Page 1

BÜCHI Rotavapor R-220

Table of Contents

Table of Contents

1 Scope of Delivery 2

2 Safety 3

3 Function 6

3.1 Principle of Operation 6

4 Putting into Operation 7

4.1 Installation Location 7

4.2 Unpacking 7

4.3 Setting up the Support Rod 8

4.4 Attachment of the EasyClamp 9

4.5 Removal of the EasyClamp 9

4.6 Installation of the Reflux Glass Assembly 10

4.7 Installation of the Descending Glass Assembly 11

4.8 Installation of the Descending Glass Assembly

with a 2nd Cooler 12

4.9 Installation of the Receiving Fixture 13

4.10 Attaching and Removing Flasks 14

4.11 Hose Coupling 16

4.12 Operating the Shut-off tap 18

4.13 Bath Replenishment (Optional) 18

4.14

Reset of the over-temperature protection 19

4.15 Heating Medium 19

4.16 Checking Installation 19

5 Operation 20

5.1 Arrangement of the Operator Control and

Display Elements 20

5.2 Adjusting the Maximum Set-Point Temperature

and Automatic Lowering of the Bath in Case of

a Power Interruption 20

5.3 Tips and Tricks 21

5.4 Table of Solvents 22

6 Maintenance 23

6.1 Taking Apart the Snap Flange Coupling 23

6.2 Assembling the Snap Flange Coupling 24

6.3 Removing the Evaporating Flask Seal 24

6.4 Inserting the Evaporating Flask Seal 25

6.5 Replacement of the Seals for the Distribution Head 25

6.6 Replacement of the Vacuum Seal 26

6.7 Cleaning 26

6.8 Vacuum Seal 26

6.9 Testing for Leaks 27

6.10 Customer Service 27

7 Taking out of Operation 28

8 Spare Parts and Accessories 29

8.1 Glass Assemblies D, D2, DB, DB2 30/31

8.2 Glass Assemblies R, RB, C 32/33

8.3 Miscellaneous 34

8.4 Accessories 37

9 Appendix 42

9.1 Technical Data 42

9.2 Materials Used 42

9.3 Error Messages 43

9.4 FCC requirements (for USA and Canada) 44

9.5 Declaration of Conformity 45

Read this Operating Manual through carefully before using

the Büchi Rotavapor R-220. Always keep these Instructions

readily available in the immediate vicinity of the unit so that

they make be consulted at any time.

Chapter 2 contains important safety rules which must be observed to ensure the safe operation of the rotary evaporator.

We reserve the right to make technical changes without

prior notification. No portion of this Operating Manual

may be reproduced, processed using electronic or optical

systems, duplicated, or distributed in any form without

the prior written approval of Büchi Labortechnik AG.

All rights reserved.

en, Version F (46 Pages) Ordering No.

R-220 Operation Manual 96737

© Büchi Labortechnik AG, 1999-2001

1

Page 2

1 Scope of Delivery

BÜCHI Rotavapor R-220

1 Scope of Delivery

Component

1 Chassis, complete, with control and

driving unit and with heating bath

1 6L, 10L or 20L Evaporation flask

1 Receiving flask 1 x 10L Single receiver or

2 x 10L Interchangeable receivers

1 Glass assembly

(Refer to Chap. 4.6 - 4.8 for Figure)

Table 1: Scope of Supply

Standard Accessories: Ordering No.

1 Seal tool 20057

1 Operating Manual

German 96736

English 96737

French 96738

Italian 96739

Spanish 96740

Table 2: Standard Accessories

Fig. 1: R-220, Overall View

2

Page 3

BÜCHI Rotavapor R-220

2 Safety

2 Safety

This unit has been built in accordance with the latest state of

the art and with recognized rules of safety.

Nevertheless there are certain risks and dangers entailed with

this unit:

• whenever the unit is operated by individuals who lack

sufficient training;

• whenever the unit is used for some purpose other than its

authorized use.

2.1 Symbols

Stop

Information on dangers that can cause serious material

damage and severe personal injuries or death.

Warning

Information on dangers that can be injurious to one’s health

or cause material damage.

Note

Information pointing out technical requirements. A failure to

observe such information can lead to malfunctions, uneconomical operation, and losses in production.

2.2 Responsibilities of the Operator

This unit may only be used by technical staff and by individuals

who, based on their training or their professional experience,

have a good understanding of the dangers that can arise

from the its operation.

Staff who do not have this training and individuals who are

currently in training must be given careful instructions. This

Operating Manual should be used as the basis for such training.

2.3 Authorized Use

The rotary evaporator has been designed for use in technical

laboratories and in production. It is authorized for use in applications that work with the evaporation and condensation of

solvents.

It is used for:

• Evaporation of solvents and suspensions

• Drying of powders and granulates

• Re-crystallization

• Reactions under reflux

• Synthesis and Cleaning of refined chemicals

• Recycling and concentration of solvents

The authorized use of the Rotavapor also includes its care,

upkeep, and careful handling in accordance with the provisions

in this Operating Manual.

3

Page 4

2 Safety

BÜCHI Rotavapor R-220

2.4 Unauthorized Use

Any use other than those indicated above, and any use that

is not in conformity with the Technical Data is considered to

be misuse. The operator himself bears sole responsibility for

all damage or injuries arising from any such use.

The following applications in particular are strictly forbidden:

• The production and processing of materials that can cause

spontaneous reactions, e.g., explosives;

• Working without the evaporation flask being immersed in

the water bath (risk of breakage);

• The drying of hard, brittle materials (e.g., stones, soil samples) that might cause damage to the receiving flask;

• Sudden shock-cooling of the evaporating flask.

The Rotavapor R-220 is not intended for work done under

overpressures.

2.5 Basic Dangers

Basic dangers arise when working with the following:

• The hot water or oil bath (risk of being scalded);

• Contaminated solvents that produce residues from distillation which could cause spontaneous reactions (e.g., metal

hydrides);

• Solvents that can produce peroxides (risk of explosions);

• Mixtures with unknown compositions or contamination;

• Damaged glassware;

• Electrostatic charges while working, e.g., during the transfer of combustible solutions and while drying powders;

• Temperatures of coolants that lie below the freezing point

of the distillate (A clogging of the distillate cooler due to

freezing out can result in too great an overpressure).

2.6 Safety Precautions

All regional and local laws and regulations must be observed.

The Rotavapor has been grounded internally to dissipate any

electrostatic charges on it.

4

Page 5

BÜCHI Rotavapor R-220

2 Safety

It is always mandatory to wear personal protective gear such

as protective eyewear and protective clothing.

The machine must never be rotated without the snap flange

coupling and evaporation flask being closed.

No distillation may be started unless the evaporating flask is

immersed in the bath. There is always the risk that the neck

of the flask might break off due to the great weight involved.

There is a risk of becoming scalded while changing evaporating

flasks. Wearing gloves prevents this.

Check the glass components regularly for possible damage,

spreading impact marks, or cracks.

Never interrupt the grounding conductor (protective conductor).

Otherwise there will be the risk of an electrical shock!

The operator bears responsibility for providing proper instruction

of his operating staff. To aid him in doing this, translations of

this Operating Manual are also available in several other

languages. As an integral component of the rotary evaporator,

this Operating Manual must be readily available at all times to

the operating staff at the location where they are using the

unit.

The operator must inform the manufacturer immediately of

any and all events relevant to safety that occur in his use of

this equipment.

2.7 Modifications

No modifications are permissible without consulting with and

obtaining the written approval of the manufacturer.

No glass assemblies other than those recommended by the

manufacturer may be used, nor may any glass components

be put together arbitrarily.

Only those components of the rotary evaporator intended for

fulfillment of its function may be installed in or removed from

the unit. This may be done either by hand, or with the use of

the tool supplied along with the unit. The removal of safety

devices or covers using some commercially available tool is

— other than for authorized commissioning personnel — strictly

forbidden. Contact with parts that are electrically live may

result in fatal injury!

5

Page 6

3 Function

햴

햶

BÜCHI Rotavapor R-220

3 Function

A vacuum rotary evaporator is used for quick single-stage

distillations that treat the product gently. The process is based

on the evaporation and condensation of solvents in a rotating

evaporating flask.

It is possible to work under a vacuum to ensure gentler treatment of the product and increase productive output.

Distillation may be done either under a vacuum or at atmospheric pressure.

A secure closeness is guaranteed in the low pressure range.

3.1 Principle of Operation

햲 Evaporation Zone

The solvent in the evaporating flask is heated by the heating

bath. The rotation of the evaporating flask ensures an intensive exchange of heat and mass within the contents of

the flask, forming a thin film of solvent on the inner surface

of the flask. This combination of turbulence and film prevents

local overheating and ensures high distillation speed.

햵

Fig. 2: Principle of operation of the R-220

햳

햲

햳 Rotary Drive

The drive unit ensure the uniform rotation of the evaporating

flask.

햴 Cooling Zone

The solvent vapor flows into the cooler at a high speed.

This is where the energy in the solvent vapor is transferred

to the cooling medium (e.g., water). The solvent condenses.

햵 Receiving Flask

The receiving flask is used to collect the condensate.

햶 Vacuum Cover

The system pressure is reduced so as to lower the boiling

point of the solvent. The reduction in thermal loading that

results ensures gentle treatment of the product and offers

energetic advantages.

The pressure (vacuum) of distillation, the temperature of the

heating bath, the rotational speed, and the size of the evaporating flask all affect the evaporation output. Refer to Chapter

5.3 for how to select the optimum conditions of distillation.

6

Page 7

BÜCHI Rotavapor R-220

4 Putting into Operation

4 Putting into Operation

The danger zone around the Rotavapor R-220 can extend

outward by up to 10 m. When working inside this danger

zone, there is a risk of damaging the glass parts, which could

cause them to implode.

The electrical connection must be installed and checked

by an authorized person.

4.1 Installation Location

Always set the unit up on a clean, stable, and flat surface.

Never at a location where there is a great deal of personal

traffic (breaking or broken glass) !

The dimensions of the rotary evaporator are:

Height:

without trolley Reflux 1700 mm

Descending 1800 mm

Bullfrog Reflux 1430 mm

Bullfrog Descending 1550 mm

with trolley Reflux 2300 mm

Descending 2400 mm

Width:

Reflux 1100 mm

Descending 1250 mm

Descending, with 2 coolers 1250 mm

Depth:

Single receiver 550 mm

Interchangeable receivers 650 mm

4.2 Unpacking

Take care not to break the glass when opening cartons that

contain glassware.

Look for any damage after unpacking. It is important that any

damage in transit be identified right when unpacking. If necessary, make an immediate assessment of the situation (Notify

the post office, the railroad, or the shipping company involved).

Save the original packing for possible transport at a later date.

7

Page 8

4 Putting into Operation

햵

햴

BÜCHI Rotavapor R-220

4.3 Setting up the Support Rod

• Place the support rod 햳 into the holder provided for it and

lower it into the foot hole at the back. Fix it tight using the

locking screw 햲.

• Put the positioning ring 햴 on over the rod, 150 mm below

the upper edge.

• Lay the pivoting clamp 햵 on top of the positioning ring.

• Attach the pivoting clamp for the receiving flask 200 mm

above the bottom edge of the rod.

Fig. 3: Support rod

햳

햲

When installing an interchangeable receiver:

• Place the short support rod into the holder at the front and

lower it into the foot hole. Screw it tight using the locking

screw.

• Attach the pivoting clamp approx. 200 mm above the lower

edge of the rod.

8

Page 9

BÜCHI Rotavapor R-220

4 Putting into Operation

4.4 Attachment of the EasyClamp

• Carefully lay the EasyClamp around the glass and fold the

top and bottom segments together, closing them at their

open connection point.

• Insert the bolt that does not have a spacer spring, and

tighten the knurled nuts slightly.

• Tighten all knurled nuts uniformly by hand.

Note:

Always tighten the knurled nuts by hand and not to the block

(with the spring pressed together completely). Otherwise the

prestressing will be lost.

There must always be a gap of about 2 mm between the

knurled nut and the support surface.

Fig. 4: Attachment of the EasyClamp

Fig. 5: Removal of the EasyClamp

4.5 Removal of the EasyClamp

On all EasyClamp connections, only the bolt without a

spacer spring has to be removed in order to open the con-

nection.

• Release the knurled nuts on all (2 or 3) bolts until the springs

have been relieved. Do not, however, screw the nut all

the way off.

• On the bolt that does not have a spacer spring, release

the knurled nut far enough (without removing it completely)

so that the bolt can be tilted out and removed as a unit.

• At the connection point, which is now open, spread the

top and bottom segments apart and carefully remove the

EasyClamp.

9

Page 10

4 Putting into Operation

햶

BÜCHI Rotavapor R-220

4.6 Installation of the Reflux Glass Assembly

All glassware used must be intact, with no signs of cracks,

spreading impact marks, or other damage. Inspect the glassware visually before installing it.

• Fix the reflux distribution head 햲 in position on the gear

head using a DN70 EasyClamp connection.

• Introduce the cooler 햳, together with the cooler holder

햴, into the pivoting clamp 햵 and connect it to the distribution head (DN45 EasyClamp connection).

햴

햵

햳

햶

햸

햲

햺

햹

햷

햻

• Align the cooler 햳 in a vertical position and fix it in place

with the pivoting clamp 햵.

• Screw the cooling water hose nipples 햶 onto the cooler

햳.

• Insert the shut-off tap 햷 into the distribution head 햲 and

tighten it firmly.

• Introduce the stop cock 햸 into the distribution head with

the PTFE hose attached to it, and secure it with a standard

joint clamp 햹.

• Attach the condensate cooler 햺 to the distributor head

with a DN25 EasyClamp connection and fix it in position.

• Screw the temperature sensor 햻 into the distribution head

햲.

• Check all EasyClamp connections and tighten them evenly

and in parallel.

→ The installation of the receiving fixture is described on Page

13.

Fig. 6: Reflux glass assembly

10

Page 11

BÜCHI Rotavapor R-220

4 Putting into Operation

4.7 Installation of the Descending Glass Assembly

All glassware used must be intact, with no signs of cracks,

spreading impact marks, or other damage. Inspect the glassware visually before installing it.

• Fix the descending distributor head 햲 in position on the

gear head using a DN70 EasyClamp connection.

햸

햴

햷

햸

햻

햽

햺

햹

햾

햷

햶

햳

햲

• Put the expansion vessel 햳 onto the distribution head

and fix it in position with a DN45 EasyClamp connection.

• Introduce the cooler 햴, together with the cooler holder

햵, into the pivoting clamp 햶 and connect it to the distribution head (DN45 EasyClamp connection).

• Connect to the cooler and the expansion vessel using the

U-tube 햷 and fix in position with two DN45 EasyClamp

connections.

• Align the cooler 햴 and the expansion vessel 햳 in their

vertical positions and fix them in place with a pivoting clamp

햶.

• Screw the cooling water hose nipples 햸 onto the cooler

햴.

• Insert the stop cock 햹, with the PTFE hose mounted on

it, into the distribution head, and secure it with a standard

joint clamp 햺.

• Fasten the vacuum connector 햻 to the Y-connection 햽

with a DN45 EasyClamp connection and fix the unit in

place on the lower end of the cooler with a DN45

EasyClamp.

• Screw the temperature sensor 햾 into the support connection in the U-tube 햷.

• Check all EasyClamp connections and tighten them evenly

and in parallel.

Fig. 7: Downgrade glass assembly

→ The installation of the receiving fixture is described on Page

13.

11

Page 12

4 Putting into Operation

BÜCHI Rotavapor R-220

4.8 Installation of the Descending Glass Assembly

with a 2nd Cooler

All glassware used must be intact, with no signs of cracks,

spreading impact marks, or other damage. Inspect the glassware visually before installing it.

• Fix the descending distributor head 햲 in position on the

gear head using a DN70 EasyClamp connection.

햽

햺

햹

햸

햽

햻 햿햾

헀

햷

햴

햶

햵

햳

햲

• Place the expansion vessel 햳 on the distribution head

and fix it in position with a DN45 EasyClamp connection.

• Introduce the cooler 햴, together with the cooler holder

햵, into the pivoting clamp 햶.

• Connect the cooler and the expansion vessel with the U-

tube 햷 and fix them in position with two DN45 EasyClamp

connections.

• Insert the second cooler 햸, together with the cooler holder

햹, into the pivoting clamp 햺.

• Join the two coolers with the Y-connection 햻 and fix them

in position with two DN45 EasyClamp connections.

• Align the coolers (햴 and 햸) and the expansion vessel 햳

in their vertical positions and fix them in place with pivoting

clamps (햶 and 햺).

• Screw the cooling water hose nipples 햽 onto coolers 햴

and 햸.

• Insert the stop cock 햾, with the PTFE hose mounted on

it, into the distribution head, and secure it with a standard

joint clamp 햿.

• Screw the temperature sensor 헀 into the support connec-

tion in the U-tube.

Fig. 8: Downgrade glass assembly with two coolers

12

• Check all EasyClamp connections and tighten them evenly

and in parallel.

→ The installation of the receiving fixture is described on Page

13.

Page 13

BÜCHI Rotavapor R-220

햵

햲

햴

Fig. 9: Single receiver, reflux

햳

햷

햶

햵

햲

햴

햳

Fig.10: Single receiver, downgrade

4 Putting into Operation

4.9 Installation of the Receiving Fixture

All glassware used must be intact, with no signs of cracks,

spreading impact marks, or other damage. Inspect the glassware visually before installing it.

Single Receiver

• Fasten the support ring 햲 to the support rod with a pivoting

clamp 햳.

• Screw the outlet valves 햴 on the receiving flask 햵 on

tight using a DN25 EasyClamp connection.

• Place the receiving flask on the support ring 햲.

With a reflux glass assembly:

• Bring the support up and fix the flask in position on the distillate cooler using a DN25 EasyClamp connection.

With a descending glass assembly:

• Attach the branching piece 햶 to the opening at the bottom

of the Y-connection with a DN45 EasyClamp connection.

• Insert the shut-off tap 햷 into the branching piece 햶 and

tighten it firmly.

• Bring the support up and fix the receiving flask 햵 in position

on the branching piece 햶 using a DN25 EasyClamp connection.

햶

햶

햸

햵

햲

햴

Fig. 11: Interchangeable receiver

햳

햷

햴

햲

햳

Dual Receiver

• Fasten the support rings 햲 to the support rods at the

front and back using pivoting clamps 햳.

• Screw the outlet valves 햴 firmly onto the receiving flask

햵 using DN25 EasyClamp connections.

• Place the receiving flasks 햵 on the support rings 햲.

• Screw the two shut-off taps 햶 into the branching pieces

(햷 and 햸) and tighten them.

• Connect the branching pieces with a DN25 EasyClamp

connection. Place them on the receiving flasks 햵, and

fasten them with DN25 EasyClamp connections.

With a reflux glass assembly:

• Bring the receiving flask up, and fasten the branching piece

햸 to the condensate cooler using a DN25 EasyClamp

connection.

With a descending glass assembly:

• Bring the receiving flask up, and fasten the branching piece

햸 to the Y-connection using a DN25 EasyClamp connection.

13

Page 14

4 Putting into Operation

BÜCHI Rotavapor R-220

4.10 Attaching and Removing Flasks

Bring up the flask

• With the snap flange coupling open, lay the flask in position.

• Close the first segment of the snap flange coupling( T h e

hook must latch in).

Fig. 12: Snap flange coupling, with flask laid in place

Fig. 13: Closing the snap flange coupling

• Close the second segment of the snap flange coupling.

• Insert the closure hook and press down the closure lever.

A clear resistance must be felt when this is done. If not,

readjust the tension on the closure.

Adjusting the tension on the closure:

Open the closure hook up, and turn it.

Turning clockwise increases pressure

Turning counterclockwise reduces pressure

Fig. 14: Adjusting the tension on the closure

14

If the flange of the evaporating flask is outside of a certain

tolerance, the adjustment with the hook is not possible.

This evaporating flask must not be used!

Page 15

BÜCHI Rotavapor R-220

4 Putting into Operation

Removing flasks

• Place your hand under the flask to hold it from below.

• Open the closure lever 햲.

햳

Fig. 15: Opening the closure

햴

햲

• Use your thumb to release the closure hook 햳.

• Flip up the first segment of the snap flange coupling.

• With your hand under the flask, lift it lightly slightly from

below and relieve pressure on it.

• Press the hook 햴 in.

• Open the second segment of the snap flange coupling.

• Lift the flask out at the top and remove it.

Fig. 16: Opening the second segment

15

Page 16

4 Putting into Operation

햳

햶

햲

BÜCHI Rotavapor R-220

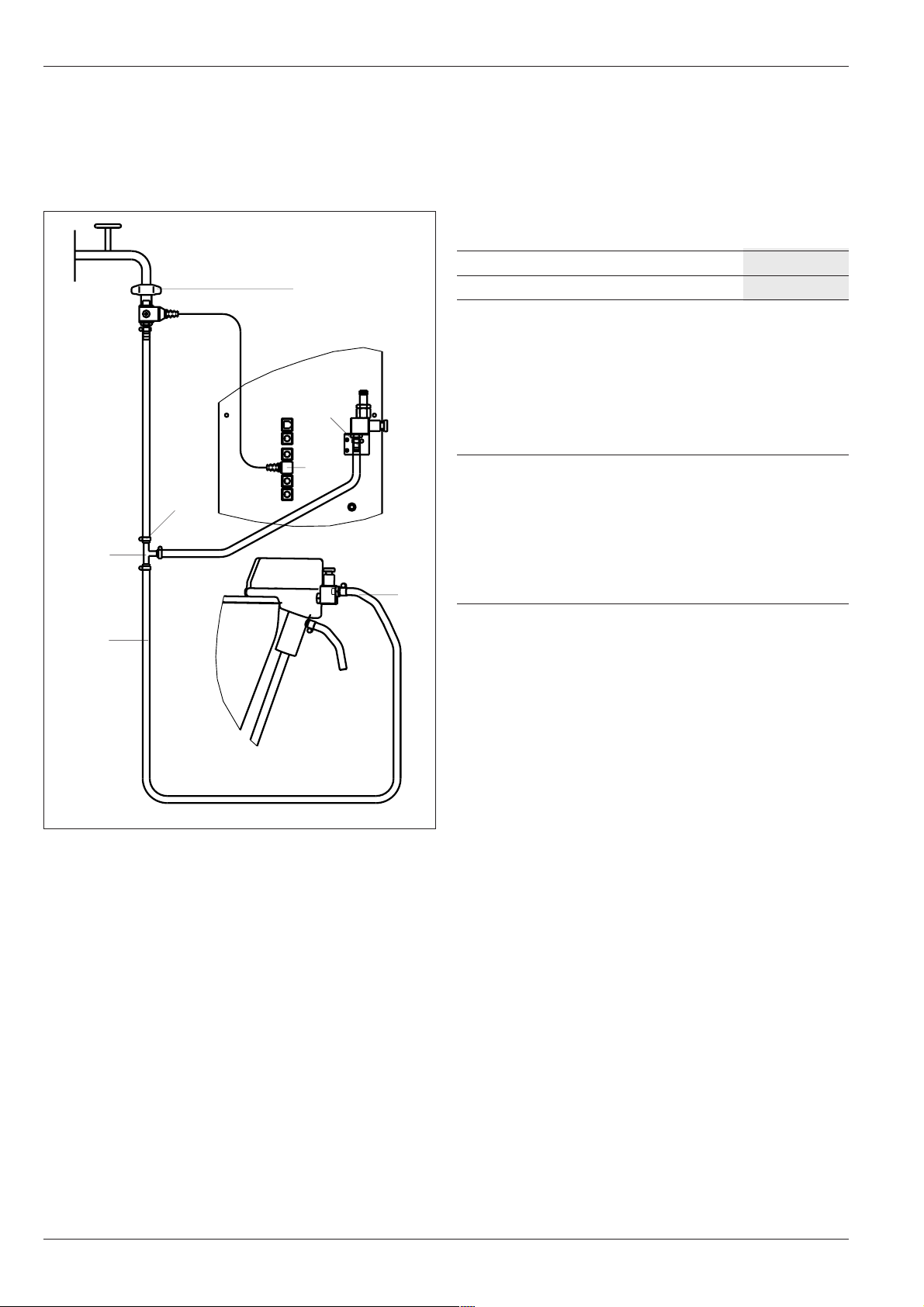

4.11 Hose Couplings

In general, observe the following items for all glass assemblies.

The cooling water inlet is always at the lower condenser

connection.

When there are two condensers (D2 und DB2), the two condensers can be connected serially, the additional condenser

being cooled first.

The following is the key for all of the hose diagrams on these

two pages.

햲 Cooling water inlet for first condenser

햳 Cooling water outlet for first condenser

햴 Cooling water inlet for second condenser

햵 Cooling water outlet for second condenser

햶 Vacuum connection

햷 Vacuum controller

햸 T-piece (026117)

햲

햳

햷

햵

햴

Fig. 17: Hose Couplings 1

16

Page 17

BÜCHI Rotavapor R-220

4 Putting into Operation

The following is the key for all of the hose diagrams on these

two pages.

햴

햵

햳

햲

햷

햶

햵

햲 Cooling water inlet for first condenser

햳 Cooling water outlet for first condenser

햴 Cooling water inlet for second condenser

햵 Cooling water outlet for second condenser

햶 Vacuum connection

햷 Vacuum controller

햸 T-piece (026117)

햷

햸

햶

햷

햳

햲

Fig. 18: Hose Couplings 2

17

Page 18

4 Putting into Operation

Fig. 19: Shut-off tap

햲

햳

햳

BÜCHI Rotavapor R-220

4.12 Operating the Shut-off tap

The shut-off tap is of a special design. It does not have a

continuous thread on its inside for tightening it, but rather a

sliding plane with two fixed latching positions. The closing pressure when it is in a closed position is provided by a prestressed

spring.

• Insert the shut-off tap on the distribution head and turn

the white lower section of the grip 햲 clockwise until the

shut-off tap is tightly seated.

• To open:

Turn the gray upper section of the grip 햳 clockwise until

the shut-off tap latches into the 1st position.

If the opening is not large enough, continue turning until

the shut-off tap reaches the 2nd position.

Fig. 20: Bath replenishment

햴

햲

햳

4.13 Bath Replenishment (Optional)

햲 Bath replenishment inlet

Hose nipple, Diam.14 mm

햳 Bath replenishment outlet

Hose nipple, Diam.14 mm

Opening the needle valve 햴 slightly by one-quarter turn produces a continuous supply flow.

Introduce the Open/Shut valve supplied with the unit into the

bath replenishment inlet 햲 and connect it to “CW Valve” on

the back wall of the unit. This interrupts the replenishment of

the bath when rotation stops.

The installation of the water valve is described in chapter

8, Replacement Parts, Water Valve.

If oil is used as heating medium, the bath replenishment

has to be emptied and disconnected from the water inlet.

Otherwise, there is a risk of water pouring into the hot oil

bath.

Operating Instructions!

Fig. 21: Bath replenishment

18

When rotation stops, the cooling water and bath replenishment

water switch OFF after short delay. As soon as rotation starts,

the valve reopens and the water flows once again.

Page 19

BÜCHI Rotavapor R-220

4 Putting into Operation

4.14 Reset of the over-temperature protection

If the heater heats up over 205°C (e.g. if no heating medium

is in the bath), it is cut off by a mechanical overtemperature

protection.The overtemperature protection is reset by pushing

the button under the heating block.

Fig. 22:

Reset of the over-temperature protection

4.15 Heating Medium

Never operate the heating bath when there is no heating medium in it!

Suitable heating media include:

• Water

(some Borax should be added when using

deionized water)

• Heat transfer oils suitable for use at temperatures up to

160° C (e.g., Ucon HTF 14, Fluka AG).

• Water-soluble polyethylene glycol

(e.g., Polyethylene glycol 600, Fluka AG).

After the oil bath has been standing opened for a prolonged

period, condensation water can collect on the bottom. When

the bath is used again, it must be heated above 100°C with

rotating flask in order to drive the water out.

4.16 Checking Installation

After installation has been completed and before doing the

first distillation, check to make sure the installation has been

carried out correctly:

• Inspect the glass visually for possible damage.

• Check that all connections (steam, water, vacuum) have

been fixed properly in position.

• Check the tightness of the vacuum.

19

Page 20

5 Operation

BÜCHI Rotavapor R-220

5 Operation

Make certain that the unit has been commissioned properly

as described in Chapter 4.

5.1 Arrangement of the Operator Control and

Display Elements

햲 Main breaker switch

햻

햺

햹

햸

햷

햽

Fig. 23: Operator control elements for the R-220

햶

햵

햴

햳

햲

햳 Lift for the bath

햴 Rotation ON/OFF

햵 Rotating speed adjustment

햶 Rotating speed display

햷 Heater ON/OFF

햸 Input: Set-point temperature for bath

햹 Temperature UP/DOWN

햺 Display for bath temperature

햻 Display for vapour temperature

햽 Aeration

The bath is lowered automatically when the unit is switched

off or in case of a power failure to ensure that the evaporating

flask will in all cases remain outside the source of heat (optional).

5.2 Adjusting the Maximum Set-Point

Temperature and Automatic Lowering of

the Bath in Case of a Power Interruption

20

Setting the Maximum Set-Point Temperature

• Press the button “SET TEMP” 햸, simultaneously switching

on the main breaker switch 햲. This activates the input for

setting the maximum set-point temperature.

• The value can be set at any level desired by pressing the

“DOWN” and “UP” buttons 햹.

• The input is stored and the unit switched into the operating

mode only after the “AERATE” button 햽 is then pressed.

Page 21

BÜCHI Rotavapor R-220

5 Operation

Adjusting the Optional Automatic Lowering of the

Bath in Case of a Power Interruption

• Press the button “LIFT down” 햳, simultaneously switching

on the main breaker switch 햲.

This results in the display “ON” or “OFF”.

On = The lift lowering has been switched ON

Off = The lift lowering has not been switched ON.

• To switch back and forth between ON and OFF, press

repeatedly on the button “LIFT down” 햳.

• The input is stored and the unit switched into the operating

mode only after the “AERATE” button 햽 is then pressed

repeatedly.

5.3 Tips and Tricks

Selection of the Distillation Temperature

In order to attain optimum distillation conditions, the energy

supplied to the distillation from the bath must be dissipated

again across the cooler. In order to ensure this, it is best to

work according to the following rule of thumb:

Cooling water ∆T2 Boiling temperature ∆T1 Bath

max. 20 ºC 40 ºC 60 ºC

How do you attain these conditions?

• Set the bath temperature at 60 ºC.

• Adjust the cooling water. Its temperature should not be

higher than 20 ºC.

• Allow the cooling water to flow through the cooler at a rate

of about 120–150 liters/hr.

• Select the working vacuum so that the boiling point of the

solvent is at 40 ºC.

• Obtain the corresponding value for the vacuum from the

Table of solvents.

Advantages of a Bath Temperature of 60 °C

• Evaporating flasks can be changed without any danger of

scalding.

• The rate of water evaporation out of the heating bath is

not yet very high.

• The energy in the heating bath is being utilized very efficiently.

The solvent should condense out in approx. 2/3 to 3/4 of the

lengths of the cooling coils present.

21

Page 22

5 Operation

BÜCHI Rotavapor R-220

5.4 Table of Solvents

Solvent Formula Molar Mass Evaporation Boiling Point Spec.Gravity Vacuum in mbar for a

3

Boiling Point at 40°C

Acetic acid C2H4O

in g/mol Energy in J/g at 1013 mbar in g/cm

2

60.0 695 118 1.049 44

Acetone C3H6O 58.1 553 56 0.790 556

n-Amyl alcohol, n-Pentanol C5H12O 88.1 595 37 0.814 11

Benzene C6H

6

78.1 548 80 0.877 236

n-Butanol, tert. Butanol C4H10O 74.1 620 118 0.810 25

(2-Methyl-2-Propanol) C4H10O 74.1 590 82 0.789 130

Carbon tetrachloride CCI

4

153.8 226 77 1.594 271

Chlorobenzene C6H5CI 112.6 377 132 1.106 36

Chloroform CHCI

Cyclohexane C6H

12

119.4 264 62 1.483 474

3

84.0 389 81 0.779 235

Diethyl ether C4H10O 74.0 389 35 0.714 850

1,2,-Dichlorethane C2H4CI

1,2,-Dichlorethylene (cis) C2H2CI

1,2,-Dichlorethylene (trans) C2H2CI

99.0 335 84 1.235 210

2

97.0 322 60 1.284 479

2

97.0 314 48 1.257 751

2

Diisopropyl ether C6H14O 102.0 318 68 0.724 375

Dioxane C4H8O

2

88.1 406 101 1.034 107

DMF (Dimethylformamide) C3H7NO 73.1 153 0.949 11

Ethanol C2H6O 46.0 879 79 0.789 175

Ethyl acetate C4H8O

Heptane C7H

Hexane C6H

2

16

14

88.1 394 77 0.900 240

100.2 373 98 0.684 120

86.2 368 69 0.660 335

Isoamyl alcohol, 3-Methyl-1-Butanol C5H12O 88.1 595 129 0.809 14

Isopropyl alcohol C3H8O 60.1 699 82 0.786 137

Methanol CH4O 32.0 1227 65 0.791 337

Methylene chloride, Dichloromethane CH2CI

2

84.9 373 40 1.327 850

Methylethylketon C4H8O 72.1 473 80 0.805 243

Pentachlorethane C2HCI

Pentane C5H

12

202.3 201 162 1.680 13

5

72.1 381 36 0.626 850

n-Propyl alcohol C3H8O 60.1 787 97 0.804 67

1,1,2,2,-Tetrachloroethane C2H2CI

Tetrachloroethylene C2CI

4

167.9 247 146 1.595 35

4

165.8 234 121 1.623 53

THF (Tetrahydrofurane) C4H8O 72.1 67 0.889 357

Toluol C7H

1,1,1,-Trichlorethane C2H3CI

Trichlorethylene C2HCI

8

3

92.2 427 111 0.867 77

133.4 251 74 1.339 300

3

131.3 264 87 1.464 183

Water H2O 18.0 2261 100 1.000 72

Xylol (Mixture) C8H

10

106.2 389 25

(o) 144 0.880

(m) 139 0.864

(p) 138 0.861

Table 3: Table of Solvents (CRC Handbook, 65th Ed)

22

Page 23

BÜCHI Rotavapor R-220

6 Maintenance

6 Maintenance

Please note all rules aimed at keeping the rotary evaporator

in a functional condition. These also include periodic cleaning

and inspection for any damage that might have occurred.

Make certain that supply of power to the unit has been interrupted before doing any maintenance work on the unit. Always

support the bath from below, on the underside of the bath

whenever doing any repair work.

6.1 Taking Apart the Snap Flange Coupling

• Close the two segments of the snap flange coupling.

• Turn the snap flange coupling by 180°, until the closure

faces down.

Fig. 24: Snap flange coupling, closed

• Have Tool No. 20075 ready at hand.

• Reopen the closure.

• Lift the 1st segment of the snap flange coupling to open it.

• Lift the 2nd segment of the snap flange coupling to open it.

• With three fingers at the tip, reach under the middle segment and raise it up.

• Insert Tool No. 20075 in at the side, between the lugs on

the positional lock. Turn lightly until the pin becomes unlatched. Take the snap flange coupling assembly off.

• Clean the snap flange coupling.

23

Page 24

6 Maintenance

BÜCHI Rotavapor R-220

6.2 Assembling the Snap Flange Coupling

• Insert the snap flange coupling from above, until the pins

in the lock latch into the hole on the lug.

• Close the two segments of the snap flange coupling.

• Turn the snap flange coupling again by 180°, until the closure

lies at the top.

• Lift the two segments of the snap flange coupling to open

them.

• Lay the neck of the glass flask into the middle segment

and raise the flask slightly.

• Pull the segment on the left back slightly and close it until

the hook latches in place.

• Close the segment on the right.

Fig. 25: Assembling the snap flange coupling

• Insert the closure hook and close the snap flange coupling

with the closure lever. A clear resistance must be felt when

doing this. Otherwise no seal can be fully guaranteed.

6.3 Removing the Evaporating Flask Seal

• Seal the holder for the seal by 180°, until the opening faces

up.

• Take hold of the seal with both hands, from above and

from the front, and pull it out slowly.

• Tilt the seal slightly and carefully pull it all the way out. Be

careful not to damage the glass centering bulge when

doing so.

• Remove the vapor duct.

Fig. 26: Removing the evaporating flask seal

24

Page 25

BÜCHI Rotavapor R-220

햲

햳

6 Maintenance

6.4 Inserting the Evaporating Flask Seal

• Insert the vapor duct.

• Insert the seal. Using gentle pressure, shove it across the

lock preventing it from twisting out of position, and then

shove it all the way in. Press it with both thumbs until it

latches in position.

• The knob 햲 in the gearhead must come to rest in the

notch 햳 in the vapour duct.

Fig. 27: Inserting the evaporating flask seal 1

햲

Fig. 28: Inserting the evaporating flask seal 2

햲

햳

6.5 Replacement of the Seals for the Distribution

Head

• Open the DN70 EasyClamp by releasing the knurled nuts

on all 3 bolts, but do not screw the nuts completely off.

• Tilt the top bolt out toward the back.

• Open the upper and lower EasyClamp segments and

carefully lift the distribution head off the glass assembly.

Fig. 29: Replacement of the seals for the distribution head

• Take out the seal 햲 laid in at the front and replace it.

25

Page 26

6 Maintenance

Fig. 30: Replacement of the Vacuum Seal 1

BÜCHI Rotavapor R-220

6.6 Replacement of the Vacuum Seal

• Remove the DN70 EasyClamp completely and take off

the distribution head.

• Pull the cylindrical seal holder out and turn it over.

• Insert Tool No. 20075 into the metal guide on the seal and

pull the seal out.

• Put in the new seal with the dark scraper ring facing the

inside and the metal guide ring facing outward.

• Insert the cylinder with the seal at the back lying on the inside.

• Insert the seal at the front.

• Provisionally install the EasyClamp using 2 bolts.

• Set the distribution head of the glass assembly on top of

the seal.

• Close the segments of the EasyClamp. Flip the top bolt up

and in, and hand-tighten all 3 knurled nuts.

Tip:

When the glass assembly "R" is in place, the vacuum seal

can be taken out and/or cleaned without the glass assembly

having to be removed.

Fig. 31: Replacement of the Vacuum Seal 2

• Remove the complete DN70 EasyClamp assembly from

the distribution head.

• Using a socket wrench, release the fastening for the support rod.

• Carefully turn the glass assembly out around the support

rod as an axis.

• Remove the seal.

6.7 Cleaning

Use commercially available cleaning agents to clean the glassware.

26

Merely wipe the housing off with a damp cloth (without using

any organic solvents).

Use a commercially available de-liming agent to dissolve residues of lime in the bath and flush the bath out well.

Page 27

BÜCHI Rotavapor R-220

6 Maintenance

6.8 Vacuum Seal

The seal should be cleaned whenever necessary, but at least

once every six months.

During the intake phase, which lasts approx. 10 hours, the

seal will show signs of greater material loss due to wear. This

is normal for a PTFE seal.

Cleaning

Before the packet of seals can be removed, the distribution

head must be released and screwed off. The complete seal

packet can then be taken out and cleaned.

Wipe off the sealing lip using a soft, dry cloth. Clean the running

surface on the vapor duct well.

Regular cleaning of the seal will result in a longer service life

for it.

6.9 Testing for Leaks

After the rotary evaporator has been completely assembled

and before putting it into operation, i.e., while it is clean and

dry, check for tightness of the vacuum. To do this, evacuate

the unit to below 100 mbar and then close the vacuum line.

The rate of pressure rise must not exceed 3 to 5 mbar per 15

minutes.

A greater pressure rise indicates a leak in the vacuum seal. In

such a case, recheck all EasyClamp connections and all valves.

6.10 Customer Service

No intervention on or in the unit is permissible except when

done by authorized Service personnel. These are individuals

with a well-backed technical professional training and

knowledge of the dangers that result from a failure to observe

the safety precautions required. BÜCHI’s Customer Service

representatives have available to them a Service Manual

specific to the unit in question. That manual is issued only to

authorized Service personnel.

The addresses of BÜCHI’s official Customer Service representatives are shown on the back cover of this Operation Manual.

Please turn to these representatives should you have any

malfunctions, technical questions, or problems in using the unit.

BÜCHI’s Customer Service Dept. will be ready and happy to

offer the following services:

• Spare parts service

• Repair service

• Maintenance service

• Technical consultation.

27

Page 28

7 Taking out of Operation

BÜCHI Rotavapor R-220

7 Taking out of Operation

Remove all hazardous materials and clean the unit thoroughly.

This prevents any risk that individuals could suffer injuries due

to contact with hazardous materials.

7.1 Storage

Always store the unit and spare parts for it in a clean and dry

location.

7.2 Packing / Transport

The original packing has been specially designed for transporting the unit and the glass parts for it. Use only the original

packing materials for any further transport.

7.3 Waste Disposal

Table 7 in the Appendix, Chapter 9, contains a list of the materials, including their material codes, used for the most important

components of the unit. This list has been provided in order to

enable environmentally correct disposal of the rotary evaporator. It ensures that the parts can be separated and sent for

appropriate recycling. Please refer to the pertinent guidelines

when disposing of electrical parts. In addition, observe all

regional and local laws covering waste disposal.

Used batteries may be returned directly to your BÜCHI representative for disposal.

28

Page 29

BÜCHI Rotavapor R-220

8 Spare Parts and Accessories

8 Spare Parts and Accessories

Only original BÜCHI accessories and spare parts ensure safe

operation and a proper functioning of the unit. The use of

spare parts and accessories other than those from BÜCHI is

permissible only with prior approval of the manufacturer. The

Spare Parts Catalog may be used for purposes of assembly

and disassembly only in conjunction with the corresponding

Chapters 4 and 7 in this Operation Manual. Dis-closure and

distribution to third parties, and manufacturing based on this

manual are strictly forbidden.

Copyright by Büchi AG. All rights reserved.

29

Page 30

8 Spare Parts and Accessories

BÜCHI Rotavapor R-220

DD2

27289

27308

41155

1129

3577/5155

27338

1169

41130

41348

27150

41076

41131

1165

41151 / 41156

41335

27277/

41164

27289

41155

41159

1169

41130

27150

41076

27308

41131

1165

41335

27277/

41164

41348

DB DB2

27837

41120

27825

1169

41076

1165

41335

27277/

41354

41348

27837

41120

27824

27825

41166

41348

41076

1165

41335

27277

41354

/

30

Fig. 32: Spare parts, Glass Assemblies D, D2, DB, DB2

Page 31

BÜCHI Rotavapor R-220

41151

41156

41241 (DN40)

41155

41120 (Bullfrog)

41240 (DN25)

8 Spare Parts and Accessories

8.1 Spare Parts: Glass Assemblies D, D2, DB, DB2

Component Ordering No.

Vacuum connector PLG 01129

Expansion vessel PLG 01165

Y-connection PLG 01169

Threaded sleeve Svl 22 03577

Seal Svl 22 Id 17 PTFE 05155

U-tube PLG 27150

PTFE hose, Outer Diam. 10.0x1.0 27277

Screwed fitting Svl 22 27289

Cooler, 3 coil PLG 27308

Hose nipple 27338

Cooler Bullfrog, closed, PLG 27824

Cooler Bullfrog PLG 27825

U-Tube Bullfrog PLG 27837

Temperature sensor B, complete 41076

Glass holder B, complete 41120

EasyClamp, DN25 41130

EasyClamp, DN40 41131

Pivoting clamp, complete 41151

Glass holder, complete 41155

Clamping lever 41156

Cooler, 3-coil, closed PLG 41159

Y-connection Bullfrog PLG 41166

Set of bolts for EasyClamp, DN25 41240

Set of bolts for EasyClamp, DN40 41241

Inlet valve, complete 41348

Connection PTFE 41354

Distribution piece “D” PLG 41335

Table 4: Spare parts, Glass Assemblies D, D2, DB, DB2

31

Page 32

8 Spare Parts and Accessories

BÜCHI Rotavapor R-220

RRB

3577

41159

5155

27338

41151/

41156

27289

41348

41373

41162

C

41155

41060

41076

41228

27277 /

41164

27289

25979 /

25981

41167

41348

41373

41162

27289

27824

41120

41228

27277 /

41164

3577

5155

27338

41348

41373

41162

25124

25978

41079

41060

41076

41228

27277/

41164

Fig.33: Spare parts, Glass Assemblies R, RB, C

32

Page 33

BÜCHI Rotavapor R-220

41151

41156

41241 (DN40)

41155

41120 (Bullfrog)

41079 (Cold trap)

41240 (DN25)

8 Spare Parts and Accessories

8.2 Spare Parts: Glass Assemblies R, RB, C

Component Ordering No.

Threaded sleeve Svl 22 03577

Seal Svl 22 Id 17 PTFE 05155

Cold trap 25124

Cold trap, PLG 25978

Cold trap cover 25979

Cover seal 25981

PTFE hose, Outer Diam. 10.0x1.0 27277

Screwed fitting Svl 22 27289

Hose nipple 27338

Cooler Bullfrog, closed, PLG 27824

Shut-off tap, large, complete 41060

Temperature sensor B, complete 41076

Glass holder C, complete 41079

Glass holder B, complete 41120

EasyClamp, DN25 41130

EasyClamp, DN40 41131

Pivoting clamp, complete 41151

Glass holder, complete 41155

Clamping lever 41156

Cooler, 3-coil, closed PLG 41159

Condensate cooler 41162

Cold trap, complete 41167

Set of 10 teflon discs 41228

Set of bolts for EasyClamp, DN25 41240

Set of bolts for EasyClamp, DN40 41241

Inlet valve, complete 41348

Connection, PTFE 41354

Distribution piece "R" 41373

Table 5: Spare parts, Glass Assemblies R, RB, C

33

Page 34

8 Spare Parts and Accessories

41062

37569

41049

41048

BÜCHI Rotavapor R-220

8.3 Miscellaneous

Component Ordering No.

Interchangeable receiver (W)

Receiving flask 10L 37569

Branching piece 1 PLG 41048

Branching piece 2 PLG 41049

Outlet valve, DN25/2 41061

Shut-off tap, small, complete 41062

EasyClamp, DN25 41130

Pivoting clamp, complete 41151

Base for flask 41252

41061

Fig. 34: Interchangeable receiver (W)

41053

41151

41062

41130

37569

41252

41252

41151

Single receiver (E)

Receiving flask 10L 37569

Branching piece PLG 41053

Outlet valve, DN25/2 41061

Shut-off tap, small, complete 41062

EasyClamp, DN25 41130

Pivoting clamp, complete 41151

Base for flask 41252

Fig. 35: Single receiver (E)

34

41061

Hose Connections

Softaflex hose, Inside Diam. 8.0 (3.4 m) 04113

Vacuum hose, Inside Diam. 10.0x5.0 (3.5 m) 04125

Plastic hose, Inside Diam. 10.0x2.0 (4.5 m) 27146

PTFE hose, Outside Diam.10.0x1.0 (2.0 m) 27277

Page 35

BÜCHI Rotavapor R-220

8 Spare Parts and Accessories

20075

Fig. 36: Sealing elements

41231

41094 41095

41135

41230

41121

41084

27378

41229

Component Ordering No.

Fig. 37: Inlet valve, complete

41346

41946

03549

41354

03223

00398

41147

Sealing elements

Support ring inlet valve 41147

Seal SVL 30 00398

Screw Cap SVL 30 03223

Screw Cap SVL 15 03549

Seal tool 20075

O-ring 130x5.0 Fpm70 27378

Vapor duct 41084

Seal holder 41094

Vacuum seal 41095

Evaporating flask seal, complete 41121

Easy Clamp element, DN70 41135

Set of 5 O-rings 64x5.0 41229

Set of 10 cover caps, D11 Pa 41230

Set of distribution head sealings 41231

Glass body 41346

Inlet valve, complete 41348

Connection, PTFE 41354

PTFE bellow 41388

Set of 5 SVL 15 seals 41946

35

Page 36

8 Spare Parts and Accessories

Fig. 38: Machine leg

41110

BÜCHI Rotavapor R-220

Component Ordering No.

Adjustable machine leg 41018

41111

Clip 41110

Detent 41111

Snap flange coupling, completel. 41112

Fig. 39: Snap flange coupling, complete

Fig. 40: Protective screen

41112

Protective screen 41214

36

Page 37

BÜCHI Rotavapor R-220

8 Spare Parts and Accessories

8.4 Accessories

Fig. 41: Lamella curtain

햳

햲

Component Ordering No.

Lamella curtain

Lamella curtain 41256

Individual lamella 41267

Installation Instructions!

1) Put the lamella curtain 햲 on the support rod 햳.

2) Turn the lamella curtain until position is parallel to the edge

of the chassis.

3) Tighten the screw.

Fig. 42: Foam detector

Foam detector

The foam detection consists of a special distribution piece for

the descending glass configuration, the sensor, power supply

and the aeration valve. The system will detect the rising foam

and aerate the system for a split second.

Foam detector 40507

37

Page 38

8 Spare Parts and Accessories

Fig. 43: Evaporating flask

BÜCHI Rotavapor R-220

Component Ordering No.

6 L Evaporating flask 27470

10 L Evaporating flask 27469

20 L Evaporating flask 27468

Fig. 44: Drying flask

This special flask is particularly suited for drying powdery substances or a homogeneous mixture of solid products. The

baffles attached on the circumference of the flask ensure an

intensive circulation of the contents inside the flask.

10 L Drying flask 28592

20 L Drying flask 28593

38

Page 39

BÜCHI Rotavapor R-220

햳

8 Spare Parts and Accessories

Component Ordering No.

Splash Protection

Splash Protection 41201

Protective shield 41204

Protective shield seal 41259

Installation Instructions!

1) Switch the unit OFF.

2) Remove the two bolts 햲 and the plastic cover 햳.

3) Put on the seal 햵.

햴

햵

햶

햲

4) Plug in the plug 햴.

5) Fasten the splash protection in place with the bolts 햶.

6) Switch the unit ON.

Operating Instructions!

Opening the splash protection switches the rotation OFF. When

the splash protection is closed again, the flask starts to rotate

once more when the rotation button is pressed.

Fig. 45: Splash Protection

39

Page 40

8 Spare Parts and Accessories

BÜCHI Rotavapor R-220

Component Ordering No.

Water Valve

Water valve cpl. 41191

햲

T-piece 26835

Installation Instructions!

햴

햳

Fig. 46: Water valve

햷

2) Connect the water valve 햲 to the water cock.

1) Switch the unit OFF.

햸

With optional bath replenishment

햵

3) Connect the water hose 햳 to the tee 햴 and secure them

with pivoting clamps 햵.

4) Connect the end of the water hose 햶 to the control valve

for bath replenishment and secure it with pivoting clamps.

햶

5) Connect the end of the hose 햷 at “CW-in” on the R-220

and secure it with pivoting clamps.

6) Connect the valve plug 햸 on the R-220 at the CW-Valve.

7) Switch the unit ON.

Operating Instructions!

When rotation stops, the cooling water and bath replenishment

water switch OFF after short delay. As soon as rotation starts,

the valve reopens and the water flows once again.

40

Page 41

BÜCHI Rotavapor R-220

햳

햲

8 Spare Parts and Accessories

Component Ordering No.

Support for Controller

Support for controller, complete 41223

Installation Instructions!

1) Remove the cover 햲.

2) Fasten the support using the bolt supplied with the unit 햳.

Fig. 47: Support for the controller

햴

햵

햲

햳

Vacuum Controller V-800 for R-220

Vacuum Controller V-800, 230 V 40721

Vacuum Controller V-800, 120 V 40722

Vacuum Controller V-805, 230 V 40723

Vacuum Controller V-805, 120 V 40724

햶

Connections

햲 Temperature probe 41076

햳 Vacuum valve 31354

햴 Control cable V-1000 38010

햵 Control cable V-800/V-805 40758

햶 Coolingwater valve 41191

Fig. 48: Connections to R-220

41

Page 42

9 Appendix

BÜCHI Rotavapor R-220

9 Appendix

9.1 Technical Data

R-220

Power Connection 4.2 kW

Connection Voltage 200 V / 230 V / 400 V

Evaporator output Up to 4 l/h water, higher for other solvents

(depending on the heat of evaporation)

Frequency 50 - 60 Hz

site condition maximum relative humidity 80% for temperatures up to 31° C

decreasing linearly to 50% relative humidity at 40° C

Rotary drive Induction motor with external fan, 180 W

Speed control Electronic, continuous, 5 to 140 RPM

Bath output 3600 W, Heat introduction 3W/cm

Bath dimensions Diam. 430 mm x 240 mm,

Bath capacity 20 l, without flask immersed

Bath pan Stainless steel X2CrNiMo 17 13 2 (1.4404 or 316L)

Bath heater control Electronic, with PT-1000, Control accuracy ± 1°C

Range of bath temperatures 20°C – 180°C

Overheating protection Separate monitoring circuit.

Responds at 15°C over set-point temperature

Bath lift Linear drive, Safety Class IP 65

Battery Battery, PB 12V

Measurement of vapor temperature PT-1000

Displays Vapor temperature, bath temperature, rotary speed

Aeration Integrated valve, aerated in case of power failure or by button,

with inert gas connection

Installation category II

degree of pollution 2

Vacuum pump Recommended suction output 2 – 4 m3/h

Cooling water consumption 120 – 200 l/h, with needle valve control

Cooling water pressure max. 1.7 bar abs., without any pulsation

Weight 65 kg, without glass

Dimensions Refer to pertinent chapter

Table 6: Technical Data

2

42

9.2 Materials Used

Material

Part Description Code

Chassis X5CrNi 18 10 1,4301 or 304

Bath pan X2CrNiMo 17 13 2 1,4404 or 316L

Glass Borosilicate 3,3

Seals Polytetrafluorethylene PTFE

Taps Polytetrafluorethylene PTFE

Table 7: Materials Used

Page 43

BÜCHI Rotavapor R-220

9 Appendix

9.3 Error Messages

Error messages indicate a defect on the unit and are signalled

on the bath temperature display. They appear with an “E” at

the start, followed by a specific number:

E0 : Message: Output from the bath sensor not within the valid range.

Cause: Sensor defective or a short-circuit has occurred.

Action: The bath heater is switched OFF. The bath is lowered. Rotation stops.

Acknowledgment: Switch the unit OFF.

E2 : Message: The bath is not reaching the intended maximum height.

Cause: The motor is defective or blocked. No voltage.

Action: The lift motor switches OFF. Rotation and heating continue.

Acknowledgment: Switch the unit OFF.

E3 : Message: The rotary drive does not reaching the required speed, or is turning too quickly.

Cause: Drive defective. Mechanical blocking. No power. Semi-conductor relay defective.

Action: Bath heater is switched OFF. Bath is lowered.

Acknowledgment: Switch the unit OFF.

E4 : Message: Battery voltage too low. Displayed only when starting the unit.

Cause: PB battery defective

Action: None

Acknowledgment: Press the “Aerate” button.

E5 : Message: EEPROM error.

Cause: Hardware defect.

Action: None.

Acknowledgment: Press the “Aerate” button. Work can then be continued, but a Service technician

must be notified of the problem.

E6 : Message: Overload of the valve output

Cause: Valve defective or wrong connections

Action: None.

Acknowledgment: Switch the unit OFF

Table 8: Error messages

To let all possible error messages appear, the device must be

shut off and on at least once per 24 h.

43

Page 44

BÜCHI Rotavapor R-2209 Appendix

9.4 FCC requirements (for USA and Canada)

English:

This equipment has been tested and found to comply with the limits for a Class A digital device, pusuant to

both Part 15 of the FCC Rules and the radio interference regulations of the Canadian Department of Communications. These limits are designed to provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment.

This equipment generates, uses and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio communications. Operation

of this equipment in a residential area is like to cause harmful interference in which case the user will be

required to correct the interference at his own expense.

Français:

Cet appareil a été testé et s'est avéré conforme aux limites prévues pour les appareils numériques de classe

A et à la partie 15 des règlementation FCC à la règlementation des radio-interférences du Canadian Department of communications. Ces limites sont destinées à fournir une protection odéquate contre les interférences

nétastes lorsque l'appareil est utilisé dans un environnement commercial.

Cet appareil génère, utilise et peut radier une énergie à fréquence radioélectrique, il est en outre susceprible

d'engendrer des interferences avec les communications radio, s'il n'est pas installé et utilisé conformément

aux instructions du mode d'emploi. L'utilisation de cet appareil dans les zones résidentielles peut causer des

interférences nèfastes, auquel cas l'exploitant sera amené à prendre les dispositions utiles pour polier aux

interférences à ses propres frais.

44

Page 45

BÜCHI Rotavapor R-220

We

BÜCHI Labortechnik AG

P.O.Box, CH-9230 Flawil, Switzerland

declare on our own responsibility that the product:

BÜCHI Rotavapor R-220

to which this declaration refers conforms to the following standards:

EN 61010-1:1993 (~ IEC 1010-1, VDE 0411-1)

Safety Rules for Electrical Measurement, Control, and Laboratory Equipment: General Requirements

9 Appendix

9.5 Declaration of Conformity

EN 61326-1:1997

Electrical Equipment for Measurement, Control and Laboratory Use. EMC Requirements

EN 61000-3-2: 1995/1996

Limits for harmonic current emissions

EN 61000-3-3: 1995

Limitation of voltage fluctuations and flicker

In accordance with the provisions of the EU Guidelines:

73/23/EWG (Guidelines for low voltage electrical equipment)

89/336/EWG (Electromagnetic compatibility)

Flawil, 15.01.2001

BÜCHI Labortechnik AG

Meierseggstrasse 40

9230 Flawil

Schweiz

Tel +41 (0)71 394 63 63 Guido Worch

Fax +41 (0)71 394 65 65 Qualitymanager

buchi@buchi.com

www.buchi.com

45

Page 46

9 Appendix

BÜCHI Rotavapor R-220

46

Loading...

Loading...