Page 1

GasPoint

Gas Transmitter

4-20 mA Fixed Gas Gas Monitor

Installation and Operating Instructions

Page 2

Limited Warranty & Limitation of Liability

BW Technologies LP (BW) warrants this product to be free from defects in material and workmanship under normal use and service for a

period of two years, beginning on the date of shipment to the buyer. This warranty extends only to the sale of new and unused products to

the original buyer. BW’s warranty obligation is limited, at BW’s option, to refund of the purchase price, repair, or replacement of a defective

product that is returned to a BW authorized service center within the warranty period. In no event shall BW’s liability hereunder exceed the

purchase price actually paid by the buyer for the Product.

This warranty does not include:

a) fuses, disposable batteries or the routine replacement of parts due to the normal wear and tear of the product arising from use;

b) any product which in BW’s opinion, has been misused, altered, neglected or damaged by accident or abnormal conditions of

c) any damage or defects attributable to repair of the product by any person other than an authorized dealer, or the installation of

unapproved parts on the product; or

The obligations set forth in this warranty are conditional on:

a) proper storage, installation, calibration, use, maintenance and compliance with the product manual instructions and any other

applicable recommendations of BW;

b) the buyer promptly notifying BW of any defect and, if required, promptly making the product available for correction. No goods shall be

returned to BW until receipt by the buyer of shipping instructions from BW; and

c) the right of BW to require that the buyer provide proof of purchase such as the original invoice, bill of sale or packing slip to establish

that the product is within the warranty period.

THE BUYER AGREES THAT THIS WARRANTY IS THE BUYER’S SOLE AND EXCLUSIVE REMEDY AND IS IN LIEU OF ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTY OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE. BW SHALL NOT BE LIABLE FOR ANY SPECIAL, INDIRECT, INCIDENTAL OR

CONSEQUENTIAL DAMAGES OR LOSSES, INCLUDING LOSS OF DATA, WHETHER ARISING FROM BREACH OF WARRANTY OR

BASED ON CONTRACT, TORT OR RELIANCE OR ANY OTHER THEORY.

Since some countries or states do not allow limitation of the term of an implied warranty, or exclusion or limitation of incidental or

consequential damages, the limitations and exclusions of this warranty may not apply to every buyer. If any provision of this warranty is held

invalid or unenforceable by a court of competent jurisdiction, such holding will not affect the validity or enforceability of any other provision.

BW Technologies LP BW America BW Europe

2840 – 2nd Ave. SE 3279 West Pioneer Parkway 5 Canada Close,

Calgary, AB Arlington, TX Banbury, Oxfordshire

Canada T2A 7X9 USA 76013 United Kingdom OX16 2RT

operation, handling or use;

Page 3

Table of Contents

Title Page

Safety Information – Read First ............................................................................................................ v

Contacting BW Technologies................................................................................................................ v

Introduction............................................................................................................................................ 1

Installation .............................................................................................................................................3

Operation............................................................................................................................................. 13

Calibration ...........................................................................................................................................16

Maintenance........................................................................................................................................ 18

Specifications ...................................................................................................................................... 20

Replacement Parts and Accessories.................................................................................................. 23

Manufacturer’s Notes and Warnings ..................................................................................... v

Sensor Location..................................................................................................................... 3

Mounting the Enclosure......................................................................................................... 4

System Design Specifications ............................................................................................... 5

Cable Installation ................................................................................................................... 5

4-20 mA Loop Installation...................................................................................................... 6

Relay Cable Installation......................................................................................................... 6

Connecting the Controller and Power Supply .......................................................................6

Remote Sensor Separation Kit .............................................................................................. 6

Mounting the Sensor Separation Kit Enclosure..................................................................... 8

Factory Settings..................................................................................................................... 9

Dip Switch Overview.............................................................................................................. 9

Changing the Alarm and Calibration Gas Setpoints.............................................................. 9

Dip Switch Settings.............................................................................................................. 10

Connecting the Controller and Power Supply .....................................................................11

Controller Calibration ........................................................................................................... 11

Changing the Alarm Setpoints............................................................................................. 12

Changing the Calibration Gas Concentration Level ............................................................ 12

Changing the Low Alarm Setpoint....................................................................................... 12

Changing the High Alarm Setpoint ...................................................................................... 12

Gas Alarm Conditions and Advice....................................................................................... 14

Fault Alarm Conditions and Advice .....................................................................................15

Guidelines............................................................................................................................ 16

Remote Calibration ..............................................................................................................16

Calibration Procedure .......................................................................................................... 17

Cleaning a Sensor ............................................................................................................... 18

Clearing a Sensor ................................................................................................................ 18

Troubleshooting ................................................................................................................... 18

Servicing the GasPoint ........................................................................................................ 19

Sensor Assembly Replacement ..........................................................................................19

Other Component Replacement.......................................................................................... 19

Sensor Specifications .......................................................................................................... 20

Relative Sensitivity of Combustible Gases/Vapors .............................................................21

Specifications....................................................................................................................... 22

i

Page 4

Gas Point

User Manual

ii

Page 5

List of Tables

Table Title Page

1. Ratings and Certification........................................................................................................ 1

2. GasPoint Monitor .................................................................................................................. 2

3. Control Bay ............................................................................................................................ 2

4. Liquid Crystal Display ............................................................................................................ 2

5. Transmitter with Catalytic/IR Combustible Sensor ................................................................ 5

6. Transmitter with Toxic/Oxygen Sensor.................................................................................. 5

7. Distances for Sensor Separation Kit...................................................................................... 6

8. Factory Default Settings; Select Measuring Ranges............................................................. 9

9. Dip Switches ........................................................................................................................ 10

10. Alarms..................................................................................................................................14

11. Fault Conditions................................................................................................................... 15

12. Calibration Diagnostics Protection....................................................................................... 16

13. Troubleshooting Tips ........................................................................................................... 18

14. Sensor Wiring Configuration................................................................................................ 19

15. GasPoint Replacement Parts ..............................................................................................19

16. Operating and Calibration Specifications ............................................................................ 20

17. Catalytic Sensor Relative Sensitivity of Common Combustible Gases/Vapors .................. 21

18. Standard Model IR GasPoint Relative Sensitivity to

Applicable Combustible Gases/Vapors

............................................................................... 21

List of Figures

Figure Title Page

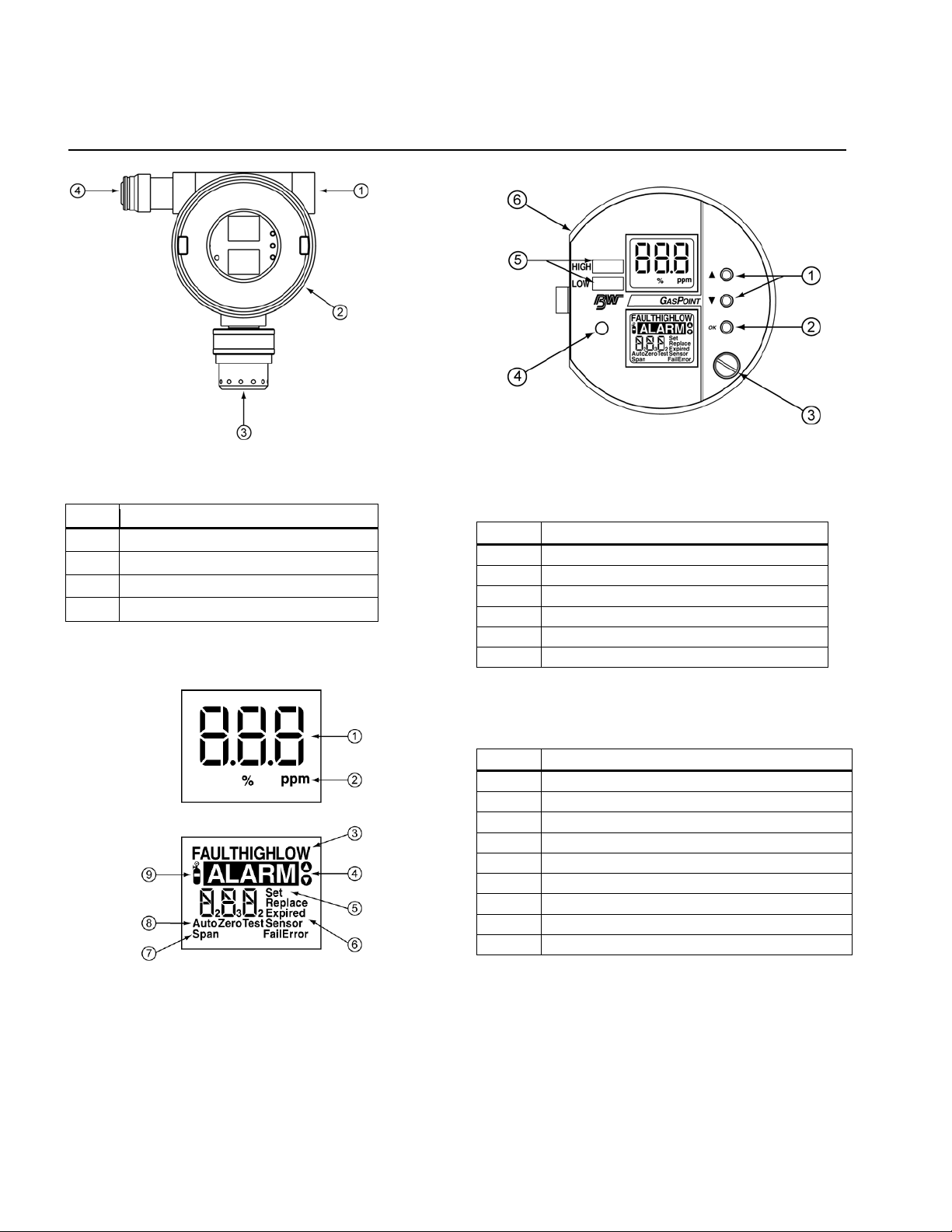

1. GasPoint Monitor ................................................................................................................... 2

2. User Interface ........................................................................................................................2

3. Liquid Crystal Display ............................................................................................................ 2

4. Outline Drawing ..................................................................................................................... 4

5. System Wiring Diagram......................................................................................................... 7

6. Sensor separation Kit Wiring Diagram ..................................................................................8

7. Applying Gas to the Sensor................................................................................................. 16

8. Assembly Drawing............................................................................................................... 19

9. Sensor Wiring Diagram........................................................................................................ 19

iii

Page 6

Gas Point

User Manual

iv

Page 7

Safety Information – Read First

IMPORTANT

Users of the GasPoint (“the transmitter”) require a full understanding of the operating and maintenance instructions. Use the

transmitter only as specified in this manual, otherwise the protection provided by the transmitter may be impaired. Read the

following Warnings and Cautions before using the transmitter.

a Warnings

⇒ Do not paint the sensor assembly or the transmitter.

⇒ Calibrate the transmitter at start-up and BW recommends a calibration check on a regular schedule, once at least

every 90 days. More frequent checks or inspections are encouraged to spot problems such as mud collections on

the sensor head, accidental painting over the sensor head, etc.

⇒ Do not use the transmitter if it is damaged. Before you use the monitor, inspect the case. Look for cracks or

missing metals or plastics. If the transmitter is damaged or something is missing,

immediately.

⇒ Make sure the cover is properly fastened before you operate the transmitter.

⇒ Use only a sensor assembly specifically designed for your GasPoint model. Refer to

Accessories.

⇒ Periodically test the sensor’s response to gas by exposing the monitor to a targeted gas concentration that

exceeds the high alarm setpoint. Manually verify that visual alarms are activated.

⇒ Opening the sensor will invalidate the calibration.

a Cautions

Do not expose the monitor to electrical shock and/or severe continuous mechanical shock.

⇒

⇒ Do not attempt to disassemble, adjust, or service the monitor unless instructions for that procedure are contained in

the manual and/or that part is listed as a

⇒ Do not allow liquids to condense and/or use high power sprays on the instrument.

⇒ The warranty will be voided if customer personnel or third parties damage the monitor during repair attempts. Non-BW

Technologies repair/service attempts void this warranty.

IMPORTANT

replacement part.

contact BW Technologies

Replacement Parts and

The GasPoint is only to be used for the purposes specified in this manual. BW Technologies’ authorized service representatives and

parts must be employed in carrying out repairs to the unit in order to maintain the validity of the warranty. Modification of

components, use of non-BW parts, or use of incomplete or used parts will also invalidate the warranty.

CAUTION: FOR SAFETY REASONS THIS EQUIPMENT MUST BE OPERATED AND SERVICED BY QUALIFIED

PERSONNEL ONLY. READ AND UNDERSTAND INSTRUCTION MANUAL COMPLETELY BEFORE OPERATING OR

SERVICING.

Contacting BW Technologies

To contact BW Technologies, call: Address correspondence to:

USA: 1-888-749-8878 BW Technologies LP

Canada: 1-800-663-4164 2840 – 2 Avenue S.E.

Europe: +44 (0) 1295 700300 Calgary, AB T2A 7X9

Other countries: +1-403-248-9226 CANADA

ISO 9001

Email us at: info@bwtnet.com

Visit BW Technologies’ website at:

www.gasmonitors.com

Manufacturer’s Notes and Warnings

1. Read the Safety Warnings and Cautions at the beginning of this manual.

2. The GasPoint is fully tested and calibrated in the factory. Installation of the GasPoint should be done by qualified personnel

v

Page 8

Page 9

GasPoint

Introduction

The GasPoint (“the transmitter”) provides continuous monitoring of the atmosphere for hazardous gases in the workplace and is

virtually maintenance-free. Its revolutionary design utilizes advanced microcontrollers and allows for enhanced diagnostics and fault

analysis. Advanced design features make installation and operation simpler than ever, saving you time and money.

The transmitter provides a 4-20 mA output signal which can be connected to any control system (DCS, PLC, etc.). Designed with

non-volatile memory, the transmitter has total memory retention.

The pushbutton, non-intrusive calibration can be easily performed by one person with no tools or magnet keys. Normally, only a

periodic calibration check is needed to assure dependable performance. The backlight automatically activates in low light conditions

and in an alarm condition.

The LCD is an intuitive user interface, indicating the following:

• When a toxic or combustible sensor has “failed” its self-test;

• Gas type monitored and concentration level (%LEL or ppm);

Alarm level (field settable) and the type encountered (low, high, or fault);

•

• When to apply gas during calibration; and

• When a toxic or combustible sensor has “failed” its self-test.

The flexibility of the transmitter’s modular design affords efficient installation. Wiring of the transmitter itself is straightforward. Field

interchangeable plug-in sensor assemblies enable the user to change the gas monitored at any time. The transmitter recognizes the

sensor installed and tests and resets itself to that sensor type.

The poison-resistant sensors have the fastest response times available. The transmitter is capable of responding to a momentary

puff of gas that would otherwise remain undetected. The sensors have a proven history of reliable, long-term performance and are

relatively unaffected by temperature or humidity variations. Gas enters the transmitter’s sensor by convection and diffusion through

a sintered stainless steel or wire-mesh screened opening.

The transmitter’s explosion-proof design allows operation in areas where the combustible gas concentration may exceed the lowerexplosive limit (LEL). Its rugged construction ensures a long life span in almost any environment.

The transmitter incorporates the best of both proven and new technologies that offer versatility in addition to reliable safety

mechanisms.

n

Table 1. Ratings and Certification

All gases, except Cl2, ClO2, and HCl

Approved by CSA (Canadian Standards Association) for use in both the USA and Canada

Class I, Div. 1, Groups B, C, D

Class II, Groups E, F, G (Toxic only)

Combustible Performance Standards: ANSI/ISA. ISA—S12.13

CSA: C22.2 No 152

GasPoint Cl2, ClO2, and HCl

Approved by CSA (Canadian Standards Association) for use in both the USA and Canada for ordinary locations

Approved Non-Incendive for installations in Class I, Division 2, Groups B, C, D

Location’s when both input power and relay outputs are connected to non-incendive sources not to exceed

32 Vdc (power input) and 24 Vdc (relay output)

CSA: C22.2 No.213, UL: 1604

1

Page 10

GasPoint

User Manual

a Warning

Opening the sensor

will invalidate the

Figure 1. GasPoint Monitor

Table 2. GasPoint Monitor

Item Description

1 Cable conduit access

2 Explosion-proof enclosure

3 Sensor

4 Calibration pushbutton

Figure 2. User Interface

Table 3. Control Bay

Item Description

1 Edit buttons

2 OK button

3 Faceplate security screw

4 Low light sensor

5 High/Low alarm settings

6 Slip Hinge

Table 4. Liquid Crystal Display

Item Description

1 Numeric reading

2 Units of measure (ppm or %)

3 Alarm level/type

4 Increment/decrement prompt arrows

5 Set value arrow prompts

6 Sensor advice

7 Span advise icon

8 Automatic zero advise icon

9 Apply gas advise icon

Figure 3. Liquid Crystal Display

2

Page 11

GasPoint

Installation

Installation

Sensor Location

Several factors should be considered when selecting locations to install sensors. The following general suggestions should be

considered to assure the detection of the target gas. Select the most suitable location for each sensor.

Air Currents: If there are fans, wind, or other sources of air movement, gases may tend to rise or collect in certain areas of a

facility. The local air currents should be assessed to aid in selecting the sensor location. Outdoor situation considerations, such as

prevailing winds, should also be accounted for. Air convection can often be more important in determining gas concentrated areas

than factors of vapor density.

Vapor Density: When there are no air currents in the area, sensor placement may be affected where the gas (vapor) to be

monitored is lighter or heavier than air. For gases lighter than air, BW suggests placing the sensor approximately 12 in. (30 cm)

above the level of a potential gas release, or close to the ceiling or roof in indoor installation. For gases heavier than air, BW

suggests placing the sensor 12 in. (30 cm) below the release site, or near the floor or ground. Gases with a density equal to air or

slightly greater than air tend to rise (particularly when air currents are present).

Gas Emission Sources: As a rule, at least one sensor should be located in close proximity to each point where a leak is likely to

occur. This is particularly important when a liquid with a low volatility is being monitored.

Environmental Factors: Designed for rugged outdoor use, consider the following in selecting a location.

• Install sensors where they are protected from wind, dust, snow, water, vibration, and/or shock.

• Observe the operating temperature range of the sensor. Refer to

Sensor Specifications.

3

Page 12

GasPoint

User Manual

Mounting the Enclosure

Modular design simplifies the installation of the transmitter. The transmitter’s main board is mounted to the inner control door, which

is equipped with slip hinges. The transmitter’s back enclosure contains the relays and power board and is equipped with a threaded

3/4 inch NPT conduit fitting outlet and pre-drilled mounting flanges. Power and signal lines connect to the plug-in terminal block on

the power board. The transmitter may be disassembled, simplifying the installation.

a Caution: Qualified personnel should perform the installation according to applicable electrical codes, regulations, and

safety standards. Ensure correct cabling and sealing fitting practices are implemented.

Install the transmitter. The predrilled mounting flanges: I.D. 0.25 on 5.5 inch centers.

It is preferable to attach the transmitter to a wall or bracket, using bolts through the two mounting holes. These mountings, however,

may be omitted if the electrical conduit is sufficiently rigid to support the weight of the transmitter.

Note: The sensor should never be installed pointed upwards.

4

Figure 4. Outline Drawing

Page 13

GasPoint

Installation

System Design Specifications

Supply Voltage: 12 to 32 volts

Power Consumption: Catalytic Combustible Sensors: 100 mA @ 24 Vdc

IR Combustible Sensors: 75 mA @ 24 Vdc

Toxic/Oxygen Sensors: 40 mA @ 24 Vdc

Relays: 50 mA per relay (150 mA total)

Memory: Non-volatile memory, a battery back-up is not necessary to retain values in the event of power outages.

Loop Resistance: 650 ohms maximum

Cable: 4-20 mA: 3 conductor, 14 to 24 AWG; Relays: 3 conductor, 14 to 24 AWG

Sensor Separation Kit: 4 conductor, 16 to 22 AWG

Relays: 5 amp at 24 Vdc or 115 Vac SPDT; low, high, and fault

Low/High Relays: Field selectable for normally energized/de-energized; latching/non-latching

Fault Relay: Energized; non-latching

Sensor Separation Kit: Transmission distances (see tables below)

Cable Installation

Transmission Range: The distance the 4-20 mA signal can travel is dependent on several factors including the cable gauge.

Maximum cable resistance is 650 ohms less the controller resistance.

The tables below assume a constant 24 volt power supply (at 20°C) copper wire and a controller resistance of

250 ohms. The signal range from the controller to the transmitter takes into account the return loop.

Note: The BW CR-4000 Controller has a resistance of only 120 ohms.

Table 5. Transmitter with Catalytic/IR Combustible Sensor

(Maximum cable lengths between the controller and transmitter)

Conductor Size

Sq mm AWG feet meters feet meters feet meters feet meters

0.64 22 3,356 1,022 2,368 722 1,830 557 1,491 454

Relays Not Used One Relay Connected Two Relays Connected Three Relays Connected

0.75 20 5,336 1,626 3,767 1,148 2,910 887 2,371 722

1.0 18 8,476 2,583 5,983 1,823 4,623 1,409 3,767 1,148

1.5 16 13,474 4,106 9,511 4,106 7,749 2,240 5,988 1,825

Ic Current Factor

Conductor Size Relays Not Used One Relay Connected Two Relays Connected Three Relays Connected

Sq mm AWG feet meters feet meters feet meters feet meters

0.64 22 6,712 2,045 3,661 1,115 2,517 767 1,917 584

0.75 20 10,953 3,253 5,821 1,774 4,002 1,219 3,049 929

1.0 18 16,953 5,167 9,247 2,818 6,357 1,937 4,843 1,476

1.5 16 26,948 8,213 14,699 8,213 10,105 3,080 7,699 2,346

Ic Current Factor

For other operating parameters use the formula below to establish the transmission range.

Formula: Maximum distance =

where: VP = power supply voltage (minimum)

V

I

R

R

0.12 0.17 0.23 0.28

Table 6. Transmitter with Toxic/Oxygen Sensor

(Maximum cable lengths between the controller and transmitter)

0.06 0.110 0.160 0.210

{((V

— VT)/I

P

)-RC}/(2xR

c

)

L

= transmitter supply voltage (minimum) 12 volt

T

= current through conductor (See Table 5 and 6 for factors)

c

= total controller resistance

C

= line resistance per 350 m (1,160 ft.)

L

5

Page 14

GasPoint

User Manual

4-20 mA Loop Installation

Cable Routing: Separate cables are required for each transmitter. In classified areas the cable should be in conduit or it should

be an approved hazardous location cable.

Power Supply: Ensure power supply meets the minimum requirements of all components of your system

(i.e., alarms, relays, etc.). BW recommends that the power supply be regulated.

a Caution: Polarity must be observed. If the Return and +24 volt wires are reversed, the transmitter will not work. Do not

apply electrical power to the transmitter until all connections are made, the sensor is in place, and the transmitter is

complete.

1. Remove the transmitter cover, open the inner hinged control door and remove, if desired.

2. Attach the conduit, if applicable, and pull cable(s) into the enclosure.

3. Connect the 3-pin power terminal block.

Return (R): 4-20 mA signal to the labeled terminal

Supply (V): (+) positive (12-32 volts) to the labeled terminal

Ground (G): Ground wire to the labeled terminal

Note: (If using shielded cable) To avoid radio frequency interference (RFI), the shield (including Mylar) must be grounded. Simply

tying a bare drain wire to ground does not ground a shield. Keeping the shield as short as possible, tie the shield to the

internal grounding screw. Tie any unused wires to ground.

Relay Cable Installation

The transmitter is equipped with three relays: low gas alarm, high gas alarm, and fault alarm. Select to connect the applicable relays

required in each situation. Relay connections are labeled: NO (normally open), C (common), and NC (normally closed). Attach wires

as required to the applicable terminals.

Note: The fault relay connections are reversed.

Set the alarm dip switches before applying power. Once power is applied, if desired, change the alarm setpoints.

Connecting the Controller and Power Supply

Ensure the transmitter’s external cover is in place before applying power. Follow the procedures and recommendations in the control

systems manual to complete the installation.

1. Ensure the transmitter is tied to the controller ground, to the earth ground, and to the negative terminal of the power supply.

2. Attach wires to the controller and power supply as shown in the wiring diagram. Refer to Figure 5.

Remote Sensor Separation Kit

The transmitter sensor separation kit can be mounted at the following distances dependent of the cable size.

Table 7. Distances for Sensor Separation Kit

Conductor Size

Sq mm AWG feet meters feet meters

0.64 22 619 188.5 1,548 472

0.75 20 985 300 2,463 750

1.0 18 1,564 476 3,912 1,174

1.5 16 2,487 758 6,218 1,895

Catalytic/IR Combustible

Sensor

Toxic/O2 Sensor

6

Page 15

GasPoint

Installation

Figure 5. System Wiring Diagram

Modbus Expansion Module Note: For wiring of GasPoints equipped with the Modbus Communication

Expansion Module, see the Modbus manual for additional wiring information.

7

Page 16

GasPoint

User Manual

Figure 6. Sensor separation Kit Wiring Diagram

Mounting the Sensor Separation Kit Enclosure

1. The separation kit is equipped with predrilled flanges: I.D. 3065 (7.68 mm) on 4.35 in. (10.6 mm) centers.

Disconnect the wires from the transmitter terminal block and remove the sensor from the transmitter. Screw the sensor fully into

2.

the separation kit housing and install the wires, as shown on the diagram, to the adjacent terminal block in the separation kit.

Install cable as shown. Ensure correct cabling and sealing fitting practices are implemented.

3.

8

Page 17

GasPoint

Installation

Factory Settings

The transmitter is calibrated and tested before shipping. Commonly used values are set at the factory. To change the factory default

settings, refer to

Changing the Alarm Setpoints.

The following settings are field selectable:

Dip Switch Overview

1. Calibration Time Delay: To set span, select a time delay of 30 seconds or 6 minutes. For remote calibration use the 6 minute

setting to allow time for the gas to reach the sensor. To save time and calibration gas, the transmitter begins the span

procedure when it senses the calibration gas.

Note: The factory default is 30 seconds. See dip switch 3 (CAL TIME) to change to 6 minutes.

2. Measuring Range: Select from up to four measuring ranges by setting Block 1 switch 4 and switch 5 to open or closed. Both

switch 4 and 5 are factory set to open. Refer to Table 8.

3. Low and/or High Relays: Select non-latching or latching. Factory default is set to open (non-latching).

4. Low and/or High Relays: Select de-energized or energized. Factory default is set to open (de-energized).

Changing the Alarm and Calibration Gas Setpoints

5. Gas Alarms: Gas alarm levels are set to Occupational Safety & Health Administration (OSHA) standards prior to shipping. The

transmitter is equipped with two alarm levels, low and high. To set, select two, one, or no alarm levels and set selected levels to

any value desired. To change the levels, refer to

Changing the Alarm Setpoints. The factory defaults are listed in Table 8.

6. Calibration Gas Concentration Level: To facilitate the auto span, the calibration gas concentration expected is preset. It can

be changed at any time for the toxic and combustible gas sensors. Set the standard generally used in your facility. Refer to

Changing the Calibration Gas Concentration Level to change the value.

The oxygen sensor span is set to 20.9% and cannot be adjusted (For O2 calibrate in normal 20.9% ambient air, or if the

atmosphere may be deficient or enriched, use pure air calibration gas.)

Table 8. Factory Default Settings; Select Measuring Ranges

Select Measuring Range

Gas Sensed

Hydrogen sulfide (H2S) ppm

Carbon monoxide (CO) ppm

Combustibles 0-100% LEL

(Catalytic or IR)

Oxygen (O2) % by vol.

Sulfur dioxide (SO2) ppm

Hydrogen cyanide (HCN) ppm

Chlorine (Cl2) ppm

Chlorine dioxide (ClO2) ppm

Hydrogen (H2) ppm

Hydrogen chloride (HCl) ppm

Ammonia (NH3) ppm

Nitrogen dioxide (NO2) ppm

* BW recommends that the calibration gas factory default values be changed if selecting higher measuring ranges than the factory default measuring range. Refer to

Changing the Alarm Setpoints and Sensor Specifications.

Units of

Measure

%LEL

Factory Default

4. Open

5. Open

1

0 to 100

0 to 500

0 to 100

0 to 30.0%

0 to 100

0 to 20.0

0 to 5.0

0 to 1.00

0 to 100

0 to 10.0

0 to 50

0 to 50.0

Or Select

4. Closed

5. Open

0 to 50 0 to 500 0 to 20 10 ppm 15 ppm 20 ppm

0 to 1000 0 to 100 0 to 50 35 ppm 200 ppm 200 ppm

N/A N/A N/A 10% 20% 50% LEL

N/A N/A N/A 19.5% 18.5% 20.9% ambient/pure air

0 to 50 0 to 20 0 to 10 2 ppm 5 ppm 20 ppm

N/A N/A N/A 4.7 ppm 10 ppm 17 ppm

0 to 10.0 0 to 50.0 0 to 99.9 0.5 ppm 1.0 ppm 3.0 ppm

0 to 5.00 N/A N/A 0.20 ppm 0.30 ppm 0.56 ppm

0 to 200 0 to 800 N/A 30 ppm 50 ppm 100 ppm

0 to 20.0 0 to 99.9 N/A 0.2 ppm 0.5 ppm 6.6 ppm

0 to 100 0 to 500 0 to 999 25 ppm 50 ppm 50 ppm

0 to 10.0 0 to 20 0 to 99.9 2 ppm 5 ppm 10 ppm

Or Select

4. Open

5. Closed

2 3 4

Range LO: 4

Range HI: 5

Or Select

4. Closed

5. Closed

Alarm Setpoints Calibration Gas

Factory Defaults

(Field Settable)

LOW HIGH

Factory Default

Value Level

Expected*

9

Page 18

GasPoint

User Manual

Dip Switch Settings

The dip switches are located on the upper control board. To

access the dip switch banks, remove the top of the

explosion-proof enclosure, loosen the control board access

screw (located just below the buttons), and open the control

door which is on slip hinges. The dip switches are clearly

labeled.

a Caution: The transmitter must be powered down

before removing the outer cover. If it is in a classified

area, either remove the transmitter or declassify the

area.

Note: Any latched relay will be released upon one push of

the external button.

Table 9. Dip Switches

Dip Switch Function

Block 1: Calibration and Measuring Ranges

1 OPT B Not used

2 OPT A Not used

3 CAL TIME

4 RANGE LO Set measuring range

5 RANGE HI Set measuring range

Block 2: Gas Alarm Relay Settings

HI L

1

(High alarm)

LOW L

2

(Low alarm)

3 OPT C Not used

HI E

4

(High alarm)

LOW E

5

(Low alarm)

Calibration wait period

Open - 0.5 min.

Closed - 6 min.

Open - Non-latching relay

Closed - Latching relay

Open - Non-latching relay

Closed - Latching relay

Open - De-energized relay

Closed - Energized relay

Open - De-energized relay

Closed - Energized relay

10

Page 19

GasPoint

Installation

Connecting the Controller and Power Supply

Ensure the transmitter’s external cover is in place before applying power. Follow the procedures and recommendations in the control

systems manual to complete installation.

Note: Ensure the transmitter is tied to the controller ground, to the earth ground, and to the negative terminal of the power supply.

1. Attach wires to the controller and power supply as shown in Figure 5. When power is applied, the transmitter automatically

activates.

2. The LCD shows all the display elements, and the elements flash twice. Then each icon displays separately and stays lit until all

icons are displayed. The LCD backlight then activates.

3. The word Test displays on the LCD. The transmitter then begins a 2-minute countdown from 999 to 000.

During the countdown to normal operation the transmitter communicates with the sensor, determines the sensor type, tests the

sensor integrity, tests all the circuitry, and allows the sensor to stabilize before normal operation begins. The transmitter also

determines the sensor range. Once initialization is complete, the transmitter enters normal operational mode (in the system

loop) providing a signal to the controller of the gas present.

4. After the countdown, the LCD displays the current low alarm and high alarm setpoints. Each alarm setpoint is displayed for

4 seconds. To review them, press and release the external pushbutton after normal operation begins.

5. Upon a successful self-test, the transmitter enters normal operation and displays the ambient gas present. The backlight remains

activated for 5 seconds after normal operation begins. If the unit fails the self-test, refer to

Fault Alarm Conditions and Advice.

Controller Calibration

Follow the procedures and recommendations in the control system manual to calibrate the control system.

1. Calibrate the control system (see your control manuals). Set the controller as follows:

• 4 mA = ZERO

• 20 mA = FULL SCALE

2. Calibrate the transmitter with gas and then refer to

Changing the Alarm Setpoints and Calibration Gas Setpoints

11

Page 20

GasPoint

User Manual

Changing the Alarm Setpoints

The setpoint mode allows the user to change the calibration gas concentration level, the low alarm setpoint, and the high alarm

setpoint. Refer to

1. Screw off the enclosure top. (Allows access to edit buttons.)

2. Press the OK button for 2 seconds to access setpoint mode and change factory default settings.

The transmitter is equipped with two setpoints, low and high. If only one setpoint is required, set one level to zero to

deactivate. Set the other setpoint as desired.

To deactivate both alarm levels, set both setpoints to zero. If both low and high are set to the same value, the transmitter will

trigger a high alarm condition if that setpoint is met or exceeded.

Factory Settings for factory default settings. To change the values:

Changing setpoint LCD icons displayed Display

Changing the Calibration Gas Concentration Level

The LCD first displays the current calibration gas value. Press OK to

accept the displayed value or proceed to change the value. The

factory default value for O

1. Press ▲ to increment the value or ▼ to decrement the value.

2. Press OK to accept the new displayed value and end set

calibration gas level.

is set for 20.9% and cannot be adjusted.

2

Changing the Low Alarm Setpoint

The next screen displays the current low alarm setpoint. Press OK to

accept the current low alarm setpoint or proceed to change the

value.

1. Press ▲ to increment the value or ▼ to decrement the value.

2. Press OK to accept the new displayed value and end set low

alarm setpoint.

Changing the High Alarm Setpoint

The next screen displays the current high alarm setpoint. Press OK

to accept the current high alarm setpoint or proceed to change the

value.

1. Press ▲ to increment the value or ▼ to decrement the value.

2. Press OK to accept the new displayed value and end set high

alarm setpoint.

Note: Oxygen low and/or high gas alarm setpoints can be set to either enrichment and/or deficiency alarms as desired. If the alarm

setpoint is set below 20.9% (deficiency alarm), an alarm is triggered if the concentration present is below 20.9%. If the alarm

setpoint is set above 20.9% (enrichment alarm), an alarm is triggered if the concentration present exceeds 20.9%. You can

choose to set both alarms above or below 20.9%, or one alarm above and one below 20.9%

• Numeric display shows

current calibration gas

value expected

• Set Span icon flashes

• K flash

• ▲▼ flash

• Numeric display shows

current low alarm setpoint

• LOW ALARM set icon

flashes

• ▲▼ flash

• Numeric display shows

current high alarm setpoint

• HIGH ALARM set icon

flashes

• ▲▼ flash

3. Test the transmitter using a gas cylinder other than the one used in the calibration steps. The gas concentration should not

exceed the sensor’s detection range. Confirm that the display shows the expected concentration.

12

Page 21

GasPoint

Operation

Operation

The transmitter provides continuous monitoring for the target gas. In the event of power failure, the

transmitter will automatically reset itself back into the system loop after power is restored. The transmitter

has non-volatile memory and will not be affected by a power disruption. All programmed information is

protected with total memory retention.

Note: BW recommends the transmitter be calibrated before first time use.

LCD: The LCD diplays the current ppm or % reading of the target gas present.

View Alarm Setpoints: To view the alarm setpoints at any time, press the external pushbutton (for one

second) and release. The LCD displays the current low alarm setpoint and then the high alarm setpoint.

Relays:

Fault: The fault relay is always energized under normal operations. The relay will de-energize only if the transmitter is

•

addressing a fault condition or when power is released.

Low/High Gas Alarms: The gas alarm relays connected are energized or de-energized (latching or non-latching) according to

•

the transmitter dip switch settings you have selected.

Reset Latched Relay Alarm (Alarm Acknowledge): If a gas alarm relay has been set to latching mode, acknowledge the

•

alarm condition.

Press the external pushbutton for one second until the display reads low alarm setpoint, then release the external button. The

transmitter releases the latched alarm(s) and displays the current low and high alarm setpoints.

Note: If an alarm condition exists, the transmitter will not allow the user to reset a latched alarm or display the alarm setpoints.

Output: The 4-20 mA loop output is normal (from 4 to 20 mA according to calibrated values) except in a fault condition.

Backlight: The backlight activates in low light conditions. When ambient light conditions return to normal, the backlight automatically

deactivates.

13

Page 22

GasPoint

User Manual

Gas Alarm Conditions and Advice

If the current gas concentration meets or exceeds either alarm setpoint, the transmitter gas alarm functions will activate.

Note: If both or either gas alarm is set to zero, then no gas alarm condition exists for that alarm level.

The following alarm advice activates in any gas alarm condition (low or high):

The backlight activates.

•

•

The 4-20 mA loop output is normal (from 4 to 20 mA according to calibrated values).

When the alarm condition no longer exists, the transmitter exits alarm mode and enters normal operation.

Note: If a relay is set to the latching position on either low or high gas alarm, the relay remains on until the alarm is reset

(acknowledged). Press the external button to reset the relay.

If the alarms are disabled, then no alarm icons will be displayed.

An oxygen alarm level depends on which alarm setpoints have been set to low and high. The oxygen low and/or high gas

alarm setpoints are user selectable for either enrichment and/or deficiency alarms as desired.

a Caution: High off-scale readings may indicate an explosive concentration.

Table 10. Alarms

Alarm condition Alarm relay Alarm Display

LOW GAS ALARM

The current gas

concentration present meets

or exceeds the low alarm the

low alarm setpoint

Low alarm relay triggers

field interface if the relay is

connected and a low alarm

setpoint is entered.

• Numeric display will

show the gas

currently presnet

(ppm/%)

• LOW icon displays

• ALARM icon flashes

HIGH GAS ALARM

If the current gas

concentration present meets

or exceeds the high alarm

setpoint

OVER RANGE (over level

or over range) GAS

High alarm relay triggers a

field interface if the relay is

connected and a high alarm

setpoint is entered.

• Numeric display will

show the gas

currently present

(ppm/%)

• HIGH icon displays

• ALARM icon flashes

• OL icon displays

• HIGH icon displays

CONDITION

If the gas concentration

meets or exceeds the full

measuring range

14

Page 23

GasPoint

Operation

Fault Alarm Conditions and Advice

In the event of a fault condition, the fault alarm triggers activating any connected field interface. The transmitter advises which fault

condition has occurred.

Under the fault alarm conditions:

•

The non-latching fault relay is activated (de-energized) during a fault condition.

• The backlight activates.

When the problem is corrected, the transmitter automatically returns to normal operation.

Table 11. Fault Conditions

Fault Condition

Sensor Self-Test Fail

4-20 mA

Output

2.00 mA

(At start-up, the self-test has

failed)

Sensor Fault 2.00 mA

• Three (3) bars flash on the numeric display

• FAULT icon displays

• ALARM icon flashes

• Sensor Fail icon displays

• Numeric display will read the last value

(ppm/%) present before sensor fault occurs

LCD Icons Displayed Display

• FAULT icon displays

• ALARM flashes

• Sensor Fail displays

Sensor Drift 2.00 mA

• Numeric display reads 00

• FAULT icon displays

• ALARM icon flashes

• Sensor Error icon displays and flashes

15

Page 24

GasPoint

User Manual

Calibration

Guidelines

When calibrating the transmitter, adhere to the following guidelines.

• Calibration accuracy is never better than the calibration gas accuracy. BW Technologies recommends a premium-grade

calibration gas. Gases with National Institute of Standards and Technology (NIST) traceable accuracy improves the validity of

the calibration. Do not use a gas cylinder beyond its expiration date.

• Calibrate a new sensor before use. Allow the sensor to stabilize before starting calibration (approximately 5 minutes).

• Calibrate the transmitter on a regular schedule. (BW recommends once every 90 days (3 months), depending on use and

sensor exposure to poisons and contaminants.)

• Calibrate the transmitter if the ambient gas display value varies at start-up.

• It is best to calibrate the sensor before changing the alarm setpoints.

• Calibrate only in a clean atmosphere, which is free of target gas.

• Use teflon or stainless steel hose on all electrochemical sensors.

• Tygon will poison a catalytic combustible sensor over time.

a Warning

Opening the sensor will invalidate the calibration

Table 12. Calibration Diagnostics Protection

If calibration is incomplete, the transmitter automatically returns to normal operation and all prior (former) calibration data is

retained. Common cause for the transmitter to refuse calibration or for an incomplete calibration include the following:

Background interfering gas is present

If interfering gas is present during auto zero, the transmitter

refuses to auto zero and exits the calibration routine.

Calibration gas cylinder runs empty during calibration

Calibration gas concentration is too low or too high

Calibration gas concentration is not within expected

parameters—either the concentration of applied gas (ppm or %)

is too high or too low.

The transmitter refuses to set span if the calibration gas is not

within the expected parameters and exits the calibration routine.

Gas applied at the wrong time

Gas is applied before requested to do so, or if gas is applied

during auto zero, the transmitter refuses to proceed and exits the

calibration routine. The prior (former) auto zero value will be

retained.

Combustible and Toxic sensors: wait for the transmitter to

return to normal operation. Then apply pure air (zero gas) and

repeat calibration.

Wait for unit to return to normal operation. Replace the empty

gas cylinder with a full cylinder and repeat calibration.

Change the value to equal the calibration gas concentration

being applied.

Restart the calibration routine and apply gas only when the gas

cylinder icon flashes.

Remote Calibration

The length of time depends on the length of hose the

calibration gas must travel. If the wait period is longer than 30

seconds, the CAL TIME dip switch must be set to 6 minutes.

To save gas and time, the transmitter begins to span when it

senses calibration gas.

Apply the calibration gas for approximately 2 minutes plus the

time estimated for the gas to reach the sensor.

16

Figure 7. Applying Gas to the Sensor

Page 25

GasPoint

ration Calib

Calibration Procedure

The transmitter provides continuous monitoring for the target gas. In the event of power failure, the transmitter automatically resets itself

back into the system loop after power is restored. The transmitter has non-volatile memory and will not be affected by a power

disruption. All programmed information is protected with total memory retention.

For calibration gas concentrations and flowrates for each gas, refer to Table 16.

Calibration steps LCD icons displayed Display

START CALIBRATION

1. Press and hold the external button down while

the LCD displays the high and low alarm

setpoints. Continue to hold the button until the

LCD displays CAL and the CAL icon lights for

3 seconds. Then release the button.

Note: The 4-20 mA output will be 3mA throughout

calibration. Calibrating the transmitter will not

cause false alarms at the controller

AUTO ZERO

2. The transmitter then takes a zero level

reading.

• Combustible and Toxic sensors: If target

• First, the low and high

alarm setpoints are

displayed (8 seconds

approximately)

• Next the CAL icon

displays for 3 seconds

• Backlight is activated

• Numeric display reads

00

• Auto zero icon

flashes

Auto Zero Auto Zero Fail

gas is present, apply zero gas (pure air

or 100% nitrogen) to zero the sensor.

Restart the calibration sequence.

• Oxygen sensor: Gas is not required. Auto

zero sequence takes 30 to 60 seconds.

AUTO SPAN

3. Insert calibration cap. Refer to Figure 7 and

apply gas to the sensor for approximately 2

minutes (5 minutes for ammonia). Refer to

Table 16 for gas concentrations and flowrates.

4. When the countdown from 300 to 00 begins,

span is complete. Disconnect the gas cylinder.

• If Span fails: check the calibration gas cylinder

used and the concentration expected.

Replace the cylinder and/or change the

calibration gas expected, if required.

Recalibrate

• Oxygen sensor: Use pure air calibration gas

(20.9 % O

) in case of deficient or enriched

2

atmosphere.

CALIBRATION FAIL OR ERROR

Auto zero Fail: If the Fail icon displays, the LCD

displays a countdown from 300 to 00, before the

transmitter begins normal operation.

Auto Span Error: If the Error icon displays, the

LCD displays a countdown from 300 to 00, before

the transmitter enters normal operation.

Note:If either fail condition occurs, all previous

information values are retained. Retry calibration

• Numeric display

shows calibration

gas value expected

Auto Span Auto Span

Error

• K flashes

• Span icon displays

• Gas type is

constantly displayed

• After a successful

calibration, the

transmitter

automatically returns

to normal operation

and displays the

current reading (ppm

or %) present.

Auto Zero: If the target or an interfering gas is present, the transmitter

refuses to auto zero. The Fail icon displays. The Fail icon also displays if the

external pushbutton is pressed during auto zero.

Span: If the calibration gas is not within expected values, the transmitter

refuses to span. The Error icon displays.

17

Page 26

GasPoint

User Manual

Maintenance

To keep the transmitter in good operating condition, perform the following basic maintenance as required:

• Calibrate, test, and inspect the transmitter at regular intervals and after exposure to high concentrations.

• Keep an operations log of all maintenance, calibrations, and alarm events.

• Clean the exterior with a soft, damp cloth. Do not use solvents, soaps, or polishes.

• Do not immerse the transmitter in liquids.

Cleaning a Sensor

The sensors are equipped with a stainless steel sintered or a hastelloy sintered flame arrestor screen (dependent on gas). Clean

only with a dry brush being careful not to clog the screen. Replace the sensor if the screen is plugged.

Clearing a Sensor

The sensor has a high degree of resistance to common vapors and gases. The sensor most likely clears itself if you remove the

transmitter to a clean environment and wait 10 to 30 minutes. Do not expose a sensor to the fumes of inorganic solvents (such as

paint fumes) or organic solvents.

Troubleshooting

With enhanced diagnostics the transmitter provides extensive fault analysis and fault advice, refer to Fault Alarm Conditions and

Advice. The troubleshooting chart deals with other factors and is to be used as a guide. Prior to reaching any conclusion that a

problem may exist, check the following:

•

All terminal blocks are fully seated on the boards.

Power and signal connections are correct and complete.

•

No response to gas

Apparent false alarm

No signal at controller

Table 13. Troubleshooting Tips

Problem Possible Cause Solution

• Sensor screen dirty • Clean or replace sensor

• Puff of gas

• Not properly calibrated

• Solvent fumes or interference from high

levels of interfering gas

• Radio frequency interference

• Maximum distance reached

• Controller does not operate

• Monitor is functioning

• Recalibrate

• Remove source

• Check grounds and shielding are correct

• Verify loop resistance, change wire

AWG, or increase supply

• Troubleshoot controller

18

Page 27

GasPoint

Servicing the GasPoint

Servicing the GasPoint

Disassembling: Observe all safety and electrical codes and regulations before removing front cover. Unscrew the thumbscrew and

open the service bay door.

Assembling: When reassembling the transmitter, ensure that it is electrically complete. Close the service bay door. Ensure the

thumbscrew is aligned and tighten it down. Replace the outside glass cover. Reapply power and reinitialize the transmitter’s powerup procedure, refer to

Connecting the Controller and Power Supply. Change the alarm setpoints if desired.

Important: Calibrate the transmitter whenever a component is replaced.

Sensor Assembly Replacement

To replace the entire sensor assembly, complete the

following steps:

1. Power down the transmitter.

2. Disconnect the wires from the 4-pin plug-in terminal block

at J5 on the power board and remove the old sensor.

3. Feed the new wires through the opening. Fully screw in

the new sensor. Attach the wires to the plug-in terminal

block. Ensure that all colored wires are correctly matched

to the board labels from left to right. Refer to Figure 6.

a Caution: Check that all connections are correct.

Incorrect wiring may damage the sensor and/or the

power board.

4. Refer to Table 8 to select a measuring range if required.

Refer to

numbers.

Replacement Parts and Accessories for part

Table 14. Sensor Wiring Configuration

Board Label Wire Color Description

1 Pwr 8 Vdc Red Power 8 Vdc (left)

2 TX Grey Transmission

3 RX White Signal

4 GND Black Ground (right)

Other Component Replacement

1. Power down the transmitter.

2. Unplug the sensor terminal block from the power board

if required.

3.

Replace the component, ensuring all wiring connections

are complete and reassemble as shown in Figure 8.

Refer to

Ensure all field selectable options are set (measuring

4.

range, etc.).

Apply power and reinitialize power-up.

5.

Set the alarm setpoints if required.

6.

Installation

a Warning

Opening the sensor

will invalidate the

calibration.

Figure 9. Sensor Wiring Diagram

Table 15. GasPoint Replacement Parts

Qty Description Rating/TOL Part #

1 1 External faceplate window cover M1147

2 1 Internal hinged door faceplate cover M2345

3 1 Transmitter main LCD board (PCB) E2737/2

4 3 #6-32 x ¼ inch machine Phillips screws M0262

5 1 Threaded stand-off – accepts thumbscrews M2364

6 2 #6-32 x ¼ inch machine Phillips screws M0262

7 1 Plug-in ribbon cable E2800

8 1 Power/relay board (PCB) E2739/1

9 1 Transmitter housing c/w external switch M2346K

10 1 Sensor assembly various

Figure 8. Assembly Drawing

19

Page 28

GasPoint

User Manual

Specifications

Sensor Specifications

Table 16. Operating and Calibration Specifications

IR

Specifications

Repeatability % of signal 1 1 1 1 1 <10 0.5 2 0.1

Temperature Range °C

Relative Humidity Range 0 to 100%

Long Term Drift

% of signal loss per month Span:

LCD Increments 1% 1% 1 ppm 1 ppm 1 ppm 1 ppm 0.1 ppm 0.1 ppm 0.1%

Calibration1

Flow Rate (min). mls/minute

at a % or ppm reading of:

Sensor:

Replacement Part Numbers

Zero:

Combustibles

%LEL

-40 to +50

°F

-40 to +122

Non Condensing

Nominal

<1

250

50% LEL

IR-RW03 SS-RW02 SS-RH02 SS-RM02 SS-RS02 SS-RA02 SS-RZ02 SS-RD02 SS-RX02

1: It is recommended that the calibration gas concentration

for toxic sensors be 50% of the selected measuring range.

(Factory default values are shown.)

Auto span. Values expected by the transmitter for toxic

gases can be changed at any time. Refer to

Alarm Setpoints and Calibration Gas Setpoints section.

2: For oxygen use pure air calibration gas

Note: Performance data is based on conditions at

20°C, 50% RH, 1013 mBar.

Do not adjust the oxygen sensor span value.

Catalytic

Combustibles

%LEL

-40 to +90

-40 to +194

Nominal

<1

250

50% LEL

Changing the

Hydrogen

sulfide

H2S ppm

-40 to +50

-40 to +122

Nominal

<2

250

20 ppm

Carbon

monoxide

CO ppm

-20 to +50

-4 to +122

Nominal

<2

150

200 ppm

Sulfur dioxide

SO2 ppm

-20 to +50

-4 to +122

5 to 95% Non-condensing

Nominal

<2

250

20 ppm

Ammonia

NH3 ppm

-10 to +50

+14 to

+122

Nominal

<2

500

50 ppm

Hydrogen

cyanide

HCN ppm

-20 to +50

-4 to +122

Nominal

<2

250

15 ppm

Nitrogen

dioxide

NO2 ppm

-20 to +50

-4 to +122

Nominal

<2

1,000

10 ppm

Sensors:

Toxic and Oxygen: Electrochemical

Combustible: Catalytic or Infrared (IR)

Position Sensitivity: None

Operation Pressure Range: 900 to 1100 mBar

(atmospheric +/-10%)

Calibration Notes:

For maximum accuracy, calibrate with a mixture in the range

most measurements are made. For most purposes a 2

minute exposure is satisfactory. (NH

need a 5 minute exposure.)

, Cl2, ClO2, and HCl

3

-20 to +50

-4 to +122

Nominal

<1%

250

20.9 %

Oxygen

O2 % v/v

2

20

Page 29

GasPoint

Specifications

Relative Sensitivity of Combustible Gases/Vapors

Recommend: For the most accurate measurements, calibrate using the gas or vapor under investigation. Where this is not

possible see the applicable catalytic or infrared relative sensitivity table for combustible gases/vapors. The transmitter catalytic and

combustible sensors are calibrated to methane (with 50% methane calibration gas) at the factory prior to shipping.

Table 17. Catalytic Sensor Relative Sensitivity of Common

Gas/Vapor Relative

Methane 100 Carbon

Propane 60 Hydrogen 100

n-Butane 60 Ammonia 125

n-Pentane 50 Cyclohexane 50

n-Hexane 40 Ethylene 85

Acetylene 80

Each sensitivity has been rounded to the nearest 5%

Combustible Gases/Vapors

Gas/Vapor Relative

Sensitivity

monoxide

Sensitivity

105

Catalytic Bead Combustible Sensor

The table shows the variation of the catalytic combustible

sensor on exposure to a range of gases and vapors at the

same %LEL concentration. The figures are expressed

relative to the methane signal (=100).

The results are intended for guidance only. For a more

accurate measurement calibrate using the gas or vapor

under investigation.

Special Note on the Combustible Sensor

Certain substances have a detrimental effect on all catalytic

bead sensors. The GP-WD combustible sensor has a higher

degree of poison resistance and will outperform other

catalytic bead sensors in poisonous atmospheres. However,

catalytic sensors should not be exposed for prolonged

periods of time to lead or sulfur containing compounds,

silicones, or phosphates. Damage is cumulative and may

result in an irreversible decrease in sensitivity. Certain other

Table 18. Standard Model IR GasPoint Relative Sensitivity to

Gas/Vapor Relative

cis-Butane-2 450 Propane 410

trans-Butane-2 450 Propanol 230

Ethyl chloride 120* Mythyl chloride 100*

*The relative sensitivity is just an estimate.

This table is intended for guidance only.

Always calibrate using the gas or vapor under investigation.

Applicable Combustible Gases/Vapors

Sensitivity

Acetone 60 n-Hexane 325

n-Butane 450 Methane 100

iso-Butane 450 n-Pentane 390

Butane-1 450 iso-Pentane 390

Ethane 450 Propylene 310

Ethanol 330 o-Xylene 100

Ethylene 80 m-Xylene 100

n-Heptane 325 p-Xylene 100

MEK 365* Methanol 80*

IPA 410* Toulene 25*

Gas/Vapor Relative

Sensitivity

compounds, such as halogenated hydrocarbons and

hydrogen sulfide, may temporarily inhibit the sensor

performance, but in most cases it will recover after a period

in clean air.

Infrared (IR) Combustible Sensor

The standard model IR Combustible GasPoint is calibrated to

methane. The table shows the variation of the IR combustible

sensor on exposure to applicable group combustible

hydrocarbon gases and vapors at the same %LEL

concentration. The figures are expressed relative to the

methane signal (=100).

The results are intended for guidance only. For a more

accurate measurement, calibrate using the gas or vapor

under investigation.

a Caution: IR systems should always be calibrated as

soon as you install the system to compensate for any

change in pressure.

Note: If the hydrocarbon desired is not listed, special models

are available for other groups of hydrocarbons.

For IR sensors, use the specified gas to calibrate the

system. IR sensors work very well in low or no oxygen

conditions. IR sensors monitors the molar

concentration of the specific gases by a physical

method. No chemical reaction takes places inside the

sensor.

21

Page 30

GasPoint

User Manual

Specifications

Monitor: 3-wire, 4-20 mA gas transmitter with advanced micro-controller based circuitry

Power Input: 12 to 32 volts dc

Output Current: Normal Operation: Isolated linear 4-20 mA output

Calibration Mode: Steady 3 mA (automatic reset to normal operation)

Fault Mode: 2 mA signal (and less)

Current Consumption:

Toxic Versions: 40 mA at 24 Vdc

Catalytic Combustible Version: 100 mA at 24 Vdc

Infrared Combustible Version: 75 mA at 24 Vdc

Relays: 50 mA per relay at 24 Vdc

Sensors: Plug-in, logic sensors

Self-Test: Automatic self-test of sensor integrity upon power on

Calibration: Non-intrusive, via pushbutton

Auto Zero and Auto Span

Displays:

LCD 1: 3 digit continuous readout of the gas present (ppm or %LEL)

LCD 2: Alphanumeric diagnostic status display

Alarm Setpoints: Two (2) setpoints - User selectable

Relay Contacts:

Low/High: Field selectable for normally energized/de-energized and latching/non-latching

Fault: Normally energized and non-latching

Controls:

Calibration: Non-intrusive via external pushbuttonM

Alarm Setpoints: Simple up/down pushbuttons with LCD readout of setpoints

Physical:

Size (w x l x h): 6.8 x 7 x 4.3 in. (17 x 17.8 x 10.8 cm) including sensor

Weight: 4.85 lb. (2.2 kg) approximately

Enclosure: Explosion-proof, anodized aluminum enclosure c/w mounting flanges

Sensor: Stainless steel enclosure

Wiring Port: 3/4 inch n.p.t.

Warranty:

Instrument: 2 years non-prorated

Sensor: 2 years warranty

FCC Statement: This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to

Approval: Approved by CSA to both U.S. and Canadian standards:

Class I, Group B, C, D

Approved by CSA to both U.S. and Canadian standards:

Class II, Group E, F, G for toxic gas transmitter only

Approved to Combustible Performance Standards ISA-S12.13 and C22.2 No. 152

Two backlit liquid crystal displays (LCD)

Three field retro-fittable SPDT relays; 5 amps @ 250 Vac

Part 15 of the FCC Rules and ICES-003 Canadian EMI requirements. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed

and used in accordance with the instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely to cause harmful interference in

which case the user will be required to correct the interference at his own expense.

22

Page 31

GasPoint

Specifications

Replacement Parts and Accessories

Transmitters c/w Sensor Assemblies and Relays

Model No. Description Qty

GP-WD Transmitter c/w combustible sensor 1

GP-IR-WD Transmitter c/w IR combustible sensor 1

GP-HD Transmitter c/w hydrogen sulfide

GP-MD Transmitter c/w carbon monoxide

GP-SD Transmitter c/w sulfur dioxide sensor 1

GP-ZD Transmitter c/w hydrogen cyanide

GP-XD Transmitter c/w oxygen sensor 1

GP-AD Transmitter c/w ammonia sensor 1

GP-DD Transmitter c/w nitrogen dioxide

GP-CD Transmitter c/w chlorine sensor 1

GP-VD* Transmitter c/w chlorine dioxide

GP-YD* Transmitter c/w hydrogen sensor 1

GP-LD* Transmitter c/w hydrogen chloride

Add Suffix "-SS" for optional stainless steel transmitter enclosure

*Contact BW Technologies for sensor availability.

,ClO2 and HCl sensors are only certified for ordinary locations.

Cl

2

Sensor Assembly enclosures are stainless steel (standard)

Accessories and Spares

Model No. Description Qty

D2DT Duck mounting kit

GP-DUC-K1 Duct mount adapter

GP-1 Gas transmitter only c/w LCDs

GP-SEP Sensor separation kit

GP-MBUS3 MODBUS communication

GP-MBUS4 MODBUS communication

IR-RW03 IR combustible sensor

SS-RA02 Ammonia sensor assembly

SS-RC02 Chlorine sensor assembly

SS-RD02 Nitrogen dioxide sensor

SS-RH02 Hydrogen sulfide sensor

SS-RL02 Hydrogen chrloride sensor

SS-RM02 Carbon monoxide sensor

SS-RS02 Sulfur dioxide sensor assembly

sensor

sensor

sensor

sensor

sensor

sensor

and relays (no sensor)

expansion module

expansion module

assembly

assembly

assembly

assembly

assembly

Model No. Description Qty

SS-RW02 Combustible sensor assembly

SS-RX02 Oxygen sensor assembly

SS-RZ02 Hydrogen cyanide sensor

assembly

1

1

E0036 Calibration plug

GP-CAL-3 Non-conductive remote

1

1

1

1

1

calibration cup and splash

guard

1

GP-SSPLASH4 Stainless Steel splash guard

GP-SSCAL4 Stainless steel remote

1

1

calibration cup and splash

guard

1

GPOINT-B GasPoint pushbutton protective

1

boot

1

1

GP-FP-MPCB1 PCB – main control board with

LCDs and internal faceplate

GP-MPCB1 PCB - main control board with

LCD

GP-PPCB1 PCB – power board with relays

GP-HART Hart communication expansion

module (2-wire system)

GP-2210 Internal faceplate with hinge

and label

M1147 Enclosure with glass window

1

1

1

GP-POWER1 Power supply 110/220 Vac – 24

Vdc

GP-SSPB Stainless steel process baffle

GP-SSPB-2 Stainless steel process baffle

1

1

D1374 User manual

with NPT fitting

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

23

Page 32

GasPoint

User Manual

24

Page 33

GasPoint

Specifications

25

Page 34

GasPoint

User Manual

26

Page 35

D1374/5 (English)

iERP: 122635

© 2006 BW Technologies, all rights reserved. Printed in Canada.

All product names are trademarks of their respective companies.

Page 36

Corporate Headquarters

Calgary, Alberta

Calibration Flow Rates

The following information has changed in the user manual.

D1374/4 Page 26

D1374/5 Page 20

Operating and Calibration Specifications

Hydrogen

Specifications

Calibration

Flow rate (min). ml/minute

at a % or ppm reading of:

1: It is recommended that the calibration

gas concentration for toxic sensors be

50% of the selected mesuring range.

(Factory default values are shown).

Auto span. Values expected by the

transmitter for toxic gases can be changed

at any time. Refer to Changing the Alarm

Setpoints and Calibration Gas Setpoints in

the user manual.

2: For oxygen use pure air calibration gas.

1

:

sulfide

H2S ppm

250–500

20 ppm

Carbon

monoxide

CO ppm

250–500

200 ppm

Sulfur

dioxide

SO2 ppm

250–500

20 ppm

Note:

Ammonia

NH3 ppm

500–1000

50 ppm

Performance data is based on conditions at 20°C, 50%

RH, 1013 mBar.

Do not adjust the oxygen sensor span value.

Hydrogen

cyanide

HCN ppm

250–500

15 ppm

Nitrogen

dioxide

NO2 ppm

500–1000

10 ppm

Oxygen

O2 % v/v

250–500

20.9%

123179

GasPoint

2

Loading...

Loading...