Page 1

GasAlertMicro

H2S, CO, O2, SO2, Combustibles

1, 2, 3, and 4 Gas Detectors

Quick Reference Guide

Page 2

BW Technologies LP (BW) warrants this product to be free from defects in material and workmanship under normal use and service for a

period of two years, beginning on the date of shipment to the buyer. This warranty extends only to the sale of new and unused products to

the original buyer. BW’s warranty obligation is limited, at BW’s option, to refund of the purchase price, repair, or replacement of a defective

product that is returned to a BW authorized service center within the warranty period. In no event shall BW’s liability hereunder exceed the

purchase price actually paid by the buyer for the Product. This warranty does not include:

a) fuses, disposable batteries or the routine replacement of parts due to the normal wear and tear of the product arising from

use;

b) any product which in BW’s opinion, has been misused, altered, neglected or damaged by accident or abnormal conditions of

operation, handling or use;

c) any damage or defects attributable to repair of the product by any person other than an authorized dealer, or the installation

The obligations set forth in this warranty are conditional on:

THE BUYER AGREES THAT THIS WARRANTY IS THE BUYER’S SOLE AND EXCLUSIVE REMEDY AND IS IN LIEU OF ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTY OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE. BW SHALL NOT BE LIABLE FOR ANY SPECIAL, INDIRECT, INCIDENTAL OR

CONSEQUENTIAL DAMAGES OR LOSSES, INCLUDING LOSS OF DATA, WHETHER ARISING FROM BREACH OF WARRANTY OR

BASED ON CONTRACT, TORT OR RELIANCE OR ANY OTHER THEORY.

Since some countries or states do not allow limitation of the term of an implied warranty, or exclusion, or limitation of incidental or

consequential damages, the limitations and exclusions of this warranty may not apply to every buyer. If any provision of this warranty is

held invalid or unenforceable by a court of competent jurisdiction, such holding will not affect the validity or enforceability of any other

provision.

of unapproved parts on the product; or

a) proper storage, installation, calibration, use, maintenance and compliance with the product manual instructions and any other

applicable recommendations of BW;

b) the buyer promptly notifying BW of any defect and, if required, promptly making the product available for correction. No

goods shall be returned to BW until receipt by the buyer of shipping instructions from BW; and

c) the right of BW to require that the buyer provide proof of purchase such as th e original invoice, bill of sale, or packing slip to

establish that the product is within the warranty period.

Limited Warranty & Limitation of Liability

Contacting BW Technologies

USA: 1-888-749-8878 Canada: 1-800-663-4164

Europe: +44 (0) 1869 233004 Other countries: +1-403-248-9226

Email us at:

Visit BW Technologies’ web site at: www.gasmonitors.com

info@bwtnet.com

Page 3

GasAlertMicro

Introduction

This quick reference guide provides basic information for the

GasAlertMicro. Refer to the user manual on the accompanying

CD-ROM for complete operating instructions. The

GasAlertMicro gas detector (“the detector”) warns of hazardous

gas at levels above user-selectable alarm setpoints.

The detector is a personal safety device. It is your responsibility

to respond properly to the alarm.

Note

The detector is shipped with English as the displayed

language. The Portuguese, Spanish, German, and

French guides have their screenshots displayed in the

corresponding language.

Safety Information - Read First

Use the detector only as specified in this guide, otherwise

the protection provided by the detector may be impaired.

Read the following Cautions before using the detector.

a Cautions

⇒ Warning: Substitution of components may

impair Intrinsic Safety.

⇒ Caution: For safety reasons, this equipment

must be operated and serviced by qualified

personnel only. Read and understand the user

manual completely before operating or

servicing.

⇒ Calibrate the detector before first-time use and

then on a regular schedule, depending on use

and sensor exposure to poisons and

contaminants. BW recommends at least once

every 180 days* (6 months).

* See Specifications

1

Page 4

GasAlertMicro

Quick Reference Guide

⇒ BW recommends to “bump test” the sensors,

before each day’s use, to confirm their ability

to respond to gas by exposing the detector to

a gas concentration that exceeds the high

alarm setpoints. Manually verify that the

audible and visual alarms are activated.

Calibrate if the readings are not within the

specified limits.

⇒ It is recommended that the combustible

sensor be checked with a known

concentration of calibration gas after any

known exposure to catalyst

contaminants/poisons (sulfur compounds,

silicon vapors, halogenated compounds, etc.).

⇒ Only the combustible gas detection portion of

this instrument has been assessed for

performance.

⇒ The combustible sensor is factory calibrated

to 50% LEL methane. If monitoring a different

combustible gas in the % LEL range, calibrate

the sensor using the appropriate gas.

⇒ Caution: High off-scale readings may indicate

an explosive concentration.

⇒ Electromagnetic interference may cause

incorrect operation under certain

circumstances.

2

⇒ Protect the combustible sensor from exposure

to lead compounds, silicones, and chlorinated

hydrocarbons. Although certain organic

vapors (such as leaded gasoline and

halogenated hydrocarbons) may temporarily

inhibit sensor performance, in most cases, the

sensor will recover after calibration.

⇒ Any rapid up-scaling reading followed by a

declining or erratic reading may indicate a gas

concentration beyond upper scale limit, which

may be hazardous.

⇒ Do not change or charge batteries in a

hazardous location. Doing so will impair the

Intrinsic Safety of the unit and may lead to fire

or explosion.

⇒ For use only in potentially explosive

atmospheres where oxygen concentrations do

not exceed 20.9% (v/v).

⇒ Extended exposure of the GasAlertMicro to

certain concentrations of combustible gases

and air may stress a detector element, which

can seriously affect its performance. If an

alarm occurs due to high concentration of

combustible gases, recalibration should be

performed, or if needed, the sensor replaced.

Page 5

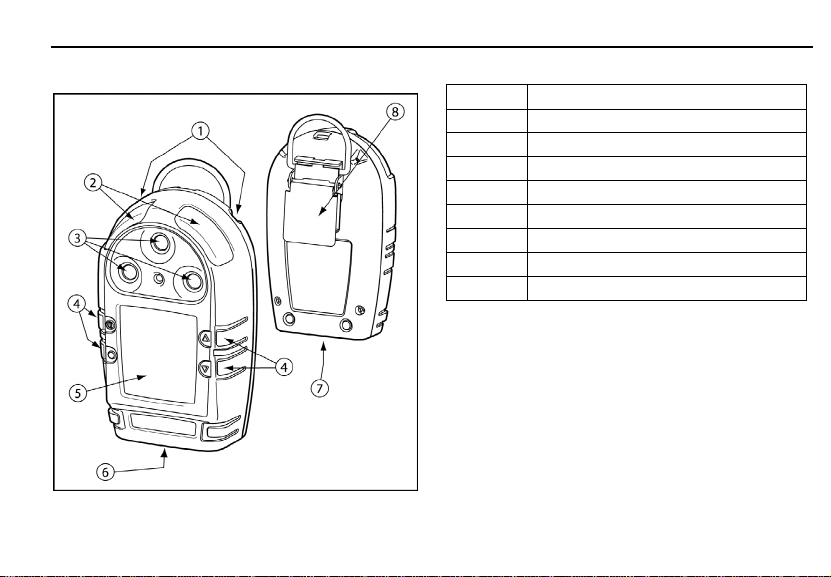

Parts of the GasAlertMicro

Parts of the GasAlertMicro

GasAlertMicro

Item Description

1 Audible alarm

2 Visual alarm bars

3 Sensors

4 Pushbuttons

5 Display

6 Battery holder

7 Datalogger (optional)

8 Alligator clip

3

Page 6

GasAlertMicro

Quick Reference Guide

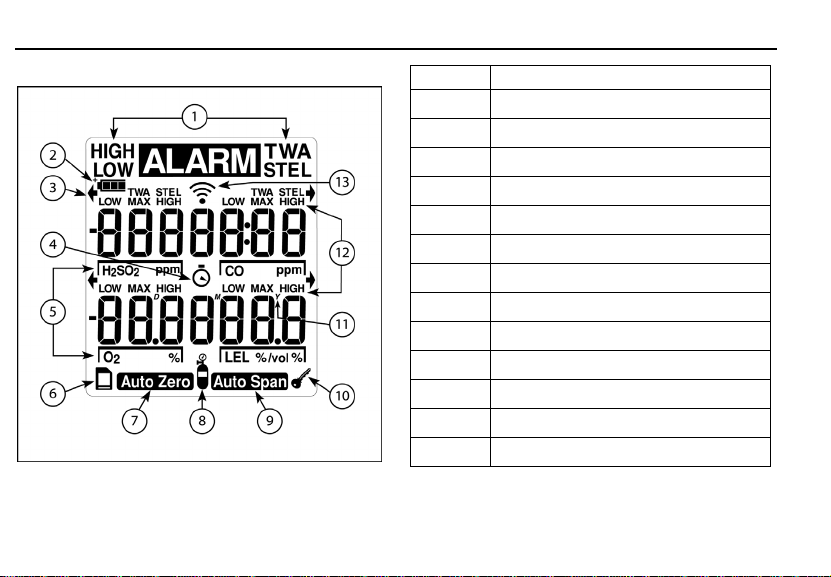

Display Elements

4

Item Description

1

2

3

4

5

6

7

8

9

10

11

12

13

Alarm condition

Battery life indicator

Button indicator

Clock

Gas identifier bars

Optional datalogger card indicator

Automatically zero sensor

Gas cylinder

Automatically span sensor

Pass code lock

Real time calendar

Alarm condition

Future use

Page 7

GasAlertMicro

Pushbuttons

Pushbuttons

Pushbutton Description

• To turn on the detector press A.

A

• To turn off the detector, press A and hold for 5 seconds.

• To activate or deactivate the confidence beep, press and hold C then press A at startup.

• To increment the displayed value press G.

G

• To enter the user options menu, press G and H simultaneously and hold for 5 seconds.

• To clear the TWA, STEL, and maximum gas exposure readings, press C and G

simultaneously.

• To decrement the displayed value press H.

H

C

• To initiate calibration and setting alarm setpoints, press C and H simultaneously and hold for

5 seconds.

• To view the TWA, STEL, and maximum (MAX) hold readings, press C.

• To acknowledge latched alarms press C.

5

Page 8

GasAlertMicro

Quick Reference Guide

Installing the Batteries

Activating the Detector

To activate the detector, press A in a normal atmosphere (20.9% oxygen).

Deactivating the Detector

To turn off the detector, press A and hold for 5 seconds.

6

Page 9

Calibration

Procedure Display Procedure Display

1. In a clean atmosphere, press C

and H simultaneously and hold for

5 seconds. The detector beeps

4 times. The detector then beeps

once more signifying that

calibration has started.

2. The display flashes N while

the detector zeroes the H

and combustible sensors. The

detector beeps twice at the end of

the auto zero stage.

S, CO,

2

4. Press H or G to change the alarm

setpoint. Press A to skip to the

next setpoint. Press

The detector beeps four times at

the end of the alarm setpoint stage.

C to save.

5. Press H or G to change the next

calibration due date. Press C to

save. The detector beeps five times

indicating that calibration is

complete.

GasAlertMicro

Calibration

3. When the display flashes K,

connect the calibration bottle and

apply gas at a flow rate of 250 to

500 ml/min. The detector beeps

three times at the end of the span

stage. Remove the calibration gas.

Note

The calibration cap should only be used during the

calibration process.

7

Page 10

GasAlertMicro

Quick Reference Guide

Attach the Gas Cylinder to the Detector

8

Page 11

Alarms

The following table lists the numerous alarms of the detector.

Alarm Display Alarm Display

Low Alarm

• Slow tone and flash

• L and target gas bar flash

• Vibrator alarm activates

High Alarm

• Fast tone and flash

• L and target gas bar flash

• Vibrator alarm activates

STEL Alarm

• Fast tone and flash

• L and target gas bar flash

• Vibrator alarm activates

Multi-Gas Alarm

• Alternating low and high alarm

tone and flash

• L and target gas bars flash

• Vibrator alarm activates

TWA Alarm

• Slow tone and flash

• L and target gas bar flash

• Vibrator alarm activates

Over Range Alarm

(Over Level Exposure)

• Fast tone and flash

• L and target gas bar flash

• Vibrator alarm activates

GasAlertMicro

Alarms

9

Page 12

GasAlertMicro

Quick Reference Guide

Alarm Display Alarm Display

Sensor Alarm

• Slow tone and flash

• L and gas bar(s) flash

• Vibrator alarm activates

Low Battery Alarm

(Confidence Beep disabled)

• 1 beep and 1 flash every

10 seconds

• LOW flashes

Confidence Beep

• 2 fast beeps every 15 seconds.

10

Automatic Shutdown Alarm

• 8 beeps and flashes

• LOW displays periodically

• Vibrator alarm temporarily

activates

Normal Shutdown

• 4 beeps and flashes

• Vibrator alarm temporarily

activates

Note

Alarms can be set to be latching or non-latching. To

confirm this setting, go to the latching alarm option in

the user options menu.

Page 13

User Options Menu

To access the user options, press G and H simultaneously.

To choose the desired option, press

select the option. The following are the available user options:

• Finish options: exits the user options menu;

• Latching alarms: alarm persists until the user

acknowledges it;

• Safe display: LCD displays SAFE when no gas is

measured;

• Combustible sensor measuring selection: measures and

displays in either 0-100% LEL or 0-5.0% vol.;

• Language selection: LCD displays in English, French,

German, Spanish, or Portuguese;

• Sensor option: enable/disable a sensor;

• Pass code protection: prevents access to the user

options menu and the calibration menu;

• Automatic oxygen calibration: enables oxygen calibration

at startup;

H or G. Press C to

GasAlertMicro

User Options Menu

• Span concentration values: change each sensor’s span

concentration value for calibration;

• STEL period: set the STEL calculation period between

5-15 minutes;

• Stealth mode: disables the audible and visual alarms;

• Automatic backlight: disables the automatic backlight

regardless of the lighting situation;

• MicroBatt: acknowledges that the detector is using the

GA MicroBatt;

• Bump due: enables a note to display upon startup if the

detector has not been bumped within the last 24 hours;

• Adjust clock: adjusts the real-time clock and calendar

(datalogger model only);

• Logger rate: adjust the rate between 1-127 seconds

(datalogger model only).

Note

To quickly scroll through the options press and hold H

or G.

11

Page 14

GasAlertMicro

Quick Reference Guide

Maintenance

To keep the detector in good operating condition, perform

the following basic maintenance as required:

• Calibrate, bump check, and inspect the detector at

regular intervals.

• Keep an operations log of all maintenance, bump

checks, calibrations, and alarm events.

• Clean the exterior with a soft damp cloth. Do not use

solvents, soaps, or polishes.

• Do not immerse the detector in liquids.

12

Replacing a Sensor or Sensor Filter

For full instructions on how to replace a sensor/sensor filter,

please refer to the user manual.

Item Description

1 Front shell

2 Triple sensor filter

3 Oxygen sensor

4 LEL sensor

5 CO/H2S sensor

6 Sensor locator

7 PCB assembly

8 Rear shell

9 Alligator clip

10 Machine screw (1)

11 Thread cutting screws (6)

Page 15

GasAlertMicro

Maintenance

13

Page 16

GasAlertMicro

Quick Reference Guide

Specifications

Instrument dimensions: 6 x 10 x 3.3 cm (2.4 x 4.0 x 1.3 in.)

Weight: 211 g (7.4 oz.)

Operating and storage conditions:

Temperature: -20°C to +50°C (-4ºF to +122ºF)

Humidity: 5% to 95% relative humidity (non-condensing)

Pressure: 95 to 110 kPa

Alarm setpoints: May vary by region and are user-settable

Detection range:

CO: 0-500 ppm in 1 ppm increments

H

S, SO2: 0-100 ppm in 1 ppm increments

2

O

: 0-30% in 0.1% increments

2

Combustibles: field settable for:

0-100% LEL in 1% LEL increments or

0-5.0% v/v methane

Sensor type:

H

S/CO: Twin plug-in electrochemical cell

2

O

, SO2, H2S, CO: Single plug-in electrochemical cell

2

Combustibles: Plug-in catalytic bead

measuring principle: Capillary controlled concentration

O

2

sensor

14

Alarm conditions: TWA alarm, STEL alarm, low alarm, high

alarm, multi-gas alarm, sensor alarm, low battery alarm,

confidence beep, automatic shutdown alarm

Audible alarm: 95 dB at 1 ft. (0.3 m) variable pulsed dual

beepers

Visual alarm: Dual red light-emitting diodes (LED)

Display: Alphanumeric liquid crystal display (LCD)

Backlight: Automatically activates whenever there is

insufficient light to view the display and during alarm conditions

Self-test: Initiated at activation

Calibration: Automatic zero and automatic span

Oxygen sensor: Automatic span on activation (selectable)

User field options: Confidence beep, latching low and high

alarms, pass code protection, enable/display SAFE display

mode, combustible sensor measurement (0-100% LEL or 0-

5.0% v/v methane, sensor disable, set calibration due date,

TWA and STEL, stealth mode, language selection,

enable/disable automatic oxygen calibration, set span

concentration values, set STEL calculation period,

enable/disable automatic backlight, and distinguish use of the

GA MicroBatt battery

Datalogger models only: adjust clock calendar, set sampling

rate, and enable/disable bump due note

Page 17

Battery operating time:

2 alkaline cells: 16-18 hours

2 rechargeable NiMH cells: 14-16 hours (Quest Platinum

HGAAC1800G)

Approved batteries:

North America

Approved batteries for product (standards EN50020, UL913,

C22.2 No. 157)

Alkaline: Temperature code

Duracell MN1500 T3C (139.8°C)

Energizer E91 T3B (163°C)

NiMH rechargeable:

Quest Platinum HGAAC1800G T2 (211.4°C)

Quest HG1600AACS T3 (199°C)

Energizer NH15 1700 mAh T2D (205°C)

Maha Powerex 1700 mAh MH-AA170 T3 (192°C)

Maha Powerex 1800 mAh MH-AA180 T2D (201.1°C)

Yuasa Delta 1300 mAh DHA1400AA T2D (209°C)

Yuasa Delta 1500 mAh DHA1600AAC T2D (204.4°C)

Uniross 1300 mAh T3 (198°C)

Uniross 1700 mAh T3 (186.8°C)

GA MicroBatt:

GAMIC-BAT-03 T4 (120°C)

GAMIC-BAT2-03 T4

Worst case temperature code:

Alkaline: 163°C

NiMH: 212°C

GA MicroBatt: 120°C

Ambient: -20°C ≤ Ta ≤ +50°C

Europe

Approved batteries for product (standards EN50020)

Alkaline: Temperature code

Duracell MN1500 T4 (129.8°C)

NiMH rechargeable:

Quest HG1600AACS T3 (189°C)

Ambient: -20°C ≤ Ta ≤ +40°C

GA MicroBatt:

GAMIC-BAT-03 T4 (120°C)

GAMIC-BAT2-03 T4

Ambient: -20°C ≤ Ta ≤ +50°C

Battery charger (optional): Quest™ Q2 4-port rapid NiMH

battery charger with country-specific mains adapter

First-time charge: 1-4 hours per battery

Normal charge: 1 hour per battery

Warranty: Full 2 year warranty including all sensors

GasAlertMicro

Specifications

15

Page 18

GasAlertMicro

Quick Reference Guide

Approvals: Approved by CSA to both U.S. and Canadian

Standards

Approved: Class I, Division 1, Group A, B, C, and D;

Class I, Zone 0, Group IIC

Standards: CAN/CSA C22.2 No. 157 and C22.2 152

ANSI/UL – 913 and ANSI/ISA –S12.13 Part 1

CE (LCIE): EEx ia IIC ATEX g II 1 G

ATEX: LCIE 03 ATEX 6091 X

BAM 04 ATEX 0002 X

* It is recommended that BAM certified detectors be

calibrated once every 90 days.

IECEx

ABS Type Approved: VA-348-169-X

O

measuring function: BAM/ZBA/008/04

2

16

This equipment has been tested and found to comply with the

limits for a Class B digital device, pursuant to Part 15 of the

FCC Rules and ICES-003 Canadian EMI requirements. These

limits are designed to provide reasonable protection against

harmful interference in a residential installation. This equipment

generates, uses and can radiate radio frequency energy and, if

not installed and used in accordance with the instructions, may

cause harmful interference to radio communications. However,

there is no guarantee that interference will not occur in a

particular installation. If this equipment does cause harmful

interference to radio or television reception, which can be

determined by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of

the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and

receiver.

• Connect the equipment into an outlet on a circuit

different from that to which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician

for help.

Page 19

Page 20

D5554/6 English

iERP: 118237

© 2005 BW Technologies. All rights reserved. Printed in Canada.

All product names are trademarks of their respective companies.

Loading...

Loading...