Page 1

CADDY CORPORATION

Air SystemsFood Service Equipment

Cold Food Caddys

Page 2

CADDY

CADDY Food Service Systems

CADDYCADDY

page 1 of 2

Food Service Systems

Food Service SystemsFood Service Systems

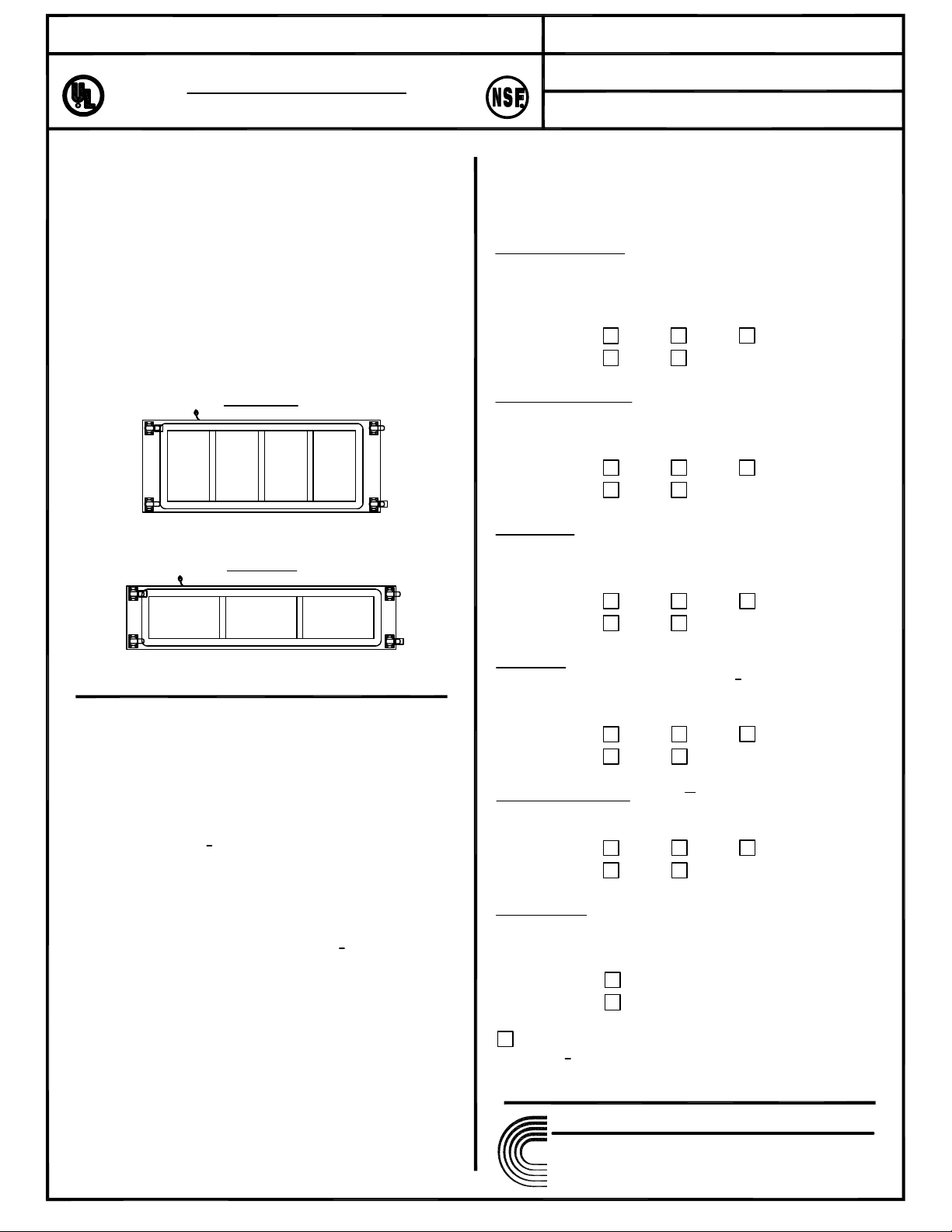

Cold Food Caddys

R

Regular or slimline

ITEM NO:

PROJECT:

LOCATION:

Uniquely designed, with special wells, to

assure consistent food temperatures.

Excellent for Cook-Chill systems or plating cold

food. Far superior to ordinary cold food

equipment. Foods placed in these units will

remain at constant temperatures until ready for

reconstitution or serving.

REGULAR

(RIF-604 Shown)

SLIMLINE

Unit to be provided with the following accessories:

Accessories

Folding Tray Slide - To be 1" square 16 gauge stainless

steel tubing, 10" overall width, welded to intermediate lateral

supports and mounted on control side on folding brackets.

Slide to be removable.

2 Well 3 Well 4 Well

26" wide units

18" wide units

A-68

A-88

A-69

A-89

Folding Work Shelf - 16 gauge stainless steel with all

edges turned down and welded corners, 10" overall width,

mounted on control side on folding brackets. Shelf to be

removable.

26" wide units

18" wide units

2 Well 3 Well 4 Well

A-72

A-90

A-73

A-91

Undershelf - To be 18 gauge stainless steel with channel

reinforced longitudinal edges, located 7" above floor and

secured to pedestals at both ends.

2 Well 3 Well 4 Well

26" wide units

18" wide units

A-92

A-95

A-93

A-96

A-70

A-74

A-94

(RIF-613 Shown)

General Specifications

Cold Food Caddy to be Caddy Corporation model

RIF-_______________.

Unit to have all stainless steel exterior. Top to be 18 gauge

stainless steel turned down into 2" wide channel edges, with

corners welded. Each opening for cold food wells to be die

formed with 1" wide,

perimeter of opening. Top turndown into cold bain marie

with a thermal breaker under turndown on all sides. Unit to

be provided with 1/4 hp, 120V, 60HZ, 1PH compressor with

thermal overload protection and on/off switch.

Cold food wells to measure 12" x 20" x 6

seamless drawn stainless steel with cove corners, fully

insulated with copper coils and encased in separate metal

housing. Wells to accommodate full or partial size pans up

to 6" deep.*

Frame structure to consist of 18 gauge stainless steel

formed pedestals to be reinforced with 16 gauge stainless

steel channels, to have full height extruded plastic vertical

bumpers. Casters are to be 4" diameter heavy duty, double

ball bearing, swivel type with polyurethane tires. Two

casters to be provided with foot brakes. Unit to be

completely wired and provided with a 6'-0" long cord and

plug located at rear of unit from worker's side.

1

" high, raised pan rest around

8

3

" deep, of

8

* Pans not included.

Overshelf - To be 16 gauge stainless steel, 10" wide with

1

channel edges. Supports to be 1" x

" flat bar. Shelf to be

4

located rear of unit 15" above work top.

2 Well 3 Well 4 Well

26" wide units

18" wide units

A-64

A-86

Sneeze Protector** - To be

A-65

A-87

3

" clear polycarbonate plastic,

16

A-66

suspended from 16 gauge stainless steel overshelf.

2 Well 3 Well 4 Well

26" wide units

18" wide units

A-60

A-84

A-61

A-85

A-62

Push Handle - To be 1" O,D. 16 gauge stainless steel

tubing with two 16 ga. stainless steel support brackets and

3" neoprene donut bumpers. Specify which end, when

facing control panel, at time of order.

26" wide units

18" wide units

A-15

A-16

ACC-52 - Vertical corner bumpers only. Easy to replace.

1

(Add 1

" to length and width)

4

** Includes overshelf.

CADDY CORPORATION

509 Sharptown Road P.O. Box 345

Bridgeport, NJ 08014-0345

Tel: 856-467-4222 Fax: 856-467-5511

internet: www.caddycorp.com

08/08

Page 3

CADDY

CADDY Food Service Systems

CADDYCADDY

page 2 of 2

Food Service Systems

Food Service SystemsFood Service Systems

Cold Food Caddys

R

Regular or slimline

ITEM NO:

PROJECT:

LOCATION:

¤

Full height vertical corner bumpers ¤ Insulated cold food wells with coils ¤ Thermostat control

¤

Heavy duty, double ball bearing swivel casters with polyurethane tires.

RIF-602 RIF-603 RIF-604 RIF-605 RIF-606

All Cold Food Caddys feature:

Model

RIF-602

RIF-603

RIF-604

RIF-605

RIF-606

Dimensions

Length

52"

67"

82"

97"

Width

26"

26"

26"

26"

Height

1

34

2

1

34

2

1

34

2

1

34

2

1

34

2

Model Volts

"26"37"

"

"

"

"

RIF-602 120

RIF-603 120 1

RIF-604 120 1

RIF-605 120 1

RIF-606 120

Electrical Data

Phase

Amps

5.8 5-15P15-15R

5.8

5.8

8.8

1

* Outlet not supplied by Caddy Corporation.

8.8

NEMA

Plug

Outlet *

5-15P 5-15R

5-15P 5-15R

5-15P 5-15R

5-15P 5-15R

RIF-612 RIF-613 RIF-614

Model

RIF-612

RIF-613

RIF-614

Dimensions

Length

76"

99"

Width

18"53"

18"

18"

Height

1

34

2

1

34

2

1

34

2

Model Volts

"

"

"

RIF-612 120

RIF-613 120 1

RIF-614 120

Electrical Data

Phase

Amps

5.8 5-15P1 5-15R

5.8

1

* Outlet not supplied by Caddy Corporation.

5.8

CADDY CORPORATION

509 Sharptown Road P.O. Box 345

Bridgeport, NJ 08014-0345

Tel: 856-467-4222 Fax: 856-467-5511

internet: www.caddycorp.com

NEMA

Plug

Outlet *

5-15P 5-15R

5-15P 5-15R

08/08

Loading...

Loading...