Page 1

Caddx® Installation Instructions Package

This package includes instructions for the following Caddx products:

■ NetworX NX-E Series Receiver Modules—NX-408E & NX-408E-I, NX-416E & NX-416E-I, NX-448E & NX-448E-I

(Document Number 466-1427)

■ NX-450 & NX-451 Door/Window Sensor (Document Number 466-1303-CDX)

■ 60-686-43-EUR Door/Window Sensor (Document Number 466-1578)

■ NX-470 & 60-659-43-EUR 4-Button Keychain Touchpad (Document Number 466-1478)

■ NX-480 & 60-639-43-EUR Wireless Motion Sensor (Document Number 466-1479)

1420 NORTH MAIN STREET | Gladewater, TX | 75647 | 800-727-2339 | www.caddx.com | www.interlogixsecurity.com

©2001 Interlogix,™ Inc. Interlogix is a t rademark of Interlogix, Inc. Caddx and ITI are regist ered trademarks of Int erlogix, Inc.

For reprints of this package, order part number 466-1486.

Document Numbe r: 46 6-1486 Rev. G

Page 2

Page 3

1HWZ RU ;1 ; ( 6 HULHV

5HFHLY HU0RGXOHV

ITI Part No. 60-904

Document Number: 466-1427 Rev. G

December 2001

Product Summary

The NX-E Series Receiver Modules (8-zone NX-408E, 16zone NX-416E, and 48-zone NX-448E) add wireless capabilities to the Caddx

®

NetworX NX-4, NX-6, NX-8, and

NX-8E control panels. Adding a receiver module makes

these control panels compatible with NX wireless transmitters and keychain touchpads (keyfobs).

The receiver modules mount inside the control panel cabinet and require just three wire connections for power and

data communications to the motherboard.

Installation Guidelines

Use the following guidelines when installing receiver modules:

❑ Leave at least 10" above the control panel for the mod-

ule’s antennas.

❑ Avoid areas that are likely to expose the module to

moisture.

❑ Avoid areas with excessive metal or electrical wiring,

including furnace and utility rooms.

Installing the Receiver Module

The following steps describe mounting the circuit board

edge guide standoff, s ecuring the module to the ca binet, and

inserting the antennas.

9740G15A.DS4

Installation Instructions

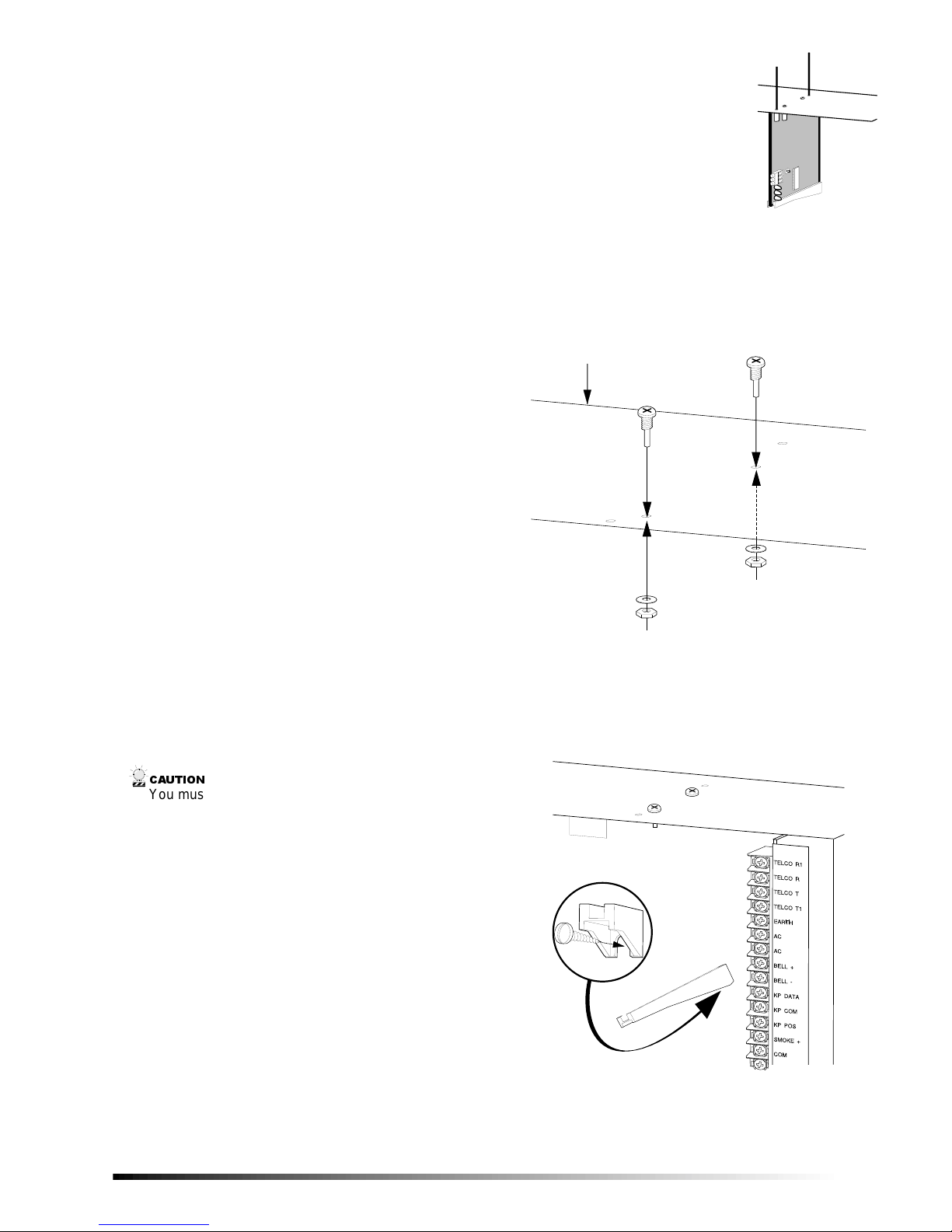

1. After mounting the control panel cabinet, install the

ground plane screws, washers, and nuts (included) in

the holes on top of the cabinet (see Figure 1).

TOP OF

ENCLOSURE

9740G05A.DS4

Figure 1. Installin g the Ground Plane Screws, Wash-

ers, and Nuts

2. Install the circuit board edge guide standoff in the

lower mounting hole, in either of the two spaces

located just to the left of the motherboard (see Figure

2). Do not tighten the standoff at this time.

&$87,21

You must be free of static electricity before handling

circuit boards. Touch a bare metal surface or wear a

grounding strap to discharge yourself.

9740G08A.DS4

Figure 2. Installing the Circuit Board Edge Guide

Standoff

1

Page 4

Installation Guidelines

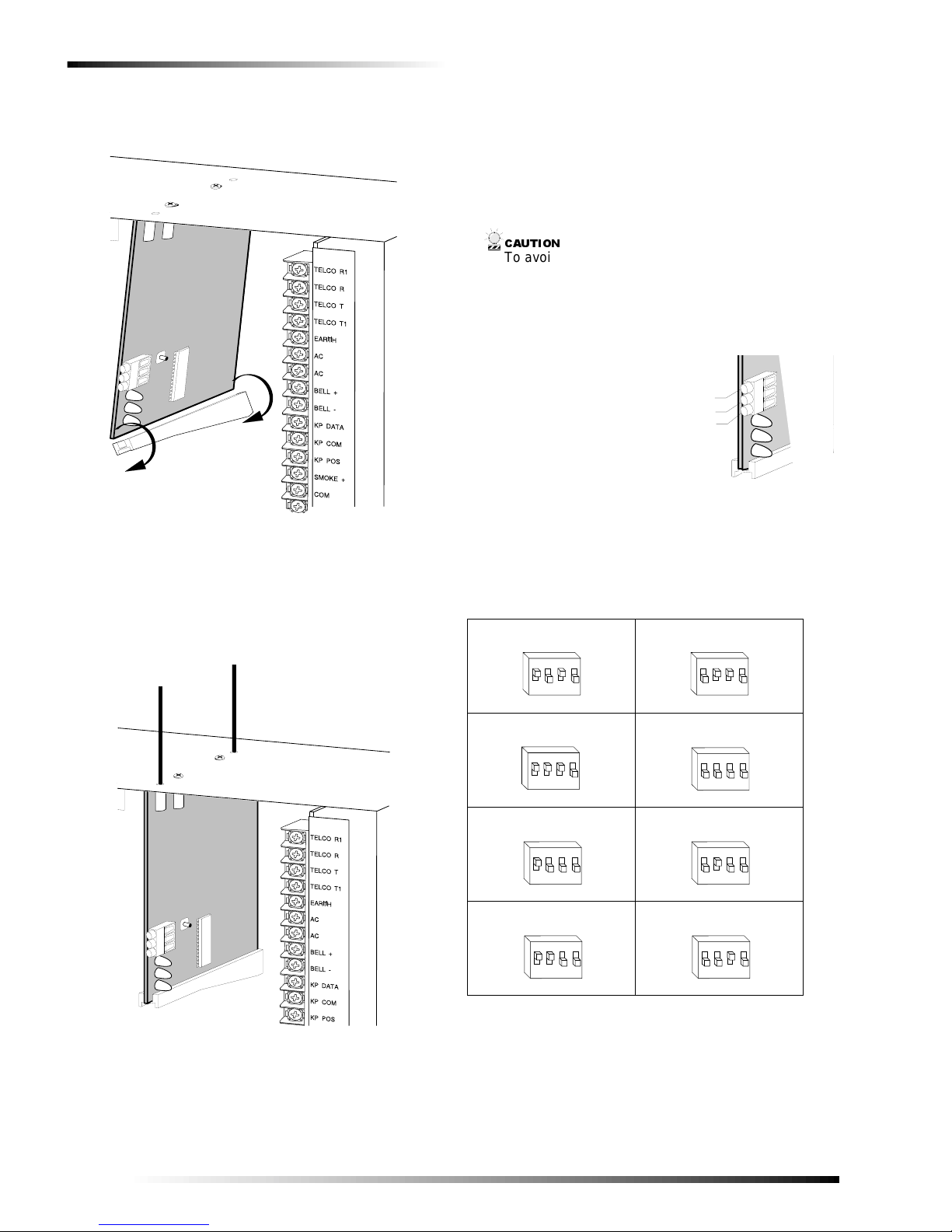

3. Install the module into the cabinet by turning the standoff sideways, then sli de the mo dule up onto the ground

plane screw posts (see Figure 3).

9740G04A.DS4

Figure 3. Installing the Module into the Cabinet

4. Turn the standoff so the slot is facing up, insert the

back corner of the module into the standoff slot, then

press up at the front of the standoff and tighten the

standoff screw.

5. Insert the antennas through the holes on top o f the cabinet and into the module antenna sockets (see Figure 4).

Wiring, Module Number DIP Switch

Settings, and Power Up

The following steps describe wiring the module to the control panel, setting the module number DIP switches, and

powering up the control panel.

1. Remove power (if applied) from the control panel.

&$87,21

To avoid possible equipment damage or personal

injury, remove power from the control panel before

making any wiring connections to the module.

2. Connect the module power, ground, and data terminals

to the control panel power, common, and data terminals

using 22-gauge or larger, stranded wire (see Figure 5).

P O W E R + ( T O P A N E L A U X P W R + )

Figure 5. Wiring the Module Power and Data Terminals

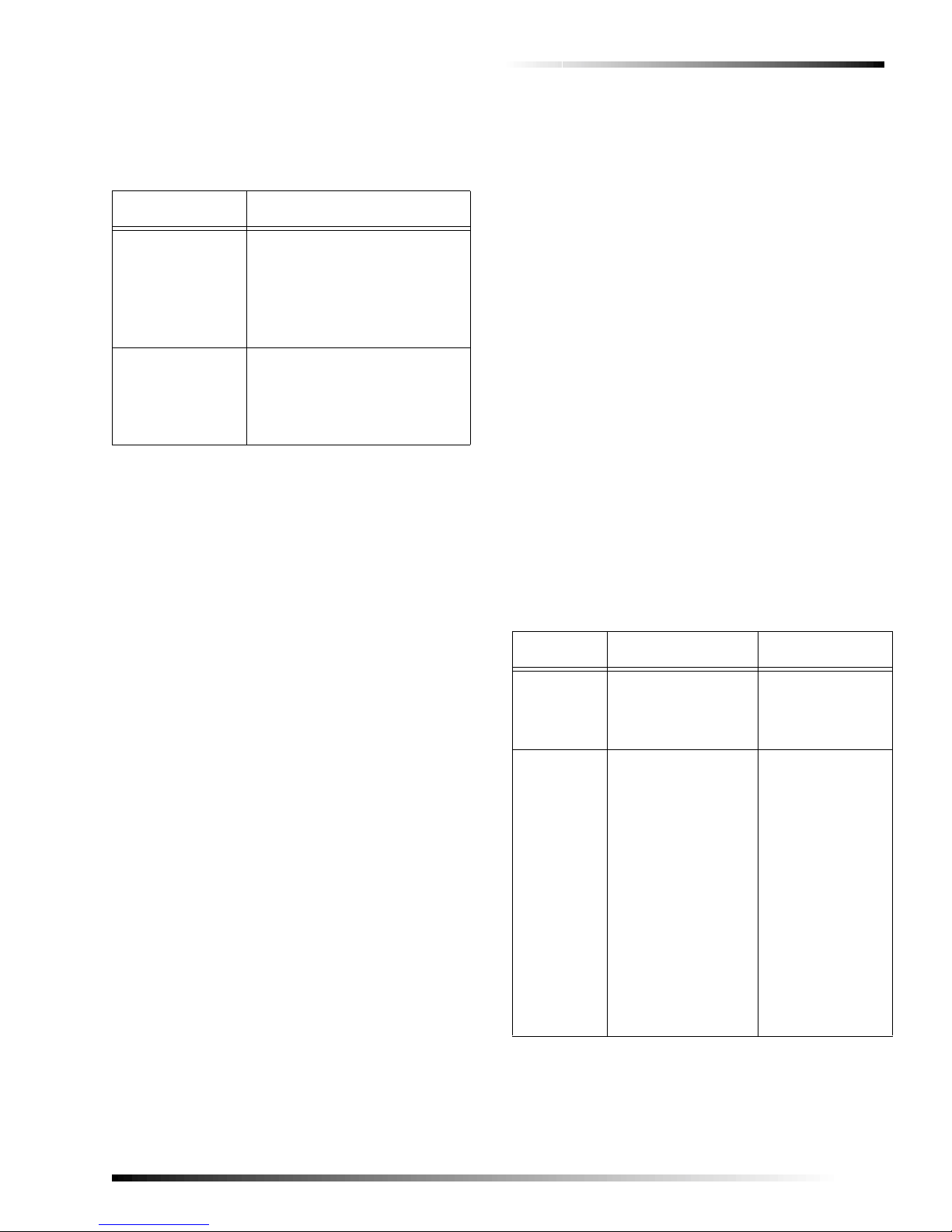

3. Set the module DIP switches to the desired mod ule

number (see Table 1).

Table 1. Receiver Module Number Settings

Module Number 32 Module Number 33

O N

1 2

G N D ( T O P A N E L C O M )

D A T A ( T O P A N E L K P D A T A )

9 7 4 0 G 1 4 B . D S 4

to the Panel Power and Data Terminals

E D G O N

43

E D G

43

1 2

Module Number 34 Module Number 35

O N

E D G

43

1 2

ON

EDG

43

1 2

Module Number 36 Module Number 37

O N

E D G O N

43

1 2

E D G

43

1 2

Module Number 38 Module Number 39

O N

E D G O N

43

1 2

9740G10A.DS4

Figure 4. Inserting the Antennas

2

E D G

43

1 2

Page 5

Programming

4. Apply power to the control panel. The middle (red)

LED on the module should start blinking. Table 2

describes the module’s status based on LED conditions.

Table 2. Module Status Conditions

LED Module Status

Red-blinking

Normal data communication with

the control panel.

Red-off

No data communication with

control panel. Check wiring and

power source.

Yellow-blinking

Receiving radio signals from

wireless sensors.

Yellow-off

No radio signals currently being

received.

Note

The red LED at the bottom of the module may emit a dim

glow but is not used as an indicat or and can be ignored.

Programming

Special Settings for Door/Window Transmitters

Use the following guidelines when setting features 4 and 5

for door/window transmitters and wireless smoke detectors.

❑ Feature 4—Input Option 1

For door/window transmitters, turn on thi s feature to

disable the transmitter’s internal reed switches.

For wireless smoke detectors with tamper switches, turn on

this feature to enable the tamper feature.

Note

Feature 4—Input Option 1, must be off (disabled) when

using wireless smoke detectors without tamper switches.

❑ Feature 5—Input Option 2

For door/window transmitters that use a normally open

external contact, leave this feature off (N/O).

For door/window transmitters that use a normally

closed external contact, turn this feature on (N/C).

Light and Star Buttons on 4-Button Keyfobs

When using 4-button keyfobs, turning on Input Option 1

(feature 4) changes the light button to Keyfob Function 1.

Turning on Input Option 2 (feature 5) changes the star button to Keyfob Function 2. These functions can be used to

control relays, outputs, or X-10 devices.

This section describes the following programming steps:

❑ Determine Programming Settings—provi des tables to

record wireless transmitter and partition settings.

❑ Enroll the Module—sets up the module to be super-

vised by the control panel.

❑ Program the Module—puts the module into program so

you can program zone bank settings, transmitters, and

enter the settings for transmitters and partitions.

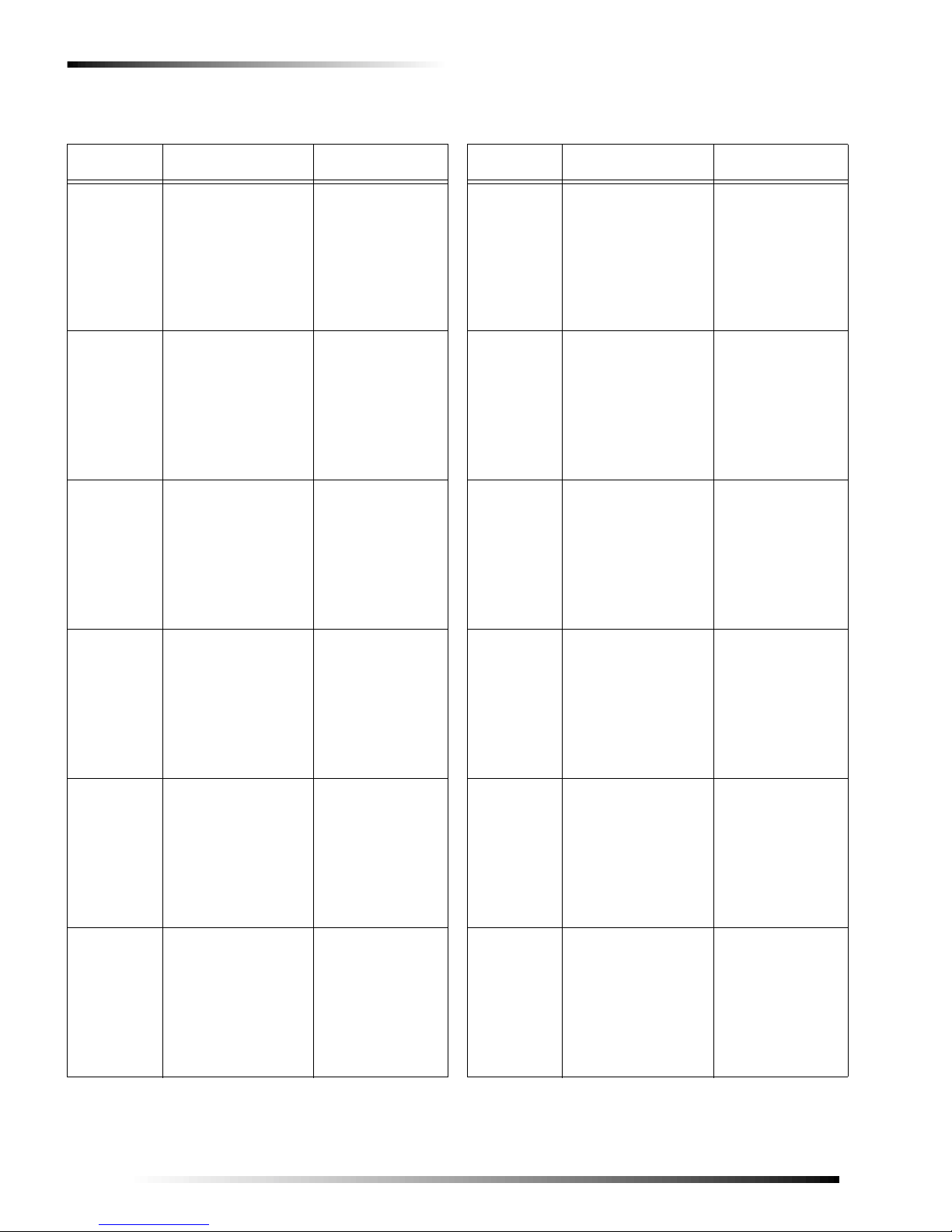

Determine Programming Settings

When programming wireless transmitters into the module,

there are various options and partitions you can set for each

transmitter. These settings appear in segments of each programming location.

Use “T able 3: Module Programming Settings” on pages 3 7 to record zone assignments and settings. Be sure to circle

the module type in the location column to help identify

where each zone resides; RM = receiver module, HE =

hardwire expander, P = panel. This gives you all the programming information in one place and helps speed up the

programming process.

Zone Locations 1 - 192

Zone locations 1 - 192 are not numbered in Table 3 since

these locations vary depending on location 194—Receiver

Zone Bank Setting (see page 8).

For example, if location 194 is set to 3, the first available

location is 25. The total number of available locations is

dependant on the zone limits for both the pan el and receiver.

Note

The default settings shown fo r Se gm ents 1 and 2 in the

first zone location apply to all zone locations.

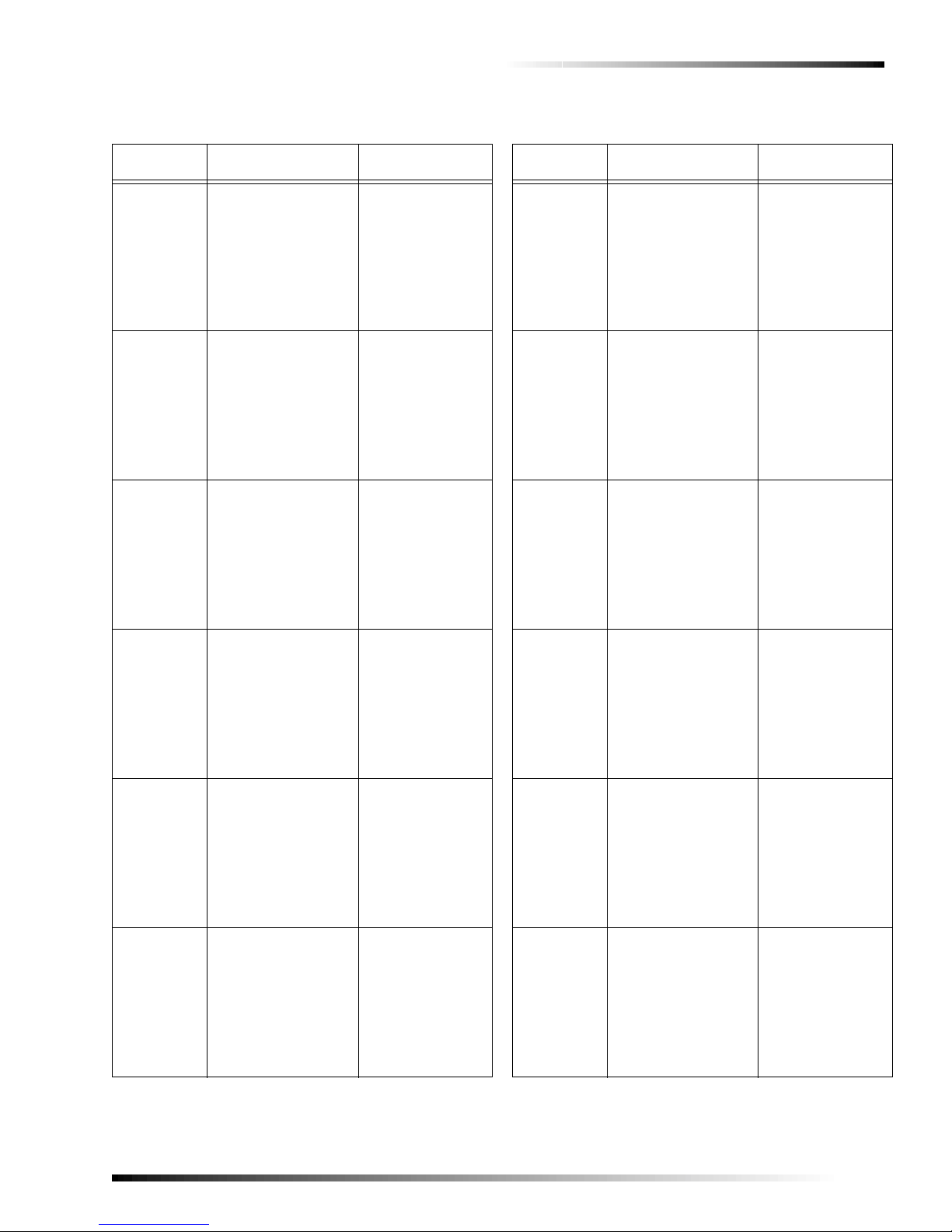

Table 3. Module Programming Settings

Location Segment 1 Segment 2

0

Transmitter

to be programmed)

Zone _____

Assigned to

module

#_____.

RM HE P

None None

1 - Enable senso r ❏

(default = off)

2 - Supervised ❏

(default = on)

3 - Fire supervision ❏

(default = off)

4 - Input option 1 ❏

(default = off)

5 - Input option 2 ❏

(default = off)

6 - 8 Not used

Partition 1 keyfob ❏

(default = on)

Partition 2 keyfob ❏

(default = off)

Partition 3 keyfob ❏

(default = off)

Partition 4 keyfob ❏

(default = off)

Partition 5 keyfob ❏

(default = off)

Partition 6 keyfob ❏

(default = off)

Partition 7 keyfob ❏

(default = off)

Partition 8 keyfob ❏

(default = off)

3

Page 6

Programming

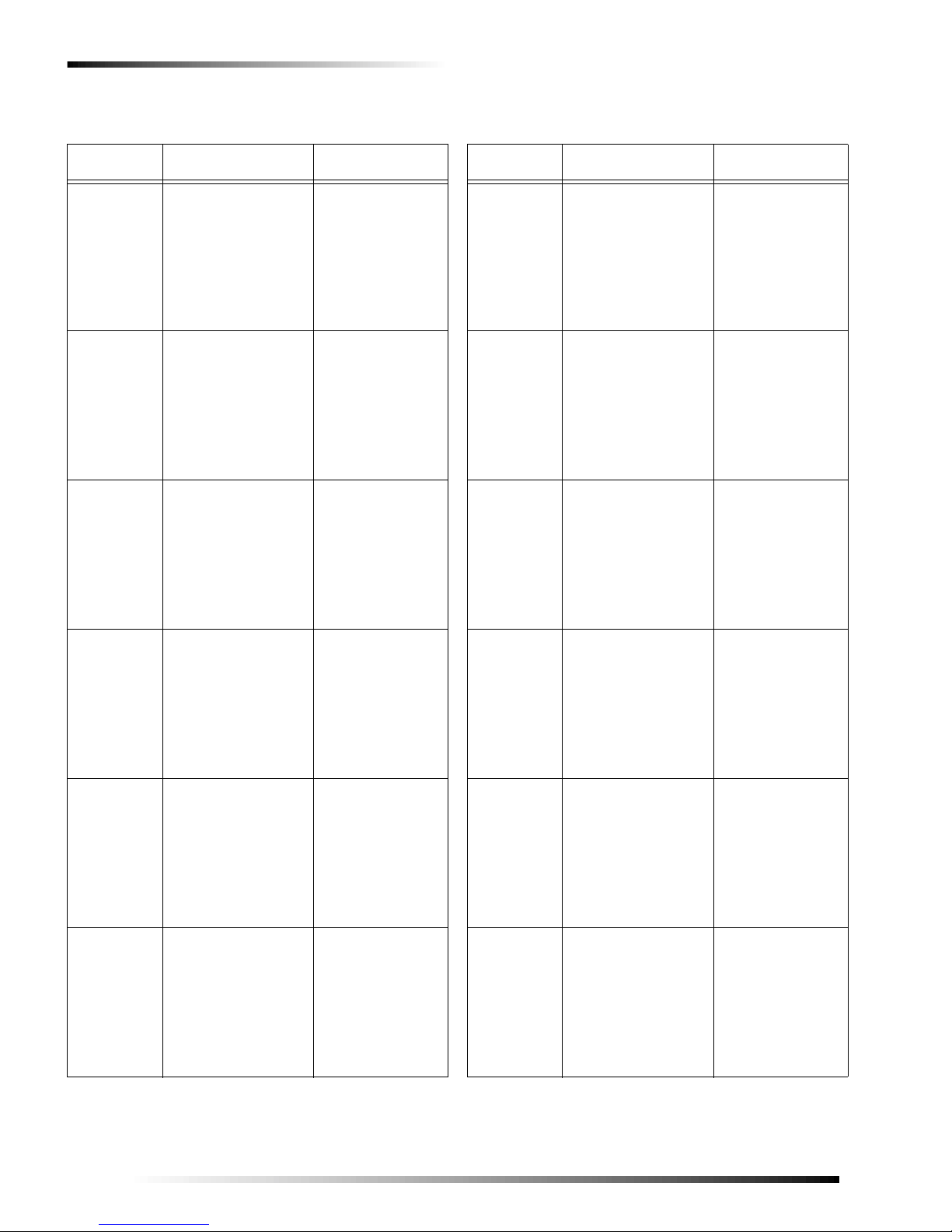

Table 3. Module Programming Settings

(Continued)

Location Segment 1 Segment 2

Zone _____

Assigned to

module

#_____.

RM HE P

Zone _____

Assigned to

module

#_____.

RM HE P

Zone _____

Assigned to

module

#_____.

RM HE P

1 - Enable sensor ❏

2 - Supervised ❏

3 - Fire supervision ❏

4 - Input option 1 ❏

5 - Input option 2 ❏

6 - 8 Not used

1 - Enable sensor ❏

2 - Supervised ❏

3 - Fire supervision ❏

4 - Input option 1 ❏

5 - Input option 2 ❏

6 - 8 Not used

1 - Enable sensor ❏

2 - Supervised ❏

3 - Fire supervision ❏

4 - Input option 1 ❏

5 - Input option 2 ❏

6 - 8 Not used

Partition 1 keyfob ❏

Partition 2 keyfob ❏

Partition 3 keyfob ❏

Partition 4 keyfob ❏

Partition 5 keyfob ❏

Partition 6 keyfob ❏

Partition 7 keyfob ❏

Partition 8 keyfob ❏

Partition 1 keyfob ❏

Partition 2 keyfob ❏

Partition 3 keyfob ❏

Partition 4 keyfob ❏

Partition 5 keyfob ❏

Partition 6 keyfob ❏

Partition 7 keyfob ❏

Partition 8 keyfob ❏

Partition 1 keyfob ❏

Partition 2 keyfob ❏

Partition 3 keyfob ❏

Partition 4 keyfob ❏

Partition 5 keyfob ❏

Partition 6 keyfob ❏

Partition 7 keyfob ❏

Partition 8 keyfob ❏

Table 3. Module Programming Settings

(Continued)

Location Segment 1 Segment 2

Zone _____

Assigned to

module

#_____.

RM HE P

Zone _____

Assigned to

module

#_____.

RM HE P

Zone _____

Assigned to

module

#_____.

RM HE P

1 - Enable senso r ❏

2 - Supervised ❏

3 - Fire supervision ❏

4 - Input option 1 ❏

5 - Input option 2 ❏

6 - 8 Not used

1 - Enable senso r ❏

2 - Supervised ❏

3 - Fire supervision ❏

4 - Input option 1 ❏

5 - Input option 2 ❏

6 - 8 Not used

1 - Enable senso r ❏

2 - Supervised ❏

3 - Fire supervision ❏

4 - Input option 1 ❏

5 - Input option 2 ❏

6 - 8 Not used

Partition 1 keyfob ❏

Partition 2 keyfob ❏

Partition 3 keyfob ❏

Partition 4 keyfob ❏

Partition 5 keyfob ❏

Partition 6 keyfob ❏

Partition 7 keyfob ❏

Partition 8 keyfob ❏

Partition 1 keyfob ❏

Partition 2 keyfob ❏

Partition 3 keyfob ❏

Partition 4 keyfob ❏

Partition 5 keyfob ❏

Partition 6 keyfob ❏

Partition 7 keyfob ❏

Partition 8 keyfob ❏

Partition 1 keyfob ❏

Partition 2 keyfob ❏

Partition 3 keyfob ❏

Partition 4 keyfob ❏

Partition 5 keyfob ❏

Partition 6 keyfob ❏

Partition 7 keyfob ❏

Partition 8 keyfob ❏

Zone _____

Assigned to

module

#_____.

RM HE P

Zone _____

Assigned to

module

#_____.

RM HE P

Zone _____

Assigned to

module

#_____.

RM HE P

1 - Enable sensor ❏

2 - Supervised ❏

3 - Fire supervision ❏

4 - Input option 1 ❏

5 - Input option 2 ❏

6 - 8 Not used

1 - Enable sensor ❏

2 - Supervised ❏

3 - Fire supervision ❏

4 - Input option 1 ❏

5 - Input option 2 ❏

6 - 8 Not used

1 - Enable sensor ❏

2 - Supervised ❏

3 - Fire supervision ❏

4 - Input option 1 ❏

5 - Input option 2 ❏

6 - 8 Not used

Partition 1 keyfob ❏

Partition 2 keyfob ❏

Partition 3 keyfob ❏

Partition 4 keyfob ❏

Partition 5 keyfob ❏

Partition 6 keyfob ❏

Partition 7 keyfob ❏

Partition 8 keyfob ❏

Partition 1 keyfob ❏

Partition 2 keyfob ❏

Partition 3 keyfob ❏

Partition 4 keyfob ❏

Partition 5 keyfob ❏

Partition 6 keyfob ❏

Partition 7 keyfob ❏

Partition 8 keyfob ❏

Partition 1 keyfob ❏

Partition 2 keyfob ❏

Partition 3 keyfob ❏

Partition 4 keyfob ❏

Partition 5 keyfob ❏

Partition 6 keyfob ❏

Partition 7 keyfob ❏

Partition 8 keyfob ❏

Zone _____

Assigned to

module

#_____.

RM HE P

Zone _____

Assigned to

module

#_____.

RM HE P

Zone _____

Assigned to

module

#_____.

RM HE P

1 - Enable senso r ❏

2 - Supervised ❏

3 - Fire supervision ❏

4 - Input option 1 ❏

5 - Input option 2 ❏

6 - 8 Not used

1 - Enable senso r ❏

2 - Supervised ❏

3 - Fire supervision ❏

4 - Input option 1 ❏

5 - Input option 2 ❏

6 - 8 Not used

1 - Enable senso r ❏

2 - Supervised ❏

3 - Fire supervision ❏

4 - Input option 1 ❏

5 - Input option 2 ❏

6 - 8 Not used

Partition 1 keyfob ❏

Partition 2 keyfob ❏

Partition 3 keyfob ❏

Partition 4 keyfob ❏

Partition 5 keyfob ❏

Partition 6 keyfob ❏

Partition 7 keyfob ❏

Partition 8 keyfob ❏

Partition 1 keyfob ❏

Partition 2 keyfob ❏

Partition 3 keyfob ❏

Partition 4 keyfob ❏

Partition 5 keyfob ❏

Partition 6 keyfob ❏

Partition 7 keyfob ❏

Partition 8 keyfob ❏

Partition 1 keyfob ❏

Partition 2 keyfob ❏

Partition 3 keyfob ❏

Partition 4 keyfob ❏

Partition 5 keyfob ❏

Partition 6 keyfob ❏

Partition 7 keyfob ❏

Partition 8 keyfob ❏

4

Page 7

Programming

Table 3. Module Programming Settings

(Continued)

Location Segment 1 Segment 2

Zone _____

Assigned to

module

#_____.

RM HE P

Zone _____

Assigned to

module

#_____.

RM HE P

Zone _____

Assigned to

module

#_____.

RM HE P

1 - Enable senso r ❏

2 - Supervised ❏

3 - Fire supervision ❏

4 - Input option 1 ❏

5 - Input option 2 ❏

6 - 8 Not used

1 - Enable senso r ❏

2 - Supervised ❏

3 - Fire supervision ❏

4 - Input option 1 ❏

5 - Input option 2 ❏

6 - 8 Not used

1 - Enable senso r ❏

2 - Supervised ❏

3 - Fire supervision ❏

4 - Input option 1 ❏

5 - Input option 2 ❏

6 - 8 Not used

Partition 1 keyfob ❏

Partition 2 keyfob ❏

Partition 3 keyfob ❏

Partition 4 keyfob ❏

Partition 5 keyfob ❏

Partition 6 keyfob ❏

Partition 7 keyfob ❏

Partition 8 keyfob ❏

Partition 1 keyfob ❏

Partition 2 keyfob ❏

Partition 3 keyfob ❏

Partition 4 keyfob ❏

Partition 5 keyfob ❏

Partition 6 keyfob ❏

Partition 7 keyfob ❏

Partition 8 keyfob ❏

Partition 1 keyfob ❏

Partition 2 keyfob ❏

Partition 3 keyfob ❏

Partition 4 keyfob ❏

Partition 5 keyfob ❏

Partition 6 keyfob ❏

Partition 7 keyfob ❏

Partition 8 keyfob ❏

Table 3. Module Programming Settings

(Continued)

Location Segment 1 Segment 2

Zone _____

Assigned to

module

#_____.

RM HE P

Zone _____

Assigned to

module

#_____.

RM HE P

Zone _____

Assigned to

module

#_____.

RM HE P

1 - Enable senso r ❏

2 - Supervised ❏

3 - Fire supervision ❏

4 - Input option 1 ❏

5 - Input option 2 ❏

6 - 8 Not used

1 - Enable senso r ❏

2 - Supervised ❏

3 - Fire supervision ❏

4 - Input option 1 ❏

5 - Input option 2 ❏

6 - 8 Not used

1 - Enable senso r ❏

2 - Supervised ❏

3 - Fire supervision ❏

4 - Input option 1 ❏

5 - Input option 2 ❏

6 - 8 Not used

Partition 1 keyfob ❏

Partition 2 keyfob ❏

Partition 3 keyfob ❏

Partition 4 keyfob ❏

Partition 5 keyfob ❏

Partition 6 keyfob ❏

Partition 7 keyfob ❏

Partition 8 keyfob ❏

Partition 1 keyfob ❏

Partition 2 keyfob ❏

Partition 3 keyfob ❏

Partition 4 keyfob ❏

Partition 5 keyfob ❏

Partition 6 keyfob ❏

Partition 7 keyfob ❏

Partition 8 keyfob ❏

Partition 1 keyfob ❏

Partition 2 keyfob ❏

Partition 3 keyfob ❏

Partition 4 keyfob ❏

Partition 5 keyfob ❏

Partition 6 keyfob ❏

Partition 7 keyfob ❏

Partition 8 keyfob ❏

Zone _____

Assigned to

module

#_____.

RM HE P

Zone _____

Assigned to

module

#_____.

RM HE P

Zone _____

Assigned to

module

#_____.

RM HE P

1 - Enable senso r ❏

2 - Supervised ❏

3 - Fire supervision ❏

4 - Input option 1 ❏

5 - Input option 2 ❏

6 - 8 Not used

1 - Enable senso r ❏

2 - Supervised ❏

3 - Fire supervision ❏

4 - Input option 1 ❏

5 - Input option 2 ❏

6 - 8 Not used

1 - Enable senso r ❏

2 - Supervised ❏

3 - Fire supervision ❏

4 - Input option 1 ❏

5 - Input option 2 ❏

6 - 8 Not used

Partition 1 keyfob ❏

Partition 2 keyfob ❏

Partition 3 keyfob ❏

Partition 4 keyfob ❏

Partition 5 keyfob ❏

Partition 6 keyfob ❏

Partition 7 keyfob ❏

Partition 8 keyfob ❏

Partition 1 keyfob ❏

Partition 2 keyfob ❏

Partition 3 keyfob ❏

Partition 4 keyfob ❏

Partition 5 keyfob ❏

Partition 6 keyfob ❏

Partition 7 keyfob ❏

Partition 8 keyfob ❏

Partition 1 keyfob ❏

Partition 2 keyfob ❏

Partition 3 keyfob ❏

Partition 4 keyfob ❏

Partition 5 keyfob ❏

Partition 6 keyfob ❏

Partition 7 keyfob ❏

Partition 8 keyfob ❏

Zone _____

Assigned to

module

#_____.

RM HE P

Zone _____

Assigned to

module

#_____.

RM HE P

Zone _____

Assigned to

module

#_____.

RM HE P

1 - Enable senso r ❏

2 - Supervised ❏

3 - Fire supervision ❏

4 - Input option 1 ❏

5 - Input option 2 ❏

6 - 8 Not used

1 - Enable senso r ❏

2 - Supervised ❏

3 - Fire supervision ❏

4 - Input option 1 ❏

5 - Input option 2 ❏

6 - 8 Not used

1 - Enable senso r ❏

2 - Supervised ❏

3 - Fire supervision ❏

4 - Input option 1 ❏

5 - Input option 2 ❏

6 - 8 Not used

Partition 1 keyfob ❏

Partition 2 keyfob ❏

Partition 3 keyfob ❏

Partition 4 keyfob ❏

Partition 5 keyfob ❏

Partition 6 keyfob ❏

Partition 7 keyfob ❏

Partition 8 keyfob ❏

Partition 1 keyfob ❏

Partition 2 keyfob ❏

Partition 3 keyfob ❏

Partition 4 keyfob ❏

Partition 5 keyfob ❏

Partition 6 keyfob ❏

Partition 7 keyfob ❏

Partition 8 keyfob ❏

Partition 1 keyfob ❏

Partition 2 keyfob ❏

Partition 3 keyfob ❏

Partition 4 keyfob ❏

Partition 5 keyfob ❏

Partition 6 keyfob ❏

Partition 7 keyfob ❏

Partition 8 keyfob ❏

5

Page 8

Programming

Table 3. Module Programming Settings

(Continued)

Location Segment 1 Segment 2

Zone _____

Assigned to

module

#_____.

RM HE P

Zone _____

Assigned to

module

#_____.

RM HE P

Zone _____

Assigned to

module

#_____.

RM HE P

1 - Enable sensor ❏

2 - Supervised ❏

3 - Fire supervision ❏

4 - Input option 1 ❏

5 - Input option 2 ❏

6 - 8 Not used

1 - Enable sensor ❏

2 - Supervised ❏

3 - Fire supervision ❏

4 - Input option 1 ❏

5 - Input option 2 ❏

6 - 8 Not used

1 - Enable sensor ❏

2 - Supervised ❏

3 - Fire supervision ❏

4 - Input option 1 ❏

5 - Input option 2 ❏

6 - 8 Not used

Partition 1 keyfob ❏

Partition 2 keyfob ❏

Partition 3 keyfob ❏

Partition 4 keyfob ❏

Partition 5 keyfob ❏

Partition 6 keyfob ❏

Partition 7 keyfob ❏

Partition 8 keyfob ❏

Partition 1 keyfob ❏

Partition 2 keyfob ❏

Partition 3 keyfob ❏

Partition 4 keyfob ❏

Partition 5 keyfob ❏

Partition 6 keyfob ❏

Partition 7 keyfob ❏

Partition 8 keyfob ❏

Partition 1 keyfob ❏

Partition 2 keyfob ❏

Partition 3 keyfob ❏

Partition 4 keyfob ❏

Partition 5 keyfob ❏

Partition 6 keyfob ❏

Partition 7 keyfob ❏

Partition 8 keyfob ❏

Table 3. Module Programming Settings

(Continued)

Location Segment 1 Segment 2

Zone _____

Assigned to

module

#_____.

RM HE P

Zone _____

Assigned to

module

#_____.

RM HE P

Zone _____

Assigned to

module

#_____.

RM HE P

1 - Enable senso r ❏

2 - Supervised ❏

3 - Fire supervision ❏

4 - Input option 1 ❏

5 - Input option 2 ❏

6 - 8 Not used

1 - Enable senso r ❏

2 - Supervised ❏

3 - Fire supervision ❏

4 - Input option 1 ❏

5 - Input option 2 ❏

6 - 8 Not used

1 - Enable senso r ❏

2 - Supervised ❏

3 - Fire supervision ❏

4 - Input option 1 ❏

5 - Input option 2 ❏

6 - 8 Not used

Partition 1 keyfob ❏

Partition 2 keyfob ❏

Partition 3 keyfob ❏

Partition 4 keyfob ❏

Partition 5 keyfob ❏

Partition 6 keyfob ❏

Partition 7 keyfob ❏

Partition 8 keyfob ❏

Partition 1 keyfob ❏

Partition 2 keyfob ❏

Partition 3 keyfob ❏

Partition 4 keyfob ❏

Partition 5 keyfob ❏

Partition 6 keyfob ❏

Partition 7 keyfob ❏

Partition 8 keyfob ❏

Partition 1 keyfob ❏

Partition 2 keyfob ❏

Partition 3 keyfob ❏

Partition 4 keyfob ❏

Partition 5 keyfob ❏

Partition 6 keyfob ❏

Partition 7 keyfob ❏

Partition 8 keyfob ❏

Zone _____

Assigned to

module

#_____.

RM HE P

Zone _____

Assigned to

module

#_____.

RM HE P

Zone _____

Assigned to

module

#_____.

RM HE P

1 - Enable sensor ❏

2 - Supervised ❏

3 - Fire supervision ❏

4 - Input option 1 ❏

5 - Input option 2 ❏

6 - 8 Not used

1 - Enable sensor ❏

2 - Supervised ❏

3 - Fire supervision ❏

4 - Input option 1 ❏

5 - Input option 2 ❏

6 - 8 Not used

1 - Enable sensor ❏

2 - Supervised ❏

3 - Fire supervision ❏

4 - Input option 1 ❏

5 - Input option 2 ❏

6 - 8 Not used

Partition 1 keyfob ❏

Partition 2 keyfob ❏

Partition 3 keyfob ❏

Partition 4 keyfob ❏

Partition 5 keyfob ❏

Partition 6 keyfob ❏

Partition 7 keyfob ❏

Partition 8 keyfob ❏

Partition 1 keyfob ❏

Partition 2 keyfob ❏

Partition 3 keyfob ❏

Partition 4 keyfob ❏

Partition 5 keyfob ❏

Partition 6 keyfob ❏

Partition 7 keyfob ❏

Partition 8 keyfob ❏

Partition 1 keyfob ❏

Partition 2 keyfob ❏

Partition 3 keyfob ❏

Partition 4 keyfob ❏

Partition 5 keyfob ❏

Partition 6 keyfob ❏

Partition 7 keyfob ❏

Partition 8 keyfob ❏

Zone _____

Assigned to

module

#_____.

RM HE P

Zone _____

Assigned to

module

#_____.

RM HE P

Zone _____

Assigned to

module

#_____.

RM HE P

1 - Enable senso r ❏

2 - Supervised ❏

3 - Fire supervision ❏

4 - Input option 1 ❏

5 - Input option 2 ❏

6 - 8 Not used

1 - Enable senso r ❏

2 - Supervised ❏

3 - Fire supervision ❏

4 - Input option 1 ❏

5 - Input option 2 ❏

6 - 8 Not used

1 - Enable senso r ❏

2 - Supervised ❏

3 - Fire supervision ❏

4 - Input option 1 ❏

5 - Input option 2 ❏

6 - 8 Not used

Partition 1 keyfob ❏

Partition 2 keyfob ❏

Partition 3 keyfob ❏

Partition 4 keyfob ❏

Partition 5 keyfob ❏

Partition 6 keyfob ❏

Partition 7 keyfob ❏

Partition 8 keyfob ❏

Partition 1 keyfob ❏

Partition 2 keyfob ❏

Partition 3 keyfob ❏

Partition 4 keyfob ❏

Partition 5 keyfob ❏

Partition 6 keyfob ❏

Partition 7 keyfob ❏

Partition 8 keyfob ❏

Partition 1 keyfob ❏

Partition 2 keyfob ❏

Partition 3 keyfob ❏

Partition 4 keyfob ❏

Partition 5 keyfob ❏

Partition 6 keyfob ❏

Partition 7 keyfob ❏

Partition 8 keyfob ❏

6

Page 9

Programming

Table 3. Module Programming Settings

(Continued)

Location Segment 1 Segment 2

Zone _____

Assigned to

module

#_____.

RM HE P

Zone _____

Assigned to

module

#_____.

RM HE P

Zone _____

Assigned to

module

#_____.

RM HE P

1 - Enable senso r ❏

2 - Supervised ❏

3 - Fire supervision ❏

4 - Input option 1 ❏

5 - Input option 2 ❏

6 - 8 Not used

1 - Enable senso r ❏

2 - Supervised ❏

3 - Fire supervision ❏

4 - Input option 1 ❏

5 - Input option 2 ❏

6 - 8 Not used

1 - Enable senso r ❏

2 - Supervised ❏

3 - Fire supervision ❏

4 - Input option 1 ❏

5 - Input option 2 ❏

6 - 8 Not used

Partition 1 keyfob ❏

Partition 2 keyfob ❏

Partition 3 keyfob ❏

Partition 4 keyfob ❏

Partition 5 keyfob ❏

Partition 6 keyfob ❏

Partition 7 keyfob ❏

Partition 8 keyfob ❏

Partition 1 keyfob ❏

Partition 2 keyfob ❏

Partition 3 keyfob ❏

Partition 4 keyfob ❏

Partition 5 keyfob ❏

Partition 6 keyfob ❏

Partition 7 keyfob ❏

Partition 8 keyfob ❏

Partition 1 keyfob ❏

Partition 2 keyfob ❏

Partition 3 keyfob ❏

Partition 4 keyfob ❏

Partition 5 keyfob ❏

Partition 6 keyfob ❏

Partition 7 keyfob ❏

Partition 8 keyfob ❏

Table 3. Module Programming Settings

(Continued)

Location Segment 1 Segment 2

Zone _____

Assigned to

module

#_____.

RM HE P

Zone _____

Assigned to

module

#_____.

RM HE P

Zone _____

Assigned to

module

#_____.

RM HE P

1 - Enable senso r ❏

2 - Supervised ❏

3 - Fire supervision ❏

4 - Input option 1 ❏

5 - Input option 2 ❏

6 - 8 Not used

1 - Enable senso r ❏

2 - Supervised ❏

3 - Fire supervision ❏

4 - Input option 1 ❏

5 - Input option 2 ❏

6 - 8 Not used

1 - Enable senso r ❏

2 - Supervised ❏

3 - Fire supervision ❏

4 - Input option 1 ❏

5 - Input option 2 ❏

6 - 8 Not used

Partition 1 keyfob ❏

Partition 2 keyfob ❏

Partition 3 keyfob ❏

Partition 4 keyfob ❏

Partition 5 keyfob ❏

Partition 6 keyfob ❏

Partition 7 keyfob ❏

Partition 8 keyfob ❏

Partition 1 keyfob ❏

Partition 2 keyfob ❏

Partition 3 keyfob ❏

Partition 4 keyfob ❏

Partition 5 keyfob ❏

Partition 6 keyfob ❏

Partition 7 keyfob ❏

Partition 8 keyfob ❏

Partition 1 keyfob ❏

Partition 2 keyfob ❏

Partition 3 keyfob ❏

Partition 4 keyfob ❏

Partition 5 keyfob ❏

Partition 6 keyfob ❏

Partition 7 keyfob ❏

Partition 8 keyfob ❏

Zone _____

Assigned to

module

#_____.

RM HE P

Zone _____

Assigned to

module

#_____.

RM HE P

Zone _____

Assigned to

module

#_____.

RM HE P

1 - Enable senso r ❏

2 - Supervised ❏

3 - Fire supervision ❏

4 - Input option 1 ❏

5 - Input option 2 ❏

6 - 8 Not used

1 - Enable senso r ❏

2 - Supervised ❏

3 - Fire supervision ❏

4 - Input option 1 ❏

5 - Input option 2 ❏

6 - 8 Not used

1 - Enable senso r ❏

2 - Supervised ❏

3 - Fire supervision ❏

4 - Input option 1 ❏

5 - Input option 2 ❏

6 - 8 Not used

Partition 1 keyfob ❏

Partition 2 keyfob ❏

Partition 3 keyfob ❏

Partition 4 keyfob ❏

Partition 5 keyfob ❏

Partition 6 keyfob ❏

Partition 7 keyfob ❏

Partition 8 keyfob ❏

Partition 1 keyfob ❏

Partition 2 keyfob ❏

Partition 3 keyfob ❏

Partition 4 keyfob ❏

Partition 5 keyfob ❏

Partition 6 keyfob ❏

Partition 7 keyfob ❏

Partition 8 keyfob ❏

Partition 1 keyfob ❏

Partition 2 keyfob ❏

Partition 3 keyfob ❏

Partition 4 keyfob ❏

Partition 5 keyfob ❏

Partition 6 keyfob ❏

Partition 7 keyfob ❏

Partition 8 keyfob ❏

Zone _____

Assigned to

module

#_____.

RM HE P

Zone _____

Assigned to

module

#_____.

RM HE P

1 - Enable senso r ❏

2 - Supervised ❏

3 - Fire supervision ❏

4 - Input option 1 ❏

5 - Input option 2 ❏

6 - 8 Not used

1 - Enable senso r ❏

2 - Supervised ❏

3 - Fire supervision ❏

4 - Input option 1 ❏

5 - Input option 2 ❏

6 - 8 Not used

Partition 1 keyfob ❏

Partition 2 keyfob ❏

Partition 3 keyfob ❏

Partition 4 keyfob ❏

Partition 5 keyfob ❏

Partition 6 keyfob ❏

Partition 7 keyfob ❏

Partition 8 keyfob ❏

Partition 1 keyfob ❏

Partition 2 keyfob ❏

Partition 3 keyfob ❏

Partition 4 keyfob ❏

Partition 5 keyfob ❏

Partition 6 keyfob ❏

Partition 7 keyfob ❏

Partition 8 keyfob ❏

7

Page 10

Programming

Table 3. Module Programming Settings

(Continued)

Location Segment 1 Segment 2

193

Receiver

Options (All

default off)

194

Receiver

Zone Bank

Setting

(Default =

0—set this

before learning any sensors. See step

5 under “To

program the

module.”)

195

Supervision

Windows

1 - Enable jam detect ❏

2 - Enable auto

advance to next

zone number ❏

3 - Keyfob user ID ❏

(off = all key f obs

report as user 99;

on = keyfob rep ort s

as learned zone #)

4 - Enable antenna

tamper (Only

selectable on International versions;

reports as box

tamper) ❏

5 - Enable case

tamper ❏

6-8 Not used

Starting zone numbers

by bank setting:

0 = 1 ❏

1 = 9 ❏

2 = 17 ❏

3 = 25 ❏

4 = 33 ❏

5 = 41 ❏

6 = 49 ❏

7 = 57 ❏

8 = 65 ❏

9 = 73 ❏

10 = 81 ❏

11 = 89 ❏

12 = 97 ❏

13 = 105 ❏

14 = 113 ❏

15 = 121 ❏

16 = 129 ❏

17 = 137 ❏

18 = 145 ❏

19 = 153 ❏

20 = 161 ❏

21 = 169 ❏

22 = 177 ❏

23 = 185 ❏

1 - Normal ______hrs.

(0 - 255 hours;

default = 24 hours)

(Do not change Segment 3 setting unless

required. See step 9

under “Changing the

Transmitter Supe rvi sion Windows.”)

None

Fire ______hrs.

(0 - 255 hours;

default = 4 hours)

Segment 3

Transmitter Checkin Window ____min

(1 - 30 minutes,

default = 40—dis-

abled)

Table 3. Module Programming Settings

(Continued)

Location Segment 1 Segment 2

200

Number of

rounds

received

from last

transmitter

learned

None None

Program m ing the Module

This section describes programming guidelines, how to get

the module into program mode and set receiver options,

zone banks, supervision windows, and program transmitters

into memory.

Programming Guidelines

❑ NX-4 and NX-6 control panels can have receivers

added with zones that overlap those contained in the

control panel. No hardwire expanders can be used.

❑ NX-8 control panels may have expansion zones (hard-

wire or wireless) set the same as those contained in the

control panel. To do this you must disable the onboard

control panel zones. All zone expansion modules must

not overlap any blocks of 8 zones.

❑ All other control panels can have wireless zones added

to any zone. If a hardwire input (on either the control

panel or hardwire expander) is also present on the same

zone as an enabled wireless zone, the wireless transmitter takes priority.

To program the module:

1. Enter [✻] [8] at the keypad. The five function lights

should start flashing.

2. Enter the “Go T o Program Code” (factory default is 9 7

1 3). The service light should flash and the five function lights should change from flashing to on steady.

3. Enter [XX] [#], where [XX] is the DIP switch setting

module number and [#] is the entry key. The Armed

LED should turn on, indicating the control panel is

waiting for a programming location entry.

4. For new installations, enter [9] [1] [0] [#] to load factory defaults and clear any unwanted information in

memory before any further programming.

5. For new installations, set the receiver zone bank (Location 194) to determine the starting zone number for the

specific receiver module. This must be set bef ore learning sensors. The bank setting is based on the zone capabilities of both the receiver and the panel.

6. Enter [0] [#] to enter the sensor learning location. The

Ready LED should turn on and the Ar med LED should

turn off.

8

Page 11

Programming

7. Enter [XXX] [✻], where [XXX] is a zone number (1

through 192) and [

Notes

Three beeps from the keypad indicates an entry error.

This occurs if you enter a transmitter number that is not

within the module’s zone block or if you try learning a

sensor that is already learned into the module.

If you change your mind about your entry, terminate programming by entering [0] [#] [0] [

step 6.

✻] is the entry key.

✻] and start over from

8. Trip the desired transmitter (within 250 seconds) as

described in Table 4. Listen for the ‘ding do ng’ for co nfirmation.

Table 4. Tripping Transmitters for Learning

Transmitter Action

Door/Window, Shock,

Glass Guard, Freeze

Door/Window with External Contact

Recesse d Door /Window Activat e t amp er swi t ch b y

Micro Door/Window Slide the battery about

PIR Activat e t amp er swi t ch b y

Smoke Detector Press and hold the test but-

Heat Detector Press, then release the

Fire Pull Activat e t amp er swi t ch b y

Single Button Panic Press and hold the button.

Dual Button Panic Press and hold both but-

Keyfobs Press and hold the arm and

Repeater Press, then release the

Activat e t amp er swi t ch b y

removing cover.

Activat e t amp er swi t ch b y

removing cover. (Note:

Feature 4—Input Option

1, must be on.)

removing circuit board

until tamper switch is

exposed.

half-way out of the battery

holder, then back.

removing back plate from

PIR.

ton.

tamper switch.

removing sensor cov er.

tons together.

disarm buttons together.

tamper switch.

Program Transmitter and Partition

Settings

This section describes programming guidelines, how to

change the supervision windows, and program the transmitter and partition settings using the information you entered

in “Table 3: Module Programming Settings.”

Changing the Transmitter Supervision

Windows

Note

For UL Listed installations, the normal supervision window must be set to 24 hours and the fire supervision window must be set to 4 hours.

&$87,21

Do not set the normal or fire su perv is io n win dows to 1

hour. This causes false trouble reports from all learned

wireless transmitters.

1. Enter [✻] [8] at the keypad. The five function lights

should start flashing.

2. Enter the “Go T o Program Code” (factory default is 9 7

1 3). The service light should flash and the five function lights should change from flashing to on steady.

3. Enter [XX] [#], where [XX] is the DIP switch setting

module number and [#] is the entry key. The Armed

LED should turn on, indicating the control panel is

waiting for a programming location entry.

4. Enter [195] [#] to enter location 195, segment 1.

5. Enter the new normal supervision time (0 - 255).

Note

Choosing 0 sets the norma l supervisi on window to 256

hours.

6. Press [✻] to save any changes and automatically enter

segment 2.

7. Enter the new fire supervision time (0 - 255).

Note

Choosing 0 sets the fire supervision window to 256

hours.

8. Press [✻] to save any changes and automatically enter

segment 3.

9. Enter new short supervision time (up to 30 minutes).

Note

Segment 3 is a short supervision window setting (up to

30 minutes) that preven ts arming if a transmitter has not

checked in within the set time . Th i s app l ie s only to specific coun t ries outs i de the U.S. Check the control panel

installation manual to determine if this setting is available.

Entering a number higher th an 30 (the default value is

40) disables the feature.

10. Press [✻] to save any changes. The panel is now waiting for the next location entry.

Note

Pressing [#] does not save changes to the current segment, but does save chan ges made in previous segments.

11. Enter [EXIT] [EXIT] when all changes are completed.

9. Program remaining transmitters by repeating steps 5-7.

10. Exit program mode by entering [EXIT] [EXIT].

9

Page 12

Testing Wireless Transmitters

Programming Transmitter and Partition

Settings

1. Enter [

✻] [8] at the keypad. The five function lights

should start flashing.

2. Enter the “Go T o Program Code” (factory default is 9 7

1 3). The service light should flash and the five function lights should change from flashing to on steady.

3. Enter [XX] [#], where [XX] is the DIP switch setting

module number and [#] is the entry key. The Armed

LED should turn on, indicating the control panel is

waiting for a programming location entry.

4. Enter [XX] [#] to enter a location. For example, enter

[1] [#] to enter location 1, segment 1. The Armed LED

should turn on and the zone LEDs display t he binary

data for the current settings.

or-- Enter [1] [#] [✻] to enter location 1, segment 2.

5. Enter [X] [✻], where [X] is the setting number (1 - 8)

from Table 3 that corresponds to the desired feature or

partition setting number and [

✻] is the entry key. The

keypad displays the settings for that location and segment.

6. Press the keypad button that corresponds to the feature

number you want changed. Ligh ts correspo nding to the

feature number turn on or off each time the button is

pressed. Lights that turn on indicate the feature is on,

lights that turn off indicate the feature is off.

For example, turn on transmitter features 1 (Transmitter

Enabled) and 4 (Input Option 1) by pressing [1] [ 4] . The 1

and 4 LEDs turn on to indicate the features are turned on and

the Ready LED flashes to indicate the change request.

7. Press [✻] to enter the changes and automatically

advance to segment 2.

Note

Pressing [#] does not save changes to the current segment, but does save chan ges made in previous segments. Repeat steps 4 - 7 to re-enter and make changes

to a location and segment.

8. Press the keypad button that corresponds to the partition number you want changed. Lights corresponding

to the partition number turn on or off each time the button is pressed. Lights that turn on indicate the keyfob is

active in that partition, lights that turn off indicate the

keyfob is inactive.

9. Repeat steps 4 - 8 to continue programming transmitter

partition settings.

10. Enter [EXIT] [EXIT] when finished.

2. Enter the “Go T o Program Code” (factory default is 9 7

1 3). The service light should flash and the five function lights should change from flashing to on steady.

3. Enter [XX] [#], where [XX] is the DIP switch setting

module number and [#] is the entry key. The Armed

LED should turn on, indicating the control panel is

waiting for a programming location entry.

4. Enter [XX] [#] to enter the zone location to be deleted.

The Armed LED should turn on and the zone LEDs

display the binary data for the current settings.

5. Change transmitter feature 1 (Transmitter Enabled) by

pressing [1]. The 1 LED turns off to indicate the feature

change and the Ready LED flashes to indicate the

change request.

6. Enter [

✻] [#]. The Ready LED stops flashing, indicat-

ing the new settings are stored in memory and the system automatically exits from that location.

7. Continue deleting transmitters by entering the d e sir e d

locations and segments in steps 4 through 6.

8. Enter [9] [1] [0] [#] to delete all transmitters and load

factory defaults.

9. Enter [EXIT] [EXIT] when finished.

Testing Wireless Transmi tters

Test all transmitters to verify correct programming and

operation by following the “Walk Test” instructions in the

specific control panel installation manual.

Troubleshooting

Any transmitters that consistently test below margin should

be rotated in mounting position (90°, 180°, or 270°) and

retested.

If rotating the transmitter mounting position does not

improve signal reception or is not practical, move the transmitter to different locations near the desired mounting area.

Test each location until the transmitter consistently tests

good, then mount the transmitter.

Deleting Transmitters

The following steps describe how to delete transmitters

from the module.

This procedure makes the module ignore a transmitter but

does not remove transmitter identification from the module’s memory. The transmitter can be reactivated later or a

new one can be learned into the zone.

1. Enter [

10

✻] [8] at the keypad. The five function lights

should start flashing.

Page 13

Specifications

Specifications

Compatibility: NX-4, NX-6, NX-8, NX-8E control panels

Frequency: 319.5 MHz (NX-408E, NX-416E, & NX-448E)

433 MHz (NX-408E-I, NX-416E-I, &

NX-448E-I)

Required Power: 12.0 VDC (provided by panel)

Current Draw: 20 mA maximum

Operating Temperature Range: 32° to 120 °F ( 0° to 49°C)

Storage Temperature: -30° to 14 0 °F (- 34 ° to 60°C)

Maximum Humidity: 90% relative humidity, non-

condensing

Dimensions: 4.65" (11.8 cm) x 3.20" (8.1 cm)

U.L. Lis tings

The NetworX NX-E Series Receiver Modules (60-904) are

U.L. Listed for UL1023 Household Burglary, UL985

Household Fire, and are listed for use with the following

U.L. Listed devices:

NX-451 Door/Window Sensor (60-670-95R)

NX-470 4-Button Keychain Touchpad (60-659-95R)

NX-475 Water-Resistant Pendant Panic Button (60-578)

NX-480 PIR Motion Sensor (60-639-95R)

NX-490 Wireless Smoke Sensor (60-506)

Notices

This device complies with FCC Rul es Part 15. Operation is subject to

the following two conditions:

1. This device may not cause h armful interference.

2. This device mu s t accept any interference that may be re ceived,

including interferenc e that may cause undesired operation.

Changes or modifications not expressly approved by Interlogix, Inc. can

void the user’s authority to operate the equipment.

Declaration of Conformity

Manufacturer’s Name: ..Interlogix, Inc.

Manufacturer’s Address:

2266 North 2nd Street

North St. Paul, MN, USA 55109

EU Representative: .......Interlogix B.V.

Kelvinstraat 7

6003DH Weert

The Netherlands

Product Identification:

Product: Wireless Receiver, 433.92 MHz

Model Number: 60-904-43-8Z, 60-904-43-16Z, 60-904-43-

48Z, RX814CA, RX814CA-PCB,

RX814CS-PCB, RX16I4CA, RX16I4CAPCB, RX16I4CS-PCB, NX408E-I,

NX416E-I, NX448E-I

Brand: ITI / Caddx / Aritech

Means of Conformity

We declare under our sole responsibility that this product is

in conformity with Directive 93/68/EEC (CE Marking) and/

or complies to the essential requirements and all other relevant provisions of the 1999/5/EC (R&TTE) based on test

results using (non)harmonized standards in accordance with

the Directives mentioned.

EMC and Safety Standards:

ETS 300 220

EN 50130-4/A1 (1998),

EN55022 class B equip. (1997)

IEC 60950: 3rd ed. (1999-4)

Test Reports (at manufacturing

site)

0123

Notices

Approved for use in the countries marked with a check (9).

(9) Austria () Liechtenstein

Luxembourg

(9) Belgium

(9) Denmark (9) Netherlands

(9) Finland

(9) France

(9) Germany

(9) Greece

(9) Iceland

(9) Ireland

(9) Italy

(9)

Norway

(9)

Poland

(9)

Portugal

(9)

Spain

(9)

Sweden

(9)

Switzerland

(9)

United Kingdom

(9)

11

Page 14

Notices

1420 NORTH MAIN STREET | Gladewater, TX | 75647 | 800-727-2339 | www.interlogixinc.com

©2001 Interlogix,™ Inc. Interlogix is a trademark of Interl ogix, Inc. Caddx, and ITI are registered tradema rks of Interlogix, Inc.

12

Page 15

NX-450, NX-451 Door/

8959g08a

Sensor

Magnet

w

Window Sensors

Document Number: 466-1303-C DX Rev. B

September 1997

60-670-95R

Installation

Instructions

Product Summary

NX-450, NX-451 Door/Window Sensors

■ If possible, locate sensors within 100 feet of the

panel. While a transmitter may have a range of

500 feet or more out in the open, the environment

at the installation site can have a significant effect

on transmitter range. Sometimes a c hange in sensor location can help overcome adverse wireless

conditions.

■ Make sure the alignment arrow on the magnet

points to the alignment mark on the sensor (see

Figure 2).

Doorframe

Align Arro

and Mark

The NX-450 (white) and NX-451 (brown) Door/Window Sensors can be installed on doors, windows, or

many other objects that open and close. The sensors

transmit signals to the control panel when a magnet

mounted near the sensor is moved away from or closer

to the sensor.

The sensors include an input that accepts external

hardwired devices such as flush-mounted door/window contacts.

Installation Guidelines

Use the following guidelines for installing Door/Window sensors.

■ Mount the sensor on the door frame and the mag-

net on the door (see Figure 1). If the sensor is to be

used on double doors, mount the sensor on the

least-used door and the magnet on the other door.

Figure 1. Sensor and Magnet Locations

2 - AAA Batteries

8959G16B.DS4

Figure 2. Aligning the Door/Window Sensor

and Magnet

■ Place sensors at least 5 inches above the floor to

avoid damaging them.

■ Avoid mounting sensors in areas where they will

be exposed to moisture or where the operating

temperature (10°-120°F) will be exceeded.

■ Use spacers (not included) to keep sensors and

magnets away from metal or metallic surfaces

such as foil wallpaper.

Materials Needed

■ #6 flathead screw s

■ Screwdriver or brad driver

Installing the Sensor

1. Remove the sensor cover by pressing the button

on the narrow end.

2. Remove the batteries to access the mounting

holes.

3. Mount the sensor base with two #6 flathead

screws at the locations shown in Figure 3. If you

need to connect external switches, they should be

installed at this point. Use the procedure for connecting external switches.

Page 1

Page 16

NX-450, NX-451 Door/Window Sensors

Figure 3. Mounting Hole Locations (Bottom

View)

4. Remove the magnet from its base. Line up the

arrow on the magnet with the mark on the sensor.

5. Mount the magnet base no more than 3/8-inch

away from the sensor base. Replace the magnet

cover.

6. Re-install the batteries and circuit board; and

attach the sensor cover to the sensor base.

Programming

MOUNTING HOLES

For complete progra m mi ng instr u c ti ons, refer to the

NX-Series Receiver Modules Installation Instructions.

Testing Door/Window Sensors

8888G01A.DS4

Testing sensors is recommended after all programming is completed and whenever a sensor-related

problem occurs, to verify radio signal integrity and

confirm control panel p rogramming and response.

Note: While the sens or test is a valuable tool, it only

tests sensor operation for the current conditions.

A sensor test should be done after any change in

environment, equipment, or programming.

Note:

When window or doo r co nstruction does not

allow the transmitte r to be i ns ta lled next to the

magnet, install an exter nal sw i t ch and connect it

to the Door/Window Sensor.

Connecting External Switches

External switches used with Door/Window Sensors

allow you to protect doors and w indows when ther e is

inadequate room for directly mounting the sensor or

when you want to locate the Door/Window Sensor in

an adjacent, but less visible place.

Materials Ne ed ed

■ Hermetically sealed external sw itc he s (sealed

reed switch) that supply a minimum 250-millisecond open or closure on alarm

■ Stranded 22-gauge wire

Installing External Switches

1. Install the external switch according to the manu-

facturer’s instructions.

2. Remove the cover and batteries from the Door/

Window Sensor.

3. Feed the wires on the extern al switch t hrough the

rear opening at the bottom of the Door/Window

Sensor.

4. Attach each wire to one side of the screw termi-

nal. Press the screw terminal over the wire posts.

5. Mount the sensor.

6. Replace the batteries and sensor cover.

1. Place the system in test mode.

2. Trip the sensor by moving the magnet away from

the sensor and listen for the correct system

response. If the system does not r espond, pr oceed

to the “Troubleshooting “section.

Troubleshooting

Use the following guidelines if the system does not

respond correctly when the sensor is activated.

■ Check programming and re-program sensor into

panel if necessary.

■ Use an RF Sniffer (NX-468) test tool to verify that

the sensor is transmitting. Constant beeps from

the RF Sniffer indicate a runaway (faulty) sensor.

Replace the sensor.

■ Change the position of or move the sensor to

another location and test for correct response.

To reposition a sensor:

1. Rotate the sensor and test for improved sensor

communication at 90 and 180 degrees from the

original position.

2. If poor communication persists, relocate the sen-

sor as described below.

To relocate a sensor:

1. Test the sensor a few inches from the original

position.

2. Increase the distance from the original position

and retest until an acceptable location is found.

3. Mount the sensor in the new location.

4. If no location is acceptable, replace the sensor.

Page 2

Page 17

To replace a sensor:

1. Test a known good sensor at the same location.

2. If the system does not respond, avoid mounting a

sensor at that location.

3. If the replacement sensor functions, return the

problem sensor for repair or replacement.

Specifications

■ Power source: 2 AAA Alkaline batteries

■ Dimensions: L = 4.5” X W = 1.2” H = .94”

■ Typical batte ry life: 4-6 years (not verified by UL )

■ Operating temperature range: 10° to 120° F

Notices

These devices comply with part 15 of the FCC rules. Operation is subject to the following two conditions:

1. These devices may not cause harmful interference.

2. These devices must accept any interference received, including

interference that may cause undesired operation.

Changes or modifications not expressly approved by Interactive Technologies, Inc. can void the users’ authority to operate the equipment.

NX-450, NX-451 Door/Window Sensors

Page 3

Page 18

NX-450, NX-451 Door/Window Sensors

Page 4

Caddx Controls, Inc. 1420 North Main Street Gladewater, Texas 75647

Toll Free: 1-800-727-2339 FAX: (903) 845-6811

Caddx is a registered trade m ark of Caddx Controls, Inc.

Page 19

Door/Window

8867g01a.ds4

Sensor

Document Number: 466-1578 Rev. B

May 1998

60-686-43-EUR

Door/Window Sensor

■ Mount sensors with screws or brads, not double-

sided tape.

■ Place sensors at least 5 inches above the floor to

avoid damaging them.

■ Use spacers (not included) to keep sensors and

magnets away from metal or metallic surfaces

such as foil wallpaper.

Door/Window Sensor Spacers

White: Part #60-189

INSTALLATION

INSTRUCTIONS

Product Summary

The Door/Window Sensor can be installed on doors,

windows, or virtually anything that opens and closes.

During normal operation, the sensors transmit open

(TRIP) and close (RESTORE) signals to the panel.

The sensors also send a supervisory signal to the

panel every 64 minutes.

Sensors transmit open and close signals to the panel

when a magnet (mounted near the sensor) is moved

away from or closer to the sensor.

The sensor is powered by a 3.6-volt lithium battery.

Tools Needed

■ #6 flathead screws or 18-gauge brads

■ Screwdriver or brad drive r

■ Small wire cutters

■ Sensor and magnet spacers (optional)

Installation Guidelines

Magnet Spacers

White: Part #60-188

■ Avoid mounting sensors in areas with a large

quantity of metal or electrical wiring, such as a

furnace or utility room.

■ Avoid mounting sensors in areas where they will

be exposed to moisture.

■ Avoid mounting sensors in locations where the

operating temperature (10° to 120° F) will be

exceeded.

Installation

CAUTION: You must be free of all static electricity when

handling electronic components. Touch a

grounded, bare metal surface before touching a circuit board or wear a gro unded wrist

strap.

1) Decide if the sensor should be mounted horizontally or vertically by locating the alignment

marks on the sensor and magnet plastic (see Figure 1.)

The marks indicate reed switch locations. Each

sensor uses only one of the two switches. You

will remove the unused switch in step 4.

■ Keep all sensors within 100 feet of the panel.

■ Mount the sensor on the door frame and the mag-

net on the door. If the sensor is to be used on double doors, mount the sens or on the least used do or

and the magnet on the other door.

Page 1

Page 20

Door/Window Sensor

SENSOR END VIEW SENSOR SIDE VIEW

MAGNET

Figure 1. Alignment marks

ALIGNMENT MARKS

ALIGNMENT MARK

ALIGNMENT MARKS

8867G03A.DS4

2) Remove the sensor cover by squeezing the cover

ends firmly to release the tab on the cover from

the slot on the sensor base.

3) Remove the circuit board f rom the sens or base by

pulling back the plastic tab and lifting the battery

to release the circuit board.

4) Remove the unused reed switch, clipping the

leads as close to the board as possible (see Figure

2.)

WIRE

ENTRY

TAMPER SWITCH

TERMINALS

REED SWITCH

8867G04B.DS4

Figure 2. Door/Window Sensor Circuit Board

5) Mount the sensor base with screws or brads. Use

spacers to compensate for metal surfaces or

height variations.

6) Remove the magnet from its base. Mount the

magnet base no more than 3/8 inches away from

the sensor base (see Figure 3). Replace magnet

cover.

MAGNET

DOOR

SENSOR

DOOR FRAME

8867G02A.DS4

Figure 3. Mounted Sensor and Magnet

NOTE: Mount the magne t so it w on’t interfere with door

or window openings. D o no t us e t w o- si ded tape.

7) Reattach the circuit board to the sensor base.

8) Reattach the sensor cover to the sensor base.

Connecting External Switches

Door/window sensors can be connected to either normally open (close on alarm) or norm ally closed (open

on alarm) external switches. Wire multiple, normally

closed switches in series. Wire multiple, normally

open switches in parallel.

Do not attempt to use the built-in reed switches and an

external switch on the same door/window sensor. For

high security installations, always remove both reed

switches when connecting an external switch to the

sensor terminals.

Page 2

Materials Needed

■ Hermetically sealed external switches (sealed

reed switch) that supply a minimum 250-millisecond open or closure on alarm.

■ Stranded 22-gauge wire.

Page 21

Door/Window Sensor

Installation Guidelines

■ Do not use solid core wire.

■ Do not use mechanical switches.

■ If you are connecting an external device to a do or/

window sensor, do not use the built-in reed

switches.

■ Do not connect fast pulse devices (such as Win-

dow Bugs) to door/window sensors.

■ Do not use more than 25 feet of 22-gauge,

stranded wire in any wire run.

■ Do not use more than 6 feet of untwisted wire in

any wire run.

■ Do not connect more than five switches, or more

than one alarm screen to a door/window sensor.

■ Do not run wires parallel to electrical wires. If

you can’t avoid a parallel wire run, keep it at least

18 inches away from electrical wiring.

■ If necessary, you may cross electrical wires at a

90 degree angle.

Programming

For complete programming instructions, refer to the

NX-Series Receiver Modules Installation Instructions.

Troubleshooting

Use the following guidelines if the system does not

respond correctly when the sensor is activated.

■ Check programming and re-program sensor into

panel if necessary.

■ Use an RF Sniffer (NX-468) test tool to verify

that the sensor is transmitting. Constant beeps

from the RF Sniffer indicate a runaway (faulty)

sensor. Replace the sensor.

■ Change the po sition of or move the sensor to

another location and test for correct response.

To reposit i on a sensor:

1. Rotate the sensor and test for improved sensor

communication at 90 and 180 degrees from the

original position.

2. If poor communication persists, relocate the sensor as described below.

To relocate a sensor:

1. Test the sensor a few inches from the original

position.

2. Increase the distance from the original position

and retest until an acceptable location is found.

3. Mount the sensor in the new location.

4. If no location is acceptable, replace the sensor.

Testing Door/Window Sensors

Testing sensors is recommended after all programming is completed and whenever a sensor-related

problem occurs, to veri fy radio signal integrity a nd

confirm control panel programming and response.

NOTE: While the sensor test is a valuable tool, it only

tests sensor operation for the current conditions.

A sensor test should be done after any change in

environment, equipment, or program m i ng.

1. Place the system in test mode.

2. Trip the sensor by movi n g the magn et away from

the sensor and listen for the correct system

response. If the system does not re spond, pro ceed

to the “Troubleshooting “section.

To replace a sensor:

1. Test a known good sensor at the same location.

2. If the system does not respond, avoid mounting a

sensor at that location.

3. If the replacement sensor functions, return the

problem sensor for repair or replace ment.

Page 3

Page 22

Door/Window Sensor

Specifications

Frequency: 433 MHz.

Operating

Temperature Range: 1 0° to 120° F.

Compatibility: NX-408-I, NX-416-I, and

Power Source: 3.6-volt lithium battery

Transmit Range: At least 500 feet, open air

Dimensions: L = 3.25” x W = 1.55”

FCC Notice

This device complies w ith FCC Rules Part 15. Operation is subject to th e following two

conditions:

This device may n ot cause harmful interference.

The device must accept any interference that may be received, including interference

that may cause undesired operation.

Changes or modifications not expressly approved by Interactive Technologies, Inc. can

void the user’s authority to operate the equipment.

NX-448-I

x W = 1.0”

Page 4

Caddx Controls, Inc. 1420 North Main Street Gladewater, Texas 75647

Toll Free: 1-800-727-2339 FAX: (903) 845-6811

Caddx is a registered trade m ark of Caddx Controls, Inc.

Page 23

NX-470 KeyChain

NX-470 Keychain To uc hp ad

Touchpad

Document Number: 466-1478 Rev. E

May 1998

60-659

Installation

Instructions

Product Summary

Keychain Touchpads provide users with convenient

options for the following system operations:

■ Arm the system (doors, windows, and motion

sensors)

■ Arm the system with no entry delay

■ Disarm the system

■ Activate panic an d medical alarms

The touchpad is alkaline battery-powered and

designed to fit on a keychain, in a pocket or purse.

■ Light Button - arms system to STAY/INSTANT.

■ Star Button - performs EXIT button function.

■ Light and Star Buttons - when pressed simulta-

neously, activates a medical alarm.

Specifications

Power source: 12 V, 33 mAh al kaline battery

Frequency: 319.5 MHz. (NX-470)

433 MHz. (60-659-43-EUR)

Dimensions: L = 2.30” x W = 1.45” x H =.48”

Typical battery life: 5 - 8 years

Operating temperature range: 10° to 120° F

Notices

These devices comply with part 15 of the FCC rules. Operation is subject to the following two conditions:

1. These devices may not cause harmful interference.

2. These devices must accept any interference received, including

interference that may cause undesired operation.

Changes or modifications not expressly approved by Interactive Technologies, Inc. can void the users’ authority to operate the equipment.

Programming

For complete programming information, refer to the

NX-Series Receiver Modules Installation Instructions.

Testing Keychain Touchpads

T est the Keychain Touchpad by pressing the buttons as

described below:

■ Unlock Button -disarms the system. Doors, win -

dows, and motion sensors are disa rmed.

■ Lock Button - arms doors and windows.

■ Lock and Unlock Buttons - when pressed simulta-

neously, activates a panic alarm. These two buttons are also used to test the sensor.

Page 1

Page 24

NX-470 Keychain

Page 2

Caddx Controls, Inc. 1420 North Main Street Gladewater, Texas 75647

Toll Free: 1-800-727-2339 F AX: (903) 845-681 1

Caddx is a registered trademark of Caddx Controls, Inc.

Page 25

NX-480 Wireless

60-639

Motion Sensor

Document Number: 466-1479 Rev. D

May 1998

Installation

Instructions

Product Summary

A motion sensor (passive-infrared or PIR) detects

movement within a specific area by sensing the infrared energy emitted from a body as it moves across the

sensor’s field of view, causing a temperatur e change in

the sensor’s zones. When this motion is detected, the

sensor transmits an alarm signal to the control panel.

Use motion sensors to protect locations where door/

window sensors are impractical or not needed. For

example, use a motion sensor to protect large areas or

open floor plans. Motion sensors also provide backup

protection for door/window sensors.

The NX-480 Wireless Motion Sensor includes the following features:

■ 35 feet by 40 feet coverage area for standard and

animal- alley lenses

■ Masking kit provided to block portions of cover-

age area

■ 3-minute transmi tter lockout time aft er an alarm

that helps extend battery life

■ Cover-activated tamper (optional wall-activated

tamper is included)

■ Supervisory signal trans m itted every 64 min utes

to the control panel

■ Sensor low battery reports (trouble) to the control

panel

■ Field-selectable sensitivi ty opti ons

NX-480 Wireless Motion Sensor

Installation Guidelines

Motion sensors ar e ideal w henever it is not pr acti cal to

install Door/W indow sensors on every opening. La rge

areas in an open floor plan, downstairs family rooms,

and hallways are candidates for motion sensors.

Motion sensors are not suitable for rooms where pets

can enter.

Use the following guidelines for installin g motion sen sors.

■ If possible, locate sensors within 100 feet of the

panel. While a transmitter may have a range of

500 feet or more out in the open, the environment

at the installation site can have a significant effect

on transmitter range. Sometimes a c hange in sensor location can help overcome adverse wireless

conditions.

■ Mount the motion sensor on an in sulated , out side

wall facing in.

■ Mount the motion sensor on a rigid surface wh ich

is free from vibrations.

■ Position the sensor so it faces a solid reference

point, like a wall.

■ Do not aim the sensor at windows, fireplaces, air

conditioners, area heaters, forced air heating

vents, or place it in direct sunlight. Sudden

changes in temperature may trigger a false al arm

from these devices.

■ Do not mount the senso r near duct work or o t her

large metallic surfaces which may affect the RF

signals (see RF Testing). Actual acceptable transmitter range should be verified for each installation.

■ Mount the sensor permanently on a flat wall or in

a corner. Do not set it on a shelf.

■ Windows should be closed in any area which has

an armed motion sensor.

■ A pet will trigger a motion sensor. See Animal

Alley lens guidelines to use a motion sensor when

pets are present.

■ Position the sensor to protect an area where an

intruder would be most likely to wal k across the

detection pattern (see Figure 1).

Page 1

Page 26

NX-480 Wirele ss Moti on Senso r

8362G04B.DS4

Person walking across detection path

2

2

2

8

4

0

m

m

m

m

TOP VIEW

11 m

6 m

3 m

0 m

3 m

0 ft

10 ft

0 ft

0 ft

0 m

Figure 1. Overhead (Bird’s Eye View) Detection Path

■ For best coverage, mount the sensor from 5 to 8

feet high in the corner of the area you want t o pro tect. See the Animal Alley lens guidelines for

mounting the Animal Alley lens. Higher mount-

8 ft

0 ft

0 ft

0 m

SIDE VIEW

35 ft

11 ft

6 m

2.4 m

ing provides better range (up to 35 feet), and

lower mounting provides better protection close

4 ft

1.2 m

to the motion sensor (see Figures 2 and 3).

0 m

35 ft

8362G07A.DS4

Animal Alley Lens Guidelines

0 ft

0 ft

VERTICAL TILT OF 12 DEGREES

The animal alley lens provides protection in installations where pets move about freely.

■ Allowed mounting height is between 3 and 5 feet.

■ Position the sensor to have a clear line of sight

across the protected room.

■ For best results, instal l the sensor higher than the

highest point that the pet might reach in the

detection area.

■ If the detection area contains furniture or other

objects upon which the pet could climb or jump,

either remove these objects, mount the PIR a safe

distance above these objects, or mask these areas.

Figure 2. Top Graph Shows Both Standard & Animal

Alley Lens Coverage Area . Low er G raph shows Side

View Coverage Area Using the Animal Alley Lens

SIDE VIEWS (STANDARD LENS)

0 m

ft

ft

ft

0 ft

7 1/2 FOOT MOUNTING HEIGHT

11 ft

35 ft

2.4

1.2

0 m

Page 2

0 m

8 ft

4 ft

0 ft

0 ft

Figure 3. Side Views Show the Differences in the

5 FOOT MOUNTING HEIGHT

11 ft

2.4

1.2

0 m

35 ft

8362G09A.DS4

Coverage Area when using the standard lens

mounted at Different Heights.

Page 27

Mounting the Sensor

The sensor can be flush-mounted, inclin e-mo unt ed, or

corner-mounted depending on the application (see

Figure 4).

FLUSH MOUNT

CORNER MOUNT

INCLINED MOUNT

USE WITH

ANIMAL ALLEY LENS

WALL

TAMPER

KNOCKOUT

USE WITH

STANDARD LENS

Figure 5. PIR Mounting Plate Knockouts

NX-480 Wireless Motion Sensor

8362G01B.DS4

8362G03A.DS4

Figure 4. Wall Mount Options: use the inclined

position for surface or corner mounting with the

standard lens. Use the flush position for surface or

corner mounting with the animal alley lens.

Use the following procedure to mount the sensor.

1. Remove the mounting plate by depressing the

button on the top of the sensor body. With the

opposite hand pull the mounting plate away from

the body of the sensor.

2. Punch out the mounting holes that best fit your

application. See Figure 4 for wall mount options.

See also Figure 5 to determin e which knock outs to

use when mounting the motion sensor. Use the

lower-side holes for corner mounting, or the

lower-back holes for surface mounting with the

standard lens.

For applications without pets, use the lower

mounting holes. For applications with pets, use

the upper mounting holes and the animal alley

lens.

3. If you desire wall-tamper functionality, remove

the wall-tamper knockout (see Figure 5).

Note: The wall-tamper switch cannot be used when the

sensor is swivel or corne r m ounted.

4. Mark the location of the required holes on the

mounting surface.

5. Use wall anchors and screws to secure into

place.Attach the sensor to the mounting plate.

Lens Replacement:

1. To change the lens, first remove the sensor from

its mounting plate by depressin g the button on

the top of the sensor.

2. Remove the cove r by depressing the two tabs on

the top and the one tab on the bottom of the sensor body and sliding the cover off (see Figure 7).

3. Remove the installed lens by gently placing pres-

sure on the lens from the outs ide of the lens.

4. Replace with the appropriate lens by aligning its

notches with the appropriate tabs in the co ver.

5. Install the new lens with the smooth side facing

out and the grooved side facing in.

6. Replace the cover and then replace the sensor in

its mounting plate.

Setting the Sensitivity

The PIR is set to standard sensitivity at the factory.

This sensitivity is preferred for most applications and

provides the best immunity to false alarms.

CAUTION:

High sensitivity should only be used

in extremely quiet environ m ent s

where thermal transients ar e not

expected.

Page 3

Page 28

NX-480 Wirele ss Moti on Senso r

1. Locate the sensitivity pins by firs t removing the

mounting p late and the s ensor cove r as describ e d

in steps 1 and 2 of Lens Replacement process.

STANDARD

HIGH

Figure 6. Sensitivity Pins Locations

8362G06A.DS4

2. Locate the sensitivity pins under the battery on

the right side of the PIR w hen lo okin g a t th e front

of the PIR.

3. The sensor is set to standard sensitivity at the fac-

tory. To change this to high sensitivity move the

shorting jumper to the pair of pins that are closer

to the top of the PIR (see Figure 6)

Note: When the walk test m ode has ended, an alarm

can be transmitted on ly afte r 3 m i nut es have

passed since the pr evious alarm. This 3 minute

lockout time reduces unnecessary RF transm i ssions in high traffic areas thereby ext ending battery life.

Environment Testing

Turn on all heating or air conditioning sourc es which

would normally be active during the protection

period. Stand away from the sensor and outside the

coverage patter n and watch for alarms.

Coverage Masking

After walk-testing and environment tes ting are completed, apply masking labels to the sensor’s lens to

block detection of desired areas. The masking labels

provided are cut to match the corresponding lens segments.

1. Determine which dete c t ion zo n e/lens segment

needs a masking label.

2. Peel the desired mask label from its backing and

apply to the inside of the lens segment to be

blocked.

Note:

If the shorting jumper is not used or placed incorrectly, the sensor defaults to standard sensitivity.

4. Walk test the PIR to verify the sensitivity.

Walk-Testing

Wa lk- testing should be done to determine the sensor’s actual coverage area. The edge of the coverage

pattern is determined by the first flash of the LED.

This may change slightly depending upon the sensitivity setting. Walk test the unit from both directions to

determine the pattern boundaries.

1. Removing the sensor body from the mounted

mounting plat e and then remounting the body to

activate the 60-second walk test mode.

2. W alk acr oss the co verage p atter n to dete rmine the

coverage area, indicated by LED activation. Each

activation extends th e walk test mode for an a ddi tional 60 seconds.

After the walk test mode has expired, th e LED will not

activate when motion is detected.

Note: Excessive use of the walk test mode may reduce

battery life. Use only for initial setup and maintenance testing.

Programming

For complete progra m mi ng instr u c ti ons, refer to the

NX-Series Receiver Modules Installation Instructions.

Maintenance

At least once a year, the range and coverage should be

verified for proper operation. The end user should be

instructed to put the sensor in walk test mode and

walk through the far end of the coverage pattern to

verify prop e r de tec t i on.

Replacing Batteries