Page 1

BÜCHI Vacuum Controller B-720

Contents

Contents

1 Scope of delivery 2

2 Safety 3

3 Function 5

4 Putting into operation 7

5 Operation 10

6 Maintenance 15

7 Taking out of operation 17

8 Replacement parts 18

9 Appendix 23

Read these operating instructions carefully before you use the

Büchi Vacuum Controller B-720. Keep these instructions in a

safe place preferably close to the Vacuum Controller for quick

reference whenever required.

Chapter 2, Safety contains important notes concerning safety.

It is imperative to read these notes in order to operate the Vacuum

Controller safely.

Contents are subject to change without prior notice. No part of

these operating instructions may be reproduced in any form or

be processed, duplicated or distributed by electronic or optical

means without the written permission of Büchi Labortechnik AG.

All rights reserved. Copyright © Büchi Labortechnik AG, 1995

en, Version D (24 pages) Order No.

B-720 Instructions 96601

1

Page 2

1 Scope of delivery

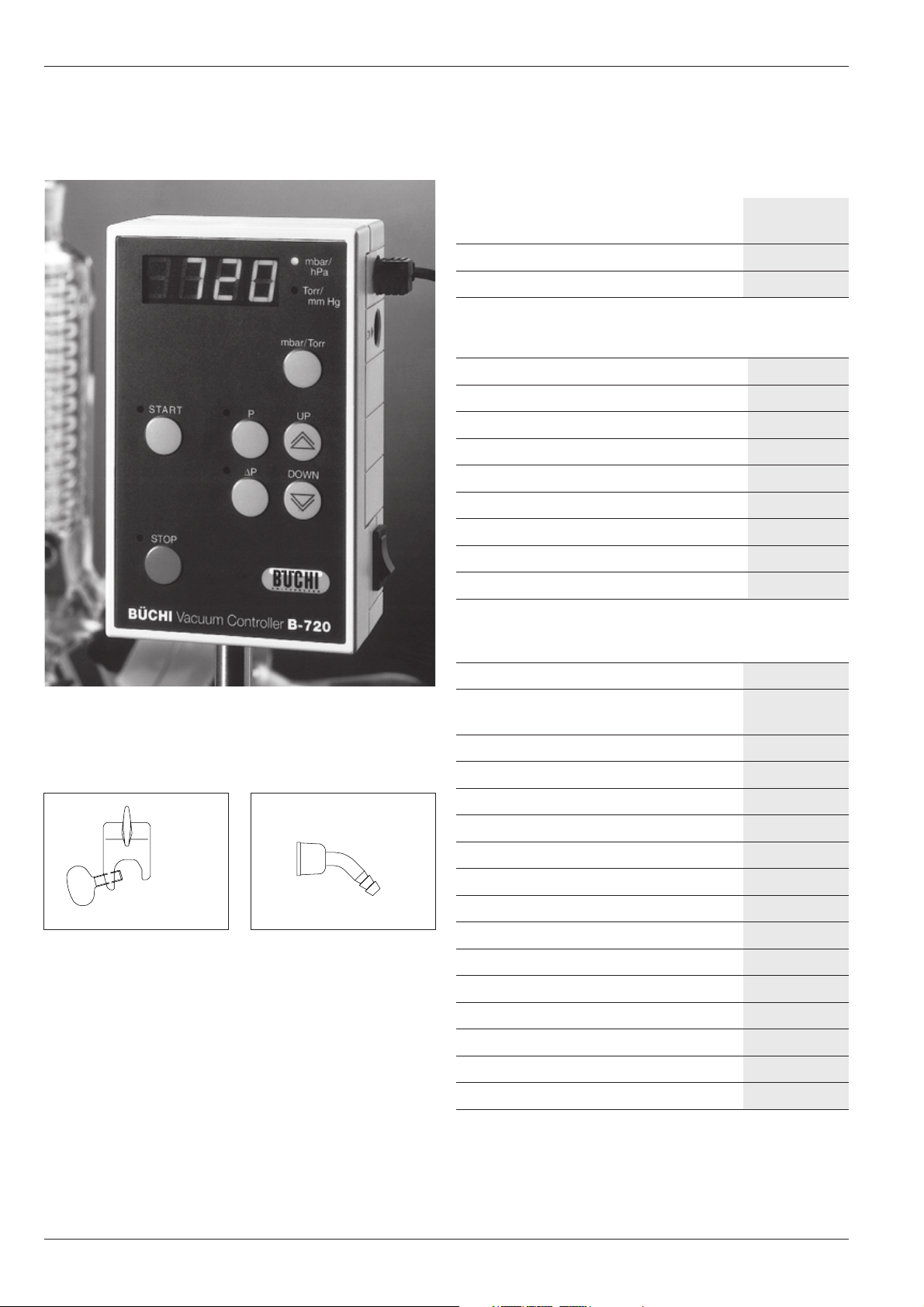

BÜCHI Vacuum Controller B-720

1 Scope of delivery

Description

Models: Order No.

Büchi Vacuum Controller B-720 230 V 34860

Büchi Vacuum Controller B-720 120 V 34960

Table 1: Scope of delivery

Enclosed items:

1 D12-16 cross clamp, complete 27347

1 GL 14 hose connector, complete 32885

1 Instructions in the following languages:

German 96600

English 96601

Figure 1: General view of the B-720

Figure 2: complete D12– 16 cross

clamp

Figure 3: complete GL14 hose

connector

French 96602

Italian 96603

Spanish 96604

1 Packaging, complete

Table 2: Enclosed items

Optional accessories:

Water jet pump B-764, complete 31358

Water jet pump B-767, complete with 31357

cooling valve

Cooling water valve, complete 31356

Two-way solenoid valves, 24 VDC:

Type for 1-liter Rotavapor 31353

Type for 20-liter Rotavapor 31354

Type for 50-liter Rotavapor 31355

Büchi Switch-box B-745:

Type CH 36410

Type D 36411

Type International 36412

Adapter cable 31225

U.S. adapter cable 33369

Woulff bottle trap, PLASTIC+GLAS 25519

Bottle clamp 11152

Rod 32008

Table 3: Optional accessories

2

Page 3

BÜCHI Vacuum Controller B-720

2 Safety

2 Safety

The Vacuum Controller is built in accordance with the art of

engineering and the recognized rules of safety.

Nevertheless, it can still be a source of risks and hazards:

• if used by persons with insufficient training.

• if used for purposes other than that for which it is intended.

2.1 Symbols

Stopp

Information about hazards which can lead to extensive material

damage or cause serious or potentially fatal injury.

Warning

Information about hazards which can be harmful to your health

or lead to material damage.

Please note

Information about technical requirements. Non-observance can

lead to malfunctions, inefficiency and possibly even lost production.

2.2 Requirements to be met by the customer

The Vacuum Controller may only be operated by persons

capable of comprehending the hazards that can arise during

its use.

2.3 Proper use

The Vacuum Controller is designed and built for laboratory

operation. It is to monitor and control vacuum levels over a

working range from 0 mbar to atmospheric pressure.

Typical applications include:

• Distillation apparatus, especially rotary evaporators

• Vacuum filtration

• Vacuum impregnation

For the Vacuum Controller to be used properly, it must also be

cleaned and maintained with routine care.

3

Page 4

BÜCHI Vacuum Controller B-7202 Safety

2.4 Improper use

Any use other than those already listed and any application that

does not conform with the technical data is deemed to be a

case of mis-use. The customer shall bare sole responsibility for

any damage caused by such mis-use.

The following applications in particular are prohibited:

• Use as a calibrating unit for other equipment

• Use as a barometer

• Use in hazardous duty areas or areas designated as Explo-

sion Proof

• Operation in overpressure

·

2.5 Safety measures

It is imperative to wear personal safety items such as goggles,

protective clothing and gloves.

These operating instructions are to be considered part of the

B-720 Vacuum Controller. They must always be kept near the

unit so operating personnel can consult them at any time.

The customer is responsible for instructing subordinate

personnel. These operating instructions can be ordered in other

languages for this purpose.

The customer shall notify the manufacturer immediately of any

safety incidents involving the B-720 Vacuum Controller.

2.6 Safety elements

A built-in ventilation valve vents the system automatically upon

reaching a level of overpressure in excess of 1400 mbar.

4

Page 5

BÜCHI Vacuum Controller B-720

3 Function

3 Function

The B-720 keeps a selected level of vacuum constant. It

automatically compensates any loss of vacuum in the evacuated

system by re-adjusting the vacuum to the set pressure level. It

does so by actuating a two-way valve in the vacuum line or by

directly switching the vacuum source on and off.

Solvent can be condensed with hight efficiency if the optimum

vacuum level is selected for the specific solvent. This results in

an immense reduction of solvent through the vacuum pump or

in a laboratory’s waste water.

You can also use the B-720 to control the flow of cooling water

during distillation. This is done by actuating a cooling water valve.

Water savings of up to 95% are possible this way.

All B-720 models are delivered as standard with an aeration

valve, also used for purging with inert gas, a cross clamp for

mounting on a stand, and a GL14 hose connector for connecting

the vacuum hose.

3.1 Functions of the various keys

«P» You can set the desired value of your choice with

the arrow keys. If no key is pressed within 3 seconds,

the display will switch to its initial state and the

setdesired value will be saved automatically.

«욼P» You can set the desired hysteresis in mbar or Torr

with the arrow keys. If no key is pressed within 3

seconds, the display will switch to its initial state

and the setdesired value will be saved automatically.

«UP» Press this key to increase the desired value.

«DOWN» Reduces the pressure or hysteresis during distil-

lation.

«mbar/Torr»Switches the LED display from mbar/hPa to Torr/

mm Hg.

«START» Starts the evacuation process.

«STOP» Stops the vacuum process. The system is ventilated,

but the cooling water valve does not close until 5

minutes later. Press twice for the cooling water to

be switched off immediately.

Figure 4: The keypad on the B-720

5

Page 6

3 Function

BÜCHI Vacuum Controller B-720

P

407 mbar

400 mbar

0

0

Figure 5: Manual hysteresis

P

412 mbar

400 mbar

0

0

Figure 6: Automatic hysteresis

1

1

3.2 Manual hysteresis

The tolerance range of the operating point can be selected

automatically as well as manually.

2

7 mbar

3

Example:

Nominal pressure 400 mbar, manual hysteresis 7 mbar.

The pump evacuates to the desired pressure of 400 mbar,

the two-way valve closes or the vacuum pump switches

off.

t

The pressure rises by 7 mbar.

The pump evacuates again to the desired value.

3.3 Automatic hysteresis

The automatic hysteresis function works by continuous (linear)

degression.

2

12 mbar

• 30 mbar for a desired value of 1000 mbar

• 1 mbar for a desired value of 2 mbar

Example:

Nominal pressure 400 mbar, automatic hysteresis 12 mbar.

The pump evacuates to the desired value of 400 mbar,

the two-way valve in the main vacuum line closes or the

vacuum pump switches off.

t

The hysteresis tolerance range for this desired value

amounts to 12 mbar.

6

Page 7

BÜCHI Vacuum Controller B-720

4 Putting into operation

4 Putting into operation

Check that the voltage of the power supply corresponds to the

value marked on the B-720 rating plate.

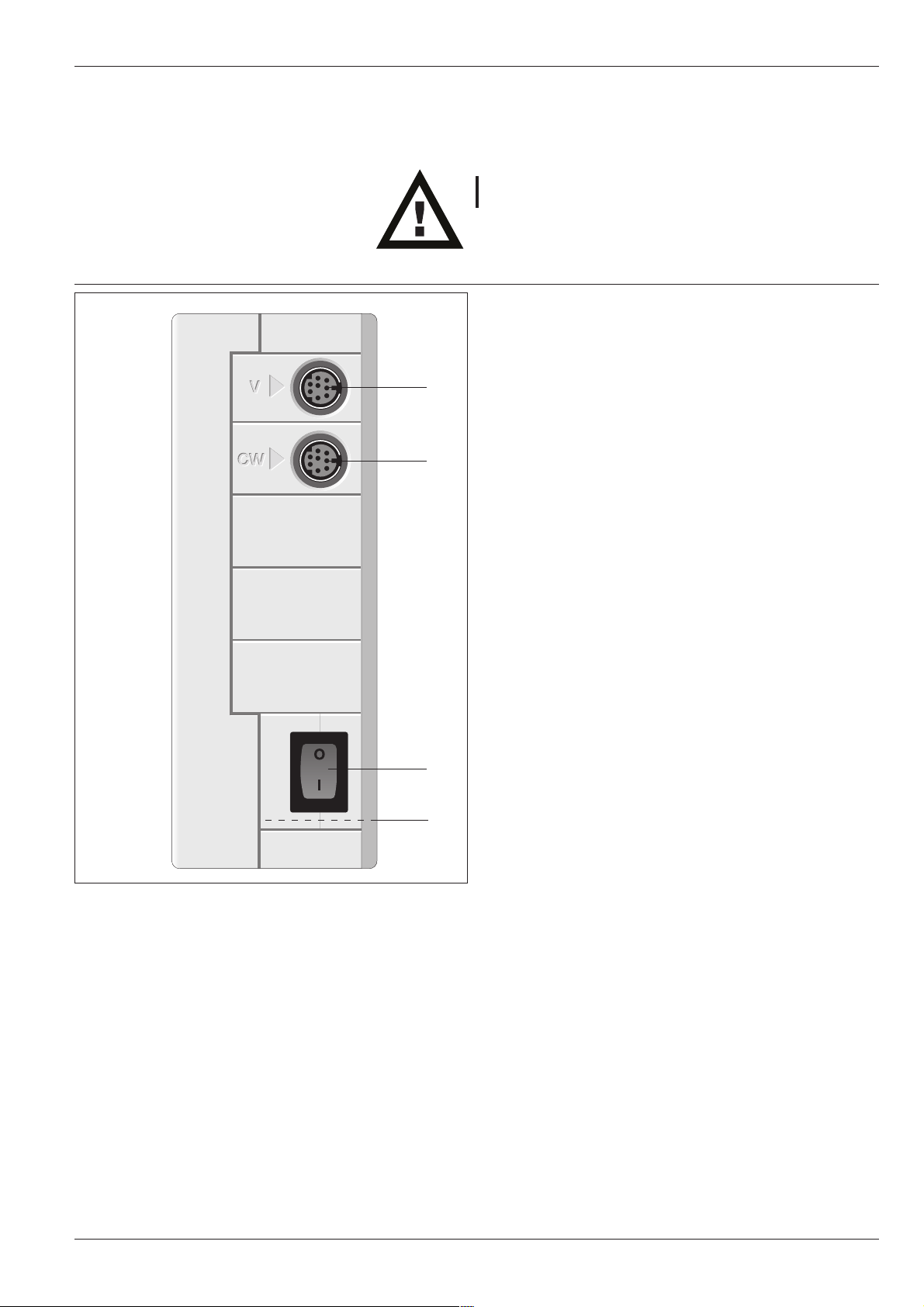

4.1 Connections on the side

V Valve connection

V

CW

CW Cooling water valve connection

Power switch

Fuse (at the left-hand side of the housing)

Figure 7: The right-hand side of the B-720 housing

7

Page 8

4 Putting into operation

BÜCHI Vacuum Controller B-720

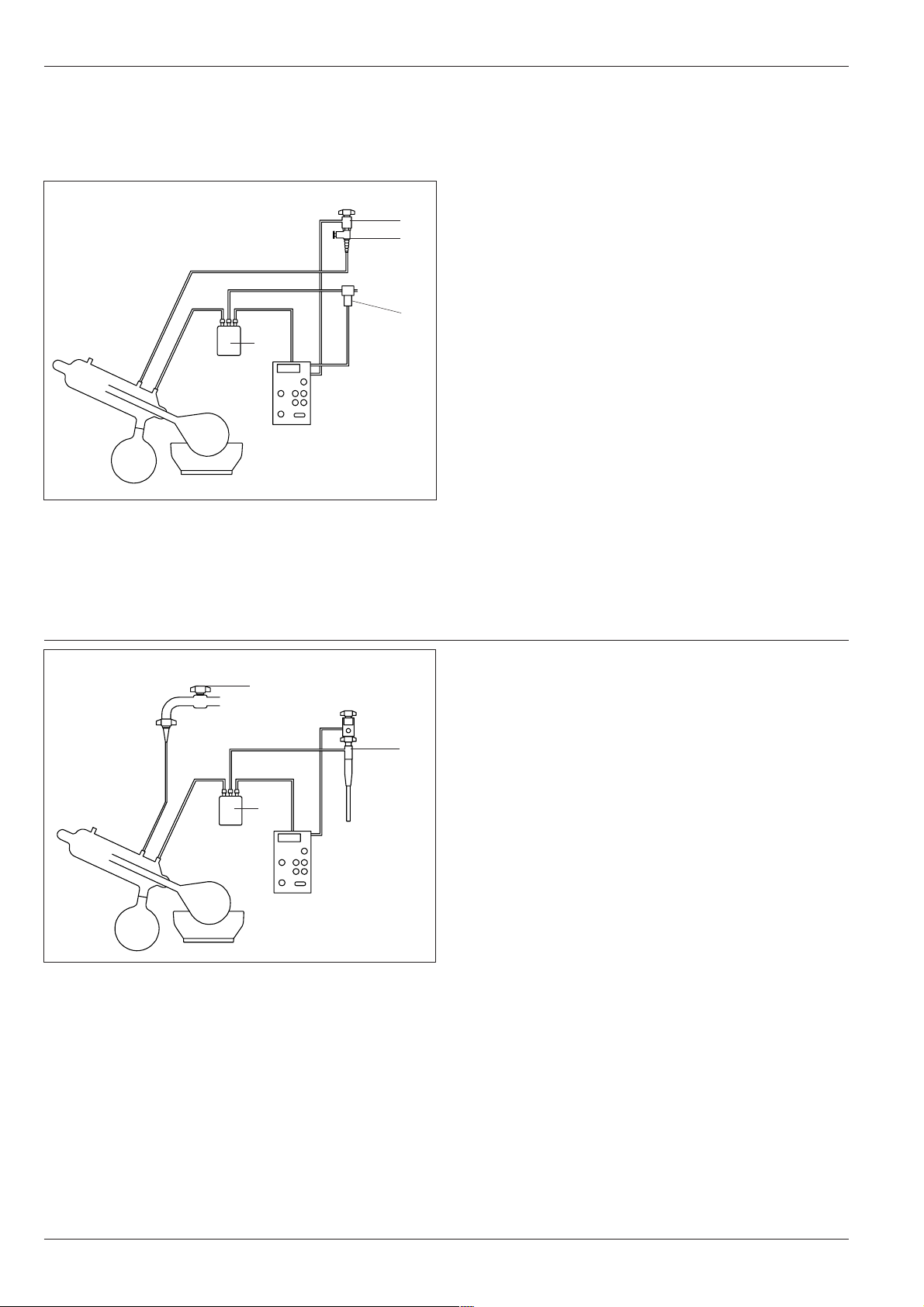

Figure 8: The B-720 with a two-way valve and a cooling water valve

4.2 Installation with a two-way valve and a

cooling water valve

• Install the two-way valve between the vacuum pump

and the woulff bottle .

• Connect the two-way valve to the socket V.

• Screw the cooling water valve onto the water faucet

(remember the seal and screen).

• Insert the cooling water valve plug in the socket CW.

• Connect the cooling water hoses.

• Connect the B-720 to the power supply.

• Switch on the B-720.

• Turn the water faucet on and use the needle valve to

adjust the flow through the condenser.

Water faucet

Woulff bottle trap

Needle valve

Cooling water valve

Vacuum pump

Two-way valve

Figure 9: The B-720 with a B-764 water jet pump

4.3 Installation with a B-764 water jet pump

• Attach the B-764 water jet pump to the water faucet.

• Insert the valve plug in the socket V.

• Fully open the water faucet .

• Connect the cooling water hoses.

• Connect the B-720 to the power supply.

• Switch on the B-720.

• Turn on the water faucet .

Water faucet

Woulff bottle trap

B-764 water jet pump

Water faucet

8

Page 9

BÜCHI Vacuum Controller B-720 4 Putting into operation

4.4 Installation with a combination water jet pump

B-767

The water jet pump B-767 has a built-in cooling water valve.

• Attach the water jet pump B-767 onto the water fau-

cet .

• Insert the valve plug in the socket V.

• Connect the cooling water hoses.

• Connect the B-720 to the power supply.

• Switch on the B-720.

• Turn the water faucet on and use the needle valve to

adjust the flow through the condenser.

Water faucet

Woulff bottle trap

Needle valve

B-767 Water jet pump

Figure 10: The B-720 with a B-767 Water jet pump

Figure 11: The B-720 with a vacuum pump, a B-745 Switch-box and a

cooling water valve

4.4 Installation with a vacuum pump, a B-745

Switch-box and a cooling water valve

• Connect the B-745 to a socket-outlet.

• Plug the vacuum pump into the B-745 with the power

cable.

• Place the non-return valve in the vacuum line leading to

the woulff bottle trap .

• Plug the connecting cable from the B-745 into the socket

V of the controller.

• Attach the cooling water valve onto the water faucet .

• Insert the valve plug in the socket CW.

• Connect the cooling water hoses.

• Connect the B-720 to the power supply.

• Switch on the B-720.

• Turn the water faucet on and use the needle valve to

adjust the flow through the condenser.

Water faucet

Woulff bottle trap

Needle valve

Cooling water valve

Vacuum pump

Büchi Switch-box B-745

Non-return valve

Connecting cable

9

Page 10

5 Operation

START

∆P

BÜCHI Vacuum Controller B-720

5 Operation

The unit is not splash-proof.

5.1 Controls on the membrane keypad

Set desired pressure «P».

mbar/

hPa

Torr/

mm Hg

mbar/ Torr

P

UP

DOWN

Set hysteresis «욼P».

Increase the displayed value, ventilate the system during

distillation «UP».

Decrease the displayed value, lower the pressure during

distillation «DOWN».

Change the display from mbar or hPa to Torr or mmHg

«mbar Torr».

Start the distillation process «START».

Stop the distillation process «STOP».

STOP

B†CHI Vacuum Controller B-720

BÜCHI

Figure 12: The membrane keypad on the B-720

SWITZERLAND

5.2 Normal operation

1. Set the power switch to ON.

2. Use «P» with «UP» or «DOWN» to select and set the desired

value of your choice.

3. Use «욼P» to check the hysteresis and change if necessary

with «UP» or «DOWN».

4. Press «START».

10

5. Distillation begins.

6. Press «STOP»; the unit is ventilated.

7. Set the power switch to OFF; the last set point values entered

will be saved.

Page 11

BÜCHI Vacuum Controller B-720 5 Operation

5.3 Detailed description of the various functions

The numbers used in the following examples were chosen at

random and serve only to explain the functions.

Action Display Function

Switch on «On» switch 957 • Displays actual system pressure

the unit (current system pressure) • Ventilation valve open

• Cooling water valve open for approx. 5 min., but can be closed

by pressing the «STOP» key

Set desired «P» Press e.g. 147 • Displays the desired pressure which can be varied with the

pressure (desired pressure) «UP» and «DOWN» keys (0– 1400 mbar)

• If no entry is made within 3 sec., the displayed value will be

saved automatically and the display will return to its initial state

• The desired value can be changed at any time

Hysteresis «욼P» H 10 • Displays the hysteresis key which can be varied with «UP»

and «DOWN» keys (1– 100 mbar and A)

HA • Automatic hysteresis, i.e. 30 mbar at 1000 mbar, infinitely

reducible to 1mbar at 2 mbar pressure

• If no entry is made within 3 sec., the displayed value will be

saved automatically and the display will return to its initial state

Destillation «START» 957 • System is evacuated to the preselected desired value and is

controlled there within the set hysteresis

147 • LED «START» lights up

(current system pressure) • Cooling water valve opens

Stop «STOP» 957 • Aborts the control function

(current system pressure) • System is ventilated (ventilation valve remains open)

• The cooling water valve remains open for approximately 5 min.

• Press «STOP» twice and the cooling water will switch off

immediately

Table 4: Description of the Functions

11

Page 12

5 Operation

5.4 Hold state

After distillation is started, you can use the arrow keys to

intervene in the automatic control sequence at any time. Pressing

«UP» causes an immediate increase of the system pressure

(the system is aerated), pressing «DOWN» decreases the system

pressure.

Action Display Function

Hold state «ON» switch 957 • The unit is switched on.

(current system pressure)

«START» 957 • Distillation is started.

147

(current system pressure)

«UP» 387 • The evacuation process is interrupted and the LED of «START»

(current system pressure) flashes.

• Hold state.

Keep key depressed • The system pressure is adapted as long as the key is kept

depressed, i.e. while «DOWN» is pressed, the pressure will

be lowered continually; press «UP» and the ventilation valve

will be opened.

• After you release «UP» or «DOWN», the new pressure will be

controlled with the saved hysteresis.

• Press briefly on «START» to continue the function that was

active before the interruption.

Table 5: Hold state

BÜCHI Vacuum Controller B-720

12

Page 13

BÜCHI Vacuum Controller B-720 5 Operation

5.5 Working example

The values in the following example apply for the distillation of

ethanol. For the values of other solvents, please consult the

table at the end of this section. Check the following items before

each distillation:

• Cooling water connected

• All the electrical connections OK

• All the hose connections OK

• Vacuum source connected

Action Display Function

Distillation «ON» switch 957 • The system pressure is displayed.

of ethanol (current system pressure)

«P» 147 • The desired pressure is displayed and can be varied with

(desired pressure) «UP» and «DOWN» (1 mbar-atmospheric pressure).

«욼P» H 16 • The hysteresis displayed.

«DOWN» key until H 5 • Set hysteresis 5.

desired hysteresis is set

«START» 957 • The system is evacuated to the preselected desired value of

72 72 and is conntrolled there within the set hysteresis of 5.

(current system pressure)

«UP» Current system pressure • System is ventilated for as long as the key is kept depressed

«START» Current system pressure • The system is evacuated to the initial set-point value

«STOP» 957 • The system is ventilated (the ventilation valve remains open)

Press «STOP» 2 x 957 • Press «STOP» twice for the cooling water to switch off

briefly (current system pressure) immediately

Table 6: Working example

If there is any foaming or severe splashing, it is possible to

intervene directly with «UP»/«DOWN» Hold state.

• When the key is released, the pressure is adjusted to the new

set-point value.

• The LED «START» flashes.

• When «START» is released, the pressure is adjusted to the

current value.

• The LED «START» lights up.

Press the «START» key for the distillation to continue, i.e. the

system will operate at the set desired pressure.

(current system pressure) • The LED «STOP» lights up

• The cooling water valve remains open for about another 5

min.

13

Page 14

5 Operation

BÜCHI Vacuum Controller B-720

5.6 Solvent

Solvent Formula Molary weight Energie of Boiling point in °C Tightness Vacuum in mbar

in g/mol evaporation in J/g at 1013 mbar in g/cm3for boiling at 40 ºC

Acetic acid C2H4O

2

60.0 695 118 1.049 44

Aceton C3H6O 58.1 553 56 0.790 556

N-Amylalcohol, n-Pentanol C5H12O 88.1 595 37 0.814 11

Benzene C6H

6

78.1 548 80 0.877 236

n-Butanol, tert. Butanol C4H10O 74.1 620 118 0.810 25

2-Methyl-2-Propanol C4H10O 74.1 590 82 0.789 130

Carbontetrachloride, tetra Chloromethane CCI

4

153.8 226 77 1.594 271

Chlorobenzene C6H5CI 112.6 377 132 1.106 36

Chloroform CHCI

Cyclohexane C6H

3

12

119.4 264 62 1.483 474

84.0 389 81 0.779 235

Diethyl ether C4H10O 74.0 389 35 0.714 850*

1,2,-Dichloroethane C2H4CI

1,2,-Dichloroethylene (cis) C2H2CI

1,2,-Dichloroethylene (trans) C2H2CI

2

2

2

99.0 335 84 1.235 210

97.0 322 60 1.284 479

97.0 314 48 1.257 751

Di isopropyl ether C6H14O 102.0 318 68 0.724 375

Dioxane C4H8O

2

88.1 406 101 1.034 107

DMF (Dimethylformamide) C3H7NO 73.1 153 0.949 11

Ethanol C2H6O 46.0 879 79 0.789 175

Ethyl acetat C4H8O

Heptane C7H

Hexane C6H

2

16

14

88.1 394 77 0.900 240

100.2 373 98 0.684 120

86.2 368 69 0.660 335

Isopropyl alcohol C3H8O 60.1 699 82 0.786 137

Isoamyl alcohol, 3-Methyl-1-Butanol C5H12O 88.1 595 129 0.809 14

Methyl ethyl ketone C4H8O 72.1 473 80 0.805 243

Methanol CH4O 32.0 1227 65 0.791 337

Methylenechloride, Dichloromethane CH2CI

Pentane C5H

2

12

84.9 373 40 1.327 850*

72.1 381 36 0.626 850*

n-Propyl alcohol C3H8O 60.1 787 97 0.804 67

Pentachlorethane C2HCI

1,1,2,2,-Tetrachloroethane C2H2CI

1,1,1,-Trichloroethane C2H3CI

Tetrachloroethylene C2CI

5

4

3

4

202.3 201 162 1.680 13

167.9 247 146 1.595 35

133.4 251 74 1.339 300

165.8 234 121 1.623 53

THF (Tetrahydrofurane) C4H8O 72.1 67 0.889 357

Toluene C7H

Trichloroethylene C2HCI

8

3

92.2 427 111 0.867 77

131.3 264 87 1.464 183

Water H2O 18.0 2261 100 1.000 72

Xylene (Isomers mixture) C8H

10

106.2 389 25

(o) 144 0.880

(m) 139 0.864

(p) 138 0.861

Table 7: Solvents * only possible when cooling water is 20°C

14

Page 15

BÜCHI Vacuum Controller B-720

6 Maintenance

6 Maintenance

Compulsory inspection and maintenance

You must follow all the instructions aimed at keeping the Vacuum

Controller in proper working order. This includes cleaning and

checking it regularly for signs of damage.

6.1 Cleaning

Clean the case with just a damp cloth (never use detergents!)

and examine simultaneously for signs of defects (controls, plugs).

6.2 Calibration

Press «STOP» for 3 seconds simultaneously with the main power

switch. On the display you will first see «C---» for 1 second,

then the pressure reading. This value can be changed with «UP»

and «DOWN». To confirm the entry, press «START».

«C---E» appears on the display to indicate the end of the

calibration before the unit returns to operating mode.

If you press «STOP» for longer than 3 seconds during the

calibration, «CC--» will appear on the display and the offset for

the pressure reading will be reset to 0.

The calibration range is ± 20 mbar.

6.3 Customer service

Only authorized customer service technicians are permitted to

intervene service the Vacuum Controller B-720. They have

undergone thorough professional training and are familiar with

the hazards that ensue from ignoring safety precautions. The

addresses of Büchi Customer Service Centers are listed on the

back cover of these operating instructions.

Please contact these centers if you have any technical questions,

problems with an application or trouble with your Vacuum

Controller.

You are welcome to contact the Büchi Customer Service Centers for: Spare parts service (please quote the order numbers

printed in the operating instructions), repair service, maintenance

service for technical consulting, please contact the Büchi agent

in your country by phone, letter, fax or telex.

15

Page 16

6 Maintenance

BÜCHI Vacuum Controller B-720

6.4 Function check

The following parameters must be checked after every service

intervention:

• Switch on the B-720

• Display shows 8888 (1 sec.)

• Display shows the software function A 1.1 (1 sec.)

• Display shows the current atmospheric pressure

• The valve is triggered audibly

• The cooling water valve is open

6.5 Block diagram of the B-720

Membrane keypad

CPU print

Power print

Euro power plug

Ceramic pressure sensor

Ventilation valve

Figure 13: Block diagram of the B-720

6.6 Troubleshooting

Malfunction Possible cause Remedy

Valve opens and closes at high rate System has a leak Check all sealing points

Hysteresis too small Select higher hysteresis value

Valve does not open or close Valve does not close Dirty coil

Wrong flow direction

Valve not inserted in the proper position

No display Defective fuse Replace fuse

Check power plug and insert

Error code E--3 Pressure sensor is defective Replace pressure sensor

Error code E--4 Pressure differential too small during calibration Increase pressure differential

sensor defective Replace pressure sensor

Error code E--7 Pressure sensor not calibrated Call service center

Error code E-10 Hardware error Call service center

Table 8: Malfunction

16

Page 17

BÜCHI Vacuum Controller B-720 7 Taking out of operation

7 Taking out of operation

7.1 Storage/ Transportation

The unit should be stored in a dry place in its original packaging.

7.2 Disposal

Material codes are marked on each large component. Please

observe your regional and local laws concerning the disposal of

waste materials.

17

Page 18

8 Replacement parts

BÜCHI Vacuum Controller B-720

8 Replacement parts

The Vacuum Controller’s operational safety and serviceability

are guaranteed only by original Büchi parts. The use of

other makes of replacement parts and accessories is permitted

only with the express consent of Büchi.

The replacement parts catalog may be used only in conjunction

with Chapter 5 of these instructions for installation and

dismantling purposes. Third parties are not allowed access to

or possession of this manual. The use of this manual for

production purposes is prohibited. Copyright is retained by

Büchi.

8.1 Replacement parts

Cross clamp, open, complete 27347

Wing screw 27343

GL14 hose connector, complete 32885

Fuse 400mAT 13701

Table 9: Replacement parts

8.2 Accessories

B-764 Water jet pump 31358

Figure 15: B-764 Water jet pump

18

Page 19

BÜCHI Vacuum Controller B-720

8 Replacement parts

B-767 Water jet pump 31357

Figure 16: B-767 Water jet pump

Figure 17: Cooling water valve

Cooling water valve 31356

19

Page 20

8 Replacement parts

Figure 18: Two-way valve for 1-liter Rotavapor

BÜCHI Vacuum Controller B-720

Two-way valve 24 VDC 31353

Ø 8 mm for 1-liter Rotavapor

Figure 19: Two-way valve for 20-liter Rotavapor

Two-way valve 24 VDC 31354

Ø 12 mm for 20-liter Rotavapor

Two-way valve 24 VDC 31355

Ø 20 mm for 50-liter Rotavapor

Figure 20: Two-way valve for 50-liter Rotavapor

20

Page 21

BÜCHI Vacuum Controller B-720

8 Replacement parts

Büchi Switch-box B-745 CH 36410

Connecting cable, non-return valve incl.

Figure 21: Switch-box B-745 CH

Figure 22: Switch-box B-745 D

B†CHI Switch-box

B†CHI Switch-box

B-745

B-745

Büchi Switch-box B-745 D 36411

Connecting cable, non-return valve incl.

Büchi Switch-box B-745 International 36412

Connecting cable, non-return valve incl.

Figure 23: Switch-box B-745 International

Figure 24: Adapter cable

B-720 Adapter cable 31225

(In connection with the former model

B-167/B-164 or line valve)

21

Page 22

8 Replacement parts

Figure 25: Vacuum hose

BÜCHI Vacuum Controller B-720

Vacuum hose 16 / 6 mm 17622

Nyflex hose 14 x 8

(Alternative to the vacuum hose 17622) 04113

Figure 26: Woulff bottle trap, PLASTIC + GLAS

Woulff bottle trap, PLASTIC+ GLAS, complete

25519

Bottle clamp Ø 100 mm 11152

Figure 27: Bottle clamp Ø 100 mm

Figure 28: Rod

22

Rod Ø 12 mm, L= 300 mm 32008

Page 23

BÜCHI Vacuum Controller B-720

9 Appendix

9 Appendix

9.1 Technical data

Voltage 230 V /50 … 60 Hz

120 V/ 50…60 Hz

Power consumption 14 W

Solenoid valve input 28 VDC

Control range pressure 1 mbar/ Torr– atmospheric pressure

Max. system deviation ± 0,5% full scale

Pressure range 1–1400 mbar

1– 1050 Torr

Hysteresis Automatic or 1– 100 mbar

Fuses 400 mAT

Dimensions (WxHxD) 90x145x55 mm

Weight 960 g

Ambient temperature +5 °C …+ 40 °C

Table 10: Technical data

9.2 Materials used

Part Material Material code

Case Grillamide PA

Pressure sensor

Faceplate Foil Polyester

Circuit board Glass fibre epoxy resin

Cable Polyvinyl chloride PVC

Table 11: Material used

Ceramic

23

Page 24

9 Appendix

9.3 Declaration of EC conformance

We

BÜCHI Labortechnik AG

Postfach, CH-9230 Flawil

Switzerland

declare under our sole responsibility that the product:

BÜCHI Vacuum Controller B-720

to which this declaration relates is in conformity with the following standards:

EN 61010-1:1993 (~ IEC 1010-1, VDE 0411-1)

Safety requirements for electrical equipment for mesurement, control an laboratory use: General requirements

EN 55011:1991/B (~ VDE 0875/B, VDE 0871/B)

Limits and methods of measurement of radio disturbance characteristics of industrial, scientific and medical

radiofrequency equipment

EN 50082-1:1992

Electromagnetic compatibility - Generic immunity standard: Residential, commercial, light industry.

BÜCHI Vacuum Controller B-720

following the provisions of EU-Directive:

Directive 73/23/EEC

Directive 89/336/EEC

Flawil, Dezember 1. 1996

D. Simmler

Quality management

BÜCHI Labortechnik AG

24

Loading...

Loading...