Page 1

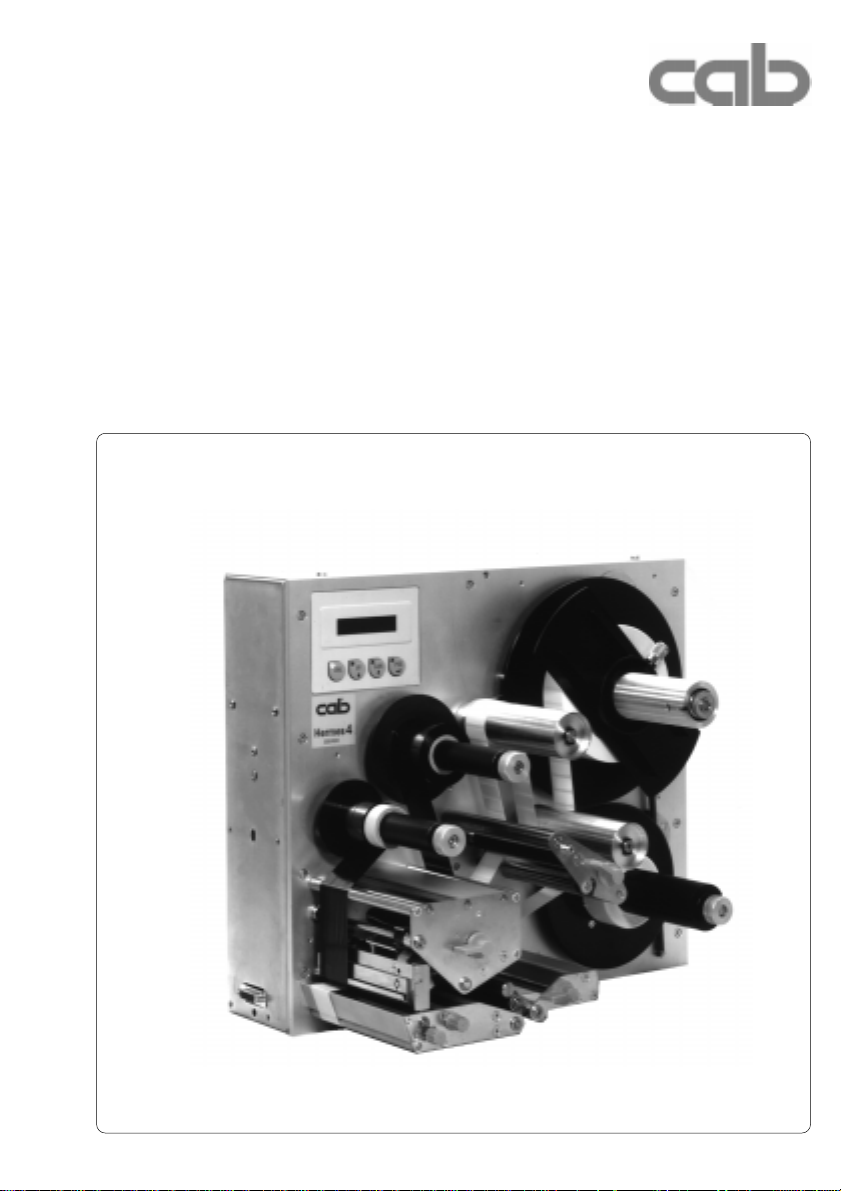

Transfer Printer

Hermes

Hermes 4N / Hermes 5N

Hermes 4F / Hermes 5F

Technical Information

Edition 8/00

Page 2

cab-Produkttechnik

Gesellschaft für

Computer- und AutomationsBausteine mbH & Co.KG

Postfach 19 04 D-76007 Karlsruhe

Wilhelm-Schickard-Str. 14 D-76131 Karlsruhe

T elefon 0721 / 66 26-00

T elefax 0721 / 66 26-249

copyright by cab / 900 8127 / K34 / 1

T echnische Änderungen vorbehalten

In accordance with our policy of continual product improvement, we reserve the right to alter specifications without notice

Données technique modifiables sans prévais

2 cab - Produkttechnik GmbH

Page 3

Hermes

Thermal Transfer Printer

Thermal Transfer Printer

Technical Information

Technical Information

All rights reserved, including those of the translations.

No part of this manual nor any translation may be reproduced or transmitted in any

form or by any means, for any purpose other than the purchaser's personal use,

without the express written permission of cab - Produkttechnik GmbH Karlsruhe.

Edition 8/00

Printed in Germany

3cab - Produkttechnik GmbH

Page 4

Table of Contents

A General Guide to the Documentation............................................................................... 6

Compliances ........................................................................................................................... 7

Trademarks ............................................................................................................................. 7

Characteristics of the Thermal Printhead ........................................................................... 8

1. Product Description ........................................................................................................ 9

General Information........................................................................................................... 9

Important Information about Printing with Hermes ........................................................... 9

Overview of the Hermes Types ....................................................................................... 10

Overview of the Optional Features.................................................................................. 10

Technical Specifications .................................................................................................. 11

Optional Features ............................................................................................................ 14

Warning Sensor Label End / Ribbon End................................................................. 14

Warning Light ............................................................................................................ 14

Memory Card............................................................................................................. 14

Keyboard Adapter ..................................................................................................... 14

Label Design Software EASYLABEL for Windows .................................................. 14

Print Media.......................................................................................................................15

Print Media for Direct Thermal Printing .................................................................... 16

Print Media for Thermal Transfer Printing ................................................................ 16

Label/ Tag Media Specifications ............................................................................... 17

Transfer Ribbon......................................................................................................... 18

2. General Safety Instructions .......................................................................................... 19

3. Delivery Contents .......................................................................................................... 19

4. Printer Component Location ........................................................................................ 20

5. Connecting the Printer.................................................................................................. 28

Connection to Power Supply ........................................................................................... 28

Connection to a Computer .............................................................................................. 29

Switch on the Printer ....................................................................................................... 30

6. Media Loading ............................................................................................................... 31

Preparation of the Label Supply Hub .............................................................................. 31

Loading Labels ................................................................................................................ 32

Loading Transfer Ribbon ................................................................................................. 34

7. Adjustments Concerning the Labels ........................................................................... 35

Adjustment of the Label Edge Sensor ............................................................................ 35

Adjustment of the Printhead Support .............................................................................. 36

Adjustment of the Label Tracking .................................................................................... 37

Adjustment of the Transfer Ribbon ................................................................................. 38

4 cab - Produkttechnik GmbH

Page 5

8. Options ........................................................................................................................... 39

Applicators ....................................................................................................................... 39

Non-cab-Applicators.................................................................................................. 39

cab-Applicators ......................................................................................................... 40

Bracket............................................................................................................................. 42

Feet .................................................................................................................................. 44

Warning Light ...................................................................................................................45

Warning Sensors ............................................................................................................. 46

Warning Sensor Label End ....................................................................................... 46

Warning Sensor Ribbon End .................................................................................... 48

9. Control Panel .................................................................................................................51

System Mode ONLINE .................................................................................................... 52

System Mode OFFLINE .................................................................................................. 52

System Mode PRINT....................................................................................................... 52

System Mode PAUSE...................................................................................................... 53

System Mode LABEL FROM CARD ............................................................................... 53

10. Setup ............................................................................................................................... 54

11. Error Messages .............................................................................................................. 56

Correctable Errors ........................................................................................................... 56

Irrecoverable Errors ......................................................................................................... 56

Appendices

Appendix A - Built-in Dimensions .................................................................................... A-1

Hermes 4N..................................................................................................................... A-2

Hermes 4F ..................................................................................................................... A-3

Hermes 5N..................................................................................................................... A-4

Hermes 5F ..................................................................................................................... A-5

Appendix B - Pin Assignment of the Interface Connectors .......................................... B-1

Pin Assignment of the Serial Interface Connector........................................................ B-1

Interface Cable for RS-232............................................................................................ B-2

Interface Cable for RS-422 / RS-485 ............................................................................ B-3

Pin Assignment of the Parallel Interface Connector ..................................................... B-4

Centronics Interface Cable ............................................................................................ B-4

Pin Assignment of the Peripheral Port for Non-cab-Applicators .................................. B-5

Appendix C - Spare Parts List (Extract)........................................................................... C-1

EC-Conformity Declaration

5cab - Produkttechnik GmbH

Page 6

A General Guide to the Documentation

T echnical Information

The present manual contains beside the Technical Specification and the most

important instructions for the operator especially information for the integrators

of Hermes printers. This covers the built-in dimensions, the description of the

different interfaces and the pin assignments of the interface cables.

Note the directions for use on recommended material and the properties of the

thermal printhead in order to avoid damage and premature failure of your

Hermes .

Every effort has been made in the creation of this manual to provide as much

information as possible in an understandable manner.

We welcome your comments and suggestions regarding additions or

corrections to improve future editions of this manual. Please, let us know if you

have any questions.

Further Documentation

Complete information on the use of the Hermes printers are included in the

Operator's Manual.

The programming of the Hermes printers is completely compatible to the

programming of cab's Apollo. Therefore it is possible to use the information,

that can be found in the "Programming Instructions - Apollo".

Detailed information about service and maintenance are included in the

"Service Manual" of the Hermes. (e.g. replacement of components, adjustment

instructions, circuit diagrams, spare parts lists, etc.)

6 cab - Produkttechnik GmbH

Page 7

Compliances

Hermes complies with the following safety regulations :

CE : Hermes complies with the following safety requirements:

FCC : Hermes complies with the requirements of the FCC regulations part 15 for

- EC Low Voltage Directive (73/23/EEC)

- EC Machinery Directive (89/392/EEC)

- EC Electromagnetic Compatibility Directive

(89/336/EEC/ foll. 93/31/EEC)

class A computers. Under disadvantageous circumstances, the operation of

these devices may cause interference with radio or TV reception, which has to

be eliminated by the operator.

Trademarks

Centronics

Corporation.

MacintoshMicrosoft

Bitstream

Speedo

TrueType

Easylabel

® is a registered trademark of Microsoft Corporation.

® is a registered trademark of Bitstream, Inc.

™ is a registered trademark of Bitstream, Inc.

™ is a registered trademark of Apple Computer, Inc.

® is a registered trademark of Centronics Data Computer

Computer is a product of Apple Computer, Inc.

® is a registered trademark of Tharo Systems, Inc.

7cab - Produkttechnik GmbH

Page 8

Characteristics of the Thermal Printhead

CAUTION !

The thermal printhead is the most sensitive part of your printer.

Pay special attention to the following guidelines :

1) The glass cover on the printhead must not be touched with the hand.

Do not use any sharp items, such as knives or screwdrivers, to clean

the printhead.

2) During printing, always take care that there is no dirt or foreign

objects on the labels in order to avoid impurification of the printhead.

This way, the printhead might be damaged.

3) Use proper label material with a smooth surface only.

A rough surface will affect the printhead and may cause damage and

reduce its operating life.

4) Clean the printhead regularly with a special printhead cleaning pen, or

an isopropyl alcohol soaked cotton swab.

5) Print with the lowest possible printhead temperature.

Careful use will allow you to print approximately between 18 to 30 miles

(30 to 50 km) of print media before the printhead needs replacing.

Improper usage can cause damage to the printhead.

8 cab - Produkttechnik GmbH

Page 9

1 Product Description

General Information

The Thermal Transfer Printers of the Hermes family are especially developed

for fully automatic labelling. Therefore the print mechanism is totaly aligned to

dispense labels. The printhead is arranged low within the devices to minimize

the way of the labels from the peel-off position to labelling position on the

product and to increase the labelling rate.

After removing the dispensed label the label strip can be fed back. So the

printing of the next label may start at the front label edge.

Hermes has two separate label transport systems for forward and backward

feed. These systems guarantee a high precision in printing and applying labels

independent from the size of the label supply roll.

The Hermes is an innovative label printer which may be used in either direct

thermal or thermal transfer mode. The programming of the Hermes is

completely compatible to the Apollo printers.

With the high-class printheads (305 dpi near edge printhead at Hermes 4N/5N

or 300 dpi flat printhead at Hermes 4F/5F) it is possible to print bar codes and

graphics quick, brilliant and tidy .

The double lined LCD display keeps the operator constantly informed about the

current status of the printer. The setup menu allows easy configuration

changes whenever desired.

The options PCMCIA-memory-card and keyboard adapter, which are offered in

the Apollo-program, may also be used for Hermes.

Important Information about Printing with Hermes

The print mode of the Hermes is designed for fully automatic labelling.

Therefore after the start of a print job Hermes needs two additional signals for

the processing of every single label :

- a start signal that releases printing and dispensing of the label

- a signal that shows the removing of the label from the peel position.

NOTICE !

If you operate Hermes with a non-cab-applicator make sure that the

applicator or the control system can generate these two signal.

A simple print mode without the "start" and the "removed" signals is not

available.

All cab applicators provide the needed signals.

9cab - Produkttechnik GmbH

Page 10

Overview of the Hermes T ypes

The present documentation contains the description of four different Hermes

types :

Part.-No. Description

5537500 Hermes 4N

5537501 Hermes 5N

5537503 Hermes 4F

5537506 Hermes 5F

The most important differences between Hermes types are :

- the type of the printhead

Hermes 4N/5N : Near edge printhead with 305 dpi

Hermes 4F/5F : Flat printhead with 300 dpi

- the maximum diameter of the label supply roll

Hermes 4N/4F : 7.9" / 200 mm

Hermes 5N/5F : 11.8" / 300 mm

Further the devices only will be called as Hermes, where are no differences

between the types.

Overwiew of the Optional Features

For the devices of the Hermes familiy the following optional features are

available.

Part.-No. Description

5537742 Warning Sensor Label End Hermes 4

5537743 Warning Sensor Ribbon End Hermes 4

5537744 Warning Sensor Label End Hermes 5

5537745 Warning Sensor Ribbon End Hermes 5

5537747 Warning Light

5537748 Feet Hermes 4/5

5942471 Bracket Hermes 4

5942472 Bracket Hermes 5

5533900 PC Keyboard Adapter

5560406 PC Card, 2 MB

5560405 PC Card, 4 MB

10 cab - Produkttechnik GmbH

Page 11

T echnical Specifications

Type : Direct thermal/ Thermal transfer printer

Printhead : Hermes 4N/5N : Thin film transfer printhead in near edge technology

Resolution: Hermes 4N/5N : 305 dpi = 12 dots / mm

Number of dots/ line : 1280

Print width : Hermes 4N/5N : 4.2 in (106.6 mm)

Print speed : Hermes 4N/5N : 4, 5, 6, 7, 8 ips (100, 125, 150, 175, 200 mm/s)

Available fonts : 5 Bitmap fonts incl. OCR-A and OCR-B

Character sets : Windows 1252/1250, IBM Codepage 850/852,

Character size : For scaleable fonts : width and height .035 to 5 in ( 0,9 - 128mm)

Font style : bold, italic, underlined, mirror-inverted, outlined, revers, grey

Font rotation : Bitmap fonts/Bar codes : 0°, 90°, 180°, 270°

Graphic elements : Line, box, circle, ellipse, fill-in segment, arrow

Graphic file type: .PCX, .IMG, .BMP, .TIF, .GIF und .MAC files

Bar codes : Lineal codes for industry, logistics, medicine :

Hermes 4F/5F : Thin film transfer printhead in flat head technology

Hermes 4F/5F : 300 dpi = 11.8 dots / mm

Hermes 4F/5F : 4.3 in (108 mm)

Hermes 4F/5F : 2.6, 4, 5.2, 6.5, 8 ips (66, 100, 133, 166, 200 mm/s)

3 scaleable fonts (Speedo™) - internally

Speedo™ and TrueType™fonts - to load externally

ISO 8859-1, ISO 8859-8, EBCDIC, Macintosh,

Supports all Western and Eastern European Latin characters

are individually changeable

For Bitmap fonts : width and height .04 to .12 in (1 - 3 mm )

the size is selectable up to a factor of 10

Scaleable fonts : optional, texts in circular format

Code 39, Code 93, Code 128 A,B,C, Codabar,FIM, HIBC,

Interleaved 2/5, Ident-/Leitcode der Deutschen Post AG,

MSI, Plessey, Postnet,

Lineal codes for the trade :

EAN-8, EAN-13, EAN-128, EAN/UCC 128, EAN/UPC

App 2, EAN/UPC App 5, JAN-8, JAN-13, UPC-A, UPC-E

Area codes :

Data Matrix, PDF417, UPS-Maxicode

Bar code height, modul with, and ratio are variable, with/without

check digit, human readable character, start/stop character

11cab - Produkttechnik GmbH

Page 12

Processor : 32 Bit, Motorola

Memory : Internal memory 2 MB

PCMCIA connector : for PC Card 512 KByte, 2 MByte, 4 MByte

Interface : Serial : RS-232, RS-422, RS-485 1200-57600 Baud

Peripheral ports : - Interface for the connection of non-cab-applicators and

Ribbon saver : The printhead only will be pressed against the print roller if the printer

Backfeed : In order to start the print of a label always from the front edge the

Test features : System test when switching on

Label material : Thermal paper, normal paper, plastic foil,

Internal rewinder : To rewind the backing paper

Parallel : Centronics

for the signals of the warning sensors label/ribbon end

- SPI-Interface for the connection of cab-applicators

has to print information. At the other time the printhead will be lifted

and the transport of the transfer ribbon will be stopped.

label strip may fed back after the completion of the previous label

print.

To avoid an abrasion of the transfer ribbon at the label the printhead

wil be lifted during the backward transport.

Self test with printout of firmware data and system parameters

PE, PP, PVC, Polyamide

Adhesive labels : 60-160 g/sqm

Material width : 4.7 in (120 mm)

Label width : .4-to 4.5 in (10-116 mm)

Label length : .2 to 21.5 in (5-546 mm)

Core diameter : 3 in (76 mm)

Supply roll diameter : Hermes 4N/4F : up to 7.9 in (200 mm)

Hermes 5N/5F : up to 11.8 in (300 mm)

Labels may be wound face-in or face-out on the supply roll

Core diameter : 1.6" (40 mm)

Max. rewinding diameter : Hermes 4N/4F : 5.7 in (145 mm)

Hermes 5N/5F : 8.3 in (210 mm)

Material recognition : - Gap sensor ("see through")

- Bottom reflective sensor

- Top reflective

adjustable from .08 to 1.85 in (2 to 47 mm)

12 cab - Produkttechnik GmbH

Page 13

Transfer ribbon : Type : Hermes 4N/5N : preferably ribbons designed for the

Hermes 4F/5F : standard ribbons

Length : 1476' in (450 m)

Width : max. 4.3 in (110 mm)

Core diameter : 1 in (25 mm)

Max. roll diameter : 3.6 in (92 mm)

Colour : inside or outside

Control panel : 4 Function keys with LED display

Backlit LCD with 2 lines of text, 16 characters per line

LCD can be set to display in 8 different languages

Control features : Print stop and error message at the LCD display at

- Paper out

- Ribbon out

- Printhead/ Transport system open

Information via peripheral interface and warning light at

- passing the adjusted minimum diameter of the supply roll of

labels or transfer ribbon (if the warning sensors are installed)

Dimensions : Hermes 4N/4F : Heigth : 15.4 in (390 mm), Width : 10.9 in (277 mm),

Hermes 5N/5F : Heigth : 21.3 in (542 mm), Width : 10.9 in (277 mm),

Weight : Hermes 4N/4F : 46.3 lb. (21 kg)

Hermes 5N/5F : 55.2 lb. (25 kg)

Operating voltage : Switcheable between 230 V A.C/ 50 Hz or 115 V A.C/ 60 Hz

Maximum 1,5 A (at 230 V) / 3 A (at 115 V)

power input :

Circuit protection : T 4 A (at 230 V) / T 6.3 A (at 115 V)

Environment : Operation at 50° to 95°F (10° to 35°C) at a humidity of 30 to 85%

Transport at -13° to 158°F (-25° to +70°C) at a max. humidity of 95%

Storage at 41° to 104°F (5° to 40°C) at a humidity of 5 bis 85%

use with near edge printheads

1968' in (600 m) on inquiry

Depth :16.5 in (420 mm)

Depth : 21.3 in (542 mm)

non-condensing

13cab - Produkttechnik GmbH

Page 14

Optional Features

Warning Sensor Label End / Transfer Ribbon End

These sensors signalize, when the diameter of the label supply roll respectively

the transfer ribbon roll has decreased below a preset thresould value. The

messages will be shown by switching on the yellow lamp of the warning light

(option). The signals also can be sent to a control system by using the

peripheral interface. So the user has the possibility to optimize the moment for

loading new media by regarding the whole process.

Warning Light

By using the warning light it is possible to recognize the state of the printer with

one view. The different colors of the lamps show the several possibilities,

whether the printer is switched on, there is an printer error or the preset

minimum quantity of labels or transfer ribbon is passed.

PC Memory Card

Hermes includes an option for using memory cards in order to permanently

store graphics, fonts, databases or whole label formats.

The data can be downloaded via interface.

PCMCIA 2.1 conforming sRAM cards or Flash-EPROM cards are accepted.

The maximum capacity is 4 MegaByte.

Using a memory card, the printer can be operated without being connected to

a computer which represents a great advantage regarding the flexibility.

Keyboard Adapter

The keyboard adapter allows you to connect your Hermes to a MF-2

compatible PC keyboard using the serial interface. This will allow you to modify

variable data stored on a memory card.

Label Design Software EASYLABEL for Windows

EASYLABEL is an intelligent and useful label design software which is easy to

use in connection with your Hermes.

EASYLABEL can be run on all Microsoft Windows compatible computers.

For further information about EASYLABEL, contact your local reseller.

14 cab - Produkttechnik GmbH

Page 15

Print Media

Hermes can be operated in direct thermal as well as thermal transfer mode.

For direct thermal mode, only use print material with a thermal-reactive coating.

The print image is transferred by heating the material at the printhead, causing

a reaction on the surface of the paper and, consequently, darkening the

material.

In thermal transfer mode, not only standard paper labels are needed but also

the thermal transfer ribbon with a color surface. The printout is created by

heating the transfer ribbon, causing a transfer of color particles onto the label.

Hermes allows to regulate the heat level and also the print speed. Thus, the

Hermes offers a wide range of opportunities for usage.

Hermes 4N and Hermes 4F are able to print on labels with a maximum supply

roll diameter of 8 in (200 mm) and a core diameter of 3 in (76 mm). Hermes 5N

and Hermes 5F can use labels with a maximum supply roll diameter of 12 in

(300 mm) and a core diameter of 3 in (76 mm).

The ability of label edge recognition, which guarantees the precise position of

the printer output, is accomplished by a moveable photocell. This sensor is

controlled by the processor of the Hermes and ensures recognition for different

sorts of material. There is no need for additional electronic adjustment.

On the following pages, you will find detailed information and specifications

concerning suitable materials.

If in doubt, we will perform test prints with your label material to find the best

suitable transfer ribbon.

15cab - Produkttechnik GmbH

Page 16

Print Media for Direct Thermal Printing

The print material must correspond to several important specifications, in order

to ensure high quality printing, and to avoid damage to the printhead or early

wear.

Using labels which we have tested and which we recommend to our

customers, will guarantee a gentle treatment of the printhead. If you want to

use material by another supplier, please note the following requirements

regarding the condition of thermal printer paper :

1. To avoid damage to the printhead, the surface coating must cover the

thermal-reactive layer. If the coating is too thin, this may cause a 'pitting'

effect on the printhead, i.e. very small explosions during the chemical

reaction of the thermal coating quickly resulting in damage to the printhead.

2. The surface of the labels should be very smooth to avoid a 'sandpaper'

effect on the printhead.

3. Always choose material which can be printed on with the lowest possible

heat level. The greater the heat level, the shorter the life of the printhead.

Moreover, with highest heat levels the phases of heating up and cooling

down extend. This may have a negative effect on the print quality,

especially if a high print speed is required.

Print Media for Thermal Transfer Printing

In thermal transfer mode, a wide range of different label materials may be

used. (e.g. normal paper, tag stock, a variety of synthetic material such as

polyester foil, etc.)

NOTICE !

The print quality greatly depends on the right combination of label

material and transfer ribbon.

The surface of the labels determines which ribbon material may be used.

Unsuitable ribbons may cause an extremely poor print image.

16 cab - Produkttechnik GmbH

Page 17

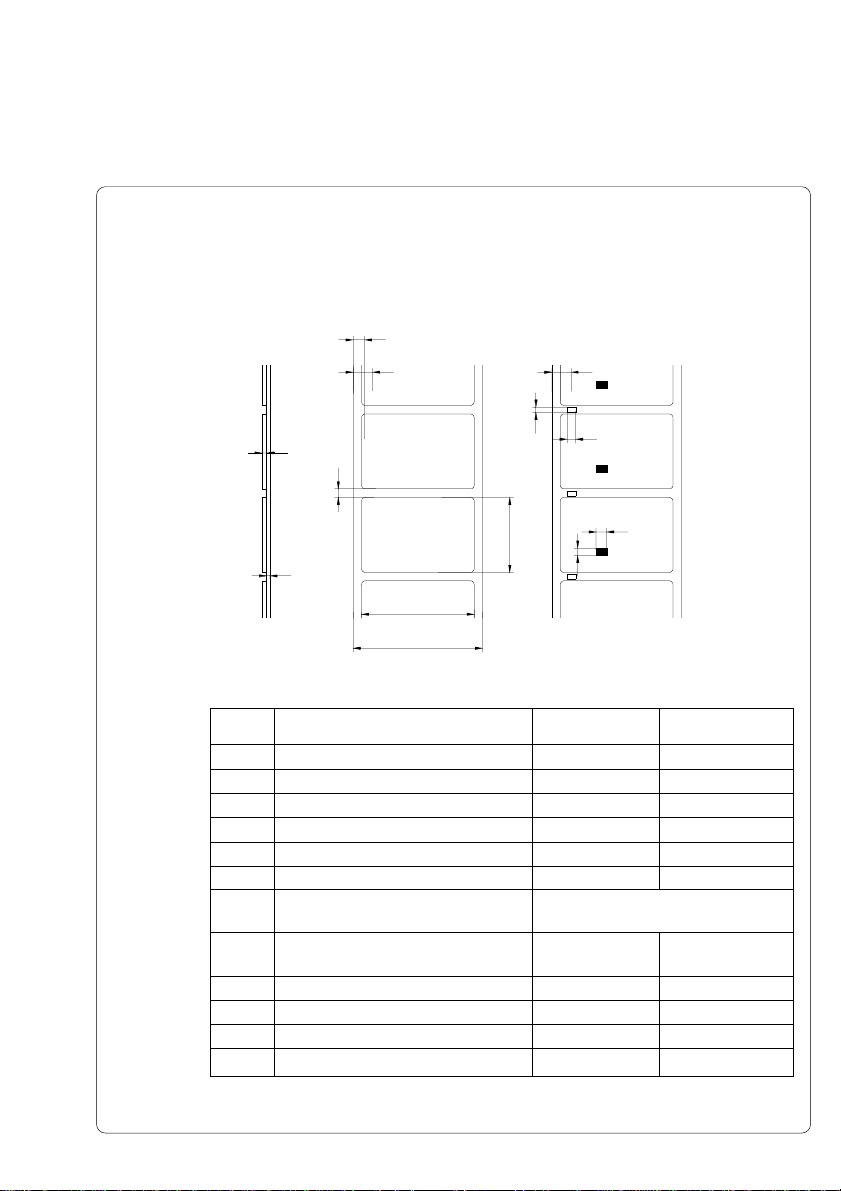

Label/ Tag Media Specifications

Label and tag media to be used for the Hermes can be found in the table

below. Note this information before ordering your labels.

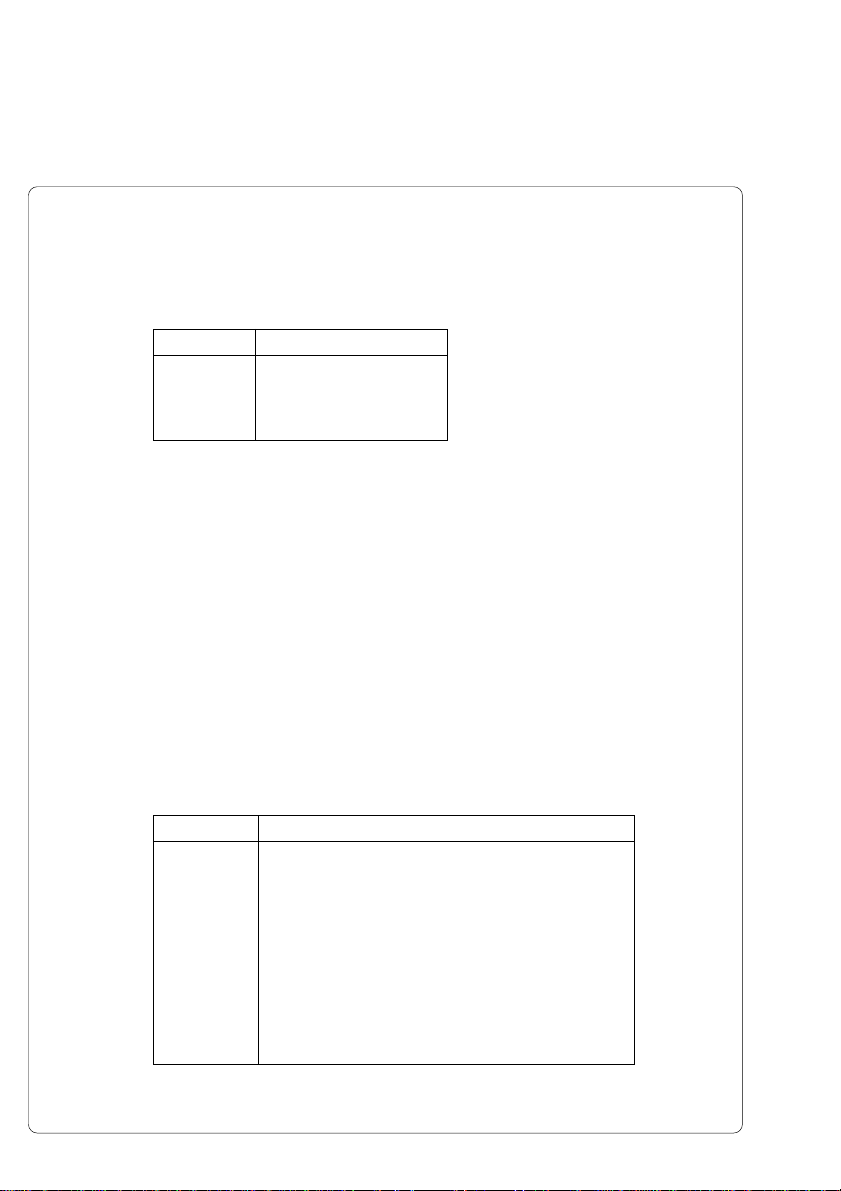

G

H

E

D

H

K

I

C

F

A

B

Fig. 1 Label formats

Item MIN. MAX.

A Label width .4(10) 4.6(116)

B Width of the silicon liner .4(10) 4.7(120)

C Label length .2(5) 21.5(546)

D Gap between labels .08(2) 21.5(546)

E Label thickness .0024(.06) .01(.25)

F Thickness of silicon liner .002(.05) .004(.1)

G Distance of the first printing point

from the edge of silicon liner 0

H Distance of the label sensor

from the edge of silicon liner .08(2) 1.85(47)

I Width of punch hole .2(5) K Height of punch hole .08(2) .2(5)

L Width of reflective mark .2(5) M Height of reflective mark .08(2) .2(5)

L

M

Table 1 Label formats in inches (figures in brackets are in mm)

17cab - Produkttechnik GmbH

Page 18

Transfer Ribbon

The choice of a suitable transfer ribbon is important for the print quality of your

printer as well as the useful life of the printhead.

NOTICE !

Hermes 4N and Hermes 4F are equipped with a near edge printhead. For

that reason choose transfer ribbons which are especially designed for the

use with near edge printheads.By using other ribbons only a poor print

quality is reacheable. The printouts have no brilliance, the surfaces are

dull.

For Hermes 4F and Hermes 5F standard transfer ribbons are usable.

CAUTION !

Transfer ribbons of inferior quality may cause premature deterioration of

the printhead !

The material must be extremely resistant to high temperatures to avoid melting

the ribbon with the printhead.

The heat which arises during printing must be carried off by the label and by

the transfer ribbon itself. Transfer ribbons of inferior quality are often poor heat

conductors. This may cause overheating of the printhead in spite of electronic

protection.

Poor transfer ribbons also tend to lose parts of the coating which leads to

accumulating dirt on the printhead and the sensors. With some ribbons the

color rubs off and soils the printhead. All of these effects contribute to poor

print quality.

We have carried out numerous tests with many different ribbons and we

recommend you use transfer ribbons made by well-known/ brand

manufacturers only. Depending on the label material, several transfer ribbons

may be suitable.

The quality of print is determined by the right combination of these materials.

The recognition of the transfer ribbon is sensed by the rotation control of the

transfer ribbon unwinder, rather than by photocell sensors. As a result, ribbons

with a thinner coating or those with a colored coating can be used safely. To be

able to print all labels up to the exact end of the transfer ribbon, the length of

the uncoated trailer is limited.

NOTICE !

When buying transfer ribbons, make sure that

- the trailer of the ribbon has a maximum length of 4 in (100 mm).

- the trailer is made of nonconductive material of is coated with a

nonconductive film.

- the trailer easily can come loose from thecardboard core (F<3N).

18 cab - Produkttechnik GmbH

Page 19

2 General Safety Instructions

CAUTION !

- The printers of the Hermes series are built exclusively to print labels.

- Connect the printer only to an outlet with the correct voltage !

The printer is configured for either 230V or 115V power supply, which can

be switched using the input voltage selector at the back of the printer.

Connect only to a power outlet with a grounded contact.

- The printer must only be connected to devices which have extra low

voltage.

- Power must be OFF before plugging in any accessory or connecting the

printer to a computer, etc. Also switch power off on all appliances before

disconnecting.

- Do not expose the printer to any moisture, or use in damp or wet areas.

- The printer will operate with the cover open if necessary. This is not

recommended, as moving or rotating parts become accessible. Keep long

hair, jewelry, loose clothes away from the moving parts.

- During the print process the printhead will become hot. Use extra caution

when touching the printhead.

3 Delivery Contents

Inspect the Hermes packaging and contents immediately after receipt for

possible damage caused by shipping.

The supplied equipment of the Hermes depends on the requested options.

Compare the delivered accessories with your order.

NOTICE !

Please keep the original packaging in case the printer must be returned.

19cab - Produkttechnik GmbH

Page 20

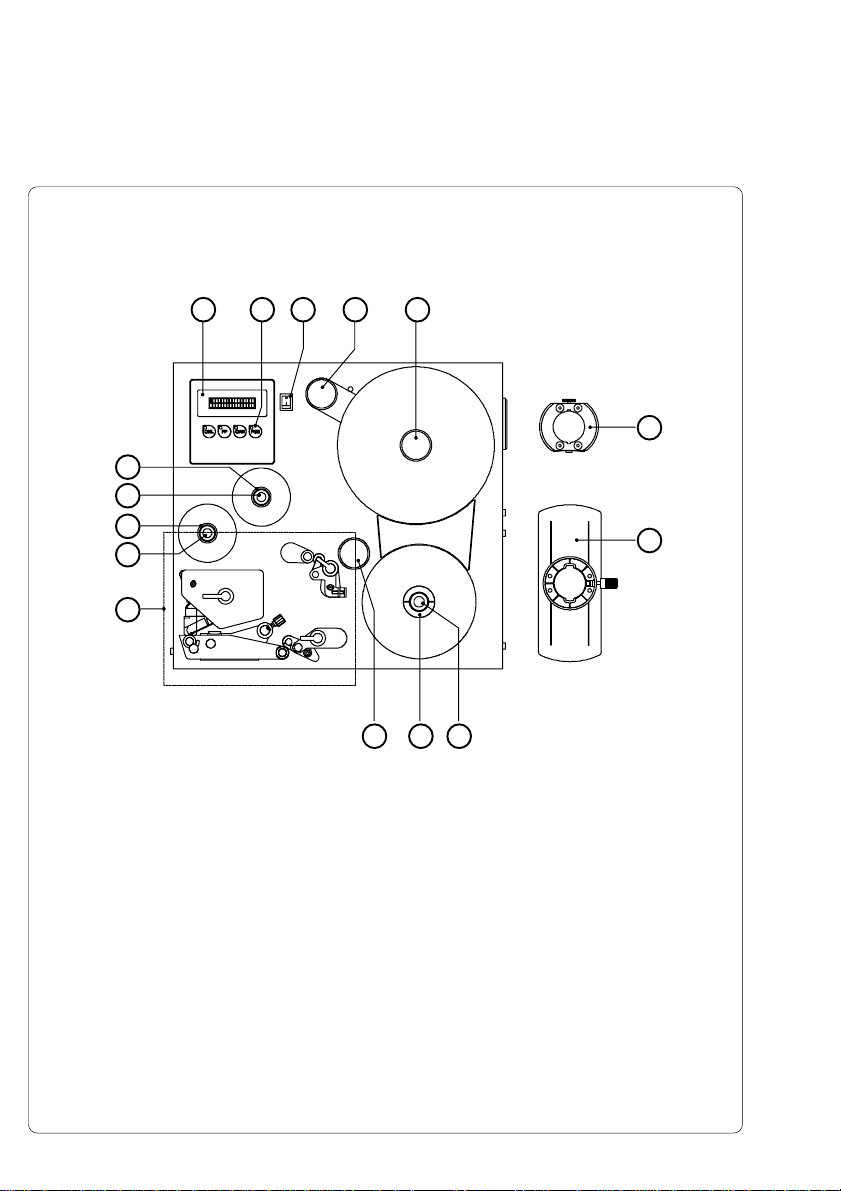

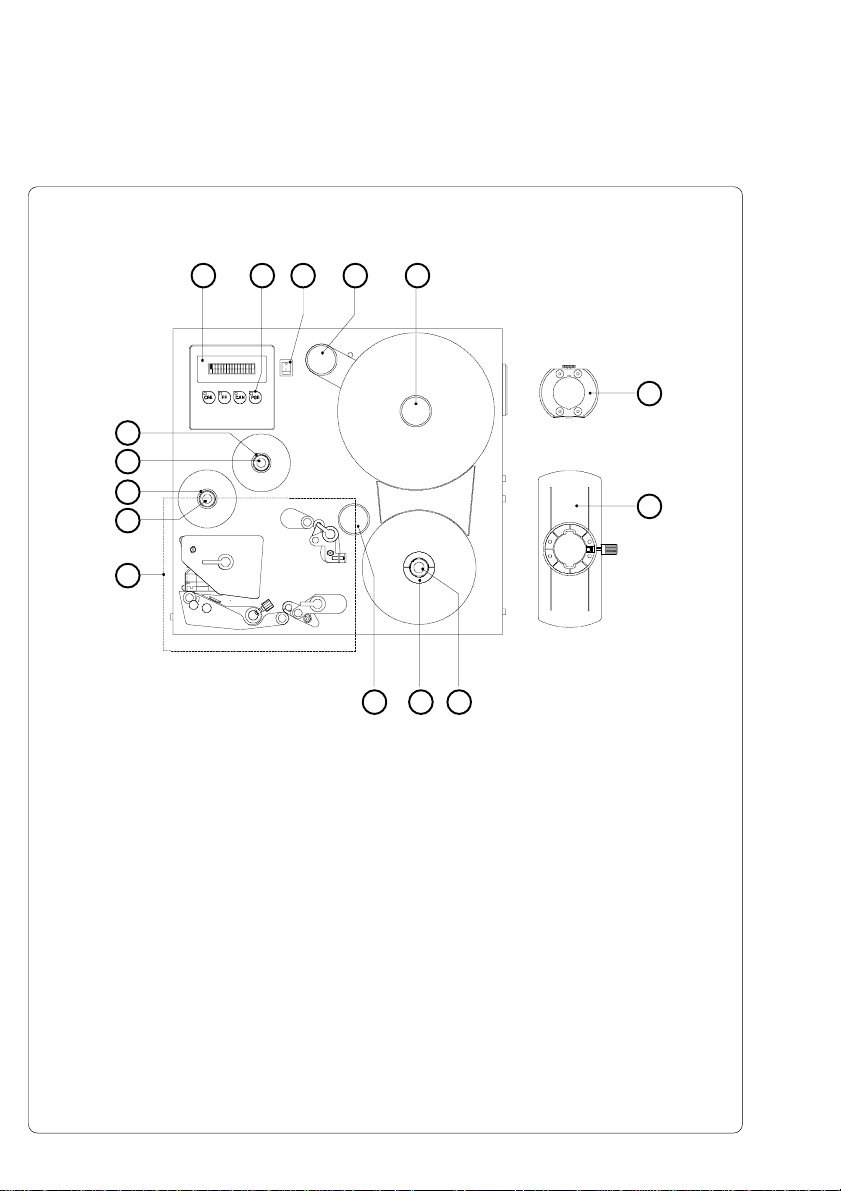

4 Printer Component Location

1 2 3 4

15

14

13

12

11

Fig. 4a Side view Hermes 4N

1 - Display

2 - Function keys with indicator LEDs

3 - Power switch

4 - Swing arm with guide roller

5 - Media supply hub

6 - Adapter

7 - Flange

8 - Knurled knob

9 - Media rewind hub

10 - Guide roller

11 - Print mechanism (Fig. 4e)

12 - Knurled knob

13 - Ribbon take up hub

14 - Knurled knob

15 - Ribbon supply hub

5

6

7

8910

cab - Produkttechnik GmbH20

Page 21

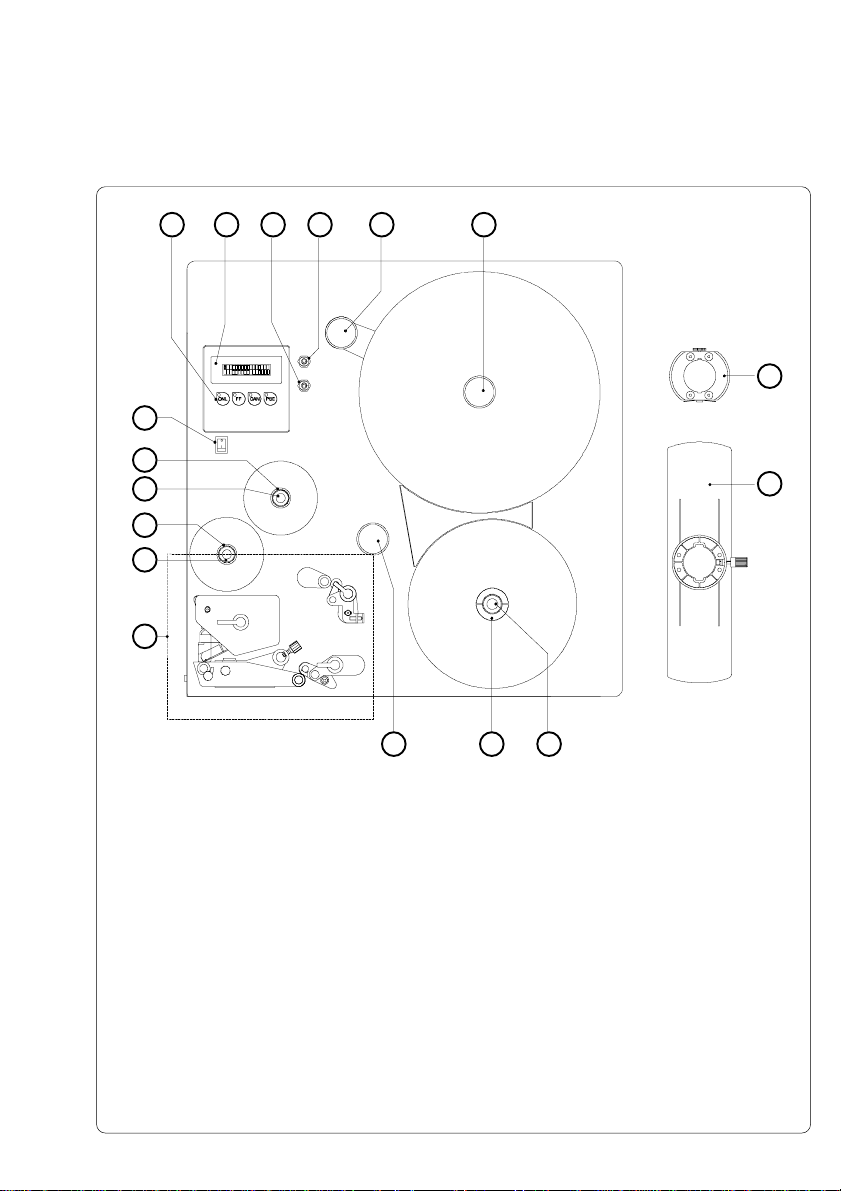

1 2 3 4 5 6

17

16

15

14

13

12

Fig. 4b Side view Hermes 5N

1 - Function keys with indicator LEDs

2 - Display

3 - Connector warning sensor transfer ribbon end

4 - Connector warning sensor label end

5 - Swing arm with guide roller

6 - Media supply hub

7 - Adapter

8 - Flange

9 - Knurled knob

10 - Media rewind hub

11 - Guide roller

12 - Print mechanism (Fig. 4e)

13 - Knurled knob

14 - Ribbon take up hub

15 - Knurled knob

16 - Ribbon supply hub

17 - Power switch

7

8

91011

21cab - Produkttechnik GmbH

Page 22

1 2 3 4

15

14

13

12

11

Fig. 4c Side view Hermes 4F

1 - Display

2 - Function keys with indicator LEDs

3 - Power switch

4 - Swing arm with guide roller

5 - Media supply hub

6 - Adapter

7 - Flange

8 - Knurled knob

9 - Media rewind hub

10 - Guide roller

11 - Print mechanism (Fig. 4f)

12 - Knurled knob

13 - Ribbon take up hub

14 - Knurled knob

15 - Ribbon supply hub

5

6

7

8910

cab - Produkttechnik GmbH22

Page 23

1 2 3 4 5 6

17

16

15

14

13

12

Fig. 4d Side view Hermes 5F

1 - Function keys with indicator LEDs

2 - Display

3 - Connector warning sensor transfer ribbon end

4 - Connector warning sensor label end

5 - Swing arm with guide roller

6 - Media supply hub

7 - Adapter

8 - Flange

9 - Knurled knob

10 - Media rewind hub

11 - Guide roller

12 - Print mechanism (Fig. 4f)

13 - Knurled knob

14 - Ribbon take up hub

15 - Knurled knob

16 - Ribbon supply hub

17 - Power switch

7

8

91011

23cab - Produkttechnik GmbH

Page 24

21

3

20

19

18

17

16

15

14

10111213

Fig. 4e Detailed view of the print mechanism Hermes 4N/5N

1 - Backfeed roller

2 - Backfeed system locking unit

3 - Backfeed system locking lever

4 - Locking screw for label track adjustment

5 - Set screw for label track adjustment

6 - Media guide with locking screw

7 - Media guide axle

8 - Transport system locking lever

9 - Transport system locking unit

10 - Transport roller

11 - Label edge sensor

12 - Knurled knob to adjust the label edge sensor

13 - Printhead levelling adjustment screw

14 - Print roller

15 - Socket of the peripheral port for cab-applicators

16 - Peel-off edge

17 - Thermal printhead

18 - Printhead locking lever

19 - Adjustable axle for ribbon track adjustment

20 - Locking screw for ribbon track adjustment

4

5

6

7

89

cab - Produkttechnik GmbH24

Page 25

21

3

21

20

19

18

17

16

15

8914

Fig. 4f Detailed view of the print mechanism Hermes 4F/5F

1 - Backfeed roller

2 - Backfeed system locking unit

3 - Backfeed system locking lever

4 - Locking screw for label track adjustment

5 - Set screw for label track adjustment

6 - Transport system locking lever

7 - Transport system locking unit

8 - Transport roller

9 - Media guide with locking screw

10 - Media guide axle

11 - Label edge sensor

12 - Knurled knob to adjust the label edge sensor

13 - Printhead levelling adjustment screw

14 - Print roller

15 - Socket of the peripheral port for cab-applicators

16 - Peel-off edge

17 - Ribbon shield

18 - Thermal printhead

19 - Printhead locking lever

20 - Adjustable axle for ribbon track adjustment

21 - Locking screw for ribbon track adjustment

4

5

6710111213

25cab - Produkttechnik GmbH

Page 26

1

7

2

3

4

5

6

Fig. 4g Rear view

1 - Input voltage selector / Fuse holder

2 - Input voltage selector cover

3 - Power supply connector

4 - Connector warning sensor transfer ribbon end (Hermes 4N/4F only)

5 - Connector warning sensor label end (Hermes 4N/4F only)

6 - Connector warning light

7 - Drillings for mounting a compressed air service unit (option)

8 - Memory card module slot

9 - Drillings for mounting a bracket (option)

10 - Parallel interface port

11 - Serial interface port

12 - Plug of the peripheral port for non-cab-applicators

8

9

10

11

12

cab - Produkttechnik GmbH26

Page 27

27cab - Produkttechnik GmbH

Page 28

5 Connecting the printer

Connection to Power Supply

The Hermes is designed for use with 230V A.C/50 Hz (standard) or 115V A.C/

60 Hz.

CAUTION !

Before connecting the printer to the power supply, make sure that the

voltage selected on the power supply module of the printer is the same as

your main power supply ! Pay attention that the power switch (4/5) is in

position "O" (OFF).

1

2

3

5

1 - Voltage selector

2 - Cover

3 - Power supply connector

4 - Power switch Hermes 4N/4F

5 - Power switch Hermes 5N/5F

6 - Fuses

Fig. 5a Power supply module / power switch

To change the voltage setting, open the cover (2) and remove the voltage

selector (1) from the power unit.

CAUTION !

If you have changed the operating voltage of your printer the fuses (6)

need replacing as stated below !

230V - 2 x T 4A 115V - 2 x T 6,3A

When delivered, the correct fuses for the pre-selected operative voltage are

installed. You will find the necessary fuses for the other voltage in the

accessories package. Slide the voltage selector back into the power supply

module so that the correct voltage is visible in the lid window of the cover (2).

Connect the printer to a grounded outlet using the power cable supplied in the

accessories package.

4

6

1 6

cab - Produkttechnik GmbH28

Page 29

Connection to a Computer

Hermes is equipped with three serial interfaces, these are RS-232, RS-422,

and RS-485, all of them using the 25 pin interface connector (2) at the back.

In most cases, you can use the RS-232 interface for the connection to the

computer. If your computer is located more than 50 ft (15 m) away from the

printer you should use the RS-422 interface.

The RS-485 interface is provided for using the Hermes as part of a networked

system.

In addition to the serial port, the Hermes also provides a parallel (Centronics)

interface which offers a faster transfer of data than the serial interfaces.

Therefore, we recommend you use the parallel interface for those applications

where a large number of loadable fonts or complex graphics have to be printed.

For the Centronics interface use the 36 pin interface connector (1).

Select the required interface settings using the Setup procedure and connect

the printer to the computer by a suitable interface cable.

CAUTION !

Make sure that all connected computers and their connecting cables are

correctly grounded.

1

2

Fig. 5b Interface ports (rear view of the printer)

1- Parallel interface port

2- Serial interface port

29cab - Produkttechnik GmbH

Page 30

Switch on the printer

2

Fig. 5c Switch on the printer

After making all connections switch on the printer at the power switch (1/2).

The printer carries out a short system test and following the display is shown

the system mode "ONLINE".

If a hardware failure occurs during the system test the type of the failure will be

shown. In this case the printer should be switched off and on again. If the

failure occurs again call the service.

If the display is not showing anything after switching on the printer, please

check the following whether:

- the connection of the power switch is correct

- the setting of the voltage selector corresponds with the power supply voltage

- the fuses in the voltage selector are not defective

1 - Power switch Hermes 4N/4F

1

2 - Power switch Hermes 5N/5F

If all these conditions are true and the device nevertheless cannot be switched

on call for service, please.

CAUTION !

If the fuses in the voltage selector are defective do not use the fuses of

the delivery contents as spare parts.

These fuses are only for using at the other operation voltage.

By using the fuses of the delivered contents without changing the setting

of the voltage selector, the printer may be damaged.

cab - Produkttechnik GmbH30

Page 31

6 Media loading

Preparation of the label supply hub

1 2 3 4 2 3

Fig. 6a Preparation of the label supply hub

Hermes is equipped with a rotating label supply hub, which is able to take up

rolls with a core diameter of 3 in (76 mm).

To take up these label rolls it is necessary to mount two adapters (3) onto the

supply hub :

1. Put the first adapter (3) onto the supply hub (4) and slide it to the wind plate

(1) until it blocks. Tighten the knurled srew (2).

2. Put the second adapter onto the supply hub (4) and slide it against the

wind plate until the distance between the outer edge of the adapter and the

wind plate (1) is a little less than the width of the label roll. Tighten the

knurled screw.

31cab - Produkttechnik GmbH

Page 32

Loading Labels

19

18

17

16

15

1 2 3 4 5

10

Fig. 6b Media loading Hermes 4N/5N

1. Place the label roll (1) onto the prepared media hub (3) and slide it against

the wind plate (5). The solid line represents the feed path of outside-rolled

labels, the broken line of inside-rolled labels.

2. Put the flange (4) on the supply hub (3), slide it against the label roll (1) and

fix it at the supply hub by tightening the knurled knob (2).

3. Swing the three levers (9, 19 und 16) clockwise until they stop and open

this way the transport system (10,11) and the backfeed system (17,18).

The printhead (15) also will be unlocked from the print roller.

4. Loosen the knurled knob (12) and slide the media guide (13) into its

outermost position.

678911121314

cab - Produkttechnik GmbH32

Page 33

16

15

10 911121314

Fig. 6c Media loading Hermes 4F/5F

5. Unroll a length of label stock from the media roll and feed it first to the

printhead (15) as shown in figure 6b.

NOTICE !

It is particularly important to ensure that the media strip slides properly

between the fittings of the adjustable photocell assembly (14).

6. Feed the label stock out of the front side of the printer until there is enough

material to reach the internal rewinder. Take all labels off the outstanding

liner, and feed the liner as shown in figure 6b to the internal rewinder (8).

7. Slide the media strip under the rewinder clamps (6) to the wind plate. Hold

the rewinder and turn the knurled knob (7) clockwise. That way the label

strip will be fixed at the rewinder.

8. Turn the rewinder (8) clockwise for tightening the label strip.

9. Slide the guide (13) against the outer edge of the label strip and tighten the

knurled knob (12).

10. Swing all levers (9, 19 and 16) counterclockwise until they block. In this

way the transport system (10,11) and the backfeed system (17,18) will be

closed and the printhead (15) will be locked.

NOTICE !

If you do not use the printer for an extended period of time, lift the

printhead to avoid possible flattening of the print roller.

33cab - Produkttechnik GmbH

Page 34

Loading Transfer Ribbon

6

1

2

3

4

5

Hermes 4N/5N Hermes 4F/5F

Fig. 6d Loading thermal transfer ribbon

1. To lift the printhead (5), turn the printhead lever (4) clockwise until it stops.

2. Slide the roll of transfer ribbon (6) onto the ribbon supply hub (7) as far as

possible.

NOTICE !

Pay attention to the side of the ribbon material which is coated with ink !

The inked side is generally the dull side. When the ribbon is inserted, the

inked side must face the opposite side of the printhead !

In Figure 6c, the solid line shows the path of inside wound ribbon, and

the broken line represents the path of outside wound ribbon.

3. Hold tight the ribbon supply hub (7) and rotate the knurled knob (8)

clockwise until it stops. That way the transfer ribbon roll (6) will be attached

to the ribbon supply hub (7).

4. Slide an empty cardboard core (1) onto the ribbon take up hub (2) and fix it

by clockwise turning the knurled knob (3).

5. From the side, feed the transfer ribbon along the path as shown in

Figure 6d, then attach it to the core (1) using adhesive tape or a label.

6. Turn take up hub (2) counterclockwise in order to smooth and stretch the

ribbon.

7. To lock the printhead (5), turn the lever (4) counterclockwise until it stops.

7

8

1

2

3

4

5

6

7

8

cab - Produkttechnik GmbH34

Page 35

7 Adjustments Concerning the Labels

Adjustment of the Label Edge Sensor

21 2 1

Hermes 4N/5N Hermes 4F/5F

Fig. 7a Adjustment of the label edge sensor

To accommodate a variety of print jobs, the position of the label edge sensor

(2) can be adjusted cross to the path of the paper feed. This setting is

particullary usefull if the required labels are either narrow, or have punch holes

or reflective markings, or deviate from the square or rectangular shape.

It is important to ensure that the sensor is positioned in a way that the gaps

between the labels or the markings can be recognized by the photocell. (The

position of the sensor is marked by a notch in the sensor holder.)

If using labels with an unconventional shape (i.e. round or curved) the sensor

should be positioned at the front edge of the label.

Adjust the sensor position using the knurled knob (1).

By turning the knob clockwise the sensor moves outward, and by rotating the

knob anticlockwise it moves inwards.

35cab - Produkttechnik GmbH

Page 36

Adjustment of the Printhead Support

2 3b

3a14

Hermes 4N/5N Hermes 4F/5F

Fig. 7b Adjustment of the printhead support

When printing narrow labels (label width less than the half of the maximum

print width), it is possible that the printhead will come into direct contact with

the drive roller. This will lead to premature wear on the printhead. In addition,

the printhead will be at a slight angle to the label, thus, the uneven pressure

may result in an inconsistent image density from one edge of the label to the

other.

To correct this problem, the printhead support (2) may be adjusted.

Adjust printhead support as follows :

1. Loosen the knurled screw (3).

2. Move the knurled screw (3) as required within the adjustment slot (4). This

will cause the cam shaped printhead support (2) to rotate, in effect,

providing a higher or lower base on which the printhead mounting (1) rests.

3. It is convenient to use the position 3a to print large labels. In this case the

printhead support (2) is totally inactiv.

4. By using small labels it is necessary to adjust the printhead support. In this

case insert a second strip of the label at the front side of the print roller.

Now slide the knurled knob (3) as far as possible to position 3b in the

adjustment slot (4), until the printhead support (2) touches the printhead

mounting (1). Take away the second label strip.

5. Tighten the knurled screw (3).

2 3b

3a14

cab - Produkttechnik GmbH36

Page 37

Adjustment of the Label Tracking

1 2 3

Fig. 7c Adjustment of the label tracking (backfeed system)

It is necessary to adjust the label tracking, if the label strip sideward leaves the

normal path.

Such a drift may cause :

- a sideward displacement of the printed images at the label.

- a sideward displacement of the peel position.

- a paper jam or a damage of the label strip.

To correct this problem, the backfeed system may be adjusted as follows :

1. Loosen the locking screw (2) at the backfeed system.

2. Adjust the label tracking by turning the set screw (3).

If the labels drift inwards ð Turn the set screw clockwise.

If the labels drift outwards ð Turn the set screw counterclockwise.

Repeat the adjustment as long as necessary. After every adjustment step

open and close the backfeed system by turning the lever (1).

3. Tighten the locking screw (2).

37cab - Produkttechnik GmbH

Page 38

Adjustment of the Transfer Ribbon

1

2

3

4

Hermes 4N/5N Hermes 4F/5F

Fig. 7d Adjustment of the transfer ribbon

If creases, lines or black patches appear in the print image resulting in a poor

print quality, this may be caused by wrinkles in the transfer ribbon (4). To

remove the wrinkles, the tension of the ribbon should be made even from the

left to the right by slanting the axle (1).

1. Loosen the locking screw (2).

2. The axle may be slanted by moving the locking screw (2) as required inside

the adjustment slot (3). Moving it to the bottom will tightened the ribbon on

the inner edge. In the other case it will be done on the outer side of the

transfer ribbon.

To reduce the formation of wrinkles the ribbon must be tightened at this

side where the wrinkles will be built

1

2

3

4

3. After completing the adjustment, tighten the locking screw (2).

cab - Produkttechnik GmbH38

Page 39

8 Options

Applicators

Non-cab-Applicators

The Thermal Transfer Printers of the Hermes family are especially developed

for fully automatic labelling. Therefore all types of Hermes are equipped with a

peripheral port with a minimum configuration of signals. That way it is possible

to operate many different non-cab-applicators at the Hermes.

Fig. 8 a Peripheral port for non-cab-applicators

For the use of Hermes with a non-cab-applcator two input signals are needed :

1. "Print start"

Since the label will be dispensed from the liner directly after printing, it is

necessary to make sure, that the applicator is ready to take the label when

sending the signal "Print start".

1

2. "Label is taken"

This signal is needed to start the backfeed of the label material. After the

backfeed the print of the next label can be started from the front edge.

It is also necessary to activate this signal, if the parameter "Backfeed" in

the setup is set to "smart". Otherwise the next "Print start" signal will not be

accepted.

Beside the described input signals it is possible to get some status information

via the peripheral port.

The complete interface description is included in the appendix B.

39cab - Produkttechnik GmbH

Page 40

cab-Applicators

Fig. 8 b cab-Applicators for Hermes

1 2 3 4

cab offers a own line of applicators (1) for the printers of the Hermes family. To

connect these applicators the cab-types of Hermes have aditionally a second

peripheral port (3) at the front side.

Typically for the cab-applicators, the dispensed label will be taken by a vacuum

plate (2). After that different pneumatic cylinders move the plate to the labelling

position where the label will be pressed or blown onto the product.

The size of the vacuum plate is specified for the label size.

40 cab - Produkttechnik GmbH

Page 41

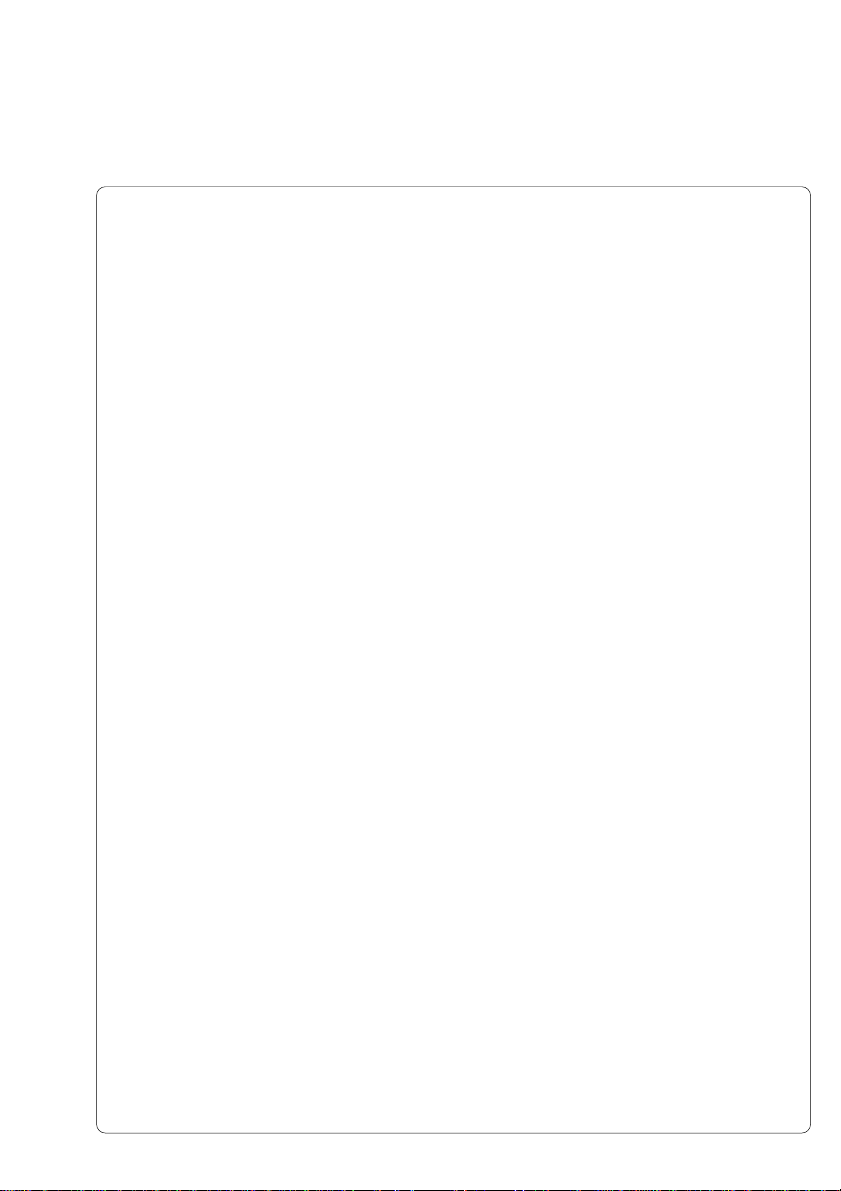

The following table shows some standard versions of cab-applicators :

Applicator type Labelling destin. Labelling type

Tamp Applicator downwards press on

with Lift Cylinder

Tamp Blow Applicator downwards blow on

with Lift Cylinder

Tamp Applicator sidewards press on

with Swing & Lift Cylinder

Blow Applicator sidewards/ blow on

with Swing Cylinder upwards

Table 8 cab-applicator types

For use in a networked system all cab-applicators are equipped with a PLC

interface with potential free inputs and outputs .

For the detailled description of the cab-applicators several Operator's Manuals

are available.

41cab - Produkttechnik GmbH

Page 42

Bracket

The delivery program of the Hermes series includes brackets for Hermes 4

and Hermes 5. These mounting elements allow to hang in the printer in to a

production line. For that the bracket first must be mounted onto a profile.

After that the printer can be hung in into the bracket and fixed by screws.

The delivery contents of the bracket (1) include a clamp (2) for mounting the

bracket (1) at a profile with a cross-section of 50mmx50mm. The clamp is

made of three parts assembled by screws (3).

1 2 3

Fig. 8 c Bracket with clamp

The form of the clamp allows to mount the bracket onto a horizontal as well as

a vertical profile. Besides the bracket can be moved sideward inside the

clamp. This way the bracket can be adjusted to different centers of gravity

when differnt applicators are used at the Hermes.

Fig. 8 d Samples of the bracket mounting

42 cab - Produkttechnik GmbH

Page 43

4

1

5

Fig. 8 e Mounting the printer at the bracket

Hermes has one each bolt (4) at the front and the rear side. Using these bolts

the printer is hung in into the grooves of the bracket (1). After that the printer is

fixed at the bracket with six screws (5).

43cab - Produkttechnik GmbH

Page 44

Feet

Using the profile feet Hermes can be put directly on a table. Its also possible to

mount the printer onto a customer specific head plate.

The feet are fixed from below with four screws at the frame of the printer. The

shorter foot has to be mounted below the print machanism.

Fig. 8 f Feet

Fig.8 g Set up the printer on a table

Fig. 8 h Set up the printer on a head plate

44 cab - Produkttechnik GmbH

Page 45

Warning Light

By using the warning light it is possible to recognize the state of the printer with

one view.

For mounting the warning light it is recommended to use the option "Bracket".

Fig. 8 i Connection of the warning light

1. Fix the warning light (1) at the bracket (3). Use the two screws (2) which

1

2

3

4

5

are included in the delivery contents of the light.

2. Contact the connection cable (4) of the warning light at the socket (5).

During the operation the lamps have following functions :

green Device is switched on, voltage is available.

yellow Warning : labels respectively transfer ribbon have passed the

preset minimum quantity.

Function is only available when the warning sensor label end is

mounted.

red Printer error

Further information about the kind of error is shown at the display.

45cab - Produkttechnik GmbH

Page 46

Warning Sensors

The sensors recognize, when the diameter of the label supply roll respectively

the transfer ribbon roll decreases below a preset thresould value.

NOTICE !

The messages of the sensors are only intended to inform the operator.

They do not influence the operation of the Hermes, i.e. the operation is

not interrupted.

The messages will be shown by switching on the yellow lamp of the warning

light (option). The signals also can be sent to a control system by using the

peripheral interface.

Warning Sensor Label End

Mounting

1. Switch off the printer

2. Slide the sensor holder (1) with the warning sensor label end (2) behind the

wind plate (6) of the media supply hub.

3. Attach the sensor holder with the slotted head screw (7) and the hexagon

socket head screw (3) to the mounting plate. The hexagon socket head

screw (3) must be used at this side, where the elongated hole is located in

the sensor holder.

4. Plug the cable (4). For that Hermes 4 has a 5-pin connector at the rear

side of the frame. The connector (10) at Hermes 5 is beside the control

panel.

Adjustment

With this setting the threshold diameter (3.3 to 4.3 in / 84 to 110mm) for the

warning message can be adjusted.

1. Slide a label roll (9) with the intended threshold diameter onto the media

supply hub.

2. Switch on the printer. The sensor (2) sends out a beam (5). If the label roll

does not interrupt the path of the beam, the beam is mirrored at the

reflective foil (8) and detected again by the sensor. In that case the LED at

the sensor is on.

3. Loosen the hexagon socket head screw (3) and swing the sensor holder

against the axle of the media supply hub as near as possible.The LED at

the sensor is off.

4. Slowly swing the sensor holder away from the axle until the LED at the

sensor goes on.

5. Tighten the hexagon socket head screw (3).

46 cab - Produkttechnik GmbH

Page 47

1 2 3 4 5

Fig. 8 k Warning sensor label end Hermes 4

10 4 2 7 1 6

6

7

8

9

4

Fig. 8 l Warning sensor label end Hermes 5

5

8

3

9

47cab - Produkttechnik GmbH

Page 48

Warning Sensor Ribbon End

NOTICE !

The warning sensor ribbon end is analyzed by the printer electronics only

if the warning sensor label end is installed too.

Mounting

1. Switch off the printer

2. Attach the sensor holder (7) with the warning sensor ribbon end (8) using

the screws (6) to the mounting plate.

3. Plug the cable (9). For that Hermes 4 has a 3-pin connector at the rear

side of the frame. The connector (10) at Hermes 5 is beside the control

panel.

4. The contents of delivery include a reflective foil (2).

Remove the covering foil from the glued surface an stick the reflective foil

(2) onto the bracket (3) below the ribbon hubs as shown in fig.8m. Make

sure that the distance between the reflective foil and the mounting plate (1)

is about 0.6in (15mm).

Fig. 8 m Placing the reflective foil

15

15

1

2

20

3

Adjustment

With this setting the threshold diameter (1.4 to 1.6in / 34 to 41mm) for the

warning message can be adjusted.

1. Slide a transfer ribbon roll (4) with the intended threshold diameter onto the

media supply hub.

2. Switch on the printer. The sensor (8) sends out a beam (5). If the ribbon roll

does not interrupt the path of the beam, the beam is mirrored at the

reflective foil (2) and detected again by the sensor. In that case the LED at

the sensor is on.

3. Loosen the screws (6) and move the sensor holder to the right as far as

possible.The LED at the sensor is off.

4. Slowly move back the sensor holder to the left until the LED at the sensor

goes on.

5. Tighten the screws (6).

48 cab - Produkttechnik GmbH

Page 49

76 98

5

4

2

3

Fig. 8 n Warning sensor ribbon end Hermes 4

10

9

8

6

7

4

5

2

3

3

Bild 8 o Warning sensor ribbon end Hermes 5

49cab - Produkttechnik GmbH

Page 50

50 cab - Produkttechnik GmbH

Page 51

9 Control Panel

The front control panel of the Hermes is fitted with 4 function keys with

indicator LEDs, and a 2x16 character digital LCD display.

Fig. 9 Control Panel

The control panel display constantly provides the operator with the actual

information concerning the current printer mode and label processing. The

indicator LEDs support the information shown in the display by indicating which

keys have to be pressed. (e.g. in the event of a fault)

On the following pages, you will find descriptions of the system modes of the

Hermes, the related indications by the LCD display an the LEDs as well as a

description of the function keys under differing conditions.

51cab - Produkttechnik GmbH

Page 52

System Mode ONLINE

ONL key Switch into OFFLINE mode (LED ONL off)

FF key Provides label feed. The leading edge of the next label to be

CAN key Deletes data of the previous print job in internal memory.

PSE key Repeats the print of the last label, after the previous print job has

ONL key Pressing both keys together for at least 5 seconds will switch

+ into the SETUP mode.

CAN key (LED ONL off)

printed is in print position.

Following that, "Pause reprint" is not available.

(see PSE key)

been completed. (only if setup parameter 'Pause reprint' is on)

System Mode OFFLINE

ONL key Switch into ONLINE mode (LED ONL on)

FF key Provides label feed. The leading edge of the next label to be

CAN key Switch into LABEL FROM CARD mode.

PSE key Display shows current printer mode

printed is in print position.

(only if memory card is installed and formats are stored it)

System Mode PRINT

CAN key short pressing : Cancels the current print job,

longer pressing (>1s): Cancels the current print job,

PSE key Interrupts the current print job,

Switch into PAUSE mode (LED PSE on)

52 cab - Produkttechnik GmbH

Switch to the next job in the input buffer

Deletes the input buffer

(LED CAN blinks),

Switch into ONLINE mode

Page 53

System Mode P AUSE

FF key Provides label feed. The leading edge of the next label to be

CAN key Cancels the current print job,

PSE key Continues the current print job,

printed is in position.

Switch into ONLINE mode (LED PSE off)

Switch into PRINT mode (LED PSE off)

System Mode LABEL FROM CARD

ONL key Switch into OFFLINE mode

FF key For scrolling down within the file list stored on the card.

CAN key For scrolling up within the file list of the card.

PSE key Confirms file selection.

Reduces the quantity of labels to be print.

Increases the quantity of labels to be printed.

Moves the cursor to be right when setting the quantity of labels

to print.

Switch into PRINT mode

53cab - Produkttechnik GmbH

Page 54

10 Setup

This mode is initiated by either simultaneously pressing the key and the

system test is completed, or in ONLINE mode, press the same two keys down

for at least 5 seconds.

In this mode a lot of printer parameters could be adapted to the concrete using.

The setup mode can be left at any point by pressing the key.

The confirmed parameters will be saved.

To return to the original factory default settings, press all three keys, the

key, the key, and the key simultaneously and keep them pressed

down until the display shows "--- RESTORE ---".

Function keys in the SETUP mode

key when switching on the printer and keep them pressed down until the

ONL key Stores the chosen settings of the setup-parameters and

FF key Skips to next setup parameter.

CAN key Skips to previous setup parameter.

PSE key Confirms selected settings for parameters.

54 cab - Produkttechnik GmbH

completes the SETUP mode.

(i.e. switch into ONLINE mode (LED ONL on)

Reduces numerical setup values.

Increases numerical setup values.

Page 55

Overview of the Setup Parameters

Country Deutschland France

Schweiz Suisse Belgie Suomi

Italia España

United Kingdom

Ceska republika

Transfer print On Off

Label sensor Gap sensor

Interface RS-232C RS-422 RS-485 Centronics

Peel position + y.y mm - y.y mm

Printhead position X: ?.x mm Y: + y.y mm Y: - y.y mm

Baud rate Baud rate Baud rate

Protocol Protocol

± ?.y mm ± ?.y mm

± y.? mm ± y.? mm

X: x.? mm Y: ± ?.y mm Y: ± ?.y mm

Bottom-Reflect

Y: ± y.? mm Y: ± y.? mm

Top-reflect

Network address

Heat level + h - h

Printer info Version xxxxx xxx m / xxx h

Set date DD.00.0000 00.MM.0000 00.00.YYYY

Set time hh.00.00 00.mm.00 00.00.ss

Character set

ISO 8895-1 Codepage 850 EBCDIC Macintosh

Codepage 852 ISO 8895-8 Windows 1252 Windows 1250

Format card No Yes

Copy memory card Yes No

Backfeed

head lift-off* head down* * Selection "head down" only possible at Hermes 4F/5F

smart always

USA

Danmark

Debug mode Off On

Pause reprint On Off

55cab - Produkttechnik GmbH

Page 56

11 Error Messages / Problem Solution

Correctable Errors

While processing a print job, an error has occured which may be corrected by

the operator, and also allows you to continue the print job after fault correction.

Display : The top line of the display shows alternately the type of fault

LED Display : LED CAN on, LED PSE is flashing.

Function Keys

CAN key Cancels the current print job.

PSE key Continues current print job after error correction.

Irrecoverable Errors

While switching on the printer or during printing, a fault has occured which

cannot be cleared by the operator without cancelling the current print run

(e.g. hardware fault).

Display : This display shows the type of fault.

LED Display : LED CAN is flashing.

Function Keys

and the total of the remaining labels of the current print job.

Switch into ONLINE mode.

(LED ONL on, LED CAN off, LED PSE off)

Switch into PRINT mode.

(LED ONL on, LED CAN off, LED PSE off)

Taste CAN Cancels the current print job.

56 cab - Produkttechnik GmbH

Switch into ONLINE mode.

(LED ONL on, LED CAN off, LED PSE off)

If ONLINE mode cannot be entered, switch printer on and off

again.

If the fault remains again, contact Technical Service.

Page 57

Appendix A - Built-in Dimensions

The devices of the Hermes-family are prepared to build in an assembling line.

For that reason there will be offered a fitting clamp for the hanging mounting

and in the other case feet for a standing mounting.

Of course you are able to order Hermes without any options and use own fitting

elements.

Certainly by ordering the option clamp the fitting holes for the mounting of the

warning light (option), a compressed air service unit for the pneumatic

applicator and standard mounting elements (e.g. flange FKV 50 respectively

profile EV 50 of the firm Rose&Krieger Verbindungstechnik GmbH) will be

delivered.

The feet of Hermes are shaped in such a way that the printer may be fitted at

the setting area with suitable clamps and so the Hermes will be saved against

sliding.

CAUTION !

If you have purchased the printer without feet, avoid to place it upright.

Due to the missing feet, the printer may fall on its front side, where its

own weight rests on the print mechanism. This may cause damage to the

printer.

The drawings at the next pages show the most important function dimensions

to integrate the Hermes :

Page A-2 : Hermes 4N

Page A-3 : Hermes 4F

Page A-4 : Hermes 5N

Page A-5 : Hermes 5F

cab - Produkttechnik GmbH A-1

Page 58

s

f

277

113

89

55.5

22

4

420

157

o

3xM6 on both sides

223 36

43

220

16

2

4xM5 on the bottom

7.8

55.4

1

10

27

33443

50

17

2.5

3

490

390

164

97.5

252.5

77

1

212

42.7

128

28

245.7

245.7

1

Bracket

et

5942471

71

2

Feet

5537748

48

3

Compressed air servi ce

ressed air service unit

4

Tamp Applicator with Li

Applicator with Lift Cylinder Type 1100-220 H

5537950

50

15max.120

18

Transfer Printer Herme

fer Printer Hermes 4N

5537500

00

A-2cab - Produkttechnik GmbH

Page 59

d

277

113

89

55.5

22

4

420 157

o

3xM6 on both sides

36

223

55

220

16

2

7.72

55.4 27

1

10

33443

o50

17

2.5

3

1

502

390

212

42.7

128

128

245.7

245.7

152

1

Bracket

ket

5942471

2471

2

Feet

158

98

t

5537748

7748

3

Compressed air service unit

pressed air service unit

4

Tamp Applicator with Lift Cylin

4xM5 on the bottom

15max.120

7718

p Applicator with Lift Cylinder Type 1100-220 H

5537950

7950

Transfer Printer Hermes 4F

nsfer Printer Hermes 4F

7503

5537503

A-3cab - Produkttechnik GmbH

Page 60

277

113

89

55.5

22

4

3xM6 on both sides

542

457

o

542

3

1

490

230 36

43

220

7.87.8

2

1

15

max.120

10

55.4

27

457

33443

50

2.5

16

17

164

253

193

7718

219

43

42.7

128

128

245.7

245.7

1

Bracket

et

5942472

472

2

Feet

5537748

748

3

pressed air service unit

Compressed air service unit

4

Tamp Applicator with Lift Cylinder Type 1

Applicator with Lift Cylinder Type 1100-220H

5537950

950

fer Printer Hermes 5N

Transfer Printer Hermes 5N

5537501

501

A-4cab - Produkttechnik GmbH

Page 61

277

113

89

55.5

22

4

3xM6 on both sides

502

457

o

542

3

1

542

230 36

55

220

2

1

15

max.120

10

55.4

27

457

33443

50

2.5

16

17

152

253

193

7718

219

42.7

128

8

245.7

245.7

1

Bracket

5942472

2

Feet

5537748

3

4

sed air service unit

Compressed air service unit

Tamp Applicator with Lift Cylinder Type 1

plicator with Lift Cylinder Type 1100-220H

5537950

Printer Hermes 5F

Transfer Printer Hermes 5F

5537506

A-5cab - Produkttechnik GmbH

Page 62

Appendix B - Pin Assignment of the Interface Connectors

Pin Assignment of the Serial Interface Connectors

Hermes provides a 25 pin SUB-D connector for the serial interfaces which are

internally available, i.e. RS-232, RS-422 and RS-485.

Pin 1Pin 13

Pin 14Pin 25

Fig. B-1 Connector of the serial interface (rear of the printer)

Pin Signal Function

1 CG Protective Ground

2 TxD Transmit Data (RS-232)

3 RxD Receive Data (RS-232)

4 RTS Request to send

5 CTS Clear to send

7 GND Logic Ground

9 TDATA+ Transmit Data (RS-422, RS-485)

10 TDATA- Transmit Data (RS-422, RS-485)

18 RDATA+ Receive Data (RS-422, RS-485)

19 RDATA- Receive Data (RS-422, RS-485)

20 DTR Data Terminal Ready

Table B-1 Signals of the serial interface connector

cab - Produkttechnik GmbH B-1

Page 63

Interface Cable for RS-232

The following chapter shows some typical RS-232 interface cable configurations. Note, that the pin assignment may vary for different computers. If you

have any problems with the connections, contact the manufacturer of your

computer on the pin assignment of the interface. Use the pin assignment of the

printer as shown in Table B-1 to obtain a suitable cable.

PC Hermes

11

23

32

520

77

64

85

20

25 pin connector 25 pin plug

Fig. B-2 Interface cable with 25 pin computer connector

for RS-232 with protocol " ---" or "XON/XOFF"

PC Hermes

22

33

57

820

14

45

6

9 pin connector 25 pin plug

Fig. B-3 Interface cable with 9 pin computer connector

B-2 cab - Produkttechnik GmbH

for RS-232 with protocol " ---" or "XON/XOFF"

Page 64

PC Hermes

11

23

32

45

54

77

6

8

20

25 pin connector 25 pin plug

Fig. B-4 Interface cable with 25 pin computer connector

Fig. B-5 Interface cable with 9 pin computer connector

for RS-232 with protocol " RTS/CTS" or "XON/XOFF"

PC Hermes

22

33

57

75

84

1

4

6

9 pin connector 25 pin plug

for RS-232 with protocol "RTS/CTS" or "XON/XOFF"

Interface Cable for RS-422 / RS-485

To control the Hermes by RS-422/ RS-485 interface, only the signals TDATA+,

TDATA-, RDATA+, and RDATA- are necessary.

Check the pin assignment for the interface of your computer, and use the pin

assignment of the printer as shown in table B-1 to obtain a suitable cable. The

connectors of TDATA+ and RDATA+ as well as TDATA- and RDATA- at the

plug-in-connection of the cable must be united. If there is a very large transfer

distance a termination of the cables is recommended.

cab - Produkttechnik GmbH B-3

Page 65

Pin Assignment of the Parallel Interface Connector

Hermes provides a 36 pin connector for the parallel Centronics interface.

Pin 18 Pin 1

Pin 19Pin 36

Fig. B-6 Centronics interface connector (rear of the printer)

Pin Signal Pin Signal Pin Signal Pin Signal

1 /STROBE 10 /ACKNLG 19 GND 28 GND

2 DATA 1 11 BUSY 20 GND 29 GND

3 DATA 2 12 PE 21 GND 30 GND

4 D ATA 3 13 SLCT 22 GND 31 nc

5 DATA 4 14 nc 23 GND 32 nc

6 DATA 5 15 nc 24 GND 33 nc

7 DATA 6 16 GND 25 GND 34 nc

8 DATA 7 17 nc 26 GND 35 nc

9 DATA 8 18 nc 27 GND 36 nc

Table B-2 Signals of the Centronics interface

Centronics Interface Cable

The cables used for Centronics interface connectors are standard cables, so

that normally there are no problems with the external control of the Hermes.

In the event of any difficulties, consult the manufacturer of your computer on