connections by applicable trades.

Waterwash Ventilator With Ceiling Supply Plenum

page 1 of 2

Page 14

3"

4"

1'-0"

1'-0"

1'-6"

40% OPEN STN./STL.

PERFORATED DIFFUSER

1'-6" MIN.

4'-0" MAX.

8'-6"

FIN. CLG.

HEIGHT

[ ] VERIFY

6'-6"

A.F.F.

_'-_"

EQUIPMENT

UNDER HOODS

BY K.E.C.

2'-0"

10"

3"

SIMPLEX WATER WASH

TYPE GREASE EXTRACTOR

DUAL ACTION

SPRAY MANIFOLD

4"

FENWAL

THERMOSTAT

SECTION

MODEL:

DRAWINGS NOT TO SCALE

SHW-C-W- - -

ENGINEERING DATA

Ventilator Length

Maximum ventilator length in a single section is 14'-0".

For lengths greater than 14'-0", join two or more sections.

Verify access conditions into building and kitchen space

prior to length selection.

Ventilator Hanging Weight

Wt./ lineal ft. Lbs. 105

Electrical Requirements

Provide 120 volt, single phase, 60 hertz, 15 amp (min.) 24 hour service

to CPE control panel (refer to CPE engineering

cut sheet). Control panel to be fused separately. Light fixtures to be

powered by a 120/1/60 circuit.

Mechanical Requirements

The volume of exhaust required is a function of the type of

cooking equipment served by the ventilator, and the type

and volume of product cooked. Refer to the CADDY AirSystems

Master Engineering Data Chart to determine exhaust volume,

duct collar sizes, static pressure drop, water consumption and

ventilator drain sizes.

NOTE: Refer to CADDY AirSystems

Master Engineering Data Sheet in engineering

data section for determining light, medium, and heavy duty cooking

equipment, C.F.M. requirements (exhaust and supply), duct collar

sizes and static pressure requirements.

STANDARD LIGHT FIXTURES

(__) 100 WATT INCANDESCENT

(__) RECESSED INCANDESCENT

(__) RECESSED FLUORESCENT

(IF RECESSED FLUORESCENT

SPECIFY SIZE)

CONSULT FACTORY FOR

NON-STANDARD HEIGHTS

22" MIN. FRONT OVERHANG

6" MIN. SIDE OVERHANG

(12" MIN. SIDE OVERHANG

FOR CHARBROILER)

ITEM #

EST. WEIGHT

LENGTH

WIDTH

HEIGHT

EXHAUST-CFM

DUCT SIZE

S.P.

H.W. INLET SIZE

DRAIN SIZE

GPM @ 40 PSI

:$7(57(03))

NOTE: 5 MIN. WASH CYCLE

PER 24 HR PERIOD

CADDY AirSystems

R

R

CADDY

Air Systems

All specifications subject to change without notice

08/07

______X______

DIMENSION VARIES

WITH DEPTH OF THE

EQUIPMENT AND

REQUIRED OVERHANG

EXHAUST DUCT

COLLAR LOCATED

IN CENTER OR AT

ANY POINT ALONG

LENGTH OF THE

PLENUM

14'-0" MAX. UNIT LENGTH. FOR

GREATER LENGTH, JOIN TWO

OR MORE UNITS TOGETHER.

ALLOW 6"MIN. OVERHANG AT

EACH END. IF CHARBROILER

IS AT END, OVERHANG 12"

ADD THE OVERALL

LENGTH (IN INCHES) OF

THE VENTILATOR AFTER

MODEL DESIGNATION

ADD THE OVERALL WIDTH

(IN INCHES) OF THE

VENTILATOR AFTER

MODEL DESIGNATION

DAMPER TYPE

ND - NO DAMPER

FL - FUSIBLE LINK

T - THERMOSTAT

page 2 of 2

Page 15

CADDY CORPORATION

Air SystemsFood Service Equipment

Commercial Kitchen

Exhaust Systems

Model SHW

Single Island Style

Page 16

PROJECT:

ITEM NO:

Model SHW-C-I

LOCATION:

General Specifications

Furnish CADDYAirSystems Exhaust Hood Model SHW-C-I

as shown on the plans and as described in the following

specifications.

Waterwash Ventilator

Application

Island style cooking applications for use over all types of

cooking equipment.

509 Sharptown Road P.O. Box 345

Bridgeport, NJ 08014-0345

Tel: 856-467-4222 Fax: 856-467-5511

internet: www.caddycorp.com

CADDY CORPORATION

CADDY Air Systems

All specifications subject to change without notice

08/07

Light Fixtures

All light fixtures shall be pre-wired to a single connection

point. Ventilators built in multiple sections to be furnished

with junction boxes for ease of field connection by the

electrical trades. Light bulbs furnished and installed by the

Kitchen Equipment Contractor.

Exhaust Fans

Exhaust fans are to be provided and installed by others in

compliance with local codes. Fans should be induced

draft, squirrel cage design, equipped with backward

inclined blades.

Fire Protection

NFPA 96 and local codes require a fire extinguishing system

for protection of the duct collar and plenum of all ventilators,

as well as for the protection of various cooking appliances

such as deep fat fryers, griddles, ranges, and broilers, which

may be a source of ignition of grease. Consult factory and

local fire officials for exact requirements. UL Listed fire

protection systems may be pre-piped by Caddy at the time of

manufacture, assuring concealment of piping and detectors.

Approvals

Ventilator shall be UL Listed, listed by NSF and be in

accordance with all of the recommendations set forth by

NFPA 96. All ventilators must meet all applicable codes.

Description

The CADDYAirSystems0RGHO³6+:³9HQWLODWRULVD

water-wash type and is UL Listed under the standards set

forth in UL 710 "Exhaust Hoods for Commercial Cooking

Equipment". This ventilator is 95% grease extraction

efficient when operated and maintained in accordance with

design specifications. This high efficiency is accomplished

by utilizing a high velocity centrifugal grease extractor, with

the air inlet opening parallel to the cooking equipment it

serves. Each ventilator shall have three full-length horizontal

baffles for centrifugal grease extraction and shall be

equipped with one full-length wash manifold with upper and

lower brass spray nozzles for superior extraction.

Ventilators shall operate at air quantities as illustrated on

plans.

General

Exhaust hood shall be constructed of 18 gauge type 300

series stainless steel. All exposed surfaces to have a

number # 4 finish. Construction to meet all requirements of

NFPA 96 and NSF Standard No.2. To include necessary

hanger brackets at front and rear for suspending from

building overhead structure.

Accessibility and Inspection

Full length removable inspection doors shall be provided so

that service can be performed on all interior components.

Automatic Washdown System

Ventilator to be equipped with one full length wash manifold

with spray nozzles for automatic detergent injected wash

XVLQJ)WR)KRWZDWHU3OXPELQJDQGHOHFWULFDO

components for operation of the automatic wash system to

be housed in the CADDYAirSystems0RGHO³&3(³FRQWURO

panel.

Plumbing/Electrical

Ventilators to be factory pre-plumbed and pre-wired to a

single connection point. Ventilators built in multiple sections

to be furnished with unions and junction boxes for field

connections by applicable trades.

page 1 of 2

Page 17

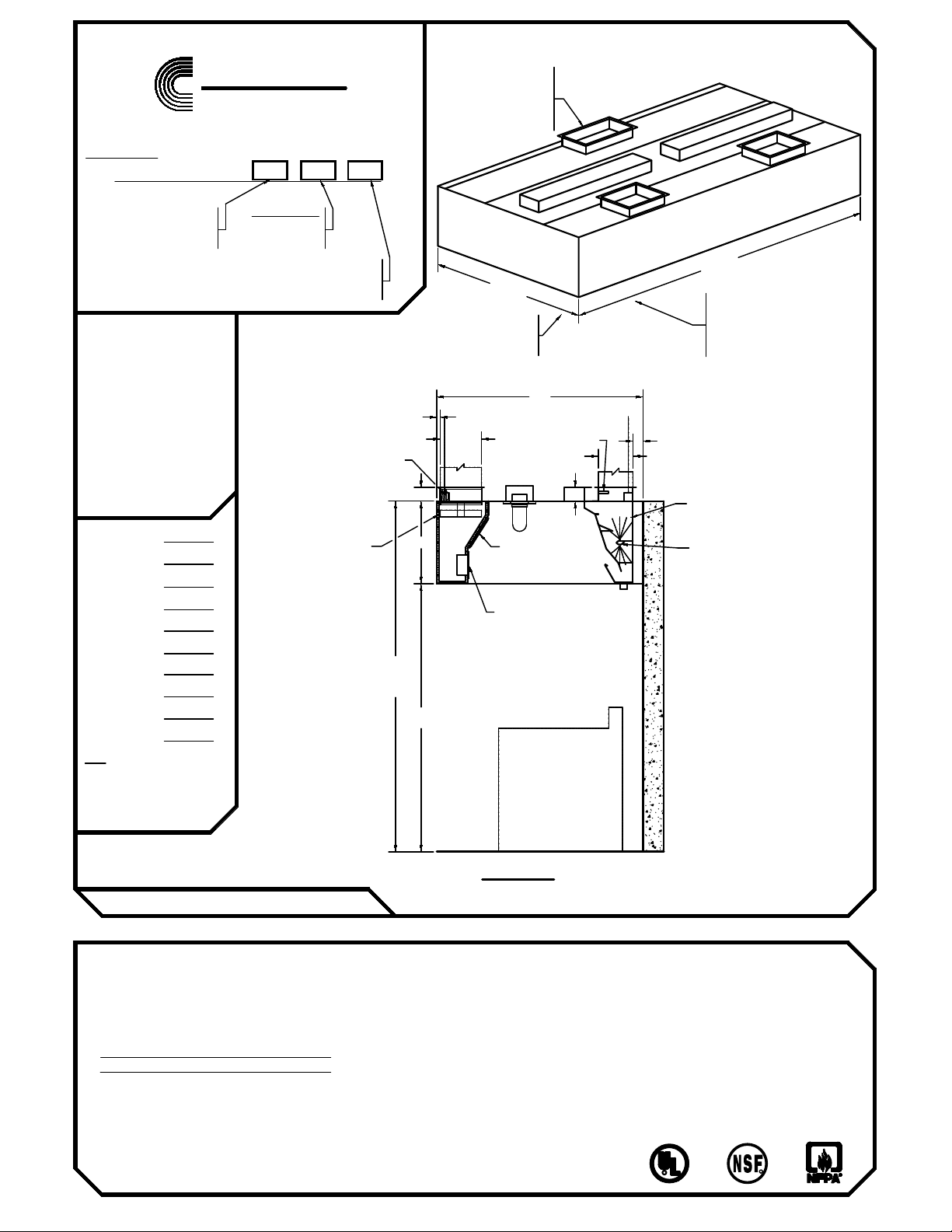

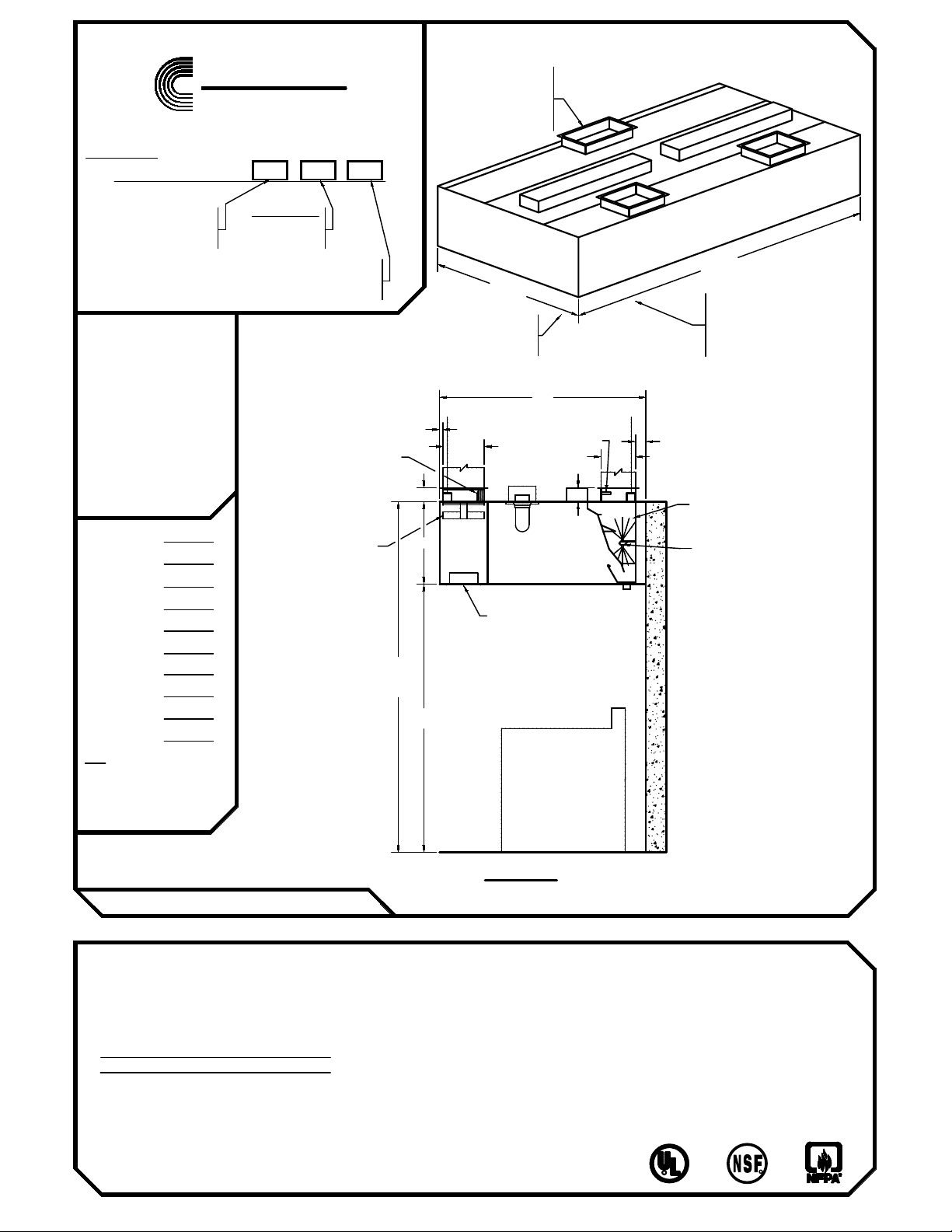

EQUIPMENT

UNDER HOODS

BY K.E.C.

EQUIPMENT

UNDER HOODS

BY K.E.C.

3"

10"

3"

10"

4" 4"

__'-__"

__'-__"

8'-6"

FIN. CLG.

HEIGHT

[ ] VERIFY

6'-6"

A.F.F.

2'-0"

SECTION

SIMPLEX WATER

WASH TYPE GREASE

EXTRACTOR

DUAL ACTION

SPRAY MANIFOLD

MODEL:

ADD THE OVERALL

LENGTH (IN INCHES) OF

THE VENTILATOR AFTER

MODEL DESIGNATION

ADD THE OVERALL WIDTH

(IN INCHES) OF THE

VENTILATOR AFTER

MODEL DESIGNATION

DAMPER TYPE

ND - NO DAMPER

FL - FUSIBLE LINK

T - THERMOSTAT

DRAWINGS NOT TO SCALE

SHW-C-I- - -

______X______

EXHAUST DUCT

COLLAR LOCATED

IN CENTER OR AT

ANY POINT ALONG

LENGTH OF THE

PLENUM

14'-0" MAX. UNIT LENGTH. FOR

GREATER LENGTH, JOIN TWO

OR MORE UNITS TOGETHER.

ALLOW 6"MIN. OVERHANG AT

EACH END. IF CHARBROILER

IS AT END, OVERHANG 12"

DIMENSION VARIES

WITH DEPTH OF THE

EQUIPMENT AND

REQUIRED OVERHANG

ENGINEERING DATA

Ventilator Length

Maximum ventilator length in a single section is 14'-0".

For lengths greater than 14'-0", join two or more sections.

Verify access conditions into building and kitchen space

prior to length selection.

Ventilator Hanging Weight

Wt./ lineal ft. Lbs. 90

Electrical Requirements

Provide 120 volt, single phase, 60 hertz, 15 amp (min.) 24 hour service

to CPE control panel (refer to CPE engineering

cut sheet). Control panel to be fused separately. Light fixtures to be

powered by a 120/1/60 circuit.

Mechanical Requirements

The volume of exhaust required is a function of the type of

cooking equipment served by the ventilator, and the type

and volume of product cooked. Refer to the CADDY AirSystems

Master Engineering Data Chart to determine exhaust volume,

duct collar sizes, static pressure drop, water consumption and

ventilator drain sizes.

NOTE: Refer to

CADDY AirSystems

Master Engineering Data Sheet in engineering

data section for determining light, medium, and heavy duty cooking

equipment, C.F.M. requirements (exhaust and supply), duct collar

sizes and static pressure requirements.

STANDARD LIGHT FIXTURES

(__) 100 WATT INCANDESCENT

(__) RECESSED INCANDESCENT

(__) RECESSED FLUORESCENT

(IF RECESSED FLUORESCENT

SPECIFY SIZE)

CONSULT FACTORY FOR

NON-STANDARD HEIGHTS

12" MIN. FRONT OVERHANG

6" MIN. SIDE OVERHANG

(12" MIN. SIDE OVERHANG

FOR CHARBROILER)

ITEM #

EST. WEIGHT

LENGTH

WIDTH

HEIGHT

EXHAUST-CFM

DUCT SIZE

S.P.

H.W. INLET SIZE

DRAIN SIZE

GPM @ 40 PSI

:$7(57(03))

NOTE: 5 MIN. WASH CYCLE

PER 24 HR PERIOD

CADDY AirSystems

R

R

CADDY

Air Systems

All specifications subject to change without notice

08/07

page 2 of 2

Page 18

PROJECT:

ITEM NO:

Model SHW-C-I-PA

LOCATION:

General Specifications

Furnish CADDYAirSystems Exhaust Hood Model

SHW-C-I-PA as shown on the plans and as described in

the following specifications.

Waterwash Ventilator

Make-Up Air (Front Face Discharge)

Ventilator shall have 40% open stainless steel perforated

screens along front face for face discharge of tempered

make-up air. This type of make-up air is the most common

and advantageous method of bringing air into the kitchen via

the kitchen exhaust ventilator. Typically supply volume is

80%, or more depending upon the desired air balance.

6XSSO\DLUWHPSHUDWXUHVKRXOGUDQJHIURP))EXW

PD\EHDVORZDV)GHSHQGLQJRQDLUYROXPH

distribution, internal heat load, and desired ambient room

temperature.

Application

Island style cooking applications for use over all types of

cooking equipment where integral MUA is required.

509 Sharptown Road P.O. Box 345

Bridgeport, NJ 08014-0345

Tel: 856-467-4222 Fax: 856-467-5511

internet: www.caddycorp.com

CADDY CORPORATION

CADDY Air Systems

All specifications subject to change without notice

08/07

Light Fixtures

All light fixtures shall be pre-wired to a single connection

point. Ventilators built in multiple sections to be furnished

with junction boxes for ease of field connection by the

electrical trades. Light bulbs furnished and installed by the

Kitchen Equipment Contractor.

Exhaust Fans

Exhaust fans are to be provided and installed by others in

compliance with local codes. Fans should be induced

draft, squirrel cage design, equipped with backward

inclined blades.

Fire Protection

NFPA 96 and local codes require a fire extinguishing system

for protection of the duct collar and plenum of all ventilators,

as well as for the protection of various cooking appliances

such as deep fat fryers, griddles, ranges, and broilers, which

may be a source of ignition of grease. Consult factory and

local fire officials for exact requirements. UL Listed fire

protection systems may be pre-piped by Caddy at the time of

manufacture, assuring concealment of piping and detectors.

Approvals

Ventilator shall be UL Listed, listed by NSF and be in

accordance with all of the recommendations set forth by

NFPA 96. All ventilators must meet all applicable codes.

Description

The CADDYAirSystems0RGHO³6+:³9HQWLODWRULVD

water-wash type and is UL Listed under the standards set

forth in UL 710 "Exhaust Hoods for Commercial Cooking

Equipment". This ventilator is 95% grease extraction

efficient when operated and maintained in accordance with

design specifications. This high efficiency is accomplished

by utilizing a high velocity centrifugal grease extractor, with

the air inlet opening parallel to the cooking equipment it

serves. Each ventilator shall have three full-length horizontal

baffles for centrifugal grease extraction and shall be

equipped with one full-length wash manifold with upper and

lower brass spray nozzles for superior extraction.

Ventilators shall operate at air quantities as illustrated on

plans.

General

Exhaust hood shall be constructed of 18 gauge type 300

series stainless steel. All exposed surfaces to have a

number # 4 finish. Construction to meet all requirements of

NFPA 96 and NSF Standard No.2. To include necessary

hanger brackets at front and rear for suspending from

building overhead structure.

Accessibility and Inspection

Full length removable inspection doors shall be provided so

that service can be performed on all interior components.

Automatic Washdown System

Ventilator to be equipped with one full length wash manifold

with spray nozzles for automatic detergent injected wash

XVLQJ)WR)KRWZDWHU3OXPELQJDQGHOHFWULFDO

components for operation of the automatic wash system to

be housed in the CADDYAirSystems0RGHO³&3(³FRQWURO

panel.

Plumbing/Electrical

Ventilators to be factory pre-plumbed and pre-wired to a

single connection point. Ventilators built in multiple sections

to be furnished with unions and junction boxes for field

connections by applicable trades.

page 1 of 2

Page 19

EQUIPMENT

UNDER HOODS

BY K.E.C.

EQUIPMENT

UNDER HOODS

BY K.E.C.

3"

10"

3"

10"

4" 4"

__'-__"

__'-__"

8'-6"

FIN. CLG.

HEIGHT

[ ] VERIFY

6'-6"

A.F.F.

2'-0"

SECTION

SIMPLEX WATER

WASH TYPE GREASE

EXTRACTOR

DUAL ACTION

SPRAY MANIFOLD

40% OPEN STN./STL.

PERFORATED DIFFUSER

1"

4"

1'-0"

MODEL:

ADD THE OVERALL

LENGTH (IN INCHES) OF

THE VENTILATOR AFTER

MODEL DESIGNATION

ADD THE OVERALL WIDTH

(IN INCHES) OF THE

VENTILATOR AFTER

MODEL DESIGNATION

DAMPER TYPE

ND - NO DAMPER

FL - FUSIBLE LINK

T - THERMOSTAT

DRAWINGS NOT TO SCALE

SHW-C-I-PA- - -

______X______

EXHAUST DUCT

COLLAR LOCATED

IN CENTER OR AT

ANY POINT ALONG

LENGTH OF THE

PLENUM

14'-0" MAX. UNIT LENGTH. FOR

GREATER LENGTH, JOIN TWO

OR MORE UNITS TOGETHER.

ALLOW 6"MIN. OVERHANG AT

EACH END. IF CHARBROILER

IS AT END, OVERHANG 12"

DIMENSION VARIES

WITH DEPTH OF THE

EQUIPMENT AND

REQUIRED OVERHANG

ENGINEERING DATA

Ventilator Length

Maximum ventilator length in a single section is 14'-0".

For lengths greater than 14'-0", join two or more sections.

Verify access conditions into building and kitchen space

prior to length selection.

Ventilator Hanging Weight

Wt./ lineal ft. Lbs. 105

Electrical Requirements

Provide 120 volt, single phase, 60 hertz, 15 amp (min.) 24 hour service

to CPE control panel (refer to CPE engineering

cut sheet). Control panel to be fused separately. Light fixtures to be

powered by a 120/1/60 circuit.

Mechanical Requirements

The volume of exhaust required is a function of the type of

cooking equipment served by the ventilator, and the type

and volume of product cooked. Refer to the CADDY AirSystems

Master Engineering Data Chart to determine exhaust volume,

duct collar sizes, static pressure drop, water consumption and

ventilator drain sizes.

NOTE: Refer to

CADDY AirSystems

Master Engineering Data Sheet in engineering

data section for determining light, medium, and heavy duty cooking

equipment, C.F.M. requirements (exhaust and supply), duct collar

sizes and static pressure requirements.

STANDARD LIGHT FIXTURES

(__) 100 WATT INCANDESCENT

(__) RECESSED INCANDESCENT

(__) RECESSED FLUORESCENT

(IF RECESSED FLUORESCENT

SPECIFY SIZE)

CONSULT FACTORY FOR

NON-STANDARD HEIGHTS

12" MIN. FRONT OVERHANG

6" MIN. SIDE OVERHANG

(12" MIN. SIDE OVERHANG

FOR CHARBROILER)

ITEM #

EST. WEIGHT

LENGTH

WIDTH

HEIGHT

EXHAUST-CFM

DUCT SIZE

S.P.

H.W. INLET SIZE

DRAIN SIZE

GPM @ 40 PSI

:$7(57(03))

NOTE: 5 MIN. WASH CYCLE

PER 24 HR PERIOD

CADDY AirSystems

R

R

CADDY

Air Systems

All specifications subject to change without notice

08/07

page 2 of 2

Page 20

PROJECT:

ITEM NO:

Model SHW-C-I-ASI

LOCATION:

General Specifications

Furnish CADDYAirSystems Exhaust Hood Model

SHW-C-I-ASI as shown on the plans and as described in

the following specifications.

Waterwash Ventilator

Make-Up Air (Internal Discharge)

Ventilator shall have a fully insulated supply plenum, with

duct collar/fire damper assemblies, and air registers

internally mounted for discharging untempered make-up air

directly into canopy of ventilator. The amount of make-up air

supplied through this design is directly related to the type of

cooking equipment located beneath the hood. The

percentage of supply air distributed will vary as a function of

the thermal currents generated by each individual appliance.

When specifying this style, consult factory for specific supply

volumes. This air may be untempered in most areas,

depending upon climatic conditions and the type of cooking

equipment. If the winter design temperature is below 10

degrees F, consult factory for air supply volumes and design

considerations.

Application

Island style cooking applications for use over all types of

cooking equipment where integral make-up air is required.

509 Sharptown Road P.O. Box 345

Bridgeport, NJ 08014-0345

Tel: 856-467-4222 Fax: 856-467-5511

internet: www.caddycorp.com

CADDY CORPORATION

CADDY Air Systems

All specifications subject to change without notice

08/07

Light Fixtures

All light fixtures shall be pre-wired to a single connection

point. Ventilators built in multiple sections to be furnished

with junction boxes for ease of field connection by the

electrical trades. Light bulbs furnished and installed by the

Kitchen Equipment Contractor.

Exhaust Fans

Exhaust fans are to be provided and installed by others in

compliance with local codes. Fans should be induced

draft, squirrel cage design, equipped with backward

inclined blades.

Fire Protection

NFPA 96 and local codes require a fire extinguishing system

for protection of the duct collar and plenum of all ventilators,

as well as for the protection of various cooking appliances

such as deep fat fryers, griddles, ranges, and broilers, which

may be a source of ignition of grease. Consult factory and

local fire officials for exact requirements. UL Listed fire

protection systems may be pre-piped by Caddy at the time of

manufacture, assuring concealment of piping and detectors.

Approvals

Ventilator shall be UL Listed, listed by NSF and be in

accordance with all of the recommendations set forth by

NFPA 96. All ventilators must meet all applicable codes.

Description

The CADDYAirSystems0RGHO³6+:³9HQWLODWRULVD

water-wash type and is UL Listed under the standards set

forth in UL 710 "Exhaust Hoods for Commercial Cooking

Equipment". This ventilator is 95% grease extraction

efficient when operated and maintained in accordance with

design specifications. This high efficiency is accomplished

by utilizing a high velocity centrifugal grease extractor, with

the air inlet opening parallel to the cooking equipment it

serves. Each ventilator shall have three full-length horizontal

baffles for centrifugal grease extraction and shall be

equipped with one full-length wash manifold with upper and

lower brass spray nozzles for superior extraction.

Ventilators shall operate at air quantities as illustrated on

plans.

General

Exhaust hood shall be constructed of 18 gauge type 300

series stainless steel. All exposed surfaces to have a

number # 4 finish. Construction to meet all requirements of

NFPA 96 and NSF Standard No.2. To include necessary

hanger brackets at front and rear for suspending from

building overhead structure.

Accessibility and Inspection

Full length removable inspection doors shall be provided so

that service can be performed on all interior components.

Automatic Washdown System

Ventilator to be equipped with one full length wash manifold

with spray nozzles for automatic detergent injected wash

XVLQJ)WR)KRWZDWHU3OXPELQJDQGHOHFWULFDO

components for operation of the automatic wash system to

be housed in the CADDYAirSystems0RGHO³&3(³FRQWURO

panel.

Plumbing/Electrical

Ventilators to be factory pre-plumbed and pre-wired to a

single connection point. Ventilators built in multiple sections

to be furnished with unions and junction boxes for field

connections by applicable trades.

page 1 of 2

Page 21

EQUIPMENT

UNDER HOODS

BY K.E.C.

EQUIPMENT

UNDER HOODS

BY K.E.C.

3"

10"

3"

10"

4" 4"

__'-__"

__'-__"

8'-6"

FIN. CLG.

HEIGHT

[ ] VERIFY

6'-6"

A.F.F.

2'-0"

SECTION

SIMPLEX WATER

WASH TYPE GREASE

EXTRACTOR

DUAL ACTION

SPRAY MANIFOLD

ACCESS

PANEL

AIR REGISTER(S)

40% OPEN STN./STL.

PERFORATED DIFFUSER

UL 555 CLASSIFIED

FIRE DAMPER

))86,%/(/,1.

1"

1'-0"

4"

MODEL:

ADD THE OVERALL

LENGTH (IN INCHES) OF

THE VENTILATOR AFTER

MODEL DESIGNATION

ADD THE OVERALL WIDTH

(IN INCHES) OF THE

VENTILATOR AFTER

MODEL DESIGNATION

DAMPER TYPE

ND - NO DAMPER

FL - FUSIBLE LINK

T - THERMOSTAT

DRAWINGS NOT TO SCALE

SHW-C-I-ASI- - -

______X______

EXHAUST DUCT

COLLAR LOCATED

IN CENTER OR AT

ANY POINT ALONG

LENGTH OF THE

PLENUM

14'-0" MAX. UNIT LENGTH. FOR

GREATER LENGTH, JOIN TWO

OR MORE UNITS TOGETHER.

ALLOW 6"MIN. OVERHANG AT

EACH END. IF CHARBROILER

IS AT END, OVERHANG 12"

DIMENSION VARIES

WITH DEPTH OF THE

EQUIPMENT AND

REQUIRED OVERHANG

ENGINEERING DATA

Ventilator Length

Maximum ventilator length in a single section is 14'-0".

For lengths greater than 14'-0", join two or more sections.

Verify access conditions into building and kitchen space

prior to length selection.

Ventilator Hanging Weight

Wt./ lineal ft. Lbs. 105

Electrical Requirements

Provide 120 volt, single phase, 60 hertz, 15 amp (min.) 24 hour service

to CPE control panel (refer to CPE engineering

cut sheet). Control panel to be fused separately. Light fixtures to be

powered by a 120/1/60 circuit.

Mechanical Requirements

The volume of exhaust required is a function of the type of

cooking equipment served by the ventilator, and the type

and volume of product cooked. Refer to the CADDY AirSystems

Master Engineering Data Chart to determine exhaust volume,

duct collar sizes, static pressure drop, water consumption and

ventilator drain sizes.

NOTE: Refer to

CADDY AirSystems

Master Engineering Data Sheet in engineering

data section for determining light, medium, and heavy duty cooking

equipment, C.F.M. requirements (exhaust and supply), duct collar

sizes and static pressure requirements.

STANDARD LIGHT FIXTURES

(__) 100 WATT INCANDESCENT

(__) RECESSED INCANDESCENT

(__) RECESSED FLUORESCENT

(IF RECESSED FLUORESCENT

SPECIFY SIZE)

CONSULT FACTORY FOR

NON-STANDARD HEIGHTS

22" MIN. FRONT OVERHANG

6" MIN. SIDE OVERHANG

(12" MIN. SIDE OVERHANG

FOR CHARBROILER)

ITEM #

EST. WEIGHT

LENGTH

WIDTH

HEIGHT

EXHAUST-CFM

DUCT SIZE

S.P.

H.W. INLET SIZE

DRAIN SIZE

GPM @ 40 PSI

:$7(57(03))

NOTE: 5 MIN. WASH CYCLE

PER 24 HR PERIOD

CADDY AirSystems

R

R

CADDY

Air Systems

All specifications subject to change without notice

08/07

page 2 of 2

Page 22

PROJECT:

ITEM NO:

Model SHW-C-I-AA

LOCATION:

General Specifications

Furnish CADDYAirSystems Exhaust Hood Model

SHW-C-I-AA as shown on the plans and as described in

the following specifications.

Waterwash Ventilator

Application

Island style cooking applications for use over all types of

cooking equipment where integral make-up air is required.

509 Sharptown Road P.O. Box 345

Bridgeport, NJ 08014-0345

Tel: 856-467-4222 Fax: 856-467-5511

internet: www.caddycorp.com

CADDY CORPORATION

CADDY Air Systems

All specifications subject to change without notice

08/07

Light Fixtures

All light fixtures shall be pre-wired to a single connection

point. Ventilators built in multiple sections to be furnished

with junction boxes for ease of field connection by the

electrical trades. Light bulbs furnished and installed by the

Kitchen Equipment Contractor.

Exhaust Fans

Exhaust fans are to be provided and installed by others in

compliance with local codes. Fans should be induced

draft, squirrel cage design, equipped with backward

inclined blades.

Fire Protection

NFPA 96 and local codes require a fire extinguishing system

for protection of the duct collar and plenum of all ventilators,

as well as for the protection of various cooking appliances

such as deep fat fryers, griddles, ranges, and broilers, which

may be a source of ignition of grease. Consult factory and

local fire officials for exact requirements. UL Listed fire

protection systems may be pre-piped by Caddy at the time of

manufacture, assuring concealment of piping and detectors.

Approvals

Ventilator shall be UL Listed, listed by NSF and be in

accordance with all of the recommendations set forth by

NFPA 96. All ventilators must meet all applicable codes.

Description

The CADDYAirSystems0RGHO³6+:³9HQWLODWRULVD

water-wash type and is UL Listed under the standards set

forth in UL 710 "Exhaust Hoods for Commercial Cooking

Equipment". This ventilator is 95% grease extraction

efficient when operated and maintained in accordance with

design specifications. This high efficiency is accomplished

by utilizing a high velocity centrifugal grease extractor, with

the air inlet opening parallel to the cooking equipment it

serves. Each ventilator shall have three full-length horizontal

baffles for centrifugal grease extraction and shall be

equipped with one full-length wash manifold with upper and

lower brass spray nozzles for superior extraction.

Ventilators shall operate at air quantities as illustrated on

plans.

General

Exhaust hood shall be constructed of 18 gauge type 300

series stainless steel. All exposed surfaces to have a

number # 4 finish. Construction to meet all requirements of

NFPA 96 and NSF Standard No.2. To include necessary

hanger brackets at front and rear for suspending from

building overhead structure.

Accessibility and Inspection

Full length removable inspection doors shall be provided so

that service can be performed on all interior components.

Automatic Washdown System

Ventilator to be equipped with one full length wash manifold

with spray nozzles for automatic detergent injected wash

XVLQJ)WR)KRWZDWHU3OXPELQJDQGHOHFWULFDO

components for operation of the automatic wash system to

be housed in the CADDYAirSystems0RGHO³&3(³FRQWURO

panel.

Plumbing/Electrical

Ventilators to be factory pre-plumbed and pre-wired to a

single connection point. Ventilators built in multiple sections

to be furnished with unions and junction boxes for field

connections by applicable trades.

Make-Up Air (Front Face Register Discharge)

Ventilator shall have air registers along front face for

discharge of tempered make-up air. Supply volume is 80%,

or designed to the desired air balance.

page 1 of 2

Page 23

EQUIPMENT

UNDER HOODS

BY K.E.C.

EQUIPMENT

UNDER HOODS

BY K.E.C.

3"

10"

3"

10"

4" 4"

__'-__"

__'-__"

8'-6"

FIN. CLG.

HEIGHT

[ ] VERIFY

6'-6"

A.F.F.

2'-0"

SECTION

SIMPLEX WATER

WASH TYPE GREASE

EXTRACTOR

DUAL ACTION

SPRAY MANIFOLD

1'-0"

AIR REGISTER(S)

4"

1"

40% OPEN STN./STL.

PERFORATED DIFFUSER

MODEL:

ADD THE OVERALL

LENGTH (IN INCHES) OF

THE VENTILATOR AFTER

MODEL DESIGNATION

ADD THE OVERALL WIDTH

(IN INCHES) OF THE

VENTILATOR AFTER

MODEL DESIGNATION

DAMPER TYPE

ND - NO DAMPER

FL - FUSIBLE LINK

T - THERMOSTAT

DRAWINGS NOT TO SCALE

SHW-C-I-AA- - -

______X______

EXHAUST DUCT

COLLAR LOCATED

IN CENTER OR AT

ANY POINT ALONG

LENGTH OF THE

PLENUM

14'-0" MAX. UNIT LENGTH. FOR

GREATER LENGTH, JOIN TWO

OR MORE UNITS TOGETHER.

ALLOW 6"MIN. OVERHANG AT

EACH END. IF CHARBROILER

IS AT END, OVERHANG 12"

DIMENSION VARIES

WITH DEPTH OF THE

EQUIPMENT AND

REQUIRED OVERHANG

ENGINEERING DATA

Ventilator Length

Maximum ventilator length in a single section is 14'-0".

For lengths greater than 14'-0", join two or more sections.

Verify access conditions into building and kitchen space

prior to length selection.

Ventilator Hanging Weight

Wt./ lineal ft. Lbs. 105

Electrical Requirements

Provide 120 volt, single phase, 60 hertz, 15 amp (min.) 24 hour service

to CPE control panel (refer to CPE engineering

cut sheet). Control panel to be fused separately. Light fixtures to be

powered by a 120/1/60 circuit.

Mechanical Requirements

The volume of exhaust required is a function of the type of

cooking equipment served by the ventilator, and the type

and volume of product cooked. Refer to the CADDY AirSystems

Master Engineering Data Chart to determine exhaust volume,

duct collar sizes, static pressure drop, water consumption and

ventilator drain sizes.

NOTE: Refer to CADDY AirSystems

Master Engineering Data Sheet in engineering

data section for determining light, medium, and heavy duty cooking

equipment, C.F.M. requirements (exhaust and supply), duct collar

sizes and static pressure requirements.

STANDARD LIGHT FIXTURES

(__) 100 WATT INCANDESCENT

(__) RECESSED INCANDESCENT

(__) RECESSED FLUORESCENT

(IF RECESSED FLUORESCENT

SPECIFY SIZE)

CONSULT FACTORY FOR

NON-STANDARD HEIGHTS

12" MIN. FRONT OVERHANG

6" MIN. SIDE OVERHANG

(12" MIN. SIDE OVERHANG

FOR CHARBROILER)

ITEM #

EST. WEIGHT

LENGTH

WIDTH

HEIGHT

EXHAUST-CFM

DUCT SIZE

S.P.

H.W. INLET SIZE

DRAIN SIZE

GPM @ 40 PSI

:$7(57(03))

NOTE: 5 MIN. WASH CYCLE

PER 24 HR PERIOD

CADDY AirSystems

R

R

CADDY

Air Systems

All specifications subject to change without notice

08/07page 2 of 2

Page 24

PROJECT:

ITEM NO:

Model SHW-C-I-ASII

LOCATION:

General Specifications

Furnish CADDYAirSystems Exhaust Hood Model

SHW-C-I-ASII as shown on the plans and as described in

the following specifications.

Waterwash Ventilator

Application

Island style cooking applications for use over all types of

cooking equipment where integral make-up air is required.

Description

The CADDYAirSystems0RGHO³6+:³9HQWLODWRULVD

water-wash ventilator that is UL Listed under the standards

set forth in UL 710 "Exhaust Hoods for Commercial Cooking

Equipment". Each ventilator shall be a high velocity

centrifugal grease extractor, with the air inlet opening

parallel to the cooking equipment it serves. Each ventilator

shall have three full-length horizontal baffles for centrifugal

grease extraction. Each ventilator shall be equipped with

one full-length wash manifold with upper and lower brass

spray nozzles for superior extraction chamber cleaning

action. Each ventilator shall have a grease extraction

efficiency of 95% when operated within design parameters.

This efficiency shall be achieved without the use of filters,

catridges, or constant running water. Ventilators shall

operate at air quantities as illustrated on plans.

General

Exhaust hood shall be constructed of 18 gauge type 300

series stainless steel with all exposed surfaces a number 4

finish. Construction to meet all requirements of NFPA 96

and NSF Standard No.2. To include necessary hanger

brackets at front and rear for suspending from building

overhead structure.

Accessibility and Inspection

Full length removable inspection doors shall be provided so

that service can be performed on all interior components.

Automatic Washdown System

Ventilator to be equipped with one full length wash manifold