Page 1

Operator's Manual

Label Dispenser

HS/VS

Made in Germany

Page 2

2 2

Operator's Manual

- Translation of the Original Version for the following products

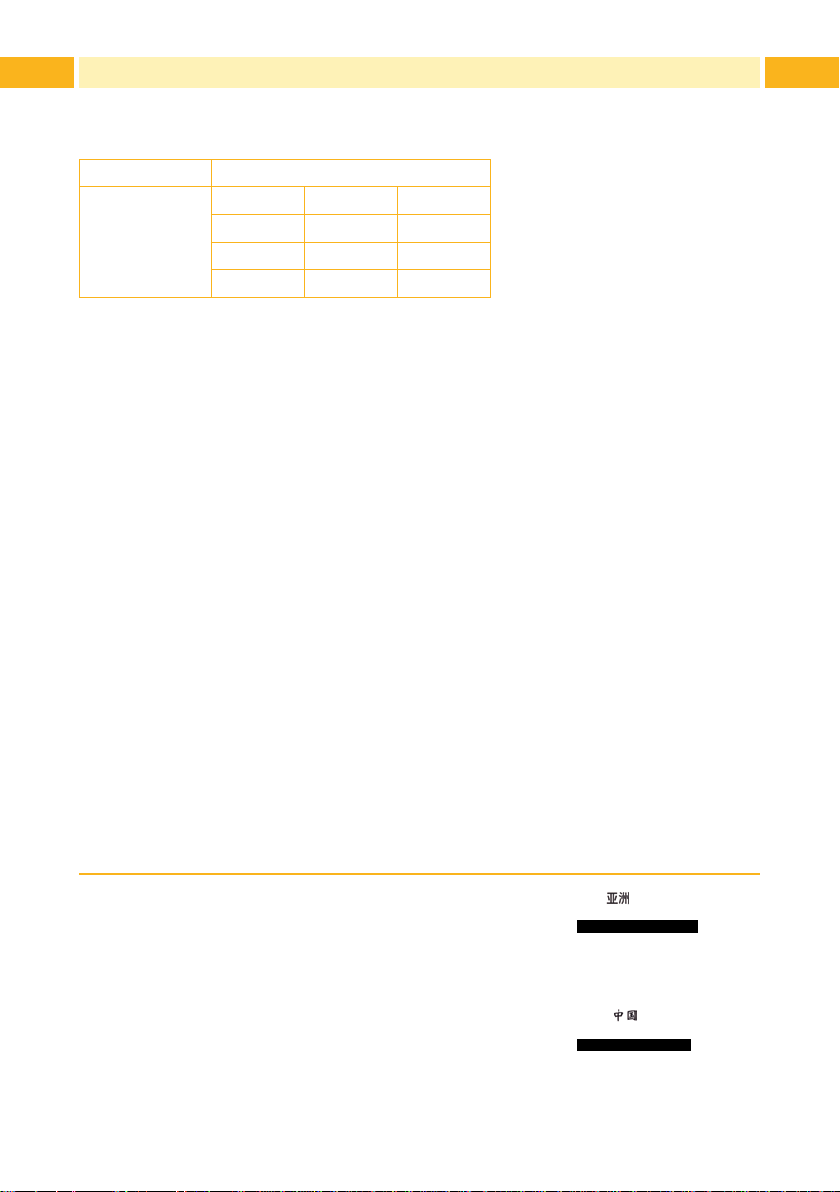

Family Type

HS/VS HS 60 HS 120 -

HS 60+ HS 120+ HS 180+

VS 60 VS 120 -

VS 60+ VS 120+ VS 180+

Edition: 02/2016 - Part No. 9009292

Copyright

This documentation as well as translation hereof are property of cab Produkttechnik GmbH &

Co. KG.

The replication, conversion, duplication or divulgement of the whole manual or parts of it for

other intentions than its original intended purpose demand the previous written authorization by

cab.

Editor

Regarding questions or comments please contact cab Produkttechnik GmbH & Co. KG.

Topicality

Due to the constant further development of our products discrepancies between documentation

and product can occur.

Please check www.cab.de for the latest update.

Terms and conditions

Deliveries and performances are effected under the General conditions of sale of cab.

Germany

cab Produkttechnik

GmbH & Co KG

Postfach 1904

D-76007 Karlsruhe

Wilhelm-Schickard-Str. 14

D-76131 Karlsruhe

Telefon +49 721 6626-0

Telefax +49 721 6626-249

www.cab.de

info@cab.de

Representatives in other countries on request

France

cab technologies s.a.r.l.

F-67350 Niedermodern

Téléphone +33 388 722 501

www.cab.de/fr

info.fr@cab.de

USA

cab Technology Inc.

Tyngsboro MA, 01879

Phone +1 978 649 0293

www.cab.de/us

info.us@cab.de

Asia

cab Technology Co., Ltd.

Junghe, Taipei, Taiwan

Phone +886 2 8227 3966

www.cab.de/tw

info.asia@cab.de

China

cab (Shanghai)Trading Co., Ltd.

Phone +86 21 6236-3161

www.cab.de/cn

info.cn@cab.de

Page 3

1 Introduction ....................................................................................4

1.1 Product Description .........................................................................4

1.2 Instructions ......................................................................................4

1.3 Intended Use ...................................................................................5

1.4 Safety Instructions ...........................................................................5

1.5 Environment .....................................................................................6

2 Installation ......................................................................................7

2.1 Device Overview ..............................................................................7

2.2 Unpacking and Setting-up the Device .............................................8

2.3 Connecting the Device .....................................................................8

2.3.1 Connecting to the Power Supply ..................................................8

2.3.2 Connecting to the External Control ..............................................9

3 Loading Material ..........................................................................10

3.1 Loading Labels ..............................................................................10

3.2 Adjusting the Present Sensor ........................................................11

4 Operation ......................................................................................12

4.1 HS / VS ..........................................................................................12

4.1.1 Operation ....................................................................................12

4.1.2 Error Treatment ..........................................................................13

4.2 HS+ / VS+ ......................................................................................14

4.2.1 Switching on the Device .............................................................14

4.2.2 Operation Modes ........................................................................15

4.2.3 Setting Speed .............................................................................16

4.2.4 Resetting Counter ......................................................................16

4.2.5 Error Treatment ..........................................................................16

4.2.6 Adjusting the Dispense Plate .....................................................17

32 Table of Contents

5 EU Declaration of Conformity .....................................................18

Page 4

4 4

!

!

i

1 Introduction

1.1 Product Description

The device is a semiautomatic label dispenser for peeling-off and presenting

labels from roll for further manual processing.

1.2 Instructions

Important information and instructions in this documentation are designated

as follows:

Danger!

Draws your attention to an exceptionally grave, impending danger

to your health or life.

Warning!

Indicates a hazardous situation that could lead to injuries or

material damage.

Attention!

Draws attention to possible dangers, material damage or loss of

quality.

Notice!

Gives you tips. They make a working sequence easier or draw

attention to important working processes.

Environment!

Gives you tips on protecting the environment.

Handling instruction

Reference to section, position, illustration number or document.

Option (accessories, peripheral equipment, special ttings).

Page 5

i

1 Introduction

1.3 Intended Use

• The device is intended exclusively for peeling-off suitable label materials.

Any other use or use going beyond this shall be regarded as improper use.

The manufacturer/supplier shall not be liable for damage resulting from

unauthorized use; the user shall bear the risk alone.

• The device is manufactured in accordance with the current technological

status and the recognized safety rules. However, danger to the life and

limb of the user or third parties and/or damage to the device and other

tangible assets can arise during use.

• The device may only be used for its intended purpose and if it is in perfect

working order, and it must be used with regard to safety and dangers as

stated in the operating manual.

• Usage for the intended purpose also includes complying with the operating

manual, including the manufacturer‘s maintenance recommendations and

specications.

Notice!

The complete documentation can also currently be found in the

Internet.

1.4 Safety Instructions

• The device is congured for voltages of 100 to 240 V AC. It only has to be

plugged into a grounded socket.

• Switch off all affected devices before connecting or disconnecting.

• The device may only be used in a dry environment, do not expose it to

moisture (sprays of water, mists, etc.).

• Do not use the device in an explosive atmosphere.

• Do not use the device close to high-voltage power lines.

• Ensure that people‘s clothing, hair, jewelry etc. do not come into contact

with the exposed rotating parts.

• Perform only those actions described in this operating manual.

Work going beyond this may only be performed by trained personnel or

service technicians.

• Unauthorized interference with electronic modules or their software can

cause malfunctions.

• Other unauthorized work on or modications to the device can also

endanger operational safety.

• Always have service work done in a qualied workshop, where the

personnel have the technical knowledge and tools required to do the

necessary work.

54

Page 6

6 6

1 Introduction

• There are various warning stickers on the device. They draw your attention

to dangers.

Warning stickers must therefore not be removed, as then you and other

people cannot be aware of dangers and may be injured.

• The maximum sound pressure level is less than 70 dB(A).

Danger!

Danger to life and limb from power supply.

Do not open the device casing.

Notice for Service :

Danger!

Double pol/neutral fusing !

1.5 Environment

Obsolete devices contain valuable recyclable materials that should be sent

for recycling.

Send to suitable collection points, separately from residual waste.

The modular construction of the device enables it to be easily disassembled into its component parts.

Send the parts for recycling.

Page 7

2 Installation

2.1 Device Overview

765

Fig. 1 Overview HS / HS+

76

4321

1 Control Panel

2 Brake

3 Roll retainer

4 Margin stop

5 Present sensor

6 Dispense plate

7 Rewinder

765

Fig. 2 Overview VS / VS+

4321

1 Control Panel

2 Present sensor

3 Roll retainer

4 Margin stop

5 Brake

6 Dispense plate

7 Rewinder

Page 8

8 82 Installation

i

!

2.2 Unpacking and Setting-up the Device

Lift the device out of the box and set it up on a level surface.

Check device for damage which may have occurred during transport.

Check delivery for completeness.

Contents of Delivery:

• Label Dispenser

• Margin Stop

• Power Cable Type E+F

• Operator's Manual German / English

Notice!

Please keep the original packaging in case the device must be

returned.

Attention!

The device and materials will be damaged by moisture and wetness.

Set up the device only in dry locations protected from splashed

water.

2.3 Connecting the Device

1

1 Power switch

2

2 Power connection jack

3 Peripheral port for external control

(HS+/VS+)

3

Fig. 3 Connections

2.3.1 Connecting to the Power Supply

The device is equipped with a wide area power unit for a supply voltage of

100 V to 240 V.

1. Check that the device is switched off.

2. Plug the power cable into the power connection jack (2).

3. Plug the power cable into a grounded socket.

Page 9

2.3.2 Connecting to the External Control

for devices with peripheral port only

The peripheral port allows to control the device in a network.

1. Check that the device is switched off.

2. Connect the external control to the 9 pin SUB-D connector of the

peripheral port (3 / Fig. 3):

98 2 Installation

Pin1

Pin5

Fig. 4 Peripheral port

Pin Signal Direction Function Activation /

1 ERROR Output Error 0V at Pin

2 ESP Output Label in peel position +24V at Pin

3 EXTGND (Input) External ground (0V)

4 STRT Input Start Switch on +24V

5 EXTAN Input Evaluation STRT Connect with Pin 9 !!!

6 EXT24P (Input) External voltage 24V

7 - - do not use

8 - - do not use

9 INTGND (Output) Internal ground (0V)

Table 1 Pin assignment of the peripheral port

Pin

ERROR

ESP

EXTGND

STRT

EXTAN

EXT24P

-

-

INTGND

Fig. 5 External minimum circuit

1

2

3

4

5

6

7

8

9

STRT ERROR, ESP

Pin6

Pin9

GND

24P

ERROR

ESP

EXTGND

STRT

EXTAN

EXT24P

-

INTGND

Active state

Pin

1

Imax = 50 mA

2

3

4

5

6

7

8

9

ERROR

ESP

24P

Page 10

10 103 Loading Material

6 75431

98

2

6 754

98

1

3 2

3.1 Loading Labels

HS / HS+ VS / VS+

Fig. 6 Loading labels

1. Turn ring (7) counterclockwise, so that the arrows points to the symbol ,

and thus release the margin stop (6) from the roll retainer (5).

2. Load label roll (4) on the roll retainer (5) in such a way that the labels are

visible from above at HS 120 / from below at VS 120.

3. Re-mount the margin stop (6) and push against the label roll as far as

possible.

4. Turn ring (7) clockwise, so that the arrow points to the symbol , and thus

x the margin stop (6) on the roll retainer (5).

5. Swing away the brake (3).

6. Remove the labels manually from the label strip on the rst 20 cm.

7. Guide label strip over the dispense plate (1) to the rewinder (9) as shown

in gure 6. The broken line shows the path for inside wound labels.

8. Hold rewinder (9) rmly and turn knob (8) clockwise until it stops.

9. Push liner under a bracket (2) of the rewinder (9) and turn knob (8)

counterclockwise until it stops.

The rewinder is fully spread, thus gripping the liner rmly.

10. Swing the brake (3) against the label strip.

11. Adjust the present sensor..

Page 11

3.2 Adjusting the Present Sensor

1

2

3

2

1

4

HS / HS+ VS / VS+

4

Fig. 7 Adjusting the present sensor

Reaching the peel position will be recognized by displacement of the feeler (1)

by the label to be peeled-off.

1. Release the present sensor (2) by turning the knob (3) counterclockwise.

2. Move the present sensor (2) sideward to adapt the sensor position to width

and shape of the labels.

3. Swing the present sensor (2) to adjust the distance between feeler (1) and

dispense plate (4).

4. Hold the sensor (2) rmly in the needed position and x it by turning the

knob (3) clockwise.

1110 3 Loading Material

3

Fig. 8 Sensor settings

Page 12

12 124 Operation

!

4.1 HS / VS

4.1.1 Operation

Switch the device on at the power switch (1 / Fig. 3).

The green LED (2) lights up.

The rst label will immediately be fed to the peel position.

Take the label.

The next label will be fed to the peel position.

Attention!

Risk of unintended start-up.

Do not touch the feeler of the present sensor excepting the

error treatment.

Display

1 Error

2 Ready / Label in peel position

1

2

Fig. 9 Control panel HS / VS

Page 13

4 Operation

4.1.2 Error Treatment

If no label is detected by the present sensor within 5 seconds after starting

the peel-off operation, the label transport will be stopped and an error will be

signalized :

• The red LED (1) is ashing.

Cause Remedy

Out of labels Insert new material

The peeled label does not activate

the present sensor

Table 2 Fault Correction

Rectify error.

Continue operation by releasing the present sensor manually.

Adjust present sensor

1312

Page 14

14 144 Operation

!

4.2 HS+ / VS+

4.2.1 Switching on the Device

Attention!

Risk of button malfunction.

Do not touch the buttons when switching on the device.

Switch the device on at the power switch (1 / Fig. 3).

The device starts up in the operation mode "Peel-off on demand"

Counter and speed setting are in the state of the last switching-off.

1

2

7

8

Display

1 Label counter

2 External control connected

3 Automatic peel-off

4 Peel-off on demand

3

5 Low speed

4

6 High speed

5

6

Buttons

7 Reset counter

9

8 Switch Automatic peel-off / Peel-off on

demand

9 Switch High speed / Low speed

10

10 Release peel-off on demand

Fig. 10 Control panel HS+ / VS+

Page 15

!

i

4 Operation

4.2.2 Operation Modes

Check the operation mode by means of the LEDs (2 / 3 / 4).

Touch button for changing the operation mode.

Automatic Peel-Off

After switching in the "Automatic peel-off" mode the rst label will

immediately be fed to the peel position.

Take the label.

The next label will be fed to the peel position.

Attention!

Risk of unintended start-up.

Do not touch the feeler of the present sensor excepting the

error treatment.

Peel-Off on Demand

For peeling-off a label touch button .

Take the label.

For peeling-off the next label touch button again.

Peel-Off on Demand with External Control

for devices with peripheral port only

1514

If an external control is connected LED (2) is illuminated.

Notice!

With an external control connected the device cannot be switched to

the "Automatic peel-off" mode.

The release button has no function.

Send a start signal.

A label will be fed to the peel position

Take the label.

Send a new start signal.

Page 16

16 164 Operation

4.2.3 Setting Speed

Check the chosen speed by means of the LEDs (5 / 6).

Touch button for changing the speed setting.

4.2.4 Resetting Counter

Touch button for resetting the counter.

4.2.5 Error Treatment

If no label is detected by the present sensor within 5 seconds after starting

the peel-off operation, the label transport will be stopped and an error will be

signalized :

• The counter display is ashing.

• The LED for the chosen operation mode is ashing.

Cause Remedy

Out of labels Insert new material

The peeled label does not activate

the present sensor

Material transport is interrupted Reduce speed

Table 2 Fault Correction

Adjust present sensor

Remove material from rewinder

Rectify error.

Continue operation by touching button respectively sending a

start signal or releasing the present sensor manually.

Page 17

4.2.6 Adjusting the Dispense Plate

The label material must run parallel to the chassis, failing this :

Loosen screw (2).

If the material (1) runs away from the chassis, pull the dispense plate a

little out of the guiding (4).

If the material (1) runs against the chassis, push the dispense plate a little

into the guiding (4).

Tighten screw (2) .

Dispense several labels to test the material run.

1

2

3

1716 4 Operation

4

2

3

1

Fig. 11 Material run

2

3

2

3

Fig. 12 Adjusting the dispense plate

Page 18

18 185 EU Declaration of Conformity

cab Produkttechnik

GmbH & Co KG

Wilhelm-Schickard-Str. 14

D-76131 Karlsruhe,

Germay

EU Declaration of Conformity

We declare herewith that the following device as a result of design, construction and the version

put in circulation complies with the relevant fundamental regulations of the EU Rules for Safety

and Health. In the event of any alteration which has not been approved by us being made to any

device as designated below, this statement shall thereby be made invalid.

Device: Label Dispenser

Type: HS 60, VS 60, HS 120, VS 120

Applied EU Regulations and Standards: Applied Standards:

Directive 2006/42/EC on machinery

Directive 2014/30/EU relating to electromagnetic compatibility

Directive 2011/65/EU on the restriction of

the use of certain hazardous substances in

electrical and electronic equipment

Person authorised to compile the technical le : Erwin Fascher

HS 60+, VS 60+, HS 120+, VS 120+

HS 180+, VS 180+

• EN ISO 12100:2010

• EN ISO 13849-1:2008

• EN 60204-1:2006+A1:2009

• EN 61000-3-2:2006+A1:2009+A2:2009

• EN 61000-3-3:2008

• EN 61000-6-1:2007

• EN 61000-6-2:2005

• EN 61000-6-3:2007+A1:2011

• EN 50581:2012

Am Unterwege 18/20

99610 Sömmerda

Signed for, and on behalf of the Manufacturer :

cab Produkttechnik Sömmerda

Gesellschaft für Computerund Automationsbausteine mbH

99610 Sömmerda

Sömmerda, 01.02.2016

Erwin Fascher

Managing Director

Loading...

Loading...