Cabletron Systems MicroMMAC-24E, MicroMMAC-34E, MicroMMAC-22E, MicroMMAC-32E, MicroMMAC-22ES Installation Manual

...Page 1

MicroMMAC

10BASE-T INTELLIGENT STACKABLE HUB

INSTALLATION GUIDE

MicroMMAC-24E

CABLETRON

MicroMMAC-24

RESET

DISPLAY

MicroMMAC-34E

CABLETRON

MicroMMAC-34

RESET

DISPLAY

10BASE-T HUB

COM 1COM 2

10BASE-T HUB

COM 1COM 2

LANVIEW

RCV

LNK

RCV

LNK

LANVIEW

RCV

LNK

RCV

LNK

12 11 10

24 23 22

12 11 10

24 23 22

R

21 20 19

987

R

21 20 19

987

18 17 16

654

18 17 16

654

E

15 14 13

2

E

321

1

12X 11X 10X 9X 8X 7X 6X 5X 4X 3X 2X 1X

E

15 14 13

2

E

321

1

20X

22X23X24X

21X

19X

24X 13X

12X 1X

18X 17X 16 X

EPIM 2

15 X 14X 13X

EPIM 1

EPIM 2

EPIM 1

WITH

PWR

CPU

CLN

WITH

PWR

CPU

CLN

Page 2

NOTICE

Cabletron Systems reserves the right to make changes in specifications and other information

contained in this document without prior notice. The reader should in all cases consult Cabletron

Systems to determine whether any such changes have been made.

The hardware, firmware, or software described in this manual is subject to change without notice.

IN NO EVENT SHALL CABLETRON SYSTEMS BE LIABLE FOR ANY INCIDENTAL,

INDIRECT, SPECIAL, OR CONSEQUENTIAL DAMAGES WHATSOEVER (INCLUDING BUT

NOT LIMITED TO LOST PROFITS) ARISING OUT OF OR RELATED TO THIS MANUAL OR

THE INFORMATION CONTAINED IN IT, EVEN IF CABLETRON SYSTEMS HAS BEEN

ADVISED OF, KNOWN, OR SHOULD HAVE KNOWN, THE POSSIBILITY OF SUCH

DAMAGES.

Copyright 1996 by Cabletron Systems, Inc., P.O. Box 5005, Rochester, NH 03866-5005

All Rights Reserved

Printed in the United States of America

Order Number: 9030908-02 April 1996

SPECTRUM, LANVIEW, MicroMMAC

Manager, EPIM, EPIM-A, EPIM-F1, EPIM-F2, EPIM-F3, EPIM-T, EPIM-X, FOT-F, FOT-F3

HubSTACK, SEH, SEHI

All other product names mentioned in this manual may be trademarks or registered trademarks of

their respective companies.

, and

TMS-3

, and

BRIM

are trademarks of Cabletron Systems, Inc.

are registered trademarks and

Element

,

MicroMMAC Installation Guide i

Printed on Recycled Paper

Page 3

Notice

FCC NOTICE

This device complies with Part 15 of the FCC rules. Operation is subject to the following two

conditions: (1) this device may not cause harmful interference, and (2) this device must accept any

interference received, including interference that may cause undesired operation.

NOTE:

device, pursuant to Part 15 of the FCC rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is operated in a commercial environment.

This equipment uses, generates, and can radiate radio frequency energy and if not installed in

accordance with the operator’s manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause interference in which case the user

will be required to correct the interference at his own expense.

WARNING:

party responsible for compliance could void the user’s authority to operate the equipment.

This equipment has been tested and found to comply with the limits for a Class A digital

Changes or modifications made to this device which are not expressly approved by the

DOC NOTICE

This digital apparatus does not exceed the Class A limits for radio noise emissions from digital

apparatus set out in the Radio Interference Regulations of the Canadian Department of

Communications.

Le présent appareil numérique n’émet pas de bruits radioélectriques dépassant les limites applicables

aux appareils numériques de la class A prescrites dans le Règlement sur le brouillage radioélectrique

édicté par le ministère des Communications du Canada.

VCCI NOTICE

This equipment is in the 1st Class Category (information equipment to be used in commercial and/or

industrial areas) and conforms to the standards set by the Voluntary Control Council for Interference

by Information Technology Equipment (VCCI) aimed at preventing radio interference in commercial

and/or industrial areas.

Consequently , when used in a residential area or in an adjacent area thereto, radio interference may be

caused to radios and TV receivers, etc.

Read the instructions for correct handling.

ii MicroMMAC Installation Guide

Page 4

Notice

CABLETRON SYSTEMS, INC. PROGRAM LICENSE AGREEMENT

IMPORTANT:

This document is an agreement between you, the end user, and Cabletron Systems, Inc. (“Cabletron”)

that sets forth your rights and obligations with respect to the Cabletron software program (the

“Program”) contained in this package. The Program may be contained in firmware, chips or other

media. BY UTILIZING THE ENCLOSED PRODUCT, YOU ARE AGREEING TO BECOME

BOUND BY THE TERMS OF THIS AGREEMENT, WHICH INCLUDES THE LICENSE AND

THE LIMITATION OF WARRANTY AND DISCLAIMER OF LIABILITY. IF YOU DO NOT

AGREE TO THE TERMS OF THIS AGREEMENT, PROMPTLY RETURN THE UNUSED

PRODUCT TO THE PLACE OF PURCHASE FOR A FULL REFUND.

Before utilizing this product, carefully read this License Agreement.

CABLETRON SOFTWARE PROGRAM LICENSE

1. LICENSE

package subject to the terms and conditions of this License Agreement.

You may not copy, reproduce or transmit any part of the Program except as permitted by the

Copyright Act of the United States or as authorized in writing by Cabletron.

2. OTHER RESTRICTIONS. You may not reverse engineer, decompile, or disassemble the

Program.

3. APPLICABLE LA W. This License Agreement shall be interpreted and governed under the laws

and in the state and federal courts of New Hampshire. You accept the personal jurisdiction and

venue of the New Hampshire courts.

. You have the right to use only the one (1) copy of the Program provided in this

EXCLUSION OF WARRANTY AND DISCLAIMER OF LIABILITY

1. EXCLUSION OF

writing, Cabletron makes no warranty, expressed or implied, concerning the Program (including

its documentation and media).

CABLETRON DISCLAIMS ALL WARRANTIES, OTHER THAN THOSE SUPPLIED TO

YOU BY CABLETRON IN WRITING, EITHER EXPRESSED OR IMPLIED, INCLUDING

BUT NOT LIMITED TO IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE, WITH RESPECT TO THE PROGRAM, THE

ACCOMPANYING WRITTEN MA TERIALS, AND ANY A CCOMPANYING HARDWARE.

2. NO LIABILITY FOR CONSEQUENTIAL DAMAGES. IN NO EVENT SHALL

CABLETRON OR ITS SUPPLIERS BE LIABLE FOR ANY DAMAGES WHATSOEVER

(INCLUDING, WITHOUT LIMITATION, DAMAGES FOR LOSS OF BUSINESS,

PROFITS, BUSINESS INTERRUPTION, LOSS OF BUSINESS INFORMATION, SPECIAL,

INCIDENTAL, CONSEQUENTIAL, OR RELIANCE DAMAGES, OR OTHER LOSS)

ARISING OUT OF THE USE OR INABILITY TO USE THIS CABLETRON PRODUCT,

EVEN IF CABLETRON HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH

DAMAGES. BECAUSE SOME STATES DO NOT ALLOW THE EXCLUSION OR

LIMITATION OF LIABILITY FOR CONSEQUENTIAL OR INCIDENTAL DAMAGES, OR

ON THE DURATION OR LIMITATION OF IMPLIED WARRANTIES, IN SOME

INSTANCES THE ABOVE LIMITATIONS AND EXCLUSIONS MAY NOT APPLY TO

YOU.

WARRANTY. Except as may be specifically provided by Cabletron in

MicroMMAC Installation Guide iii

Page 5

Notice

UNITED STATES GOVERNMENT RESTRICTED RIGHTS

The enclosed product (a) was developed solely at private expense; (b) contains “restricted computer

software” submitted with restricted rights in accordance with Section 52227-19 (a) through (d) of the

Commercial Computer Software - Restricted Rights Clause and its successors, and (c) in all respects

is proprietary data belonging to Cabletron and/or its suppliers.

For Department of Defense units, the product is licensed with “Restricted Rights” as defined in the

DoD Supplement to the Federal Acquisition Regulations, Section 52.227-7013 (c) (1) (ii) and its

successors, and use, duplication, disclosure by the Government is subject to restrictions as set forth in

subparagraph (c) (1) (ii) of the Rights in Technical Data and Computer Software clause at

252.227-7013. Cabletron Systems, Inc., 35 Industrial Way, Rochester, New Hampshire 03867-0505.

iv MicroMMAC Installation Guide

Page 6

DECLARATION OF CONFORMITY

Notice

Application of Council Directive(s):

Manufacturer’s Name:

Manufacturer’ s Address:

European Representative Name:

European Representative Address:

Conformance to Directive(s)/Product Standards:

Equipment Type/Environment:

89/336/EEC

73/23/EEC

Cabletron Systems, Inc.

35 Industrial Way

PO Box 5005

Rochester, NH 03867

Mr. J. Solari

Cabletron Systems Limited

Nexus House, Newbury Business Park

London Road, Newbury

Berkshire RG13 2PZ, England

EC Directive 89/336/EEC

EC Directive 73/23/EEC

EN 55022

EN 50082-1

EN 60950

Networking Equipment, for use in a

Commercial or Light

Environment.

Industrial

We the undersigned, hereby declare that the equipment packaged with this notice conforms to

the above directives.

Manufacturer Legal Representative in Europe

Mr. Richard Michaud Mr. J. Solari

___________________________________ ___________________________________

Full Name Full Name

Manager of Engineering Services Managing Director - E.M.E.A.

___________________________________ ___________________________________

Title Title

Rochester, NH, USA Newbury, Berkshire, England

___________________________________ ___________________________________

Location Location

MicroMMAC Installation Guide v

Page 7

Contents

CHAPTER 1 INTRODUCTION

1.1 How to Use This Manual .............................................................1-1

1.2 Manual Organization ...................................................................1-1

1.3 Document Conventions...............................................................1-2

1.4 MicroMMAC Overview.................................................................1-3

1.5 MicroMMAC Features..................................................................1-4

1.6 Stackable Capabilities.................................................................1-6

1.7 Remote Network Management Capabilities................................1-7

1.8 Optional Features........................................................................1-8

1.9 Related Manuals..........................................................................1-9

1.10 Getting Help...............................................................................1-10

CHAPTER 2 CONTROLS AND INDICATORS

2.1 Identifying MicroMMAC Components..........................................2-1

2.2 Turning the MicroMMAC ON and OFF........................................2-2

2.3 Using the LCD and LCD DISPLAY Button ..................................2-2

2.3.1 Static System Messages ................................................2-3

2.3.2 Saved Alarm Messages..................................................2-4

2.3.3 Unsaved Initialization Messages ....................................2-5

2.3.4 Saved System Messages ...............................................2-6

2.4 Using the Reset Button................................................................2-7

2.5 Using the NVRAM Switch............................................................2-8

CHAPTER 3 INSTALLATION

3.1 Unpacking the MicroMMAC.........................................................3-1

3.2 Removing the Chassis Cover......................................................3-2

3.3 Setting the Mode Switches..........................................................3-4

3.4 Upgrading the FLASH SIMM.......................................................3-6

3.5 Adding/Replacing EPIMs.............................................................3-8

3.6 Adding/Replacing BRIMs.............................................................3-9

3.7 Testing the MicroMMAC..............................................................3-9

3.8 Installing the MicroMMAC..........................................................3-10

3.8.1 Shelf or Tabletop Installation ........................................3-11

3.8.2 Attaching the Strain-Relief Bracket...............................3-12

3.8.3 Rack Mounting the MicroMMAC...................................3-13

3.8.4 Stacking the MicroMMAC .............................................3-14

MicroMMAC Installation Guide vii

Page 8

Contents

CHAPTER 4 CONNECTING TO THE NETWORK

4.1 Connecting the MicroMMAC to the Network................................4-1

4.1.1 Connecting a 10BASE-T Segment to the MicroMMAC-22E

and MicroMMAC-24E4-2

4.1.2 Connecting a 10BASE-T Segment to the MicroMMAC-32E

and MicroMMAC-34E4-3

4.1.3 Connecting a 10BASE-T Segment to an EPIM-T............4-5

4.1.4 Connecting a 10BASE-F Segment to an EPIM-F1..........4-6

4.1.5 Connecting a 10BASE-F Segment to an EPIM-F2 or

EPIM-F34-8

4.1.6 Connecting a 10BASE2 Segment to an EPIM-C...........4-10

4.1.7 Connecting an AUI Segment to an EPIM-A ..................4-11

4.1.8 Connecting an AUI Segment to an EPIM-X ..................4-13

CHAPTER 5 TROUBLESHOOTING

5.1 Using LANVIEW...........................................................................5-1

5.2 Troubleshooting Checklist............................................................5-3

APPENDIX A MicroMMAC SPECIFICATIONS

A.1 Operating Specifications............................................................. A-1

A.2 Power Supply Requirements ...................................................... A-1

A.3 Environmental Requirements...................................................... A-2

A.4 Agency Approvals....................................................................... A-2

A.5 EMI Requirements ...................................................................... A-2

A.6 EMC Requirements..................................................................... A-2

A.7 Physical Specifications ............................................................... A-2

APPENDIX B EPIM SPECIFICATIONS

B.1 EPIM-T........................................................................................ B-1

B.2 EPIM-F1 and EPIM-F2................................................................ B-2

B.3 EPIM-F3...................................................................................... B-3

B.4 EPIM-C ....................................................................................... B-5

B.5 EPIM-A and EPIM-X ................................................................... B-6

viii MicroMMAC Installation Guide

Page 9

Contents

APPENDIX C NETWORK PLANNING AND CONFIGURATION

C.1 Network Cable Requirements......................................................C-1

C.1.1 HubSTACK Interconnect Cable ......................................C-1

C.1.2 10BASE-T UTP and STP Cable......................................C-2

C.1.3 Multimode Fiber Optic Cable...........................................C-4

C.1.4 Single Mode Fiber Optic Cable .......................................C-5

C.1.5 10BASE2 Thin Coaxial Cable .........................................C-6

C.1.6 AUI Cable........................................................................C-7

C.2 Network Port Specifications.........................................................C-7

C.2.1 MicroMMAC-22E and MicroMMAC-24E

Network PortsC-8

C.2.2 MicroMMAC-32E and MicroMMAC-34E

Network PortsC-8

C.3 COM Port Specifications ...........................................................C-10

C.4 Transceiver Requirements ........................................................C-10

INDEX

MicroMMAC Installation Guide ix

Page 10

CHAPTER 1

INTRODUCTION

Welcome to the Cabletron Systems

Intelligent Stackable Hub Installation Guide

MicroMMAC 10BASE-T

. This manual provides

installation instructions and reference information for the

MicroMMAC-22E, MicroMMAC-24E, MicroMMAC-32E,

MicroMMAC-34E, MicroMMAC-22ES, MicroMMAC-24ES,

MicroMMAC-32ES, and MicroMMAC-34ES.

Unless it is noted differently in this guide, the term MicroMMAC

NOTE

refers to the MicroMMAC-22E, MicroMMAC-24E,

MicroMMAC-32E, MicroMMAC-34E, MicroMMAC-22ES,

MicroMMAC-24ES, MicroMMAC-32ES, and

MicroMMAC-34ES.

1.1 HOW TO USE THIS MANUAL

Read through this manual to gain an understanding of the features and

capabilities of the MicroMMAC. A general knowledge of Ethernet and

IEEE 802.3 type data communications networks and their physical layer

components is helpful when installing the MicroMMAC.

1.2 MANUAL ORGANIZATION

This manual contains the following chapters and appendices:

Chapter 1,

describes MicroMMAC features, and concludes with a list of related

manuals.

Chapter 2,

the MicroMMAC.

Chapter 3,

stackable or standalone device.

Chapter 4,

MicroMMAC to the network using the various media types.

MicroMMAC Installation Guide Page 1-1

Introduction

Controls and Indicators

Installation

, outlines the contents of this manual, briefly

, shows the controls and indicators of

, describes how to install the MicroMMAC as a

Connecting to the Network

, explains how to connect the

Page 11

Chapter 1:

Introduction

Chapter 5,

Troubleshooting

, describes how to use the LANVIEW LEDs

to troubleshoot network problems.

Appendix A,

MicroMMAC Specifications

, provides the physical

properties, environmental operating requirements, agency approvals, and

power requirements.

Appendix B,

EPIM Specifications

, lists specifications for each of the

optional EPIMs available for the MicroMMAC.

Appendix C,

Network Planning and Configuration

, provides network

cable requirements.

1.3 DOCUMENT CONVENTIONS

The following conventions are used throughout this document:

Note

symbol. Calls the reader’s attention to any item of

NOTE

information that may be of special importance.

TIP

!

CAUTION

Tip

symbol. Conveys helpful hints concerning procedures or

actions.

Caution

damage to the equipment.

Warning

equipment damage, personal injury or death.

symbol. Contains information essential to avoid

symbol. Warns against an action that could result in

Page 1-2 MicroMMAC Installation Guide

Page 12

MicroMMAC Overview

1.4 MicroMMAC OVERVIEW

The MicroMMAC is an intelligent, repeating hub that provides complete

SNMP management to as many as four Stackable Ethernet Hub (SEH)

series non-intelligent hubs. The MicroMMAC has front panel ports for

network connections and a rear panel HubSTACK Interconnect Bus port

for stackable connections. In addition, the MicroMMAC has a rear panel

port that supports one Cabletron Systems Bridge Router Interface Module

(BRIM). BRIMs provide bridging/routing capability for Asynchronous

Transfer Mode (ATM), Ethernet, Fiber Distributed Data Interface (FDDI),

Token Ring, and Wide Area Network (WAN) connections.

The MicroMMAC provides front panel Ethernet connections using either

RJ45 connectors or RJ21 connectors. In addition, the MicroMMAC

provides two ports for Ethernet Port Interface Modules (EPIMs). EPIMs

provide connectivity for unshielded twisted pair, shielded twisted pair,

multimode fiber optic, single mode fiber optic, or thin coaxial cable.

The following list describes each configuration of the MicroMMAC:

MicroMMAC-22E

•

provides 12 RJ45 network ports, one EPIM port,

and one BRIM port.

•

MicroMMAC-24E

provides 24 RJ45 network ports, two EPIM ports,

and one BRIM port.

•

MicroMMAC-32E

provides one RJ21 connector (providing 12

twisted pair segments), one EPIM port, and one BRIM port.

•

MicroMMAC-34E

provides two RJ21 connectors (providing 24

twisted pair segments), two EPIM ports, and one BRIM port.

•

MicroMMAC-22ES

one BRIM port, and Cabletron Systems LANVIEW

•

MicroMMAC-24ES

ports, one BRIM port, and Cabletron Systems LANVIEW

•

MicroMMAC-32ES

provides 12 RJ45 network ports, one EPIM port,

SECURE

.

provides 24 RJ45 network ports, two EPIM

SECURE

provides one RJ21 connector (providing 12

twisted pair segments), one EPIM port, one BRIM port, and Cabletron

Systems LANVIEW

SECURE

.

.

•

MicroMMAC-34ES

twisted pair segments), two EPIM ports, one BRIM port, and

Cabletron Systems LANVIEW

MicroMMAC Installation Guide Page 1-3

provides two RJ21 connectors (providing 24

SECURE

.

Page 13

Chapter 1:

Introduction

1.5 MicroMMAC FEATURES

Repeater Functionality

The MicroMMAC fully conforms to the IEEE 802.3 Repeater, AUI, and

10BASE-T specifications, and provides the flexibility to connect

networks using IEEE 802.3, Ethernet Version 1 or Version 2 equipment.

The MicroMMAC transmits retimed data packets, regenerates the

preamble, extends fragments, and arbitrates collisions.

The MicroMMAC automatically partitions problem segments, and

reconnects repaired segments to the network. This feature minimizes the

impact on network operation resulting from a problem on one segment by

isolating the problem segment. Only devices on the problem segment are

affected. When the problem is solved, the MicroMMAC automatically

reconnects the isolated segment to the network.

Polarity Detection and Correction

Each twisted pair port on the MicroMMAC incorporates a Polarity

Detection and Correction feature. This feature allows the MicroMMA C to

pass data regardless of the polarity of the twisted pair segment’s receive

link. Cabletron Systems does not recommend operating in this condition.

If you discover this condition, remove the segment from the network and

wire it correctly. This reduces the potential for problems in the future if

equipment changes are made.

Local Management

Local Management allows you to manage the MicroMMAC and all its

attached segments. It also provides full packet and error statistics for the

entire stack, individual device, or individual port. You access Local

Management by attaching a DEC VT320 terminal or a PC using VT320

emulation software to the MicroMMA C’s RJ45 COM 2 port. Refer to the

MicroMMAC Local Management User’s Guide

for instructions on how to

use Local Management.

LANVIEW LED

Cabletron Systems LANVIEW status monitoring and diagnostics system

is a troubleshooting tool that helps diagnose power failures, collisions,

cable faults, and link problems. LANVIEW LEDs are conveniently

located on the MicroMMAC front panel.

Page 1-4 MicroMMAC Installation Guide

Page 14

MicroMMAC Features

LCD

The MicroMMAC is equipped with an LCD that provides information

about the MicroMMAC such as po wer up diagnostics, firmware re visions,

MAC and IP addresses, and error alerts.

Reset Button

The Reset button lets you re-boot and initialize the processor.

Intelligence

The MicroMMAC is equipped with an advanced Intel i960

microprocessor to provide a scalable RISC-based architecture.

Management Information Base (MIB) Support

The MicroMMAC provides IETF MIB support which includes the

following:

• Remote Monitoring MIB (RMON)

• Bridge MIB

• MIBII

Serial Connections

The MicroMMAC provides two RJ45 ports (COM 1 and COM 2) for

serial connections. The COM ports allow access to Local Management by

locally connecting a DEC VT220 or VT320 terminal, or a PC using VT

emulation software. The COM ports also provide a connection for an

Uninterruptible Power Supply (UPS).

DLM

Cabletron Systems Distributed LAN Monitor (DLM) is a software option

for the MicroMMAC. DLM pro vides a method to locally poll and monitor

any Simple Network Management Protocol (SNMP) or Internet Protocol

(IP) device using a remote management application.

MicroMMAC Installation Guide Page 1-5

Page 15

Chapter 1:

FLASH EEPROMs

Introduction

The MicroMMAC uses FLASH Electrically Erasable Programmable

Read Only Memory (EEPROM) which allows you to download new and

updated firmware using SPECTRUM Element Manager for Windows or

any device using BOOTP or tftp protocols.

The MicroMMAC supports the following download applications:

Standard Download

•

- the MicroMMAC automatically becomes

disabled while the new firmware image loads directly into Local

not

Dynamic Random Access Memory (LDRAM). You can

perform a

Standard Download through a BRIM interface.

•

Runtime Download - the MicroMMAC continues to operate without

interruption while you download the ne w firmware image directly into

FLASH memory. The original firmware image in LDRAM continues

to run until the MicroMMAC is reset. You can perform a Runtime

Download through any network port, including the BRIM.

1.6 STACKABLE CAPABILITIES

The MicroMMAC can be stacked together with Cabletron Systems SEH

series of non-intelligent hubs. You can stack as many as four

non-intelligent hubs with one MicroMMAC. The MicroMMAC provides

complete management for the stack, including full packet and error

statistics for the entire stack, individual de vice, or individual port. Y ou can

also add or remove hubs from the stack without having to power down.

Stackable configurations let you maintain only one IEEE repeater hop

while providing up to 130 Ethernet ports. The rear panel HubSTACK

Interconnect Bus Out port of the MicroMMAC lets you daisy chain hubs

together using the HubSTACK Interconnect cable. Figure 1-1 shows a

typical stackable configuration.

Page 1-6 MicroMMAC Installation Guide

Page 16

Remote Network Management Capabilities

REAR VIEW

MicroMMAC MANAGING 4 SEH NON-INTELLIGENT HUBS

HubSTACK

SEH-24

HubSTACK

SEH-24

HubSTACK

SEH-24

HubSTACK

SEH-24

10BASE-T

OUT

10BASE-T

OUT

10BASE-T

OUT

10BASE-T

OUT

MicroMMAC-34E

HUB

WITH

SEH INTERCONNECT

HUB

WITH

SEH INTERCONNECT

HUB

WITH

SEH INTERCONNECT

HUB

WITH

LANVIEW®

SEH INTERCONNECT

10BASE-T

LINE:

100-125V - 4.0A

200-250V - 2.0A

50/60Hz

LANVIEW®

LANVIEW®

LANVIEW®

HUB

WITH

SN

IN

IN

IN

IN

LANVIEW®

SEH INTERCONNECT

OUT

090802

Figure 1-1 Typical Stackable Configuration

1.7 REMOTE NETWORK MANAGEMENT CAPABILITIES

You can manage the MicroMMAC remotely by any SNMP network

management system. Cabletron Systems offers the following remote

management packages:

• Cabletron Systems SPECTRUM

• Cabletron Systems SPECTRUM Element Manager for Windows

• Cabletron Systems Remote SPECTRUM Portable Management

Applications

MicroMMAC Installation Guide Page 1-7

Page 17

Chapter 1: Introduction

1.8 OPTIONAL FEATURES

The following features are not included with the MicroMMA C, but can be

purchased separately from Cabletron Systems.

Bridging/Routing Capabilities

Bridge Router Interface Modules (BRIMs) provide the MicroMMAC

with bridging/routing capability. Cabletron Systems offers BRIMs that

support the following technologies:

• Asynchronous Transfer Mode (ATM)

• Ethernet

• Fast Ethernet

• Fiber Distributed Data Interface (FDDI)

• Token Ring

• Wide Area Network (WAN)

Refer to the release notes included with the MicroMMAC for a

NOTE

Ethernet Port Interface Modules (EPIMs)

list of available BRIMs.

EPIMs provide the MicroMMAC with Ethernet connectivity to a variety

of media. Cabletron Systems offers the EPIMs shown in Table 1-1.

Page 1-8 MicroMMAC Installation Guide

Page 18

Related Manuals

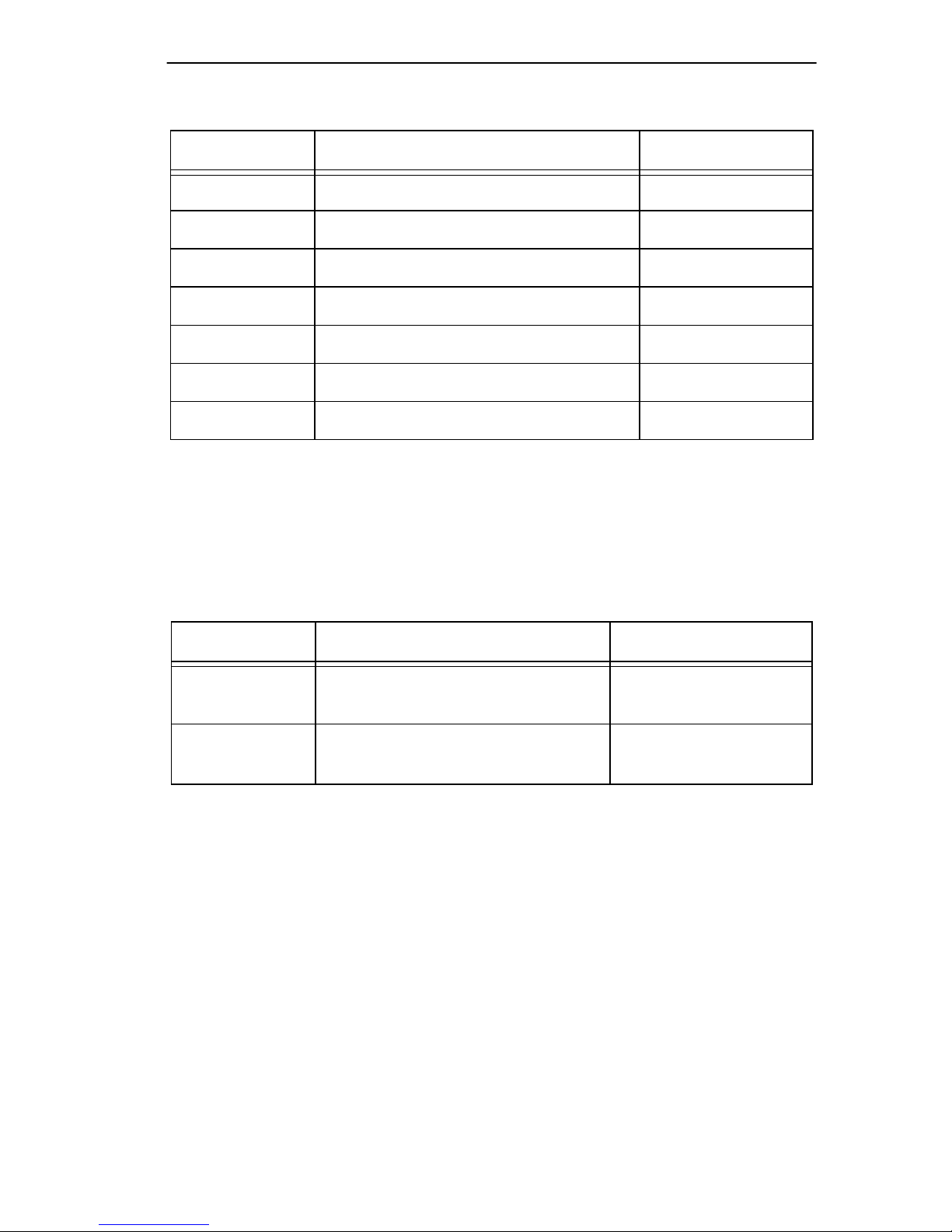

Table 1-1 EPIMs

EPIM Media T ype Connectors

EPIM-A AUI DB15 (Female)

EPIM-C 10BASE2 Thin Coaxial BNC

EPIM-F1 Multimode Fiber SMA

EPIM-F2 Multimode Fiber ST

EPIM-F3 Single Mode Fiber ST

EPIM-T 10BASE-T Unshielded Twisted Pair RJ45

EPIM-X Standard Transceiver DB15 (Male)

HubSTACK Interconnect Cables

HubSTACK Interconnect cables link the MicroMMAC to SEH hubs in

the stack. Table 1-2 lists the part number and application for each cable.

Table 1-2 HubSTACK Interconnect Cables

Part Number Description Application

9380110 12” HubSTACK Interconnect

Cable

9380111 18” HubSTACK Interconnect

Cable

SEH to SEH

connections

MicroMMAC to SEH

connections

1.9 RELATED MANUALS

Use the following manuals to supplement the procedures and other

technical data provided in this manual. The procedures contained in the

following manuals are referenced where appropriate, but not repeated in

this manual.

• Cabletron Systems SEH Series User’s Guides

• Cabletron Systems BRIM User's Guides

MicroMMAC Installation Guide Page 1-9

Page 19

Chapter 1: Introduction

1.10 GETTING HELP

If you need additional support related to the MicroMMAC, or if you ha ve

any questions, comments, or suggestions concerning this manual, contact

Cabletron Systems Technical Support:

By phone (603) 332-9400

Monday – Friday; 8

By CompuServe GO CTRON from any ! prompt

By Internet mail support@ctron.com

By FTP ctron.com (134.141.197.25)

Login anonymous

Password your email address

Before calling Cabletron Systems Technical Support, have the following

information ready:

• A description of the failure

A.M. – 8 P.M. Eastern T ime

• A description of any action(s) already taken to resolve the problem

(e.g., changing mode switches, rebooting the unit, etc.)

• A description of your network environment (layout, cable type, etc.)

• Network load and frame size at the time of trouble (if known)

• The serial and revision numbers of all Cabletron Systems products in

the network

• The device history (i.e., have you returned the device before, is this a

recurring problem, etc.)

• Any previous Return Material Authorization (RMA) numbers

Page 1-10 MicroMMAC Installation Guide

Page 20

CHAPTER 2

CONTROLS AND INDICATORS

This chapter describes how to identify and use the controls and indicators

of the MicroMMAC.

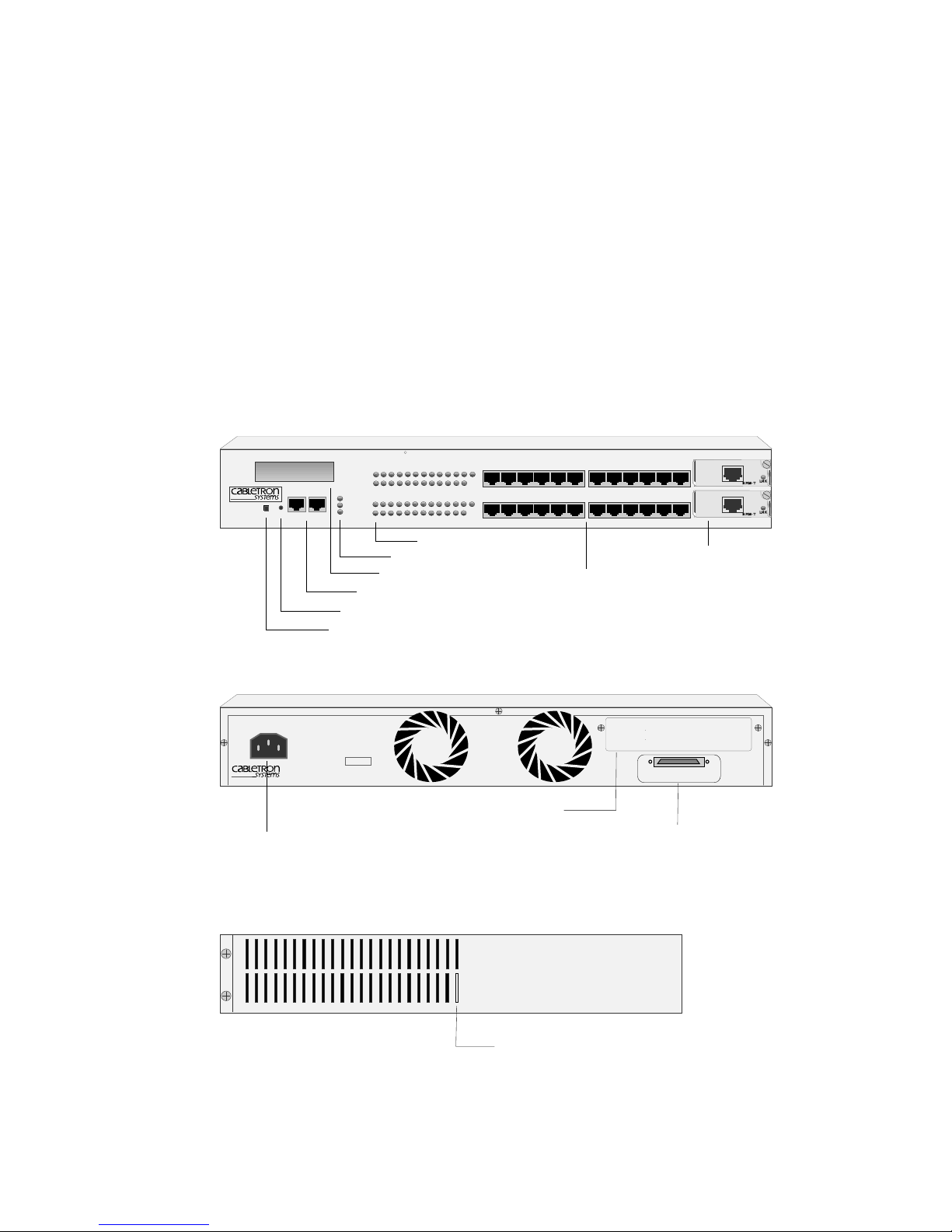

2.1 IDENTIFYING MicroMMAC COMPONENTS

Figure 2-1 shows each of the MicroMMAC’s operational components.

FRONT VIEW

10BASE-T HUB

MicroMMAC-24E

CABLETRON

MicroMMAC-24

RESET

DISPLAY

COM 1COM 2

WITH

PWR

CPU

CLN

COM PORTS

RESET BUTTON

LCD DISPLAY BUTTON

MicroMMAC-24E 10BASE-T HUB WITH LANVIEW®

SN

LINE:

100-125V - 4.0A

200-250V - 2.0A

50/60Hz

POWER CORD CONNECTOR

LANVIEW

RCV

LNK

24 23 22

RCV

LNK

12 11 10

SYSTEM LEDS

LCD

R

18 17 16

654

15 14 13

321

21 20 19

987

PORT STATUS LEDS

E

2

E

1

12X 11X 10X 9X 8X 7X 6X 5X 4X 3X 2X 1X

20X

22X23X24X

21X

19X

18X 17X 16 X

NETWORK PORTS

BRIM PORT

HubSTACK INTERCONNECT PORT

15 X 14 X 13 X

EPIM PORTS

REAR VIEW

SEH INTERCONNECT

OUT

EPIM 2

EPIM 1

MicroMMAC Installation Guide Page 2-1

SIDE VIEW

NVRAM SWITCH ACCESS

090829

Figure 2-1 MicroMMAC Components

Page 21

Chapter 2: Controls and Indicators

2.2 TURNING THE MicroMMAC ON AND OFF

The MicroMMAC is NOT equipped with a Power ON/OFF

NOTE

To power-on the MicroMMAC, perform the following steps:

1. Plug the power cord into the power cord connector on the back panel

of the MicroMMAC.

2. Plug the other end of the power cord into a grounded wall outlet.

3. Verify that the PWR LED is on, indicating that the MicroMMAC is

receiving power. After the MicroMMAC runs a self test, the CPU

LED blinks green indicating normal operation. If the LED remains

red, the processor is faulty; contact Cabletron Systems Technical

Support.

switch.

To power-off the MicroMMAC, disconnect the power cord from the

power outlet.

2.3 USING THE LCD AND LCD DISPLAY BUTTON

The LCD provides information about the operation of the MicroMMAC

and network activity. Four types of messages appear on the LCD:

• Static System Messages

• Saved Alarm Messages

• Unsaved Initialization Messages

• Saved System Messages

The following sections describe each type of LCD message and provide

instructions for displaying them.

Page 2-2 MicroMMAC Installation Guide

Page 22

Using the LCD and LCD DISPLAY Button

2.3.1 Static System Messages

Static System messages provide MicroMMA C configuration information.

Table 2-1 lists each message. To view Static System messages, perform

the following steps:

1. Press and immediately release the Display button to view the first

Static System Message in the queue.

2. Press and release the Display button to display each subsequent

message.

If the Display button is not pressed again for ten seconds, the LCD

defaults to the product name.

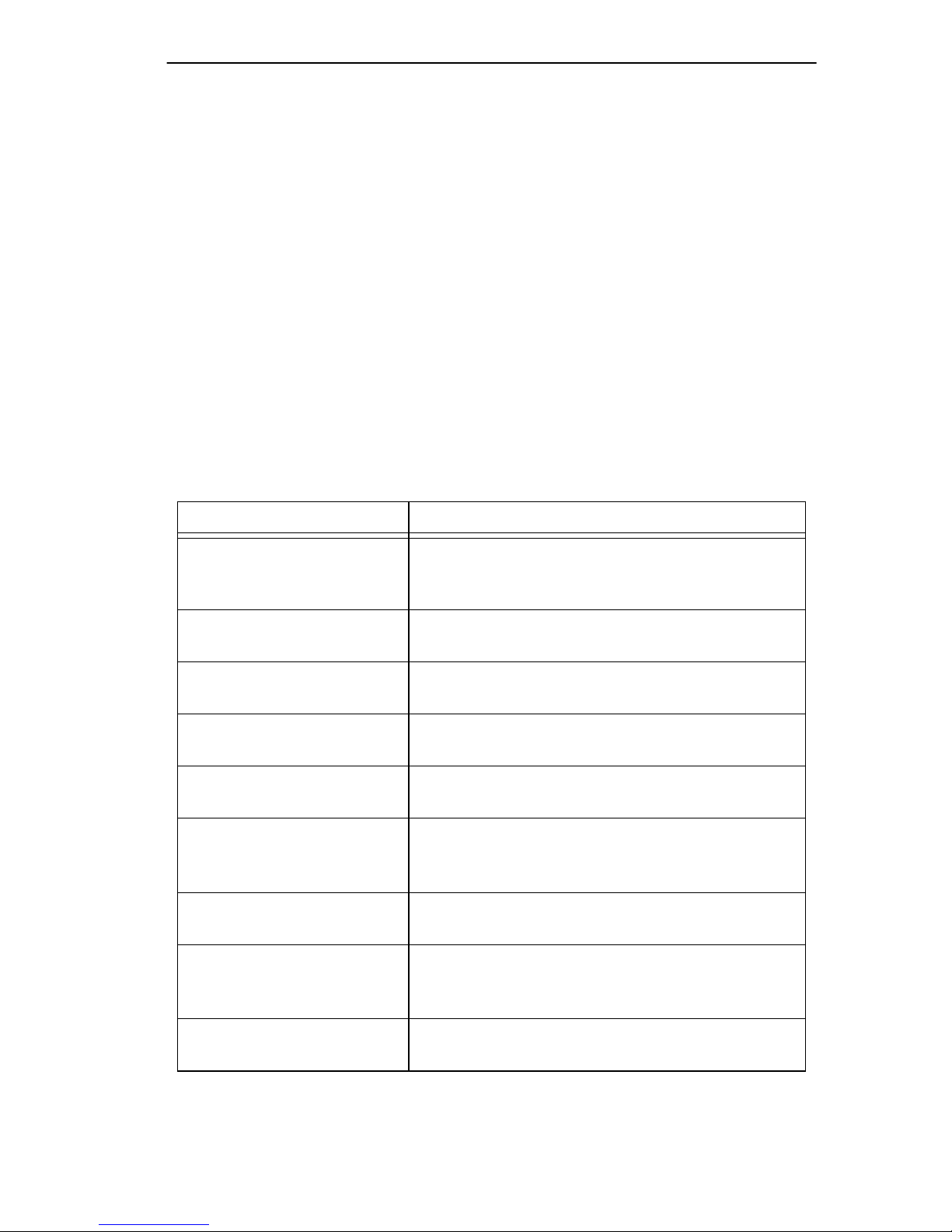

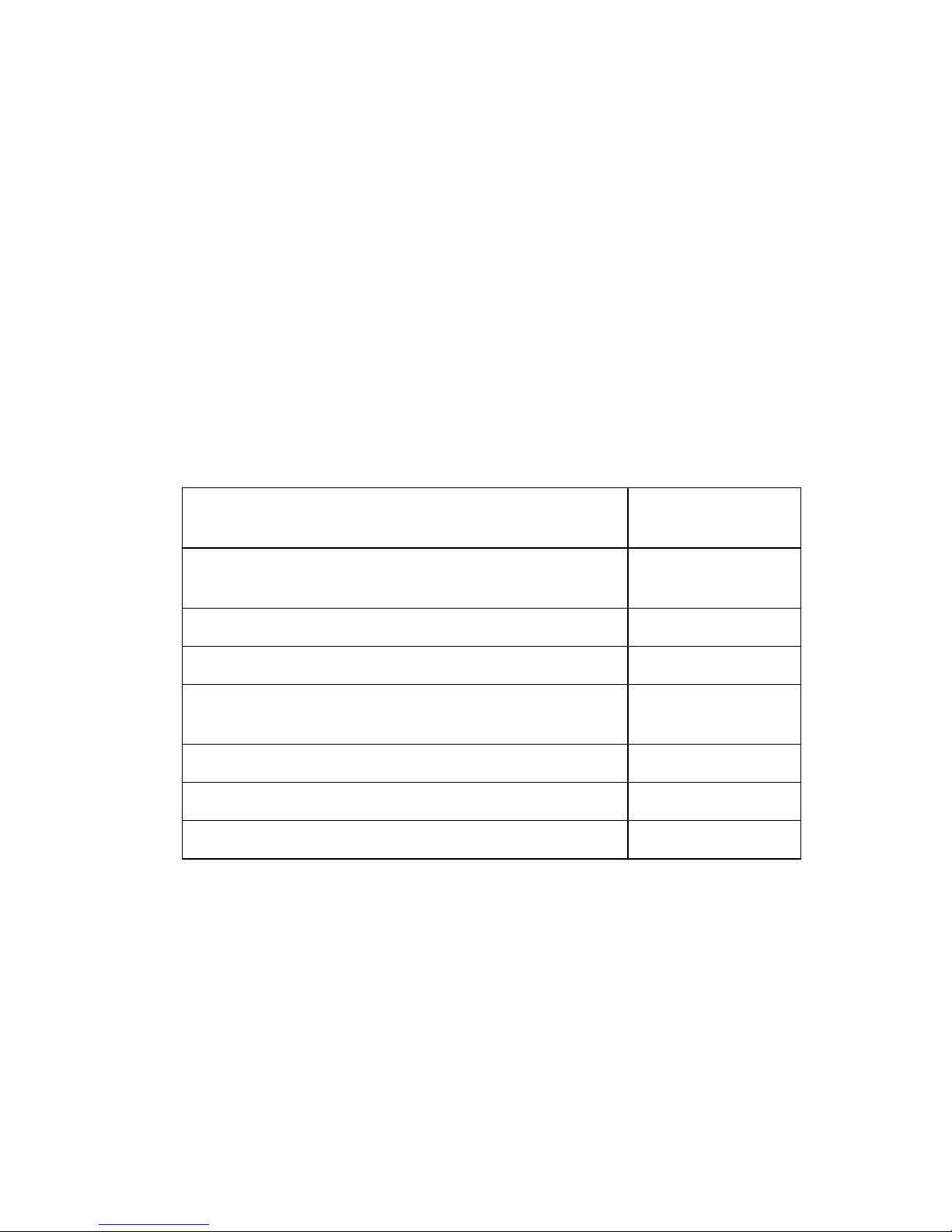

Table 2-1 Static System Messages

Displayed Messages Comments

IP Address

xxx.xxx.xxx.xxx

MAC Address

00001dxxxxxx

RAM Image

Rev. xx.xx.xx

Boot PROM

Rev. xx.xx.xx

Flash Programmed

xx Times

COM 1 Port

Baud Rate xxxxx

COM 1 Port

Function xxxxx

COM 2 Port Baud Rate

xxxxx

Displays the MicroMMAC’s IP address. The IP

address can be changed through Local

Management.

Displays the MicroMMAC’s MAC address (this

address is also called the physical address).

Displays the revision number of the image

currently executing in FLASH.

Displays the revision number of the internal

Boot PROM.

Displays the number of times FLASH has been

programmed.

Displays the Baud Rate f or the COM 1 port. The

default setting is AUTO because the

MicroMMAC uses Auto-Baud detection.

Displays the current function of the COM 1 Port

(N/A, UPS, LM).

Displays the baud rate for the COM 2 port. The

default setting is AUTO because the

MicroMMAC uses Auto-Baud detection.

COM 2 Port

Function xxxxxx

MicroMMAC Installation Guide Page 2-3

Displays the current function of the COM 2 Port

(N/A, UPS, LM).

Page 23

Chapter 2: Controls and Indicators

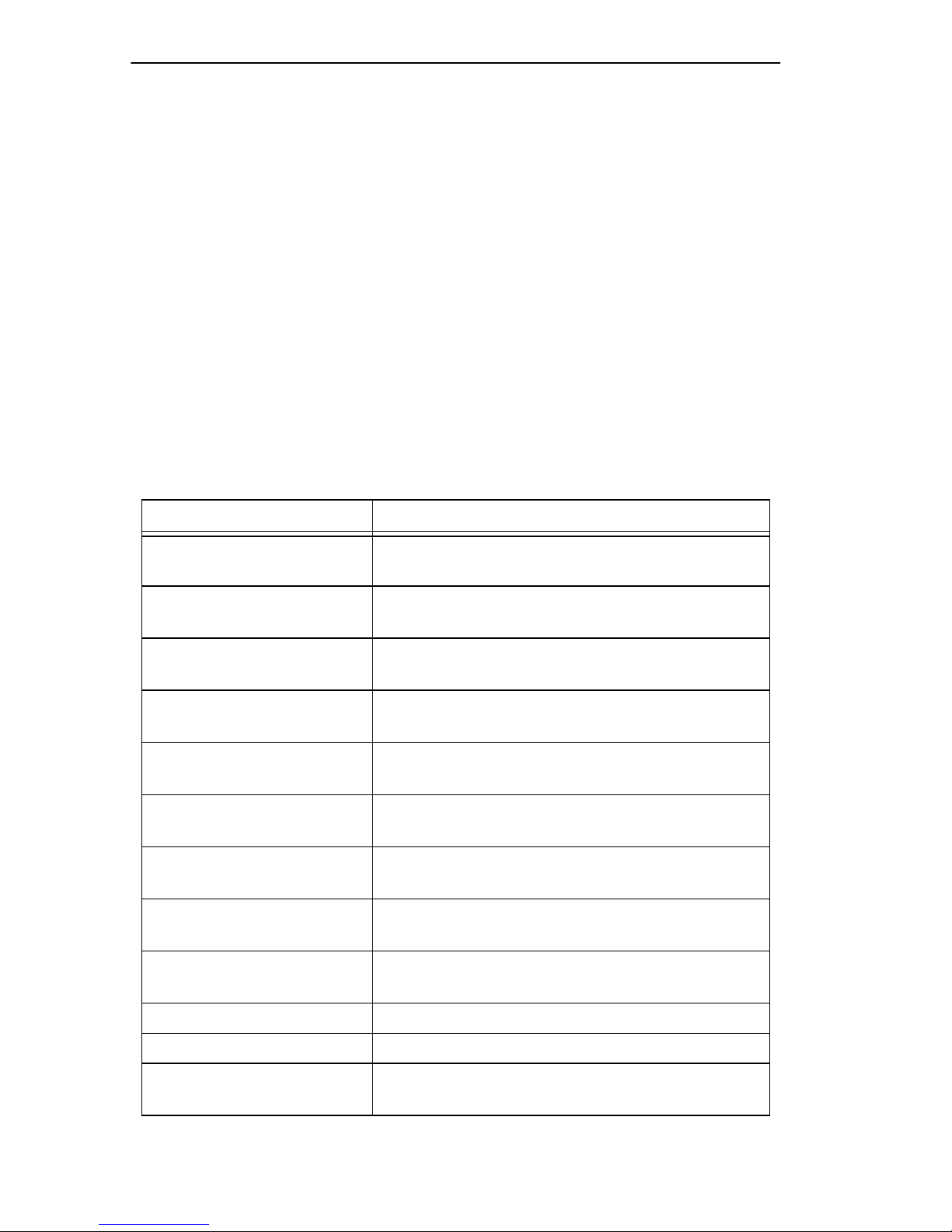

2.3.2 Saved Alarm Messages

Saved Alarm messages describe events that occur within the

MicroMMAC or on the network. Table 2-2 shows each Saved Alarm

message. To view Saved Alarm messages, perform the following steps:

1. Press the Display button for five seconds and then release to view the

first Saved Alarm message in the message queue.

2. Press and immediately release the Display button to scroll through

each subsequent message.

If the Display button is not pressed again for 10 seconds, the LCD

defaults to the product name.

Table 2-2 Saved Alarm Messages

Displayed Messages Comments

No Messages in Queue No Alarm messages in queue. This is the

default setting.

Port xxxxxx

Segmented

Port xxxxxx

UnSegmented

Port xxxxxx

Link Established

Port xxxxxx

Not Linked

EPIM-x

Inserted

EPIM-x

Removed

EPIM-x

Security Violation

Displays segmentation status of network ports

1–24, EPIM-1 or EPIM-2.

Displays segmentation status of network ports

1–24, EPIM-1, or EPIM-2.

Displays link status of network ports 1–24,

EPIM-1, EPIM-2, or BRIM-1.

Displays link status of network ports 1–24,

EPIM-1, EPIM-2, or BRIM-1.

Displays installation status of EPIM-1 or

EPIM-2.

Displays installation status of EPIM-1 or

EPIM-2.

Indicates unauthorized access attempt at

EPIM-1 or EPIM-2.

CableRedun Fail

Port EPIM-x

CableRedun Enable Indicates redundant link enabled.

Port EPIM-x EPIM-1 or EPIM-2.

Port xxxxxx

Disabled

Page 2-4 MicroMMAC Installation Guide

Indicates failure of redundant link at EPIM-1 or

EPIM-2.

Indicates network ports 1–24, EPIM-1, or

EPIM-2 disabled.

Page 24

Using the LCD and LCD DISPLAY Button

Table 2-2 Saved Alarm Messages (Continued)

Displayed Messages Comments

Port xxxxxx

Enabled

Port xx Security

Violation

Cable Redundancy

Port xxxxxx Failure

Cable Redundancy

Enable Port xxxxxx

Indicates network ports 1–24, EPIM-1, or

EPIM-2 enabled.

Indicates unauthorized access attempt at ports

1–24.

Indicates failure of redundant link at ports 1–24,

EPIM-1, or EPIM-2.

Indicates redundant link enabled at ports 1–24,

EPIM-1, or EPIM-2.

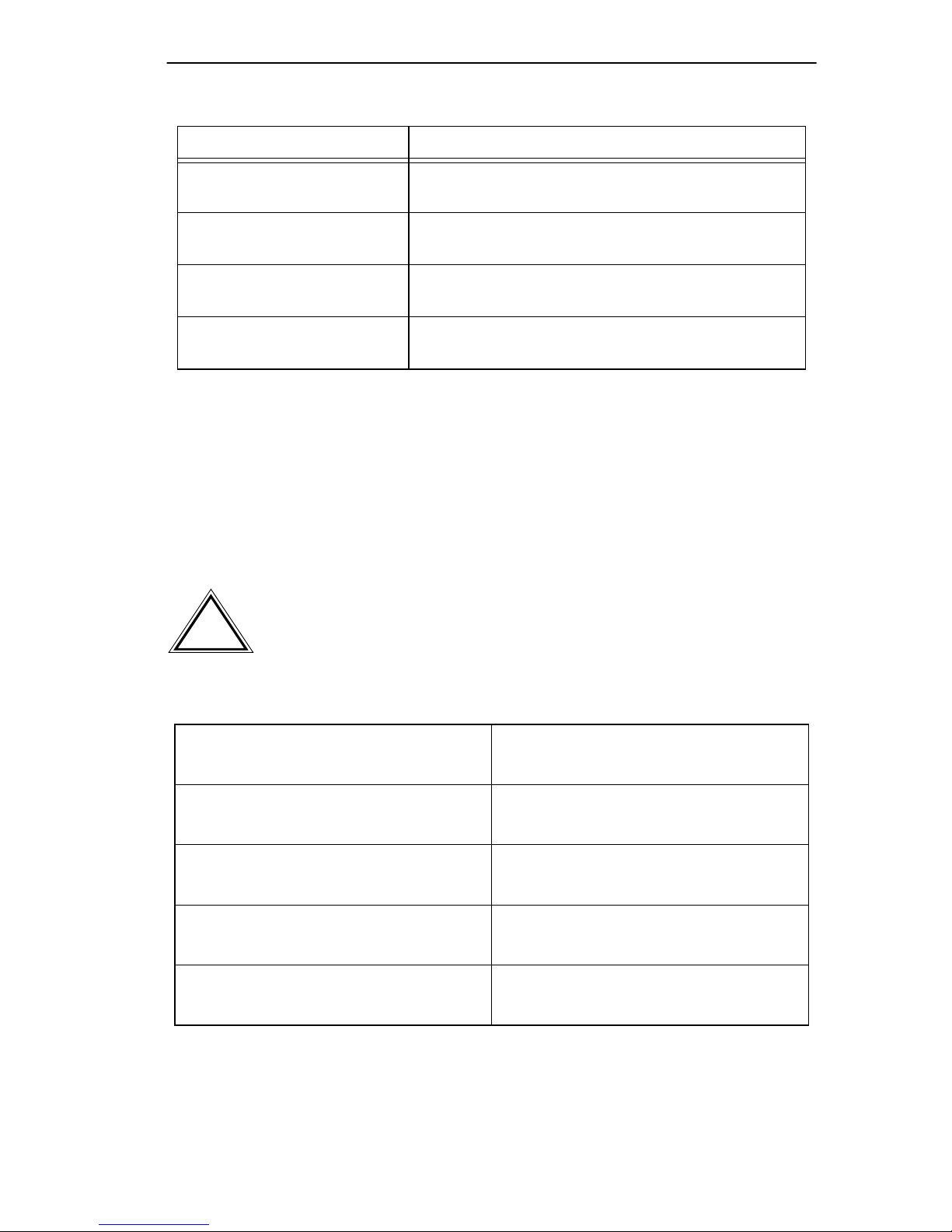

2.3.3 Unsaved Initialization Messages

Unsaved Initialization messages are po wer-up messages that appear as the

event occurs, but are not saved in a buffer for future recall. Table 2-3 lists

Unsaved Failure or Error messages and Table 2-4 lists normal Unsaved

Initialization messages.

If Failure or Error Messages appear, call Cabletron Systems

!

CAUTION

Technical Support.

Table 2-3 Unsaved Failure or Error Messages

Cabletron

Ctrl. Reg. Err.

Cabletron

SDRAM Failure

Cabletron

SONIC Failure

Cabletron

Console SCC Error

Cabletron

82C54 Failure

Cabletron

BBRAM Failure

Cabletron

Modem SCC Error

Cabletron

Bit Swap Failure

Cabletron

LDRAM Failure

MicroMMAC Installation Guide Page 2-5

Page 25

Chapter 2: Controls and Indicators

Table 2-4 Normal Unsaved Initialization Messages

Cabletron

Hardware Init

Cabletron

BOOTP Discovery

Cabletron

TFTP Req. State

Cabletron

TFTP Complete

Cabletron

Programming Flash

Cabletron

Boot Complete

Cabletron

Boot From Flash

Cabletron

RARP Req. State

Cabletron

TFTP in Progress

Cabletron

Erasing Flash

Cabletron

Flash Programmed

Cabletron

Test in Progress

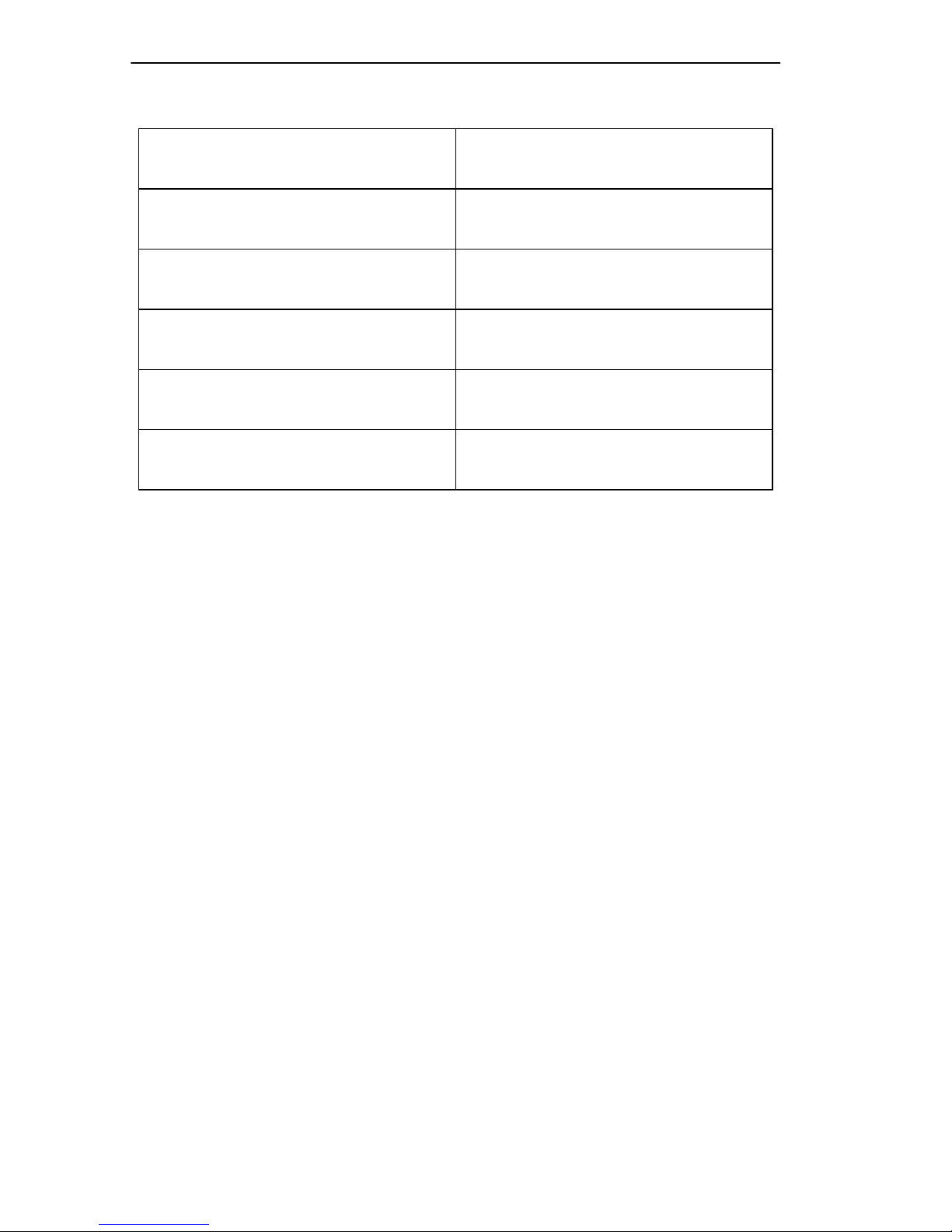

2.3.4 Saved System Messages

Saved System messages are de vice related startup or boot strap messages,

BOOTP/tftp host, or startup error messages. To access the Saved System

messages queue, perform the following steps:

1. Enter the Saved Alarm messages queue as described in Section 2.3.2.

2. Press the Display button for two seconds and then release to display

the first Saved System message.

3. Press and immediately release the Display button to display each

subsequent message.

If the Display button is not pressed again for ten seconds, the LCD

defaults to the product name.

Page 2-6 MicroMMAC Installation Guide

Page 26

Table 2-5 Saved System Messages

Displayed Messages Comments

Using the Reset Button

BootP Host

xxx.xxx.xxx.xxx

TFTP Host

xxx.xxx.xxx.xxx

Last TFTP Host

xxx.xxx.xxx.xxx

TFTP File

xxxxxxxxxxxxxxxx

Last TFTP File

xxx.xxx.xxx.xxx

The IP address of the server from which a

BootP image was downloaded to the

MicroMMAC.

The IP address of the server from which a

BootP image was downloaded to the

MicroMMAC.

The IP address of the server from which the

most recent BootP image was downloaded to

the MicroMMAC.

The filename of an image downloaded to the

MicroMMAC.

The filename of the most recently downloaded

image to the MicroMMAC.

2.4 USING THE RESET BUTTON

Use the Reset button to initialize (reboot) the MicroMMAC processor.

Pressing the Reset button causes the hub to clear all counters, run self-test

diagnostics, and reload the firmware image into Local Dynamic Random

Access Memory (LDRAM).

The Reset button does not clear Non-Volatile Random Access

NOTE

Memory (NVRAM).

Use a pen or pencil to press the Reset button. The MicroMMAC re-boots

and initializes the processor.

MicroMMAC Installation Guide Page 2-7

Page 27

Chapter 2: Controls and Indicators

2.5 USING THE NVRAM SWITCH

It is not necessary to remove the chassis cover from the

NOTE

NVRAM (Non-Volatile Random Access Memory) stores user-entered

parameters such as community names, port configuration settings, and the

IP address. The NVRAM switch is accessible through the last lower

circulation vent on the right side panel (see Figure 2-2). To clear

NVRAM, perform the following steps:

MicroMMAC to gain access to the NVRAM switch.

To prevent the possibility of electrical shock, use only a

non-metallic tool when operating the NVRAM switch.

Do not clear NVRAM unless you intend to reset the

!

CAUTION

MicroMMAC user parameters to the factory default settings.

1. Ensure that the MicroMMAC is powered-on.

2. Use a non-metallic tool to change the state of the NVRAM switch.

For example: Move the switch from one position to another.

3. Press the Reset button. The MicroMMAC reboots and returns all

user-entered parameters to the factory default settings.

Page 2-8 MicroMMAC Installation Guide

Page 28

NVRAM SWITCH LOCATED

BEHIND CIRCULATION VENT

Using the NVRAM Switch

REAR OF CHASSIS

Figure 2-2 NVRAM Switch Location

149005

MicroMMAC Installation Guide Page 2-9

Page 29

CHAPTER 3

INSTALLATION

This chapter provides instructions for the following:

• Unpacking the MicroMMAC

• Removing the MicroMMAC chassis cover

• Setting the mode switches

• Adding/Replacing EPIMs

• Testing the MicroMMAC

Only qualified personnel should perform installation

procedures.

3.1 UNPACKING THE MicroMMAC

Unpack the MicroMMAC as follows:

1. Remove the shipping material covering the MicroMMAC.

2. Carefully remove the MicroMMAC from the shipping box and set it

aside to prevent damage.

3. Visually inspect the MicroMMAC. If there are any signs of damage,

contact Cabletron Systems Technical Support immediately.

4. Read the MicroMMAC Release Notes included in the shipping box.

Cabletron Systems includes 3-1/2" disks with the MicroMMAC

NOTE

that contain a backup copy of the MicroMMAC FLASH

Firmware Image File. Download the file to the MicroMMAC if

the existing image becomes corrupted.

MicroMMAC Installation Guide Page 3-1

Page 30

Chapter 3: Installation

3.2 REMOVING THE CHASSIS COVER

This section describes how to remove the chassis cover of the

MicroMMAC . The chassis cover must be removed to install BRIMs or

SIMMs, and to set the mode switch bank. Refer to the applicable BRIM

User’s Guide for installation instructions.

Figure 3-1 shows how to remove the chassis cover and the location of the

BRIM slot. You need a Phillips-head screwdriver to remove the chassis

cover.

Do not remove the chassis cover from the MicroMMAC while

power is applied to the unit.

Do not power up the MicroMMA C f or an y reason until the co v er

and screws are in place. Hazardous voltages are present that

could damage the unit or cause personal injury.

The components and boards associated with the MicroMMAC

!

CAUTION

are sensitive to static discharges. Be sure to use an antistatic

wrist strap and observe all static precautions during this

procedure. Failure to do so could result in damage to the

MicroMMAC.

To remove the chassis cover, perform the following steps:

1. Disconnect the MicroMMAC from the network as follows:

a. Disconnect the power cord from the rear of the MicroMMAC.

b. Disconnect all network cables attached to the MicroMMAC. Note

the ports to which these cables attach.

c. If the MicroMMAC is rack mounted, remove it from the rack.

Page 3-2 MicroMMAC Installation Guide

Page 31

Removing the Chassis Cover

2. Use a Phillips-head screwdriver to remove the seven screws that attach

the chassis cover to the MicroMMAC. Place the screws aside. See

Figure 3-1.

3. Remove the chassis cover from the MicroMMAC. See Figure 3-1.

MicroMMAC-24E

10BASE-T HUB

WITH

LANVIEW®

LINE:

SN

100-125V - 4.0A

200-250V - 2.0A

50/60Hz

SEH-INTERCONNECT

OUT

MicroMMAC-24E

10BASE-T HUB

WITH

LANVIEW®

LINE:

SN

100-125V - 4.0A

200-250V - 2.0A

50/60Hz

SEH-INTERCONNECT

OUT

090830

Figure 3-1 Removing the Chassis Cover Screws

MicroMMAC Installation Guide Page 3-3

Page 32

Chapter 3: Installation

3.3 SETTING THE MODE SWITCHES

Figure 3-2 shows the location and factory default settings of the mode

switches. Check these switches to ensure that they are in the correct

position for normal MicroMMAC operation.

MicroMMAC TOP VIEW

ON

OFF

1 2 3 4 5 6 7 8

FRONT PANEL

Figure 3-2 The MicroMMAC Mode Switches and FLASH SIMM Location

FLASH MEMORY SIMM

090816

Switch definitions are as follows:

• Switch 1 - Cabletron Systems use only.

• Switch 2 - Cabletron Systems use only.

• Switch 3 - Cabletron Systems use only.

• Switch 4 - Cabletron Systems use only.

• Switch 5 - Cabletron Systems use only.

Page 3-4 MicroMMAC Installation Guide

Page 33

Setting the Mode Switches

• Switch 6 - Forced Download. Changing the state of this switch (i.e.,

moving the switch from one position to another) clears download

information from NVRAM and forces the MicroMMAC to do wnload

an image file from the station acting as the BOOTP/TFTP serv er of the

MicroMMAC.

–

CAUTION

!

DO NOT change the state of Switch 6 unless

–you have a station acting as a BOOTP server, and a tftp

server that contains the MicroMMAC image file. The BOOTP

server and the tftp server could be different servers.

–you intend to set up a station to act as a BOO TP server for the

MicroMMAC .

After changing the state of this switch, and repowering the device, the

MicroMMAC requests a new image until it either receives a new

image, or you reset the MicroMMAC again by using the Reset button

on the front panel.

Reset the MicroMMAC a second time. The device attempts to locate

a BOOTP server again. However, the BOOTP request times out after

about one minute, and the MicroMMAC boots from FLASH memory.

• Switch 7 - Cabletron Systems use only.

• Switch 8 - Password Defaults. Changing the state of this switch clears

user-entered passwords stored in NVRAM, and restores default

passwords. Once you reset the MicroMMA C, you can use the defaults

or re-enter your passwords.

Do not change the state of Switch 8 unless you want to reset

!

CAUTION

MicroMMAC Installation Guide Page 3-5

the MicroMMAC user-configured passwords to their factory

default settings.

Page 34

Chapter 3: Installation

3.4 UPGRADING THE FLASH SIMM

The MicroMMAC allows memory upgrades for the FLASH EEPROM.

Figure 3-2 shows the location of the FLASH SIMM Slot.

Before you can install the new FLASH SIMM, you need to remove the

existing FLASH SIMM.

The internal components and boards associated with the

!

CAUTION

To remove the FLASH SIMM, refer to Figure 3-3 and perform the

following steps:

MicroMMAC are static sensitive devices. Use the antistatic

wrist band and observe standard antistatic safety procedures

when the cover is removed. Failure to do so could cause

damage or severely limit the life expectancy of the

MicroMMAC.

1. Push the two connector clips away from the FLASH SIMM to release

it.

2. Tilt the FLASH SIMM upward.

3. Pull the FLASH SIMM out of the socket.

3

SIMM

2

CONNECTOR CLIP

CONNECTOR CLIP

1

Figure 3-3 Removing a FLASH SIMM

Page 3-6 MicroMMAC Installation Guide

1742-32

Page 35

Upgrading the FLASH SIMM

T o install the replacement FLASH SIMM, refer to Figure 3-4 and perform

the following steps:

1. With the SIMM notch positioned as shown in Figure 3-4, gently insert

the FLASH SIMM into the SIMM connector.

2. Carefully rock the FLASH SIMM back towards the connector clips

until the clips snap into place and secure the FLASH SIMM.

SIMM

NOTCH

2

1

CONNECTOR CLIP

CONNECTOR

Figure 3-4 Installing a FLASH SIMM

CONNECTOR CLIP

1742-33

MicroMMAC Installation Guide Page 3-7

Page 36

Chapter 3: Installation

3.5 ADDING/REPLACING EPIMS

This section explains how to add/replace an Ethernet Port Interface

Module (EPIM) to upgrade or change the capabilities of the

MicroMMAC.

EPIMs are sensitive to static discharge. Be sure to use an

!

CAUTION

To install an EPIM, perform the following steps:

!

CAUTION

antistatic wrist strap and observe all static precautions during

this procedure. Failure to do so could result in damage to the

EPIM.

When removing an EPIM, make sure to pull the module straight

out. Failure to do so could result in damage to the connector.

1. Remove the coverplate or the EPIM (whichever applies).

2. Slide the EPIM into place, making sure the connector on the EPIM

attaches to the connector inside the MicroMMAC. See Figure 3-5.

3. Install the mounting screw.

EPIM-2

13X

14X

15X

16X

17X

18X

1X

2X

3X

4X

5X

6X

EPIM-1

Page 3-8 MicroMMAC Installation Guide

LNK

EPIM-T

090828

Figure 3-5 Installing an EPIM

Page 37

Adding/Replacing BRIMs

3.6 ADDING/REPLACING BRIMS

To add or replace a Bridge/Router Interface Module (BRIM) in the

MicroMMAC, refer to the applicable BRIM user’s guide.

3.7 TESTING THE MicroMMAC

Before installing the MicroMMAC in a live network, test the hub in a

controlled situation to ensure that it is bridging packets. Perform this test

with two workstations as shown in Figure 3-6.

To test the MicroMMAC, perform the following steps:

1. Connect the first workstation to a MicroMMAC network port, EPIM,

or BRIM.

2. Connect the second workstation to a MicroMMAC network port,

EPIM, or BRIM.

3. Designate the first workstation as a file server and the second

workstation as the client.

To configure a workstation as a file server or client, refer to the

NOTE

documentation included with the workstation.

4. Send packets between the two workstations to verify the proper

operation of the MicroMMAC.

A “ping” test of each workstation verifies that the MicroMMAC

NOTE

is operating properly.

MicroMMAC Installation Guide Page 3-9

Page 38

Chapter 3: Installation

MicroMMAC-24E

CLIENT WORKSTATION

Figure 3-6 Installation Check-Out

CABLETRON

MicroMMAC-24

RESET

DISPLAY

10BASE-T HUB

COM 1COM 2

R

WITH

LANVIEW

RCV

LNK

21 20 19

24 23 22

PWR

RCV

CPU

CLN

LNK

12 11 10

987

E

15 14 13

18 17 16

2

22X23X24X

21X

E

321

1

654

12X 11X 10X 9X 8X 7X 6X 5X 4X 3X 2X 1X

20X

19X

18X 17X 16 X

15X 14 X 13X

EPIM 2

EPIM 1

FILE SERVER WORKSTATION

090831

3.8 INSTALLING THE MicroMMAC

The MicroMMAC may be installed on a tabletop, shelf, or in a 19-inch

rack and may be configured as a standalone or stacked hub. Cabletron

Systems provides an accessory kit with the MicroMMAC that includes

rackmount brackets, mounting screws, and a strain-relief bracket.

The following sections provide instructions for stacking the MicroMMA C

or installing it as a standalone device. Follow the instructions that are

applicable to your installation needs.

Page 3-10 MicroMMAC Installation Guide

Page 39

Installing the MicroMMAC

3.8.1 Shelf or Tabletop Installation

Before installation, ensure that you locate the MicroMMAC within reach

of the network cabling and follow the requirements listed below:

• A single phase grounded power receptacle that meets the po wer supply

requirements listed in Appendix A, Section A.2, Power Supply

Requirements, must be located within seven feet of the

MicroMMAC.

• In a shelf installation, the shelf must be able to support 30 pounds of

static weight for each device in the stack.

• The temperature for the selected location must maintain a temperature

between 5˚C and 40˚C (41˚F and 104˚F), and fluctuate less than 10˚C

(18˚F) per hour.

• There must be sufficient clearance around the unit for proper

ventilation.

For a shelf or tabletop installation, locate the MicroMMAC within 7 feet

of its power source and with an unrestricted free surface area 21 inches

wide, 18 inches deep and 6 inches high, as shown in Figure 3-7.

21 INCHES

18 INCHES

6 INCHES

MicroMMAC-24E

10BASE-T HUB

R

WITH

LANVIEW

7-FOOT POWER CORD

EPIM 2

EPIM 1

Figure 3-7 Shelf or Tabletop Installation

MicroMMAC Installation Guide Page 3-11

090811

Page 40

Chapter 3: Installation

3.8.2 Attaching the Strain-Relief Bracket

To attach the strain-relief bracket to the bottom of the MicroMMAC,

perform the following steps:

1. Locate the strain-relief bracket and four 8-32 x 3/8-inch screws from

the MicroMMAC-ACCY-KIT package.

Do NOT attempt to attach the strain-relief bracket with screws

other than the 8-32 x 3/8-inch screws included with the

MicroMMAC accessory kit. Use of longer screws may damage

the unit or cause electrical shock.

2. Attach the strain-relief bracket to the bottom of the MicroMMAC as

shown in Figure 3-8.

EPIM 1

EPIM 2

SCREWS (4)

STRAIN-RELIEF BRACKET

10BASE-T HUB

WITH

LANVIEW

R

090807

Figure 3-8 Attaching the Strain-Relief Bracket

MicroMMAC-24E

Page 3-12 MicroMMAC Installation Guide

Page 41

Installing the MicroMMAC

3.8.3 Rack Mounting the MicroMMAC

Refer to Figure 3-9 and perform the following steps to install the

MicroMMAC in a 19-inch rack.

1. Remove four cover screws (two from each side) located along the

front edges of each side of the MicroMMAC.

Do not remove the cover from the MicroMMAC. Do not remove

any other screws from the unit.

2. Using the four cover screws removed in step 1, attach the rack

mounting brackets to each end of the MicroMMAC.

WALL/RACK MOUNTING

BRACKETS (2)

MicroMMAC-24E

10BASE-T HUB

WITH

LANVIEW

R

EPIM 2

EPIM 1

SCREWS (4)

090808

Figure 3-9 Installing the Rackmount Brackets

3. Ensure that the rack used to install the unit will support the unit and

that the rack will remain stable with the unit installed in it. Support the

MicroMMAC securely from underneath and align the brackets of the

MicroMMAC chassis with the screw holes in the equipment rack as

shown in Figure 3-10. Fasten the MicroMMAC to the 19-inch rack

securely.

The cooling fans at the rear panel of the MicroMMAC must

!

CAUTION

have adequate clearance (two inches on either side and in

the rear) for unrestricted air flow.

MicroMMAC Installation Guide Page 3-13

Page 42

Chapter 3: Installation

19-INCH RACK

MicroMMAC-24E

10BASE-T HUB

WITH

LANVIEW

R

EPIM 2

EPIM 1

Figure 3-10 Installing the MicroMMAC in the Rack

3.8.4 Stacking the MicroMMAC

The rear panel of the MicroMMAC has an Interconnect Bus Out Port

(male connector) for stackable connections. To attach non-intelligent hubs

to the MicroMMAC, use Cabletron Systems HubSTACK Interconnect

cables. Table 3-1 describes each cable.

Table 3-1 HubSTACK Interconnect Cables

Part Number Description Application

9380110 12” HubSTACK Interconnect

Cable

9380111 18” HubSTACK Interconnect

Cable

SEH to SEH

connections

MicroMMAC to SEH

connections

To stack the MicroMMAC together with an SEH non-intelligent hub,

perform the following steps:

1. Attach the MicroMMAC HubSTACK Interconnect cable to the OUT

port on the rear panel of the MicroMMAC as shown in Figure 3-11.

2. Attach the other end of the MicroMMAC HubSTACK Interconnect

cable to the IN port on the rear panel of the SEH.

Page 3-14 MicroMMAC Installation Guide

Page 43

Installing the MicroMMAC

To stack SEH non-intelligent hubs together, perform the following steps:

1. Attach the SEH HubSTACK Interconnect cable to the OUT port on

the rear panel of the SEH as shown in Figure 3-11.

2. Attach the other end of the SEH HubSTACK Interconnect cable to the

IN port on the rear panel of the SEH next in the stack.

SEH HubSTACK

INTERCONNECT CABLES (PN 9380110)

HubSTACK 10BASE-T HUB WITH LANVIEW®

SEH-24

OUT

SEH INTERCONNECT

HubSTACK 10BASE-T HUB WITH LANVIEW®

SEH-24

OUT

SEH INTERCONNECT

HubSTACK 10BASE-T HUB WITH LANVIEW®

SEH-24

IN

IN

OUT

SEH INTERCONNECT

HubSTACK 10BASE-T HUB WITH LANVIEW®

SEH-24

OUT

SEH INTERCONNECT

MicroMMAC-34E 10BASE-T HUB WITH LANVIEW®

SN

LINE:

100-125V - 4.0A

200-250V - 2.0A

50/60Hz

Figure 3-11 Stacking the MicroMMAC

IN

IN

SEH INTERCONNECT

OUT

090805

MicroMMAC HubSTACK

INTERCONNECT CABLE (PN 9380111)

MicroMMAC Installation Guide Page 3-15

Page 44

Chapter 3: Installation

If you temporarily disconnect one end of a HubSTACK Interconnect

cable and leave the other end attached to the hub, ensure that you

disconnect the cable from the OUT port as shown in Figure 3-12. This

ensures proper termination of the HubSTACK cable.

DISCONNECT MicroMMAC AND SEH

INTERCONNECT CABLES AT THE "OUT" PORT.

HubSTACK

10BASE-T

HUB

WITH

SEH-24

HubSTACK

SEH-24

OUT

10BASE-T

OUT

LANVIEW®

SEH INTERCONNECT

HUB

WITH

LANVIEW®

SEH INTERCONNECT

IN

IN

MicroMMAC-34E

10BASE-T

LINE:

100-125V - 4.0A

200-250V - 2.0A

50/60Hz

HUB

WITH

LANVIEW®

SN

SEH INTERCONNECT

OUT

Figure 3-12 Disconnecting the HubSTACK Interconnect Cable

090806

Page 3-16 MicroMMAC Installation Guide

Page 45

CHAPTER 4

CONNECTING TO THE NETWORK

This chapter explains how to connect the MicroMMAC to a network

using the network ports and EPIMs.

4.1 CONNECTING THE MicroMMAC TO THE NETWORK

The procedure for connecting network segments to the MicroMMAC

varies depending on the media and ports being connected. Refer to the

following list and perform the procedure described in the subsections that

apply to your MicroMMAC:

Connecting a 10BASE-T Segment to the

MicroMMAC-22E and MicroMMAC-24E

Connecting a 10BASE-T Segment to the

MicroMMAC-32E and MicroMMAC-34E

Connecting a 10BASE-T Segment to an EPIM-T Section 4.1.3

Connecting a 10BASE-F Segment to an EPIM-F1 Section 4.1.4

Connecting a 10BASE-F Segment to an EPIM-F2

or EPIM-F3

Connecting a 10BASE2 Segment to an EPIM-C Section 4.1.6

Connecting an AUI Segment to an EPIM-A Section 4.1.7

Connecting an AUI Segment to an EPIM-X Section 4.1.8

Section 4.1.1

Section 4.1.2

Section 4.1.5

MicroMMAC Installation Guide Page 4-1

Page 46

Chapter 4: Connecting to the Network

4.1.1 Connecting a 10BASE-T Segment to the

MicroMMAC-22E and MicroMMAC-24E

The MicroMMAC-22E and MicroMMAC-24E have RJ45 network ports

that support unshielded twisted pair segments. Each RJ45 port on the

MicroMMAC incorporates a Polarity Detection and Correction feature.

The Polarity Detection and Correction feature allows the MicroMMA C to

pass data regardless of the polarity of the twisted pair segment’s receive

link. Cabletron Systems does not recommend operating in this condition

and if this condition is discovered, the segment should be removed from

the network and wired correctly by a technician.

To attach twisted pair segments to the RJ45 network ports of the

MicroMMAC, perform the following steps:

1. Insert the RJ45 connector from each twisted pair segment into the

desired network port on the MicroMMAC. See Figure 4-1.

EPIM-2

LNK

EPIM-T

13X

14X

15X

18X

6X

17X

16X

1X

2X

3X

4X

5X

LNK

EPIM-T

EPIM-1

090812

Figure 4-1 MicroMMAC-22E/24E Network Ports

2. Check that the associated LNK LED for the port is on. If the LED is

not on, perform each of the following steps until it is:

a. Check that the 10BASE-T device at the other end of the twisted

pair segment is powered up.

b. Verify that the RJ45 connector on the twisted pair segment has the

proper pinouts. Refer to Figure 4-4.

Page 4-2 MicroMMAC Installation Guide

Page 47

Connecting the MicroMMAC to the Network

c. Check that the twisted pair connection meets dB loss and cable

specifications outlined in Appendix C, Network Planning and

Configuration.

If a link still has not been established, contact Cabletron Systems

Technical Support.

4.1.2 Connecting a 10BASE-T Segment to the

MicroMMAC-32E and MicroMMAC-34E

The MicroMMAC-32E has one RJ71 connector and the

MicroMMAC-34E has two RJ71 connectors. Each RJ71 connector

supports twelve 10BASE-T segments.

Refer to Appendix C, Network Planning and Configuration,

NOTE

for RJ71 pinouts.

To connect the MicroMMAC in an existing twisted pair wiring system,

perform the following steps:

1. Connect an RJ71 connector to an RJ71 port on the MicroMMAC as

shown in Figure 4-2.

EPIM-2

LNK

EPIM-T

13X

24X

1X

12X

LNK

EPIM-T

EPIM-1

090813

Figure 4-2 MicroMMAC-32E/34E Network Ports

MicroMMAC Installation Guide Page 4-3

Page 48

Chapter 4: Connecting to the Network

2. Attach wires of the 25-pair cable to a punch down block, or patch

panel.

3. At the device end of a segment, attach the segment to a 10BASE-T

compliant Ethernet device.

4. Check that the link LED on the 10BASE-T Ethernet device and the

applicable LNK LEDs on the MicroMMAC are on. If the LEDs are

not on, perform each of the following steps until the LEDs are on:

a. Check that the 10BASE-T device and the MicroMMAC have

power.

b. Verify the cabling between the MicroMMAC and the 10BASE-T

device.

c. Check the cable for continuity.

If a link has not been established, contact Cabletron Systems Technical

Support.

Page 4-4 MicroMMAC Installation Guide

Page 49

Connecting the MicroMMAC to the Network

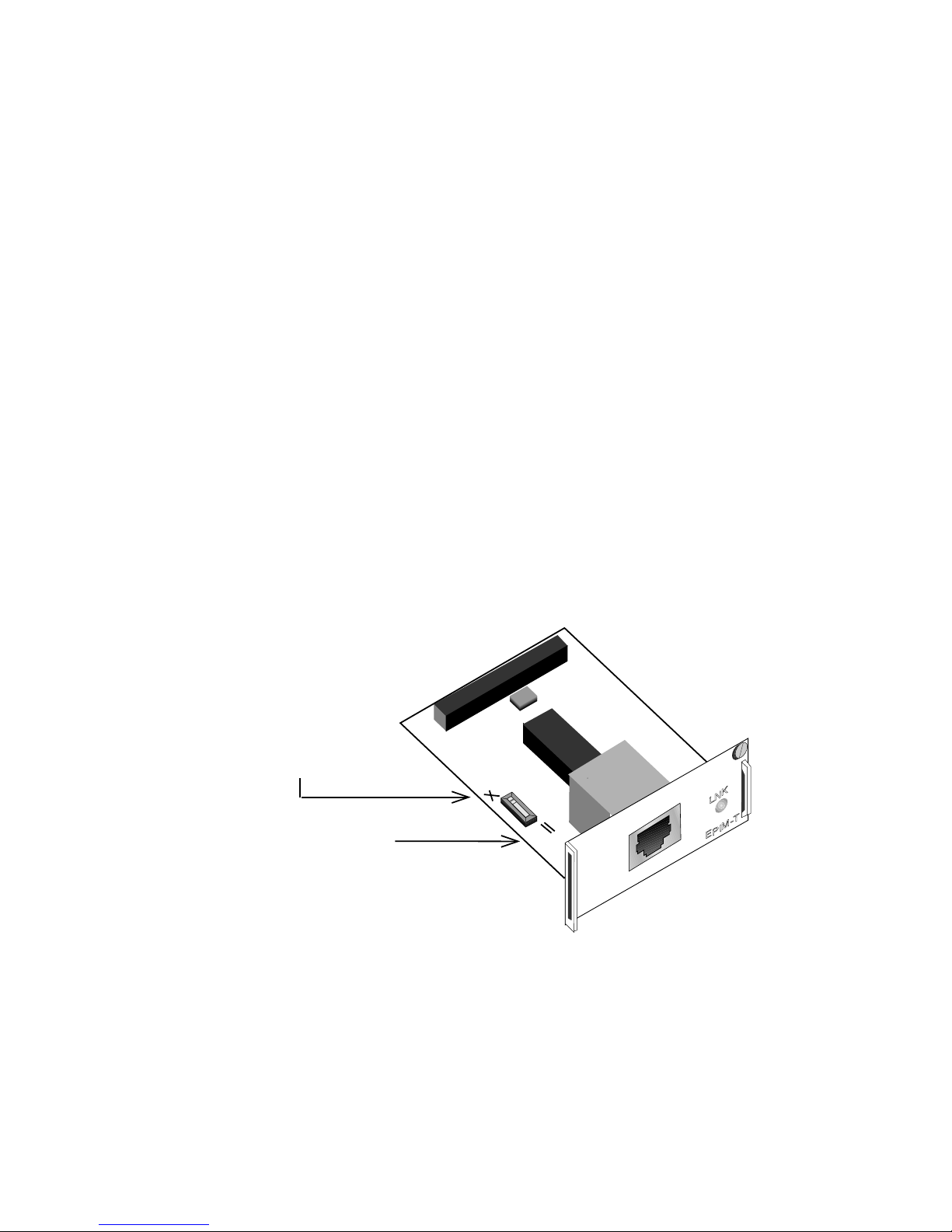

4.1.3 Connecting a 10BASE-T Segment to an EPIM-T

Before connecting a segment to the EPIM-T, check each end of the

segment to determine the proper crossover. If the wires do not cross over,

use the switch on the EPIM-T to internally cross over the RJ45 port. Refer

to Figure 4-3 to properly set the EPIM-T crossover switch.

POSITION X

(CROSSED OVER)

1. RX+

2. RX-

3. TX+

4. NC

5. NC

6. TX-

7. NC

8. NC

POSITION =

(NOT CROSSED OVER)

1. TX+

2. TX-

3. RX+

4. NC

5. NC

6. RX-

7. NC

8. NC

149014

Figure 4-3 EPIM-T Crossover Switch

To connect an EPIM-T to a twisted pair segment, perform the following

steps:

1. Connect the twisted pair segment to the module by inserting the RJ45

connector on the twisted pair segment into the RJ45 port on the

module. See Figure 4-3.

2. Check that the EPIM’s LNK LED is on. If the LED is not on, perform

each of the following steps until it is:

a. Check that the 10BASE-T device at the other end of the twisted

pair segment is powered up.

MicroMMAC Installation Guide Page 4-5

Page 50

Chapter 4: Connecting to the Network

b. Verify that the RJ45 connector on the twisted pair segment has the

proper pinouts. Refer to Figure 4-4.

MicroMMAC

RJ45 PORT

PIN 1 Tx+

PIN 2 TxPIN 3 Rx-

PIN 4 Rx+

RX+/RX- AND TX+/TX- MUST SHARE A COMMON PAIR.

Figure 4-4 Cable Pinouts RJ45 Port

10BASE-T

DEVICE PORT

Tx+ PIN 1

Tx- PIN 2

Rx- PIN 3

Rx+ PIN 6

c. Check the cable for continuity.

d. Check that the twisted pair connection meets dB loss and cable

specifications outlined in Appendix C.

090833

e. Check that the crossover switch is in the correct position.

If a link still has not been established, contact Cabletron Systems

Technical Support.

4.1.4 Connecting a 10BASE-F Segment to an EPIM-F1

When connecting a fiber optic link segment with SMA 906

!

CAUTION

Each fiber optic link consists of two strands of fiber optic cabling: the

transmit (TX) and the receive (RX). The transmit strand from a module

port connects to the receive port of a fiber optic Ethernet device at the

other end of the segment. The receive strand of the applicable port on the

module connects to the transmit port of the fiber optic Ethernet device.

connectors to an EPIM-F1 with SMA ports, make sure each

connector uses half alignment, NOT full alignment, sleeves. A

full alignment sleeve damages the receive port. SMA 905

connectors do not need alignment sleeves.

Page 4-6 MicroMMAC Installation Guide

Page 51

Connecting the MicroMMAC to the Network

Cabletron Systems recommends labeling fiber optic cables to indicate

receive and transmit ends. Many cables are prelabeled, providing

matching labels or tapes at both ends of each strand of cable.

1. Remove the protective plastic covers from the fiber optic ports on the

applicable port on the module, and from the ends of the connectors on

each fiber strand.

Do not touch the ends of the fiber optic strands, and do not let

!

CAUTION

the ends come in contact with dust, dirt, or other contaminants.

Contamination of cable ends causes problems in data

transmissions. If necessary, clean contaminated cable ends

using alcohol and a soft, clean, lint-free cloth.

2. Attach one fiber to the receive port (RX) on the EPIM-F1. Insert the

SMA connector into the port. Turn the connector clockwise until the

connector will no longer turn easily. Do not overtighten the connector.

3. Attach the other fiber of the pair to the applicable transmit port on the

module. Use the same procedure for insertion of the ST connector.

MicroMMAC Installation Guide Page 4-7

109814

Figure 4-5 SMA Connector Insertion

Page 52

Chapter 4: Connecting to the Network

4. At the other end of the fiber optic cable, attach the fiber pair to the

transmit and receive ports of the device.

If link indicators are present for the fiber optic connection, check that they

are ON. If an indicator is present but not ON, that port does not have a

valid link. Perform each of the follo wing steps until you reach a resolution

of the problem and achieve a link.

• Check that the device at the other end of the link is ON.

• V erify proper cross-o ver of the fiber strands. Try sw apping the transmit

and receive connections at only one end of the link.

• Verify that the fiber connection meets the dB loss specifications

outlined in Appendix C, Network Planning and Configuration.

If you are still unable to establish a link, attempt to make the connection

between the devices with another fiber optic cable. If this is unsuccessful,

contact Cabletron Systems Technical Support.

4.1.5 Connecting a 10BASE-F Segment to an EPIM-F2 or

EPIM-F3

Each fiber optic link consists of two strands of fiber optic cabling: the

transmit (TX) and the receive (RX). The transmit strand from a module

port connects to the receive port of a fiber optic Ethernet device at the

other end of the segment. The receive strand of the applicable port on the

module connects to the transmit port of the fiber optic Ethernet device.

Cabletron Systems recommends labeling fiber optic cables to indicate

receive and transmit ends. Many cables are prelabeled, providing

matching labels or tapes at both ends of each strand of cable.

1. Remove the protective plastic covers from the fiber optic ports on the

applicable port on the module, and from the ends of the connectors on

each fiber strand.

Page 4-8 MicroMMAC Installation Guide

Page 53

Connecting the MicroMMAC to the Network

Do not touch the ends of the fiber optic strands, and do not let

!

CAUTION

the ends come in contact with dust, dirt, or other contaminants.

Contamination of cable ends causes problems in data

transmissions. If necessary, clean contaminated cable ends

using alcohol and a soft, clean, lint-free cloth.

2. Attach one fiber to the applicable receive port on the module. Insert

the ST connector into the port with the alignment slot on the connector

inserted over the locking key on the port. Turn the connector

clockwise to lock it down.

090834

Figure 4-6 ST Connector Insertion

3. Attach the other fiber of the pair to the applicable transmit port on the

module. Use the same procedure for insertion of the ST connector.

4. At the other end of the fiber optic cable, attach the fiber pair to the

transmit and receive ports of the device.

If link indicators are present for the fiber optic connection, check that they

are ON. If an indicator is present but not ON, that port does not have a

valid link. Perform each of the follo wing steps until you reach a resolution

of the problem and achieve a link.

• Check that the device at the other end of the link is ON.

• V erify proper cross-o ver of the fiber strands. Try sw apping the transmit

and receive connections at only one end of the link.

MicroMMAC Installation Guide Page 4-9

Page 54

Chapter 4: Connecting to the Network

• Verify that the fiber connection meets the dB loss specifications

outlined in Appendix C, Network Planning and Configuration.

If you are still unable to establish a link, attempt to make the connection

between the devices with another fiber optic cable. If this is unsuccessful,

contact Cabletron Systems Technical Support.

4.1.6 Connecting a 10BASE2 Segment to an EPIM-C

To connect a 10BASE2 thin coaxial segment to an EPIM-C, perform the

following steps:

Before attaching a male BNC connector to a f emale BNC barrel

NOTE

connector or terminator, look into the end of the connector to

verify that the gold contact pin is present and centered. Any

bent or broken pins may not connect properly and should be

replaced.

1. Set the Internal Termination (TERM) Switch, located to the right of

the port and labeled TERM to one of the following settings:

a. ON position ( ) to internally terminate the thin coaxial cable

segment at the port. Thin coaxial cable segments may be directly

connected to the port.

b. OFF position ( ) to not internally terminate the thin coaxial cable

segment at the port. Segments may only be connected through

T-connectors which are connected to properly terminated

segments on both ends.

Failure to terminate each T-connector segment may result in

NOTE

improper segment operation. Place a terminator on any open

female connection on the T-connector.

c. Attach another thin coaxial cable segment or a terminator to the

other female connector on the T-connector.

Page 4-10 MicroMMAC Installation Guide

Page 55

Connecting the MicroMMAC to the Network

2. Align the guide channels of the BNC (male) metal housing with the

locking keys of the BNC barrel (female) connector on the EPIM. Slide

the metal housing of the male connector straight over the metal

housing of the female connector.

3. Once the housing stops moving in, turn the metal housing clockwise

while continuing to apply light forward pressure.

149016

Figure 4-7 BNC Connector Insertion

4. The locking keys of the female connector will pull the connector in

until they reach the circular locking holes at the end of the guide

channels. The keys will click the connector into place and hold it there.

To remove the BNC connector, perform the steps above in reverse order,

turning the metal housing counter-clockwise and pulling the connector

straight off of the female BNC connector.

4.1.7 Connecting an AUI Segment to an EPIM-A

Ensure that the external transceiver to which the EPIM-A

!

CAUTION

connects does not have the Signal Quality Error (SQE or

“heartbeat”) test function enabled. The EPIM does not operate

if the transceiver has the SQE test function enabled. Refer to

the applicable transceiver manual for additional information.

MicroMMAC Installation Guide Page 4-11

Page 56

Chapter 4: Connecting to the Network

To connect an EPIM-A to an external network segment, perform the

following steps:

1. Attach an AUI cable, no longer than 50 meters in length, to the

external transceiver.

2. Align the DB15 connector of the AUI cable with the AUI port of the

EPIM as shown in Figure 4-8. The port will only connect if it is

properly aligned.

3. Firmly press the AUI connector over the AUI port. If there is a slide

latch present for the AUI connector, slide it over the locking posts on

the DB15 port.

If the transceiver PWR LED is OFF with the AUI cable connected:

a. Check the AUI connections for proper pinouts.

b. Check the cable for continuity.

c. Reconnect the AUI cable to the MicroMMAC and the device.

If the transceiver PWR LED remains OFF, contact Cabletron Systems

Technical Support.

Page 4-12 MicroMMAC Installation Guide

090814

Figure 4-8 The EPIM-A