Page 1

#

&g8;2'

Audio Mixing Console

-056#..#6+10#n#95'4#1#07#.

Page 2

CADAC Electronics

One New Street

Luton

Bedfordshire

LU1 5DX

England

Tel + 44 (0) 1582 404 202

Fax +44 (0) 1582 412 799

email: info@cadac-sound.com

While every effort has been taken to ensure the accuracy of the contents in this manual, CADAC Audio Mixing Consoles are subject to continu ous development, hence the inform ation in this manual may not reflect the latest product updates.

© Copyright CADAC Electronics plc. 2005.

Page 3

Table of Contents iii

7DEOH#RI#&RQWHQWV

6(&7,21 3$*(

*HQHUDO#3UHFDXWLRQV 1111111111111111111111111111111111111111111111 #LLL

,QWURGXFWLRQ11111111111111111111111111111111111111111111111111111111111111#Y

4 &RQQHFWLQJ#WKH#PL[HU#V\VWHPV1111111111111111111111111111 #404

1.1 Console modularity ....................................................................... 1-1

1.2 Frame rear connections................................................................1-1

1.3 Connect Power supply systems.................................................... 1-2

1.4 Connecting the console frames .................................................. 1-11

1.5 Connect Console Automation System ........................................ 1-14

1.6 Connect main frame facilities from modules to frame.................1-19

1.7 Switching ON .. .... ............... .... .... .... ............... .... .... .... ............... ... 1-20

5 &HQWUDO#&RQWURO#0RGXOH#:;<9 1111111111111111111111111111111 #504

2.1 CCM Front Panel switches and displays ......................................2-1

2.2 CCM rear panel connectors.......................................................... 2-6

2.3 Internal module settings................................................................ 2-8

2.4 Module level software................................................................... 2-8

2.5 The System Setup menu ............................................................ 2-10

6 ,QSXW#&KDQQHO#PRGXOH#::4; 111111111111111111111111111111111 #604

3.1 Input Channel module 7718 - front panel...................................... 3-2

3.2 Input Channel module 7718 - rear panel ...................................... 3-8

7 ,QSXW#&KDQQHO#PRGXOH#:;;< 111111111111111111111111111111111 #704

4.1 Input Channel module 7889 - front panel...................................... 4-2

4.2 Input Channel module 7889 - rear panel .................................... 4-12

8 6WHUHR#,QSXW#PRGXOH#::94 11111111111111111111111111111111111 #804

5.1 Stereo Input module 7761 - front panel ........................................ 5-2

5.2 Stereo Input Module 7761 - rear panel ......................................... 5-8

9 *URXS#0RGXOH#::89 1111111111111111111111111111111111111111111111 #904

6.1 Group module 7756 - front panel.................................................. 6-2

6.2 Group module 7756- rea r panel............ .... .... .... ............... .... .... .... . 6-9

: *UDQG#0DVWHU#*URXS#PRGXOH#::<811111111111111111111111 #:04

7.1 Grand Master Group module 7795 - front panel........................... 7-2

7.2 Grand Master module 7795 - rear panel....................................... 7-9

; 0DWUL[#0RGXOH#:::3 111111111111111111111111111111111111111111111 #;04

8.1 Matrix Module 7770 - front panel .................................................. 8-2

8.2 Matrix module 7770 - rear panel...................................................8-6

< $X[LOLDU\#2XWSXW#0RGXOH#:79; 11111111111111111111111111111 #<04

9.1 Auxiliary Output module 7468 - front panel................................... 9-2

9.2 Auxiliary Output Module 7468 - rear panel ................................... 9-3

43 /LVWHQ#0RGXOH#:;<4 11111111111111111111111111111111111111111111 #4304

10.1 Listen Module 7891 - front panel ................................................ 10-2

10.2 Listen Module 7891 - rear panel ................................................. 10-6

44 2VF/#&RPPV#)#3)/#PRGXOH################################################

::8;#+007\SH#JURXSV, 1111111111111111111111111111111111111111 #4404

11.1 Osc, Comms & PFL module 7758 - front pane l ........ ... .... .... ....... 11-2

11.2 Osc, Comms & PFL Module 7758 - rear panel ......... ... .... .... .......11-9

Revision B2005-2 B-Type

Page 4

iv Table of Contents

45 2VF/#&RPPV#)#3)/#PRGXOH##################################################

:968#+)07\SH#JURXSV,# 4504

12.1 Osc, Comms & PFL module 7635 - front panel.......................... 12-2

12.2 Osc, Comms & PFL Module 7635 - rear panel........................... 12-7

$SSHQGLFHV11111111111111111111111111111111111111111111111111111111#$330,

,QGH[111111111111111111111111111111111111111111111111111111111111111111 #,1'0,

B-Type Revision B2005-2

Page 5

General Precautions v

*HQHUDO#3UHFDXWLRQV

'DPDJH

(QYLURQPHQW

&OHDQLQJ

7UDQVSRUW

6DIHW\#,QVWUXFWLRQV

Do not place heavy objects on the contr ol surface, expose it to sharp objects or handle the console in any way that may cause damage e.g. rough handling and/or

excessive vibration.

Do not subject the equipment to dirt, dust, heat or vibration during op eration or storage. Never expose the console to rain or moisture in any form. Should the console

become wet, turn it off and disconnect from mains without further delay. The console

should be given sufficient time to dry out, before recommencing operation.

When cleaning the console , never use chemicals, abrasive substances or solvents.

The console control panels should be cleaned using a soft brush and a dry lint-free

cloth. For pe rsistent ma r k s, us e a soft cloth and is opropyl alcoh o l . Swi tches and

potentiometers do NOT require cleaning or lubrication. For faders, see below.

Transport the console in its purpose bu ilt flight-case; whilst at the same time taking

precautions to protect th e control surface from any damage. Always ma ke sure adequate manpower is available and correct lifting methods are taken when moving the

console.

Read the following before using the equipment

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

:

,QVWUXFWLRQV

,QVWDOODWLRQ

&RYHUV

3RZHU

3RZHU#FRUG

:DUQLQJ

0RLVWXUH

9HQWLODWLRQ

Keep these instructions for future reference. Follow all warnings in this manual and

those printed on the power supply units.

The console must be installed following the guide lines in this manual. Never connect

power amplif ier outputs directly to the console. Connectors and pl ugs must n ever be

used for any other purpose than for what they are intended.

Never use the power supply units without covers fitted. All service work must be carried out by qual ified personnel only.

The power su pply uni ts must always be connected to correctly rated mains power as

referred to in this manual and marked on the power supply units. The power supply

units must, at all times, be connected to the local mains power supply using the supplied po w er c or d. In c ase s w her e th e supp l ie d p lu g d oes not fi t , a qu al if i ed elec tr ic ia n

must be consulted.

The power cord must be routed in such a way that the risks of accidentally stepping

on it, stretching it or it being pinched, are minimized.

THIS EQUIPMENT MUST BE EARTHED !

In order to min imize risks of fire hazards and/or electric shock, the power supply unit

must ne v er be e x pos ed to moi st ur e or wa te r in any f orm; or b e us ed i n a damp or w et

environment . Never place liquid containers, such as for instance coffee/tea mugs, on

the power supp ly unit, so as to avoid spillage into openings.

Ventilation slots on the power supply or the console must never be covered or in any

other way obstructed. Air flow required for safe operation may otherwise be

restricted. Whe re the console is to be operated in its flight-case, then this must be

located in suc h a way that it allows for proper ventil ation.

6HUYLFH

Revision B2005-2 B-Type

Refer servicin g to qualified technical personnel only.

Page 6

vi General Precautions

B-Type Revision B2005-2

Page 7

Introduction vii

,QWURGXFWL RQ

CADAC consoles have an impressive track record when it comes to delivering faultless performance night after night, year a fter year, on almost every imaginable type

of production. International musicals, the world’s most prestigious theatres and

opera houses, major awards ceremonies - for critical applications where quality is

paramount, the CADAC name is synonymous with top quality audio within a rugged,

reliable package.

The introduction of B-Type Live Broadcast Console is CADAC’s first dedicated desk

fo r live studio applications. it was designed in response to t he broadcast industry’s

requirement for a more versatile, higher quality console that could provide an integrated solution - taking up a smaller footprint whilst offering a much more powerful

matrix and flexible output options. It provides crucial information at a glance switches are i lluminated for clarity in low light conditions, assignable VCA masters

are labelled wit h assignable alpha-numeric displays and modu les can be put in any

position in the frame to suit the operator ’s requirements.

The B-Type is designed to meet the needs of modern live broadcast programming offe ri ng mo dula ri ty wit h ea sy up gradeabi li ty, protect i ng y ou r inves tmen t f or t he fut ur e.

All without compromising the renowned CADAC reputation for superior audio quality,

reliability and enduring perform ance.

Revision B2005-2 B-Type

Page 8

viii Introduction

B-Type Revision B2005-2

Page 9

Connecting the mixer systems 1-1

4 &RQQHFWLQJ#WKH#PL[HU#V\VWHPV

414 &RQVROH#PRGXODULW\

The B-Type features CADAC ’s unique frame design which allow users to put any

module in any position, thus configuring the console to suit the project in hand. Each

module is fitted with XLR connectors and jack sockets on the rear vertical face,

enabling the module to be moved quickly and easily.

The B-Type module’s design features a motherboard, with plug-in daughter boards

fo r all audio and digital control functions. This ensures servicing simplicity and fast

replacement of any faulty component. Each module may be plugged into any p osition in the console frame, by means of top quality two-part connector system, which

is designed as a mating pair to provide excellent mechanical and electrical reliability.

A rail system is used to guide each module into its correct position. Also, the console

design allows modules to be removed or inserted without powering down.

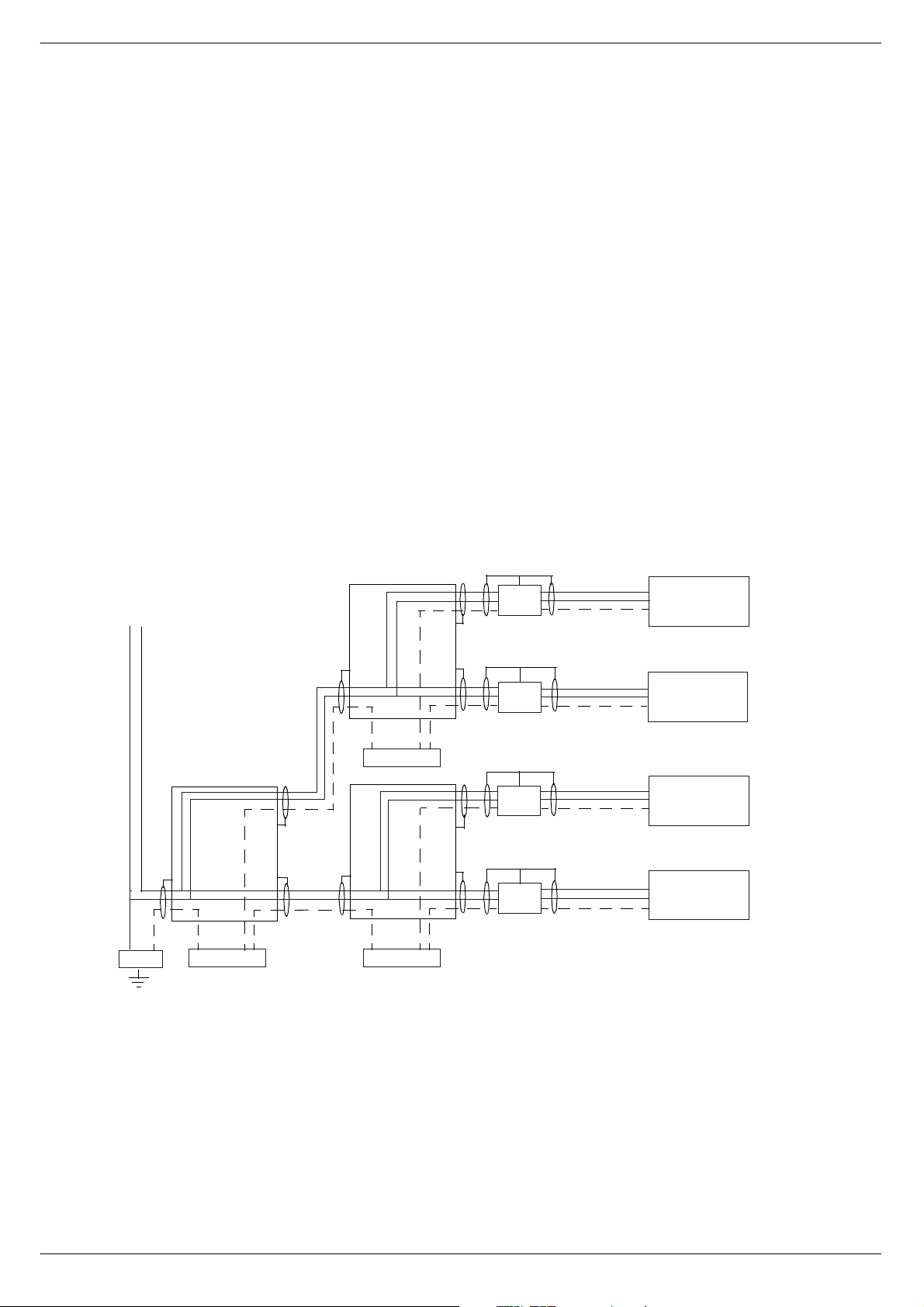

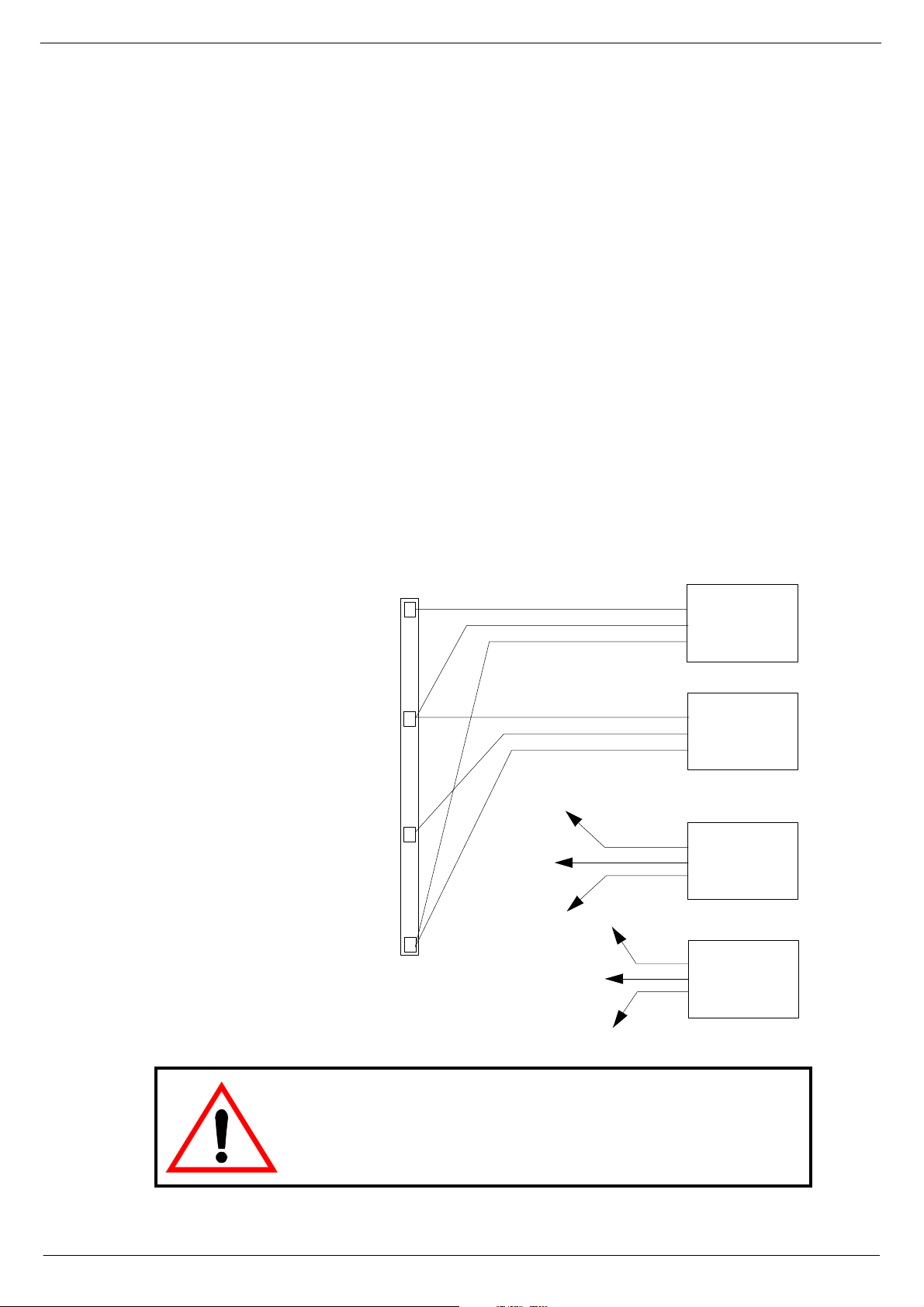

415 )UDPH#UHDU#FRQQH FWLR QV

HEADPHONES NEXT FRAME

4

5

AUDIO BUS

FIG 1-1. B-Type frame rear connections.

6

7

DATA BUS

FRAME TO FRAME

FRAME

SELECTOR

The connections on the B-Type console rear frame include the following (from left to

right):

■■■■

■■■■

■■■■

■■■■

■■■■

■■■■

■■■■

■■■■

■■■■

■■■■

■■■■

■■■■

■■■■

■■■■

■■■■

INPUT TO H EADPHO NES JACK SOC K ETS

COMMS TO CCM

PSU 1

PSU 2

PSU INDICATOR

FROM PFL NEXT LIGHTS

GND - 0 - FRAME

5 AMP FA N FUS E

Audio Bus - fr ame to frame, up to 4 frames can be connected.

Data Bus - fr ame to frame

Frame selector

Comms to CCM

PFL output to next frame.

PFL input from mod ule.

PSU1 co nnector

PSU2 co nnector

Output for monitoring of PSUs

GND - 0 - FRAME

Littlite input from PFL module.

Littlite output to next frame.

Littlite output to lights

Audio Bus

Data Bus

4

5

AUDIO BUS

FRAME TO FRAME

6

7

DATA BUS

The use of these co nnectors is describe d in 1.3.5 Main and extension frame power

connections, 1.4 Connecting the console frames and 1.5 Connect Console Automation System.

Revision B2005-2 B-Type

Page 10

1-2 Connecting the mixer systems

416 &RQQHFW#3RZHU#VXSSO\#V\VWHP V

41614 3RZHU#VXSSO\#V\VWHP#GHVFULSWLRQ

Cadac consoles are designed to allow th e use of two independent power supply systems in a redundant configuration – “main” and “backup ”. Both sets of power supply

units are used to power the console system so that under normal conditions, the

‘loa d’ is sh ar ed b etw e en th e “ m ai n” a nd “ bac ku p” PS U’s. I f a f a ul t o cc ur s in on e o f t he

power units ( c ausing it to ‘shut-down’), the remaining power unit will power the console.

For smaller B-Type consoles (consuming no more than 44A), it is possible to use the

8400 PSU. See 1. 3. 7 8 400 switch-mode power supp ly uni t.

One ±18V PSU and one +13V/+48V PSU is referred to as a “PSU System”.

Designate one pair of power supply units as “SYSTEM 1" and the other as “SYSTEM

2". PSU System 1 and PSU System 2 should be connected to the same

on the same ‘spur’, wherever possible. In situations where it is necessary to provide

a separate ‘feed’ to each PSU system pair, make sure that the cable lengths are the

same. This is to minimize any induced a.c. power input noise by ensuring that the

“EARTH IMPEDANCE” is the same for both PSU systems.

phase

and

$5($#%5$1&+#3$1(/

1#/

$5($#%5$1&+#3$1(/

*1'#%$5 *1'#%$5

0$,1#*5281'#5()(5(1 &(#($57+#(/(&752'(#6<67(0

$5($#%5$1&+#3$1(/

/

368#4$

-

-

-

-

1

(

/

1

(

/

1

(

/

1

(

368#4%

368#5$

368#5%

FIG 1-2. AC mains grounding diagram (single phase 200-240V)

B-Type Revision B2005-2

Page 11

Connecting the mixer systems 1-3

The a.c.-input connectors on each power supply unit have three conductors: ‘LIVE’

(brown), ‘NEUTRAL’ (blue) and ‘EARTH’ (yellow/green). For safety and electromagnetic compatibility considerations, it is essential that the ‘EARTH’ conductor is connected on all PSUs

continuous c ircuit to the “zero-signal reference potential” point in t he building. The

ZSRP point in a building is usually found near the place where the a.c. ‘mains’ supply

enters the building (often referred to as the “MAIN GROUND REFERENCE EARTH

ELECTRODE SYSTEM”). The basic concept for correct a.c. mains wiring distribution

is shown in figure 1-1. If you need further information about this complex subject,

please refer to “Grounding Systems and their Implementation” by Charles Atkinson

and Philip Giddins published in the AES Journal Vol. 43, No. 6 – June 1995.

The grounding scheme in CADAC consoles is designed to meet the rigorous EEC

Elec tromagne tic Compatibility

induced in the console frame(s) is directed to the “local” ZSRP, which is the metalwork of the power supply units. In order to take full advantage of the “RF noise immunity” capability of the CADAC system, PSU a.c. mains cables an d the a.c. mains

supply EARTH conductor must be connecte d correctly.

the a.c. supply has an ‘EARTH’ conductor that has a

and

requirements (EMC Directi ve - 1996 ). Any RF noise

41615 $&#SRZHU#UHTXLUHPHQWV

CADAC power supply units are designed to run from a minimum of 208 V up to a

maximum of 260V, 50/60Hz a.c. In many parts of the world the normal a.c. singlephase supply is 100-127V, this means that the CADAC power supply units must be

connected across two of the phases in the three-phase a.c. supply, see 1.3.4 Connecting to a 3-phase outlet.

41616 6ZLWFK00RGH#3RZHU#6XSSO\#8QLWV

CADAC 8019 and 8020 switch-mode power supply units are designed to run from a

minimum of 208V up to a maximum of 260V a.c, 50/60Hz.

The 80 19 “18 V ” uni t is r a te d at 10 0A per r a il an d the 8 020 “1 3V” un it is rat ed at 100A.

See also Appendices, B. Switch-Mode Power Supply Units,

;34<#´4;9µ#VZLWFK0PRGH#SRZHU#VXSSO\#XQLW

The ol der version of 8019 ±18v unit is based on two ADVANCE F20006 ‘powerblocks’, with additional circuitry as shown on CADAC dr awing number C3.8015. The

new version is based on PowerOne PSUs (serial number 3494 9 onwards).

The a .c. input is connected to the PSU via a 3-core cable, CMA reference 3183TQ –

BASEC approved, rated at 20A.

FIG 1-3. 8019 power supply unit

Revision B2005-2 B-Type

Page 12

1-4 Connecting the mixer systems

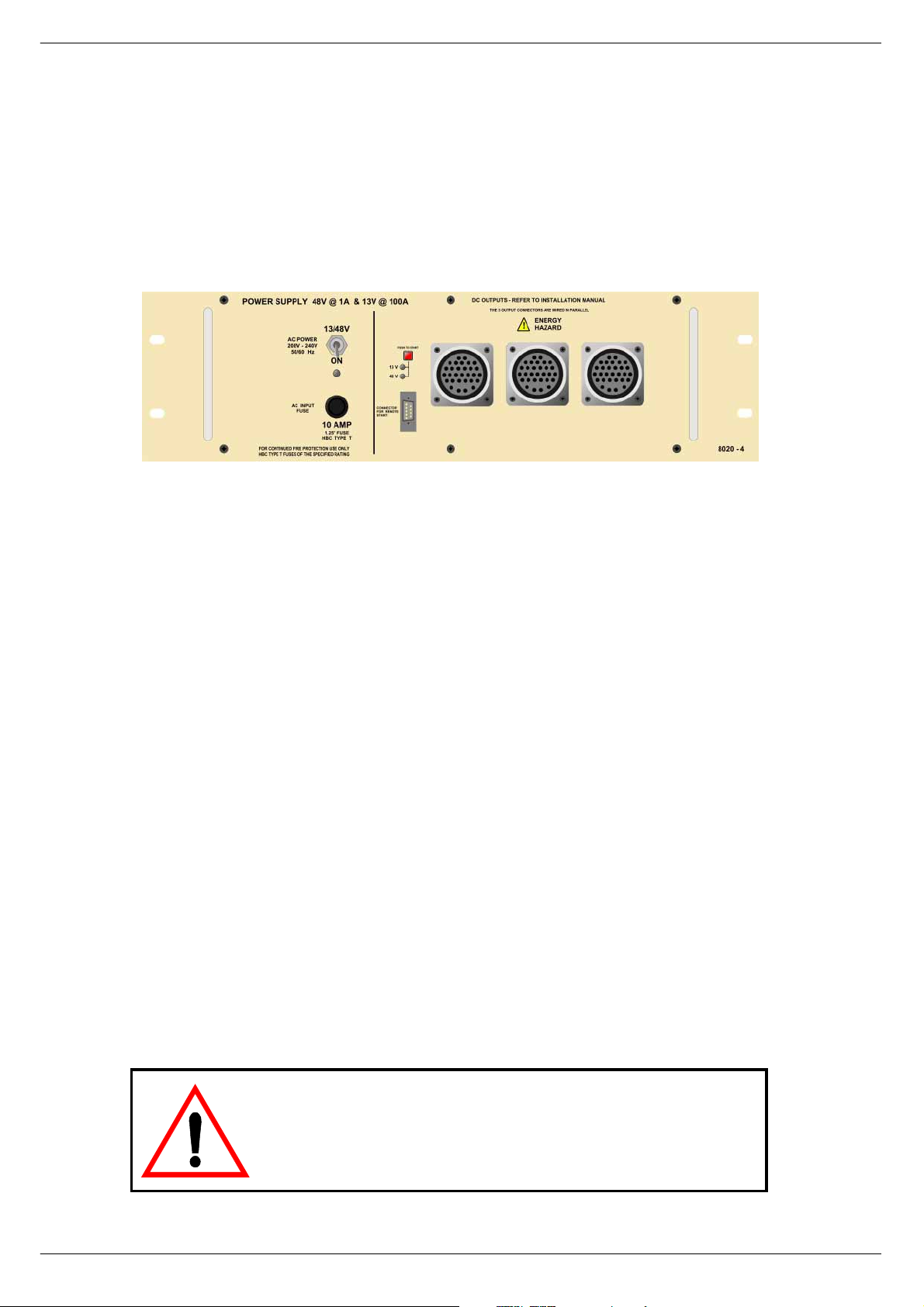

;353#´469µ#VZLWFK0PRGH#SRZHU#VXSSO\#XQLW

The ol der version of 8020 +13v/48v unit is based on one ADVANCE F20006 ‘pow erblock’, with additional circuitry as shown on CADAC drawing number C3.8016. The

new version is based on Pow erOne PSUs (serial numb er 34949 onwards).

The a .c. input is connected to the PSU v ia a 3-core cable, CMA reference 3183TQ –

BASEC approved, rated at 20A.

FIG 1-4. 8020 power supply unit

5HSODFLQJ#D#SRZHU#VXSSO\#XQLW

If replacing a switch-mode power supply unit is required, please note the following:

Make sure that the power supply s ystem’s power switches are in t he position

■■■■

OFF and disconnected from the mains.

The work should only be carried out by a suitably qualified electrician.

■■■■

Be careful to observe corr ect polarity when connecting the new PSU.

■■■■

Note that a console must never have one voltage without the other, f or exam ple

■■■■

+18V must never be fed into the console without -18V.

When switching the power supply system back ON after replacement has taken

place, make sure that both LEDs on the front of the PSU-system come on. If only

one LED comes on, let go of the ON push-button immediately. Failure to do so may

lead to fire hazar d and major damage to th e console.

NO TE:

Under no circumstances, should the 8019 or 8020

PSU be used without a SAFETY EARTH connection. Failure

to follow this instruction is both a fire and safety hazard.

B-Type Revision B2005-2

Page 13

Connecting the mixer systems 1-5

41617 &RQQHFWLQJ#WR#D#60SKDVH#RXWOHW

Connection to a 3-phase outlet is required on sites where the system voltage

between any one of the phases and neutral is 100-127V and the voltage between

any two of the phases is 20 0-240V. Before connecting to any 3-phase outlet, please

refer to a qualified electricia n who understands your particular installation and the

local safety and wiring regulations. Under no circumstances should the 8019 and

8020 switch-mode power supply units be operated without the green/yellow safety

earth conductor connected to the building safety earth conductor system. Each

power unit is equipped with an input supply filter whose reference ground conductor

is the chassis. Failure to connect the green/yellow safety earth conductor to the correct eart h/ground building reference is a safety and fire hazard.

1. Connect the LIVE (Brown) conductor on the “system 1” 8019 unit to the phase 1

(L1, RED) terminal on the 3-phase power outlet connecto r.

2. Connect the NEUTRAL (Blue) conductor on the “system 1” 8019 unit and the

LIVE (Brown) conductor on the “system 1” 8020 unit to the Phase 2 (L2, YELLOW) terminal on the 3-phase power outlet connector.

3. Connect the NEUTRAL (Blue) conductor on the “system 1” 8020 unit to the

Phase 3 (L3, BLUE) terminal on the 3-phase power outlet connector.

4. Connect the EARTH (Yellow/Green) conductor on the “system 1” 8019 unit and

the EAR T H ( Yellow/ Gr e en) co nd uc to r on the “sys te m1 “ 8 02 0 unit to th e SA FET Y

EAR TH (Yellow/Green) terminal on the 3-phase power outlet connector.

5. Repeat 1-4 for the “ system 2” power units.

3+$6(#4#+/4/#5(',

3+$6(#5#+/5/#<(//2:,

3+$6(#6#+/6/#%/8(,

6$)(7<#($57+

<(//2:2*5( (1

/5

6$)(7<#($57+

/4

/5

/4

/LYH

1HXWUDO

(DUWK

/LYH

1HXWUDO

(DUWK

/LYH

1HXWUDO

(DUWK

/LYH

1HXW UDO

(DUWK

;34<

;353

;34<

;353

FIG 1-5. Connecting to a 3-phase outlet

(100-127V/200-240 system voltages)

NOTE:

Connection between two phases in a 3-phase outlet should under no

6$)(7<#($57+

circumstances be carried out where the single-phase voltage (the voltage

between one of the phases and neutral) exceeds 127V. The installation

should be carried out by a qualified electrician who understands your particular installation and the local safety and wiring regulations.

Revision B2005-2 B-Type

Page 14

1-6 Connecting the mixer systems

41618 0DLQ#DQG#H[WHQVLRQ#IUDPH#SRZHU#FRQQHFWLRQV

See fig 1-4 below for schematics of the frames power connections.

1. Using a short U-LINK cab le (supplied), connect one of the outputs on the ±18V

PSU to one of the outputs on the +13V/+48V PSU in the “SYSTEM 1" power

supply rack. This operation “links” the d/c outputs on both power supply units in

the rack so that ±18V, +13V and +48V is available on all remaining output connectors on eith er power unit.

2. Co nn ec t t he seco nd s ho rt “U -LI NK” c abl e ( s up plie d) b etw e en the ± 18 V PS U an d

the +13V/+48V PSU’s in the “SYSTEM 2" power supply rack.

3. Connect a PSU cable between the “SYSTEM 1" rack and the “PSU SYSTEM 1"

connector on the MAIN FRAME.

4. Connect a PSU cable between the “SYSTEM 2" rack and the “PSU SYSTEM 2"

connector on the MAIN FRAME.

5. Connect a PSU cable between the “SYSTEM 1" rack and the “PSU SYSTEM 1"

connector on the EXTENSION FRAME 1.

6. Connect a PSU cable between the “SYSTEM 2" rack and the “PSU SYSTEM 2"

connector on the EXTENSION FRAME 1.

7. Repeat procedures 5 and 6 for EXTENSION FRAME 2 (a 3 frame console).

368#6<67 (0#4#+“4;9,

368#6<67(0#4#+7;92.469,

368#6<67(0#5#+“4;9,

368#6<67(0#5#+7;92.469,

FIG 1-6. Power connections

B-Type Revision B2005-2

Page 15

Connecting the mixer systems 1-7

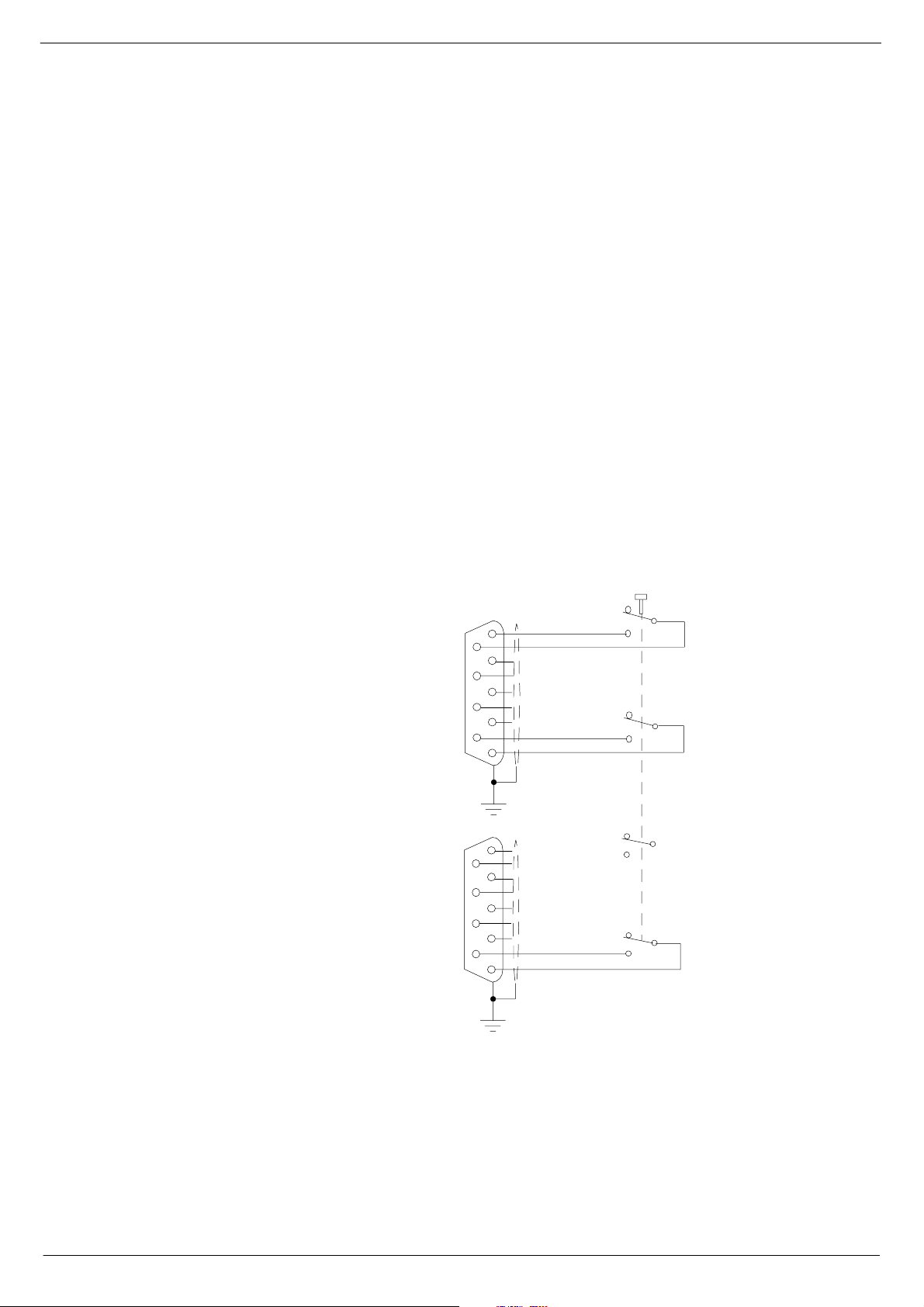

41619 ;34<#DQG#;353#FRPELQHG#5HPRWH#VWDUW

Each 801 9 and 8 02 0 s w it ch- mod e p o we r supp ly is fi t ted wi th a f ron t p an el mo un ted 9

way ‘D-type’ connector. This connector is labelled “Connections for Remote Start”.

You may connect a single remote start switch to each unit, have one switch start a

“system” pair, or wire up a single switch to start “system 1” and “system 2” all at the

same time.

Fig 1-5 applies to 8019 and 8020 PSUs up to serial number 34949 and shows the

circuit for starting up a “s ystem” pair with a single switch. This has pro ved to be the

most popular method of connecting the remote start facility. This circuit can easily be

extended to provide a single switch remote four all four PSUs if required.

For 8019 and 8020 PSUs from serial number 34950 onwards, see fig 1-6 and 1-7.

NOTE:

The remote must be a ‘momentary’ type. You will need a two-pole switch for a

■■■■

single PSU, a four-pole switch for a “system” pair, or a six-pol e switch for con trolling

all four units.

The remote switch(es) must be mounted on a metal panel.

■■■■

Use shielded cable for the remote switch wiring.

■■■■

The 9-way ‘D-type’ f ree plug must have a conductive shell. This is to ensure that

■■■■

the cable shield connects directly to the PSU unit chassis.

Connect the cable shield to the metal panel where the remote start switch(es)

■■■■

are mounted.

TO CONNECTION

FOR REMOTE START

ON 8019 FRONT PANEL

TO CO NN E C TIO N

FOR REMOTE START

ON 8020 FRONT PANEL

CUP/TAG SIDE

5

9

4

8

3

7

2

6

1

5

9

4

8

3

7

2

6

1

PANEL MOUNTED 4-POLEVIEW FROM SOLDER

MOMENTARY SWITCH

NOTE: CABLE SCREEN IS

CONNECTED AT BOTH ENDS

FIG 1-7. Remote start of 8019/8020 up to serial number 34950

Great care must be taken with the wiring of the switch(es) to ensure that no short-circuits can occur between any two power supply units.

Revision B2005-2 B-Type

Page 16

1-8 Connecting the mixer systems

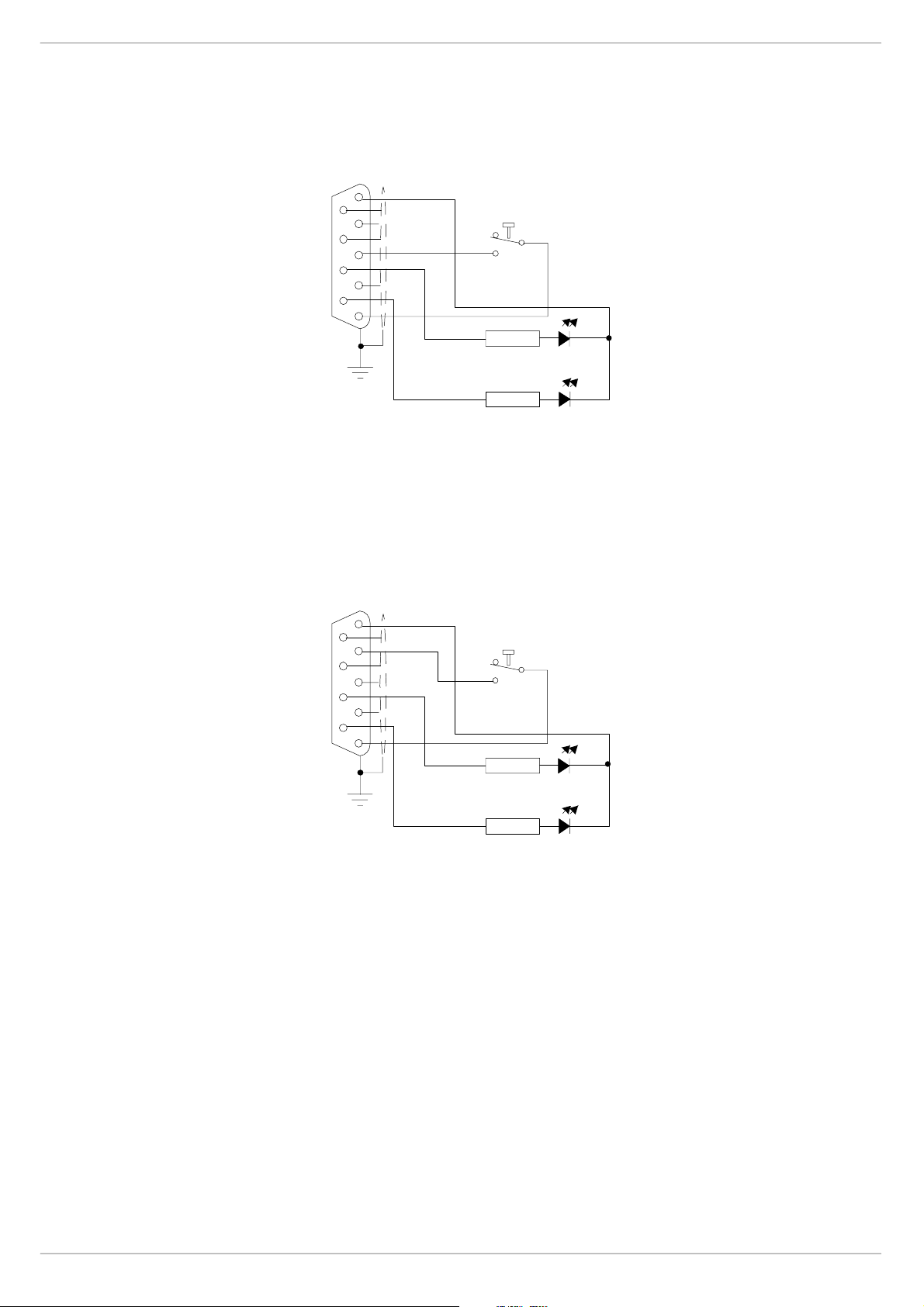

VIEW FROM SOLDER

CUP/TAG SIDE

FIG 1-8. Remote start of 8019 PSU

(from se rial number 34950)

5

9

4

8

3

7

2

6

1

VIEW FROM SOLDER

CUP/TAG SIDE

5

9

4

8

3

7

2

6

1

“START” MOMENTARY PUSH BUTTON

18V

300R

OVER

TEMPERATURE

300R

POWE R F AILURE

“START” MOMENTARY PUSH BUTTON

13V

FIG 1-9. Remote start of 8020 PSU

(from se rial number 34950)

300R

OVER

TEMPERATURE

300R

POWER FAILURE

B-Type Revision B2005-2

Page 17

Connecting the mixer systems 1-9

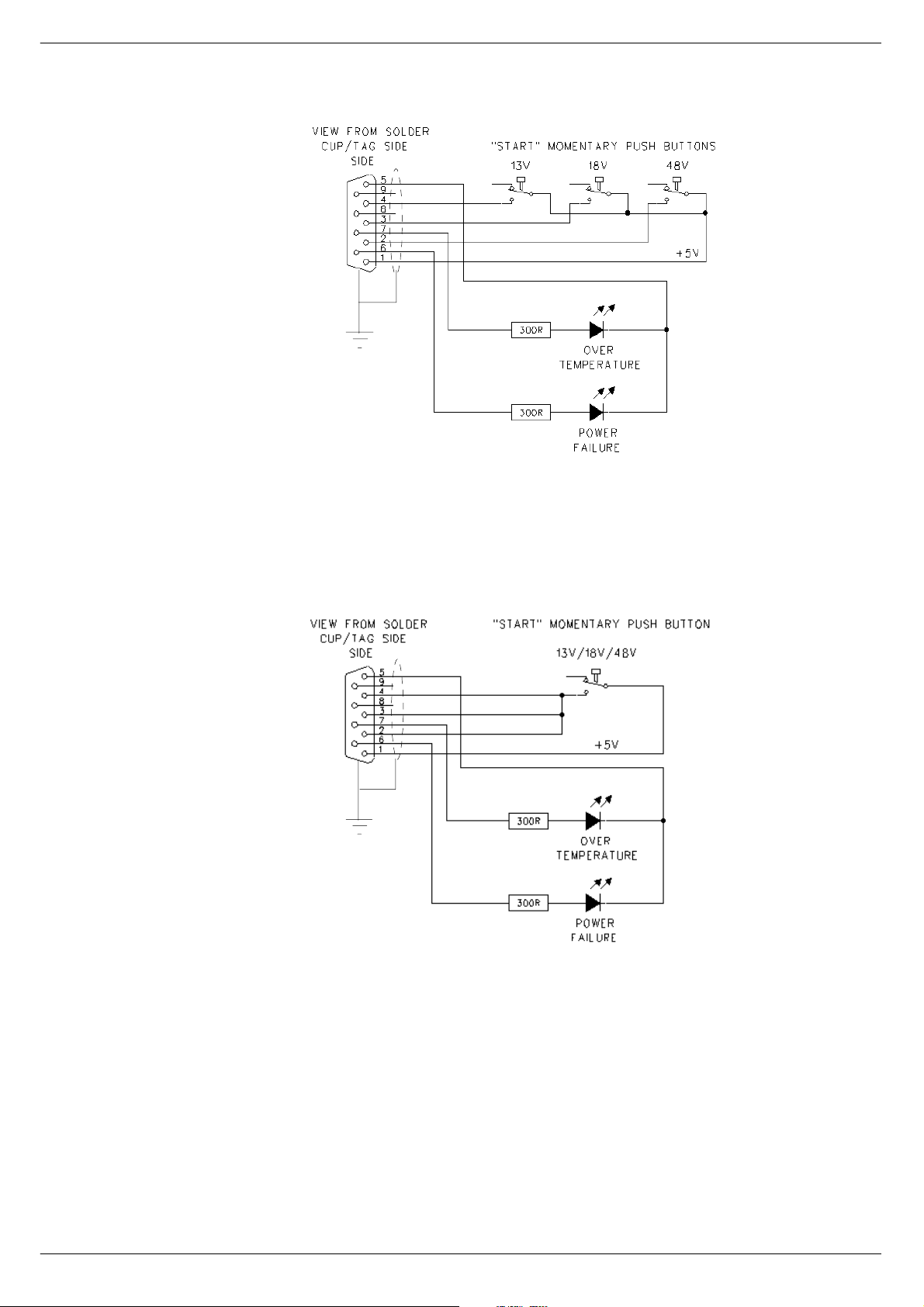

4161: ;733#VZLWFK0PRGH#SRZHU#VXSSO\#XQLW

FIG 1-10. 8400 power supply unit.

CADAC 8400 switch-mode power supply units are designed to run from a minimum

of 208V up to a maximum of 260V a.c, 50/60Hz.

The 84 00 is rated thus +13V@92A, ±18V@44A and 48V@5A.

The a .c. input is connected to the PSU via a 3-core cable, CMA reference 3183TQ –

BASEC approved, rated at 20A.

The 8400 unit is based on one POWER ONE RPMS-ETETGDGD1ETK Pow er block,

with additional circuitry as shown on CADAC drawin g number C3.8397.

4161; 5HPRWH#VWDUW#RI#;733#368

Each 8400 switch-mode power supply provides the follo wing outputs: 13v, ±18v and

48v. Each PSU is fitted with a front panel mounted 9-way 'D-type’ connector labelled

‘Connections for Remo te Start’. If a remote start facility is used, Power Failure and

Over-Temperature LEDs may also be fitted with the remote start switches if required.

Fig 3-15 shows the circuit for starting up a “system” with a single switch. This has

proved to be the most popular method of connecting the remote start facility. This circuit can easily be extended to provide a single switch remote four all four PSUs if

required. If muliple switches are to be used, see fig 3-14.

NOTE:

The remote start switch must be a ‘momentary’ type. You can use 3 separate sin-

■■■■

gle pole switches for each Power Supply to turn on 13v,±18v and 48v outputs of the

PSU alternatively use one single pole for the whole lot.

The remote switch(es) must be mounted on a metal panel.

■■■■

Use shielded cable for the remote switch wiring.

■■■■

The 9-way ‘D-type’ f ree plug must have a conductive shell. This is to ensure that

■■■■

the cable shield connects directly to the PSU unit chassis.

Connect the cable shield to the metal panel where the remote switch(es) are

■■■■

mounted.

Revision B2005-2 B-Type

Page 18

1-10 Connecting the mixer systems

FIG 1- 11. R emote s tart o f

PSU 8400 with multiple

switches.

FIG 1-12. Remote start of PSU

8400 with a single switch

Great care must be taken when wiring the s witch(es) to ensure that no short-circuits

can occur between any two power supply units.

B-Type Revision B2005-2

Page 19

Connecting the mixer systems 1-11

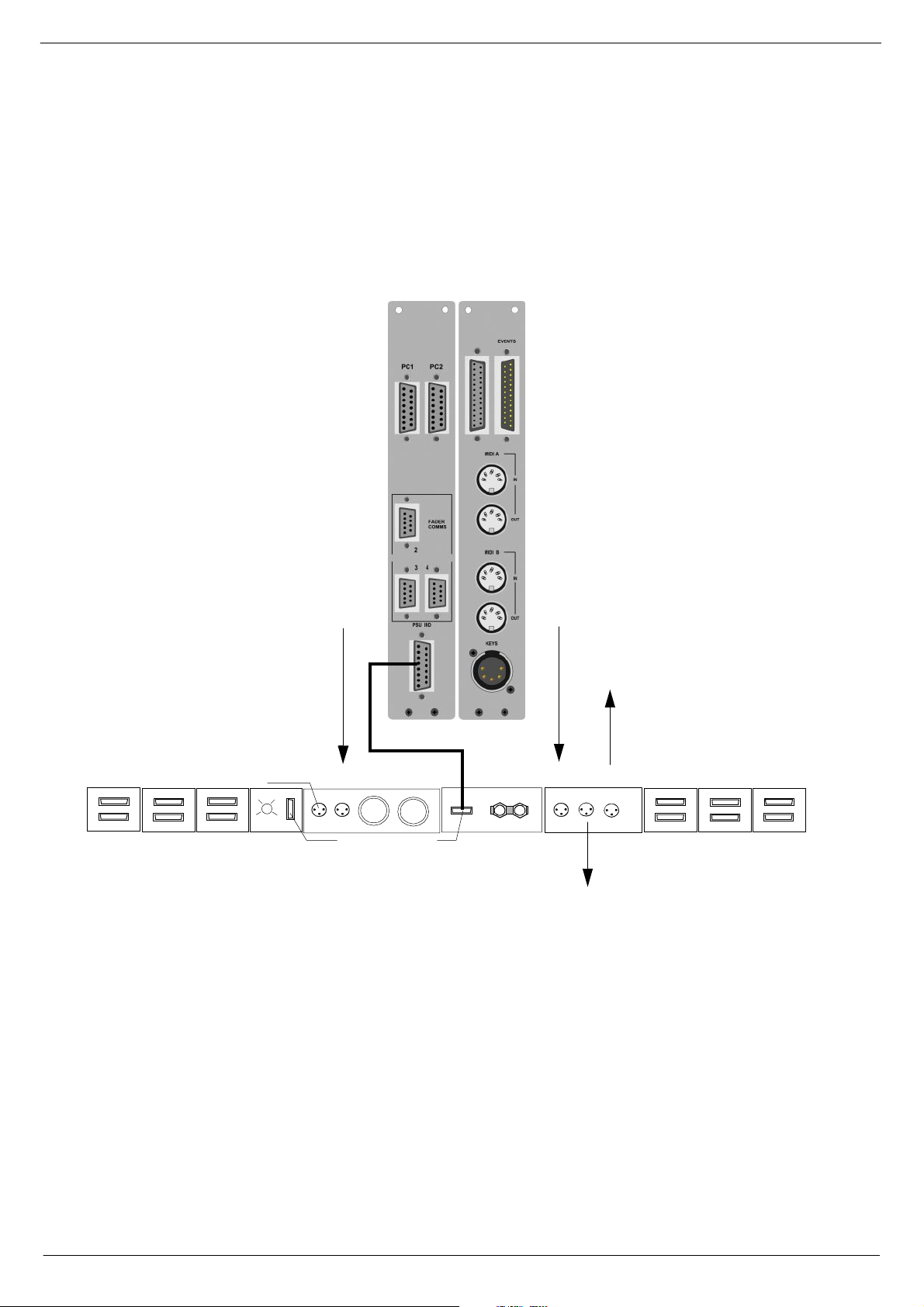

417 &RQQHFWLQ J#WKH#FRQVROH#IUDPHV

41714 $XGLR#%XV#2#'DWD#%XV#&RQQHFWLRQV

If the console is used in a multi-fram e configuration then the busses need to be connected in a ‘daisy chain’ fashion.

four audio and two data busses plus fader bus (see fig 1-13). The bus cables are

simply linked between s imilar connectors on the end of the nearest f rame.

Make sure that each frame has its “Frame Select” switch set to a different number.

Each end

of a frame has seven bus connectors -

FIG 1-13. Audio/Data Bus connections.

See also appendix A. Impor tant information regarding EMC.

41715 )DGHU#FRPPXQLFDWLRQV

When motor faders are used in extension frames, a 9-way “FADER COMMS” cable

must be connec ted between the CCM c onnectors shown (see fig 1-3) an d the

COMMS input on the extension frame rear panel.

Extension frames fitted with motor- faders r equire control dat a from the CCM. Three

9-pin femal e connectors Three 9-pin female connectors located on the rear panel of

the CCM are connected direct ly

comms’ cable. The frame containing the CCM sends motor data fader data, via the

7303 interface module (always mou nted directly below the CCM on J-type consoles).

Thus , a 3 frame console wou ld requir e two “FADER COMMS” cabl es:

4

5

AUDIO BUS

FRAME TO FRAME

6

7

DATA BUS

FRAME

COMMS TO CCM

SELECTOR

to the extension frame using the supplied ‘fader

“FADER COMMS on EXTENSION FRAME 1 TO “FADER COMMS 2” on CCM

“FADER COMMS on EXTENSION FRAME 2 TO “FADER COMMS 3” on CCM

41716 3)/

PFL mixing amplifiers ar e located in the “Oscillator /Communications” module. There

are two PFL outputs:

PFL Direct is a line level output that appears on an XLR 3-32 connector on the

■■■■

rear panel of the OSC/Comms module, labelled “PFL DIRECT”;

PFL to H eadphone s is a high level output suitable for driving headpho nes that

■■■■

appears on an XLR 3-32 connector

panel of the OSC/C omms module, labelled “PFL TO HP”.

The PFL to Headph ones signal can be connected to the TRS jack sockets mounted

on the front of the console frame by using the “OSC/COMM TO FRAME” cable supplied. This cable has a male XLR 3-pin connector on one end and a female XLR 3pin on the other end. Connect one end of the “Oscillator/ Communications” module’s

“PFL TO HP” connector and the other end to the rear frame connector labell ed

Revision B2005-2 B-Type

a TRS jack socket connector on the rear

and

Page 20

1-12 Connecting the mixer systems

“FROM PFL HEADPHONE XLR”.

Additional inter-frame connec tions are required to enable the PFL signals from modules i n extens ion (side) frames to be monitored. Use the cable(s) labelled “PFL

FRAME TO FRAME” to interconnect two or more frames:

Connect one en d of a “PF L FRAME TO FRAME” cable to the connector labelled

■■■■

“TO NEXT FRAME” on the console frame containing the “Osc/Communications”

module.

Connect the other end of a “PFL FRAME TO FRAME” cable to the connector

■■■■

label led “FROM PFL HEADPHONE XLR” on the next frame.

Repeat this procedure for all other frames in the console system.

41717 /LWWOLWHV

Surface illumination of the console is provided b y the use of two or more “Littlite”

units that plug into the top bar of the console frame. Control for the “Littlites” - on/off

and in tensity - is located on the “Oscillator/Communications” mod ule. The variable

voltage power supply is mounted inside the console fr ame.

Two cables are requir ed to inte rconnect the “Litt lite” controls, t he variable voltage

power supply and the lamp units.

Connect one of the cable labelled “OSC TO LITTLITES” to the connector on the

■■■■

rear panel of the “Oscillator/Communications” module labelled “LITTLITES” (this

cable has 4-pi n XLR male and female connectors).

Connect the other end of the cable labelled “OSC TO LITTLITE” to the connector

■■■■

on the rear panel of the console frame labelled “F ROM PFL MOD ULE”;

Connect one end of the cable labelled “LITTLITE FRAM E TO BAR” to the con-

■■■■

nector on the rear panel of the console frame labelled “TO LIGHTS” (this cable has a

4-pin male XLR connector at one end and a 5-pin XLR connector at the other end).

Connect the ot her end of the cabl e labelled “LITTLITE FRAME TO BAR” to the

■■■■

5-pin XLR-connector mounted at the rear of the top bar on the console fra m e.

Additional inter-frame connec tions are required to enable the LITTLITE control signals to be delivered to any extension frame(s) in the console system. Use the

cable(s) labelled “LITTLITE FRAME TO FRAME” to interconnect two or more frames.

Connect one end of a “LITTLITE FRAME TO FRAME” cable to the connector

■■■■

labelled “TO NEXT FRAME” on the console frame containing the “Oscillator/Communications” module;

Connect the other end of a “LITTLITE FRAME TO FRAME” cable to the connec-

■■■■

tor labelled “FROM PFL MODULE” on the next frame;

Connect one end of a cable labelled “LITTLIT E FRAME TO BAR” to th e connec-

■■■■

tor on the rear panel of the console frame labelled “TO LIGHTS” (this cable has a 4pin male XLR connector at one end and a 5-pin XLR connector at the other end.

Connect the ot her end of a cable labelled “LITTLITE FRAME TO BAR” to the 5-

■■■■

pin XLR connector mounted at the rear of the top bar on the console frame.

Repeat this procedure for all other frames in the console system.

41718 368#,QGLFDWRU

Two sets of four LEDs are incorpora ted into the CCM front panel to give the operator

visual indication that the “main” (PSU System 1) and “backup” (PSU System 2)

power supply units are working correctly. A cable, labelled “PSU IND.” is supplied to

interconnect the CCM and t he console frame.

Connect one end of the “PSU IND” cable to the “PSU IND” 15-way male D-sub

■■■■

connector on the CCM.

Connect the other end of the “PSU IND” cable to the “PSU IND” 15-way female

■■■■

D-sub connector on the rear con s ole frame adjacent to the two multi-pin power input

connectors.

B-Type Revision B2005-2

Page 21

Connecting the mixer systems 1-13

41719 (DUWK/#39#DQG#)UDPH#&RQQHFWLRQV

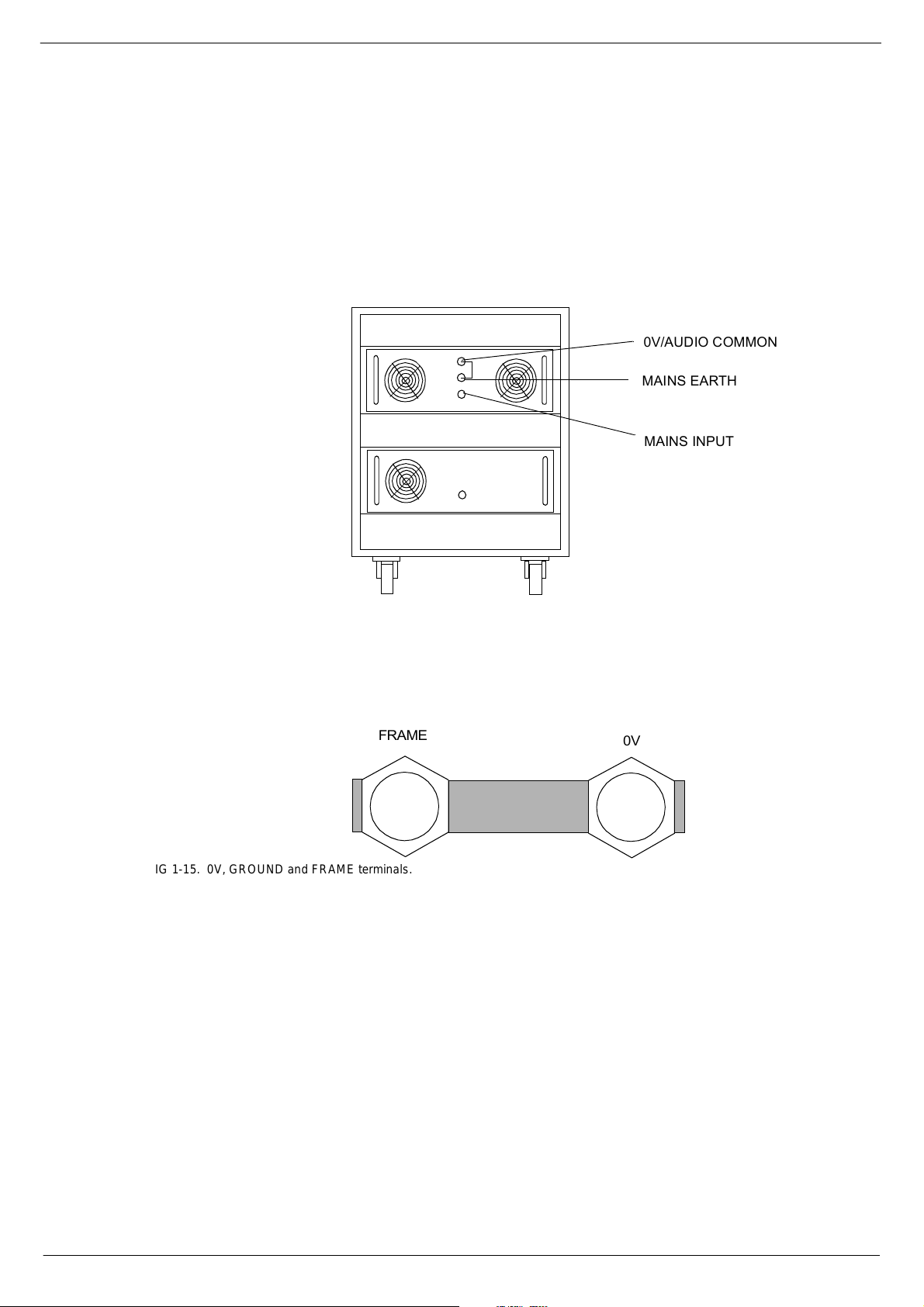

Figure 1-6 shows the rear panels of the power su pply units in a single PSU system.

Under normal conditions, the 0V and Mains-Earth terminals can be connected on

both PSU systems. However, if the a.c. input lines to each pair of PSU’s has a different length, you may find that t he 0V and Mains -Earth terminals can only be linked on

set of power supplies, for minimum system noise.

one

FIG 1-14. PSU system.

The 0V or FRAME termi nals on a PSU need

or FRAM E connections on con s ole frames. The shielded po wer supply cables are

connected to the frame at both ends.

be dir ec tly co nn ec te d t o th e 0 V and/

not

392$8',2#&20021

0$,16#($57+

0$,16#,1387

In addition to the terminals on the back of the PSUs, there are

nections on the rear of each console f rame. The shorting-bar link between the 0V

and “FRAME” terminals on each frame

large diameter ‘frame-link’ cables (supplied with multi-frame consoles), must be connected. Always make sure that ‘frame-link’ cable nuts are tightened against the copper bar.

be conn ected. For minimum noise, the

must

0V

and

FRAME

con-

)5$0(

IG 1-15. 0V, GROUND and FRAME terminals.

The 0V and FRAME t erminals are linked in the factory with a copper bar. This bar

should never be removed when the console is in normal use. Note that

cannot be delivered from the input modules to the 48V bus if the copper bar is

Power

missin g, beca us e t he scre en ed mic rop ho ne input ca b l es w il l not be te rmina te d. I t wil l

also cause damage to the motor faders.

39

Phantom

Revision B2005-2 B-Type

Page 22

1-14 Connecting the mixer systems

418 &RQQHFW#&RQVROH#$XWR PD WL RQ#6\VWHP

41814 &RQQHFWLRQV#0#%1&

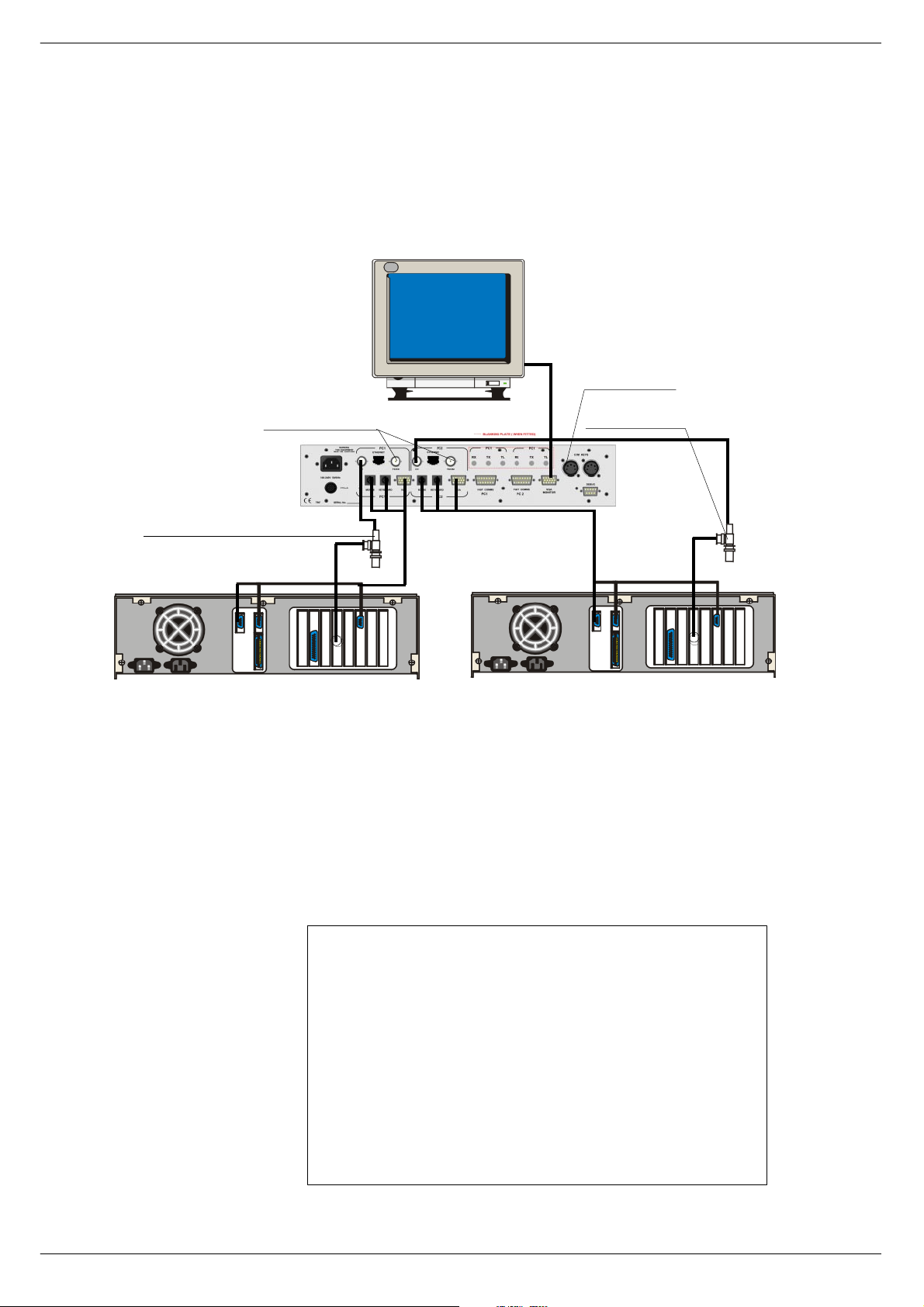

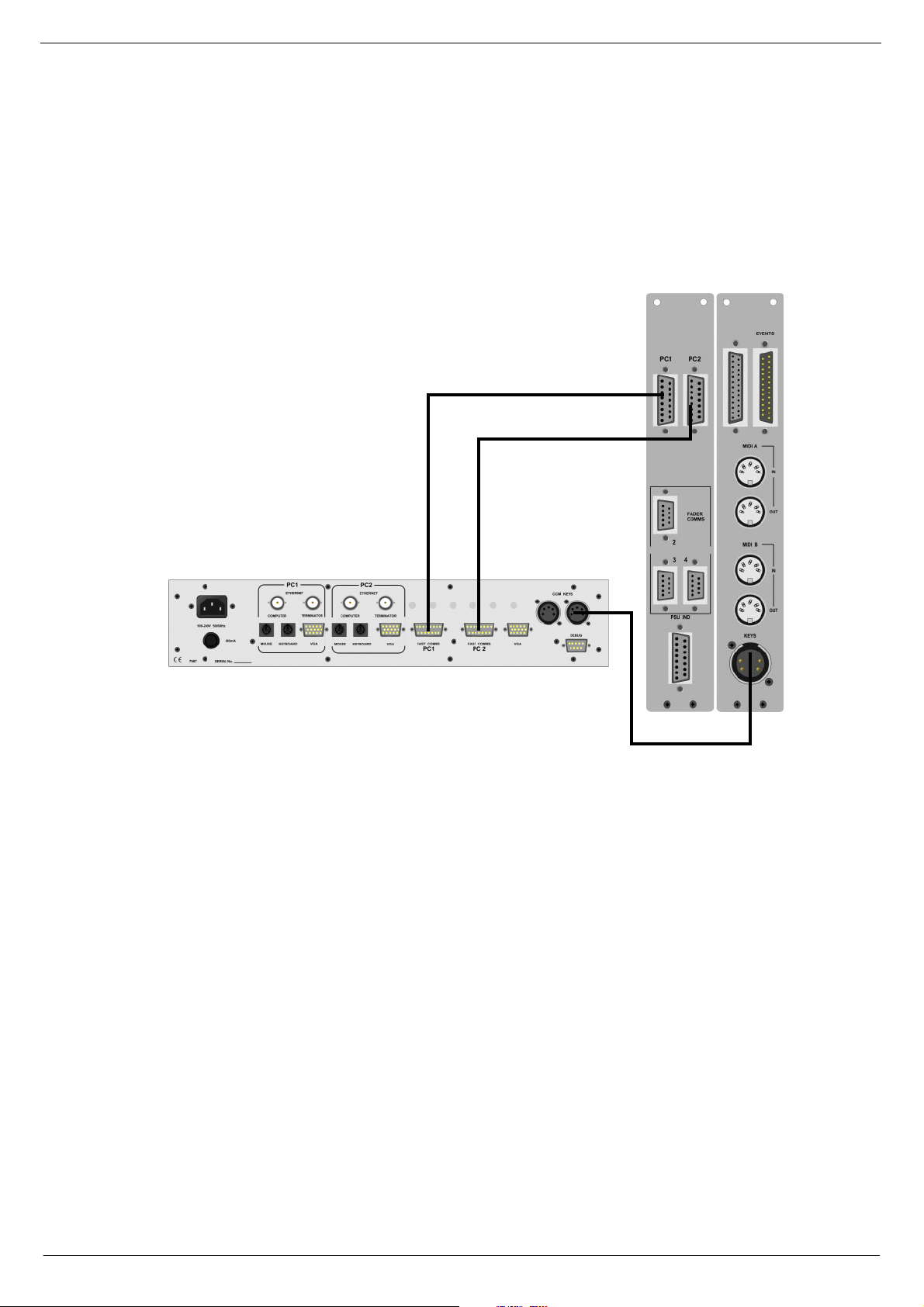

Figu res 1 - 9 be lo w a nd 1- 1 1 s how h o w t o c onn ec t th e S éan ce box to th e c on sol e an d

the co mputers running SAM., BNC type connection.

7R#UHPRWH#3.1

83#RKP#WHUPLQDWLRQ

(WKHUQHW#WHUPLQDWHG#DW#3&#HQG

0RXVH

.H\ERDUG

9*$

(WKHUQHW#WHUPLQDWHG#DW#3&#HQG

0RXVH

.H\ERDUG

9*$

3&4#ZLWK#(WKHUQHW#FDUG 3&5#ZLWK#(WKHUQHW#FDUG

FIG 1-16. Séance rear panel connections for BNC

41815 (WKHUQHW#0#%1&

The Séance box communicates with the PCs over a 10Base-2 Ethernet connection

via a 50 ohm BNC cable terminated at each end with a 50 ohm terminator. The

Séance box has two BNC connectors for each P C interface, w hich are wired in parallel in side. A 50 ohm terminator plugs into the BNC socket labelled TERMINATOR

and th e Ethernet cable plugs into the BNC socket labelled COMPUTER. A t erminator and T-piece are used to connect the Ethernet cable to the PC.

0LQLPXP#VSHFLILFDWLRQ#IRU#D#3&#XVHG#ZLWK#WKH#############

6RXQG#$XWRPDWLRQ#0DQDJHU#6RIWZDUH

To run the Sound Automation Manager software requires a PC with at least the

performance and peripherals as listed below:

PC Pentium 133 or later or compatible computer

Windows ®’98 (second edition), 2000, XP or XP Pro

Graphics card 1024 x 768 pixels, 16 bit colour or bette r

Ethernet interface 10Mbit/sec with 10base2 connector (BNC)

128MB RAM

20 MB free hard disk space

PS/2 keyboard (older 5-pin DIN keyboard can be used with adapter)

PS/2 mouse or pointing device (9-pin’D’-serial devices cannot be used) PS/2

keyboard (o lder 5-pin DIN keyboard can be used wit h adapter)

B-Type Revision B2005-2

Page 23

Connecting the mixer systems 1-15

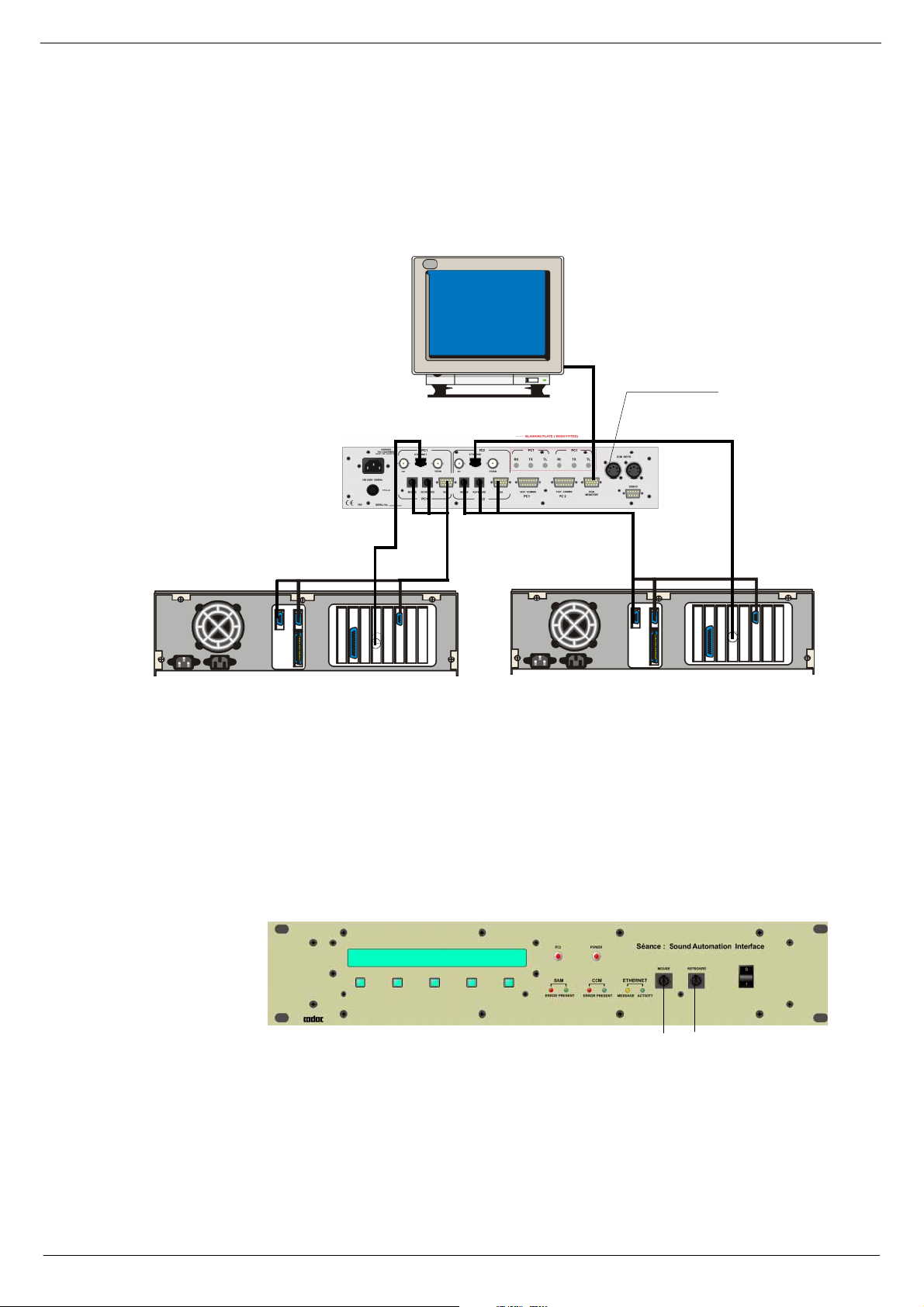

41816 &RQQHFWLRQV#0#5-78

Figu re 1-10 below and fig 1-11 show how to con nect the Seance bo x to the cons ole

and the computers running SAM, using RJ45 connection.

7R #UHPRWH#3.1

3&4#ZLWK#(WKHUQHW#FDUG

FIG 1-17. Séance rear panel connections for RJ45

41817 (WKHUQHW#0#5-78

The Seance box can also communicate with the PC via an RJ45 connector depending

on the type of Ethernet-card in the computer. The Séance box has two RJ45 connectors, one for each PC interface. These connectors should be connected directly into

a comp uter. It is also poss ib l e to c onn ec t th e R J45 so c k ets t o a hu b . F or d eta il s a bo ut

this , contact CADAC technical support.

0RXVH

.H\ERDUG

9*$

0RXVH

.H\ERDUG

9*$

3&5#ZLWK#(WKHUQHW#FDUG

FIG 1-18. Séance front panel connections - BNC and RJ45

0RXVH .H\ERDUG

41818 0RXVH

Each PC has a ‘one-to-one’ PS2 mouse cable, which connects betwe en the PC’s

mouse port and the mouse connector on the r ear panel of the Séance box. The

mouse plugs into the mouse connector on the front panel of the Séance box.

Revision B2005-2 B-Type

Page 24

1-16 Connecting the mixer systems

41819 .H\ERDUG

Each PC h as a ‘ o ne-o ne ’ PS2 k e yboa r d c ab le , whi ch co nn ects be tw ee n t he PC ’ s k e yboard port and the keyboard connector on the rear panel of the Séance box. The keyboar d connects into the keyboard connector on the front pa nel of the Séance box.

Converters are supplied to connect to a 5-pin DIN keyboard and 5-pin DIN connectors

on the PC.

4181: 9*$

Each PC has a VGA cable connected between the c omputer’s VGA output and the

corresponding VGA connector on the rear panel of the Séance box. The VGA monitor

cable plug s int o the VGA con ne c tor.

4181; &&0#NH\V

The Séance interface reads the PC2 switch on the console’s CCM. The 5-pin XLR

connectors are paralleled together inside the Séance. A ‘female-female, on e-one cable ’ conn ects to the k eys conne ctor on th e CCM an d the ot her ca n be us ed to c onnec t

to remote PREV and NEXT keys if required.

4181< )DVW#FRSSHU#FRPPXQLFDWLRQV

CADAC’s 15 way “f ast copper communications” cables are used to connect between

the Séance box’s fast comms connectors and the CCM. The cable plugged into Fast

comms PC1 on the Séance box must be connected to PC1 on the CCM.

418143 'HEXJ#SRUW

The debug port is standard PC 9-pin serial port that can be used to access the

Séance box’s computer.

418144 0DLQV

The Séance box has a universal power supply and can be connected to AC mains 100

– 240V, 50/60Hz.

418145 )XVH

20mm 315mA fuse.

B-Type Revision B2005-2

Page 25

Connecting the mixer systems 1-17

418146 &RQQHFW#6pDQFH#WR#FRQVROH

Figure 1-12 below shows how to connect the Séance Interface to the CCM in the

main co nsole.

FIG 1-19. Connect Séance to CCM.

Using the cables supplied, make the following connections:

1. CCM PC1 to Séance box PC1.

2. CCM PC2 to Séance box PC2.

3. CCM KEYS to Séance box KEYS.

Details on Seance set-up can be found in the Seance I nterface 7975 User & Installation manu al.

Revision B2005-2 B-Type

Page 26

1-18 Connecting the mixer systems

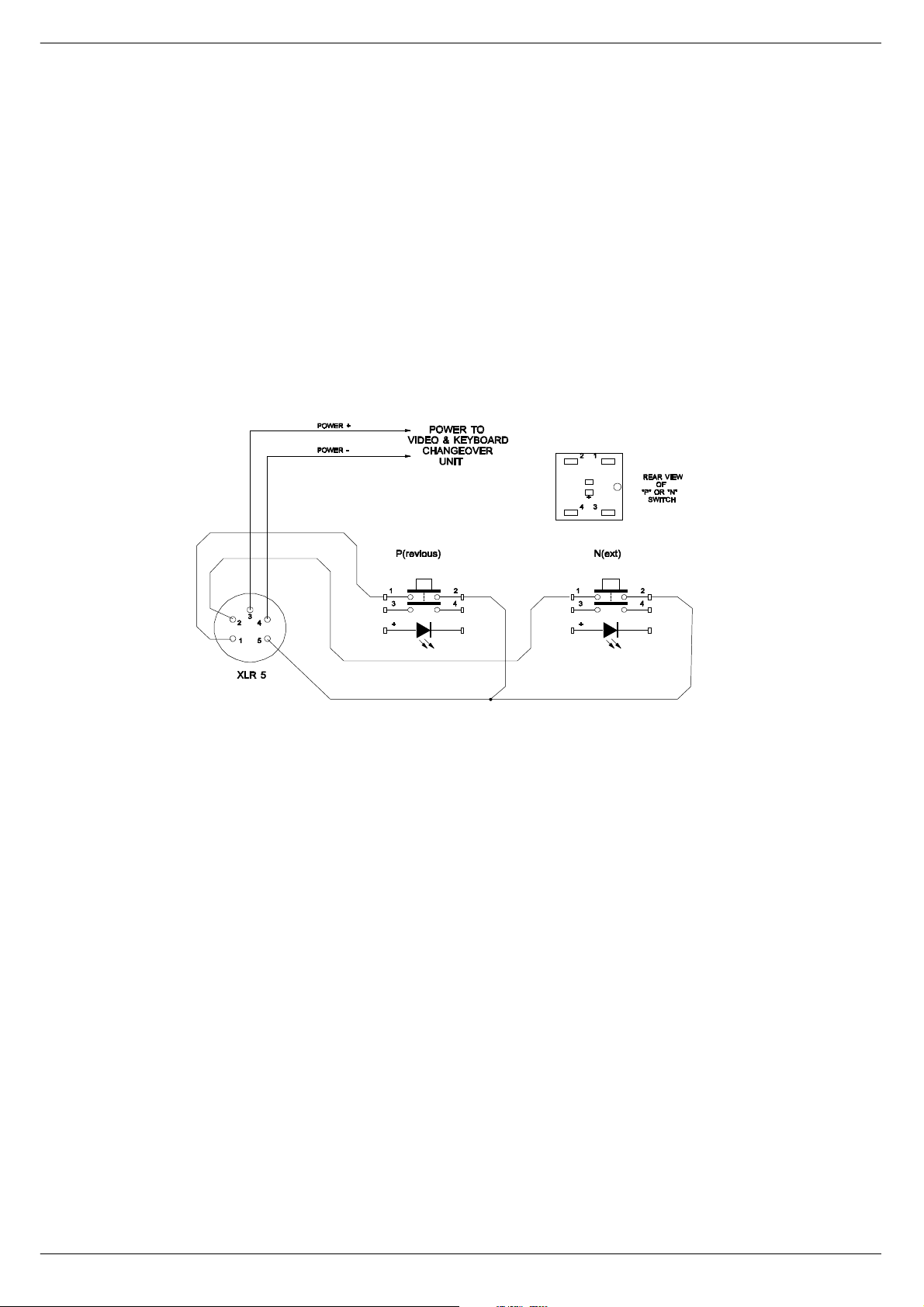

418147 8VLQJ#WKH#9LGHR#DQG#.H\ERDUG#&KDQJH#RYHU#IXQFWLRQ#ZLWK#

6pDQFH#

A single keyboard, mouse and monitor can be used with two computers for main/

back-up vi a th e Séance-box.

The Séance-box is supplied with a cable-kit allowing connections for one keyboard,

one monitor, one mouse and two computers PC1 and PC2.

Using the 5 pin XLR to XLR cable supplied, make the following connection:

CCM KEYS (at the console end) to one of the KEYS-connectors on the rear of

■■■■

the Séance-box.

The second keys connection on Séance is for use with

(see fig 1-20 ).

FIG 1-20. Remote P & N switch wiring detail.

Remote P and N

buttons,

418148 3&5#V\QFKURQLVDWLRQ

Using a Null modem serial interface cable with the appropriate c onnectors for the

computers in use, make the following connection between the two computers.

PC1 COM 1 or 2 to PC2 COM 1 or 2 (selectable in SA M)

■■■■

Two serial port configurations are in common use with 9 way or 25 way 'D-Type' connectors.

The two computers will only “track” each others’ Cue position if the SAM tracking feature has been enabled, see the SAM manual for details.

B-Type Revision B2005-2

Page 27

Connecting the mixer systems 1-19

419 &RQQHFW#PDLQ#IUDPH#IDFLOLWLHV#IURP#PRGXOHV#WR#

IUDPH

See figure below for instructions on how to connect main frame facilities from modules to frame.

)URP#&2006#PRGXOH#+3)/,

HEADPHONES NEXT FRAME

4

5

AUDIO BUS

6

7

DATA BUS

FRAME TO FRA ME

FRAME

SELECTOR

COMMS TO CCM

FIG 1-21. Connecting the main frame facilities from modules to frame.

PSU 1 PSU 2

PSU INDICATOR

)URP#&2006#PRGXOH

FROM PFL NEXT LIGHTS

FRAME - 0V

7R#QH[W#IUDPH

7R #IUDPH#WRS#EDU

AUDIO BUS

4

5

6

7

FRAME TO FRAM E

Revision B2005-2 B-Type

Page 28

1-20 Connecting the mixer systems

41: 6ZLWFKLQJ#21

41:14 6\VWHP#SRZHU0XS#SURFHGXUH

CADAC con s oles are designed to work continuously with two power supply systems

- ‘mai n’ an d ‘b ac k u p’ . The ‘ma in ’ po w er sup ply pai r ( 1 off ‘1 8v ’ un it an d 1 of f 13V/ 48 V

unit ) are designated ‘System 1’. The ‘backup’ power supply pair (1 off ‘18V’ unit and

1 off 13V/48V unit) are designated ‘System 2’.

On each power s upply, tu rn all AC input switches to the ON-position.

Start the ±18 V an d 13V/ 4 8V PSU s (in one PSU syst em) simu lt an eo us ly, by pressing

and holding the START-buttons until you hear the relay click. The CCM will cycle

through its self-test routines and any Master Mute swit ches previously selected will

be set ON, thus protecting external equipment from possible DC pu lses when the

±18V PSUs ar e sta r ted.

Repeat for PSU system 2. If you cannot start the PSUs simultaneously, start the 13V/

48V first. However, do NOT operate the console for long periods without all power

lines on.

41:15 3RZHULQJ0XS#VHTXHQFH#RI#3&V

Always use the following pr ocedure:

Power up console

■■■■

Powe r up Séance box

■■■■

Select PC1 on the CCM and power up the first computer. Wait until the P C1

■■■■

computer has comp leted its boot-up routine, t hen...

Switch to PC2 on the CCM and power-up the second computer and wait until it

■■■■

has completed its boot-up routine.

Once both computers have booted correctly, they should allow the keyboard and

monitor to be switched back and forth without problems.

If the overall cable length for the keyboard and monitor are very long (greater than

5m), it may be necessary to use a keyboard and a monitor booster unit to retain keyboard reliability and a clean monitor display.

41:16 6\VWHP#SRZHU0GRZQ#SURFHGXUH

1. On the CCM, press all Master Mute switches to the ON (down) position.

2. Cl os e down the SA M so ft w are o n ea ch PC , sh ut do w n Wi nd o ws® a nd s wit c h t he

computers off.

3. Switch off the AC mains supply to PSU system 1.

4. Switch off the AC mains supply to PSU system 2.

5. Switch off Séance Box.

.

B-Type Revision B2005-2

Page 29

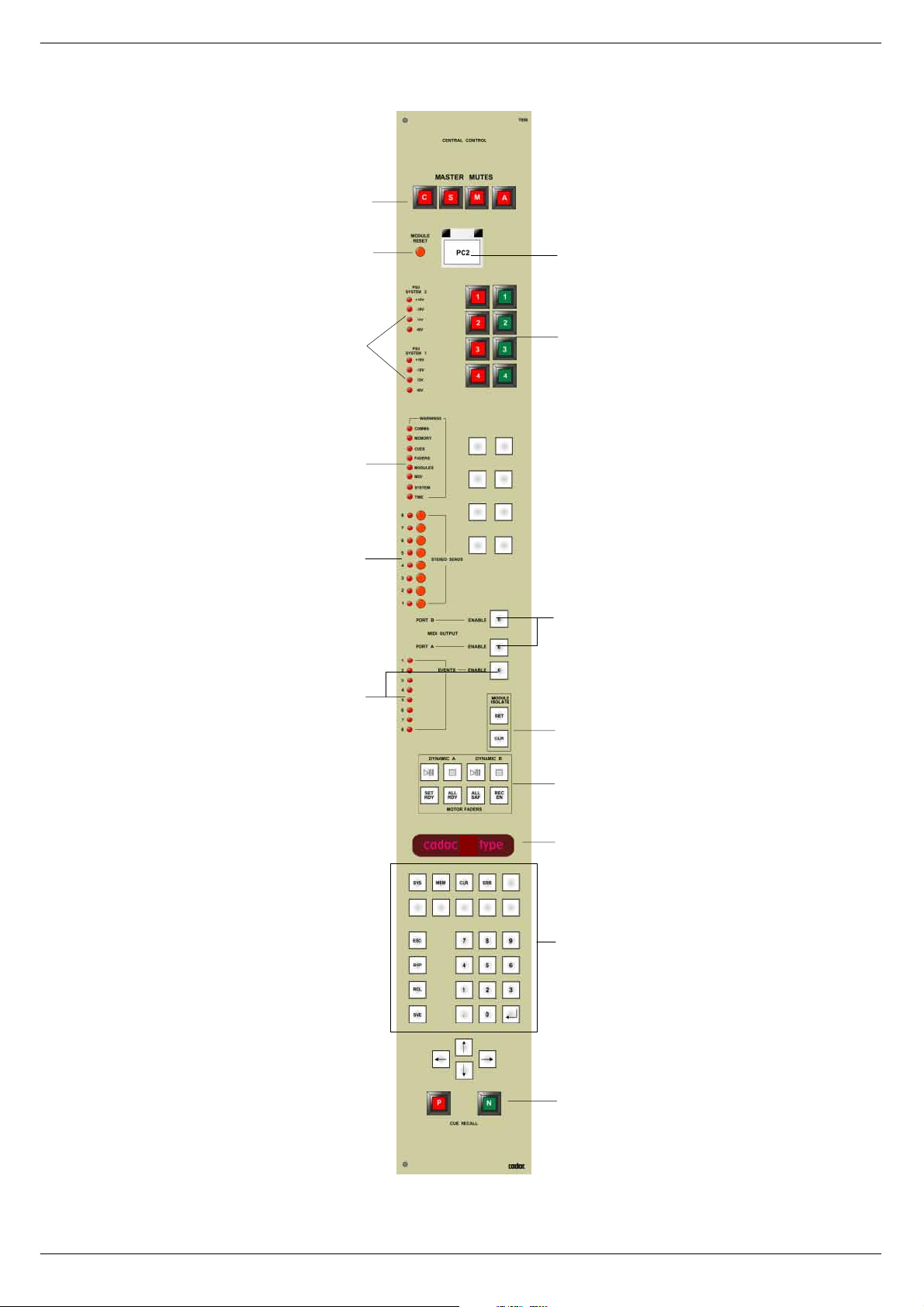

Central Control Module 7896 2-1

5 &HQWUDO#&RQWURO#0RGXOH#:;<9

514 &&0#)URQW#3DQHO#VZLWFKHV#DQG#GLVSOD\V

Please re f er t o fi g 2 - 1 o n pag e 2 - 2 f o r the l oc at i on of t he s wi tc he s an d d ispl ays on th e

B-Type CCM fron t panel issue 7896 described on the next page.

D, 0DVWHU#0XWHV

Fo ur separate sw itches to globally mute the channels, subgroups, matrix groups and

aux gr oups. All four switches work independen tly, so that any comb ination o f master

muting may be selected at any time. The switches are intended for manual operation

only, and their condition will not be recorde d with a cue state.

E, 5HVHW

Resets the microprocessors within this module (roughly equivalent to turning the

power off then on again). Pressing reset does not clear the internal memories, maps

etc.

F, 3&5

The Sound Automation Manager software allows two computers to be used with the

syste m , PC1 and PC2. Separate connectors for each computer can be found on the

rear panel of the CCM. Whe n the PC2 switch is pressed, al l data to and from th e

CCM will go to or come from PC2.

G, 368#6\VWHP#4#DQG#368#6\VWHP#5

The J-Type console is designed to be able to use two sets of power supplies simultaneously. These eight LEDs continuously show the status of the tw o sets of ±1 8V,

+13V and 48V power supply units. See 2.2 CCM rear panel connectors for conn ec tion details.

H, *2#0#6723

These are user configured switches for example remote control of cart machines,

tape recorders etc.

I, :DUQLQJ#/('V

These LEDs illuminate when a system function needs to be brought to the o perator ’s

attention. This may be an error condition, a “prompt”, or merely useful system information. The LEDs are labelled with the titles of each part of the automation system

about which the information is available:

1. COMMS Communications with the PC (s), Fast Copper connecti ons.

2. MEMORY Storage space used by the mi croprocess or to hold it ems such

as maps a nd memories

3. CUES Recall of console states from the PC.

4. FADERS Console fader s : channel, master and motorised.

5. MODULES Programmable modules.

6. MIDI Midi i nputs and outputs.

7. SYSTEM General category covering miscellaneous operations within the

CCM.

8. TIME Any timing activity, such as the current date and time.

Revision B2005-2 B-Type

Page 30

2-2 Central Control Module 7896

D

E

G

F

H

I

J

K

M

FIG 1-1. B- Type CCM con tr ol pa ne l.

N

P

B

Q

S

T

B-Type Revision B2005-2

Page 31

Central Control Module 7896 2-3

J, 6WHUHR#VHQGV

Eight momentary switches allowing you to put the associa ted aux group in stereomode. The LED to the left of the switch illuminates when the Aux group is in stereo.

K, 0,',#(QDEOH#VZLWFKHV

ON s witches for MIDI po rts A and B. The switches are momentary and illumi nate

when the functions are enabled.

M, (9(17#/('V#DQG#(1$%/(

The LEDs show the operation of the EVENTS relays. The LEDs will only illuminate

when the ENABLE switch is O N.

N, 0RGXOH#,VRODWH#0#VHW#DQG#FOHDU

These two s witches perform global s witching of ISOLATE function for progr ammabl e

functions such as channels a nd groups, in order to disconnect the con s ole automation system.

P, 0RWRU#)DGHUV

This group of buttons provides a quick and convenient way of setting the console

autom ation system to both re cord and control the mo vement sequences of motor

faders.

The to p left pair control the play /pause an d stop for the firs t dynamic sequence

(dynamic A) in a Cue.

The top right pair control the play/pause and st op for the second dynamic sequence

(dynamic B) in a Cue.

Both dynamics can be run simultaneously in the same cue.

Accidental movement of the motor faders can be prevented by use of the ALL SFE

and ALL RDY keys. In SAFE mode, touching the faders knob will have no impact on

the recorded sequence. In READY mode touching the fader knob will cause the

motor fader logic to toggle between READY and WRITE modes.

Therefore , editing of a reco rded sequence can be performed for as long as the fader

knob is actually touched and the fader remains in the READY mode.

Revision B2005-2 B-Type

Page 32

2-4 Central Control Module 7896

FIG 1-2. Keypad for controlling dynamics.

############

PLA Y/P A USE ( 1)

PLA Y/P A USE (2)

STOP (3, 4)

SET READ Y (5)

ALL READ Y (6)

ALL SAFE (7)

RECORDING ENABLED (8)

Stops the recorded sequence of motor fa der

This mo de allows individual faders to be “toggled”

Plays, pauses or continues a recorded sequence of

motor fader movements a ssociated with dynamic A. If

recording is enabled with the push-button (8), then this

but ton starts either a new recording, or starts an update

of an existing dynamic.

Plays, pauses or continues a recorded sequence of

motor fader movements a ssociated with dynamic B.

movements.

between safe and ready mode by touching the fader

knob.

Sets all motor faders to ready mode.

Sets all motor faders to safe mode.

Prepares the computer for recording of a dynamic

sequence. Pressing button (1) starts the actual

recording.

Q, 0XOWL#IXQFWLRQ#DOSKD0QXPHULF#GLVSOD\

The 16 character alphanumeric display is the communication window between the

operator and the B-Type operating system.

In normal operating conditions the display will show one of the following:

CUE number, or

Current Mem ory numb er, or

“cadac ‘B-Type’ “ if no cue or memory is select ed

The display is also used for system messages via the [err] button and to traverse the

various menus for testing, mapping, etc.

B-Type Revision B2005-2

Page 33

Central Control Module 7896 2-5

S, .H\SD G

The numeric keys [0] to [9] and the decimal point [.] are used to select a particular

cue or m emory number in conjunct ion with one of the fun c tion keys listed below.

Key MeaningFunction

[Sys] SYSTEM Calls up the SYSTEM SETUP menu.

[Mem] MEMORYSelects one of the non-volatile internal memories.

[Clr] CLEAR Clears a selected memory ( i.e. sets everythi ng to

OFF)

[Err] ERROR Writes error message or information to alphanumeric

[Esc]

[Bsp] BACKSPACE Deletes the last number entered.

[Rcl] RECALL Recall a cue or memory.

[Sve] SAVE Store a cue or memory.

[↵] ENTER Selects a menu item, starts or acknowledges

The arrow keys, [←], [→], [↑] and [↓] are us ed to help navigate in the various m enus.

The buttons are back-lit by LEDs, and will illuminate or flash to indicate that they will

perform a useful function if pressed at that time, or that their function has been

selected.

display.

ESCAPE Moves backwards through a menu, or aborts an

operation, can be thought of as a “cancel” button.

operations.

Unlabelled buttons are reserved for use in future software updates.

T, 35(9#DQG#1(;7#EXWWRQV

Use the previous or next button to recall snapshots from the automati on cue list to

the console.

51414 6DIH25HDG\2:ULWH

The following instructions refer to the group of switches on the CCM labelled

“MOTOR FADERS”. See also 3.1.15 RDY LED and 2.1 m) Motor Faders.

To put all motor faders in SAFE mode: Press “ALL SAFE” switch.

To put all motor faders in READY mode: Press “ALL READY” switch.

To put a small number of motor faders in READ Y mode:

a) Press the “SET READY” switch.

b) Touch each fader knob that is to be recorded and make fader movement required.

c) Press the “SET READ Y” switch (to cancel the function).

Revision B2005-2 B-Type

Page 34

2-6 Central Control Module 7896

515 &&0#UHDU#SDQHO#FRQQH FWRUV

Please refer to figure 2-3 for the location of the connecto rs on the B-Type CCM module rear pa ne l de sc ribed below.

D, )DVW#&RSSHU#&RPPXQLFDWLRQV#,22

Two cables provide the “fast copper” data link between the C CM and up to two IBM®

PC or compatible comp uters if these are fitted with a CADAC Fast Copper Communications board 7 514. Otherwise the cables run between the CCM and th e Séance

box, see 1.5.1 Connections - BNC and 1.5.3 Connections - RJ45. Two cables are

normal ly supplied, one f or PC1 and the other for PC2. The connectors are labelled

differently at each end. Make sure that the “CONNECT TO CCM” end is connected

to the CCM! The other ends of the cables are labelled “PC1” and “PC2” respectively.

If the cables are not connected correctly, the communi cations sys tem cannot work.

E,# 368#,QGLFDWRUV

A cable with a 15 way 'D-Type' male connec tor at one end to a 15 way 'D-Type'

fe male connector at the other end is supplied for interconnection between the

Indicators

the console frame.

male connector on the CCM and the

PSU Indicators

fem ale connector on

PSU

The

PSU System 1

will not work un less this connection is made.

and

PSU System 2

LEDs on the CCM front panel (e) in fig 2-1)

F, 5HPRWH#&RQWURO#

The 25 way female 'D-Type' connector labelled RC, is for use with the eight “STOP”

and “START” switches mounted near the top of the front panel (c) in figure 1.11).

Unless special instructio ns are received fro m the customer, this connector is not

D

J

F

I

G

E

FIG 1-3. B-Type CCM rear panel

B-Type Revision B2005-2

H

Page 35

Central Control Module 7896 2-7

wired dir ec tly t o the “STOP” an d “S TART” switches, but term i nates in a 25 way IDCconnector. This allows the user to configure the switch wiring to suit the equipment

they are intended to control. Great care must be taken with the wiring of the

switch(es) to ensure that no short-circuits can occur between any two power supply

units.

+G, 0,',#LQSXWV#DQG#RXWSXWV

Fo ur 5 pin DIN, standard MIDI connectors for the two banks A and B are inclu ded.

The outputs may be connected to any MIDI compatible outboard equipment that

respond s t o pro gram change s , not e on / no te of f and v el oc it y in f orma tio n. See S ou nd

Automation Manager or SAM manual - MIDI, for programming details.

+H, .H\V

See 1.5.8 CCM keys and 1.5.14 Using the Video and Keyboard Change over func-

tion with Séance.

+I, )DGHU#FRPPXQLFDWLRQV

See 1.4.1 Audio Bus / Data Bus Connectio ns, chapte r 1.

+J,# (YHQWV

The 25 way male 'D-Type' connector labelled

tacts to be wired out for external equipment control. The wiring details are shown in

. See SAM manual for details.

Tab le 1

Pin no. Relay no. Function

01 1 normally C LOSED contact

14 1 MO VING contact (wiper)

02 1 norm ally OPEN co nt ac t

15 2 normally C LOSED contact

03 2 MO VING contact (wiper)

16 2 norm ally OPEN co nt ac t

04 3 normally C LOSED contact

17 3 MO VING contact (wiper)

05 3 norm ally OPEN co nt ac t

18 4 normally C LOSED contact

EVENTS

allows the EVENT relay con-

06 4 MO VING contact (wiper)

19 4 norm ally OPEN co nt ac t

07 5 normally C LOSED contact

20 5 MO VING contact (wiper)

08 5 norm ally OPEN co nt ac t

21 6 normally closed contact

09 6 MO VING contact (wiper)

22 6 norm ally OPEN co nt ac t

Revision B2005-2 B-Type

Page 36

2-8 Central Control Module 7896

Pin no. Relay no. Function

10 7 normally C LOSED contact

23 7 MOVING contact (wiper)

11 7 norm ally OPEN co nt ac t

24 8 normally C LOSED contact

12 8 MOVING contact (wiper)

25 8 norm ally OPEN co nt ac t

13 GROUND

516 ,QWHUQDO#PRGXOH#VHWWLQJV

51614 0RGXOH#SRZHU0XS#VWDWH#+,VR21LVR#VHOHFWLRQ,

When the console is first powered up, programmable modules may be set to power

up in ISOLATE mode or in NOT ISOLATE mode. This option is user selectable by

setting links on the motherboard. The factory setting is NOT ISOLATE.

51615 6HOHFWLQJ#RU#FKDQJLQJ#WKH#RSWLRQV

Plac e the CCM module on a fla t surface so that the front panel is f acing you and the

mothe r board is laying on the surface. Locate the three way male molex connector

. This can be found on the mother board near the MIDI B LED25, close to the

CN29

front panel.

The factory setting is NOT ISOLATE, so that the

pins 2 and 3.

To change the POWER-UP STATE to ISOLATE:

Pull off the

programmable jumper

and replace it so that pins 1 and 2 are linked.

517 0RGXOH#OHYHO#VRIWZDUH

When first switched on or after being reset, the CCM display briefly shows the software version number and then performs a check of its internal memory.

Assuming all is found to be well, the display then changes to “cadac B-Type” and the

CCM is ready to be us ed. This is one of the “root” displ ays, and it is always possible

to get back to this point by pressing the

several times). The ot her “root” display possibilities ar e a

[Esc]

memory number

show which will perform a useful function if pressed at this point.

. If this is the case, the appropriate keypad buttons will illuminate to

key (it may be necessary to pre ss

[Esc]

programmable jumper

cue nu m ber

is set to link

or a

The basic operations that can be performed from the “root” display can be summa rized as follows, where button names are shown in

Operation:Type:

Recall cue at the EDIT pointer on PC

Save cue to CURRENT EDIT pointer on PC

Recall cue number nnn.n from PC

Save cue number nnn.n to PC

Recall internal memory n

B-Type Revision B2005-2

Mem n Rcl

Rcl

nnn.n Rcl

nnn.n Sve

Sve

bold

type:-

Page 37

Central Control Module 7896 2-9

Save internal memory n

Clear internal memory n

(where n is a number 0 - 9)

Expl ain a warnin g LED (if applicabl e)

Start the “System setup” menu

The P(revious) and N(ext) buttons can always be used at any time to recall the previous or next cue f rom the PC to the cons ole.

It is not necessary to give a complete four digit cue number, for example, cue

■■■■

25.0 can be entered as just “25”.

When a memory is “Cleared ” all switches are set to be OFF, all fader grou ps to 0

■■■■

and all master displays to be blank.

51714 6DYLQJ#D#&XH

To save a Cue, the CCM must be at one of its “root” displays, (see above for descriptions of the root displays). You can always get back to the root display by pressing

the

Enter the number required for the Cue, us ing the CCM keypad and press the [Sve]

key .

The console status will be saved to that Cue number (in RAM) and the Cue number

will appear in the Cue List Window on the PC.

key one or two times.

[Esc]

Mem n Sve

Mem n Clr

Err

Sys

If the Cue number already exists, the CCM display wil l prompt with “Overwrite

CUE?”. Similarly, the PC will prompt with:

“Cue n exists

Press ENTER to overwrite”

Press [↵] to confirm or

■■■■

pad or the equivalent keys on the PC's keyboard.

If you press the [Sve] key with no number, the system will try to save the console status to the Cue at the current pointer on the PC and will respond with the same

prompts as set ou t above. This does

Window, (this would be the case if you were starting to program a new Show). When

the Cue List Window is empty, [Sve] create s a Cue and gives it the number 1.0.

An invalid Cue number, (outside the range 0.01 to 9999.99), will result in the error

prompt “Bad cue number”, on the CCM display, and “Bad cue number from CCM”, on

the PC monitor. Press [↵] or

51715 5HFDOOLQJ#D#&XH

To recall a Cue, the CCM must be at one of its “root” displays, (see above for descriptions of the root displays). You can always get back to the root display by pressing

the

Enter the number required for the Cue, us ing the CCM keypad and press the [Rcl]

key .

key one or two times.

[Esc]

to cancel. You may use the keys on the CCM key-

[Esc]

apply if there are no Cues in the Cue List

not

to continue.

[Esc]

If the Cue number exists, the console status will be updated to the data contained in

that Cue number (the last time it was saved).

If the Cue number does not exist, the CCM display will show the error prompt, “nonexistent cue” and the PC will show the error as “Cue n does not exist”. Press [↵] or

to continue.

[Esc]

Revision B2005-2 B-Type

Page 38

2-10 Central Control Module 7896

51716 6DYLQJ#D#FRQVROH#VWDWH#WR#DQ#LQWHUQDO#PHPRU\

To save a console state to an internal memory, the CCM must be at one of its “root”

displ a ys , (see ab o v e fo r de sc ript io ns of t he ro ot d is pla y s) . You can al w a y s ge t ba ck to

the root display by pr essing th e

Press the [Mem] key.

■■■■

Enter the number for the internal memory.

■■■■

Press the [Sve] key.

■■■■

The console state is saved to the internal memory.

key several times.

[Esc]

51717 5 HFDOOLQJ#D#FRQVROH#VWDWH#IURP#WKH#LQWHU QDO#PHPRU\

To recall a console state from an internal memory, the CCM must be at one of its

“root” displays, (s ee above for descriptions of the root displays). You can always get

back to the root display by pressing the

Press the [Mem] key.

■■■■

Ente r the number of the internal memory required.

■■■■

Press the [Rcl] key.

■■■■

key one or two ti mes.

[Esc]

The current console state is replaced by the state stored in the internal memory.

518 7KH#6\VWHP#6HWXS#PHQX

This is a set of menus which are navigated by using the

and [↓], with selections being made by pressing

.

[Esc]

Menu items appear in the display with either a question mark (?) or pair of

arrows(⇑⇓) on the right. The arrows indicate that this is the title of the current menu

and that the user should press the up and down arrow keys to make a selection. The

question mark means that this is a selectable item, (press [↵] to select). The menu

wraps around, so if you move down from “User setup?” you get to “System setup

“again. In order to speed up the action of traversing these menus, they

⇑⇓

reset themselves to the title position each time that they are used. For example; if

“Map Faders?” was selected the last time the [Sys] k ey was pr essed, then the “Map

Faders?” option will appear again, the next time the [Sys] is pressed (provided that

the CC M has not bee n reset).

Press the [Sys] key.

The first menu contains the follo wing items:

#

System setup

Map Faders ?

Test Routines ?

User setup ?

The Map Faders, options will immediately perform that operation, whereas the Test

System , User Setup, M IDI recorder and MIDI mu ting selectio ns lead on to other

menus:

Title

⇑⇓

Perform fader mapping.

Move to the system test menu

Move to the user setup menu

and

up

down

], and cancelled by pressing

enter [↵

arrow keys [↑]

do not

System Test

Inc All Faders ?

Show MFdr data ?

Test Motor Fdrs ?

Test Key s ?

Test M IDI ?

Test Events ?

Test Fdr Comms ?

Show Time ?

Show Date ?

View Error Log ?

Clear Error Log ?

B-Type Revision B2005-2

Title

⇑⇓

Test routines for channel and group faders

Read information from the motor f aders

Check mechanical operation of motor faders

Check keys indicate on the display

Send programme c hanges to MIDI-connections

Check relays and indication of events

Check communications busses

Show real-time clock

Show real-time cl ock and da te

Look through the last recorded errors

Clear the error log

Page 39

Central Control Module 7896 2-11

.

.. and...

User Setup

Enable options ?

Set P&N Keys ?

Midi PC Filter ?

MIDI All off ?

Show Map Add r e ss es?

Faders GrpL nk ?

Twi n Ma sters ?

Event Duration ?

Revert Mode ?

Revert Time ?

PC Comms Error ?

Global Level ?

51814 0DSSLQJ

Before the console automation can be used, all faders and programmable modules

must be mapped. Each Map is stored in non-volatile memory within the CCM. Mapping operations should only need to be performed if the layout of the modules within

the frame have been changed. A new console is always mapped by CADAC before it

leaves th e factory.

Each module po sition in a frame is i dentified by a unique n umber (the address). This

number is set by a combinati on of a small PCB fixed to the f rame beneath each module and the frame number switch at the back of a frame. As each fader i s connecte d

to a module, it too can be given a unique address.

Title

⇑⇓

Set 2n d Function on or off

Select how the P and N buttons are illuminated.

Program change filter on/off

All no tes off mes s ages on/off

Shows Module/Fader addr.while mapping on/off

Configure channel faders relative to master

Set number of twin masters

Set duration of event (i.e. length of pulse required

for control of external equipm ent)

Set motorized faders to revert to original position

when moved

Set the time it takes for a motorized fader to revert

to its original position

51815 )DGHU#0DSSLQJ

Ensure all faders are

the sys tem setup menu and press [↵].

The display changes to “Wait......”, as the CCM checks for faders in the console.

When the ch ec k is c omp le t e, t he di splay change s t o “Faders: 0". The CCM i s no w

ready for mapping to begin.

Press the

usually the left-most fader in the frame. The

ext inguish - the CCM display should now read “Faders: 1 “. Now press the

button of the channel fader you wish to be

along - the CCM display should now read “Faders: 2 “. Continue setting each fader

into MUTE until all the c hannel f aders ha ve been mapped.

Continue pressing the Mute buttons for the MASTER faders. The number shown in

the CCM display shows the

MASTE R bus controlled by each master fader is set by switches on the fader PCB

and is

not

If y ou are satisfied that the console faders have been mapp ed correctly, press [↵] to

stop ma ppin g and sto re th e new map, ot he rw is e pres s

button of the channel fader that you wish t o be

MUTE

affected by fader mapping.

NOT ISOLATED

number of faders in the console. Note that the DC

total

and

NOT MUTED

MUTE

“channel fader 2"

. Select “Map Faders?” from

“chann el fad er 1"

led will illuminate briefly then

, usual ly the next one

to cancel this operation.

[Esc]

MUTE

,

Revision B2005-2 B-Type

Page 40

2-12 Central Control Module 7896

51816 7HVW #5RXWLQHV

See below for options .

D, 6\VWHP#WHVW#²#7HVW#IDGHUV#4

In the system menu, select “

The display shows “

Press [↵], followed by the Down Arrow button, until the display shows “

■■■■

”

Faders?

Press [↵]. The display changes to “

■■■■

The group number display on each of the channel s faders increment s from 0 to C,

before returning to zero.

At the same time on the channel, the following automated switches cycle:

At the end of ea ch cy cle:

Test Routines?”

Test Routines?”.

MIC 1 ON

MIC 2 ON

PAN

LP FILTER

HP FILTER

EQ 1 IN

EQ 2 IN

INS

VCA MUTE

NEXT TIME

AUX

NEXT TIME

VCA MUTE & AUX

using the Up or Down ar row butto n.

Testing Faders

”.

Inc All

Meanwhile the groups automated switches c ycle:

INS A

INS B

MAT PRE

SUB INS

At the end of each cycle the DC Master MUTE turns ON and OFF.

Press

to return to the system menu or Down arrow to perform next test.

[Esc]

E, 6KRZ#0)GU#'DWD

In the system menu, select “

The display shows “

Press [↵], followed by the Down Arrow button, until the display shows “

■■■■

”

ers 2?

These tests are for the operati on of Motor faders o nly

the console, skip these tests and go to 2.3.11 “

Press [↵]. Check that all Motor faders are responding and that their positions are

■■■■

correc tl y displayed.

Using the Left and Right arrow keys, select the fader to test. (Press [↵] to go

■■■■

directly to th e channel faders.)

The display shows: “Group 1:0000 00”

Test Routines?”

Test Routines?”.

using the Up or Down ar row butto n.

. If there are no Motor faders in

Test keys

”.

Test fad-

The left and right arrow keys may be used to select each fader in turn, group 1

through 16, then channel 1 upwards. The numbers displayed after the colon represent the raw fader data. If you encounter difficulties, please contact CADAC.

B-Type Revision B2005-2

Page 41

Central Control Module 7896 2-13

F, 7H V W#PRWRU#IDGHUV

In the system menu, select “

The display shows “

Press [↵], followed by the Down Arrow button, until the display shows “

■■■■

”

Fders?

Press [↵]. The Motor faders should now move up and down (they move slower at

■■■■

the bo ttom end). Check that all Motor fad ers are moving at the same rate an d that

they run smoothly.

■■■■

Press

to return to the system menu or Down arrow to perform next test.

[Esc]

Test Routines?”

Test Routines?”.

using the Up or Down arrow button.

T est Motor

G, 7H V W#NH\V

In the system menu, select “

The display shows “

Press [↵], followed by the Down Arrow button, until the display shows “

■■■■

”

Keys?

Press [↵]. The display shows

■■■■

Press ea ch of th e b u tto ns , inc ludi ng th e P & N but t on s (b ut not th e Esc b u tto n) in

■■■■

turn, ensuring that the display shows what button has been pressed.

Check also the external P & N.

■■■■

Press

to return to the system menu.

[Esc]

Test Routines?”

Test Routines?”.

“Button = ...”

using the Up or Down arrow button.

Test

H, 7H V W#0,',

In the system menu, select “

The display shows “

Test Routines?”.

Test Routines?”

using the Up or Down arrow button.

Press [↵], followed by the Down Arrow button, until the display shows “

■■■■

”

MIDI?

Press [↵]. This test outputs programme change to the MIDI-connections on the

■■■■

back of the CCM, indicating channel changes in ascending order for MIDI A (1-16)

and in descending order for MIDI B (16-1).

To perform a cable test and to ensure MIDI-cables have not been crossed over, a

cable can be connected between MIDI out and MIDI in. This will cause a flashing “A”

if connected between MIDI A output and MIDI A input and a flashing “B” if connected

between MIDI B output and MID I B input.

Press [Esc] to return to the system menu or Down arrow to perform next test.

Test

I, 7H V W#HYHQWV

In the system menu, select “

The display shows “

Press [↵], followed by the Down Arrow button, until the display shows “

■■■■

”

Events?

Press [↵]. Make sure that the Events enable switch is on. The LED’s indicating

■■■■

events should now come on and off in sequence. Turning the enable sw itch off

should cause all the LED’s to extinguish.

Press [Esc] to return to the system menu or Down arrow to perform next test.

■■■■

Test Routines?”

Test Routines?”.

using the Up or Down arrow button.

Test

J, 7H V W#)GU#&RPPV

In the system menu, select “

The display shows “

Test Routines?”.

Test Routines?”

using the Up or Down arrow button.

Press [↵], followed by the Down Arrow button, until the display shows “

■■■■

Press [

”

]. The display sho ws “Comms busses OK” for a few seconds before

↵↵↵↵

Test Comms?”

Comms?

■■■■

returning to “

Revision B2005-2 B-Type

Test

Page 42

2-14 Central Control Module 7896

If there is a f ault, a fault code is display ed indicating the type of fault.

■■■■

This test automatically returns to “Test comms?”.

K, 6KRZ#7LPH

In the system menu, select “

The display shows “

Press [↵], followed by the Down Arrow button, until the display shows “

■■■■

”

Time?

Press [↵]. The display shows the time as set in the PC.

■■■■

Press [Esc] to return to the system menu or Down arrow to perform next test.

Test Routines?”

Test Routines?”.

using the Up or Down ar row butto n.

Show

L, 6KRZ#'DWH

In the system menu, select “

The display shows “

Press [↵], followed by the Down Arrow button, until the display shows “

■■■■

”

Date?

Press [↵]. The display shows the date as set in the PC.

■■■■

Press [Esc] to return to the system menu or Down arrow to perform next test.

The Time/Date do not increment when power is removed from the console.

NOTE:

They rely upon SA M updating them when communicat ions are fir st estab lished.

Test Routines?”

Test Routines?”.

using the Up or Down ar row butto n.

Show

M, 9LHZ#(U U RU#/RJ

In the system menu, select “

The display shows “

Test Routines?”.

Test Routines?”

using the Up or Down ar row butto n.

Press [↵], followed by the Down Arrow button, until the display shows “

■■■■

”

Log?

Press [↵]. The display lists the time and date of errors/events.

■■■■

Select

■■■■

■■■■

■■■■

NOTE:

are not in themselves errors. Examples are Time/Date reset

the display a re not errors.

Press [Esc] to return to the system menu.

Time/Date

Press the Right arrow key to display the type of error.

Press the Left arrow key to get back to the list of time/date.

Some mes s ages are included in the erro r log for debugging purposes that

with the arrow keys.

or

Host is Sé ance

N, &OHDU#(UURU#/RJ

In the system menu, select “

The display shows “

Press [↵], followed by the Down Arrow button, until the display shows “

■■■■

Press [

”

]. The log is cleared and the event is entered in the Error log.

↵↵↵↵

Error Log?

■■■■

This test automatically returns to the system menu.

Test System?”

Test System?”.

using the Up or Do wn arrow button.

View Error

on

Clear

B-Type Revision B2005-2

Page 43

Central Control Module 7896 2-15

51817 8VHU#6HWXS

See below for options .

D, (QDEOH#RSWLRQV

The

you to override the setting of one or both MIDI ports and/or the Events for one Cue

only.