Page 1

Operator's Manual

External Rewinder

ER4 / ER6 / ER8

Made in Germany

Page 2

Operator's Manual - Translation of the Original Version

2 2

for the following products

Part No. Description Type

5948100 External Rewinder ER4/210

5946090 External Rewinder ER4/300

5946420 External Rewinder ER6/300

5945804 External Rewinder ER8/300

Edition: 03/2016 - Part No. 9008926

Copyright

This documentation as well as translation hereof are property

of cab Produkttechnik GmbH & Co. KG.

The replication, conversion, duplication or divulgement of the

whole manual or parts of it for other intentions than its original

intended purpose - in particular the procurement of spare

parts for products sold by cab - demand the previous written

authorization by cab.

Trademark

Windows is a registered trademark of the Microsoft

Corporation.

Editor

Regarding questions or comments please contact

cab Produkttechnik GmbH & Co. KG.

Topicality

Due to the constant further development of our products

discrepancies between documentation and product can occur.

Please check www.cab.de for the latest update.

Terms and conditions

Deliveries and performances are effected under the General

conditions of sale of cab.

Germany

cab Produkttechnik

GmbH & Co KG

Postfach 1904

D-76007 Karlsruhe

Wilhelm-Schickard-Str. 14

D-76131 Karlsruhe

Telefon +49 721 6626-0

Telefax +49 721 6626-249

www.cab.de

info@cab.de

Representatives in other countries on request

France

cab technologies s.a.r.l.

F-67350 Niedermodern

Téléphone +33 388 722 501

www.cab.de/fr

info.fr@cab.de

USA

cab Technology Inc.

Tyngsboro MA, 01879

Phone +1 978 649 0293

www.cab.de/us

info.us@cab.de

Asia

cab Technology Co., Ltd.

Junghe, Taipei, Taiwan

Phone +886 2 8227 3966

www.cab.de/tw

info.asia@cab.de

China

cab (Shanghai)Trading Co., Ltd.

Phone +86 21 6236-3161

www.cab.de/cn

info.cn@cab.de

Page 3

Table of Contents

1 Introduction ............................................................................................................................................4

1.1 Notes ........................................................................................................................................................4

1.2 Intended Use ............................................................................................................................................4

1.3 Safety Instructions ....................................................................................................................................5

1.4 Environment .............................................................................................................................................5

2 Product Description ...............................................................................................................................6

2.1 Function ...................................................................................................................................................6

2.2 Technical Data ..........................................................................................................................................6

2.3 Device Overview ......................................................................................................................................7

3 Start-Up ...................................................................................................................................................8

3.1 Contents of Delivery .................................................................................................................................8

3.2 Connecting to Power Supply ....................................................................................................................8

4 Settings ...................................................................................................................................................9

4.1 Setting the Winding Direction ...................................................................................................................9

4.2 Adjusting the Guide Axle ..........................................................................................................................9

5 Operation ..............................................................................................................................................10

5.1 Rewinding Directly onto the Rewind Axle ...............................................................................................10

5.2 Rewinding onto 40 mm (1.6 in) Cardboard Core ....................................................................................11

5.3 Rewinding onto 76 mm (3 in) Cardboard Core ......................................................................................12

6 Licences ................................................................................................................................................13

6.1 EU Declaration of Conformity .................................................................................................................13

6.2 FCC ........................................................................................................................................................14

3

Page 4

1 Introduction

!

!

!

!

i

i

4 4

1.1 Notes

Important information and instructions are designated as follows:

Danger!

Draws attention to an exceptionally great, imminent danger to your health or life due to hazardous

voltages.

Danger!

Draws attention to a danger with high risk which, if not avoided, may result in death or serious injury.

Warning!

Draws attention to a danger with medium risk which, if not avoided, may result in death or serious injury.

Caution!

Draws attention to a danger with low risk which, if not avoided, may result in minor or moderate injury.

Attention!

Draws attention to potential risks of property damage or loss of quality.

Note!

Advices to make work routine easier or on important steps to be carried out.

Environment!

Advices on protecting the environment.

Handling instruction

Reference to section, position, illustration number or document.

Option (accessories, peripheral equipment, special ttings).

Time

Information in the display.

1.2 Intended Use

• The device is manufactured in accordance with the current technological status and the recognized safety rules.

However, danger to the life and limb of the user or third parties and/or damage to the device and other tangible

assets can arise during use.

• The device may only be used for its intended purpose and if it is in perfect working order, and it must be used with

regard to safety and dangers as stated in the operating manual.

• The device is intended exclusively for rewinding suitable materials that have been approved by the manufacturer.

Any other use or use going beyond this shall be regarded as improper use. The manufacturer/supplier shall not be

liable for damage resulting from unauthorized use; the user shall bear the risk alone.

• Usage for the intended purpose also includes complying with the operating manual, including the manufacturer‘s

maintenance recommendations and specications.

Note!

The complete documentation can also currently be found in the Internet.

Page 5

1.3 Safety Instructions

!

!

• The device may only be used in a dry environment, do not expose it to moisture (sprays of water, mists, etc.).

• Do not try to manipulate or repair parts they are not described in the manuals of the external rewinder or the

printer.

Caution!

Risk of injury by rotating parts!

During operation, rotating parts are freely accessible.

Ensure that people‘s clothing, hair, jewelry etc. do not come into contact with the exposed rotating

parts.

Attention!

Risk of gear defect!

Switch off the device before changing the winding direction.

1.4 Environment

Obsolete devices contain valuable recyclable materials that should be sent for recycling.

Send to suitable collection points, separately from residual waste.

Send the parts for recycling.

51 Introduction

Page 6

2 Product Description

6 6

2.1 Function

The External Rewinders are peripheral devices for transfer printers of different manufacturers.

During processing of large print jobs it is possible to take up and rewind large label roles independently of the printer.

An adjustable guide axle ensures that the label strip is led horizontally from each printer into the rewinder.

For a correct alignment of the External Rewinders with the printers of the A+- and XC-Series Adapter Kits are offered.

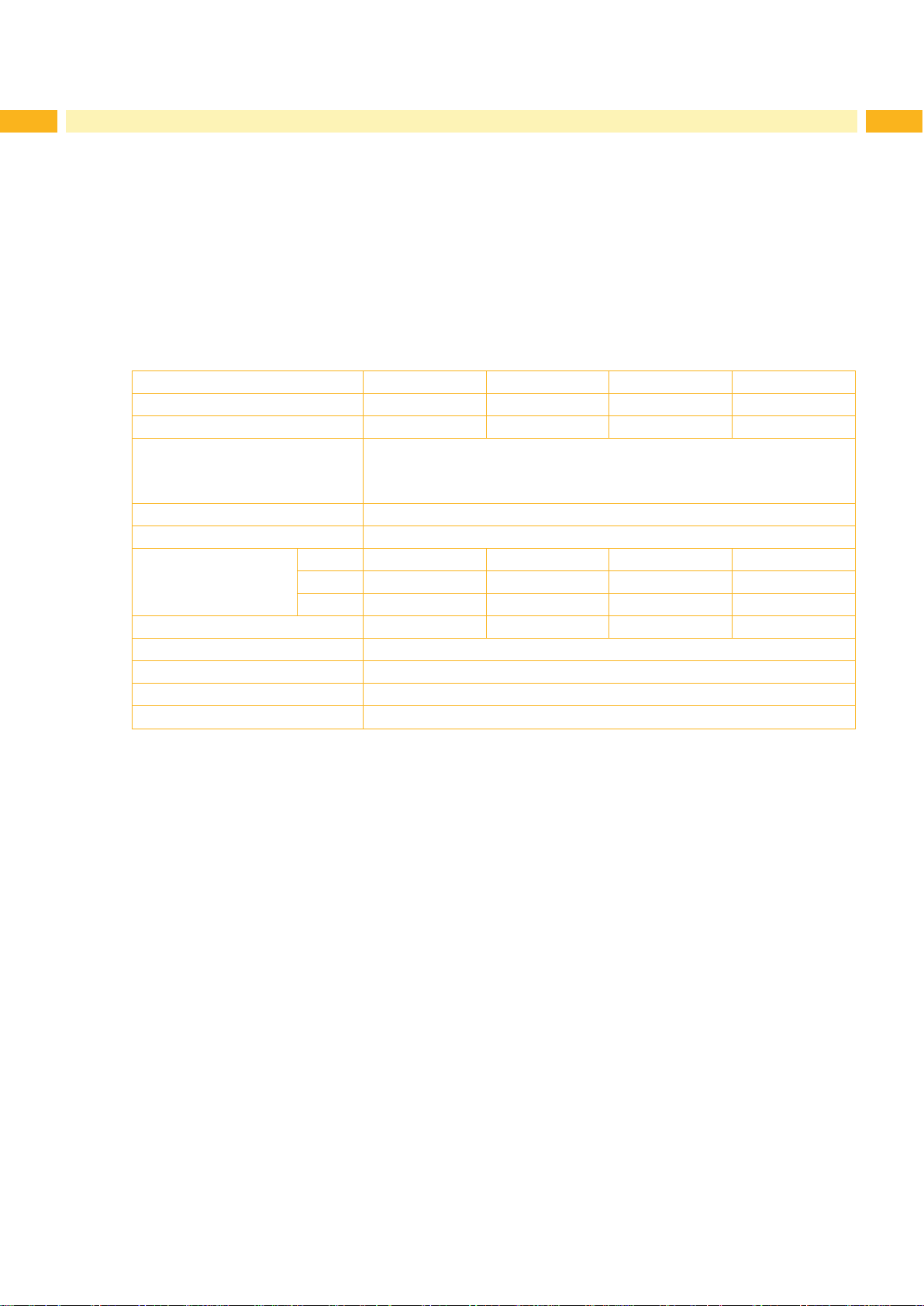

2.2 Technical Data

ER4/210 ER4/300 ER6/300 ER8/300

Max. Material Width 120 mm (4.7 in) 120 mm (4.7 in) 180 mm (7.1 in) 235 mm (9.2 in)

Max. Rewinder Diameter 205 mm (8.1 in) 300 mm (11.8 in) 300 mm (11.8 in) 300 mm (11.8 in)

Core Diameter 40 mm (1.6 in) on rewind axle

40 mm (1.6 in) on cardboard core

76 mm (3 in) on cardboard core with adapter

Rewind Speed max. 300 mm/s (12 in/s)

Label Rewinding Labels in- or outside

Dimensions Height 280 mm (11) 350 mm (13.8) 350 mm (13.8) 350 mm (13.8)

Width 260 mm (10.2) 280 mm (11) 340 mm (13.4) 395 mm (15.5)

Depth 270 mm (10.6) 390 mm (15.3) 390 mm (15.3) 390 mm (15.3)

Weight 5,0 kg (11 lb) 6,0 kg (13.2 lb) 6,3 kg (13.9 lb) 6,6 kg (14.6 lb)

Operating Temperature 5 - 40 °C, at humidity 10 - 85 % not condensing

Storage Temperature 0 - 60 °C, at humidity 20 - 80 % not condensing

Transport Temperature -25 - 60 °C, at humidity 20 - 80 % not condensing

Operating Voltage 110 - 240 V~ / 50 - 60 Hz

Table 1 Technical Data

Page 7

2 Product Description

2.3 Device Overview

7

Figure 1 Overview ER4/210

7 9654321

7 9105432 18

8

Figure 2 Overview ERx/300

1 Switch Winding Direction

2 Rewind Axle

3 Roller

4 Guide Axle

5 Rewind Adapter

6 Plate ER4/210

7 Clamp

8 Power Switch

9 Power Input Module

10 Plate ERx/300

Page 8

3 Start-Up

i

!

8 8

3.1 Contents of Delivery

Check the external rewinder for damages in transit and completeness.

Contents of delivery:

• External Rewinder

• Clamp

• 2 Rewind Adapters

• Plate for ER4/210 or Plate for ERx/300

• Power Cable

• Documentation

Note!

Please keep the original packaging in case the device must be returned.

3.2 Connecting to Power Supply

The rewinder is equipped with a wide range power unit (100-240 V~), so it is possible to use the printer both with a

voltage of 230 V~/50 Hz and with a voltage of 115 V~/60 Hz without changes.

Caution!

Risk of injury by rotating parts!

Ensure that the power switch (1) is in position „O“ (OFF) before connecting the printer to a power

supply !

When switching on the Rewinder starts immediately without or with loose material.

ERx/300ER4/210

1

2

1

2

3

Figure 3 Connecting to power supply

Connect the supplied power cable (3) to the power input module (2) and to a grounded outlet.

3

Page 9

4 Settings

!

4.1 Setting the Winding Direction

With the setting of the winding direction it is possible to rewind the labels inside or outside.

Attention!

Risk of gear defect!

Switch off the device before changing the winding direction.

9

ER4/210

1

Figure 4 Setting the winding direction

Select the winding direction with the switch (1):

Rewinding with labels inside

Rewinding with labels outside

ERx/300

1

ER4/210 ERx/300

4.2 Adjusting the Guide Axle

Depending on the used printer the guide axle should be adjusted so that the label strip is led horizontally from the

printer to the rewinder.

Figure 5 Adjusting the guide axle

1. Loosen the guide axle (1) by turning it

counterclockwise.

2. Move the axle in the guide plate (2) to the

1

2

desired position.

3. Fasten the guide axle (1) by turning it clockwise.

Page 10

5 Operation

i

!

5 4321

i

i

10 10

5.1 Rewinding Directly onto the Rewind Axle

Note!

Remove the spring (2) from the rewind axle!

Caution!

Risk of injury by rotating parts!

When switching on the rewinder starts immediately and winds until the material is tightened.

1. Loosen the screws (1) and remove the spring (2).

Note!

Consider the selected winding direction:

• The broken line is valid for inside wound

labels.

• The solid line is valid for outside wound labels.

2. Feed the label strip over the guide axle (9) and under the

roller (8) to the rewind axle (7).

Note!

When using a rewinder of the type ERx/300

for winding labels inside, lead the label strip

additionally over the guide axle (10).

Ensure that the label strip touches the disc (6).

7 4563 8 9

3. Attach the label strip appropriately to the rewind axle by

sliding the clamp (5) over the label strip with the clamp

set in the groove of the rewind axle (7).

4. Slide the clamp (5) as far as possible towards the disc

(6).

5. Slide the plate on ER4/210 (4) or ERx/300 (4) onto the

rewind axle so that it slightly touches the label strip. The

label strip must be able to move between the disc and the

plate.

6. Tighten the knurled screw (3) on the plate.

7. Switch on the rewinder at the power switch.

ER4/210

5763 4 108 9

ERx/300

Figure 6 Rewinding Directly onto the Rewind Axle

Page 11

i

!

i

i

i

5 Operation

5.2 Rewinding onto 40 mm (1.6 in) Cardboard Core

Note!

Ensure that the spring (1) is mounted on the rewind axle (2)!

Consider that the cardboard core (3) should be about 1 mm (0.04 in) broader than the label strip

Caution!

Risk of injury by rotating parts!

When switching on the rewinder starts immediately and winds until the material is tightened.

11

ER4/210

76 2 3 8

3 5421

1. Put the cardboard core (3) on the rewind axle (2).

Note!

Consider the selected winding direction:

• The broken line is valid for inside wound

labels.

• The solid line is valid for outside wound labels.

2. Feed the label strip over the guide axle (8) and under the

roller (7) up to the cardboard core (3).

Note!

When using a rewinder of the type ERx/300

for winding labels inside, lead the label strip

additionally over the guide axle (9).

Ensure that the label strip touches the disc (6).

3. Afx the end of the label strip with consideration of the

selected rewinding direction to the cardboard core using

adhesive tape or label.

4. Slide the plate (5) with the knurled screw outward onto

the rewind axle until it stops.

Note!

When using small labels it is possible that the

cardboard core does not cover the spring over

the whole length. In this case the groove on

the plate must be aligned so that it ts to the

spring of the rewind axle.

5. Tighten the knurled screw (4) on the plate.

6. Switch on the rewinder at the power switch.

976 2 3 8

ERx/300

Figure 7 Rewinding onto 40 mm cardboard core

Page 12

i

!

i

i

5 Operation

12 12

5.3 Rewinding onto 76 mm (3 in) Cardboard Core

Note!

Remove the spring from the rewind axle!

Consider that the cardboard core (3) should be about 1 mm (0.04 in) broader than the label strip.

Caution!

Risk of injury by rotating parts!

When switching on the rewinder starts immediately and winds until the material is tightened.

ER4/210

5 7621 23 3 4

981 4 3

981 4 3 10

1. Put the rst rewind adapter (3) onto the rewind axle (4)

and slide it up to the disc (1) until it stops. Make sure that

the knurled screw (2) of the rewind adapter is led in the

groove of the rewind axle. Tighten the knurled screw (2).

2. Put the second rewind adapter (3) onto the rewind

axle (4) and slide it towards the rst adapter until the

clearance between the outer edge of it and the disc (1) is

a little less than the width of the cardboard core. Tighten

the knurled screw (2).

3. Put the cardboard core (5) on the rewind axle (2).

Note!

Consider the selected winding direction:

• The broken line is valid for inside wound

labels.

• The solid line is valid for outside wound labels.

4. Feed the label strip over the guide axle (9) and under the

roller (8) up to the cardboard core (5).

Note!

When using a rewinder of the type ERx/300

for winding labels inside, lead the label strip

additionally over the guide axle (10).

Ensure that the label strip touches the disc (1).

5. Afx the end of the label strip with consideration of the

selected rewinding direction to the cardboard core using

adhesive tape or label.

6. Slide the plate (7) with the knurled screw outward onto

the rewind axle until it stops.

7. Tighten the knurled screw (6) on the plate.

8. Switch on the rewinder at the power switch.

ERx/300

Figure 8 Rewinding onto 76 mm cardboard core

Page 13

6 Licences

6.1 EU Declaration of Conformity

cab Produkttechnik

GmbH & Co KG

Wilhelm-Schickard-Str. 14

D-76131 Karlsruhe

Germany

EU Declaration of Conformity

We declare herewith that as a result of the manner in which the device designated below was designed, the type of

construction and the devices which, as a result have been brought on to the general market comply with the relevant

fundamental regulations of the EU Rules for Safety and Health. In the event of any alteration which has not been

approved by us being made to any device as designated below, this statement shall thereby be made invalid.

Device: External Rewinder

Type: ER4 / ER6 / ER8

13

Applied EU Regulations and Standards

Directive 2006/42/EC on machinery

Directive 2014/30/EU relating to electromagnetic compatibility

Directive 2011/65/EU on the restriction of the use of certain

hazardous substances in electrical and electronic equipment

Person authorised to compile the technical le : Erwin Fascher

Signature for the producer :

cab Produkttechnik Sömmerda

Gesellschaft für Computerund Automationsbausteine mbH

99610 Sömmerda

• EN ISO 12100:2010

• EN ISO 13849-1:2008

• EN 60950-1:2006

+A11:2009+A12:2011+A1:2010+A2:2013

• EN 61558-1:2005+A1:2009

• EN 55014-1:2006+A1:2009+A2:2011

• EN 55014-2:1997+A1:2001+A2:2008

• EN 61000-3-2:2006+A1:2009+A2:2009

• EN 61000-3-3:2008

• EN 50581:2012

Am Unterwege 18/20

99610 Sömmerda

Sömmerda, 22.02.2016

Erwin Fascher

Managing Director

Page 14

6 Licences

14 14

6.2 FCC

NOTE : This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against

harmful interference when the equipment is operated in a commercial environment. The equipment

generates, uses, and can radiate radio frequency and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications. Operation of this equipment in

a residential area is likely to cause harmful interference in which case the user may be required to correct the

interference at his own expense.

Loading...

Loading...