OPERATOR’S

This online version differs from

the printed version.

Certain information that is not intended

for patients has been removed.

MANUAL

Model 6100 and 6101

Ambulatory

Infusion

Pump

This manual concerns only the CADD-Prizm® VIP (Variable Infusion Profile)

Model 6100 and Model 6101 ambulatory infusion pumps. The pump has the

following delivery modes:

PCA PCA 6210 (all revision letters)

Continuous CONTIN 6220 (all revision letters)

TPN TPN 6230 (all revision letters)

Intermittent INTERMT 6240 (all revision letters)

This manual is intended for clinician use only. Do not permit patients to have

access to this manual. The pump has three security levels designed to limit

patient access. Do not disclose the pump’s security codes or any other information that would allow inappropriate access to programming and operating

functions.

The issue date of this Operator’s Manual is included for the clinician’s information. In the event one year has elapsed between the issue date and product use,

the clinician should contact Smiths Medical MD, Inc. to see if a later revision

of this manual is available.

Technical Assistance

If you have comments or questions concerning the operation of the CADDPrizm® pump, please call the number given below. When calling, please specify

the pump’s software module. This information is located in the pump’s start-up

screen.

Our staff at Smiths Medical MD is available to help clinicians twenty-four

®

hours a day with the programming and operation of the CADD-Prizm

infu-

sion system.

Smiths Medical MD, Inc.

1265 Grey Fox Road

St. Paul, Minnesota 55112 U.S.A.

1 800.426.2448

+1 651.633.2556

ii

Read this entire Operator’s Manual before operating the CADD-Prizm® VIP

ambulatory infusion pump.

Failure to properly follow warnings, cautions, and instructions could result in

death or serious injury to the patient.

WARNINGS

• This Operator’s Manual should be used by clinicians only. Do not permit

patients to have access to this manual, as the information contained would

allow the patient complete access to all programming and operating

functions. Improper programming could result in death or serious injury

to the patient.

• For those patients who are likely to be adversely affected by unintended

operations and failures, including interrupted medication or fluid delivery

from the device, close supervision and provision for immediate corrective

action should be provided.

• If the pump is used to deliver life-sustaining medication, an additional

pump must be available.

• The pump is not to be used for delivery of blood or cellular blood products.

• If the pump is dropped or hit, inspect the pump for damage. Do not use a

pump that is damaged or is not functioning properly. Contact Customer

Service to return a pump for service.

™

• Use of a syringe with the CADD

UNDER-DELIVERY of medication. Syringe function can be adversely

affected by variations in plunger dimension and lubricity, which can result

in greater force required to move the syringe plunger. A syringe plunger

will lose lubrication as it ages and, as a result, the amount of underdelivery will increase which could on occasion, be significant. Therefore,

the type of medication and delivery accuracy required must be considered

when using a syringe with the CADD® pump.

Administration Set may result in

Clinicians must regularly compare the volume remaining in the syringe to

the pump’s displayed values such as RES VOL and GIVEN in order to

determine whether under-delivery of medication is occurring and if necessary, take appropriate action.

• System delivery inaccuracies may occur as a result of back pressure or

fluid resistance, which depends upon drug viscosity, catheter size, and

extension set tubing (for example, microbore tubing).

iii

• Do not administer drugs to the epidural space or subarachnoid space

unless the drug is indicated for those spaces.

• To prevent the infusion of drugs that are not indicated for epidural space

or subarachnoid space infusion, DO NOT use administration sets that

incorporate injection sites.

• If a Medication Cassette Reservoir, CADD

™

Extension Set or CADD

™

Administration Set is used for epidural space or subarachnoid space drug

delivery, it is strongly recommended that it be clearly differentiated from

those used for other routes of infusion, for example, by color coding, or

other means of identification.

• When the Air Detector is not installed, or is installed but turned off, the

pump will not detect air in the fluid path. It is recommended that you

periodically inspect the fluid path and remove any air to prevent air

embolism.

• Follow the Instructions for Use provided with the Medication Cassette

™

Reservoir and CADD

Extension Set, or the CADD™ Administration

Set, paying particular attention to all warnings and cautions associated

with their use.

• When the Upstream Occlusion Sensor is turned Off, the pump will not

detect occlusions upstream (between pump and fluid container). It is

recommended that you periodically inspect the fluid path for kinks, a

closed clamp, or other upstream obstructions. Upstream occlusions may

result in under- or non-delivery of medications.

• Do not disclose to the patient the pump’s security codes or any other

information that would allow the patient complete access to all programming and operating functions.

• Ensure that the ±6% System Delivery Accuracy specification is taken into

account when programming the pump and/or filling the Medication

Cassette Reservoir. Failure to do so may result in medication in the reservoir becoming depleted sooner than expected.

• Do not use rechargeable NiCad or nickel metal hydride (NiMH) batteries.

Do not use carbon zinc (“heavy duty”) batteries. They do not provide

sufficient power for the pump to operate properly.

• Always have new batteries available for replacement. If power is lost, nondelivery of drug will occur.

iv

• There is no pump alarm to alert users that a battery has not been properly

installed or has become dislodged. An improperly installed or dislodged

battery could result in loss of power and non-delivery of drug.

• If the pump is dropped or hit, the battery door may become broken or

damaged. Do not use the pump if the battery door is damaged because the

battery will not be properly secured; this may result in loss of power or

non-delivery of drug.

• When you enter a new Demand Dose Lockout time, any lockout time in

effect will be cleared. A Demand Dose could be requested and delivered

immediately upon starting the pump, resulting in over-delivery.

• When you enter a new Max Doses per Hour value, any lockout time in

effect will be cleared. A Demand Dose could be requested and delivered

immediately upon starting the pump, resulting in over-delivery.

• Exercise care when using the Clinician Bolus function. Since there are no

limits on the frequency of delivering a bolus, and since the amount of the

bolus can be set as high as 20 ml (or the mg or mcg equivalent), you

should not permit the patient to become familiar with the procedure for

giving a Clinician Bolus.

• To prevent the patient from accessing the Clinician Bolus function, do not

let the patient know the Clinician Bolus code.

• Always close the fluid path tubing with the clamp before removing the

cassette from the pump to prevent unregulated gravity infusion.

• Attach the cassette properly. A detached or improperly attached cassette

could result in unregulated gravity infusion of medication from the fluid

container or a reflux of blood.

If you are using a Deltec administration set medication cassette reservoir

that does not have the flow stop feature (reorder number does not start

™

with 21-73xx): you must use a CADD

Extension Set with anti-siphon

valve or a CADD™ Administration Set with either an integral or add-on

anti-siphon valve to protect against unregulated gravity infusion that can

result from an improperly attached cassette.

• Do not prime the fluid path with the tubing connected to a patient as this could result in over-delivery of medication or air embolism.

• Ensure that the entire fluid path is free of all air bubbles before connecting

to the patient to prevent air embolism.

v

• If Demand Doses are currently locked out, changing the Date and/or Time

will cancel the lockout period. This will allow a Demand Dose to be

requested and delivered as soon as you restart the pump, resulting in overdelivery.

CAUTIONS

• Do not operate the pump at temperatures below +2°C (36°F) or above

40°C (104°F).

• Do not store the pump at temperatures below -20°C (-4°F) or above 60°C

(140°F). Do not store the pump with a Medication Cassette Reservoir or

CADD

• Do not expose the pump to humidity levels below 10% or above 90%

relative humidity.

• Do not store the pump for prolonged periods with the battery installed.

Battery leakage could damage the pump.

• If you are using a Medication Cassette Reservoir in which the medication

is frozen, thaw at room temperature only. Do not heat in a microwave

oven as this may damage the product and cause leakage.

• Do not immerse the pump in cleaning fluid or water. Do not allow solution to soak into the pump, accumulate on the keypad, or enter the battery

compartment, Data In/Out jack, Power jack or Air Detector port area.

Moisture build-up inside the pump may damage the pump.

™

Administration Set attached.

• Do not clean the pump with acetone, other plastic solvents, or abrasive

cleaners, as damage to the pump may occur.

• Do not expose the pump to therapeutic levels of ionizing radiation as

permanent damage to the pump’s electronic circuitry may occur. The best

procedure to follow is to remove the pump from the patient during therapeutic radiation sessions. If the pump must remain in the vicinity during a

therapy session, it should be shielded, and its ability to function properly

should be confirmed following treatment.

• Do not expose the pump directly to ultrasound, as permanent damage to

the pump’s electronic circuitry may occur.

• Do not use the pump in the vicinity of magnetic resonance imaging (MRI)

equipment as magnetic fields may adversely affect the operation of the

pump. Remove the pump from the patient during MRI procedures and

keep it at a safe distance from magnetic energy.

vi

• Do not use the pump near ECG equipment as the pump may interfere with

the operation of the equipment. Monitor ECG equipment carefully when

using this pump.

• Do not sterilize the pump.

• Do not use the pump in the presence of flammable anesthetics or explosive

gases.

• Use only Smiths Medical MD accessories as using other brands may

adversely affect the operation of the pump.

• Check appropriate medication stability for time and temperature to assure

stability with actual pump delivery conditions.

vii

Table of Contents

WARNINGS iii

CAUTIONS vi

Section 1: General Description and Basic Operations 1

Introduction ............................................................................................... 1

Indications ................................................................................................. 1

Epidural/Subarachnoid ............................................................................... 1

Pump Diagram ........................................................................................... 3

Description of Keys, Display and Features ................................................. 4

The Main Screen ........................................................................................ 8

Getting Help Using the Å Key ................................................................. 9

Lock Levels ................................................................................................ 10

AutoLock ......................................................................................... 10

Security Codes ................................................................................. 10

Customizing the Security Codes ....................................................... 10

Lock Level Table ........................................................................................ 11

Section 2: Pump Setup and Programming 13

Installing a battery ...................................................................................... 13

Watching Power-Up .................................................................................... 15

Changing the Lock Level ............................................................................ 16

PCA Delivery Method

PCA Programming Screens ............................................................... 18

PCA Programming Example ............................................................ 23

PCA: Programming with Upper Limits, Adjusting Doses in

Lock Level 1 ............................................................................... 29

PCA: Starting a Clinician Bolus ........................................................ 30

PCA: Starting a Demand Dose ......................................................... 32

PCA: Stopping a Demand Dose or Clinician Bolus ........................... 33

viii

Continuous Delivery Mode

Continuous Programming Screens .................................................... 34

Continuous Programming Example ................................................. 37

CONTIN: Programming with Upper Limits, Adjusting Rate in

Lock Level 1 ............................................................................... 39

TPN Delivery Mode

TPN Programming Screens .............................................................. 40

TPN Programming Example ............................................................ 44

TPN: Starting Daily Infusion ............................................................ 47

Intermittent Delivery Mode

Intermittent Programming Screens ................................................... 48

Intermittent Programming Example ................................................. 52

INTERMT: Stopping the Pump During the Cycle ............................ 55

Section 3: Operating the Pump 57

Removing a Cassette .................................................................................. 57

Attaching a Cassette .................................................................................. 58

Priming the Tubing and Connecting to the Patient ..................................... 61

Setting the Lock Level for the Patient ......................................................... 63

Starting the Pump ...................................................................................... 65

Stopping the Pump...................................................................................... 65

Resetting the Reservoir Volume ................................................................. 66

Description

General

Programming

Setup &

Reservoir or

Admin Set

Options

Section 4: Options 67

Overview: Accessing Options ..................................................................... 67

Immediate Taper-Down: TPN .................................................................... 68

Prime ......................................................................................................... 69

Time Remaining: Intermittent .................................................................... 70

Extended History, Viewing: PCA ............................................................... 71

Change the Delivery Mode ........................................................................ 73

AutoLock ................................................................................................... 74

Time .......................................................................................................... 75

Date ........................................................................................................... 76

Air Detector On/Off .................................................................................. 77

Event Log, Viewing .................................................................................... 78

ix

Toolbox

Biomed

Troubleshooting

Reference &

Section 5: Biomed Toolbox 79

Overview: Accessing the Biomed Toolbox .................................................. 79

Micrograms On/Off (PCA Only) ............................................................... 80

Concentration Customization (PCA Only) ................................................. 80

Extended History On/Off (PCA Only) ....................................................... 82

Max Doses Per Hour On/Off (PCA Only) .................................................. 82

PM (Preventive Maintenance) Reminder .................................................... 83

Custom Lock Level Code ........................................................................... 83

Date Format .............................................................................................. 84

Power Source Status Display ...................................................................... 85

Upstream Sensor On/Off (Model 6101 only) ............................................. 85

Air Detector Requirement .......................................................................... 86

Section 6: Reference & Troubleshooting 87

Troubleshooting ......................................................................................... 87

Alarms and Messages, Alphabetical List .................................................... 89

Cleaning the Pump and Accessories ........................................................... 98

Exposure to Radiation or Magnetic Resonance Imaging (MRI) ................. 100

PCA Delivery Mode: Continuous Rate Scroll Ranges ................................ 101

PCA Delivery Mode: Demand Dose, Clinician Bolus Scroll Ranges,

Milliliters ............................................................................................. 101

PCA Delivery Mode: Demand Dose, Clinician Bolus Scroll Ranges,

Milligrams ........................................................................................... 102

PCA Delivery Mode: Demand Dose, Clinician Bolus Scroll Ranges,

Micrograms ......................................................................................... 103

Military Time Conversion Chart ................................................................ 104

Specifications (Nominal) ............................................................................ 105

Printed Reports ........................................................................................... 109

Index ......................................................................................................... 110

Limited Warranty ...................................................................................... 114

x

Section 1: General Description

Section 1: General Description and Basic Operations

Introduction

The CADD-Prizm® ambulatory infusion pump provides measured drug therapy

to patients in hospital or outpatient settings. Therapy should always be overseen by a physician or a certified, licensed healthcare professional. As appropriate, the patient should be instructed in using the pump.

Indications

The CADD-Prizm® pump is indicated for intravenous, intra-arterial, subcutaneous, intraperitoneal, epidural space, or subarachnoid space infusion.

PCA (Patient-Controlled Analgesia) delivery is used for therapies that require a

continuous rate of infusion, patient-controlled demand doses, or both, such as

patient-controlled analgesia.

Continuous delivery allows the infusion of drug at a constant, programmed

rate.

Description

General

TPN (Total Parenteral Nutrition) delivery allows the infusion of nutritional

solutions or other fluids, with optional tapering at the beginning and end of

infusion.

Intermittent delivery allows the infusion of a specific volume of drug at a

regular, programmed interval.

Epidural/Subarachnoid Administration

The selected drug must be used in accordance with the indications included in

the package insert accompanying the drug. Administration of any drug by this

pump is limited by any warnings, precautions, or contraindications in the drug

labeling.

Analgesics

Administration of analgesics to the epidural space is limited to use with indwelling catheters specifically indicated for either short- or long-term drug

delivery.

1

General

Description

Section 1: General Description

Administration of analgesics to the subarachnoid space is limited to use with

indwelling catheters specifically indicated for short-term drug delivery.

Anesthetics

Administration of anesthetics to the epidural space is limited to use with

indwelling catheters specifically indicated for short-term drug delivery.

WARNING:

• Do not administer drugs to the epidural space or subarachnoid space unless

the drug is indicated for administration to those spaces. Drugs not intended

for epidural or subarachnoid space infusion could result in death or serious

injury to the patient.

• To prevent the infusion of drugs that are not indicated for epidural space or

subarachnoid space infusion, DO NOT use administration sets that incor-

porate injection sites. The inadvertent use of injection sites for infusion of

such drugs may cause death or serious injury to the patient.

™

• If a Medication Cassette Reservoir, CADD

Extension Set or CADD

Administration Set is used for epidural space or subarachnoid space drug

delivery, it is strongly recommended that it be clearly differentiated from

those used for other routes of infusion, for example, by color coding, or

other means of identification. Drugs not intended for epidural or subarachnoid space infusion could result in death or serious injury to the patient.

™

2

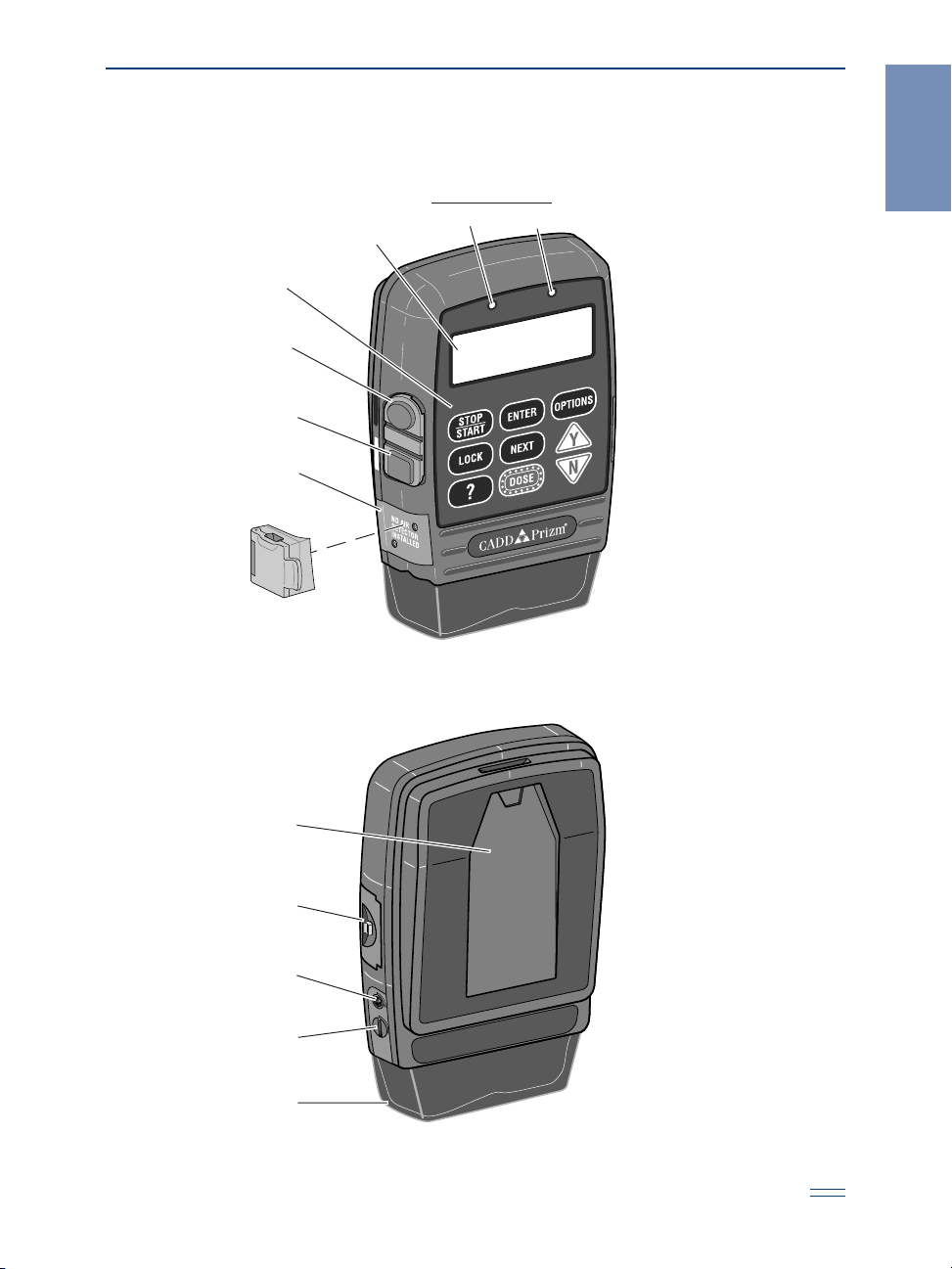

Pump Diagram

Keypad

Display

Indicator Lights

Amber

Green

Section 1: General Description

Description

General

Power jack

Data In/Out

jack

Air Detector

Port Cover

Air Detector

(optional)

Polemount

Bracket

Recess

Battery

compartment

2000-03-07 D. Zurn

«Prizm Rear 3/4 (dark BW)»

Front View

®

Rear View

Cassette

lock

Cassette

latch

Cassette

®

3

Section 1: General Description

Description of Keys, Display and Features

General

Description

Indicator Lights

Green: The green light blinks approximately every 3 seconds when the pump is

running and delivering fluid as programmed.

Amber: The amber light flashes when the pump is stopped or an alarm condi-

tion exists. It stays on continuously when the pump is inoperable. The

display briefly describes the condition.

If both lights blink, delivery is still occurring but a condition exists of which you

should be aware (for example, a low battery). Look at the display for a brief

description of the condition.

Display with backlighting

The liquid crystal display (LCD) shows programming information and messages. Backlighting helps keep the display visible in low light.

After a period of no key presses, backlighting turns off and the display blanks

to save battery power (except during an alarm or when an external power

source is in use). Press any key to turn the display back on.

NOTE: If you press

you wish to start or stop the pump; press

the display back on; this may deliver an inadvertent dose.

Keypad

The keys on the keypad are described below. A key beeps when pressed if it is

operable in the current lock level.

, the display will reappear with a message asking if

⁄

or Î. Do not use

´

Í

to turn

⁄

Œ

Å

¤

4

starts and stops pump delivery.

is used to view or change the pump’s current lock level. Lock levels

are used to limit patient access to certain programming and operating functions. (See Lock Levels, this section.) This key is also used

to access the Clinician Bolus in the PCA delivery mode.

is the “Help” key. It is used to display help for a screen or an alarm

message. (See Getting Help, this section.)

is used to enter, or save, a new value in the pump’s memory when

programming new pump settings. It is also used to select an item

from the Options Menu (Section 4) or Biomed Toolbox Menu

(Section 5).

„

Section 1: General Description

Description

General

is used to move from one programming screen to the next without

changing the setting or value displayed. It is also used to return

from the Biomed Toolbox Menu to the Options Menu, or from the

Options Menu to the main screen. (See Sections 4 and 5.)

Í

‹

´

Î

is used only in the PCA delivery mode. It allows the patient to

deliver a programmed amount of medication upon request.

is used to access the Options Menu, which contains such features as

time, date, and the Event Log. (See Section 4, Options.)

allows you to answer “yes” to a question on the pump’s display,

“scroll up” or increase a value (for example, a dose amount), or

scroll through items on a menu.

allows you to answer “no” to a question on the pump’s display,

“scroll down” or decrease a value, scroll through items on a menu,

or cancel printing.

Power jack

You may plug a CADD™ External Power Source (EPS) System Power Pack or

an AC Adapter into the Power jack as an alternate source of power.

Data In/Out jack

The Data In/Out jack is used for attaching the following accessories:

• Interface Cable for printing reports

• Remote Dose Cord for remote operation of the dose key

• Modem cable for communications

For more information on the Remote Dose Cord, printing or communications,

see the instructions for use provided with those products.

Air Detector Port Cover

This encloses the Air Detector port when the Air Detector is not attached.

Air Detector accessory (optional)

The Air Detector attaches to the pump in the area shown in the diagram. If air

is detected in the part of the tubing that passes through the Air Detector, an

alarm sounds and delivery stops. (See Section 6 for Air Detector specifications.)

The pump may be customized to require an Air Detector. (See Section 5,

Biomed Toolbox.) If an Air Detector is attached but not required, it may be

turned off.

5

General

Description

Section 1: General Description

WARNING: When the Air Detector is not installed, or is installed but turned

off, the pump will not detect air in the fluid path. It is recommended that you

periodically inspect the fluid path and remove any air to prevent air embolism.

Air embolism could result in death or serious injury to the patient.

Cassette

The cassette is the portion of the Medication Cassette Reservoir or CADD

Administration Set that attaches to the bottom of the pump. The following

single use products are compatible with the CADD-Prizm® pump:

• Medication Cassette Reservoir (50 or 100 ml), used with a CADD

Extension Set

• CADD

• CADD-Prizm

™

Administration Set

™

High Volume Administration Set, for rates up to 350 ml/hr

(not for use in PCA mode)

WARNING: Follow the Instructions for Use provided with the Medication

Cassette Reservoir and CADD™ Extension Set, or the CADD™ Administration Set, paying particular attention to all warnings and cautions associated

with their use. Incorrect preparation and/or use of these products could

result in serious patient injury or death.

™

™

Polemount Bracket recess

The optional Polemount Bracket slides into the recess on the back of the pump,

allowing you to attach the pump to an IV pole.

Battery compartment

The 9 volt battery fits into this compartment. The 9 volt battery serves as the

primary source of power, or as a backup when an EPS System power pack or

AC Adapter is in use.

Cassette latch

This attaches the cassette (the part of the Medication Cassette Reservoir or

CADD

detects whether the cassette is latched properly. Delivery will stop and an alarm

will occur if the cassette becomes unlatched.

™

Administration Set that attaches to the pump) to the pump. The pump

Cassette lock

6

Section 1: General Description

This allows you to secure the cassette to the pump using the key provided. The

cassette must be latched before it can be locked. In the PCA delivery mode, the

cassette must be locked onto the pump or the pump will not run.

Downstream Occlusion Sensor (Not Shown)

The pump contains a downstream occlusion sensor. When a downstream

occlusion (between pump and patient) is detected, an alarm will sound, delivery will stop, and the display will show “High Pressure.”

Upstream Occlusion Sensor (Model 6101 only; Not Shown)

The pump contains an upstream occlusion sensor. This feature may be turned

on or off (see Section 5, Biomed Toolbox). When the sensor is turned on, and

an upstream occlusion (between pump and fluid container) is detected, an

alarm will sound, delivery will stop, and the display will show “Upstream

Occlusion.”

WARNING: When the Upstream Occlusion Sensor is turned off, the pump will

not detect occlusions upstream (between pump and fluid container). It is

recommended that you periodically inspect the fluid path for kinks, a closed

clamp, or other upstream obstructions. Upstream obstructions may result in

under- or non-delivery of medications to the patient. If undetected, these

occlusions could lead to death or serious injury to the patient.

Description

General

Reservoir Volume Alarm (Not Shown)

Reservoir Volume is a feature that indicates when the fluid in the fluid container is low or depleted. Each time you change the fluid container, you may

reset the Reservoir Volume to the originally programmed volume. Then, as

medication is delivered, the Reservoir Volume automatically decreases.

™

Medication Cassette Reservoir or CADD

pump calculates that 5 ml remain in the fluid container and a “Reservoir

Volume Low” message appears. This alarm recurs at every subsequent decrease

of 1 ml until the Reservoir Volume reaches 0 ml, at which point the pump

stops.

™

CADD-Prizm

High Volume Administration Set: When the pump calculates

that 25 ml remain in the fluid container, beeps sound and “Reservoir Volume

Low” appears. This alarm recurs at every subsequent decrease of 5 ml until the

Reservoir Volume reaches 0 ml, at which point the pump stops.

Administration Set: When the

7

Section 1: General Description

The Main Screen

General

Description

The main screen is the starting point for programming or viewing the pump’s

settings. If no keys are pressed, the display will eventually revert to the main

screen. The main screen within each delivery mode displays information about

the delivery status, as shown below.

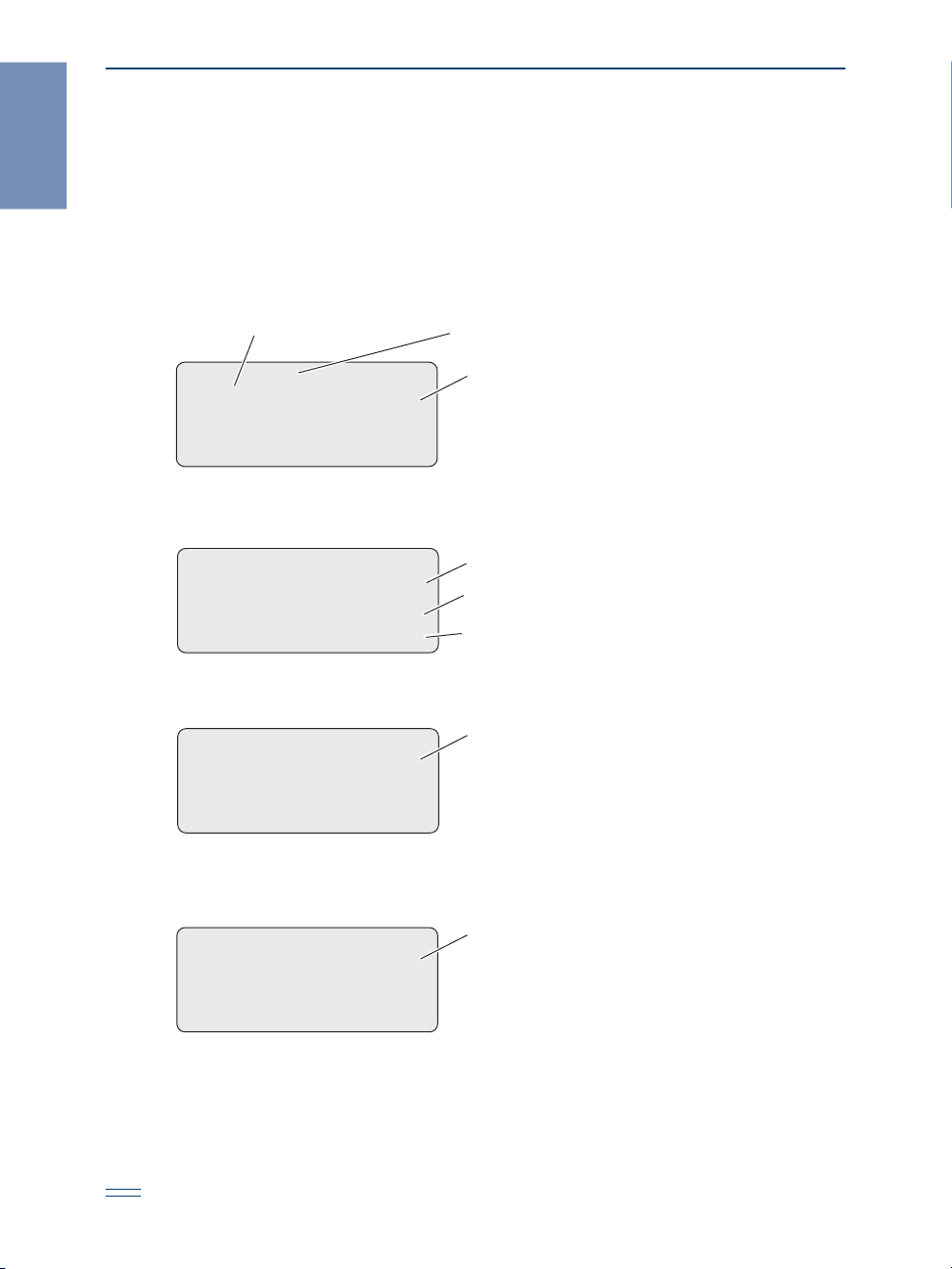

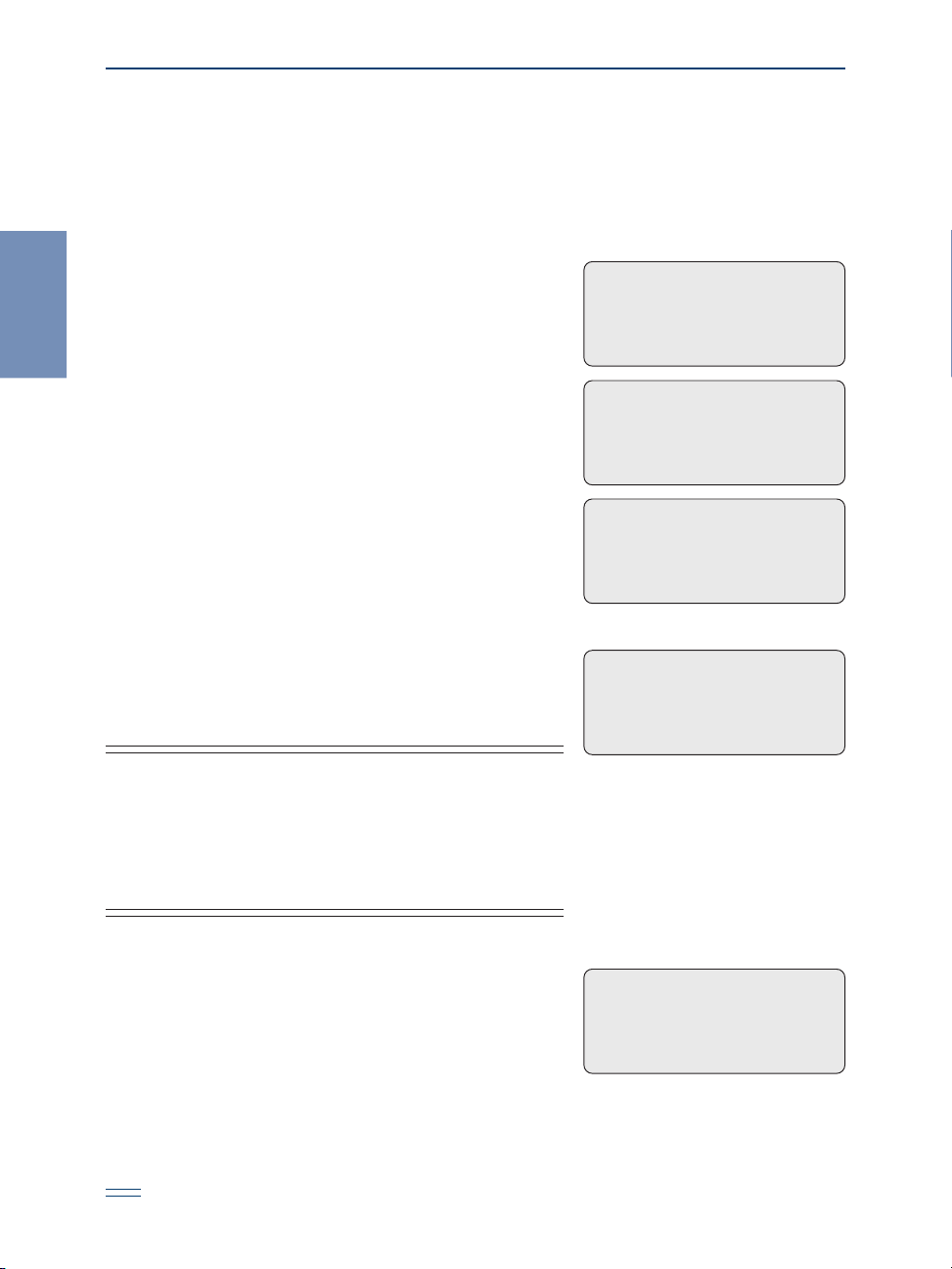

PCA Delivery Mode

Power source status†

*** PCA 6210X ***

Battery Low RUNNING

Res Vol 50.0 ml

Press NEXT to advance

Delivery mode

“RUNNING” if the pump is running

“DOSING” if a Demand Dose is in progress

“STOPPED” if the pump is stopped

Continuous Delivery Mode

“RUNNING” if the pump is running

*** CONTIN 6220X ***

Battery Low RUNNING

Res Vol 50.0 ml

Press NEXT to advance

TPN Delivery Mode

*** TPN 6230X ***

Battery Low RUNNING ¤

Res Vol 50.0 ml

Press NEXT to advance

“STOPPED” if the pump is stopped

The current Reservoir Volume

Reminder that the NEXT key advances to

programming screens

“RUNNING ¤” if delivery is tapering up

“RUNNING ≥” if delivering at the plateau rate

“RUNNING ™” if delivery is tapering down

“RUNNING K” if delivering the KVO

“RUNNING I” if immediately tapering down

“STOPPED” if the pump is stopped

Intermittent Delivery Mode

*** INTERMT 6240X ***

Battery Low DOSING

Res Vol 50.0 ml

Press NEXT to advance

† The Power Source Status will only display when the 9 volt battery is low, unless the

pump has been customized to always show the type of power source in use. (See

Biomed Toolbox, Section 5.)

8

“DOSING” if a dose is in progress

“KVO” if the KVO rate is in progress

“KVO=0” if the pump is running but no KVO is

programmed

“STOPPED” if the pump is stopped

“DELAY” if the dose is delayed by Next Dose

Start Time (KVO is delivering)

Section 1: General Description

Getting Help Using the

For more information about a screen or message on the pump’s display, press

the

display. They may also explain why a screen or message appeared and what to

do next.

key to view help screens. Help screens describe what you see on the

Å

Å

Key

Description

General

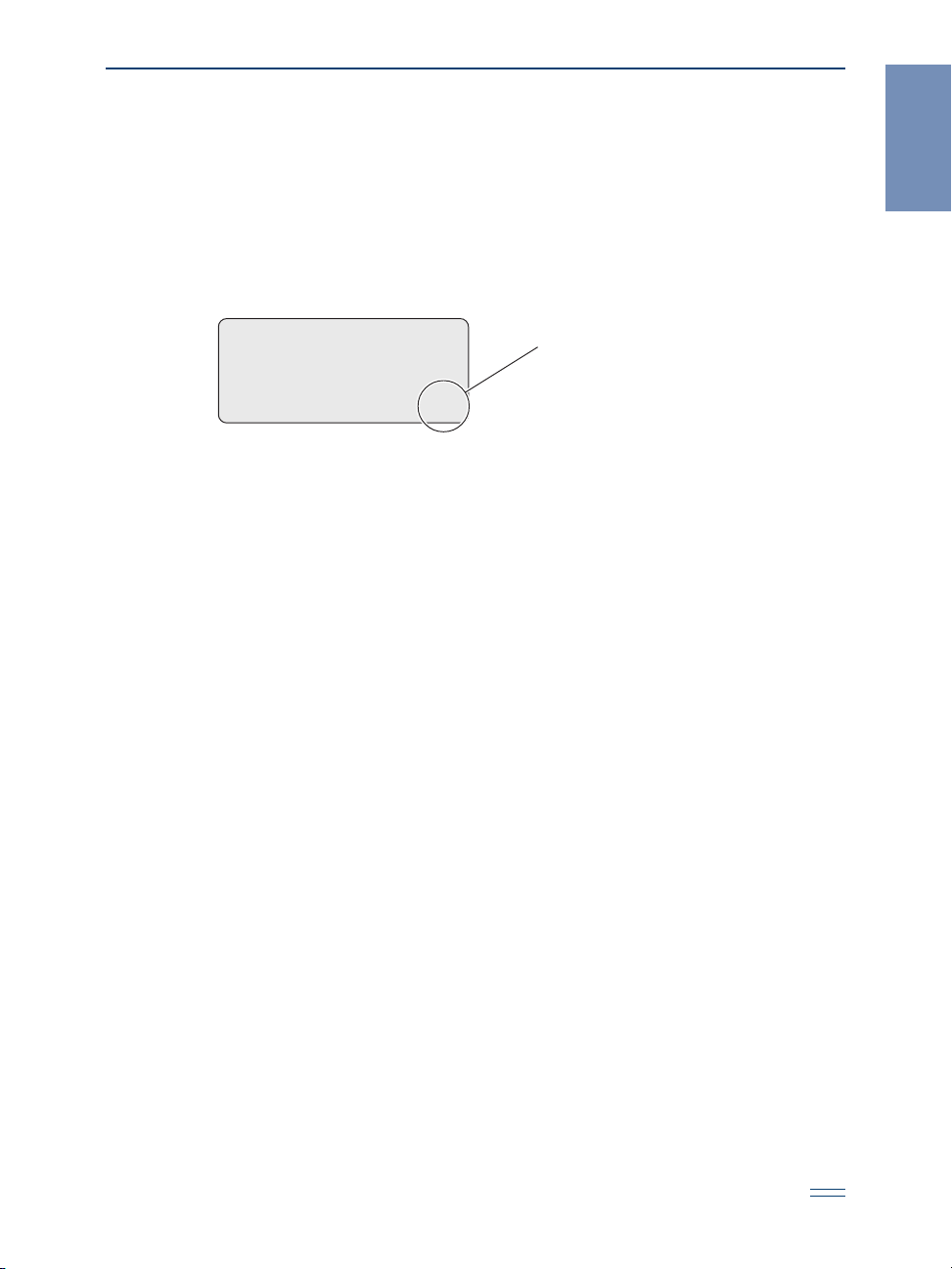

This is the

calculated amount of

fluid left in the

reservoir. ?≥

• To page through all the help screens, press

original screen will reappear when no further help is available.

• To exit help, press any key (other than the

bring you back to the original screen.

• If a help screen tells you to press a certain key, first exit help, then

press that key.

Help screens are lock level dependent. If the pump’s current lock level prevents

access to a certain function, the function will not be described in the help

screens.

This symbol in the lower right

corner means there are additional

help screens. Press the

again to see the next help screen.

repeatedly. The

Å

key). This will

Å

Å

key

9

Section 1: General Description

Lock Levels

General

Description

Lock levels are used to limit patient access to certain programming and operating functions. The table on the next page lists the functions that are accessible

in Lock Level 0 (LL0), Lock Level 1 (LL1), and Lock Level 2 (LL2). When a

function is accessible, the key associated with the function beeps when pressed.

If a function is not accessible, the pump ignores the key press and a beep does

not sound. Section 2, Pump Setup and Programming, describes how to change

the lock level.

AutoLock

AutoLock is one of the Options. This feature automatically changes the lock

level from LL0 to LL1 or LL2 when the pump is started (instead of requiring

you to manually change the lock level before giving the pump to the patient).

See Section 4 for more information on using AutoLock.

Security Codes

The following security codes are preset by the manufacturer for the clinician’s

use:

• The Lock Level Code, 061 (the first two digits of the pump’s model

number), allows you to change the pump’s lock level.

• The Access Code, 071 (Lock Level Code + 10), allows you to

change the delivery mode and access Communications.

• The Clinician Bolus Code, 997, allows you to deliver a ClinicianActivated bolus.

• The Biomed Toolbox Code, 161 (Lock Level Code + 100), allows

access to the Biomed Toolbox settings.

WARNING: Do not disclose to the patient the pump’s security codes or any

other information that would allow the patient complete access to all programming and operating functions. Improper programming could result in death or

serious injury to the patient.

Customizing the Security Codes

If it becomes necessary to change the Lock Level Code, Access Code, and

Biomed Toolbox Code to ensure that a patient will be unable to access these

features, you may customize the Lock Level Code in the Biomed Toolbox. (See

Section 5.) Customizing the Lock Level Code will not affect the Clinician Bolus

Code.

10

Section 1: General Description

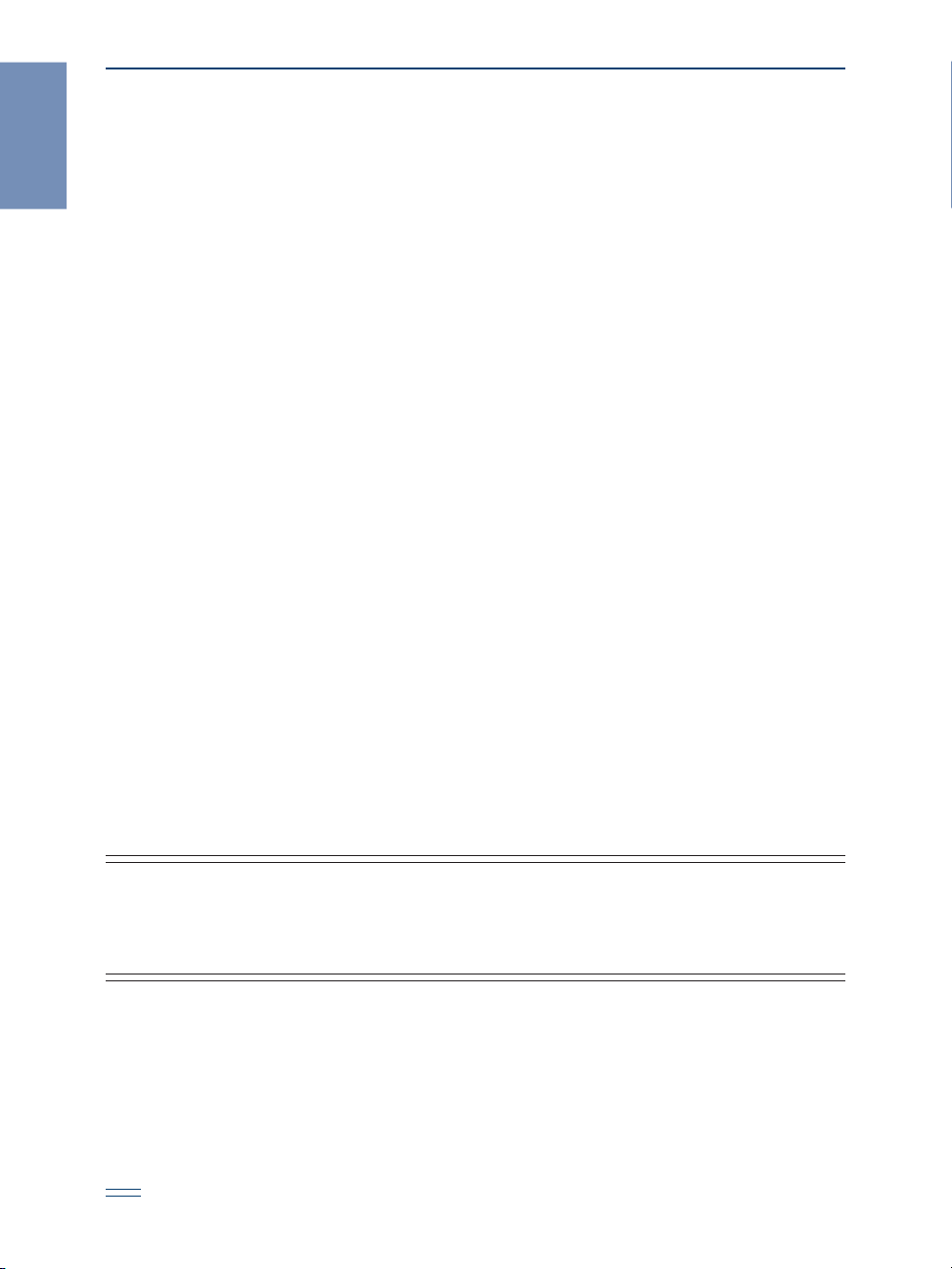

Lock Level Table

This table shows the features that can be accessed in each lock level. LL0

permits complete access to all programming and operating features. LL1

permits limited programming and access, and LL2 permits only minimal access.

Description

General

Pump Operations

and Programming LL0 LL1 LL2

Stop/Start the pump Yes Yes Yes

View Help screens Yes Yes Yes

Print Yes Yes Yes

Reset Reservoir Volume Yes Yes Yes

Reset Infusion Profile (TPN) Yes Yes Yes

Change the lock level Yes, w/code Yes, w/code Yes, w/code

Change the program Yes Within LL0 Limits†

Change Next Dose Start Yes

Time (INTERMT)

Clear Given amount Yes Yes

Clear Dose Counters (PCA) Yes Yes

Options

Immediate Taper-Down Yes, Yes, Yes, not

(TPN) programmable programmable programmable

Prime Yes Yes

Time Remaining, view (INTERMT) Yes Yes Yes

Extended History, view (PCA) Yes Yes Yes

Change Delivery Modes Yes, w/code

AutoLock Yes View only View only

Time Yes View only View only

Date Yes View only View only

Air Detector On/Off Yes View only View Only

Event Log, view Yes Yes Yes

Biomed Toolbox Yes, w/code

Stopped

No

No No

No

No

No

No No

No No

† In PCA and CONTIN delivery modes

11

General

Description

Section 1: General Description

12

Section 2: Pump Setup and Programming

Section 2: Pump Setup and Programming

Installing a Battery

Use a new, 9 volt alkaline or lithium battery such as the DURACELL® Alkaline

MN 1604, the EVEREADY® ENERGIZER® Alkaline #522 or the

ULTRALIFE® Lithium U9VL battery. The pump retains all programmed values

while the battery is removed. If the pump is running, you may connect an

external power source to keep the pump running for 3 minutes while you

change the battery.

Dispose of used batteries in an environmentally safe manner, and according to

any regulations which may apply.

WARNING:

• Do not use rechargeable NiCad or nickel metal hydride (NiMH) batteries.

Do not use carbon zinc (“heavy duty”) batteries. They do not provide

sufficient power for the pump to operate properly, which could result in

death or serious injury to the patient.

• Always have new batteries available for replacement. If power is lost, nondelivery of drug will occur and, depending on the type of drug being administered, could result in death or serious injury to the patient.

• There is no pump alarm to alert users that a battery has not been properly

installed or has become dislodged. An improperly installed or dislodged

battery could result in loss of power and non-delivery of drug and, depending on the type of drug being administered, could result in death or serious

injury to the patient.

Programming

Setup &

• If the pump is dropped or hit against a hard surface, the battery door may

become broken or damaged. DO NOT USE the pump if it has been damaged in this way because the battery will not be properly secured; this may

result in loss of power, non-delivery of drug, and, depending on the type of

drug being administered, death or serious injury.

13

Section 2: Pump Setup and Programming

Ope

t

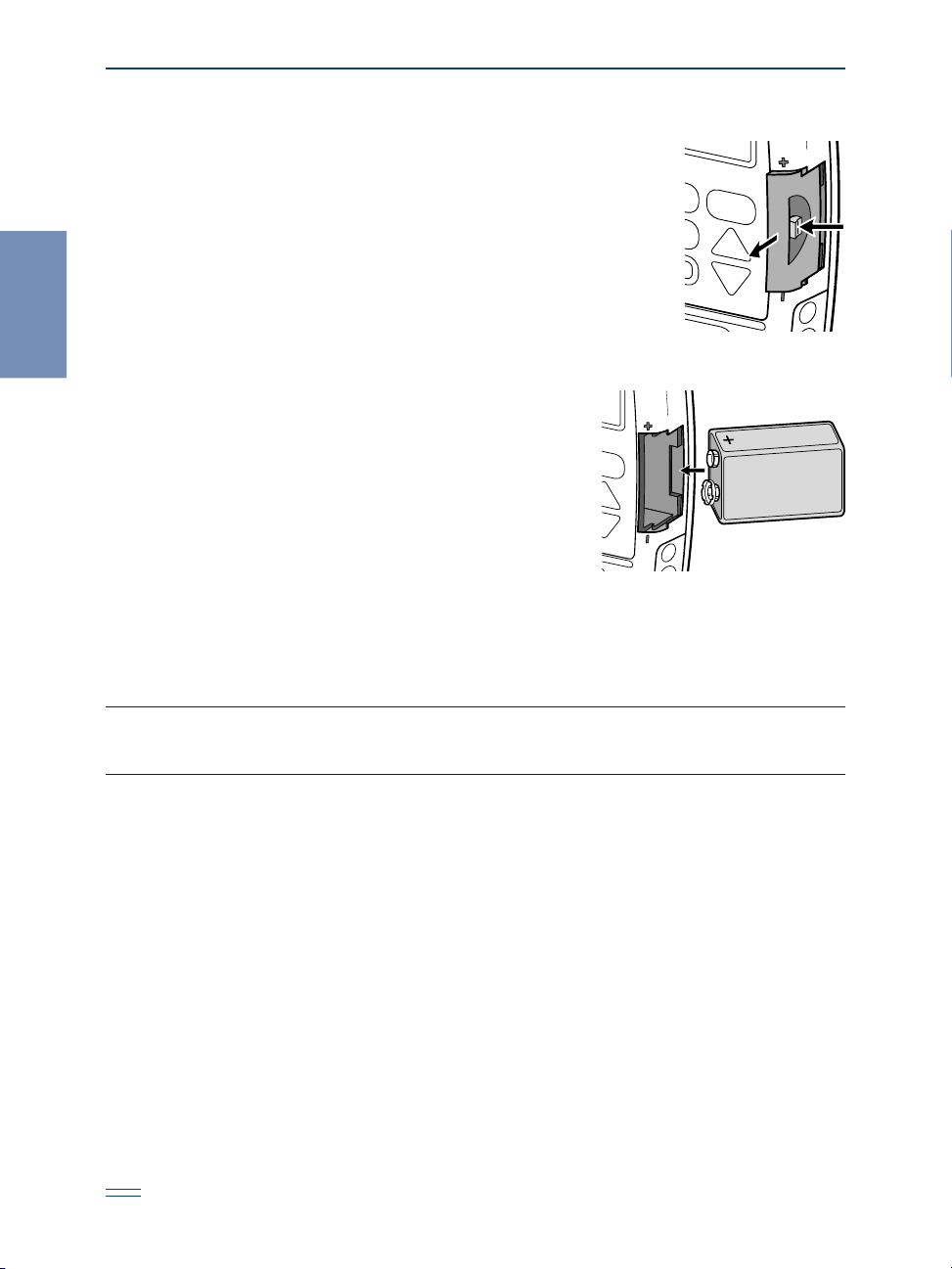

To install a battery

Setup &

Programming

1. Make sure the pump is stopped. Press the

button on the battery door and slide the battery

door forward. Remove the used battery.

2. Match the + and - markings on the

new battery with the markings on the

pump. Insert the battery. The pump

will beep if the battery is inserted

correctly.

3. Replace the battery door.

NOTE: If you put the battery in

backwards, the display will remain

blank. Reinsert the battery, making

sure to match the + and - markings.

/Button»

atch

ery»

CAUTION: Do not store the pump for prolonged periods with the battery

installed. Battery leakage could damage the pump.

NOTE:

• Battery life is dependent on the amount of medication delivered,

delivery rate, battery age, temperature, frequent screen display and

backlighting and frequent printing.

• The power of the battery will be quickly depleted at temperatures

below +10˚C (50˚F).

14

Section 2: Pump Setup and Programming

Watching Power Up

When you install a battery, the pump will start its power up sequence during

which it performs self-tests and displays programmed values. Watch for the

following:

• Pump model number, last error code (“lec”), if any, and serial

number (“sn”) will appear.

• The delivery modes contained in the pump and its software version

will appear. Make sure the desired delivery modes are displayed.

• The display will turn completely on. Look for any stripes, which

would indicate a faulty display.

• If no Air Detector is attached, “No Air Detector attached” will

appear. The pump’s program screens will appear, followed by

screens showing the lock level setting. AutoLock setting (if in use),

Air Detector status (if an Air Detector is attached), time, and date.

You may need to confirm certain settings before power up will

continue. If messages appear, see the Alarms and Messages Table in

Section 6 for further explanation and instructions.

Programming

Setup &

NOTE:

• When power up is complete, “Power Up Successful” will appear, six

beeps will sound, and the pump will be stopped.

• Make sure the pump is in the desired delivery mode. If not, change

the delivery mode before programming (Section 4, Options).

• When the pump is powered up in Lock Level 0 with an Air Detector

attached, the pump will automatically turn on the Air Detector (the

Air Detector setting in Options will change to “Turned On.”)

• To move quickly through the power up screens, press

edly. To skip the automatic review entirely, press Î.

„

repeat-

15

Section 2: Pump Setup and Programming

Changing the Lock Level

Before programming the pump, make sure the lock level is LL0. LL0 allows the

clinician to access all programming and operating functions.

Setup &

Programming

To change the lock level

1. Make sure the pump is stopped.

Press

appear. (If the pump is already in the

desired lock level, press

. The current lock level will

Œ

„

to exit.)

Lock Level

| LL2

or

2. Press

3. Press

4. Press

WARNING: Do not disclose to the patient the

pump’s security codes or any other information

that would allow the patient complete access to

all programming or operating functions. Improper programming of the pump could result in

death or serious injury to the patient.

5. Press

´

level appears.

Œ

NOTE: If <Custom> appears on the

screen, the Lock Level Code has been

customized. Enter the custom Lock

Level Code in the next step.

´

Code “061” (or the custom code)

appears.

Œ

Watch the display to verify that the

correct lock level is being entered. If

you do not see this message, the lock

level has not changed. Repeat the

above steps.

until the desired lock

Î

again. “000” will appear.

or

until the Lock Level

Î

to set the new lock level.

Lock Level

LL0

Lock Level Code

000

Lock Level Code

061

Lock Level

LL0

<Changing...>

NOTE: To check the lock level, press

To return to the screen you were on, press

16

Œ

. The current lock level will appear.

.

„

Section 2: Pump Setup and Programming

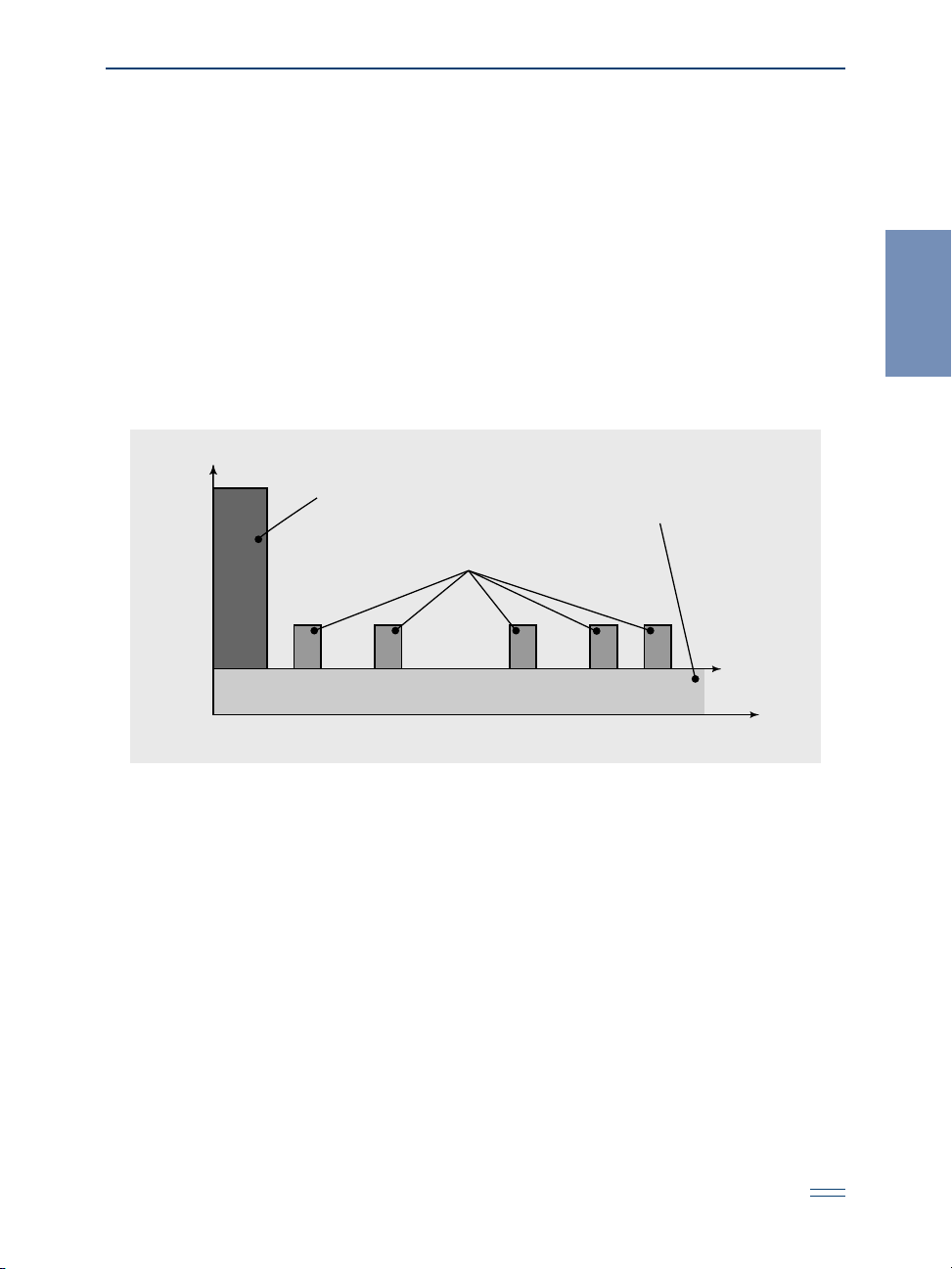

PCA Delivery Method

The PCA delivery method provides the following methods of delivery:

• Continuous Rate

• Demand Dose, activated by the patient

• Clinician Bolus, a dose activated by the clinician.

You may program each of the methods individually or in combination with

each other. The following graph illustrates the combined delivery methods.

Ranges and programming increments are listed in the Specifications in Section 6.

Clinician Bolus

(used here as a

loading dose)

Demand Doses

Dosage

Continuous Rate

Programming

Setup &

Time

17

Section 2: Pump Setup and Programming

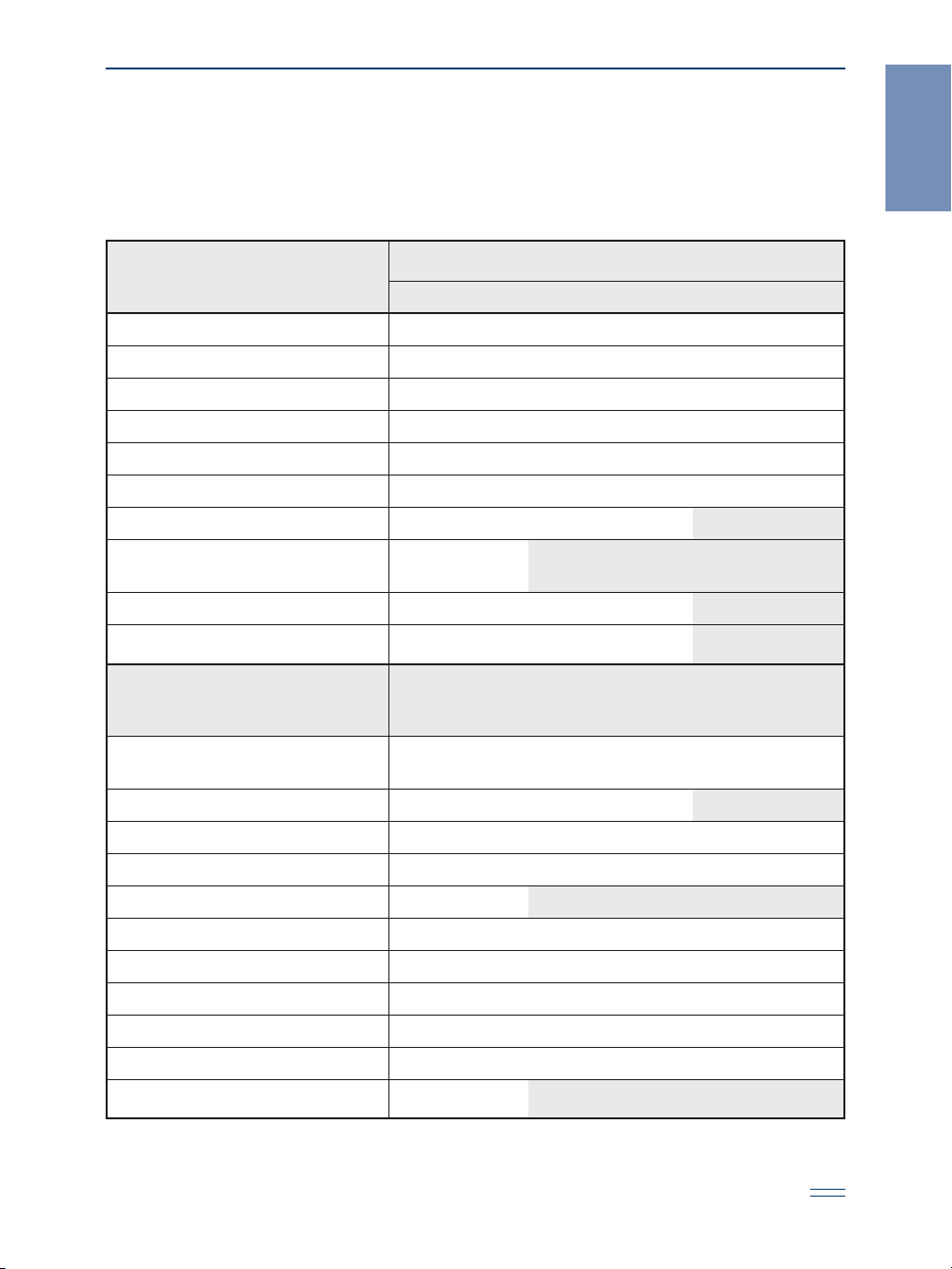

PCA Programming Screens

These are the programming screens for the PCA delivery method. Descriptions

of the screens follow.

Setup &

Programming

PCA Main Screen

Reservoir Volume

Units

*** PCA 6210X ***

STOPPED

Press NEXT to advance

Reservoir Volume

| 100.0 ml

<Range: 1 - 9999>

Units

| Milligrams

<Range: mg or ml>

Concentration

(ml, mg or mcg)

Continuous Rate

Demand Dose

Demand Dose Lockout

Concentration

| 1.0 mg/ml

<Range: 0.1 - 100>

Continuous Rate

| 5.00 mg/hr

<Range: 0 - 30.00>

Demand Dose

| 2.50 mg

<Range: 0 - 9.90>

Demand Dose Lockout

| 15 Min

<Range: 5 min-24 hr>

18

Max. Doses per Hour

Dose Counters

(Units) Given

Air Detector (review)

Section 2: Pump Setup and Programming

Max Doses Per Hour

| 2

<Range: 1 - 4>

Dose Counters

Given/Attempt: 0/ 0

since 06/08/05 10:35

Press ENTER to clear

Milligrams Given

0.00 mg

since 06/08/05 10:35

Press ENTER to clear

Air Detector

Required

<Review Only>

Programming

Setup &

To insert New Patient

New Patient Marker (optional)

Marker and clear

Extended History press

ENTER

Reservoir Volume

Enter the volume of fluid contained in a filled fluid container. The Reservoir

Volume value decreases as the pump delivers fluid or you use the priming

feature. When you change the fluid container and reset the Reservoir Volume,

the value resets to the value entered on this screen. If you do not wish to use

the Reservoir Volume feature, scroll down to “Not In Use” (located before 1

and after 9999 in the range of values).

Units

Enter the programming units. Possible settings are milliliters and milligrams.

Micrograms will also be one of the choices if the Micrograms settings in the

Biomed Toolbox is “On.” When you change the Units, the pump requires you

19

Section 2: Pump Setup and Programming

to enter or verify the Continuous Rate and Demand Dose. If the units are mg

or mcg, you must also enter the Concentration. Changing the Units clears the

amount Given and the Extended History.

Concentration

If Units are mg or mcg, enter the concentration of drug in mg/ml or mcg/ml.

When you enter a new Concentration, the pump requires you to enter a new

Setup &

Continuous Rate and Demand Dose.

Programming

Continuous Rate

Enter the continuous rate of medication delivery (in mg/hr, ml/hr, or mcg/hr,

depending on the Units). The maximum rate is 30 ml/hr or the mg or mcg

equivalent. If the prescription does not call for a Continuous Rate, enter zero.

NOTE: If you intend to run the pump in Lock Level 1 so the Continuous Rate

can be varied, you should enter the maximum allowable rate while programming in Lock Level 0. After programming, you may then change to Lock Level

1 and decrease the rate to its starting value. See Programming with Upper

Limits, Adjusting Doses in LL1 at the end of this section

Demand Dose

Enter the amount of drug to be delivered when the patient presses the

(or the Remote Dose Cord button, if attached). If the prescription does not call

for a Demand Dose, enter zero.

NOTE: If you intend to run the pump in Lock Level 1 so the Demand Dose

can be varied, you should enter the maximum allowable dose while programming in Lock Level 0. After programming, you may then change to Lock Level

1 and decrease the dose to its starting value. See Programming with Upper

Limits, Adjusting Doses in LL1 at the end of this section.

Í

key

Demand Dose Lockout

If you programmed a Demand Dose, enter the minimum amount of time that

must elapse between the time one Demand Dose starts and the time the next

Demand Dose starts. This lockout period is unaffected by removal of the

battery or stopping of the pump.

20

Loading...

Loading...