B&W Trailer Hitches RVK3600 User Manual

<THESE INSTRUCTIONS MUST BE GIVEN TO THE END USER>

B&W Trailer Hitches

1216 Hawaii Road / PO Box 186

Humboldt, KS 66748

P:620.473.3664

F:620.473.3766

RAM OEM Mount System Installation Instructions

25,000 LBS. TRAILER WEIGHT

6,250 LBS. TRAILER TONGUE WEIGHT

Call or Email us for Installation Support

hitches@turnoverball.com www.turnoverball.com

Model 3600

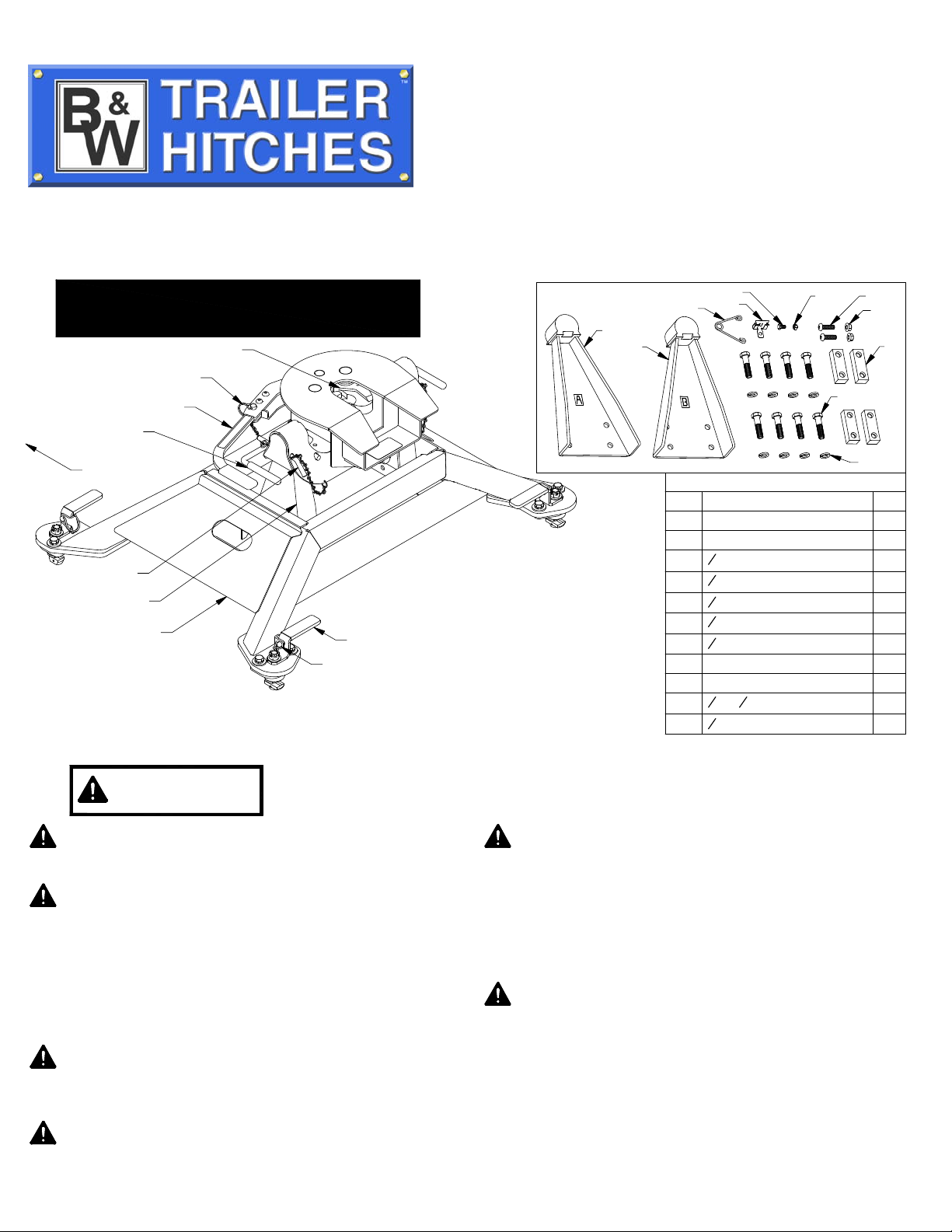

COUPLER JAWS

COUPLER CAM

HANDLE SAFETY PIN

COUPLER CAM HANDLE

SADDLE HANDLE

TRUCK CAB

SADDLE

LOCKING PINS

PIVOT ARM

BASE ASSEMBLY

REQUIRED TOOLS

Installation of the Companion hitch requires a large torque wrench capable of

measuring 80 ft−lbs, a 3/4" socket, a 7/16", and 9/16" socket or wrench, a 7/32"

allen wrench and a pair of needle−nose pliers.

LATCH HANDLE

LATCH PIN

10

9

8

1

2

PARTS LIST

ITEM

1

Pivot Arm A

2

Pivot Arm B

1

" Split Lock Washers

3

2

1

" X 2" Hex Cap Screw

4

2

3

5

" Threaded Block

4

3

" Button Head Cap Screws

6

8

3

7

" Lock Nut

8

8

Wire Torsion Spring

9

Mounting Clip

1

1

" X

4

2

1

" Finish Nut

4

" Cap Screw

10

11

11

6

7

5

4

3

QTYDESCRIPTION

1

1

8

8

4

2

2

1

1

1

1

Failure to comply with the safety information in these

WARNING

Read all installation and operating instructions along

with all labels before using this product.

Without proper knowledge, towing can be a

dangerous activity. Understand all the risks involved

with towing before proceeding. For information on

towing safety, see

to Understanding Trailer and Towing Safety"

the National Association of Trailer Manufacturers,

www.NATM.com.

Do not modify this product in any manner. Doing so

could alter its integrity and lead to a loss of attachment

between the trailer and the tow vehicle.

Regularly check that all bolted connections are at the

correct torque specification. A visual inspection should

be performed before each time you tow.

"The Trailer Handbook: A guide

instructions could result in serious injury or death.

from

Do not exceed tow or tongue rating of coupler, tow or

tongue rating of hitch, or tow or weight ratings of truck

or trailer. See vehicle and trailer manufacturer

information for ratings. Exceeding these ratings may

cause damage to towing components or loss of

attachment between the trailer and truck.

Adding components to the chassis of any vehicle can

be hazardous. There is potential for damage to

vehicle, injury from tool usage and many other

hazards. This installation must be completed by

someone who is aware of the hazards involved. This

person must be knowledgeable of proper safety

procedures for a vehicle installation of this nature, and

for usage of the equipment required to perform the

installation.

PREPARING TO INSTALL

WARNING: Components of the Companion hitch are

heavy and cumbersome to handle. Failure to use

proper lifting techniques when moving and handling

these parts could result in property damage or

serious injury.

Remove all parts from the packaging and familiarize

yourself with all the parts and tools required. Use the

parts list on the front page to verify that all parts and

hardware are present.

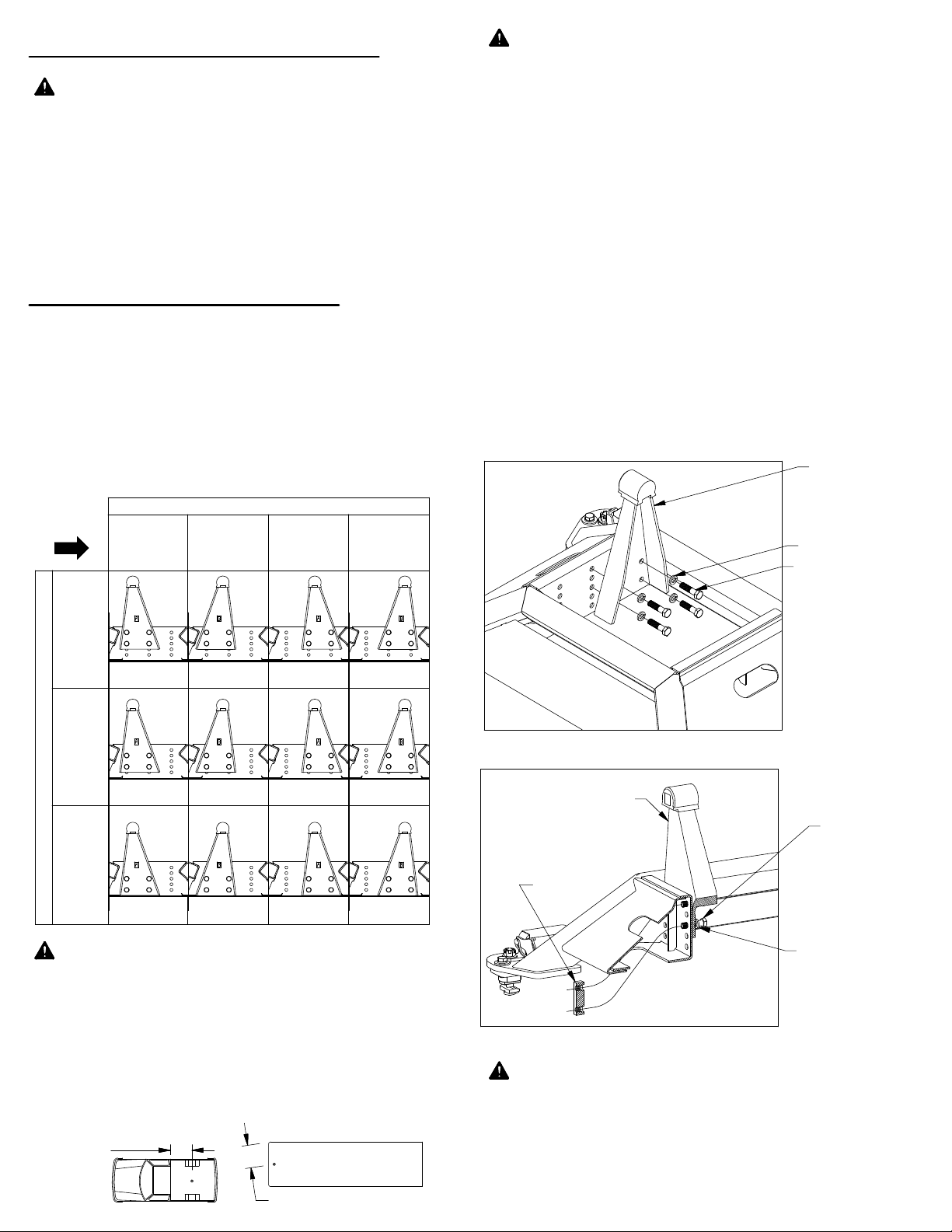

INSTALL PIVOT ARMS

1.

Mount the pivot arms using one of the twelve different

locations illustrated in Table A1. These twelve

locations allow flexibility in coupler height (vertical

adjustment) and distance from the cab (horizontal

adjustment). Choose a location so that your trailer will

be as level as possible and have adequate turning

clearance while towing.

TABLE A1: Pivot arm position table (driver side)

CAB

DIRECTION

4" BEHIND

AXLE

(FARTHEST

FROM CAB)

HORIZANTAL ADJUSTMENT

See warnings below.

2"

BEHIND

AXLE

OVER

AXLE

2" IN FRONT

OF AXLE

(CLOSEST

TO CAB)

WARNING: B&W also recommends that you check

the clearance between the bed side and the underside

of the front of the trailer and to allow adequate

clearance for the pitch and roll of the trailer while

towing.

2.

Locate both pivot arms, the four 3/4" threaded blocks,

eight 1/2" cap screws, and eight 1/2" split lock

washers. Place the lock washers over the cap screws.

Align the flat side of the pivot arm flat against the bolt

plate and install four 1/2" cap screws through the

holes on the arm, holding the arm in place, as shown

in figure A2. Locate the threaded blocks. Note that

the sides of the block have threaded holes on one side

and smooth bored holes on the other side. When

installing the threaded blocks it is critical that the side

with the smooth holes is flat against the bolt plate

when installed. Pass the threaded block under the

bases side and align the block with each set of screws

and start each screw, as shown in figure A3. After all

the screws are started through the arms, torque each

bolt to 80 ft−lbs.

PIVOT ARM

1/2" LOCKWASHER

1/2" X 2" CAP SCREW

S

T

N

S

)

O

"

I

E

9

T

H

I

1

(

G

S

I

O

H

P

T

N

E

T

M

H

T

S

G

S

I

N

U

E

J

D

A

L

A

C

I

T

R

E

V

)

O

"

I

H

8

T

I

1

M

(

S

U

I

O

D

P

E

M

S

T

N

S

)

O

"

I

E

7

T

I

1

W

(

S

O

O

L

P

WARNING: B&W recommends that you check the

clearance between the truck cab and the trailer.

Compare the measurement taken from the center of

the Coupler to the cab, to the measurement taken

from the center of the king pin to the farthest forward

corner point of the trailer. These measurements will

allow you to see how much clearance you will have

between the cab and the trailer while towing and

turning.

CENTER OF

COUPLER

TO CAB

KING PIN TO EDGE OF TRAILER

FIGURE A2: Passenger pivot arm mounting location.

PIVOT ARM

1/2" X 2"

CAP SCREW

THREADED

BLOCK

1/2" LOCKWASHER

WARNING: Installing the thread blocks backwards

will not allow the pivot arms to be fully tightened in the

base and could lead to hitch failure. Before coupling

hitch, be sure that none of the 1/2" x 2" bolts are loose

and the pivot arms are securely attached to the bolt

plate. Failure to check threaded block orientation

could cause serious injury or death.

Loading...

Loading...