CAB HERMES Q Series, HERMES Q4L, HERMES Q2L, HERMES Q6.3L, HERMES Q4.3L Service Manual

...

Service Manual

Label Printer

HERMES Q

MADE IN GERMANY

Service Manual

2 2

for the following products

Family Type

HERMES Q HERMES Q2L

HERMES Q4L

HERMES Q4.3L

HERMES Q6.3L

HERMES Q2R

HERMES Q4R

HERMES Q4.3R

HERMES Q6.3R

Edition: 12/2019 - Part No. 9003469

Copyright

This documentation as well as translation hereof are property of cab Produkttechnik GmbH & Co. KG.

The replication, conversion, duplication or divulgement of the whole manual or parts of it for other intentions than its original

intended purpose demand the previous written authorization by cab.

Trademark

Windows is a registered trademark of the Microsoft Corporation.

Editor

Regarding questions or comments please contact cab Produkttechnik GmbH & Co. KG.

Topicality

Due to the constant further development of our products discrepancies between documentation and product can occur.

Please check www.cab.de for the latest update.

Terms and conditions

Deliveries and performances are effected under the General conditions of sale of cab.

Germany

cab Produkttechnik GmbH & Co KG

Karlsruhe

Phone +49 721 6626 0

www.cab.de

France

cab Technologies S.à.r.l.

Niedermodern

Phone +33 388 722501

www.cab.de/fr

USA

cab Technology, Inc.

Chelmsford, MA

Phone +1 978 250 8321

www.cab.de/us

Mexico

cab Technology, Inc.

Juárez

Phone +52 656 682 4301

www.cab.de/es

Taiwan

cab Technology Co., Ltd.

Taipei

Phone +886 (02) 8227 3966

www.cab.de/tw

China

cab (Shanghai) Trading Co., Ltd.

Shanghai

Phone +86 (021) 6236 3161

www.cab.de/cn

China

cab (Shanghai) Trading Co., Ltd.

Guangzhou

Phone +86 (020) 2831 7358

www.cab.de/cn

South Africa

cab Technology (Pty) Ltd.

Randburg

Phone +27 11 886 3580

www.cab.de/za

Table of Contents

1 Introduction ............................................................................................................................................4

1.1 Instructions ...............................................................................................................................................4

1.2 General Safety Instructions ......................................................................................................................4

1.3 Protective Devices ...................................................................................................................................5

1.4 Handling Electricity ..................................................................................................................................5

1.5 Procedure in Case of Accidents ..............................................................................................................5

1.6 Environment .............................................................................................................................................5

2 Tools ........................................................................................................................................................6

3 Maintenance ...........................................................................................................................................7

3.1 Cleaning by the Operator .........................................................................................................................7

3.2 Cleaning the Label Sensor .......................................................................................................................7

4 Replacing Assembly Units .................................................................................................................... 8

4.1 Replacing the Printhead ...........................................................................................................................8

4.2 Replacing the Print Roller and the Transport Roller ...............................................................................10

4.3 Replacing the Slipping Clutches .............................................................................................................11

4.4 Replacing the Label Sensor ...................................................................................................................13

4.5 Replacing the PCB CPU ........................................................................................................................14

4.6 Replacing the Power Supply Unit ...........................................................................................................15

5 Adjustments .........................................................................................................................................16

5.1 Measuring and Adjusting the Winding Torques ......................................................................................16

5.1.1 Measuring the Winding Torques ....................................................................................................... 16

5.1.2 Adjusting the Winding Torques ......................................................................................................... 19

5.2 Adjusting the Brake at the Label Unwinder ............................................................................................20

5.3 Adjusting the Label Feed Path ...............................................................................................................21

5.4 Adjusting the Printing Mechanism ..........................................................................................................22

5.4.1 Preparing the Printer for Adjustment ................................................................................................22

5.4.2 Aligning the Printhead to the Print Roller..........................................................................................23

5.4.3 Adjusting the Printhead Pressure .....................................................................................................24

5.4.4 Adjusting the Distance of the Printhead from the Paper Guiding Edge ............................................25

5.4.5 Adjusting the Transfer Ribbon Feed Path.........................................................................................26

5.4.6 Final Test ..........................................................................................................................................27

5.5 Adjusting the Tension at the Rewinder Belt and the Transport Roller Belt .............................................28

5.6 Adjusting the Automatic Ribbon Saver ...................................................................................................29

5.6.1 Setting the Eccentrics .......................................................................................................................29

5.6.2 Adjusting the Magnetic Clutch ..........................................................................................................30

6 Troubleshooting and Error Treatment ................................................................................................31

6.1 Failure of Device Functions ....................................................................................................................31

6.2 Permanent Hardware Faults ..................................................................................................................31

7 Block Diagram ......................................................................................................................................32

3

8 Layout Diagram PCB CPU ...................................................................................................................33

9 Index ......................................................................................................................................................34

1 Introduction

!

!

!

!

i

!

4 4

1.1 Instructions

Important information and instructions in this documentation are designated as follows:

Danger!

Draws attention to an exceptionally great, imminent danger to your health or life due to hazardous

voltages.

Danger!

Draws attention to a danger with high risk which, if not avoided, may result in death or serious injury.

Warning!

Draws attention to a danger with medium risk which, if not avoided, may result in death or serious injury.

Caution!

Draws attention to a danger with low risk which, if not avoided, may result in minor or moderate injury.

Attention!

Draws attention to potential risks of property damage or loss of quality.

Note!

Advices to make work routine easier or on important steps to be carried out.

Environment!

Gives you tips on protecting the environment.

Handling instruction

Reference to section, position, illustration number or document.

Option (accessories, peripheral equipment, special ttings).

Information in the display.

Time

1.2 General Safety Instructions

This service manual is intended for use by qualied service and maintenance personnel. For more operation and

conguration information, refer to the user or conguration manual.

Follow the general safety rules below:

• Keep the area around the device clean at all times!

• Work with safety in mind.

• Parts of device that are removed during the maintenance work must be put in a safe place.

• Avoid risks of tripping over.

Danger!

Double pole/neutral fusing.

N

Danger!

Danger to life and limb from increased current ow through metal parts in contact with the device.

Do not wear clothing with metal parts.

Do not wear jewelry.

Do not wear spectacles with metal frames.

Warning!

Items of clothing drawn into the device by moving parts can lead to injuries.

Do not wear any items of clothing which could get caught by moving parts.

1.3 Protective Devices

!

Warning!

There is a risk of injury if protective devices are missing or defective.

Replace all protective devices (covers, safety notices, grounding cables etc) after maintenance work

has been completed.

Replace parts that have become defective or unusable.

Wear protective goggles for:

• Knocking pins or similar parts in or out with a hammer.

• Using spring hooks.

• Inserting or removing springs, retaining rings or grip rings.

• Using solvents, cleansers or other chemicals.

1.4 Handling Electricity

The following work may only be done by trained and qualied electricians:

• Work on electrical components.

• Work on an open device still connected to the mains supply.

General precautions before starting maintenance work:

• Find out where the emergency and power switches are so that they can be quickly thrown in an emergency.

• Disconnect the current supply before carrying out the following work:

- Installing or removing power units.

- Working in the immediate vicinity of open power supply components.

- Mechanical check of power supply components.

- Modifying circuits in the device.

• Test the zero potential of the device parts.

• Check the working area for possible sources of danger, such as wet oors, defective extension cables, defective

protective conductor connections.

51 Introduction

Additional precautions in the case of exposed voltages:

• Ask a second person to remain near the working site. This person must know where the emergency and power

switches are, and how to switch the current off if danger arises.

• Only use one hand to work on electric circuits of devices that are switched on. Keep the other hand behind your

back or in your pocket.

This prevents electricity from owing through your own body.

1.5 Procedure in Case of Accidents

• Act calmly and with great care.

• Avoid danger to yourself.

• Switch off power.

• Request medical assistance.

• Give rst aid, if necessary.

1.6 Environment

Obsolete assemblies contain valuable recyclable materials that should be sent for recycling.

Send to suitable collection points, separately from residual waste.

Send the parts for recycling.

2 Tools

6 6

Do not use any worn of damaged tools.

Only use tools and testing devices that are suitable for the task at hand.

cab special tools:

• Test collar for transfer ribbon winder (cab Part-No. 5540932)

• Distance caliber 0,1 mm (cab Part-No. 5961064)

• Gauge for brake adjustment at the label unwinder HERMES Qx/xxx-2 (cab Part-No. 5961092)

• Gauge for brake adjustment at the label unwinder HERMES Qx/xxx-3 (cab Part-No. 5961694)

Standard tools:

• Screw driver Torx, size TX 10, TX 20

• Allen key 1,5 mm

• Phillips-head screwdriver, size 1

• Allen key 2,5 mm (included)

• Snap ring pliers ZGG 0

• Snap ring pliers ZGG 1

• Cylindrical dynamometer (spring scale), 0 - 10 N

• Cylindrical dynamometer (spring scale), 0 - 25 N

• Scale Magnier

• Digital Circuit Analyzer

3 Maintenance

i

3.1 Cleaning by the Operator

The following cleaning work is described in the Assembly Instructions.

• Cleaning the device

• Cleaning the printhead

• Cleaning the print roller

3.2 Cleaning the Label Sensor

Note!

At HERMES Q2, HERMES Q4 and HERMES Q4.3 the label sensor can be cleaned with rear cover closed.

At HERMES Q6.3 the label sensor cable must be unplugged. For that purpose the rear cover must be

removed.

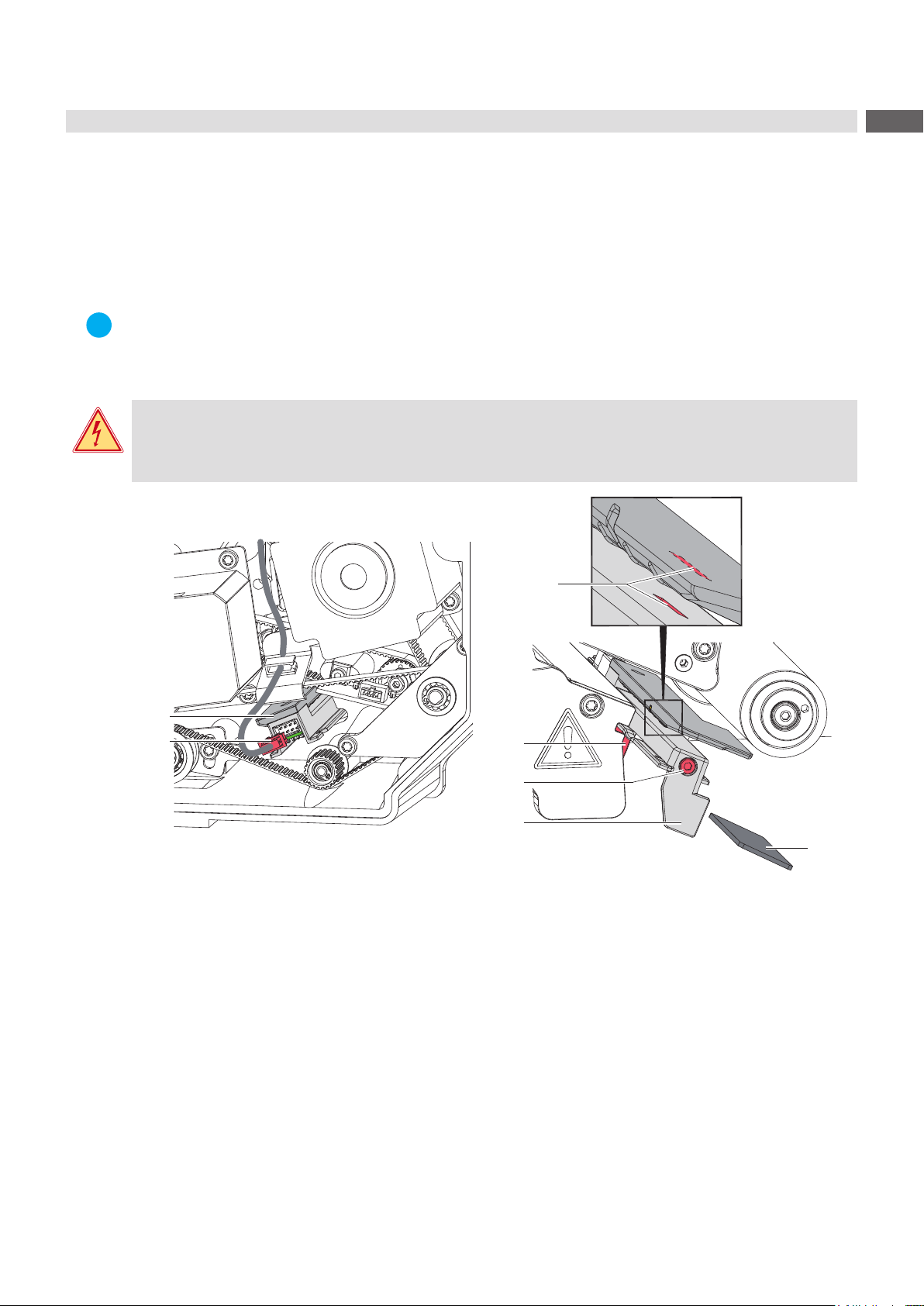

Danger!

Risk of death via electric shock!

Before opening the housing cover, disconnect the device from the mains supply and wait at least one

minute until the power supply unit has discharged.

7

3

1

2

4

5

6

Figure 1 Cleaning the label sensor

1. Remove the material from the printer.

2. * HERMES Q6.3: Remove the rear cover.

3. * HERMES Q6.3: Disconnect the plug (2) from the label sensor (1).

4. Loosen the screw (5).

5. Hold pressed the knob (4) and pull the label sensor with the handle (6) out of the prole.

* HERMES Q6.3: That way the distance plate (7) is pushed out of label sensor guide.

6. Clean the label sensor slots (3) with brush or cotton swab soaked in pure alcohol.

7. * HERMES Q6.3: Push label sensor back into the guide.

8. * HERMES Q6.3: Push the distance plate (7) into the guide of the label sensor.

9. * HERMES Q6.3: Connect the plug (2) to the label sensor (1).

10. * HERMES Q6.3: Mount the rear cover.

11. Adjust label sensor mechanically and tighten the screw (5) Assembly Instructions.

7

4 Replacing Assembly Units

3

5

!

8 8

4.1 Replacing the Printhead

The printhead of the label printer can be replaced without the need for ne adjustment. The printhead must be

replaced if worn or when switching to a printhead with higher or lower resolution.

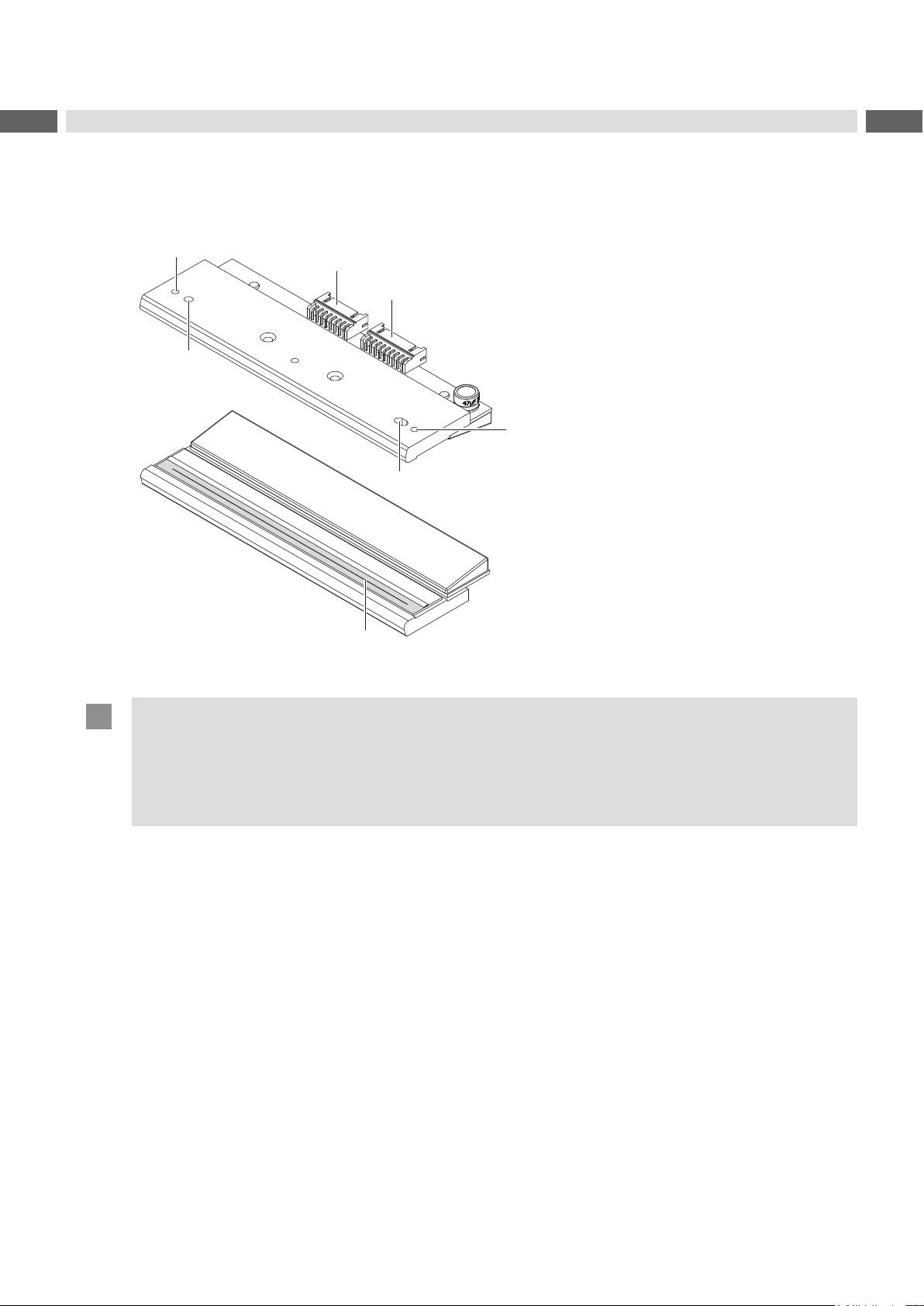

1

2

4

1 Data connector

3

4

2 Power connector

3 Threaded holes

4 Catching holes

5 Heating line

Figure 2 Structure of the printhead

Attention!

The printhead can be damaged by static electricity discharges and impacts!

Set up printer on a grounded, conductive surface.

Ground your body, e.g. by wearing a grounded wristband.

Do not touch contacts on the plug connections (1, 2).

Do not touch heating line (5) with hard objects or your hands.

4 Replacing Assembly Units

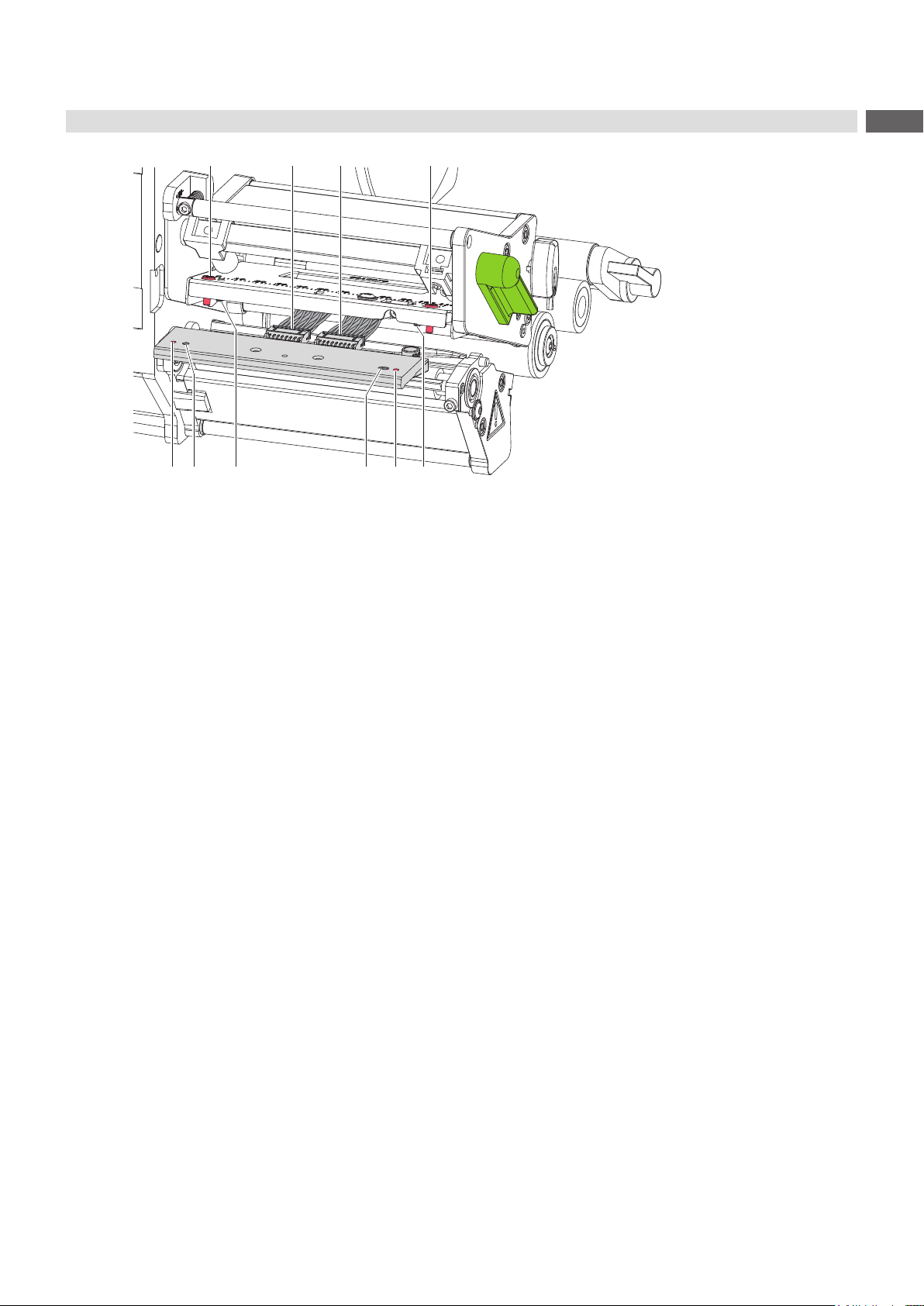

6

6

7 8

3

3

4

4 99

Figure 3 Replacing the printhead

Dismounting the Printhead

1. Remove the media from the printer.

2. Lock the printhead.

3. Loosen two screws (6).

4. Open the printhead locking and if necessary remove the printhead from the pins (9).

5. First unplug the power cable (8), followed by the data cable (7).

9

Mounting the Printhead

1. First connect the data cable (7), followed by the power cable (8).

2. Place the printhead into the printhead assembly and insert the pins (9) into the holes (4).

3. Press down the printhead carriage and x the printhead with the screws (6) at the carriage using the threaded

holes (3).

4. Clean the heating line with the cleaning cloth included in the contents of delivery.

5. Reload labels and transfer ribbon.

1 2 5 64 7 8 1093 11

4 Replacing Assembly Units

10 10

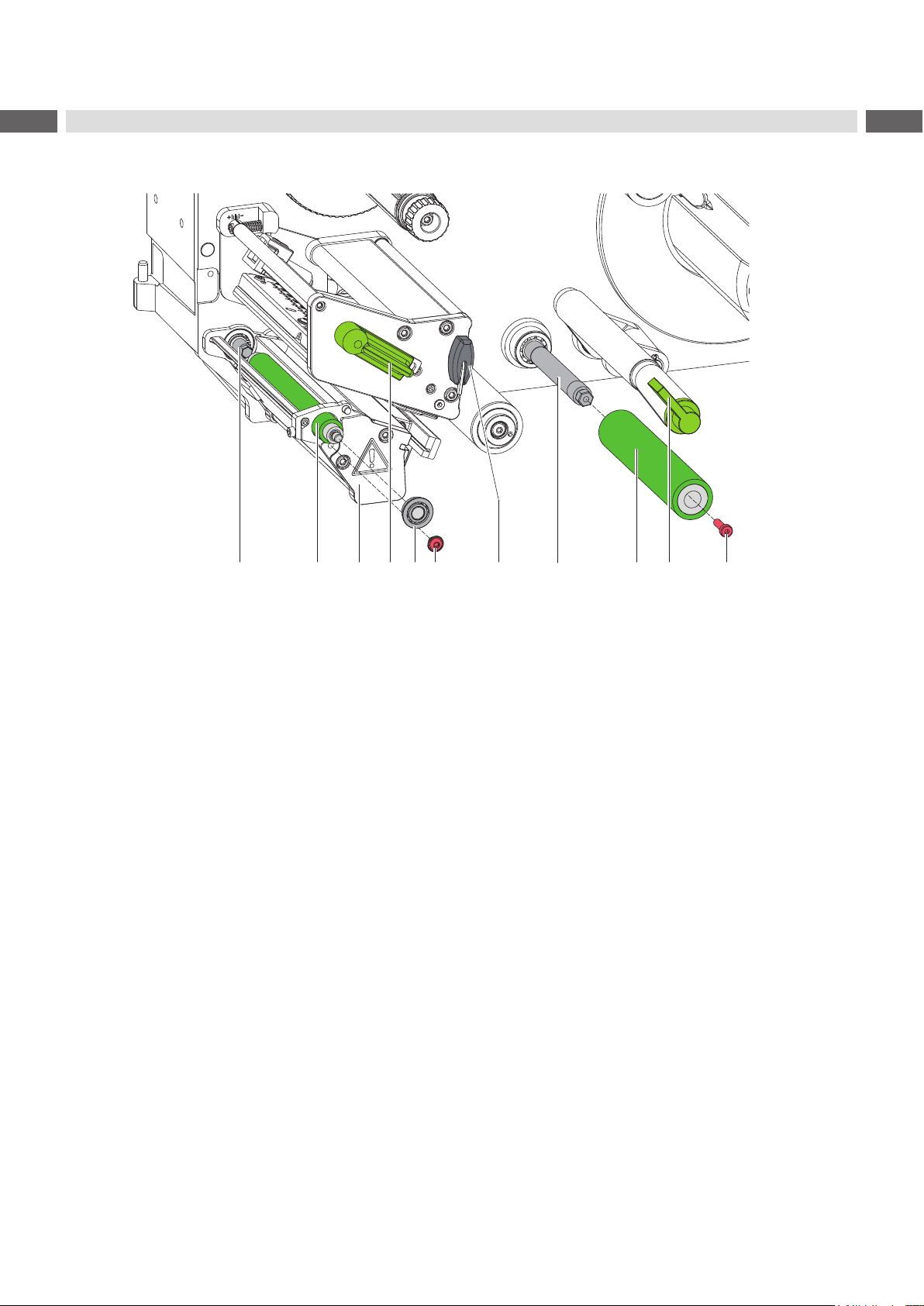

4.2 Replacing the Print Roller and the Transport Roller

Figure 4 Replacing print roller and transport roller

Replacing the print roller

1. Turn lever (4) counterclockwise to lift the printhead assembly.

2. Loosen screw (6).

3. Remove ball bearing (5) and print roller (2) through the plate (3).

4. Guide the new print roller through the plate (3) to the axle (1). Turn the roller to align it to the hexagonal end of the

axle and push the roller further until it stops.

5. Insert the ball bearing (5) in to the plate (3) and x it with screw (6).

Replacing the transport roller

1. Turn lever (10) clockwise to open the transport system.

2. Loosen screw (11).

3. Remove the transport roller (9) from the axle (8).

4. Put the new roller onto the axle (8). Turn the roller easily to align it to the hexagonal end of the axle and push the

roller further until it stops.

5. Fix the roller (9) with the screw (11).

1 2 3

4 Replacing Assembly Units

4.3 Replacing the Slipping Clutches

The rewinder for the transfer ribbon and the internal rewinder are coupled with slipping clutches to the main drive.

The supply hub of the transfer ribbon is braked with a slipping clutch during printing.

Replace a slipping clutch when the set value of the torque cannot be set 5.1 on page 16.

Removal and installation of the slipping clutch is also required for replacement of a winder.

11

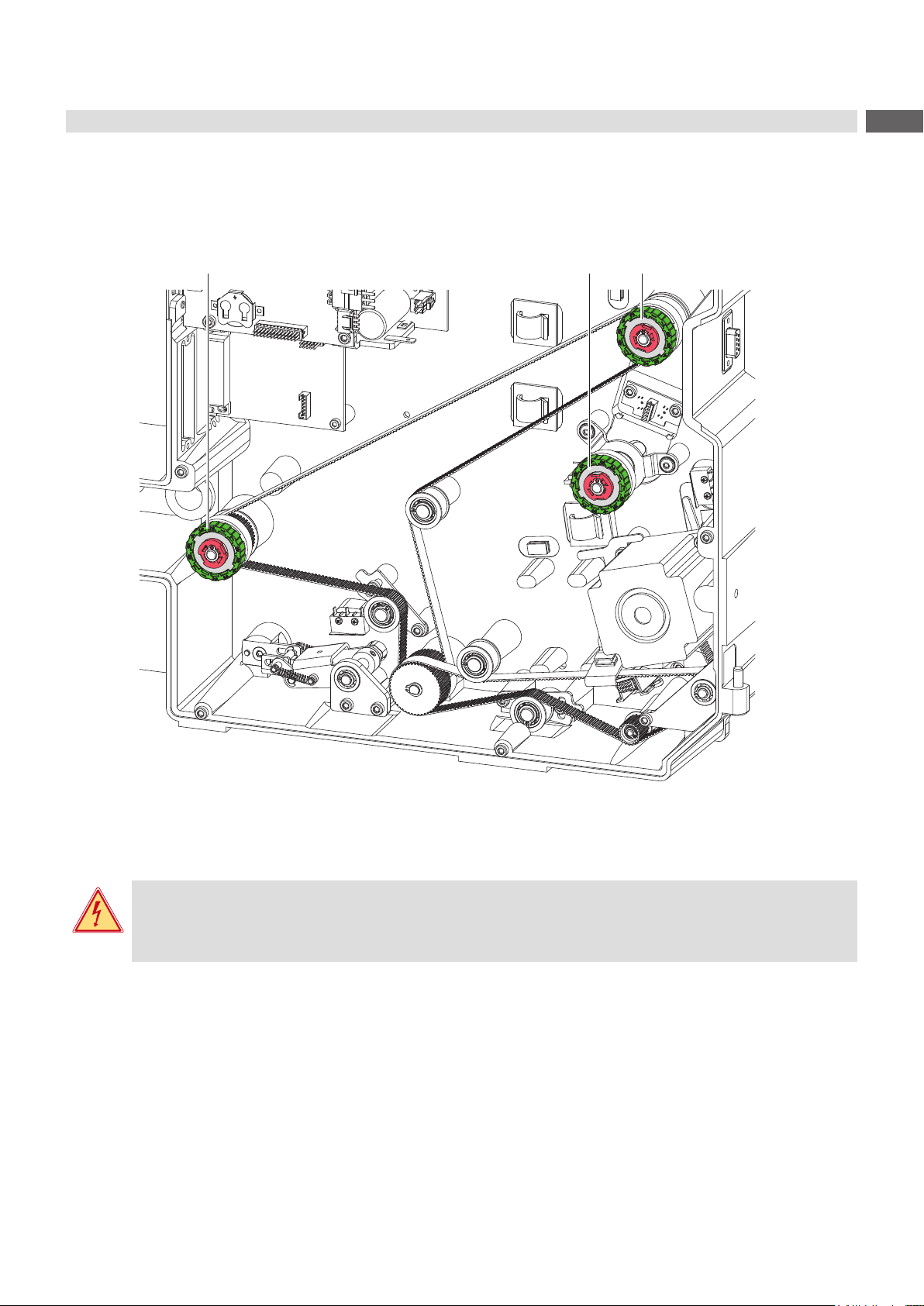

1 Internal rewinder: coupling

2 Ribbon supply hub: brake

3 Ribbon take up hub: coupling

Figure 5 Slipping clutches

Danger!

Risk of death via electric shock!

Before opening the housing cover, disconnect the device from the mains supply and wait at least one

minute until the power supply unit has discharged.

Loading...

Loading...