Page 1

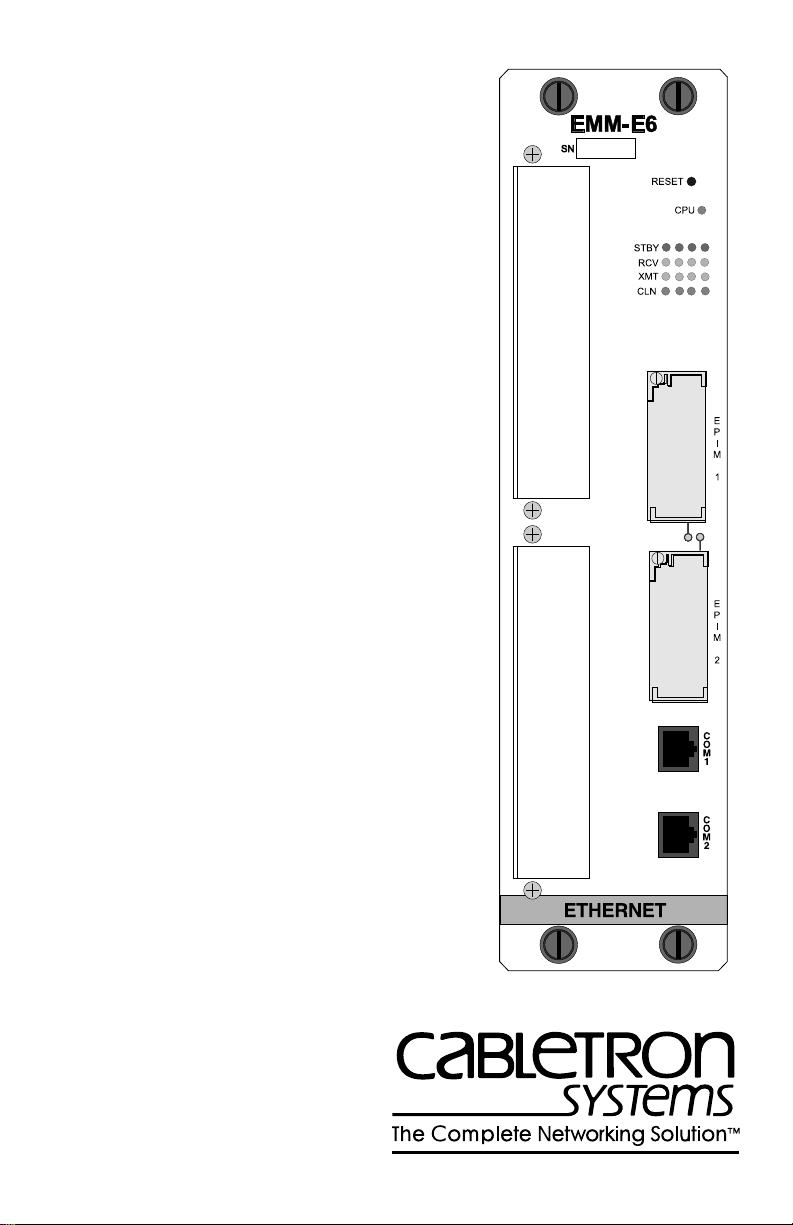

EMM-E6

ETHERNET BRIDGE/

MANAGEMENT MODULE

INSTALLATION GUIDE

DCBA

E

F

Page 2

Page 3

NOTICE

Cabletron Systems reserves the right to make changes in specifications and other information

contained in this document without prior notice. The reader should in all cases consult Cabletron

Systems to determine whether any such changes have been made.

The hardware, firmware, or software described in this manual is subject to change without notice.

IN NO EVENT SHALL CABLETRON SYSTEMS BE LIABLE FOR ANY INCIDENTAL,

INDIRECT, SPECIAL, OR CONSEQUENTIAL DAMAGES WHATSOEVER (INCLUDING BUT

NOT LIMITED TO LOST PROFITS) ARISING OUT OF OR RELATED TO THIS MANUAL OR

THE INFORMATION CONTAINED IN IT, EVEN IF CABLETRON SYSTEMS HAS BEEN

ADVISED OF, KNOWN, OR SHOULD HAVE KNOWN, THE POSSIBILITY OF SUCH

DAMAGES.

Copyright 1996 by Cabletron Systems, Inc., P.O. Box 5005, Rochester, NH 03866-5005

All Rights Reserved

Printed in the United States of America

Order Number: 9031926 August 1996

SPECTRUM, LANVIEW, MMAC

EMM-E6, APIM, CRBRIM, FPIM, EPIM, EPIM-A, EPIM-C, EPIM-F1, EPIM-F2, EPIM-F3

EPIM-T

, and

EPIM-X

are trademarks of Cabletron Systems, Inc.

All other product names mentioned in this manual may be trademarks or registered trademarks of

their respective companies.

, and

BRIM

are registered trademarks and

Element Manager

FCC NOTICE

This device complies with Part 15 of the FCC rules. Operation is subject to the following two

conditions: (1) this device may not cause harmful interference, and (2) this device must accept any

interference received, including interference that may cause undesired operation.

NOTE:

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to Part 15 of the FCC rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is operated in a commercial environment.

This equipment uses, generates, and can radiate radio frequency energy and if not installed in

accordance with the operator’s manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause interference in which case the user

will be required to correct the interference at his own expense.

WARNING:

party responsible for compliance could void the user’s authority to operate the equipment.

Changes or modifications made to this device which are not e xpressly appro v ed by the

Printed on Recycled Paper

,

,

EMM-E6 Installation Guide i

Page 4

Notice

DOC NOTICE

This digital apparatus does not exceed the Class A limits for radio noise emissions from digital

apparatus set out in the Radio Interference Regulations of the Canadian Department of

Communications.

Le présent appareil numérique n’émet pas de bruits radioélectriques dépassant les limites applicables

aux appareils numériques de la class A prescrites dans le Règlement sur le brouillage radioélectrique

édicté par le ministère des Communications du Canada.

VCCI NOTICE

This equipment is in the 1st Class Category (information equipment to be used in commercial and/or

industrial areas) and conforms to the standards set by the Voluntary Control Council for Interference

by Information T echnology Equipment (VCCI) aimed at preventing radio interference in commercial

and/or industrial areas.

Consequently, when used in a residential area or in an adjacent area thereto, radio interference may be

caused to radios and TV receivers, etc.

Read the instructions for correct handling.

CABLETRON SYSTEMS, INC. PROGRAM LICENSE AGREEMENT

IMPORTANT:

This document is an agreement between you, the end user, and Cabletron Systems, Inc. (“Cabletron”)

that sets forth your rights and obligations with respect to the Cabletron software program (the

“Program”) contained in this package. The Program may be contained in firmware, chips or other

media. BY UTILIZING THE ENCLOSED PRODUCT, YOU ARE AGREEING TO BECOME

BOUND BY THE TERMS OF THIS AGREEMENT, WHICH INCLUDES THE LICENSE AND

THE LIMITATION OF WARRANTY AND DISCLAIMER OF LIABILITY. IF YOU DO NOT

AGREE TO THE TERMS OF THIS AGREEMENT, PROMPTLY RETURN THE UNUSED

PRODUCT TO THE PLACE OF PURCHASE FOR A FULL REFUND.

Before utilizing this product, carefully read this License Agreement.

ii EMM-E6 Installation Guide

Page 5

Notice

CABLETRON SOFTWARE PROGRAM LICENSE

1. LICENSE

package subject to the terms and conditions of this License Agreement.

You may not copy, reproduce or transmit any part of the Program except as permitted by the

Copyright Act of the United States or as authorized in writing by Cabletron.

2. OTHER RESTRICTIONS. You may not reverse engineer, decompile, or disassemble the

Program.

3. APPLICABLE LA W. This License Agreement shall be interpreted and governed under the laws

and in the state and federal courts of New Hampshire. You accept the personal jurisdiction and

venue of the New Hampshire courts.

. You have the right to use only the one (1) copy of the Program provided in this

EXCLUSION OF WARRANTY AND DISCLAIMER OF LIABILITY

1. EXCLUSION OF

writing, Cabletron makes no warranty, expressed or implied, concerning the Program (including

its documentation and media).

CABLETRON DISCLAIMS ALL WARRANTIES, OTHER THAN THOSE SUPPLIED TO

YOU BY CABLETRON IN WRITING, EITHER EXPRESSED OR IMPLIED, INCLUDING

BUT NOT LIMITED TO IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE, WITH RESPECT TO THE PROGRAM, THE

ACCOMP ANYING WRITTEN MA TERIALS, AND ANY A CCOMP ANYING HARDWARE.

2. NO LIABILITY FOR CONSEQUENTIAL DAMAGES. IN NO EVENT SHALL

CABLETRON OR ITS SUPPLIERS BE LIABLE FOR ANY DAMAGES WHATSOEVER

(INCLUDING, WITHOUT LIMITATION, DAMAGES FOR LOSS OF BUSINESS,

PROFITS, BUSINESS INTERRUPTION, LOSS OF BUSINESS INFORMATION, SPECIAL,

INCIDENTAL, CONSEQUENTIAL, OR RELIANCE DAMAGES, OR OTHER LOSS)

ARISING OUT OF THE USE OR INABILITY TO USE THIS CABLETRON PRODUCT,

EVEN IF CABLETRON HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH

DAMAGES. BECAUSE SOME STATES DO NOT ALLOW THE EXCLUSION OR

LIMITATION OF LIABILITY FOR CONSEQUENTIAL OR INCIDENTAL DAMAGES, OR

ON THE DURATION OR LIMITATION OF IMPLIED WARRANTIES, IN SOME

INSTANCES THE ABOVE LIMITATIONS AND EXCLUSIONS MAY NOT APPLY TO

YOU.

WARRANTY. Except as may be specifically provided by Cabletron in

UNITED STATES GOVERNMENT RESTRICTED RIGHTS

The enclosed product (a) was developed solely at private expense; (b) contains “restricted computer

software” submitted with restricted rights in accordance with Section 52227-19 (a) through (d) of the

Commercial Computer Software - Restricted Rights Clause and its successors, and (c) in all respects

is proprietary data belonging to Cabletron and/or its suppliers.

For Department of Defense units, the product is licensed with “Restricted Rights” as defined in the

DoD Supplement to the Federal Acquisition Regulations, Section 52.227-7013 (c) (1) (ii) and its

successors, and use, duplication, disclosure by the Government is subject to restrictions as set forth in

subparagraph (c) (1) (ii) of the Rights in Technical Data and Computer Software clause at

252.227-7013. Cabletron Systems, Inc., 35 Industrial Way, Rochester, New Hampshire 03867-0505.

EMM-E6 Installation Guide iii

Page 6

Notice

DECLARATION OF CONFORMITY

Application of Council Directive(s):

Manufacturer’s Name:

Manufacturer’s Address:

European Representative Name:

European Representative Address:

Conformance to Directive(s)/Product Standards:

Equipment T ype/Environment:

We the undersigned, hereby declare that the equipment packaged with this notice conforms to

the above directives.

Manufacturer Legal Representative in Europe

89/336/EEC

73/23/EEC

Cabletron Systems, Inc.

35 Industrial Way

PO Box 5005

Rochester, NH 03867

Mr. J. Solari

Cabletron Systems Limited

Nexus House, Newbury Business Park

London Road, Newbury

Berkshire RG13 2PZ, England

EC Directive 89/336/EEC

EC Directive 73/23/EEC

EN 55022

EN 50082-1

EN 60950

Networking Equipment, for use in a

Commercial or Light

Environment.

Industrial

Mr. Richard Michaud Mr. J. Solari

___________________________________ ___________________________________

Full Name Full Name

Manager of Engineering Services Managing Director - E.M.E.A.

___________________________________ ___________________________________

Title Title

Rochester, NH, USA Newbury, Berkshire, England

___________________________________ ___________________________________

Location Location

iv EMM-E6 Installation Guide

Page 7

CONTENTS

CHAPTER 1 INTRODUCTION

1.1 EMM-E6 Overview.......................................................................1-1

1.2 How to Use This Manual ............................................................. 1-1

1.3 Document Conventions...............................................................1-3

1.4 Related Documents..................................................................... 1-4

1.5 Getting Help.................................................................................1-4

CHAPTER 2 CONTROLS AND INDICATORS

2.1 The Faceplate..............................................................................2-1

2.2 Internal Components...................................................................2-2

S

2.3 LANVIEW LED

CHAPTER 3 INSTALLATION

3.1 Unpacking the EMM-E6...............................................................3-1

3.2 Setting Mode Switches................................................................ 3-3

3.3 Pre-Installation Test.....................................................................3-5

3.4 Installation ................................................................................... 3-7

3.5 Connecting to the Network........................................................3-10

3.5.1 Connecting a 10BASE-T Segment to an EPIM-T.........3-10

3.5.2 Connecting a 10BASE-F Segment to an EPIM-F2

or EPIM-F3 ...................................................................3-13

3.5.3 Connecting a 10BASE-F Segment to an EPIM-F1.......3-15

3.5.4 Connecting an AUI Segment to an EPIM-X

or EPIM-A .....................................................................3-17

3.5.5 Connecting a 10BASE2 Segment to an EPIM-C..........3-18

3.6 Backplane Test..........................................................................3-20

...................................................................2-6

CHAPTER 4 TROUBLESHOOTING

S

4.1 Using LANVIEW LED

4.2 Troubleshooting Checklist...........................................................4-4

4.3 Using the Reset Switch ............................................................... 4-7

APPENDIX A SPECIFICATIONS

A.1 Physical Specifications................................................................A-1

A.2 Operating Specifications..............................................................A-1

A.3 Environmental Requirements......................................................A-2

A.4 Certification..................................................................................A-2

A.5 COM Port Pinout .........................................................................A-2

..........................................................4-1

EMM-E6 Installation Guide v

Page 8

Contents

APPENDIX B UPGRADING THE EMM-E6

B.1 Locating BRIM Connectors.........................................................B-1

S

B.2 Adding EPIM

B.3 SIMM Upgrades..........................................................................B-3

B.3.1 Locating SIMMs.............................................................. B-3

B.3.2 Installing SIMMs ............................................................. B-4

APPENDIX C ETHERNET CABLING REQUIREMENTS

C.1 Network Requirements ...............................................................C-1

C.1.1 10BASE-T Twisted Pair Network....................................C-1

C.1.2 Multimode Fiber Optic Network......................................C-3

C.1.3 Single Mode Fiber Optic Network...................................C-4

C.1.4 10BASE2 Coaxial Cable Network...................................C-5

C.1.5 Transceiver Requirements..............................................C-5

INDEX

......................................................................B-2

vi EMM-E6 Installation Guide

Page 9

CHAPTER 1

INTRODUCTION

Welcome to the Cabletron Systems

manual provides installation instructions and reference information for

the EMM-E6 Ethernet Bridge/Management Module.

EMM-E6 Installation Guide

. This

1.1 EMM-E6 OVERVIEW

The EMM-E6 is a high-speed Ethernet bridge that also performs

comprehensive SNMP-based chassis and network management functions.

The EMM-E6 provides six bridge ports consisting of three chassis

interfaces, one external interface, and two Bridge/Router Interface

Module (BRIM) interfaces.

1.2 HOW TO USE THIS MANUAL

T o gain a full understanding of this device and its capabilities, and to help

eliminate any potential problems during or after installation, please be

sure to read and understand all of the instructions/information in this

document and in the release notes supplied with your EMM-E6.

You should have a general working knowledge of Ethernet or IEEE 802.3

type data networks prior to installing the EMM-E6. The following

summarizes the organization of this manual.

Chapter 1,

EMM-E6 Installation Guide

obtaining assistance from Cabletron Systems, and provides a list of

related documentation.

Introduction

, discusses the use and conventions of the

, details the procedures to follow for

Chapter 2,

components and monitoring indicators that make up the EMM-E6. This

chapter contains information that is essential to the understanding of the

procedures in the rest of the manual.

EMM-E6 Installation Guide 1-1

Controls and Indicators

, identifies and describes the

Page 10

Chapter 1:

Introduction

Chapter 3,

Installation

, details the procedures to follow when unpacking,

testing, and installing the EMM-E6. This chapter contains information

and step-by-step instructions for connecting network cabling to the

EMM-E6 and closes with a procedure which may be used to test the

operation of the EMM-E6 in the network.

Chapter 4,

Troubleshooting

, describes how to use LANVIEW LEDs on

the EMM-E6. The chapter defines the different LED conditions and

provides a table of simple troubleshooting instructions for module-related

difficulties.

Appendix A,

Specifications

, provides the physical specifications and

operating requirements of the EMM-E6. This appendix also contains

serial port pinout tables for constructing Local Management cables.

Appendix B,

Upgrading the EMM-E6

, details the procedures that must

be followed when expanding the capabilities of the EMM-E6. This

appendix contains information on memory upgrades and the addition of

EPIM modules to the EMM-E6.

Appendix C,

Ethernet Cabling Requirements

, describes the test

characteristics that Ethernet cables must adhere to in order to be

standards-compliant. An y Ethernet link or cable that is to be connected to

the EMM-E6 should be verified to be within the specifications and

limitations provided in this appendix.

1-2 EMM-E6 Installation Guide

Page 11

Document Conventions

1.3 DOCUMENT CONVENTIONS

The following conventions are used throughout this document:

Note

NOTE

symbol. Calls the reader’s attention to any item of

information that may be of special importance.

!

CAUTION

Caution

damage to the equipment.

Electrical Hazard Warning

that could result in personal injury or death due to an electrical

hazard.

symbol. Contains information essential to avoid

symbol. Warns against an action

Figures throughout the document are identified by chapter and illustration

number. Many figures contain small numbers at the lower right-hand

corner of the illustration. These are Cabletron Systems document control

numbers and are not essential to an understanding of the document.

References to chapters or sections within this document will be printed in

boldface

References to other publications or documents will be printed in

type.

italic

type.

EMM-E6 Installation Guide 1-3

Page 12

Chapter 1:

Introduction

1.4 RELATED DOCUMENTS

Use the following manuals to supplement the procedures and other

technical data provided in this manual. This manual references procedures

in these manuals, where appropriate, but does not repeat them.

Cabletron Systems

Cabletron Systems

Cabletron Systems

MMAC Overview and Setup Guide

EMM-E6 Local Management Guide

SPECTRUM Element Manager User’s Guide

1.5 GETTING HELP

If you need additional support related to this device, or if you have any

questions, comments, or suggestions concerning this manual, contact

Cabletron Systems Technical Support:

By phone (603) 332-9400

A.M

Monday – Friday; 8

By CompuServe GO CTRON from any ! prompt

By Internet mail support@ctron.com

By FTP ctron.com (134.141.197.25)

Login

Password

anonymous

your email address

Before calling Cabletron Systems Technical Support, have the following

information ready:

• A description of the failure

• A description of any action(s) already taken to resolve the problem

(e.g., changing mode switches, rebooting the unit, etc.)

. – 8 P.M. Eastern Time

• A description of your network environment (layout, cable type, etc.)

• Network load and frame size at the time of trouble (if known)

• The serial and revision numbers of all Cabletron Systems products in

the network

• The device history (i.e., have you returned the device before, is this a

recurring problem, etc.)

• Any previous Return Material Authorization (RMA) numbers.

1-4 EMM-E6 Installation Guide

Page 13

CHAPTER 2

CONTROLS AND INDICATORS

This chapter identifies and describes the components and operational

indicators of the EMM-E6.

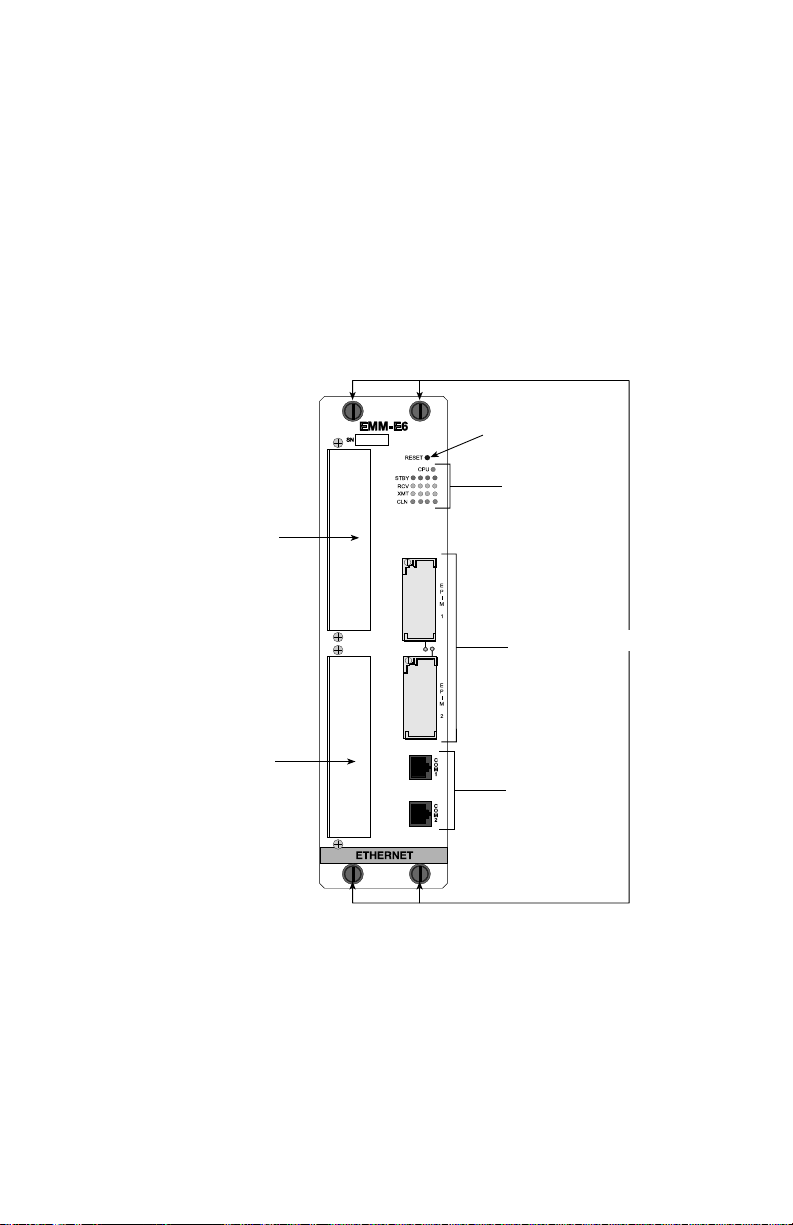

2.1 THE FACEPLATE

Reset Switch

LANVIEW LEDs

Interface E BRIM Slot

E

Interface F BRIM Slot

F

Figure 2-1 The EMM-E6 Faceplate

EPIM Slots

Serial Ports

Knurled Knobs

1926n01

Knurled Knobs

The black plastic knurled knobs on the faceplate of the EMM-E6 are used

to turn the securing screws that hold the EMM-E6 module in place in the

MMAC chassis.

EMM-E6 Installation Guide 2-1

Page 14

Chapter 2:

Reset Switch

Controls and Indicators

The recessed reset switch re-initializes the EMM-E6 processor. The

activation of this switch will not initialize Non-Volatile Random Access

Memory (NVRAM) where the EMM-E6 stores configuration and

management parameters. The reset switch may be pressed with the point

of a pencil or pen. Once pushed in, the EMM-E6 will re-initialize itself.

LANVIEW LEDs

The EMM-E6 incorporates the LANVIEW status monitoring and

diagnostic system. LANVIEW LEDs can help diagnose many problems,

such as a fault in network cabling. LANVIEW LEDs are identified in

Section 2.3,

EPIM (Ethernet Port Interface Module) Slot

LANVIEW LEDS.

The EPIM slot is a covered opening in the EMM-E6 faceplate that can be

configured with an optional EPIM module.

Serial Ports

The EMM-E6 faceplate provides two serial communications ports for the

connection of out-of-band management devices.

BRIM (Bridge/Router Interface Module) Slots

The BRIM slot is a covered opening in the faceplate that can be

configured with a BRIM module.

2.2 INTERNAL COMPONENTS

The components listed in the following entries are all hidden inside the

MMAC chassis when the EMM-E6 has been installed. These components

may be located by removing the EMM-E6 from the chassis and holding

the module in the orientation shown in Figure 2-2 and Figure 2-3.

2-2 EMM-E6 Installation Guide

Page 15

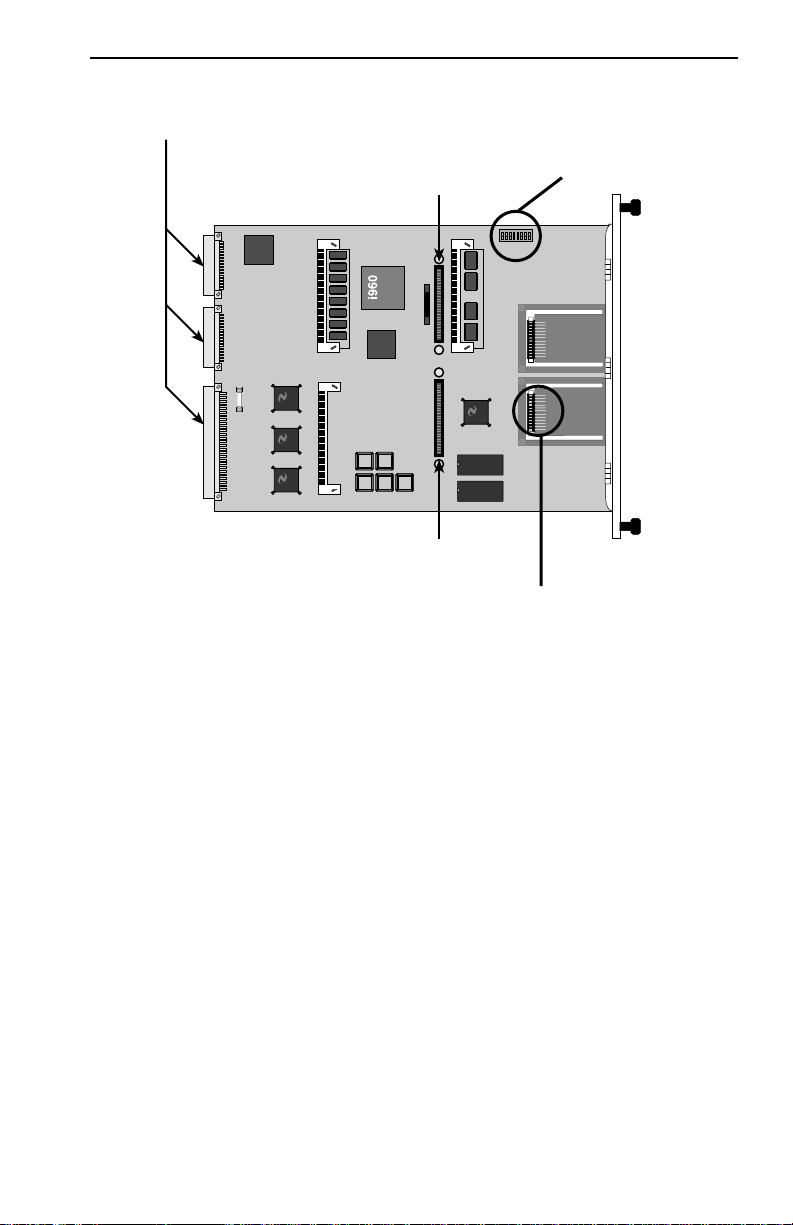

Chassis Backplane Connections

Internal Components

Channel E BRIM Connector

Dip Switch Bank

LSI

Logic

Logic

LSI

Channel F BRIM Connector

EPIM Connector Pins

1926n02

Figure 2-2 EMM-E6 Internal Components

Chassis Backplane Connections

The EMM-E6 connects to the backplane buses of the MMAC chassis

through these multipin connectors.

Dip Switch Bank

The EMM-E6 provides a bank of eight dual-position, or “dip” switches.

Several of these switches are used for testing purposes during the

manufacturing process. The dip switches can also be used to clear the

NVRAM of the EMM-E6, which contains configuration and local

management settings, or to force the EMM-E6 to request a new firmware

image from a properly configured BootP server.

BRIM Connectors

The Channel E and Channel F BRIM connectors allow the EMM-E6 to

connect BRIM modules to Ethernet Channels E and F of the EMM-E6.

EMM-E6 Installation Guide 2-3

Page 16

Chapter 2: Controls and Indicators

EPIM Connector Pins

The EPIM connector pins are two sets of built-in pins that connect the

EMM-E6 Ethernet Channel D to optional EPIM modules. The proper

insertion of the EPIM will automatically connect these pins to the

connector located on the EPIM.

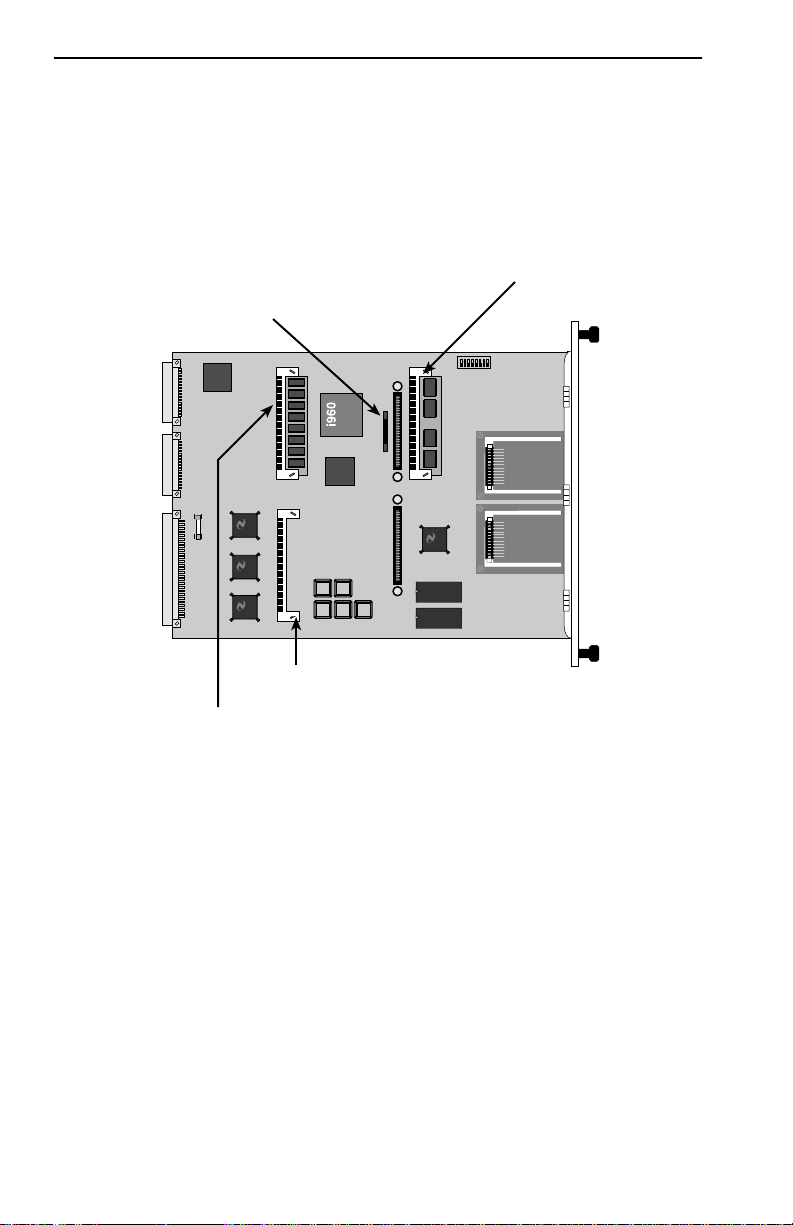

FLASH Memory SIMM Slot (shown populated)

BRIM-F Ribbon Connector

LSI

Logic

Logic

LSI

SDRAM SIMM Slot

LDRAM SIMM Slot (shown populated)

Figure 2-3 EMM-E6 Internal Components

1926n03

SDRAM SIMM Slot

The EMM-E6 motherboard provides the option of upgrading memory

capacity by using Single In-line Memory Modules (SIMMs).

The EMM-E6 comes with 4 Megabytes (MB) of Shared Dynamic

Random Access Memory (SDRAM) built into the module. The SDRAM

temporarily stores the packets received be the module while forwarding,

filtering, and error checking operations are performed.

2-4 EMM-E6 Installation Guide

Page 17

Internal Components

LDRAM SIMM Slot

The EMM-E6 comes with 4 MB of Local Dynamic Random Access

Memory (LDRAM) built into the module and one 4 MB SDRAM SIMM,

for a total of 8 MB of Shared Dynamic RAM. LDRAM is the “Main”

memory from which the switching functionality of the EMM-E6 operates.

NOTE

FLASH Memory SIMM Slot

Some advanced EMM-E6 operations, such as extended

RMON or Cabletron Systems Routing Services, require an

EMM-E6 with greater than 8 MB of LDRAM. In these cases, the

4 MB SIMM that is shipped in the LDRAM slot must be

upgraded to a higher-capacity SIMM. Contact your Cabletron

Systems Sales Representative for more information about

available memory upgrades for the EMM-E6.

The EMM-E6 incorporates 2 MB of FLASH Electrically Erasable

Programmable Read Only Memory (FLASH EEPROM). FLASH

memory holds the operating instruction code of the EMM-E6. When the

module is activated, the instruction code (firmware) held in FLASH

memory is forwarded to Main memory, decompressed, and used to start

up the EMM-E6.

The use of FLASH memory, in conjunction with the runtime download

capabilities of the EMM-E6, allows the downloading of firmware to the

module without requiring that the module be shut down. The firmware

download may be performed at any time during the operation of the

module, and the new firmware image will be used at the next reset of the

module.

BRIM-F Ribbon Connector

The BRIM-F ribbon connector provides a connection point for the special

ribbon cable used to connect FDDI BRIMs (the BRIM-F6 or BRIM-F0)

to Ethernet Channel E of the EMM-E6.

EMM-E6 Installation Guide 2-5

Page 18

Chapter 2: Controls and Indicators

2.3 LANVIEW LEDS

The LANVIEW LEDs on the EMM-E6 faceplate provide diagnostic and

status monitoring information. The LEDs are identified by labels which

border the LED in question.

RESET

CPU

ABCD

STBY

RCV

XMT

CLN

Figure 2-4 EMM-E6 LANVIEW LEDs

The use of these LEDs for troubleshooting is covered in Chapter 4,

Troubleshooting. The following LEDs are on the faceplate of the

EMM-E6:

CPU

The CPU LED indicates the operating status of the EMM-E6, and is

primarily concerned with the operation of the onboard i960 RISC

processor.

NOTE

The STBY, RCV, XMT, and CLN LEDs are in a matrix, which

provides these indicators for four of the EMM-E6 Ethernet

channels. To read the LEDs, the vertical column indicates the

interface or channel the LED designates (D, C, B, or A), while

the horizontal row denotes the condition or statistic being

monitored.

1926n04

2-6 EMM-E6 Installation Guide

Page 19

LANVIEW LED

STBY

The STBY LED lights to indicate the associated port has been placed in

standby mode, either through management operations or by the operation

of the Spanning Tree Algorithm.

RCV

The RCV LED indicates the reception of Ethernet frames by the

associated port or interface.

XMT

The XMT LED indicates the transmit status of the associated port or

interface.

CLN

The CLN LED flashes to indicate that a collision has been detected on the

associated segment.

S

EMM-E6 Installation Guide 2-7

Page 20

Chapter 2: Controls and Indicators

2-8 EMM-E6 Installation Guide

Page 21

CHAPTER 3

INSTALLATION

This chapter contains instructions for the following procedures:

• Preparing the EMM-E6 for installation

• Testing the EMM-E6 prior to network connection

• Installing the EMM-E6 into a Multi Media Access Center (MMAC)

• Connecting the EMM-E6 to a network

• Testing the installed EMM-E6

3.1 UNPACKING THE EMM-E6

Unpack the EMM-E6 as follows:

Observe all antistatic precautions when handling sensitive

electronic equipment.

!

CAUTION

1. Remove the shipping material covering the EMM-E6.

2. Verify the contents of the packing carton. The carton, as shipped,

should contain the following items:

Table 3-1 Contents of EMM-E6 Carton

Item Quantity

EMM-E6 1

Disks containing

firmware images

Grounding Strap 1

RJ45 Adapter Kit 1

Release Notes 1

Cabletron Systems

Hardware Manuals

CD-ROM

EMM-E6 Installation Guide 3-1

2

1

Page 22

Chapter 3: Installation

3. Carefully remove the module from the shipping box. Leave the

module inside its non-conductive bag until you are ready to install it.

4. Visually inspect the non-conductive bag. If there are any signs of

damage, contact Cabletron Systems Technical Support immediately.

5. Place the static grounding strap properly upon your wrist before

opening the non-conductive bag.

6. Open the non-conductive bag by tearing the black and yellow tape

seal.

Do not cut the bag open, as damage to the EMM-E6 may

result.

!

CAUTION

7. Perform a second visual inspection of the module.

3-2 EMM-E6 Installation Guide

Page 23

Setting Mode Switches

3.2 SETTING MODE SWITCHES

A bank of dip switches, located at the top of the EMM-E6 (Figure 3-1),

provides several configuration options. All switches ship in the OFF

position.

Never adjust switch settings while the EMM-E6 is on. Not only

is this dangerous, but the change in state (i.e., position) only

activates the switch function after restarting or cycling power to

the board.

ON

A L C O G D S O 8 S

12345678

LSI

Logic

Logic

LSI

Figure 3-1 EMM-E6 Dip Switches

On

Off

1926n05

EMM-E6 Installation Guide 3-3

Page 24

Chapter 3: Installation

Switch definitions are as follows:

• Switch 1: Cabletron Systems use only.

• Switch 2: Cabletron Systems use only.

• Switch 3: Not Used.

• Switch 4: Not Used.

• Switch 5: Cabletron Systems use only.

• Switch 6: Forced Download. Changing the state of this switch

(i.e., moving the switch from one position to another) forces a BootP

download.

After changing the position of Switch 6 and restarting the EMM-E6,

the EMM-E6 requests a new image download until it either receives a

new image or the reset button on the front panel is pressed. When the

reset button is pressed, the EMM-E6 continues trying to contact a

BootP server, but will timeout in approximately one minute. If the

EMM-E6 times out, the image is loaded from its FLASH memory.

NOTE

Do NOT change the state of Switch 6 unless you ha v e a station

acting as a BootP server for the EMM-E6. This BootP station

must reference a station that is acting as a TFTP (Trivial File

Transfer Protocol) server and that contains the EMM-E6 image

file. The EMM-E6 will request the location of the image file from

the BootP server and use TFTP to download that file from the

TFTP server.

If one of these requirements is not met, the EMM-E6 Forced

Download operation will not be completed correctly.

• Switch 7: NVRAM Reset. The EMM-E6 uses NVRAM to store

user-entered parameters such as IP addresses, device name, etc.

Changing the state of this switch (i.e., moving the switch from one

position to another) resets these parameters to the factory defaults.

3-4 EMM-E6 Installation Guide

Page 25

Pre-Installation Test

Once the EMM-E6 resets, you can either use the defaults or re-enter

your own parameters. The EMM-E6 stores these parameters in

NVRAM when the device powers down. These parameters remain in

NVRAM until the state of the switch changes again.

Do not

NOTE

change the state of Switch 7 unless you intend to reset

the EMM-E6 user parameters to the factory default settings.

• Switch 8: Password Defaults. Changing the state of this switch

(i.e., moving the switch from one position to another and leaving it

there) clears user-entered passwords stored in NVRAM, and restores

default passwords. Once reset you can use the defaults or re-enter your

passwords.

Do not

NOTE

change the state of Switch 8 unless you want to reset

the EMM-E6 user-configured passwords to their f actory default

settings.

3.3 PRE-INSTALLATION T EST

Before installing the EMM-E6 in a live network, you may want to test the

module in a controlled situation to ensure that it is bridging traffic. You

can perform this test with two workstations (see Figure 3-2), using an

MMAC with an EMM-E6 and Ethernet Media Interface Module (MIM,

RMIM, or XMIM) installed and set up as follows:

1. Install the EMM-E6 into an MMAC that is not attached to a network.

2. Install an Ethernet Media Interface Module (MIM), Repeating Media

Interface Module (RMIM), or Port Assignment Media Interface

Module (XMIM) in the MMAC. Follow the installation instructions

found in the Installation or User’s Guide shipped with that product.

EMM-E6 Installation Guide 3-5

Page 26

Chapter 3: Installation

MMAC-M3FNB

M3FM

Figure 3-2 Pre-Installation Test Configuration

M3PSM

1926n06

3. Connect the first workstation to an EPIM that has been inserted in the

EMM-E6 EPIM slot 1.

4. Connect the second workstation to an active port on the Media

Interface Module that has been placed in the MMAC chassis.

5. Designate the first workstation as a file server and the second one as

the client (refer to individual workstation manuals for instructions on

assigning server/client relationships).

6. Send packets between the two workstations to verify the proper

operation of the EMM-E6.

If a failure occurs, contact Cabletron Systems Technical Support.

3-6 EMM-E6 Installation Guide

Page 27

Installation

3.4 INSTALLATION

Installing the EMM-E6 into any MMAC hub is an easy operation and

requires no special tools. Howev er , when you install your device, k eep the

following in mind:

Any installation operations should be performed only by

qualified personnel.

You may only install the EMM-E6 in slots 1 and 2 (farthest slots

to the right) of the MMAC chassis. The EMM-E6 uses both

!

CAUTION

CAUTION

Install the EMM-E6 into the MMAC-FNB (backplane) as follows:

slots.

Observe all antistatic precautions when handling sensitive

electronic equipment.

!

NOTE

We recommend powering down your MMAC when inserting or

removing modules, even though Cabletron Systems modules

have “hot swap” capabilities.

1. Remove the safety bars that protect the chassis and remove any

module to be replaced or blank MMAC slot covers, in accordance with

the installation and removal procedures for these items.

2. Holding the EMM-E6 by the front panel, or by the edges of the board,

align the bottom and top edges of the printed circuit board with the

guides. Make sure that both the bottom and top edges of the printer

circuit board rest in these guides.

3. Slide the EMM-E6 (Figure 3-3) into slots 1 and 2 of the MMAC

chassis.

Forcing a misaligned module into place can damage the

EMM-E6 or the MMAC backplane.

!

CAUTION

EMM-E6 Installation Guide 3-7

Page 28

Chapter 3: Installation

4. Firmly press the module connections into the backplane. Do not try to

force the module into place or use the knurled knobs to draw the

module into the backplane.

1926n07

Module Guide Channels

Figure 3-3 Installing the EMM-E6

5. Secure the module to the MMAC chassis by tightening the knurled

knobs. If you do not tighten the knurled knobs, vibration can cause the

module to lose contact with the backplane and disrupt your network.

6. Reinstall the MMAC chassis safety bars.

7. Power-up the MMAC (if it is not already ON).

8. Observe the status of the LANVIEW LEDs (Figure 3-4) on the

EMM-E6. When the CPU LED is amber, the module is in boot state.

During this approximately one minute period the EMM-E6 cycles

through a series of internal diagnostics.

3-8 EMM-E6 Installation Guide

Page 29

RESET

STBY

RCV

XMT

Installation

CPU

ABCD

CLN

Figure 3-4 EMM-E6 LANVIEW LEDs

9. After the system boot procedure, the CPU LED should be flashing

green, indicating proper EMM-E6 operation.

Proceed to Section 3.5, Connecting to the Network, to connect the

appropriate network segments to the EMM-E6 and individual EPIMs (for

connections to individual BRIMs, refer to the appropriate BRIM Guides).

1926n04

EMM-E6 Installation Guide 3-9

Page 30

Chapter 3: Installation

3.5 CONNECTING TO THE NETWORK

This section gives procedures for connecting the EMM-E6 and various

EPIMs to the network. Refer to the list below and follow the procedures

in the subsection for appropriate module type:

• Connecting a 10BASE-T Segment to an EPIM-T: Section 3.5.1

• Connecting a 10BASE-F Segment to an EPIM-F2 or EPIM-F3:

Section 3.5.2

• Connecting a 10BASE-F Segment to an EPIM-F1: Section 3.5.3

• Connecting an AUI Segment to an EPIM-X or EPIM-A:

Section 3.5.4

• Connecting a 10BASE2 Segment to an EPIM-C: Section 3.5.5

3.5.1 Connecting a 10BASE-T Segment to an EPIM-T

NOTE

For proper operation, the EPIM-T module to be configured for

use in the EMM-E6 module must be of EPIM board revision 04

or greater. Board revision numbers are found f ollowing the part

number printed on the Printed Circuit Board of the EPIM.

Before connecting a segment to the EPIM-T, check each end of the

segment to determine wire crossover. If the wires do not cross over, use

the switch on the EPIM-T to internally cross over the RJ45 port. Refer to

Figure 3-5 to properly set the EPIM-T crossover switch.

NOTE

3-10 EMM-E6 Installation Guide

To establish a link, you must have an odd number of

crossovers (preferably one) between 10BASE-T devices of the

same type (i.e., from repeater to repeater or transceiver to

transceiver).

Page 31

Position X

(crossed over)

Connecting to the Network

1. RX+

2. RX-

3. TX+

4. NC

5. NC

6. TX-

7. NC

8. NC

Position =

(not crossed over)

1. TX+

2. TX-

3. RX+

4. NC

Figure 3-5 EPIM-T Crossover Switch

5. NC

6. RX-

7. NC

8. NC

1926n08

1. Align the RJ45 connector with the socket of the RJ45 port. The

connector will only insert and lock if the raised locking clip of the

RJ45 connector is inserted into the correct location.

2. Press the RJ45 connector into the port until the click of the locking clip

is felt. The pressure required to perform this should be minimal. If you

encounter resistance or excessive friction, remove the connector and

check the port for obstruction. Also, verify that the connector and the

port are of the same type.

Once the locking clip snaps into place, the RJ45 connector will remain

in the port.

3. Check that the LNK indicator LED is ON. If the indicator is not ON,

the port does not have a valid link. Perform each of the following steps

until you reach a resolution of the problem and achieve a link.

a. Check that the 10BASE-T device at the other end of the twisted

pair segment is ON.

b. Verify that the RJ45 connectors on the twisted pair segment have

the proper pinouts.

EMM-E6 Installation Guide 3-11

Page 32

Chapter 3: Installation

Tx+

1

Tx-

2

Rx-

3

Rx+

6

RX+/RX- and TX+/TX- must share a common

Figure 3-6 Cable Pinouts - RJ45 Port

Straight-Through

color pair

10BASE-T Device PortEPIM-T RJ45 Port

1

Rx+

Rx-

2

Tx-

3

6

Tx+

1926n09

c. Check the cable for continuity.

d. Check that the twisted pair connection meets dB loss and cable

specifications outlined in Appendix C, Ethernet Cabling

Requirements.

4. If you still cannot establish a link, contact Cabletron Systems

Technical Support.

T o remo ve the RJ45 connector from the port once it is locked in, grasp the

cable where it enters the network device. Using your finger or a

non-conductive probe (the cap of a ballpoint pen is a useful tool for

recessed ports) pinch the exposed arm of the locking clip towards the

main body of the housing. When the arm contacts the housing, the locking

clip has been disengaged. W ithout releasing the arm, gently pull the RJ45

connector directly out of the port.

If the connector will not come out, there may be damage to the locking

clip. Examine the arm of the locking clip. While pressing the arm back

toward the shell of the connector, verify that the clip, located within the

port, is being moved. If the clip is broken, you may need to use a

non-conductive probe to disengage the locking clip.

Do not place foreign objects into device ports while they are

connected to a power source.

3-12 EMM-E6 Installation Guide

Page 33

Connecting to the Network

3.5.2 Connecting a 10BASE-F Segment to an EPIM-F2

or EPIM-F3

NOTE

For proper operation, the EPIM-F2 module to be configured f or

use in the EMM-E6 module must be of EPIM board revision 05

or greater. EPIM-F3 modules used in the EMM-E6 must be of

EPIM board revision 02 or greater. Board revision numbers are

found following the part number printed on the Printed Circuit

Board of the EPIM.

Each fiber optic link consists of two strands of fiber optic cabling: the

transmit (TX) and the receive (RX). The transmit strand from a module

port connects to the receive port of a fiber optic Ethernet device at the

other end of the segment. The receive strand of the applicable port on the

module connects to the transmit port of the fiber optic Ethernet device.

Cabletron Systems recommends labeling fiber optic cables to indicate

receive and transmit ends. Many cables are prelabeled, providing

matching labels or tapes at both ends of each strand of cable.

Do not touch the ends of the fiber optic strands, and do not let

the ends come in contact with dust, dirt, or other contaminants.

!

CAUTION

Contamination of cable ends causes problems in data

transmissions. If necessary, clean contaminated cable ends

using alcohol and a soft, clean, lint-free cloth.

1. Remove the protective plastic covers from the fiber optic ports on the

applicable port on the module, and from the ends of the connectors on

each fiber strand.

2. Attach one fiber to the applicable receive port on the module. Insert

the ST connector into the port with the alignment slot on the connector

inserted over the locking key on the port. Turn the connector

clockwise to lock it down.

EMM-E6 Installation Guide 3-13

Page 34

Chapter 3: Installation

1926n10

Figure 3-7 ST Connector Insertion

3. Attach the other fiber of the pair to the applicable transmit port on the

module. Use the same procedure for insertion of the ST connector.

4. At the other end of the fiber optic cable, attach the fiber pair to the

transmit and receive ports of the device.

If link indicators are present for the fiber optic connection, check that they

are ON. If an indicator is present but not ON, that port does not have a

valid link. Perform each of the following steps until you reach a resolution

of the problem and achieve a link.

• Check that the device at the other end of the link is ON.

• Verify proper crossover of the fiber strands. Try sw apping the transmit

and receive connections at only one end of the link.

• Verify that the fiber connection meets the dB loss specifications

outlined in Appendix C, Ethernet Cabling Requirements.

If you are still unable to establish a link, attempt to make the connection

between the devices with another fiber optic cable. If this is unsuccessful,

contact Cabletron Systems Technical Support.

3-14 EMM-E6 Installation Guide

Page 35

Connecting to the Network

3.5.3 Connecting a 10BASE-F Segment to an EPIM-F1

NOTE

CAUTION

For proper operation, the EPIM-F1 module to be configured f or

use in the EMM-E6 module must be of EPIM board revision 05

or greater. Board revision numbers are found f ollowing the part

number printed on the Printed Circuit Board of the EPIM.

When connecting a fiber optic link segment with SMA 906

connectors to an EPIM-F1 with SMA ports, make sure each

!

connector uses half alignment, NOT full alignment, sleeves.

A full alignment sleeve damages the receive port. SMA 905

connectors do not need alignment sleeves.

Each fiber optic link consists of two strands of fiber optic cabling: the

transmit (TX) and the receive (RX). The transmit strand from a module

port connects to the receive port of a fiber optic Ethernet device at the

other end of the segment. The receive strand of the applicable port on the

module connects to the transmit port of the fiber optic Ethernet device.

Cabletron Systems recommends labeling fiber optic cables to indicate

receive and transmit ends. Many cables are prelabeled, providing

matching labels or tapes at both ends of each strand of cable.

Do not touch the ends of the fiber optic strands, and do not let

the ends come in contact with dust, dirt, or other contaminants.

!

CAUTION

Contamination of cable ends causes problems in data

transmissions. If necessary, clean contaminated cable ends

using alcohol and a soft, clean, lint-free cloth.

1. Remove the protective plastic covers from the fiber optic ports on the

applicable port on the module, and from the ends of the connectors on

each fiber strand.

2. Attach one fiber to the receive port (RX) on the EPIM-F1. Insert the

SMA connector into the port. Turn the connector clockwise until the

connector will no longer turn easily. Do not overtighten the connector.

EMM-E6 Installation Guide 3-15

Page 36

Chapter 3: Installation

1926n11

Figure 3-8 SMA Connector Insertion

3. Attach the other fiber of the pair to the applicable transmit port on the

module.

4. At the other end of the fiber optic cable, attach the fiber pair to the

transmit and receive ports of the device.

If link indicators are present for the fiber optic connection, check that they

are ON. If an indicator is present but not ON, that port does not have a

valid link. Perform each of the following steps until you reach a resolution

of the problem and achieve a link.

• Check that the device at the other end of the link is ON.

• Verify proper crossover of the fiber strands. Try sw apping the transmit

and receive connections at only one end of the link.

• Verify that the fiber connection meets the dB loss specifications

outlined in Appendix C, Ethernet Cabling Requirements.

If you are still unable to establish a link, attempt to make the connection

between the devices with another fiber optic cable. If this is unsuccessful,

contact Cabletron Systems Technical Support.

3-16 EMM-E6 Installation Guide

Page 37

Connecting to the Network

3.5.4 Connecting an AUI Segment to an EPIM-X or

EPIM-A

NOTE

Ensure that the external transceiver to which the EPIM-A

connects does not have the signal quality error (SQE or

“heartbeat”) test function enabled. The EPIM does not operate

if the transceiver has the SQE test function enabled. Refer to

the applicable transceiver manual for additional information.

Attach an external transceiver to the network segment intended for AUI

port connection. For additional information, refer to the applicable

transceiver manual.

Attach an AUI cable, no longer than 50 meters in length, to the external

transceiver.

1. Align the DB15 connector of the AUI cable with the AUI port of the

EPIM as shown in Figure 3-9. The port will only connect if it is

properly aligned.

2. Firmly press the AUI connector over the AUI port. If there is a slide

latch present for the AUI connector, slide it over the locking posts on

the DB15 port.

1926n12

Figure 3-9 AUI Connector Insertion

EMM-E6 Installation Guide 3-17

Page 38

Chapter 3: Installation

3. If the transceiver PWR LED is OFF with the AUI cable connected,

perform the following steps:

a. Check the AUI connections for proper pinouts.

b. Check the cable for continuity.

c. Reconnect the AUI cable to the EMM-E6 and the device.

If the transceiver PWR LED remains OFF, contact Cabletron Systems

Technical Support.

3.5.5 Connecting a 10BASE2 Segment to an EPIM-C

NOTE

For proper operation, the EPIM-C module to be configured for

use in the EMM-E6 module must be of EPIM board revision 05

or greater. Board revision numbers are found f ollowing the part

number printed on the Printed Circuit Board of the EPIM.

To connect a thin coaxial cable segment to an EPIM-C perform the

following steps:

Before attaching a male BNC connector to a female BNC barrel

connector or terminator, look into the end of the connector to verify that

the gold contact pin is present and centered. An y bent or brok en pins may

not connect properly and should be replaced.

1. Set the Internal Termination (TERM) switch, located to the right of the

port and labeled TERM, to one of the following positions:

a. The ON position ( ) to internally terminate the thin coaxial cable

segment at the port. Thin coaxial cable segments may be directly

connected to the port.

b. The OFF position ( ) to not internally terminate the thin coaxial

cable segment at the port. Segments may only be connected

through T-connectors which are connected to properly terminated

segments on both ends.

3-18 EMM-E6 Installation Guide

Page 39

Connecting to the Network

NOTE

Failure to terminate each T-connector segment may result in

improper segment operation. Place a terminator on any open

female connection on the T-connector.

2. Align the guide channels of the BNC (male) metal housing with the

locking keys of the BNC barrel (female) connector on the EPIM. Slide

the metal housing of the male connector straight over the metal

housing of the female connector.

3. Once the housing stops moving in, turn the metal housing clockwise

while continuing to apply light forward pressure.

1926n13

Figure 3-10 BNC Connector Insertion

4. The locking keys of the female connector will pull the connector in

until they reach the circular locking holes at the end of the guide

channels. The keys will click the connector into place and hold it there.

To remove the BNC connector, perform the steps above in reverse order,

turning the metal housing counter-clockwise and pulling the connector

straight off of the female BNC connector.

EMM-E6 Installation Guide 3-19

Page 40

Chapter 3: Installation

3.6 BACKPLANE T EST

Once the EMM-E6 has been installed in the network environment, you

may wish to test the operation of the Ethernet bridging functionality and

the EMM-E6’s connection to the chassis backplane. Again, you can use

two workstations set up as file server and client. See Figure 3-11.

1. After the EMM-E6 is installed in the MMAC, connect the client

workstation to the EMM-E6 EPIM 1 port.

2. Connect the server workstation to another Ethernet MIM that is

accessible from an Ethernet channel in the MMAC-FNB hub.

3. Send packets between the two workstations to verify the proper

operation of the EMM-E6. A “ping” test will send packets from one

station to another.

If a failure occurs, contact Cabletron Systems Technical Support.

M5PSM M5PSM

1926n14

Figure 3-11 Backplane Test Configuration

3-20 EMM-E6 Installation Guide

Page 41

CHAPTER 4

TROUBLESHOOTING

This chapter provides diagnostic and troubleshooting information.

4.1 USING LANVIEW LEDS

The EMM-E6 uses the Cabletron Systems built-in visual diagnostic and

status monitoring system called LANVIEW. With LANVIEW, you can

quickly scan the EMM-E6 LEDs to observe network status or diagnose

network problems.

NOTE

provides these indicators for four of the EMM-E6 Ethernet

channels. To read the LEDs, the vertical column indicates the

interface or channel the LED designates, while the horizontal

row denotes the condition or statistic being monitored.

Table 4-1 LANVIEW LED Messages

LED Color Description

The STBY, RCV, XMT, and CLN LEDs are in a matrix, which

Green

(Flashing)

CPU

Red CPU error condition.

Normal operation.

Error Condition/

Recommended Action

If the LED is not lit, the

EMM-E6 may not be

receiving power. See the

Troubleshooting Checklist.

Press the Reset switch on

the EMM-E6 front panel to

re-initialize the board. This

may clear the error. If the

board does not re-initialize, it

has probably failed. Call

Cabletron Systems Technical

Support.

EMM-E6 Installation Guide 4-1

Page 42

Chapter 4: Troubleshooting

Table 4-1 LANVIEW LED Messages (Continued)

LED Color Description

Indicates packets

will not be

forwarded for one

of two reasons:

Either the Spanning

Tree Algorithm has

put the

corresponding

STBY Amber

RCV Amber

Bridge Port into a

standby mode due

to detecting a data

loop condition, or

the bridging

functionality for the

port has been

disabled through

management.

LED flashes to

indicate that a

segment is

receiving a frame.

Error Condition/

Recommended Action

Check with your Network

Administrator to find out if

the EMM-E6 was placed

intentionally in standby

mode.

If a Data loop does exist,

reconfigure the network to

remove the data loop.

If none of the receive LEDs

is flashing, the EMM-E6 is

not receiving frames on any

of the segments.

Check that each module is

firmly installed in the MMAC.

Ensure that all connected

ports are enabled.

4-2 EMM-E6 Installation Guide

Page 43

Using LANVIEW LED

Table 4-1 LANVIEW LED Messages (Continued)

S

LED Color Description

LED flashes to

indicate that a

segment is

transmitting a

frame.

XMT Green

CLN Red

If not connected to

the LAN, the LED

flashes every two

seconds to indicate

the device is

transmitting BPDU

frames.

Collision detected

on a segment.

When the LAN is

operating properly,

occasional flashing

is normal.

Error Condition/

Recommended Action

If none of the transmit LEDs

are flashing, the EMM-E6 is

not transmitting frames on

any of the segments.

Ensure that the network is

actually producing Ethernet

traffic. Contact Cabletron

Systems T echnical Support

for assistance.

Excessive flashing, or a solid

light, indicates an inordinate

number of collisions.

Ensure that the SQE test is

disabled for any transceiver

connected to the EMM-E6

external channels (D, E, or

F). Check cabling for data

loops or defective cables.

EMM-E6 Installation Guide 4-3

Page 44

Chapter 4: Troubleshooting

4.2 TROUBLESHOOTING CHECKLIST

If your EMM-E6 is not operating properly, the following checklist

describes some of the problems that may occur with the EMM-E6

installed in an MMAC, possible causes for the problem, and suggestions

for resolving the problem.

Table 4-2 Troubleshooting Checklist

Condition Possible Cause Recommended Action

Check the proper installation of the

MMAC power supply module and

its access to a live outlet. Check

power cables for viability.

Check that the MMAC has

Loss of power to

the MMAC.

adequate power. Some

configurations, especially those

including FDDI modules, require

that more than one power supply

be installed in the MMAC.

All LEDs are off.

No Local

Management

Password Screen.

EMM-E6 not

properly

installed.

EMM-E6

connector pin

damage.

MMAC power

bus failure.

Incorrect

terminal setup.

Improper

console cable

pinout.

Check to see that all power supply

LEDs are green.

Re-install EMM-E6 in hub

according to instructions in

Chapter 3.

Examine EMM-E6 backplane

connectors for evidence of bent or

broken pins.

Contact Cabletron Systems

Technical Support.

Review terminal or emulation

settings for accordance with

requirements.

Refer to Appendix A for proper

console port pinouts.

4-4 EMM-E6 Installation Guide

Page 45

Troubleshooting Checklist

Table 4-2 Troubleshooting Checklist (Continued)

Condition Possible Cause Recommended Action

Cannot contact

the EMM-E6 from

in-band

management.

A port on a MIM

managed by the

EMM-E6 cannot

access the

network, while

other ports on the

same MIM are

able to access.

User Parameters

(IP address,

Device and

Module Name,

etc.) are lost when

device is

powered down.

Improperly

configured

Community

Names table.

EMM-E6 does

not have an IP

address.

No link to

device.

Frames are

being bridged by

a permanent

entry.

The port is

either off or

segmented.

Port cable is

defective.

Switch 7 has

been toggled

and

user-entered

parameters

have been reset

to factory

default.

NVRAM may be

defective.

Refer to

Management Guide

Community Names table setup.

Refer to

Management Guide

Setup Screen information.

Check link to device f or validity and

proper functioning of all

intermediary devices.

Check Static Database.

Enable the port via local or remote

management.

Try connecting the port with a

different cable.

Reset one or more parameters and

cycle power to module. If

parameter altered has remained in

memory, re-configure remaining

parameters.

position of switch 7 to attempt to

rectify this situation. See Chapter

3, Installation, for details.

If NVRAM is defective, call

Cabletron Systems Technical

Support.

EMM-E6 Local

for

EMM-E6 Local

for IP address

Do not

change the

EMM-E6 Installation Guide 4-5

Page 46

Chapter 4: Troubleshooting

Table 4-2 Troubleshooting Checklist (Continued)

Condition Possible Cause Recommended Action

No power to an

external

transceiver

connected to an

EPIM-A.

High number of

collisions on EPIM

port.

Ports go into

standby for no

apparent reason.

AUI cable is

defective.

EPIM is

defective or

improperly

installed.

External

transceiver has

SQE enabled.

Configurations

where devices

connected

across EMM-E6

channels can

cause the

EMM-E6 to

detect a looped

condition.

Replace AUI cable.

Replace EPIM. See Chapter 3,

Installation, for details.

Disable SQE.

Discuss these configurations with

Cabletron Technical Support

before implementing them into

your network.

4-6 EMM-E6 Installation Guide

Page 47

Using the Reset Switch

4.3 USING THE RESET SWITCH

The EMM-E6 incorporates a recessed reset switch, located above the

LANVIEW LEDs (See Chapter 2, Controls and Indicators, for

location). This reset switch initializes the EMM-E6 processor . This switch

does not initialize Non-Volatile Random Access Memory (NVRAM), the

non-volatile random access memory where the EMM-E6 stores network

management parameters.

To use the reset switch, use a pen or pencil to press the switch in. When

this is done, the EMM-E6 initializes itself.

NOTE

The reset sequence for the EMM-E6 may last approximately

one minute. The final time may change depending upon the

configuration of the chassis in which the EMM-E6 is located.

Only after the reset sequence is completed will internetworking

operations resume.

EMM-E6 Installation Guide 4-7

Page 48

Chapter 4: Troubleshooting

4-8 EMM-E6 Installation Guide

Page 49

APPENDIX A

SPECIFICATIONS

This appendix lists some of the important specifications and specified

requirements for the EMM-E6. Cabletron Systems reserves the right to

change these specifications at any time and without notice.

A.1 PHYSICAL SPECIFICATIONS

Dimensions: 29.21 H x 7.64 W x 34.07 D cm

(11.5 H x 3 W x 13.4 D in)

Weight (unit): 1.25 kg (2.75 lbs)

Weight (as shipped): 1.74 kg (3.83 lbs)

A.2 OPERATING SPECIFICATIONS

Internal Processor(s): Intel 80960

Ethernet Controller: 4 DP83932 Controllers

Shared Memory: 4 MB (Expandable to 12 MB)

Read Only Memory (NVRAM): 128 K

FLASH Memory: 2 MB (Expandable to 14 MB)

CPU Memory (Local Memory): 8 MB (4 MB + 4 MB SIMM)

(Expandable to 12 MB)

Filtering Table: 8,191 entries maximum

Aging Time: 5 minutes (default)

EMM-E6 Installation Guide A-1

Page 50

Appendix A: Specifications

A.3 ENVIRONMENTAL REQUIREMENTS

Operating T emperature: 5°C to 40°C (41°F to 104°F)

Storage T emperature: -30°C to 90°C (-22°F to 194°F)

Operating Humidity: 5% to 95% (non-condensing)

A.4 CERTIFICATION

Safety: UL 1950, CSA C22.2 No. 950, EN 60950, and

IEC 950

Emission: FCC Part 15 Class A, VCCI Class I, and

EN 55022 Class A

Immunity: EN 50082-1

This unit has been tested by Bellcore and found to comply with the

following Bellcore standards:

TR-NWT-000063 Network Equipment Building System (NEBS)

Generic Equipment Requirements

GR-1098-CORE EMC and Electrical Safety Generic Criteria for

Network Telecommunications Equipment

A.5 COM PORT PINOUT

Type: Standard RJ45 port

Pin Function Connection Attitude

1 Transmit Data (XMT) From COM 2 port

2 Data Carrier Detect (DCD) From COM 2 port

3 Data Set Ready (DSR) To COM 2 port

4 Receive Data (RCV) To COM 2 port

5 Signal Ground (GND) NA

6 Data Terminal Ready (DTR) From COM 2 port

7 Request to Send (RTS) To COM 2 port

8 Clear to Send (CTS) NA

A-2 EMM-E6 Installation Guide

Page 51

APPENDIX B

UPGRADING THE EMM-E6

This appendix describes how to incorporate additional or expanded

capabilities into the EMM-E6. This appendix describes the procedures for

the addition of a BRIM or EPIM module and the addition of Single

In-line Memory Modules (SIMMs).

B.1 LOCATING BRIM CONNECTORS

This section points out Bridge Router Interface Module (BRIM)

connector locations on your EMM-E6 board. Refer to your BRIM Guide

for specific installation procedures and additional information.

The following diagram (Figure B-1) shows BRIM connector locations for

the EMM-E6:

Channel E BRIM Connector

BRIM-F Ribbon Connector

LSI

Logic

Logic

LSI

1926n15

Channel F BRIM Connector

Figure B-1 BRIM Connector Locations

EMM-E6 Installation Guide B-1

Page 52

Appendix B: Upgrading the EMM-E6

B.2 ADDING EPIMS

This section contains procedures for adding or replacing an Ethernet

Port Interface Module (EPIM) to upgrade or change the capabilities of

your EMM-E6. After installing your new EPIM, refer to Chapter 3,

Installation, for network connection instructions.

NOTE

CAUTION

The EMM-E6 EPIM slots are designed to provide redundancy.

Only one EPIM will be active at any time. The inactive EPIM

port will be held in standby , and will be immediately activ ated in

the event of a filure ofthe primary EPIM port.

Observe all antistatic precautions when handling sensitive

electronic equipment.

!

To install an EPIM, perform the following steps:

When removing an existing EPIM, make sure to pull the

module straight out to avoid damage to the connector.

!

CAUTION

1. Remove the coverplate or the existing EPIM (whichever applies).

2. Slide your new EPIM into place, making sure the connectors on the

rear of the module and inside the EMM-E6 attach properly. Refer to

Figure B-2.

3. Secure the EPIM to the EMM-E6 by tightening the mounting screw.

Mounting

Screw

LNK

EPIM

1926n16

Figure B-2 Installing an EPIM

B-2 EMM-E6 Installation Guide

Page 53

SIMM Upgrades

B.3 SIMM UPGRADES

The EMM-E6 allows memory upgrades for Shared DRAM, Local

DRAM, and FLASH EEPROM. This section explains how to locate and

add/replace a Single In-line Memory Module (SIMM) for any of these

memory types. For information on the available SIMM upgrades and

information on ordering them, contact your Cabletron Systems Sales

Representative.

B.3.1 Locating SIMMs

Each memory type has a specific SIMM slot location on the EMM-E6

motherboard. When installing SIMM boards, make sure that you place

them in their proper slots. Figure B-3 illustrates the EMM-E6 SIMM slot

locations and the direction (indicated by the white arrow) in which to

install the SIMMs.

These slots are shipped populated

FLASH SIMM SlotLDRAM SIMM Slot

LSI

Logic

Direction of

Insertion

1926n17

SDRAM SIMM Slot

Figure B-3 SIMM Slot Locations

EMM-E6 Installation Guide B-3

Page 54

Appendix B: Upgrading the EMM-E6

B.3.2 Installing SIMMs

The EMM-E6 uses an angle-down slot (where the SIMM rotates down to

a horizontal locked position). Installing a SIMM in any slot is a simple

two-step process. After finding the proper SIMM slot location

(Figure B-3), refer to the procedures below.

Observe all antistatic precautions when handling sensitive

electronic equipment.

!

CAUTION

1. Insert the SIMM between the connector teeth in the SIMM slot.

2. Pivot the SIMM down until it locks into the clips in the SIMM slot,

and the SIMM holes fit over the SIMM slot posts. (See Figure B-4.)

SIMM Slot

Connector

Teeth

Clips

1

2

SIMM

SIMM Hole

Figure B-4 Installing a Horizontal SIMM

B-4 EMM-E6 Installation Guide

SIMM Slot

Post

Alignment Notch

1926n18

Page 55

APPENDIX C

ETHERNET CABLING REQUIREMENTS

This chapter contains general networking guidelines. Before attempting

to install the EMM-E6 or any additional EPIMs or BRIMs, review the

requirements and specifications outlined in this chapter.

NOTE

Your network installation must meet the conditions, guidelines,

specifications, and requirements included in this chapter to

ensure satisfactory performance of this equipment. Failure to

follow these guidelines may result in poor network

performance.

C.1 NETWORK REQUIREMENTS

Take care in planning and preparing the cabling and connections for your

network. The quality of the connections, the length of cables, and other

conditions of the installation play critical roles in determining the

reliability of your network.

Refer to the sections which follow that apply to your specific network

configuration.

C.1.1 10BASE-T Twisted Pair Network

When connecting a 10BASE-T segment to an EMM-E6 (using an

EPIM-T), ensure the network meets the following requirements:

• Length: The IEEE 802.3 10BASE-T standard requires that

10BASE-T devices transmit over a 100 meter (328 foot) link using

22-24 AWG unshielded twisted pair wire. However, cable quality

largely determines maximum link length. If you use high quality, low

attenuation cable, you can achieve link lengths of up to 200 meters.

Cable delay limits the maximum link length to 200 meters.

NOTE

EMM-E6 Installation Guide C-1

Losses introduced by connections at punch-down blocks and

other equipment reduce total segment length. For each

connector or patch panel in the link, subtract 12 meters from

the total length of your cable.

Page 56

Appendix C: Ethernet Cabling Requirements

• Insertion Loss: Between frequencies of 5.0 and 10.0 MHz, the

maximum insertion loss must not exceed 11.5 dB. This includes the

attenuation of the cables, connectors, patch panels, and reflection

losses due to impedance mismatches in the link segment.

• Impedance: Cabletron Systems 10BASE-T products work on twisted

pair cable with 75 to 165 ohms impedance. Unshielded Twisted Pair

cables typically have an impedance of between 85 and 110 ohms. You

can also use Shielded Twisted Pair cables, such as IBM Type 1 cable,

but keep in mind that this cable has an impedance of 150 ohms. The

high impedance of the IBM Type 1 cable increases signal reflection.

However, due to cable shielding and the subsequent lack of crosstalk

between shielded pairs, signal reflection has little effect on the quality

of the received signal.

• Jitter: Intersymbol interference and reflections can cause jitter in the

bit cell timing, resulting in data errors. 10BASE-T links must not

generate more than 5.0 ns of jitter. Make sure your cable meets

10BASE-T link impedance requirements to rule out jitter as a concern.

• Delay: The maximum propagation delay of a 10BASE-T link se gment

must not exceed 1000 ns. This 1000 ns maximum delay limits the

maximum link segment length to no greater than 200 meters.

• Crosstalk: Signal coupling between different cable pairs within a

multi-pair cable bundle causes crosstalk. 10BASE-T transceiver

design alleviates concerns about crosstalk, provided the cable meets

all other requirements.

• Noise: Crosstalk, or externally induced impulses, can cause noise.

Impulse noise may cause data errors if the impulses occur at very

specific times during data transmission. Generally, noise is not a

concern. If you suspect noise-related data errors, you may need to

reroute the cable or eliminate the source of the impulse noise.

C-2 EMM-E6 Installation Guide

Page 57

Network Requirements

• Temperature: Multi-pair PVC 24 AWG telephone cables typically

have an attenuation of approximately 8-10 dB/100 m at 20°C (68°F).

The attenuation of PVC insulated cable varies significantly with

temperature. At temperatures greater than 40°C (104°F), we strongly

recommend using plenum-rated cable to ensure attenuation remains

within specification.

C.1.2 Multimode Fiber Optic Network

When connecting a multimode fiber optic link segment to the EMM-E6

(using an EPIM-F1/F2), ensure the network meets the following

requirements:

• Cable T ype: Use the following multimode fiber optic media:

- 50/125 µm fiber optic cabling

- 62.5/125 µm fiber optic cabling

- 100/140 µm fiber optic cabling

• Attenuation: You must test the fiber optic cable with a fiber optic

attenuation test set adjusted for an 850 nm wavelength. This test

verifies that the signal loss in a cable falls within the following

acceptable levels:

- 13.0 dB or less for a 50/125 µm fiber cable segment

- 16.0 dB or less for a 62.5/125 µm fiber cable segment

- 19.0 dB or less for a 100/140 µm fiber cable segment

• Budget and Propagation Delay: When you determine the maximum

fiber optic cable length to incorporate fiber runs into your network, you

must calculate and consider the fiber optic budget (a total loss of

10.0 dB or less is permissible between stations) and total network

propagation delay.

To determine the fiber optic budget, combine the optical loss due to

the fiber optic cable, in-line splices, and fiber optic connectors.

Typical loss for a splice and connector (together) equals 1 dB or less.

EMM-E6 Installation Guide C-3

Page 58

Appendix C: Ethernet Cabling Requirements

Network propagation delay is the amount of time it takes a packet to

travel from the sending device to the receiving device. Total

propagation delay allowed for the entire network must not exceed

25.6 µs in one direction (51.2 µs round trip). If the total propagation

delay between any two nodes on the network exceeds 25.6 µs, you

must use bridges or switches.

• Length: The maximum possible multimode fiber optic cable length is

2 Km (1.24 miles). However, IEEE 802.3 FOIRL specifications

specify a maximum of 1 Km (0.62 miles).

C.1.3 Single Mode Fiber Optic Network

When connecting a single mode fiber optic link segment to a hub (using

an EPIM-F3), ensure the network meets the following requirements:

• Cable T ype: Fiber optic link segments should consist of 8/125 or

12/125 µm single mode fiber optic cabling. You can also use

62.5/125 µm multimode cable with the EPIM-F3; however, multimode

cable allows for greater optical loss, and limits the possible distance to

2 Km.

• Attenuation: You must test the fiber optic cable with a fiber optic

attenuation test set adjusted for a 1300 nm wavelength. This test

verifies that the signal loss in a cable falls within the acceptable level

of 10.0 dB or less for any given single mode fiber optic link.

• Budget and Propagation Delay: When you determine a maximum

fiber optic cable length, you must calculate and consider the fiber optic

budget (a total loss of 10.0 dB or less between stations) and total

network propagation delay.

To determine the fiber optic budget, combine the optical loss due to

the fiber optic cable, in-line splices, and fiber optic connectors.

Typical loss for a splice and connector (together) equals 1 dB or less.

Network propagation delay is the amount of time it takes a packet to

travel from the sending device to the receiving device. Total

propagation delay for the entire network must not exceed 25.6 µs in

one direction (51.2 µs round trip). If the total propagation delay

exceeds 25.6 µs, you must use bridges or switches to re-time the

signal.

C-4 EMM-E6 Installation Guide

Page 59

Network Requirements

• Length: If you meet all system budgets, the maximum single mode

fiber optic cable length can reach 5 Km (3.1 miles) with bridges or

switches at each segment end. FOIRL specifications specify a

maximum of 1 Km (0.62 miles).

C.1.4 10BASE2 Coaxial Cable Network

When connecting a thin coaxial cable segment to your hub (using an

EPIM-C), ensure your network meets the following requirements:

• Cable T ype: Use only 50 ohm RG-58 A/U type coaxial cable for thin

coaxial cable segments.

• Length: The thin coaxial cable segment must not exceed 185 meters.

• Terminators: Terminate each end of a thin coaxial cable segment.

• Connectors: You can use up to 29 T-connectors throughout the length

of the cable segment for host connections. Ensure that all connections

are spaced 0.5 meters or more from one another or from terminators.

If you use an excessive number of barrel connectors within the cable

segment (e.g., finished wall plates with BNC feed-throughs), you may

need to reduce the number of host connections. For special network

design information, contact Cabletron Systems Technical Support.

• Grounding: For safety, ground only one end of a thin coaxial cable

segment. Do NOT connect EPIM BNC ports to earth ground.

Connecting a thin coaxial cable segment to earth ground at

more than one point could produce dangerous ground currents.

C.1.5 Transceiver Requirements

When you connect an external network segment to an EPIM-A in your

hub through a transceiver, that transceiver must meet IEEE 802.3

standards or Ethernet version 1.0 or 2.0 requirements. The transceiver

must also have SQE disabled.

EMM-E6 Installation Guide C-5

Page 60

Appendix C: Ethernet Cabling Requirements

C-6 EMM-E6 Installation Guide

Page 61

INDEX

Numerics