Page 1

1, 2, 3, 4, 5 Gas Detector

Quick Reference Guide

Page 2

BW Technologies LP (BW) warrants the product to be free from defects in material and workmanship under normal use and service for a period of

two years, beginning on the date of shipment to the buyer. This warranty extends only to the sale of new and unused products to the original buyer.

BW’s warranty obligation is limited, at BW’s option, to refund of the purchase price, repair or replacement of a defective product that is returned to

a BW authorized service center within the warranty period. In no event shall BW’s liability hereunder exceed the purchase price actually paid by the

buyer for the Product.

This warranty does not include:

a) fuses, disposable batteries or the routine replacement of parts due to the normal wear and tear of the product arising from use;

b) any product which in BW’s opinion, has been misused, altered, neglected or damaged, by accident or abnormal conditions of operation,

handling or use;

c) any damage or defects attributable to repair of the product by any person other than an authorized dealer, or the installation of unapproved

parts on the product; or

The obligations set forth in this warranty are conditional on:

a) proper storage, installation, calibration, use, maintenance and compliance with the product manual instructions and any other applicable

recommendations of BW;

b) the buyer promptly notifying BW of any defect and, if required, promptly making the product available for correction. No goods shall be

returned to BW until receipt by the buyer of shipping instructions from BW; and

c) the right of BW to require that the buyer provide proof of purchase such as the original invoice, bill of sale or packing slip to establish that the

product is within the warranty period.

THE BUYER AGREES THAT THIS WARRANTY IS THE BUYER’S SOLE AND EXCLUSIVE REMEDY AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED,

INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. BW SHALL NOT BE LIABLE FOR ANY

SPECIAL

, INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES OR LOSSES, INCLUDING LOSS OF DATA, WHETHER ARISING FROM BREACH OF WARRANTY OR

BASED ON CONTRACT

Since some countries or states do not allow limitation of the term of an implied warranty, or exclusion or limitation of incidental or consequential

damages, the limitations and exclusions of this warranty may not apply to every buyer. If any provision of this warranty is held invalid or

unenforceable by a court of competent jurisdiction, such holding will not affect the validity or enforceability of any other provision.

, TORT OR RELIANCE OR ANY OTHER THEORY.

Warranty Registration

Limited Warranty and Limitation Liability

http://www.honeywellanalytics.com/support/product-registration

Contacting BW Technologies by Honeywell

USA & Canada: 1-888-749-8878 Europe: 00800-333-222-44 Other countries: 1-403-248-9226

Bwa.customerservice@honeywell.com www.honeywellanalytics.com

Page 3

GasAlertMicro 5/PID/IR

Table of Contents

Limited Warranty and Limitation Liability ..............0

Warranty Registration ..............................................0

Contacting BW Technologies by Honeywell .........0

Introduction ..............................................................1

Safety Information - Read First ............................... 1

Informations de sécurité – À lire au préalable ......4

Sensor Poisons and Contaminants ........................7

Parts of the GasAlertMicro 5/PID/IR .......................8

Display Elements .....................................................9

Button ......................................................................10

Connecting the Gas Cylinder to the Detector .....10

Single Gas Calibration Cap .........................................11

Removing the Cap .................................................. 11

Pump .......................................................................12

Identifying the Pump ...................................................12

Pump Features ...........................................................13

Pump Alarm ................................................................13

Confined Space Sampling ..........................................13

Maximum Hose Length when Confined Space

Sampling ................................................................. 14

Bump Test ...............................................................15

Performing a Bump Test .............................................15

Calibration ..............................................................16

Alarms .....................................................................18

User Options Menu ................................................21

Maintenance ...........................................................22

Replacing Battery Cells and Packs ...................... 23

Replacing Alkaline Batteries ...................................... 24

Replacing Lithium Battery Packs ............................... 25

WEEE Directive and Battery Directive ....................... 25

Removal and Disposal of the Battery Pack ............ 25

Removal and Disposal of the Coin Cell.................. 26

Replacing a Sensor or Sensor Filter .......................... 28

Replacing the Pump Filter (Generation 2 Pump only) 29

Replacing the Pump Nozzle (Generation 2 Pump only)

30

Specifications .........................................................30

Information Required for European Regulations

Compliance .............................................................34

Tested Sensors ...................................................... 35

Performance Data According to EN 45544 Part 1 and 2

35

Troubleshooting .....................................................36

Replacement Parts and Accessories ................... 42

i

Page 4

Page 5

GasAlertMicro 5/PID/IR

Introduction

GasAlertMicro 5/PID/IR

Introduction

The quick reference guide provides basic information to operate

the GasAlertMicro 5, GasAlertMicro 5 PID, and GasAlertMicro 5

IR gas detectors. For complete operating instructions, refer to

the GasAlertMicro 5/PID/IR User Manual provided on the

CD-ROM.

The GasAlertMicro 5, GasAlertMicro 5 PID, and

GasAlertMicro 5 IR detectors (“the detector”) are designed to

warn of hazardous gas levels above user-defined alarm

setpoints.

Note

Unless reference is made to a specific detector

model, the GasAlertMicro 5, GasAlertMicro 5 PID,

and GasAlertMicro 5 IR detectors are referred to as

GasAlertMicro 5/PID/IR.

The detector is shipped with English as the default

displayed language. Additional languages provided

are French, German, Spanish, and Portuguese. The

screens for the additional languages are displayed on

the detector and in the corresponding quick reference

guide.

Safety Information - Read First

Use the detector only as specified in this quick reference guide

and the user manual, otherwise the protection provided by the

detector may be impaired.

The detector is a personal safety device. It is your responsibility

to respond properly to the alarm.

Read the following

• Warning: Substitution of components may impair

Intrinsic Safety.

• Caution: For safety reasons, this equipment must be

operated and serviced by qualified personnel only. Read

and understand the user manual completely before

operating or servicing.

• Charge the detector before first-time use. BW

recommends the detector be charged after every

workday.

• Charge the battery pack immediately when a low battery

alarm occurs.

• Read and adhere to the battery cautions provided in

Replacing Battery Cells and Packs on page 23.

Cautions before using the detector.

a

Cautions

1

Page 6

GasAlertMicro 5/PID/IR

Quick Reference Guide

• BW recommends that the combustible sensor be

checked with a known concentration of calibration gas

after any exposure to contaminants/poisons such as

sulfur compounds, silicon vapors, halogenated

compounds, etc.

• BW recommends to bump test the sensors before each

day’s use to confirm their ability to respond to gas by

exposing the detector to a gas concentration that

exceeds the alarm setpoints. Manually verify that the

audible and visual alarms are activated. Calibrate if the

readings are not within the specified limits.

• For an additional bump test caution relating to the

European Regulations, refer to

• Calibrate the detector before first-time use and then on

a regular schedule, depending on use and sensor

exposure to poisons and contaminants. The sensors

must be calibrated regularly and at least once every

180 days (6 months).

• Calibrate only in a safe area that is free of hazardous

gas in an atmosphere of 20.9% oxygen.

• Only the combustible gas detection portion of this

instrument has been assessed for performance by CSA

International.

• The combustible sensor is factory calibrated to 50%

LEL methane. If monitoring a different combustible gas

in the % LEL range, calibrate the sensor using the

appropriate gas.

• Caution: High off-scale LEL readings may indicate an

explosive concentration.

page 15.

2

• Protect the combustible sensor from exposure to lead

compounds, silicones, and chlorinated hydrocarbons.

Although certain organic vapors (such as leaded

gasoline and halogenated hydrocarbons) may

temporarily inhibit sensor performance, in most cases,

the sensor will recover after calibration.

• For use only in potentially explosive atmospheres

where oxygen concentrations do not exceed 20.9%

(v/v). Oxygen deficient atmospheres (<10% v/v) may

suppress some sensor outputs.

• Any rapid up scaling reading followed by a declining or

erratic reading may indicate a gas concentration

beyond the upper scale limit, which can be hazardous.

• Extended exposure of the GasAlertMicro 5,

GasAlertMicro 5 PID, or GasAlertMicro 5 IR to certain

concentrations of combustible gases and air may stress

the detector element that can seriously affect its

performance. If an alarm occurs due to a high

concentration of combustible gases, recalibration

should be performed or, if needed, the sensor replaced.

• The BW pump module (M5-PUMP) is certified for use

with the GasAlertMicro 5, GasAlertMicro 5 PID, and

GasAlertMicro 5 IR models only.

• Protect the PID sensor from exposure to silicone

vapors.

• When calibrating O

in the Toxic 2 position of the detector, a single gas

calibration cap must be used to ensure accurate

calibration.

and ClO2 sensors that are located

3

Page 7

• Replace the sensors only in a safe and non-hazardous

area that is free of hazardous gas in an atmosphere of

20.9% oxygen.

• Warning: The battery pack (M5-BAT08) is equipped with

a lithium battery that may present a risk of fire or

chemical burn hazard if misused. Do not disassemble,

heat above 212ºF (100ºC), or incinerate.

• Warning: Do not use any other lithium batteries that are

not designed for use with the GasAlertMicro 5,

GasAlertMicro5 PID, or GasAlertMicro5 IR detectors.

Use of any other cell can cause fire and/or explosion. To

order and replace the M5-BAT07 or the M5IR-BAT08

lithium battery pack, contact BW Technologies by

Honeywell.

• Warning: Lithium polymer cells exposed to heat at

266°F (130°C) for 10 minutes can cause fire and/or

explosion.

• Dispose of used lithium cells immediately. Do not

disassemble and do not dispose of in fire. Do not mix

with the solid waste stream. Spent batteries must be

disposed of by a qualified recycler or hazardous

materials handler.

• Keep lithium cells away from children.

• Before using common products around sensors, refer

to

Sensor Poisons and Contaminants on page 4.

GasAlertMicro 5/PID/IR

Safety Information - Read First

• High concentrations of certain toxic gases, for example

H

S, may have an adverse effect on the LEL sensor.

2

This effect, known as inhibition, is usually temporary

but in extreme circumstances can impair the sensitivity

of the LEL sensor.

• After any gas exposure that causes an alarm in the toxic

gas sensors, the LEL sensor should be verified with a

bump test, and recalibrated if necessary.

• Products may contain materials that are regulated for

transportation under domestic and international

dangerous goods regulations. Return product in

compliance with appropriate dangerous goods

regulations. Contact freight carrier for further

instructions.

The detector contains either alkaline batteries or a lithium

polymer battery. Refer to the following warnings.

ce Warning

This instrument contains alkaline batteries. Do not mix

with the solid waste stream. Spent batteries must be

disposed of by a qualified recycler or hazardous materials

handler.

ce Warning

This instrument contains a lithium polymer battery.

Dispose of lithium cells immediately. Do not disassemble

and do not dispose of in fire. Do not mix with the solid

waste stream. Spent batteries should be disposed of by a

qualified recycler or hazardous materials handler.

3

Page 8

GasAlertMicro 5/PID/IR

Quick Reference Guide

Informations de sécurité – À lire au préalable

Utilisez le détecteur dans le seul but indiqué dans ce mémento

et dans le manuel d'utilisation, sous peine de porter préjudice à

la protection assurée par le détecteur.

Le détecteur est un appareil de sécurité individuel. Il est de

votre responsabilité de réagir à l'alarme de manière appropriée.

Lisez les

Mises en garde suivantes avant d'utiliser le détecteur.

a

• Avertissement : Le remplacement d'un composant de

l'appareil peut compromettre la sécurité intrinsèque du

détecteur.

• Attention : Pour des raisons de sécurité, cet appareil

doit être utilisé et entretenu par du personnel qualifié

uniquement. Lisez attentivement le manuel d'utilisation

avant d'utiliser l'appareil ou d'en assurer l'entretien et

assurez-vous d'en avoir bien compris les instructions.

• Chargez le détecteur avant sa première utilisation. BW

recommande de recharger le détecteur après chaque

journée d'utilisation.

• Chargez la batterie dès l'émission d'une alarme de

batterie faible.

• Lisez et respectez les avertissements donnés à la section

Remplacement des batteries et des piles, page 23.

4

Mises en garde

• BW recommande de contrôler le capteur de gaz

combustibles à l'aide d'une concentration connue de

gaz d'étalonnage après toute exposition à des

contaminants/poisons (composés de soufre, vapeurs de

silicium, produits halogénés, etc.)

• Avant chaque utilisation quotidienne, BW recommande

d'effectuer un test fonctionnel des capteurs afin de

vérifier qu'ils réagissent bien aux gaz présents, en

exposant le détecteur à une concentration de gaz

supérieure aux seuils d'alarme. Vérifiez manuellement

que les alarmes sonore et visuelle sont activées.

Étalonnez l'appareil si les relevés ne sont pas

conformes aux limites spécifiées.

• Pour une mise en garde supplémentaire sur le test

fonctionnel en rapport avec la réglementation

européenne, reportez-vous à la

• Étalonnez le détecteur avant sa première utilisation,

puis de manière régulière, en fonction de l'utilisation et

de l'exposition du capteur aux poisons et autres

contaminants. Les capteurs doivent être étalonnés

régulièrement et au moins une fois tous les 180 jours

(6 mois).

• Veillez à effectuer l'étalonnage dans une zone sûre,

exempte de gaz dangereux, dans une atmosphère

contenant 20,9 % d'oxygène.

• Seul l'élément de détection de gaz combustibles de cet

appareil a fait l'objet d'une évaluation des performances

homologuée par CSA International.

page 15.

Page 9

• Le capteur de gaz combustibles est étalonné en usine

au méthane, à une concentration de 50 % de la LIE. Si la

surveillance porte sur un autre gaz combustible dans la

plage % LIE, étalonnez le capteur en utilisant le gaz

approprié.

• Attention : Des valeurs LIE hors échelle élevées peuvent

indiquer la présence d'une concentration explosive.

• Protégez le capteur de gaz combustibles contre toute

exposition aux composés de plomb, aux silicones et

aux hydrocarbures chlorés. Bien que certaines vapeurs

organiques (comme l'essence au plomb ou les

hydrocarbures halogénés) puissent neutraliser

provisoirement les performances du capteur, dans la

plupart des cas, le capteur retrouvera son

fonctionnement normal après étalonnage.

• Cet appareil est destiné uniquement à une utilisation

dans des atmosphères potentiellement explosives, dans

lesquelles la concentration d'oxygène ne dépasse pas

20,9 % (v/v). Les atmosphères appauvries en oxygène

(<10 % v/v) peuvent inhiber certaines sorties du capteur.

• Toute mesure en rapide augmentation suivie d'une

diminution ou d'une mesure fantaisiste peut indiquer

une concentration de gaz au-delà de la limite d'échelle

supérieure, risquant donc d'être dangereuse.

Informations de sécurité – À lire au préalable

GasAlertMicro 5/PID/IR

• L'exposition prolongée du GasAlertMicro 5,

GasAlertMicro 5 PID ou GasAlertMicro 5 IR à certaines

concentrations de gaz combustibles et d'air peut

fortement solliciter l'élément du détecteur et nuire

gravement à ses performances. En cas d'alarme suite à

une forte concentration de gaz combustible, il convient

d'effectuer un réétalonnage, voire de remplacer le

capteur si nécessaire.

• Le module de pompe BW (M5-PUMP) est certifié pour

les modèles GasAlertMicro 5, GasAlertMicro 5 PID et

GasAlertMicro 5 IR uniquement.

• Protégez le capteur à photo-ionisation (PID) des

expositions aux vapeurs de silicium.

• Pour garantir un étalonnage précis des capteurs d'O

de ClO

placés en position toxique 2 du détecteur,

2

employez un seul capuchon d'étalonnage monogaz.

• Remplacez les capteurs uniquement en zone sûre et non

dangereuse, dans une atmosphère exempte de gaz

dangereux et contenant 20,9 % d'oxygène.

• Avertissement : La batterie (M5-BAT08) est constituée

d'une pile au lithium qui pourrait présenter un risque

d'incendie ou de brûlure chimique en cas de mauvaise

utilisation. Ne pas la démonter ni la chauffer au-delà de

100 °C (212 °F) ou l'incinérer.

et

3

5

Page 10

GasAlertMicro 5/PID/IR

Quick Reference Guide

• Avertissement : N'utilisez jamais d'autres piles au

lithium avec les détecteurs GasAlertMicro 5,

GasAlertMicro5 PID ou GasAlertMicro5 IR Toute autre

batterie pourrait provoquer un incendie et/ou une

explosion. Pour commander ou remplacer la batterie au

lithium M5-BAT07 ou M5IR-BAT08, contactez BW

Technologies by Honeywell.

• Avertissement : Les batteries au lithium polymère

exposées à une température supérieure à 130 °C

(266 °F) pendant plus de 10 minutes peuvent provoquer

un incendie et/ou une explosion.

• Mettez immédiatement au rebut les batteries au lithium

usagées. Veillez à ne jamais les démonter ou les jeter au

feu. Ne pas les mélanger aux autres déchets solides.

Les piles usagées doivent être éliminées par un centre

de recyclage agréé ou un centre de traitement des

matières dangereuses.

• Conservez les batteries au lithium hors de portée des

enfants.

• Avant d'utiliser des produits usuels à proximité des

capteurs, reportez-vous à la section

contaminants des capteurs, page 5.

Poisons et

6

• Des concentrations élevées en certains gaz toxiques, tels

que H

S, peuvent avoir un effet néfaste sur le capteur

2

LIE. Cet effet, appelé inhibition, est généralement

temporaire, mais peut, dans des conditions extrêmes,

altérer la sensibilité du capteur LIE.

Après toute exposition à un gaz entraînant le

déclenchement d'une alarme des capteurs de gaz

toxiques, le capteur LIE devra subir un test fonctionnel

et être réétalonné si nécessaire.

• Les produits peuvent contenir des matériaux qui sont

réglementés pour le transport en vertu des règlements

nationaux et internationaux de marchandises

dangereuses. Retourner le produit conformément à la

réglementation sur les marchandises dangereuses

appropriées. Contactez transporteur pour plus

d'instructions.

Le détecteur contient des piles alcalines ou une batterie au

lithium polymère. Reportez-vous aux avertissements suivants.

Avertissement CE

Cet appareil contient des piles alcalines. Ne pas les

mélanger aux autres déchets solides. Les piles usagées

doivent être éliminées par un centre de recyclage agréé ou

un centre de traitement des matières dangereuses.

Avertissement CE

Cet appareil contient une batterie au lithium polymère.

Mettez immédiatement au rebut les batteries au lithium

Page 11

usagées. Veillez à ne jamais les démonter ou les jeter au

feu. Ne pas les mélanger aux autres déchets solides. Les

piles usagées doivent être éliminées par un centre de

recyclage agréé ou par un centre de traitement des

matières dangereuses.

Sensor Poisons and Contaminants

Several cleaners, solvents, and lubricants can contaminate and

cause permanent damage to sensors. Before using cleaners,

solvents, and lubricants in close proximity to the detector

sensors, read and adhere to the following caution and table.

a

Caution

Use only the following BW Technologies by Honeywell

recommended products and procedures:

• Use water based cleaners.

• Use non-alcohol based cleaners.

• Clean the exterior with a soft, damp cloth.

• Do not use soaps, polishes, or solvents.

Sensor Poisons and Contaminants

GasAlertMicro 5/PID/IR

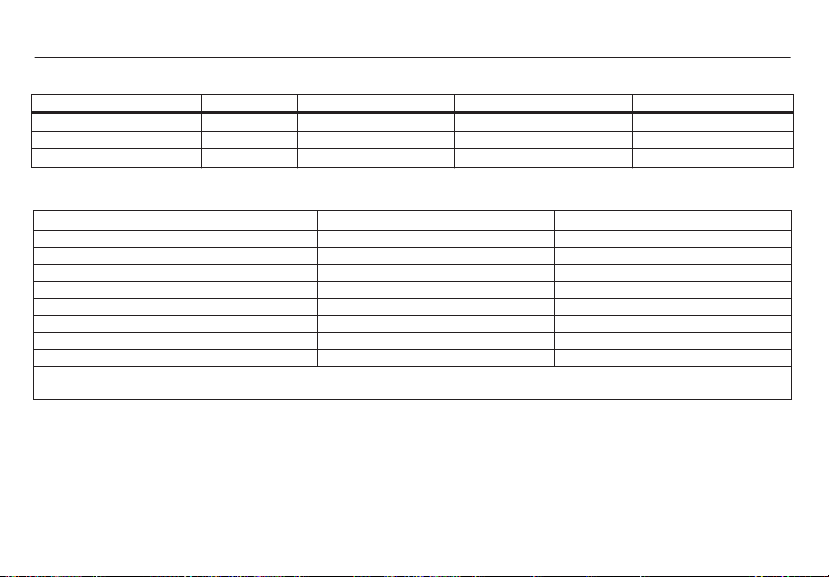

The following table lists common products to avoid using

around sensors.

Cleaners and

Lubricants

• Brake cleaners

• Lubricants

• Rust inhibitors

• Window and glass

cleaners

• Dishsoaps

• Citrus based

cleaners

• Alcohol based

cleaners

• Hand sanitizers

• Anionic detergents

• Methanol (fuels and

antifreezes)

Silicones Aerosols

• Silicone based

adhesives, sealants, and

gels

• Hand/body and

medicinal creams

containing silicone

• Tissues containing

silicone

• Mold releasing agents

• Polishes

• Bug

repellents

and sprays

• Lubricants

• Rust

inhibitors

• Window and

glass

cleaners

7

Page 12

GasAlertMicro 5/PID/IR

Quick Reference Guide

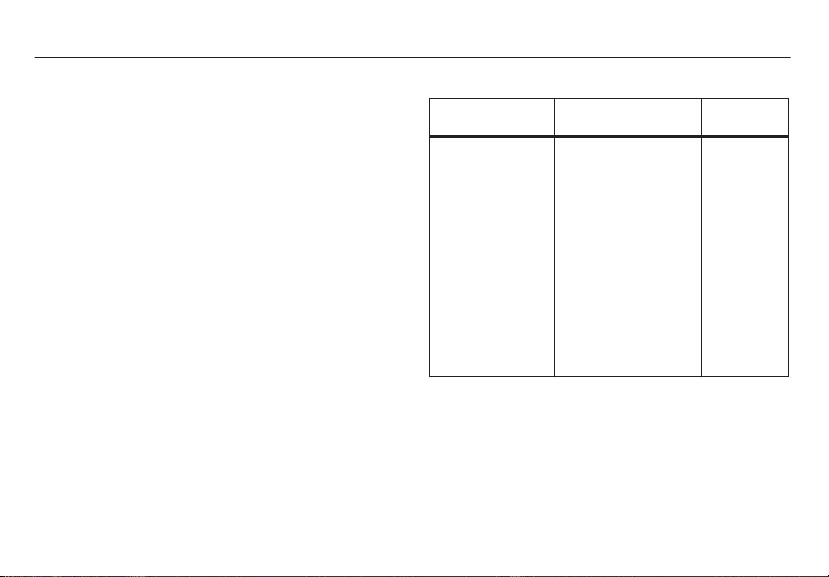

Parts of the GasAlertMicro 5/PID/IR

8

Item Description

1 Liquid crystal display (LCD)

2 Pushbuttons

3 Audible alarms

4 Toxic 2 sensor

Toxic 1/PID sensor (GasAlertMicro 5 PID), or

5

Toxic 1/IR (CO

6 Visual alarm indicators (LEDs)

7 LEL sensor

8 Oxygen sensor

9 Pushbuttons

10 Battery pack

11 Alligator clip

) sensor (GasAlertMicro 5 IR)

2

Page 13

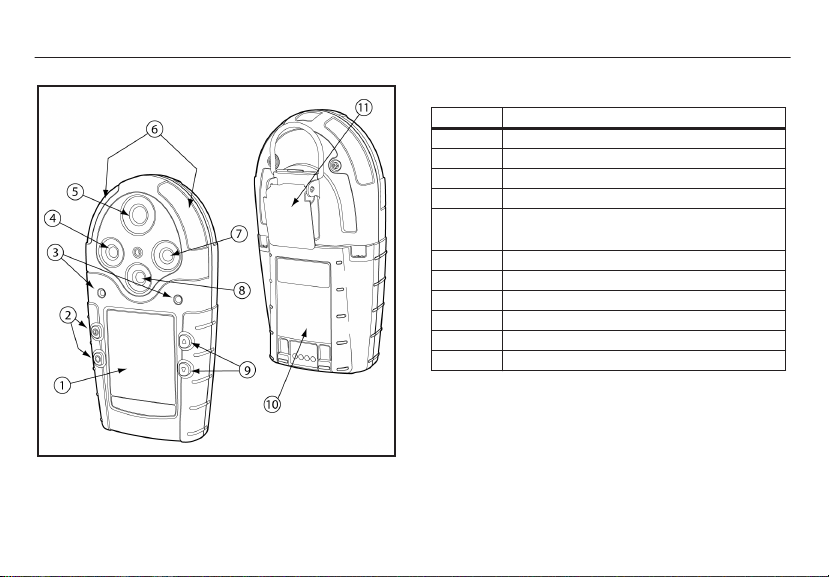

Display Elements

GasAlertMicro 5/PID/IR

Item Description

1 Alarm condition

2 Automatically span sensor

3 Gas cylinder

4 Gas identifier bars

5 Battery life indicator

6 Passcode lock

7 Data transmission

8 Clock

9 Stealth mode

10 Optional pump indicator

11 Datalog card indicator (optional)

12

13 Automatically zero sensor

Alarm condition (low, high, TWA, STEL, or

multi) or view TWA, STEL and peak (MAX)

gas exposures

Display Elements

9

Page 14

GasAlertMicro 5/PID/IR

Quick Reference Guide

Button Connecting the Gas Cylinder to the Detector

Button Description

• To activate the detector, press A.

A

G

H

C

10

• To deactivate the detector, press and hold

A until the countdown is complete.

• To increment the displayed value or scroll

• To enter the user option menu, press

• To clear the TWA, STEL, and peak (MAX)

• To view the date and time, alarm setpoints

• To decrement the displayed value or scroll

• To initiate calibration and setting alarm

• To view the TWA, STEL, and peak (MAX)

• To acknowledge latched alarms, press

G.

up, press

and H simultaneously and hold until the

countdown is complete.

gas exposure readings, press C and G

simultaneously and hold until the

countdown is complete.

(TWA, STEL, low, and high) of all sensors,

and the LEL correction factor (if

applicable), press

down, press

setpoints, press

and hold until the countdown is complete.

readings, press

G.

H.

C and H simultaneously

C.

G

C.

Page 15

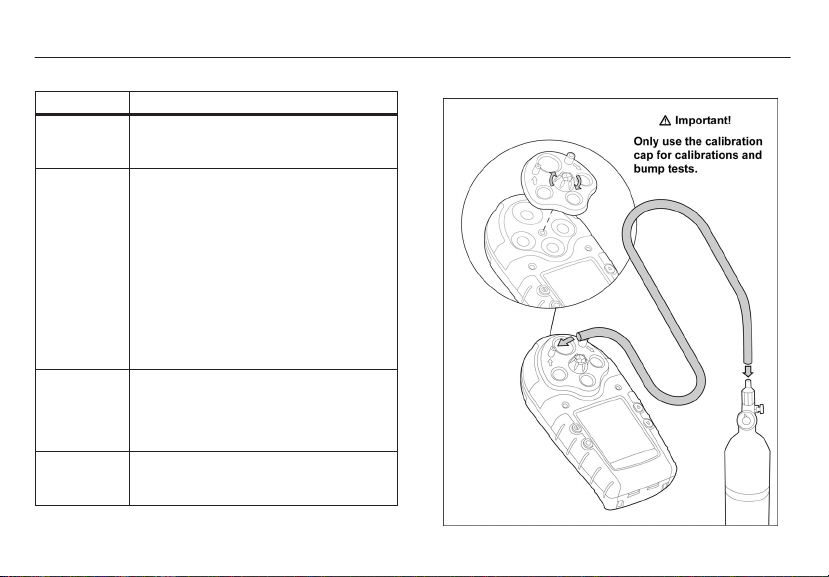

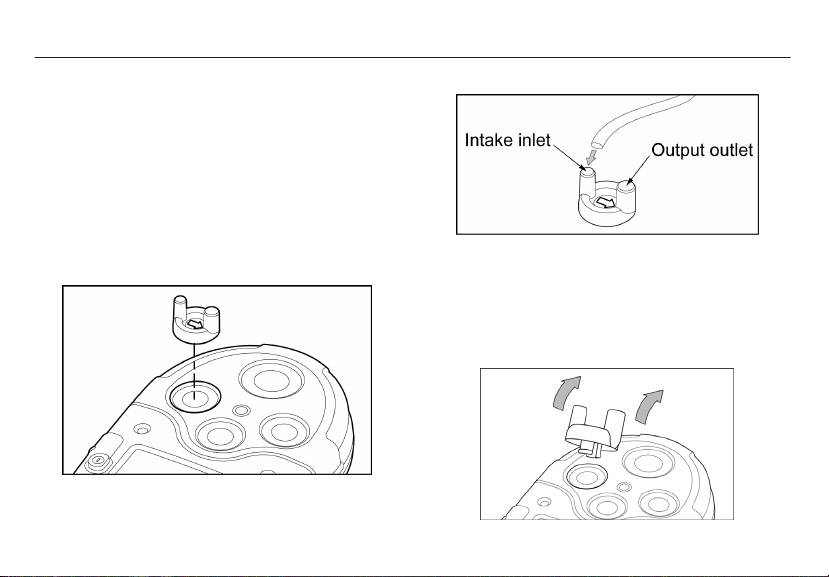

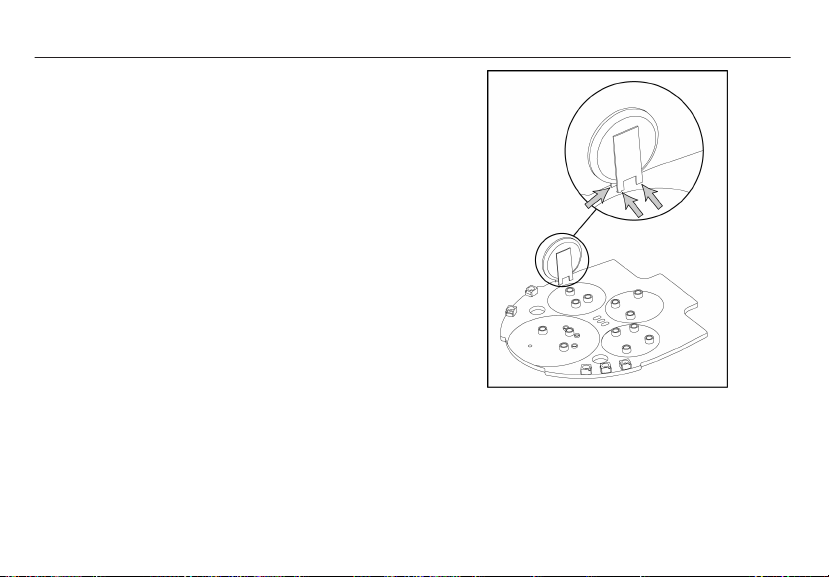

Single Gas Calibration Cap

a Caution

If an O3 or ClO2 sensor is located in the Toxic 2 sensor

position, a single gas calibration cap must be used to

ensure accurate calibration.

Only use the single gas calibration cap during the

calibration process.

To calibrate O

calibration cap, refer to the following procedures and

illustrations.

and ClO2 sensors using the single gas

3

1. Insert the cap into the Toxic 2 sensor position on the

detector. Press firmly until the release tabs click.

Connecting the Gas Cylinder to the Detector

GasAlertMicro 5/PID/IR

2. Connect the calibration hose to the gas cylinder and

to the intake inlet on the cap.

Note

The arrow on the cap indicates the direction of gas

flow from intake to outtake.

Removing the Cap

Using your thumb, push forward against both the inlet and

outlet simultaneously to remove the cap from the detector.

11

Page 16

GasAlertMicro 5/PID/IR

Quick Reference Guide

Pump

When using the pump module, attach it and the pump

accessories prior to activating the detector.

For more information on the pump, refer to the

GasAlertMicro 5/PID/IR User Manual.

a

Warning

If the pump module is installed on the detector, the

following three things must occur during start-up. If any

one of the conditions below does not occur, discontinue

use of the detector and contact BW Technologies by

Honeywell immediately.

• The detector prompts for a pump test during start-up

• The pump module passes the pump test at start-up

when the pump inlet or sample chain inlet is blocked

• The J icon displays on the LCD

To ensure accurate gas detection, the sensors must be

calibrated immediately when the pump module is

replaced by the diffusion cap and vice versa.

When using the sample probe at -10°C to +0°C (14°F to

32°F), keep the sample probe in your hand.

a

Caution

A demand flow regulator must be used to manually

calibrate the GasAlertMicro 5/PID/IR detector when the

pump module is installed.

The calibration cap is designed for use with the diffusion

cap only. It cannot be used with the pump module.

12

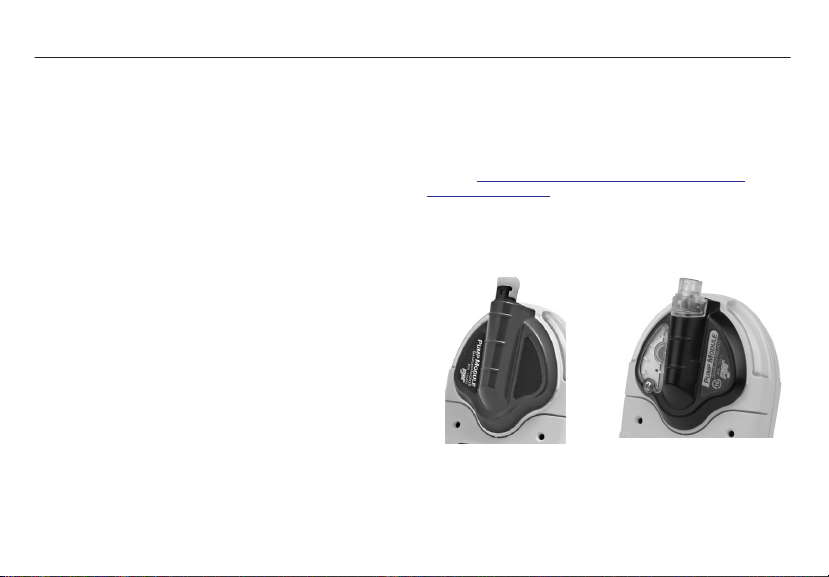

Identifying the Pump

There are two generations of pump. The best way to

differentiate the Generation 2 pump from the Generation 1

pump is the inline filter that is visible on the Generation 2 pump

on the left-hand side.

Each model of pump has different operating specifications.

Refer to

Maximum Hose Length when Confined Space

Sampling on page 14.

Generation 1: 116885-L3

(yellow) and 118933-L3

(black)

Performance approved conditions

Generation 2: 130916-L3*

(yellow) and 130917-L3

(black)

*Note

Page 17

Pump Features

To replace the pump filter and pump nozzle for the Generation 2

pump, refer to

only) on page 29 and Replacing the Pump Nozzle (Generation

2 Pump only) on page 30.

To replace the pump filter for the Generation 1 pump, refer to

the GasAlertMicro 5/PID/IR User Manual. The pump nozzle

cannot be replaced.

Replacing the Pump Filter (Generation 2 Pump

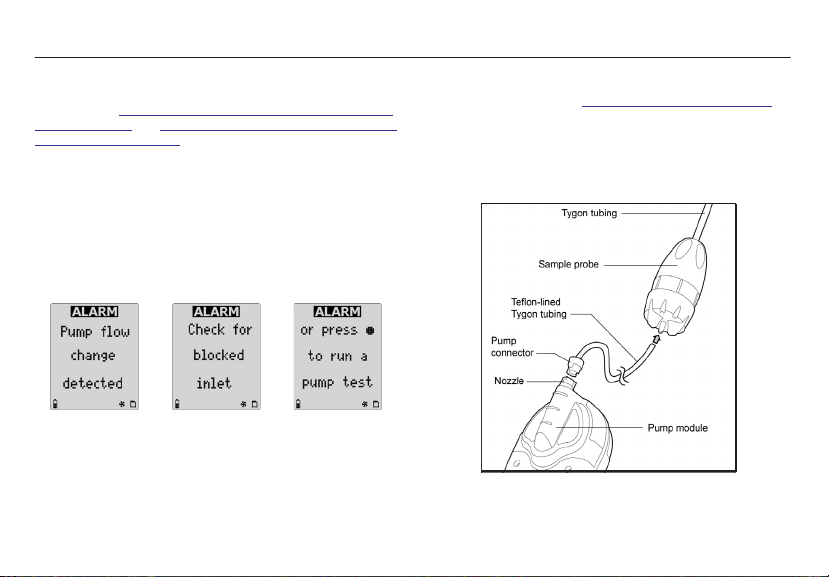

Pump Alarm

The external pump draws air over the sensors continually. If the

pump stops operating or becomes blocked, the detector

activates the pump alarm and the pump alarm latches. The

following screens display.

a

Caution

Ensure the blockage is cleared before pressing C to

acknowledge the latched pump alarm.

When C is pressed, the detector automatically launches a

pump test to reset the pump module.

GasAlertMicro 5/PID/IR

Pump

If the pump test is successful, the detector returns to normal

operation, otherwise the pump alarm continues. If the pump

alarm persists, refer to the

the guide or in the Pump Operation section in Troubleshooting

in the GasAlertMicro 5/PID/IR User Manual.

Pump Operation Troubleshooting in

Confined Space Sampling

To measure hazardous gas in a confined space, refer to the

following illustration and steps 1-5.

The detector and pump module can also be used with a

sintered filter.

13

Page 18

GasAlertMicro 5/PID/IR

Quick Reference Guide

a Warning

To measure hazardous gas in a confined space, the

sample probe must be used with the pump module.

a

Caution

To prevent the teflon lining inside the Tygon tubing from

causing a blockage when connecting it to the sample

probe, the end of the tubing must be flared. Refer to

steps 2 and 3.

1. Attach the pump connector end of the teflon-lined

Tygon tubing to the pump module.

2. Gently insert needle nose pliers into the other end of

the teflon-lined Tygon tubing. Using a circular motion,

flare the end of the tubing.

3. Connect the flared end of the tubing to the sample

probe. Ensure the teflon-lining does not separate

from the Tygon tubing, as it will block the tube and

generate a pump alarm.

4. Activate the detector. Ensure all connections are

secure before sampling.

5. Insert the sample probe into the confined space.

a

Warning

Depending upon the length of the tubing and the type of

gas in the confined space, allow a minimum of 3 seconds

per foot of tubing to ensure the readings stabilize before

entering the area.

Example: 10 ft. = 30 seconds

14

Maximum Hose Length when Confined Space Sampling

Maximum sample hose length is dependent on pump model,

operating temperature, and sampling accessory. Refer to the

tables below.

a

Caution

Maximum sample hose length is dependent on an inner

1/16” hose diameter.

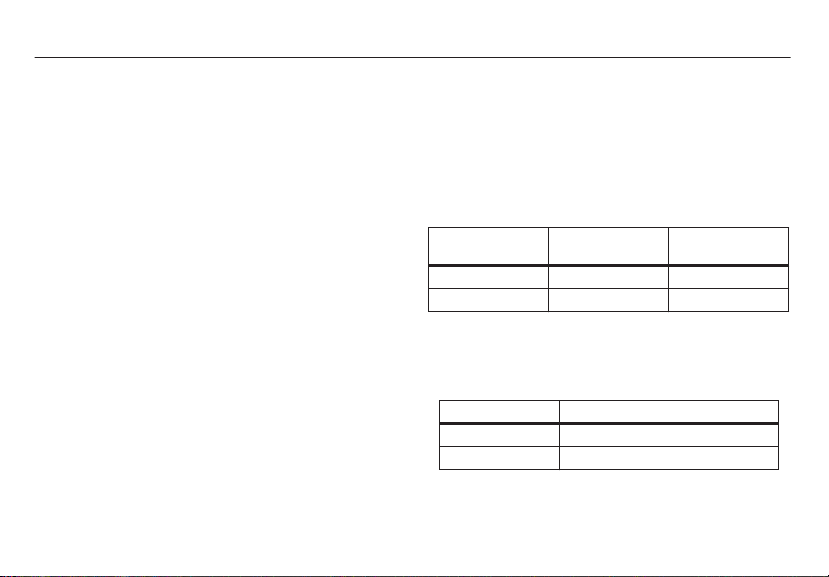

Table 1. Generation 1 Pump

-10°C to +0°C

(14°F to 32°F)

Sintered filter 3 m (10 ft.) 9.1 m (30 ft.)

Sample Probe 3 m (10 ft.) 3 m (10 ft.)

a Warning

When using the sample probe at -10°C to +0°C (14°F to

32°F), keep the sample probe in your hand.

0°C to 50°C

(32°F to 122°F)

Table 2. Generation 2 Pump

-20°C to 50°C(-4°F to 122°F)

Sintered filter 20 m (66 ft.)

Sample Probe 3 m (10 ft.)

Page 19

Bump Test

A bump test is the process of applying a small amount of test

gas to force the detector into alarm. A bump test should be

performed regularly to confirm the sensors are responding

correctly to gas, and that the audible, visual, and vibrator

alarms activate during an alarm condition. Calibrate if the

readings are not within specified limits.

Performing a Bump Test

a Caution

BW recommends to bump test the sensors before each

day’s use to confirm their ability to respond to gas by

exposing the sensors to a gas concentration that exceeds

the alarm setpoints.

Should the user wish to comply with European

Regulations, a bump test must be completed before each

day’s use. Refer to EN 60079-29-2.

To perform a manual bump test refer to

Cylinder to the Detector on page 10 and the following steps 1-6.

Follow this procedure when Bump Daily is enabled.

Note

If performing a bump test on a pump unit, connect the

calibration hose directly to the pump module.

1. Connect the calibration hose to the 0.5l/min regulator

on the gas cylinder.

Connecting the Gas

GasAlertMicro 5/PID/IR

Bump Test

Note

Only use the calibration cap for bump tests and

calibrations.

2. Connect the calibration hose to the intake inlet on the

calibration cap. Arrows on the calibration cap indicate

the direction of gas flow.

3. Attach the calibration cap and tighten the knob.

Refer to

Connecting the Gas Cylinder to the Detector

on page 10.

Note

Ensure the knob is securely fastened before applying

gas. Do not overtighten the calibration cap. Ensure

strong air currents are kept away from the exhaust

side of the calibration cap, as this can affect the bump

test accuracy.

4. Apply gas. Verify the visual, audible, and vibrator

alarms activate.

5. Close the regulator and remove the calibration cap

from the detector. The detector will temporarily

remain in alarm until the gas clears from the sensors.

6. Disconnect the calibration hose from the cap and

regulator.

15

Page 20

GasAlertMicro 5/PID/IR

Quick Reference Guide

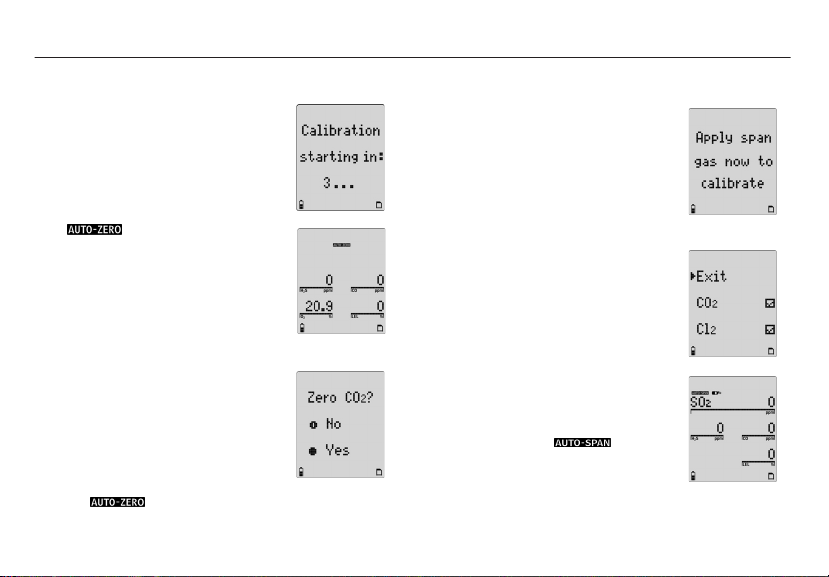

Calibration

Calibrate only in a safe area in an

atmosphere of 20.9% oxygen.

1. Activate the detector. To enter calibration,

press and hold C and H

simultaneously. The detector beeps and

flashes to the corresponding countdown.

The LCD then displays Starting

calibration.

2. flashes while the detector

zeros all of the sensors (except CO

calibrates the oxygen sensor. If a sensor

fails to auto zero, that sensor will bypass

the span.

If calibrating a GasAlertMicro 5 or

GasAlertMicro 5 PID, proceed to step #4.

Step #3 for Micro 5 IR Only

3. The Zero-CO2? screen displays. Press

C to zero the CO

bypass.

If C is pressed to zero the CO2 sensor,

the following screens display:

- Apply CO2 zero gas now (nitrogen

must be used to zero the CO

4. - The Auto-Zero CO

and flashes.

16

sensor, or press A to

2

sensor).

2

screen displays,

2

) and

2

5. The following three screens display:

- Apply span gas now to calibrate

- or press C to select sensor(s)

A to skip calibration

- or press

If none of the buttons are pressed,

proceed to step #6.

C is pressed, proceed to step #5.

If

If

A is pressed, proceed to the end of

step #7.

6. Select which sensor to span. Press

or H to scroll to the required sensor

and then press C to select. Sensors

must be spanned in the following order:

- Exotics (NH

- Single gases

- Quad gases (H

7. Attach the calibration cap and apply gas

at a flow rate of 500 ml/min.

K flashes while the detector determines

which gas is being applied.

After 30 seconds, flashes and

a countdown displays while the detector

completes the span.

, ClO2, O3, and CO2)

3

S, CO, O2 and LEL).

2

G

Page 21

GasAlertMicro 5/PID/IR

Calibration

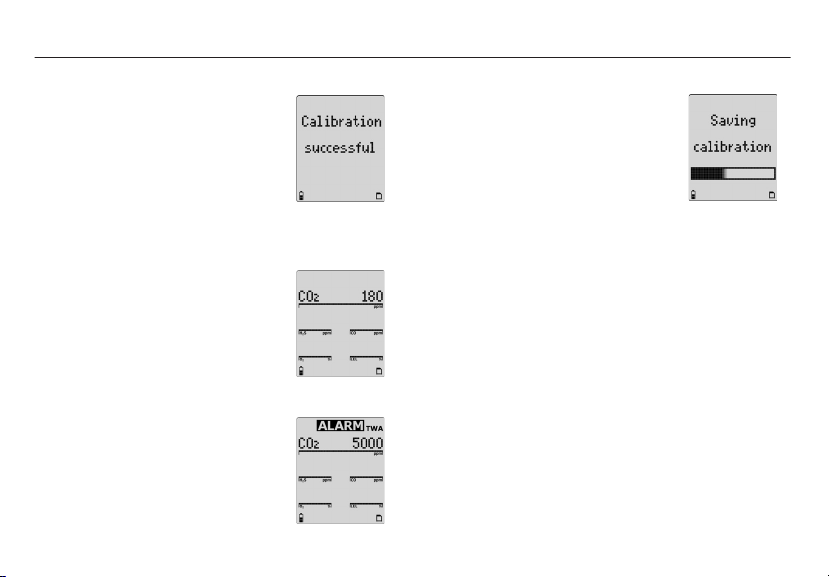

8. When the span is complete, the following

three screens display:

- Calibration successful

G to apply a new cal gas

- Press

- Press

H to end span

Repeat steps #4-7 to calibrate the

remaining sensors.

The LCD displays the following options:

C to set the calibration due

- Press

dates or press A to bypass.

G or H to change the calibration

9. Press

due date. Press C to accept the value

and proceed to the next due date. If a

sensor fails or does not span, the

calibration due date cannot be changed

for that sensor.

The LCD displays the following options:

C to change the calibration due

- Press

dates or press A to bypass.

G or H to change the alarm

10.Press

setpoint. Press C to save the value and

proceed to the next setpoint.

Define the remaining setpoints. The

detector beeps twice when all of the

alarm setpoints have been defined or

bypassed.

11.When calibration is complete, Saving

calibration displays.

Note

Only use the calibration cap and single

gas calibration cap during calibration and

bump tests.

For additional information about performing calibrations and

bump tests, refer to the GasAlertMicro 5/PID/IR User Manual.

17

Page 22

GasAlertMicro 5/PID/IR

Quick Reference Guide

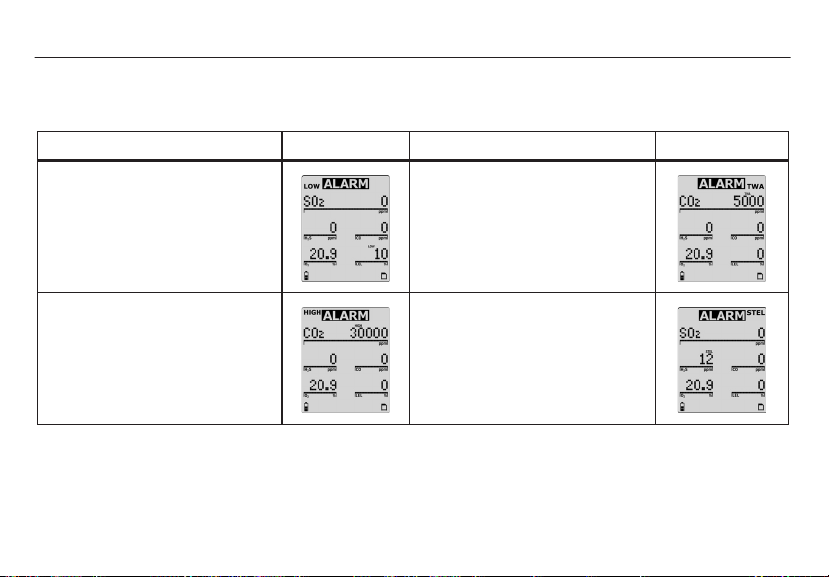

Alarms

Refer to the following table for information about alarms and

corresponding screens. During an alarm condition, the

Alarm Screen Alarm Screen

Low Alarm

• Fast beep

• Slow flash

• L and target gas bar flash

• Vibrator alarm activates

backlight activates and the LCD displays the ambient gas

readings.

TWA Alarm

• Fast beep

• Slow flash

• L and target gas bar flash

• Vibrator alarm activates

High Alarm

• Constant beep

• Fast flash

• L and target gas bar flash

• Vibrator alarm activates

18

STEL Alarm

• Constant beep

• Fast flash

• L and target gas bar flash

• Vibrator alarm activates

Page 23

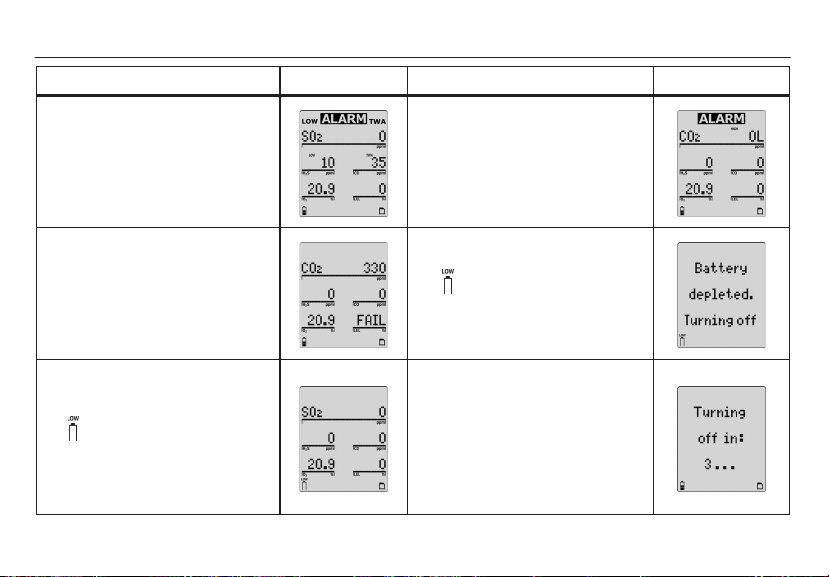

Alarm Screen Alarm Screen

Multi Alarm

• Alternating low and high alarm beep

and flash

• L and target gas bars flash

• Vibrator alarm activates

GasAlertMicro 5/PID/IR

Alarms

Over Limit (OL) Alarm

• Fast beep and flash

• L and target gas bar flash

• Vibrator alarm activates

Sensor Alarm

• One beep every 15 seconds

• FAIL flashes above the failed sensor

Low Battery Alarm

• One beep and two flashes every

25 seconds

• flashes

a

Caution

Charge the battery immediately when

a low battery alarm occurs.

Automatic Deactivation Alarm

• Eight beeps and flashes

• displays

• Vibrator alarm temporarily activates

Battery depleted screen displays and

•

the detector deactivates

Normal Deactivation

• Three beeps and flashes

19

Page 24

GasAlertMicro 5/PID/IR

Quick Reference Guide

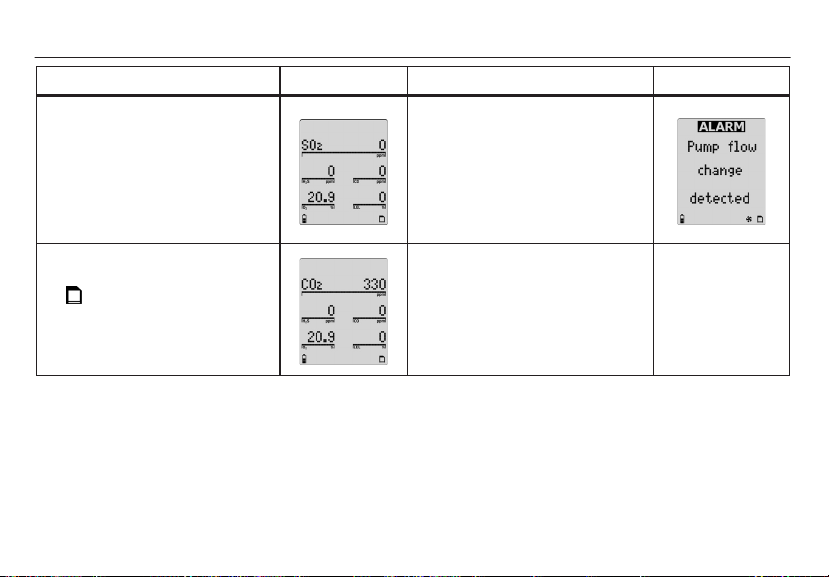

Alarm Screen Alarm Screen

Confidence Beep

• One beep, one flash, and one

vibration every 10 seconds

Note

The Confidence Beep option is

automatically disabled during a

low battery alarm.

MMC Fail Alarm

Pump Alarm

• Screen flashes:

- Pump flow change detected

- Check for blocked inlet

- or press

• Two fast beeps and alternating flashes

C to run a pump test

• Vibrator alarm activates

• L and J flash

• One beep every 5 seconds

• flashes

Note

If enabled, during an alarm condition the

vibrator) to persist until the alarm is acknowledged by pressing C and the gas concentration is below the low alarm setpoint.

The peak concentrations display continually until the alarm condition no longer exists. Local regulations may require the

option be enabled.

Latch (latching alarms) option causes the low and high gas alarms (audible, visual, and

To comply with European Regulations, the Latch option must be enabled.

20

Latch

Page 25

User Options Menu

To access the user options, press and hold G and H

simultaneously until the detector completes the countdown. To

scroll through the options press G or H. Press C to select the

option. The following options are available.

Exit: Exits the user options menu.

User Options:

•

Backlght (backlight): Enables/disables the automatic

backlight in low-light conditions.

•

Confibeep (confidence beep): If enabled, the confidence

beep provides continuous confirmation that the detector is

operating correctly (audible beep every 10 seconds).

•

Due-lock (calibration user lockout): If enabled, upon

startup a passcode is required to operate a detector that is

overdue for calibration.

•

Latch (latched alarm): Enable to ensure an alarm persists

until it is acknowledged (press C to acknowledge).

•

Passcode (passcode protection): Enable to prevent

unauthorized personnel from accessing the user options

menu, calibration function, and alarm setpoint adjust

function.

•

Safe (safe mode): If enabled, Safe displays continuously

on the LCD unless an alarm condition occurs.

•

Language: Displays the LCD screens in English, Français

(French),

Deutsch (German), Español (Spanish), or

Português (Portuguese).

Note

The detector is shipped displaying English as the

default language.

GasAlertMicro 5/PID/IR

User Options Menu

Sensors:

•

Sens on (sensor enabled): Enables/disables a sensor (the

detector continues to operate if a sensor is disabled).

a

Warning

Use extreme caution when disabling a sensor. The

disabled sensor cannot detect and alarm against the

applicable gas.

• Span gas: Define the span gas concentration for each

sensor (must match the gas concentration on the gas

cylinder).

• Stel period (Short Term Exposure Limit): The short term

exposure limit (STEL) provides protection for workers from

over exposure to high concentrations of gas, and is based

on user-defined 5-15 minute intervals.

When the maximum STEL is reached, the detector alarms

to notify the worker. Set the STEL period from

5-15 minutes (applicable to toxic sensors only).

• TWA method (Time Weighted Average): This option is a

safety measure that calculates the accumulated averages

of gases to warn the worker when the maximum average

has accumulated. Select one of the following options:

- OSHA Method: 8 hour moving average—oldest value

(first hour) is replaced by the newest value (ninth hour).

- ACGIH Method: Infinite accumulated average to 8 hours

- total accumulation, whether it is 2 hours or 8 hours.

• Resolution: Defines the resolution of the gas

measurement as either regular or extra (if applicable).

21

Page 26

GasAlertMicro 5/PID/IR

Quick Reference Guide

• %vol CO2: Enable to display the carbon dioxide (CO2)

reading as %vol.

• %vol CH4: Enable to display the LEL readings as %vol

assuming a methane environment.

Note

If changing the measurement unit from % LEL to %

Vol. or from % Vol. to % LEL, a calibration must be

completed and the alarm setpoints changed. For

calibration information refer to

and for alarm setpoint information refer to Alarm

Setpoints in Calibration Procedure in the

GasAlertMicro 5/PID/IR User Manual.

•

Correction Factor (%): Enter a compensation factor for

hydrocarbons other than methane. The factor can only be

applied if the LEL sensor has been calibrated with

methane (LEL only).

•

Autocal (automatic oxygen calibration): Enable/disable the

detector to automatically calibrate the oxygen sensor

during startup.

Logger (Datalogging): Define how often the detector records a

datalog sample (once every 1 to 127 seconds).

Clock: Define the date and time for the detector.

Calibration on page 16

22

Maintenance

To maintain the detector in good operating condition, perform

the following basic maintenance as required.

• Calibrate, bump test, and inspect the detector on a regular

schedule.

• Maintain an operations log of all maintenance, bump tests,

calibrations, and alarm events.

• Clean the exterior with a soft damp cloth. Do not use

solvents, soaps, or polishes. Refer to

Contaminants on page 4.

• Do not immerse the detector in liquids.

Sensor Poisons and

Page 27

Replacing Battery Cells and Packs

a Warning

To avoid personal injury and/or property damage, adhere

to the following battery cautions:

• Replace the alkaline cells or rechargeable battery pack

immediately when the detector emits a low battery

alarm.

• Use only batteries that are recommended by

BW Technologies by Honeywell.

• Use only approved alkaline batteries that are properly

installed in the battery pack. Refer to Specifications.

• To order lithium battery packs (M5-BAT08/M5-BAT07),

contact BW Technologies by Honeywell.

• Charge the batteries and battery packs using only a

recommended BW charger. Failure to adhere to this

caution can lead to fire and/or explosion.

• The detector must be deactivated to charge the

battery pack.

• Do not calibrate the detector immediately after

charging is complete.

• Both the lithium battery pack and the alkaline battery

pack are user-changeable in hazardous locations, but

the alkaline battery cells inside the pack can only be

replaced in a safe area that is free of hazardous gas.

• Warning: The M5-BAT08 and M5-BAT07 battery packs

are equipped with lithium batteries that can present a

risk of fire or chemical burn hazard if misused. Do not

Replacing Battery Cells and Packs

GasAlertMicro 5/PID/IR

recharge, disassemble, heat above 212°F (100°C), or

incinerate.

• Warning: Do not use any other lithium batteries with

the GasAlertMicro 5, GasAlertMicro 5 PID, and

GasAlertMicro 5 IR detectors. Use of any other cell

can cause fire and/or explosion.

• Warning: Lithium polymer cells exposed to heat at

266°F (130°C) for 10 minutes can cause fire and/or

explosion.

• Dispose of used lithium cells immediately. Do not

disassemble and do not dispose of in fire. Do not mix

with the solid waste stream. Spent batteries must be

disposed of by a qualifies recycler or hazardous

materials handler.

• Keep lithium cells away from children.

23

Page 28

GasAlertMicro 5/PID/IR

Quick Reference Guide

Replacing Alkaline Batteries

a Warning

Always deactivate the detector before removing the

battery pack. The battery packs are user-changeable in

hazardous locations, but the alkaline battery cells inside

the pack must be changed in a safe area that is free of

hazardous gas.

24

To charge the rechargeable battery pack, refer to the

GasAlertMicro 5/PID/IR Battery Charger User Manual.

To replace the alkaline batteries, refer to the following

procedures and illustration.

1. Press and hold C to deactivate the detector.

2. Open the latch on the bottom of the detector.

3. Remove the battery pack by lifting the bottom of the

pack upward from the detector.

4. On the battery pack, unscrew the two captive screws

and open.

5. Replace the three alkaline battery cells.

6. Replace the cover and reinsert the two captive

screws.

7. Replace the battery pack on the detector.

8. Close the latch.

Page 29

Replacing Lithium Battery Packs

a Warning

Do not disassemble the lithium battery pack. Read and

adhere to the cautions in

Packs.

To replace the lithium battery pack, refer to the following

illustration and steps 1-4.

Replacing Battery Cells and

Replacing Battery Cells and Packs

GasAlertMicro 5/PID/IR

1. Press and hold C to deactivate the detector.

2. Open the latch on the bottom of the detector.

3. Remove the battery pack by lifting the bottom of the

pack upward from the detector.

4. Replace the battery pack with a fully charged lithium

battery pack.

5. Close the latch.

WEEE Directive and Battery Directive

Failure to comply with the following battery removal and

disposal instructions may result in battery shorting, battery

leakage, and/or other damage. Ensure a qualified technician

completes the following procedures.

Removal and Disposal of the Battery Pack

Only a qualified technician should complete the following

procedures.

To remove the alkaline batteries, refer to steps #1 to #4 in

Replacing Alkaline Batteries on page 24.

To remove the lithium battery pack, refer to steps #1 and #2 in

Replacing Lithium Battery Packs on page 25.

Dispose of the battery pack according to local laws.

25

Page 30

GasAlertMicro 5/PID/IR

Quick Reference Guide

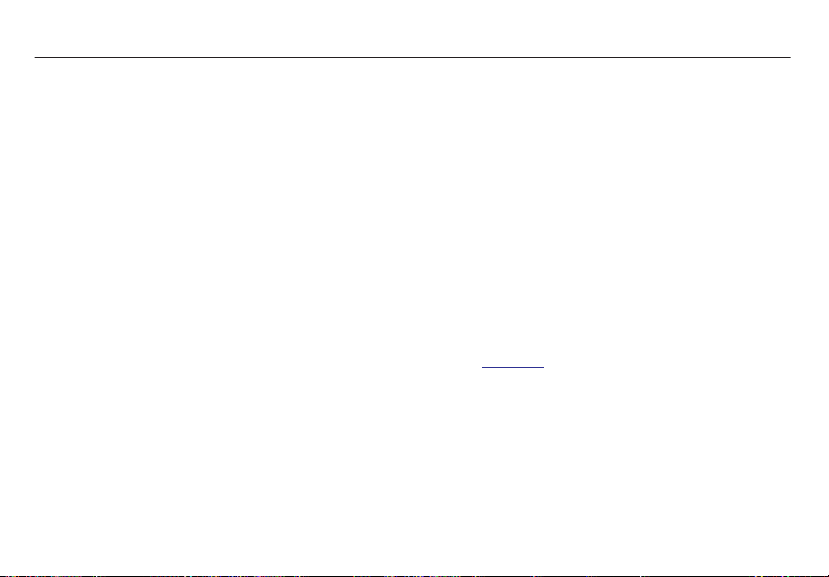

Removal and Disposal of the Coin Cell

26

Item Description

1 Diffusion cap

2 Sensor filter

3 Sensors

4 Front shell

5 Sensor board

6 Back shell

Machine screws (for

7

diffusion cap)

8 Battery pack

9 Datalog card

Machine screws (for

10

rear shell)

Page 31

The detector contains a coin cell to power the real-tlime clock.

Only a qualified technician should complete the following

procedure.

1. Press and hold C to deactivate the detector.

2. Open the latch on the bottom of the detector.

3. Remove the battery pack by lifting the bottom of the

pack upward from the detector.

4. Remove the MMC card.

5. Remove the two machine screws on the rear shell

and then remove the diffusion cap or pump module.

6. Remove the sensors.

7. Remove the four machine screws in the battery pack

cavity.

8. Remove the rear shell.

9. The coin cell sits on the sensor board.

Gently remove the sensor board.

10. The coin cell is connected to the board by four leads.

Clip the four leads individually to remove the coin cell.

11. Dispose of the coin cell according to local laws.

a

Caution

Do not touch two or more leads while disconnecting the

coin cell.

Replacing Battery Cells and Packs

GasAlertMicro 5/PID/IR

Note

Image above shows three of the four battery leads

that must be clipped.

27

Page 32

GasAlertMicro 5/PID/IR

Quick Reference Guide

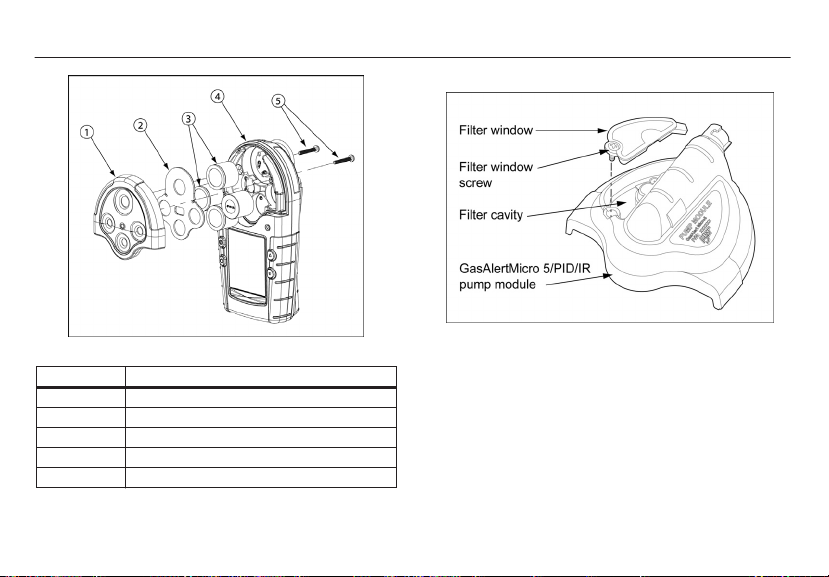

Replacing a Sensor or Sensor Filter

To replace a sensor or sensor filter, refer to the following illustration, table, and steps 1-7.

Warning

a

To avoid personal injury and/or property damage, only use sensors that are specifically designed for the detector.

Replace the sensors in a non-hazardous area.

Note

Detectors that are configured for 1, 2, or 3 gases may contain a dummy sensor in one of the four sensor locations.

1. Deactivate the detector.

2. Remove the two machine screws on the rear shell and then remove the sensor cover or pump module cover.

3. Remove the sensor filter and/or sensor(s).

4. Insert the new filter and/or sensor(s). Ensure the sensor posts are aligned correctly.

5. Re-assemble the detector.

6. If the sensor is replaced with a different type of sensor (e.g. SO

Sensors in the Tech Mode section of the GasAlertMicro 5/PID/IR User Manual.

7. Activate the detector and then calibrate the new sensor(s). Refer to Calibration.

to an H2S), the detector must be reconfigured. Refer to

2

28

Page 33

Item Description

1 Sensor cover

2 Sensor filter

3 Sensors

4 Detector

5 Machine screws (2)

Replacing Battery Cells and Packs

GasAlertMicro 5/PID/IR

Replacing the Pump Filter (Generation 2 Pump only)

Note

If replacing the pump filter on the Generation 1 pump,

refer to the GasAlertMicro 5/PID/IR User Manual.

1. Deactivate the detector.

2. Remove the filter window screw and the filter window.

3. Remove the old filter.

4.

Important! Ensure the filter cavity and filter window

are clean and free of debris. Insert a new filter.

5. Replace the filter window and screw.

29

Page 34

GasAlertMicro 5/PID/IR

Quick Reference Guide

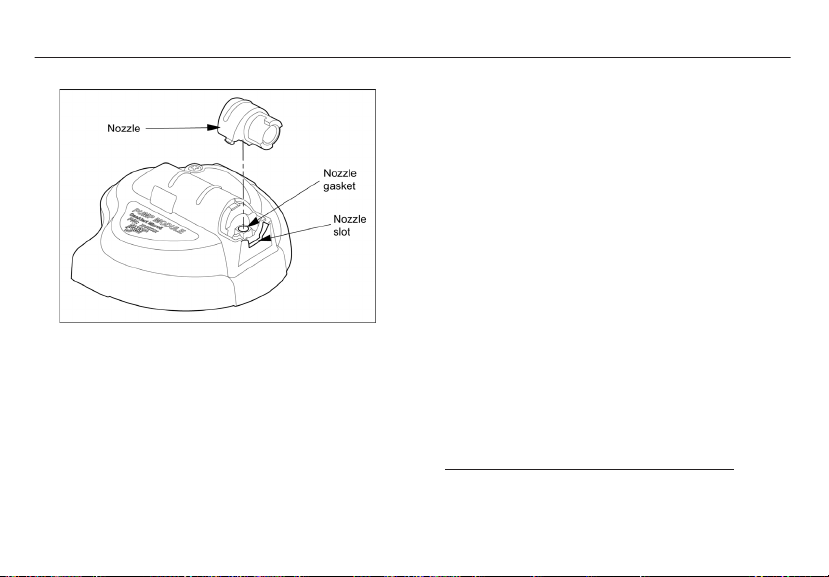

Replacing the Pump Nozzle (Generation 2 Pump only)

Note

If the nozzle is damaged, replace it immediately to

ensure accurate pump flow.

Only the Generation 2 pump has a replaceable

nozzle.

1. Deactivate the detector.

2. Gently insert a medium sized flathead screwdriver

into the nozzle slot. Lift and remove the damaged

nozzle.

3. Insert the new nozzle. Ensure the nozzle post inserts

correctly into the nozzle gasket.

30

Specifications

Instrument dimensions: 14.5 x 7.4 x 3.8 cm

(5.7 x 2.9 x 1.5 in.)

Weight: 370 g (13.1 oz.)

Operating and storage conditions:

Operating Temperature:

VOC: -10°C to +40°C (14°F to +104°F)

Other gases: -20°C to +50°C (-4°F to +122°F)

Combustible gas sensor: Certified by CSA International to ±3%

LEL accuracy from -10°C to +40°C (4°F to 104°F)

Storage temperature:

-25°C to +60°C

Operating humidity:

O

: 0% to 90%1 relative humidity (non-condensing)

2

VOC: 0% to 95% relative humidity (non-condensing)

Combustibles: 5% to 95% relative humidity (non-condensing)

Cl

: 10% to 95% relative humidity (non-condensing)

2

HCN, ClO

Other gases: 15% to 90%

Pressure: 95 to 110 kPa

: 15% to 90%1 relative humidity (non-condensing)

2

1

relative humidity (non-condensing)

1

Dust and moisture ingress: IP65/66

1. Standard release data. This product has extended characteristics. For specifications refer to EAC Ex certificate and Pattern Approval document

1

1

Page 35

Alarm setpoints: May vary by region and are user-defined

Detection range:

O

: 0 - 30.0% vol. (0.1% vol. increments)

2

CO: 0 - 999 ppm (1 ppm increments)

CO (TwinTox sensor): 0 - 500 ppm (1 ppm increments)

H

S: 0 - 500 ppm (1 ppm increments)

2

H

S TwinTox sensor): 0 - 500 ppm (1 ppm increments)

2

Combustible (LEL): 0 - 100% LEL (1% LEL increments) or

0 - 5.0% v/v methane; certified by CSA International to C22.2

No. 152 and ISA 12.13.01 within 0 - 60% or 3.0% v/v methane

PH

: 0 - 5.0 ppm (0.1 ppm increments)

3

: 0 - 150 ppm (1 ppm increments)

SO

2

Cl

: 0 - 50.0 ppm (0.1 ppm increments)

2

NH

: 0 - 100 ppm (1 ppm increments)

3

NO

: 0 - 99.9 ppm (0.1 ppm increments)

2

HCN: 0 - 30.0 ppm (0.1 ppm increments)

ClO

: 0 - 1.00 ppm (1.00 ppm increments)

2

O

: 0 - 1.00 ppm (0.01 ppm increments)

3

VOC: 0 - 1000 ppm (1.0 ppm increments)

CO

IR: 0 - 50,000 ppm (50 ppm increments) or 0-5.0% v/v CO

2

(Sensors not certified for use with the GasAlertMicro 5 IR:

ClO

, HCN, NO2, PH3, Cl2)

2

Sensor type:

H

S/CO: Twin plug-in electrochemical cell

2

Combustibles: Plug-in catalytic bead

VOC: Photoionization detector (PID)

CO

: IR detector

2

Other gases: Single plug-in electrochemical cell

1

GasAlertMicro 5/PID/IR

Specifications

measuring principle: Capillary controlled concentration

O

2

sensor

Alarm conditions: TWA alarm, STEL alarm, low alarm, high

alarm, multi alarm, over limit (OL) alarm, sensor alarm, pump

alarm, MMC/SD fail alarm, low battery alarm, confidence beep,

automatic deactivation alarm

Audible alarm: 95 dB at 0.3 m (1 ft.) variable pulsed dual

beepers

Visual alarm: Dual red light-emitting diodes (LEDs)

Display: Alphanumeric liquid crystal display (LCD)

Backlight: Activates briefly during startup, when there is

insufficient light to view the display (if enabled), and during

alarm conditions

Self-test: Initiated during activation

Calibration: Automatic zero and automatic span

Oxygen sensor: Automatic span during startup (if enabled)

User field options: Confidence beep, latching low and high

alarms, passcode protection, enable/disable safe display mode,

combustible sensor measurement, sensor enable/disable,

language selection, enable/disable automatic O

2

span concentration values, set STEL calculation period, set

TWA method, gas measurement resolution, enable/disable

automatic backlight, adjust clock/calendar, set datalogging rate

(datalog models only), CO

Datalog Models:

Approved for GasAlertMicro 5 and GasAlertMicro 5 PID

Models: Delkin 128 MB SD card and 64 MB Unigen SD card

sensor measurement

2

calibration, set

2

31

Page 36

GasAlertMicro 5/PID/IR

Quick Reference Guide

Approved for GasAlertMicro 5 IR Models: Delkin 128 MB

MMC, Delkin 128 MB SD card, Transcend 128 MB SD, and

64 MB Unigen SD card

Battery operating time:

Toxic, O

, and LEL sensor configuration: Three alkaline cells

2

or one lithium battery pack at 20°C/68°F provides 20 hours

operating runtime

Toxic, O

, LEL, and PID sensor configuration: Three alkaline

2

cells or one lithium battery pack at 20°C/68°F provides 15 hours

operating runtime

Toxic, O

, LEL, and CO2 sensor configuration: Three

2

alkaline cells or one lithium battery pack at 20°C/68°F provides

15 hours operating runtime

Approved Batteries:

Approved batteries for GasAlertMicro 5, GasAlertMicro 5

PID, and GasAlertMicro 5 IR product:

Alkaline (M5-BAT02): as per standards EN 60079-11,

EN 60079-0, UL913, CSA C22.2 No. 157

Lithium-ion polymer (M5-BAT07), as per standards

EN 60079-11, EN 60079-0, UL913, CSA C22.2 No. 157

Lithium-ion polymer (M5-BAT08): as per standards

EN 60079-11, EN 60079-0, EN 60079-29-1, EN 50104, UL913,

CSA C22.2 No. 157, EN 45544-1 and EN 45544-2.

Rechargeable battery (M5-BAT08) Temperature code

Lithium polymer -20°C ≤ Ta ≤ +50°C T4

Alkaline batteries

1

Duracell MN1500 -20°C ≤ Ta ≤ +50°C T4 (129.9°C)

Energizer E91VP -20°C ≤ Ta ≤ +50°C T3C (135.3°C)

32

Battery charger: GasAlertMicro 5/PID/IR battery charger

First-time charge: Lithium 6 hours

Normal charge: Lithium 6 hours

Warranty: 2 years including sensors (1 year NH

PID lamp)

Year of manufacture: The detector's year of manufacture is

determined from the serial number. The second and third

number after the first letter determines the year of manufacture.

Example: H3

Approvals:

GasAlertMicro 5 and GasAlertMicro 5 PID (Zone 0):

Approved by CSA to both U.S. and Canadian Standards

Standards: CAN/CSA C22.2 No. 157 and C22.2 152

11-001000 = 2011 year of manufacture.

sensor and

3

ANSI/UL – 913 and ANSI/ISA – S12.13 Part 1

ABS Type Approved: VA-348169-X

CSA Class I, Division 1, Group A, B, C, and D

ATEX

IECEx Ex da ia IIC Ga IECEx CSA 06.0011X

1. Standard release data. This product has extended char-

Class I, Zone 0, Group IIC

g II 1 G Ex da ia IIC Ga

CE 0539

KEMA 06 ATEX 0206

EN 60079-0, EN 60079-1, EN 60079-11

IEC 60079-0, IEC 60079-1, IEC 60079-11

acteristics. For specifications refer to EAC Ex certificate and Pattern Approval document

Page 37

KTL

Inmetro Ex ia IIC T4 Ga DNV 12.0138 X

a. http://www.honeywellanalytics.com/~/media/honeywell-analytics/

products/gasalertmicro-5-series/documents/certifications/

kc-certificate-gasalertmicro-550118920025.pdf?la=en

GasAlertMicro 5 IR (Zone 1):

Approved by CSA to both U.S. and Canadian Standards

Standards: CAN/CSA C22.2 No. 157 and C22.2 152

ANSI/UL – 913 and ANSI/ISA – S12.13 Part 1

ABS Type Approved: VA-348169-X

CSA Class I, Division 1, Group A, B, C, and D

ATEX

IECEx Ex d ia IIC Gb IECEx CSA 06.0011X

KTL

Inmetro Ex d ia IIC T4 Gb DNV 12.0138 X

a. http://www.honeywellanalytics.com/~/media/honeywell-analytics/

products/gasalertmicro-5-series/documents/certifications/

kc-certificate-gasalertmicro-550118920025.pdf?la=en

12-KB4BO-0055X

Class I, Zone 1, Group IIC

CE 0539

KEMA 06 ATEX 0206

EN 60079-0, EN 60079-1, EN 60079-11,

IEC 60079-0, IEC 60079-1, IEC 60079-11

12-KB4BO-0055X

a

g II 2 G Ex d ia IIC Gb

a

GasAlertMicro 5/PID/IR

Specifications

This equipment has been tested and found to comply with the

limits for a Class B digital device, pursuant to Part 15 of the

FCC Rules and ICES-003 Canadian EMI requirements. These

limits are designed to provide reasonable protection against

harmful interference in a residential installation. This equipment

generates, uses and can radiate radio frequency energy and, if

not installed and used in accordance with the instructions, may

cause harmful interference to radio communications. However,

there is no guarantee that interference will not occur in a

particular installation. If this equipment does cause harmful

interference to radio or television reception, which can be

determined by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of

the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and

receiver.

• Connect the equipment into an outlet on a circuit different

from that to which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician

for help.

33

Page 38

GasAlertMicro 5/PID/IR

Quick Reference Guide

Information Required for European Regulations Compliance

Should the user wish to comply, the detector must be operated

in the following manner.

Daily bump test: A bump test must be completed before each

day’s use.

Condition of use: The detector may only be used with the

concussion-proof boot (GA-BM5-1 if it is a diffusion unit, or

GA-BM5-2 if it is a pump unit).

Stealth mode: Stealth mode must be disabled.

Latching alarms: The latching alarm option must be enabled.

Warm up time: 60 seconds; ≤ 90 seconds for pump unit

Stabilization time for methane sensor: ≥ 120 seconds

Stabilization time for oxygen sensor: ≥ 120 seconds

Methane response time t

Oxygen response time t

Oxygen response time t

Changing measurement range from % LEL to % Vol.: If

changing the measurement unit from % LEL to % Vol. or from %

Vol. to % LEL, a calibration must be completed and the alarm

setpoints changed. For calibration information refer to

Calibration on page 16 and for alarm setpoint information refer

to Alarm Setpoints in Calibration Procedure in the

GasAlertMicro 5/PID/IR User Manual.

34

: 10 seconds

90

: 15 seconds for oxygen deficiency

90

: 14 seconds for oxygen surplus

90

Effect of other toxic gases on the LEL sensor: High

concentrations of certain toxic gases, for example H

have an adverse effect on the LEL sensor. This effect, known

as inhibition, is usually temporary but in extreme circumstances

can impair the sensitivity of the LEL sensor.

After any gas exposure that causes an alarm in the toxic gas

sensors, the LEL sensor should be verified with a bump test,

and recalibrated if necessary.

Approved batteries for GasAlertMicro 5, GasAlertMicro 5

PID, and GasAlertMicro 5 IR product: Lithium-ion polymer

(M5-BAT08): as per standards EN 60079-11, EN 60079-0,

UL913, CSA C22.2 No. 157

General Use: For use only in potentially explosive

atmospheres where oxygen concentrations do not exceed

20.9% (v/v). Oxygen deficient atmospheres (<10% v/v) may

suppress some sensor outputs.

S, may

2

Page 39

Information Required for European Regulations Compliance

Tested Sensors

BW Part Number Sensor Type Manufacturer Description

BW 4COSH3

BW 4P-90 (USP 5601693) LEL City Technology Limited CiTipel® 4P-90

-A2 O

Oxygen O

2

Performance Data According to EN 45544 Part 1 and 2

Target Gas CO H2S

Time of response 35s 17s

Time of recovery 33s 16s

Alarm response time 6s 4s

Zero variation 11 ppm (v/v) 1,3 ppm (v/v)

Overall uncertainty 8% of the measuring value 12%

Lower limit of measuring range 6 ppm (v/v) 0,7 ppm (v/v)*

Drift under zero gas (3 month) 1 ppm (v/v) 1 ppm (v/v)

Maximum calibration period under test conditions 3 month 3 month

(under operation conditions the calibration period may differ from value under test conditions)

*Please Note: The configured dead band is 1.5 ppm (v/v) H

CO and H

2

S

City Technology Limited City 4COSH CiTicel® rev.03

2

O

Alphasense Ltd.

S

2

-A2 Oxygen Sensor

2

GasAlertMicro 5/PID/IR

35

Page 40

GasAlertMicro 5/PID/IR

Quick Reference Guide

Troubleshooting

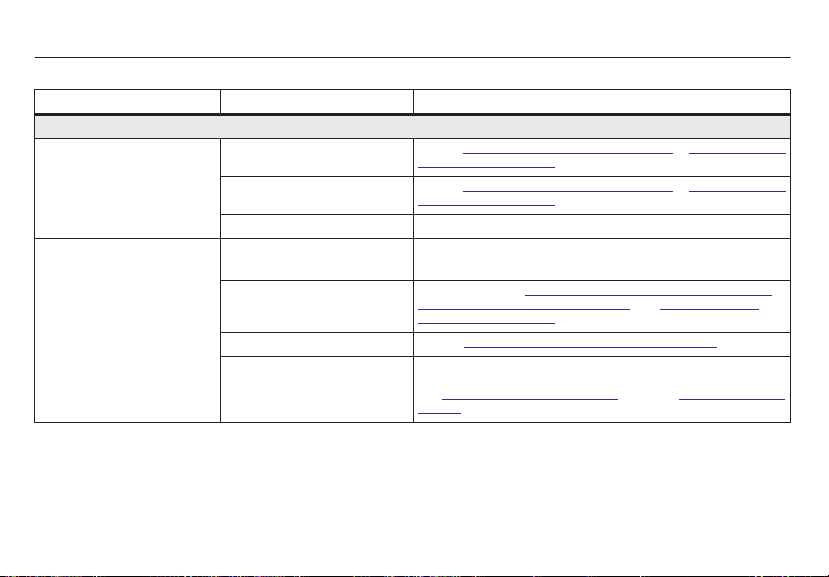

Problem Possible Cause Solution

Startup Troubleshooting

The detector does not activate. No batteries Refer to Replacing Alkaline Batteries on page 24 or Replacing Lithium

Depleted batteries Refer to Replacing Alkaline Batteries on page 24 or Replacing Lithium

Damaged or defective detector Contact BW Technologies by Honeywell

The detector immediately enters

alarm mode when activated.

Sensor needs to stabilize Used sensor: wait 60 seconds.

Low battery alarm Refer to cautions in Replacing Battery Cells and Packs on page 23,

Sensor alarm Refer to Replacing a Sensor or Sensor Filter on page 28.

Pump alarm If the sampling hose is attached, determine if it is obstructed. If not,

If a problem persists, contact BW Technologies by Honeywell.

Battery Packs on page 25.

Battery Packs on page 25

New sensor: wait 5 minutes.

Replacing Alkaline Batteries on page 24, and Replacing Lithium

Battery Packs on page 25.

clean or replace the pump filter. If the pump alarm persists, refer to

Pump Operation Troubleshooting” section in Troubleshooting on

the “

page 36.

36

Page 41

GasAlertMicro 5/PID/IR

Troubleshooting

Problem Possible Cause Solution

The startup self-test fails. General fault Ensure that the sensors and battery pack are installed correctly and

Detector Operation Troubleshooting

Detector does not display normal

ambient gas readings after

startup self-test.

Detector does not respond to

pushbuttons.

Sensor not stabilized Used sensor: wait 60 seconds

Detector requires calibration Calibrate the sensors. Refer to

Target gas is present Detector is operating properly. Use caution in suspect areas.

Batteries are depleted Refer to cautions in Replacing Battery Cells and Packs on page 23,

Detector is performing operations

that do not require user input

then reactivate the detector.

If the fault persists, record the error message and contact

BW Technologies by Honeywell.

New sensor: wait 5 minutes

Calibration on page 16.

Replacing Alkaline Batteries on page 24, and Replacing Lithium

Battery Packs on page 25.

Pushbutton function restores automatically when the operation ends.

37

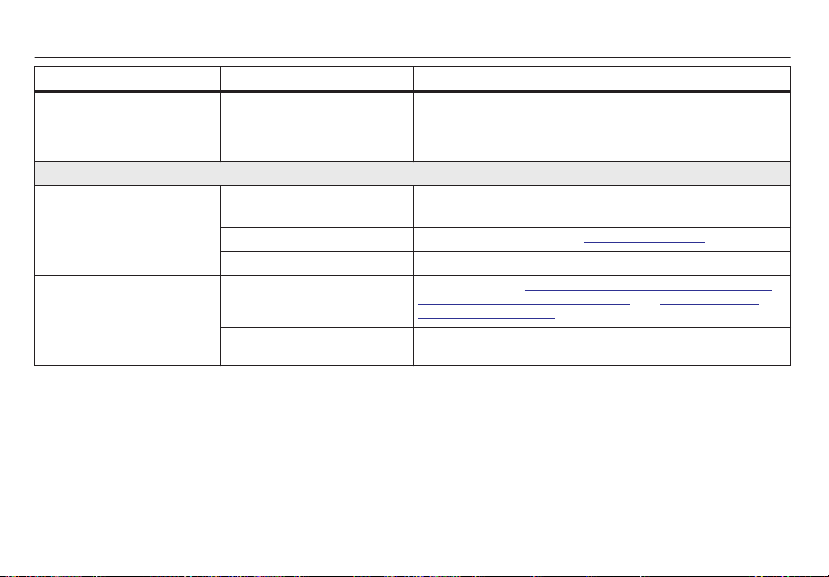

Page 42

GasAlertMicro 5/PID/IR

Quick Reference Guide

Problem Possible Cause Solution

Detector does not accurately

measure gas.

MMC/SD Card Troubleshooting

Detector requires calibration Calibrate the sensors. Refer to Calibration on page 16.

Detector is colder/hotter than

ambient gas

Sensor filter is blocked Clean the sensor filter. Refer to

The MMC/SD card is not inserted. Insert the MMC/SD card. Refer to Inserting the MMC/SD Card in the

Allow the detector to adjust to ambient temperature before using.

on page 28.

GasAlertMicro 5/PID/IR User Manual.

Replacing a Sensor or Sensor Filter

38

The MMC/SD card that is inserted

in the detector has a storage size

that is not supported by the

detector.

Insert an approved MMC/SD card:

• 128 MB Delkin MMC

• 128 MB Delkin SD card

• 128 MB Transcend SD card

• 64 MB Unigen SD card

Page 43

Problem Possible Cause Solution

Alarms Troubleshooting

Detector does not enter alarm

mode.

Detector intermittently enters

alarm without any apparent

reason.

Detector enters alarm with LEL

reading displaying as OL (over

limit).

GasAlertMicro 5/PID/IR

Troubleshooting

The detector has lost

communication with the MMC/SD

card.

Alarm setpoint(s) are set

incorrectly.

Alarm setpoint(s) are set to zero. Reset alarm setpoints. Refer to

Detector requires calibration. Calibrate the sensors. Refer to Calibration on page 16.

Ambient gas levels are near alarm

setpoint or the sensor is exposed

to a puff of the target gas.

Alarms setpoints are set

incorrectly.

Missing or faulty sensor. Refer to

Pump flow rate is set too high. Refer to the last solution in Pump Operation troubleshooting on the

Retry communication

Insert a new approved MMC or SD card. Refer to Inserting the MMC/

SD Card in the GasAlertMicro 5/PID/IR User Manual.

Reformat the MMC or SD card in windows and then reinsert into the

detector.

Contact BW Technologies by Honeywell.

Reset alarm setpoints. Refer to Calibration on page 16

Calibration on page 16.

Detector is operating normally. Use caution in suspect areas. Check

MAX gas exposure reading.

Reset alarm setpoints. Refer to

Replacing a Sensor or Sensor Filter on page 28.

following page.

Calibration on page 16.

39

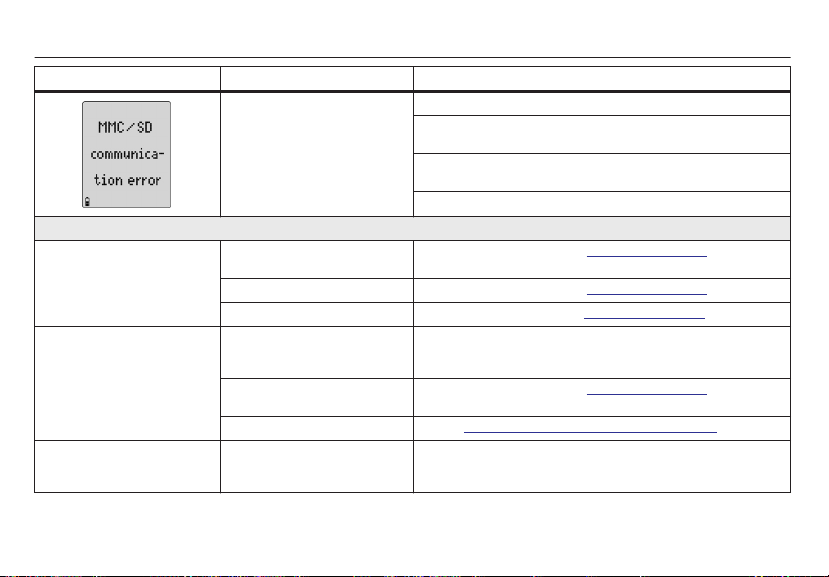

Page 44

GasAlertMicro 5/PID/IR

Quick Reference Guide

Problem Possible Cause Solution

Automatic Deactivation Troubleshooting

Detector automatically

deactivates.

Pump Operation Troubleshooting

Automatic shutdown activated

because of weak batteries.

Calibration is overdue and the

Due-lock (calibration user

lock-out) option is enabled.

There is an obstruction in the

tubing.

Filter needs to be replaced. Generation 1: 116885-L3 (yellow) and 118933-L3 (black) on page 12

40

Refer to the GasAlertMicro 5/PID/IR Charger Instruction Sheet.

Enter the password to enter calibration. Calibrate the sensor(s). Refer

Calibration on page 16.

to

Generation 1: 116885-L3 (yellow) and 118933-L3 (black) on page 12

If using tubing that is attached to the sample probe, determine if it is

obstructed. If not, replace the pump filter. Refer to the

GasAlertMicro 5/PID/IR User Manual.

Generation 2: 130916-L3* (yellow) and 130917-L3 (black) on page 12

If using tubing that is attached to the sample probe, determine if it is

obstructed. If not, clean or replace the pump filter. Refer to

the Pump Filter (Generation 2 Pump only) on page 29

If using tubing that is attached to the sample probe, determine if it is

obstructed. If not, replace the pump filter. Refer to the

GasAlertMicro 5/PID/IR User Manual.

Generation 2: 130916-L3* (yellow) and 130917-L3 (black) on page 12

If using tubing that is attached to the sample probe, determine if it is

obstructed. If not, clean or replace the pump filter. Refer to

the Pump Filter (Generation 2 Pump only) on page 29.

Replacing

Replacing

Page 45

Problem Possible Cause Solution

Clock Errors Troubleshooting

Clock icon is flashing. The clock has failed. Contact BW Technologies by Honeywell.

There is communication failure. Contact BW Technologies by Honeywell.

The detector displays a clock

error message using last

recorded time.

General fault. Reactivate the detector. If the same error message displays, reset the

clock in the user options menu. Reactivate the detector.

If the error message still displays, contact BW Technologies by

Honeywell.

GasAlertMicro 5/PID/IR

Troubleshooting

41

Page 46

GasAlertMicro 5/PID/IR

Quick Reference Guide

Replacement Parts and Accessories

a Warning

To avoid personal injury and/or damage to the detector,

use only the specified replacement parts.

To order parts or accessories, contact BW Technologies by

Honeywell.

Table 3. Replacement Parts and Accessories

Model No. Description Qty

Sensors

SR-B04 Carbon dioxide (CO

SR-Q07 PID sensor 1

D4-RHM04 TwinTox CO/H

PS-RH04S Hydrogen sulfide (H2S) sensor 1

PS-RM04 Carbon monoxide (CO) sensor 1

PS-RS04 Sulfur dioxide (SO

PS-RC10 Chlorine (Cl2) sensor 1

PS-RZ10 Hydrogen cyanide (HCN) sensor 1

PS-RD04 Nitrogen dioxide (NO

SR-A04 Ammonia (NH3) sensor 1

SR-P04 Phosphine (PH3) sensor 1

SR-X10-C1 Oxygen (O2) sensor 1

SR-G04 Ozone (O3) sensor 1

42

) sensor 1

2

S sensor 1

2

) sensor 1

2

) sensor 1

2

Model No. Description Qty

SR-V04 Chlorine dioxide (ClO2) sensor 1

SR-W04 Combustible (LEL) sensor

SR-W04-UF Combustible (LEL) sensor

SR-DUMM1 Dummy sensor 3-pin O

SR-DUMM2 Dummy sensor for LEL location 1

SR-DUMM3 Dummy sensor for PID location 1

Sensor Replacement Parts and Accessories

RL-PID10.6 Lamp for PID sensor 1

M5PID-ES-1 Electrode stack for PID sensor 2

M513PID-CLN-K1Cleaning kit for PID sensor lamp 1

M5-SS Sensor filters (quad) kit of 2 1

Gas Cylinders

REG-0.5 Regulator (0.5 l/min) 1

CG-Q58-4 Quad calibration gas, CH

CG-Q34-4 Quad calibration gas, CH4-2.5%, O2-

(with silicone protection filter)

(no silicone protection filter)

or TwinTox 1

2

-2.5%, O2-

18.0%, H2S-25 ppm, CO-100 ppm,

bal. N2 (58 l)

18.0%, H2S-25 ppm, CO-100 ppm,

bal. N2 (34 l)

4

1

1

1

1

Page 47

Model No. Description Qty

CG-2-JX-34 Two gas calibration cylinder, 50%

CG2-C-5-58 Calibration gas, Cl

CG2-M-100-103 Calibration gas, CO 100 ppm (103 l) 1

CG2-Z-10-58 Calibration gas, HCN 10 ppm (58 l) 1

G0042-H25 Calibration gas, H

CG2-D-10-58 Calibration gas, NO2 10 ppm (58 l) 1

CG2-P-1-34 Calibration gas, PH3 1 ppm (34 l) 1

CG2-S-25 Calibration gas, SO2 25 ppm (58 l) 1

CG-BUMP1 Bump alarm gas aerosol (CH4-2.5%,

CG-BUMP-H25 H2S bump test gas 1

GasAlertMicro 5/PID/IR Alkaline Battery Packs

M5-BAT0501 Alkaline battery pack (yellow) 1

M5-BAT0502 Alkaline battery pack with European

GasAlertMicro 5/PID/IR Lithium Battery Packs

M5-BAT08 Lithium rechargeable battery pack

M5-BAT08B Lithium rechargeable battery pack

GasAlertMicro 5/PID/IR Chargers and Kits

-2.5%) O2-20.9%, bal. N2

LEL (CH

4

(34 l)

5 ppm (58 l) 1

2

S 25 ppm, (58 l) 1

2

O2-10%, H2S-40 ppm, CO-200 ppm)

screw (yellow)

(yellow)

(black)

Replacement Parts and Accessories

GasAlertMicro 5/PID/IR

Model No. Description Qty

1

1

1

1