Page 1

#

*g8;2'

Audio Mixing Console

-056#..#6+10#n#95'4#1#07#.

Page 2

CADAC Electronics

One New Street

Luton

Bedfordshire

LU1 5DX

England

Tel +44 (0) 1582 404 202

Fax +44 (0) 1582 412 799

email: info@cadac-sound.com

While ev er y eff or t ha s b ee n ta ke n t o ensu re the a ccu racy o f th e c onte nt s in thi s m an ua l, C AD AC Live P erf orma nc e A u dio Mix in g Con s ol es are

subject to continuous development, hence the information in this manual may not reflect the latest product updates.

© Copyright CADAC Electronics plc. 2005.

Page 3

Table of Contents iii

7DEOH#RI#&RQWHQWV

6(&7,21 3 $*(

*HQHUDO#3UHFDXWLRQV 111111111111111111111111111111111111111111111111#Y

,QWURGXFWLRQ111111111111111111111111111111111111111111111111111111111111#YLL

4 &RQQHFWLQJ#WKH#PL[HU#V\VWHPV1111111111111111111111111111 #404

1.1 Console modularity ....................................................................... 1-1

1.2 Frame rear connections................................................................1-1

1.3 Connect Power supply systems.................................................... 1-2

1.4 Connecting the console frames .................................................. 1-11

1.5 Connect Console Automation System ........................................ 1-14

1.6 Connect main frame facilities from modules to frame.................1-19

1.7 Switching ON .. .... ............... .... .... .... ............... .... .... .... ............... ... 1-20

5 &HQWUDO#&RQWURO#0RGXOH#:;<9 1111111111111111111111111111111 #504

2.1 CCM Front Panel switches and displays ......................................2-1

2.2 CCM rear panel connectors.......................................................... 2-6

2.3 Internal module settings................................................................ 2-8

2.4 Module level software................................................................... 2-8

2.5 The System Setup menu ............................................................ 2-10

6 ,QSXW#PRGXOHV 111111111111111111111111111111111111111111111111111111 #604

3.1 VCA Input Modul e 7583.. ............... .... ... .... ................ ... .... .... ......... 3-1

3.2 VCA Input Module 7583 - rear panel ............................................3-8

7 6WHUHR#,QSXW#PRGXOH#::94 11111111111111111111111111111111111 #704

4.1 Stereo Input module 7761 - front panel ........................................ 4-2

4.2 Stereo Input Module 7761 - rear panel ......................................... 4-8

8 9&$#*URXS#PRGXOH#:8:; 11111111111111111111111111111111111111 #804

5.1 VCA Group modu le 7578 - front pane l.......... ............... .... .... .... .....5-2

5.2 VCA Group Modu le 7578 - rear panel ...................... ... .... .... ......... 5-7

9 'LVSOD\#*URXS#PRGXOH#:79: 111111111111111111111111111111111 #904

6.1 Display Group module - front panel .............................................. 6-2

6.2 Display Group Module 7467 - rear panel...................................... 6-7

: 6WHUHR#5HWXUQV#0RGXOH#:9:; 1111111111111111111111111111111 #:04

7.1 Stereo returns module 7678 ......................................................... 7-2

7.2 Stereo Returns Module 7678 - rear panel.....................................7-4

; 2VF/#&RPPV#)#3)/#PRGXOH#:;68 111111111111111111111111 #;04

8.1 Osc, Comms & PFL module 7635 - front pane l ........ ... .... ............. 8-2

8.2 Osc, Comms & PFL Module 7635 - rear panel ......... ... .... .... .........8-7

< $X[LOLDU\#2XWSXW#0RGXOH#:79; 11111111111111111111111111111 #<04

9.1 Auxiliary Output module 7468....................................................... 9-2

9.2 Auxiliary Output Module 7468 - rear panel ................................... 9-3

$SSHQGLFHV11111111111111111111111111111111111111111111111111111111#$330,

,QGH[111111111111111111111111111111111111111111111111111111111111111111 #,1'0,

Revision F2005-2 F-Type

Page 4

iv Table of Contents

F-Type Revision F2005-2

Page 5

General Precautions v

*HQHUDO#3UHFDXWLRQV

'DPDJH

(QYLURQPHQW

&OHDQLQJ

7UDQVSRUW

6DIHW\#,QVWUXFWLRQV

Do not place heavy objects on the control surf ace, e xpose it to sharp objects or handle the console in any way that may cause damage e.g. rough handling and/or

excessive vibration.

Do not subject the equipme nt to dirt, dust, heat or vibration during operation or storage. Never expose the console to rain or moisture in any form. Should the console

become wet, turn it off and disconnect from mains without further delay. The console

should be given sufficient time to dry out, before reco mmencing operation.

When cleaning th e console, never use chemicals, abrasive substances or solvents .

The console control panels should be cleaned using a soft brush and a dry lint-free

cloth. For pe rsistent ma r k s, us e a soft cloth and is opropyl alcoh o l . Swi tches and

potentiometers do NOT require cleaning or lubrication. For faders, see below.

Transport the console in its purpose built flight-case; whilst at the same tim e taking

precautions to protect the contro l surface from any damage. Alway s make sure adequate manpower is available and correct lifting methods are taken when moving the

console.

Read the following before using the equipment

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

:

,QVWUXFWLRQV

,QVWDOODWLRQ

&RYHUV

3RZHU

3RZHU#FRUG

:DUQLQJ

0RLVWXUH

9HQWLODWLRQ

Keep these instructions for future reference. Follow all warnings in this manual and

those printed on the power supply units.

The console must be installed following the guide lines in this manual. Never connect

power amplifier outp uts directly to the console. Connec tors and plugs must never be

used for any other purpose than for what they are intended.

Never use the power supply units without covers fitted. All service work must be carried out by qualified personnel only.

The power supply units must always be connected to correctly ra ted main s power as

referred to in this manual and marked on the power supply units. The power supply

units must, at all times, be connected to the local mains power supply using the supplied po w er c or d. In c ase s w her e th e supp l ie d p lu g d oes not fi t , a qu al if i ed elec tr ic ia n

must be consulted.

The power cord must be routed in such a way that the risks of accidentally stepping

on it, stretching it or it being pinched, are minimized.

THIS EQUIPMENT MUST BE EARTHED !

In order to minimize risks of fi re hazards and/or electric shock, the pow er supply unit

must ne v er be e x pos ed to moi st ur e or wa te r in any f orm; or b e us ed i n a damp or w et

environment. Never place liquid containers, such as for instanc e coff ee/tea mugs, on

the power supply unit, so as to avoid spill age into op enings.

Ventilation slots on the power supply or the console must never be covered or in any

other way obstructed. Air flow required for safe operation may otherwise be

restricted. Whe re the cons ole is to be operated in its flight-case, then this must be

located in such a way that it al lows for proper ventilation .

6HUYLFH

F-Type Revision F2005-2

Refer servicing to quali fied technical personnel only.

Page 6

vi General Precautions

Revision F2005-2 F-Type

Page 7

Introduction vii

,QWURGXFWLRQ

The F-Type mixing cons ole was designed especially for the live sound industry

where large numbers of loudspeakers are required t o deliver the sound to the audience. In addition to an integrated show based cue recall system, F-Type has the following features:

Routing to 12 sub groups

■■■■

A 12 X 24 output matrix

■■■■

Channel direct outputs (optional)

■■■■

8 stereo auxiliary sends switchable pre/post, on/off (or 16 mono aux sends)

■■■■

4 band parametric equalizer plus high and low-pass filters per channel

■■■■

VCA channel faders with up to 12 DC Master faders

■■■■

Motor fader option

■■■■

One of the major features of the F-Type console is that module positions may b e

changed at will. Each module carries its own connectors, and “standard wiring” is

applied to every module position in the frame. Users have the ability to change the

fo rmat of the console at any time. The only thing you must rem ember is th at when

modules are re-arranged, you must “re-map” the console in order to use the automation facilities! A version for

frame wiring required in order that the console can interface directly with a jack field

via “multi-way connectors”, then fixes module positions as in most other consoles.

Touring compan ie s who us e a j ac k- fi el d, but st ill req ui re t he fle x ib il ity of v a riab l e mo dule positions add a ‘multi-way connector to XLR’ wiring pod at the rear of each frame

in the console, known as the “dog-house”.

fixed installations

can also be supplied , but the extra

The basic F-Type system

F-Type consoles can be supplied in almost any configuration defined by the c ustomer. Relatively small co nsoles (32 input channels, 12 group modules, 2 au x send

modules, CCM and an Osc./PFL/Comms. module) can be assembled in a single

frame, whereas larger consoles require a multi-frame format. Up t o 4 separate

frames may be specified, each frame having a maximum of 63 module positions.

Input channels can be supplied wit h one or two inputs. Eith er input c an be used for

micro phone or line level sources. E ach input has a programma ble “On” switch which

allows both inputs to be mixed relative to the individual gain settings. Main signal

routing is to 12 sub-grou ps with selectable pan pot (pan pot in/ out switch is programmable), 16 mon o Aux Sends or 8 stereo Aux Sends. An insert point is p rovided

before the equalizer with balanced send and return and the insert s witch is programmable. The 4 band parametric equalizer high and low-pass filters (with indiv idual “on/

off” switches for each filter) can be selected to I/P 1, I/P 2 or both. The EQ IN/OUT

and FILTER ON/OFF switches are programmable. The Direct Output (optional) is

switchable between Pre or Post fader. The fader is int egrated into the module.

Up to 12 group modules may be specified, each containing a DC Master fader, audio

sub-group mixing amplifier, fader, additional input to the mixing bus, sub group insert

point , sub group output with LED meter and rou ting pote ntiometers for 24 Matrix

group s ( 1A to 1 2 A an d 1B to 12B) . T he up per p art o f th e mo du l e co ntai n s t wo M at ri x

groups with individual mixing amplifiers, matrix group insert points, output level

potentiometers, additional inputs to the mixing busses and the matrix outputs. All

three INSERT switches are programmable.

Up to 240 input channels with VCA faders plus 12 DC maste r faders may be specified . The channels and/or group modules can be supplied with motor faders.

Two other audio modules are supplied as standard - Au x mix groups 1A to 8A (or 1B

to 8B for the 16 Aux version); Oscillator (multi-frequency sine wave plus pink noise),

PFL, Communicat ions.

Revision F2005-2 F-Type

Page 8

viii Introduction

F-Type Revision F2005-2

Page 9

Connecting the mixer systems 1-1

4 &RQQHFWLQJ#WKH#PL[HU#V\VWHPV

414 &RQVROH#PRGXODULW\

The F-Type features CADAC’s unique frame design which allow users to put any

module in any position, th us confi guring the console to suit the pr oject in hand. Each

module is fitted with XLR connectors and jack sockets on the rear vertical face,

enabling the module to be moved quickly and easily.

The F-Type module’s design features a motherboard, with plug-in daughter boards

fo r all audio and digit al control functi ons. This ensures s ervicing simplicity and fast

replacement of any faulty compo nent. Each module may be plugged into any position in the console frame, by means of top quality two-part connector system, which

is designed as a matin g pair to provide excellent mechanic al and el ectrical reliabi lity.

A rail system is us ed to guide each module into its correct position. Also, the console

design allows modules to be removed or inserted without powering down.

415 )UDPH#UHDU#FRQQH FWLR QV

HEADPHONES NEXT FRAME

4

5

AUDIO BUS

FIG 1-1. F-Type frame rear connections.

6

7

DATA BUS

FRAME TO FRAME

FRAME

SELECTOR

The connections on the F-Type console rear frame include the following (from left to

right):

■■■■

■■■■

■■■■

■■■■

■■■■

■■■■

■■■■

■■■■

■■■■

■■■■

■■■■

■■■■

■■■■

■■■■

■■■■

INPUT TO H EADPHO NES JACK SOC K ETS

COMMS TO CCM

PSU 1

PSU 2

PSU INDICATOR

FROM PFL NEXT LIGHTS

GND - 0 - FRAME

5 AMP FA N FUS E

Audio Bus - fr ame to frame, up to 4 frames c an be connected.

Data Bus - frame to frame

Frame selector

Comms to CCM

PFL output to next frame.

PFL input from module.

PSU1 co nnector

PSU2 co nnector

Output for monitoring of PSUs

GND - 0 - FRAME

Littlite input from PFL module.

Littlite output to next frame.

Littlite output to lights

Audio Bus

Data Bus

4

5

AUDIO BUS

FRAME TO FRAME

6

7

DATA BUS

The use of these connectors is described in 1.3.5 Main and extension frame power

connections, 1.4 Connecting the console frames and 1.5 Connect Console Automation System.

Revision F2005-2 F-Type

Page 10

1-2 Connecting the mixer systems

416 &RQQHFW#3RZHU#VXSSO\#V\VWHP V

41614 3RZHU#VXSSO\#V\VWHP#GHVFULSWLRQ

Cadac consoles are designed to allow the use of two independent power supply systems in a redundant configuration – “main” and “ backup”. Both sets of power supply

units are used to power the console system so that under normal conditions, the

‘loa d’ is sh ar ed b etw e en th e “ m ai n” a nd “ bac ku p” PS U’s. If a f a ul t oc c urs i n on e o f th e

power units (causing it to ‘shut-down’), the remaining power unit will power the console.

For smaller B-Type consoles (consuming no more than 44A), it is possible to use the

8400 PSU. See 1. 3. 7 8 400 switch-mode power supp ly uni t.

One ±18V PSU and one +13V/+48V PSU is referred to as a “PSU System”.

Designate one pair of power supply units as “SYSTEM 1" and the other as “SYSTEM

2". PSU System 1 .and PSU System 2 should be connected to the same

on the same ‘spur’, wherever possible. In situations where it is necessary to provide

a separate ‘feed’ to each PSU system pair, make sure that the cable lengths are the

same. This is to minimize any induced a.c. power input noise by ensuring that the

“EARTH IMPEDANCE” is the same for both PSU systems.

phase

and

$5($#%5$1&+#3$1(/

1#/

$5($#%5$1&+#3$1(/

*1'#%$5 *1'#%$5

0$,1#*5281'#5()(5(1 &(#($57+#(/(&752'(#6<67(0

$5($#%5$1&+#3$1(/

/

368#4$

-

-

-

-

1

(

/

1

(

/

1

(

/

1

(

368#4%

368#5$

368#5%

FIG 1-2. AC mains grounding diagram (single phase 200-240V)

F-Type Revision F2005-2

Page 11

Connecting the mixer systems 1-3

The a.c.-input connectors on each power supply unit have three conductors: ‘LIVE’

(brown), ‘NEUTRAL’ (blue) and ‘EARTH’ (yellow/green). For safety and electromagnetic compatibility cons iderations, it is essential that the ‘EARTH’ conductor is connected on all PSUs

continuous c i rcuit to the “ze ro-signal reference potential” point in the building. The

ZSRP point in a building is usually found near the place where the a.c. ‘mains’ supply

enters the building (often referred to as the “MAIN GROUND REFERENCE EARTH

ELECTRODE SYSTEM”). The basic concept for correct a.c. mains wiring distribution

is shown in figure 1-1. If you need further information about this complex subject,

please refer to “Grounding Systems and their Implementation” by Charles Atkinson

and Philip Giddins published in the AES Journal Vol. 43, No. 6 – June 1995.

The grounding scheme in CADAC consoles is designed to meet the rigorous EEC

Elec tromagne tic Compatibility

induced in the console frame(s) is directed to the “local” ZSRP, which is the metalwork of the power supply units. In order to take full advantage of the “RF noise immunity” capability of the CADAC system, P SU a.c. mains cables and the a.c. mains

supply EARTH conductor mus t be connected correctl y.

the a.c. supply has an ‘EARTH’ conductor that has a

and

requirements (EMC Directive - 1996). Any RF noise

41615 $&#SRZHU#UHTXLUHPHQWV

CADAC power supply units are designed to run from a minimum of 208 V up to a

maximum of 260V, 50/60Hz a.c. In many parts of the world the normal a.c. singlephase supply is 100-127V, this means that the CADAC power supply units must be

connected across two of the phases in the three-phase a.c. supply, see 1.3.4 Connecting to a 3-phase outlet.

41616 6ZLWFK00RGH#3RZHU#6XSSO\#8QLWV

CADAC 8019 and 8020 switch- m ode power supply units are designed to run from a

minimum of 208V up to a maximum of 260V a.c, 50/60Hz.

The 80 19 “18 V ” uni t is r a te d at 10 0A per r a il an d the 8 020 “1 3V” un it is rat ed at 100A.

See also Appendices, B. Switch-Mode Power Supply Units,

;34<#´4;9µ#VZLWFK0PRGH#SRZHU#VXSSO\#XQLW

The ol der version of 8019 ±18v unit is based on two AD VANCE F20006 ‘powerblocks’, with additional circuitry as shown on CADAC drawing number C3.801 5. The

new versio n is based on PowerOne PSUs (serial number 34949 onwar ds).

The a .c. inpu t is connected to the PSU via a 3-core cable, CMA reference 3183TQ –

BASEC approved, rated at 20A.

FIG 1-3. 8019 power supply unit

Revision F2005-2 F-Type

Page 12

1-4 Connecting the mixer systems

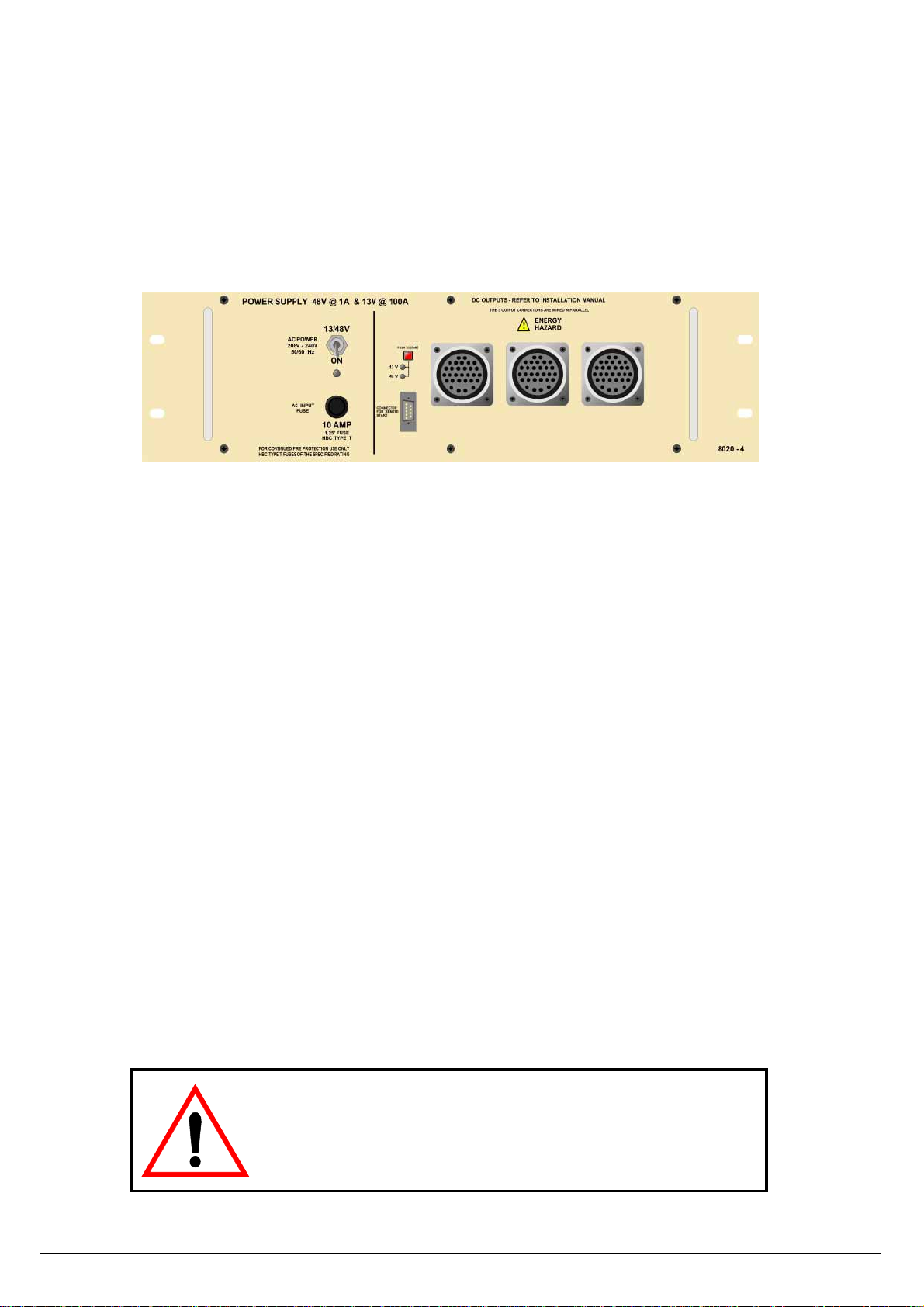

;353#´469µ#VZLWFK0PRGH#SRZHU#VXSSO\#XQLW

The ol der version of 8020 +13v/48v un it is based on one ADVANCE F20006 ‘p owerblock’, with additional circuitry as shown on CADAC drawing number C3.8016. The

new version is based on PowerOne PSUs (serial number 34949 onwards).

The a .c. inpu t is connected to the PSU via a 3-core cable, CMA reference 3183TQ –

BASEC approved, rated at 20A.

FIG 1-4. 8020 power supply unit

5HSODFLQJ#D#SRZHU#VXSSO\#XQLW

If replacing a switch-mode power supply unit is required, please note the following:

Make sure that the pow er supply s ystem’ s power switches are in the position

■■■■

OFF and disconnected from the mains.

The work should only be carried out by a s uitably qualified electrician.

■■■■

Be careful to observe correct polari ty when connecting the new PSU.

■■■■

Note that a console must never have one voltage without the ot her, for example

■■■■

+18V must never be fed into the console without -18V.

When switching the power supply system back ON after replacement has taken

place, make sure that both LEDs on the front of the PSU-system come on. If only

one LED comes on, let go of the ON push-button immediately. Failure to do so may

lead to fire hazar d and major damage to the console.

NO TE:

Under no circumstances, should the 8019 or 8020

PSU be used without a SAFETY EARTH connection. Failure

to follow this instruction is both a fire and safety hazard.

F-Type Revision F2005-2

Page 13

Connecting the mixer systems 1-5

41617 &RQQHFWLQJ#WR#D#60SKDVH#RXWOHW

Connection to a 3-phase outlet is r equired on sites where the system vol tage

between any one of the phases and neutral is 100-127V and the voltage between

any two of the phases is 200-240V. Before connecting to any 3-phase outlet, please

refer to a qualified electrician who under stands your partic ular installation and the

local safety and wiring regulations. Under no circumstances should the 8019 and

8020 switch-mode power supply units be operated without the green/yellow safety

earth conductor connected to the building safety earth conductor system. Each

power unit is equipped with an input supply filter whose reference ground conductor

is the chassis. Failure to connect the green/yellow safety earth conductor to the correct eart h/ground building reference is a safety and fire hazard.

1. Connect the LIVE (Brown) conductor on the “system 1” 8019 unit to the phase 1

(L1, RED) terminal on the 3-phase power outlet connector.

2. Connect the NEUTRAL (Blue) conductor on the “system 1” 8019 unit and the

LIVE (Brown) conductor on the “system 1” 8020 unit to the Phase 2 (L2, YELLOW) terminal on the 3-phase power outlet connector.

3. Connect the NEUTRAL (Blue) conductor on the “system 1” 8020 unit to the

Phase 3 (L3, BLUE) terminal on the 3-phase powe r outlet connector.

4. Connect the EARTH (Yel low/Green) conductor on the “system 1” 80 19 unit and

the EAR T H ( Yello w/ Gr een ) co nd uc to r on the “sys te m1 “ 8 020 un it to th e SA FET Y

EAR TH (Yellow/Green) t erminal on the 3-phase power outlet connector .

5. Repeat 1-4 for the “system 2” power units.

3+$6(#4#+/4/#5(',

3+$6(#5#+/5/#<(//2:,

3+$6(#6#+/6/#%/8(,

6$)(7<#($57+

<(//2:2*5( (1

/5

6$)(7<#($57+

/4

/5

/4

/LYH

1HXWUDO

(DUWK

/LYH

1HXWUDO

(DUWK

/LYH

1HXWUDO

(DUWK

/LYH

1HXW UDO

(DUWK

;34<

;353

;34<

;353

FIG 1-5. Connecting to a 3-phase outlet

(100-127V/200-240 system voltages)

NOTE:

Connection between two phases in a 3-phase outlet should under no

6$)(7<#($57+

circumstances be carried out where the single-phase voltage (the voltage

between one of the phases and neutral) exceeds 127V. The installation

should be carried out by a qualified electrician who understands your particular installation and the local safety and wiring regulations.

Revision F2005-2 F-Type

Page 14

1-6 Connecting the mixer systems

41618 0DLQ#DQG#H[WHQVLRQ#IUDPH#SRZHU#FRQQHFWLRQV

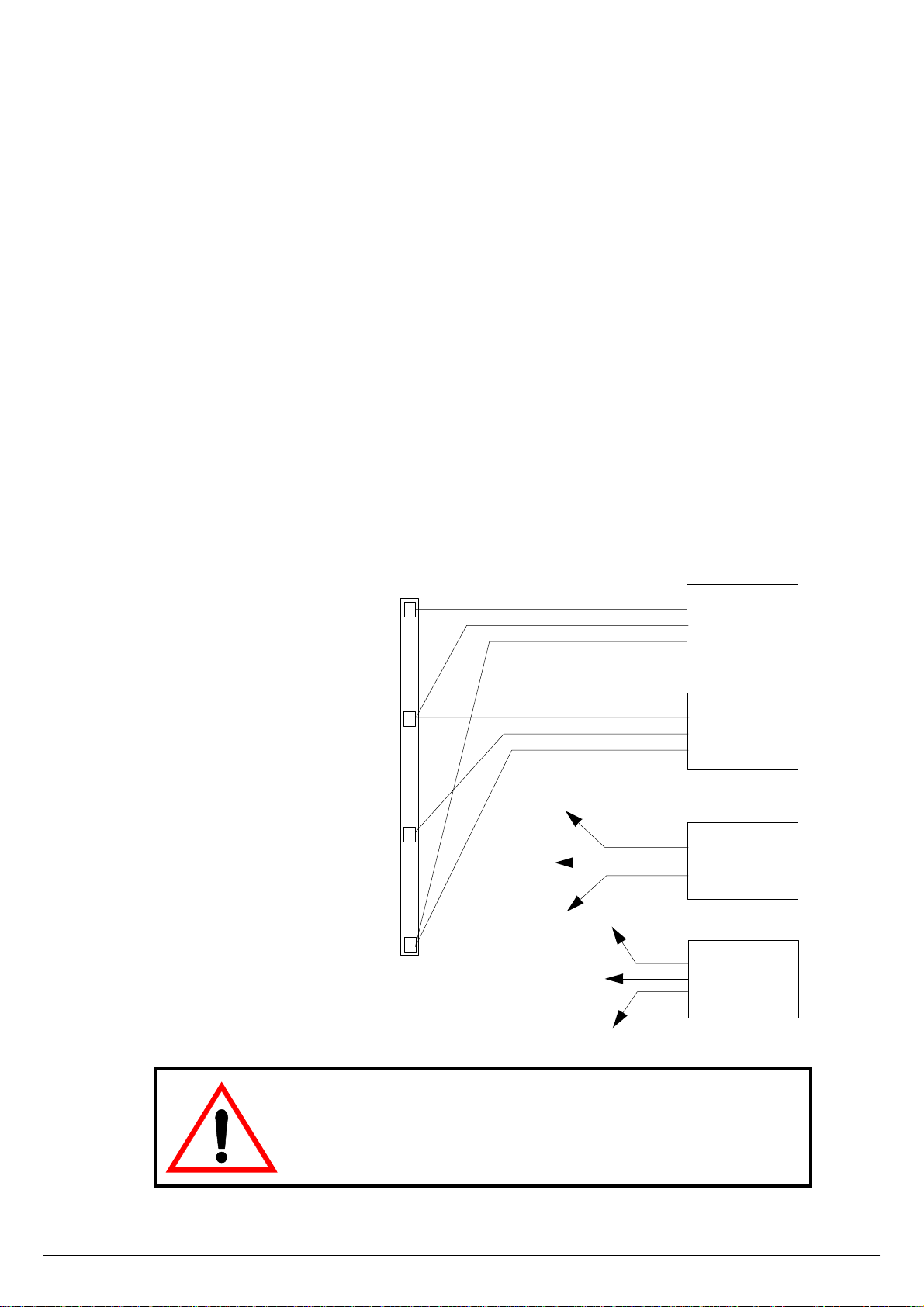

See fig 1-4 below for schematics of the frames power connections.

1. Using a short U-LINK cable (supplied), co nnect one of the outputs on the ±18V

PSU to one of the outputs on the +13V/+48V PSU in the “SYSTEM 1" power

supply rack. This operation “links” the d/c outputs on both power supply units in

the rack so that ±18V, +13V and +48V is available on all remaining output connectors on either power unit.

2. Co nn ec t t he seco nd s ho rt “U -LI NK” c abl e ( s up plie d) b etw e en the ± 18 V PS U an d

the +13V/+48V PSU’s in the “SYSTEM 2" power supply rack.

3. Connect a PSU cable between the “SYSTEM 1" rack and the “PSU SYSTEM 1"

connector on the MAIN FRAME.

4. Connect a PSU cable between the “SYSTEM 2" rack and the “PSU SYSTEM 2"

connector on the MAIN FRAME.

5. Connect a PSU cable between the “SYSTEM 1" rack and the “PSU SYSTEM 1"

connector on the EXTENSION FRAME 1.

6. Connect a PSU cable between the “SYSTEM 2" rack and the “PSU SYSTEM 2"

connector on the EXTENSION FRAME 1.

7. Repeat procedures 5. and 6. for EXTENSION FRAME 2 (a 3 fram e console).

368#6<67 (0#4#+“4;9,

368#6<67(0#4#+7;92.469,

368#6<67(0#5#+“4;9,

368#6<67(0#5#+7;92.469,

FIG 1-6. Power connections

F-Type Revision F2005-2

Page 15

Connecting the mixer systems 1-7

41619 ;34<#DQG#;353#FRPELQHG#5HPRWH#VWDUW

Each 801 9 and 8 02 0 s w it ch- mod e p o we r supp ly is fi t ted wi th a f ron t p an el mo un ted 9

way ‘D-type’ connector. This connecto r is labelled “Connections for Remote Start”.

You may connect a single remote start switch to each unit, have one switch start a

“system” pair, or wire up a sing le switch to start “system 1” and “system 2” all at the

same time.

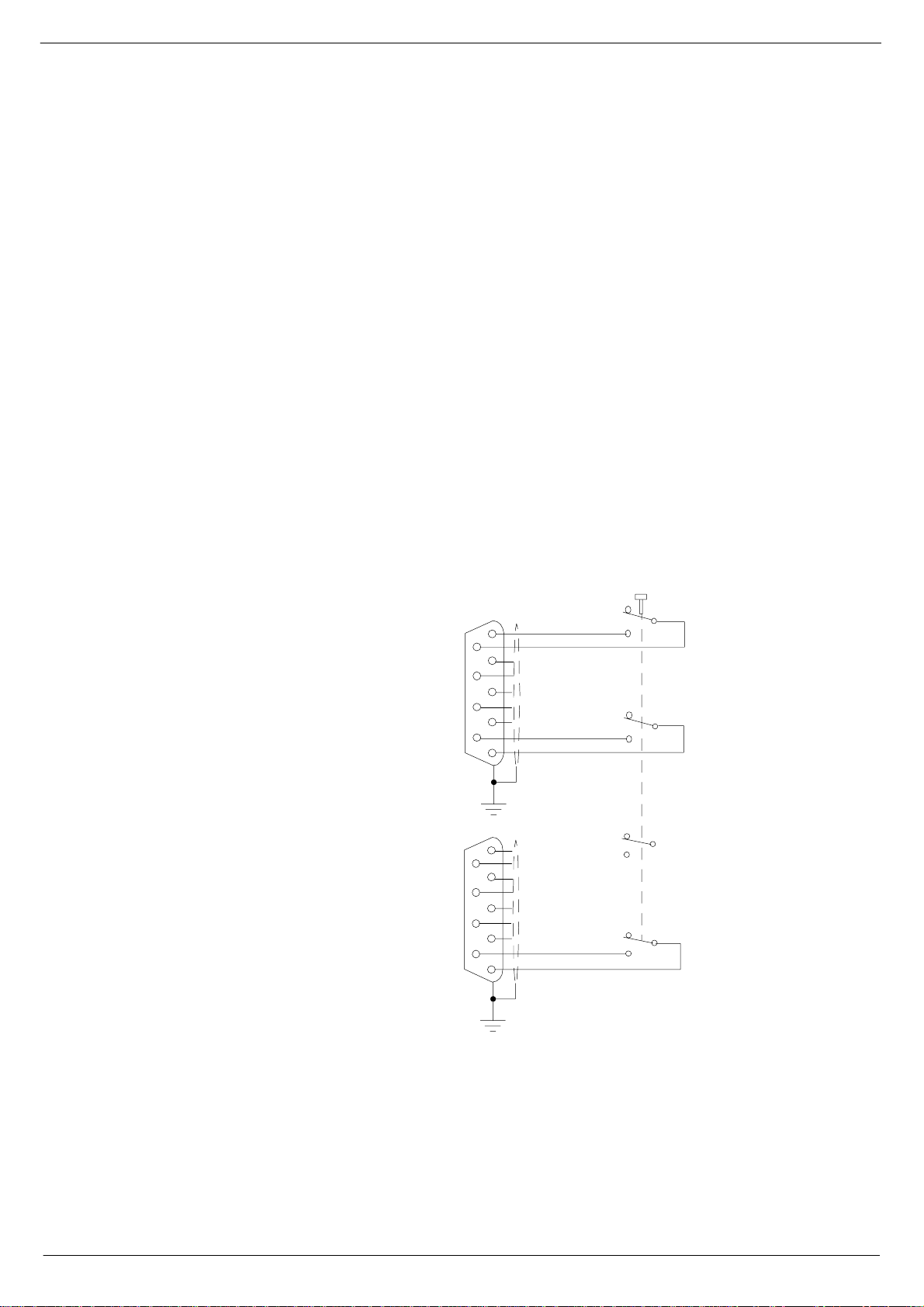

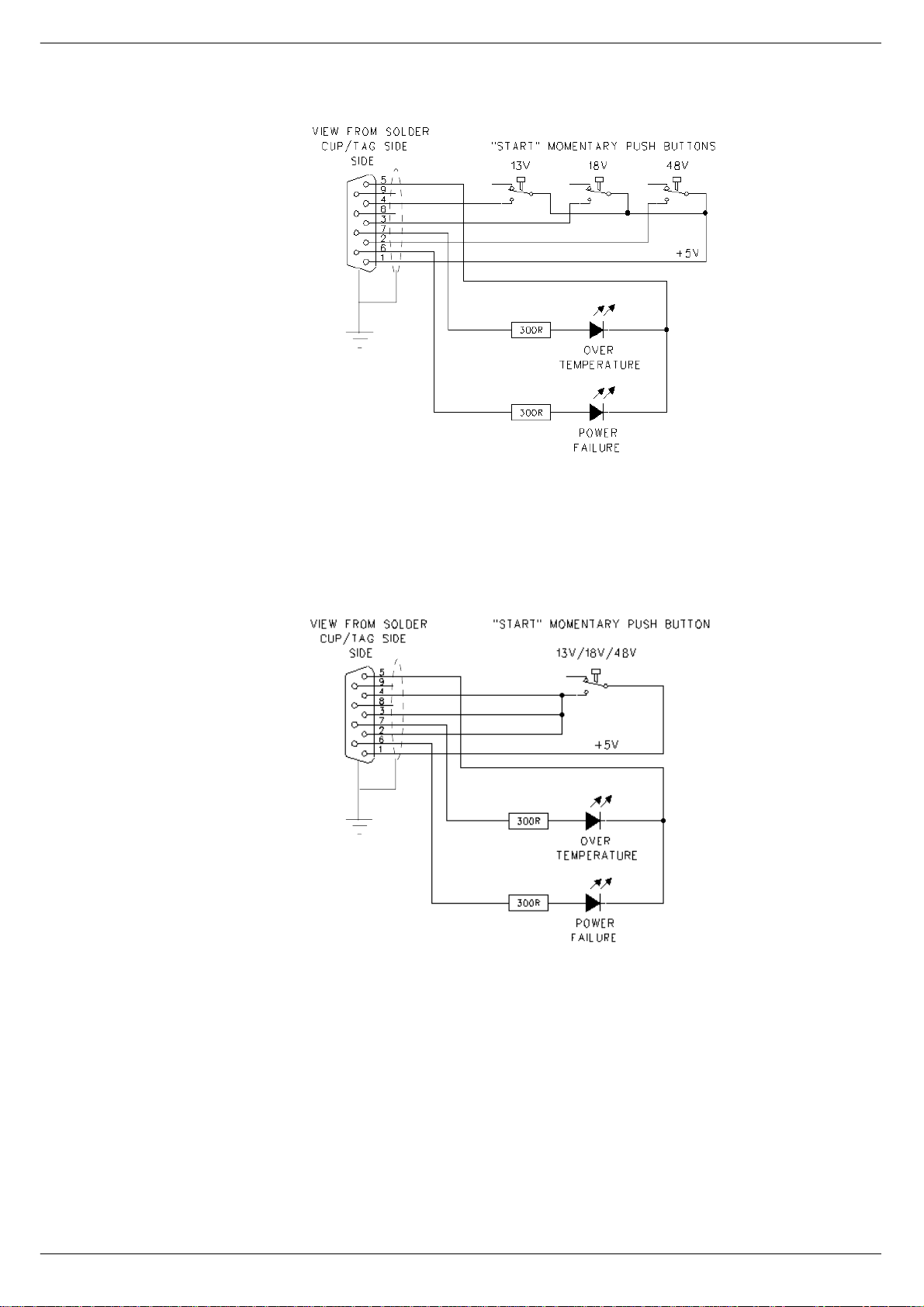

Fig 1-5 applies to 8019 and 8020 PSUs up to serial number 34949 and shows the

circuit for starting up a “system” pair with a single switch. This has pr oved to be the

most popular method of connecting the remote start facility. This circuit can easily be

extended to provide a single switch remote for all four PSUs i f required.

For 8019 and 8020 PSUs from serial number 34950 onwards, see fig 1-6 and 1-7.

NOTE:

The remote must be a ‘momentary’ type. You will need a two-pole switch for a

■■■■

single PSU, a four-pole switch for a “syste m” pair, or a six-pole switch fo r controlling

all four units.

The remote switch(es) must be mounted on a metal panel.

■■■■

Use shielded cable fo r the remote switch w iring.

■■■■

The 9-way ‘D-type’ free plug must have a conductive shell. This is to ensure that

■■■■

the cable shield connects directly to the PSU unit chassis.

Connect the cable shield to the metal panel where the remote start switch(es)

■■■■

are mounted.

TO CONNECTION

FOR REMOTE START

ON 8019 FRONT PANEL

TO CO NN E C TIO N

FOR REMOTE START

ON 8020 FRONT PANEL

CUP/TAG SIDE

5

9

4

8

3

7

2

6

1

5

9

4

8

3

7

2

6

1

PANEL MOUNTED 4-POLEVIEW FROM SOLDER

MOMENTARY SWITCH

NOTE: CABLE SCREEN IS

CONNECTED AT BOTH ENDS

FIG 1-7. Remote start of 8019/8020 up to serial number 34950

Great care must be taken with the wiring of the switch(es) to ensure that no short-circuits can occur between a ny two power supply units.

Revision F2005-2 F-Type

Page 16

1-8 Connecting the mixer systems

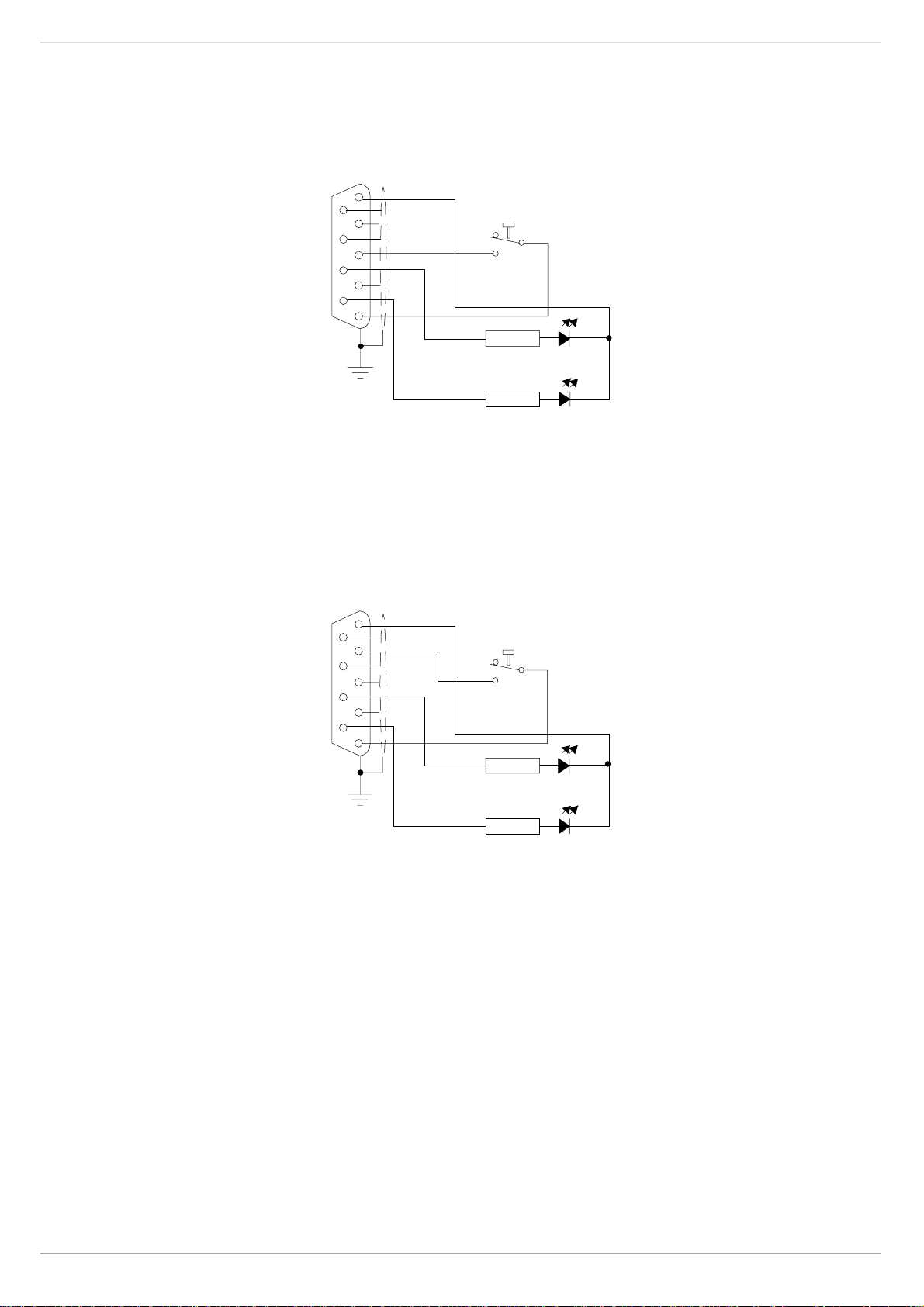

VIEW FROM SOLDER

CUP/TAG SIDE

FIG 1-8. Remote start of 8019 PSU

(from se rial number 34950)

5

9

4

8

3

7

2

6

1

VIEW FROM SOLDER

CUP/TAG SIDE

5

9

4

8

3

7

2

6

1

“START” MOMENTARY PUSH BUTTON

18V

300R

OVER

TEMPERATURE

300R

POWE R F AILURE

“START” MOMENTARY PUSH BUTTON

13V

FIG 1-9. Remote start of 8020 PSU

(from se rial number 34950)

300R

OVER

TEMPERATURE

300R

POWER FAILURE

F-Type Revision F2005-2

Page 17

Connecting the mixer systems 1-9

4161: ;733#VZLWFK0PRGH#SRZHU#VXSSO\#XQLW

FIG 1-10. 8400 po wer supply unit.

CADAC 840 0 switch- mode power supply units are designed to run from a minimum

of 208V up to a maximu m of 260V a.c, 50/60Hz.

The 84 00 is rated thus +13V@92A, ±18V @44A and 48V@5A.

The a .c. inpu t is connected to the PSU via a 3-core cable, CMA reference 3183TQ –

BASEC approved, rated at 20A.

The 8400 unit is based on one POWER ONE RPMS-ETETGDGD1ETK Pow er block,

with additional circuitry as shown on CADAC drawing numbe r C3.8397.

4161; 5HPRWH#VWDUW#RI#;733#368

Each 8400 switch-mode power supply pro v ides the following outputs: 13v, ±18v and

48v. Each PSU i s fitted with a front panel mounted 9-way 'D-t ype’ connector labelled

‘Connections for Remo te Start’. If a remote start facil ity is used, Power Failure and

Over-Temperature LEDs may also be fitted with the remote start switches if required.

Fig 3-15 shows the circuit for starting up a “system” with a single switch. This has

proved to be the most popular method of connecting the remote start facility. This circuit can easily be extended to provide a single switch remote for all four PSUs if

required. If muliple switches are to be used, see fig 3-14.

NOTE:

The remote start switch must be a ‘momentary’ type. You can use 3 separate sin-

■■■■

gle pole swit ches for each Power Supply to turn on 13v,±18v and 48v outputs of the

PSU alternatively use one single pole for the whole lot.

The remote switch(es) must be mounted on a metal panel.

■■■■

Use shielded cable fo r the remote switch w iring.

■■■■

The 9-way ‘D-type’ free plug must have a conductive shell. This is to ensure that

■■■■

the cable shield connects directly to the PSU unit chassis.

Connect the cable shield to the metal panel where the remote switch(es) are

■■■■

mounted.

Revision F2005-2 F-Type

Page 18

1-10 Connecting the mixer systems

FIG 1- 11. R emote s tart o f

PSU 8400 with multi ple

switches.

FIG 1-12. Remote start of PSU

8400 with a single switch

Great care mus t be take n when wiring the switch(es) to ensure that no short-circuits

can occur between any two power supply units.

F-Type Revision F2005-2

Page 19

Connecting the mixer systems 1-11

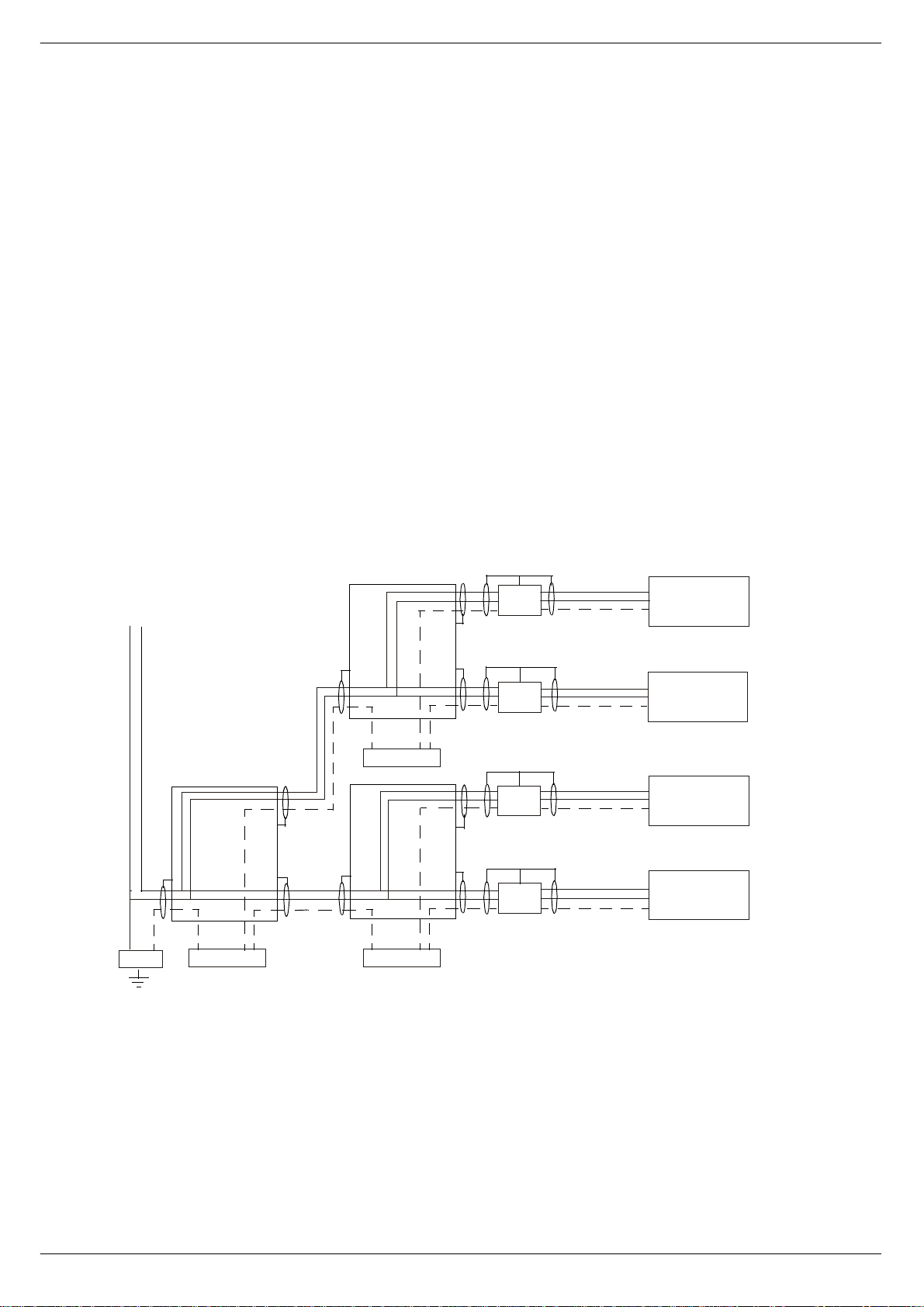

417 &RQQHFWLQ J#WKH#FRQVROH#IUDPHV

41714 $XGLR#%XV#2#'DWD#%XV#&RQQHFWLRQV

If the console i s used in a mul ti-fram e configuration then the busses need to be connected in a ‘daisy chain’ fashion.

four audio and two data busses plus fader bus (see fig 1-13). The bus cables are

simply linked between similar co nnectors on the end of the nearest frame.

Make sure that each frame has its “Frame Select” switch set to a different number.

Each end

of a frame has seven bu s connectors -

FIG 1-13. Audio/Data Bus connections.

See also appendix A. Important information re garding EMC .

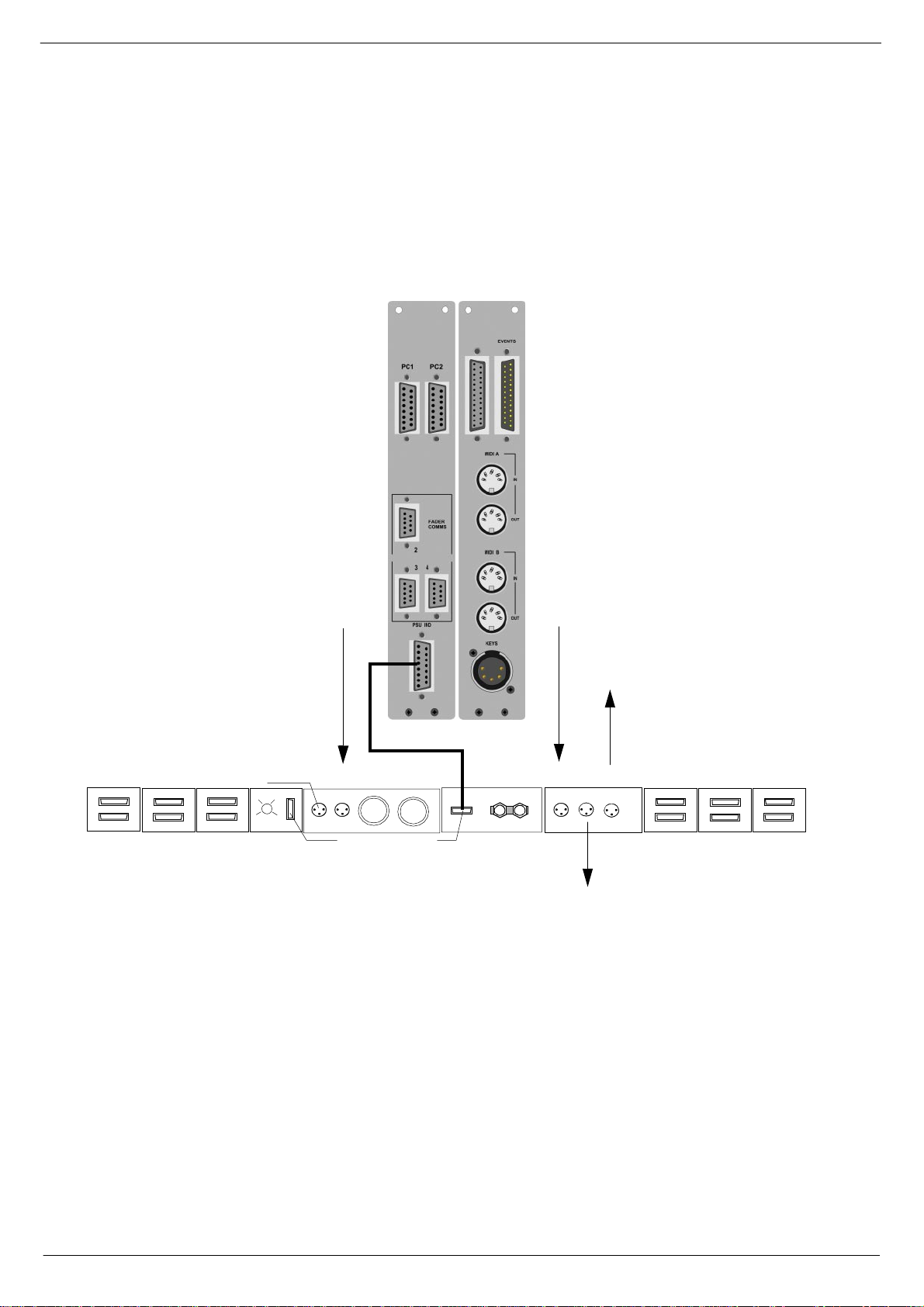

41715 )DGHU#FRPPXQLFDWLRQV

When motor faders are used in ext ension frames, a 9-way “FADER COMMS” cable

must be connec ted between the CCM connectors shown (see fig 2-3) and the

COMMS input on the extension fr ame rear panel.

Extension frames fitted with motor-fader s require control da ta from the CCM. Three

9-pin female connec to rs lo ca te d o n the r e ar pa ne l of t he CCM ar e co nn ecte d dir ec tly

to the extension frame us ing the supplied ‘fader comms’ cable. The frame containing

the CCM sends motor data fader data, via the 7303 interface module (always

mounted directly below the CCM on J-type consoles).

4

5

AUDIO BUS

FRAME TO FRAME

6

7

DATA BUS

COMMS TO CCM

FRAME

SELECTOR

Thus , a 3 frame console would requi re two “FADER COMMS” cables:

“FADER COMMS on EXTENSION FRAME 1 TO “FADER COMMS 2” on CCM

“FADER COMMS on EXTENSION FRAME 2 TO “FADER COMMS 3” on CCM

41716 3)/

PFL mixing amplifiers are located in the “O scillat or/Commu nications ” module. There

are two PFL outputs:

PFL Direct is a line lev el output that appear s on an XLR 3-32 connector on the

■■■■

rear panel of the OSC/Comms module, labelled “ PFL DIRECT”;

PFL to H eadphones is a high level output suitab le for driving headphones that

■■■■

appears on an XLR 3-32 connector

panel of the OSC/Comms module,labelled “PFL TO HP”.

Revision F2005-2 F-Type

a TRS jack socket connector on the rear

and

Page 20

1-12 Connecting the mixer systems

The PFL to Head ph on es sig na l c an be co on ne ct ed to th e T RS jack sockets mo unte d

on the front of the console frame by using the “OSC/COMM TO FRAM E” cable supplied. This cable has a male XLR 3-pin connector on one end and a female XLR 3pin on the other end. Connect one end of the “Osc illator/Communications” module’s

“PFL TO HP” connector and the other end to the rear frame connector labelled

“FROM PFL HEADPHONE XLR”.

Additional in ter-frame connections are required to enable the PFL signals from modules i n extension (side) frames to be monit ored. Use the cable(s) labelled “PFL

FRAME TO FRAME” to interconnect two or more frames:

Connect one end of a “PFL FRAME TO FRAME” cable to the connector labelled

■■■■

“TO NEXT FRAME” on the console frame containing the “Osc/Communications”

module.

Connect the other end of a “PFL FRAME TO FRAME” cable to the connector

■■■■

label led “FR O M PFL HEADPHONE XLR” on the next f rame.

Repeat this procedure for all other frames in the c onsole system.

41717 /LWWOLWHV

Surface illumination of the console is provided by the use of two or more “Littlite”

units that plug into the top bar of the console frame. Control for the “Littlites” - on/off

and in tensity - is located on the “Oscillator/Communi c ations” module. The variable

voltage power supply is mounted inside the console f rame.

Two cables are required to interconnect the “Littlit e” controls, the variable volt age

power supply and the lamp units.

Connect one of the cable labelled “OSC TO LITTLITES” to the connector on the

■■■■

rear panel of the “Oscillator/Communications” module labelled “LITTLITES” (this

cable has 4-pin XLR male and female connectors).

Connect the other end of the cable labelled “OSC TO LITTLITE” to the connector

■■■■

on the rear panel of the conso le frame labelled “FROM PFL MODULE”.

Connect one end of the cable labe lled “LITTLITE FRAME TO BAR” to the con-

■■■■

nector on the rear panel of the console frame labelled “TO LIGHTS” (this cable has a

4-pin male XLR connector at one end and a 5-pin XLR connector at the other end).

Connect the other end of the cable labelled “LITTLITE FRAME TO BAR” to the

■■■■

5-pin XLR-connector mounted at the rear of the top bar on the console frame.

Additional in ter-frame connections are required to enable the LITTLITE control signals to be delivered to any extension frame(s) in the console system. Use the

cable(s) labelled “LITTLITE FRAME TO FRAME” to interconnect two or more frames.

Connect one end of a “LITTLITE FRAME TO FRAME” cable to the connector

■■■■

labelled “TO NEXT FRAME” on the console frame containing the “Oscillator/Communications” module;

Connect the other end of a “LITTLITE FRAME TO FRAME” cable to the connec-

■■■■

tor labelled “FROM PFL MODULE” on the next frame;

Connect one end of a cable labelled “LITTLI TE FRAME TO BAR” to the connec-

■■■■

tor on the rear panel of the console frame labelled “TO LIGHTS” (this cable has a 4pin male XLR connector at one end and a 5-pin XLR co nnector at the other end.

Connect the other end of a cable labelled “LITTLITE FRAME TO BAR” to the 5-

■■■■

pin XLR connector mounted at the rear of the top bar on the console frame.

Repeat this procedure for all other frames in the c onsole system.

41718 368#,QGLFDWRU

Two sets of four LEDs are in corporatedinto the CCM front panel to give the operator

visual indication that the “main” (PSU System 1) and “backup” (PSU System 2)

power supply units are working correctly. A cable,labelled “PSU IND.” is supplied to

interconnect the CCM and the console frame.

F-Type Revision F2005-2

Page 21

Connecting the mixer systems 1-13

Connect one end of the “PSU IND” cable to the “PSU IND” 15-way male D-sub

■■■■

connector on the CCM.

Connect the other end of the “PSU IND” cable to the “PSU IND” 15-way female

■■■■

D-sub connector on the rear console frame adjacent to the two multi-pin power input

connectors.

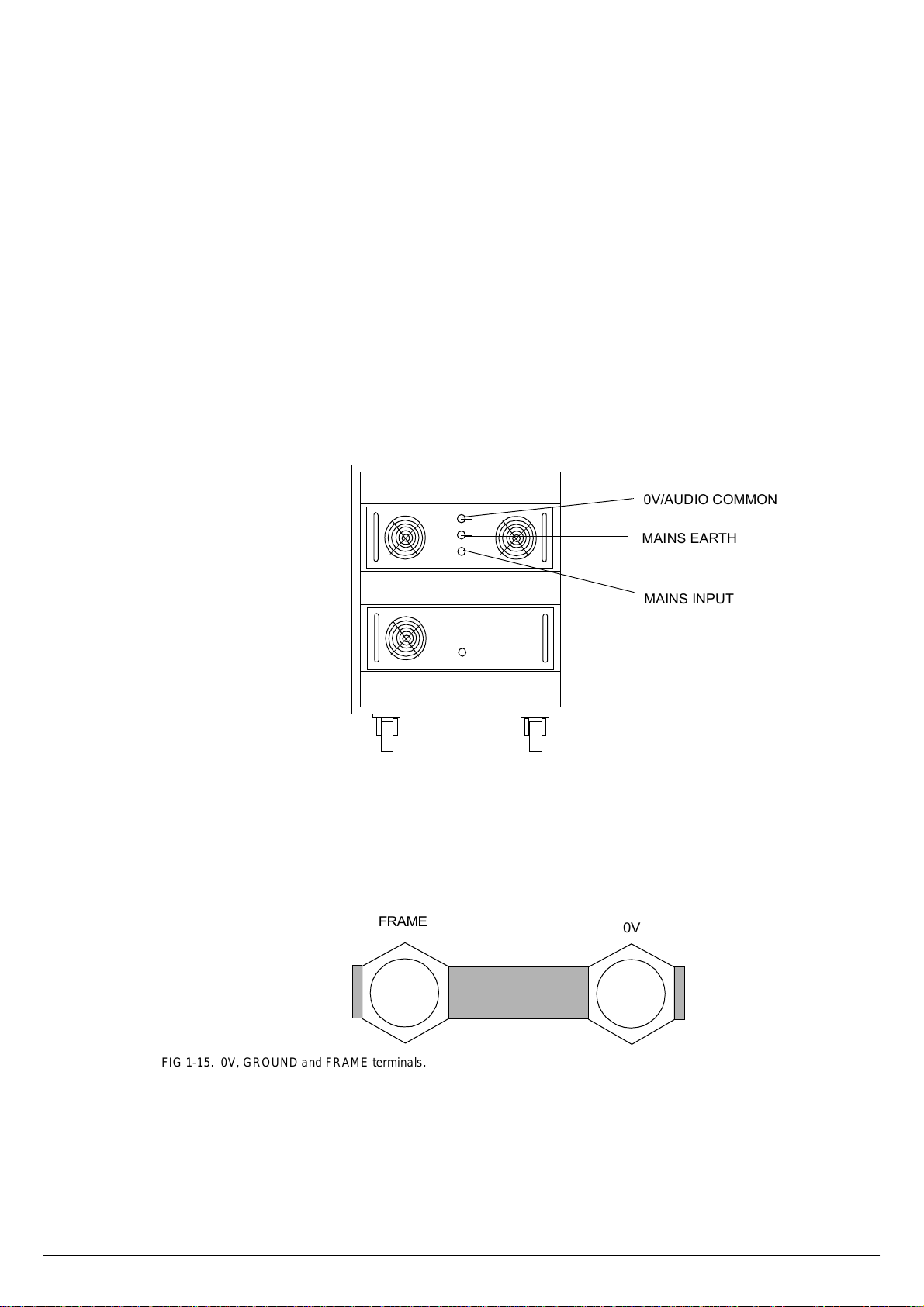

41719 (DUWK/#39#DQG#)UDPH#&RQQHFWLRQV

Figure 1-6 shows the rear panels of the power supply units in a single PSU system.

Under normal conditions, the 0V and Mains-Earth terminals can be connected on

both PSU systems. However, if the a.c. input lines to each pair of PSU’s has a different length, you may find that the 0V and Mains-Earth terminals can only be linked on

set of power supplies, f or minimum system noise .

one

FIG 1-14. PSU system.

The 0V or FRAME terminals on a PSU need

or FRAM E connections on console frames. The shielde d power supply cables are

connected to the frame at both en ds.

be dir ec tly co nn ec te d t o th e 0 V and/

not

392$8',2#&20021

0$,16#($57+

0$,16#,1387

In addition to the terminals on the back of the PSUs, there are

nections on the rear of ea ch console frame. The shorting-bar link between the 0V

and “FRAME” terminals on each frame

large diameter ‘frame-link’ cables (supplied with multi-frame consoles), must be connected. Always make sure that ‘frame-link’ cable nuts are tightened against the copper bar.

be conn ected. For minimum noise, the

must

0V

and

FRAME

con-

)5$0(

FIG 1-15. 0V, GROUND and FRAME terminals.

The 0V and FRAME t e rminals are linked in the factory with a copper bar. This bar

should never be removed when the console is in normal use. Note that

cannot be delivered from the input modules to the 48V bus if the copper bar is

Power

missin g, beca us e t he scre en ed mic rop ho ne input ca b l es w il l not be te rmina te d. I t wil l

also cause damage to the motor faders.

Revision F2005-2 F-Type

39

Phantom

Page 22

1-14 Connecting the mixer systems

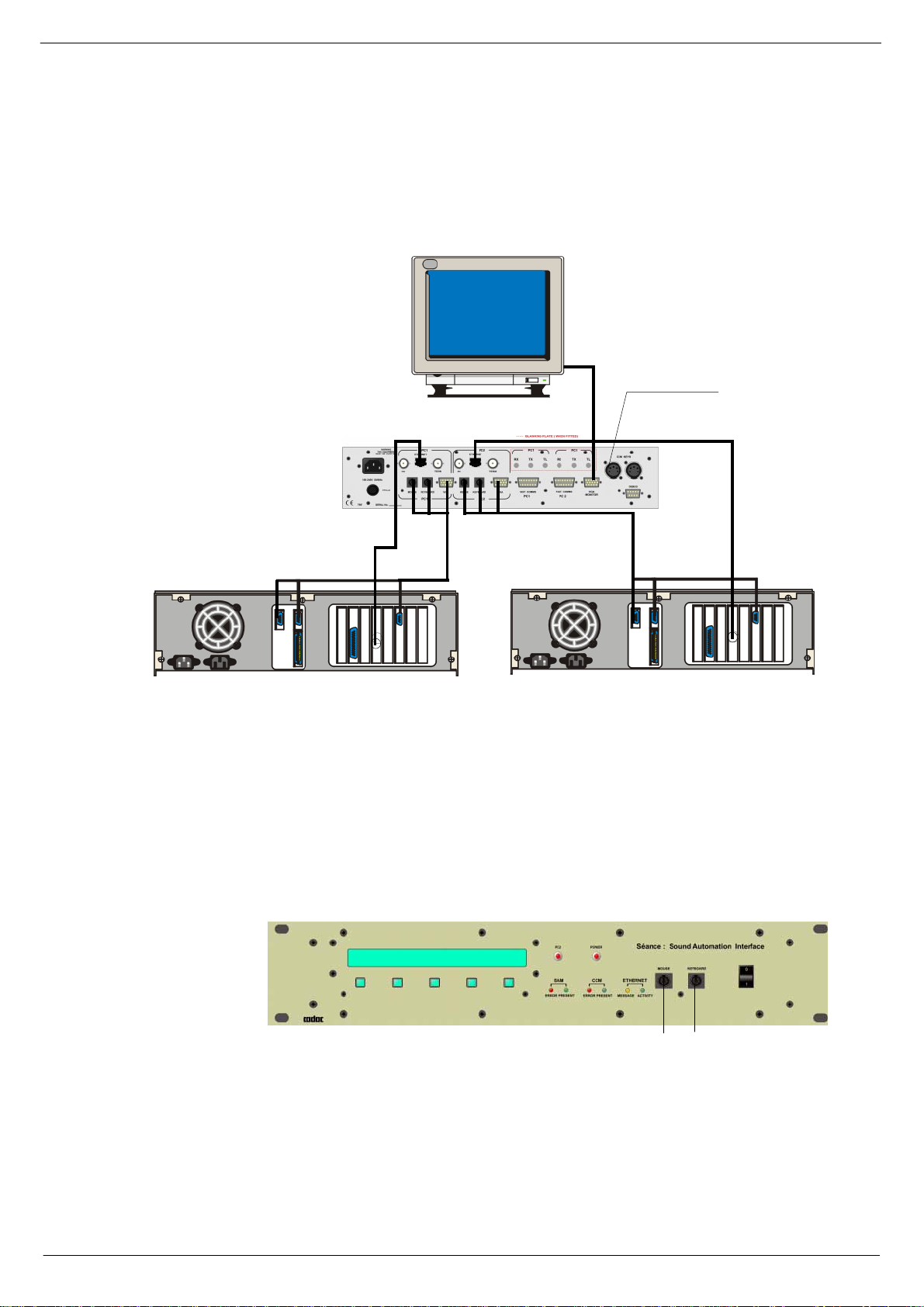

418 &RQQHFW#&RQVROH#$XWR PD WL RQ#6\VWHP

41814 &RQQHFWLRQV#0#%1&

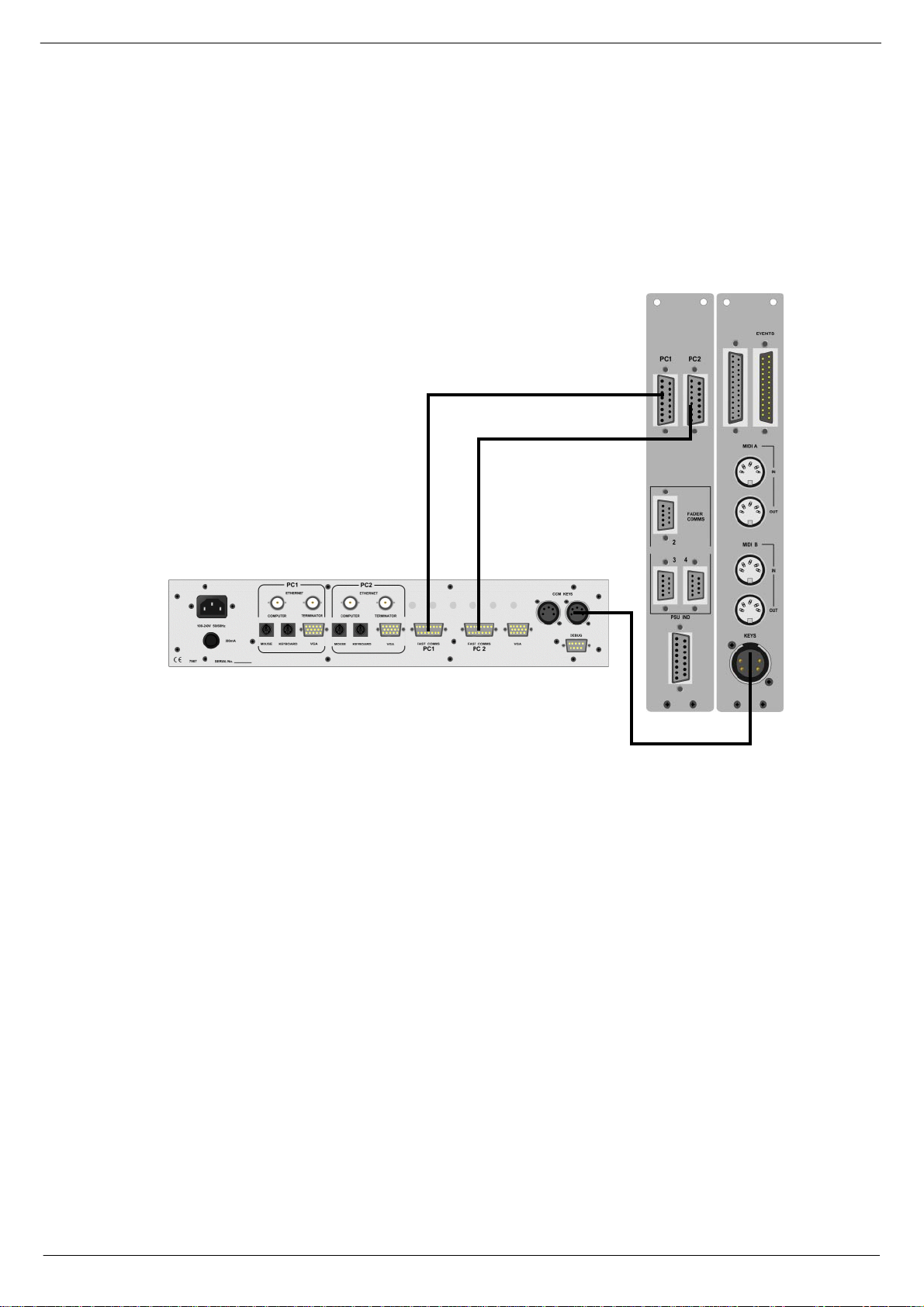

Figu res 1 - 9 be lo w a nd 1- 1 1 s how h o w t o c onn ec t th e S éan ce box to the cons ole an d

the co mputers running SAM., BNC type c onnection.

7R#UHPRWH#3.1

83#RKP#WHUPLQDWLRQ

(WKHUQHW#WHUPLQDWHG#DW#3&#HQG

0RXVH

.H\ERDUG

9*$

(WKHUQHW#WHUPLQDWHG#DW#3&#HQG

0RXVH

.H\ERDUG

9*$

3&4#ZLWK#(WKHUQHW#FDUG 3&5#ZLWK#(WKHUQHW#FDUG

FIG 1-16. Séance rear panel connections for BNC

41815 (WKHUQHW#0#%1&

The Séance box communicates with the PCs over a 10Base-2 Ethernet connection

via a 50 ohm BNC cable terminated at each end with a 50 ohm terminator. The

Séance box has two B NC connectors for each PC interface, which are wired in parallel in side. A 50 ohm terminat or plugs into the BNC socket la belled TERMINATOR

and th e Ethernet ca ble plug s into the BNC socket labelled COMPUTER. A terminator and T-piece are used to connect the Ethernet cable to the PC.

0LQLPXP#VSHFLILFDWLRQ#IRU#D#3&#XVHG#ZLWK#WKH#############

6RXQG#$XWRPDWLRQ#0DQDJHU#6RIWZDUH

To run the Sound Automation Manager software requires a PC with at least the

performance and peripher als as listed below:

PC Pentium 133 or later or compatible computer

Windows ®’98 (second edition), 2000, XP or XP Pro

Graph ics card 1024 x 768 pix els, 16 bit colour or better

Ethernet interface 10Mbit/sec with 10base2 c onnector (BNC)

128MB RA M

20 MB free hard disk space

PS/2 keyboard (older 5-pin DIN keyboard can be used with adapter)

PS/2 mouse or pointing device (9-pin’D’-serial devices cannot be used)PS/2

keyboard (older 5-pin DIN keyboar d can be used with adapter)

F-Type Revision F2005-2

Page 23

Connecting the mixer systems 1-15

41816 &RQQHFWLRQV#0#5-78

Figu re 1-10 below and fi g 1-11 show how to connect the Seance box to the console

and the computers running SAM, using RJ45 connection.

7R #UHPRWH#3.1

3&4#ZLWK#(WKHUQHW#FDUG

FIG 1-17. Séance rear panel connections for RJ45

41817 (WKHUQHW#0#5-78

The Seance box can also communicate with the PC via an RJ45 connector depending

on the type of Ethernet-card in the computer. The Séance box has two RJ45 connectors, one for each PC interface. T hese conn ectors should be connected directly into

a comp uter. It is al so po ss ib l e to c onn ec t th e R J45 so ck e ts t o a hub. For det ail s a bo ut

this , contact C ADAC technical support.

0RXVH

.H\ERDUG

9*$

0RXVH

.H\ERDUG

9*$

3&5#ZLWK#(WKHUQHW#FDUG

FIG 1-18. Séance front panel connec tions - BNC and RJ45

0RXVH .H\ERDUG

41818 0RXVH

Each PC has a ‘one-to-one’ PS2 mouse cable, which connects between the PC’s

mouse port and the mouse connec tor on the rear panel of the Séance box. The

mouse plugs into the mouse connector on the front panel of the Séance box.

Revision F2005-2 F-Type

Page 24

1-16 Connecting the mixer systems

41819 .H\ERDUG

Each PC h as a ‘ o ne-o ne ’ PS2 k e yboa r d c ab le , whi ch co nn ects be tw ee n t he PC ’ s k e yboard port and the keyboard connector on the rear panel of the Séance box. The keyboar d connects into the keyboard connector on the front panel of the Séance box.

Converters are supplied to connect to a 5-pin DIN keyboard and 5-pin DIN connectors

on the PC.

4181: 9*$

Each PC has a VGA cable connected between the computer’s VGA output and the

corresponding VGA connector on the rear panel of the Séance box. The VGA monitor

cable plug s int o the VGA con ne c tor.

4181; &&0#NH\V

The Séance interface r eads the PC2 switch on the console’s CCM. The 5-pin XLR

connectors are paralleled together inside the Séan ce. A ‘female-female, one-one cable ’ conn ects to the k eys conne ctor on th e CCM an d the ot her ca n be us ed to c onnec t

to remote PREV and NEXT keys if required.

4181< )DVW#FRSSHU#FRPPXQLFDWLRQV

CADAC’s 15 way “fast copper communications” cables are used to connect between

the Séance box’s fast comms connectors and the CCM. The cable plugged into Fast

comms PC1 on the Séance box must be connected to PC1 on the CCM.

418143 'HEXJ#SRUW

The debug port is standard PC 9-pin serial port that can be used to access the

Séance box’s computer.

418144 0DLQV

The Séance box has a universal power supply and can be connected to AC mains 100

– 240V, 50/60Hz.

418145 )XVH

20mm 315mA fuse

F-Type Revision F2005-2

Page 25

Connecting the mixer systems 1-17

418146 &RQQHFW#6pDQFH#WR#FRQVROH

Figure 1-12 below shows how to connect the Séance Interface to the CCM in the

main co nsole.

FIG 1-19. Connect Séance to CCM.

Using the cables supplied, make the following connections:

1. CCM PC1 to Séance box PC1.

2. CCM PC2 to Séance box PC2.

3. CCM KEYS to Séance box KEYS.

Details on Seance set-up can be found in the Seance Interf ace 7975 User & Installation manu al.

Revision F2005-2 F-Type

Page 26

1-18 Connecting the mixer systems

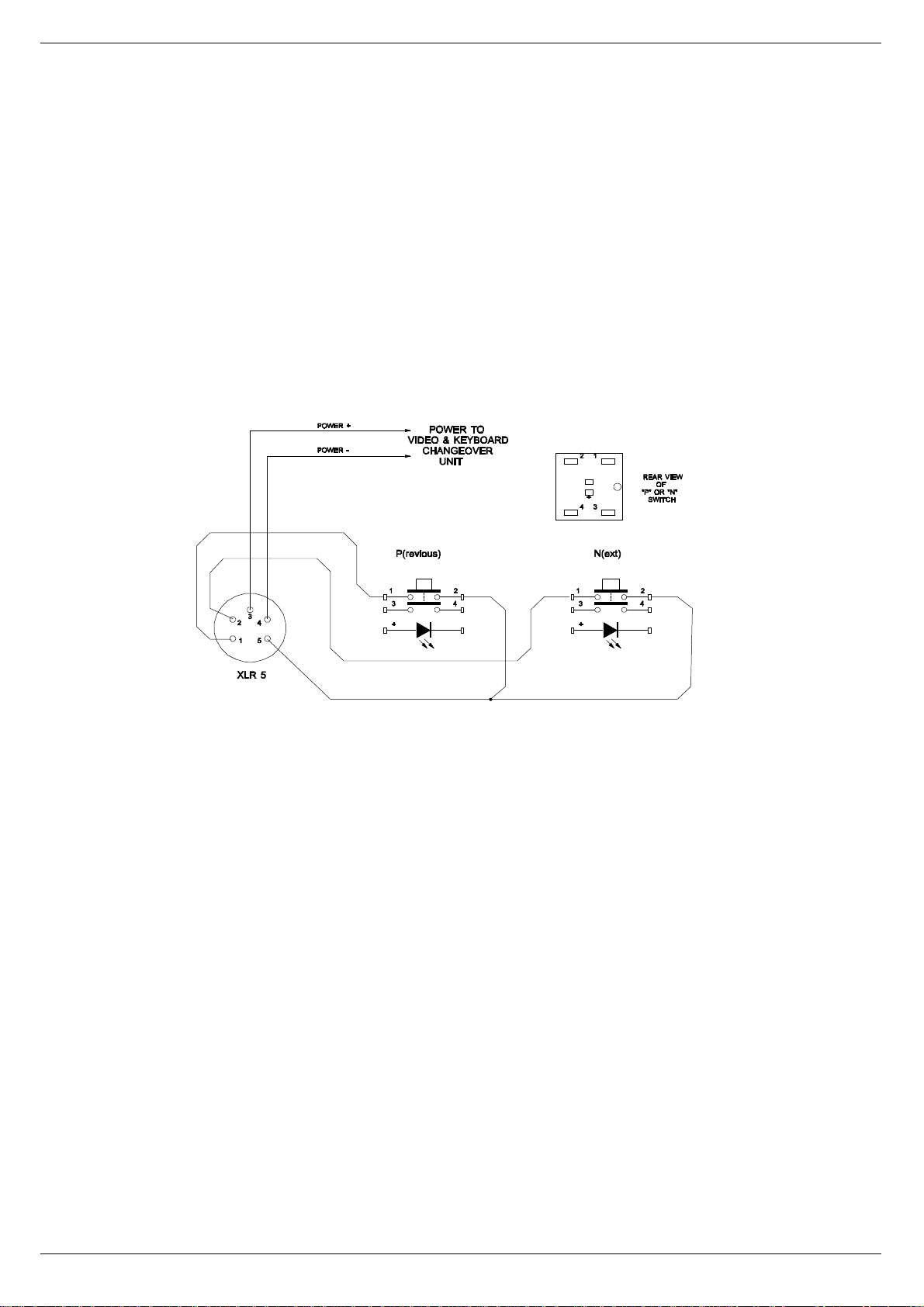

418147 8VLQJ#WKH#9LGHR#DQG#.H\ERDUG#&KDQJH#RYHU#IXQFWLRQ#ZLWK#

6pDQFH#

A single keyboard, mouse and monitor can be used with two computers for main/

back-up vi a th e Séance-box.

The Séance-box is supplied with a cable-kit allowing connections for one keyboard,

one monitor, one mouse and two computers PC1 and PC2.

Using the 5 pin XLR to XLR cable supplied, make the following connection:

CCM KEYS (at the console end) to one of the KEYS-connectors on the rear of

■■■■

the Séance-box.

The second keys connection on Séance is for use with

(see fig 1-20 ).

FIG 1-20. Remote P & N switch wiring detail.

Remote P and N

buttons,

418148 3&5#V\QFKURQLVDWLRQ

Using a Null modem serial interface cable with the appropriate connectors for the

computers in use, make the following connecti on between the two computer s.

PC1 COM 1 or 2 to PC2 COM 1 or 2 (select able in SA M)

■■■■

Two serial port configurations ar e in common use with 9 way or 25 way 'D-Type' connectors.

The two computers will only “trac k” each others’ Cue position if the SAM tracking feature has been enabled, see the SAM manual for details.

F-Type Revision F2005-2

Page 27

Connecting the mixer systems 1-19

419 &RQQHFW#PDLQ#IUDPH#IDFLOLW LH V#IURP#PRGXOHV#WR#

IUDPH

See figure below for instructions on how to connect main frame facilities from modules to frame.

)URP#&2006#PRGXOH#+3)/,

HEADPHONES NEXT FRAME

4

5

AUDIO BUS

6

7

DATA BUS

FRAME TO FRA ME

FRAME

SELECTOR

COMMS TO CCM

FIG 1-21. Connecting the main frame facilities from modules to frame.

PSU 1 PSU 2

PSU INDICATOR

)URP#&2006#PRGXOH

FROM PFL NEXT LIGHTS

FRAME - 0V

7R#QH[W#IUDPH

7R #IUDPH#WRS#EDU

AUDIO BUS

4

5

6

7

FRAME TO FRAM E

Revision F2005-2 F-Type

Page 28

1-20 Connecting the mixer systems

41: 6ZLWFKLQJ#21

41:14 6\VWHP#SRZHU0XS#SURFHGXUH

CADAC consoles are designed to work continuously with two power supply systems

- ‘mai n’ an d ‘b ac k u p’ . The ‘ma in ’ po w er sup ply pai r ( 1 off ‘1 8v ’ un it an d 1 of f 13V/ 48 V

unit ) are designated ‘System 1’. The ‘backup’ power supply pair (1 of f ‘18V’ unit and

1 off 13V/48V unit) are designated ‘System 2’

On each power supply, turn all AC input switches to the ON-position.

Start the ±18 V an d 13V/ 4 8V PSU s (in one PSU syst em) simu lt an eo us ly, by pressi ng

and holding the START-buttons until you hear the relay click. The CCM will cycle

through its self-test routines and any Master Mute sw itches previously selected will

be set ON, thus protecting external equipment from possible DC pulses when the

±18V PSUs ar e sta r ted.

Repeat for PSU system 2. If you cannot start the PSUs simultaneously, start the 13V/

48V first. However, do NOT operate the console for long periods without all power

lines on.

41:15 3RZHULQJ0XS#VHTXHQFH#RI#3&V

Always use the following procedure:

Power up console

■■■■

Powe r up Séance box

■■■■

Select PC1 on the CCM and power up the first computer. Wait until th e PC1

■■■■

computer has completed it s boot-up ro utine, then...

Switch to PC2 on the CCM and p ower-u p the second computer and wait until it

■■■■

has completed its boot-up routine.

Once both comput ers have boote d correctly, they should allow the k eyboard and

monitor to be switched back and forth without problems.

If the overall cable length for the keyboard and monitor are very long (greater than

5m), it may be necessary to use a keyboard and a monitor booster unit to retain keyboard reliability and a clean monitor display.

41:16 6\VWHP#SRZHU0GRZQ#SURFHGXUH

1. On the CCM, press all Master Mute switches to the ON (down) position.

2. Cl os e down the S A M so ftw ar e o n ea ch PC , sh ut do wn Wi nd ow s® a nd sw it c h the

computers off.

3. Switch off the AC mains supply to PSU system 1.

4. Switch off the AC mains supply to PSU system 2.

5. Switch off Séance Box

.

F-Type Revision F2005-2

Page 29

Central Control Module 7896 2-1

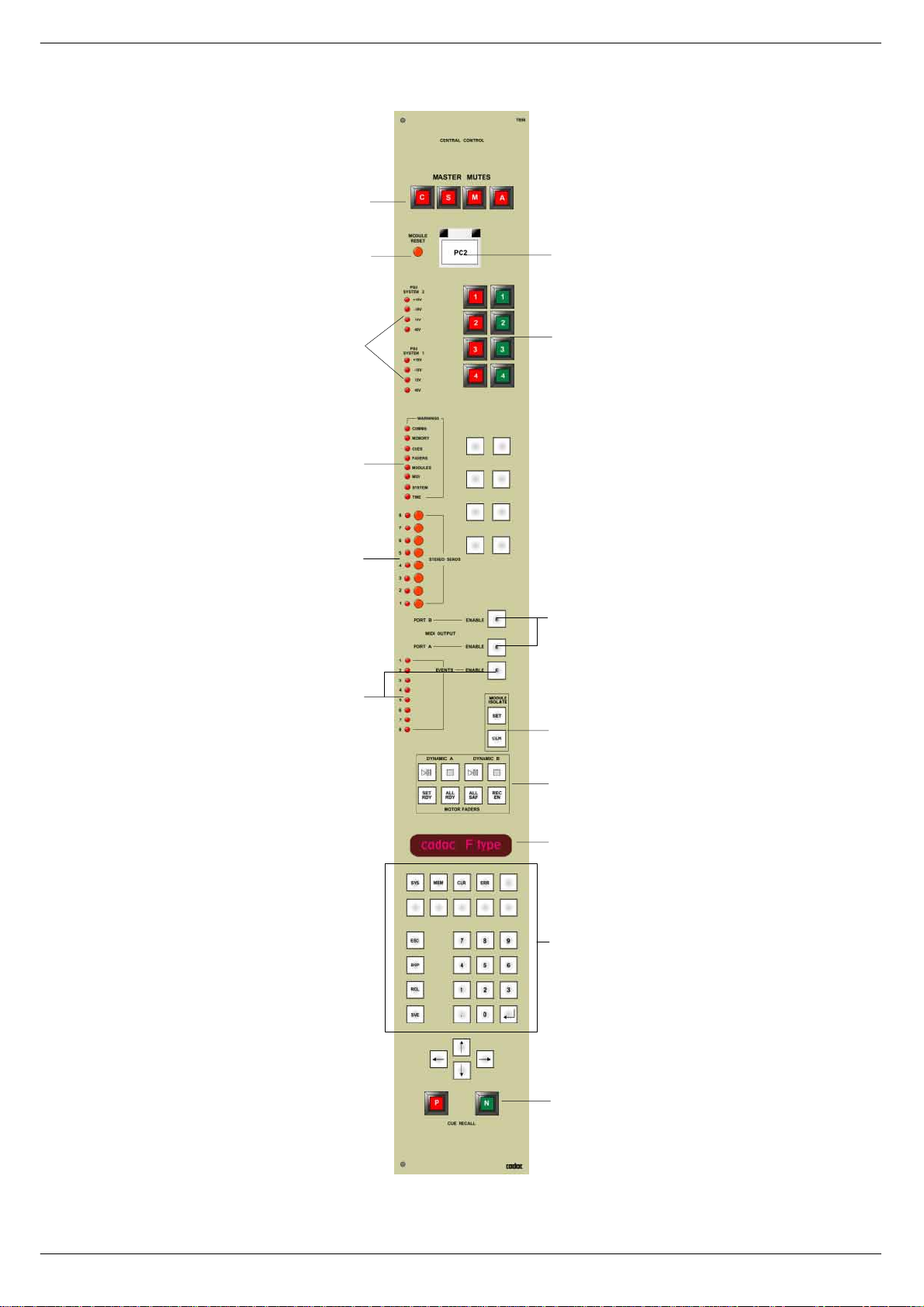

5 &HQWUDO#&RQWURO#0RGXOH#:;<9

514 &&0#)URQW#3DQHO#VZLWFKHV#DQG#GLVSOD\V

Please re f er t o fi g 2 - 1 o n pag e 2 - 2 f o r the l oc at i on of t he s wi tc he s an d d ispl ays on the

F-Type CCM front panel issue 7896 described on the next page.

D, 0DVWHU#0XWHV

Fo ur separate switches to globally mute the channe ls, subgroups, matrix groups and

aux gr oups. A ll four switches work in dependently, so that any combination of master

muting may be selected at any time. The switches are intended for manual operation

only, and their condition will not be recorded with a cue state.

E, 5HVHW

Resets the microprocessors within thi s module (rou ghly equivalent to turning the

power off then on again). Pressing reset does not clear the internal memories, maps

etc.

F, 3&5

The Sound Automation Manager software allows two computers to be used with the

syste m , PC1 and PC2 . Separate connect ors for each computer can be found on the

rear panel of the CCM. When the PC2 switch is pressed, all data to and from the

CCM will go to or come from PC2.

G, 368#6\VWHP#4#DQG#368#6\VWHP#5

The F-Type console is designed to be able to use two sets of power supplies simultaneously. These eight LED s continu ously show the status of the two sets of ±18V,

+13V and 48V power supply units. See 2.2 CCM rear panel connectors for connection details.

H, *2#0#6723

These are user configured switches for example remote control of cart machines,

tape recorders etc.

I, :DUQLQJ#/('V

These LEDs illuminate when a system function needs to be brought to the operator’s

attention. This may be an error condition, a “prompt”, or merely useful system information. The LEDs are labelled with the titles of each part of the automation system

about which the information is available:

1. COMMS Communications with the PC(s), Fast Copper connections.

2. MEMORY Storage space used by the microprocessor to hold items such

as maps a nd memories

3. CUES Recall of console states from the PC.

4. FADERS Console faders: channel, master and motorised.

5. MODULES Programmable modules.

6. MIDI Midi i nputs and ou tputs.

7. SYSTEM General category covering miscellaneous operations within the

CCM.

8. TIME Any timing activity, such as the current date and time.

Revision F2005-2 F-Type

Page 30

2-2 Central Control Module 7896

D

E

G

F

H

I

J

K

M

FIG 2- 1. F-Type CCM control panel.

N

P

Q

S

T

F-Type Revision F2005-2

Page 31

Central Control Module 7896 2-3

J, 6WHUHR#VHQGV

Eight momentary switches allowing you to put the associated aux group in stereomode. The LED to the left of the switch illuminates when the Aux group is in stereo.

K, 0,',#(QDEOH#VZLWFKHV

ON s witches for MIDI ports A and B. Th e switches are momentary and ill uminate

when the functions are enabled.

M, (9(17#/('V#DQG#(1$%/(

The LEDs show the operation of the EVENTS relays. The LEDs will only illuminate

when the ENABLE switch is ON.

N, 0RGXOH#,VRODWH#0#VHW#DQG#FOHDU

These two s witches perform g lobal switchi ng of ISOLATE function for programmable

functions such as channels and groups , in order to disconnect the console automation system.

P, 0RWRU#)DGHUV

This group of buttons provides a quick and convenient way of setting the console

autom ation system to both record and co ntrol the movement sequenc es of motor

faders.

The to p left pair control the play/pause and stop for the fir st dynamic sequence

(dynamic A) in a Cue.

The top right pair control the play/pause and stop for the second dynamic sequence

(dynamic B) in a Cue.

Both dynamics can be run simultaneously in the same cue.

Accidental movement of the motor faders can be prevented by use of the ALL SFE

and ALL RDY keys. In SAFE mode, touching the faders knob will have no impact on

the recorded sequence. In READY mode touching the fader knob will cause the

motor fader logic to toggle between READY and WRITE modes.

Therefore, editing of a recorded sequence can be performed for as long as the fader

knob is actually touched and the f ader remains in the READY mode .

Revision F2005-2 F-Type

Page 32

2-4 Central Control Module 7896

FIG 2-2. Keypad for controlling dynamics.

############

PLA Y/P A USE ( 1)

PLA Y/P A USE (2)

STOP (3, 4)

SET READ Y (5)

ALL READ Y (6)

ALL SAFE (7)

RECORDING ENABLED (8)

Stops the recorded sequence of motor fader

This mo de allows individ ual fa ders to be “toggled”

Plays, pauses or continues a recorded sequence of

motor fader movements associated with dynamic A. If

recording is enabled with the push-button (8), then this

but ton starts either a new recording, or starts an update

of an existing dynamic.

Plays, pauses or continues a recorded sequence of

motor fader movements associated with dynamic B.

movements.

between safe and ready mode by touching the fader

knob.

Sets all motor faders to ready mode.

Sets all motor faders to safe mode.

Prepares the computer for recording of a dynamic

sequence. Pressing button (1) starts the actual

recording.

Q, 0XOWL#IXQFWLRQ#DOSKD0QXPHULF#GLVSOD\

The 16 character alphanumeric display is the communication window between the

operator and the F-Type operating system.

In normal operating conditions the display will show one of the following:

CUE number, or

Current Mem ory numb er, or

“cadac ‘F-Type’ “ if no cue or memory is selected

The display is also used for system messages via the [err] button and to traverse the

various menus for testing, mapping, etc.

F-Type Revision F2005-2

Page 33

Central Control Module 7896 2-5

S, .H\SD G

The numeric keys [0] to [9] and the decimal point [.] are used to select a particular

cue or m emory number in conjunction with one of the function keys listed below.

Key Meaning Function

[Sys] SYSTEM Calls up the SYSTEM SETUP menu.

[Mem] MEMORY Selects one of the non-volatile internal memories.

[Clr] CLEAR Clears a selected memory (i.e. sets everything to

OFF)

[Err] ERROR Writes error message or information to alphanumeric

[Esc]

[Bsp] BACKSPACE Deletes the last number entered.

[Rcl] RECALL Recall a cue or memory.

[Sve] S AVE Store a cue or me m ory.

[↵] ENTER Selects a menu item, starts or acknowledges

The arrow keys, [←], [→], [↑] and [↓] are us ed to help navigate in the various menus.

The buttons are back-lit by LEDs, and will illuminate or flash to indicate that they will

perform a useful functi on if pressed at that time, or that their function has been

selected.

ESCAPE Moves backwards through a menu, or aborts an

display.

operation, can be thought of as a “cancel” button.

operations.

Unlabelled buttons are reserved for use in future software updates.

T, 35(9#DQG#1(;7#EXWWRQV

Use the previous or ne xt button to recall snapshots from the automation cue li st to

the console.

51414 6DIH25HDG\2:ULWH

The following instructions refer to the group of swit ches on the CCM labelled

“MOTOR FADERS”. See also 3.1.25 Ready and 2.1 m) Motor Faders.

To put all motor faders in SAFE mode: Press “ALL SAFE” switch.

To put all motor faders in READY mode: Press “ALL READY” switch.

To put a small number of motor faders in READY mode:

a) Press the “SET READY” switch.

b) Touch each fader knob that is to be recorded and make fader movement required.

c) Press the “SET READ Y” switch (to cancel the function).

Revision F2005-2 F-Type

Page 34

2-6 Central Control Module 7896

515 &&0#UHDU#SDQHO#FRQQH FWRUV

Please refer to figure 2-3 for the location of the connectors on the F-Type CCM module rear pa ne l de sc ribed below.

+D, )DVW#&RSSHU#&RPPXQLFDWLRQV#,22

Two cables provide the “f ast copper” data link between the CCM and up to two IBM®

PC or compati ble comp uters if these are fitted with a CADAC Fast Copper Communications board 7514. Other wise the cables run between the CCM and the Séance

box, see 1.5.1 Connections - BNC and 1.5.3 Connections - RJ45. T wo cables are

normal ly supplied, one for PC1 and the other for PC2. The conne c tors are labelled

differently at each end. Make sure that the “CONNECT TO CCM” end is connected

to the CCM! The other ends of the cables are lab elled “PC1” and “PC2” respectively

If the cables are not connected corr ectly, the communications system cannot work.

+E,# 368#,QGLFDWRUV

A cable with a 15 way 'D-Type' male connector at one end to a 1 5 way 'D-Type'

fe male connector at the other end is supplied for interco nnection between the

Indicators

the console frame.

male connector on the CCM and the

PSU Indicators

fem ale connector on

PSU

The

PSU System 1

will not work un less this connection is made.

and

PSU System 2

LEDs on the CCM front panel (e) in fig 2-1)

+F, 5HPRWH#&RQWURO#

The 25 way female 'D-Type' connector labelled RC, is for use with the eight “STOP”

and “START” swi tches mounted near t he top of the front panel (c) in figure 1.11).

Unless special instructions are received from the customer, this connector is not

D

J

F

I

G

E

FIG 2-3. F-Type CCM rear panel

F-Type Revision F2005-2

H

Page 35

Central Control Module 7896 2-7

wired dir ec tly t o the “STOP” an d “S TART” switches, but term i nates in a 25 way IDCconnector. This allows the user to configure the switch wiring to suit the equipment

they are intended to control. Great c are must betake n with the wiring of the

switch(es) to ensure that no short-circuits can occur between any two power supply

units.

+G, 0,',#LQSXWV#DQG#RXWSXWV

Fo ur 5 pin DIN, standard MIDI conn ectors for the two banks A and B are included.

The outputs may be connected to any MIDI compatible outboard equipment that

respond s t o pro gram change s , not e on / no te of f and vel oc it y in f orma tio n. Se e Sou nd

Automation Manager or SAM manual - MIDI, for programming details.

+H, .H\V

See 1.5.8 CCM key s and 1.5.14 Using the Video and Keyboard Change over func-

tion with Séance.

+I, )DGHU#FRPPXQLFDWLRQV

See 1.4.1 Audio Bus / Data Bus Co nnections, chapter 1.

+J,# (YHQWV

The 25 way male 'D-Type' connector labelled

tacts to be wired out for external equipment control. The wiring details are shown in

. See SAM manual for details.

Tab le 1

Pin no. Relay no. Function

01 1 normally C LOSED contact

14 1 MO VING contact (wiper)

02 1 norm ally OPEN co nt ac t

15 2 normally C LOSED contact

03 2 MO VING contact (wiper)

16 2 norm ally OPEN co nt ac t

04 3 normally C LOSED contact

17 3 MO VING contact (wiper)

05 3 norm ally OPEN co nt ac t

18 4 normally C LOSED contact

EVENTS

allows the EVENT relay con-

06 4 MO VING contact (wiper)

19 4 norm ally OPEN co nt ac t

07 5 normally C LOSED contact

20 5 MO VING contact (wiper)

08 5 norm ally OPEN co nt ac t

21 6 normally closed contact

09 6 MO VING contact (wiper)

22 6 norm ally OPEN co nt ac t

Revision F2005-2 F-Type

Page 36

2-8 Central Control Module 7896

Pin no. Relay no. Function

10 7 normally C LOSED contact

23 7 MOVING contact (wiper)

11 7 norm ally OPEN co nt ac t

24 8 normally C LOSED contact

12 8 MOVING contact (wiper)

25 8 norm ally OPEN co nt ac t

13 GROUND

516 ,QWHUQDO#PRGXOH#VHWWLQJV

51614 0RGXOH#SRZHU0XS#VWDWH#+,VR21LVR#VHOHFWLRQ,

When the console is first powered up, programmable modules may be set to power

up in ISOLATE mode or in NOT ISOLATE mode. This option is user selectable by

setting links on the motherboard. The factory setting is NOT ISOLATE.

51615 6HOHFWLQJ#RU#FKDQJLQJ#WKH#RSWLRQV

Plac e the CCM module on a flat surf ace so that the front panel is facing you and the

mothe r board is laying on the surface. Locate the three way male mol ex connector

. This can be found on th e mother board near the MIDI B LED25, close to the

CN29

front panel.

The factory setting is NOT ISOLATE, so that the

pins 2 and 3.

To change the POWER-UP STATE to ISOLATE:

Pull off the

programmable jumper

and replace it so that pins 1 and 2 are linked.

517 0RGXOH#OHYHO#VRIWZDUH

When first switched on or after being reset, the CCM display briefly shows the software version number a nd then executes a check of its internal memory.

Assuming all is found to be well, the display then changes to “cadac F-Type” and the

CCM is ready to be u s ed. This is one of the “root” displays, and it is always possible

to get back to this point by pressing the

several ti mes). The ot her “root” display possibilities are a

[Esc]

memory number

show which will perform a useful function if pressed at this point.

. If this is the case, the appropriate keypad buttons will illuminate to

key (it may be necessary to press

[Esc]

programmable jumper

cue nu m ber

is set to link

or a

The basic operations that can be performed from the “root” display can be summarized as follows, where button names are shown in

Operation:Type:

Recall cue at the EDIT pointer on PC

Save cue to CURRENT EDIT pointer on PC

Recall cue number nnn.n from PC

Save cue number nnn.n to PC

Recall internal memory n

F-Type Revision F2005-2

Mem n Rcl

Rcl

nnn.n Rcl

nnn.n Sve

Sve

bold

type:-

Page 37

Central Control Module 7896 2-9

Save internal memory n

Clear internal memory n

(where n is a number 0 - 9)

Expl ain a warning LED (if applicable)

Start the “System setup” menu

The P(revious) and N(ext) buttons can always be used at any time to recall the previous or next cue f rom the PC to the cons ole.

It is not necessary to give a complete four digit cue number, for example, cue

■■■■

25.0 can be entered as just “25”.

When a memory is “Cleared” all switche s are set to be OFF, all fader groups to 0

■■■■

and all master displays to be blank.

51714 6DYLQJ#D#&XH

To save a Cue, the CCM must be at one of its “root” displays, (see above for descriptions of the root displays). You can always get back to the root display by pressing

the

Enter the number required for the Cue, using the CCM keypad and press the [Sve]

key .

The console status will be saved to that Cue number (in RAM) and the Cue number

will appear in the Cue List Window on the PC.

If the Cue number already exists , the CCM display will prompt with “Overwrite

CUE?”. Similarly, the PC will prompt with:

key one or two times.

[Esc]

Mem n Sve

Mem n Clr

Err

Sys

“Cue n exists

Press ENTER to overwrite”

Press [↵] to confirm or

■■■■

pad or the equivalent keys on the PC's keyboard.

If you press the [Sve] key with no number, the system will try to save the console status to the Cue at the current pointer on the PC and will respond with the same

prompts as set out above. This does

Window, (this would be the case if you were starting to program a new Show). When

the Cue List Window is empty, [Sve] creates a Cue and gives it the number 1.0.

An invalid Cue number, (outside the range 0.01 to 9999.99), will result in the error

prompt “Bad cue number”, on the CCM display, and “Bad cue number from CCM”, on

the PC monitor. Press [↵] or

51715 5HFDOOLQJ#D#&XH

To recall a Cue, the CCM must be at one of its “root” displays, (see above for descriptions of the root displays). You can always get back to the root display by pressing

the

Enter the number required for the Cue, using the CCM keypad and press the [Rcl]

key .

If the Cue number exis ts, the console status will be updated to the data contained in

that Cue number (the last time it was saved).

key one or two times.

[Esc]

to cancel. You may use t he keys on the CCM key-

[Esc]

apply if there are no Cues in the Cue List

not

to continue.

[Esc]

If the Cue number does not exist, the CCM display will show the error prompt, “nonexistent cue” and the PC will show the error as “Cue n does not exist”. Press [↵] or

to continue.

[Esc]

Revision F2005-2 F-Type

Page 38

2-10 Central Control Module 7896

51716 6DYLQJ#D#FRQVROH#VWDWH#WR#DQ#LQWHU QDO#PHPRU\

To save a console state to an internal memory, the CCM must be at one of its “root”

displ a ys , (see ab o v e fo r de sc ript io ns of t he ro ot d is pla y s) . You ca n al w a y s ge t bac k t o

the root displ ay by pr essing the

Press the [Mem] key.

■■■■

Enter the number for t he internal memory.

■■■■

Press the [Sve] key.

■■■■

The console state is saved to the internal memory.

key several times.

[Esc]

51717 5HFDOOLQJ#D#FRQVROH#VWDWH#IURP#WKH#LQWHUQDO#PHPRU\

To recall a c onsole state from an internal memory, the CCM must be at one of its

“root” displays, (see above for descri ptions of the root displays). You can always get

back to the root display by pressing the

Press the [Mem] key.

■■■■

Ente r the num ber of the internal memory required.

■■■■

Press the [Rcl] key.

■■■■

key one or two times.

[Esc]

The current console state is replaced by the state stored in the internal memory.

518 7KH#6\VWHP #6HWXS#PH QX

This is a set of menus which are navigated by using the

and [↓], with selections being made by pressing

.

[Esc]

Menu items appear in the display with either a question mark (?) or pair of

arrows(⇑⇓) on the right. The arrows indicate that this is the title of the current menu

and that the user should press the up and down arrow keys to make a selection. The

question mark means that this is a selectable item, (press [↵] to select). The menu

wraps around, so if you move down from “User setup?” you get to “System setup

“again. In order to speed up the action of traversing these menus, they

⇑⇓

reset themselves to the title position each time that they are used. For example; if

“Map Faders?” was selected the last time the [Sys] key w as pressed, then the “M ap

Faders?” option will appear again, the next time the [Sys] is pressed (provided that

the CC M has not been reset).

Press the [Sys] key.

The first menu contains the following items:

#

System setup

Map Faders ?

Test Routines ?

User setup ?

The Map Faders, options will immediately perform that operation, whereas the Test

System , User Setup, M IDI recorder and MIDI mu ting selectio ns lead on to other

menus:

Title

⇑⇓

Perform fader mapping.

Move to the system test menu

Move to the user setup menu

and

up

down

], and cancelled by pressing

enter [↵

arrow keys [↑]

do not

System Test

Inc All Faders ?

Show MFdr data ?

Test Motor Fdrs ?

Test Key s ?

Test M IDI ?

Test Events ?

Test Fdr Comms ?

Show Time ?

Show Date ?

View Error Log ?

Clear Error Log ?

F-Type Revision F2005-2

Title

⇑⇓

Test routines for channel and group faders

Read information from the motor faders

Check mechanical operation of motor faders

Check keys in dicate on the display

Send programme changes to MIDI-connections

Check relays and indication of events

Check communicat ions busses

Show real-time clock

Show real-time clock and date

Look through the last record ed errors

Clear the error log.

Page 39

Central Control Module 7896 2-11

.

.. and...

User Setup

Enable options ?

Set P&N Keys ?

Midi PC Filter ?

MIDI All off ?

Show Map Add r e ss es ?

Faders GrpL nk ?

Twi n Ma sters ?

Event Duration ?

Revert Mode ?

Revert Time ?

PC Comms Error ?

Global Level ?

51814 0DSSLQJ

Before the console automation can be used, all faders and programmable modules

must be mapped. Each Map is s tored in non-volatile me mory within the CCM. Mapping operati ons should only need to be performed i f the layout of the modul es within

the frame have been changed. A new console is always mapped by CADAC before it

leaves the factory.

Each module position in a fr ame is identified by a unique number (the address) . This

number is set by a combination of a small PCB fixed to the frame beneath each module and the fram e number switch at the bac k of a frame. As each fader is connected

to a module, it too can be given a unique address.

Title

⇑⇓

Set 2nd Function on or off

Select how the P and N buttons are illuminated.

Program change filter on/off

All notes off messages on/off

Shows Module/Fader addr .while mapping on/off

Configure channel faders relative to master

Set number of twin masters

Set duration of event (i.e. length of pulse required

for control of external equipment)

Set motorized faders to revert to original position

when moved

Set the time it takes for a motorized fader to revert

to its original po sition

51815 &KDQQHO#0DSSLQJ

Ensure all faders are

the sys tem setup menu and press [↵].

The display changes to “Wait......”, as the CCM checks for faders in the console.

When the ch ec k is c omp le t e, t he di splay changes to “Faders: 0". The CCM is no w

ready for mapping to begin.

Press the

1"

then extinguish - the CC M display should now read “ Faders: 1 “. Now press the

MUTE VCA

next one along - the CCM display should now read “Faders: 2 “. Continue setting

each channel into

have been mapped.

To map the DC Master F a de rs , co nt in u e alon g t he cons ole f rom lef t t o right , pr es si ng

the

shows the

controlled by each Master Fader is set by switches on the fade r PCB and is

affected by fader mapping.

If y ou are satisfied that the cons ole fad ers hav e been mapped correctly, press [↵] to

stop ma ppin g and sto re th e new map, ot her wis e pr es s

MUTE VCA

, usually the left-most fader in the frame. The

button of the channel fader you wish to be

buttons for the MASTER faders. The number sho wn in the CCM display

MUTE

total

NOT ISOLATED

but ton of the channel fader that yo u wish to be

MUTE

number of fa ders in the console . Note that the DC MASTE R bus

*URXS#0RGXOH

with their

and

NOT MUTED

MUTE VCA

. Select “Map Faders?” from

“chann el fader

MUTE VCA

button until al l the channel fad ers

led will illuminate briefl y

“cha nnel f ader 2"

, usua lly the

not

to cancel thi s operation.

[Esc]

To map the DC Ma ster Fader, press the MUTE button located abov e the DC Master

Fader.

Revision F2005-2 F-Type

Page 40

2-12 Central Control Module 7896

51816 7HVW#5RXWLQHV

See below for options.

D, 6\VWHP#WHVW#²#7HVW#IDGHUV#4

In the system menu, select “

The display shows “

Press [↵], followed by the Down Arrow button, until the display shows “

■■■■

”

Faders?

Press [↵]. The display changes to “

■■■■

The group number display on each of the channels faders increments from 0 to C,

before returning to zero.

At the same time on the channel, the following automated switches cycle:

At the end of ea ch cy cle:

Meanwhile the groups automated switches cycle:

Test Routines?”

Test Routines?”.

MIC 1 ON

MIC 2 ON

PAN

LP FILTER

HP FILTER

EQ 1 IN

EQ 2 IN

INS

VCA MUTE

NEXT TIME

AUX

NEXT TIME

VCA MUTE & AUX

using the Up or Down ar row butto n.

Testing Faders

”.

Inc All

INS A

INS B

MAT PRE

SUB INS

At the end of each cycle the DC Master MUTE turns ON and OFF.

Press

to return to the system menu or Down arrow to perform next test.

[Esc]

E, 6KRZ#0)GU#'DWD

In the system menu, select “

The display shows “

Press [↵], followed by the Down Arrow button, until the display shows “

■■■■

”

ers 2?

These tests are for the operation of Motor faders only

the console, skip these tests and go to 2.3.11 “

Press [↵]. Check that all Motor faders are responding and that their positions are

■■■■

corre ctl y displayed.

Using the Left and Right arrow keys, select the fader to test. (Press [↵] to go

■■■■

directly to the channel faders.)

The display shows: “Group 1:0000 00”

The left and right arrow keys may be used to select each fader in turn, group 1

through 16, then channel 1 upwards. The numbers displayed after the colon represent the raw fader data. If you are experiencing difficulties, please contact CADAC.

Test Routines?”

Test Routines?”.

using the Up or Down ar row butto n.

Test fad-

. If there are no Motor faders in

Test keys

”.

F-Type Revision F2005-2

Page 41

Central Control Module 7896 2-13

F, 7H V W#PRWRU#IDGHUV

In the system menu, select “

The display shows “

Press [↵], followed by the Down Arrow button, until the display shows “

■■■■

”

Fders?

Press [↵]. The Motor faders should now move up and down (they move slower at

■■■■

the bottom end). Check that all Mot or fader s are moving at the same rate and

that they run smoothly.

■■■■

Press

to return to the system menu or Down arrow to perform next test.

[Esc]

Test Routines?”

Test Routines?”.

using the Up or Down arrow button.

T est Motor

G, 7H V W#NH\V

In the system menu, select “

The display shows “

Press [↵], followed by the Down Arrow button, until the display shows “

■■■■

”

Keys?

Press [↵]. The display shows

■■■■

Press ea ch of th e b u tto ns , inc ludi ng th e P & N but t on s (b ut not th e Esc b u tto n) in

■■■■

turn, ensuring that the display shows what button has been pressed.

Check also the external P & N.

■■■■

Press

to return to the system menu.

[Esc]

Test Routines?”

Test Routines?”.

“Button = ...”

using the Up or Down arrow button.

H, 7H V W#0,',

In the system menu, select “

The display shows “

Test Routines?”.

Test Routines?”

using the Up or Down arrow button.

Test

Press [↵], followed by the Down Arrow button, until the display shows “

■■■■

”

MIDI?

Press [↵]. This test outputs programme change to the MIDI-connections on the

■■■■

back of the CCM, indicating channel changes in ascending order for MIDI A (1-

16) and in descending order for MIDI B ( 16-1).

To perform a cable test and to ensure MIDI-cables have not been crossed over, a

cable can be connected between MIDI out and MIDI in. This will cause a flashing “A”

if connected between MIDI A output and MIDI A input and a flashing “B” if connected

between MIDI B out put and MID I B input.

Press [Esc] to return to the system menu or Down arrow to perform next test.

Test

I, 7H V W#HYHQWV

In the system menu, select “

The display shows “

Press [↵], followed by the Down Arrow button, until the display shows “

■■■■

”

Events?

Press [↵]. Make sure that the Events enable switch is on. The LED’s indicating

■■■■

events should now come on and off in sequence. Turning the enable switch off

should cause all the LED’s to extinguish.

Press [Esc] to return to the system menu or Down arrow to perform next test.

■■■■

Test Routines?”

Test Routines?”.

using the Up or Down arrow button.

Test

J, 7H V W#)GU#&RPPV

In the system menu, select “

The display shows “

Test Routines?”.

Test Routines?”

using the Up or Down arrow button.

Press [↵], followed by the Down Arrow button, until the display shows “

■■■■

Comms?

Press [

■■■■

returning to “

Revision F2005-2 F-Type

”

]. The display shows “Comms busses OK” for a few seconds before

↵↵↵↵

Test Comms?”

Test

Page 42

2-14 Central Control Module 7896

If there is a fault, a fault code is displayed indicating the type of fault .

■■■■

This test automatically returns to “Test comms?”.

K, 6KRZ#7LPH

In the system menu, select “

The display shows “

Press [↵], followed by the Down Arrow button, until the display shows “

■■■■

”

Time?

Press [↵]. The display shows the time as set in the PC.

■■■■

Press [Esc] to return to the system menu or Down arrow to perform next test.

Test Routines?”

Test Routines?”.

using the Up or Down ar row butto n.

Show

L, 6KRZ#'DWH

In the system menu, select “

The display shows “

Press [↵], followed by the Down Arrow button, until the display shows “

■■■■

”

Date?

Press [↵]. The display shows the date as set in the PC.

■■■■

Press [Esc] to return to the system menu or Down arrow to perform next test.