B&W Trailer Hitches 3400 User Manual

SLIDER OPERATION

WARNING: Use extreme caution when moving the

truck and trailer in the maneuvering position. Never

exceed 5 mph (roughly walking speed) when in the

maneuvering position, doing so may result in

property damage, serious injury or death.

CAUTION

be attempted while on smooth flat terrain.

Moving from towing position to maneuvering

position. (Figure F3 to F4)

1.

While the trailer is coupled, set the trailer brakes

and/or chock the trailer wheels.

Pull the handle towards the rear of the truck to move

2.

it to the unlocked position

Pull the truck forward slowly until the handle falls and

3.

is in the locked position

Release the trailer brakes, un−chock the trailer and

4.

maneuver the trailer as needed.

: Use of the slider mechanism should only

, shown in figure F2.

, shown in figure F1.

WARNING: The maneuvering position is only

intended for parking maneuvers and not for towing.

Using the slider in any other capacity could result

serious injury or death.

WARNING

: Never hold onto the handle or force it in

any direction while the truck is moving. Failure to

stand clear of the handle when the slider is in

operation could result in serious injury.

Moving from the maneuvering position to the

towing position. (Figure F4 to F3)

5.

Once the trailer is satisfactorily positioned, set the

trailer brakes and/or chock the trailer wheels.

Pull the handle towards the rear of the truck to move

6.

it to the unlocked position

, shown in Figure F2.

Move the truck slowly in reverse until the handle falls

7.

and is in the locked position

, shown in Figure F1.

Release the trailer brakes and un−chock the trailer.

8.

B&W Trailer Hitches

1216 Hawaii Road / PO Box 186

Humboldt, KS 66748

P:620.473.3664

F:620.473.3766

NOTE:

We recommend reading instructions before beginning the installation.

Companion Slider Hitch Installation Instructions

18,000 LBS. TRAILER WEIGHT

4,500 LBS. TRAILER TONGUE WEIGHT

Call or Email us for Installation Support

hitches@turnoverball.com www.turnoverball.com

Model 3400

3

SLIDER LOCKING HANDLE

FIGURE F1; Side view of Slider Base.

LOCKED HANDLE POSITION

SLIDER LOCKING HANDLE

TRUCK CAB

FIGURE F2; Side view of Slider Base.

UN−LOCKED HANDLE POSITION

HELPFUL TIPS:

Approximately 15%−25% of the trailer weight should

be on the hitch.

The height of the king pin box and pivot arms should

be adjusted so that the trailer is approximately level

for towing.

Allow adequate clearance between the bed side and

the underside of the front of the trailer for pitch and

roll of the trailer.

Lubricate top surface of coupler with automotive type

chassis grease or use a nylon lube plate to provide a

lubricated surface.

Copyright 2013, B&W Custom Truck Beds, Inc. ALL RIGHTS RESERVED

SLIDER CARRIAGE

FIGURE F3; View of Slider Base with

the Carriage in a forward position.

TOWING POSITION

TRUCK CAB

FIGURE F4; View of Slider Base with

the Carriage in a back position.

MANEUVERING POSITION

The Slider hitch was designed to be used with the

Turnoverball

™ hitch mounting system. Other uses

will void the warranty and are expressly prohibited by

B&W Trailer Hitches.

Grease jaws with automotive type chassis grease.

Grease the saddle through

the grease zerk approximately

every six months with

mult−purpose grease. this

allows the coupler to pivot

freely, see figure G1

GREASE ZERK

FIGURE G1; Underside view of Coupler Head

RVK3400 11 15 2013

2

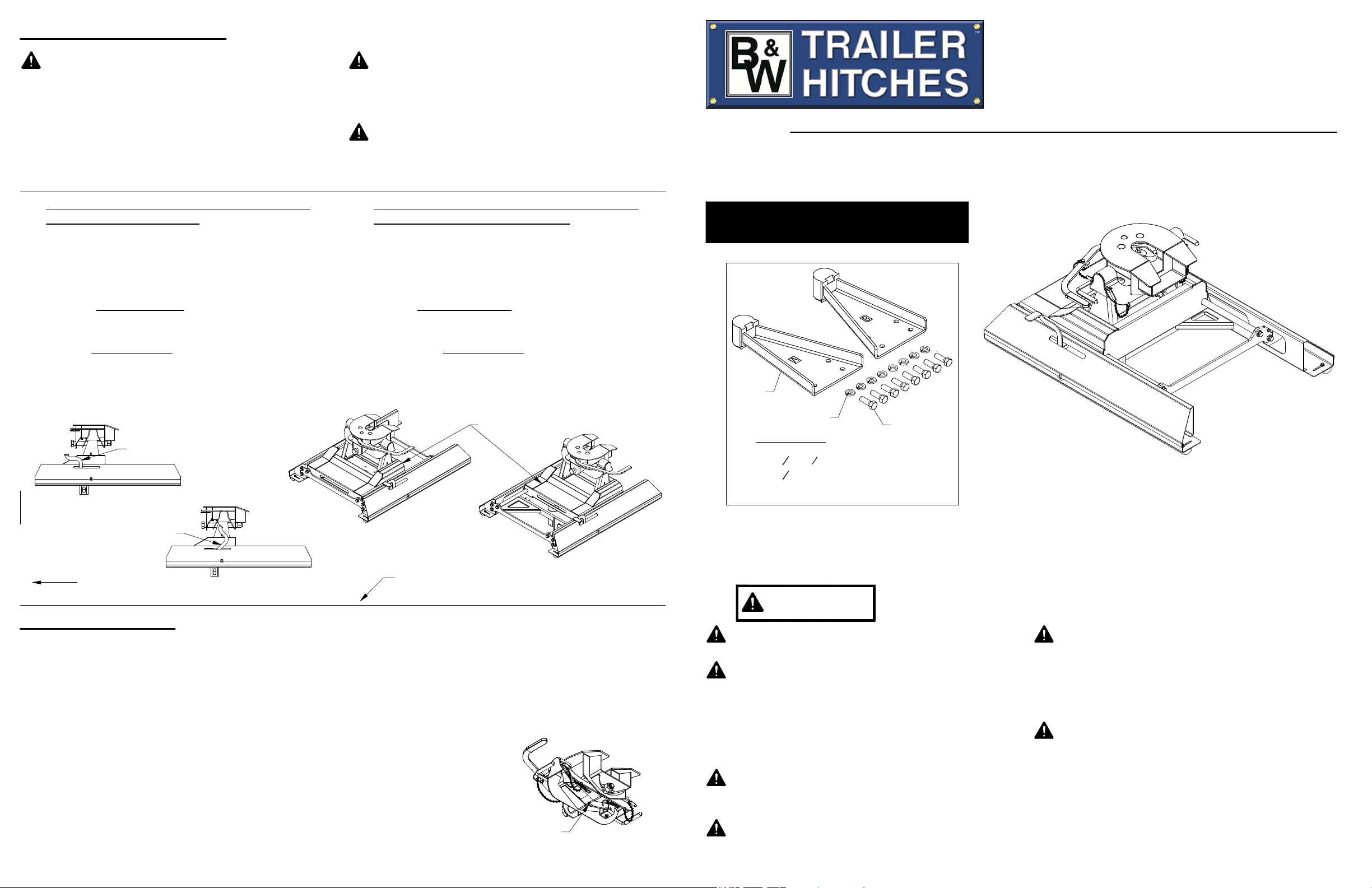

HARDWARE KIT

ITEM DESCRIPTION QTY

1

1

2

3 Pivot Arms 2

" X 1

2

1

" Split Lock Washers 8

2

1

" Hex Cap Screws 8

2

1

REQUIRED TOOLS

Installation of the slider hitch requires a large torque wrench

capable of measuring 80 ft−lbs, a 3/4" socket, and a 7/16"

socket or wrench

The Slider accessory will work with all Turnoverball

ATTENTION:

gooseneck hitches

Failure to comply with the safety information in these

WARNING

Read all installation and operating instructions along

with all labels before using this product.

Without proper knowledge, towing can be a

dangerous activity. Understand all the risks involved

with towing before proceeding. For information on

towing safety, see

to Understanding Trailer and Towing Safety"

the National Association of Trailer Manufacturers,

www.NATM.com.

Do not modify this product in any manner. Doing so

could alter its integrity and lead to a loss of attachment

between the trailer and the tow vehicle.

Regularly check that all bolted connections are at the

correct torque specification. A visual inspection should

be performed before each time you tow.

"The Trailer Handbook: A guide

instructions could result in serious injury or death.

from

except GNRK1309 and GNRK1257.

Do not exceed tow or tongue rating of coupler, tow or

tongue rating of hitch, or tow or weight ratings of truck

or trailer. See vehicle and trailer manufacturer

information for ratings. Exceeding these ratings may

cause damage to towing components or loss of

attachment between the trailer and truck.

Adding components to the chassis of any vehicle can

be hazardous. There is potential for damage to

vehicle, injury from tool usage and many other

hazards. This installation must be completed by

someone who is aware of the hazards involved. This

person must be knowledgeable of proper safety

procedures for a vehicle installation of this nature, and

for usage of the equipment required to perform the

installation.

PREPARING TO INSTALL

WARNING: Components of the slider hitch are heavy

and cumbersome to handle. Failure to use proper

lifting techniques and an adequate amount of people

when moving and handling these parts could result in

property damage or serious injury.

WARNING: Whenever the slider base is being

moved, the slider handle must be in the locked

position, and the carriage must be unable to slide,

see figure A1. Failure to ensure that the handle is in

the locked position can lead to property damage, or

serious injury.

SLIDER HANDLE

IN LOCKED POSITION

SOCKET ADJUSTER

FIGURE A1; View of driver side of Slider Base.

SLIDER CARRIAGE

INSTALL SLIDER BASE

NOTICE

liner or mat. It should be removed or it must be cut to

allow the base to directly connect with the bed. It is

acceptable to install the RV base over a spray in bed

liner.

1.

Check that the bed of the truck is clean, and that all

debris is removed before beginning installation.

2.

Loosen the four ¼" cap screws securing the

polyurethane pads on either side of the slider hitch,

see figure B1.

POLYURETHANE

FIGURE B1; View looking at the Slider Base from the cab of the truck .

3.

Locate the GN latch pin handle of the Turnoverball

Gooseneck Hitch in the driver’s side fender well.

Retract the GN latch pin handle all the way until it

stops and then rotate it clockwise. Remove the

Turnoverball from the GN hitch receiver socket.

4.

With the help of 2 or 3 people, carefully lift and

position the slider base into the GN hitch socket in the

back of the truck bed. Re−engage the GN latch pin

handle by turning it counter−clockwise.

WARNING: Check the latch pin under the truck. Make

sure that the latch pin has passed through both sides

of the socket and that the pin is covered up inside the

socket by the socket adjuster, see figure A1. If the pin

is visible inside the GN hitch socket retract the GN

latch handle and use the Draw−Down bolt to adjust the

socket adjuster.

: If truck is equipped with a removable bed

1/4" BOLT

PADS

5.

Square the Slider base legs with the ribs of the truck.

Position the polyurethane pads so that they are both in

a bottom rib along their entire length, See figure B3.

Tighten the four ¼" bolts holding the pads to the base.

Slider Base Leg

Polyurethane Pad

6.

Secure the base of the Slider to the truck bed by

1/4" Bolt

Bottom of Bed Rib

tightening the 1/2" x 3−1/2" draw−down bolt to 80 ft−lbs,

see figure B4

WARNING:

DO NOT lubricate the draw down bolt, the

torque value is for dry threads only.

Draw−Down Bolt

FIGURE B4; View looking into the top of the Slider Base.

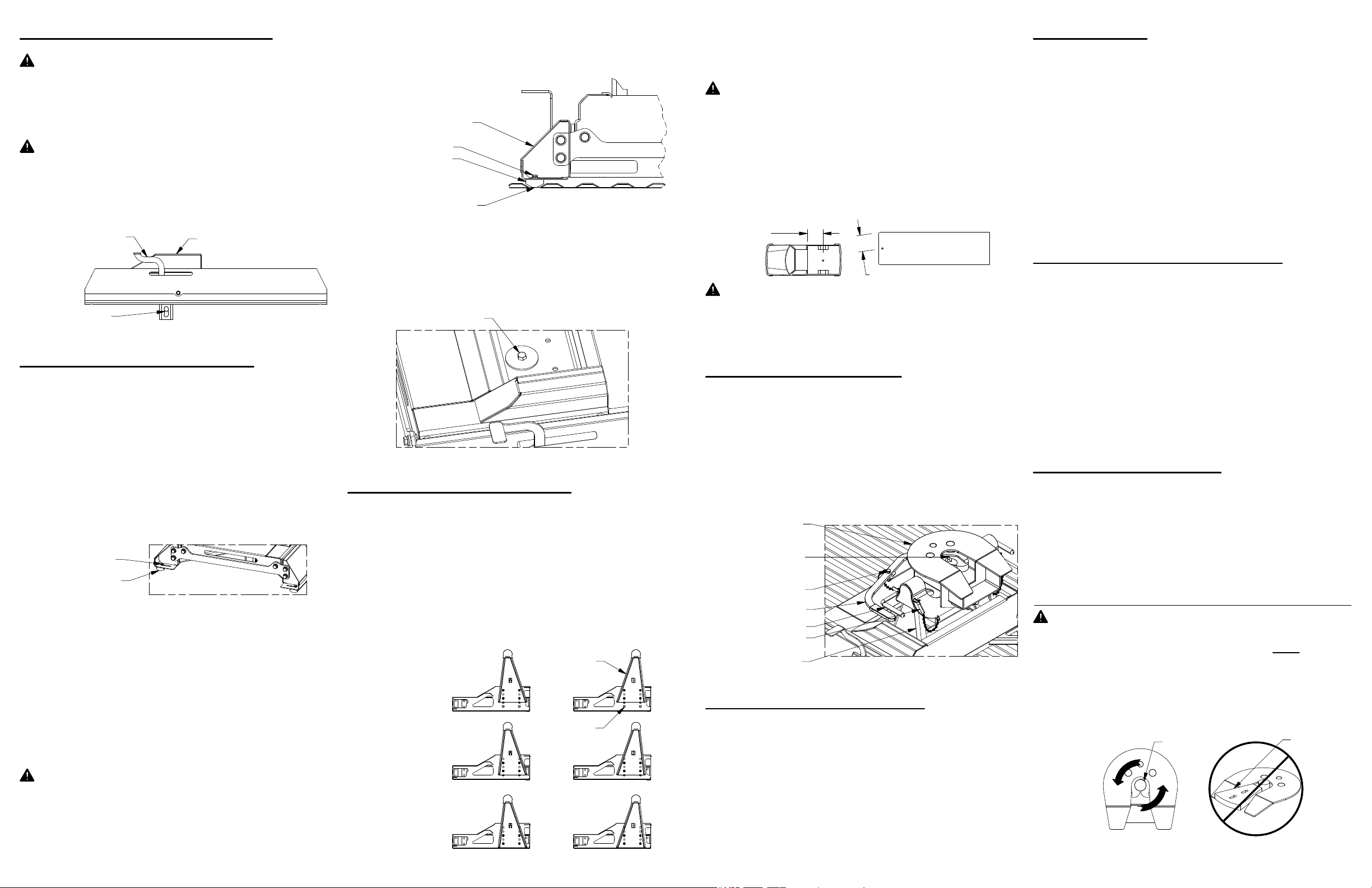

INSTALL PIVOT ARMS

1.

Mount the pivot arms using one of the six different

locations illustrated in figure C1. These six locations

allow flexibility in coupler height and distance from the

cab. Choose a location so that your trailer will be as

level as possible and have adequate turning clearance

while in the towing position (with the slider in the

foward position). See warnings after step 2.

™

BED FLOOR TO TOP

OF COUPLER

HIGHEST

POSITION

(19")

MIDDLE

POSITION

(18")

LOWEST

POSITION

(17")

POSITION

CLOSEST TO CAB

FIGURE C1; Cut away view of

Slider Carriage arm positions.

FIGURE B3; Back view of the

driver side leg of the Slider Base.

POSITION FARTHEST FROM

CAB (ARMS REVERSED)

PIVOT ARM

BOLT PLATE

2.

With the flat side of the Pivot arm flat against the bolt

plate in the slider base, install four 1/2" x 1−1/2" bolts

and four 1/2" split lock washers for each arm. Torque

each bolt to 80 ft−lbs.

WARNING: B&W recommends that you check the

clearance between the truck cab and the trailer in both

the Towing position and the maneuvering position.

Compare the measurement taken from the center of

the Slider Coupler to the cab, to the measurement

taken from the center of the king pin to the farthest

forward corner point of the trailer. These

measurements will allow you to see how much

clearance you will have between the cab and the

trailer while towing and turning.

CENTER OF

COUPLER

TO CAB

KINGPIN TO EDGE OF TRAILER

WARNING: B&W also recommends that you check

the clearance between the bed side and the underside

of the front of the trailer and to allow adequate

clearance for the pitch and roll of the trailer while

towing.

INSTALL COUPLER

Lubricate the polyurethane bushings on top of pivot

arms with high grade lithium grease (available at your

local hardware/automotive store). Place the coupler

over the pivot arms. (The saddle handles should be

parallel with the Slider Base in the latched position.)

Place the saddle lock pins through the saddle, then

insert the hairpins through the holes in the end of the

saddle lock pins to secure the coupler to the pivot

arms, see figure D1

COUPLER

COUPLER JAWS

COUPLER CAM

HANDLE SAFETY PIN

COUPLER CAM HANDLE

SADDLE HANDLES

SADDLE LOCK PINS

PIVOT ARM

FIGURE D1; View of Slider Base

and Coupler Head assembled.

ATTACHING TRAILER

Remove the coupler cam handle safety pin and rotate

the cam handle to the open position. Adjust the height

of the 5th wheel trailer so that the king pin plate is

slightly lower than the top of the Coupler. Back the

truck towards the trailer, centering the trailers king pin

in the Coupler, until the king pin has engaged the

jaws. Ensure that the Coupler cam handle has

completely closed before inserting the cam handle

safety pin through the cam handle and the coupler.

Hook up brake and lighting connections before towing.

PULL TEST

Have the truck stationary with the emergency brake

on, the trailer wheels blocked and landing gear still

resting firm on the ground supporting the weight of the

trailer. Make sure no one is between the truck and

trailer, return to the cab of the truck. Release the

emergency brake and apply the trailer brakes. Try to

pull the trailer forward with the truck. If the trailer is

properly hooked up, the wheel blocks and trailer

brakes should not allow the truck to move forward. If

trailer is not hitched correctly, the trailer will separate

from the truck. However, with the landing gear resting

firmly on the ground, it will support the trailer and not

allow it to drop or fall on the truck sides.

UNATTACHING TRAILER

Lower landing gear and block the trailer wheels.

Raise the trailer until the tongue weight is removed

from the truck. Then, unpin the Coupler handle and

rotate to the open position to unlatch the jaws. If the

jaws do not open, readjusting the landing gear may

relieve pressure and allow them to open. Use the

safety pin to lock the handle in the open position and

when you are sure that the landing gear will support

the trailer, move the truck forward to release the jaws

from the kingpin. The jaws will always open when the

pressure of the trailer is taken off the Coupler as the

truck pulls away.

UNINSTALL HITCH

To uninstall the Slider hitch, remove the Saddle lock

pins, grab the saddle handles and lift to remove the

Coupler from the pivot arms. To remove the Slider

base, loosen the draw down bolt and retract the

Turnoverball gooseneck latch pin handle all the way

out until it stops and then rotate it clockwise. With the

help of 2 or 3 people, carefully lift and position the

slider base out of the Goosenech hitch socket.

WARNING:

any device that changes the location of the king pin

pivot point. The king pin on your trailer must

the jaws of the Slider Coupler, see figure E1.

Preventing the king pin from rotating within the jaws of

the Slider Coupler with a wedge, see figure E2, or any

other device, such as a Reese Sidewinder or Reese

Revolution , could result in property damage, serious

injury or death.

Top view of coupler head.

Do not use the Slider 5th wheel hitch with

®

®

KING PIN

PIVOT POINT

FIGURE E1;

®

Reese is a registered trademark of Cequent performance products.

Coupler Head with locking wedge.

FIGURE E2;

rotate in

WEDGE

Loading...

Loading...