Page 1

Installation and operating instructions

for the MAX CADDY WOOD FURNACE

(PF01102 model)

Certified according to CSA B415.1-10, CSA B366.1, UL391,

CSA C22.2 NO.236, UL 1995, CAN/CSA B140.4 and UL 727

FURNACE MODELS INCLUDED IN THIS MANUAL

COMBINATION

WOOD ONLY

20 kW / 25 kW AND OIL

Read these instructions carefully before installing

and operating your furnace.

CONGRATULATIONS!

You have purchased one of the finest wood or combination furnaces available

on the market. We are confident that your furnace will provide years of comfort

and safe operation.

Please keep this document!

This manual is available for free download on the manufacturer’s

Verified and tested for Canada and

the United States by an accredited

laboratory.

Eco-energy at the hearth

of your home

45833A

Printed in Canada 07-06-2016

web site. It is a copyrighted document. Re-sale is strictly

prohibited. The manufacturer may update this manual from time

to time and cannot be responsible for problems, injuries, or

damages arising out of the use of information contained in any

manual obtained from unauthorized sources.

PSG

250, de Copenhague,

St-Augustin-de-Desmaures (Quebec)

CANADA G3A 2H3

Page 2

TABLE OF CONTENT

1. INTRODUCTION ......................................................................................................................................................................... 5

2. APPLIANCE PERFORMANCE

3. GENERAL FEATURES .............................................................................................................................................................. 7

4. SPECIFICATIONS ...................................................................................................................................................................... 8

5. MAX CADDY FURNACE TECHNICAL DATA ........................................................................................................................... 9

6. FURNACE DIMENSIONS ........................................................................................................................................................... 9

7. CHIMNEY AND DRAFT ............................................................................................................................................................ 11

8. SAFETY RULES ....................................................................................................................................................................... 11

8.1.

GENERAL REQUIREMENTS .......................................................................................................................................... 11

8.2.

ODOUR FROM THE PAINT ............................................................................................................................................. 11

8.3.

ASH DISPOSAL ............................................................................................................................................................... 11

8.4.

CREOSOTE BUILD-UP AND REMOVAL......................................................................................................................... 11

8.5.

SMOKE DETECTOR ....................................................................................................................................................... 12

8.6.

DOOR GLASS ................................................................................................................................................................. 12

8.6.1. GLASS SPECIFICATIONS .............................................................................................................................................. 12

8.7.

ASH DRAWER ................................................................................................................................................................. 12

8.8.

ASH GRATE .................................................................................................................................................................... 12

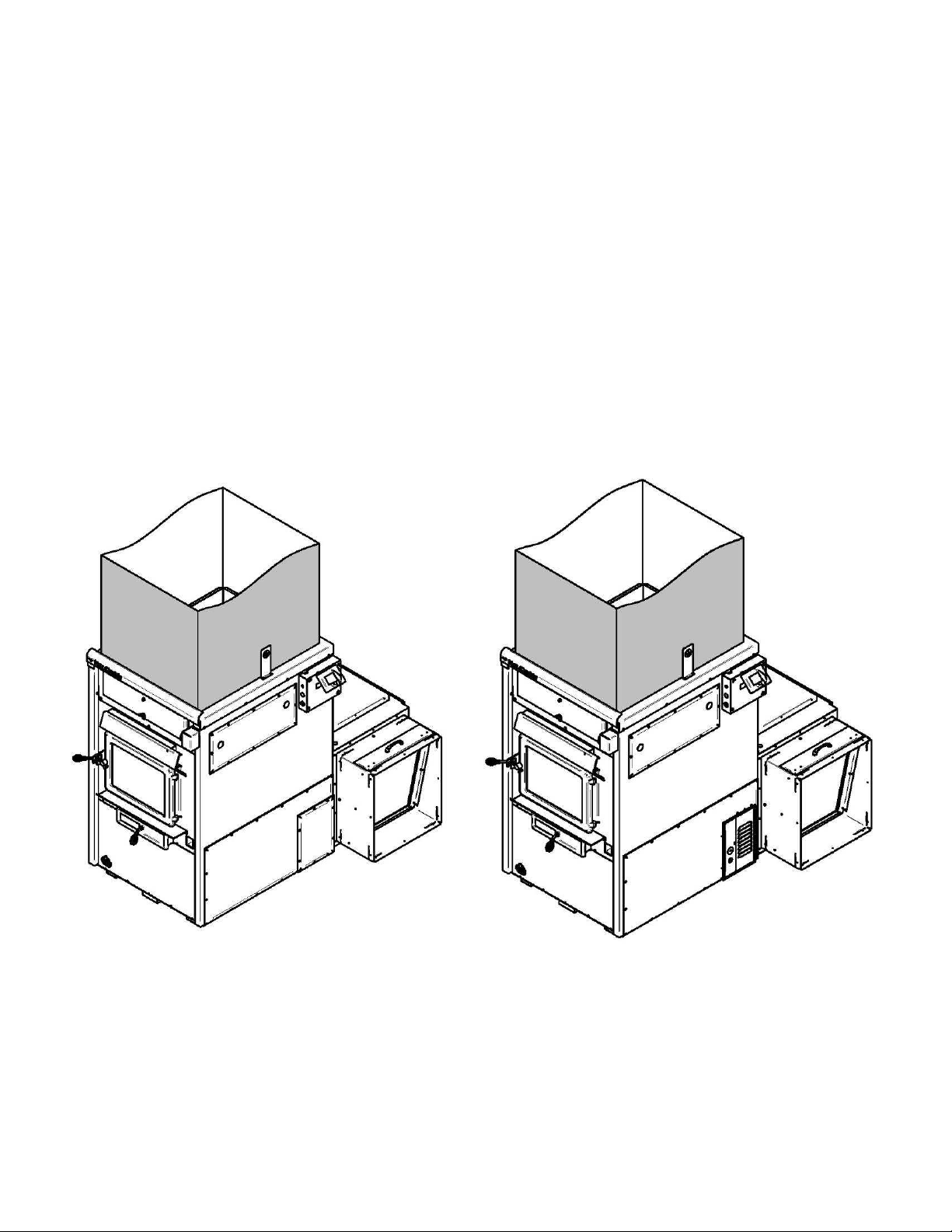

MAX CADDY WOOD ONLY FURNACE, COMBINED WOOD / ELECTRIC OR PARALLEL ADD-ON PF01102 ............................ 13

9. INSTALLATION INSTRUCTIONS ............................................................................................................................................ 14

9.1.

BLOWER INSTALLATION ............................................................................................................................................... 14

9.2.

LINK BOARD INSTALLATION AND CONNECTION ........................................................................................................ 14

9.3.

TOUCHSCREEN INSTALLATION AND CONNECTION .................................................................................................. 18

9.4.

HOT AIR PLENUM TEMPERATURE PROBE INSTALLATION AND CONNECTION (RTD) ............................................ 19

9.5.

SERVOMOTOR INSTALLATION AND CONNECTION.................................................................................................... 20

9.6.

UNIT LOCATION ............................................................................................................................................................. 21

9.7.

MINIMUM CLEARANCES TO COMBUSTIBLE MATERIALS AND FLOOR PROTECTION ............................................. 21

9.7.1. MINIMUM CLEARANCES TO COMBUSTIBLE MATERIALS .......................................................................................... 22

9.7.2. MINIMUM CLEARANCES TO COMBUSTIBLES MATERIALS FOR AIR RETURN DUCT ............................................... 23

9.7.3. MINIMUM CLEARANCES TO COMBUSTIBLES MATERIALS FOR HOT AIR PLENUM ................................................. 23

9.7.4. FLOOR PROTECTION .................................................................................................................................................... 23

9.8.

FLUE AND BAROMETRIC DRAFT CONTROL CONNECTION ....................................................................................... 24

9.9.

ELECTRICAL CONNECTIONS ....................................................................................................................................... 25

9.10. DAMPER ......................................................................................................................................................................... 25

9.11. COMBUSTION AIR AND FRESH AIR INTAKE ADAPTER INSTALLATION (OPTIONAL) ............................................... 25

9.12. HOT AIR PLENUM ........................................................................................................................................................... 26

9.13. PARALLEL INSTALLATION (US ONLY) .......................................................................................................................... 26

9.14. ELECTRICAL ELEMENT INSTALLATION (OPTIONAL).................................................................................................. 29

9.14.1. INTRODUCTION ............................................................................................................................................................. 29

9.14.2. CONNECTING THE ELECTRICAL ELEMENT ................................................................................................................ 29

10. THERMOSTAT INSTALLATION .............................................................................................................................................. 30

10.1. WOOD FURNACE ONLY................................................................................................................................................. 30

10.1.1. COMBINATION WOOD-ELECTRIC OR WOOD-OIL FURNACE ..................................................................................... 30

10.1.2. COMBINATION WOOD-ELECTRIC-OIL ......................................................................................................................... 30

10.2. INSTALLATION OF AN AIR CONDITIONING UNIT ......................................................................................................... 31

10.3. HEATPUMP INSTALLATION ........................................................................................................................................... 31

10.4. INSTALLATION OF A DOMESTIC WATER PRE-HEATING SYSTEM OR A HUMIDIFIER ............................................. 32

11. CONFIGURATION AND OPERATING INSTRUCTIONS ......................................................................................................... 32

11.1. CONTROLS SYSTEM ..................................................................................................................................................... 32

11.2. SYSTEM CONFIGURATION ........................................................................................................................................... 33

11.3. TOUCH SCREEN ............................................................................................................................................................ 33

11.3.1. ICONS DESCRIPTION .................................................................................................................................................... 33

11.3.2. LANGUAGE SELECTION AND TEMPERATURE UNIT................................................................................................... 34

11.4. ADDING AUXILIARY HEATING SOURCE AND SELECTION OF OPTIONS ................................................................... 34

11.4.1. TRANSITION TO AN AUXILIARY HEAT SOURCE .......................................................................................................... 34

11.4.2. TRANSITION SETTINGS ................................................................................................................................................ 34

11.4.3. AUXILIARY HEAT SOURCE PRIORITIZATION .............................................................................................................. 35

11.4.4. EXTERNAL TEMPERATURE PROBE ............................................................................................................................. 35

11.4.4.1. “BI-ENERGY” FUNCTION ............................................................................................................................................... 35

11.5. DISTRIBUTION BLOWER SPEED CONFIGURATION ................................................................................................... 36

11.5.1. DISTRIBUTION FAN SPEEDS ........................................................................................................................................ 36

11.6. SYSTEM BALANCING .................................................................................................................................................... 36

11.7. OPERATING INSTRUCTIONS ........................................................................................................................................ 37

11.7.1. HEAT M

2

ODE

..................................................................................................................................................................... 37

(1)

................................................................................................................................................ 6

Page 3

11.7.2. COOL M

11.7.3. CIRC M

11.8. WOOD HEATING ............................................................................................................................................................ 38

11.8.1. LIGHTING ........................................................................................................................................................................ 38

11.8.2. PREHEATING ................................................................................................................................................................. 38

11.8.3. HEATING ......................................................................................................................................................................... 38

11.8.4. EARLY SIGNS OF AN OVERFIRED FURNACE: ............................................................................................................. 38

11.8.5. WOOD AS HEATING FUEL ............................................................................................................................................. 39

11.8.6. PROLONGED POWER FAILURE .................................................................................................................................... 39

11.8.7. CHIMNEY FIRES ............................................................................................................................................................. 39

11.8.8. LOCAL FIRE DEPARTMENT ........................................................................................................................................... 39

12. MAINTENANCE ........................................................................................................................................................................ 40

12.1. MAINTENANCE OF THE EXCHANGERS ....................................................................................................................... 40

12.2. CHIMNEY MAINTENANCE ............................................................................................................................................. 41

12.3. SMOKE PIPE INSPECTION ............................................................................................................................................ 41

12.4. BLOWER MOTOR MAINTENANCE ................................................................................................................................ 41

12.5. FILTERS .......................................................................................................................................................................... 41

12.5.1. AIR FILTER DIMENSIONS .............................................................................................................................................. 41

12.6. DOOR GASKET MAINTENANCE .................................................................................................................................... 41

12.6.1. DOOR ADJUSTMENT PROCEDURE ............................................................................................................................. 41

13. REPLACEMENT PARTS .......................................................................................................................................................... 42

13.1. DOOR GLASS ................................................................................................................................................................. 42

13.2. GASKET .......................................................................................................................................................................... 42

14. TROUBLESHOOTING .............................................................................................................................................................. 42

14.1. VALIDATING STATUS OF A COMPONENT .................................................................................................................... 43

14.1.1. DISTRIBUTION BLOWER ............................................................................................................................................... 43

14.1.2. AIR DAMPER, HOT WATER AND HUMIDIFIER .............................................................................................................. 43

14.1.3. TEMPERATURE PROBE (RTD) ...................................................................................................................................... 44

14.2. MAIN ERROR CODES, POSSIBLE CAUSES AND SOLUTIONS .................................................................................... 44

14.2.1. UNIT OVERHEAT ............................................................................................................................................................ 44

14.2.2. NO HEAT ......................................................................................................................................................................... 45

14.2.3. COMMUNICATION ERROR ............................................................................................................................................ 45

14.2.4. SMOKE SMELL ............................................................................................................................................................... 46

14.2.5. THE LCD TOUCH SCREEN DOES NOT LIGHTUP. ........................................................................................................ 46

14.2.6. AUXILIARY OVERRIDE .................................................................................................................................................. 46

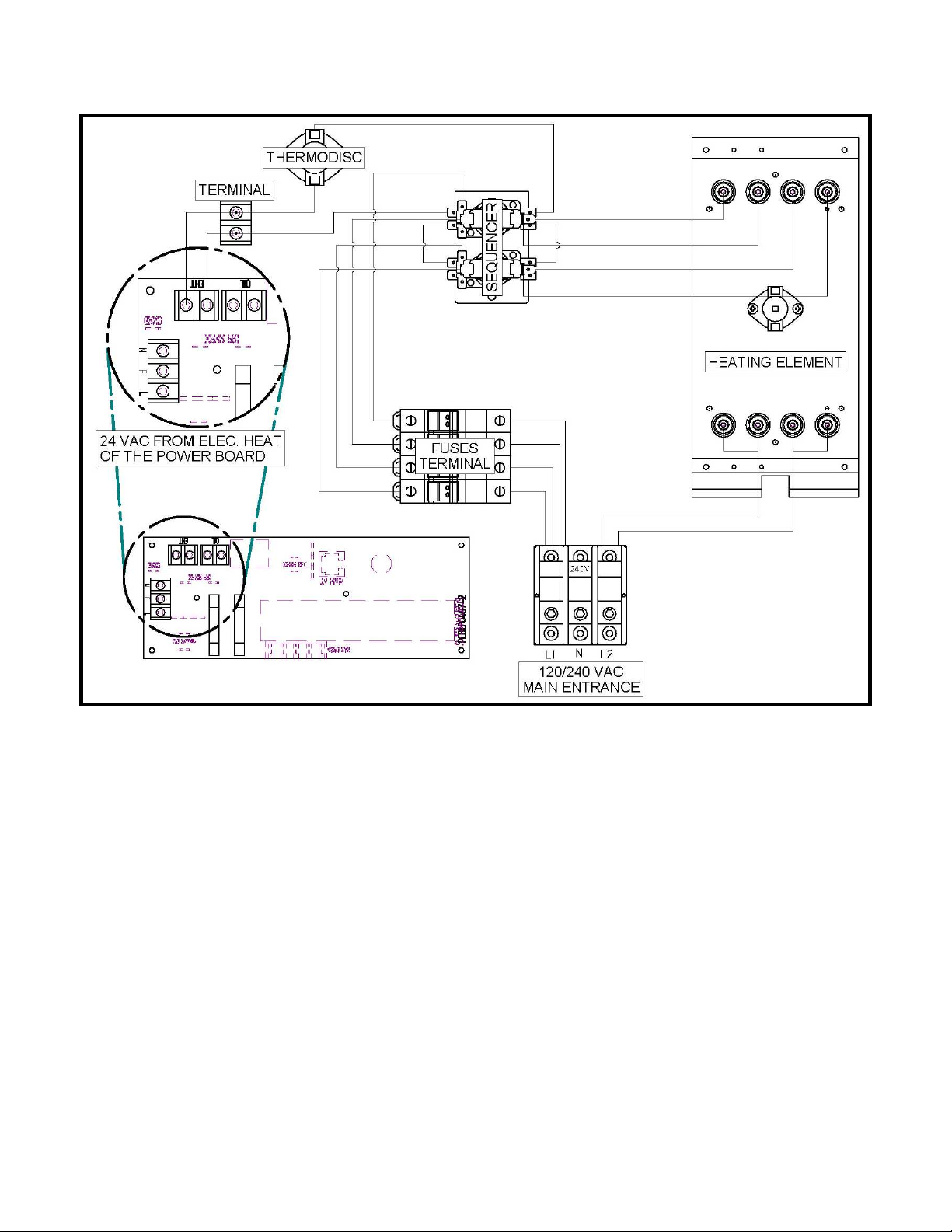

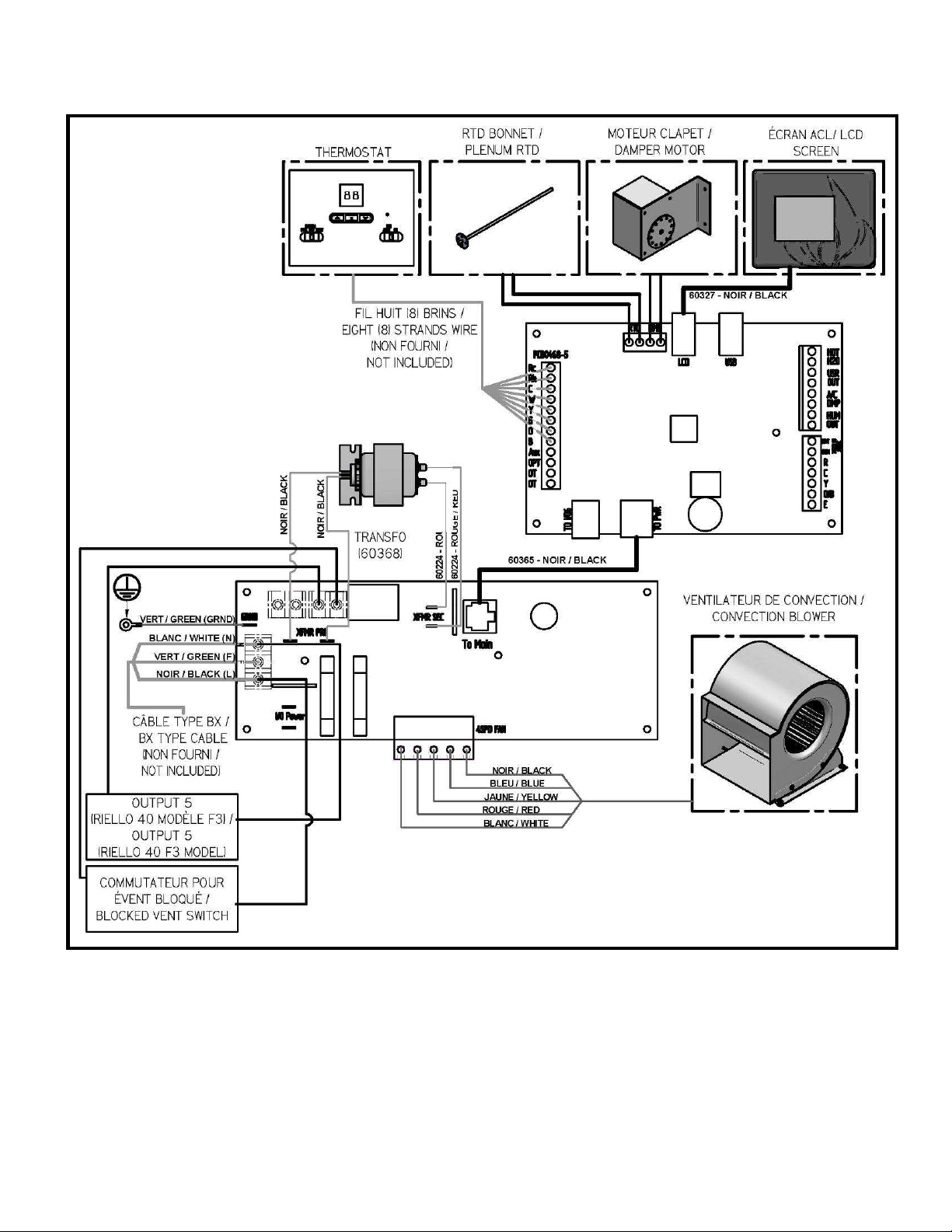

15. GENERAL ELECTRICAL DIAGRAM ....................................................................................................................................... 47

16. ELECTRICAL DIAGRAM FOR PARALLEL FURNACE .......................................................................................................... 48

17. ELECTRICAL DIAGRAM FOR ELECTRIC UNIT ..................................................................................................................... 49

WOOD/OIL COMBINATION FURNACE ............................................................................................................................................ 50

18. GENERAL NOTES ................................................................................................................................................................... 52

19. DRAFT AND CHIMNEY ............................................................................................................................................................ 52

20. OIL TANK AND PIPING ........................................................................................................................................................... 52

21. BURNER PUMP........................................................................................................................................................................ 52

22. APPLIANCE INSTALLATION .................................................................................................................................................. 53

22.1. UNIT LOCATION ...................................................................................................................................................................... 53

22.2. PARALLEL INSTALLATION .................................................................................................................................................... 53

22.3. MINIMUM CLEARANCES TO COMBUSTIBLE MATERIALS ................................................................................................. 53

22.4. FLOOR PROTECTION ............................................................................................................................................................. 54

22.5. HOT AIR PLENUM ................................................................................................................................................................... 54

22.6. CONNECTING PIPE AND MANUAL DAMPER ....................................................................................................................... 54

22.7. DIFFERENT INSTALLATION ................................................................................................................................................... 55

22.8. COMBUSTION AIR................................................................................................................................................................... 56

22.9. ELECTRICAL WIRING ............................................................................................................................................................. 56

22.10.

THERMOSTAT ................................................................................................................................................................ 56

23. OPERATION INSTRUCTION ................................................................................................................................................... 56

23.1. FAN SPEED CONTROL ........................................................................................................................................................... 56

23.2. COMBUSTION SAFETY CONTROL ........................................................................................................................................ 56

23.3. PRE-PURGE ............................................................................................................................................................................. 56

23.4. SAFE OPERATION .................................................................................................................................................................. 56

ODE

..................................................................................................................................................................... 37

ODE (AIR CIRCULATION

) ........................................................................................................................................... 37

3

Page 4

23.5. TEMPORARY DISENGAGEMENT OF THE BURNER ............................................................................................................ 56

23.6. COMBUSTION ADJUSTMENT AND VERIFICATION ............................................................................................................. 57

23.6.1. COMBUSTION VERIFICATION PROCEDURE: .............................................................................................................. 57

23.6.2. ELECTRODES SETTING ................................................................................................................................................ 58

23.7. APPLIANCE START-UP .......................................................................................................................................................... 59

23.8. PROLONGED CLOSING .......................................................................................................................................................... 59

24. TECHNICAL DATA ................................................................................................................................................................... 59

24.1. UH –MAX CADDY .................................................................................................................................................................... 59

25. MAINTENANCE ........................................................................................................................................................................ 59

25.1. MAINTENANCE ........................................................................................................................................................................ 59

25.2. SERVICE .................................................................................................................................................................................. 60

25.3. FILTERS ................................................................................................................................................................................... 60

26. ELECTRICAL DIAGRAM BECKETT OIL UNIT ....................................................................................................................... 61

27. ELECTRICAL DIAGRAM RIELLO OIL UNIT ........................................................................................................................... 62

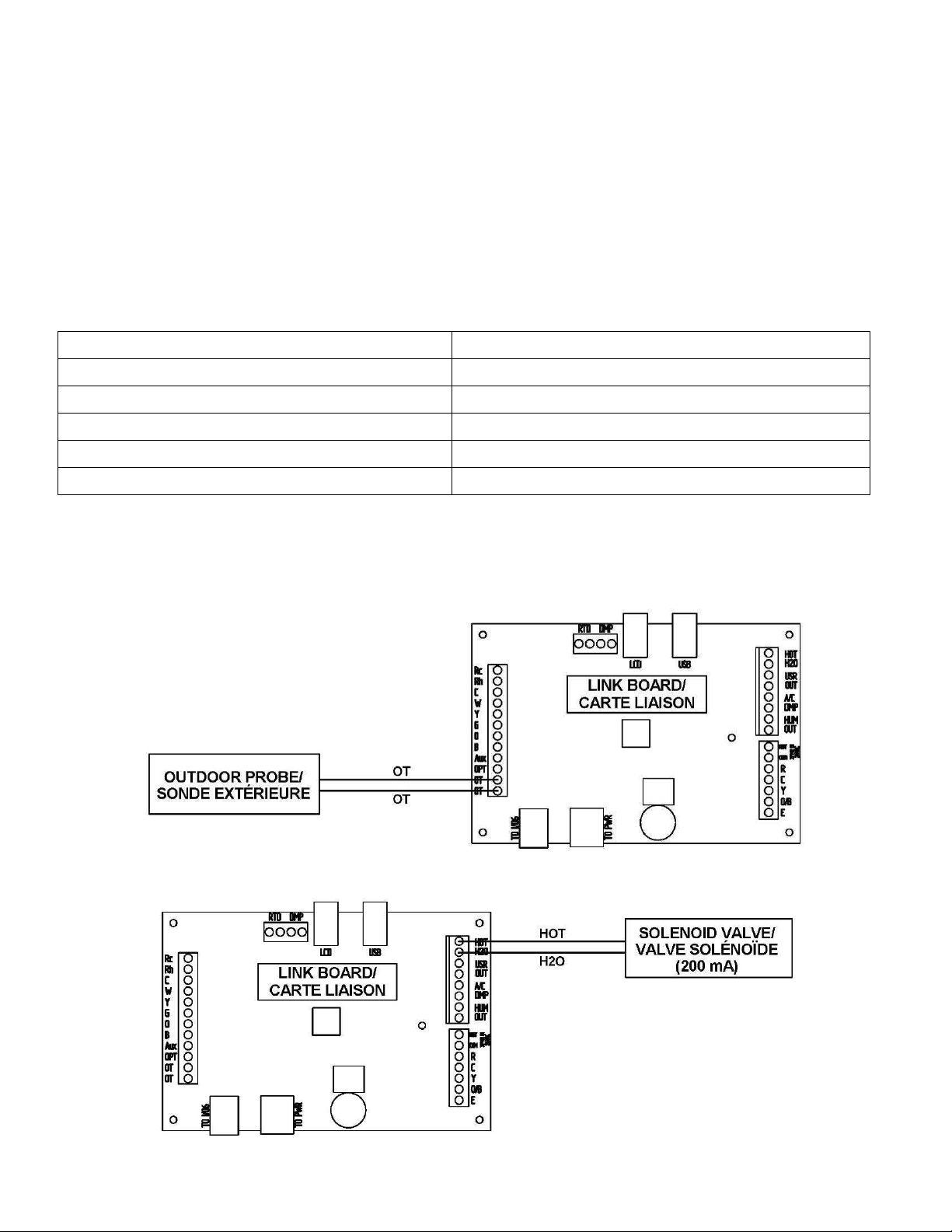

28. LINK BOARD OPTIONS CONNECTIONS ............................................................................................................................... 63

28.1. ELECTRICAL CONSUMPTION ................................................................................................................................................ 63

28.2. OUTDOOR PROBE .................................................................................................................................................................. 63

28.3. HOT WATER ............................................................................................................................................................................ 63

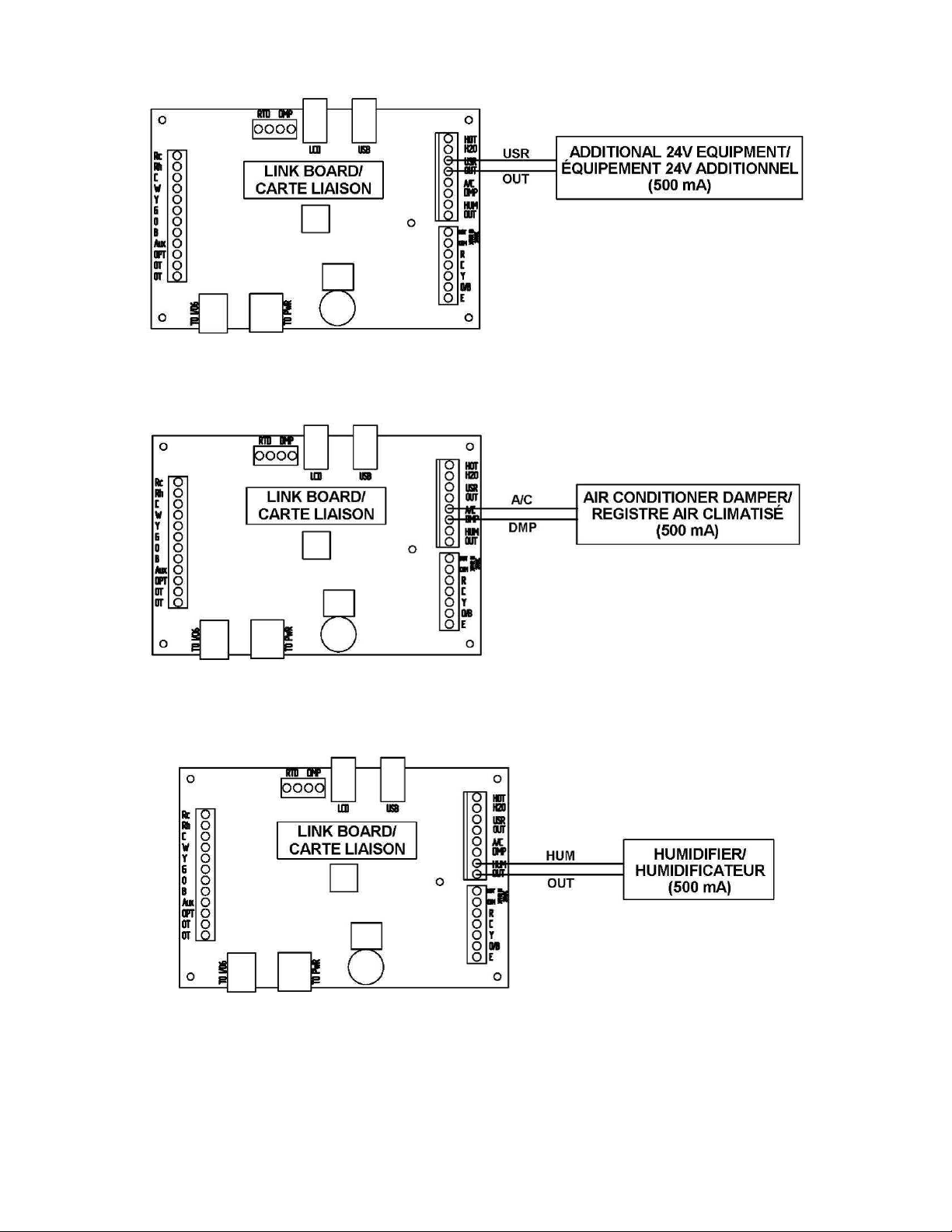

28.4. 24V ADDITIONNAL EQUIPMENT ............................................................................................................................................ 64

28.5. AIR CONDITIONNING DAMPER.............................................................................................................................................. 64

28.6. HUMIDIFIER ............................................................................................................................................................................. 64

28.7. HEAT PUMP ............................................................................................................................................................................. 65

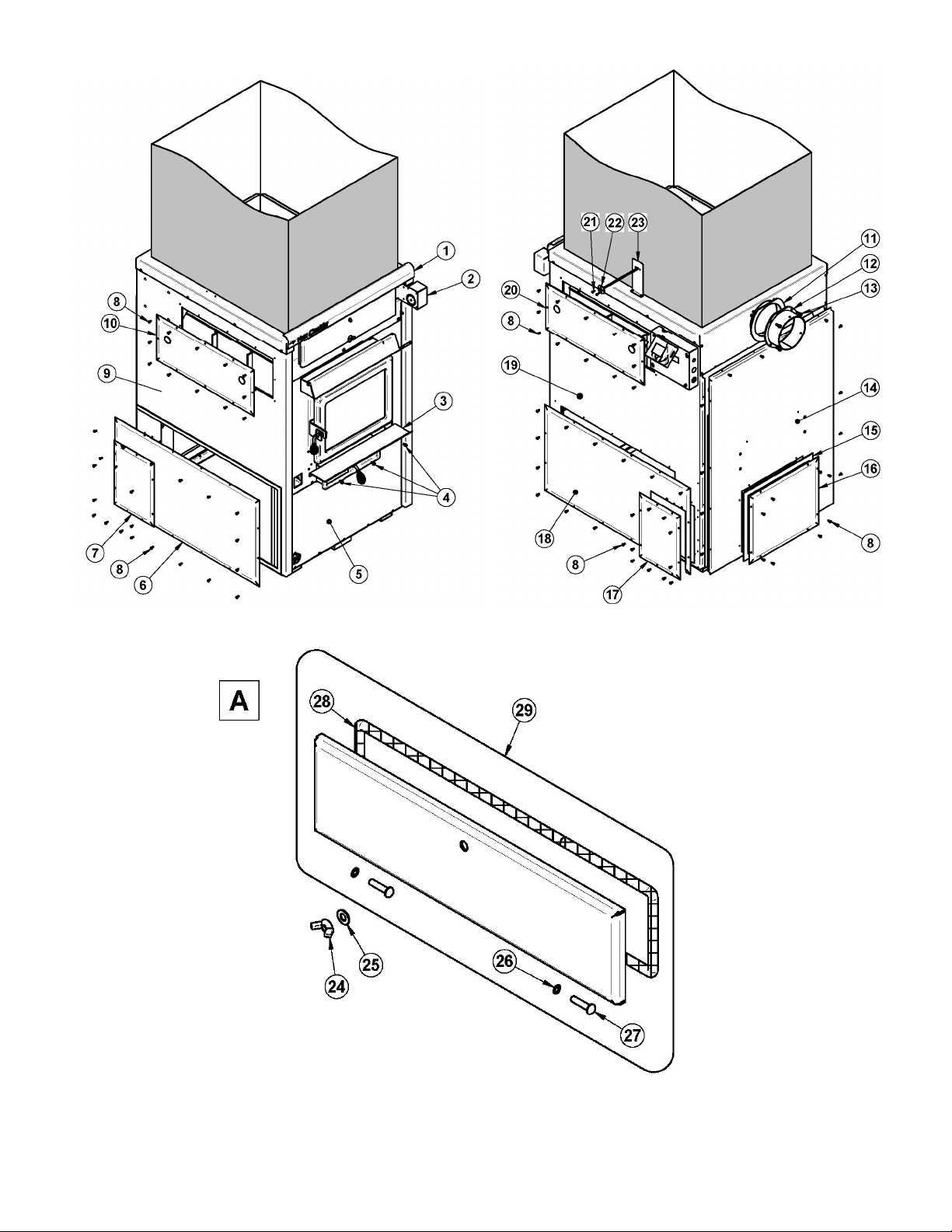

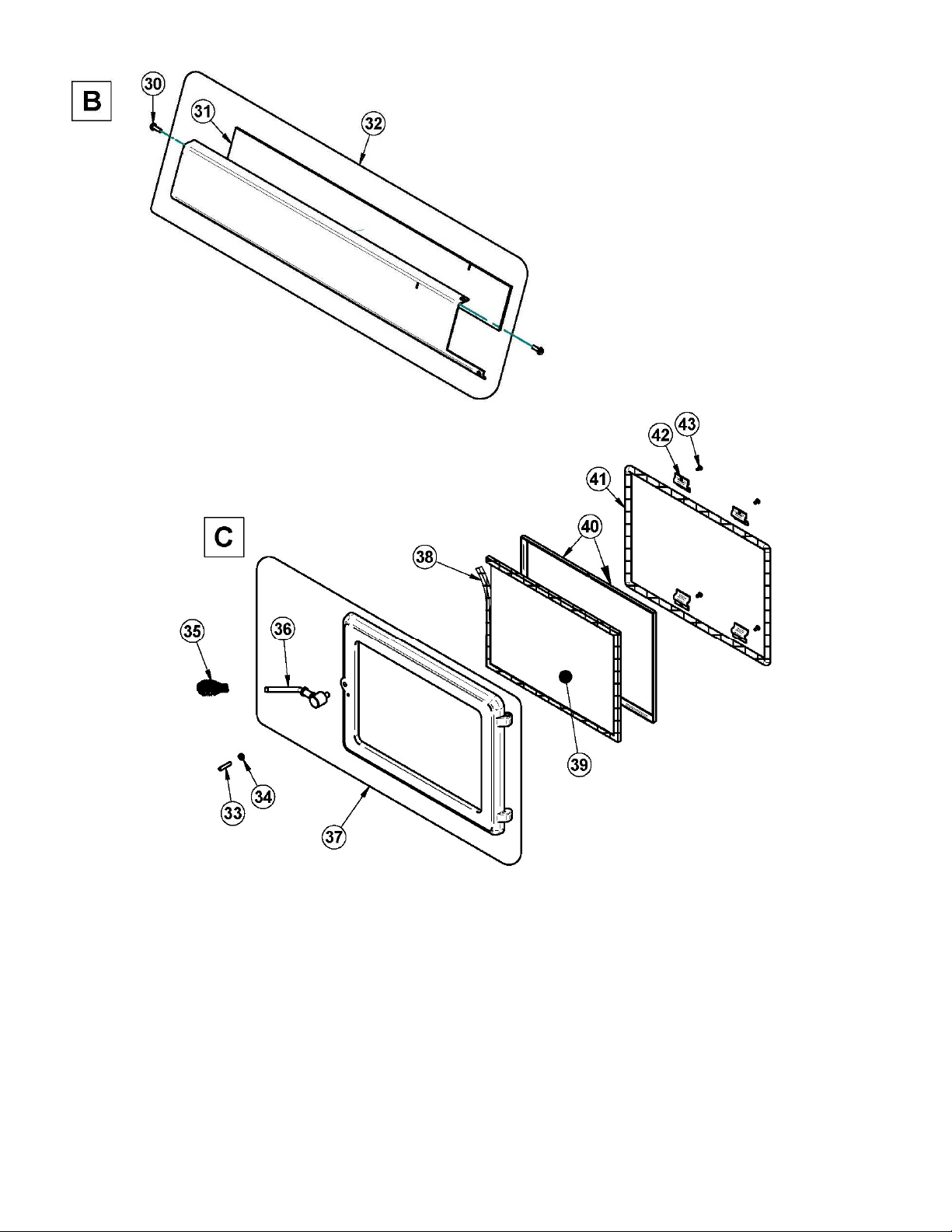

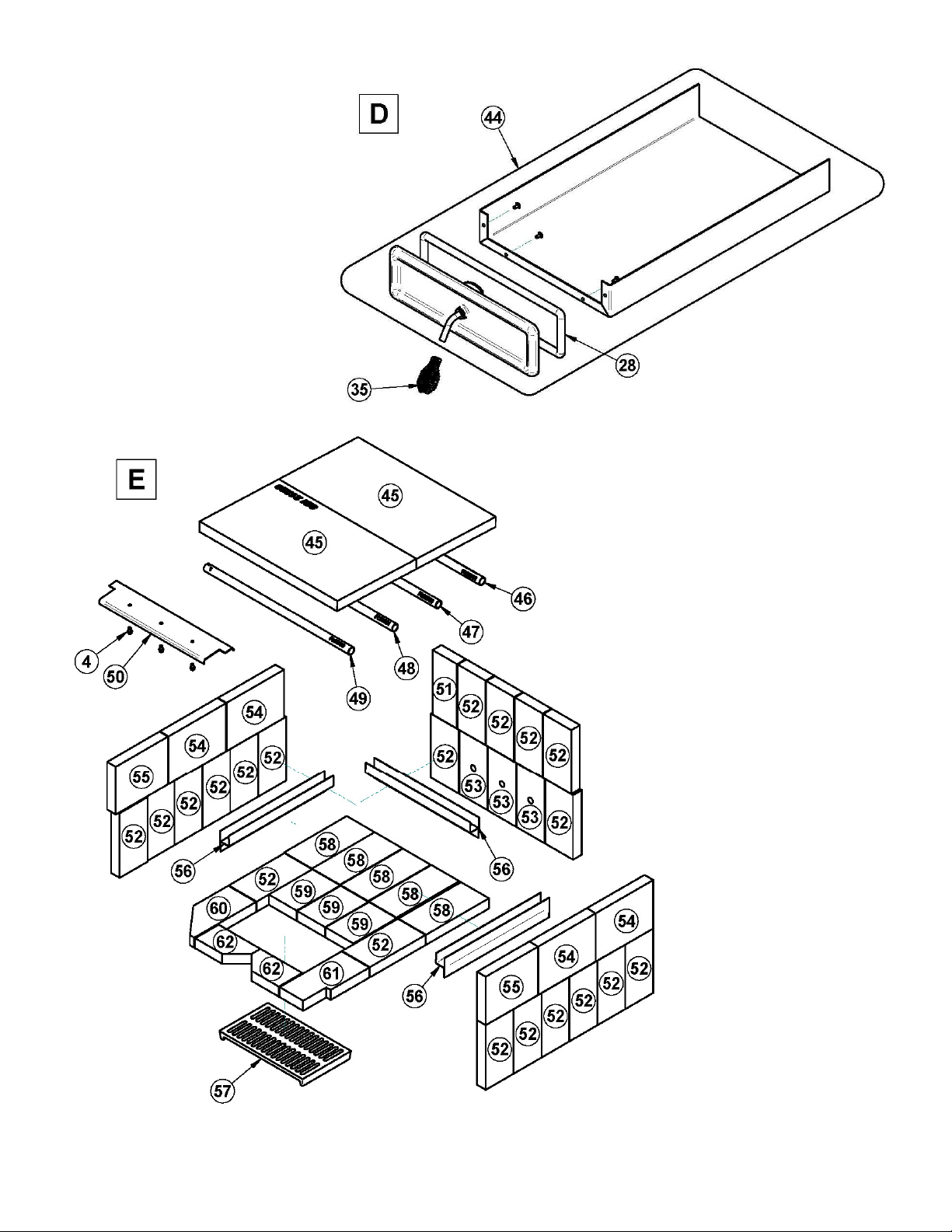

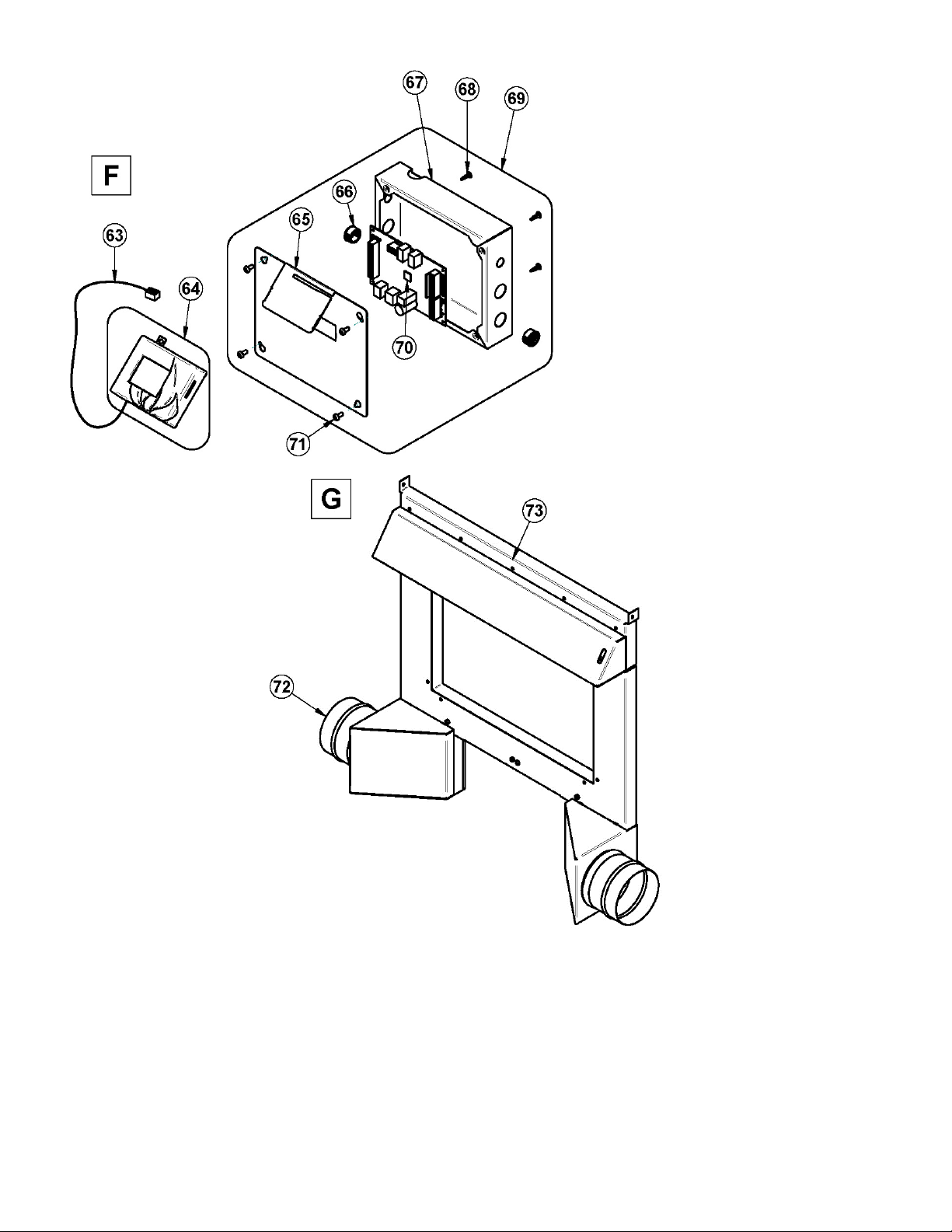

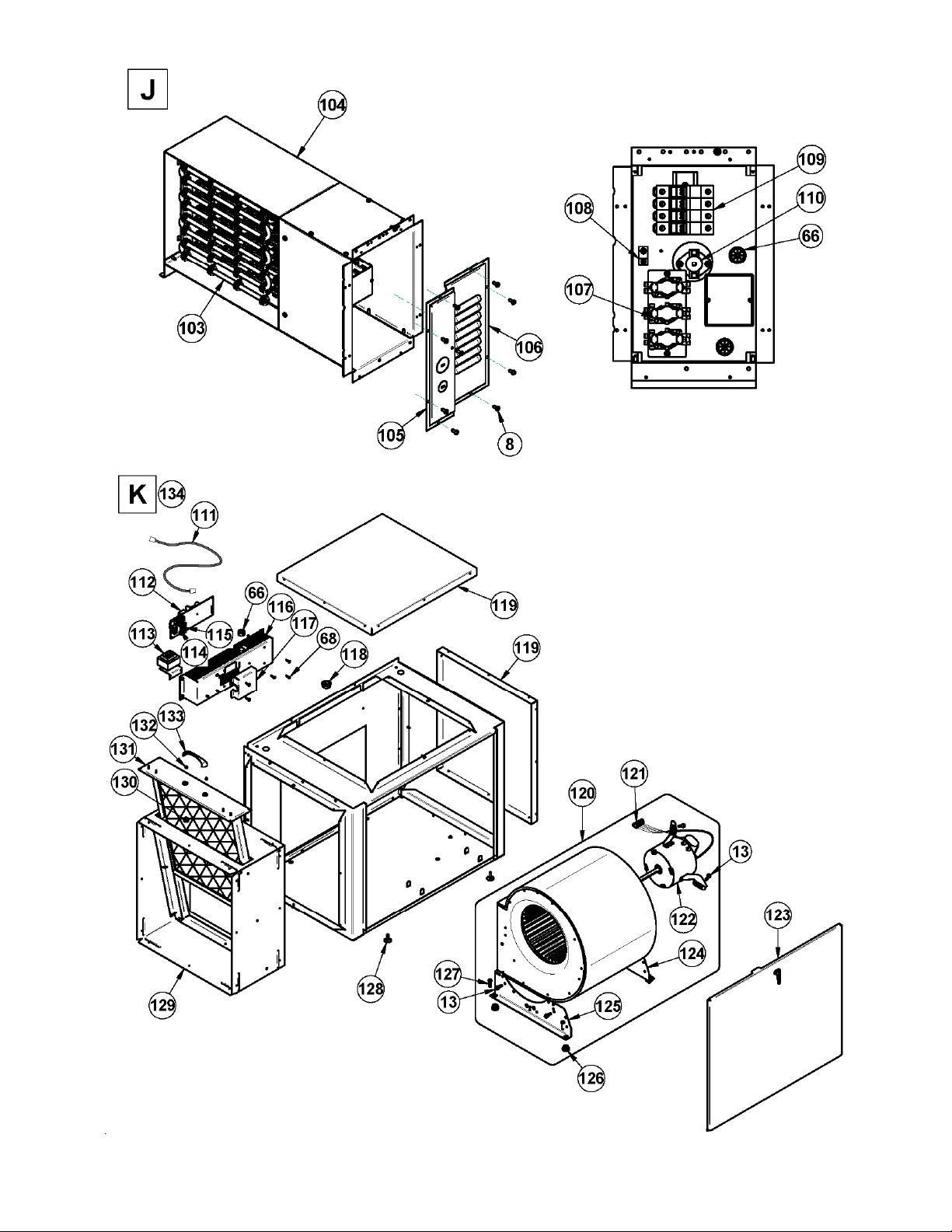

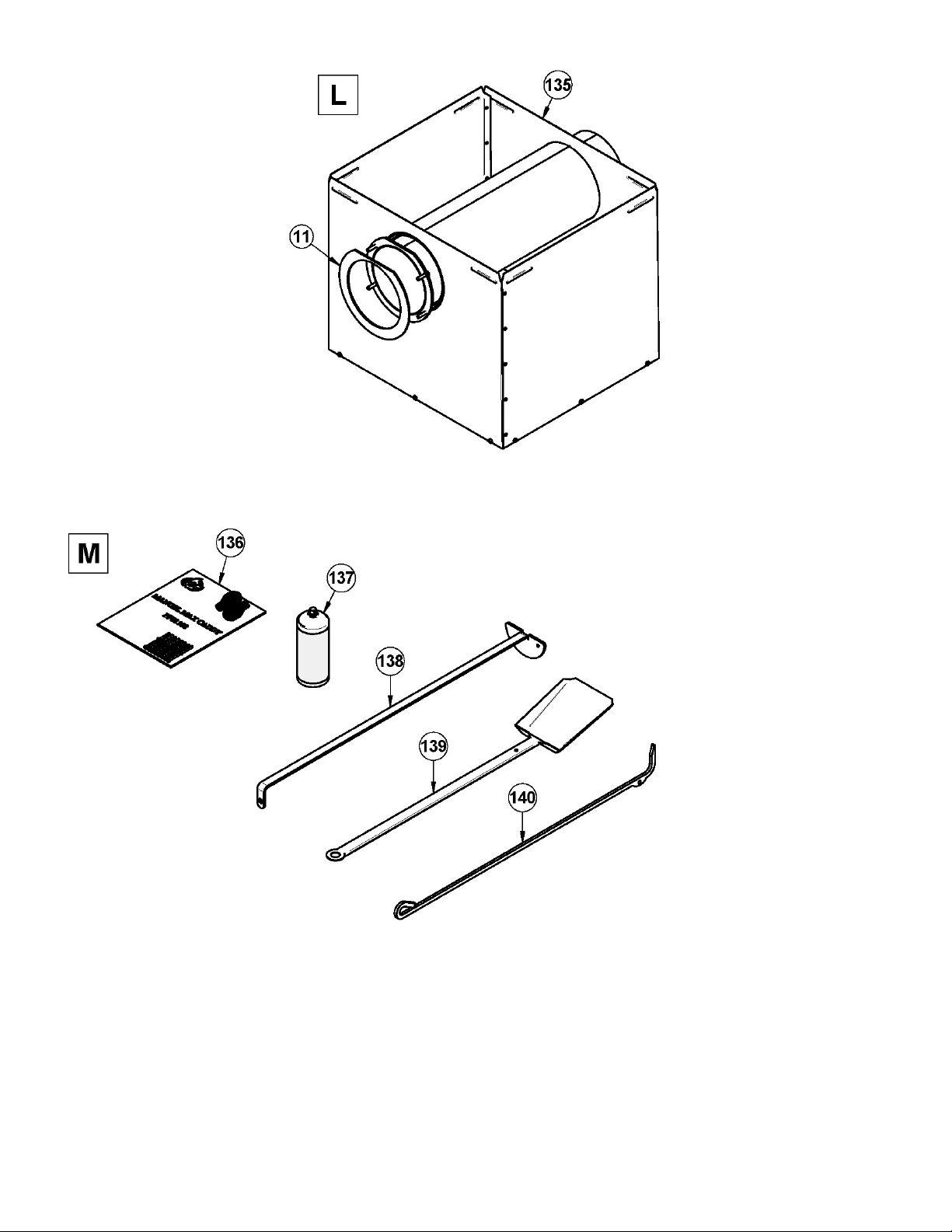

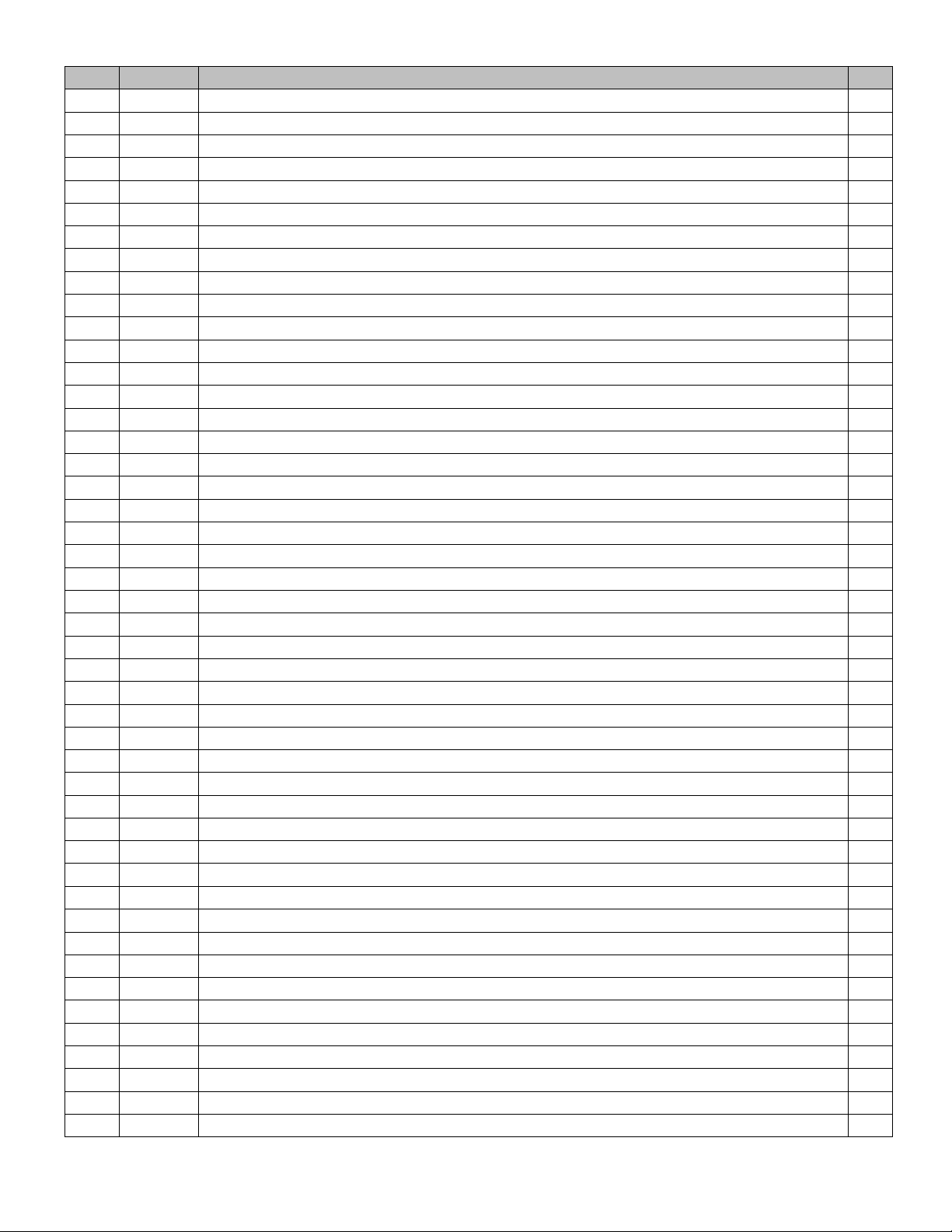

29. EXPLODED VIEW AND PART LIST ........................................................................................................................................ 65

PSG LIMITED LIFETIME WARRANTY (REGULAR) ......................................................................................................................... 78

PSG LIMITED LIFETIME WARRANTY (PRIVILEGE) ....................................................................................................................... 79

4

Page 5

IMPORTANT NOTE:

THE INSTALLATION OF THIS CENTRAL HEATING SYSTEM MUST BE PERFORMED BY A

QUALIFIED TECHNICIAN. PSG RESERVES ITSELF THE RIGHT TO VOID ITS WARRANTY

OR DENY TECHNICAL ADVICE IF THE FURNACE HAS NOT BEEN SOLD OR INSTALLED BY

A PROFESSIONAL.

REGISTER YOU WARRANTY ONLINE

To receive full warranty coverage, you will need to show evidence of the date

you purchased your furnace. Keep your sales invoice. We also recommend

that you register your warranty online at

http://www.caddyfurnaces.com/en/warranty/warranty-registration

Registering your warranty online will help us track rapidly the information we

need on your furnace.

WARNING : THE INSTALLATION OF THIS APPLIANCE REQUIRES THE ADDITION OF A BLOWER ASSEMBLY

(PA08566) NOT INCLUDED.

1. INTRODUCTION

Take note that this furnace operates like an EPA wood burning stove. This applies to the lighting, the ember bed, and

the minimum combustion air intake which was determined based on the use of good seasoned cordwood.

The Max Caddy furnace was tested and approved according to the CSA B415.1-10 Standard.

To optimize the efficiency of your furnace, here is some advice that you should follow when installing or operating your

Max Caddy.

• Respect the local codes (when in doubt, consult your local dealer);

• Make sure your furnace is installed according to the instructions on the certification label;

• All controls and adjustments must be performed by a qualified technician. The blower speed must conform to

the recommendations of local codes and should respect the static pressure ranges in the warm air plenum of

the furnace.

We recommend that our wood burning hearth products be installed and serviced by professionals who are certified in

the United States by NFI (National Fireplace Institute®) or in Canada by WETT (Wood Energy Technical Training) or in

Quebec by APC (Association des Professionnels du Chauffage).

5

Page 6

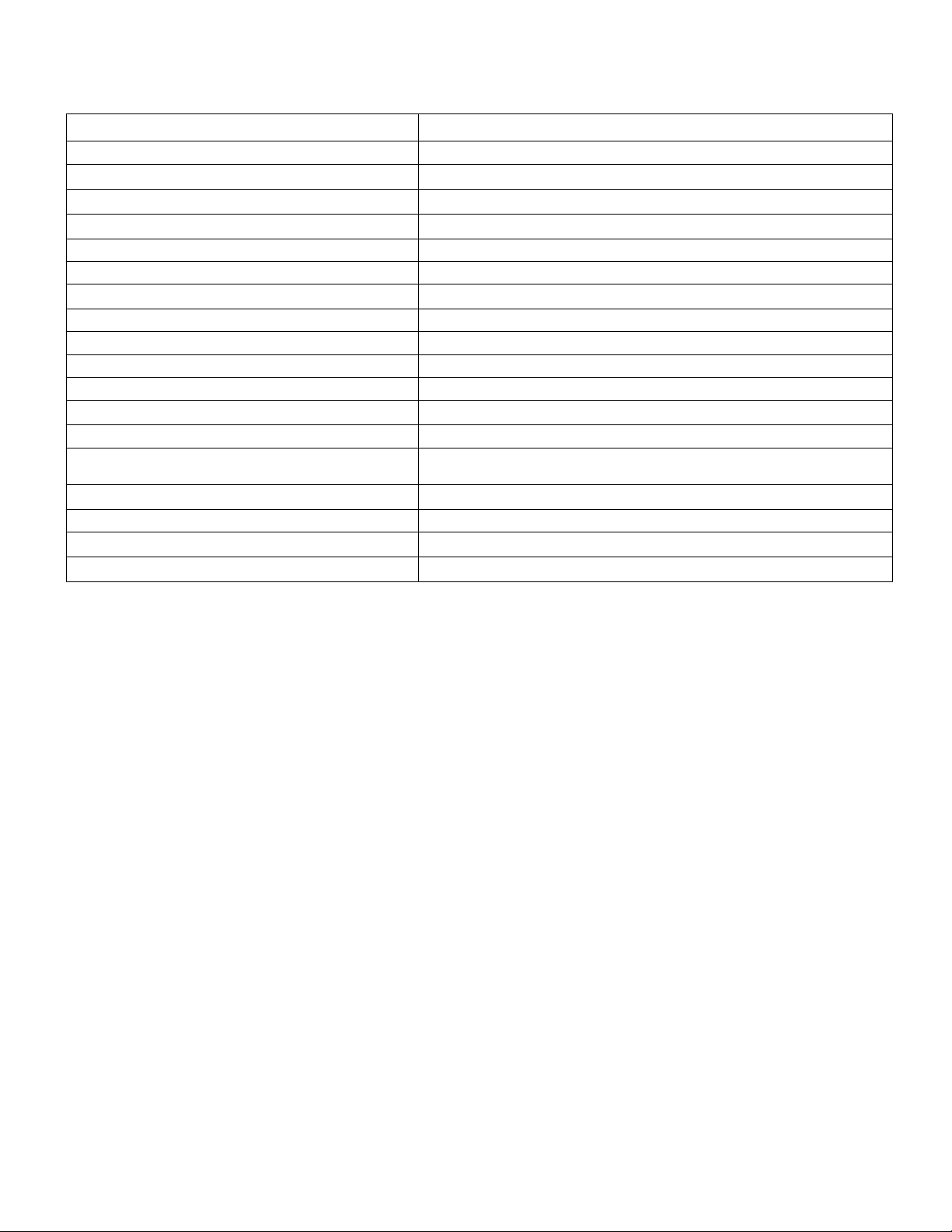

2. APPLIANCE PERFORMANCE

[*]

[*]

(2)

(3)

(4)

(5)

(6)

(7)

(8)

(5)

(6)

(9)

(10)(11)

(12)

(13)

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

(9)

(10)

(11)

(12)

(13)

(1)

Fuel type Dry cordwood

Recommended heating area

1,500 to 3,500 ft² (139 to 325 m²)

Firebox volume 4.9 ft³ (0.139 m³)

Maximum burn time

Maximum input capacity (dry cordwood)

Overall heat output rate (min. to max.)

17 h

421,000 BTU

19,243 BTU/h to 67,069 BTU/h (5.6 kW to 19.6 kW)

Nominal heat output at 15lb/ft³ fuel loading density 100,000 BTU/h

Average overall efficiency

Delivered heat output rate (min. to max.)

Average delivered efficiency

Optimum efficiency

Average particulate emissions rate

Average CO

13.67 lb/mmBTU (5.88 g/MJ)

Average electrical power consumption

[*]

Recommended heating area and maximum burn time may vary subject to location in home, chimney draft, heat loss factors,

climate, fuel type and other variables. The recommended heating area for a given appliance is defined by the manufacturer as its

capacity to maintain a minimum acceptable temperature considering that the space configuration and the presence of heat

distribution systems have a significant impact in making heat circulation optimum.

Values are as measured per CSA B415.1-10, except for the recommended heating area, firebox volume, maximum burn time

and maximum input capacity. Performances based on a fuel load prescribed by the standard at 10 lb/ft³ and with moisture

content between 18% and 28%.

Input value at 10lb/ft³ fuel loading density and dry energy value of 8,600BTU/lb.

Overall: Radiated and delivered heat together at10lb/ft³ fuel loading density over one total burn cycle.

Efficiency based on delivered heat when allowing cycling from high to low burn to simulate thermostat demand.

Higher Heating Value of the fuel.

Lower Heating Value of the fuel.

78.9% (HHV)

16,109 BTU/h to 54,578 BTU/h (4.7 kW to 16.0 kW)

64.8% (HHV)

85.8%

0.735 lb/mmBTU (0.316 g/MJ)

360 Wh

85 % (LHV)

70.2% (LHV)

Delivered: Remotely provided to other rooms through ducting at 10 lb/ft³ fuel loading density over one total burn cycle.

Efficiency based on radiated and delivered heat when allowing cycling from high to low burn to simulate thermostat demand.

Optimum overall efficiency at a specific burn rate (LHV).

Based on delivered heat output.

This appliance is officially tested and certified by an independent agency.

Carbon Monoxyde. Based on overall heat output at 10lb/ft³ fuel loading density.

Unless stated otherwise, measures were taken directly at the main power source and include all electrical components present in

the appliance.

6

Page 7

3. GENERAL FEATURES

Maximum log length 25 in (635 mm) / north-south*

Diameter of the flue collar 6 in (152 mm)

Recommended connector pipe diameter 6 in (152 mm) if installed as wood only or combined wood-electric

Mandatory connector pipe diameter 7 in (178 mm) if installed as combined wood-oil

Recommended chimney diameter

Mandatory chimney diameter 7 in (178 mm) if installed as combined wood-oil

Required type of chimney CAN/ULC S629, UL 103 HT (2100 °F)

Baffle material C-Cast

Add-on installation US only

Alcove installation Not approved

Mobile home installation‡ Not approved

Appliance weight (without option) 614 lb (279 kg)

Shipping weight (without option) 729 lb (331 kg)

Blower (wood or wood/electric options only) 1/2 HP, direct drive, 4 speeds, 2,100 CFM

Filter – dimensions (Width x Depth x Height)

(included with optional blower assembly)

Filter – quantity 1

Particulate emission standard EPA / CSA B415.1-10

USA standard (safety)

Canadian standard (safety)

6 in (152 mm) if installed as wood only or combined wood-electric

16 in x 20 in x 1 in (406 mm x 508 mm x 25 mm)

UL 391, UL 1995, UL 727

CSA B366.1, CSA C22.2 no 236, CAN/CSA B140.4

** East-west: through the door you see the longitudinal sides of the logs; north-south: through the door you see the tips of the logs.

‡

Mobile home (Canada) or manufactured home (USA): The US department of Housing and Urban Development describes

“manufactured homes” better known as “mobile homes” as followed; buildings built on fixed wheels and those transported on

temporary wheels/axles and set on a permanent foundation. In Canada, a mobile home is a dwelling for which the manufacture and

assembly of each component is completed or substantially completed prior to being moved to a site for installation on a foundation

and connection to service facilities and which conforms to the CAN/CSA-Z240 MH standard.

7

Page 8

4. SPECIFICATIONS

Color Grey

Thermostatic control Yes

Door type Single, glass with cast iron frame

Glass type Ceramic glass

Air return plenum – dimensions (Depth or Height) 17 15/16 in

Air return plenum – dimension (Width) 19 15/16 in

Hot air plenum – dimensions (Depth or Height) 32 1/8 in

Hot air plenum – dimension (Width) 25 3/8 in

Ash pan – dimensions (Width x Depth x Height) 11 15/16 in x 19 5/8 in x 2 5/8 in

Clearance – front 48 in

Clearance – back wall 24 in from the blower housing recommended service clearance

Clearance – side wall 6 in without options installed

Clearance – opposite side wall 24 in recommended service clearance

Clearances – ducts 6 in for the first 6 feet with heat shield and 1 in after

Clearance – recommended for maintenance on

option side

Burner – efficiency Beckett AFG : 85 % / Riello : 87%

Burner – standard Beckett AFG

Burner – other brands approved Riello

Burner – location Left or right

Burner – recommended clearance for maintenance 24 in

Burner – mandatory connector pipe diameter

(Wood-oil)

Burner – mandatory exhaust pipe diameter 5 in

Burner – location of exhaust pipe Left or right

Burner – capacity at input #1 / #2 Beckett 91,000 BTU (27 kW) / 120,000 Btu (35 KW)

Burner – orifice at input #1 / #2 Beckett 0,65 gal/h* 70° W (2,46 l/h) for both inputs

Burner – pump pressure at input #1 / #2 Beckett 100 PSI / 175 PSI

Burner – capacity at input #1 / #2 Riello 91,000 BTU (27 kW) / 120,000 Btu (35 KW)

Burner – orifice at input #1 / #2 Riello 0.50 gal/h* 70° W (1.89 l/h) / 0.65 gal/h* 70° W (2.46 l/h)

Burner – pump pressure at input #1 / #2 Riello 150 PSI / 165 PSI

Electric element – location Left or right

Electric element – clearance recommended for

maintenance

Electric element – recommended (maximum

output)

Electric element – other optional (maximum output) 25 kW

Top cold air plenum option – material Galvanized steel

Top cold air plenum option – dimensions

(Width x Depth x Height)

Top cold air plenum option – smoke pipe diameter 6 in

Fresh air intake adapter option 5 in

Fresh air intake adapter – connection location Left or right

Fresh air intake adapter – connecting pipe

diameter

Tested and listed as per applicable standards By an accredited laboratory (CAN/USA)

Warranty

24 in

7 in

24 in

20 kW

20 in x 18 in x 17 1/4 in

6 in

Limited lifetime

* US Gallon (1 US Gallon = 0,83 Imperial Gallon)

8

Page 9

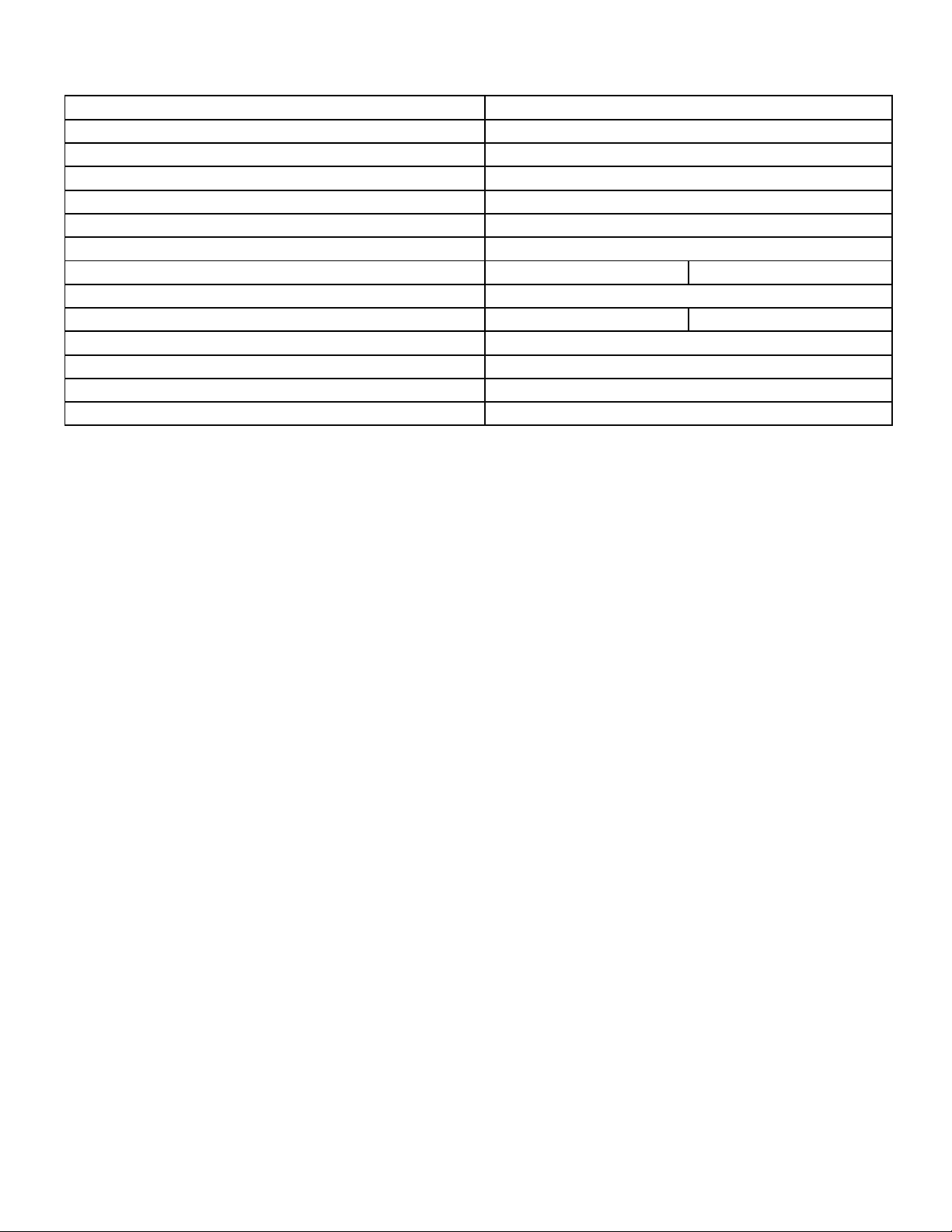

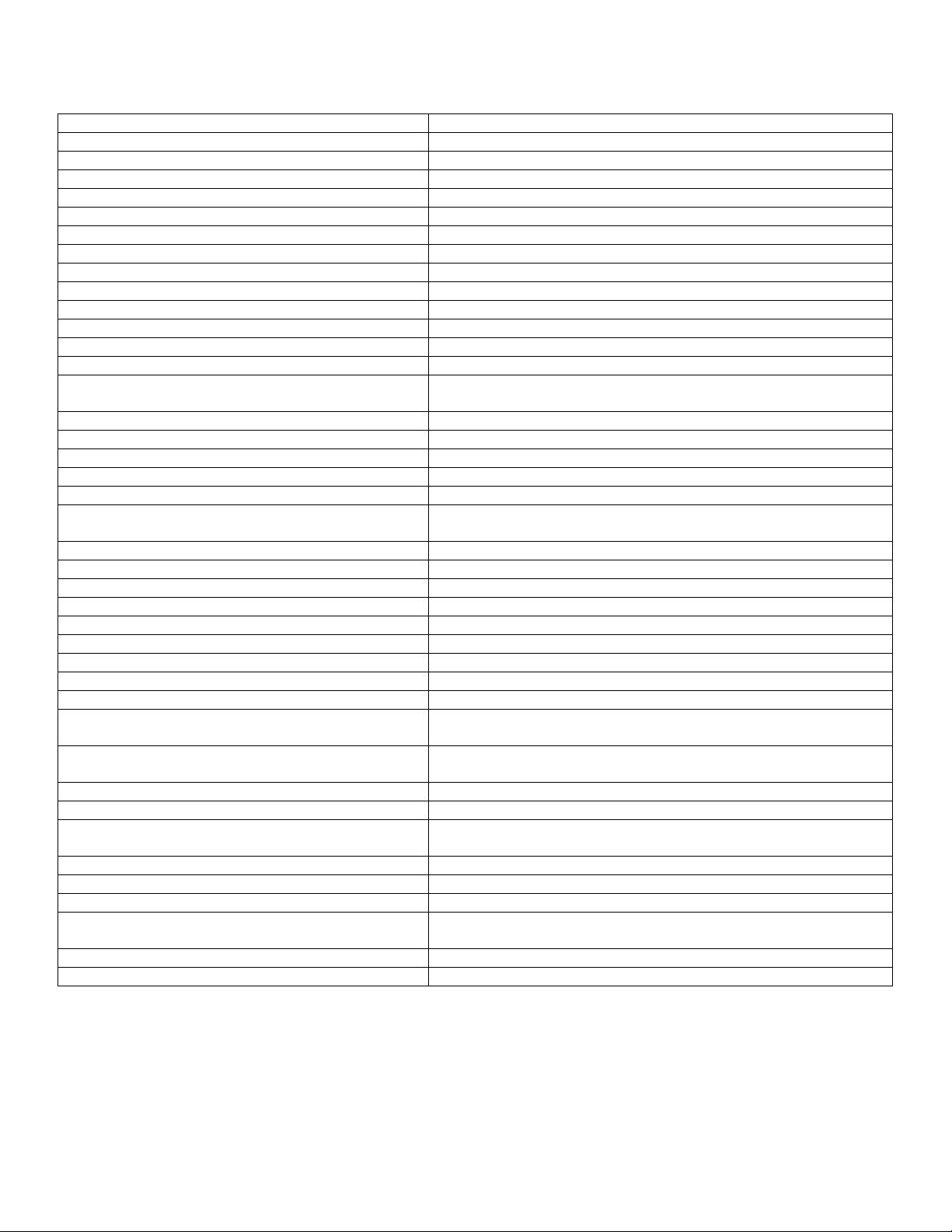

5. MAX CADDY FURNACE TECHNICAL DATA

WOOD AND WOOD/ELECTRIC

WOOD/OIL

MODEL (DIRECT DRIVE)

VENT MOT. VIT. (CFM) (OF) MIN. MAX. (1)

INCH H2O

MAX CADDY WITH

BLOWER / MAX CADDY

ADD-ON (PARALLEL)

G-10 1/2 4 2,100 100 0,2 0,5 16" x 20" x 1"

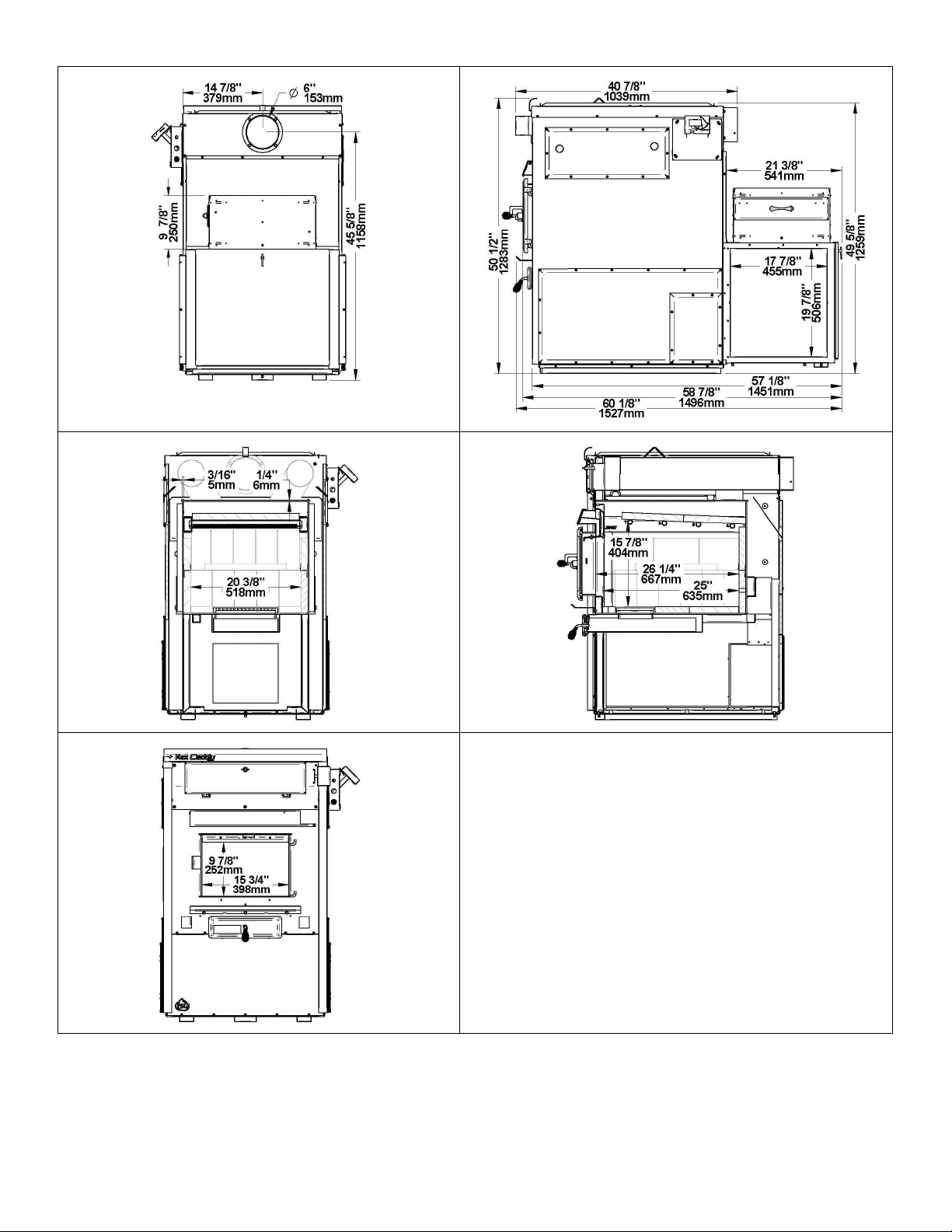

6. FURNACE DIMENSIONS

THEORETICAL

DEBIT

TEMP

VAR.

STATIC PRESSURE FILTER

9

Page 10

10

Page 11

7. CHIMNEY AND DRAFT

This furnace must be connected to a chimney certified for use with wood burning heating appliances. A 7-inch chimney

and connector must be installed for the Max Caddy if it is used as a wood-oil unit, a wood-electrical-oil unit or if an oil

option may be installed in the future. If the furnace is to be used as a wood only unit or a wood-electric, then a 6-inch

chimney is recommended.

The unit is not to be connected to a chimney flue serving another appliance. If the chimney draft exceeds 0.06 IN.W.C.,

a barometric draft control should be installed on the smoke pipe. Never install a manual damper. The barometric

control must be adjusted so that the maximum draft measured at the furnace outlet does not exceed -0.06 IN.W.C.

Please note that a draft exceeding 0.06 IN.W.C. could produce an uncontrollable fire. On the other hand, the

minimum draft required is 0.04 IN.W.C. in the evacuation pipe on the wood side, no matter what type of furnace

(WOOD, WOOD/ELECTRIC OR WOOD/OIL). The adjustment should in no case be modified to increase

combustion.

8. SAFETY RULES

WARNING:

THE INFORMATION GIVEN ON THE CERTIFICATION LABEL AFFIXED TO THE APPLIANCE ALWAYS

OVERRIDES THE INFORMATION PUBLISHED, IN ANY OTHER MEDIA (OWNER’S MANUAL, CATALOGUES,

FLYERS, MAGAZINES AND/OR WEB SITES).

8.1. GENERAL REQUIREMENTS

MAKE SURE THE CHIMNEY OUTLET AND THE PIPES ARE CLEAN AND IN GOOD CONDITION.

DO NOT USE CHEMICAL PRODUCTS OR LIQUIDS TO LIGHT THE FIRE.

DO NOT BURN WOOD COATED WITH PAINT, GLUE OR CHEMICAL PRODUCTS.

DO NOT BURN WASTES OR FLAMMABLE LIQUIDS SUCH AS GASOLINE, NAPHTHA, MOTOR OIL, OR OTHER

UNSUITABLE MATTERS.

DO NOT STORE WOOD IN THE VICINITY OF THE FURNACE. RESPECT THE REQUIRED CLEARANCES

BETWEEN COMBUSTIBLE MATERIALS AND THE SOURCE OF HEAT.

WARNING

THE ASH DRAWER AND EXCHANGERS ACCESS PANEL GET VERY HOT. DO NOT MANIPULATE

WITH BARE HANDS.

8.2. ODOUR FROM THE PAINT

It is normal that smoke and odours emanate from the unit when you first light it. It is recommended to burn it at high

rate and ventilate the building until the odours disappear. The smoke is not toxic. This should be done before the

ducts are connected to the furnace to prevent smoke dispersion in the house.

8.3. ASH DISPOSAL

Ashes must be placed in a metal container with a tight fitting lid. The container should be stored outdoor, well away

from combustible materials. This container should not contain any other type of waste. If the ashes are meant to be

buried in soil, wait until all embers have thoroughly cooled before burying.

8.4. CREOSOTE BUILD-UP AND REMOVAL

When wood is burned slowly, it produces tar and other organic vapours which, when combined with moisture, form

creosote. The creosote vapours condensate in a relatively cool chimney flue. As a result, creosote residues

accumulate inside the flue lining and the exchangers.

N.B.: To minimize the frequency of the chimney cleaning, buy your firewood at least one year before using it. Store it

in a dry place in order to obtain the minimum moisture rate and optimize the efficiency. Do not store wood or

combustible materials within the installation minimum clearances or the space required to reload the appliance and

remove ashes.

11

Page 12

When ignited, creosote produces an extremely hot fire inside the chimney.

In the first year of use, inspect the chimney system at regular intervals to determine a cleaning cycle. Depending on

the type of wood used and its quality, a semi-annual cleaning may be required. A yearly cleaning is mandatory. If a

significant layer of creosote has accumulated, it must be removed immediately to eliminate the risk of chimney

fire.

Remember that a small, hot fire is preferable to a large smouldering one to prevent creosote build-ups within the

system. Prepare an emergency procedure in case of a chimney fire. It is recommended to clean the heat

exchangers thoroughly at the end of season in order to prevent corrosion.

8.5. SMOKE DETECTOR

We highly recommend the use of a smoke detector. It must be installed at least 15 feet (4,57 m) from the appliance in

order to prevent undue triggering of the detector when reloading.

8.6. DOOR GLASS

To maintain a clean and safe installation, do not build your fire too close to the glass or allow logs to lean on the glass.

Do not operate your furnace at too low a setting. Keep the air inlet opened long enough during the fire start-up to

prevent the fire from smouldering, which could stain the glass.

An intense fire will help keep the glass clean. However, in the event that your glass gets stained, which should not

occur under normal operating conditions, you will have to clean it using a wet cloth and a fireplace glass cleaner. Clean

the glass ONLY when the unit has cooled down. Do not use abrasive cleanser.

WARNING: Avoid knocking or scratching the glass. It could crack or break.

8.6.1. GLASS SPECIFICATIONS

The glass is made of 3/16" (5mm) thick ceramic glass.

Do not operate your wood furnace with a broken glass, as this could seriously damage your furnace.

You can purchase a replacement glass from your PSG dealer.

8.7. ASH DRAWER

Your furnace is equipped with an ash drawer to collect ashes produced by the combustion of wood. This drawer must

not be left open during combustion as this may cause over firing and serious damages to the furnace. Moreover, the

additional air created could cause the dispersion of ashes in the ventilation system. The drawer must be cleaned

regularly. Use a vacuum cleaner to remove any ashes around the drawer in order to avoid the dispersion of

ashes in the ventilation system.

It is important that the door and the ash drawer be kept closed while the appliance is in use.

Maintain all gaskets in good condition; in case of deterioration, contact your dealer for a genuine

replacement gasket.

8.8. ASH GRATE

You must replace the ash grate if it is damaged and a replacement may be obtained from your dealer.

12

Page 13

INSTALLATION AND OPERATION

MAX

CADD

Y FURNACE

– WOOD ONLY

MAX CADDY

FURNACE

– COM

BINED

INSTRUCTIONS FOR

MAX CADDY WOOD ONLY FURNACE,

COMBINED WOOD / ELECTRIC OR

PARALLEL ADD-ON (US ONLY)

PF01102

WOOD/ELECTRIC

13

Page 14

9. INSTALLATION INSTRUCTIONS

Installation must be made in accordance with the CSA B.365 « Installation code for solid-fuel-burning appliances and

equipment » standard in Canada and NFPA 90B « Standard for the installation of warm air heating and air conditioning

system » in the United States. Moreover, for all electrical connection, the Canadian standard CSA C22.1 « Canadian

electrical code » and in the United-States NFPA 70 standard « National Electrical Code » must be followed.

All controls and adjustments must be performed by a qualified technician. The blower speed must conform to the

recommendations of the Warm Air Heating and Air Conditioning National Association and should respect the static

pressure ranges in the warm air plenum of the furnace

We recommend that our woodburning hearth products be installed and serviced by professionals who are certified in

the United States by NFI (National Fireplace Institute®) or in Canada by WETT (Wood Energy Technical Training) or in

Quebec by APC (Association des Professionnels du Chauffage).

Inspect the furnace to make sure that nothing has been damaged in the shipping. Pull out the wiring kit and the

instructions manual from the firebox of the furnace and the accessories from the flue pipe.

The following section contains installation instructions for the Max Caddy wood only, Max Caddy wood / electric and

Max Caddy add-on parallel configurations.

9.1. BLOWER INSTALLATION

To use the wood only configuration, the blower assembly (PA08566 – sold separately) is required. The installation

instructions are provided with the blower.

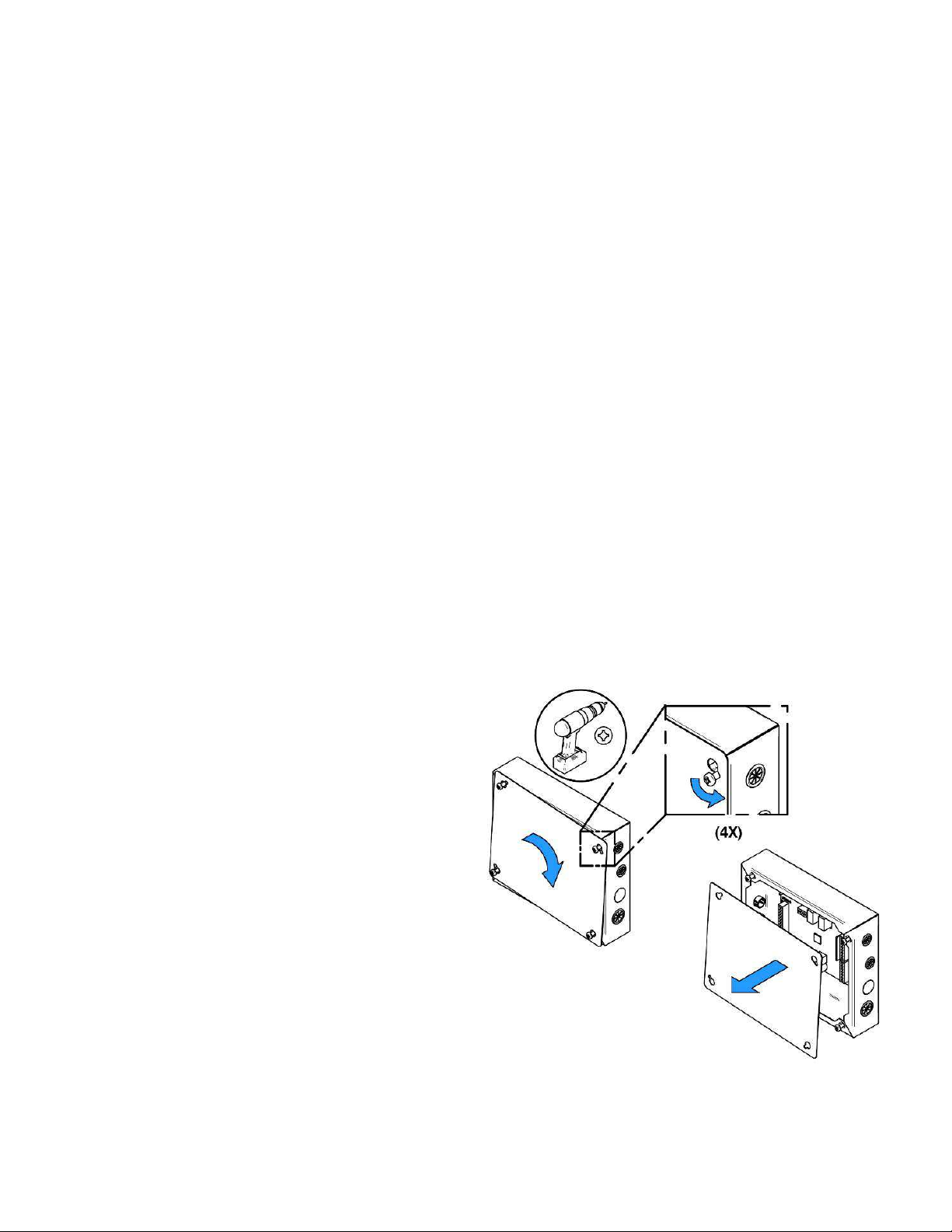

9.2. LINK BOARD INSTALLATION AND CONNECTION

The following installation instructions are identical whether the furnace controls are located on the left or on the right of

the furnace. The most accessible side is preferred to facilitate the connection of auxiliary heating sources or for

servicing.

The components to be installed are in the combustion chamber of the furnace.

Remove the link board housing cover.

14

Page 15

Remove the four screws on the

furnace, located on the side of the

desired installation.

Align the holes of the board housing

the holes on the side of the furnace.

Use the screws removed in the

previous step to secure the housing to

the furnace.

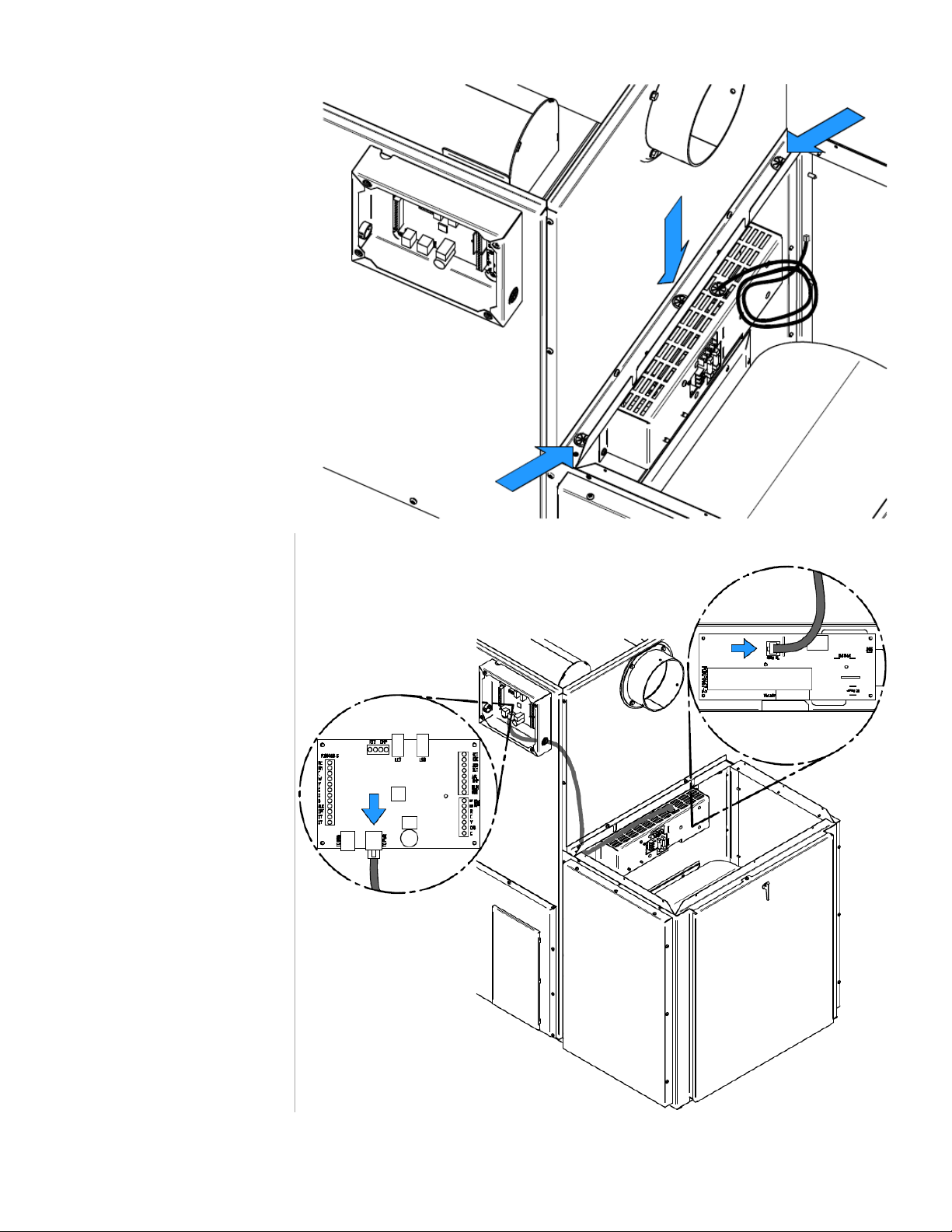

Once installed, the link board must be

connected to the system with the

telecommunication wire of the power

board. The wire is located in the

blower box. To access it, remove the

air return box.

15

Page 16

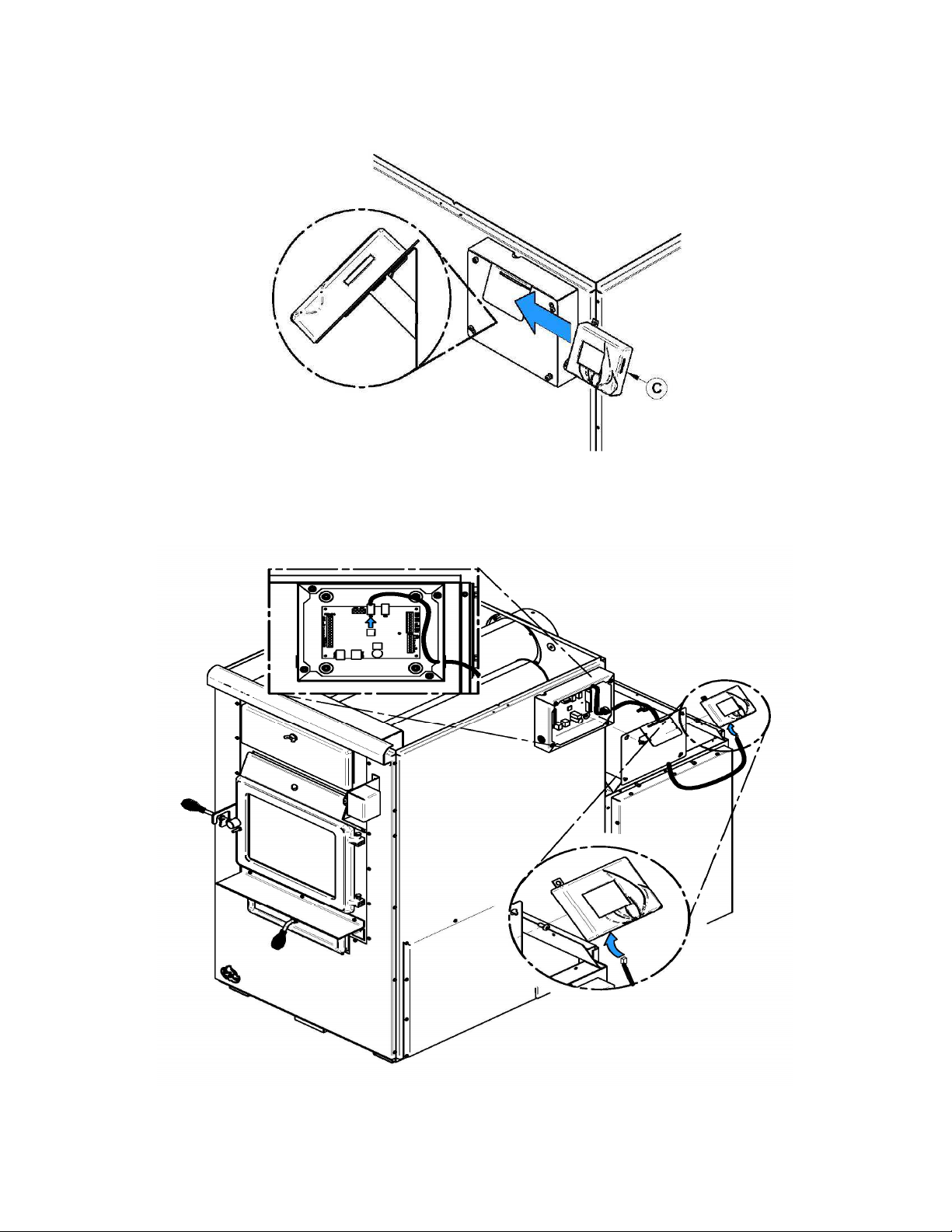

Take the telecommunication

wire and pull it through the

grommet located on the side

where the housing board is

installed.

Once the telecommunication

wire is out on the desired side,

run it along the back of the

furnace and pass it through

the grommet at the bottom of

the link board housing.

Complete the connection by

plugging the 8 strands

telecommunication wire in the

right connector, shown by the

arrow.

16

Page 17

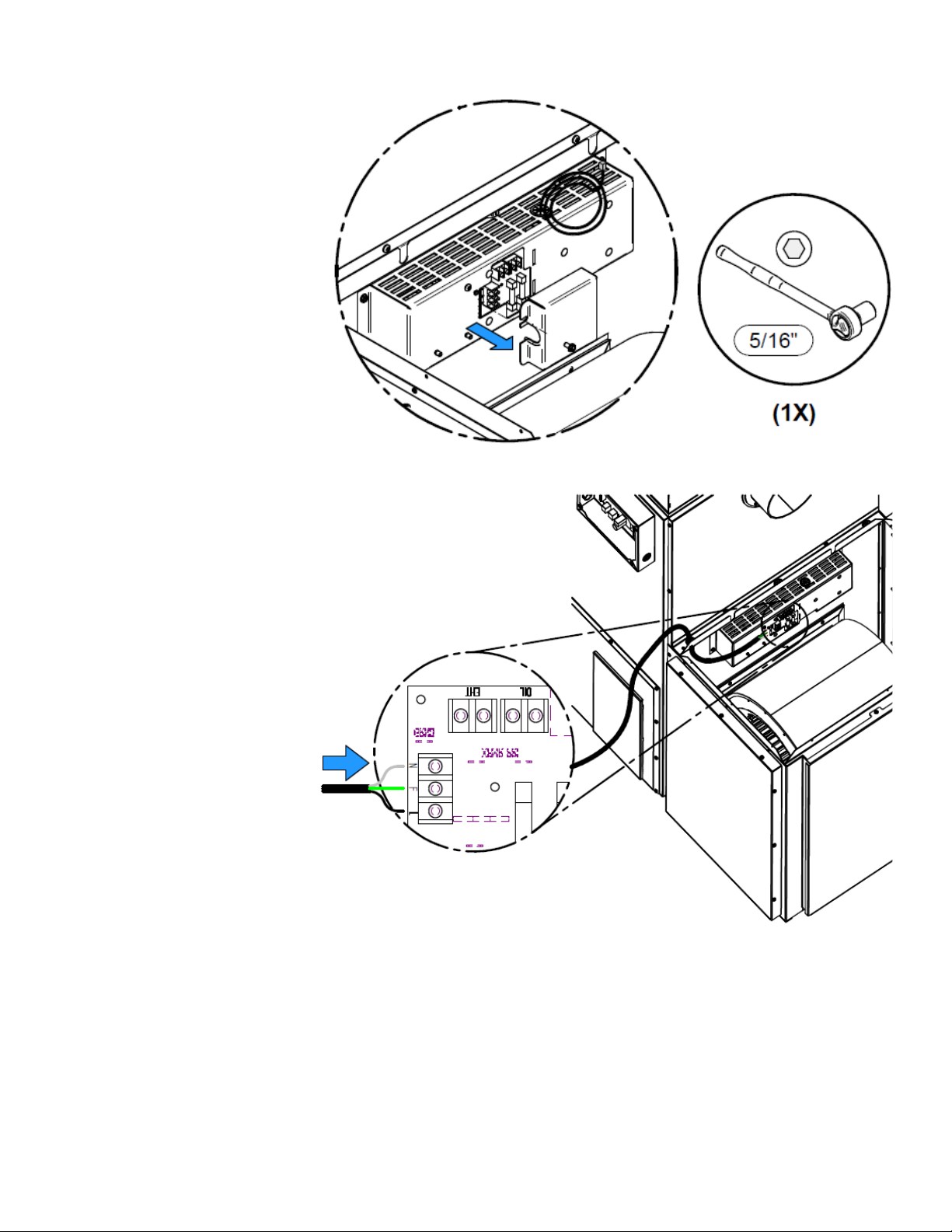

Your furnace should also be

connected to a 115V power

source. To do so, open the

cover of the power board

housing.

Connect the power cord to the

terminals N (Neutral) F

(Ground) L (Line). Refer to

wiring diagram for connecting

components. When done,

secure the wires with a BX

connector (not included) and

replace the blower box cover.

17

Page 18

9.3. TOUCHSCREEN INSTALLATION AND CONNECTION

The touch screen is used to operate the system. It must be installed on the support provided at the back of the furnace,

on the same side as the link board housing.

Connect link board with the touch screen using the telecommunication wire provided with the user manual. Plug the

telecommunication wire in connector labeled LCD and pull it out of the board housing through the top grommet. Simply

run the wire on the side of the furnace using the plastic ties supplied with the user manual. Replace the access panel

of the link board. Note that the touch screen is removable if access is restricted.

18

Page 19

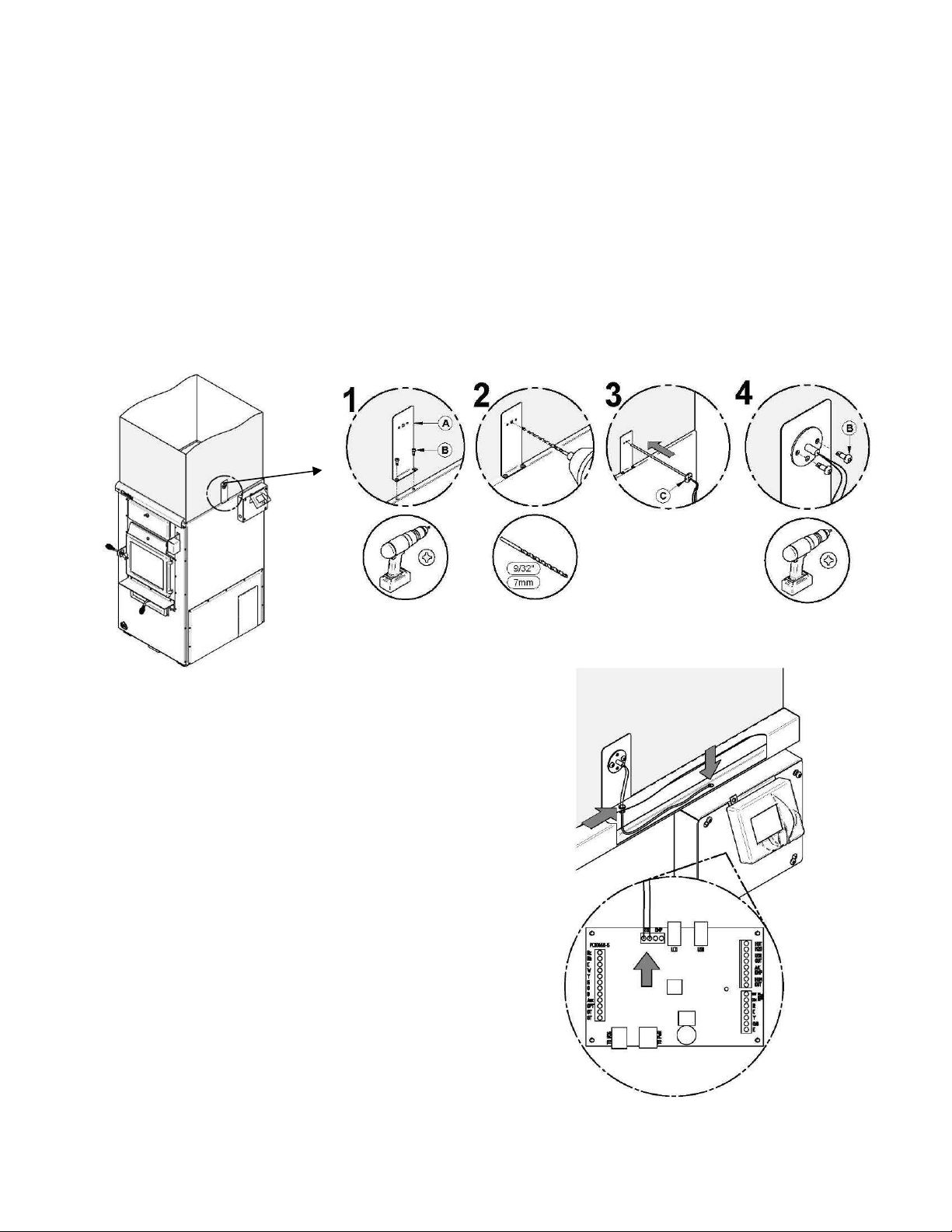

9.4. HOT AIR PLENUM TEMPERATURE PROBE INSTALLATION AND CONNECTION (RTD)

On the Max Caddy, a RTD has to be installed on the side of the furnace using the support provided with the unit. The

RTD is a sensor that reads the temperature inside the hot air plenum. It is critical to the good operation of the furnace.

Refer to electric diagram for connection details. It is important that the RTD and the RTD support be properly fixed onto

the hot air plenum.

WARNING: USE WIRING SUITABLE FOR 75 °C (not included).

STEP 1: Remove the two screws already secured to the furnace (B) on the side where you have chosen to install the

link board. Then, secure the RTD support (A) using the two screws you previously removed.

STEP 2: Using a drill and a 9/32" bit, drill a hole in the hot air plenum so that the RTD rod can pass into it.

STEP 3 and 4: Secure the RTD in place on the hot air plenum using the two self-tapping screws provided with the

owner’s manual.

Once the RTD is installed on the support, proceed to its

connection to the link board. Pass the RTD wires in the

grommet and exit them close to the link board. For board

connections, refer to the wiring diagram.

19

Page 20

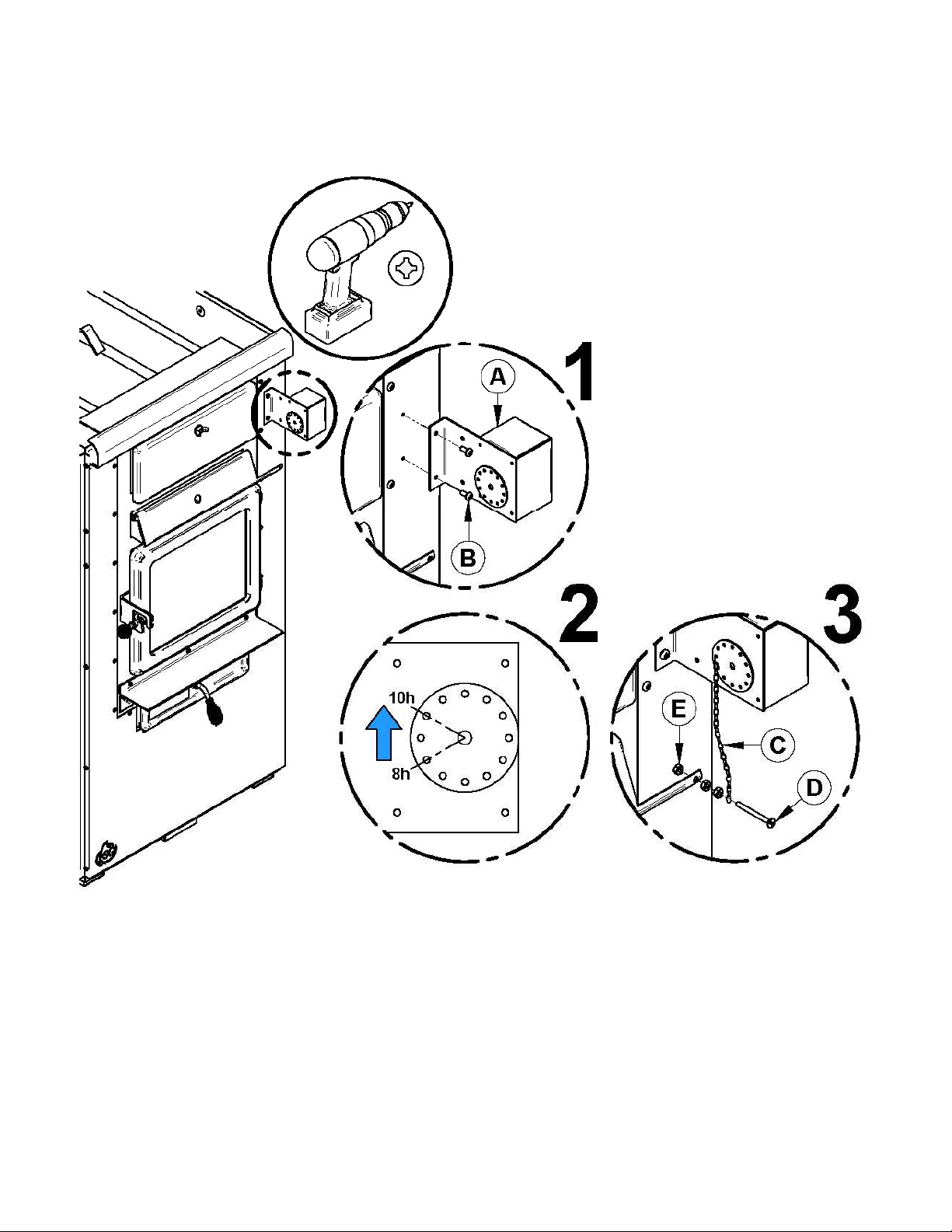

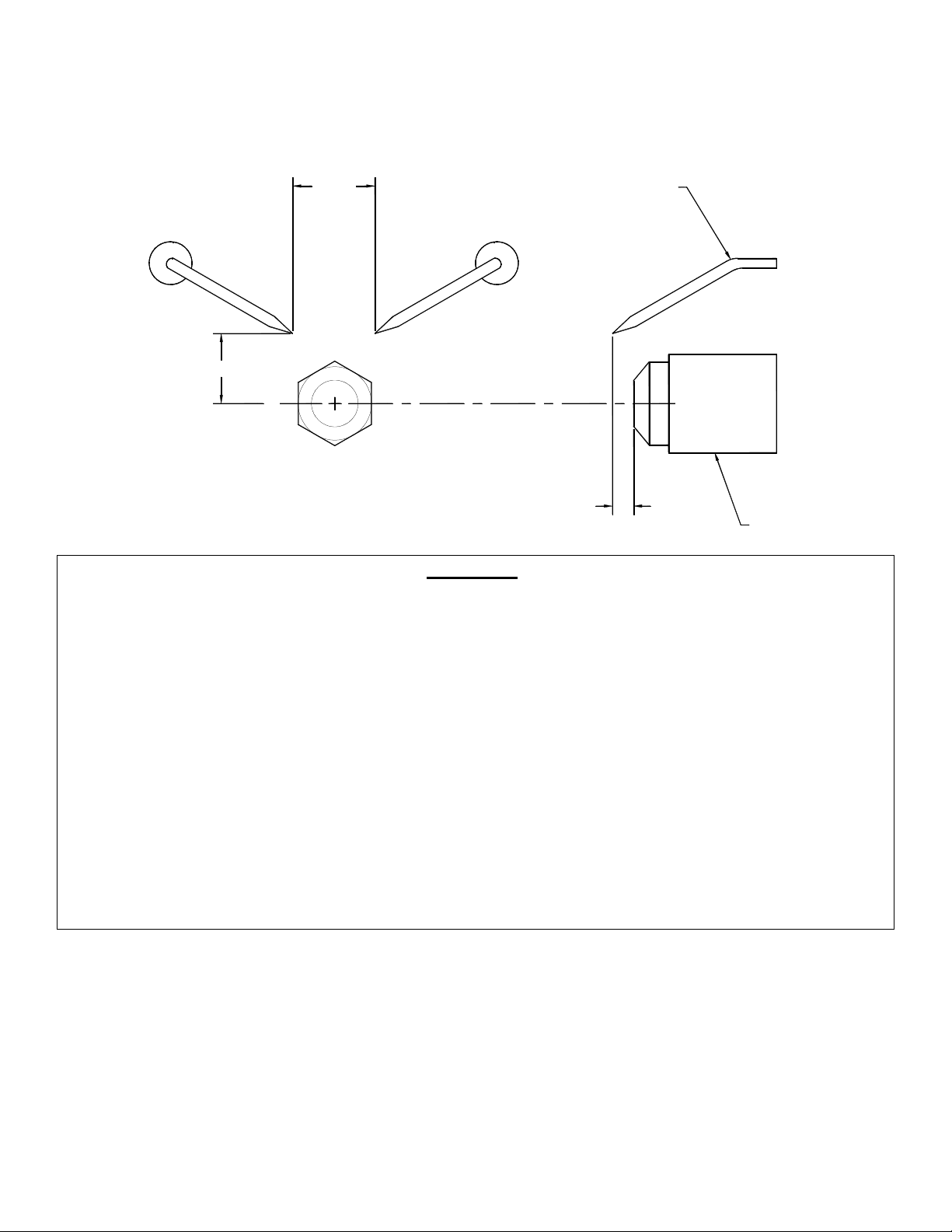

9.5. SERVOMOTOR INSTALLATION AND CONNECTION

Your Max Caddy furnace is equipped with a servomotor. To install it, simply screw it in place in the two pre-drilled holes

in the front of the furnace using two screws as shown below.

Once installed, install the chain linking the servomotor with the air inlet damper as shown above. The chain must have

a set of 1/8". When there is no call for heat, the air inlet damper must be completely closed and the chain must be

hooked to the servomotor at the “8 o’clock” position.

20

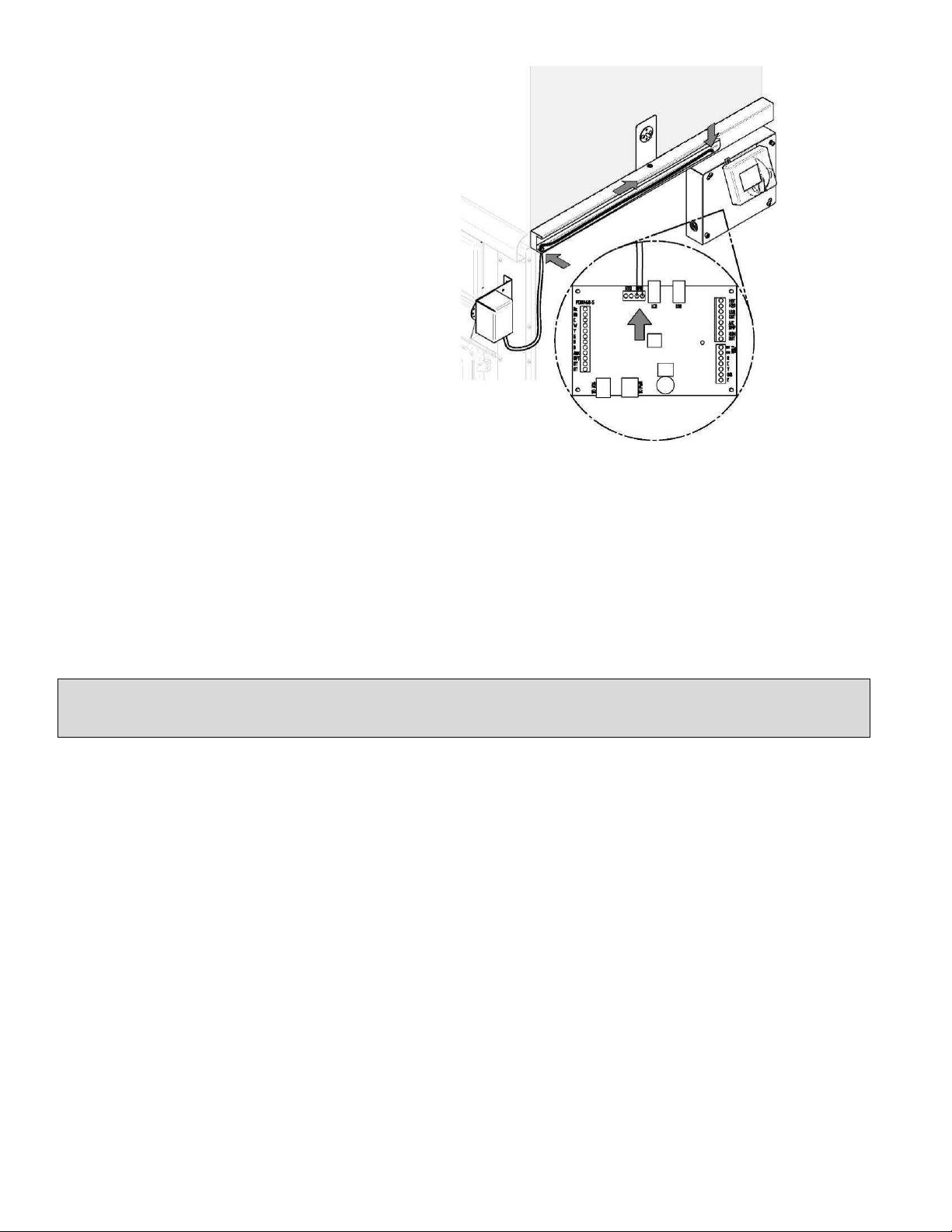

Page 21

Then, you must connect the servomotor and the link

board. Take the wires out of the servomotor and enter

the wires in the wire cover through the grommet. Pull

them out through the grommet next to the link board

housing.

For connection, refer to wiring diagram.

WARNING: USE WIRING SUITABLE FOR 75 °C

(not included).

9.6. UNIT LOCATION

For a safe and quiet operation, the furnace must be leveled in both directions and supported evenly to ensure stability.

The furnace must be installed where outside air supply will be sufficient for proper combustion. In airtight houses, it

might be necessary to install an outside air inlet (See Section 9.11 - COMBUSTION AIR AND FRESH AIR INTAKE

ADAPTER INSTALLATION (OPTIONAL))

The furnace must be positioned so that the connector is as short as possible. Minimize the use of 90o elbows.

The owner must ensure a proper installation to allow a safe operation of the appliance.

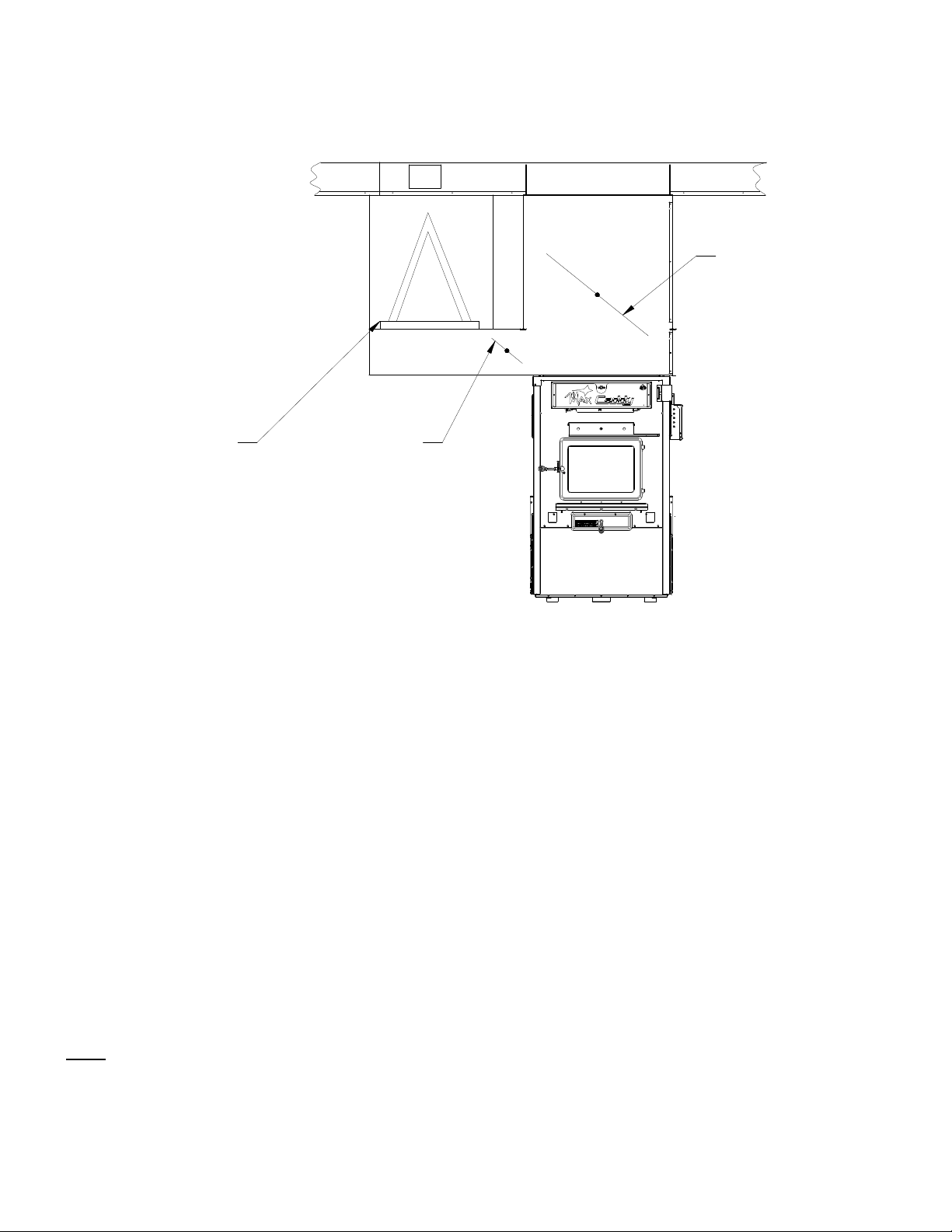

9.7. MINIMUM CLEARANCES TO COMBUSTIBLE MATERIALS AND FLOOR PROTECTION

N.B.: This appliance must be installed in accordance with the instructions on the certification plate

applied on the unit.

THE INSTALLATION OF THE HEAT SHIELD (-1-) PROVIDED WITH THE FURNACE IS

MANDATORY.

21

Page 22

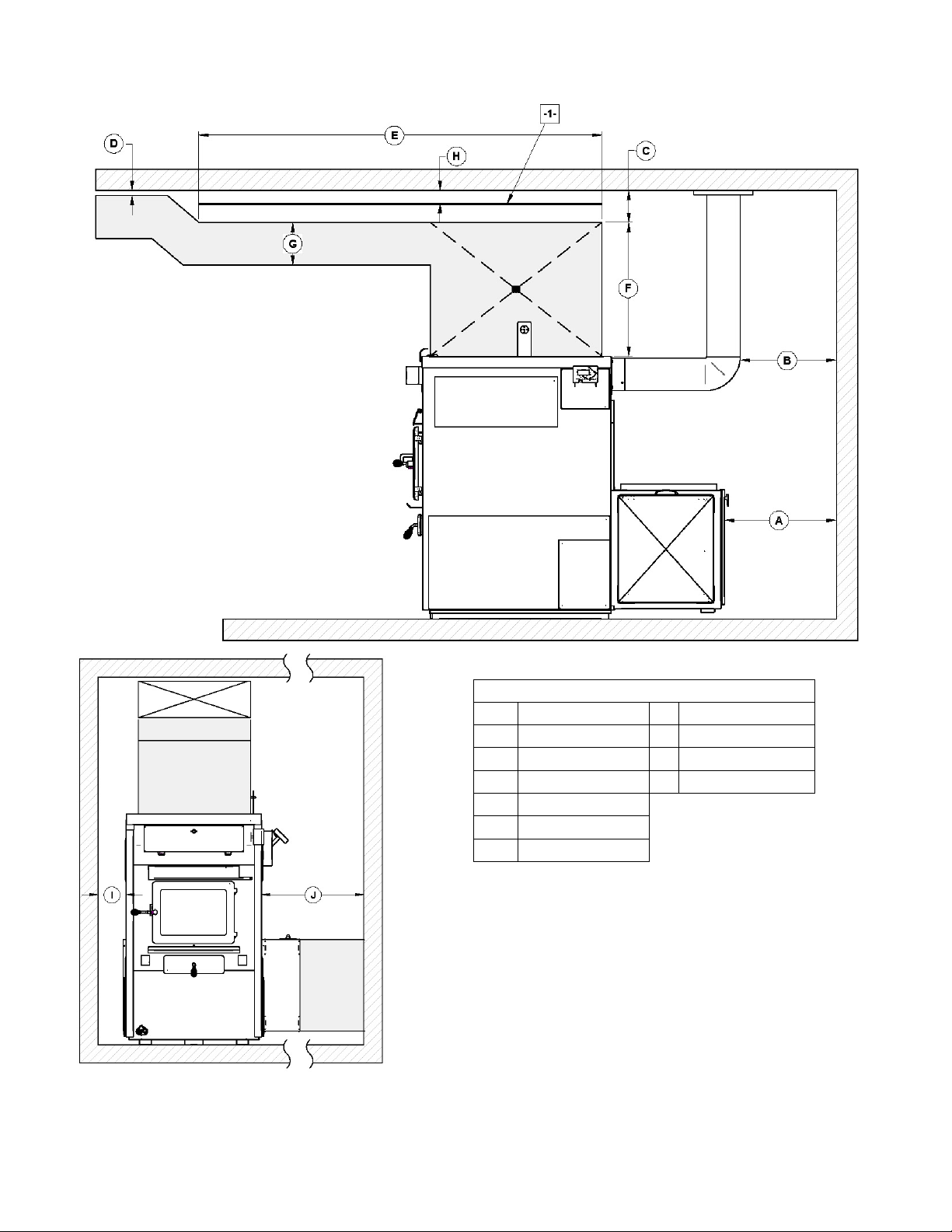

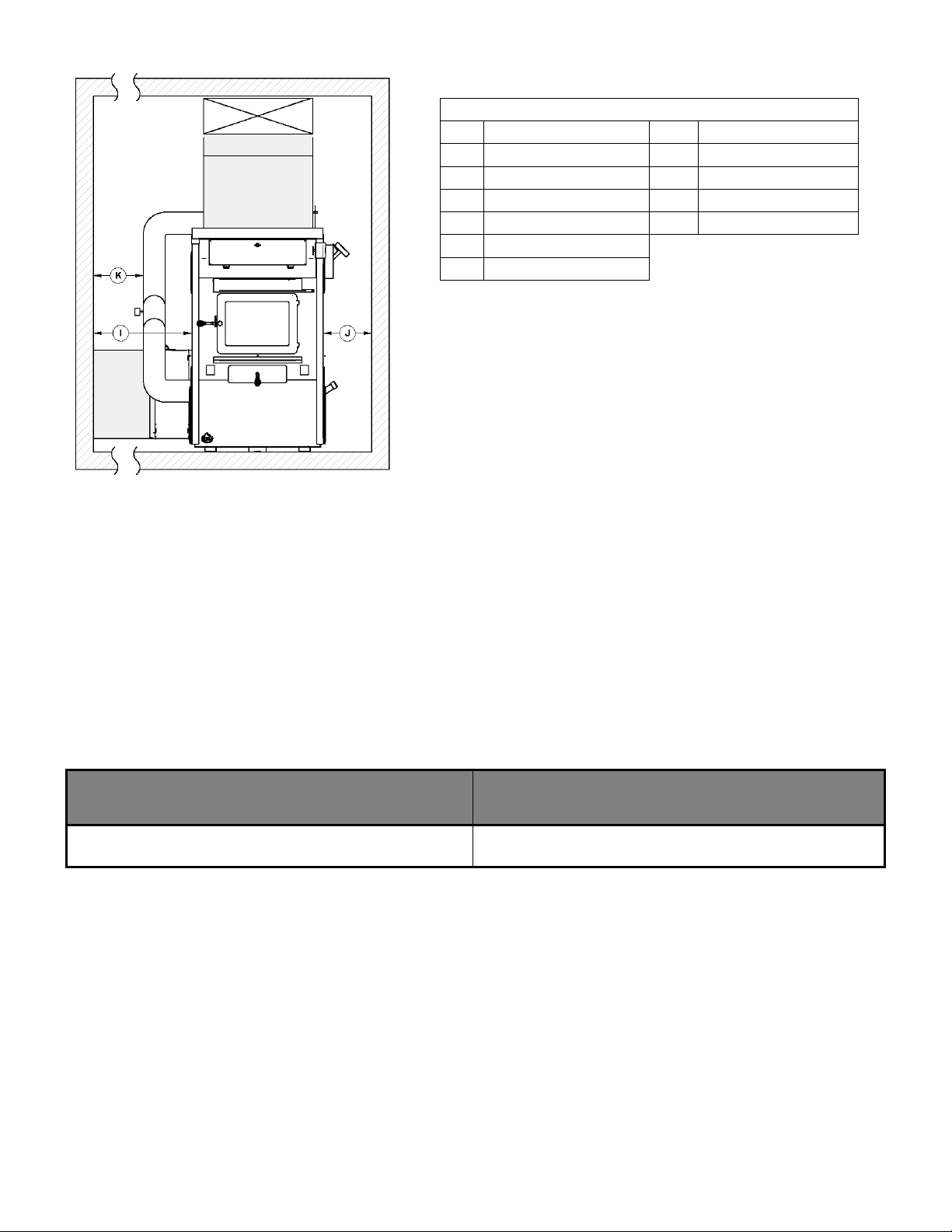

9.7.1. MINIMUM CLEARANCES TO COMBUSTIBLE MATERIALS

MINIMUM CLEARANCES

A

24" (610 mm)

B

18" (458 mm)

C

D

E

F

6" (153 mm)

1" (26 mm)

72" (1 829 mm)

24" (610 mm)

G

8" (204 mm)

H

1 1/2" (38.1 mm)

I

6" (153 mm)

J

24" (610 mm)

-1- HEAT SHIELD

22

Page 23

9.7.2. MINIMUM CLEARANCES TO COMBUSTIBLES MATERIALS FOR AIR RETURN DUCT

The return air duct should be at least equal in size to the return air plenum. The air return duct can be installed at zero

clearance to combustibles.

9.7.3. MINIMUM CLEARANCES TO COMBUSTIBLES MATERIALS FOR HOT AIR PLENUM

Plenums installed on the furnace must be made of metal in accordance with CSA B365 or NFPA 90B. The hot air duct

can be passed through the side wall with a clearance of six (6) inches around thereof.

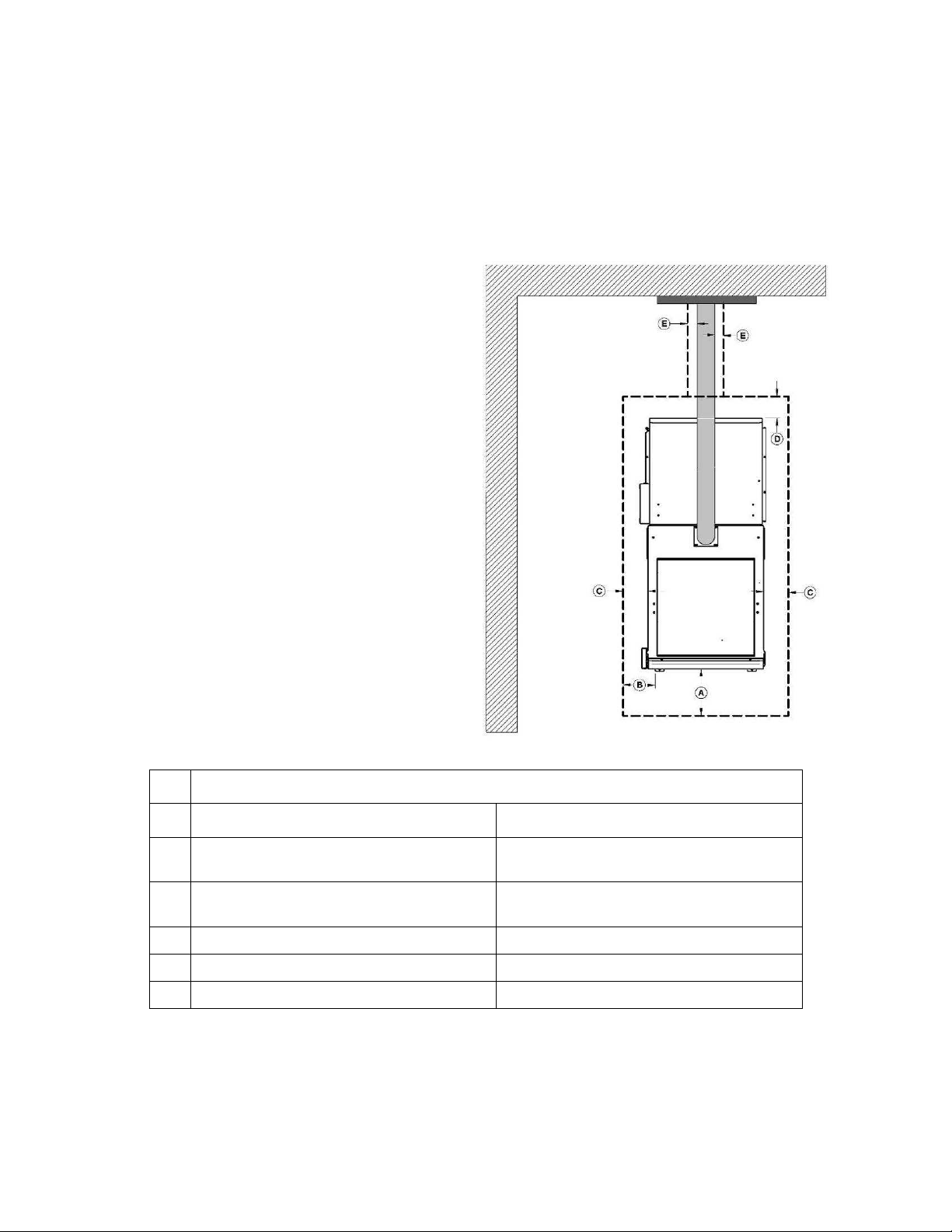

9.7.4. FLOOR PROTECTION

If the floor is made of non combustible material, no

floor protector is required.

If the floor is made of combustible material, a non

combustible material floor protector is required (see

table below).

A

B

C

D

E

*Steel with a minimum thickness of 0.015" (0.38 mm) or ceramic tiles sealed together with grout. No protection is required if the unit

is installed on a non-combustible floor (ex: concrete).

Note 1: The floor protection at the back of the furnace is limited to the furnace’s required clearance (A) if such clearance is smaller

than 8 inches (203 mm).

Note 2: Only required under the horizontal section of the connector. Must exceed each side of the connector pipe by at least 2

inches (51 mm).

CANADA USA

18" (457 mm)

From door opening

N/A (USA only)

8" (203 mm) N/A (Canada only)

8" (203 mm) – Note 1 N/A (Canada only)

N/A (USA only) Note 2

FLOOR PROTECTION*

16" (406 mm)

From door opening

8" (203 mm)

From door opening

23

Page 24

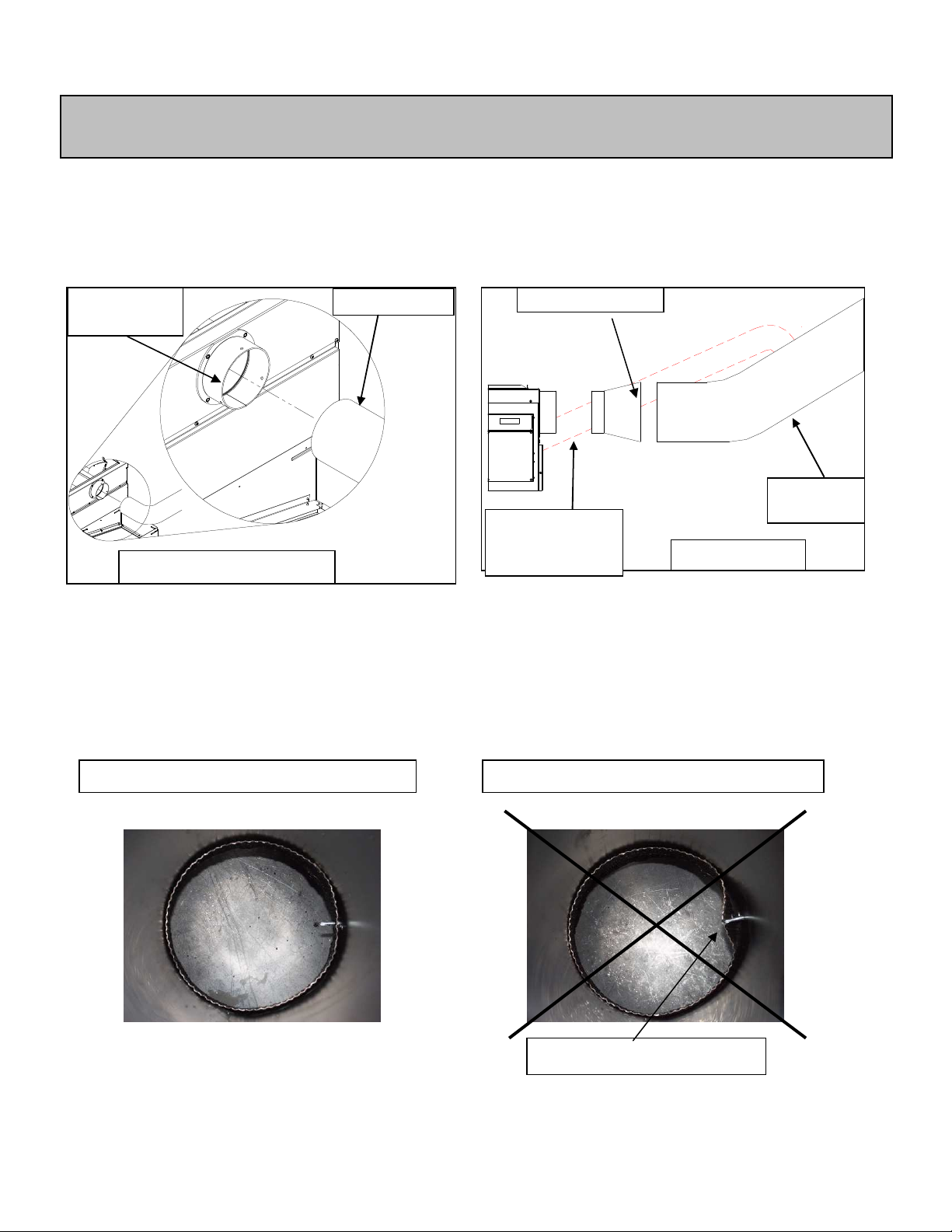

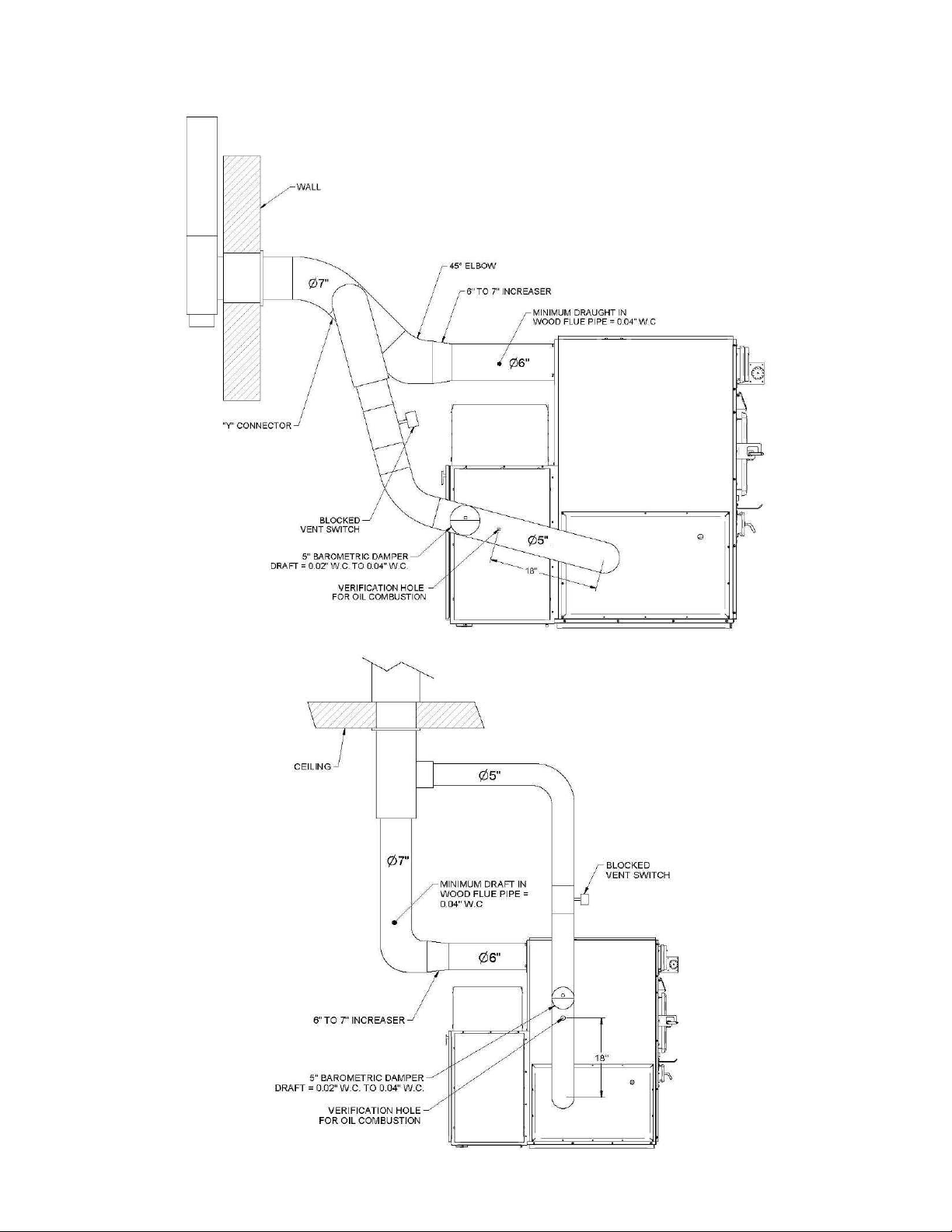

9.8. FLUE AND BAROMETRIC DRAFT CONTROL CONNECTION

removed any accessory from the flue

WOOD ONLY

Diameter

6"

WOOD/OIL

Reducer

7" to 6"

PROPER INSTALLATION

IMPROPER INSTALLATION

Before connecting the stove pipe, make sure you have

pipe such as the scraper, shovel, and the poker.

The flue outlet on the Max Caddy furnace is 6" in diameter and the wood only or wood/electric models may be installed

with a 6" chimney approved for use with wood burning heating appliances (2100°F). However, it is mandatory to use a

7" diameter chimney if the retrofit to a wood/oil configuration is probable. In that case, a 6" to 7" reducer must be

installed at the flue outlet of the furnace. If the draft exceeds 0.06 IN.W.C., a barometric control must installed. Never

install a manual damper. Secure the exhaust pipe to the flue adapter with three screws.

FLUE

ADAPTER

Diameter 7"

Unit oil

OIL UNIT’S

UTLET

Max Caddy pipe

For a proper installation, follow the advice below:

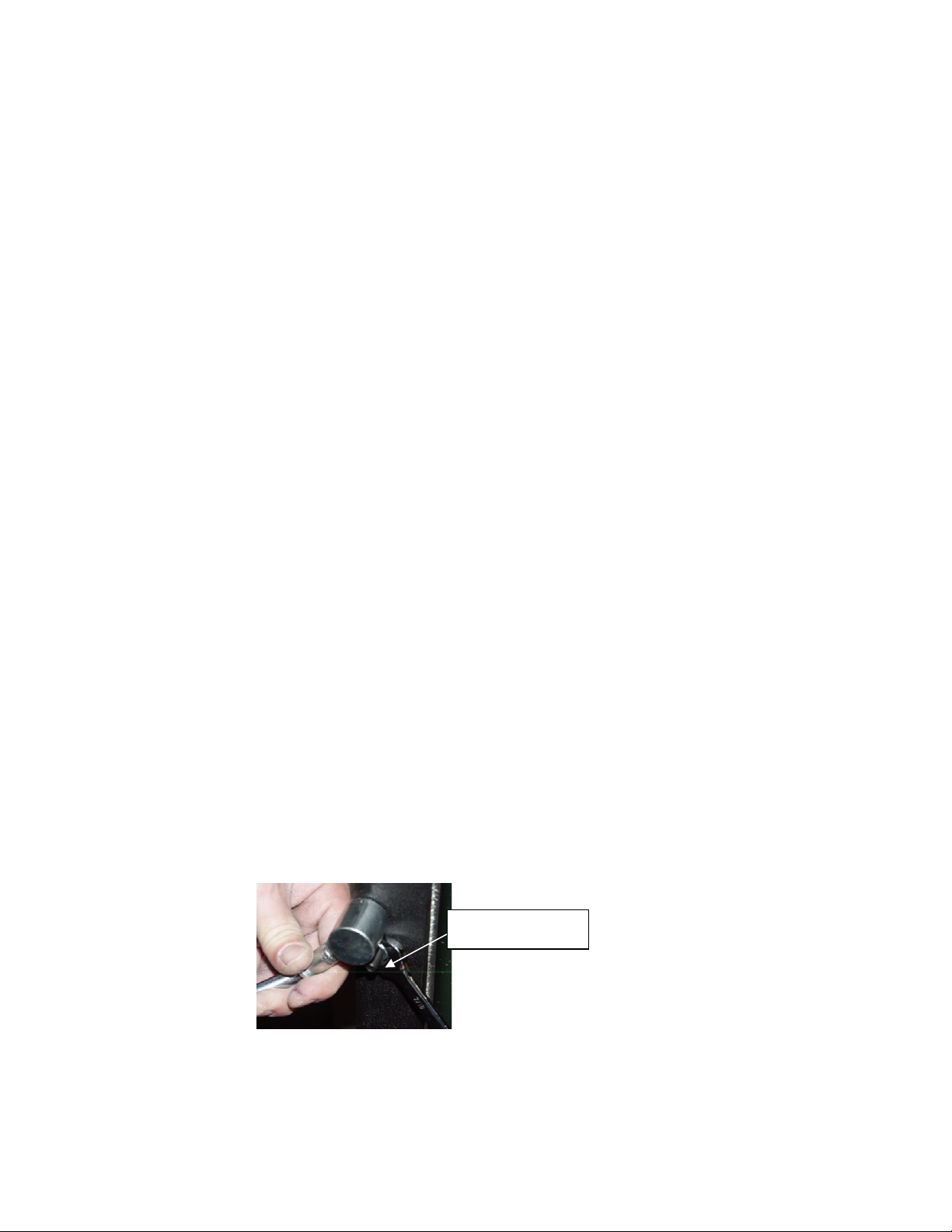

• All the exhaust pipe joints must be secured with three screws.

• Make sure that each screw goes through the inner wall of both connectors (male and female). See pictures below

showing a male-female coupling.

• A minimum rise of ¼" per horizontal foot must be respected.

CAUSES RESTRICTION

24

Page 25

9.9. ELECTRICAL CONNECTIONS

The following instructions do not replace those of the local code.

Installation and verification of this appliance must be done by a qualified service man.

All wiring from the service panel to the heating unit must comply with the electrical code in force and all local

regulations. It is recommended to feed the furnace with its own electrical circuit of 15 amps at 120 volts with a breaker

(see wiring diagram).

9.10. DAMPER

If the draft exceeds 0.06 INW.C., a barometric damper must be installed. The barometric damper must be adjusted so

that the maximum draft measured at the furnace outlet is limited to 0.06 IN.W.C. Please note that a draft higher than

0.06 IN.W.C. will reduce efficiency and could result in an uncontrollable fire. On the other hand, the minimum draft

to be respected is 0.04 IN.W.C. in the evacuation pipe on the wood side, no matter what type of furnace is use

(WOOD, WOOD/ELECTRIC, WOOD/OIL)

9.11. COMBUSTION AIR AND FRESH AIR INTAKE ADAPTER INSTALLATION (OPTIONAL)

When the furnace and the chimney are completely cold, it may be necessary to provide fresh air by opening a door or

a window for a few minutes while lighting the fire. Take note that a house constructed or renovated in order to be

airtight may lack the volume of fresh air necessary for the proper combustion of a solid-fuel heating appliance.

In such a case, when starting up the fire, do not operate appliances that evacuate air outside the house, such as:

- Range hood

- Air exchanger

- Clothes dryer

- Bathroom fan

- Ventilated central vacuum system

A fresh air supply may be necessary to prevent solid fuel units from rejecting products of combustion into the house.

The indications used to determine if an additional fresh air supply is necessary are not appropriate for all the situations.

When in doubt, it is recommended to install a fresh air supply.

A fresh air supply may be needed if:

- Solid fuel units present anomalies, such as irregular draft, smoke return, bad combustion, and/or reversed

draft (whether there is combustion or not);

- Existing solid fuel units such as a stove or fireplace release odours, heat badly, cause smoke returns, or

reversed draft (whether there is combustion or not );

- The opening of a window, even slightly, in calm weather (windless), eliminates every problem mentioned

above ;

- The house is equipped with a tight vapour barrier and adjusted windows, and/or is equipped with an interior

air mechanical evacuation device ;

- There is excessive condensation on the windows in winter; and

- The house is equipped with a ventilation system.

If, according to these symptoms or other similar ones, there is insufficient combustion air, it is necessary to ensure an

additional combustion air supply.

Additional combustion air can be provided with the following methods, provided that they satisfy chapter 5 of the CSA

B365 standard for Canada:

• Direct connection: solid fuel units can be connected directly to a source of new combustion air only if they are

certified for this kind of installation, which must respect the manufacturer’s instructions. The Max Caddy can be

installed with an optional sealed fresh air kit that has been tested with the unit. Consult your dealer.

• Indirect method: new combustion air can be brought into a pipe located within approximately 300mm (12 inches) of

the unit. If the pipe is too close to the furnace, it may interfere with its operation.

• Mechanical ventilation system: if the house is equipped with a ventilation system (air exchanger or heat recovery),

the ventilation system may provide sufficient auxiliary air to the solid fuel unit. Otherwise, the owner should be

informed that the ventilation system may have to be rebalanced by a ventilation technician after the installation of

the solid fuel unit.

25

Page 26

NOTE:

(full length)

entry

It is recommended to install an outside air inlet with

a diameter of at least 4" in the room where the

heating appliance is installed (see drawing below).

It is preferable to choose a wall which is not

exposed to dominant winds, depending on the

conditions surrounding your house.

Fresh air

intake

Exterior wall

N.B. The owner of the furnace is responsible for the room’s air quality in case of negative pressure or

temporary negative pressure.

If there is a fan in the wood storage room, make sure it does not create a depression in the room where the furnace is

installed.

For more information regarding the installation of fresh air intake adapter, refer to the option’s manual.

Insulated pipe

Free air

9.12. HOT AIR PLENUM

The hot air plenum coming out of the furnace is to have a minimum height of 24" (610 mm). These dimensions for all

hot air furnaces are in accordance with the standards CSA B140.4, UL 391 and UL 727.

NOTE: TO ENSURE ADEQUATE STATIC PRESSURE, THE SYSTEM SHOULD BE BUILT IN A WAY THAT THE

VOLUME OF COLD AIR RETURN IS AT LEAST EQUAL OR SLIGHTLY HIGHER THAN THE VOLUME OF THE HOT

AIR DISTRIBUTION.

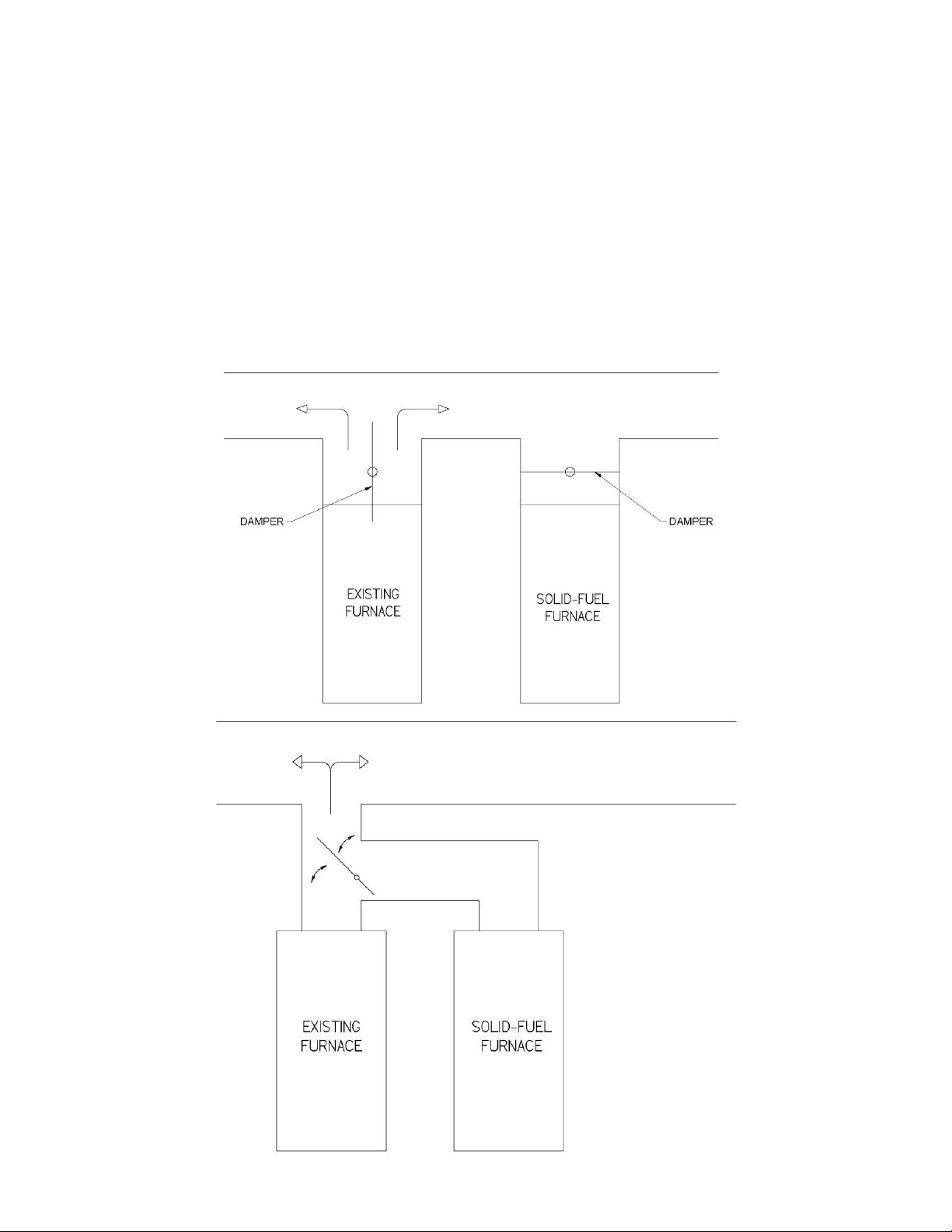

9.13. PARALLEL INSTALLATION (US ONLY)

The installation of the Max Caddy with another furnace using the same ductwork is not allowed in Canada. This type

of installation is only allowed in the United States. Ideally, the maximum BTU input of the existing oil, gas, or

electric furnace should be equal or higher than the maximum BTU input of the wood furnace. It is mandatory to

respect minimum clearances between the ductwork and combustible material as if the wood furnace was installed as a

standalone unit. The ductwork and furnace should be adjusted in order to reach a static pressure of at least 0.20

IN.WC, but not more than 0.50 IN.WC. A back-flow damper should be installed in the plenum. The back-flow damper

assures that when either unit is operated by itself, the hot air will flow into the home, and not back through the other

furnace. Depending on your installation (see figures examples below), a back-flow damper may be required in each

plenum.

CANADA; The installation in parallel i.e. the Max Caddy furnace combined with another, using the same system of hot

air ducts is not allowed in Canada.

UNITED STATES; The installation in parallel i.e. the Max Caddy furnace combined with another, using the same hot

air duct system is allowed the United States.

26

Page 27

Conditional to;

o The maximum input power of the existing gas, oil or electric furnace should be equal or lower than 120 000

Btu/h.

o The clearances required for wood furnace must be respected.

o The clearances between the hot air ducts and combustible materials must meet the highest values between

the two furnaces.

o The necessary adjustments are made to the furnace or hot air ducts to maintain a static pressure of between

0.20 and 0.50 IN.W.C.

o A backflow damper must be installed to prevent air return in one or the other of the two furnaces and to ensure

that hot air will flow into the house and will not return through the plenum of the other furnace. Depending on

your system configuration, it is possible that more than one register is required to prevent air returns in the

different hot air ducts (see examples below).

27

Page 28

To ensure a safe installation, the two furnaces must not, at any time, run simultaneously. To do so, the thermostat

controlling the existing furnace must be connected to your Max Caddy link board. This way, when a heating signal is

sent to the existing furnace, the Max Caddy receives the same signal. It will tell the Max Caddy to either not start or, to

go into a shut down cycle, if the furnace was already heating when the demand for heat was sent.

The wiring for an Add-on installation is shown below. The existing furnace’s thermostat must be connected to the Rh

and Aux terminals of the link board on the Max Caddy furnace. Those two wires must come from the R and W

terminals of the existing furnace’s thermostat so the link board receives the heat signal.

MAX CADDY

When a heat signal from the existing furnace’s thermostat will be sent, the Max Caddy furnace will shut itself down and

an envelope will appear on the LCD screen indicating that the existing furnace has taken over. This envelope will

disappear when the heat signal of the existing furnace’s thermostat will stop and the Max Caddy furnace will resume

getting orders from its own thermostat.

28

Page 29

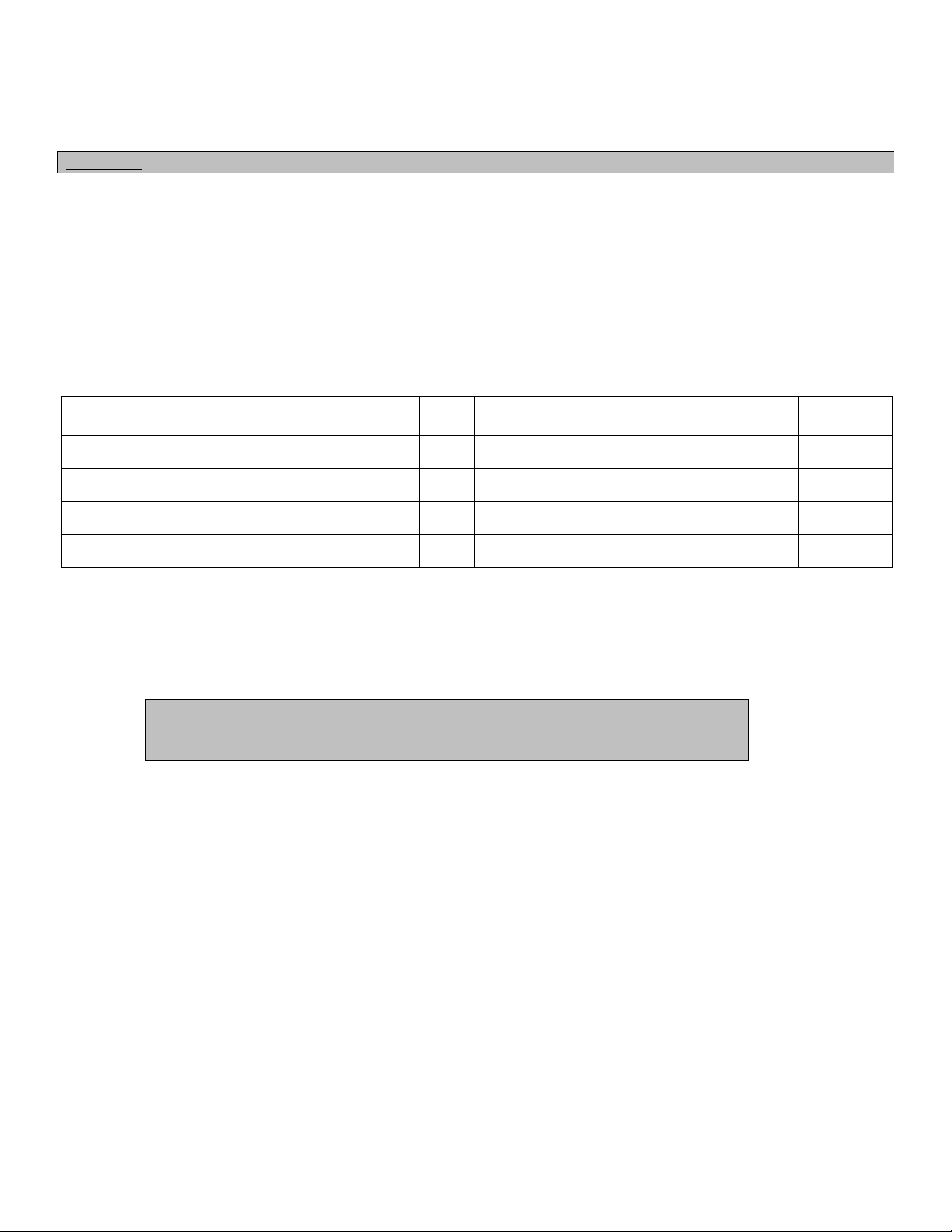

9.14. ELECTRICAL ELEMENT INSTALLATION (OPTIONAL)

9.14.1. INTRODUCTION

Two electrical elements are available for the Max Caddy: and 20Kw et 25kW. These options include all components

necessary for the installation. Instructions for installing the electrical elements are provided with the electrical element.

WARNING: USE WIRING SUITABLE FOR 75 °C (NOT INCLUDED).

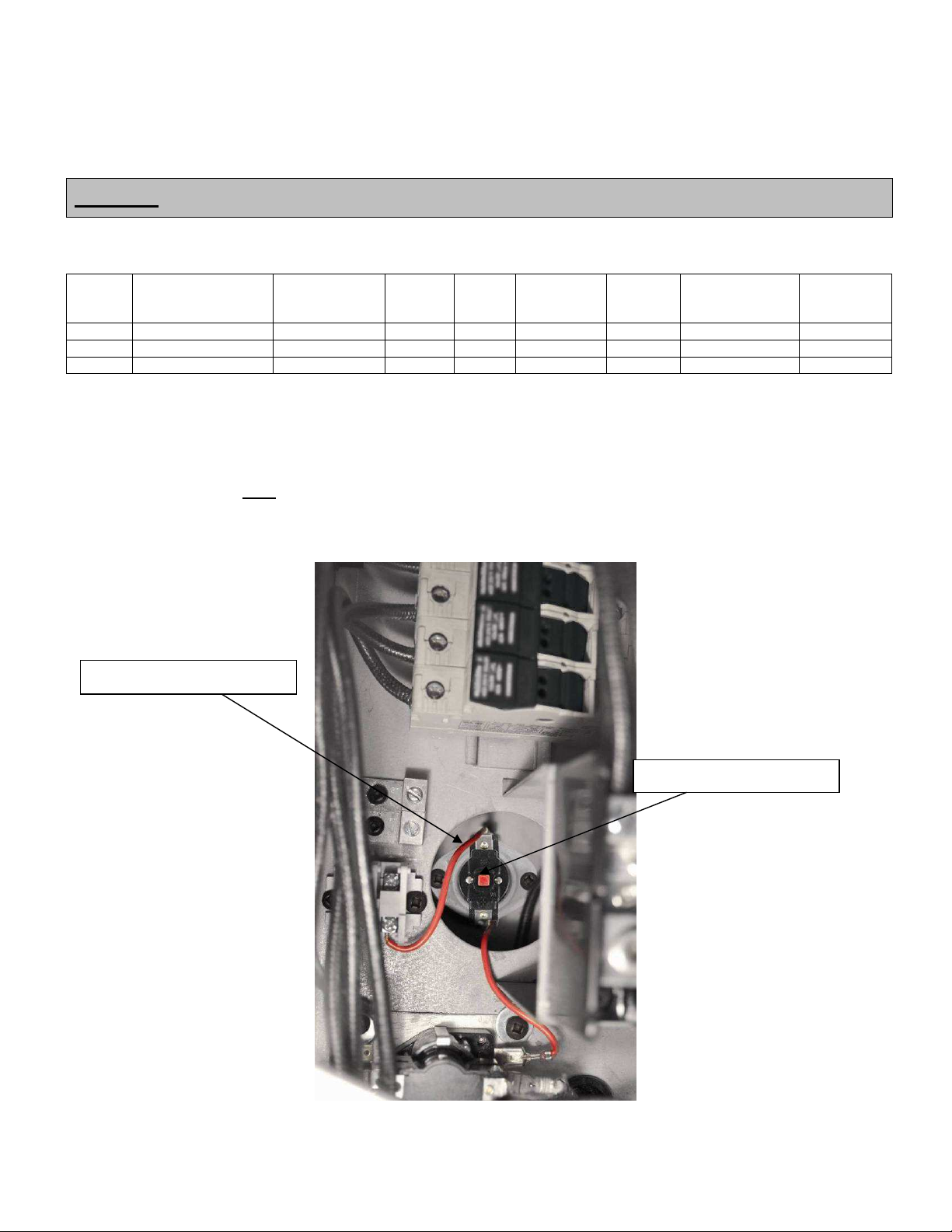

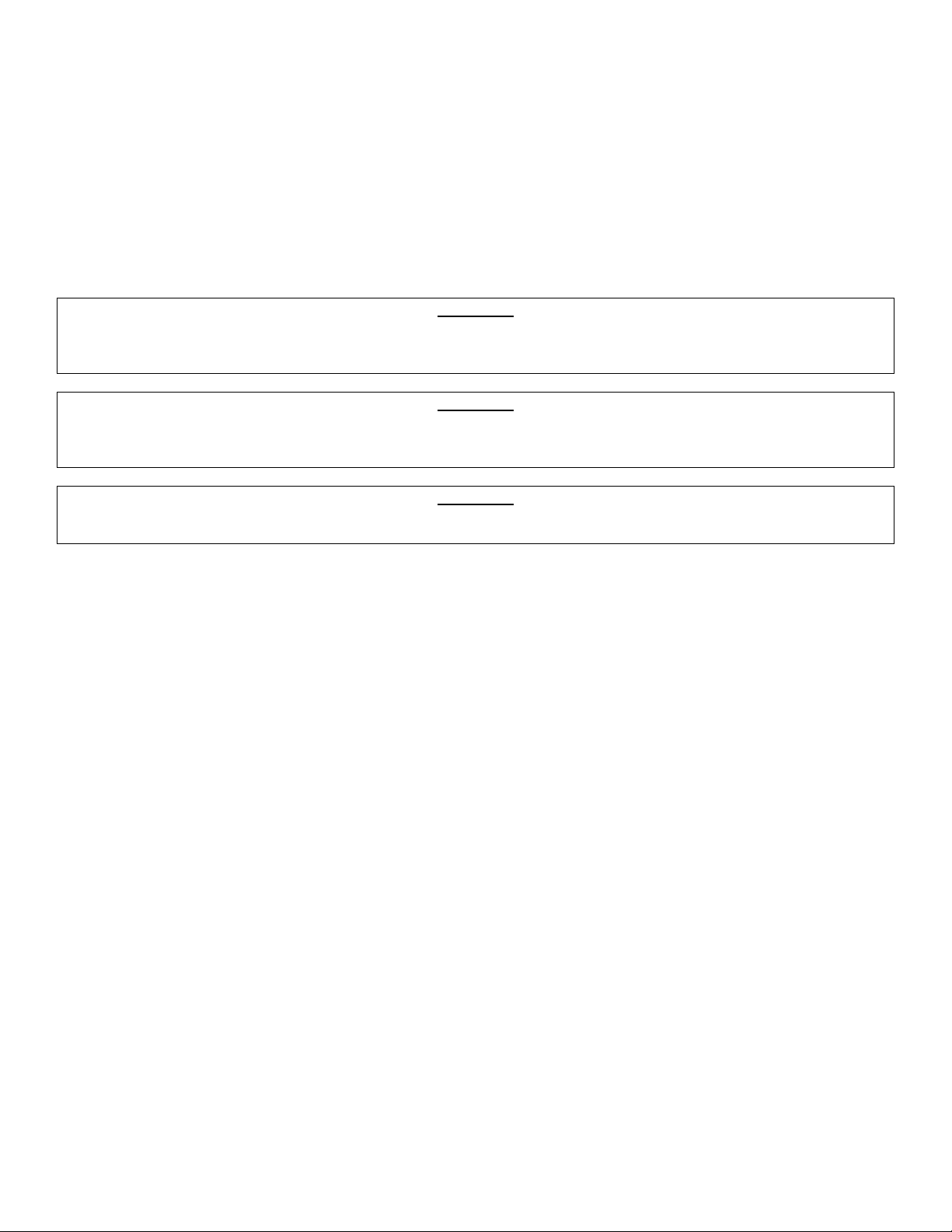

9.14.2. CONNECTING THE ELECTRICAL ELEMENT

THEORETICAL

MODEL

20 kW 2,100 75 68,240 85 125 amps 3 120/240 4 x 5 kW

25 kW 2,100 85 85,325 100 150 amps 2 120/240 5 x 5 kW

WOOD 2,100 100 180,000 5 15 amps 14 120 N/A

OUTPUT

Electrical connections must conform to the wiring diagram supplied with the option.

The electrical element must be connected to the power board (See Section 17 - ELECTRICAL DIAGRAM FOR

ELECTRIC UNIT). For security reasons, the electrical element has a manual reset thermostatic sensor that is located

inside the electrical unit. If the temperature of the electric unit exceeds the high limit, the thermostatic sensor will

disengage the elements. After finding and fixing the problem that has caused the unit to overheat (static pressure too

high, fan breakdown, etc.), reactivate by pressing the red “manual reset” button on the thermostatic sensor (L-170

thermodisc).

TEMP. VAR.

(O F)

BTU/HR

AMPS

TOTAL

INSIDE VIEW OF ELECTRIC ELEMENT

BREAKER

REQUIRED

FEEDER

GAUGE

VOLTAGE

SINGLE PHASE

ELEMENTS

QTY

L-170 Thermodisc RESET

Red button manual reset

29

Page 30

10. THERMOSTAT INSTALLATION

10.1. WOOD FURNACE ONLY

The furnace must be connected to a thermostat. You can use the one provided with the unit or use one that is already

installed in your home. The thermostat must be installed on an inside wall and located where it is not likely to be

affected by the draft coming from an air outlet. It must be installed at a minimum of 55 inches (140cm) above the floor.

It is recommended to connect the thermostat to the furnace with a seven or eight threads wire connecting terminals

Rc, Rh (connect only one of the two terminal R if there is a jumper between Rc and Rh in the thermostat), C, W, Y, G,

O and B. If the thermostat is using a dry contact (powered by batteries), it is not necessary to connect the C (common)

terminal to the thermostat. Refer to the electrical diagram.

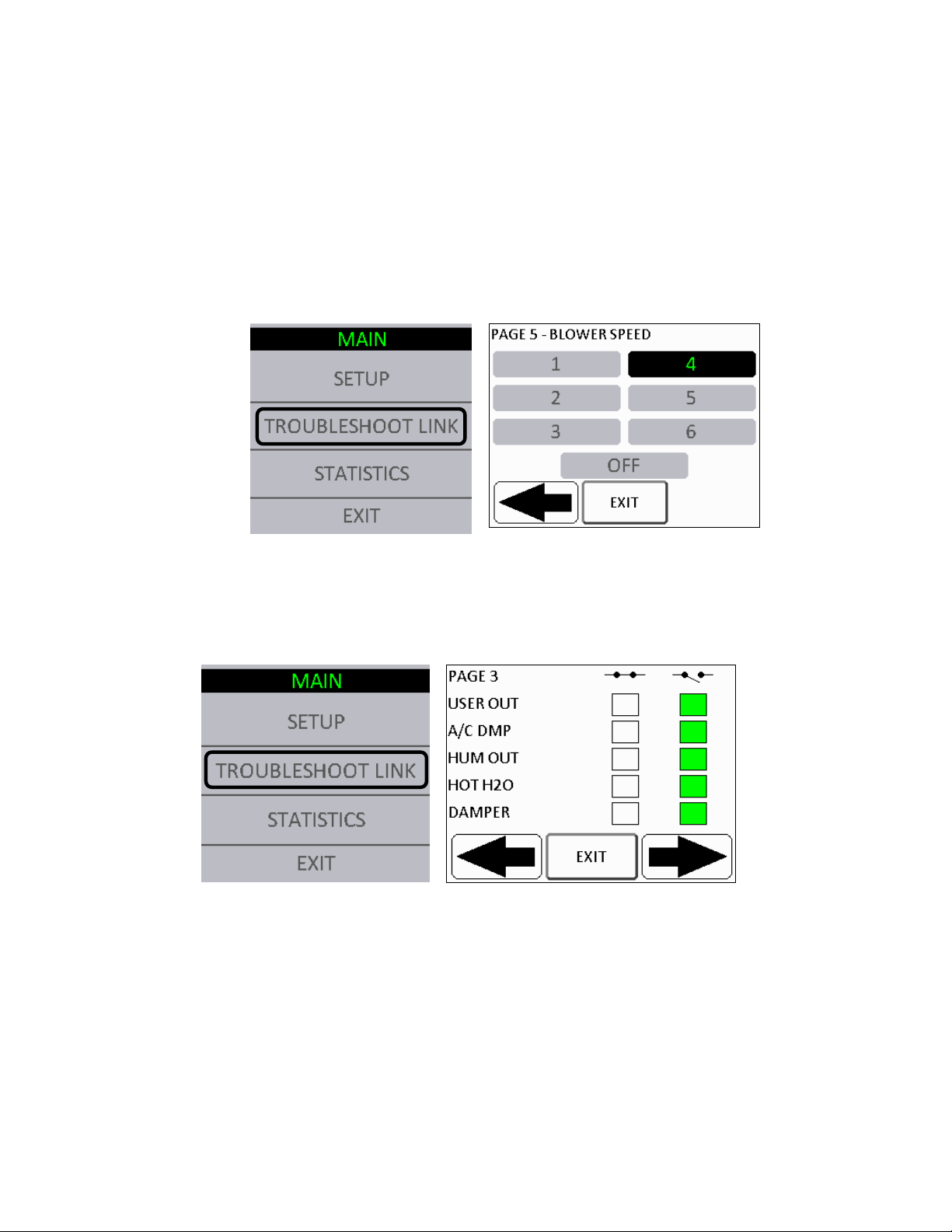

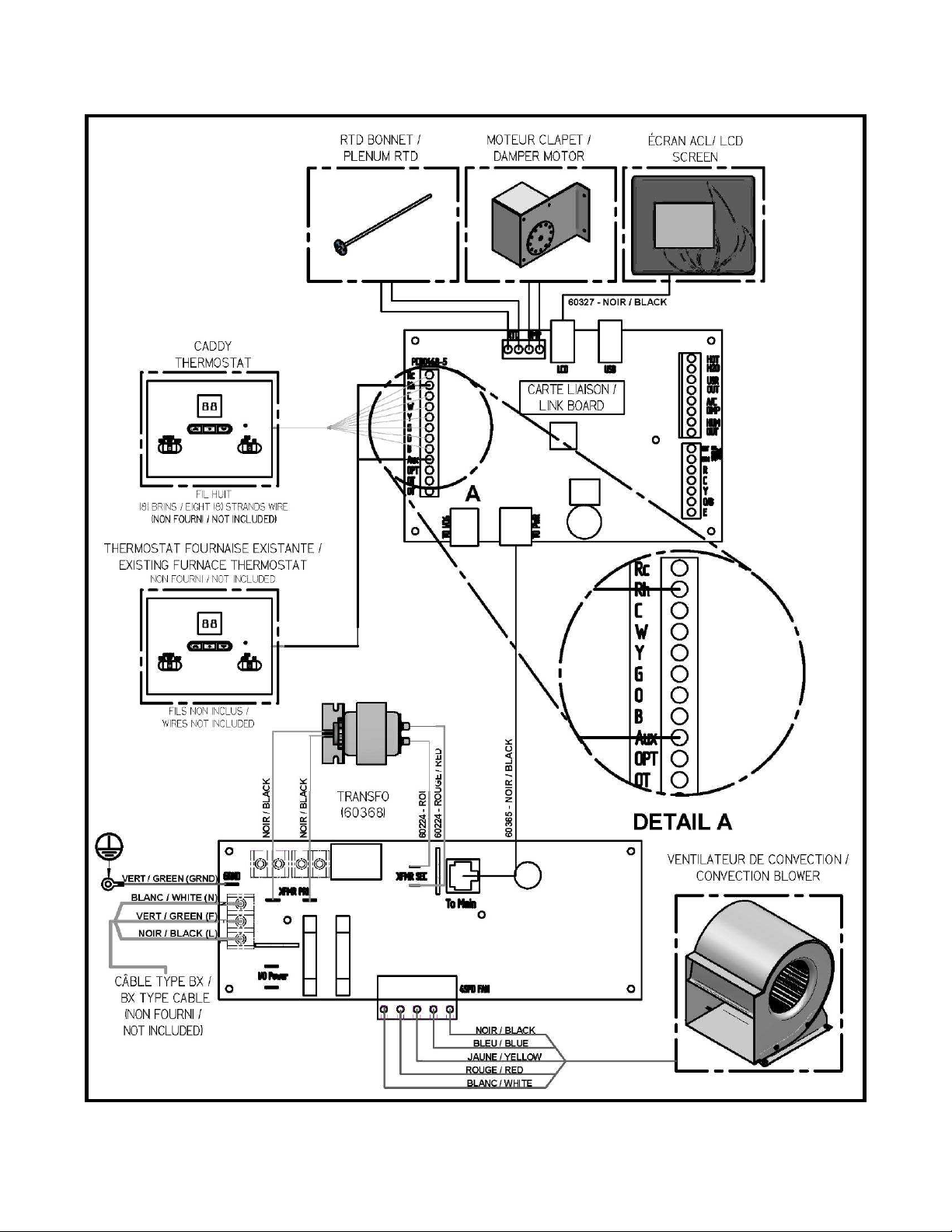

Once wired to the furnace, it is possible to verify the signals coming from the wall thermostat. Simply go on the touch

screen main menu, under the “TROUBLESHOOT LINK’’ menu and going to page 1 as shown below. When a signal is

sent from the thermostat, the circle corresponding to the signal should appear green.

10.1.1. COMBINATION WOOD-ELECTRIC OR WOOD-OIL FURNACE

Only one thermostat is necessary to control the wood furnace and any other auxiliary heating source. Installing the

thermostat is done the same way as if the furnace was wood only. See Section 11.4.1 - TRANSITION TO AN

AUXILIARY HEAT SOURCE to learn how to make it work.

10.1.2. COMBINATION WOOD-ELECTRIC-OIL

Only one thermostat is necessary to control the wood furnace and any other auxiliary heating source. Installing the

thermostat is done the same way as if the furnace was wood only. See Section 11.4.1 - TRANSITION TO AN

AUXILIARY HEAT SOURCE to learn how to make it work.

30

Page 31

10.2. INSTALLATION OF AN AIR CONDITIONING UNIT

The Max Caddy furnace has been tested with an optional air conditioning unit. If this option is chosen, we recommend

an installation as per the graphic provided below.

Damper

A/C coil

Damper

This installation will provide the most efficient and safe operation of the air conditioning unit using the distribution

blower of the Max Caddy furnace during summer. In order to complete the installation of an air conditioning unit, the

main thermostat must be a “heat/cool” type. Furthermore, the desired distribution blower speed must be programmed

on the touch screen in the blower speed menu. (See Section 11.5 DISTRIBUTION BLOWER SPEED

CONFIGURATION

It must be noted that upon thermostatic demand for cooling, the distribution blower will start immediately at the

programmed speed. For the air conditioning damper wiring see Section 28 - LINK BOARD OPTIONS

CONNECTIONS.

The capacity and characteristics of the air conditioning unit that has been tested with the MAX Caddy are stated below.

The use of another brand with similar capacity and characteristics is adequate.

Condenser brand: Goodman GSX13048

Capacity: 4 ton

Coil type: Type A, CAUF uncased indoor coil.

10.3. HEATPUMP INSTALLATION

It is possible to pair a heat pump to the Max Caddy. To determine the priority of operation of these two modes of

heating, you must go to Section 11.4.3 - AUXILIARY HEAT SOURCE PRIORITIZATION.

For connection of the heat pump to your furnace, see Section 28.7 - HEAT PUMP

Note: If a heat pump is connected to the Max Caddy, the electrical element must be installed to ensure an auxiliary

heat source. (PA08535 (20kW), PA08545 (25kW)

For installation of air conditioning coil, refer to Section 10.2 - INSTALLATION OF AN AIR CONDITIONING UNIT.

31

Page 32

10.4. INSTALLATION OF A DOMESTIC WATER PRE-HEATING SYSTEM OR A HUMIDIFIER

A water heating loop option is also available to pre-heat domestic water using the energy produced by the Max Caddy

wood furnace. This water loop kit will be inserted between the wood combustion chamber and the heat exchangers.

When heating with wood, the heat from the furnace will pre-heat domestic water that will be stored in a feed tank

before entering your existing water heater. Removable panels are installed on both sides of the furnace for quick and

easy installation of the loop. A 24 volt solenoid valve must be installed at the inlet of the loop and must be connected to

the HOT H20 terminal on the PC board; when the plenum temperature reaches 120°F, the valve opens to allow water

circulation. It closes when the temperature drops below 100°F to prevent overcooling the combustion chamber during

low firing rates. See section 28.3 -

HOT WATER

for electrical connection. Complete installation and operation

instructions for the hot water loop kit are supplied with the kit.

NOTE : NEVER INSTALL AN AUTOMATIC FEEDER.

The HUM OUT terminal may also be used to activate the 24 volt relay of a humidifier installed in the system which,

when connected to the PC Board, will be activated and deactivated at the same temperatures as the water solenoid

valve (120°F et 100°F). See section 28.6 - HUMIDIFIER for electrical connections.

To verify the status (open or closed) of the valve/relay, see section 14.1 - VALIDATING STATUS OF A COMPONENT.

11. CONFIGURATION AND OPERATING INSTRUCTIONS

11.1. CONTROLS SYSTEM

The Max Caddy has a sophisticated electronic control. This system is more versatile. All connections are made from

the control panel. Terminal blocks are provided for all components and options.

Before you configure your system and learn how to operate it, make sure that your wall thermostat is wired correctly to

your furnace, that the temperature probe (RTD) is well installed in the hot air plenum and connected to the link board

and that your air distribution system is complete.

The furnace uses a touch screen, the latest technology in control devices. Blowers, power supplies and options are

controlled from this screen.

It is important to note that your furnace is equipped with three main electronic components: the link board, the power

board and the touch screen. The power board is already installed in the blower box.

The power board is used to supply current to the different electrical components, in particular:

- Supply current to the different electronic boards;

- Supply current to the distribution fan;

- Supply current to the sequencers of the electrical unit (optional);

- Supply current to the oil burner.

The link board is used more precisely for:

- Connecting the hot air plenum’s temperature probe (RTD type);

- Connecting the wall thermostat;

- Connecting complementary equipments;

- Connecting a heat pump.

The LCD touch screen is used to operate the system. More precisely for:

- Choosing the combustion parameters;

- Selecting the options used;

- Show the temperature in the hot air plenum;

- Selecting heating priority;

- Selecting language and units displayed;

- Viewing statistics;

- Selecting distribution fan speeds;

- Troubleshooting to detect problems with the appliance.

32

Page 33

11.2. SYSTEM CONFIGURATION

Once the installation is complete and before using the unit, the furnace should be configured to activate all applicable

functions depending on options chosen. To do this, it is important to know which options are installed on your furnace.

11.3. TOUCH SCREEN

The LCD control is an electronic visual display as well as a touch screen that will light-up as you touch any location on

the display area. The main status page will then display different icons layout depending if the furnace is on or not.

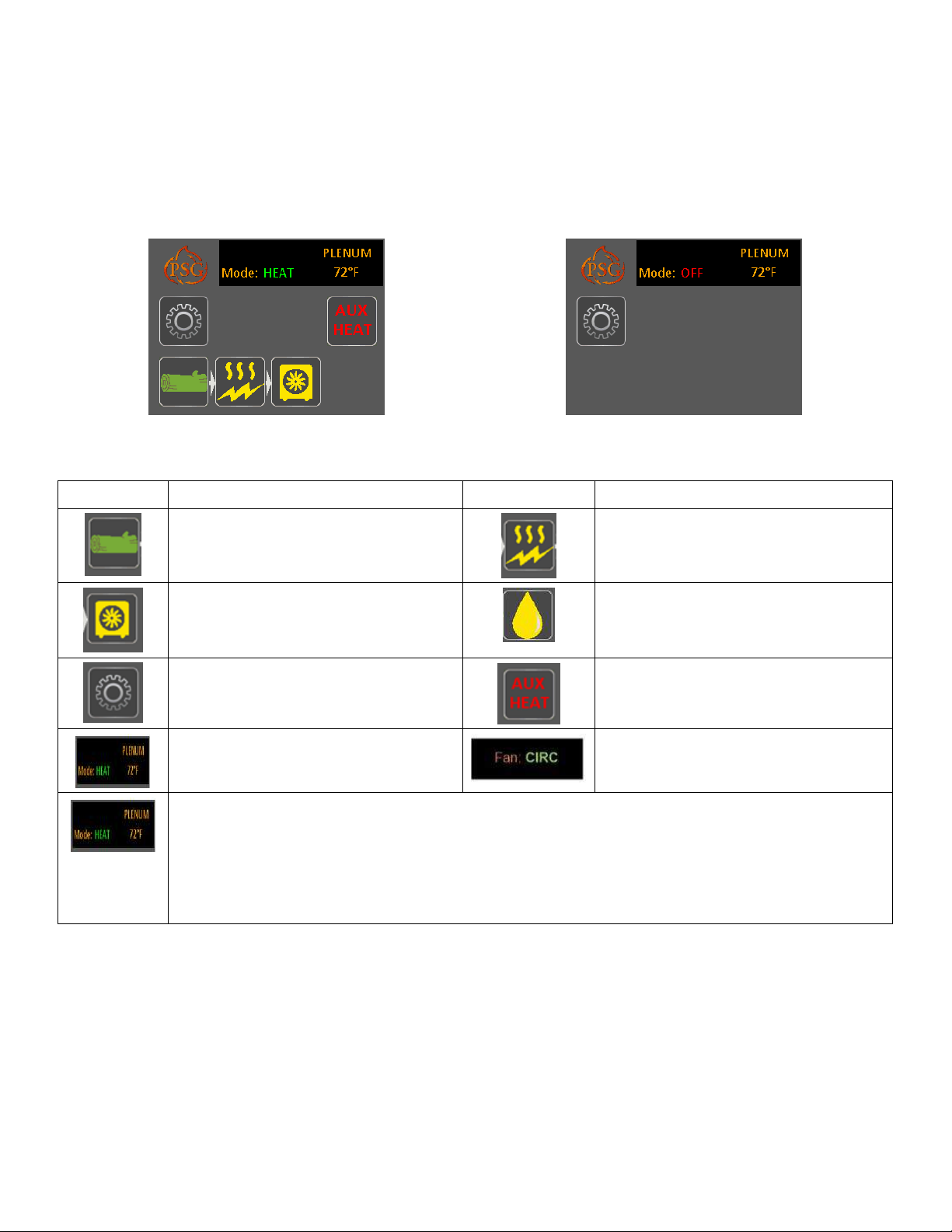

Main menu – Furnace « ON »

Main menu – Furnace « OFF »

11.3.1. ICONS DESCRIPTION

Icons Description Icons Description

Wood heating

Green : Heating mode

Yellow : Auxiliary heating mode

Heat pump

Green : Unit on

Yellow : On hold

Settings

Temperature in the hot air plenum

Possible states of the furnace:

HEAT: When the word HEAT is green, the furnace is in heating mode. If the furnace is waiting for a

demand for heating, the word HEAT is written in yellow.

COOL: When the word COOL is green, the furnace is in cooling mode. If the furnace is waiting for a

demand for cooling, the word COOL will be written in yellow.

OFF: The furnace is stopped.

Electrical Element

Green : Unit on

Yellow : On hold

Oil unit

Green : Unit on

Yellow : On hold

Displayed when an auxiliary heat source

has been selected.

Distribution blower is in circulation

mode. (CIRC)

33

Page 34

11.3.2. LANGUAGE SELECTION AND TEMPERATURE UNIT

To choose the language and temperature unit, press the "Settings" button. In the "Main" menu, choose "SETUP" and

then "GENERAL". Choose the preferred language and temperature unit.

11.4. ADDING AUXILIARY HEATING SOURCE AND SELECTION OF OPTIONS

To add an auxiliary source of heating or to add options to your furnace, press the "Settings" button. On the “MAIN”

page, choose “SETUP” and “OPTIONS”.

By default, no auxiliary source of heating or options are selected. To select an option, simply press the white square to

the left of the desired option. When an option is chosen, the selected square turns green.

To confirm the selection of your options, press the button '' SAVE + EXIT ''. This step takes you to a list of questions

about your selections that are essential for their good functioning.

11.4.1. TRANSITION TO AN AUXILIARY HEAT SOURCE

When there is a demand for heat, the furnace checks the temperature in the plenum. If the temperature is beyond the

KIP, the fan will turn on. If the temperature is below the KIP, the furnace will wait the "Rise Time" delay and check the

temperature again in the plenum. If the temperature in the plenum goes up 20°F but has not reached the KIP, the

furnace will wait for additional time ("KIP Time") and recheck the temperature in the plenum. If the temperature has not

reached the KIP, the auxiliary heating will start. The icon "Wood" will turn yellow and the auxiliary heat icon will turn

green.

For the electrical element and/or the oil unit, the fan starts as soon as the thermostat asks for heat. In other words, for

safety reasons, the fan does not wait for the hot air plenum to reach a predetermined minimum temperature.

The furnace remembers what heating source was used in the last request of the thermostat. If the last heating demand

was met by the auxiliary heater, the furnace automatically start this one.

To restart the furnace using the wood mode, go on the touch screen on the main page and press on the wood icon.

The icon will become green and the auxiliary heating source icon will become yellow.

11.4.2. TRANSITION SETTINGS

It is possible to slightly adjust the transition settings from the wood option to the auxiliary source of heating. To do this,

go to the "MAIN" page on the touch screen under the "SETUP" option and choose "WOOD SETUP ". On this page,

you can change the KIP, KOP, the Rise Time and KIP Time.

KIP (Kick-In point): Temperature of the plenum where the fan turns on.

KOP (Kick-Out point): Temperature of the plenum when the fan stops.

Rise Time: Time allowed for plenum temperature to increase by 20 ° F.

KIP Time: Additional time allowed to reach the KIP when the Rise Time ended with an increase of 20°F.

34

Page 35

11.4.3. AUXILIARY HEAT SOURCE PRIORITIZATION

If you have configured one or many auxiliary heating sources (electrical element, heat pump, oil), you must choose the

priority order when there is a heating demand. If, for example, the wood no longer provides sufficient heat, the auxiliary

heating selected in priority one will take over. If priority one no longer provides enough heat, or does not provide it fast

enough, priority 2 will take over. Heating priorities are chosen in the "MAIN" menu, under the "SETUP" option. Select

"OPTIONS" and "CONFIGURATION". Use the arrows to select the priority order.

11.4.4. EXTERNAL TEMPERATURE PROBE

It is possible to connect an external temperature probe on the Max Caddy. This temperature probe is used primarily to

reduce electricity consumption and reduce the bill by prioritizing the transition to an auxiliary heating source when it is

too cold outside or when it is the overcharging billing period (peak usage) depending on the electricity supplier.

HEAT PUMP : With a combination wood, electrical component and heat pump you can set your temperature probe to

not use your heat pump when it is too cold and the coefficient of performance becomes too low. (Electrical element

should be prioritize during configuration the outdoor temperature probe.)