Page 1

CADDY CORPORATION

Air SystemsFood Service Equipment

Control Cabinets for

Water-Wash Ventilators

Model CPE

Page 2

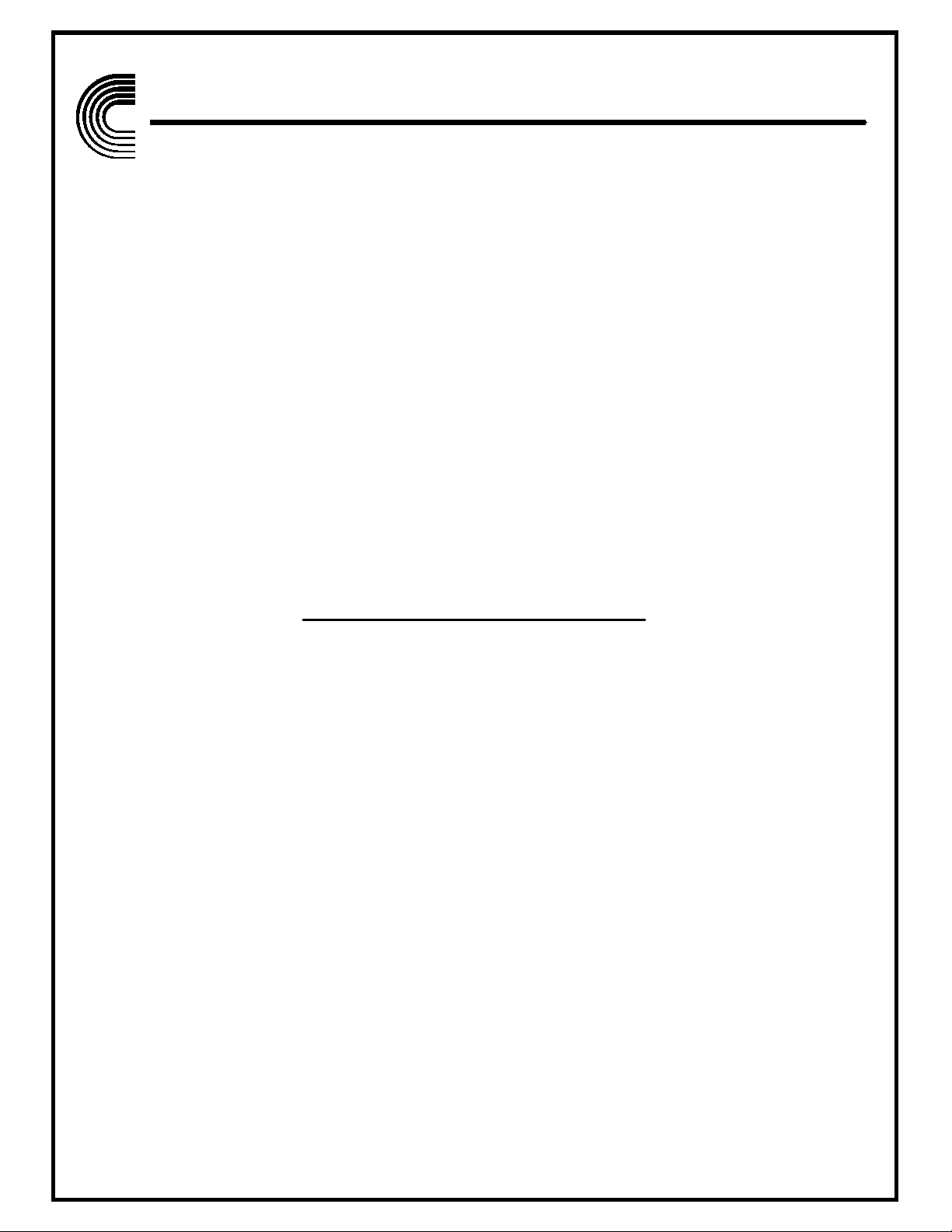

18"

50"

END VIEW

22"

32"8"

10"

32"

ELEVATION VIEW

END VIEW

22"

32"8"

10"

32"

ELEVATION VIEW

PROJECT:

ITEM NO:

Control Cabinets for Water-Wash Ventilators

Model CPE

LOCATION:

General Description (Non-sequential)

The CADDYAirSystems Model CPE waterwash control panel is

designed to work in conjunction with series"SH-W" ventilator. This

panel houses all necessary plumbing and electrical components

required to manually control the exhaust fan, operate the wash cycle,

and control the internal fire protection system. Panel to

include____vacuum breaker and check valve shipped loose for

installation by the Plumbing Contractor ____ a built-in reduced

pressure (RP) type backflow preventor as required by the Uniform

Plumbing Code (UPC), state and/or codes.

Model Number Designation

In order to determine the exact panel model number, it is first necessary

to identify which of the following options are desired. Each selected

option becomes an identitiable suffix int eh model number.

1. Number of groups in sequence (if applicable).. 2,3 or 4

2. Built-in backflow preventor (if applicable)......... RP

3. Programmable time clock................................. TC

4. Low detergent alarm......................................... LD

5. Cold water mist................................................. CM

6. Pipe inlet size ( inches)..................................... 75,1.00,1.25 or 1.50

Once options are selected, identify the exact panel model number as

illustrated by the following example:

509 Sharptown Road P.O. Box 345

Bridgeport, NJ 08014-0345

Tel: 856-467-4222 Fax: 856-467-5511

internet: www.caddycorp.com

CADDY CORPORATION

CADDY Air Systems

All specifications subject to change without notice

01/08

General Description (Sequential)

The CADDYAirSystems Model CPE waterwash control panel is

designed to work in conjunction with series"SH-W" ventilator. This the

of panel is typically required when the building hot water system is not

capable of delivering enough hot water to wash hoods during a single

period of time. This panel houses all necessary plumbing and electrical

components required to manually control the exhaust fan, operate the

wash cycle, and control the internal fire protection system. Panel to

include built-in reduced pressure (RP) type backflow preventor as

required by the Uniform Plumbing Code (UPC), state and/or codes.

This panel is designed to wash two or more groups of ventilators in

sequence ( up to four groups maximum), with a programmable delay

period between each group to allow for hot water regeneration. Upon

wash sequence activation, the exhaust fan shuts down automatically,

and the first wash cycle is initiated. At the end of the first wash cycle,

there is a programmable delay of up to 120 minutes. The wash cycle

for the next group begins at the end of the previous delay period. This

sequence of operation continues of up to four groups. The wash cycle

length is factory set at 5 minutes for optimal cleaning. Each wash cycle

duration can be field adjusted from 1-14 minutes, depending upon

internal grease accumulations.

Time Clock Operation (Optional)

Model CPE and CPE-S will include a 24 hour per day, seven day

operation is required. This clock is located within the electrical

compartment of the panel, where it is not subject to tampering.

Features include: LCD digital display, independent daily programming

capability, multiple start fan and start wash times, Holiday skip feature,

power back-up for holding clock setting and daily programming

requirements.

Number of Panels Required

One control panel can be used for multiple hood sections as long as the

total lineal footage of ventilator does not exceed the pipe size limitations

of the panel. (Non-sequential). One control panel can be used for

multiple hoods in a group wash configuration up to four groups,as long

as the total lineal footage of ventilator in each group does no exceed

the pipe size limitations of the panel. (Sequential). See "Hot Water

Pipe Inlet Size" chart below for panel limitations. Any number of

exhaust fans can be interconnected to these panels if simultaneous

operation of fans single control panel, consult factory for wiring details.

CPE -

Prefix

S___ -

No. of Groups

in Sequence

(if Applicable)

RP -

Built-in

Backflow

Preventor

(if Applicable)

TC -

Time

Clock

LD -

Low

Detergent

Alarm

CM -

Cold

Water

Mist

___

Pipe

Size

Installation

The CPE control panel is shipped as a separate component and is to be

installed, wired and plumbed by the applicable field trades. This panel

can be either surface or flush mounted. When flush mounted, specify

panel with stainless steel trim ring.

Hot Water Requirements

140 Deg. F. minimum - 180 Deg. F. maximum

40psi minimum - 80 psi maximum

Average wash cycle duration - minutes per 24 hour period

1.00 FPM per lineal foot of ventilator at 40 psi

1.25 GPM per lineal foot of ventilator at 80 psi

Control Panel Dimensions

All non-sequential panels without built-in backflow preventor are

32" W x 32" H x 8" D

All non-sequential panels with built-in backflow preventor are

32" W x 50" H x 8" D

All sequential panels up to a three sequence configuration (S-3) are

32" W x 50" H x 8" D

All sequential panels with a four sequence configuration (S-4) are

32" W x 54" H x 8" D

Control Panel Weights

All non-sequential panels : 100 LBS.

All sequential panels: 150 LBS.

Electrial Requirments

120 volt, 60 HZ, 15 amp (minimum) non-interrupted service.

MODEL CPE-1.25-RP-TC MODEL CPE-1.25-TC

page 1 of 7

Page 3

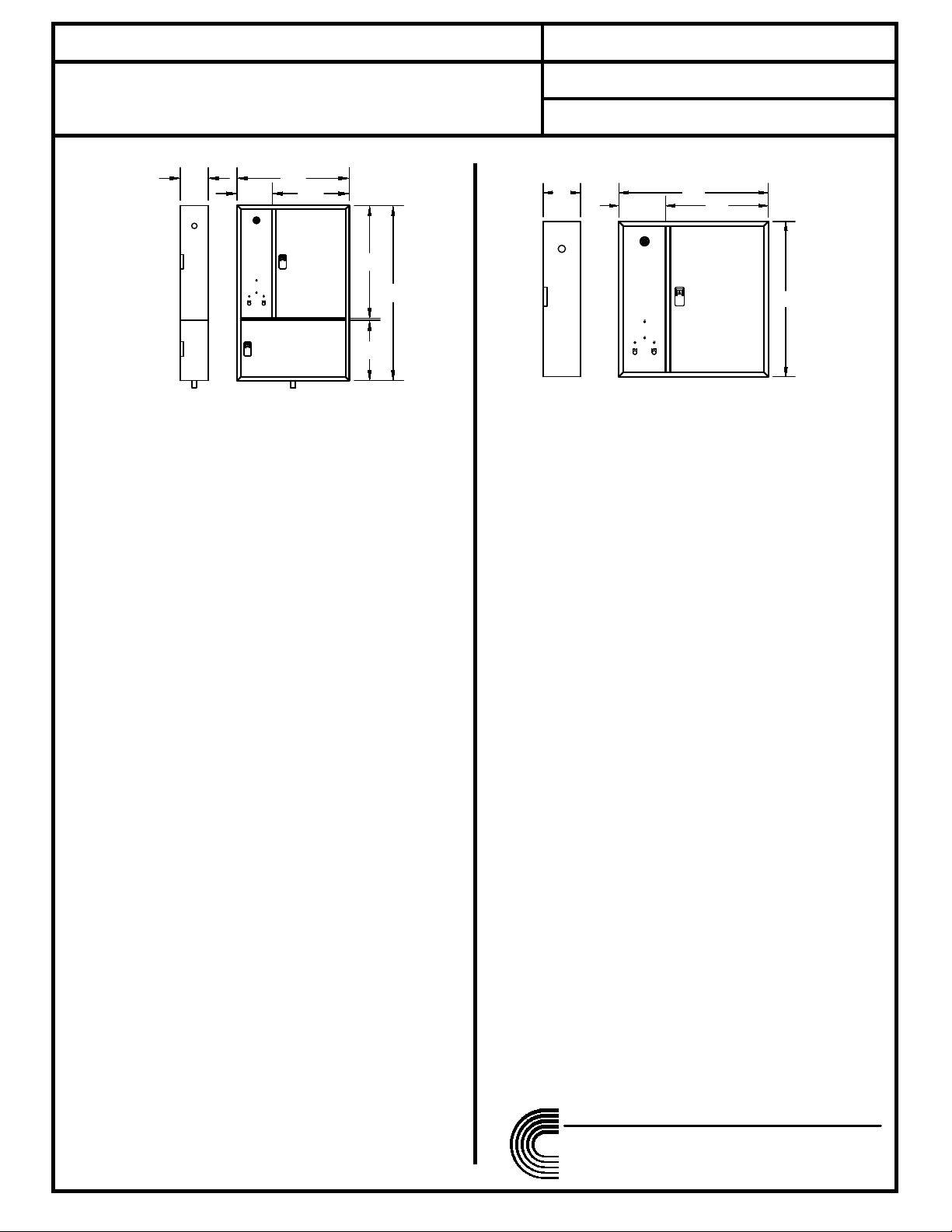

12

11

14

13

15

9

3

4

5

16

8

10

7

1

2

6

12:00

PLC.

RELAY STRIPRELAY STRIP

TERMINAL

STRIP

17

14

13

18

16

15

17

10

11

3

4

6

19

9

12

8

1

2

7

20

12:00

PLC.

RELAY STRIPRELAY STRIP

TERMINAL

STRIP

5

also be equipped with volt-free contacts to allow for connection to

a remote exhaust and supply fan motor control center. Contacts

are also provided to allow for interconnection between the internal

and system. Plumbing components to include a water shut-off

valve, pressure/ temperature gauge, normally closed water

solenoid valve, detergent pump with extended foot valve,

detergent tank and built-in reduced pressure (RP) principle device

back flow preventor. Panel shall be equipped with a catch basin

compartment with a 1" drain connection to facilitate required

testing of the "RP" device as required by code. All components

shall be pre-wired and pre-plumbed for field connection by

applicable trades. Control cabinet shall be U.L. listed.

General Specifications (Non-sequential)

CADDYAirSystems control panel model CPE-_____ to be

furnished with "SH-W" Series waterwash ventilators. This panel

shall house all plumbing and electrical components required to

service the ventilators. The panel shall be constructed of

minimum 18 gauge type 304 stainless steel with a number 4

finish, with welded corners and hinged doors to the plumbing

General Specifications (Sequential)

CADDYAirSystems control panel model CPE-S-RP_____ to be

furnished with "SH-W" Series waterwash ventilators. This panel

shall house all plumbing and electrical components required to

service the ventilators. The panel shall be constructed of

minimum 18 gauge type 304 stainless steel with a number 4

finish, with welded corners and hinged doors to the plumbing

and electrical compartments. The electrical compartment shall

be water tight to protect against direct hose spray. Electrical

controls shall include a programmable logic controller (PLC) for

control of the exhaust fan, wash cycle and internal fire protection

system. The face of the panel shall be equipped with system

status indicator lights which include "Fan On", "Wash On", and

"Fire Mode". An audio alarm to indicate "Fire Mode" is also

standard. The control panel shall be capable of washing up to

four groups of ventilators in sequence, with a delay period for hot

water regeneration between each group. The length of each

cycle shall be factory pre-set at five minutes per group. The

length of each delay period shall be field variable. Panel shall

COMPONENT DETAILS (NON- SEQUENTIAL)

509 Sharptown Road P.O. Box 345

Bridgeport, NJ 08014-0345

Tel: 856-467-4222 Fax: 856-467-5511

internet: www.caddycorp.com

CADDY CORPORATION

All specifications subject to change without notice

01/08

LEGEND

1. UNION (TYPICAL)

2. WATER SOLENOID VALVES (S)

3. PRESSURE/TEMPERATURE GAUGE

4. DETERGENT RESERVOIR

5. DETERGENT LINE WITH FOOT VALVE

6. DETERGENT PUMP

7. WATERTIGHT FLEX CONDUIT (TYPICAL)

8. WATERTIGHT POWER DISTRIBUTION JUNCTION BOX

9. PLUMBING COMPARTMENT

10. ELECTRICAL COMPARTMENT

11. FIRE TEST STATION

12. PROGRAMMABLE TIME CLOCK (OPTIONAL)

13. PROGRAMMABLE LOGIC CONTROLLER

14. INTERNAL RELAY STRIP

15. FIELD WIRING TERMINAL STRIP

16. HOT WATER OUTLET

17. HOT WATER INLET

MODEL CPE-1.25-TC

LEGEND

1. UNION (TYPICAL)

2. WATER SOLENOID VALVES (S)

3. PRESSURE/TEMPERATURE GAUGE

4. DETERGENT RESERVOIR

5. BACKFLOW PREVENTER (RP DEVICE)

WITH 1/4 TURN SHUT OFF VALVE

6. DETERGENT LINE WITH FOOT VALVE

7. DETERGENT PUMP

8. WATERTIGHT FLEX CONDUIT (TYPICAL)

9. WATERTIGHT POWER DISTRIBUTION JUNCTION BOX

10. 1" "RP" DRAIN

11. PLUMBING COMPARTMENT

12. ELECTRICAL COMPARTMENT

13. FIRE TEST STATION

14. PROGRAMMABLE TIME CLOCK (OPTIONAL)

15. PROGRAMMABLE LOGIC CONTROLLER

16. INTERNAL RELAY STRIP

17. FIELD WIRING TERMINAL STRIP

18. HOT WATER INLET

19. HOT WATER OUTLET (TYPICAL)

20. WATER HAMMER

MODEL CPE-1.25-RP-TC

page 2 of 7

Page 4

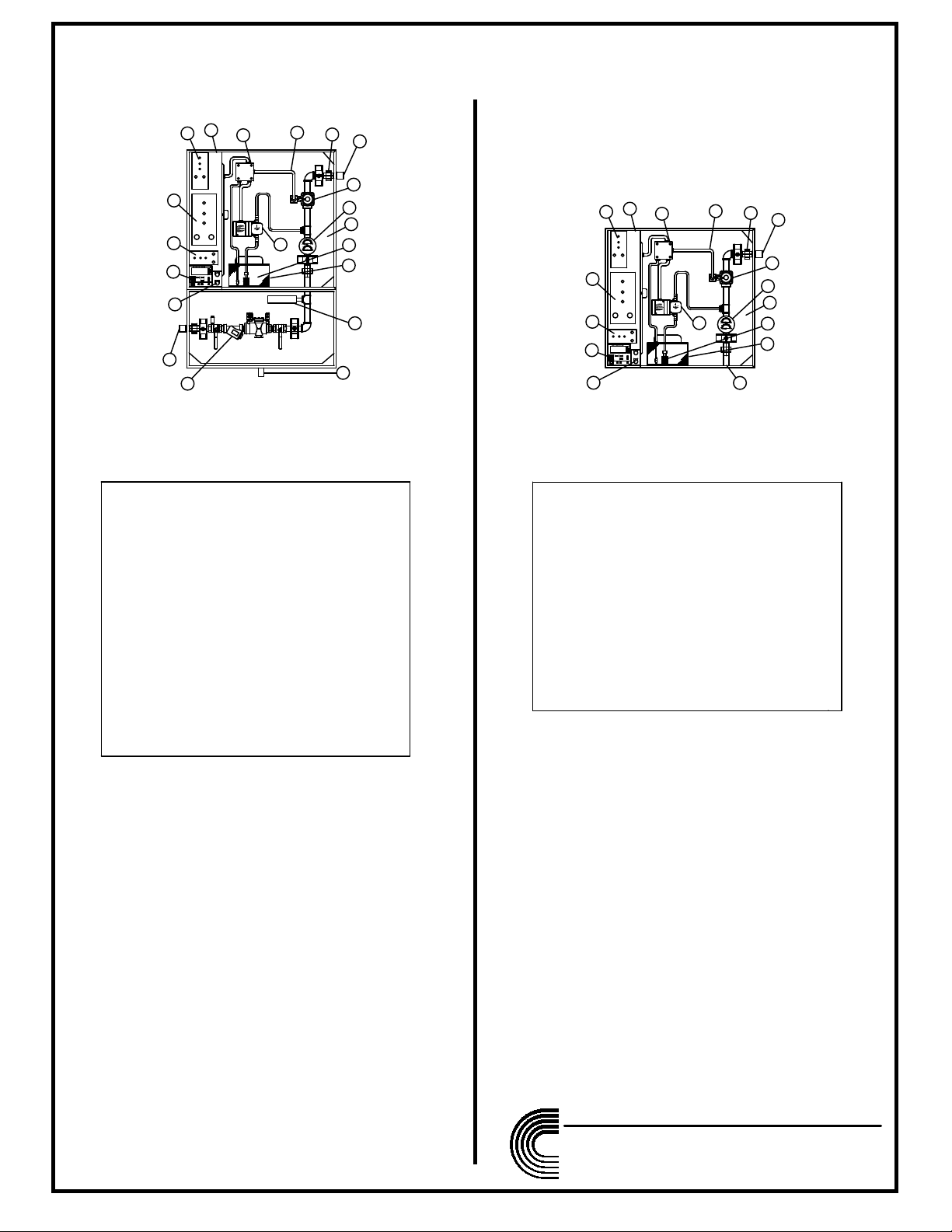

54"

17 1/4"

END VIEW

36 1/4"

8"

22"

32"

10"

21

25

22

23

25

24

12:00

PLC.

RELAY STRIP

STRIP

TERMINAL

3

18

5

13

14

15

10

7

4

6

17

12

9

16

11

8

1

19

2

20

509 Sharptown Road P.O. Box 345

Bridgeport, NJ 08014-0345

Tel: 856-467-4222 Fax: 856-467-5511

internet: www.caddycorp.com

CADDY CORPORATION

All specifications subject to change without notice

01/08

Optional Features (Non-Sequential and

Sequential)

__Time Clock-- To include a 24 hour, 7 day solid state LCD

programmable time clock for automatic operation. Program

options to include starting and stopping the exhaust fan and

starting the wash cycle automatically at a pre-determined time of

day. Time clock to be equipped with an internal battery back-up to

hold the programmed time and programmed memory fuctions.

__Low Detergent Alarm-- To include a low detergent flow switch

to initiate a visual alarm when detergent drops below a pre-set

level in the reservoir.

__Continuous Cold Water Mist-- To include provisions for

continuous cold water mist for use over solid fuel burning cooking

equipment. Components of manifold to include shut-off valve,

solenoid valve, pressure requlator and pressure gauge.

__Remote Fire Switch-- To include a remote break-glass type fire

switch for installation at the nearest exit as indicated on the plans.

__Security Package-- To include a keyed latch to prevent

unauthorizedaddess inthe control panel.

and electrical compartments. The electrical compartment shall be

water tight to protect against direct hose spray. Electrical controls

shall include a programmable logic controller (PLC) for control of

the exhaust fan, wash cycle and internal fire protection system.

The face of the panel shall be equipped with system status

indicator lights which include "Fan On", "Wash On", and "Fire

Mode". An audio alarm to indicate "Fire Mode" is also standard.

Panel shall also be equipped with volt-free contacts to allow for

connection to a remote exhaust and supply fan motor control

center. Contacts are also provided to allow for interconnection

between the internal and system. Plumbing components to

include water shut-off valve, pressure/ temperature gauge,

normally closed water solenoid valve, detergent pump with

extended foot valve, detergent tank and ______ vacuum

breaker/check valve shipped loose for installation by the Plumbing

Contractor (standard), ____ built-in reduced pressure (RP)

principle device back flow preventor (optional). When specified

with an "RP" device as required by cold. All components shall be

pre-wired and pre-plumbed for field connection by applicable

trades. Control cabinet shall be U.L. listed.

LEGEND

1. UNION (TYPICAL)

2. WATER SOLENOID VALVES (S)

3. PRESSURE/TEMPERATURE GAUGE

4. DETERGENT RESERVOIR

5. BACKFLOW PREVENTER (RP DEVICE)

WITH 1/4 TURN SHUT OFF VALVE

6. DETERGENT LINE WITH FOOT VALVE

7. DETERGENT PUMP

8. WATERTIGHT FLEX CONDUIT (TYPICAL)

9. WATERTIGHT POWER DISTRIBUTION JUNCTION BOX

10. 1" "RP" DRAIN

11. PLUMBING COMPARTMENT

12. ELECTRICAL COMPARTMENT

13. FIRE TEST STATION

14. PROGRAMMABLE TIME CLOCK (OPTIONAL)

15. PROGRAMMABLE LOGIC CONTROLLER

16. INTERNAL RELAY STRIP

17. FIELD WIRING TERMINAL STRIP

18. HOT WATER INLET

19. HOT WATER OUTLET (TYPICAL)

20. WATER HAMMER

21. START FAN SWITCH

22. START WASH SWITCH

23. SYSTEM STATUS INDICATOR LIGHTS

24. SON ALERT AUDIBLE ALARM

25. RECESSED HANDLE FOR PLUMBING

COMPARTMENT ACCESS

MODEL CPE-S-4-1.25-RP-TC

COMPONENT DETAILS (SEQUENTIAL)

page 3 of 7

Page 5

7

12:00

PLC.

RELAY STRIPRELAY STRIP

TERMINAL

STRIP

P1

P3

P2

6

12:00

PLC.

RELAY STRIPRELAY STRIP

TERMINAL

STRIP

P1

P2

7

12:00

PLC.

RELAY STRIPRELAY STRIP

TERMINAL

STRIP

E1

E2

E3

E4

E5

E6

TYPICAL PLUMBING AND ELECTRICAL

INFORMATION

509 Sharptown Road P.O. Box 345

Bridgeport, NJ 08014-0345

Tel: 856-467-4222 Fax: 856-467-5511

internet: www.caddycorp.com

CADDY CORPORATION

All specifications subject to change without notice

01/08

PLUMBING REQUIREMENTS- "RP" TYPE

PLUMBING NOTES

PLUMBING REQUIREMENTS-NON "RP" TYPE

P1 __" Hot water connection to CPE

panel by plumbing contractor.

0LQLPXPZDWHUWHPS )

0D[LPXPZDWHUWHPS )

Operating pressure between 40-80 PSI.

P2 __" Hot water connection(s) from CPE

panel to hood connection(s)

by plumbing contractor.

P3 1" drain connection to fllor sink by

plumbing contrctor.

WATER CONSUMPTION

__ G.P.M. @ 40 P.S.I. 5 min. wash

cycle per 24 hr. period.

(SHOWN WITH DOOR REMOVED

FRONT ELEVATION)

PLUMBING NOTES

P1 __" Hot water connection to CPE

panel by plumbing contractor.

0LQLPXPZDWHUWHPS )

0D[LPXPZDWHUWHPS )

Operating pressure between 40-80 PSI.

P2 __" Hot water connection(s) from CPE

panel to hood connection(s)

by plumbing contractor.

WATER CONSUMPTION

__ G.P.M. @ 40 P.S.I. 5 min. wash

cycle per 24 hr. period.

NOTE: Vacuum breaker and check

valve assembly shipped loose for

installation by plumbing contractor.

(SHOWN WITH DOOR REMOVED

FRONT ELEVATION)

HOT WATER PIPE INLET SIZE CHART

Total Linear Feet

of Ventilator

3'-0" to 12'-0"

12'-0" to 22'-0"

22'-0" to 44'-0"

44'-0" to 60'-0"

NPT Size

3/4"

1"

1 1/4"

1 1/2"

IMPORTANT NOTE: The pipe inlet size for a sequential control panel is to be the

same size as the pipe size required for the largest wash group.

TYPICAL ELECTRICAL INFORMATION

E1 120/1/60 15A. (min.) service by electrical contractor.

E2* 4 wires from control panel to hood exhaust damper

control boxes by electrical contractor.

E3 2 wires from control panel to exhaust fan magnetic starter holding coil by

electrical contractor. Holding coil to be 120v /1 phase.

Supply fan to be wired in parallel with exhaust fan.

E4 2 wires from alarm terminal dry contacts (N.O. or N.C.) located in control

panel to building alarm system by alarm contractor or electrical contractor.

E5 2 wires from remote fire pull station (if required) to FS1 and FS2

terminals in control panel by electrical contractor.

E6 2 wires from Ansul micro switch (N.O. contacts) to Ansul 1 and Ansul 2

terminals in control panel by electrical contractor (if required).

*- 5 wire loop between hood damper controls only by electrical

contractor. See damper wiring control circuit diagram.

ELECTRICAL INFORMATION

page 4 of 7

Page 6

MIST VALVE FUSE

CR1-6

CR1

CR1

10 A

CR1-9

PLC 1 AND 2

NOTES:

CR2

CR2-9CR2-6

CR1-4CR1-7

CR2

CR2-7

CR3

CR3-6

CR3-3

CR3-4

CR3-7

CR3-9

CR3-9

CR2-4

DC +

PLC INPUT 9

14

CR4

13

CR3-1

CR3-7

B. EXHAUST AND SUPPLY FAN RELAYS ARE

RATED AT 10 AMP (1/3 HP) @ 120 VAC.

A. PROVIDE 120 VOLT, 60 HZ, 15 AMP SERVICE

TO THE PANEL , FUSED SEPERATELY. POWER

CR4 DAMPER SWITCH (THERMOSTAT) - 120V IN

MUST BE AVAILABLE 24 HOURS.

CR6 DETERGENT PUMP

CR2 SUPPLY FAN - DPDT

CR1 EXHAUST FAN - DPDT

C. RELAY ASSIGNMENTS

CR5 OPT. PULL STATION - SPDT

CR3 ALARM / TROUBLE SIGNAL - DPDT

1. AC INPUT

2. AC GROUND (GROUND)

3. AC NEUTRAL (INPUT)

4. EXHAUST FAN HOT (E.FAN L)

5. EXHAUST FAN NEUTRAL (E.FAN N)

NOTE # 5

6. EXHAUST FAN NO (E.FAN NO)

7. EXHAUST FAN NO (E.FAN NO)

8. SUPPLY FAN HOT (S.FAN L)

9. SUPPLY FAN NUE (S.FAN N)

10. SUPPLY FAN NO (S.FAN NO)

11. SUPPLY FAN NO (S.FAN NO)

12. ALARM NO (ALM-OPN)

13. ALARM COM (ALM-COM)

14. ALARM NC (ALM-CLO)

15. FIRE SYS NO (FI-OPN)

16. FIRE SYS COM (FI-COM)

17. FIRE SYS NC (FI-CLO)

18. PULL STATION (FS1)

19. PULL STATION (FS2)

20. ANSUL (ANSUL 1)

21. ANSUL (ANSUL2)

22. EX. FAN OPT. JMPR (EF DIS)

23. EX. FAN OPT. JMPR (EF DIS)

24. DAMPER SW. (LAST F)

E1

E1

E1

E3

E3

E3

E3

E4

E2

26. FIRST A

H

G

N

E2

SEE NOTE #1

SEE NOTE #1

SEE NOTE #4

NOTE # 6

NOTE # 2

13

CR5

14

25. DAMPER SW. (C INPUT)

27. B-DAMPER TEST

E2

E2

SEE NOTE #3

E5

E6

120 VOLT A.C. 1 PHASE 60 HZ. 15 AMPS.

SERVICE BY ELECTRICAL CONTRACTOR

AC LOAD

DISTRIBUTION BLOCK

AC NEUTRAL

DISTRIBUTION BLOCK

509 Sharptown Road P.O. Box 345

Bridgeport, NJ 08014-0345

Tel: 856-467-4222 Fax: 856-467-5511

internet: www.caddycorp.com

CADDY CORPORATION

All specifications subject to change without notice

01/08

1. Exhaust fan N/O and supply fan N/O terminals are voltage free

N/O sets of contacts for use with a remote motor control station.

SEQUENCE OF OPERATIONS

"FAN ON" - contacts close to start exhaust and supply fans.

"Wash on" - Contacts open to stop exhaust and supply fans.

"External fire" (fire switch pulled, fire system discharged)

Exhaust fan N/O contacts close to start exhaust fan.

Supply fan N/O contacts open to stop supply fan.

"Internal fire" ( ventilator thermostat closure) contacts open to

stop exhaust and supply fan.

2. Unit is shipped with a factory installed jumper across exhaust fan

disable terminals. With jumper installed "external fire" condition will

result in exhaust and supply fan shutdown. Removal of jumper will

cause exhaust fan to start, if off, or remain running if on, and supply

fan to stop during external fire condition.

WIRING DIAGRAM AND NOTES

3. Alarm com,. alarm N/C, alarm N/O-voltage free contacts for

connection to building alarm system. Contacts transfer during

either internal or external fire mode.

4. Alarm com,. alarm N/C, alarm N/O-voltage free contacts for

connection to building alarm system. Contacts transfer during

either internal or external fire mode. (Optional)

5. Factory installed jumper. Removed jumper and install N/C

remote fire switch if required. Pulling switch will initiate external

fire mode.

6. Factory installed jumper. Removed jumper and connect to N/C

micro switch in Ansul, Kidde, or Pyrochem system. Fire system

discharge will initiate external fire mode.

page 5 of 7

Page 7

BY CADDY AIR SYSTEMS

BY ELECTRICAL CONTRACTOR

ACKNOWLEDGED ON OUR STANDARD FORM.

FABRICATION. ANY SUBSEQUENT CHANGES REQUIRED MUST BE SUBMITTED TO US IN WRITING AND

WILL BE CONSTRUCTED IN ACCORDANCE WITH OUR DRAWING(S) WHICH MUST BE APPROVED PRIOR TO

ALL WIRING AND PLUMBING AT THE JOB SITE IS THE RESPONSIBILITY OF OTHERS. EQUIPMENT

OUR ATTENTION AND ARE EXPRESSLY INCLUDED IN OUR WRITTEN QUOTATION.

TO CADDY CORPORATION OF AMERICA, UNLESS THESE CONDITIONS WERE PREVIOUSLY BROUGHT TO

REGIONAL OR LOCAL CODE REQUIREMENTS IS TO BE DONE BY OTHERS AND WITHOUT BACK CHARGE

ANY FIELD WORK RELATING TO THE MODIFICATION OF ELECTRIC OR PLUMBING SYSTEMS,TO MEET

CODES THAT ADD OR DEVIATE FROM THE ACCEPTED STANDARDS OF THE ABOVE AGENCIES.

DOES NOT ACCEPT ANY RESPONSIBILITY FOR THE REQUIREMENTS OF ANY REGIONAL AND/OR LOCAL

THE LATEST EDITION OF THE NATIONAL ELECTRICAL CODE(NEC). CADDY CORPORATION OF AMERICA

STANDARDS PUBLISHED BY THE UNDERWRITER'S LABORATORIES,INC. INSOFAR AS APPLICABLE, AND

ELECTRICAL WORK DONE BY CADDY CORPORATION OF AMERICA IS EXECUTED IN COMPLIANCE WITH

GENERAL CONTRACT CONDITIONS

BE 115 VOLTS.

HOWEVER, COIL MUST

MAKE OF STARTER

VARY ACCORDING TO

WIRING DIAGRAM MAY

MAGNETIC STARTER

MOTOR STARTER

C

E3

CUSTOMER

SUPPLY

MOTOR STARTER

MAGNETIC STARTER

WIRING DIAGRAM MAY

VARY ACCORDING TO

MAKE OF STARTER

HOWEVER, COIL MUST

BE 115 VOLTS.

EFM

C

SUPPLY

CUSTOMER

E3

1. AC INPUT

2. AC GROUND (GROUND)

3. AC NEUTRAL (INPUT)

4. EXHAUST FAN HOT (E.FAN L)

5. EXHAUST FAN NEUTRAL (E.FAN N)

NOTE # 5

6. EXHAUST FAN NO (E.FAN NO)

7. EXHAUST FAN NO (E.FAN NO)

8. SUPPLY FAN HOT (S.FAN L)

9. SUPPLY FAN NUE (S.FAN N)

10. SUPPLY FAN NO (S.FAN NO)

11. SUPPLY FAN NO (S.FAN NO)

12. ALARM NO (ALM-OPN)

13. ALARM COM (ALM-COM)

14. ALARM NC (ALM-CLO)

15. FIRE SYS NO (FI-OPN)

16. FIRE SYS COM (FI-COM)

17. FIRE SYS NC (FI-CLO)

18. PULL STATION (FS1)

19. PULL STATION (FS2)

20. ANSUL (ANSUL 1)

21. ANSUL (ANSUL2)

22. EX. FAN OPT. JMPR (EF DIS)

23. EX. FAN OPT. JMPR (EF DIS)

24. DAMPER SW. (LAST F)

E1

E1

E1

E3

E3

E3

E3

E4

E2

SFM

26. FIRST A

H

G

N

120 VOLT A.C. 1 PHASE

60 HZ. 15 AMPS. SERVICE BY

ELECTRICAL CONTRACTOR

E2

EXHAUST FAN SUPPLY FAN

SEE NOTE #1

SEE NOTE #1

SEE NOTE #3

NOTE # 6

NOTE # 2

N/C MIRCOSWITCH

IN SURFACE

PROTECTION

SYSTEM

(SEE NOTE #6)

25. DAMPER SW. (C INPUT)

27. B-DAMPER TEST

E2

E2

MIST VALVE FUSE

CR1-6

CR1

CR1

10 A

CR1-9

PLC 1 AND 2

NOTES:

CR2

CR2-9CR2-6

CR1-4CR1-7

CR2

CR2-7

CR3

CR3-6

CR3-3

CR3-4

CR3-7

CR3-9

CR3-9

CR2-4

DC +

PLC INPUT 9

14

CR4

13

CR3-1

CR3-7

B. EXHAUST AND SUPPLY FAN RELAYS ARE

RATED AT 10 AMP (1/3 HP) @ 120 VAC.

A. PROVIDE 120 VOLT, 60 HZ, 15 AMP SERVICE

TO THE PANEL , FUSED SEPERATELY. POWER

CR4 DAMPER SWITCH (THERMOSTAT) - 120V IN

AC NEUTRAL DISTRIBUTION BLOCK

MUST BE AVAILABLE 24 HOURS.

CR6 DETERGENT PUMP

CR2 SUPPLY FAN - DPDT

CR1 EXHAUST FAN - DPDT

C. RELAY ASSIGNMENTS

CR5 OPT. PULL STATION - SPDT

CR3 ALARM / TROUBLE SIGNAL - DPDT

AC LOAD DISTRIBUTION BLOCK

13

CR5

14

509 Sharptown Road P.O. Box 345

Bridgeport, NJ 08014-0345

Tel: 856-467-4222 Fax: 856-467-5511

internet: www.caddycorp.com

CADDY CORPORATION

page 6 of 7

Page 8

ITEM #

ITEM #

ITEM #

A1

B1

C

C1

1

7

D1

4

E1

F1

DAMPER CONTROL

TERMINALS

FIFTH WIRE LOOP BETWEEN ALL DAMPER

ASSEMBLIES BY ELECTRICAL CONTRACTOR.

NOTES:

1. Exhaust fan N/O and supply fan N/O terminals are voltage free

N/O sets of contacts for use with a remote motor control station.

SEQUENCE OF OPERATIONS

"FAN ON" - contacts close to start exhaust and supply fans.

"Wash on" - Contacts open to stop exhaust and supply fans.

"External fire" (fire switch pulled, fire system discharged)

Exhaust fan N/O contacts close to start exhaust fan.

Supply fan N/O contacts open to stop supply fan.

"Internal fire" ( ventilator thermostat closure) contacts open to

stop exhaust and supply fan.

2. Unit is shipped with a factory installed jumper across exhaust fan

disable terminals. With jumper installed "external fire" condition will

result in exhaust and supply fan shutdown. Removal of jumper will

cause exhaust fan to start, if off, or remain running if on, and supply

fan to stop during external fire condition.

3. Alarm com,. alarm N/C, alarm N/O-voltage free contacts for

connection to building alarm system. Contacts transfer during

either internal or external fire mode.

4. Alarm com,. alarm N/C, alarm N/O-voltage free contacts for

connection to building alarm system. Contacts transfer during

either internal or external fire mode. (Optional)

5. Factory installed jumper. Removed jumper and install N/C

remote fire switch if required. Pulling switch will initiate external

fire mode.

6. Factory installed jumper. Removed jumper and connect to N/C

micro switch in Ansul, Kidde, or Pyrochem system. Fire system

discharge will initiate external fire mode.

A2

B2

C

C2

7

D2

E2

F2

DAMPER CONTROL

TERMINALS

1

4

A3

B3

C

C3

7

D3

E3

F3

DAMPER CONTROL

TERMINALS

1

4

THE CADDY VENTILATOR TESTING,

LISTING AND APPROVAL REFERENCES:

NATIONAL FIRE PROTECTION ASSOCIATION

In Accordance with Recommendation of National Fire

Protection Association's NFPA NO. 96 "Vapor Removal From

Cooking Equipment"

NATIONAL SANITATION FOUNDATION

Standard #2 - "Food Service Equipment"

UNDERWRITERS LABORATORIES, INC

Tested under standard U.L. 710 "Exhaust Hoods for

Commercial Cooking Equipment". U.L. Listed under file number

MH8215 and MH12264

UNIFORM MECHANICAL CODE

Section 507 - Commercial Kitchen Hoods and Kitchen

Ventilation Systems

THE BOCA NATIONAL MECHANICAL CODE

Chapter 5 - Kitchen Exhaust Equipment

STANDARD MECHANICAL CODE (SBCCI)

Section 504 - Commercial Hoods

UNIFORM BUILDING CODE (ICBO)

INTERNATIONAL MECHANICAL CODE (IMC)

REV DATE BY

REVISIONS

REMARKS

P.O. BOX 345 BRIDGEPORT NJ 08014

Tel:(856) 467-4222 Fax:(856) 467-5511

R

FILE NO. MH82155P

AirSystems

509 SHARPTOWN ROAD

EQUIPMENT SCHEDULE

MASTER WIRING DIAGRAM FOR

CPE AND CPE-RP WATER WASH

CONTROL PANELS.

DATE SCALE

DR BY

DRA

APP'D BY

AS NOTED

DWG#

SHT

OF

1

1

CADDY CORPORATION

509 Sharptown Road P.O. Box 345

Bridgeport, NJ 08014-0345

Tel: 856-467-4222 Fax: 856-467-5511

internet: www.caddycorp.com

page 7 of 7

Loading...

Loading...