Page 1

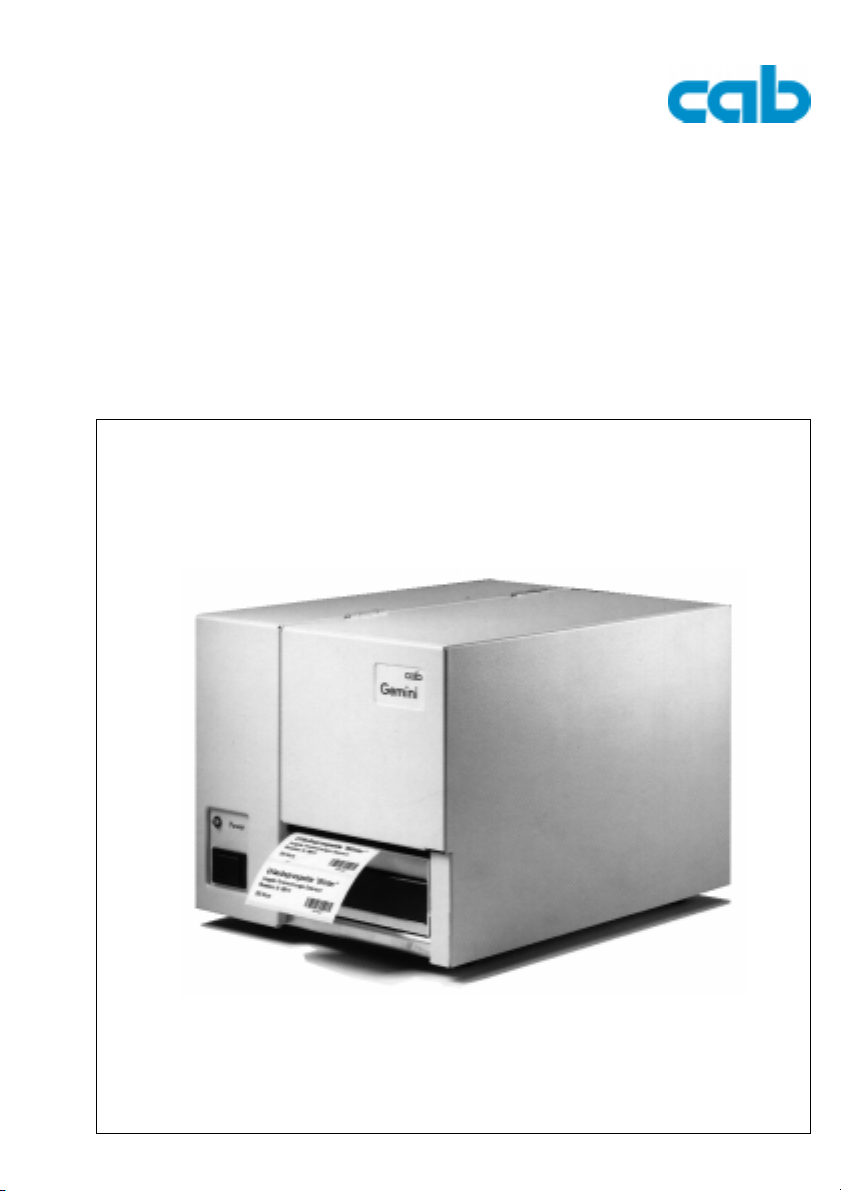

Gemini

Thermal / Thermal Transfer

Windows Label Printer

Operator's Manual

Edition 6/00

Page 2

cab-Produkttechnik

Gesellschaft für

Computer- und AutomationsBausteine mbH & Co KG

Postfach 19 04 D-76007 Karlsruhe

Wilhelm-Schickard-Str. 14 D-76131 Karlsruhe

Telefon 0721 / 66 26-0

Telefax 0721 / 66 26-249

http://www.cabgmbh.com

e-mail: info@cabgmbh.com

copyright by cab / 9008283 / N01 / 1

Technische Änderungen vorbehalten

In accordance with our policy of continual product improvement, we reserve the right to alter specifications without notice

Données technique modifiables sans prévais

2 cab Produkttechnik GmbH & Co KG

Page 3

Gemini

Thermal Transfer Printer

Thermal Transfer Printer

Operator's Manual

Operator's Manual

All rights reserved, including those of the translation

No part of this manual nor any translation may be reproduced or transmitted in any form

or by any means, for any purpose other than the purchaser's personal use, without the

express written permission of cab - Produkttechnik GmbH Karlsruhe.

Edition 6/00

Printed in Germany

3cab Produkttechnik GmbH & Co KG

Page 4

Table of contents

1. Introduction................................................................................................................. 6

Introducing the Gemini Windows Barcode Printer ......................................................... 6

Agency Compliance and Approvals............................................................................... 7

Technical Specifications ................................................................................................ 8

2. General Safety Regulations ...................................................................................... 11

3. Unpacking and Delivery Contents ............................................................................ 12

4. Printer Component Location .................................................................................... 13

5. Connecting the Printer.............................................................................................. 17

Connection to a Computer........................................................................................... 17

Connection to Power Supply ....................................................................................... 17

6. Media loading ............................................................................................................ 18

Processing Mode ....................................................................................................... 18

Loading Labels............................................................................................................ 19

Ribbon Loading ........................................................................................................... 22

7. Adjustments Concerning the Labels ........................................................................ 23

Adjustment of the Printhead Support........................................................................... 23

Adjustement of the Transfer Ribbon Feed ................................................................... 24

8. Installing and Using the Software ............................................................................ 25

Introduction ................................................................................................................. 25

Installation information ................................................................................................ 25

Updates ...................................................................................................................... 25

The Gemini Control Panel Application......................................................................... 26

Gemini Test Print......................................................................................................... 27

Printer Setup............................................................................................................... 28

Printing from Windows Applications ............................................................................ 32

4 cab Produkttechnik GmbH & Co KG

Page 5

9. Error Messages ......................................................................................................... 33

10. Maintenance / Cleaning ........................................................................................... 34

General Cleaning ........................................................................................................ 34

Cleaning the Media Feed Roller .................................................................................. 34

Cleaning the Thermal Printhead .................................................................................. 35

Removing Labels from the Dispenser Roller................................................................ 36

11. Printhead Horizontal Alignment ............................................................................... 37

12. Troubleshooting ........................................................................................................ 39

EC-Conformity Declaration ............................................................................................. 40

Trademarks

Centronics ® is a registered trademark of Centronics Data Computer Corporation.

Microsoft ® is a registered trademark of Microsoft Corporation.

TrueType is a registered trademark of Apple Computer, Inc.

Easylabel ® is a registered trademark of Tharo Systems, Inc.

5cab Produkttechnik GmbH & Co KG

Page 6

1. Introduction

Introducing the Gemini Windows Barcode Printer

The Gemini is an innovative printer designed to work only in a Windows

environment. Instead of buttons on a printer's front panel, printer configuration

and control is provided by the Gemini Control Panel Application running under

Windows. The Gemini driver allows printing from almost any Windows

application, such as MS Word, Write, WordPad, Access® and Visual

Basic, as well as Lotus® Approach®, Paradox® and dBASE® among others.

Bar code labels can be created with existing Windows applications using the

special barcode fonts built into the driver, eliminating the need for special

labeling software.

Gemini uses the true type fonts available with your Windows applications, and

accepts all graphic types supported by Windows, resulting in exceptional

flexibility in font and graphic choices. Fonts and graphics are downloaded as

needed with the high-speed bi-directional Centronics interface, providing an

exceptionally quick time to first label printing.

The Gemini is built to work only with Windows, and takes full advantage of

Windows features. Its simple design requires a minimum of effort and

expertise for loading and maintaining the printer. From configuration and setup

to ongoing operation, use of the online Gemini Control Panel Application

simplifies the operator's job. Extensive Online Help is provided covering all

features and functions available within the Control Panel Application and

Printer Setup. In addition, help topics covering 'Printing from Windows

Applications' and 'Barcode and Symbology information' are included.

The Gemini Thermal Transfer Printer is offered in two versions:

Gemini T : The device is equipped with a tear-off edge to aid the removal of

Gemini TD : This device has an additional dispensing feature for labels.

Both versions are available as 230 Volt or 115 Volt devices.

6 cab Produkttechnik GmbH & Co KG

the labels or continous material by hand after printing.

Directly after printing the label is removed from the liner and

placed in a dispense position ready for further use. The

presence of a label in the dispense position is regognized by a

sensor which interrupts the printing until the label is removed.

Page 7

Agency Compliance and Approvals

Gemini complies with the following safety regulations:

CE : The printer complies with the following safety requirements

FCC : Gemini complies with Part 15 of FCC rules.

- EC Low Voltage Directive (73/23/EEC)

- EC Machinery Directive (98/37/EEC)

- EC Electromagnetic Compatibility Directive

(89/336/EEC)

Note: This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to Part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against harmful interference when

the equipment is operated in a commercial environment. This equipment

generates , uses, and can radiate radio frequency energy, and if not installed

and used in accordance with the instructions in this manual, it may cause

harmful interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference in which case the user

will be required to correct the interference at his own expense.

WARNING !

This is a Class A product. In a domestic environment this product may cause

radio interference in which case the user may be required to take adequate

measures.

7cab Produkttechnik GmbH & Co KG

Page 8

Technical Specifications

Printing

Type : Direct thermal / Thermal transfer printer

Printhead: Resolution 203 dpi = 8 dots / mm

Print Speed : 2, 2.8 ips (50, 70 mm/s)

Label Backfeed : Label is automatically pulled back into the printer

Maximum Print Width : 4.1" (104 mm)

Maximum Print Length : 11.8" (300 mm)

Printed Images :

Character Sets : All character sets supported by Microsoft Windows

Font Expansion: Dependent on font selected, as supported by Microsoft

Bar Code Symbologies: Barcode symbologies along with a variety of check

Bar Code Density: Fixed choices are available which further define the font

Graphics: All monochrome graphic types supported in Windows.

after a tear-off or peel-off operation to allow for printing

on the entire label

Windows.

character options are provided as fonts in the Gemini

Driver. These include: Codabar, Code 128, Code 39,

Code 39-Mod 43, EAN13, EAN8, Interleaved 2 of 5,

Interleaved 2 of 5-Mod 10, MSI+10, PDF417, POSTNET,

UCC, UPC/EAN 2 digit Add On, UPC/EAN 5 digit AddOn,

UPC-A, UPC-E0, UPC-E1

being selected. Depending on the symbology, ratios

including 2:1, 3:1 and 5:2 may be selected. Also

dependent on the symbology, the bar width multipliers

range from 1 to 8.

Label Rotation: Portrait and Landscape, Reverse Portrait and Reverse

8 cab Produkttechnik GmbH & Co KG

Landscape with Flip Format option.

Page 9

Media

Label Width: 1" - 4.5"(25 - 116mm)

Label Length: .3" - 11.8" (6 - 300mm)

Label Type: Roll-fed, die-cut or continuous labels, tags or tickets;

Supply Roll: Up to 6" (150mm) diameter on 1.6" - 3" (40 - 75mm)

Label Material: Standard labels and Cardboard / Tags

Transfer Ribbon: Width up to 4.5" (114mm);

Printer

Memory: Internal memory 256KB

Interface: High-speed bi-directional Centronics Parallel

Indicators/Switches: Power-on LED above Power Switch

most direct thermal or thermal transfer materials.

cores. Labels may be wound face-in or face-out on the

roll.

Thickness: 0.0024" to 0.0098"

(0.06mm to 0.25mm)

Direct Thermal, Thermal Transfer and various Synthetics

including: thermal transfer plaincoated papers, vinyl,

Mylar, metalized paper, non-woven fabric, fine woven

fabric, thermal visible light scannable paper, infrared

scannable paper, thermal ticket/tag stock, thermally

sensitive plastic stock.

Length 1182' (360m);

Rolls up to 3" (75mm) diameter on 1" (25mm) cores.

(max 70 KB/s)

Physical

Dimensions: Height: 8.9" (226mm)

Width: 9.4" (239mm)

Depth: 12.8" (326mm)

Weight: 17.6 lbs (10Kg)

9cab Produkttechnik GmbH & Co KG

Page 10

Electrical

Operating Voltage: 115V / 60 Hz or 230V / 50 Hz

Circuit Protection: 115VAC / 60Hz use 1.6 AT fuses;

Environmental

Operating Temperature: 50°F to 95°F (10°C to 35°C)

Humidity: 30% to 85%.

Other Features

Status Indication: LED on front panel uses slow blink to indicate pause and

Sensors: "See-through" media photosensor at 0.7" (17.5 mm) from

Voltage cannot be altered on the machine

230VAC / 50Hz use 800 mAT fuses;

rapid blink to indicate error.

Status provided through the on-screen Gemini Control

Panel application includes:

Number of labels left in printer

Out of labels / Out of ribbon

Printer state - paused or not paused

Demand Mode indication

Miscellaneous error messages

the paper edge

Demand sensor (Gemini TD only)

Ribbon-out sensor

Software : Gemini Windows Printer Driver

10 cab Produkttechnik GmbH & Co KG

and Control Panel Application

Page 11

2. General Safety Regulations

- The Gemini is built exclusively to print die-cut labels, continuous media, and

- Connect the printer only to an outlet with the proper voltage. The Gemini is

- Power must be off before plugging in any accessory, connecting to a computer

- Do not expose the printer to any moisture, or use in damp or wet areas.

- The printer will operate with the cover open when necessary. This is not

- During the printing process the printhead will become hot. Use extra caution

similar materials as listed in the Technical Specifications.

configured for either a 115V or 230V power supply, which can be determined by

checking the specification label on the machine. Connect only to a power

outlet with a grounded contact.

and before performing any maintenance on the printer.

recommended, as it might allow debris to collect within the printer. If the printer

must be operated with the cover open, extra care must be taken to avoid

allowing hair, jewelry, clothing, etc. near the rotating parts.

when touching the printhead.

11cab Produkttechnik GmbH & Co KG

Page 12

3. Unpacking and Delivery Contents

Unpacking

Please inspect the Gemini's packaging and contents immediately after receipt

for possible damage during shipment. The Gemini is shipped in a styrofoam

package and is enclosed in plastic to reduce the chance of moisture damage

during shipment.

F

Please keep the original packaging in case the printer must be returned.

Equipment Supplied

Your Gemini shipping container will contain the following standard components:

- Gemini Thermal Transfer Printer

- Power Cord

- Cardboard Core for the transfer ribbon rewinder

- Gemini User Manual

- Gemini Windows Software Diskette

Note : We offer additional items that may be included in your initial shipment.

Compare the delivered accessories with your order.

12 cab Produkttechnik GmbH & Co KG

Page 13

4. Printer Component Location

2

3

1

Gemini

Figure 4 a Frot view

1 - Cover

2 - Power LED

3 - Power Switch

13cab Produkttechnik GmbH & Co KG

Page 14

1 2 53 4

7 6

Figure 4 b Side view (with cover open)

1 - Ribbon Take Up Hub

2 - Ribbon Supply Hub

3 - Media Retainer

4 - Media Hub

5 - Media Retainer Knurled Screw

6 - Media Guide

7 - Media Assist Bar

14 cab Produkttechnik GmbH & Co KG

Page 15

11

1 2 3 1 3

10

10

9

8

45

Gemini TD Gemini T

Figure 4 c Detailed View of the Print Mechanism

1 - Thermal Printhead

2 - Printhead Adjustment Screw

3 - Printhead Locking Lever

4 - Label Edge Sensor

5 - Dispenser Locking Lever

6 - Dispenser Locking Roller

7 - Dispenser Drive Roller

8 - Media Feed Roller

9 - Tear-Off / Peel-Off Plate

10 - Transfer Ribbon Shield

11 - Present Sensor

12 - Tear-Off Plate

12

8

2 47 6

15cab Produkttechnik GmbH & Co KG

Page 16

Figure 4 d Rear View

1 - Centronics Parallel Port

2 - Specifications Label (power supply and voltage information)

3 - Power Cord Connection

4 - Fuse Holder

1

2

3

4

16 cab Produkttechnik GmbH & Co KG

Page 17

5. Connecting the Printer

Figure 5 Connecting the Printer

Connection to a Computer

The Gemini is fitted with a Centronics parallel interface which uses a 36-pin

port (1).

Obtain a standard parallel cable in a length suited to your needs (not exceed 10

F

feet in the length) and use it to connect the printer to your computer.

Ensure that the interface cable is correctly grounded.

1

2

3

4

5

6

Connection to Power Supply

Check that your available power supply voltage corresponds with the

F

voltage shown on the printer's specification label (2). The voltage

requirement shown will designate either 230 V/50 Hz order 115 V/60 Hz.

Do not connect the printer to the power supply until the voltage has been

verified.

After inserting the power cord into the power supply socket (3) at the rear of the

printer, connect the power cord to a grounded power outlet.

Switch the printer ON with the power switch (6). If the status LED (5) does not

light up, check the fuse inserted in the power supply module (3) by removing

the fuse-holder (4). Ensure that a fuse of the correct rating is installed :

800 mAT for 230 V 1,6 AT for 115 V

17cab Produkttechnik GmbH & Co KG

Page 18

6. Media loading

Processing Mode

The Gemini can be operated in two different processing modes. In addition,

two methods of operation are possible. The mode and method of operation

desired dictate the method of loading the label stock.

When in the Batch Mode, the labels are printed without pausing. The labels

exit the printer out the front, still attached to the backing strip.

When in the Demand Mode, labels are printed one at a time. The printing

cycle is then stopped until the label has been removed. When the present

sensor registers the label has been removed, an automatic backfeed is

performed and the next label is printed and fed forward to the demand position.

The Demand Mode operations are available with Gemini TD only.

Note: When editing the labels in the dispense mode, make sure that the label

area that lies directly underneath the sensor is only printed up to 50% (black). A

F

further blackening may cause malfunctions of the present sensor.

While processing in Demand Mode, the following operation methods are

available :

For Tear-off operations, the labels are loaded so that they exit the printer

straight out the front, as in Batch Mode. The label exits the printer, still

attached to the backing. (How far the label protrudes can be adjusted with

Presentation Position parameter in Printer Setup). When the label has been

torn off, the present sensor registers the removal and the next label is

printed.

For Peel-off operations, the labels with the backing strip fed down below the

peel plate before it exits the printer. For succesfull peel-off, the backing strip

must not be perforated between the labels. As the backing strip is pulled

down, only the label exits the front of the printer. In effect, the label is peeledoff of the backing, while remaining attached by only a narrow edge. (The

edge width can be adjusted with the Presentation Position parameter in

Printer Setup). When the label is removed, the present sensor detects the

removal and the next label is printed.

The following steps describe media loading for the Gemini. Steps 1-7 are

common to all processing modes and methods of operation. In the remaining

steps, loading for the different operating modes and methods of operation is

detailed separately.

18 cab Produkttechnik GmbH & Co KG

Page 19

Loading Labels

Figure 6 a Media Loading - Part 1

1. Raise the printhead by rotating the printhead lever (1) clockwise until it

stops.

2. Loosen the media retainer knurled screw (5) and swing the media retainer

(3) upwards.

2 3 4 51

7 6

3. Place the roll of label stock (2) onto the media supply hub (4).

4. Swing the media retainer (3) downward and inward until it rests on the

media supply hub (4), against the side of the label roll.

Retighten the knurled screw (5) .

5. Slide the media guide (6) outward, allowing enough clearance for the label

stock's width when loaded.

6. Unroll a length of label stock from the media roll. From the side, slide the

media under the media assist bar and inside the media guide (6) as shown

in Figure 6a. It is particularly important to ensure that the media strip slides

correctly under the arm of the photocell assembly (7).

19cab Produkttechnik GmbH & Co KG

Page 20

8 1

12

11

10 9 6

Figure 6 b Media Loading - Part 2

7. Continue feeding the label strip between the tear/peel plate (12) and the

thermal printhead (8) as shown in Figure 6b.

Batch Mode Loading and Demand Mode with Tear-Off Loading

8. Route the media strip forward straight through the front of the printer as

shown in Figure 6a.

9. Check the position of the media guide (6) and if necessary, slide it inward

until it lightly touches the sides of the media strip.

10. Adjust the media roll to remove any slack, then lower the printhead by

rotating the printhead lever (1) counterclockwise until it stops.

Make sure that the dispenser locking roller (10) is open. This helps to keep

F

20 cab Produkttechnik GmbH & Co KG

the wear at the roller low.

Page 21

Demand Mode with Peel-Off Loading

8. To prepare for feeding the media down through the dispenser mechanism,

remove a few labels from the backing. Fold at leatest an inch of the

backing up to create a double-layered, stronger leading edge for easier

loading.

9. Adjust the media roll to remove excess slack, then lower the printhead by

rotating the printhead lever (1) counterclockwise until it stops. Tension on

the media is needed to complete loading.

Click the Feed-button at the Gemini Control Panel (see chapter 8) to

synchronize the media feed.

10. Rotate the dispenser locking lever (9) clockwise until itstops to lift the

dispenser locking roller (10) from dispenser drive roller (11)

11. Feed the folded backing strip downward in front of the peel plate (12) and

behind the dispenser drive roller (11) as shown in Figure 6b. Continue

feeding the backing strip through until the leading edge appears below the

dispenser drive roller (11).

12. Grasp the edge of the folded backing strip and pull it through. Then close

the dispenser locking roller by rotating the dispenser locking lever (9)

counter-clockwise until itstops.

13. Check the position of the media guide (6) and if necessary, slide it inward

until it lightly touches the sides of the media strip.

F

If you do not use the printer an extended period of time, lift the printhead to

avoid possible flattening of the print roller.

21cab Produkttechnik GmbH & Co KG

Page 22

Ribbon Loading

Figure 6 c Ribbon Feed Path

1. Raise the printhead b rotating the printhead lever (1) clockwise until it

stops.

2. Slide the roll of transfer ribbon (4) onto the ribbon supply hub (5) as far as

possible.

Note which side of the transfer ribbon is coated with ink ! the inked side is

F

generally the shinier side. When the ribbon is inserted, the inked side

must not be placed in contact with printhead ! In Figure 6c, the solid line

presents ribbon with ink on the inner side, and the broken line presents a

ribbon with ink on the outer side.

3. Slide a cardboard core (2) onto the ribbon take up hub (3).

4. From the side, slide the transfer ribbon along the path as shown in Figure

6c, than attach it to the cardboard core use adhesive tape or a label.

5. Rotate the printhead locking lever (1) counter-clockwise until the printhead

is lowered and is placing light pressure on the ribbon. Remove the slack in

the ribbon by turning the ribbon take up hub (3) counter-clockwise.

6. Continue to rotate the printhead locking lever (1) counter-clockwise until it

stops, to lock the printhead in the closed position.

2 3 4 5

1

22 cab Produkttechnik GmbH & Co KG

Page 23

7. Adjustments Concerning the Labels

Adjustment of the Printhead Support

1

2b

4

Figure 7 a Adjustment of the Printhead Support

When printing narrow label stock (width less than 2.5" or 60 mm), it is possible

that the printhead will come into direct contact with the drive roller. This will

lead to premature wear on the printhead. In addition, the printhead will be at a

slight angle to the label, and this uneven pressure may result in an inconsistent

image density from one edge of the label to the other. To correct this problem,

the printhead support (4) should be adjusted.

Adjust the printhead support as follows:

1. Loosen the locking screw (2).

2. Move the locking screw (2) as required within the adjustment slot (3). This

will cause the cam shaped printhead support (4) to rotate, in effect,

providing a higher or lower base on which the printhead mounting (1) rests.

3. When using wide labels, start with a setting of "2a"; this places the

printhead support at its' lowest position, providing the most complete

contact of the printhead to the drive roller along the entire width. When

using very narrow labels, a setting of "2b" is recommended; this places the

printhead support at its' highest position, reducing contact of the printhead

with the drive roller at the outside edge.

At the adjustment criterion, check the quality of the print image.

4. Retighten the locking screw (2).

2a

3

23cab Produkttechnik GmbH & Co KG

Page 24

Adjustment of the Transfer Ribbon Feed

1 2

Figure 7 b Adjustment of the Transfer Ribbon Feed

If creases, lines or black patches appear in the print image resulting in a poor

print quality, this may be caused by wrinkles in the transfer ribbon (1). To

remove the wrinkles, the tension of the ribbon should be made even from the

left to the right by moving the ribbon shield (4) up or down.

34

1. Loosen the locking screw (3).

2. Shift the transfer ribbon shield (4) sideways into the direction of the wrinkle.

Moving it to the left will increase the tension on the left.

Use the scale (2) provided to monitor the adjustments made. If the screw is

in position "1", the tension is highest on the outside, and if it is in position

"5" , the tension is highest on the inside.

3. After completing the adjustments, tighten the securing screw (3).

24 cab Produkttechnik GmbH & Co KG

Page 25

8. Installing and Using the Software

Introduction

The diskette(s) provided with the printer includes installation files to install the

following:

1. Gemini Windows Printer Driver - The interface between the printer and your

Windows application, which also provides the capability of printing

barcodes using its special built-in fonts.

2. Barcode Display Font - Provides a general representation of a barcode on

the screen to assist in field placement during label design (Not intended as

an accurate representation)

3. Gemini Control Panel Application - Provides control of the printer and

current print job.

Gemini drivers are available for Windows 95/98/ME as well as for Windows

NT 4.0/2000/XP and greater.

Installation information

Depending on the Windows version used, the Gemini Printer software needs to

be installed through

either : the setup program of the software package

or : via the Add Printer Wizard.

Updates

Detailled information regarding the installation of the Gemini Printer software

are to find in the "readme.txt" file of the applicable software package.

Updates for the Gemini Printer software are available on the internet at :

http://www.cabgmbh.com

25cab Produkttechnik GmbH & Co KG

Page 26

The Gemini Control Panel Application

The Control Panel Application is necessary to provide control of the printer. It

is possible to print to the Gemini without having started this application. But,

without it, there would be no way to check status, see error messages, check

number of labels remaining, pause the printer, and so on. Detailed information

on the options currently provided with the Gemini Control Panel is available

through Online Help, and will not be included here.

To start the application, (double-)click on the Gemini program group, then

(double-) click on the Gemini icon . Once started, this application should

be left open as long as the printer is turned on.

Figure 8a Startup window of the Gemini Control Panel

Figure 8b Startup window of the Gemini Control Panel

26 cab Produkttechnik GmbH & Co KG

under Windows 95, 98 and ME

under Windows NT 4.0, 2000 and XP

Page 27

Gemini Test Print

Figure 8c Gemini Test Print Example

The test print on the Gemini Label Printer is available by clicking the 'Test

Print' button in the Gemini Control Panel Window (Figure 8a,b). The Test Print

contains a test pattern and the following information:

Firmware Version:

The Gemini's current firmware version.

Gemini Printer Driver Version:

The current version of the Gemini Windows Printer Driver.

Gemini Control Panel Version:

The current version of the Gemini Control Panel software.

Windows Version:

The version of Windows the Gemini Control Panel software is running on.

Total Print Length:

The total length in inches and meters that the Gemini Printer has printed.

27cab Produkttechnik GmbH & Co KG

Page 28

Printer Setup

Printer Setup is performed on an as-needed basis. Generally, when any printer

is installed, various options such as operating mode or paper size may need to

be modified from the default setting. With the Gemini, in addition to the usual

printer default values, barcode symbology selection should be made. The

Gemini driver provides a long list of available sybologies in various ratios and

multipliers. From this list, you must select those symbologies that should be

made available to your Windows applications. Detailed information on the

features and options currently available in Printer Setup is available through

Online Help, and will not be included here.

Printer Setup can be reached in a variety of ways. This can take place from

Windows Control Panel-Printers group, or from various application software in

the Printer Setup function. In addition, the Gemini Control Panel application

provides the most convenient, direct access to Printer Setup.

Printer Setup Windows under Windows 95, 98 and ME

Figure 8d Printer Setup - Main Window under

28 cab Produkttechnik GmbH & Co KG

Windows 95, 98 and ME

Page 29

Figure 8e Printer Setup - Printer Mode Window

under Windows 95, 98 and ME

Figure 8f Printer Setup - Add or Delete Barcode Font Window

under Windows 95, 98 and ME

29cab Produkttechnik GmbH & Co KG

Page 30

Printer Setup Windows under Windows NT 4.0, 2000 and XP

Figure 8g Printer Setup - Printer Properties Window

Figure 8h Printer Setup - Document Properties Window

30 cab Produkttechnik GmbH & Co KG

under Windows NT 4.0, 2000 and XP

Window accesseable from Gemini Control Panel by the

"Properties" button only

under Windows NT 4.0 (Overview), 2000 and XP

Page 31

Figure 8i Printer Setup - Document Properties Window

under Windows NT 4.0, 2000 and XP

Section "Print Mode and Media Control "

Figure 8k Printer Setup - Document Properties Window

under Windows NT 4.0, 2000 and XP

Section "Bar Code Options"

31cab Produkttechnik GmbH & Co KG

Page 32

Printing from Windows Applications

Printing to the Gemini is accomplished in the same manner as printing to any

other Windows installed printer. The Gemini must be slected as the default

printer by using either Windows Control Panel-Printers or the application in

use. What can be printed and how printing is initiated is then dependent on the

application being used.

The following is a general description of the steps required to print a label:

1. Select the Gemini as the default printer.

2. Start the Gemini Control Panel Application by (double-)clicking the icon,

then minimized if desired.

3. Specify the label size, processing mode, etc. with Printer Setup.

4. In your Windows Application, set the margins to 0 and set the page size to

match the label size specified in Printer Setup.

5. Design the label, considering the label's dimensions, even if your

application does not display a work area that matches the actual label size.

place text, graphics and barcode fields within the dimensions of your

label.

6. If possible, use Print Preview to assist in proper field placement.

7. Print a single test label to see actual layout and size of the fields. This is

the only way to see an accurate representation of barcode fields.

The ease with which a label can be designed, and the results that can be

achieved, depend directly on the software being used. the range of software

types, including word processors, databases, spreadsheets and graphic

applications, offers a similarly wide range in results.

To assist the user in designing labels, variety of topics is available in the

Gemini's Online Help. These topics include general tips and techniques that

are independent of the specific software being used. Also included are

observations and tips regarding label design and printing with specific Microsoft® and other vendor applications.

32 cab Produkttechnik GmbH & Co KG

Page 33

9. Error Messages

If an error occurs while operating the Gemini, a message box is displayed on

the screen and the printer is paused. After solving the problem, the print job is

continued by clicking OK in the error message window. If the problem is

corrected, the print job will continue. However, If the problem still exists, the

message box will reappear.

Additionally, an error is indicated by a rapid blinking LED on the printer's front

panel. A Slow blinking LED indicates the printer is paused.

The following table contains a reference of error messages, possible causes

and solutions to the problems.

Error Message

The printer is

out of label

stock

The printer is

out of ribbon

Cannot find gap

Possible cause

Label material has run out.

Label is not inserted properly in the

label sensor photo cell.

Ribbon has run out.

Printer is loaded with thermal

labels for direct thermal mode, and

no ribbon is loaded, but the

software is set for transfer printing.

On the label material, several

labels are missing.

The label format size specified in

the software is different from the

actual label size.

Continous (endless) media is

loaded, but the software is not set

for continuous media.

Solution

Insert new supply roll, click OK

Check paper edge, then Click OK.

Insert a new ribbon.

Cancel print job. Correct software

for direct thermal mode. Start a

new print job.

Click Formfeed button in Gemini

Control Panel until the next label

on the material is accepted by the

printer.

Cancel print job, change label

format setting in the software and

start new print job.

Cancel print job. Correct the

media type to continuous

(endless) in the software.

Start a new print job.

33cab Produkttechnik GmbH & Co KG

Page 34

10. Maintenance / Cleaning

The Gemini is designed with a minimum of maintenance requirements. The

most important concern is the regular cleaning of the thermal printhead. This

will guarantee a consistent quality print image. It will also help to avoid

premature wear of the printhead. Otherwise, maintenance is limited to an

occasional general cleaning.

Adjustments ar needed only on an occasional basis. In general, the printer will

not vary its performance. Adjustments may be necessary by a change in

media (see chapter 7). If a very narrow or thick media will be used, adjustment

of the printhead support may be needed. If a different type or width of ribbon is

loaded, adjustment of the transfer ribbon feed may be needed to maintain

wrinkle-free operation.

F

Before beginning any maintenance, turn off the power and disconnect the

power cord!

General Cleaning

Remove particles of dust and paper that have accumulated inside the printer

with a soft brush.

Wipe the cover with a standard non-abrasive cleaner as needed.

Accumulations of dirt on media rollers and guides can impair the smooth

movement of media. After removing media, remove deposits with isopropyl

alcohol and a soft cloth.

Cleaning the Media Feed Roller

Accumulations of dirt on the roller can lead to impaired material transport.

Clean the roller as follows:

1. Open the printhead.

2. Remove labels and ribbon from the printer.

3. Remove all deposits with isopropyl alcohol and a soft cloth.

34 cab Produkttechnik GmbH & Co KG

Page 35

Cleaning the Thermal Printhead

During printing, the printhead will accumulate dirt such as paper dust or

particles of ink or back coating from the ribbon. This accumulation can cause a

deterioration of the print quality. To correct or avoid this problem, the prinhead

should be cleaned at regular intervals.

Frequency of cleaning:

Direct Thermal printing: - at every label roll change

Thermal Transfer printing: - at every ribbon change

Do not use sharp objects for cleaning the printhead.

F

Do not touch the protective layer of the printhead with your hands.

To clean the printhead:

1. Turn the printer power off, and disconnect the power cord.

2. Raise the printhead as far as possible.

3. Remove the labels and the ribbon from the printer.

4. Clean the surface of the printhead with a cleaning pen, or use a cotton

swab dipped in isopropyl alcohol.

5. Let the printhead dry approximately 2-3 minutes before powering on and

restarting the printer.

35cab Produkttechnik GmbH & Co KG

Page 36

Removing Labels from the Dispenser Roller

On occasion, a label might become wound around the Dispenser Roller during

a Peel-Off operation (Gemini TD). This might happen, for example, if

Presentation Position is not set correctly. To remove the label(s) :

1. Turn the power off. This will allow the rollers to be turned.

2. Rotate the printhead locking lever clockwise to the open position.

3. Soak a paper towel with WD-40 or similar solution.

4. Rotate the dispenser locking lever clockwise to the open position. Feed the

soaked paper towel into the dispenser area and place it down between the

rollers.

5. Continue feeding the soaked paper towel through by rotating the Media

Feed Roller with the palm of your hand. This will cause the Dispense Drive

Roller to rotate and feed the paper towel through.

6. Wrap the soaked paper towel around the Dispense Drive Roller as

completely as possible and leave it for about 5 minutes. When the WD-40

has softened the adhesive, remove the paper towel.

7. Begin peeling through the layers of label until you can grasp a section.

Pulling all layers from an area at once, rather than peeling each layer

separately generally works best. Grasp a section with your fingers or

tweezers and pull it away from the roller.

8. When the area facing out has been cleared of label(s), rotate the Media

Feed Roller to cause the Dispenser Drive Roller to turn. Continue rotating

and peeling the exposed label off.

9. When all the label(s) and adhesive have been removed, remove the traces

of WD-40 by thoroughly cleaning the entire area with isopropyl alcohol on a

soft cloth.

10. After the area has dried, remove any shredded bits of paper towel, cloth or

label with a soft brush, or blow-out the area with a can of compressed air.

36 cab Produkttechnik GmbH & Co KG

Page 37

11. Printhead Horizontal Alignment

For optimum print quality, the line of the heating elements on the printhead

must be parallel and aligned correctly to the print roller. This alignment has

already been performed in the factory. Nevertheless, it may become necessary

to adjust it.

A misaligned printhead causes a poor print quality which appears as described

below :

- the print image looks generally light, spotted, and irregular; or

- the print image appears uneven from one side to the other.

21

33

Figure 11 Printhead Horizontal Alignment

Adjust the printhead as follows :

1. You may leave the transfer ribbon (1) inside the printer, and simoply poke

through it with your tools.

2. Loosen thelocking screw (2) on the printhead by half a turn. This will allow

for the required horizontal adjustment of the printhead.

3. By turning the two screws underneath (3) you may shift the printhead as

follows :

- The overall distance for adjusting is .1 in or 2.5 mm.

- By turning the screws clockwise, the printhead will be shifted backwards.

(about .02 in or .5mm per turn)

- Adjust in small steps ! (quarter turns only)

- First, turn both screws constantly until at least one side of the print image

is optimum.

Following, adjust the screw which is located at the side of the label where

the quality is still poor.

37cab Produkttechnik GmbH & Co KG

Page 38

4. Note, that the printhead must be opened after every single adjustment step

to make the change effective.

5. Tighten the locking screw (2).

6. Perform a test print, for instance a wide black line over the whole width of

the label, and review the results.

7. Repeat steps 2 to 6 as necessary to complete the adjustment.

38 cab Produkttechnik GmbH & Co KG

Page 39

12. Troubleshooting

The following information covers common printer problems and possible

solutions. Additional troubleshooting information on both hardware and

software related problems is available in Gemini's Online Help.

Poor print quality - smears or voids appear within the printed image.

The printhead is dirty. Clean the printhead (Page 35)

The ribbon is creasing. Adjust the transfer ribbon feed (Page 24)

Poor print density - the image is too light or too dark.

The heat setting is too high or too low. Adjust the heat setting with Printer

Setup.

The wrong ribbon/paper combination is being used. Check with your

Dealer for recommendations on media.

The resistance value has not been adjusted for the printhead currently

installed. Check the value preceding the ohm (W) sign on the printhead

and enter it under Windows 95/Windows 98/ME in the Gemini Control

Panel, Replace Printhead function or under Windows NT 4.0/2000/XP in

the Gemini Control Panel, Printer Properties, Set Printhead Resistance

function.

Print density is uneven - the image is light on one side of the label.

The printhead is adjusted for a narrow label.

Readjust the printhead support (Page 23).

The printhead is out of alignment. Adjust the printhead (Page 37)

Printer form feeds more than one label at a time

Media is loaded incorrectly. Make sure media is beneath the arm of the

photocell assembly (7), as shown in Figure 6a.

Label edge sensor photocell needs adjusting or is malfunctioning.

Call for Service.

Printer will not turn on

Voltage of the printer and power supply do not match. Check that the

printer is configured for the correct power supply.

Fuse is blown. Remove the fuse holder from the power supply module and

inspect or replace the fuses as needed.

39cab Produkttechnik GmbH & Co KG

Page 40

Gesellschaft für Computerund AutomationsBausteine mbH

Wilhelm-Schickard-Str. 14

D-76131 Karlsruhe

EU - Conformity Declaration

We declare herewith that as a result of the manner in which the machine designated below

was designed, the type of construction and the machines which, as a result have been

brought on to the general market comply with the relevant fundamental regulations of the EU

Rules for Safety and Health. In the event of any alteration which has not been approved by

us being made to any machine as designated below, this statement shall thereby be made

invalid.

Description: Type:

Transfer Printer Gemini

Applied EU Regulations and Norms:

- EC Machinery Regulations 98/37/EU

- Machine Safety EN 292-2:1991

- EC Low Voltage Regulations 73/23/EEC

- Data and Office Machine Safety EN 60950:1992+A1:1993

- EC Electromagnetic Compatibility Regulations 89/336/EEC

- Threshold values for the Interference EN 55022:1998

of Data Machines

- Limits for harmonic current emission EN 61000-3-2:1995+A1:1998

- Limits of voltage fluctuation and flicker EN 61000-3-3:1995

- Immunity characteristics- EN 55024:1998

Limits and methods of measurement

Signed for, and on behalf of, the Manufacturer :

cab Produkttechnik Sömmerda

Gesellschaft für Computerund Automationsbausteine mbH

99610 Sömmerda

Sömmerda, 10.04.02

EN 60950+A2:1993+A3:1995

+A4:1997

+A2:1998+A14:1999:2000

Erwin Fascher

Managing Director

40 cab Produkttechnik GmbH & Co KG

Loading...

Loading...