Page 1

Label Dispenser HS 150

Part No.: 5560900

Instructions for Use

Edition 8/11

Page 2

The HS 150 is a compact unit designed to

dispense rolled self-adhesive label stock. The

machine processes label-rolls of up to 147 mm

width and 240 mm external diameter.

The minimum core diameter is 40 mm.

The unit can be switched between 230 V and

115 V mains power supply.

1. Technical Data

Label Width 19 to 147 mm (0.48“ - 5.79“)

Label Length 15 to 300 mm (0.59“ - 11.81“)

Roll Diameter max. 240 mm (9.44“)

Label Rewinder internal or external as required

Core Diameter min. 40 mm. (1.57“)

1

2

Backing Strip Winding Dia. max. 100 mm (0.93“)

Setting of Label Length via micro-switch feeler

Counter Four position LED display

Key Reset to „0“

Mains Switch ON/OFF

Mains Supply 230 V 50 Hz fuse 250 mAT

115 V 60 Hz fuse 500 mAT

Operation Temperature 10°C to 35°C

(50°F. to 95°F)

Transport and Storage Temp. -20°C to +35°C

(-4°F to +95°F)

Humidity 10%to 85% non-condensing

Approvals DIN VDE 0805 Class 1

Noise Level 60 dB(A)

Power Consumption approx. 40 W.

Dimensions 188 mm x 250 mm x 240 mm

(7.40“(H) x 9.84“(W) x 9.44“(D))

Weight Approx. 10 lbs. (4.4 Kg.)

2. Contents of Delivery

1 - HS 150 Half-Automatic Label Dispenser

3

2 - Mains cable

3 - 2 Fuses 500 mA Slowblow / 250V

(for the usage with 115 V)

4 - Operating Instructions

3. Safety Precautions

• Before switching ON, verify that the mains

supply module is switched to the relevant supply voltage.

• The HS 150 operates from mains voltage and

therefore may not be opened.

• During operation, the rotating rewinder axle is

freely accessible. Take care when switching

ON. The machine sets in motion immediately

4

2

and continues until the rst label is ready to be

dispensed.

Page 3

182410

168

5 379

11 12 13 14 15 16 17

1 - Supply roll hanger

2 - Label adjust guide

3 - Knurl screw

4 - Axle

5 - Rollers

6 - Axle

7 - Dispense plate

8 - Display with RESET button

9 - Dispensed label

10 - Microfeeler

11 - Power switch

12 - Knurl screw

13 - Axle

14 - Sensor block

15 - Rewinder clasp

16 - Rewinder hub

17 - Power cord connector

18 - Media roll

4. Operation

• Verify that the voltage setting shown on the

power cord connector (17) corresponds to the

input supply voltage, and if necessary reset

as follows: Open the ap on the module and

remove the voltage selector. Exchange the fuse

(use 250 mA for 250 V and 500 mA for 115 V),

and replace the voltage selector so that when

the module ap is closed, the relevant voltage

setting is visible through the cut-out in the ap.

• Using the mains cable supplied, connect the

HS 150 to the mains supply, ensuring that an

earthed socket is used.

• Loosen the knurled screw (3) and swing the

guide (2) upwards. Mount the label-stock roll

(18) onto the main axle (1), so that the labels to

be dispensed are visible from above.

• Slide the roll of label stock up to the side panel

of the HS 150.

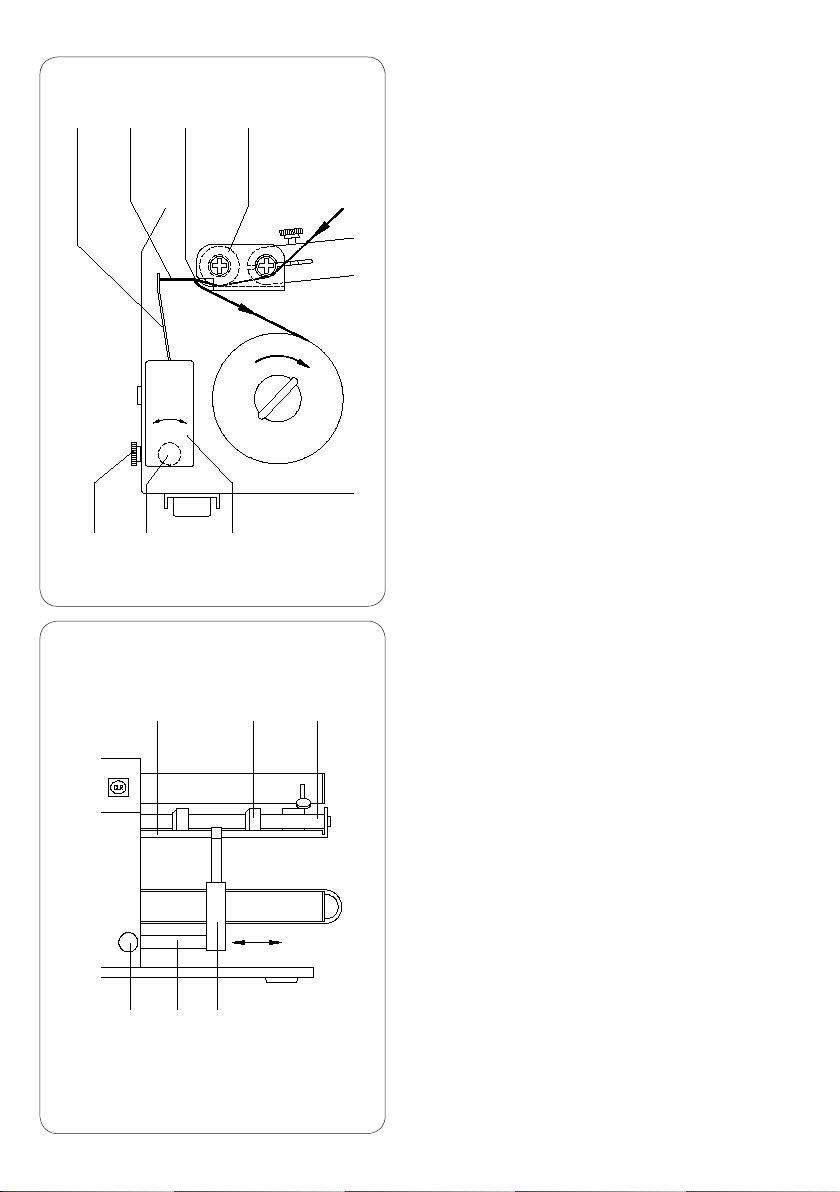

• Feed the label strip as shown in the accompanying diagram. This diagram relates to

externally wound label stock.

• Afx the end of the label strip to the rewinder

axle(16) by using the clamp provided (15),

which locates into the two longitudinal slots in

the axle.

• Note that the axle rewinds in a clockwise

direction!

• Swing the guide (2) downwards and slide it

sideways along the axle (4) until it rests against

the label roll in such a manner that when the

dispenser is in operation, the roll is lightly

retarded.

• Tighten the knurled screw (3).

• Adjust the position of the sensor block (14)

in relation to the size of labels to be dispensed

(see part 5).

• Position the rollers (5) mounted on the axle (6)

so that they press down onto the label strip.

When so positioned, the rollers improve the

donor mode when particularly irregular labelstock is being used, and thereby improve the

positioning of each peeled-off label in order to

operate the micro-switch

• Switch the machine ON (using ON/OFF switch

(11). The label feed will start immediately and

the rst label will be peeled from the backingstrip by the peel off plate (7). This label causes

the micro-switch (10) to operate and the feed is

stopped. When the label is removed, the next

label is fed into position and the feed is again

stopped.

• The total number of labels dispensed is shown

in the LED display (8). To reset the counter to

"0" press the reset button.

3

Page 4

5. Adjustment of the Sensor Block

12

910 57

13 14

7 5 6

In order to accommodate differing sizes of label

stock and formats, the positioning of the sensor

block can be altered as follows:

• Loosen the knurled screw (12).

• The sensor-block (14) can now be drawn out

on its axle (13) and if required, turned. Position

the sensor-block so that the micro-switch feeler

(10) is positioned approximately in the middle

of the front edge of the label to be dispensed.

In the event of irregularly shaped label stock,

the feeler should be positioned against the

extreme front edge of the label.

• Rotate the sensor-block (14) so that the feeler

(10) switches the feed OFF when 2-3 mm of the

label (9) remains adhered to the backing strip.

• When especially long labels are to be dispensed, it is possible to position the sensorblock (14) so that at rst, the front of the label

to be dispensed is released from the backing

strip, as the remaining part of the label is unpeeled from the backing strip, the feed provides

further material at such a speed that there is no

noticeable delay.

• Following any adjustment, the knurled screw

(12) must be re-tightened.

• When using label-rolls with a small core diameter, it is possible that as the roll draws to an

end, the extreme curvature of the remaining

label stock requires that the sensor

block (14) be readjusted.

6. Fault Finding

• Display blinks. Feed is stopped

The micro-switch feeler (10) does not operate

10 seconds after the previous label having been

removed. Possible causes are:

• the sensor-block is incorrectly set

• the label stock is torn or has come to the end

• there are a large number of different sized

labels on the roll.

When the fault has been remedied, normal

operation can be resumed by manually operating

the sensor feeler (10).

12 13 14

4

• When the machine is switched ON, the

display fails to illuminate.

Check that the fuse is in order and if required,

replace.

Page 5

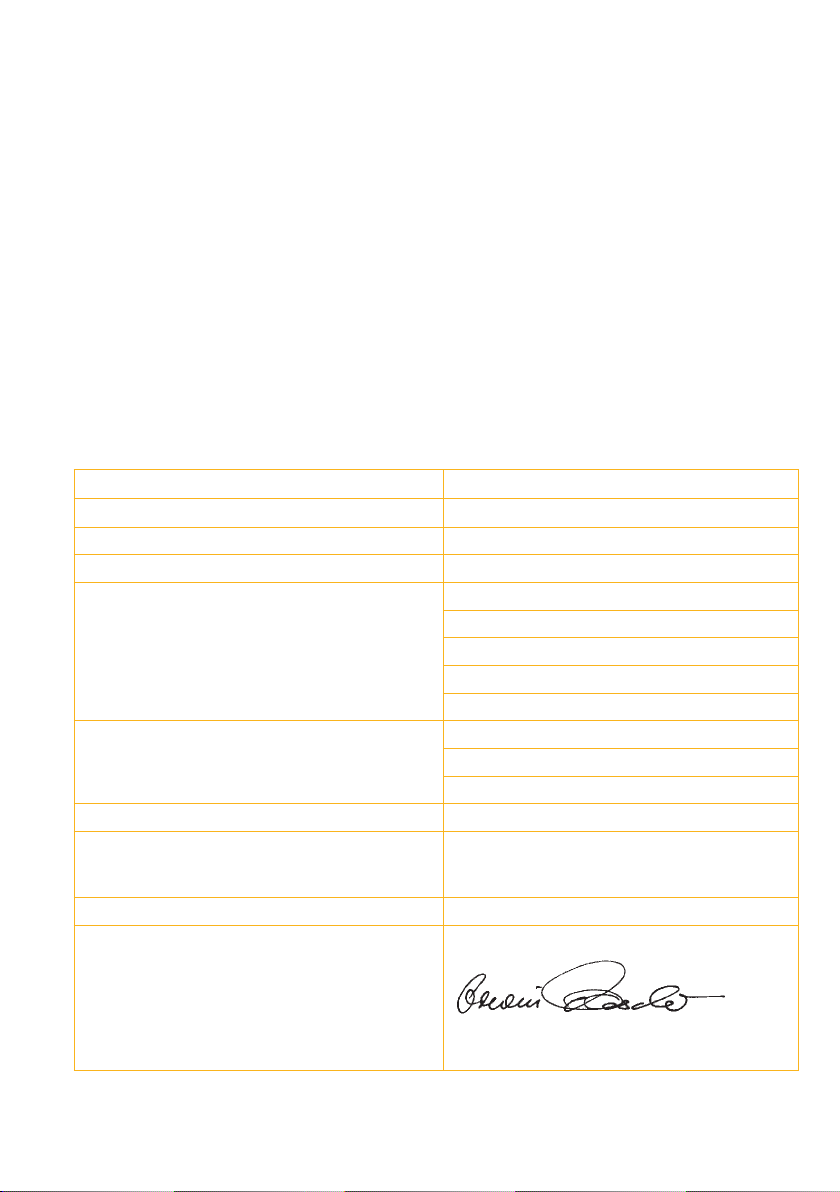

Gesellschaft für Computerund AutomationsBausteine mbH & Co KG

Wilhelm-Schickard-Str. 14

D-76131 Karlsruhe,

Germany

EC Declaration of Conformity

Herewith we declare that the following described device, from the design and style and as we sell it,

comply with the relevant EC Safety and Health Requirements.

This declaration will lose the validity if there are any changes of the device or the purpose without our

consent.

Description: Label dispenser

Device: HS150

Applied EC-Directives Applied Norms:

Directive 2006/42/EC on machinery

Directive 2004/108/EC relating to electromagnetic compatibility

• EN ISO 12100-1:2003

• EN ISO 12100-2:2003

• EN ISO 14121-1:2007

• EN 60950-1:2006+A11:2009

• EN 61558-1:2005+A1:2009

• EN 55022:2006+A1:2007

• EN 55024:1998+A1:2001+A2:2003

• EN 61000-6-2-2005

Person authorised to compile the technical le : Erwin Fascher

Signature for the producer :

cab Produkttechnik Sömmerda

Gesellschaft für Computerund Automationsbausteine mbH

99610 Sömmerda

Am Unterwege 18/20

99610 Sömmerda

Sömmerda, 01.08.11

Erwin Fascher

Managing Director

5

Page 6

cab-Produkttechnik

Gesellschaft für

Computer- und Automationsbausteine mbH & Co KG

Postfach 19 04 D-76007 Karlsruhe

Wilhelm-Schickard-Straße 14 D-76131 Karlsruhe

Telefon 0721 / 66 26-0

Telefax 0721 / 66 26-249

copyright by cab / 5521769

Technische Änderungen vorbehalten

In accordance with our policy of continual product improvement, we reserve the right to alter specications without notice

Données technique modiables sans préavis

Loading...

Loading...