CAB MACH 4.3S/300C, MACH 4.3S/200C, MACH 4.3S/200P, MACH 4S/300P, MACH 4S/300C Service Manual

...Page 1

Made in Germany

Service Manual

MACH 4S

Label Printer

Page 2

2 2

Family Type

MACH 4S - MACH 4.3S/200B

- MACH 4.3S/200P

- MACH 4.3S/200C

MACH 4S/300B MACH 4.3S/300B

MACH 4S/300P MACH 4.3S/300P

MACH 4S/300C MACH 4.3S/300C

MACH 4S/600B MACH 4S/600P MACH 4S/600C -

Edition: 12/2017 - Part No. 9003102

Copyright

This documentation as well as translation hereof are property of

cab Produkttechnik GmbH & Co. KG.

The replication, conversion, duplication or divulgement of the

whole manual or parts of it for other intentions than its original

intended purpose demand the previous written authorization by

cab.

Editor

Regarding questions or comments please contact cab

Produkttechnik GmbH & Co. KG.

Topicality

Due to the constant further development of our products

discrepancies between documentation and products can occur.

Please check www.cab.de for the latest update.

Terms and conditions

Deliveries and performances are effected under the General

conditions of sale of cab.

Service Manual

for the following product

Germany

cab Produkttechnik

GmbH & Co KG

Postfach 1904

D-76007 Karlsruhe

Wilhelm-Schickard-Str. 14

D-76131 Karlsruhe

Telefon +49 721 6626-0

Telefax +49 721 6626-249

www.cab.de

info@cab.de

France

cab technologies s.a.r.l.

F-67350 Niedermodern

Téléphone +33 388 722 501

www.cab.de/fr

info.fr@cab.de

USA

cab Technology Inc.

Tyngsboro MA, 01879

Phone +1 978 649 0293

www.cab.de/us

info.us@cab.de

Asia

cab Technology Co., Ltd.

Junghe, Taipei, Taiwan

Phone +886 2 8227 3966

www.cab.de/tw

info.asia@cab.de

China

cab (Shanghai)Trading Co., Ltd.

Phone +86 21 6236-3161

www.cab.de/cn

info.cn@cab.de

Representatives in other countries on request

Page 3

3

1 Introduction ............................................................................................................................................4

1.1 Instructions ...............................................................................................................................................4

1.1 General Safety .........................................................................................................................................5

1.2 Safety Markings .......................................................................................................................................5

1.3 Handling Electricity ..................................................................................................................................6

1.4 Conduct during Accidents ........................................................................................................................6

2 Changing Assembly Parts .....................................................................................................................7

2.1 Tools .........................................................................................................................................................7

2.2 Changing the Control Panel .....................................................................................................................7

2.3 Dismounting the Cover .............................................................................................................................8

2.4 Changing the Print Mechanism ................................................................................................................9

2.5 Changing the Printhead .........................................................................................................................10

2.6 Changing the Print Roller .......................................................................................................................12

2.7 Changing the Clutch and Brake of the Ribbon Rewinder .......................................................................13

2.8 Changing the Brake of the Ribbon Unwinder .........................................................................................14

2.9 Changing the Drive of the Cutter ............................................................................................................15

2.10 Changing the Blade of the Cutter Unit ...................................................................................................16

2.11 Changing the Circuit Board ....................................................................................................................17

2.12 Changing the Power Supply ...................................................................................................................18

3 Adjustments .........................................................................................................................................19

3.1 Measuring the Winding Force ................................................................................................................19

3.1.1 Testing the Winding Force of the Clutch and Break of the Ribbon ...................................................19

3.1.2 Measuring the Breaking Force of the Unwinder ...............................................................................20

3.2 Setting the Winding Force ......................................................................................................................21

3.3 Adjusting the Print Mechanism ...............................................................................................................22

3.3.1 Adjustable Elements .........................................................................................................................22

3.3.2 Settings.............................................................................................................................................23

4 Troubleshooting and Error Treatment ................................................................................................24

4.1 Failure of Device Functions ....................................................................................................................24

4.2 Permanently Occurring Hardware Errors ...............................................................................................24

5 Block Diagram ...................................................................................................................................... 25

6 Layout Diagram PCB CPU ................................................................................................................... 26

7 Index ......................................................................................................................................................27

Table of Content

Page 4

4 4

1.1 Instructions

Important information and the instructions in the documentation are designed as follows:

Danger!

Draws attention to an exceptionally great, imminent danger to your health or life due to hazardous

voltages.

!

Danger!

Draws attention to a danger with high risk which, if not avoided, may result in death or serious injury.

!

Warning!

Draws attention to a danger with medium risk which, if not avoided, may result in death or serious injury.

!

Caution!

Draws attention to a danger with low risk which, if not avoided, may result in minor or moderate injury.

!

Attention!

Draws attention to potential risks of property damage or loss of quality.

i

Note!

Advices to make work routine easier or on important steps to be carried out.

Environment!

Gives you tips on protecting the environment.

Handling instruction

Reference to section, position, illustration number or document.

Option (accessories, peripheral equipment, special ttings).

Time Information in the display.

1 Introduction

Page 5

5

1.1 General Safety

This service manual is intended for qualied service and maintenance personnel. Further information to the operation

of the device can be found the Operator's and Conguration Manuals.

The following rules are for your general safety

• Keep the area during and after maintenance operations clean.

• Work safety conscientious.

• Keep dismounted parts secure during maintenance operations.

• Avoid tripping hazards.

N

Danger!

Double-pole or neutral conductor safety.

Danger!

Danger of electrocution wenn stronger currents are used by connected metallic parts.

Do not wear clothing with metal.

Do not wear jewelry.

Do not wear glasses with a metal frame.

!

Warning!

Loose clothing can get caught in rotating parts of the device and can lead to injury.

When operating the device avoid wearing clothing that can get caught in rotating parts.

1.2 Safety Markings

!

Warning!

Waring of injury due to missing or damaged safety markings.

After maintenance operations reapply all protective parts, markings, covers, grounding cables, etc.

Replace all defective or damaged parts.

Wear safety goggles when:

• knocking in or out pins or similar parts with a hammer

• using spring hooks

• installing or removing springs, safety rings gripping rings

• using abrasive, cleaners, solution or other chemicals

1 Introduction

Page 6

6 6

1 Introduction

1.3 Handling Electricity

The following operations may only be performed by qualied electricians:

• Any labor performed on electrical component groups.

• Operations performed on the opened device while it is connected to the power grid.

General precautions when commencing maintenance operations:

• Locate the emergency power and/or mains switch so it is reached quickly should the need arise.

• Disconnect the power when performing the following tasks:

- Removing or installing the power supply.

- Performing work in the vicinity of opening power connectors.

- Mechanical testing of power units.

- Altering anything to do with the circuitry.

• Check that the device is not live.

• Check the work area for any potential hazards such as damp or wet oors, defective extension cords or protective

conductors.

Additional precautions when dealing with open voltage supply:

• Request a second person to stay in the vicinity and operate the emergency powers or mains switch if and when

required.

• Only use one hand when working with electronic circuits. Keep the other hand behind your back or in a pocket. By

doing so you prevent electricity from owing though the body.

1.4 Conduct during Accidents

• Act with exception caution and calmness.

• Do not put yourself at risk.

• Switch off the power.

• Request medical assistance or call an emergency doctor.

• If required and possible perform rst aid.

Page 7

7

2 Changing Assembly Parts

2.1 Tools

• Do not use worn or damaged tools.

• Only use tools and test devices for their designed purposes.

Specialized tools(cab in-house produced):

• Test devices ribbon holders (cab part no.: 5540932)

• Assembly assistance coupling (cab part no.: 5541180)

• Cylindrical dynamometer (spring scale), 0 - 10 N (cab part no.: 5906108)

Commercial tools:

• Torx screwdriver, size TX 10/200

• Allen wrenches straight, size 2,5

• Screwdriver with parallel shaft, size 4

• Flat nose pliers

2.2 Changing the Control Panel

i

Note!

When changing the control panel B or P to a control panel C (exchange to measurement version) the

dispensing edge must be removed from the device. When changing the to the other panels the dispensing

edge must be mounted. ( 2.6 on page 12).

3

2

1

4

5

2

3

Fig. 1 Changing the control panel

1. Fold the control panel (4) down.

2. Steady the device with one hand and pull the control panel along axis (3) sturdily, releasing it from its retainer (2).

3. Take hold of the control panel over the second axis and pull it until it is released from its retainer.

4. Guide the brackets (5) next to the retainers (2) out of the device.

5. Disconnect the connector (1) from the printer and set aside the control panel.

6. Connect the connector (4) of the new control panel to the printer.

7. Guide the brackets (5) along the side of the retainers (2).

8. Lift the control panel a little.

9. Push the control panel rmly into the axis (3) of the retainer (2) until you hear the axis snap into the retainer.

Page 8

8 8

2 Changing Assembly Parts

2.3 Dismounting the Cover

Danger!

Risk of death by electrocution.

Before opening or dismounting the cover disconnect the device from the power grid and wait at least

one minute until the device has discharged.

1

1

1

2

3

1

Fig. 2 Dismounting the cover

The printer cover can be dismounted completely including the front lid.

1. Open the printer cover (2) and remove the roll and material retainer.

2. Loosen 4 screws (1)

3. Remove the cover (3) with the lid (2)

To mount the cover and lid follow the above order in reverse. To make the implementation of the parts easier fold the

printing modules up.

Page 9

9

2 Changing Assembly Parts

2.4 Changing the Print Mechanism

Danger!

Risk of death by electrocution.

Before opening or dismounting the cover disconnect the device from the power grid and wait at least

one minute until the device has discharged.

6

1

2

3

4

5632

7

8

9

Fig. 3 Changing the print mechanism

1. Dismount the control panel ( 2.2 on page 7).

2. Dismount the printhead ( 2.5 on page 10).

3. Dismount the cover ( 2.3 on page 8).

4. Disconnect the cables (4) connecting the printing mechanism to the CPU circuit board.

5. Disconnect the ground wire (6) from the from CPU circuit board by undoing the screw (5).

6. After loosening the two screws (2) slide and raise the print mechanism backwards until it, with the screws (2), can

be lifted out of the adjustment slots (7).

7. Slide the new printing mechanism with the bracket (9) into the guides (8). Place the adjustment slots (7) onto the

screws (2) pushing the unit forward until the indentations (3) snap into their counterparts (6).

8. Fasten the screws (2).

9. Fasten the ground wire (6) to the CPU circuit board with screw (5).

10. Connect cables (4) to the CPU circuit board.

11. Mount the cover and lid ( 2.3 on page 8).

12. Mount the printhead ( 2.5 on page 10).

13. Mount the control panel ( 2.2 on page 7).

Page 10

10 10

2.5 Changing the Printhead

Changing a printhead can be completed without ne adjustments to the printer. Changing the printhead is necessary

when it is worn or a change of printing resolution is needed.

1

2

3

3

4

1 Connector data

2 Connector power

3 Threaded holes

4 Heating element

Fig. 4 Assembly of the printhead

!

Attention!

Damaging the printhead by electrical discharge or mechanical inuences!

Set up the printer on an grounded conduit.

Ground yourself with e.g. an anti static bracelet.

Do not touch the connectors (1, 2).

Do not touch the heating element (4) with hands or hard objects.

2 Changing Assembly Parts

Page 11

11

2 Changing Assembly Parts

5

6

7

986

12 13 126 161514 14

10 1011

Fig. 5 Changing the printhead

Removing the printhead

1. Open the cover and fold the control panel (7) down. Push the energy regulator (5) and fold the printing module up

with the printhead retainer (6).

2. Take the material out of the printer.

3. Push against the printhead retainer (6) from underneath, lifting the mounting bracket (9) over the bar (8) and then

down through the slit.

4. Pull the printhead retainer (6) out of the guide (11) of the printing module.

5. Remove the printhead (13) by undoing the screws (12) of the printhead retainer (6).

6. First remove the power cable (16) and then the data cable (15).

Installing the printhead

7. Connect the data cable (15), then the power cable (16) to the new printhead.

8. Fasten the printhead (13) with the screws (12) to the printhead retainer (6).

9. Place the printhead retainer (6) with the loop into the guide (11) and push it upward against the springs (10) where

the springs should land on the indentations (14). Guide the mounting bracket (9) through the slit towards the top

and over the bar (8) until it locks in place.

10. Install the material once more, close the control panel and cover before use.

!

Attention!

If there is a loss of quality visible on the printed label after the exchange of the printhead adjustments need

to be performed. 3.3 on page 22.

Page 12

12 12

2 Changing Assembly Parts

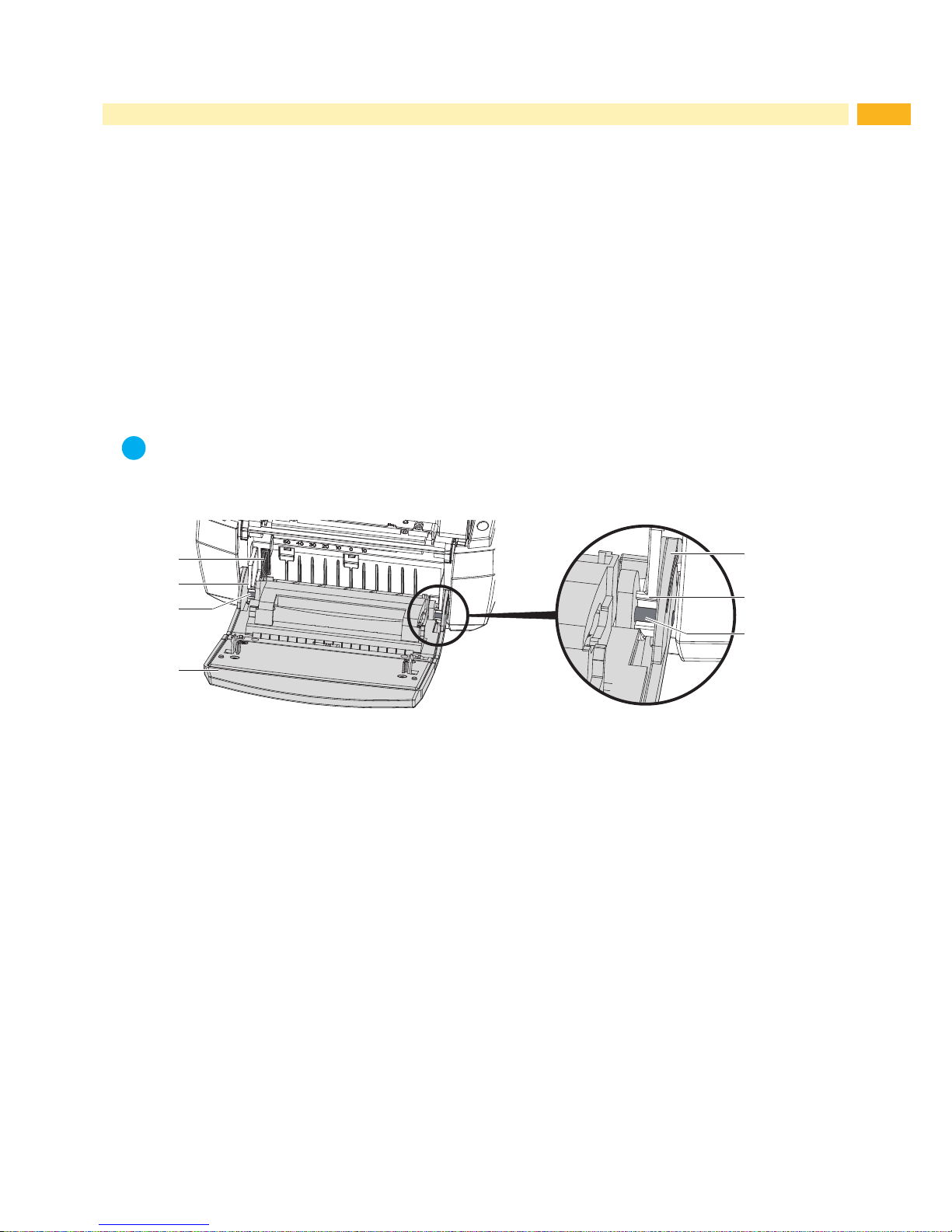

2.6 Changing the Print Roller

1 2 3

6 5

4

Fig. 6 Changing the print roller

1. Open the cover and fold the control panel down. Push the unlocking mechanism and fold the printing module up.

2. Through the openings on both sides, push the pressure points (1) until the print roller assembly (2) snaps out of

the locking mechanism. This action lifts the print roller assembly (2) a little.

3. Lift the unlocked pressure roller assembly (2) out of the device.

4. Remove the roller locking mechanism (6) from the print roller (5) and remove the dispensing edge (3) from the

roller locking mechanism (4).

5. Insert the dispensing plate (3) into the roller locking mechanism (4) of the new print roller and push the new roller

locking mechanism (6) onto the print roller and the dispensing edge.

!

Attention!

When exchanging the control panel B or P with control panel C ( 2.2 on page 7) the dispensing edge

must be removed prior to the exchange.

Connect the roll retainer (5) to the pressure roller (4) and place the assembly group, without the

dispensing edge (3), into the printer.

Follow the reverse order to achieve the opposite effect.

4. Insert the pressure roller assembly group (2) into the printer and evenly push down to lock it into place.

5. Lock the printing and control modules.

Page 13

13

2 Changing Assembly Parts

2.7 Changing the Clutch and Brake of the Ribbon Rewinder

The clutch (4) is a pre-constructed assembly group, the brake consists of the form disks (5, 7), the friction disk (6)

and three springs (9).

21

3

4

5

6

7

8

9

11

10

Fig. 7 Changing the clutch and brake of the ribbon rewinder

Dismounting

1. Fold up the printhead assembly group, loosen the three screws (2) and lift off the cover (1).

2. Close the printhead assembly group and lay the printer on its side.

3. Undo the snap ring (3) and remove clutch (4), form disks (5, 7), friction disk (6), springs (9) and tension wheel

(11).

Mounting

1. Place the springs (9) into the frame (10).

2. Place and hold the tension wheel (11) into the frame.

3. Set the form disks (7) in line with the retainers (8) of the frame.

4. Place the friction disk (6), form disks (5) and clutch (4) as illustrated.

5. Push the clutch and tension wheel against the frame and fasten the snap ring (3) on the axis of the tension wheel

(11).

6. Check the winding torque ( 3.1 on page 19) and correct the settings as necessary. ( 3.2 on page 21).

7. Fold the printhead assembly up and fasten the cover (1) with the three provided screws (2).

Page 14

14 14

2 Changing Assembly Parts

2.8 Changing the Brake of the Ribbon Unwinder

321

8654 7

5 6 7109 11 11 10 9 12

Fig. 8 Changing the brake of the ribbon unwinder

1. Fold up the printhead assembly group, undo the three screws (3) and remove the cover (2).

2. Insert the ribbon retainer (1).

3. Unhook the spring (4) from the pivot arm (5).

4. Hold the ribbon retainer (1), guide the pin of the mounting assistance (8 / Part No. 5541180) into the two allocated

spaces of the retainer (6). Push the mounting assistance against the printhead assembly group and turn it

counter-clockwise until the lock washer (7) releases and can be taken out.

5. Take off the retainer (6), spring (12), from disks (9, 11), friction screw (10) and pivot arm (5).

6. Set the new parts according to the illustration.

!

Attention!

Place the lock washer (7) with its markings to the outside.

7. Turn the lock washer (7) with the mounting assistance (8) clockwise until it locks into place.

8. Clip the spring (4) to the pivot arm (5).

9. Check the winding torque ( 3.1 on page 19) and adjust the settings it if necessary. ( 3.2 on page 21).

10. Fasten the cover (2) with the three screws (3) provided.

Page 15

15

2 Changing Assembly Parts

2.9 Changing the Drive of the Cutter

2 3 85 64 7

32

1

9 10 11 12 10 9

Fig. 9 Changing the drive of the cutter

1. Fold down the control panel (1), release the cutter (4) from the brackets (3) and fold this up too.

2. Unhook the springs (3).

3. Disconnect the plug (7).

4. Undo and remove the nuts (11), screws (9) with connecting rods and bearings.

5. Unlock the eccentric (10) from the shaft (6).

6. Lift out shaft (6) with the drive (8) from the base plate (12).

7. Pull the drive (8) from shaft (6).

8. To reconstruct the assembly follow these instructions in the reverse order. Place the drive into the adjustment slot

of the base plate (10).

!

Attention!

Align the pins of the eccentric (10) to the clock wheel (5) as illustrated.

Page 16

16 16

2 Changing Assembly Parts

2.10 Changing the Blade of the Cutter Unit

2 3 74 5 6

2

1

8 9 10 1211

Fig. 10 Changing the blade of the cutter unit

!

Danger!

Danger of lacerations!

Do not touch the blade without protective measures.

1. Fold down the control panel (1).

2. Release the cutter unit (3) by undoing the brackets (2) and fold it upwards.

3. Loosen the three screws (4) and the washers (5) and remove the bottom blade.

4. Loosen the three screws (8) and take off the top blade and the material guide (10).

5. Screw a new top blade and paper guide (11) to the base plate.

6. Screw a new bottom blade to the bracket (12).

i

Note!

If only the top blade (9) needs to be replaced the camp (12) with the bottom blade (6) can be hinged up from

the top blade by turning the screw (7) with a hexagonal key 2.5 mm.

!

Danger!

Danger of lacerations and crushing limbs!

While folding the panel up or down particularly when the panel is folded down the springs at the clamp

are under high tension. Do not reach between the blades.

Page 17

17

2 Changing Assembly Parts

2.11 Changing the Circuit Board

Danger!

Danger of electrocution.

Before opening the pinter cover disconnect the device from the power source and wait at least one

minute until the device has discharged the remaining residual energy.

2

1

2

3

2

4

9

5

6

28

7

1 Circuit board CPU

2 4 Screws

Connections

3 CON8 - stepper motor

4 CON9 - power supply

5 CON10 - printhead

6 CON11 - sensors

7 CON12 - control panel

8 Ground wire

9 CON13 - Ventilator

Fig. 11 Changing the CPU circuit board

1. If possible save the printer conguration onto an external memory medium Printer conguration.

2. Disconnect the printer from the power supply.

3. Disconnect all interface cables from the back of the printer.

4. Remove all removable storage mediums.

5. Remove the printer cover ( 2.3 on page 8).

6. Disconnect all push on connectors (3-7, 9) from the CPU circuit board.

7. Remove the four screws (2) of the circuit board.

8. Insert the new CPU circuit board (1) with the previous four screws (2) whilst connecting the ground wire (8).

9. Reconnect all the push on connectors (3-7, 9) to the circuit board.

10. Reassemble the cover ( 2.3 on page 8).

11. Reconnect all interface cables from the back of the printer.

12. Reestablish the power connection.

13. If required, guide the device through an update.

14. Synchronize the light barrier Conguration Manual.

15. If possible, load the settings from the removable storage device via the control panel Conguration Manual.

Page 18

18 18

2 Changing Assembly Parts

2.12 Changing the Power Supply

Warning!

Risk of death by electrocution!

Before opening the cover plate remove the device from the power supply and wait at least one minute

until the residual energy has dissipated.

1

2 2

2 3

Fig. 12 Changing the power supply

1. Remove the printer from the power supply.

2. Dismount the cover with the lid ( 2.3 on page 8).

3. Remove the CPU circuit board ( 2.11 on page 17).

4. Pull off the push on connectors (3).

5. Undo three screws (2).

6. Dismount the power supply (1).

7. Insert the new power supply (1) and fasten it with screws (2).

8. Connect the push on connector (3).

9. Reassemble the CPU circuit board.

10. Reconnect the cover and lid.

Page 19

19

3 Adjustments

3.1 Measuring the Winding Force

The measurement of the un- and re-winding torque of the ribbon is determined by the tensile force on the test

material that is connected to the ribbon retainer.

The physical connection between the torque and tensile force is as follows.

F= M / r

F: force [N],

M: torque [Ncm],

r: Radius of the test material (30 mm)

3.1.1 Testing the Winding Force of the Clutch and Break of the Ribbon

1

2

A B

C

3

1

2 3

1

2 3

Fig. 13 Testing the winding torque of the clutch and break.

Target Value Measurement Torque M Force F

Clutch of the rewinder ribbon A 14,4 - 17,4 Ncm 4,8 - 5,8 N

Break of the rewinder ribbon B 2,7 - 4,5 Ncm 0,9 - 1,5 N

1. Place the test device (3) on the ribbon retainer (2). Note that the Spring tip must be placed in the grove of the

ribbon retainer for a true result.

2. Close the printhead assembly group and employ the spring scale connecting it to the rewinder with the test device

(3) inserted.

3. To measure the clutch force wind the string around the test device (3) numerous times as illustrated in A.

4. Connect the spring scale [10 N] (1) to the end of the string and move it upwards vertically until the test device

starts to turn.

5. Unravel the string at least one full revolution of the test device and measure the force F of the clutch from the

spring scale.

6. If the torque deviates from the target values set it anew. ( 3.2 on page 21).

7. To measure the breaking force wind the string around the test device (3) numerous times as illustrated in B and

repeat the process.

8. If the force of the breaking force deviates from the target values the break need to be replaced as there are no

settings possible. ( 2.7 on page 13).

Page 20

20 20

3 Adjustments

3.1.2 Measuring the Breaking Force of the Unwinder

C

1

2 3

Fig. 14 Measuring the breaking force of the unwinder

Target Value Measurement Torque M Force F

Break of the unwinder ribbon C 3,9 - 4,5 Ncm 1,3 - 1,5 N

1. Insert the test device (3) onto a ribbon retainer (2). Note that the Spring tip must be placed in the grove of the

ribbon retainer for a true result.

2. Open the printhead assembly group and insert the ribbon retainer (2) with the inserted test device (3) onto the

rewinder.

3. To measure the breaking force wrap the string around the test device (3) as illustrated in C.

4. Connect the spring scale [10 N] (1) to the end of the string and pull it upwards vertically until the test device starts

to turn.

5. Pull until the test device complete a full revolution and measure the force F of the break.

6. If the results deviate from the target values change the settings.( 3.2 on page 21).

Page 21

21

3.2 Setting the Winding Force

8765

1 2 3

4

Fig. 15 Setting the winding force

The settings of the winding force of the break (5) of the unwinder and the clutch (6) of the rewinder is done in the

same way.

1. Insert the ribbon retainer (4) onto the winders.

2. Fold the printhead assembly group up and undo the three screws (8) and remove the cover (7).

3. Hold the ribbon retainer, push holder (2) towards the frame (1) turning it to the desired position and let go, taking

note that the straps of the locks (3) are all the way in the provided gaps.

4. Test the winding force again and compare it to the these to the test values and correct if necessary.

5. refasten the cover (7) with three screws (8).

i

Note!

The numbers of the retainer (2) are not setting values. They are an orientation when setting the winding

force.

1: smallest winding force, 7: largest winding force

3 Adjustments

Page 22

22 22

3 Adjustments

3.3 Adjusting the Print Mechanism

Changing the settings of the printing mechanic over and above a format change is only necessary when something

other than the printhead is exchanged or if the printhead assembly group has been demounted or altered.

The following identiers point towards resetting the printing mechanic:

- Printed image too light

- Printed image blotchy or spotty

- Printed image too light on one side

- Horizontal lines not parallel to the to the label edge

- Clear sideways drift of the ribbon

i

Note!

Check the ribbon as creases in it may cause image errors.

3.3.1 Adjustable Elements

2 3 1

4 5

1

6 6

Fig. 16 Adjustable elements

Screws for horizontal settings (1)

- Turning the screw clockwise will move the printhead forward.

- Turning the screw counter clockwise will move the printhead backwards.

For an optimal image the heat element must be set to align to the highest point of the pressure roller. In this position

the print image blackening is at its best. Besides that this setting allows the realignment of horizontal lines with the

dispensing edge.

Screws for setting the printhead (6)

- Turning of the screws in a clockwise fashion lessens the printhead pressure to the corresponding side.

- Turning the screws counter clockwise increase the pressure.

Increasing the pressure of the print by turning screw (6) counter clockwise will darken the image on the corre-

sponding side and shift the ribbon ow toward the opposite side.

!

Attention!

Turn the screw (6) counter clockwise carefully as an excess will demount parts completely.

Page 23

23

3 Adjustments

Screw for adjusting the camber (3)

- By turning the screw clockwise the printhead will be changed minimally in the center causing pressure in the

middle of the printhead.

If all else fails to decrease creases in the ribbon the printhead can be altered by turning the screw clockwise. It is

recommended to proceed with the utmost caution when performing these alterations.

!

Attention!

Danger of causing damage to parts of the device.

As soon as there is a distinguishable resistance when turning the screw do not turn it more than another

90°.

The result is that the image will be lightened along the outside edges of the image compared to the middle.

3.3.2 Settings

1. Insert material (labels and ribbon) that covers the entire printing width.

2. Congure the printer to heating power 0 and printing speed 100 mm/s.

3. Turn the camber screw (3) counter clockwise until the resistance subsides. This should be about half a revolution.

4. Undo screw (2) and by turning screw (1) align the marking (4) to the middle segments (5) of the graduation.

5. Perform test prints with "test grid" labels or the like.

6. If the horizontal lines of the test grid are not parallel to the label edge adjust the alignment with screw (1).

7. Use screw (6) to adjust the printhead pressure. Turn the screw only until turning becomes easier.

8. Reduce the heat of the heating element so far that the printed image is light. By doing misalignments become

easy to spot.

9. Test via a grind print increasing the pressure of the side of the printhead where the image is lighter. This is

achieved by turning the screw (6) counter clockwise by about a quarter revolution or until the printed image

appears evenly printed.

10. Turn screw (1) counter clockwise and push the printhead backwards until the printed image almost disappears.

Now turn screw (1) clockwise until the image has reached it darkest value. Take note of the horizontal alignment.

11. Fasten screw (2).

12. Check the ribbon uptake. If the ribbons runs to the right turn the right screw (1) by a quarter revolution counter

clockwise. If the ribbon runs left turn the left screw (1) counter clockwise by a quarter revolution. Test the ribbon

uptake after every adjustment and wait until it has stabilized before attempting further adjustments.

13. In the case of creasing on both edges simultaneously adjust the camber of the printhead. For this carefully turn

the screw (3) clockwise. Turn this screw as little as possible. A slight decrease in printing strength of the image

may be expected.

!

Attention!

Danger of causing damage to the device.

As soon as there is a distinguishable resistance when turning the screw do not turn it more than another

90°.

14. If there is no camber adjustment necessary turn screw (3) clockwise until it clamps down minimally.

15. Turn down the heating energy in the conguration to 0 and test these results of the previous adjustments. With

normal cab-standard material a clearcut, solid black printed image should have been achieved.

Page 24

24 24

4 Troubleshooting and Error Treatment

4.1 Failure of Device Functions

Function error Possible solutions

No material transport Check electronic connection between the CPU circuit board and the motor

Check the drive mechanism

Exchange the CPU circuit board

Exchange the motor

No printed image at material

transport

Check connectors of the printhead

Inspect the printhead cable for damage

Exchange the printhead

Exchange the CPU circuit board

Display does not work Check the cable connection between the CPU circuit board and the control panel

Swap out the display

Exchange the CPU circuit board

No communication over the

interface

Check the connection from the printer to the computer

With Ethernet connections check the validity of the IP address and the subnet

mask.

Check, and if necessary change, the interface cable

In case of complete outage exchange the CPU circuit board

A peripheral device does not

work

Check if the peripheral device is connected via programming

Ensure the USB cable of the peripheral device is working and exchange it if

necessary

Test the peripheral device

Exchange the CPU circuit board

Table 1 Failure of device functions

4.2 Permanently Occurring Hardware Errors

Error message Cause Solution

Printhead thermistor defect

Thermistor of the printhead

broken

Exchange the printhead

Voltage error

V

BAT

Voltage of the battery on the

CPU circuit board too low

Exchange the CPU circuit board

24 V

24 V too little Check voltage at measuring point +24V

Fig. 18 on page 26:

• Voltage too low:

Swap out power supply

• Voltage sufcient:

Exchange the CPU circuit board

24 V TPH

24 V too low for printhead Check voltage at measuring point +24V TPH

Fig. 18 on page 26:

• Voltage too low:

Swap out power supply

• Voltage sufcient:

Exchange the CPU circuit board

Table 2 Hardware errors

Page 25

25

5 Block Diagram

Printer Nr.1

MACH 4S/300... 5977444

MACH 4S/600... 5977380

MACH 4.3S/200... 5977382

MACH 4.3S/300... 5977383

Fig. 17 Block diagram

Page 26

26 26

6 Layout Diagram PCB CPU

1

L6

12

R130

L57

C185

R323

B6

22

C391

R37

P6

R131

R33

R159

2

R304

V19

1

G

B

+

C13

K

R61

R220

V11

G

X1

V

M

R305

TOP21

N

R22

C14

R268

L27

1

V1

R64

L12

AC

C16

V18

9

C205

C208

10

R270

C341

L

B3

A1

C73

C255

20

C211

4

R169

5

C192

C256

L43

L15

C214

1

R70

1

15

C246

C193

+

C215

V12

A

A

P9

N6

TOP25

C259

R96

C194

L

C216

E

C26

D

L21

K

TOP16

AA

C264

R

D4

C217

U1

V24

T

R97

V15

L60

C272

L50

3

C224

C221

TOP7

R60

D

L70

L61

C262

13

C276

CON1

C223

R170

P

K1

23

R1

L62

R140

C17

C279

C201

8

L31

C289

R84

4

K

L63

C8

C280

U7

18

C202

CD

R107

R126

C6

C

C10

3

1top

WP

C203

C232

1

R141

U8

C

K

TOP11

P

R89

H

R4

C11

Buchse

L29

TOP5

H

C210

N

R72

AE

R68

R65

T

C235

L83

R237

W

R5

C212

C291

2

R74

R42

R73

L5

6

G

1

C242

C292

1

R168

R122

TOP26

16

L13

C234

#FD2

Gn

25

C282

C324

R99

F1

C240

11

TOP17

C286

L73

R213

21

P5

L3

V14

A

2

F

R19

9

C243

C321

+

E

R119

R219

F

TOP1

U

L

L56

M

R56

R120

D3

L64

R87

AB

C252

R572

TOP20

C198

8

L53

C12

9

R88

R25

L10

K

R573

C200

19

R100

R574

R48

4

L37

L24

R101

B2

N5

D15

14

R575

CON10

L38

TOP14

24

D2

P8

2

1

R47

1

R137

TOP9

J

R568

R116

D

TOP4

C153

C

R27

U3

J

R66

C263

D13

Y

C342

C113

P

F2

K

R571

C154

R

R29

L48

R69

TOP15

C270

C314

2

L2

C348

C155

C

L18

C265

12

C116

R102

N

R6

K2

TOP23

C156

22

C293

L71

L33

3

C148

C260

R121

C266

C152

7

C1

L51

C149

C320

CON2

17

L93

P2

R142

C161

R132

L34

C9

L39

C258

B

U2

2

C184

GND

R123

R256

R35

CON12

C162

A

R59

B

N

R117

G

R215

1

R75

C261

G

R125

L68

M

C2

C28

C163

AC

D14

R71

CON4

R108

V

R136

C187

C307

R166

1

L90

V13

V7

C164

C5

5

R280

F

R77

C308

L25

R160

C213

C160

15

C207

2

R253

V21

R139

C42

C204

1

R163

C169

L42

L80

TOP6

C268

CON17

10

C15

R209

R78

C271

3

L14

#FD3

C170

N1

R98

C196

20

1

P4

CON9

C225

C209

C309

1

U4

R171

L66

H1

R31

C171

K

8

L1

C313

25

R85

E

C310

T

R172

K

B5

C27

C351

C172

R150

L30

C352

L

R2

C325

C220

C311

L59

R227

V9

C168

AA

C112

7

R58

R303

R3

C302

C312

C158

8

C183

C175

R158

J

TOP19

C199

C267

V10

18

C304

K

C345

C159

R254

L9

C180

C176

L58

C206

3

V20

2

C322

C346

C166

R255

E1

C181

C177

13

C3

N4

C323

C347

C167

23

V25

R20

R245

P7

C182

C178

R23

B1

C285

14

H

R76

C

C349

C114

TOP22

G2

R247

CON5

C150

C174

B

R62

R26

H

C4

W

N

L16

V2

C230

C237

C350

R41

P

L28

R566

V17

C151

R63

H7

B4

C283

C335

AD

C231

C239

R567

B

C222

R301

TOP13

11

D5

M

L89

R155

A2

H4

L17

TOP8

21

1

C338

C275

L72

L40

C241

1

D1

6

R298

C186

C327

L74

C274

C339

L49

TOP3

16

C245

P1

TOP24

C278

H5

E

C340

1

1bot

GND

1

L20

G6

C300

R299

C288

C66

M

F

R24

F

L

CON3

CON11

AB

C303

H6

C77

C343

U

R11

L69

L67

A

R294

R300

R55

C157

4

C344

1

E

2

14

C301

TOP12

C165

C290

L23

R

1

L36

24

R134

C277

C197

+

C173

C296

L75

R236

9

1

C295

R109

R36

C179

19

C297

P3

L87

L32

R295

R44

N2

1

D

7

C219

AE

D

R

L35

L84

J

R45

R32

N3

J

C287

#FD1

P

AD

TOP2

1

Y

R34

C269

K

CON8

L26

C299

3

C72

7

R30

R151

H

R569

R54

L4

V3

CON7

17

R21

1

T

Ye

TOP10

R111

R152

TOP18

2

R570

L52

L85

CON13

Measuring points of CON9:

GND

+24V

+V

MOT

(+24V)

Measuring point on the PCB:

TOP2 +24V

TOP3 +5V

TOP25 +24V TPH

TOP26 +V

MOT

(+24V)

LED on the PCB:

H1 +3,3V

H7 LED FPGA

on during start

procedure blinking

after the start

procedure

Fig. 18 Layout diagram PCB CPU

Page 27

27

7 Index

A

Adjustable elements

.........................22

Adjusting the print mechanism

.........22

B

Block diagram

...................................25

C

Changing the brake

of the ribbon unwinder

......................14

Changing the clutch and brake

of the ribbon rewinder

.......................13

Changing the control panel.................7

Changing the drive of the cutter

.......15

Changing the power supply

..............18

Changing the printhead

....................10

Changing the print mechanism

...........9

Changing the print roller

...................12

D

Dismounting the cover

........................8

F

Failure of device functions

................24

G

General safety

....................................5

M

Measuring the breaking force

of the unwinder

.................................20

Measuring the winding force.............19

P

Permanently occurring hardware

errors

................................................24

S

Safety markings

..................................5

Settings.............................................23

Setting the winding force

..................21

T

Testing the winding force

..................19

Tools

...................................................7

Loading...

Loading...