Page 1

R

ELECTRIC

CONVECTION

OVENS

OV-250

OV-250

(XAOO6 “Mini Roberta”)

(XAOO6 “M

OV-350

OV-350

(XA015 “Mini Arianna

w / finishing control”)

OV-400

OV-400

INSTRUCTION MANUAL

This booklet contains important

information about your CadcoUnox Convection Oven. Keep it in

a safe place.

ENGLISH

For Information

on the Cadco Oven by UNOX

Contact:

(XA030 ”Arianna”)

OV-500

OV-500

(XA085 “Elena”)

OV-600

OV-600

(XA090 “Rossella”)

202281

CADCO, LTD.

145 Colebrook River Road,

Winsted, CT 06098

Phone: 860-738-2500

Fax: 860-738-9772

E-mail: info@cadco-ltd.com

07 /

2003

OVENS PLANET

Page 2

ENGLISH

INDEX:

I. Instructions for the Installer Page 3

1. Data Plate Page 3

2. Certifications Page 3

3. Installation -Preliminary

operations Page 3

3.1 Feet Assembly Page 3

3.2 Installation Location Page 4

3.3 Remove Protective

Film Page 4

4. Installation Page 4

4.1 Electrical Connection Page 4

4.2 Water Connection

(OV-500 & OV-600 only) Page 5

4.3 Maintenance Page 5

II. Instructions for the User Page 6

WELCOME TO CADCO!

We want you to have immediate success with your new

Cadco-Unox Convection Oven.

These state of the art convection ovens are manufactured for Cadco by Unox SPA of Padua, Italy, to the highest standards. By following the guidelines and reading

the tips contained in this instruction manual you will be

convection cooking like an ol’ pro in no time. Cadco will

help you find the perfect oven for your needs, and provide

customer support after the purchase.

The Cadco website, at www.cadco-ltd.com, provides a

wealth of information relating to service and food issues.

All our Cadco staff e-mail addresses will be listed on the

website.

The Cadco toll free number gives you access to our on

staff Certified Executive Chef. Most calls are answered

within 24 hours. To reach any of the Cadco professionals

call 877.603.7393.

1. “Burn In” Oven Before First Use Page 6

2. Features and controls Page 6

2.1 Preheat Indicator Light Page 6

2.2 Temperature Control Page 6

2.3 Timer Dial Page 6

3. Special Cadco-Unox Oven

Features Page 6

3.1 “End Of Cycle” Alarm Tone Page 6

3.2 Interior Light Page 6

3.3 Finishing Feature

(only OV-350) Page 6

4. Cleaning & Maintenance Page 7

5. Door Removal Instructions Page 8

6. Troubleshooting Page 8

III. Convection Cooking Page 9

1. Cooking Principles Page 9

2. Cooking Page 9

3. Times and Temperatures Page 10

IV. Technical Data: Electrical

Schematics, Drawings Page 12

1. XA006 - OV250 Page 12

2. XA015 - OV350 Page 13

3. XA030 - OV400 Page 14

4. XA085 - OV500 Page 15

5. XA090 - OV600 Page 16

2

ENGLISH

Page 3

ENGLISH

I. INSTRUCTIONS FOR

THE INSTALLER

Dear customer, we thank you and compliment you for having purchased one of our

products.

The warnings and suggestions that follow

concern the phases for proper installation,

use and maintenance for your safety and for

the best use of the appliance.

1. DATA PLATE

The data plate is positioned on the right side

panel.

The technical characteristics are identified in

the enclosed page “technical data”.

2. CERTIFICATIONS

CSA C-US BRAND

SERIE XA

Certificate of Compliance

N.202281-1008284

Applicable Requirements:

CAN/CSA-C22.2 No. 100-1995 - Motors and

Generators.

CSA Std C22.2 No. 109-M1981 – Commercial

Cooking Appliances.

UL Std No. 197 - Commercial Electric Cooking

Appliances.

UL Std No. 1004 - Electric Motors

“ The “C” and “US” indicator adjacent to the

CSA Mark signifies that the product has been

evaluated to the applicable ANSI/UL and

CSA Standards, for use in the U.S. and

Canada. This includes products eligible to

bear the NRTL indicator. NRTL, i.e. Nationally

Recognized Testing Laboratory, is a designation granted by the U.S. Occupational Safety

and Health Administration (OSHA) to laboratories which have been recognized to perform certification to U.S. Standards.

NSF BRAND

SERIE XA

Certificate N. 79610/79610B

N. 79610/79611/B

NSF International recognizes UNOX SPA

products as complying with ANSI/NSF 04.

Standard 004 - Commercial Cooking,

Rethermalization and Powered Hot Food.

3. INST

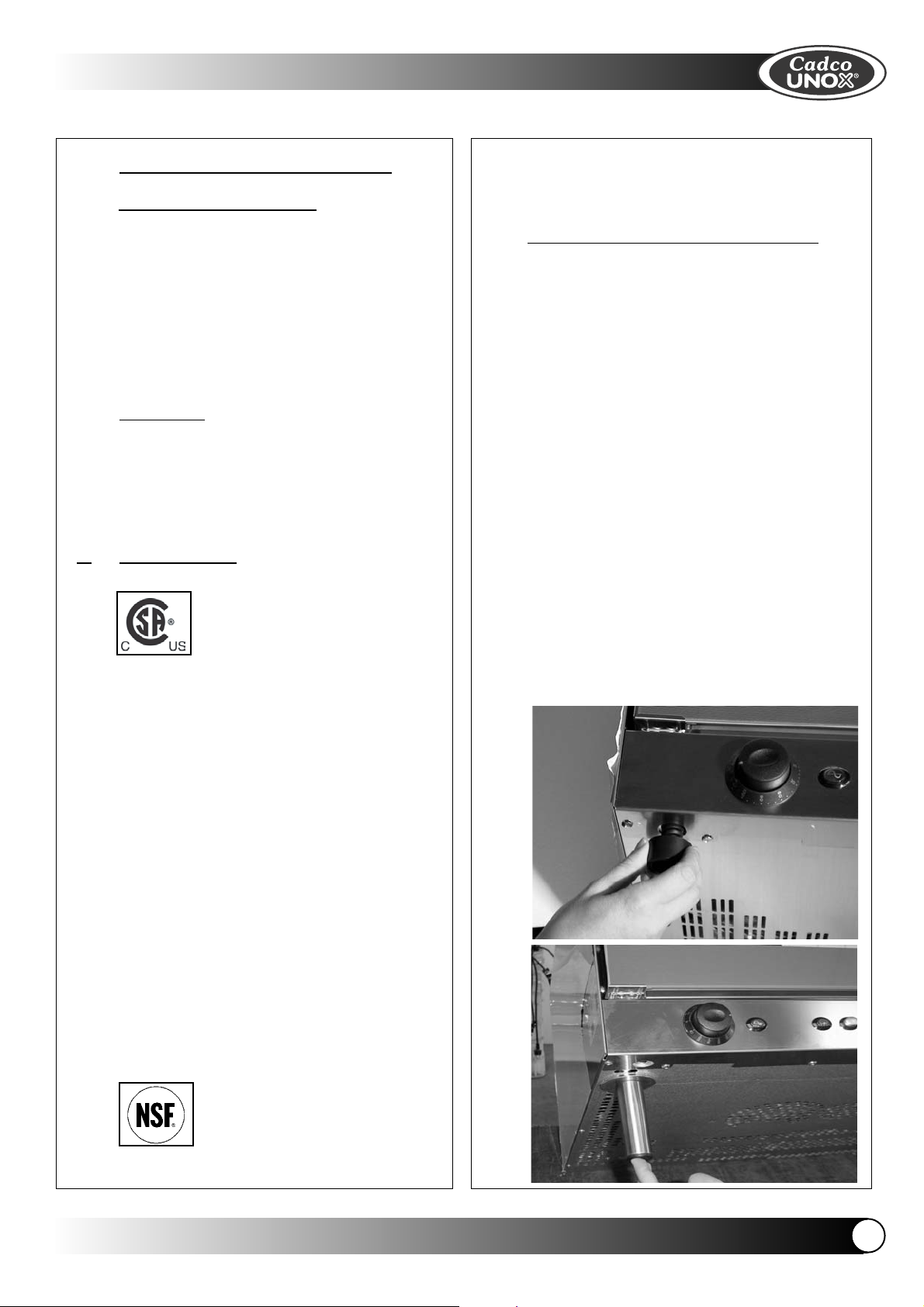

3.1 FEET ASSEMBLY (If applicable)

NOTE - DO NOT USE YOUR OVEN

ALLATION – Preliminary Operations

All the electrical connections and installations

must be done by qualified personnel in compliance with all local codes.

The Cadco-Unox models OV-250 and OV350 are shipped with feet installed. Some

other model ovens are shipped without the

feet being installed, and must be assembled.

If your convection oven has feet, do not install

or use the oven without them. The feet are

shipped in the cooking cavity and must be

assembled.

Screw the support feet into the bottom of the

oven as shown in the illustration. After

assembling the feet, the oven’s height may

be adjusted by screwing or unscrewing the

feet to level the unit.

The models OV-500 and OV-600 require

washers when the feet are assembled.

WITHOUT INSTALLING THE FEET.

ENGLISH

3

Page 4

ENGLISH

208-240V

3.2 INSTALLATION LOCATION

Make sure you have the correct power supply for the oven model you have purchased.

Check the technical data sheets at the back

of this manual if you are in doubt.

Do not install any Cadco-Unox Convection

Oven directly on the floor. Cadco has oven

stands to perfectly elevate your oven as well

as provide pan storage.

OST-34A for models OV-350 and OV-400

OST-56A for models OV-500 and OV-600

If the oven must be placed near walls,

dividers, or moldings Cadco recommends

they be made of non-combustible materials.

Be sure to observe all safety and fire codes

when positioning your convection oven.

All of our convection ovens have a vapor vent

in the back of the unit. When installing your

convection oven, leave a space of 4” [minimum] between the back of the oven and the

wall, and 2” minimum on the top and sides.

Where applicable, ventilation hood requirements vary according to local codes.

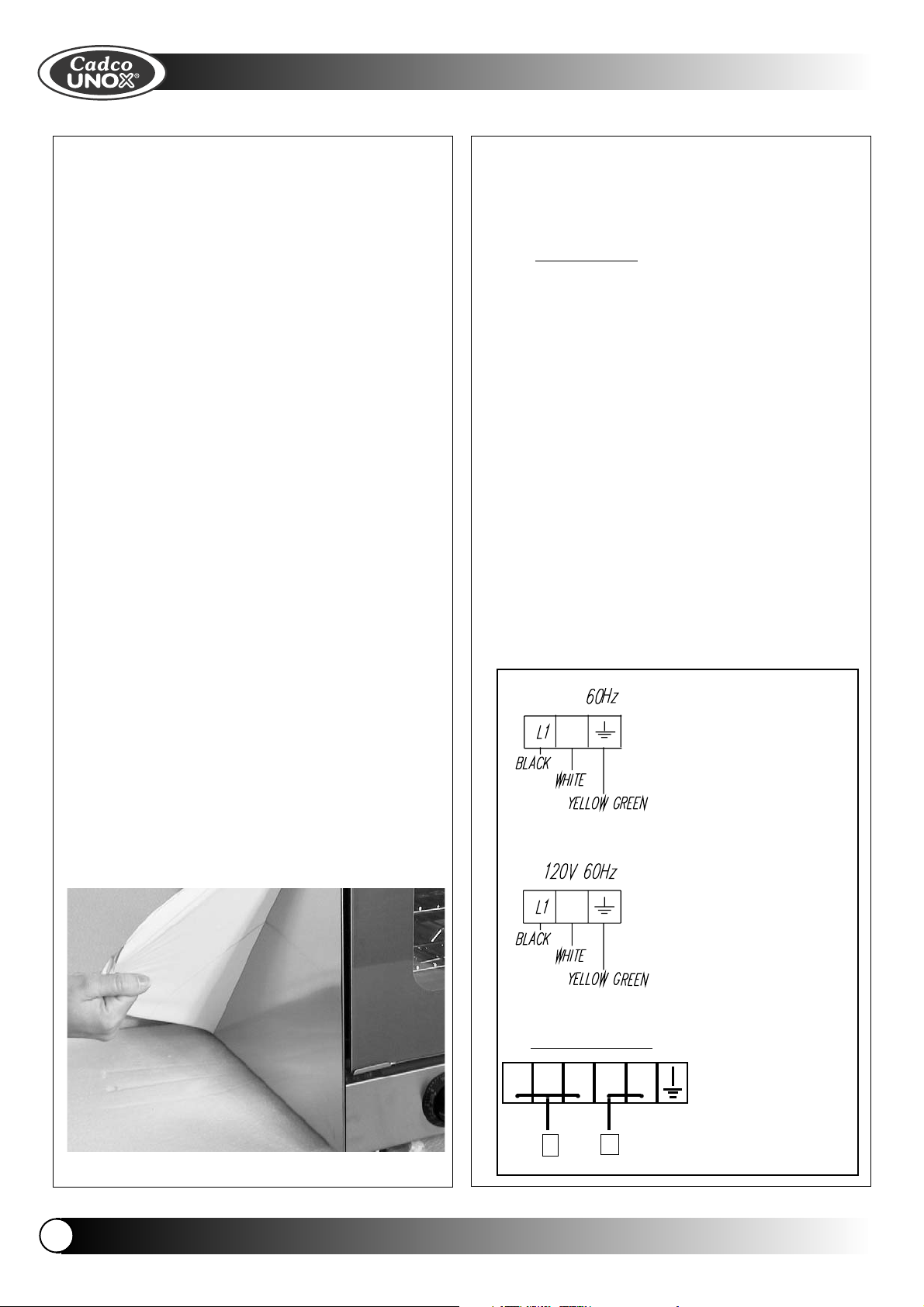

exterior walls before you begin cooking food

in your new Cadco convection oven. Most

solvents or degreasers will remove any

residue.

4. INSTALLATION

4.1 ELECTRICAL CONNECTION

The connection to the electrical power supply

network must be done according to the standards in force.

Before connecting make sure that the voltage

and the frequency correspond to that stated

on the data plate on the oven.

Place a bi-polar switch between the oven

and the network accessible after installation,

whose contacts have a minimum opening

distance of 0.1 inches, with an appropriate

input (for example, magnetothermal switch).

When the oven is in operation, the power

supply voltage must not vary from the value

of the nominal voltage by more than ± 10%.

The oven must be connected to the

ground line of the network.

We do not suggest using the Cadco-Unox

Convection Ovens for built in applications.

Measure to make sure that your new oven

will fit in your available space.

3.3 REMOVE THE PROTECTIVE FILM

Be sure to remove the laser film from the

L2

L2

208 - 240V

220-230 V ~

21 3 54

L L

XA030/OV-400

XA085/OV-500

XA006/OV-250

XA015/OV-350

XA090/OV-600

Use only AWG10 cords

4

ENGLISH

Page 5

ENGLISH

WARNING:

Connect the electrical cable to the terminalboard as indicated in the drawing: insert

screw-wise the copper bridge and the electrical cable together under the screw (see

diagram below.)

Tighten the screw taking care that the cable

and the copper bridge are well gripped

under the screw.

A wrong connection can cause an overheating of the terminal board and burn it.

(7.25 – 30 psi.) Due to variations in water

composition in different areas, you may want

to consider using a commercial water filter.

MAX 2 bar

(30 psi)

4.3 MAINTENANCE

Before carrying out any type of maintenance

it is necessary to disconnect the electrical

power supply and wait for the oven to cool

down.

OV-600 ONLY

Electrical connection must be a proper outlet

for the 3 pronged cord. Before connecting

power, make sure the voltage and frequency

correspond to the data plate on the oven

(120 volts/60hz.), and that your electrical circuit can handle the12.5 amps used by the

oven in addition to any other appliances

operating on the same circuit.

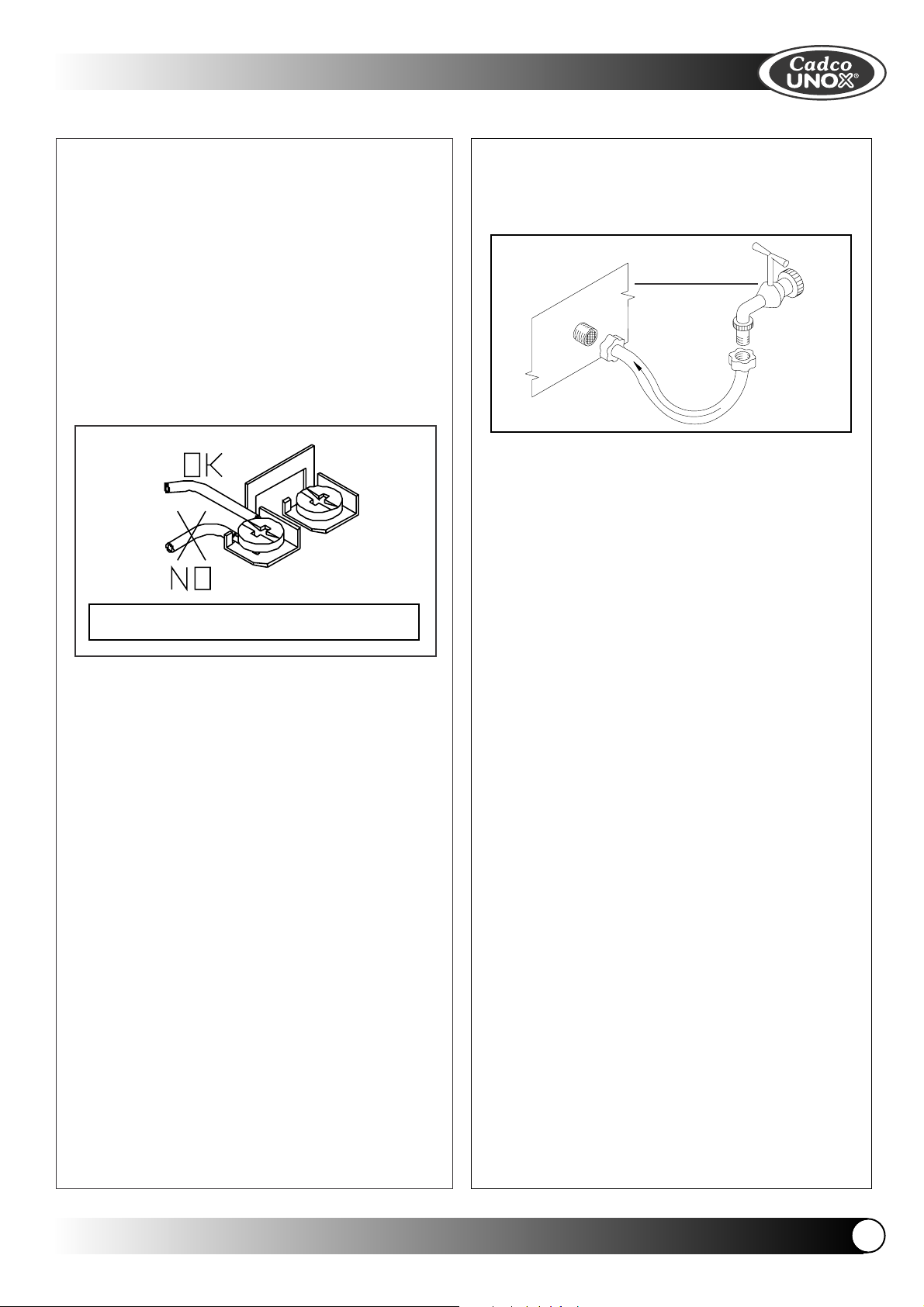

4.2 WATER CONNECTION - Applies only to OV-

500 and OV-600

WATER CONNECTION TO THE NETWORK:

Connect the decalcified water inlet ducts

placed on the back of the oven to the specific distribution network by means of a

mechanical filter and a cut-off cock. Before

connecting the filters, let a certain quantity of

water flow to clean the duct from any ferrous

slag. The water must have a hardness

between 0.5°-5°F (this in order to reduce the

formation of limestone deposits inside the

electro-valve and inside the cooking chamber) and a pressure value between 0.5-2 bar

ENGLISH

5

Page 6

ENGLISH

II. INSTRUCTIONS

FOR THE USER

1. “BURN IN” OVEN BEFORE FIRST USE

Before you start cooking with your new

Cadco-Unox Convection Oven you will want

to “burn in” the oven. This simple procedure

will get the new oven smell out of your oven

and off your food.

- Clean the oven with a mild detergent inside

and out.

- Turn the temperature control dial to 400F.

- Set the timer for 30 minutes and you’ll be

ready to start cooking at the end of the

cycle.

2. FEA

TURES AND CONTROLS

2.3 TIMER DIAL

Turning the timer

dial clockwise

allows you to set

the cooking time for

up to 120 minutes.

When the dial is

turned counterclockwise you are in manual

mode with infinite cooking time.

3. SPECIAL CADCO-UNOX OVEN FEATURES

3.1 “END OF CYCLE” ALARM TONE

All Cadco-Unox ovens indicate the end of the

cooking cycle with an alarm tone with the

exception of the models OV-250 and OV-350

2.1 PREHEAT INDICATOR LIGHT

The preheat indicator light

will be illuminated when

there is heat being added to

the cooking chamber. The

preheat indicator light will be

illuminated periodically throughout the cooking cycle as the oven controls call for more

heat.

2.2 TEMPERATURE

CONTROL

Cadco-Unox temperature controls

are extremely

accurate. The dial

will be turned

clockwise and

used to set your oven cooking temperature in

a range 175F to 500F degrees.

3.2 INTERIOR LIGHT

Models OV-250 and OV-350 do not have a

light in the cooking cavity.

3.3 FINISHING FEATURE - ONLY on Model OV-350

Model OV-350 has

a special top heating element to

enable either

browning or broiling functions. The

broiler/browning

function is activated by turning the

temperature control knob clockwise to its

most extreme right position. To activate the

broiler/browning feature, simply turn the

control dial beyond 500F to the furthest point.

You will feel a slight resistance as you turn the

dial. Beyond this resistance point the browning feature is activated. The browning/broiling feature should be used for no more than

45-60 minute cycles. It is not designed for

constant operation. Note: The oven fan

operates in browning/broiling mode.

6

ENGLISH

Page 7

ENGLISH

3.4 HUMIDITY FEATURE - ONLY on Models OV-500

and OV-600

Models OV-500 and OV-600

have a manual humidity

injection feature. The humidity

indicator light will illuminate

when the humidity feature is

being used. Pressing the silver humidity button introduces

a spritz of water to the cooking cavity creating a moist

cooking environment.

Warning!

To keep from damaging the motors, the

humidity injection button should only be

pressed for short [5-10 seconds] intermittent

periods.

4. CLEANING AND MAINTENANCE

WARNING:

Work safely, disconnect the oven and allow it

to cool before cleaning or maintenance.

Available On All Models)

To replace the internal lamp do as follows:

- Disconnect the oven from the power supply

and and let it cool.

- Take out the side rack supports.

- Unscrew the glass cover counterclockwise

and replace the lamp with one with the

same characteristics (240V-15W-300°C /

572°F).

- To reassemble, follow the reverse order.

4.1 CLEANING

The oven is not to be cleaned with pressurized water. You could damage the electrical

components and an unsafe condition could

occur.

Clean the cooking chamber with soap and

water. Never use harsh, caustic products or

acids.

The rack system is cleaned by removing the

retaining screws by the front of the cooking

chamber. The racks can then be easily

removed and washed.

4.2 REPLACEMENT OF THE INTERNAL LAMP (Not

ENGLISH

7

Page 8

5. OVEN DOOR REMOVAL

ENGLISH

Side of

Oven

Bottom

Hook

(To attach the door, reverse the directions,starting with Step 3)

Convection Oven Door Removal Instructions

Side of

Oven

open flat)

Open the door fully.

Door (fully opened; does not

Step 2

(side view)

Rotate the Hinge Lock

to up position.

Hinge Lock- must be in

up/locked position)

Side of

Oven

To p

Bottom

Hook

Top Hook Roller

Hinge Lock- in

up/locked position)

Step 1

(side view)

Hinge lock - in “down/unlocked”

position

Step 3

(side view)

)

2

(

Hinge Arm

(1)

1) Tilt door up at about 45oangle until the Top Hook

on the Hinge Arm is lower than the Top Hook Roller,

2) then pull out of the Hinge Slots.

PLEASE NOTE: Hinge Locks may become jostled into the unlocked position by rough handling of the carton during shipping,

causing the door to be unhinged from the oven when the carton is opened. If this occurs, follow the directions for attaching the door.

6. TROUBLESHOOTING

1

2

ice on your oven.

Your Cadco-Unox Convection Oven has an

automatic high temperature breaker that

protects the oven from overheating or power

fluctuations.

If your oven shuts down when you are operating at high temperatures, the following

steps will allow you to reset the breaker and

resume safe operation.

REMOVE/REPLACE BLACK CAP PUSH THE RESET

BUTTON

- Unscrew the black reset knob safety cover

at the rear of the oven next to the power

cord.

Work safely, disconnect the power and allow

- Press the reset button to the “in” position.

the oven to cool before performing any serv-

8

ENGLISH

Page 9

ENGLISH

- Securely replace the black safety cover.

- Begin food preparation after the oven is

preheated.

If the thermal breaker shuts your oven off,

before turning your oven on, be sure to

check your entire circuit to verify that the

total amps being drawn by all the appliances, lights, etc. on that circuit do not

exceed the amps available on that circuit.

All repairs should be performed by a Cadco

authorized service technician using only genuine Cadco-Unox parts.

III. CONVECTION

COOKING

Your Cadco-Unox oven is designed to prepare food, and it should be used for that purpose only.

1. COOKING PRINCIPLES

Accurate times and temperatures assure

perfectly cooked foods. Cooking is an art, not

a science. People will never agree on the

meaning of “done”, or “perfectly cooked”.

Here are some tips that will help ensure success with your convection cooking.

temperatures.

- The oven operates between 175°F and

500°F.

Proper air circulation is necessary for successful convection cooking in all convection

ovens. We suggest you allow a proper clearance of 1-3 inches between pans when cooking for best results.

Never salt foods while they are in the oven.

Salt can damage the interior surfaces of your

oven and affect the efficiency of the electrical

components.

2. COOKING

Convection ovens work by moving the air

inside the cooking chamber to create even

heat throughout the oven. This circulating air

simply removes the [cool] insulating barrier of

air between the cold food and the hot air in

the cooking chamber allowing the food to

cook more quickly. In essence, the moving air

makes heat hotter, as wind chill makes cool

colder.

You will want to rely on an instant read, pocket probe while you are getting used to convection cooking. Your probe will help you

standardize times and temperatures as well

as assuring safe internal food temperatures

have been reached.

- The temperature of the food going into the

oven will affect the cooking time. Frozen

foods take longer to cook than refrigerated

foods.

- Three trays of chicken will take longer to

cook than three pieces of chicken.

- To convert your conventional oven recipes to

convection oven production simply reduce

the cooking temperature by 25F-30F

degrees.

- Most recipes can be converted by having

shorter cooking times and/or reducing your

cooking temperatures.

- We suggest that you use an instant read

probe to help you determine the actual

internal temperature of your foods. This will

help you safely determine correct times and

Preheat your oven to 30F-50F degrees higher than you the temperature you want to cook

at. After you have loaded the product into the

oven and the door is closed turn the temperature back to your intended cooking temperature.

Check cakes and cupcakes with a toothpick

to determine if they are done. If the toothpick

comes out “clean” [no batter on it] when

pushed into the center of the product, it’s

done!

We recommend roasting meats on a cooking

rack, in a shallow sided pan to allow air to

circulate all around the roast.

ENGLISH

9

Page 10

Salt pulls moisture out of meats. Season your

entire roast but only salt the fat portion.

3. TIMES AND TEMPERA

Products vary greatly. These times and temperatures may need minor modifications to

meet your particular standards. Use your

pocket probe to determine what’s right for

you.

- Rare roast beef – 130F

- Medium roast beef – 140F

- Medium well roast beef – 150F

- Well done roast beef – 160F

- Hamburger – 165F

- Pork – 160F - 170F

- Chicken – 185F done and no “red bone”.

- Fish/Seafood – 160F

TURES

ENGLISH

boneless fresh chicken breasts – 400F for 15

minutes.

- Fish sticks [frozen, browned] – 350F for

15/18 minutes.

- Shrimp [fresh 26-30 ct.] 350F for 10 minutes.

- Salmon fillet [6 oz. fresh] 325F for 12/15 min

utes.

- Potatoes [90 ct. baked] 375F for 45/60 minutes.

- Pizza [frozen 14”] 400F for 18 minutes.

- “Pocket” type sandwiches 350F for 18/20

minutes.

- Mozzarella sticks 350F for 10 minutes.

Here is a handy “Rule of Thumb” for roasting

meats at 325F

- Rare roast beef – 15/20 minutes per pound.

- Medium roast beef – 20/25 minutes per

pound.

- Well done roast beef – 30/35 minutes per

pound.

- Pork – 20/25 minutes per pound.

- Poultry – 20/25 minutes per pound.

- Ham [cured, not fresh] – 12/18 minutes per

pound. [Cured hams are already cooked so

all we have to do is heat them to 140F]

Here are some common products and their

approximate cooking times.

- Cookies 310F-325F for about 10-20 minutes,

depending on recipe and cookie size.

- Pies [10”] 350F for 45/60 minutes.

- Cakes [2-8” pans] – 325F for 25/30 minutes.

10

Check with a tooth pick.

- Pork roast [4lb.] - 325F for 1 hour 20 minutes.

- Hamburgers [1/4 lb. frozen] or 5 oz. skinless

ENGLISH

Page 11

ENGLISH

NOTES:

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

_________________________________________________________

ENGLISH

11

Page 12

R

UNOX S.p.A.

CADCO Ltd.

MINI ROBERTT

MINI ROBER

XA006

XA006

A MANUAL

ENGLISH TECHNICAL DATA

POWER - AMPERAGE kW 1,440 - 12A

FREQUENCY 60 Hz

POWER SUPPLY CABLE TYPE SJTOW

POWER SUPPLY CABLE EXTERNAL Ø 10 ÷ 16 mm

VOLTAGE / CABLE SECTION 120 V~ / AWG 14 x 3

A MANUAL

model: OV-250

03-2003

07-2003

ESPAÑOL DATOS TECNICOS

POTENCIA - AMPERES kW 1,440 - 12A

FRECUENCIA 60 Hz

TIPO CABLE DE ALIMENTACION SJTOW

Ø EXTERNO CABLE DE ALIMENTACION 10 ÷ 16 mm

TENSION / SECCION CABLE DE ALIMENT. 120 V~ / AWG 14 x 3

L1

L2

ENGLISH - LEGEND

DRAWINGS - ELECTRICAL SCHEMAS

1. TERMINAL BOARD

2. EQUIPOTENTIAL TERMINAL SITE

3. TECNICAL DATA PLATE

4. HOT SMOKE DISCHARGE

LM OVEN INTERNAL LAMP

MO TERMINAL BOARD

R HEATING ELEMENT

S PILOT LIGHT

SIC OVERRIDE THERMOSTAT

T TIMER

TE THERMOSTAT

V1 MOTOR FAN

NETWORK GROUND LINE

ESPAÑOL - LEYENDA

DISEÑOS - ESQUEMAS ELECTRICOS

1. CAJA CONEXIONES-REGLETA

2. SEDE BORNE EQUIPOTENCIAL

3. TARJETA CARACT. TECNICAS

4. DESCARGA HUMOS CALIENTES

LM LAMPARA HORNO

MO CAJA CONEXIONES-REGLETA

R RESISTENCIA

S PILOTO ESPIA

SIC TERMOSTATO DE SEGURIDAD

T TIMER

TE TERMOSTATO

V1 MOTO-VENTILADOR

LINEA DE TIERRA DE LA RED EL.

202281

UL Std N° 197 Commercial Electric

Cooking appliances.

UL Std. No. 1004 Electric Motors.

Page 13

UNOX S.p.A.

2

CADCO Ltd.

R

MINI ARIANNA MANUAL

MINI ARIANNA MANUAL

XA015

XA015

model: OV-350

03-2003

07-2003

ENGLISH TECHNICAL DATA

POWER - AMPERAGE kW 1,440 - 12A

FREQUENCY 60 Hz

POWER SUPPLY CABLE TYPE SJTOW

POWER SUPPLY CABLE EXTERNAL Ø 10 ÷ 16 mm

VOLTAGE / CABLE SECTION 120 V~ / AWG 14 x 3

ESPAÑOL DATOS TECNICOS

POTENCIA - AMPERES kW 1,440 - 12A

FRECUENCIA 60 Hz

TIPO CABLE DE ALIMENTACION SJTOW

Ø EXTERNO CABLE DE ALIMENTACION 10 ÷ 16 mm

TENSION / SECCION CABLE DE ALIMENT. 120 V~ / AWG 14 x 3

L

L1

ENGLISH - LEGEND

DRAWINGS - ELECTRICAL SCHEMAS

1. TERMINAL BOARD

2. EQUIPOTENTIAL TERMINAL SITE

3. TECNICAL DATA PLATE

4. HOT SMOKE DISCHARGE

LM OVEN INTERNAL LAMP

MO TERMINAL BOARD

R HEATING ELEMENT

S PILOT LIGHT

SIC OVERRIDE THERMOSTAT

T TIMER

TE THERMOSTAT

V1 MOTOR FAN

NETWORK GROUND LINE

ESPAÑOL - LEYENDA

DISEÑOS - ESQUEMAS ELECTRICOS

1. CAJA CONEXIONES-REGLETA

2. SEDE BORNE EQUIPOTENCIAL

3. TARJETA CARACT. TECNICAS

4. DESCARGA HUMOS CALIENTES

LM LAMPARA HORNO

MO CAJA CONEXIONES-REGLETA

R RESISTENCIA

S PILOTO ESPIA

SIC TERMOSTATO DE SEGURIDAD

T TIMER

TE TERMOSTATO

V1 MOTO-VENTILADOR

LINEA DE TIERRA DE LA RED EL.

202281

UL Std N° 197 Commercial Electric

Cooking appliances.

UL Std. No. 1004 Electric Motors.

Page 14

UNOX S.p.A.

2

208-240V

CADCO Ltd.

R

ARIANNA MANUAL

ARIANNA MANUAL

XA030

XA030

model: OV-400

03-2003

07-2003

ENGLISH TECHNICAL DATA

POWER - AMPERAGE kW 2,650 - 12A

FREQUENCY 60 Hz

POWER SUPPLY CABLE TYPE SJTOW

POWER SUPPLY CABLE EXTERNAL Ø 10 ÷ 16 mm

VOLTAGE / CABLE SECTION 220 V~ / AWG 14 x 3

- 1 Phase

208-240 V~ / AWG 14

ESPAÑOL DATOS TECNICOS

POTENCIA - AMPERES kW 2,650 - 12A

FRECUENCIA 60 Hz

TIPO CABLE DE ALIMENTACION SJTOW

Ø EXTERNO CABLE DE ALIMENTACION 10 ÷ 16 mm

TENSION / SECCION CABLE DE ALIMENT. 220 V~ / AWG 14 x 3

L

L1

- 1 Face

208-240 V~ / AWG 14

ENGLISH - LEGEND

DRAWINGS - ELECTRICAL SCHEMAS

1. TERMINAL BOARD

2. EQUIPOTENTIAL TERMINAL SITE

3. TECNICAL DATA PLATE

4. HOT SMOKE DISCHARGE

LM OVEN INTERNAL LAMP

MO TERMINAL BOARD

R HEATING ELEMENT

S PILOT LIGHT

SIC OVERRIDE THERMOSTAT

T TIMER

TE THERMOSTAT

V1 MOTOR FAN

NETWORK GROUND LINE

ESPAÑOL - LEYENDA

DISEÑOS - ESQUEMAS ELECTRICOS

1. CAJA CONEXIONES-REGLETA

2. SEDE BORNE EQUIPOTENCIAL

3. TARJETA CARACT. TECNICAS

4. DESCARGA HUMOS CALIENTES

LM LAMPARA HORNO

MO CAJA CONEXIONES-REGLETA

R RESISTENCIA

S PILOTO ESPIA

SIC TERMOSTATO DE SEGURIDAD

T TIMER

TE TERMOSTATO

V1 MOTO-VENTILADOR

LINEA DE TIERRA DE LA RED EL.

202281

UL Std N° 197 Commercial Electric

Cooking appliances.

UL Std. No. 1004 Electric Motors.

Page 15

UNOX S.p.A.

208-240 V~ / AWG 12

CADCO Ltd.

R

ELENA MANUAL

ELENA MANUAL

XA085

XA085

model: OV-500

03-2003

07-2003

ENGLISH TECHNICAL DATA

ELECTRICAL POWER kW 3,26

FREQUENCY 50 - 60 Hz

POWER SUPPLY CABLE TYPE SJTOW

POWER SUPPLY CABLE EXTERNAL Ø 10 ÷ 16 mm

VOLTAGE / CABLE SECTION 220 - 230 V~ /AWG12

WATER PRESSURE kPa 50 - 200

41

20

20

740

5

450 10

60 Hz 1 Phase

208-240 V~ / AWG 12

420

460

752

4

75

90

187

245

832

80

3

150

1

250

2

ESPAÑOL DATOS TECNICOS

POTENCIA kW 3,26

FRECUENCIA 50 - 60 Hz

TIPO CABLE DE ALIMENTACION SJTOW

Ø EXTERNO CABLE DE ALIMENTACION 10 ÷ 16 mm

TENSION / SECCION CABLE DE ALIMENT. 220 - 230 V~ /AWG12

PRESION AGUA kPa 50 - 200

L2

60 Hz 1 Face

ENGLISH - LEGEND

DRAWINGS - ELECTRICAL SCHEMAS

1. TERMINAL BOARD

2. EQUIPOTENTIAL TERMINAL SITE

3. TECNICAL DATA PLATE

4. HOT SMOKE DISCHARGE

LM OVEN INTERNAL LAMP

MO TERMINAL BOARD

R HEATING ELEMENT

S PILOT LIGHT

SIC OVERRIDE THERMOSTAT

T TIMER

TE THERMOSTAT

V1 MOTOR FAN

NETWORK GROUND LINE

ESPAÑOL - LEYENDA

DISEÑOS - ESQUEMAS ELECTRICOS

1. CAJA CONEXIONES-REGLETA

2. SEDE BORNE EQUIPOTENCIAL

3. TARJETA CARACT. TECNICAS

4. DESCARGA HUMOS CALIENTES

LM LAMPARA HORNO

MO CAJA CONEXIONES-REGLETA

R RESISTENCIA

S PILOTO ESPIA

SIC TERMOSTATO DE SEGURIDAD

T TIMER

TE TERMOSTATO

V1 MOTO-VENTILADOR

LINEA DE TIERRA DE LA RED EL.

202281

UL Std N° 197 Commercial Electric

Cooking appliances.

UL Std. No. 1004 Electric Motors.

Page 16

UNOX S.p.A.

CADCO Ltd.

R

ROSSELLA MANUAL

ROSSELLA MANUAL

XA090

XA090

model: OV-600

03-2003

07-2003

ENGLISH TECHNICAL DATA

ELECTRICAL POWER kW 5,4

FREQUENCY 50 - 60 Hz

POWER SUPPLY CABLE TYPE SJTOW

POWER SUPPLY CABLE EXTERNAL Ø 10 ÷ 16 mm

VOLTAGE / CABLE SECTION 220 - 230 V~ /AWG12

WATER PRESSURE kPa 50 - 200

60 Hz 1 Phase

208-240 V~ / AWG 10

ESPAÑOL DATOS TECNICOS

POTENCIA kW 5,4

FRECUENCIA 50 - 60 Hz

TIPO CABLE DE ALIMENTACION SJTOW

Ø EXTERNO CABLE DE ALIMENTACION 10 ÷ 16 mm

TENSION / SECCION CABLE DE ALIMENT. 220 - 230 V~ /AWG12

PRESION AGUA kPa 50 - 200

L2

60 Hz 1 Face

208-240 V~ / AWG 10

ENGLISH - LEGEND

DRAWINGS - ELECTRICAL SCHEMAS

1. TERMINAL BOARD

2. EQUIPOTENTIAL TERMINAL SITE

3. TECNICAL DATA PLATE

4. HOT SMOKE DISCHARGE

LM OVEN INTERNAL LAMP

MO TERMINAL BOARD

R HEATING ELEMENT

S PILOT LIGHT

SIC OVERRIDE THERMOSTAT

T TIMER

TE THERMOSTAT

V1 MOTOR FAN

NETWORK GROUND LINE

ESPAÑOL - LEYENDA

DISEÑOS - ESQUEMAS ELECTRICOS

1. CAJA CONEXIONES-REGLETA

2. SEDE BORNE EQUIPOTENCIAL

3. TARJETA CARACT. TECNICAS

4. DESCARGA HUMOS CALIENTES

LM LAMPARA HORNO

MO CAJA CONEXIONES-REGLETA

R RESISTENCIA

S PILOTO ESPIA

SIC TERMOSTATO DE SEGURIDAD

T TIMER

TE TERMOSTATO

V1 MOTO-VENTILADOR

LINEA DE TIERRA DE LA RED EL.

202281

UL Std N° 197 Commercial Electric

Cooking appliances.

UL Std. No. 1004 Electric Motors.

Loading...

Loading...