Page 1

6H123-50 and 6H133-37 MicroLAN

SmartSwitch 6000 Interface Modules

User’s Guide

Ethernet

6H123-50

CPU

C

C

O

O

N

N

N

N

1

1

C

C

O

O

N

N

N

N

2

2

Ethernet

6H133-37

C

C

C

C

C

CPU

C

O

O

O

O

O

O

N

N

N

N

N

N

N

N

N

N

N

N

3

2

1

3

2

1

10

10

C

C

C

C

C

C

O

O

O

O

O

O

COM

N

N

N

N

N

N

N

N

N

N

N

N

1

2

3

1

2

3

100

100

1

1

C

C

O

O

N

N

N

N

3

3

12

12

1

12

C

C

C

C

C

C

C

C

O

O

O

O

O

O

O

O

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

4

3

2

1

4

3

2

1

10

10

C

C

C

C

C

C

C

C

COM

O

O

O

O

O

O

O

O

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

4

3

2

1

4

3

2

1

100

100

1

12

1

12

1

C

C

O

O

N

N

N

N

3

3

12

1

C

C

O

O

N

N

N

N

4

4

12

C

C

O

O

N

N

N

N

1

1

C

C

O

O

N

N

N

N

2

2

9032276-04

5

6

Page 2

Page 3

Only qualified personnel should perform installation

procedures.

NOTICE

Cabletron Systems reserves the right to make changes in specifications and other information

contained in this document without prior notice. The reader should in all cases consult Cabletron

Systems to determine whether any such changes have been made.

The hardware, firmware, or software described in this manual is subject to change without notice.

IN NO EVENT SHALL CABLETRON SYSTEMS BE LIABLE FOR ANY INCIDENTAL,

INDIRECT, SPECIAL, OR CONSEQUENTIAL DAMAGES WHATSOEVER (INCLUDING BUT

NOT LIMITED TO LOST PROFITS) ARISING OUT OF OR RELATED TO THIS MANUAL OR

THE INFORMATION CONTAINED IN IT, EVEN IF CABLETRON SYSTEMS HAS BEEN

ADVISED OF, KNOWN, OR SHOULD HAVE KNOWN, THE POSSIBILITY OF SUCH

DAMAGES.

1998 by Cabletron Systems, Inc., P.O. Box 5005, Rochester, NH 03866-5005

All Rights Reserved

Printed in the United States of America

Order Number: 9032276-04 September 1998

Cabletron Systems, SPECTRUM, LANVIEW, QuickSET, S

trademarks and

All other product names mentioned in this manual may be trademarks or registered trademarks of

their respective companies.

SecureFast Switching

and

SmartSwitch

ecureFast

are trademarks of Cabletron Systems, Inc.

, and

BRIM

are registered

FCC NOTICE

This device complies with Part 15 of the FCC rules. Operation is subject to the following two

conditions: (1) this device may not cause harmful interference, and (2) this device must accept any

interference received, including interference that may cause undesired operation.

NOTE:

device, pursuant to Part 15 of the FCC rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is operated in a commercial environment.

This equipment uses, generates, and can radiate radio frequency energy and if not installed in

accordance with the operator’s manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause interference in which case the user

will be required to correct the interference at his own expense.

WARNING:

party responsible for compliance could void the user’s authority to operate the equipment.

This equipment has been tested and found to comply with the limits for a Class A digital

Changes or modifications made to this device which are not expressly approv ed by the

6H123-50 and 6H133-37 User’s Guide i

Printed on Recycled Paper

Page 4

Notice

INDUSTRY CANADA NOTICE

This digital apparatus does not exceed the Class A limits for radio noise emissions from digital

apparatus set out in the Radio Interference Regulations of the Canadian Department of

Communications.

Le présent appareil numérique n’émet pas de bruits radioélectriques dépassant les limites applicables

aux appareils numériques de la class A prescrites dans le Règlement sur le brouillage radioélectrique

édicté par le ministère des Communications du Canada.

VCCI NOTICE

This is a Class A product based on the standard of the Voluntary Control Council for Interference by

Information Technology Equipment (VCCI). If this equipment is used in a domestic environment,

radio disturbance may arise. When such trouble occurs, the user may be required to take corrective

actions.

CABLETRON SYSTEMS, INC. PROGRAM LICENSE AGREEMENT

IMPORTANT:

This document is an agreement between you, the end user, and Cabletron Systems, Inc. (“Cabletron”)

that sets forth your rights and obligations with respect to the Cabletron software program (the

“Program”) contained in this package. The Program may be contained in firmware, chips or other

media. BY UTILIZING THE ENCLOSED PRODUCT, YOU ARE AGREEING TO BECOME

BOUND BY THE TERMS OF THIS AGREEMENT, WHICH INCLUDES THE LICENSE AND

THE LIMITATION OF WARRANTY AND DISCLAIMER OF LIABILITY. IF YOU DO NOT

AGREE TO THE TERMS OF THIS AGREEMENT, PR OMPTLY RETURN THE UNUSED

PRODUCT TO THE PLACE OF PURCHASE FOR A FULL REFUND.

Before utilizing this product, carefully read this License Agreement.

ii 6H123-50 and 6H133-37 User’s Guide

Page 5

CABLETRON SOFTWARE PROGRAM LICENSE

Notice

1. LICENSE

package subject to the terms and conditions of this License Agreement.

You may not copy, reproduce or transmit any part of the Program except as permitted by the

Copyright Act of the United States or as authorized in writing by Cabletron.

2. OTHER RESTRICTIONS. You may not reverse engineer, decompile, or disassemble the

Program.

3. APPLICABLE LA W. This License Agreement shall be interpreted and governed under the laws

and in the state and federal courts of New Hampshire. You accept the personal jurisdiction and

venue of the New Hampshire courts.

. You have the right to use only the one (1) copy of the Program provided in this

EXCLUSION OF WARRANTY AND DISCLAIMER OF LIABILITY

1. EXCLUSION OF

writing, Cabletron makes no warranty, expressed or implied, concerning the Program (including

its documentation and media).

CABLETRON DISCLAIMS ALL WARRANTIES, OTHER THAN THOSE SUPPLIED TO

YOU BY CABLETRON IN WRITING, EITHER EXPRESSED OR IMPLIED, INCLUDING

BUT NOT LIMITED TO IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE, WITH RESPECT TO THE PROGRAM, THE

ACCOMPANYING WRITTEN MA TERIALS, AND ANY A CCOMPANYING HARDW ARE.

WARRANTY. Except as may be specifically provided by Cabletron in

2. NO LIABILITY FOR CONSEQUENTIAL DAMAGES. IN NO EVENT SHALL

CABLETRON OR ITS SUPPLIERS BE LIABLE FOR ANY DAMAGES WHATSOEVER

(INCLUDING, WITHOUT LIMITATION, DAMAGES FOR LOSS OF BUSINESS,

PROFITS, BUSINESS INTERRUPTION, LOSS OF BUSINESS INFORMATION, SPECIAL,

INCIDENTAL, CONSEQUENTIAL, OR RELIANCE DAMAGES, OR OTHER LOSS)

ARISING OUT OF THE USE OR INABILITY TO USE THIS CABLETRON PRODUCT,

EVEN IF CABLETRON HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH

DAMAGES. BECAUSE SOME STATES DO NOT ALLOW THE EXCLUSION OR

LIMITATION OF LIABILITY FOR CONSEQUENTIAL OR INCIDENTAL DAMAGES, OR

ON THE DURATION OR LIMITATION OF IMPLIED WARRANTIES, IN SOME

INSTANCES THE ABOVE LIMITATIONS AND EXCLUSIONS MAY NOT APPLY TO

YOU.

UNITED STATES GOVERNMENT RESTRICTED RIGHTS

The enclosed product (a) was developed solely at private expense; (b) contains “restricted computer

software” submitted with restricted rights in accordance with Section 52227-19 (a) through (d) of the

Commercial Computer Software - Restricted Rights Clause and its successors, and (c) in all respects

is proprietary data belonging to Cabletron and/or its suppliers.

For Department of Defense units, the product is licensed with “Restricted Rights” as defined in the

DoD Supplement to the Federal Acquisition Regulations, Section 52.227-7013 (c) (1) (ii) and its

successors, and use, duplication, disclosure by the Government is subject to restrictions as set forth in

subparagraph (c) (1) (ii) of the Rights in Technical Data and Computer Software clause at

252.227-7013. Cabletron Systems, Inc., 35 Industrial Way, Rochester, New Hampshire 03867-0505.

6H123-50 and 6H133-37 User’s Guide iii

Page 6

Notice

SAFETY INFORMATION

CLASS 1 LASER TRANSCEIVERS

THE FE-100F3 FAST ETHERNET INTERFACE MODULE, FPIM-05 AND

FPIM-07 FDDI PORT INTERFACE MODULES, AND APIM-29 ATM

PORT INTERFACE MODULE USE CLASS 1 LASER TRANSCEIVERS.

READ THE FOLLOWING SAFETY INFORMATION BEFORE

INSTALLING OR OPERATING THESE MODULES.

The Class 1 laser transceivers use an optical feedback loop to maintain Class 1 operation limits. This

control loop eliminates the need for maintenance checks or adjustments. The output is factory set, and

does not allow any user adjustment. Class 1 Laser transceivers comply with the following safety

standards:

• 21 CFR 1040.10 and 1040.11 U.S. Department of Health and Human Services (FDA).

• IEC Publication 825 (International Electrotechnical Commission).

• CENELEC EN 60825 (European Committee for Electrotechnical Standardization).

When operating within their performance limitations, laser transceiver output meets the Class 1

accessible emission limit of all three standards. Class 1 levels of laser radiation are not considered

hazardous.

SAFETY INFORMATION

CLASS 1 LASER TRANSCEIVERS

LASER RADIATION AND CONNECTORS

When the connector is in place, all laser radiation remains within the fiber. The maximum amount of

radiant power exiting the fiber (under normal conditions) is -12.6 dBm or 55 x 10-6 watts.

Removing the optical connector from the transceiver allows laser radiation to emit directly from the

optical port. The maximum radiance from the optical port (under worst case conditions) is

0.8 W cm-2 or 8 x 103 W m2 sr-1.

Do not use optical instruments to view the laser output. The use of optical instruments to view

laser output increases eye hazard. When viewing the output optical port, power must be

removed from the network adapter.

iv 6H123-50 and 6H133-37 User’s Guide

Page 7

DECLARATION OF CONFORMITY

Notice

Application of Council Directive(s):

Manufacturer’s Name:

Manufacturer’ s Address:

European Representative Name:

European Representative Address:

Conformance to Directive(s)/Product Standards:

Equipment Type/Environment:

89/336/EEC

73/23/EEC

Cabletron Systems, Inc.

35 Industrial Way

PO Box 5005

Rochester, NH 03867

Mr. J. Solari

Cabletron Systems Limited

Nexus House, Newbury Business Park

London Road, Newbury

Berkshire RG13 2PZ, England

EC Directive 89/336/EEC

EC Directive 73/23/EEC

EN 55022

EN 50082-1

EN 60950

Networking Equipment, for use in a

Commercial or Light

Environment.

Industrial

We the undersigned, hereby declare, under our sole responsibility, that the equipment packaged

with this notice conforms to the above directives.

Manufacturer Legal Representative in Europe

Mr. Ronald Fotino Mr. J. Solari

___________________________________ ___________________________________

Full Name Full Name

Principal Compliance Engineer Managing Director - E.M.E.A.

___________________________________ ___________________________________

Title Title

Rochester, NH, USA Newbury, Berkshire, England

___________________________________ ___________________________________

Location Location

6H123-50 and 6H133-37 User’s Guide v

Page 8

Notice

vi 6H123-50 and 6H133-37 User’s Guide

Page 9

CONTENTS

CHAPTER 1 INTRODUCTION

1.1 Using This Guide.........................................................................1-1

1.2 Structure of This Guide................................................................1-2

1.3 Overview......................................................................................1-3

1.3.1 Connectivity ....................................................................1-5

1.3.2 Full Duplex Switched Ethernet........................................ 1-6

1.3.3 Auto-Negotiation.............................................................1-6

1.3.4 SmartTrunking ................................................................1-6

1.3.5 Management................................................................... 1-7

1.3.6 Switching Options...........................................................1-7

1.3.7 Standards Compatibility.................................................. 1-7

1.3.8 LANVIEW Diagnostic LEDs............................................1-8

1.3.9 Year 2000 Compliant......................................................1-8

1.3.10 Runtime IP Address Discovery.......................................1-8

1.3.11 Local Management Features..........................................1-9

1.4 Optional Features........................................................................1-9

1.5 Document Conventions.............................................................1-11

1.6 Getting Help...............................................................................1-12

1.7 Related Manuals........................................................................1-13

CHAPTER 2 NETWORK REQUIREMENTS

2.1 SmartTrunk..................................................................................2-1

2.2 10BASE-T Network .....................................................................2-1

2.3 100BASE-TX Network.................................................................2-2

2.4 100BASE-FX Fiber Optic Network ..............................................2-2

CHAPTER 3 INSTALLATION

3.1 Required Tools............................................................................3-1

3.2 Unpacking the 6H123-50 and 6H133-37.....................................3-1

3.3 Options........................................................................................3-2

3.4 Installing the 6H123-50 and 6H133-37 into the 6C105 Chassis..3-2

3.5 Connecting to the Network..........................................................3-5

3.5.1 Connecting UTP Cables .................................................3-6

3.5.2 Connecting a Twisted Pair Segment to the FE-100TX...3-7

3.5.3 Connecting a Fiber Optic Segment to the

FE-100FX and FE-100F3 ...............................................3-9

6H123-50 and 6H133-37 User’s Guide vii

Page 10

Contents

CHAPTER 4 TROUBLESHOOTING

4.1 Using LANVIEW...........................................................................4-1

4.2 FE-100TX LED.............................................................................4-6

4.3 Troubleshooting Checklist............................................................4-7

4.4 Using the RESET Button .............................................................4-8

CHAPTER 5 LOCAL MANAGEMENT

5.1 Overview......................................................................................5-1

5.2 Local Management Keyboard Conventions.................................5-3

5.3 Management Terminal Setup.......................................................5-4

5.3.1 Console Cable Connection..............................................5-5

5.3.2 Management Terminal Setup Parameters ......................5-6

5.3.3 Telnet Connections .........................................................5-7

5.3.4 Monitoring an Uninterruptible Power Supply...................5-8

5.4 Accessing Local Management...................................................5-10

5.4.1 Navigating Local Management Screens........................5-11

5.4.2 Selecting Local Management Menu Screen Items........5-13

5.4.3 Exiting Local Management Screens..............................5-13

5.5 Main Menu Screen.....................................................................5-15

5.6 Chassis Menu Screen................................................................5-16

5.7 Chassis Configuration Screen ...................................................5-18

5.7.1 Setting the Subnet Mask...............................................5-21

5.7.2 Setting the IP Address...................................................5-21

5.7.3 Setting the Chassis Date...............................................5-23

5.7.4 Setting the Chassis Time ..............................................5-24

5.7.5 Entering a New Screen Refresh Time...........................5-24

5.7.6 Setting the Screen Lockout Time..................................5-25

5.8 SNMP Community Names Screen.............................................5-26

5.8.1 Establishing Community Names ...................................5-28

5.9 SNMP Traps Screen..................................................................5-29

5.9.1 Configuring the Trap Table............................................5-30

5.10 Chassis Environmental Information Screen...............................5-31

5.11 Port Redirect Function Screen...................................................5-32

5.11.1 Displaying the Source and Destination Entries.............5-34

5.11.2 Changing Source and Destination Ports.......................5-35

5.12 Module Selection Screen...........................................................5-36

5.12.1 Selecting a Module........................................................5-37

5.13 Module Menu Screen.................................................................5-38

5.14 Module Configuration Menu Screen ..........................................5-40

viii 6H123-50 and 6H133-37 User’s Guide

Page 11

Contents

5.15 General Configuration Screen...................................................5-42

5.15.1 Setting the IP Address..................................................5-45

5.15.2 Setting the Subnet Mask............................................... 5-47

5.15.3 Setting the Default Gateway.........................................5-48

5.15.4 Setting the TFTP Gateway IP Address.........................5-48

5.15.5 Setting the Module Date ...............................................5-49

5.15.6 Setting the Module Time...............................................5-50

5.15.7 Entering a New Screen Refresh Time ..........................5-50

5.15.8 Setting the Screen Lockout Time.................................. 5-51

5.15.9 Setting the Operational Mode.......................................5-52

5.15.10Setting the Management Mode..................................... 5-53

5.15.11Configuring the COM Port ............................................5-54

5.15.11.1 Changing the COM Port Application ............5-56

5.15.12Clearing NVRAM ..........................................................5-57

5.15.13Enabling/Disabling IP Fragmentation ...........................5-58

5.16 SNMP Community Names Screen............................................5-58

5.16.1 Establishing Community Names...................................5-60

5.17 SNMP Traps Screen..................................................................5-62

5.17.1 Configuring the Trap Table...........................................5-63

5.18 Switch Configuration Screen.....................................................5-64

5.18.1 Setting the STA............................................................. 5-67

5.18.2 Setting the Age Time ....................................................5-67

5.18.3 Setting (Enabling or Disabling) the Port Status ............5-68

5.19 Module Specific Configuration Screen ......................................5-68

5.20 System Resources Screen........................................................5-70

5.20.1 Setting the Reset Peak Utilization ................................5-72

5.21 High Speed Interface Configuration Screen (6H123-50 Only) ..5-72

5.21.1 Configuring an FE-100FX or FE-100F3........................5-75

5.21.1.1 Setting the FE-100FX or FE-100F3

Operational Mode.........................................5-75

5.21.2 Configuring an FE-100TX.............................................5-76

5.21.2.1 Setting the FE-100TX Operational Mode.....5-76

5.21.2.2 Setting the FE-100TX Advertised Ability......5-76

5.22 Flash Download Screen ............................................................5-77

5.22.1 Image File Download Using TFTP................................5-80

5.22.2 Image File Download Using Runtime ...........................5-80

5.22.3 Image File Download Using BootP...............................5-81

5.23 Port Redirect Function Screen ..................................................5-82

5.23.1 Displaying the Source and Destination Entries............. 5-84

5.23.2 Changing Source and Destination Ports....................... 5-85

5.24 Broadcast Suppression Screen.................................................5-86

5.24.1 Setting the Threshold.................................................... 5-88

5.24.2 Setting the Reset Peak Switch .....................................5-88

6H123-50 and 6H133-37 User’s Guide ix

Page 12

Contents

5.25 VLAN Main Menu (802.1Q) Screen...........................................5-89

5.26 Repeater Configuration Menu Screen .......................................5-90

5.27 Repeater Port Configuration Screen..........................................5-92

5.27.1 Setting the Port Operating Mode...................................5-94

5.27.2 Enabling /Disabling Ports..............................................5-95

5.27.3 Setting All Ports.............................................................5-95

5.27.4 Enabling/Disabling Network Ports.................................5-96

5.28 Module Level Security Configuration.........................................5-96

5.28.1 Setting the Module Level Security.................................5-99

5.29 Port Level Security Configuration Screen................................5-100

5.29.1 Setting the Port Level Security....................................5-103

5.30 Module Statistics Menu Screen ...............................................5-104

5.31 Switch Statistics Screen...........................................................5-106

5.32 Interface Statistics Screen.......................................................5-108

5.32.1 Displaying Interface Statistics .....................................5-111

5.32.2 Using the Clear Counters Command ..........................5-112

5.33 RMON Statistics Screen..........................................................5-112

5.33.1 Displaying RMON Statistics ........................................5-116

5.33.2 Using the Clear Counters Command ..........................5-116

5.34 Repeater Statistics Screen ......................................................5-117

5.34.1 Displaying Network Statistics......................................5-120

5.34.2 Displaying Repeater Statistics ....................................5-120

5.34.3 Using the Clear Counters Command ..........................5-121

5.35 Network Tools..........................................................................5-121

5.35.1 Built-in Commands......................................................5-123

5.35.2 Special Commands.....................................................5-132

APPENDIX A SPECIFICATIONS

A.1 Device Specifications.................................................................. A-1

A.2 Physical Properties..................................................................... A-1

A.3 Environmental Requirements...................................................... A-1

A.4 Input/Output Ports....................................................................... A-2

A.5 COM Port Pinout Assignments................................................... A-2

A.6 Regulatory Compliance............................................................... A-3

APPENDIX B FE-100TX, FE-100FX AND FE-100F3

SPECIFICATIONS

B.1 FE-100TX.................................................................................... B-1

B.2 FE-100FX.................................................................................... B-2

B.3 FE-100F3.................................................................................... B-3

x 6H123-50 and 6H133-37 User’s Guide

Page 13

Contents

APPENDIX C OPTIONAL INSTALLATIONS AND

MODE SWITCH BANK SETTINGS

C.1 Required Tools............................................................................C-1

C.2 Setting the Mode Switches..........................................................C-1

C.3 Installing Optional Fast Ethernet Interface Modules....................C-4

INDEX

6H123-50 and 6H133-37 User’s Guide xi

Page 14

Contents

xii 6H123-50 and 6H133-37 User’s Guide

Page 15

CHAPTER 1

INTRODUCTION

W elcome to the Cabletron Systems

SmartSwitch 6000 Interface Modules User’s Guide

6H123-50 and 6H133-37 MicroLAN

. This guide

describes the 6H123-50 and 6H133-37 interface modules and provides

information concerning network requirements, installation,

troubleshooting, and Local Management.

1.1 USING THIS GUIDE

Read through this guide completely to understand the interface module

features, capabilities, and Local Management functions. A general

working knowledge of Ethernet and IEEE 802.3 type data

communications networks and their physical layer components is helpful

when using these devices.

Unless noted differently, the inf ormation in this guide applies to

NOTE

both SmartSwitch 6000 interface modules, which are referred

to as either the “6H123-50 and 6H133-37” or the “modules”.

6H123-50 and 6H133-37 User’s Guide 1-1

Page 16

Chapter 1:

Introduction

1.2 STRUCTURE OF THIS GUIDE

This guide is organized as follows:

Chapter 1,

Introduction

, outlines the contents of this manual, describes

the features of the 6H123-50 and 6H133-37, provides instructions on

obtaining additional help and concludes with a list of related manuals.

Chapter 2,

Network Requirements

, explains the network requirements

to consider before installing the 6H123-50 and 6H133-37 into the 6C105

SmartSwitch 6000 chassis.

Chapter 3,

Installation

, provides instructions on how to install the

modules in the chassis and connect segments to the devices.

Chapter 4,

Troubleshooting

, details the 6H123-50 and 6H133-37

LANVIEW LEDs that enable you to quickly diagnose

network/operational problems.

Chapter 5,

Local Management

, describes accessing Local Management

and using the Local Management screens to manage the 6H123-50 and

6H133-37 modules, and the 6C105 chassis.

Appendix A,

Specifications

, contains information on functionality and

operating specifications, connector pinouts, environmental requirements,

and physical properties.

Appendix B,

FE-100TX, FE-100FX and FE-100F3 Specifications

,

contains information about FE-100TX pinouts and information

concerning cable types used with the FE-100FX and FE-100F3.

Appendix C,

Optional Installations and Mode Switch Bank Settings

,

describes how to install optional Fast Ethernet Interf ace Modules and how

to set the Mode Switches.

1-2 6H123-50 and 6H133-37 User’s Guide

Page 17

Overview

1.3 OVERVIEW

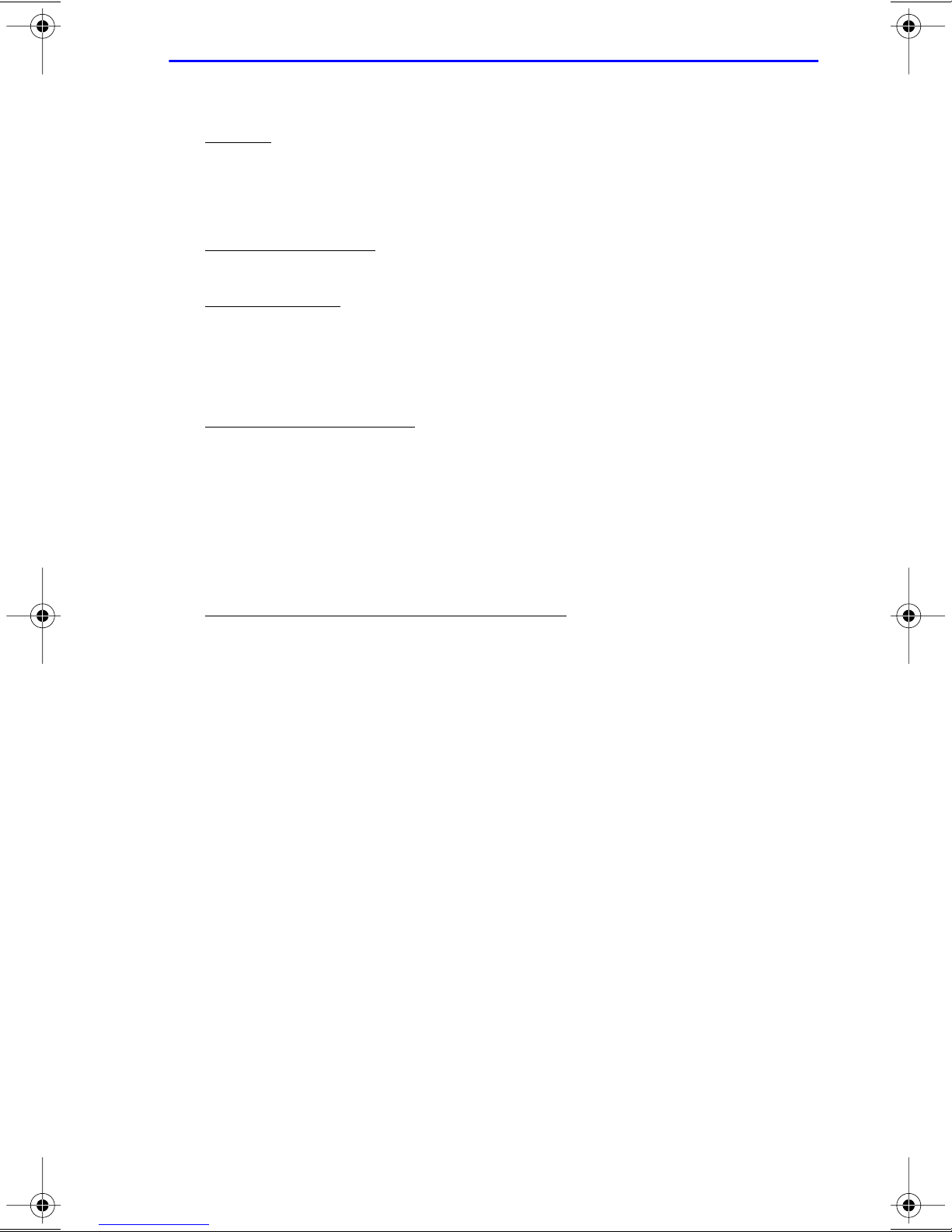

The 6H123-50 and 6H133-37, shown in Figure 1-1, are interface modules

for the Cabletron Systems 6C105 SmartSwitch 6000 chassis.

The 6H123-50 and 6H133-37 are high-speed network repeater/switch

devices. The 6H123-50 provides four Ethernet repeated segments and

four Fast Ethernet repeated segments (CONN 1 through CONN 4). The

6H133-37 provides three Ethernet repeated segments and three Fast

Ethernet repeated segments (CONN 1 through CONN 3). The RJ21

connectors each consist of 12 repeater ports that are able to reside on the

Ethernet (10 Mbps) or the Fast Ethernet (100 Mbps) segment. Each

Ethernet and Fast Ethernet segment supports 802.1D switching

(bridging), Cabletron Systems SecureFast Switching Virtual Network

technology and IEEE 802.1Q Port Based VLANs.

Slots 5 and 6 (interfaces 9 and 10) of the 6H123-50 support optional Fast

Ethernet Interface Modules providing uplinks to 100BASE-TX or

100BASE-FX Fast Ethernet networks. The 6H133-37 is capable of being

equipped with a High Speed Interface Module (HSIM) that provides for

additional connectivity to other high speed networking technologies such

as Asynchronous Transfer Mode (ATM), Fiber Distributed Data Interface

(FDDI) and Wide Area Network (WANs).

The 6H123-50 and 6H133-37 switch each Ethernet and Fast Ethernet

segment (CONN 1 through CONN 4 and CONN 1 through CONN 3) to

one another and to the optional Fast Ethernet Interface modules of the

6H123-50 or an HSIM installed in the 6H133-37.

6H123-50 and 6H133-37 User’s Guide 1-3

Page 18

Chapter 1:

Introduction

Ethernet

6H123-50

CPU

C

C

O

O

N

N

N

N

1

1

C

C

O

O

N

N

N

N

2

2

Ethernet

6H133-37

C

C

C

C

C

C

C

C

O

O

O

O

O

O

O

O

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

1

2

3

4

1

2

3

4

10

10

C

C

C

C

C

C

C

COM

1

C

O

O

O

O

O

O

O

O

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

1

2

3

4

1

2

3

4

100

100

1

C

C

O

O

N

N

N

N

3

3

COM Ports

Ethernet/Fast Ethernet

Interfaces

1 - 8

CPU

C

C

O

O

N

N

N

N

1

1

1

COM

C

C

C

C

C

C

O

O

O

O

O

O

N

N

N

N

N

N

N

N

N

N

N

N

1

2

3

1

2

3

10

10

C

C

C

C

C

C

O

O

O

O

O

O

N

N

N

N

N

N

N

N

N

N

N

N

1

2

3

1

2

3

100

100

1

C

C

O

O

N

N

N

N

3

3

1 - 6

12

1

12

1

C

C

O

O

N

N

N

N

4

4

12

1

C

C

O

O

N

N

N

N

2

2

12

12

12

12

Fast Ethernet Interface

Module Slots

(Slots 5 and 6)

5

6

HSIM Slot

2276-01

Figure 1-1 The 6H123-50 and 6H133-37

1-4 6H123-50 and 6H133-37 User’s Guide

Page 19

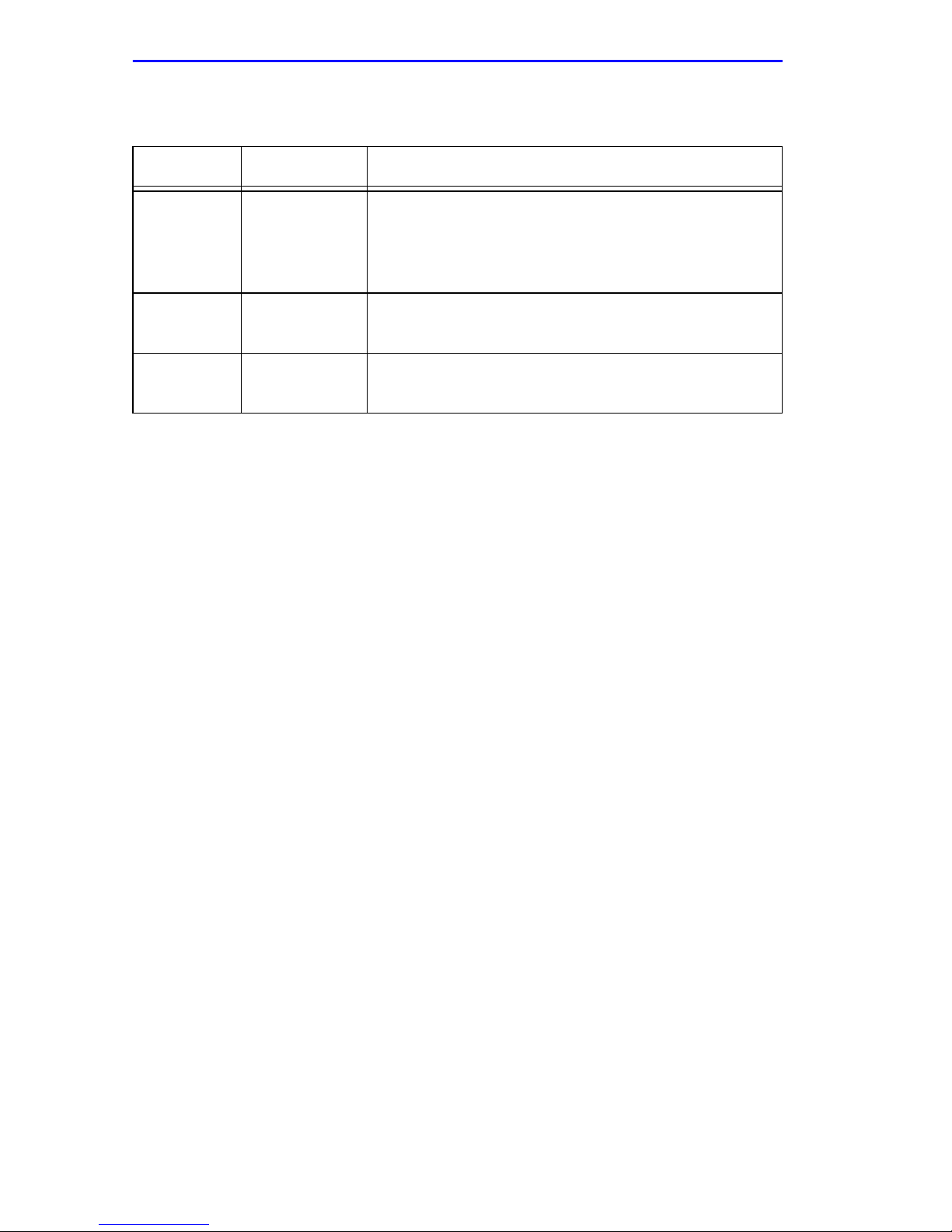

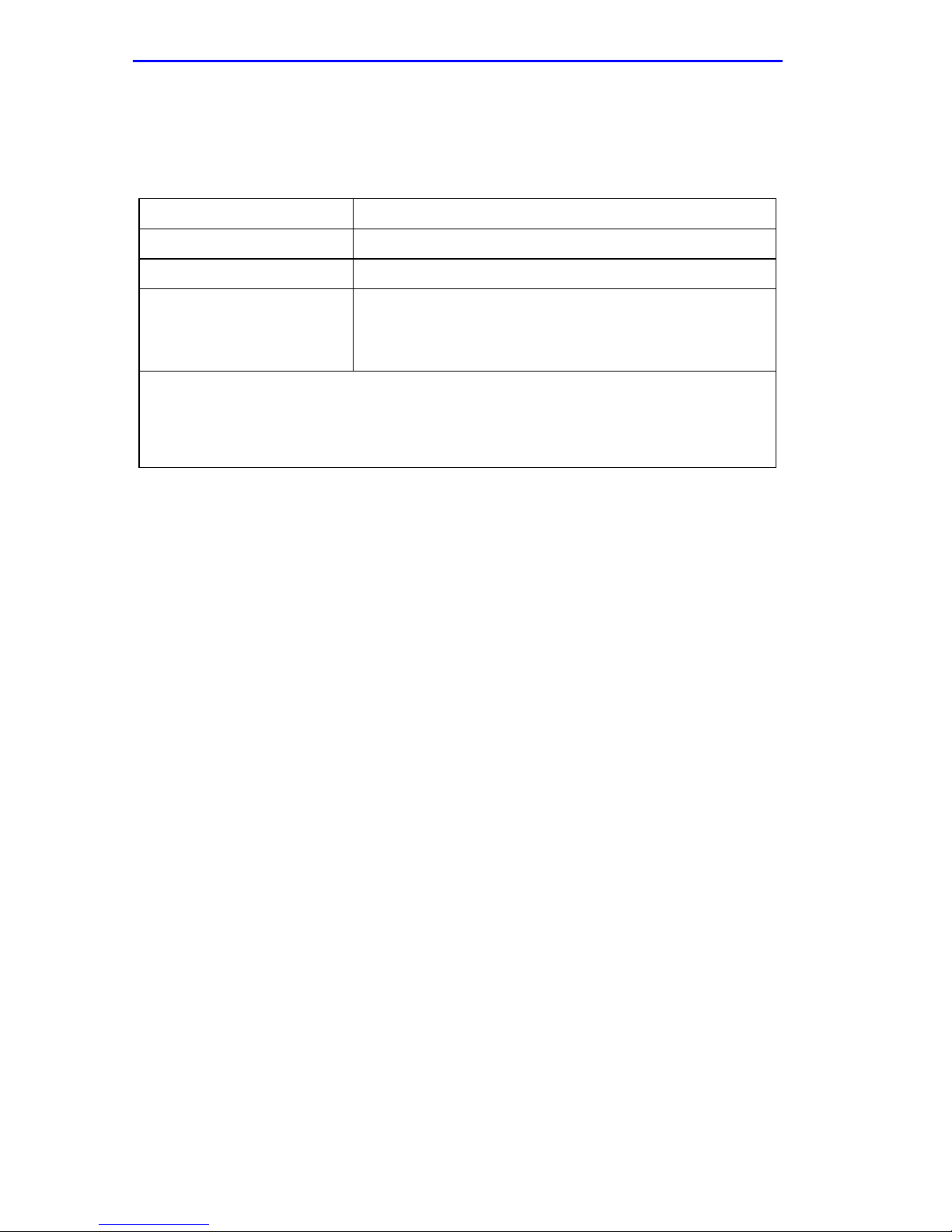

Table 1-1 shows the port organization for both modules.

Table 1-1 Port Organization

6H123-50 6H133-37

Overview

CONN 1 = Network Port 1, 10 Mbps

Network Port 2, 100 Mbps

CONN 2 = Network Port 3, 10 Mbps

Network Port 4, 100 Mbps

CONN 3 = Network Port 5, 10 Mbps

Network Port 6, 100 Mbps

CONN 4 = Network Port 7, 10 Mbps

Network Port 8, 100 Mbps

Fast Ethernet Slot 5 = Port 9

Fast Ethernet Slot 6 = Port 10

CONN 1 = Network Port 1, 10 Mbps

Network Port 2, 100 Mbps

CONN 2 = Network Port 3, 10 Mbps

Network Port 4, 100 Mbps

CONN 3 = Network Port 5, 10 Mbps

Network Port 6, 100 Mbps

HSIM = Port 7

1.3.1 Connectivity

The 6H123-50 and 6H133-37 connect to Ethernet/Fast Ethernet networks

or workstations through RJ21 ports on the front panel. Each port supports

a 25-pair cable at lengths up to 100 meters (each pair must be Category 5

compliant with an impedance of 85 to 111 ohms). The ports are IEEE

802.3 10BASE-T and IEEE 802.3u 100BASE-TX compliant.

The 6H123-50 has two front panel slots (connectors 5 and 6 or interfaces

9 and 10) for optional Fast Ethernet Interface Modules to support an

uplink to Fast Ethernet backbones or a high speed connection to a local

server.

The 6H133-37 has one front panel slot for an optional High Speed

Interface Module (Interface 7) to provide for additional connectivity to

other high speed networking technologies such as ATM, FDDI, and

WANs.

Cables available for 100BASE-TX operation include the following:

•

180° angle connector (straight-through RJ21-to-RJ21)

•

180° RJ21-to-RJ45 connector

•

120° angle connector with the same options

6H123-50 and 6H133-37 User’s Guide 1-5

Page 20

Chapter 1:

Introduction

1.3.2 Full Duplex Switched Ethernet

The optional Fast Ethernet Interface Modules for the 6H123-50 can be

configured to operate in Full Duplex Switched Ethernet mode, which

provides up to 200 Mbps of bandwidth.

1.3.3 Auto-Negotiation

The repeater ports and Fast Ethernet Interface Modules can auto-negotiate

the type of connection required to provide a link to another device.

During Auto-Negotiation, two devices automatically exchange

information “telling” each other what their operating capabilities are. The

Auto-Negotiation feature targets the maximum capabilities that can be

reached between the two devices. For example, an FE-100TX Fast

Ethernet Interface Module in a 6H123-50 can adjust to 100 Mbps when

the device on the other end of the connection can also adjust to 100 Mbps.

If the device on the other end of the connection can only operate at

10 Mbps, then the FE-100TX simply adjusts to 10 Mbps operation.

When Auto-Negotiation is supported at both ends of a link, the two

devices dynamically adjust to full or half duplex operation based on the

maximum capability that can be reached between the two devices. If the

device connected to the FE-100TX cannot auto-negotiate, the FE-100TX

Fast Ethernet Interface Module operates according to the capabilities of

the other device.

1.3.4 SmartTrunking

SmartTrunk, also referred to as SmartTrunking, is Cabletron Systems’

terminology for load balancing or load sharing. SmartTrunk technology

provides an easy-to-implement mechanism to group, or aggregate,

multiple physical links together to scale the backbone bandwidth beyond

the limitations of a single link. All links are user-configurable so

administrators can scale the backbone bandwidth by adding SmartTrunk

links. The SmartTrunk benefits are as follows:

•

All purchased bandwidth is used.

•

Distributed, resilient links increase reliability and performance.

•

Multiple technologies are supported within a single trunk for

maximum flexibility.

1-6 6H123-50 and 6H133-37 User’s Guide

Page 21

Overview

For more information about SmartTrunk, refer to the Cabletron Systems

SmartTrunk User’s Guide

.

1.3.5 Management

Management of the 6H123-50 and 6H133-37 is accomplished using

SNMP compliant management tools for in-band Local Management.

Out-of-band Local Management is provided through the RJ45 COM port

on the front panel using a VT100 terminal or a VT100 terminal emulator.

In-band remote management is possible through any SNMP compliant

Network Management Software.

Local Management provides the ability to manage the 6H123-50 and

6H133-37 and any of the optional Fast Ethernet Interface Modules

installed in slots 5 and 6 of the 6H123-50, or an optional High Speed

Interface Module (HSIM) in a 6H133-37.

The associated HSIM user’s guide provides detailed information about

the HSIM Local Management.

1.3.6 Switching Options

The 6H123-50 and 6H133-37 provide 802.1D switching, 802.1Q

switching or SecureFast Switching Virtual Network Services between all

of the front panel interfaces including Fast Ethernet Interface Modules

installed in a 6H123-50 or an HSIM installed in a 6H133-37.

IEEE 802.1Q switching and SecureFast switching allow for future

migration to Virtual Network technologies without requiring the

replacement of existing equipment.

1.3.7 Standards Compatibility

The 6H123-50 and 6H133-37 are fully compliant with the IEEE 802.3

standard and the IEEE 802.3u standard. The optional Fast Ethernet

Interface Modules are fully compliant with the IEEE 802.3u standard.

The 6H123-50 and 6H133-37 provide IEEE 802.1D Spanning Tree

Algorithm (STA) support to enhance the overall reliability of the network

and protect against “loop” conditions. The 6H123-50 and 6H133-37

support a wide variety of industry standard MIBs including RFC 1213

(MIB II), RFC 1757 (RMON), RFC 1493 (Bridge MIB) and RFC 1354

(FIB MIB). A full suite of Cabletron Systems Enterprise MIBs provide a

wide array of statistical information to enhance troubleshooting.

6H123-50 and 6H133-37 User’s Guide 1-7

Page 22

Chapter 1:

Introduction

1.3.8 LANVIEW Diagnostic LEDs

LANVIEW diagnostic LEDs serve as an important troubleshooting aid by

providing an easy way to observe the status of indi vidual ports and ov erall

network operations. Chapter 4 provides details about the 6H123-50 and

6H133-37 LANVIEW LEDs.

1.3.9 Year 2000 Compliant

These products have an internal clock that can maintain the current time

and date beyond the year 1999.

1.3.10 Runtime IP Address Discovery

This feature enables the 6H123-50 and 6H133-37 to automatically accept

an IP address from a Boot Strap Protocol (BootP) or Reverse Address

Resolution Protocol (RARP) server on the network into NVRAM without

requiring a user to enter an IP address through Local Management.

When the 6H123-50 and the 6H133-37 are connected to the network and

powered up, Runtime IP Address Discovery (RAD) checks the 6H123-50

and the 6H133-37 for an IP address. If one has not yet been assigned

(6H123-50 and 6H133-37 IP address set to 0.0.0.0), RAD checks to see if

any of the interfaces have a link. If so, RAD sends out Reverse Address

Resolution Protocol (RARP) and BootP requests to obtain an IP address

from a BootP server on the network.

The RAD requests start out at an interval of 1 second. The interval then

doubles after every transmission until an interval of 300 seconds is

reached. At this point, the interval remains at 300 seconds. The RAD

requests continue until an IP address is received from a BootP server, or

an IP address is entered using Local Management.

1-8 6H123-50 and 6H133-37 User’s Guide

Page 23

Optional Features

1.3.11 Local Management Features

Local Management provides the tools that allow management of the

6H123-50 and 6H133-37, the Fast Ethernet Interface Modules, the High

Speed Interface Module (HSIM) and the 6C105 chassis. It also allows the

following tasks to be performed:

•

Manage any module installed in the 6C105 via a single terminal

connection.

•

Assign an IP address and subnet mask to the 6H123-50, 6H133-37 and

6C105 chassis.

•

Select a default gateway.

•

Control local and remote access.

•

Designate workstations to receive SNMP traps from the 6H123-50

module, 6H133-37 module, or the 6C105 chassis.

•

Configure module specific SNMP MIB objects including the IETF

Bridge MIB objects.

Chapter 5 provides detailed information about Local Management of the

6H123-50 and 6H133-37, the optional Fast Ethernet Interface Modules

and the 6C105 chassis. The associated High Speed Interface Module

user’s guide provides detailed information about Local Management of

the applicable HSIM.

1.4 OPTIONAL FEATURES

Options for the 6H123-50 and 6H133-37 are Fast Ethernet Interface

Modules and High Speed Interface Modules, which add remote uplink

capability.

Cabletron Systems provides Fast Ethernet Interface Modules for the

6H123-50 to support uplinks to 100 Mbps Fast Ethernet backbones or

high speed connections to local servers. The Fast Ethernet Interface

Modules are listed in Table 1-2.

6H123-50 and 6H133-37 User’s Guide 1-9

Page 24

Chapter 1:

P/N Connector Application

FE-100TX

Introduction

Table 1-2 Fast Ethernet Interface Modules

Supports Shielded Twisted Pair (STP), and

Uses RJ45

connector

Category 5 Unshielded Twisted Pair (UTP)

cabling, which has an impedance of 85 to

111 ohms.

FE-100FX

FE-100F3

Uses SC

connector

Uses SC

connector

Supports multimode fiber optic cabling.

Supports single mode fiber optic cabling.

High Speed Interface Modules (HSIMs) are available from Cabletron

Systems for the 6H133-37 to provide additional connectivity to other high

speed networking technologies such as Asynchronous Transfer Mode

(ATM), Wide Area Networks (WANs) and Fiber Distributed Data

Interface (FDDI). The HSIMs a vailable for the 6H133-37 are listed in the

Release Notes.

1-10 6H123-50 and 6H133-37 User’s Guide

Page 25

Document Conventions

1.5 DOCUMENT CONVENTIONS

The following conventions are used throughout this document:

Note symbol. Calls the reader’s attention to any item of

NOTE

TIP

!

CAUTION

information that may be of special importance.

Tip symbol. Conveys helpful hints concerning procedures or

actions.

Caution symbol. Contains information essential to avoid

damage to the equipment.

Electrical Hazard Warning symbol. Warns against an action

that could result in personal injury or death due to an electrical

hazard.

6H123-50 and 6H133-37 User’s Guide 1-11

Page 26

Chapter 1: Introduction

1.6 GETTING HELP

For additional support related to this device or document, contact the

Cabletron Systems Global Call Center:

World Wide Web http://www .cabletron.com/

Phone (603) 332-9400

Internet mail support@cabletron.com

FTP ftp://ftp.cabletron.com/

Login

Password

To send comments or suggestions concerning this document, contact the

Cabletron Systems Technical Writing Department via the following

email address: TechWriting@cabletron.com

Make sure to include the document Part Number in the email message.

anonymous

your email address

Before calling the Cabletron Systems Global Call Center, have the

following information ready:

• Your Cabletron Systems service contract number

• A description of the failure

• A description of any action(s) already taken to resolve the problem

(e.g., changing mode switches, rebooting the unit, etc.)

• The serial and revision numbers of all involved Cabletron Systems

products in the network

• A description of your network environment (layout, cable type, etc.)

• Network load and frame size at the time of trouble (if known)

• The device history (i.e., have you returned the device before, is this a

recurring problem, etc.)

• Any previous Return Material Authorization (RMA) numbers

1-12 6H123-50 and 6H133-37 User’s Guide

Page 27

Related Manuals

1.7 RELATED MANUALS

The following manuals may help to set up, control, and manage the

2H23-50R and 2H33-37R:

Cabletron Systems HSIM-A6DP User’s Guide

Cabletron Systems HSIM-F6 User’s Guide

Cabletron Systems HSIM-FE6 User’s Guide

Cabletron Systems HSIM-W87 User’s Guide

Cabletron Systems HSIM-G01/G09 User’s Guide

Cabletron Systems Ethernet Technology Guide

Cabletron Systems Cabling Guide

Cabletron Systems Port Based VLAN User’s Guide

Cabletron Systems SmartTrunk User’s Guide

These manuals can be obtained from the World Wide Web in Adobe

Acrobat Portable Document Format (PDF) at the following site:

http://www.cabletron.com/

All documentation for the Cabletron Systems SecureF ast VLAN

NOTE

Manager software is contained on the VLAN Manager

CD-ROM.

Documents for the Cabletron Systems HSIM-W6 and

HSIM-W84 devices are contained on the QuickSET CD-ROM

and are also available on the World Wide Web at:

http://www.cabletron.com/

6H123-50 and 6H133-37 User’s Guide 1-13

Page 28

Chapter 1: Introduction

1-14 6H123-50 and 6H133-37 User’s Guide

Page 29

CHAPTER 2

NETWORK REQUIREMENTS

This chapter contains networking guidelines. Before installing and using

the 6H123-50 and 6H133-37 or an optional Fast Ethernet Interface

Module (FE-100TX, FE-100FX, or FE-100F3), review the requirements

and specifications outlined in this chapter concerning the following:

• SmartTrunk (Section 2.1)

• 10BASE-T Twisted Pair Network (Section 2.2)

• 100BASE-TX Twisted Pair Network (Section 2.3)

• 100BASE-FX Fiber Optic Network (Section 2.4)

The network installation must meet the guidelines to ensure satisfactory

performance of this equipment. Failure to follow the guidelines may

produce poor network performance.

NOTE

The Cabletron Systems

User’s Guide

the Cabletron Systems World Wide Web

site: http://www.cabletron.com/

, referred to in the f ollowing sections , is located on

Cabling Guide

and the

SmartTrunk

2.1 SmartTrunk

To connect the 6H123-50 and 6H133-37 to a network so they can take

advantage of the SmartTrunk feature, there are certain rules concerning

port connections and configurations that must be followed for proper

operation. Refer to the Cabletron Systems SmartTrunk User’s Guide for

additional information.

2.2 10BASE-T NETWORK

When connecting a 10BASE-T segment to any ports of CONN 1 through

CONN 4 (6H123-50) or CONN 1 through CONN 3 (6H133-37), ensure

that the network meets the IEEE 802.3 Ethernet network requirements for

10BASE-T. Refer to the Cabletron Systems Cabling Guide for details.

6H123-50 and 6H133-37 User’s Guide 2-1

Page 30

Chapter 2: Network Requirements

2.3 100BASE-TX NETWORK

When connecting a 100BASE-T segment to any ports of CONN 1

through CONN 4 (6H123-50), CONN 1 through CONN 3 (6H133-37), or

an FE-100TX installed in slot 5 or 6 of the 6H123-50, the device at the

other end of the twisted pair segment must meet IEEE 802.3u

100BASE-TX Fast Ethernet network requirements for the devices to

operate at 100 Mbps. Refer to the Cabletron Systems Cabling Guide for

details.

The 6H123-50 with an FE-100TX installed is capable of

NOTE

operating at either 10 or 100 Mbps. The FE-100TX can

automatically sense the speed of the other device and adjust

its speed accordingly.

If operating at 100 Mbps, each pair in a cable must be

Category 5 compliant with an impedance of 85 to 111 ohms.

2.4 100BASE-FX FIBER OPTIC NETWORK

Slots 5 and 6 of the 6H123-50 can also support the Cabletron Systems

FE-100FX and FE-100F3 fiber optic interface modules. The de vice at the

other end of the fiber optic segment must meet the 100BASE-FX Fast

Ethernet network requirements to operate at 100 Mbps. Refer to the

Cabletron Systems Cabling Guide for details.

Multimode Mode Fiber Optic Cable Length

The maximum multimode fiber optic cable length of a 100BASE-FX

segment is covered in the Cabletron Systems Cabling Guide.

Single Mode Fiber Cable Lengths

The maximum single mode fiber optic length of a 100BASE-FX se gment

may be no more than 5 km between Data Terminal Equipment (DTE to

DTE) in half duplex mode or 20 km (DTE to DTE) in full duplex mode.

2-2 6H123-50 and 6H133-37 User’s Guide

Page 31

CHAPTER 3

INSTALLATION

Only qualified personnel should install the 6H123-50 and

6H133-37.

This chapter provides the instructions required to install the 6H123-50

and 6H133-37, Follow the order of the sections listed below to ensure a

proper installation:

• Required tools (Section 3.1)

• Unpacking the 6H123-50 and 6H133-37 (Section 3.2)

• Installing Options (Section 3.3)

• Installing the 6H123-50 and 6H133-37 in the 6C105 chassis

(Section 3.4)

• Connecting to the network (Section 3.5)

3.1 REQUIRED T OOLS

A Phillips screwdriver is required to install the Fast Ethernet Interface

Modules in the 6H123-50.

3.2 UNPACKING THE 6H123-50 AND 6H133-37

1. Open the box and remove the packing material protecting the module.

2. Verify the contents of the carton as listed in Table 3-1.

.

Table 3-1 Contents of 6H123-50 and 6H133-37 Carton

Item Quantity

6H123-50 or 6H133-37 1

Release Notes 1

6H123-50 and 6H133-37 User’s Guide 3-1

Manual Accessory Kit 1

Page 32

Chapter 3: Installation

3.3 OPTIONS

Install any optional equipment before proceeding to

NOTE

Section 3.4.

If the 6H123-50 will be installed with an optional Fast Ethernet Interface

Module, refer to Appendix C for installation instructions. The installation

instructions for the HSIMs available for the 6H133-37 are located in the

associated user’s guide.

3.4 INSTALLING THE 6H123-50 AND 6H133-37 INTO

THE 6C105 CHASSIS

Failure to observe static safety precautions could cause

!

CAUTION

!

CAUTION

damage to the 6H123-50 and 6H133-37. Follow static safety

handling rules and properly wear the antistatic wrist strap

provided with the 6C105 chassis.

Do not cut the non-conductive bag to remove the module.

Damage could result from sharp objects contacting the board

or components.

The 6H123-50 and 6H133-37 can be installed in any of the 5 slots that are

available in the 6C105. To install a module, proceed as follows:

1. Remove the blank panel covering the slot in which the module is to be

installed. All other slots must remain covered to ensure proper airflow

and cooling. (Save the blank plate in the event you need to remove the

module.)

2. Carefully remove the module from the shipping box. (Save the box

and packing materials in the event the module must be reshipped.)

3. Locate the antistatic wrist strap shipped with the 6C105 chassis.

Attach the wrist strap to your wrist and plug the cable from the

antistatic wrist strap into the ESD grounding receptacle at the upper

right corner of the 6C105.

3-2 6H123-50 and 6H133-37 User’s Guide

Page 33

Installing the 6H123-50 and 6H133-37 into the 6C105 Chassis

4. Remove the module from the plastic bag. (Save the bag in the event

the module must be reshipped.) Observe all precautions to prevent

damage from Electrostatic Discharge (ESD).

5. Examine the module for damage. If any damage is apparent, DO NOT

install the module. Immediately contact the Cabletron Systems Global

Call Center.

To pre v ent damaging the backplane connectors in the f ollo wing

!

CAUTION

NOTE

step, ensure that the module slides in straight and properly

engages the backplane connectors.

In the following step, ensure that the top plastic locking tab

lines up with the desired slot number located on the front panel

of the chassis. Refer to Figure 3-1.

6. Locate the slot guides that line up with the number of the slot in which

the module is to be installed. Install the module in the chassis by

aligning the module circuit card between the upper and lower metal

rail guides of the desired slot, sliding it into the chassis, and locking

down the top and bottom plastic locking tabs, as shown in Figure 3-1.

Ensure that the module slides in straight and properly engages the

backplane connectors.

6H123-50 and 6H133-37 User’s Guide 3-3

Page 34

Chapter 3: Installation

Slot Number

1

2

3

45

Ethernet

6H133-37

COM

CPU

C

C

O

O

N

N

N

N

1

1

12

1

C

C

O

O

N

N

N

N

3

3

12

C

C

O

O

N

N

N

N

1

1

C

C

O

O

N

N

N

N

1

1

C

C

O

O

N

N

N

N

2

2

Plastic Locking Tab

PS1

C

C

C

C

O

O

O

O

N

N

N

N

N

N

N

N

3

2

3

2

10

10

C

C

C

C

O

O

O

O

N

N

N

N

N

N

N

N

3

2

3

2

100

100

1121

PS2

Metal Back-Panel

Figure 3-1 Installing an Interface Module

3-4 6H123-50 and 6H133-37 User’s Guide

Circuit Card

Card Guides

Plastic Locking Tab

2276_02

Page 35

Connecting to the Network

3.5 CONNECTING TO THE NETWORK

This section provides the procedures for connecting UTP and fiber optic

segments to the modules.

If the device is being installed in a network using

NOTE

The four Ethernet segments and the four Fast Ethernet segments on the

6H123-50 and the three Ethernet segments and the three Fast Ethernet

segments on the 6H133-37 can be accessed via RJ21 connectors (CONN

1 through 4 and CONN 1 through 3) for UTP connections. If a port is to

operate at 100 Mbps, each pair in a cable must be Category 5 compliant

with an impedance of 85 to 111 ohms.

SmartTrunking, there are rules concerning the cable

connections and port configurations that must be followed for

SmartTrunking to operate properly. Before connecting the

cables, refer to the Cabletron Systems

Guide

for the configuration information.

SmartTrunk User’s

Slots 5 and 6 of the 6H123-50 support FE-100TX, FE-100FX, or

FE-100F3 Fast Ethernet Interface Modules. The FE-100TX has an RJ45

connector for a Twisted Pair cable connection. The FE-100FX has an SC

style connector for a multimode fiber optic cable connection. The

FE-100F3 has an SC style connector for a single mode fiber optic cable

connection.

Refer to Section 3.5.1 to make UTP connections to interfaces CONN 1

through 4 and CONN 1 through 3 of the 6H123-50 and 6H133-37.

Refer to Section 3.5.2 to make a Twisted Pair connection to an

FE-100TX.

Refer to Section 3.5.3 to make a fiber optic connection to an FE-100FX or

FE-100F3.

Refer to the associated High Speed Interface Module user’ s guide to make

connections to an optional High Speed Interface Module installed in the

HSIM slot of a 6H133-37.

6H123-50 and 6H133-37 User’s Guide 3-5

Page 36

Chapter 3: Installation

3.5.1 Connecting UTP Cables

When facing the front panel of the 6H123-50 and 6H133-37, the RJ21

connectors represent Ethernet/Fast Ethernet segments 1 through 8 and

segments 1 through 6, respectively.

To connect a UTP segment to the 6H123-50 and 6H133-37, proceed as

follows:

1. Ensure that the device connected to the other end of the segment is

powered ON.

2. If using an RJ21 straight connector, plug it into the appropriate RJ21

port as shown in Figure 3-2.

Screw

Screw Hole

1

1

Link

Status

LEDs

C

C

O

O

N

N

N

N

3

3

12

C

C

O

O

N

N

N

N

4

4

12

Screw

Screw Hole

Figure 3-2 Connecting a Twisted Pair Segment

3-6 6H123-50 and 6H133-37 User’s Guide

2276_05

Page 37

Connecting to the Network

3. Tighten the two screws on the RJ21 connector, as applicable, to secure

it to the module.

The cable pinouts for a 25-pair cable (RJ21) can be found in

NOTE

the Cabletron Systems

details on how to obtain this document.

Cabling Guide

. Refer to Section 1.7 for

4. Verify that a link exists by checking that the port Link LEDs are on

(flashing amber, blinking green, or solid green). If any of the Link

LEDs are off, perform the following steps until they are on:

a. Verify that the de vice at the other end of the twisted pair se gment

is ON and connected to the segment.

b. Verify that the RJ21 connectors on the twisted pair segment have

the proper pinouts and check the cable for continuity.

c. Check that the twisted pair connection meets the dB loss and cable

specifications outlined in Chapter 2.

If a link is not established, contact the Cabletron Systems Global Call

Center. Refer to Section 1.6 for details.

5. Repeat steps 1 through 5, above, until all RJ21 connections are made.

3.5.2 Connecting a Twisted Pair Segment to the

FE-100TX

To ensure proper operation, use only Category 5 Unshielded

NOTE

An FE-100TX installed in slot 5 and/or 6 of the 6H123-50 has an internal

crossover switch. When connecting a workstation, use a straight-through

cabling and set the Fast Ethernet Interface Module crossover switch

shown in Figure 3-3 to the crossed over position marked X. When

connecting networking devices, such as another bridge, repeater, or

router, use a straight-through cable and set the Fast Ethernet Interface

Module crossover switch shown in Figure 3-3 to the not crossed over

position, marked with =.

Twisted Pair (UTP) cabling that has an impedance between 85

and 111 ohms.

6H123-50 and 6H133-37 User’s Guide 3-7

Page 38

Chapter 3: Installation

If the wires do not cross over, use the switch on the FE-100TX to

internally cross over the RJ45 port. Figure 3-3 shows how to properly set

the FE-100TX crossover switch.

Position X

(crossed over)

1. RX+

2. RX-

3. TX+

4. NC

5. NC

x

=

6. TX-

7. NC

FE-100TX

8. NC

Figure 3-3 FE-100TX Crossover Switch

Position =

(not crossed over)

1. TX+

10

2. TX-

100

3. RX+

4. NC

5. NC

6. RX-

7. NC

8. NC

16651_05

Connect an FE-100TX to a twisted pair segment as follows:

1. Ensure that the device connected to the other end of the segment is

powered ON.

2. Connect the twisted pair segment to the module by inserting the RJ45

connector on the twisted pair segment into the RJ45 port on the

module shown in Figure 3-3.

3. Verify that a link exists by checking that the port RX LED is on

(flashing amber, blinking green, or solid green). If the RX LED is off,

perform the following steps until it is on:

a. Verify that the 100B ASE-TX device at the other end of the twisted

pair segment is powered ON.

b. Verify that the RJ45 connector on the twisted pair segment has the

proper pinouts.

c. Check the cable for continuity.

d. Make sure that the twisted pair connection meets dB loss and cable

specifications outlined in Section 2.3.

e. Confirm that the crossover switch is in the correct position.

If a link is not established, contact the Cabletron Systems Global Call

Center. Refer to Section 1.6 for details.

3-8 6H123-50 and 6H133-37 User’s Guide

Page 39

Connecting to the Network

3.5.3 Connecting a Fiber Optic Segment to the

FE-100FX and FE-100F3

The FE-100FX and FE-100F3 have an SC style network port (see

Figure 3-4). Cabletron Systems supplies fiber optic cable that uses SC

style connectors that are keyed to ensure proper crossing over of the

transmit and receive fibers.

An odd number of crossovers (preferably one) must be

!

CAUTION

maintained between devices so that the transmit port of one

device is connected to the receive port of the other device and

vice versa.

If the fiber optic cable being used has SC style connectors that

do not resemble MIC style connectors, or has SC connectors

on one end and a different type on the other, such as ST

connectors, ensure that the proper crossing over occurs.

Fiber Optic Network Connection

1. Remove the protective plastic covers from the fiber optic ports on the

applicable port on the module and from the ends of the connectors.

The FE-100F3 uses Class 1 lasers. Do not use optical

!

CAUTION

!

CAUTION

instruments to view the laser output. The use of optical

instruments to view laser output increases eye hazard. When

viewing the output optical port, remove power from the netw ork

adapter.

Do not touch the ends of the fiber optic strands, and do not let

the ends come in contact with dust, dirt, or other contaminants.

Contamination of the ends causes problems in data

transmissions. If the ends become contaminated, blow the

surfaces clean with a canned duster. A fiber port cleaning swab

saturated with optical-grade isoprop yl alcohol may also be used

to clean the fiber optic ends.

2. Insert one end of the SC connector into the FE-100FX or FE-100F3

installed in the 6H123-50. See Figure 3-4.

3. At the other end of the fiber optic cable, attach the SC connector to the

other device.

6H123-50 and 6H133-37 User’s Guide 3-9

Page 40

Chapter 3: Installation

1960-34

Figure 3-4 Connecting a Fiber Optic Segment

TX LED

RX LED

FE-100FX

65

16

4. Verify that a link exists by checking that the port RX LED is on

(flashing amber, blinking green, or solid green). If the RX LED is off

and the TX LED is not blinking amber, perform the following steps

until it is on:

The port RX LED flashes green and amber during bootup.

NOTE

a. Check that the power is turned on for the de vice at the other end of

the link.

b. Verify proper crossing over of fiber strands between the

applicable port on the 6H123-50 and the fiber optic device at the

other end of the fiber optic link segment.

c. Verify that the fiber connection meets the dB loss specifications

outlined in Section 2.4.

If a link has not been established, contact the Cabletron Systems Global

Call Center. Refer to Section 1.6 for details.

The 6H123-50 and 6H133-37 are now ready to be set up through Local

Management. Refer to Chapter 5 to configure the modules and 6C105

chassis.

3-10 6H123-50 and 6H133-37 User’s Guide

Page 41

CHAPTER 4

TROUBLESHOOTING

This chapter provides information concerning the following:

• Using the LANVIEW diagnostic and status monitoring system

(Section 4.1)

• FE-100TX LED (Section 4.2)

• Troubleshooting network and module operational problems

(Section 4.3)

• Using the RESET button (Section 4.4)

4.1 USING LANVIEW

The 6H123-50 and 6H133-37 use Cabletron Systems built-in visual

diagnostic and status monitoring system called LANVIEW. The

LANVIEW LEDs (Figure 4-1) allow quick observation of the network

status to aid in diagnosing network problems. Refer to Table 4-1 for a

description of the LEDs.

For a functional description of the LANVIEW LED on the optional Fast

Ethernet Interface Module (FE-100TX), refer to Section 4.2.

All LEDs for the High Speed Interface Module (HSIM) are located on the

HSIM and are described in the associated HSIM user’s guide.

The terms flashing, blinking, and solid used in the LED

NOTE

definition tables of this chapter indicate the following:

Flashing indicates an irregular LED pulse.

Blinking indicates a steady LED pulse (approximately 50% on

and 50% off).

Solid indicates a steady LED light. No pulsing.

6H123-50 and 6H133-37 User’s Guide 4-1

Page 42

Chapter 4: Troubleshooting

CPU LED

Ethernet

6H133-37

CPU

C

C

O

O

N

N

N

N

1

1

C

C

O

O

N

N

N

N

2

2

12

1

1

COM

Receive (RX)

Transmit (TX)

C

C

C

C

C

C

O

O

O

O

O

O

N

N

N

N

N

N

N

N

N

N

N

N

1

2

3

1

2

3

10

10

C

C

C

C

C

C

O

O

O

O

O

O

N

N

N

N

N

N

N

N

N

N

N

N

1

2

3

1

2

3

100

100

1

Ethernet Interface Status LEDs

Fast Ethernet Interface Status LEDs

Repeater Port Status LEDs

C

C

O

O

N

N

N

N

3

3

Link Status

Operating

Speed

12

Port Status LEDs

12

2276_04

4-2 6H123-50 and 6H133-37 User’s Guide

Figure 4-1 LANVIEW LEDs

Page 43

Using LANVIEW

Table 4-1 LANVIEW LEDs

LED Color State Recommended Action

CPU Off Power off. Power up chassis.

Ethernet

Receive

Status

(RX) of

RJ21

Interfaces

10 Mbps

Segment

Red Blinking. Hardware

failure has occurred.

Solid. Resetting,

Contact the Cabletron

Systems Global Call Center.

No action.

normal power up reset.

Amber Blinking. Crippled. Contact the Cabletron

Systems Global Call Center.

Solid. Testing. No action.

Green Solid. Functional. No action.

Amber

and

Green

Off No link. No activity.

Booting. Blinks amber

and green while

booting.

No action.

No error.

Port enabled or

disabled.

Green Blinking. Port

No error.

disabled, link.

Amber Flashing. Port

No error.

enabled, link, activity.

Red Diagnostic failure. Contact the Cabletron

Systems Global Call Center

for assistance.

6H123-50 and 6H133-37 User’s Guide 4-3

Page 44

Chapter 4: Troubleshooting

Table 4-1 LANVIEW LEDs (Continued)

LED Color State Recommended Action

Ethernet

Transmit

Status

(TX) of

RJ21

Interfaces

10 Mbps

Segment

Off Port enabled, and no

activity.

Should flash green

every 2 seconds

indicating BPDUs

being sent if STA is

enabled and there is a

valid link.

Green Flashing. Indicates

activity. Rate indicates

data rate.

Amber Blinking. Port in

standby, link.

Port may be disabled

due to Spanning Tree.

Red Flashing. Indicates

collision rate.

Solid. Diagnostic

Failure.

No action.

No action.

No action.

No action.

Contact the Cabletron

Systems Global Call Center

for assistance.

Fast

Ethernet

Receive

Status

(RX) of

RJ21

Interfaces

100 Mbps

Segments

and ports

5 and 6 of

the

6H123-50

Off No link. No activity.

No error.

Port enabled or

disabled.

Green Blinking. Port

No error.

disabled, link.

Amber Flashing. Port

No error.

enabled, link, activity.

Red Diagnostic failure. Contact the Cabletron

Systems Global Call Center

for assistance.

4-4 6H123-50 and 6H133-37 User’s Guide

Page 45

Using LANVIEW

Table 4-1 LANVIEW LEDs (Continued)

LED Color State Recommended Action

Fast

Ethernet

Transmit

Status

(TX) of

RJ21

Interfaces

100 Mbps

Segments

and ports

5 and 6 of

the

6H123-50

Off Port enabled, and no

activity.

Should flash green

every 2 seconds

indicating BPDUs

being sent if STA is

enabled and there is a

valid link.

Green Flashing. Indicates

activity. Rate indicates

data rate.

Amber Blinking. Port in

standby, link.

Port may be disabled

due to Spanning Tree.

Red Flashing. Indicates

collision rate.

Solid. Diagnostic

Failure.

No action.

No action.

No action.

No action.

Contact the Cabletron

Systems Global Call Center

for assistance.

Repeater

Port

Status

Link

Status

Repeater

Port

Status

Operating

Speed

Status

Off No Link. No error.

Amber Flashing. Receiving

No error.

data. Flashing

indicates data rate.

Green Blinking. Port disabled

No error.

administratively.

Off Port operating at

No error.

10 Mbps, or there is no

link to the port.

Green Port operating at

No error.

100 Mbps.

6H123-50 and 6H133-37 User’s Guide 4-5

Page 46

Chapter 4: Troubleshooting

4.2 FE-100TX LED

The optional FE-100TX has one LED labeled 10/100. The 10/100 LED

together with the Receive LED allo ws the user to determine the link status

and the operating speed of the Fast Ethernet Interface Module. The

10/100 LED and the Receive (RX) LED are shown in Figure 4-2.

Table 4-2 and Table 4-3 provide a functional description of the FE-100TX

LED when the RX LED is on or off, respectively.

10

LED

100

=

x

Receive (RX)

LED

FE-100TX

10

100

22

5

6

2276-36

Figure 4-2 FE-100TX LED

A link exists if the associated FE-PIM Receive (RX) LED is on.

NOTE

Table 4-2 FE-100TX LED Indications When the RX LED Is On

LED Color Description

10/100 Off FE-100TX is operating at 10 Mbps.

Green FE-100TX is operating at 100 Mbps.

4-6 6H123-50 and 6H133-37 User’s Guide

Page 47

Troubleshooting Checklist

No link exists if the associated FE-PIM Receiv e (RX) LED is off .

NOTE

Table 4-3 FE-100TX LED Indications When the RX LED Is Off

LED Color Description

10/100 Off No link or no cable attached. FE-100TX

forced to 10 Mbps operation, or is

manually set to “auto-negotiate” mode.

Green No link or no cable attached. FE-100TX is

forced to 100 Mbps operation.

4.3 TROUBLESHOOTING CHECKLIST

If the 6H123-50 and 6H133-37 are not working properly, refer to

Table 4-4 for a checklist of possible problems, causes, and recommended

actions to resolve the problem.

Table 4-4 Troubleshooting Checklist

Problem Possible Cause Recommended Action

All LEDs are OFF. Loss of power to the

6C105 chassis.

6H123-50 and 6H133-37

not properly installed.

No Local

Management

Password screen.

Autobaud enabled, but

baud rate has not yet

been sensed.

Terminal setup is not

correct.

Improper console cable

pinouts.

Check the proper connection

of the power cable and its

access to a live outlet.

Check the installation.

Press ENTER (RETURN)

(may take up to four times).

Refer to Chapter 5 for proper

setup procedures.

Refer to Appendix A for

proper console port pinouts.

6H123-50 and 6H133-37 User’s Guide 4-7

Page 48

Chapter 4: Troubleshooting

Table 4-4 Troubleshooting Checklist (Continued)

Problem Possible Cause Recommended Action

Cannot contact the

6H123-50 or

6H133-37 from

in-band

management.

Port(s) goes into

standby for no

apparent reason.

User parameters (IP

address, Device and

Module name, etc.)

are lost when the

6E133-49 or

6E123-50 is

powered down.

Improper Community

Names Table.

6H123-50 or 6H133-37

does not have an IP

address.

Port is disabled. Enable port.

No link to device. Check link to device.

6H133-37 or 6H123-50

detects a looped

condition.

Mode switch (7), NVRAM

Reset, was changed

sometime before cycling

power causing the

user-entered parameters

to reset to factory default

settings.

Refer to Section 5.16

for Community Names Table

setup.

Refer to Section 5.15.1 for IP

address assignment

procedure.

1. Review network design

and delete unnecessary

loops.

2. Call the Cabletron

Systems Global Call

Center if problem

continues.

1. Reenter the lost

parameters as

necessary.

2. Call the Cabletron

Systems Global Call

Center if problem

continues.

4.4 USING THE RESET BUTTON

The RESET button, located near the upper plastic locking tab of the

module, (refer to Figure 4-3) resets the 6H123-50 and 6H133-37

processor.

Pressing the RESET button resets the device and all current

!

CAUTION

4-8 6H123-50 and 6H133-37 User’s Guide

switching being performed by the device is halted. A network

downtime of up to two minutes results from this action.

Page 49

RESET Button

Using the RESET Button

Ethernet

6H133-37

2276-37

Figure 4-3 RESET Button

To reset the 6H123-50 and 6H133-37 processor, press and release the

RESET button. The 6H123-50 and 6H133-37 go through a reset process

of approximately 20 seconds. Additional downtime occurs as the module

reenters the network.

6H123-50 and 6H133-37 User’s Guide 4-9

Page 50

Chapter 4: Troubleshooting

4-10 6H123-50 and 6H133-37 User’s Guide

Page 51

CHAPTER 5

LOCAL MANAGEMENT

This chapter explains setting up a management terminal to access

6H123-50 and 6H133-37 Local Management. It also explains using the

Local Management screens and commands.