B&W Trailer Hitches 1050 User Manual

B&W Trailer Hitches

1216 HWY 224 / PO Box 186

Humboldt, KS 66748

620.473.3664

800.248.6564

Fax:620.473.3766

NOTE: We recommend reading instructions before beginning the installation.

WARNING: The tow vehicle’s towing capacities should under NO circumstances be exceeded.

TurnoverballTM Gooseneck Hitch

Installation Instructions

Model 1050R

Chevrolet & GMC (1988 - 1998)

1/2 3/4 & 1 Ton, Short Bed Trucks

Chevrolet & GMC (1999 - 2000)

3/4 & 1 Ton Heavy Duty Short Bed Trucks

Old Body Style

Call or Email us for Installation Support

hitches@turnoverball.com

www.turnoverball.com

BEFORE INSTALLING

OVERHEAD LIFTING DEVICE

An overhead-lifting device, such as chain falls, engine hoist, or cable come-along, can be used to lift the center section of the hitch in place. Lower a loop

of rope or chain through the 4” hole in the truck bed oor and attach it to the

latch pin in the round hitch receiver tube in the center section. Use the lifting device to raise the center section until the round hitch receiver tube that

protrudes from the center section ts in the 4” hole in the truck bed oor.

Maintaining upward pressure may facilitate fastening the crossmember to the

center section, especially if the truck bed oor has been distorted downward

from heavy use. If you use an overhead-lifting device, it should be disconnected

before squaring the center section across the frame, installing the sideplates

and torquing fasteners.

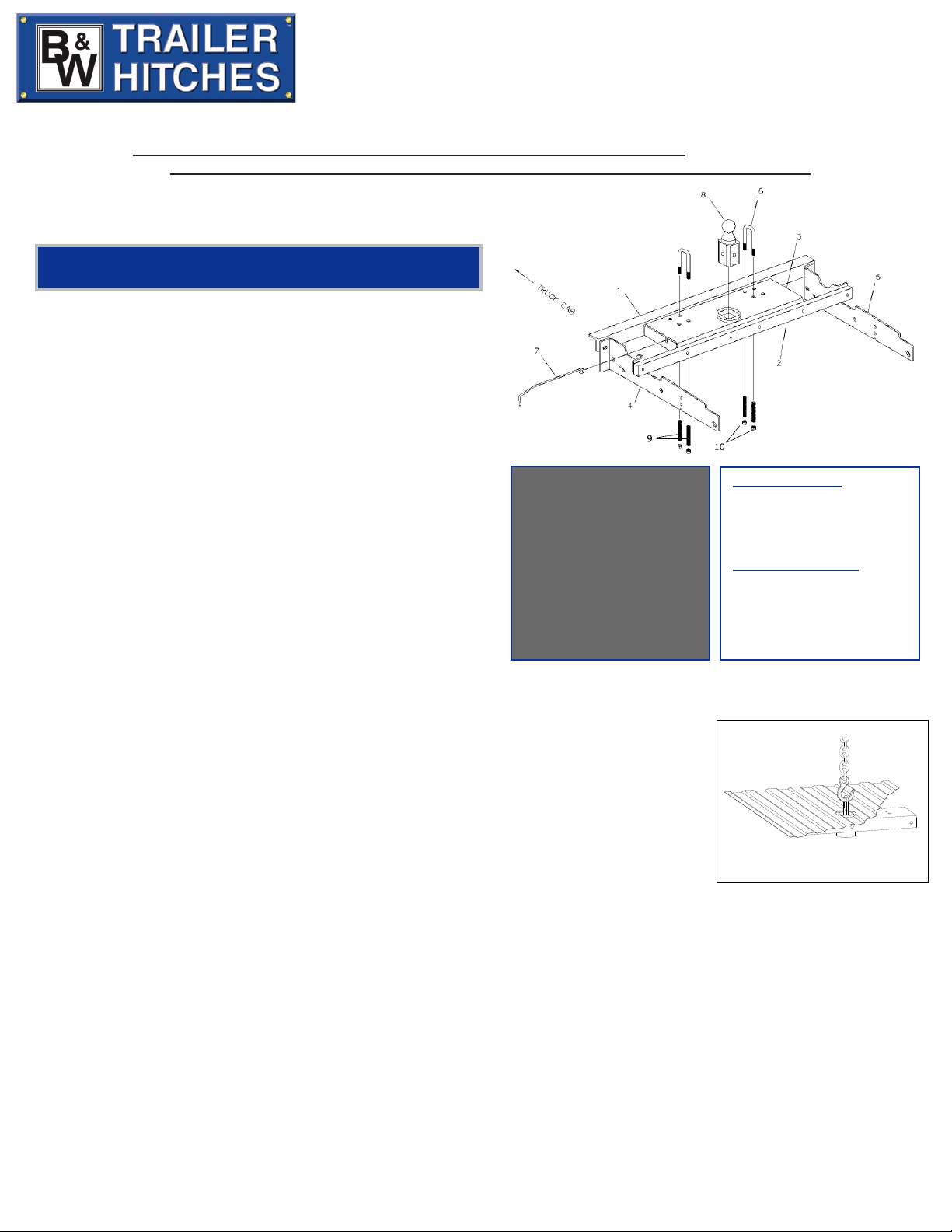

Parts List

1 - Front Crossmember

2 - Rear Crossmember

3 - Center Section

4 - Left Sideplate

5 - Right Sideplate

6 - Safety Chain U-Bolts

7 - Latch Pin Handle

8 - 2-5/16” Ball

9 - Springs

10 - Lock Nuts

Hardware Kit

15 ea. - 1/2” X 1 1/2” bolts

19 ea. - 1/2” at washers

15 ea. - 1/2” lock washers

9 ea. - 1/2” nuts

Safety Chain Kit

2 ea. - 1/2” U bolts

4 ea. - 1/2” Lock nuts

4 ea. - Springs

1 ea. - 3/8”x3/4” Bolt

1 ea. - 3/8” Lock nut

WARNING

Most trucks have FUEL LINES and/or BRAKE LINES and/or ELECTRICAL WIRES located along the frame rails where

B&W Turnoverball™ hitches install. Carefully examine the location of fuel lines, brake lines and electrical wires BEFORE INSTALLATION. Be certain you will not damage fuel lines, brake lines or electrical wires when positioning hitch

components, drilling holes, tightening fasteners, and lifting and lowering the truck bed. The fuel tank vent, located

on top of the gas tank, can be easily damaged during the installation of the hitch components. Care must be taken

when positioning the front crossmember and center section components.

Warning

On Short bed trucks, BEFORE INSTALLING THIS HITCH, check for adequate turning clearance between the front of all

of your trailers and the truck cab.

WARNING

DO NOT invert the ball in the socket when carrying heavy loads on 2 wheel drive trucks. The ball may hit the top of

the differential. Remove the ball from the socket before loading. A plug for the socket is available from B & W.

INSTALLATION INSTRUCTIONS

STEP ONE

Begin by verifying and measuring the correct hole location in the truck bed oor. Measure from the back

end (tail gate end) of the truck bed oor by hooking a tape measure over the back of the the truck bed (not

including the tailgate) and marking the oor at the 44 1/4”. Center the measurement between the wheel

wells. This location is critical to the correct installation of this hitch, so measure, mark and saw carefully. If

the truck has a plastic bed liner, you may drill through both, but it is more difcult to accurately locate the

midpoint between the wheel wells, and to be sure that the bed liner does not move while sawing the hole.

Make a 4-inch hole at this location using a four inch hole saw, or by marking a 4 inch circle and cutting it

out with a sabersaw

STEP TWO

From the underside of the truck, position the two crossmembers (1) and (2), across the top of the

frame rails, between the bed and frame. Start with the rear crossmember, (2) which is the solid bar. It is

symmetrical, so it doesn’t matter which end goes to the driver’s side. From behind the differential, raise the

passenger side end of the crossmember up over the frame rail and slide it through until the driver’s side

can be raised up over that side of the frame. Push the crossmember rearward until it is against the bed

crossmember that is directly above the truck’s axle. Now position the front angle iron crossmember across

the frame, with the slotted leg vertical, the horizontal leg at the top, and the slotted side toward the rear of

the truck. Place the angle parallel to the bar, about 9 inches apart, as shown in the diagram.

STEP THREE

Select the drivers side – side plate (4) (see diagram) and attach the rear slotted tab to the end of the rear

crossmember by threading a 1/2” bolt with a at and lock washer into the threaded hole. Repeat with the

passenger side plate. With the center section (3) latch pin mechanism on the driver’s side, raise the center

section of the hitch up between the crossmembers. Guide the center section on up against the bottom of

the oor, inserting the round receiver tube through the 4” hole cut in the oor. Pull the front crossmember

back against the center section, Insert three 1/2” x 1 1/2” bolts in the front crossmember and through the

front legs of the center section. Place at washer, lock washer and nut on the bolts. Leave these bolts loose.

Thread four 1 1/2” bolts with at and lock washers into the rear bar from inside the center section. Now

install the bolts in the front side plate tabs.

STEP FOUR

Square the hitch across the frame and align two of the sideplate holes with existing holes in the truck

frame. Install two ½” bolts, at washers and lock washers on each side. After all fasteners have been

installed, torque to 90 ft.-lbs. torque.

STEP FIVE

To install the safety chain brackets, it is necessary to drill four ½” holes through the

truck bed oor. Drill the holes from beneath the truck, through the 4 holes nearest

the round hitch receiver tube in the center section. This will locate the safety chain

brackets in the valley section of the bed oor. Drop a U-bolt through each pair of

holes from the topside of the truck bed oor. Place a spring and lock nut on each of

the four legs and tighten the lock nuts until they are ush with the bottom of the

U-bolt.

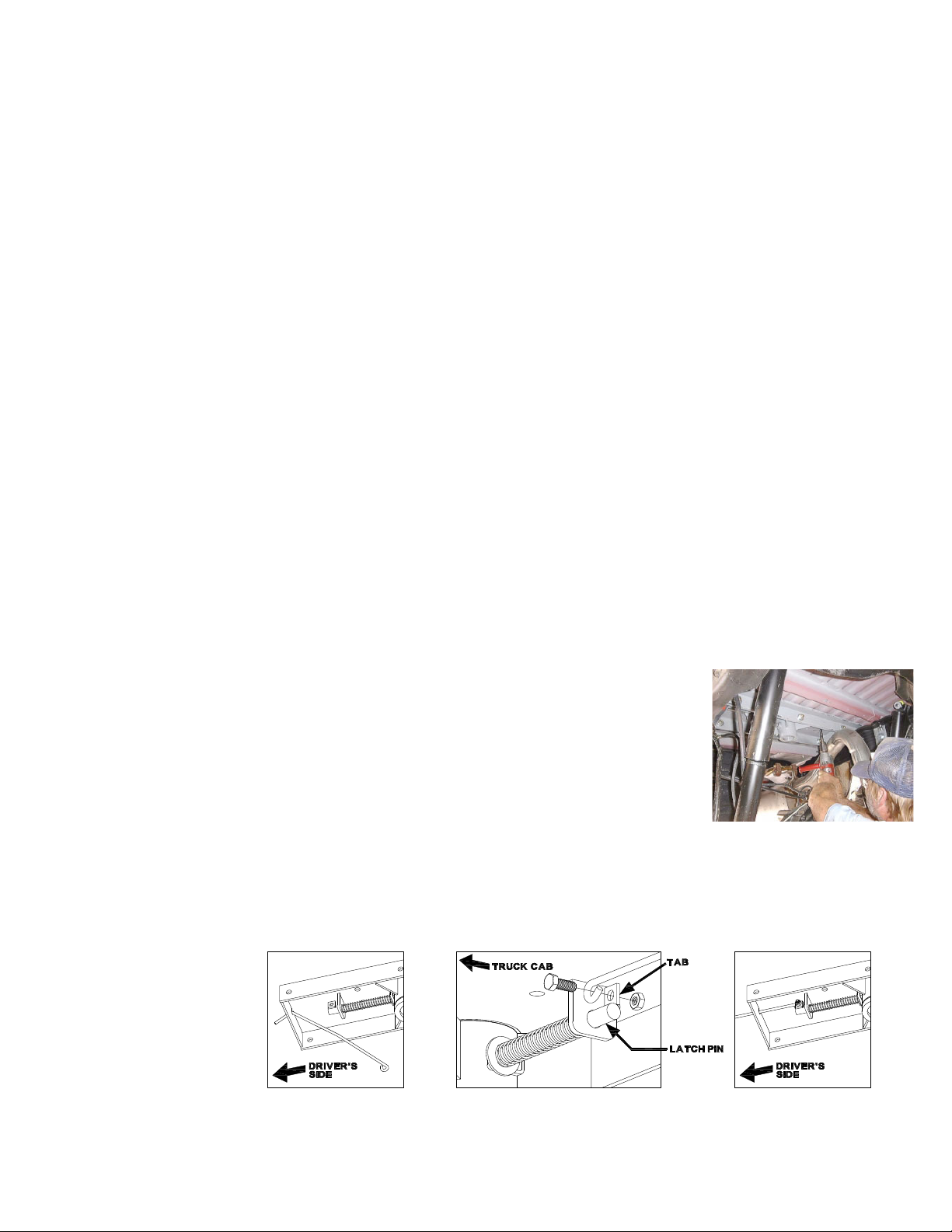

STEP SIX

WARNING: LATCH PIN WILL NOT FUNCTION PROPERLY IF HANDLE IS NOT INSTALLED

CORRECTLY.

Install the handle from underneath the truck by inserting it through the slot in the end of the center section

toward the driver’s side rear tire as shown. Attach the handle to the latch pin as shown with the handle on the

“cab side” of the square tab welded to the pin. The head of the bolt must be on the handle side, and the lock

nut must be on the tab side. The tab is welded to the pin in an offset position so that the handle will be lined

up over the center of the pin. If the handle is fastened to the other side of the tab, the handle will not function

properly. When installed

correctly the latch pin

may be disengaged from

the ball by pulling on the

handle from the driver’s

side wheel well and rotating

the handle clockwise.

STEP SEVEN

Retract the latch pin by pulling the handle out until it stops and then rotating to the lock out position. Place

the 2-5/16” ball in the hitch receiver. Engage the latch pin by rotating the handle back to center. Be certain

the latch pin passes through the holes in the 2-5/16” ball and fully engages through the hitch receiver.

Copyright 2011

B&W Custom Truck Beds, Inc.

ALL RIGHTS RESERVED

1050R 04 19 2011

Loading...

Loading...